Fetco CBS-2141XTS Service Manual

P130 rev. 002 FETCO CBS-2141 & CBS-2142XTS Brewers

User’s Guide and Operator Instructions

www.fetco.com

FETCO Extractor Touch Screen Models: CBS-2100XTS

Two Part User Guide FETCO Extractor Touch Screen Models: CBS-2100XTS

Extractor Touch Screen Commercial Hot Beverage Equipment

Table of Contents-

Part A: Universal CBS-2100 XTS Operation Instructions

First Brew........................................................................ |

2 |

Instructions for brew operation-fast brew ....................... |

2 |

Waiting Screens.............................................................. |

3 |

Service & Programming.................................................. |

4 |

Programming menu layout ............................................. |

5 |

Menu Features: Batch Parameters |

............................... 6 |

How to calibrate the flow rate...................................... |

10 |

Error Codes................................................................. |

12 |

Operator Training ........................................................ |

13 |

Part B: Installation and Service Guide for FETCO CBS-2141 & CBS-2142XTS Brewers

Contact Information

FETCO®

Food Equipment Technologies Company 600 Rose Road

Lake Zurich • IL • 60047-0429 • USA Internet: www.fetco.com

©2013-2016 Food Equipment Technologies Company

Phone: (800) 338-2699 (US & Canada) (847) 719-3000

Fax: (847) 719-3001 Email: sales@fetco.com

techsupport@fetco.com

PATENTS: WWW.fetco.com/patents

P130 |

REV:002 |

March 2016 |

First Brew

Instructions for brew operation-fast brew

Setup is simple

-Connect unit to water and electrical utilities

-Connect unit to water and electrical utilities

See instructions

-Turn unit “ON” to fill and heat

-Turn unit “ON” to fill and heat

The “READY” icon will display “Ready To Brew” with factory set defaults

-Add paper and ground coffee to brew basket

-Add paper and ground coffee to brew basket

The Specialty Coffee Association of America® (SCAA) guidelines are 55grams per liter

-Place appropriately sized, clean, empty and preheated dispenser under brewbasket.

-Place appropriately sized, clean, empty and preheated dispenser under brewbasket.

-Touch and briefly hold finger on screen as shown below to start brew -Note: “READY” icon is satisfied

-Touch and briefly hold finger on screen as shown below to start brew -Note: “READY” icon is satisfied

Factory setting total brew time is five minutes-thirty seconds. Brew time is four minutes with one and a half minute drip delay. Drip delay allows the brew basket to completely empty the brewed coffee

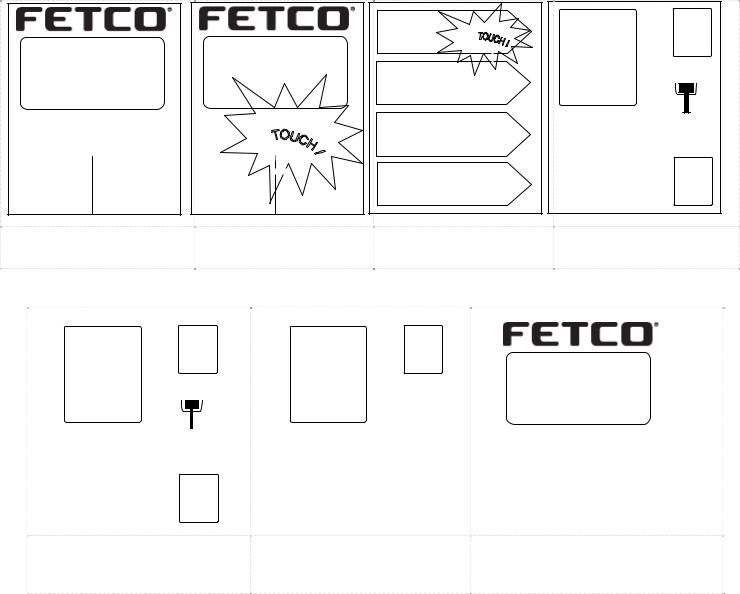

Brew operation is simple. The intuitive touch screen-STARTS THE BREW

CBS-2141XTS single side brewer is displayed. Screen shown approximately the same size as on equipment

XTS™ |

XTS™ |

||

EXTRACTOR |

EXTRACTOR |

||

TOUCHSCREEN |

TOUCHSCREEN |

||

CBS_2141 |

CBS_2131 |

||

Ready |

Touch |

Ready |

Touch |

Heating |

screen |

Heating |

screen |

Filling |

to unlock |

Filling |

-to unlock |

Regular 1 |

|

| | 0.80 |

- |

5:30 |

|

Regular 2 |

|

| | 0.80 |

|

5.30 |

|

Decaf 1 |

|

| | 0.80 |

|

5.30 |

|

Decaf 2 |

|

| | 0.80 |

|

5:30 |

|

Regular 1

INFO

| | 0.805::30 °C 93

05:30

STOP

1) With ready icon displayed 2) Hold finger on screen to activate brew menu

3)Touch and hold pennant to |

4) Brew Started |

start brew |

|

|

Regular 1 |

|

Regular 1 |

|

|

|

|

|

||||

|

INFO |

|

5:30 |

INFO |

|

XTS™ |

||||||

|

5:30 |

|

|

|

|

|

|

|

||||

|

| | 0.80 |

|

|

|

|

|

| | 0.80 |

|

|

|

|

|

|

°F 200 |

|

|

|

|

|

°F 200 |

[_ _] |

|

EXTRACTOR |

||

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

6 |

|

TOUCHSCREEN |

||

|

|

|

|

|

|

|

|

01:29 |

|

CBS_2131 |

||

|

01:30 |

|

|

|

||||||||

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

Ready |

|

Touch |

|

|

|

|

|

|

|

|

|

|

|

||

|

STOP |

|

|

|

|

Heating |

|

screen |

||||

|

|

|

|

|

Filling |

|

to unlock |

|||||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

5) Brew has completed, Drip delay |

Drip delay icon |

|

Return to home screen |

|||||||||

sequence will start. Brew is still |

(brew basket locked) |

|

|

|

|

|||||||

active |

|

|

|

|

|

|

||||||

Go to fetco.com for the latest versions of all information |

Page 2 |

Part A-User Guide & Operator instructions P130 Part A Rev. 002 March 2016 |

Regular 1 |

|

|

|

INFO |

|

|■| 0.80 |

╣║╠ |

|

5.30 |

||

°F 200 |

▐▄▌ |

|

▐ |

||

|

05:30 |

|

MENU Status Window |

|

|

-Name of batch |

Brew process |

|

-Brew size (1 gallon) |

||

phase icon and |

||

-Toatal Brew time |

||

time-out |

||

-Brew temperature |

||

|

INFO icon is present but

inactive. STOP INFO is always displayed in

box to left.

