Fetco CBS6000, CBS-61H Installation Manual

User’s Guide

www.fetco.com

CBS-6000 Series Coffee Brewers

Models:

f CBS-61H

f CBS-62H

Table of Contents

Contact Information ................................................ 2

Product Description/Features ................................. 2

Technical Data........................................................ 2

Brewing Specification.......................................... 2

Weights and Capacities ...................................... 2

Electrical Configuration and Brewing Efficiency .3

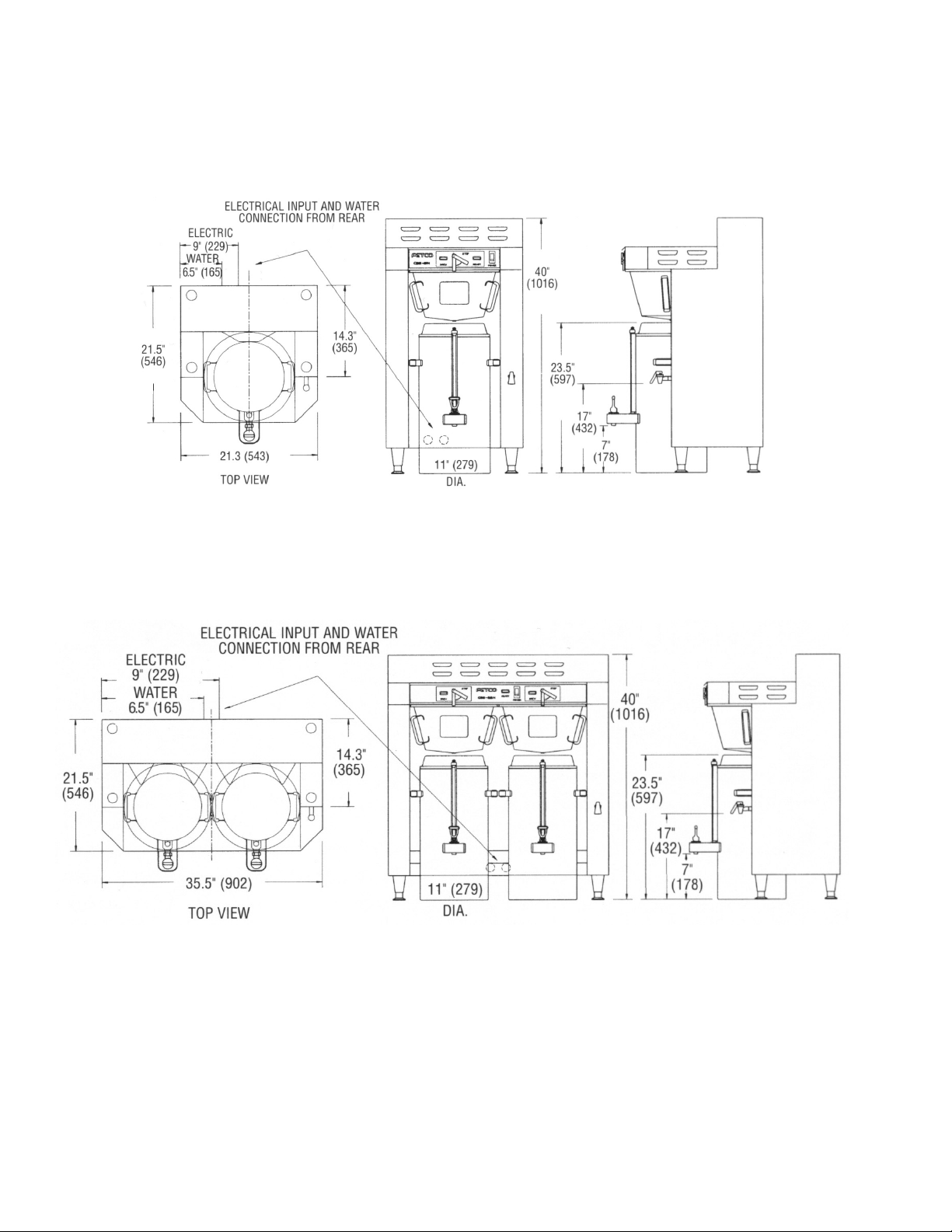

Dimensions & Utility Connections........................... 4

Installation............................................................... 5

Operating Procedures ............................................ 7

Service .................................................................... 8

FETCO® and LUXUS® are trademarks or trade names of Food Equipment Technologies Company.

