Page 1

12 Clintonville Road, Northford, CT 06472

Instruction Manual

MP-12/24

Fire Alarm Control Panel

Document 15440

6/6/96 Rev:

P/N 15440:G ECN 96-200

G

Page 2

Installation Precautions - Adherence to the following will aid in problem-free installation with long-term reliability:

WARNING - Several different sources of power can be connected to the fire alarm

control panel. Disconnect all sources of power before servicing. Control unit and

associated equipment may be damaged by removing and/or inserting cards,

modules, or interconnecting cables while the unit is energized. Do not attempt to

install, service, or operate this unit until this manual is read and understood.

CAUTION - System Reacceptance Test after Software Changes: To ensure

proper system operation, this product must be tested in accordance with NFPA 72-

1993 Chapter 7 after any programming operation or change in site-specific software.

Reacceptance testing is required after any change, addition or deletion of system

components, or after any modification, repair or adjustment to system hardware or

wiring.

All components, circuits, system operations, or software functions known to be

affected by a change must be 100% tested. In addition, to ensure that other

operations are not inadvertently affected, at least 10% of initiating devices that are

not directly affected by the change, up to a maximum of 50 devices, must also be

tested and proper system operation verified.

This system meets NFPA requirements for operation at 0-49O C/32-120O F

and at a relative humidity of 85% RH (non-condensing) at 30O C/86O F.

However, the useful life of the system's standby batteries and the electronic

components may be adversely affected by extreme temperature ranges and

humidity. Therefore, it is recommended that this system and its peripherals be

installed in an environment with a nominal room temperature of 15-27O C/60-80

F.

Verify that wire sizes are adequate for all initiating and indicating device loops.

Most devices cannot tolerate more than a 10% I.R. drop from the specified device

voltage.

Like all solid state electronic devices, this system may operate erratically or can

be damaged when subjected to lightning induced transients. Although no system is

completely immune from lightning transients and interferences, proper grounding will

reduce susceptibility. Overhead or outside aerial wiring is not recommended, due to

an increased susceptibility to nearby lightning strikes. Consult with the Technical

Services Department if any problems are anticipated or encountered.

Disconnect AC power and batteries prior to removing or inserting circuit boards.

Failure to do so can damage circuits.

Remove all electronic assemblies prior to any drilling, filing, reaming, or punching

of the enclosure. When possible, make all cable entries from the sides or rear.

Before making modifications, verify that they will not interfere with battery,

transformer, and printed circuit board location.

Do not tighten screw terminals more than 9 in-lbs. Over tightening may damage

threads, resulting in reduced terminal contact pressure and difficulty with screw

terminal removal.

This system contains static-sensitive components. Always ground yourself with a

proper wrist strap before handling any circuits so that static charges are removed

from the body. Use static suppressive packaging to protect electronic assemblies

removed from the unit.

O

Follow the instructions in the installation, operating, and programming manuals.

These instructions must be followed to avoid damage to the control panel and

associated equipment. FACP operation and reliability depend upon proper

installation.

Fire Alarm System Limitations

An automatic fire alarm system - typically made up of smoke detectors, heat

detectors, manual pull stations, audible warning devices, and a fire alarm control

with remote notification capability can provide early warning of a developing fire.

Such a system, however, does not assure protection against property damage or

loss of life resulting from a fire.

Any fire alarm system may fail for a variety of reasons:

Smoke detectors may not sense fire where smoke cannot reach the detectors such

as in chimneys, in walls, or roofs, or on the other side of closed doors. Smoke

detectors also may not sense a fire on another level or floor of a building. A second

floor detector, for example, may not sense a first floor or basement fire. Further-

more, all types of smoke detectors - both ionization and photoelectric types, have

sensing limitations. No type of smoke detector can sense every kind of fire caused

by carelessness and safety hazards like smoking in bed, violent explosions,

escaping gas, improper storage of flammable materials, overloaded electrical

circuits, children playing with matches, or arson.

IMPORTANT! Smoke detectors must be installed in the same room as the

control panel and in rooms used by the system for the connection of alarm

transmission wiring, communications, signaling, and/or power. If detectors are

not so located, a developing fire may damage the alarm system, crippling its

ability to report a fire.

While installing a fire alarm system may make lower insurance

rates possible, it is not a substitute for fire insurance!

FCC Warning

Audible warning devices such as bells may not alert people if these devices are

located on the other side of closed or partly open doors or are located on another

floor of a building.

A fire alarm system will not operate without any electrical power. If AC power fails,

the system will operate from standby batteries only for a specified time.

Rate-of-Rise heat detectors may be subject to reduced sensitivity over time. For

this reason, the rate-of-rise feature of each detector should be tested at least once

per year by a qualified fire protection specialist.

Equipment used in the system may not be technically compatible with the control.

It is essential to use only equipment listed for service with your control panel.

Telephone lines needed to transmit alarm signals from a premise to a central

monitoring station may be out of service or temporarily disabled.

The most common cause of fire alarm malfunctions, however, is inadequate

maintenance. All devices and system wiring should be tested and maintained by

professional fire alarm installers following written procedures supplied with each

device. System inspection and testing should be scheduled monthly or as required

by National and/or local fire codes. Adequate written records of all inspections should

be kept.

WARNING: This equipment generates, uses, and can radiate radio frequency

energy and if not installed and used in accordance with the instruction manual, may

cause interference to radio communications. It has been tested and found to comply

with the limits for class A computing device pursuant to Subpart B of Part 15 of FCC

Rules, which is designed to provide reasonable protection against such interference

when operated in a commercial environment. Operation of this equipment in a

residential area is likely to cause interference, in which case the user will be required

to correct the interference at his own expense.

Technical Publishing Document PRECAULG.PM6 12/31/96

Canadian Requirements

This digital apparatus does not exceed the Class A limits for radiation noise

emissions from digital apparatus set out in the Radio Interference Regulations of the

Canadian Department of Communications.

Le present appareil numerique n'emet pas de bruits radioelectriques depassant les

limites applicables aux appareils numeriques de la classe A prescrites dans le

Reglement sur le brouillage radioelectrique edicte par le ministere des Communica-

tions du Canada.