Activated brew screen menu status in box and displays time

Regular 1

INFO

|■| 0.80 |

|

|

5:30 |

[_ _] |

|

°F 200 |

||

6 |

||

|

||

|

01:59 |

STOP

Drip delay icon (brew basket locked)

Regular 1 |

Regular 1 |

|

|

|■| 0.80 |

INFO |

||

INFO |

|||

5:30 |

|

||

|■| 0.80 |

|

||

|

|

||

5:30 |

Regular 2 |

|

|

°F 200 |

|■| 0.80 |

|

|

|

5:30 |

|

|

(<)199°F |

Decaf 1 |

Heat |

|

|■| 0.80 |

|||

Unit is heating |

|

||

5:30 |

|

||

and will start |

|

||

when above |

|

|

|

200° F |

Decaf 2 |

GENERAL |

|

|

|||

START |

|■| 0.80 |

STOP |

|

|

5:30 |

|

|

Unit(singlebelowsideset temperaturebrewer) -Unit(dualbelowsideset temperaturebrewer) |

|||

Brew operation-intuitive touch screen- When brew is started-the equipment displays the brew process graphically as shown Screens for dual brewer. CBS-2132XTS shown

|

|

Regular 1 |

|

|

|

| | 3:00 |

|

XTS™ |

6:00 |

||

Regular 2 |

|||

|

|

||

EXTRACTOR |

| | 3:00 |

||

TOUCHSCREEN |

-6:00 |

||

CBS_2132 |

Decaf 1 |

||

| | 3:00 |

|||

|

|

||

Ready |

Touch |

6:00 |

|

Decaf 2 |

|||

Heating |

screen |

||

| | 3:00 |

|||

Filling-to unlock |

|||

6:00 |

|||

Regular 1 |

|

|

| | 3:00 |

INFO |

|

6:00 |

||

|

||

Regular 2 |

|

|

-| | 3:00 |

|

|

6:00 |

|

|

Decaf 1 |

05:30 |

|

| | 3:00 |

||

6:00 |

|

|

Decaf 2 |

|

|

| | 3:00 |

STOP |

|

6:00 |

|

1)Home screen activated, |

2) Recipe1-Right side |

3) Recipe 1 brew started |

twin brewer |

selected |

Starting-leftÆrecipe 1 |

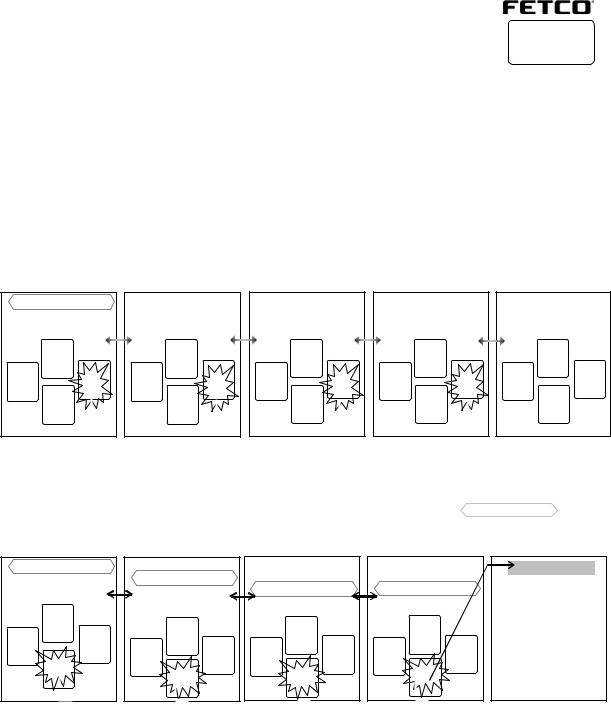

Waiting Screens

INFO INFO

05:30 |

04:44 |

STOP STOP

4) Left brew started, both sides brewing

XTS™

EXTRACTOR

TOUCHSCREEN

CBS_2132

Ready |

Tank T °F |

Heating |

≤197°F |

Filling

1)Hot water tank temp too low. Brew cannot start. Note the :READY” icon is off & the “HEATING” icon

is on. Brewer in “Automatic” temperature

Regular 1 |

INFO |

| | 3:00 |

6:00 |

°C 93 |

HEAT |

STOP |

2) Brew at Temperature feature is set to “AUTO” and hot water tank temperature is too low. Brew will start when tank is at set-point.

Regular 1 |

< |

GENERAL |

> |

||

INFO |

< Brew at Temperature > |

||||

|

|

|

|

|

|

| | 3:00 |

|

|

|

|

|

6:00 |

|

|

ON |

|

|

°F 200 |

|

|

[] |

|

. |

|

|

OFF |

ON |

AUTO |

|

(<)92°C |

|

|

|

|

|

START |

|

<< |

S |

|

>> |

3) Brew at Temperature |

4) Programming screen for |

||||

feature is “OFF”” and hot |

“Brew at Temperature” Unit |

||||

water tank temperature is |

is set by FETCO for “ON. |

||||

below set point. Pressing |

“OFF and “AUTO” settings |

||||

“START” will begin brew at |

are not recommended |

||||

low water temperature! |

|

|

|

|

|

Go to fetco.com for the latest versions of all information |

Page 3 |

Part A-User Guide & Operator instructions P130 Part A Rev. 002 March 2016 |

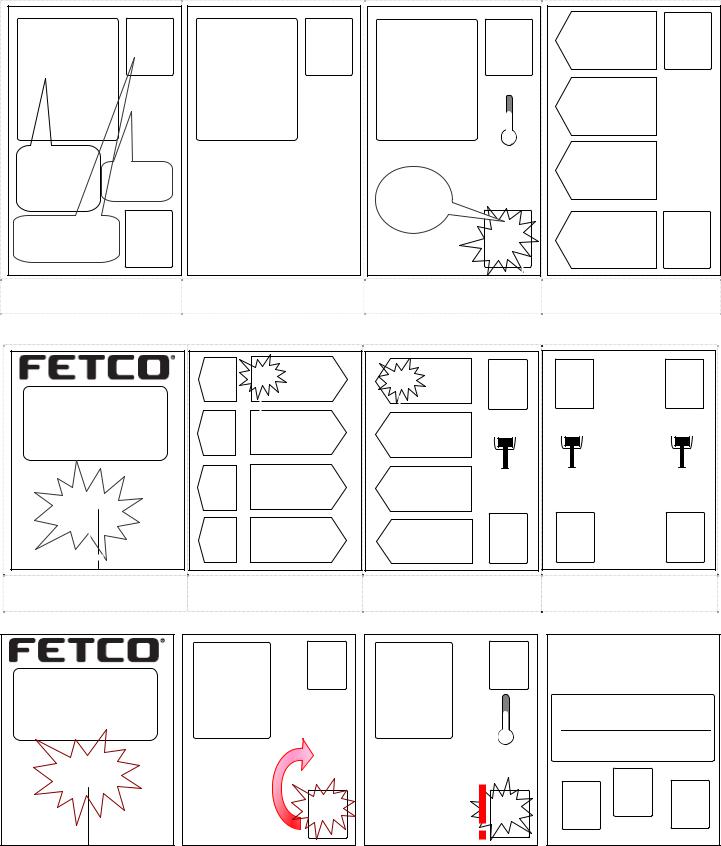

Service & Programming

Menu adjustments, name selection, programming, error codes, counters are accessed by activating touch screens.