© 2006 Food Equipment Technologies Company Part # P005 Revised January 9, 2006

Warranty.............................................................. 8

Principles of Operation........................................ 8

Adjustments ...................................................... 11

Dispenser Parts .................................................... 14

LUXUS TPD- 3.0............................................... 14

Brewer Parts ......................................................... 15

CBS 61H & 62H Parts List ................................ 15

Parts Drawing: CBS 61H & 62H ....................... 17

Troubleshooting.................................................... 18

Contact Information

FETCO

Food Equipment Technologies Company

600 Rose Road

Lake Zurich • IL • 60047-0429 • USA

Internet: www.fetco.com

Phone: (800) 338-2699 (US & Canada)

(847) 719-3000

Fax: (847) 719-3001

Email: sales@fetco.com

techsupport@fetco.com

Product Description/Features

CBS-61H - Single Coffee Brewing System

CBS-62H - Twin Coffee Brewing System

• 3 gallon, thermal, portable, all stainless steel dispensers

• Stainless steel, gourmet size brew baskets • Half batch brewing capability

• Brew basket double safety locks

• Open type, leak free dispense system • Color stainless steel finish

• Fully automatic, with electronic temperature control • Custom and export voltage

• Mercury type power contactor

• Two level tank drain system

• Total serviceability from the front

Optional Features:

(Can be added at any time)

Technical Data

Brewing Specification

Brew Volume: Temperature:

Full Batch 3 gal. (11.4 lit.)

Half Batch 1.5 gal. (5.7 lit.)

Brew Time: Bypass Range: 0 to 33%

Full Batch 5 - 5.5 min.

Half Batch 2.5 – 2.75 min.

(Allow an extra 2-4 minutes for coffee to finish dripping)