Page 3

Table of Contents

Section One: General Information.......................................................... 4

Standard Features .............................................................. 4

Section Two: Controls and Indicators.................................................... 5

Section Three: Technical Specifications .................................................. 6

System Power Requirements.............................................. 6

Detection Loop .................................................................... 6

Two-wire Smoke Detector................................................... 6

Main Notification Appliance Circuits .................................... 6

External Device Power........................................................ 6

Battery Charger................................................................... 6

Optional Modules ................................................................ 7

Section Four: Installation Instructions ................................................... 8

PC Board Removal ............................................................. 8

Optional Module Installation ................................................ 8

PC Board Installation .......................................................... 8

Field Wiring ....................................................................... 10

Alarm Initiating Devices..................................................... 11

Notification Appliance Circuits........................................... 12

Regulated DC Output........................................................ 12

AC Power Connections ..................................................... 12

Standby Battery Power ..................................................... 12

Section Five: Periodic Testing and Maintenance ................................ 13

Section Six: Troubleshooting Guide .................................................. 14

Appendix A: Battery Selection Guide.................................................. 16

MP-12/24 Fire Alarm Control Panel Document 15440:G 6/6/96

3

Page 4

Section One:

General Information

The MP-12/24 fire alarm control panel provides reliable fire signaling protection for small to medium sized

commercial, industrial, and institutional buildings. This control panel functions in accordance with the following National Fire Protection Association (NFPA) standards:

• NFPA 72-1993 Local Fire Alarm Systems

• NFPA 72-1993 Remote Station Fire Alarm Systems (requires an optional Remote Station Output

Module).

The MP-12/24 control panels were tested as fire protective signaling system control units under Underwriters

Laboratories, Inc., Standard for Safety, Number UL864.

Activation of a compatible two-wire detector or any normally open fire alarm initiating device will sound

audible signaling devices, illuminate an indicating LED at the control panel and operate an optional module.

The optional modules can be used to notify a remote station or initiate a supplementary control function.

Standard Features

•

A trouble circuit which monitors the following fault conditions:

Open detector loop(s).

Low battery voltage.

Missing or disconnected battery.

Ground fault.

Low AC voltage (Brown-out condition).

Loss of AC power.

“Off normal” switch position.

Open or shorted Notification Appliance (bell) Circuit.

•

Control switches.

Reset for control and detectors.

Trouble Silence with resound.

Disable to silence alarm.

•

LED indicating lamps.

AC power.

Alarm Annunciator(s).

Trouble.

•

Detection loop.

Compatible with many types of two-wire detectors.

Power limited for limited energy cable.

Supervised Style B (Class B) operation.

•

Supervised Style Y (Class B) audible/visual signaling circuit.

•

Compact size with solid state electronics.

•

Automatic float charger.

•

Piezoelectric transducer for audible trouble signal.

•

Panel will accept one of the following optional modules:

Supplementary alarm contacts, two Form-C.

Supplementary alarm and trouble contacts, Form-C alarm, Form-C trouble.

Remote station output, alarm only.

Remote station output, alarm and trouble.

4

MP12/24 Fire Alarm Control Panel Document 15440:G 6/6/96

Page 5

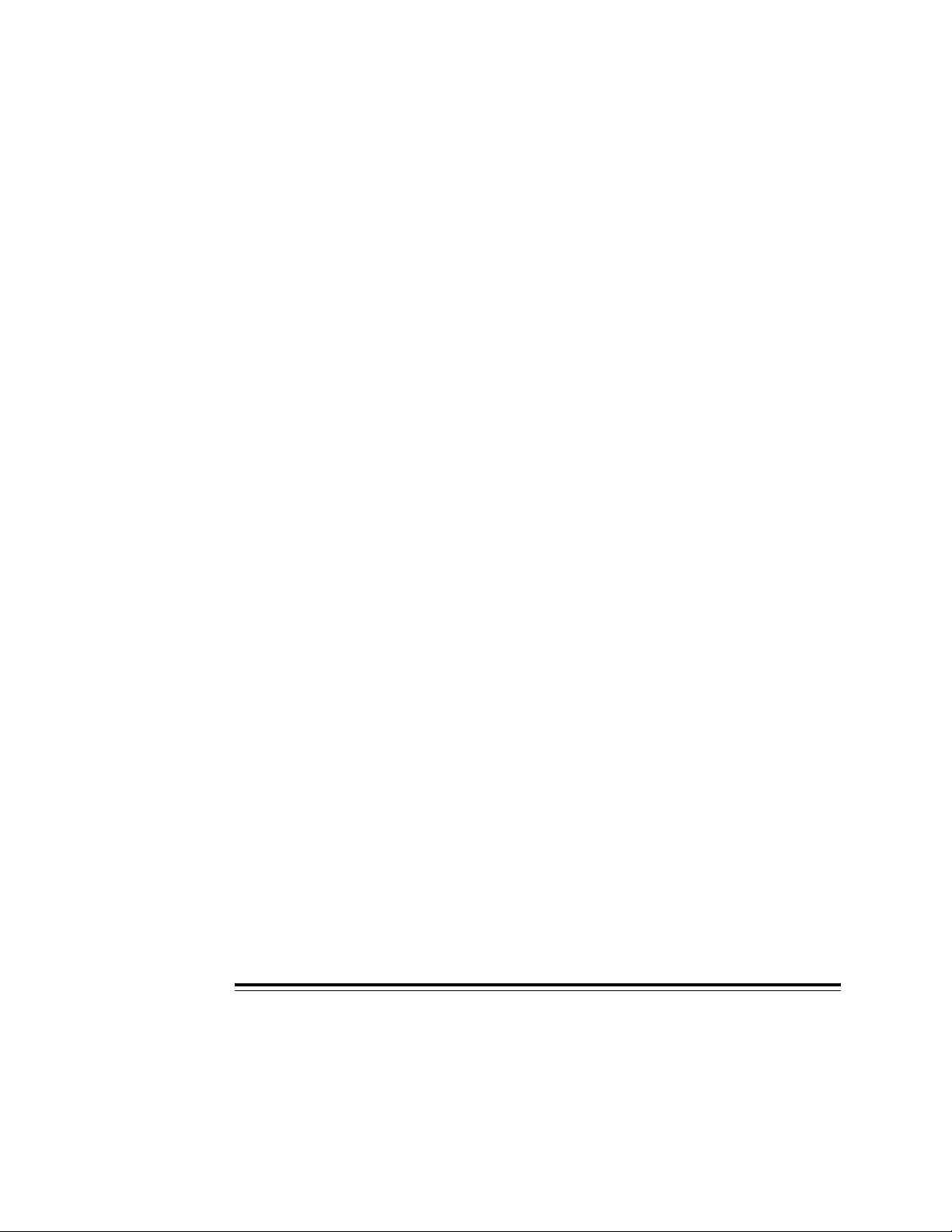

Section Two:

Controls and Indicators

RESET - The function of this switch is to reset the control panel and the smoke detectors provided the alarm

condition has been cleared. A trouble condition is indicated while this switch is depressed.