To access the General Service Menu

PROGRAM, GENERAL, INPUTS, OUTPUTS, and OTHER (Service Menu).

ÆEnter Service Menu by accessing the power switch on back of the panel |

XTS™ |

|||

1)-Switch power “OFF” with power switch located on rear of brewer |

||||

EXTRACTOR |

||||

2)-After at least ten seconds: Turn power switch “ON” |

TOUCHSCREEN |

|||

3)-Quickly touch and hold the XTS screen to enter the programming screens as shown below |

CBS_2100XTS |

|||

4)-When entering The SERVICE MENU: the first screen in the group is “PROGRAM” |

Ready |

|

Touch |

|

|

||||

5)-Use right and left arrow icons to navigate through the five main SERVICE menu groups. |

Heating |

|

screen |

|

Filling |

|

to unlock |

||

6)-The DOWN arrow navigation icon will open the FEATURE icon below. |

|

|||

|

|

|

||

- |

||||

6a)-Navigate through the Menu Item with the arrows, edit any if needed |

||||

6b)-When finished editing—press the UP arrow to go back through the menu items to save changes and exit 7)-The chart on the next page give the general service menu topics, the pages following list the details of the topics ÆWhen navigating up to “EXIT” leaves the Service Menu Screens and SAVES your settings on exiting.

The Menu Chart on the next page shows the main categories of the five SERVICE menus

When SERVICE MENU is entered—the first selection is “PROGAMMING Mode ”

Scroll through the five programming categories using the right and left arrow icons.

Five Progamming |

< PROGRAM > |

< GENERAL > |

< INPUTS > |

< OUTPUTS > |

|||||||

< Batch 1 Left > |

<Tank Temperature> |

<Display Inputs> |

<Show Summary> |

||||||||

Menus |

|

||||||||||

|

|

|

|

|

|

|

|

|

|

||

|

|

^ |

>> |

^ |

>> |

^ |

>> |

|

^ |

>> |

|

|

|

<< |

<< |

<< |

<< |

|

|||||

|

|

|

TOUCH |

|

TOUCH |

|

TOUCH |

|

|

TOUCH |

|

|

|

V |

- |

V |

- |

V |

- |

|

V |

|

|

|

Use right and left arrow icons to navigate between the five main SERVICE menus- |

||||||||||

< OTHER >

<Error Codes >

^

<< >> V

Navigating PROGRAMMING MENUES

Highlight desired menu path and location and use arrow icons to navigate service menu screens. HIGHLIGHT

First menu screen is “PROGRAM”Æ Note highlighted Path and Topic

< PROGRAM > |

< PROGRAM > |

< PROGRAM > |

< PROGRAM > |

||||

< Batch 1 Left > |

< Batch 1 Left > |

< Batch 1 Left > |

< Batch 1 Left > |

||||

|

|

< Batch Summary> |

< Batch Summary> |

||||

|

|

|

|

||||

|

|

|

|

|

|

< Display Summary > |

|

|

^ |

|

^ |

|

^ |

|

^ |

<< |

>> |

<< |

<< |

<< |

|||

|

-V |

>> |

>> |

>> |

|||

|

|

V |

|

V |

|

V |

|

|

Highlight programming-path and use arrows-to locate programming-screen |

||||||

Right 1 Summary

Batch Name |

Regular 1 |

|

Batch Volume |

3.05 liter |

|

Brew Time |

|

4 :00 |

Number of Pulses |

8 |

|

Prewet Percent |

0 % |

|

Prewet Delay |

|

0:00 |

Drip Delay |

|

2:00 |

Touch to return

Go to fetco.com for the latest versions of all information |

Page 4 |

Part A-User Guide & Operator instructions P130 Part A Rev. 002 March 2016 |

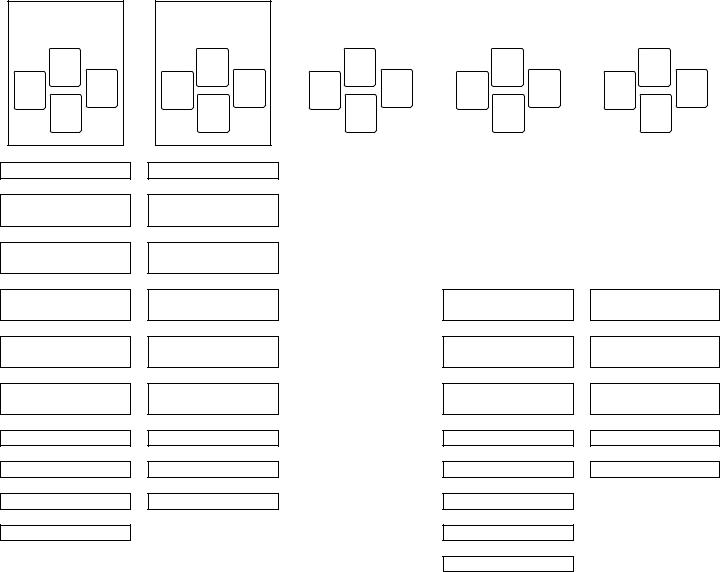

Programming menu layout

XTS Main Menu

<PROGRAM >

<Batch 1 Right >

EXIT

<< >> V

|

PROGRAM

|

Batch 1 Right*

(Or) Batch 1 Left*

|

Batch 2 Right†

Or Batch 2 Left†

|

Batch 3 Right†

Or Batch 3 Left†

|

Batch 4 Right†

Or Batch 4 Left†

|

Batch 1 Right* (Dual side brewer)

|

Batch 2 Right†

|

Batch 3 Right†

|

Batch 4 Right†

|

Batch Copy

<GENERAL>

<Tank Temp >

EXIT

<< >> V

|

GENERAL

|

Tank Temp

|

Brew at Temp

|

Units of Measure.