Coffee Filter Size: 20” X 8” – standard FETCO # F004

18” X 7½” - optional half batch FETCO # F005

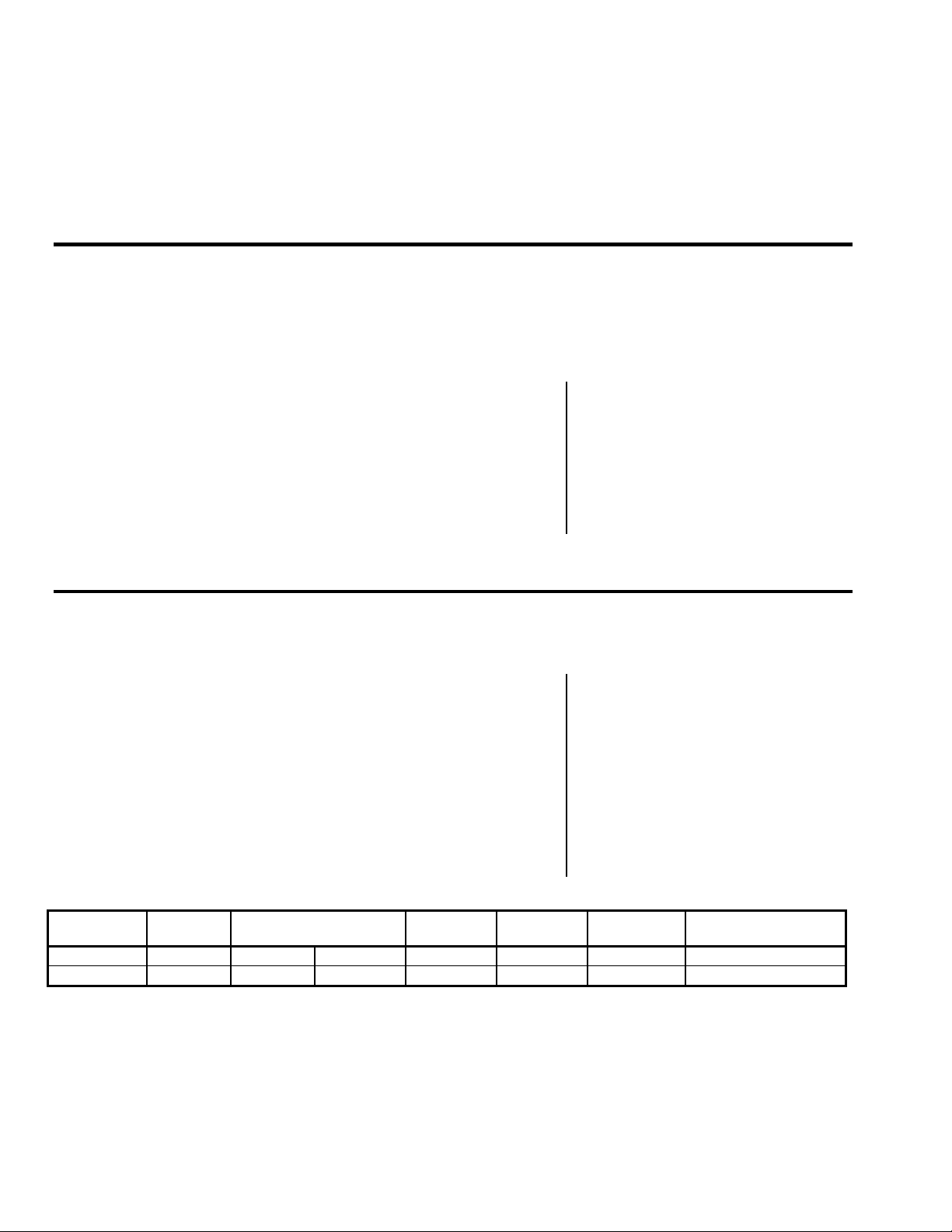

Weights and Capacities

Brewer

Model

CBS-61H 111 lbs. 8 gal. 66.4 lbs. 177 lbs. 18 lbs. 42.5 lbs. 220 lbs.

CBS-62H 195 lbs. 14 gal. 116.2 lbs. 311.2 lbs. 18 lbs. 42.5 lbs. 397 lbs.

Weight

(empty)r

Water tank

Capacity & Weight

Weight

(filled)

Dispenser

Weight, ea.

205°F inside water tank (at sea level)

195°F ± 5° at sprayhead

(Factory set at 0% unless specified)

Water Requirements:

CBS-61H: 20-75 psig, 1 gpm

CBS-62H: 20-75 psig, 2 gpm

Dispenser

Filled, ea.