TROUBLE SILENCE - This latching, two-position switch, when pressed, will silence the pulsing audible

trouble signal. The trouble LED will continue to indicate a trouble condition. An intermittent tone will sound

when the trouble is corrected to indicate that this switch should be returned to its outward (normal) position.

DISABLE - This latching, two-position switch, when pressed, will prevent the activation of Notification

Appliances and the operation of the optional modules. The alarm LED(s) will continue to indicate the alarm

conditions. A trouble condition is indicated while this switch is in the off-normal position.

ALARM - Red LED(s) which indicate an alarm condition. The DISABLE switch will not effect the ALARM

LED(s).

TROUBLE - A yellow LED which is illuminated during a fault or abnormal operating condition.

AC - The green LED is on when the control panel is operating from the AC power source. Yellow and green

LEDs both flash to indicate below normal line voltage (brown-out). An extinguished green LED indicates

complete loss of AC power.

AUDIBLE TONE - An audible tone will sound to indicate the following:

• Alarm: A continuous sounding audible tone.

• Trouble: A pulsing audible tone signal having a short on time and long off time.

NORMAL STANDBY OPERATION

• All push button switches must

be in the normal outward

position.

• Green AC power indicator on

steady.

• Red ALARM indicator(s) off.

• Yellow TROUBLE indicator off.

ALARM CONDITION

• A red Alarm indicator will light.

• Alarm Notification appliances

are activated.

• Option module (remote station or supplementary alarm relay) is activated.

• Off-Normal Trouble Silence Switch: Indicated by an intermittent audible tone signal having a long on

time and short off time.

ALARM RESET

After locating and correcting the alarm condition, reset the control panel by pressing the RESET switch.

Return all switches to their normal positions.

Figure 2.1: Controls And Indicators

TROUBLE CONDITIONS

Activation of a trouble signal under normal operation indicates a condition that requires immediate correction. Contact your local service representative. The audible signal may be silenced by depressing the

TROUBLE SILENCE switch. The trouble LED will continue to flash.

MP-12/24 Fire Alarm Control Panel Document 15440:G 6/6/96

5

Page 6

Section Three:

Technical Specifications

All specifications are typical characteristics measured under nominal conditions at 25° C, unless otherwise specified.

System Power Requirements

MP-12/24 Operating voltage: 120 VAC, 60 Hz (standard).

MP-12/24 Current Draw: 0.5 A (maximum).

MP-12/24E Operating voltage: 220/240 VAC, 50/60 Hz

MP-12/24E Current Draw: 0.250 A (maximum).

Standby battery:

Voltage: (MP-12) 12 VDC; (MP-24) 24 VDC

Capacity: 2.5 to 7.0 AH (dependent on external loading).

Detection Loop

Operation: Style B (Class B).

Voltage: (MP-12) 8.6 to 12.2 VDC, ripple 0.65 Vp-p. (MP-24) 18 to 26.2 VDC, ripple 2.0 Vp-p.

Current required to ensure alarm: 20 mA (minimum)

Short circuit current: 40 mA - 10 mA

Supervision current: 5 mA

ELR: (MP-12) 2.2 K, 0.5 W; (MP-24) 4.7K, 0.5 W

Max resistance per side: 100 ohms.

Max total zone resistance: 200 ohms.

Two-wire Smoke Detectors

Head voltage, standby: MP-12, 11 VDC; MP-24, 23 VDC.

Total standby head current per zone: 2 mA peak

Minimum head current to ensure alarm: 20 mA

Maximum alarm current supplied to initiating devices, per zone: 40 mA - 10 mA.

Main Notification Appliance (bell) Circuits

Activation: By any zone alarm

Disconnect: By DISABLE switch

Operation: Style Y (Class B).

Notification Appliances: Use polarized, UL Listed, Notification Appliances with a minimum rated voltage

range of 9-15 VDC on MP-12 and 18-30 VDC on MP-24. Refer to the Fire•Lite Device Compatibility Document for a listing of compatible devices.

Nominal output voltage: (MP-12) 12 VDC; (MP-24) 24 VDC.

Output is

Output current: Total current to all external Notification Appliances cannot exceed: (MP-12) 1.0 A; (MP-24)

0.75 A.

Special Purpose Power

(full wave rectified DC, unregulated and unfiltered).

External Device Power

Regulated DC output: Resettable power primarily for four-wire smoke detectors and/or other low power

electronic devices. Maximum current available: 100 mA

Note: Size standby battery to include external loading.

Nominal voltage: (MP-12) 12 VDC; (MP-24) 24 VDC.

Battery Charger

Float type, turned off during alarm.

Float voltage setting: (MP-12) 13.8 VDC; (MP-24) 27.6 VDC. Automatic current limiting.

Note: Since battery charger is pulsed on and off, the charger output cannot be read with a voltmeter when

battery is not connected. A typical voltmeter would read approximately 8.5 V on the MP-12 and 16.5 V on the

MP-24.

6

MP12/24 Fire Alarm Control Panel Document 15440:G 6/6/96

Page 7

Optional Modules

The MP-12/24 will accept one of the following optional modules:

• Dry Alarm Contacts (MP-AC12; MP-AC24). Two Form-C rated 3 A @ 120 VAC and 30 VDC (resistive).

• Dry Alarm and Trouble Contacts (MP-AT12; MP-AT24). One Form-C Alarm and one Form-C Trouble,

both rated 3 A @ 120 VAC and 30 VDC (resistive).

• Remote Station Output Modules Models MP-TRT12 and MP-TRT24 output alarm and trouble. Models

MP-TR12 and MP-TR24 output alarm only.

Activation: By any zone alarm.

Disconnect: By an internal service switch, off-normal switch produces audible and visual trouble signals.

Remote Station Type: (MP-12) 12 VDC polarity reversal; (MP-24) 24 VDC polarity reversal.

Internal Resistance of Remote Station Output: (MP-12) 112 ohms; (MP-24) 660 ohms.

Ripple Voltage: Less than 2.0 Vp-p.

(Not suitable for separate transmission of both alarm and trouble signals to Remote Station).