|

ECO Mode

|

LOGO

Timeout

|

Brew B. Sensor

|

Use Flojet®

|

LLC Sensitivity

Menu Chart-XTS

|

< INPUTS > |

|

|

|

< OUTPUTS > |

|

|

|

< OTHER > |

|

|||

|

< Display Inputs > |

|

|

|

<Show Summary> |

|

|

|

< Error Codes > |

|

|||

|

|

EXIT |

|

|

|

EXIT |

|

|

|

|

|

EXIT |

|

|

<< |

>> |

|

|

|

<< |

>> |

|

|

|

<< |

>> |

|

|

|

V |

|

|

|

V |

|

|

|

|

|

V |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| |

|

|

|

|

|

| |

|

|||

|

|

INPUTS |

|

|

|

OUTPUTS |

|

|

|

|

OTHER |

|

|

|

|

| |

|

|

| |

|

|

|

|

|

| |

|

|

|

|

Display |

|

|

|

Show |

|

|

|

|

Error Codes |

|

|

|

|

Inputs |

|

|

|

Summary |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

| |

|

|

| |

|

|

|

|

|

| |

|

|

|

Calibrate Touch |

|

|

|

Left Valve |

|

|

|

Copy Program |

|

|||

|

|

Screen |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L.Bypass Valve

|

Right Valve

|

R.Bypass Valve

|

Fill Valve

|

L.B.Basket Lock

|

R.B.Basket Lock

|

Heater

|

Screen

|

Upload LOGO

|

Reset to Factory

|

Counters

|

Firmware

|

DEMO Mode

Go to fetco.com for the latest versions of all information |

Page 5 |

Part A-User Guide & Operator instructions P130 Part A Rev. 002 March 2016 |

Menu Features: Batch Parameters

PROGRAM |

Programming Items |

Factory set Default |

Programming Range |

|

Notes |

|

|

|||

Batch 1 LEFT* |

• |

Batch Summary |

Display Summary |

Entire recipe display |

Example at bottom of column |

|||||

|

• |

Batch Name |

Regular 1(-16) |

Choose from list: |

|

(Regular 1-16) |

||||

|

Regular1 |

|

|

-OR- Write: any name |

||||||

Models CBS-2130, CBS- |

• |

Batch Volume |

0.80 to 3:00 gal |

3L/1gal -3.00 gal |

Screen will display in range |

|||||

2140, CBS-2150 & CBS- |

|_________[]________| |

|

and units selected |

|||||||

2160XTS- |

|

|

|

0.25-0.5gal 1.25-3.10gal |

CBS-2160XTS is 3:00 gal |

|||||

|

• |

Brew Time |

4:00mm:ss |

4:00 mm:ss |

|

|

CBS-2160XTS 4:30 min |

|||

|

[ 2:00-10.00] |

|_____[]___________| |

|

|||||||

|

|

|

2:00-4.00 min |

10:00 |

|

|

|

|

||

|

• |

Nr Of Pulses |

8 |

8 |

|

|

CBS-2160 has minimum |

|||

|

|_____[]___________| |

|

||||||||

|

|

of 2 pulses |

||||||||

|

|

|

|

1 |

30 |

|

||||

|

|

|

|

|

|

|

|

|||

|

• |

Prewet Perc. |

0% |

0 % |

|

|

|

|

|

|

|

|_[]_______________| |

|

|

|

|

|||||

|

|

|

|

0 |

15 |

|

|

|

|

|

Pause after prewet |

• |

Prewet Delay |

0% |

0:00 mm:ss |

|

This feature appears ONLY if |

||||

|_[]_______________| |

||||||||||

completes |

|

Prewet >0:00 |

||||||||

|

|

|

0:00 |

1:00 |

|

|||||

|

|

|

|

|

|

|

|

|||

|

• |

Bypass Perc. |

0% |

0 % |

|

|

|

|

|

|

|

|_[]_______________| |

|

|

|

|

|||||

|

|

|

|

0 |

40 |

|

|

|

|

|

This is a |

• |

Drip Delay |

1:30 mm:ss |

1:30 mm:ss |

|

|

Time that brew basket |

|||

2:00 mm:ss for |

|_____[]___________| |

remains locked during final |

||||||||

Safety Feature |

||||||||||

|

|

CBS-2160 |

0:30 |

5:00 |

|

drip-out |

|

|

||

|

|

|

|

|

|

|||||

Batch 2 Left** |

|

**[Batch 2-4-Right |

and Batch2-4-Left] |

may be individually |

selected-or-entirely deleted |

|||||

|

• |

Batch ON/OFF |

ON |

ON |

|

This feature is only on 2-4 |

||||

|

|_________[]________| |

|||||||||

|

Batch 1 cannot be turned off |

|||||||||

|

|

|

|

ON |

OFF |

|||||

|

|

|

|

|

|

|

|

|||

|

• |

Batch Name |

Regular 1(-16) |

Choose from list: |

|

(Regular 1-16) |

||||

|

Regular1 |

|

|

-OR- Write: any name |

||||||

Models CBS-2130, |

• |

Batch Volume |

0.80 to 3:00 gal |

3L/1gal -3.00 gal |

Screen will display in range |

|||||

CBS-2140, CBS-2150 & |

|_________[]________| |

|

and units selected |

|||||||

CBS-2160XTS- |

|

|

|

0.25-0.5gal 1.25-3.10gal |

CBS-2160XTS is 3:00 gal |

|||||

|

• |

Brew Time |

4:00mm:ss |

4:00 mm:ss |

|

|

CBS-2160XTS 4:30 min |

|||

|

[ 2:00-10.00] |

|_____[]___________| |

|

|||||||

|

|

|

2:00-4.00 min |

10:00 |

|

|

|

|

||

|

• |

Nr Of Pulses |

8 |

8 |

|

|

CBS-2160 has minimum |

|||

|

|_____[]___________| |

|

||||||||

|

|

of 2 pulses |

||||||||

|

|

|

|

1 |

30 |

|

||||

|

|

|

|

|

|

|

|

|||

|

• |

Prewet Perc. |

0% |

0 % |

|

|

|

|

|

|

|

|_[]_______________| |

|

|

|

|

|||||

|

|

|

|

0 |

15 |

|

|

|

|

|

Pause after prewet |

• |

Prewet Delay |

0% |

0:00 mm:ss |

|

This feature appears ONLY if |

||||

|_[]_______________| |

||||||||||

completes |

|

Prewet >0:00 |

||||||||

|

|

|

0:00 |

1:00 |

|

|||||

|

|

|

|

|

|

|

|

|||

|

• |

Bypass Perc. |

0% |

0 % |

|

|

|

|

|

|

|

|_[]_______________| |

|

|

|

|

|||||

|

|

|

|

0 |

40 |

|

|

|

|

|

This is a |

• |

Drip Delay |

1:30 mm:ss |

1:30 mm:ss |

|

Time brew basket remains |

||||

2:00 mm:ss for |

|_____[]___________| |

|||||||||

Safety Feature |

|

locked during drip-out |

||||||||

|

|

CBS-2160 |

0:30 |

5:00 |

|

|||||

|

|

|

|

|

|

|

||||

Batch 3 Left ** |

(See Batch 2-Left) |

|

|

|

|

|

|

|

||

|

|

|

|

Batch 1 Right … |

|

|||||

Batch 4 Left ** |

(See Batch 2-Left) |

|

|

|

|

|

||||

|

|

|

Batch Name |

Regular 1 |

||||||

Batch 1 Right * |

(See Batch 1-Left) |

|

|

|

||||||

|

|

|

Batch Volume |

3.00 gal |

||||||

Batch 2 Right ** |

(See Batch 2-Left) |

|

|

|

||||||

|

|

|

Brew Time |

4 :00 |

|

|||||

Batch 3 Right ** |

(See Batch 2-Left) |

|

|

|

|

|||||

|

|

|

|

|

|

|

||||

Batch 4 Right ** |

(See Batch 2-Left) |

|

|

|

Number of Pulses |

8 |

|

|||

Batch Copy |

Copy From Batch |

L1 |

L1-L4;R1-R4 |

|

||||||

|

Copy To Batch |

L1 |

L1-L4;R1-R4 |

Prewet Percent |

0 % |

|

||||

|

Copy? |

L1ÆL2? |

NO |

|

Prewet Delay |

0:00 |

|

|||

|

(example) |

|_______________[]__| |

Drip Delay |

1:30 |

|

|||||

|

|

|

YES |

NO |

|

|||||

*Batch 1 RIGHT Side & Batch 1 LEFT Side cannot be disabled. (TWIN Brewer CBS-2102XTS) |