Total Weight Brewer

& Dispensers, Filled

2

Electrical Configuration and Brewing Efficiency

CBS-61H

Electrical Heater Voltage Maximum Batches per Hour

Code Configuration Connection Phase Wires KW Amp draw Cold Water Hot Water

C61016 2 X 3000 watt 120/208 single 3 + ground 4.6 22.1 3.7 8.6

120/220 single. 3 + ground 5.2 23.4 4.3 9.0

120/240 single. 3 + ground 6.1 25.5 5.0 9.0

C61026 2 X 4000 watt 120/208 single. 3 + ground 6.1 29.3 5.0 9.0

120/220 single. 3 + ground 6.8 31.0 5.8 9.0

120/240 single. 3 + ground 8.1 33.8 6.6 9.0

C61036 3 X 3000 watt 120/208 three. 4 + ground 6.9 19.5 5.6 9.0

120/220 three. 4 + ground 7.7 20.6 6.5 9.0

120/240 three. 4 + ground 9.1 22.4 7.4 9.0

C61046 3 X 4000 watt 120/208 three. 4 + ground 9.1 25.8 7.4 9.0

120/220 three. 4 + ground 10.3 27.3 8.6 9.0

120/240 three. 4 + ground 12.1 29.7 9.0 9.0

C61146

Steam Heated Version

Electrical Maximum Steam Maximum Maximum

Code Steam Demand Pressure Volts Wires Amp draw Batches/Hour

C61986

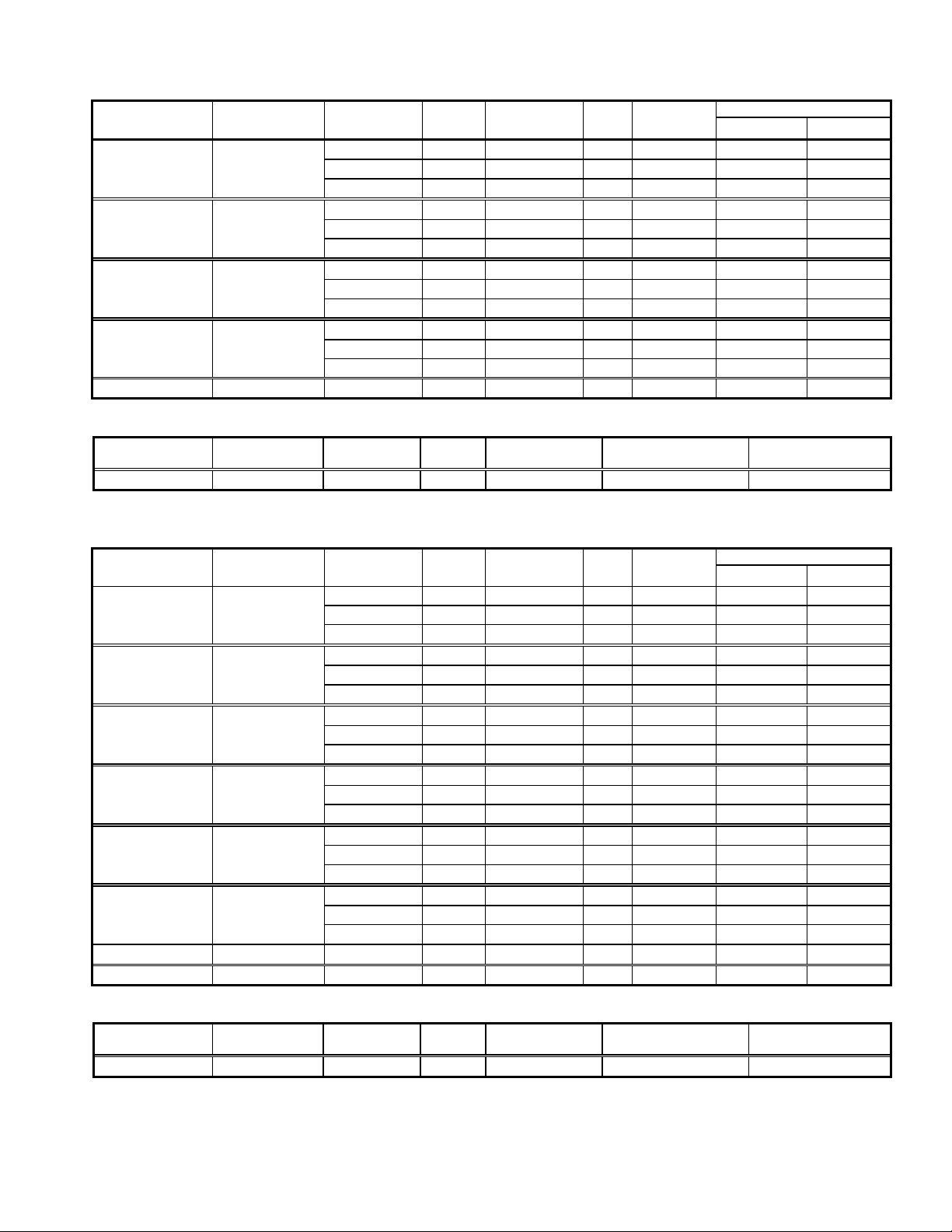

CBS-62H

Electrical Heater Voltage Maximum Batches per Hour

Code Configuration Connection Phase Wires KW Amp draw Cold Water Hot Water

C62016 3 X 3000 watt 120/208 single. 3 + ground 6.9 33.3 5.6 12.9

120/220 single. 3 + ground 7.7 35.2 6.5 14.9

120/240 single. 3 + ground 9.1 38.3 7.4 17.2

C62026 3 X 4000 watt 120/208 single. 3 + ground 9.1 44.1 7.4 17.2

120/220 single. 3 + ground 10.3 46.6 8.6 18.0

120/240 single. 3 + ground 12.1 50.8 9.9 18.0

C62036 3 X 3000 watt 120/208 three. 4 + ground 6.9 19.5 5.6 12.9

120/220 three. 4 + ground 7.7 20.6 6.5 14.9

120/240 three. 4 + ground 9.1 22.4 7.4 17.2

C62046 3 X 4000 watt 120/208 three. 4 + ground 9.1 25.8 7.4 17.2

120/220 three. 4 + ground 10.3 27.3 8.6 18.0

120/240 three. 4 + ground 12.1 29.7 9.9 18.0

C62056 6 X 3000 watt 120/208 three. 4 + ground 13.6 38.3 11.2 18.0

120/220 three. 4 + ground 15.3 40.5 12.9 18.0

120/240 three. 4 + ground 18.1 44.1 14.9 18.0

C62066 6 X 4000 watt 120/208 three. 4 + ground 18.1 50.8 14.9 18.0

120/220 three. 4 + ground 20.4 53.7 17.3 18.0

120/240 three. 4 + ground 24.1 58.5 18.0 18.0

C62146

C62166

Steam Heated Version

Electrical Maximum Steam Maximum Maximum

Code Steam Demand Pressure Volts Wires Amp draw Batches/Hour

C62986

3 X 4000 W 480 three. 3 + ground 12.1 22.5 9.0 9.0

40 lbs./hr. 10-15 PSI 120 2+ground 0.8 9.0

6 X 3000 W 480 three. 3 + ground 18.1 22.5 14.9 18.0

6 X 4000 W 480 three. 3 + ground 24.1 29.7 18.0 18.0

80 lbs./hr. 10-15 PSI 120 2+ground 0.8 18.0

3

CBS-61H

CBS-62H

Dimensions & Utility Connections

4

Installation

(For Qualified Service Technicians Only)

Keys To A Successful Installation

If not installed correctly by qualified personnel, the brewer may not operate properly and damage may result.

Damages resulting from improper installation are not covered by the warranty.

Here are the key points to consider before installation:

Electrical:

All FETCO brewers require NEUTRAL. Ground is not an acceptable substitute. Installation without neutral

may cause damage to the electronic components.

The power connection to L2 on the terminal block must be at least 105 volts. Less than 105 volts will cause

erratic behavior from the brewer.

The power switch has a built-in circuit breaker. To reset it, turn to the “off” position, and then back to the

“on” position.