System Control Switches

• Reset

• Trouble Silence

• Disable

System Status Indicators

• Red Zone alarm LED.

• Yellow system trouble LED.

• Green AC power LED.

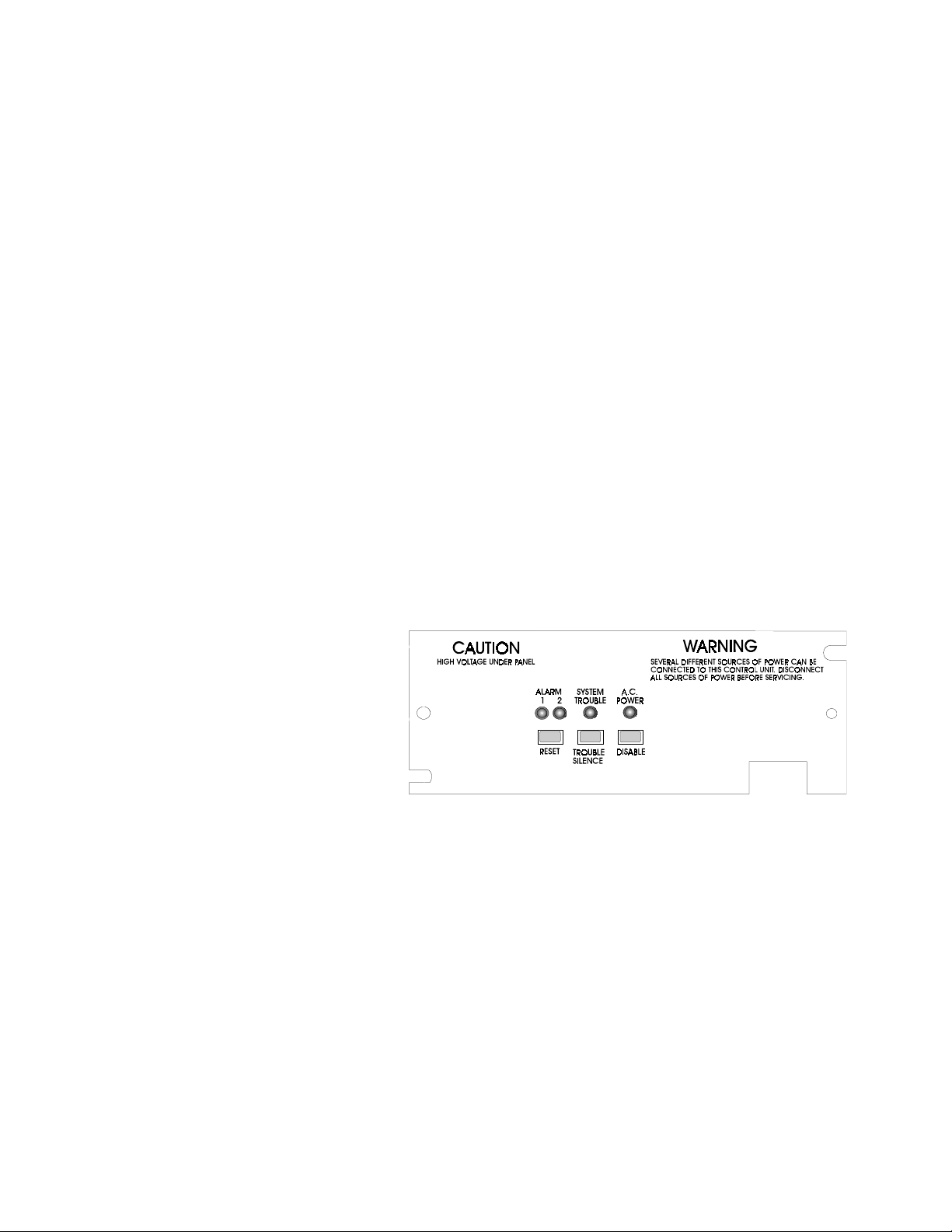

Transformer

Harness

Connector

AC Circuit

Breaker

Neutral

Hot

{

Primary

AC Power

No Connection

+ - - + -

{

Notification

Appliance

Circuit

Initiating

Device

Circuits

{

Alarm

LEDs

Reset

Switch

Optional Module

Connector

Trouble

LED

Trouble

Silence

Switch

Disable

Switch

AC Power

LED

Battery

Connector

Figure 3.1: Component and Terminal Locations

MP-12/24 Fire Alarm Control Panel Document 15440:G 6/6/96

7

Page 8

Section Four:

Installation Instructions

The following procedures, diagrams, and instructions should be followed closely to avoid damage to the

control panel and its associated equipment. Reliability of the fire system depends upon proper installation and

maintenance.

Printed Circuit Board Removal

Carefully unpack the system. Open door and remove dress panel. Inspect the cabinet, door, printed circuit

board and other components for the possibility of shipping damage. It is recommended that the printed circuit

board assembly be removed from the cabinet and stored in a clean dry area while cabinet mounting and

wiring are taking place. To remove the assembly, simply remove the dress panel, unplug the transformer

cable, and slide the assembly from cabinet (see Figure 4.1).

Figure 4.1: PC Board, Cabinet and Dress Panel

Optional Module Installation

If an optional module is required, mount it to the main printed circuit board as follows:

• Refer to Figure 3.1 for location information.

• Remove the main printed circuit board as specified above.

• Snap the two plastic supports into the large holes on the optional module, flapped end towards

module.

• Install module on main printed circuit board. Check that each of the four connector pins of P2 mate

with their receptacle contacts on optional module.

Printed Circuit Board Installation

After the cabinet has been mounted and all field wiring has been run

back into the cabinet and reconnect the transformer cable. It is recommended that a pre-installation check be

made to validate that the system was received in good condition without shipping damage. To check system:

• Connect 120 VAC to Terminals 1 and 2 on the MP12/24 or 220/240 VAC to Terminals 1 and 2 on the

MP12E/MP24E.

• Connect batteries, observing polarity.

• Check system according to Section 5.