|

|

Touch to return |

|||||||

*Batch 1 cannot be disabled. (SINGLE Brewer )**Batch 2-4 can be disabled, and removed from display |

|

|

(Example screen for |

|||||||

|

|

Batch Summary display) |

||||||||

Go to fetco.com for the latest versions of all information |

Page 6 |

Part A-User Guide & Operator instructions P130 Part A Rev. 002 March 2016 |

|

GENERAL |

Programming Items |

Factory set Default |

Programming Range |

Notes |

||||

|

|

|

|

|

|

|

|

|

|

|

|

• |

Tank Temp. |

200°F |

[200 |

°F] |

Chart to correct for |

||

|

|

|______________[]___| |

|||||||

|

|

high altitude below |

|||||||

|

|

|

|

|

|

|

77C/170F |

97C/207F |

|

|

“OFF” allows |

• |

Brew at Temp. |

“ON” |

ON |

SEE NOTE BELOW! |

|||

|

brewing at any |

|________[]_______| |

|||||||

|

temperature. |

|

|

|

|

|

OFF ON AUTO |

|

|

|

|

• |

Units of Meas. |

°C or °F |

°F |

[Switchable Units] |

|||

|

|

|___[]____________| |

|||||||

|

|

• |

Temperature |

||||||

|

|

|

|

|

°F |

°C |

|

||

|

|

|

Volume |

Gallons [Liters] |

Gallons |

[Switchable Units] |

|||

|

|

• |

|_____________[]__| |

||||||

|

|

|

|

|

|

|

Gallons |

Liters |

|

|

Energy |

• |

ECO Mode |

OFF |

ECO Mode |

If Selected: After 1 hour of |

|||

|

_______________[]_____ |

inactivityÆLowers hot water |

|||||||

|

Saving Mode |

||||||||

|

tank temperature to 170°F |

||||||||

|

|

|

|

|

|

|

ON |

OFF |

|

|

|

• |

Logo Timeout |

0:15 mm:ss |

0:15 mm:ss |

|

|||

|

|

|__[]___________| |

|

||||||

|

|

|

|

|

|

|

0:15 |

5:00 |

|

|

This is a |

|

|

|

|

|

NORMAL |

Factory or service use for |

|

|

• |

Brew B. Sensor |

|

NORMAL |

|

||||

|

|

|

|__[]____________| |

servicing. “NORMAL” is |

|||||

|

Safety Feature |

(SEE WARNINGS) |

|||||||

|

NORMAL |

OVERRIDE |

recommended for safety. |

||||||

|

|

• |

Use Flowjet |

NO |

NO |

Trims water handling |

|||

|

|

____[]_______________ |

|||||||

|

|

system for Flowjet |

|||||||

|

|

|

|

|

|

|

NO |

YES |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

“NORMAL” for |

• |

LLC Sensitivity |

NORMAL |

NORMAL |

Liquid level control sensitivity. |

|||

|

most water |

____[]______________ |

High is for reverse osmosis |

||||||

|

“HIGH” for R.O. |

|

|

|

|

|

NORMAL |

HIGH |

water or very pure water. |

BREW AT TEMPERATURE DEFINITONS |

|

|

|

||

-------------------------------------------------------------------------------- |

|

|

|

||

|

|

|

|||

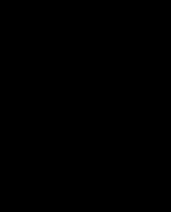

BREW AT TEMP: “ON” |

|

|

|

|

|

(DEFAULT: FACTORY PROGRAMMED INTO BREWER) |

XTS™ |

||||

“BREW START” Batch Section Pennants will not be accessible |

EXTRACTOR |

||||

until tank temperature is at set point. |

TOUCHSCREEN |

||||

The “BREW START” screens with the Batch Section Pennants |

CBS 2100XTS |

||||

■ Ready |

|

|

|||

|

|

||||

become accessible when hot water tank is at the selected |

Heating |

Tank Temp |

|||

temperature. A screen (example to the right) will display |

Filling |

|

200°F |

||

and show “BREW AT TEMP” is selected. Æ |

|

||||

|

|

|

|||

-------------------------------------------------------------------------------- |

|

|

|

||

|

|

|

|||

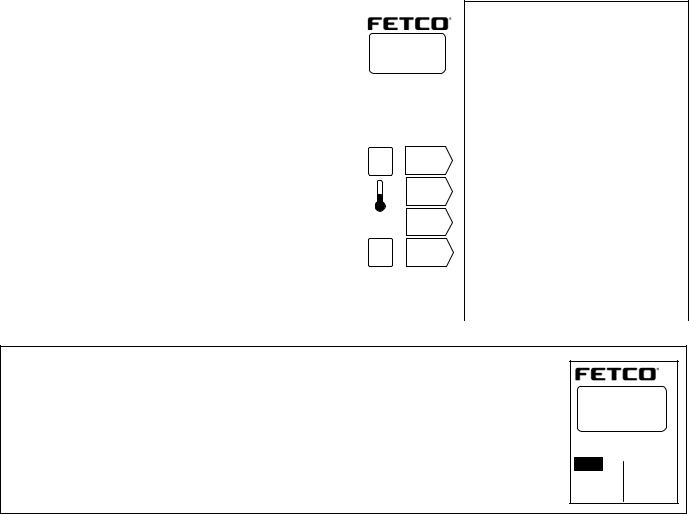

BREW AT TEMP: AUTO |

USER SELECTABLE |

|

Regular 1 |

||

“BREW START” will pause if the hot water tank is not at the |

INFO |

|■| 1:00 |

|||

|

5:30 |

||||

selected temperature—and automatically start when it is at the |

|

Regular 2 |

|||

set temperature. |

|

|

|■| 1:00 |

||

If the temperature is too low, the brewer will wait until the proper |

|

5:30 |

|||

|

Decaf 1 |

||||

temperature is reached. A screen (example to the right) will |

200°F |

||||

|■| 1:00 |

|||||

display showing a thermometer icon and the tank temperatureÆ. |

|

5:30 |

|||

|

Decaf 2 |

||||

IMPORTANT: ALWAYS have dispenser(s) under the brewer |

|

||||

STOP |

|■| 1:00 |

||||

when in the BREW AT TEMP mode |

|

5:30 |

|||

---------------------------------------------------------------------------------------------------------- |

|

||||

BREW AT TEMP: OFF |

USER SELECTABLE (Not recommended) |

||||

Allows brewing at any temperature above 170°F/82°C. |

|

|

|

||

|

|

|

|

|

|

Chart to correct for altitude for boiling point in tank water temperature.