The electrical drawing for the brewer is located on the inside of the lower cover.

Plumbing:

This equipment is to be installed to comply with the applicable federal, state, or local plumbing codes.

The water line must be flushed thoroughly prior to connecting it to the brewer to prevent debris from

contaminating the machine.

Verify that the water line will provide at least 1 gallon per minute for the CBS-61H, and 2 gallons per minute

for the CBS-62H before connecting it to the brewer.

General:

Utilize only qualified beverage equipment service technicians for installation. A Service Company Directory

may be found on our web site, http://www.fetco.com.

Installation Instructions

Brewer Setup

1. Review the Dimensions for the unit you are installing. Verify that the brewer will fit in the space intended for

it, and that the counter or table will support the total weight of the brewer and dispensers when filled.

2. The brewer’s legs are shipped inside the brew baskets. Remove the brew basket(s) and the coffee

dispenser(s). Place the brewer on its back and screw in the legs.

3. Place the brewer on the counter or stand.

4. When the brewer is in position, level it front to back

as well as side to side by adjusting the legs.

5. Remove the lower cover to access the water and

electrical connections. Knock-outs are provided in the

back and base of the brewer body for the

connections.

Warning: Legs are to be adjusted for

leveling the brew er only. Do not use

f or hei ght adjustment or extend them

higher than necessary.

Water Connection

1. Water inlet is a 3/8 inch male flare fitting.

2. The brewer can be connected to a cold or hot water line. Cold water is preferred for best coffee flavor, but

hot water will allow for faster recovery times.

3. Install a water shut off valve near the brewer to facilitate service. If an in-line water filter is used, it should

be installed after the water shut off valve and in a position to facilitate filter replacement.

4. Flush the water supply line and filter before connecting it to the brewer.

5. Verify that the water line will provide at least 1 gallons per minute for the CBS-61H, and 2 gallons per

minute for the CBS-62H, and that the water pressure is between 20 and 75 psig.

6. Use a wrench on the factory fitting when connecting the incoming water line. This will reduce stress on the

internal connections and reduce the possibility of leaks developing after the install has been completed.

5

Electrical Connections

1. Verify that the actual voltage at the electrical service connection is compatible with the specifications on the

brewer’s serial number label. Make sure the electrical service includes neutral.

2. The temperature and water tank fill level are pre-set at the factory. There is no need to turn off the heaters

during the installation process. The heaters are disabled by the control board until the tank is full of water.

The heating process will start automatically when the tank has filled.

3. Only 120vac powered units are shipped from the factory with power cords and plugs attached. For other

voltages, a terminal block is provided for connecting the incoming power wires. Consult local codes to

determine if a cord and plug can be installed, or if the unit must be hard wired.

4. A fused disconnect switch or circuit breaker on the incoming power line must be conveniently located near

the brewer, and its location and markings known to the operators.

5. The body of the brewer must be grounded to a suitable building

ground. A ground lug is provided in the brewer next to the power

terminal block. Use only 10 gauge copper wire for grounding.

6. Electrical connections must be secured in-place within the unit to

meet national and local standards.