8

MP12/24 Fire Alarm Control Panel Document 15440:G 6/6/96

, slide the printed circuit board assembly

Page 9

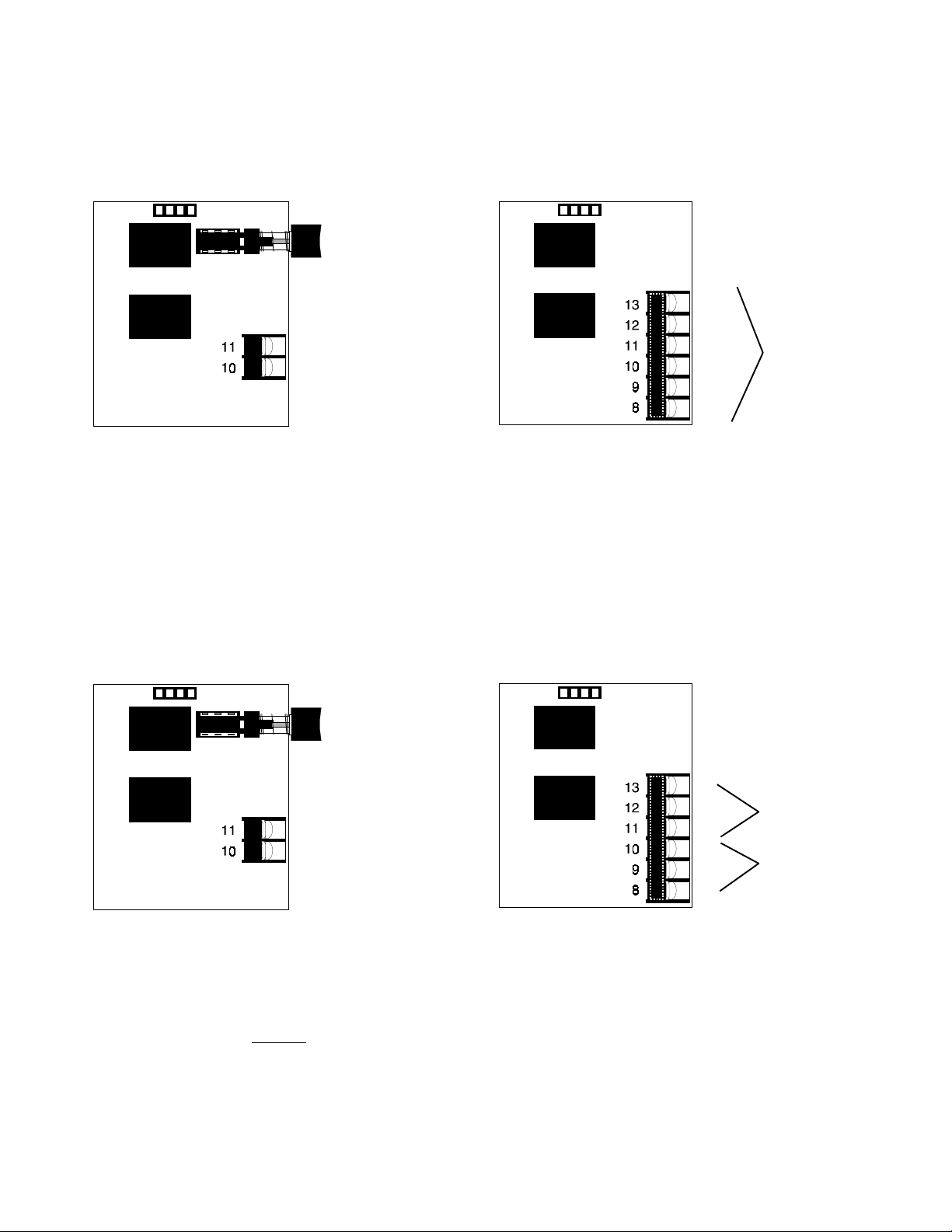

Figure 4.2: Optional Modules

MP-TR

Remote Station

disconnect switch

Reverse Polarity

+

-

Remote Station output.

Polarity shown is for

normal standby state.

Polarity reverses on

alarm.

Connect to compatible UL Listed polarity sensitive remote

station receiver, Fire•Lite RS-82 or equivalent. Output

signal: MP-12, 9 to 14 VDC; MP-24, 18 to 28 VDC.

Note 1: For wiring refer to UL power limited requirements.

Note 2: This circuit is suitable to leave the building.

Note 3: This output is power-limited.

MP-AC

NO #2

NC #2

Pole #2

Pole #1

NO #1

NC #1

Two sets

Form-C

alarm

contacts.

Rating: 3 A

resistive,

120 VAC/

30 VDC.

Note 1: For wiring refer to UL power limited requirements.

Note 2: Both sets of contacts must either be connected to

a non-power limited or a power limited circuit. Sets

of contacts cannot be mixed.

Note 3: Refer to the Protected Premises Unit label

(located on the system door) and mark the dry

contacts used as non power-limited circuits.

MP-TRT

Remote Station

disconnect switch

Reverse Polarity

Remote Station output.

+

-

Polarity shown is for

normal standby state.

Polarity reverses on

alarm. Output signal is

0 volts during nonalarm trouble condition.

Connect to compatible UL Listed polarity sensitive remote

station receiver, Fire•Lite RS-82 or equivalent. Output

signal: MP-12, 9 to 14 VDC; MP-24, 18 to 28 VDC.

Note 1: For wiring refer to UL power limited requirements.

Note 2: The MP-TRT module does not comply with the

requirement for separate trouble/alarm signal

transmission.

Note 3: This circuit is suitable to leave the building.

Note 4: This output is power-limited.

MP-AT

NO

NC

Pole

Pole

NC*

NO*

Alarm output

contacts.

Trouble output

contacts.

Note 1: *Indicates non-trouble state.

Note 2: All contacts rated 3 A, 120 VAC/30VDC.

Note 3: For wiring refer to UL power limited requirements.

Note 4: Both sets of contacts must be connected to a

non power-limited or a power limited circuit. Sets

of contacts cannot be mixed.

Note 5: Refer to the Protected Premises Unit label

(located on the system door) and mark the dry

contacts used as non power-limited circuits.

MP-12/24 Fire Alarm Control Panel Document 15440:G 6/6/96

9

Page 10

Field Wiring

All field wiring connections are made to the screw

type terminal blocks, located along the edges of the

To the ground stud located on the cabinet

next to the transformer assembly.

Power Limited circuit

Power Limited circuit

PC boards, as shown in wiring diagrams. Wiring

should be in accordance with National and/or Local

Codes for fire alarm systems. Use knockouts

provided on back and side of cabinet.

Neutral

Ground

AC Power Input

No connection

Hot

End-of-Line Resistor

(10K ohms) – mount

after the last device.