[ft] |

[m] |

Suggested |

Boiling |

Suggested |

Boiling |

|

Setting[°F] |

point[°F] |

Setting[°C] |

point [°C] |

|||

|

|

|||||

|

|

|

|

|

|

|

0 |

0 |

205 |

212.0 |

96 |

100.0 |

|

500 |

152 |

205 |

211.0 |

96 |

99.5 |

|

1000 |

305 |

200 |

210.1 |

93 |

98.9 |

|

2000 |

610 |

200 |

208.1 |

93 |

97.8 |

|

2500 |

762 |

200 |

207.2 |

93 |

97.3 |

|

3000 |

914 |

200 |

206.2 |

93 |

96.8 |

|

3500 |

1067 |

197 |

205.3 |

92 |

96.3 |

|

4000 |

1219 |

195 |

204.3 |

91 |

95.7 |

|

4500 |

1372 |

194 |

203.4 |

90 |

95.2 |

|

5000 |

1524 |

194 |

202.4 |

90 |

94.7 |

|

5500 |

1676 |

193 |

201.5 |

89 |

94.2 |

|

6000 |

1829 |

192 |

200.6 |

89 |

93.6 |

|

6500 |

1981 |

191 |

199.6 |

88 |

93.1 |

|

7000 |

2134 |

190 |

198.7 |

87 |

92.6 |

|

7500 |

2286 |

188 |

197.8 |

86 |

92.1 |

|

8000 |

2438 |

187 |

196.9 |

86 |

91.6 |

|

8500 |

2591 |

185 |

196.0 |

85 |

91.1 |

ECO MODE-Energy saving mode DEFINITONS If Selected: Turns heaters off after 1 hour of inactivity.

The hot water tank temperature will slowly decline to no lower than 60°C/170°F A screen (example to the right) will display showing “ECO Mode” is activated. Æ

To return from ECO-Mode

Tap the screen, ECO Mode turns off, and the brewer will heat to set temperature.

It takes approximately 7-15 minutes to return from 60°C/170°F to factory default 93°C/200°F

All FETCO commercial hot beverage equipment have well insulated hot water tanks and have engineered mechanical features to limit energy consumption.

Effective construction and insulation increases equipment life and lowers building HVAC costs. FETCO hot beverage equipment have the best energy savings of all major suppliers.

XTS™

EXTRACTOR

TOUCHSCREEN

CBS 2100XTS

■ ECO

Heating Tank Temp

Filling 170 °F

Go to fetco.com for the latest versions of all information |

Page 7 |

Part A-User Guide & Operator instructions P130 Part A Rev. 002 March 2016 |

INPUTS |

Programming Items |

Factory set Default |

Programming Range (display) |

Notes |

||

|

|

|

R. Brew Basket Sens. |

|

|

|

|

|

|

L. Brew Basket Sens. |

|

|

|

|

|

|

H. Liquid Level probe |

|

|

|

Display Inputs |

• Input Summery |

|

L. Liquid Level probe |

|

|

|

|

Tank Temperature Probe |

|

|

|

||

|

|

|

|

|

||

|

|

|

SD Card Recognized |

|

|

|

|

|

|

Tank Temp. 93°C |

|

|

|

|

|

|

|

|

|

|

Cal. Touch Scr |

|

Calibrate |

Calibrate |

|

If Yes: |

|

|

________________[]____ |

|

Follow directions on the |

|||

|

|

|

YES |

NO |

|

touch screen |

INPUT SUMMARY SCREEN

|

Brew Basket Sensor |

Display Inputs |

High Liquid Level Probe |

Low Liquid Level Probe |

|

(See “INPUTS” |

Tank Temp. Probe |

Service Screen) |

|

|

SD Card present |

|

Tank Temperature93C |

|

|

Use DISPLY INPUTS screen to assist in error code fault correction. There are two liquid level probes shown as High and Low High is the fill volume of the hot water tank Low probe is the level when the heaters are sufficiently covered by water to start.