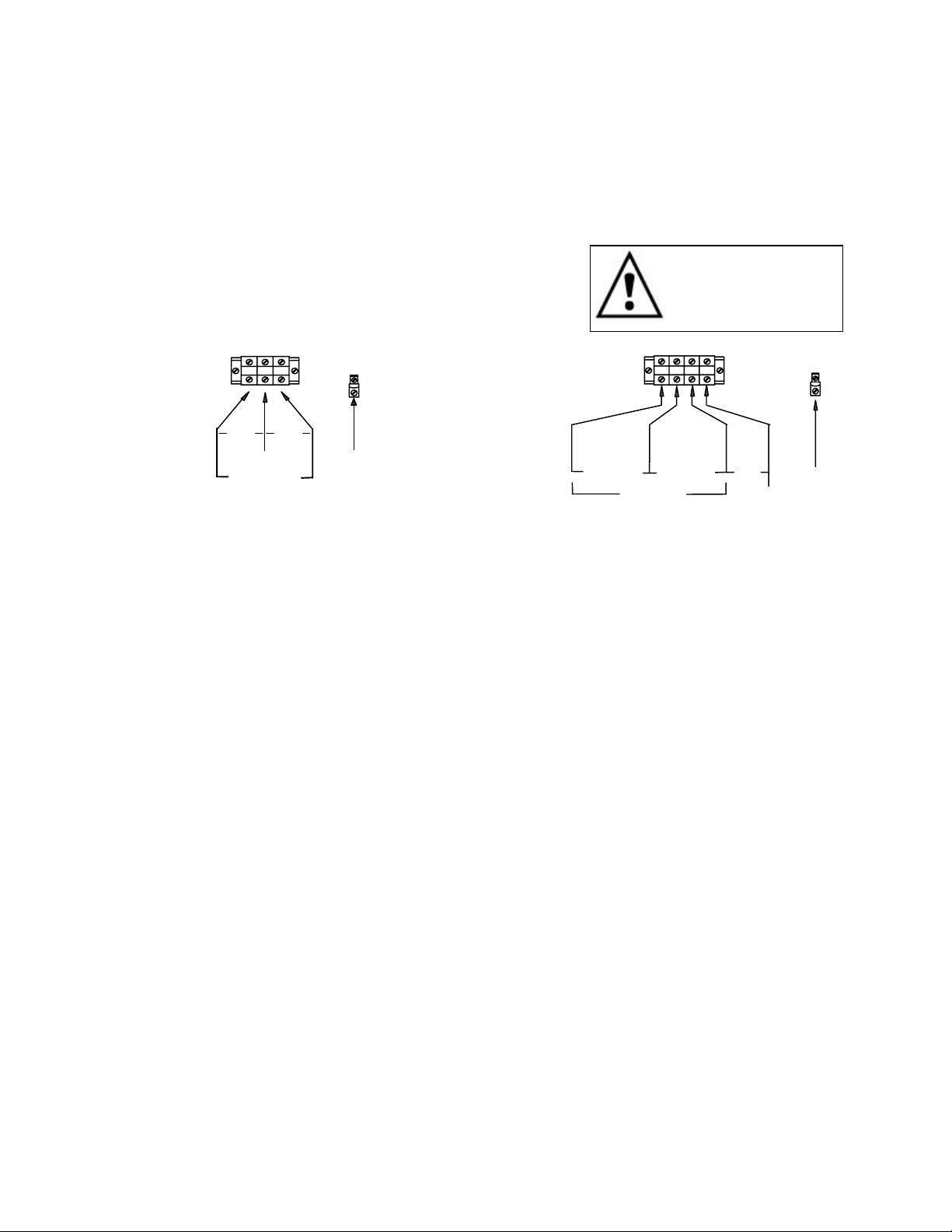

SINGLE PHASE

TERMINAL BLOCK

L1L2N

120V 120V

N

208-240V

GROUND LUG

GROUND

WIRE

TERMINAL BLOCK

3 PHASE

Warning : To prevent

electrical shock, t his

unit must be properly

gro un ded.

L1L2L3

208-240V 208-240V

208-240V

N

120V

GROUND LUG

N

GROUND

WIRE

Domestic Electrical Configurations

7. Finally, connect the incoming power wires to the terminal block in accordance with applicable codes.

Final Setup

1. Turn on the incoming water supply line and inspect both inside and outside of the brewer for leaks in all

fittings and tubes

2. Turn on the incoming power.

3. Turn on the brewer’s main power switch.

4. Within 6 seconds, the hot water tank will begin filling until the water is sensed by the probe at the top of the

tank.

5. The heaters will be disabled by the control board until the tank is full.

6. The brewer will be ready for operation as soon as the ready light comes on to show that the water tank is

up to temperature. The time required to reach brewing temperature will vary according to the electrical

configuration ordered.

7. Review the Operating Instructions. Brew one full batch (water only) on each side to confirm proper fill

levels. The brewer is factory set with water only (no coffee) to dispense the correct amount of water.

8. Re-attach the covers after one final inspection for leaks. Look closely in the top of the brewer at the

Operating Training

Review the operating procedures with whoever will be using the brewer. Pay particular attention to the following

areas:

dispense fittings during this inspection.

1. Always pre-heat the dispensers before the first use of each day by filling them half way with hot water, and

letting them stand for at least 15 minutes.

2. Don't remove the brew basket until it has stopped dripping.

3. Make sure the dispenser is empty before brewing into it.

4. Show how to attach covers, close, and or secure the thermal dispensers for transporting.

5. Show the location and operation of the water shut off valve as well as the circuit breaker for the brewer.

6. Steam from the tank will form condensation in the vent tubes. This condensation will drip into and then out

of the brew baskets. 1/4 cup discharging overnight is possible. Place an appropriate container under each

brew basket when not in use.

7. We recommend leaving the power to the brewer on overnight. The water tank is well insulated and will use

very little electricity to keep the tank hot. Leaving the brewer in the on position will also avoid delays at the

beginning of shifts for the brewer to reach operating temperature.

6

Operating Procedures

W

MAKE SURE

1. Turn brewer on/off switch (

• The power switch will illuminate to indicate that the brewer has

power and is operating.

• When the ready light

temperature. The amount of time required to gain full operating

temperature will vary depending on the electrical configuration

that was ordered, and the temperature of the incoming water.