End-of-Line Resistor –

mount after the last device.

4.7K ohms (24V system)

2.2K ohms (12V system)

.

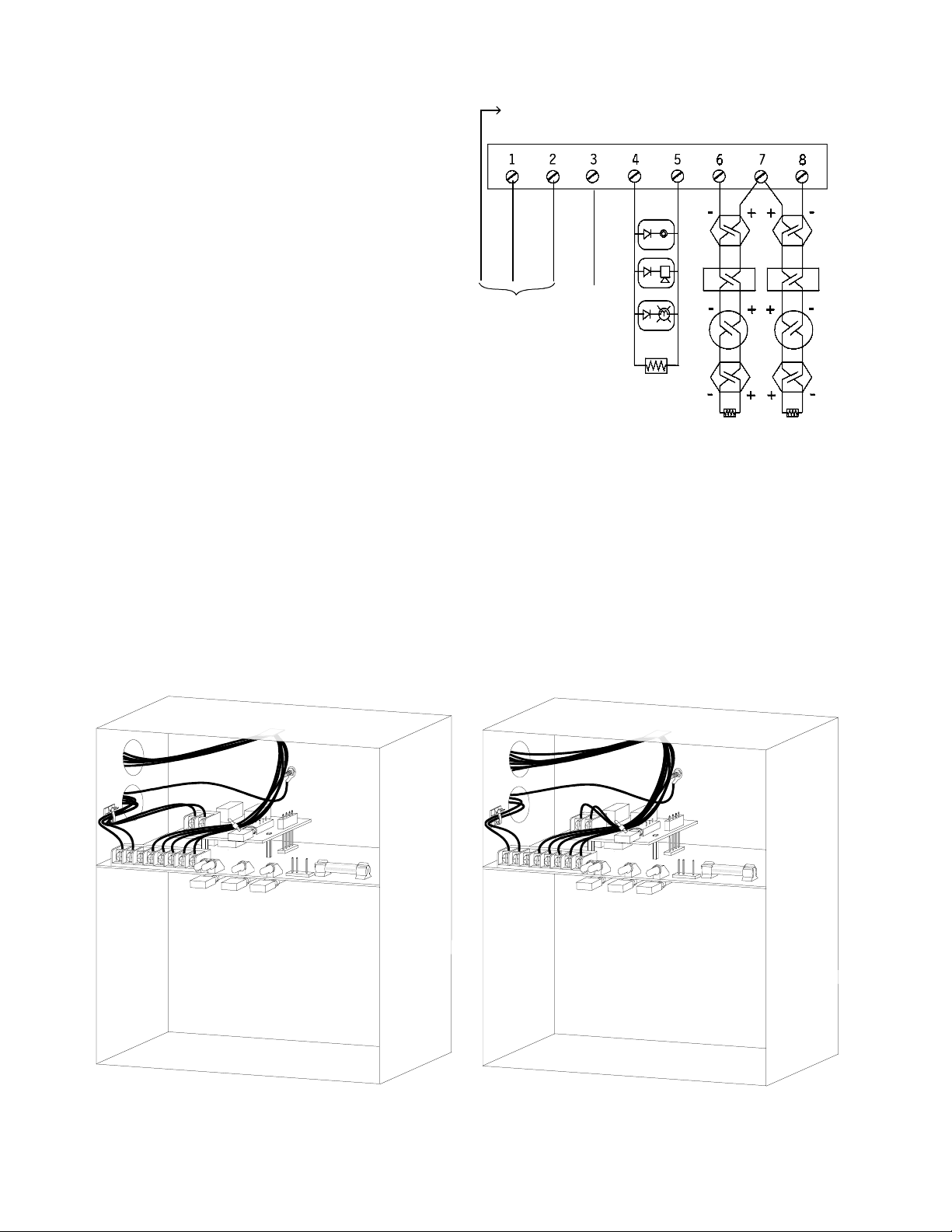

Figure 4.3: Main PC Board Wiring Diagram

UL Power Limited Wiring Requirements

Power limited and non-power limited circuit wiring must remain separated in the cabinet. All power limited

circuit wiring must remain at least 0.25" away from any non-power limited circuit wiring. Furthermore, all

power limited circuit wiring and non-power limited circuit wiring must enter and exit the cabinet through different knockouts and/or conduits. Create knockouts if necessary.

• For side knockouts, place the wire ties as shown in Figure 4.4.

• Use a lower knockout to run the wiring for non-power limited circuits and the upper knockout for

power limited circuits.

10

Module shown connected to

non power-limited circuit.

Figure 4.4: Typical wiring diagram for side knockouts

MP12/24 Fire Alarm Control Panel Document 15440:G 6/6/96

Module shown connected to

power-limited circuit.

Page 11

Power Limiting Notes Continued

• For back knockouts, place the wire ties as shown in Figure 4.5.

• Use a lower knockout to run the wiring for non-power limited circuits and the upper knockout for

power limited circuits.

Module shown connected to

non power-limited circuit.

Module shown connected to

power-limited circuit.

Figure 4.5: Typical wiring diagram for back knockouts

Alarm Initiating Devices

Wire all alarm initiating devices, including manual stations, heat detectors and smoke detectors, to zone

input terminals as shown in Figure 4.3. Refer to device data sheet for device connection information. Observe polarity when connecting polarized devices. Zone input terminals and polarity are:

Zone 1 Input: Terminal 7 positive, Terminal 6 negative.

Zone 2 Input: Terminal 7 positive, Terminal 8 negative.

All initiating devices connected to a given zone must be wired sequentially for proper supervision. Connect

the first device to the control panel, the second device connects to the first device, the third to the second

and so on. Remove the End-of-Line Resistor (ELR) from the control panel and install on terminals of the last

initiating device.

• Four-Wire Smoke Detectors

Power for four-wire smoke detectors may be obtained from terminals 5 (negative) and 7 (positive).

Supervise detector power with a listed end-of-line relay. Maximum current from terminals 5 and 7

should not exceed 100 mA. Two-wire detectors are recommended.

• Two-Wire Smoke Detectors

Compatible two-wire detectors can be connected directly to the zone input terminals. Polarity must

be observed. Two-wire detectors receive operating power from the zone terminals. Detector power

and alarm signals are transmitted through the same wires. The total peak standby detector current

per zone cannot exceed 2 mA. Compatible detectors are listed in the Device Compatibility Document.