Go to fetco.com for the latest versions of all information |

Page 8 |

Part A-User Guide & Operator instructions P130 Part A Rev. 002 March 2016 |

|

OUTPUTS |

|

Programming Items |

Factory set Default |

|

Programming Range (display) |

Notes |

|

|||||||

|

|

|

|

|

|

|

|

|

Left Brew FR |

|

|

|

3200 |

|

|

|

|

|

|

|

|

|

|

|

Left Bypass FR |

|

|

|

2400 |

|

|

Show Summary |

|

|

|

|

|

|

Right Brew FR |

|

|

|

3200 |

FR=Flow Rate ml/min |

|

||

|

• Output Summary |

|

|

|

Right Bypass FR |

|

|

|

2400 |

|

|||||

|

|

|

|

|

|

|

|

|

Screen Contrast |

|

|

|

8 |

|

|

|

|

|

|

|

|

|

|

|

Screen Brightness |

|

|

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Touch To Return |

|

|

|

||

Left Valve |

|

|

|

|

|

|

|

TEST |

|

Runs valve to verify |

|

||||

|

• Left Valve Test |

(Press to test) |

|

Press To Test |

TEST |

flow. Have container |

|

||||||||

Test OR Calibrate |

|

|

|

|

|

|

|

|

|

|

|

under brew-basket! |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

’’ ’’ |

’’ ’’ |

|

• L. Valve Calib |

Calibrate |

|

1540 to 3200 ml p m |

|

Factory or service use |

|

||||||

|

*Flow Rate |

|

|_________[]________| |

|

for flow rate adjustment |

|

|||||||||

|

|

|

|

|

|

|

1400-2800 |

1950-3800 |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|||||

L. Bypass Valve |

|

• Left Bypass |

|

(Press to test) |

|

|

TEST |

TEST |

Runs valve to verify |

|

|||||

Test OR Calibrate |

|

Valve Test |

|

|

Press To Test |

flow. Have container |

|

||||||||

|

|

|

|

|

|

|

|

|

|

under brew-basket! |

|

||||

If bypass option availble |

|

|

|

|

|

|

|

|

|

|

|

|

|||

’’ ’’ |

’’ ’’ |

|

• L. Bypass Valve |

Calibrate |

|

2150 to 2400 ml p m |

|

Factory or service use |

|

||||||

|

Calib |

|

*Flow Rate |

|

|_________[]________| |

|

for flow rate adjustment |

|

|||||||

|

|

|

|

|

|

1900-2100 |

2800 |

|

|

||||||

|

Left Valve display is only for CBS-2102XTS dual side brewer. CBS-2101XTS |

Single series displays RIGHT SIDE only |

|

||||||||||||

Right Valve |

|

|

|

(Press to test) |

|

|

TEST |

|

Runs Valve to verify flow. |

|

|||||

|

• Right Valve Test |

|

Press To Test |

TEST |

Have container under |

|

|||||||||

Test OR Calibrate |

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

brew-basket! |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

’’ ’’ |

’’ ’’ |

|

• R. Valve Calib |

Calibrate |

|

1540 to 3200 ml p m |

|

Factory or service use |

|

||||||

|

*Flow Rate |

|

|_________[]________| |

|

for flow rate |

|

|||||||||

|

|

|

|

|

|

|

1400-2800 |

1950-3800 |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|||||

R. Bypass Valve |

|

• Right Bypass |

(Press to test) |

|

|

TEST |

TEST |

Runs valve to verify |

|

||||||

Test OR Calibrate |

|

Valve Test |

|

|

Press To Test |

flow. Have container |

|

||||||||

|

|

|

|

|

|

|

|

|

|

under brew-basket! |

|

||||

If bypass option availble |

|

|

|

|

|

|

|

|

|

|

|

|

|||

’’ ’’ |

’’ ’’ |

|

• R. Bypass |

|

Calibrate |

|

2150 to 2400 ml p m |

|

Factory or service use |

|

|||||

|

Valve Calib |

|

*Flow Rate |

|

|_________[]________| |

|

for flow rate adjustment |

|

|||||||

|

|

|

|

|

|

1900-2100 |

2800 |

|

|

||||||

Fill Valve |

|

• Fill Valve Test |

(Press to test) |

|

|

TEST |

|

Operates fill valve. |

|

||||||

|

|

Press To Test |

TEST |

Have container under |

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

both brew-baskets! |

|

Left Basket Lk. |

|

• Left brew basket |

|

|

|

|

TEST |

|

Energizes brew basket |

|

|||||

|

(Press to test) |

|

Press To Test |

TEST |

lock. For factory or |

|

|||||||||

Not on CBS 2130XTS |

|

lock test |

|

|

|

|

|

|

|

|

|

service use |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Right Basket Lk. |

|

• Right brew |

|

(Press to test) |

|

|

TEST |

|

Energizes brew basket |

|

|||||

|

|

|

Press To Test |

TEST |

lock. For factory or |

|

|||||||||

Not on CBS 2130XTS |

|

basket lock test |

|

|

|

|

|

|

|

|

service use |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Heater |

|

• Heater Test |

|

(Press to test) |

|

|

TEST |

|

Energizes Heater(s) |

|

|||||

|

|

|

Press To Test |

TEST |

|

||||||||||

|

|

|

Service use only. |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Screen |

|

• Screen Contrast |

Contrast |

|

|

|

|

8 |

|

|

|

|

|||

|

|

|

|____________[]____| |

|

|

|

|||||||||

Brightness OR Contrast |

|

|

|

|

|

|

1 |

|

10 |

|

|

|

|||

|

|

|

|

• S. Brightness |

Brightness |

|

|

|

8 |

|

|

|

|

||

|

|

|

|

|

|____________[]____| |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

1 |

|

10 |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

Default-factory set Flow Rates; Brew Valve and Bypass |

|

|

|

|

|

||||||||

|

|

See “OUTPUTS” right and left brew valve and bypass valve settings and calibration |

|

|

|

|

|||||||||

|

|

CBS-2152 & CBS-2162 ml/min |

CBS-2151& CBS-2161ml/min |

|

|

|

|

||||||||

|

|

Left Brew FR |

3200 |

|

Right Brew FR |

3200 |

|

|

|

|

|||||

|

|

Left Bypass FR |

2400 |

|

Right Bypass FR |

2400 |

|

|

|

|

|||||

|

|

Right Brew FR |

3200 |

|

|

|

|

|

|

|

|

|

|

||

|

|

Right Bypass FR |

2400 |

|

|

|

|

|

|

|

|

|

|

||

|

|

CBS-2132& CBS-2142 ml/min |

CBS-2131&CBS-2141 |

ml/min |

|

|

|

|

|||||||

|

|

Left Brew FR |

1540 |

|

Right Brew FR* |

1540 |

|

|

|

|

|||||

|

|

Left Bypass FR* |

2150 |

|

Right Bypass FR* |

|

|

|

|

|

|||||

|

|

2150 |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Right Brew FR* |

1540 |

|

|

|

|

|

|

|

|

|

|

||

|

|

Right Bypass FR |

2150 |

|

|

|

|

|

|

|

|

|

|

||

|

|

-------------------------------------------------------------------------------------------------------------------- |

|

|

|

|

|||||||||

|

Go to fetco.com for the latest versions of all information |

Page 9 |

Part A-User Guide & Operator instructions P130 Part A Rev. 002 March 2016 |

||||||||||||

How to calibrate the flow rate

Set the flow rates of components to adjust for taste profile and for over or under potting.

Built-in algorithms in Brewer controller software corrects brew parameter to customer preferences or to trim variations in flow control components

NOTICE: This operation requires operator hold finger on keypad position for one minute—without lifting it.

1) MEASURE THE FLOW RATE:

It is very important to calibrate a heated brewer, preferably a brewer that has been used for brewing.

-Enter programming mode, scroll left to “OUTPUTS” -Scroll down to “Left(or)Right Valve Test”

-Place 5 liter/2gal measuring container under empty brew-basket.

One good way to measure is to weigh the test water. Use a scale for at least 5 kg/12lb

-Press To Test the Brew Valve. Æ! Keep finger on touchpad for one minute! !!DO NOT STOP!!

It is very important for this test to keep finger in place for the entire minute. After one minute [1 min.]–calibration dispense will stop automatically.

Measure the results of the flow in the 5-liter measuring container and hold the number. 2) AUTOMATIC Built-in CALIBRATE THE FLOW RATE

-Enter this number, in milliliters, into the calibration slider for the Valve tested in the OUTPUT MENU. -Use milliliters. If measured in fluid ounces (fl.oz) multiply by 29.57 to convert to milliliters

-After entering the measured volume, exit PROGRAMMING and return to the normal screens 3) MANUAL METHOD Operator input: CALIBRATE THE FLOW RATE

Use the amount measured, in milliliters, divided by programmed value and multiply by the current setting

3200 ml p m*

|_________[]________| 2800 3800

Å Example of |

Actual Volume |

X CURRENTSETTING = SETTINGNEW |

Enter new setting on the |

|

CBS-2160 brew |

|

slider shown and EXIT to |

||

Programmed Volume |

||||

valve slider |

|

save |

*Current valve flow setting in milliliters per minute [mlpm] as shown in the value above slider in OUTPUT Flow Rate box-

Obtain programmed volume from “PROGRAM” Menu under “Batch Summary”.

Note—match correct batch number to correct side, if two sided.