2. Pre-heat the dispensers.

This step is very important to the overall success of the brewing

operation. FETCO avoids the damaging affects of heat on fresh brewed

coffee by using highly insulated dispensers. The dispenser must be preheated with hot water from the brewer. This preheating process ensures

that the coffee in the first brew starts out hot. Significant heat loss will

occur when brewing coffee into a cold dispenser. Preheating is not

required for subsequent brews unless the dispenser remains empty for an

extended period of time and has cooled down.

• Slide the empty brew basket(s)

empty dispenser(s) in position under the basket for preheating.

Select the half batch mode,

• When the ready light illuminates, start a brew cycle by rotating the

brew lever

(B) to the brew position. This starts clean hot water

flowing into the brew basket and then into the dispenser.

• Stop the cycle when each dispenser is approximately 1/2 full by moving the brew lever to the off

position. This interrupts the brew cycle and resets the brewer .

• Let the dispensers stand 10-15 minutes, or until use, to allow the heat from the water to be absorbed

by the dispensers.

3. Remove the brew baskets from the brewer when you are certain that the flow of hot water has stopped

from the bottom of the basket.

• H model brewers will have a safety bar

basket a 2-handed operation. This was done to help draw attention to the basket so any residual hot

water or coffee will be noticed by the operator.

• Place a paper filter in each basket to be used. Pour into the paper filter the appropriate amount of pre-

measured, ground coffee. The amount of coffee used will depend on your personal tastes and the

recommendation of your roaster.

• Slide the brew basket back into the rails on the brewer. Insure the latch is outside of the basket.

4. Carefully drain any coffee or preheating water from the dispensers through the faucets before starting

a coffee brewing cycle.

• Overflowing of the dispensers may result if the dispensers are not completely empty when the brew

cycle begins. Verify by opening the faucet over an appropriate container or drain. The last several cups

cannot be seen in the sight gauge tube.

• CAUTION: both the coffee or water may still be hot enough to cause burns, so be careful when

draining the dispensers

5. Place the thermal dispenser(s) in position under the brew baskets.

• Ensure that the brew funnel is in place, the dispenser is empty, the faucet is closed, and the vent cap

on the sight gauge is open.

• The twist lock cover is for transporting the dispenser only. It must be removed before placing the

dispenser under the brew basket.

6. Start the brew cycle in the same manner used to start the water used to preheat the dispensers.

• It will not be necessary to interrupt the cycle while brewing coffee. The brewer will return to the stopped

and ready status automatically.

• It is normal for the ready light to go out after the start of the brew cycle. On twin brewers, there is

enough hot water in the brewer to support a second brew, even if the ready light is off. After brewing on

both sides, you must wait for the ready light to come back on.

• The electrical configuration and the electrical power connected to the brewer will determine how long

before the ready light comes back on for the next brew.