• Sprinkler System Waterflow Alarm Devices

Normally open waterflow alarm devices may be connected to this panel provided the system is used

in conjunction with a mechanical water motor gong.

MP-12/24 Fire Alarm Control Panel Document 15440:G 6/6/96

11

Page 12

Notification Appliance Circuits

Connect the Style Y (Class B) Notification Appliance Circuits as shown in Figure 4.3. Use only polarized ULlisted Notification Appliances listed in the Device Compatibility Document. Size wire for a maximum voltage

drop of 1 VDC on 12-volt systems and 2 VDC on 24-volt systems. The following resistance table for solid

copper wire at 20° C may be helpful for sizing wire.

AWG GAUGE Ohms/1,000 FT.

18 6.385

16 4.016

14 2.525

12 1.588

10 0.9989

All Notification Appliances must be wired sequentially for proper supervision. The circuit's 10 KΩ ELR must

be removed from the control panel and connected to the circuit after the last Notification Appliance.

Regulated DC Output

Restorable primary power for detector and/or other low current electronic devices may be obtained from

Terminal 5 (-) and Terminal 7 (+). Do not connect inductive loads to these terminals. Nominal voltage output

is 12 VDC on 12-volt panels and 24 VDC on 24-volt panels. Maximum current available is 100 mA.

AC Power Connections

Primary power for the MP-12/24 is 120 VAC, 60 Hz, 0.50 A. Primary power for the MP-12/24E is 220/240

VAC, 50/60 Hz, 0.250 A. Connect terminal 1 (neutral) and 2 to a separate protected circuit, coming directly

from the line side of the main power feed to the building. No other equipment may be connected to the fire

alarm power circuit. Wire must run continuously, without disconnect devices, from the power source to the

fire alarm control panel. Overcurrent protection for this circuit must comply with article 760 of the National

Electrical Code and/or local codes. Use #14 AWG or larger wire with 600 V insulation.

Standby Battery Power

Battery selection and installation:

• Determine battery capacity from Table A.1.

• Read battery instruction sheet supplied with battery.

DANGER: Polarity must be observed when connecting battery.

• Connect battery cable to battery (Red wire to + terminal of battery. Black wire to - terminal of

battery).

• Route battery cable via 1/4" wide opening in the circuit board corner nearest P3. Do not allow

battery cable to be near heat-sinks on circuit board, since heat can damage the cable.

• Plug keyed female connector on end of battery cable onto terminal P3 of the circuit board.

CAUTION: Battery contains Sulfuric Acid which can cause severe burns to the skin and eyes and damage

to fabrics. In the event the battery leaks and contact is made with the Sulfuric Acid, immediately flush skin or

eyes with water for at least 15 minutes. For eyes, seek immediate medical attention. A good neutralizing

solution for Sulfuric Acid is water and household baking soda.

12

MP12/24 Fire Alarm Control Panel Document 15440:G 6/6/96

Page 13

Section Five:

Periodic Testing And Maintenance

To ensure proper and reliable operation, it is recommended that system inspection and testing be scheduled

monthly or as required by national and/or local fire codes. Testing should be done by a qualified services

representative if a malfunction is encountered.

Before testing:

1) Notify the fire department and/or central alarm receiving station if an alarm condition is transmitted.

2) Notify facility personnel of a test so that alarm sounding devices are ignored during the test period.

3) When necessary, activation of Notification Appliances can be prevented by pressing the DISABLE

switch.

Testing:

1) Activate a zone via an alarm initiating device and check that active Notification Appliances sound and

alarm LED lights. Reset system. Repeat for each zone.

2) Momentarily activate the following switches (one at a time) and check for a trouble signal:

• RESET

• DISABLE

3) Depress the TROUBLE SILENCE switch and check for an intermittent audible signal. Return TROUBLE SILENCE switch to normal position.

4) Momentarily open the following circuits one at a time and check for a trouble signal:

• Notification Appliance (bell) Circuit.

• Initiating Zone 1.

• Initiating Zone 2 (if employed).

5) If new batteries were installed, wait 48 hours before completing this step. Remove AC power, activate

zone and check that :

• the ALARM indicator lights.

• all active Notification Appliances sound.

Measure battery voltage while the Notification Appliances are sounding. Replace any battery with

terminal voltage less than 85% of rating. Reapply AC power and press RESET.

6) Return all switches to their normal outward positions. Notify fire department, central station and/or

building personnel that test is complete.

MP-12/24 Fire Alarm Control Panel Document 15440:G 6/6/96

13

Page 14

Section Six:

Troubleshooting Guide

Detailed acceptance testing procedures are beyond the scope of this manual. Such procedures must be

developed as part of the overall system installation. In each case, before the system is accepted into

service, it must meet the operating criteria established by the specifying engineer and endorsed by the

Authority Having Jurisdiction. Following is a checklist to aid in establishing operating criteria.

When full power is applied:

• The green power LED glows. No RED or YELLOW LEDs are on and no audible devices are sounding.

When an alarm is present:

• All activated alarm devices sound.

• The red alarm LED glows and the built-in audible device sounds steady.

When a trouble is present:

• The system trouble LED glows and the built-in audible device sounds while pulsing.

Troubleshooting Tips

• Don't panic. Calmly evaluate the symptoms.

• If more than one trouble is indicated, select a specific indication and troubleshoot it. It is better to

follow a logical sequence and not introduce any new problems.

• Prior to installation, check a new panel on the bench with ELRs whenever possible.

• On the job-site, determine as soon as possible if the problem is internal to the panel or in the external

circuits.

• Spare components (known to be good) are essential to fast, efficient troubleshooting.

• Follow the step by step procedures listed in this guide. Replacing components in a random manner

may cause additional damage to the system. Troubleshoot the component which has the trouble

indication and replace the component with a known good component.

• Always use voltage measurements when troubleshooting the panel.

• If you are unable to locate the problem by following these procedures, technical service is available

from the Fire•Lite Technical Services Department.

14

motpmySsisylanAmotpmySnoitcAlaidemeR

1 .ffoDELrewoPCA.