By entering the new flow rate number into the brewer, the software automatically corrects the valve flow discrepancy

Default-factory set Flow Rates; Brew Valve and Bypass

See “OUTPUTS” right and left brew valve and bypass valve settings and calibration

CBS-2162 |

ml/min |

Left Brew FR |

3200 |

Left Bypass FR |

2400 |

Right Brew FR |

3200 |

Right Bypass FR |

2400 |

CBS-2152 |

ml/min |

Left Brew FR |

3200 |

Left Bypass FR |

2400 |

Right Brew FR |

3200 |

Right Bypass FR |

2400 |

CBS-2142 |

ml/min |

Left Brew FR |

1540 |

Left Bypass FR |

2150 |

Right Brew FR |

1540 |

Right Bypass FR |

2150 |

|

CBS-2161 |

ml/min |

|

Right Brew FR |

3200 |

|

Right Bypass FR |

2400 |

|

CBS-2151 |

ml/min |

|

Right Brew FR |

3200 |

|

Right Bypass FR |

2400 |

|

CBS-2141 |

ml/min |

|

Right Brew FR |

1540 |

|

Right Bypass FR |

2150 |

---------------------------------------------------------------------------------------------

CBS-2130XTS equipment do not have the BYPASSS feature

CBS-2132 |

ml/min |

|

CBS-2131 |

ml/min |

Left Brew FR |

1540 |

|

Right Brew FR |

1540 |

Right Brew FR |

1540 |

|

|

|

Go to fetco.com for the latest versions of all information |

Page 10 |

Part A-User Guide & Operator instructions P130 Part A Rev. 002 March 2016 |

OTHER |

Programming Items |

Factory set Default |

Programming Range (display) |

Notes |

|

Error Codes |

• Display Errors |

(Codes) |

|

1: |

See Error Code Chart |

|

2: |

for references |

|||

|

|

|

|

3: |

|

|

• Reset Errors |

(Reset) |

|

Reset |

Factory and Service |

|

|_______________[]____| |

||||

|

use only. Do Not Reset |

||||

|

|

|

YES |

NO |

|

|

|

|

|

||

NOTE )Clear error codes by cycleing the brewer “OFF” then “ON”. Do not reset the error codes. Resetting error codes should be after completing the service and factory diagnostics and correcting any brewer faults

|

|

|

|

SDÆ Brewer |

|

|

|

Setup upload |

|

|

|

|

Copy Program |

• |

From SD to B. |

SDÆ Brewer |

|

--------------------------------------------------------------------------- |

|||||||

|

[] |

|

|

Please insert SD card with |

||||||||

|

|

|________________ ____ |

|

- |

|

|

|

|||||

|

|

|

|

YES |

NO |

|

|

|

the setup data! |

|||

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

Setup download |

|||

|

• From B to SD |

BrewerÆ SD |

BrewerÆ SD |

|

|

|

Please insert an empty |

|||||

|

|________________[]____| |

|

|

|

SD card with sufficient |

|||||||

|

|

|

|

YES |

NO |

|

|

space (≤2GB). SD card |

||||

|

|

|

|

|

|

|

|

|

must be clear of files |

|||

|

|

|

|

UPLOAD LOGO |

|

|

Please insert SD card |

|||||

Upload Logo |

|

|

Upload Logo |

Are you sure |

|

|

||||||

|

|

|________________[]____| |

|

|

|

with logo file! |

||||||

|

|

|

|

|

|

|

||||||

|

|

|

|

YES |

NO |

|

|

|

|

|

|

|

Res to Factory |

See next line: |

|

Reset to Default |

|

|

Completely overwrites |

||||||

& Select |

“Select Brewer |

Reset to default |

Are you sure |

|

|

|

all user setup, incl. |

|||||

|________________[]____| |

|

|

|

|||||||||

Brewer Type |

Configuration” |

|

|

|

|

user logo. |

|

|

|

|||

|

YES |

NO |

|

|

|

|

|

|

||||

Select Brewer |

CBS_2131 3L; CBS_2131 1G |

Screen appears |

Select Model |

|

|

Scroll to your |

|

|

|

|||

CBS_2132 3L; CBS_2132 1G |

|

brewer and tap |

ENTER |

|||||||||

|

CBS_2141; CBS_2142 |

after pressing “Res |

CBS [2131-2152]Series |

|

||||||||

Configuration |

CBS_2151; CBS_2152 &2152-2G |

to Factory” [Above] |

|________________[]____| |

|

|

|

ENTER tab |

|

|

|

||

|

|

CBS_2161; CBS_2162 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Total Counters |

|

|

Identical screen for |

|||||

|

|

|

|

|

0 |

|||||||

|

|

|

|

Left Brews |

|

|

|

|

|

|

||

|

|

|

|

|

|

Resettable Counters |

||||||

|

|

|

|

Left Brew activated |

|

0 |

|

Will display when |

||||

|

|

|

|

Left Brew [litr] |

|

0 |

|

|||||

|

|

|

|

|

|

selected. See next |

||||||

|

|

|

|

Left Bypass activated |

0 |

|

||||||

|

• Display Counters |

|

Left Bypass [litr] |

|

0 |

|

line to reset to zero |

|||||

|

Counters |

Right Brews |

|

0 |

|

|

|

|

|

|

||

|

|

-OR- |

|

0 |

|

|

|

|

|

|

||

Counters |

|

Right Brew activated |

|

|

NOTE: |

|

|

|

||||

• Display |

Display Total |

0 |

|

|

|

|

|

|||||

Right Brew [litr] |

|

|

|

|

|

|

||||||

|

Resettable |

Counters |

|

0 |

|

“ |

Total Counters |

” is |

||||

|

Right Bypass activated |

|

||||||||||

|

Counters |

|

0 |

|

|

|||||||

|

|

Right Bypass [litr] |

|

|

not user resettable |

|||||||

|

|

|

|

Fill valve Activated |

|

0 |

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

Fill Valve [litr] |

|

|

See table, next |

|

|

|

||

|

|

|

|

|

0 |

|

|

|

|

|||

|

|

|

|

Heater Activated |

|

0 |

|

page, for counter |

||||

|

|

|

|

Heater “ON” time |

|

0:00 |

|

screen, definitions |

||||

|

|

|

|

Touch To Return |

|

|||||||

|

• Resets |

Reset All |

Reset All Counters |

|

|

|

Resetting will restart |

|||||

Reset Counters |

Are you sure |

|

|

|

||||||||

Counters |

Counters |

|________________[]____| |

|

|

|

counter from zero |

||||||

|

|

|

|

|||||||||

|

|

|

|

YES |

NO |

|

|

|

|

|

|

|

|

• Firmware |

|

CBS_2132 [or model type] |

|

|

|

|

|

|

|

||

Firmware |

Display Firmware |

SW ver 3.0.12 |

|

|

|

Displays firmware |

||||||

Version |

BL ver 1.1.3 |

|

|

|

||||||||

Version |

|

|

|

version |

|

|

|

|||||

|

-Software type |

QP ver. 4.5.01 |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

Flash=512kb |

|

|

|

|

|

|

|

|

|

• Update |

|

UPDATE |

|

|

|

Firmware upload |

|||||

|

UPDATE |

|

--------------------------------------------------------------------------- |

|||||||||

|

|________________ ____| |

|

- |

|

|

|

||||||

|

Firmware |

|

|

[] |

|

|

Please insert SD card with |

|||||

|

|

YES |

NO |

|

|

|

the firmware file! |

|||||

|

|

|

|

|

|

|

||||||

DEMO Mode |

DEMO ON/OFF |

|

OFF |

|

|

Demonstrates the controls for |

||||||

|

|

[] |

|

|

|

training. Disables all |

||||||

|

|

|________________ ____| |

|

|

|

|||||||

|

|

|

|

ON |

OFF |

|

|

components in demo mode. |

||||

Go to fetco.com for the latest versions of all information |

Page 11 |

Part A-User Guide & Operator instructions P130 Part A Rev. 002 March 2016 |

Loading...

Loading...