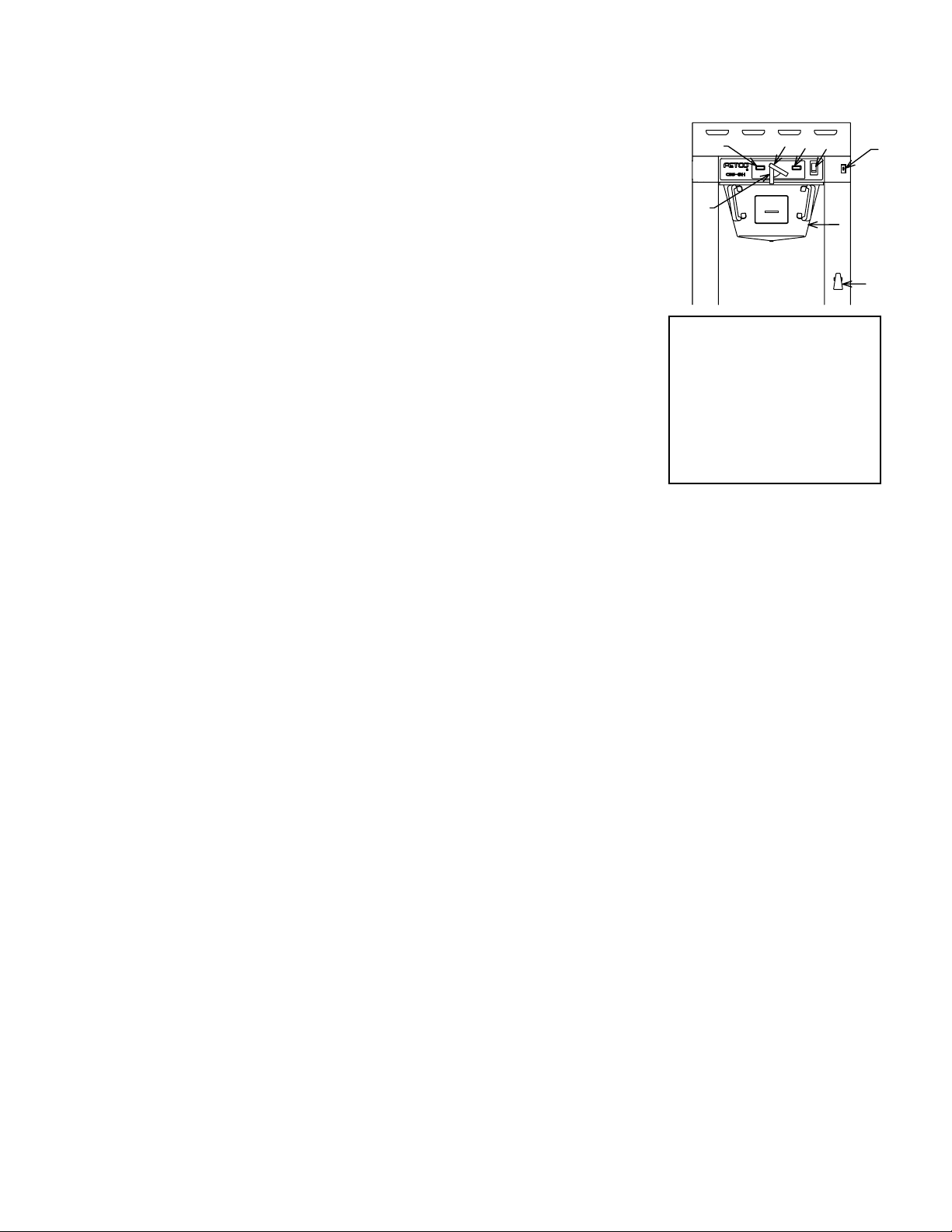

E) to the on position

(F) illuminates, the brewer is fully up to

(D) into their rails and put the

(A) if you have this option.

(C) in front of the brew basket to make removing the brew

G

BREW READY

CAUTION

C

HOT LIQUID

Legend:

Full/half batch switch

A-

Brew lever

BC-Safety bar

D-Brew basket

On/off switch

E-

Ready light

F-

Brew light

G-

Hot water faucet

H-

REMOVE BREW

B

E F

STOP

POWER

BRE

AFTER

A

D

H

7

CAUTION

p

g

p

• Do not remove the brew basket immediately after the brew cycle has finished. Wait until

dripping from the bottom of the brew basket has stopped. Carefully remove the brew basket

while inspecting the inside of the basket for hot coffee that may have been trapped or has not

finished draining.

TPD- 3.0 LUXUS Dispensers:

The LUXUS dispensers are super insulated. They will hold a 195 degree beverage hot for extended periods of

time. A full LUXUS will typically lose only 4 degrees per hour if the dispenser is preheated first with hot water.

Closing a LUXUS dispenser for transportation or storage must be done in the following steps to avoid spraying

beverages from the top of the sight gauge. Failure to follow these steps in order can cause a hydraulic reaction. By

moving the funnel vent cap down on the larger surface area of the main body an upward movement amplified many

times is created in the sight gauge. This forces the fluid out the top of the sight gauge vent.

1. Install the twist lock cover, ensuring that the safety lock

engages.

2. Close the sight gauge vent plug.

3. Close the twist lock cover funnel vent cap.

4. Open the LUXUS by reversing the above order.

Open the funnel vent cap first, then the sight gauge vent

cap.

Because the faucet body is metal, it will dissipate the beverage temperature over time. This temperature loss is

more noticeable with hot beverages than cold. If a dispenser of hot coffee goes unused, the first ounce or two will

be cool and should be discarded. Subsequent cups will be hot.

Cleaning:

Use the same techniques and products as you would use to clean any coffee urn i.e.

a) the sight gauge brush to scrub the gauge

b) urn brush for inside the dispenser

c) urn cleaner to clean the dispenser

d) stainless steel polish for the outside

e) hot water and towels for the faucet parts

Funnel Vent Ca

Twist Cover

Safety Lock

Gau

e Vent Ca

Service

Warranty

All FETCO brewers come with a limited warranty. All warranty service must be pre-authorized by calling the

FETCO Service Department at (800) 338-2699.

Principles of Operation

Fill System

The fill system consists of a liquid level control board, a water level probe at the top of the tank, a fill valve, and a fill

tube. As the water rises and touches the probe, continuity is established between the probe tip and the tank body,

and the fill valve closes.

When water is dispensed, the water level drops below the probe. After a 5 second delay, the fill valve opens until

the water touches the probe again.

The 5 second delay, and the speed that water refills the tank during brewing, results in many short bursts of water.

The sound made by these repetitive bursts will let you know the fill system is functioning normally.

8

Loading...

Loading...