.ffoDELelbuorT

.noDELelbuorT

1 .54DdegamaD. .1 .draobtiucriCecalpeR

.1 .rewopniamfossoL .1 .rewopgnimocnikcehC

.2 tiucricdegamadroesufA1degamaD

.ffoDELrewoPCA.2

.rekaerb

.3 .DEL73DdegamaD .1 .draobtiucricecalpeR

.4 .ylppusrewopdegamaD .1 .sgnidaeregatlovrof1ProtcennockcehC

MP12/24 Fire Alarm Control Panel Document 15440:G 6/6/96

.1 .rekaerbtiucricroesufA1ecalpeR

.remrofsnartrewopecalpeR:egatlovoN

.2 .CAstlov82.xorppa5-1P/2-1P

Page 15

MP-12/24 Fire Alarm Control Panel Document 15440:G 6/6/96

15

Page 16

Symptom Symptom Analysis Remedial Action

4. Zone always

in alarm.

1. Defective detector. 1. Disconnect field wiring and install

ELRs. If panel resets to normal, check for

damaged or incorrectly wired detector

and replace it.

2. Typical zone supervisory current 5 mA

(approximately)

2. Shorted heat detector. 1. Locate detector and replace.

3. Activated station 1. Locate detector and replace.

4. Too many smoke

1.Reduce number of detectors.

detectors on zone.

5. Damaged circuit card. 1. Remove zone wires and install ELR

resistor.

2. If trouble clears, check field wires.

3. If trouble does not clear, replace

circuit board.

Appendix A: Battery Selection Guide

A 2.5 AH battery will power the control panel plus compatible two-wire detectors in the non-alarmed standby

mode for 60 hours and then operate the Notification Appliances for 5 minutes. If the control panel is providing

power to external devices other than two-wire detectors and Notification Appliances, use the following table to

determine the required battery capacity. Record battery information on the door label.

25 mA

Single

Zone

30 mA

Two

Zone

Standby

Requirements

24 hour Standby,

5 minute alarm,

NFPA 72A & 72D

60 hour Standby,

5 minute alarm,

NFPA 72B & 72C

24 hour Standby,

5 minute alarm,

NFPA 72A

60 hour Standby,

5 minute alarm,

NFPA 72B & 72C

2.5 AH 4.0 AH 4.5 AH 5.0 AH 5.5 AH 6.0 AH 7.0 AH

0.058 A 0.108 A 0.125 A 0.141 A 0.158 A 0.175 A 0.191 A

0.008 A 0.028 A 0.035 A 0.041 A 0.048 A 0.055 A 0.061 A

0.053 A 0.103 A 0.120 A 0.136 A 0.153 A 0.170 A 0.186 A

0.003 A 0.023 A 0.030 A 0.036 A 0.043 A 0.050 A 0.056 A

TABLE A.1: Maximum Current Available for Various Battery System Combinations.

1) The table shows the maximum current available for the operation of external power consuming devices connected

to the control panel for different capacity standby batteries.

2) Power consuming devices include 4-wire detectors, end-of-line relays, remote trouble signal devices (bell, horns

and lamps), remote station loading on MP-TR12/24 module, and any device powered from terminals 5 and 7.

3) Table A.1 is based on 80% battery use.

4) Batteries are float charged during normal standby operation. A discharged battery will charge and obtain its float

voltage within 48 hours.

5) Batteries available from Fire•Lite:

– PS-1242 12 Volt, 4.2 AH.

– PS-1270 12 Volt, 7.0 AH.

6) Required battery voltage is 12V for the MP-12; 24V for the MP-24.

Compatible Detectors

See the Device Compatibility Document (Document 15384).

16

MP12/24 Fire Alarm Control Panel Document 15440:G 6/6/96

Page 17

NOTES

MP-12/24 Fire Alarm Control Panel Document 15440:G 6/6/96

17

Page 18

NOTES

18

MP12/24 Fire Alarm Control Panel Document 15440:G 6/6/96

Page 19

NOTES

MP-12/24 Fire Alarm Control Panel Document 15440:G 6/6/96

19

Page 20

Limited Warranty

Fire-Lite® warrants its products to be free from defects in materials and workmanship

for eighteen (18) months from the date of manufacture, under normal use and service.

Products are date stamped at time of manufacture. The sole and e xclusive ob ligation

of Fire-Lite® is to repair or replace, at its option, free of charge for parts and labor, any

part which is defective in materials or workmanship under normal use and service.

For products not under Fire-Lite® manufacturing date-stamp control, the warranty is

eighteen (18) months from date of original purchase by Fire-Lite®'s distributor unless

the installation instructions or catalog sets forth a shorter period, in which case the

shorter period shall apply. This warranty is void if the product is altered, repaired or

serviced by anyone other than Fire-Lite® or its authorized distributors or if there is a

failure to maintain the products and systems in which they operate in a proper and

workable manner . In case of defect, secure a Return Material Authorization f orm from

our customer service depar tment. Return product, transportation prepaid, to Fire-

Lite®, One Fire-Lite Place, Northford, Connecticut 06472-1653.

This writing constitutes the only warranty made by Fire-Lite® with respect to its products.

Fire-Lite® does not represent that its products will prevent any loss by fire or otherwise,

or that its products will in all cases provide the protection for which they are installed

or intended. Buyer acknowledges that Fire-Lite® is not an insurer and assumes no

risk for loss or damages or the cost of any inconvenience, transpor tation, damage,

misuse, abuse, accident or similar incident.

Fire-Lite® GIVES NO WARRANTY, EXPRESSED OR IMPLIED, OF

MERCHANT ABILITY, FITNESS FOR ANY P ARTICULAR PURPOSE, OR O THERWISE

WHICH EXTEND BEY OND THE DESCRIPTION ON THE FACE HEREOF. UNDER

NO CIRCUMSTANCES SHALL Fire-Lite® BE LIABLE FOR ANY LOSS OF OR

DAMA GE T O PROPER TY, DIRECT, INCIDENTAL OR CONSEQUENTIAL, ARISING

OUT OF THE USE OF, OR INABILITY TO USE Fire-Lite® PRODUCTS.

FURTHERMORE, Fire-Lite® SHALL NOT BE LIABLE FOR ANY PERSONAL INJUR Y

OR DEATH WHICH MAY ARISE IN THE COURSE OF, OR AS A RESULT OF,

PERSONAL, COMMERCIAL OR INDUSTRIAL USE OF ITS PRODUCTS.

This warranty replaces all previous warranties and is the only warranty made by Fire-

Lite®. No increase or alteration, written or verbal, of the obligation of this warranty is

authorized.

"Fire-Lite" is a registered trademark.

One Fire-Lite Place, Northford, CT 06472

Phone: (203) 484-7161

FAX: (203) 484-7118

Technical Publishing Document WARFBG-D.P65 11/04/98

Loading...

Loading...