Fetco CBS-2032E, CBS-2032S, CBS-2031S, CBS-2031E User Manual

User’s Guide

www.fetco.com

Models:

fCBS-2031e / CBS-2031

fCBS-2032e / CBS-2032

s s

NOTICE TO INSTALLER: Please leave this book with the machine.

Table of Contents

Contact Information .................................................. |

2 |

Operating Instructions .............................................. |

8 |

Description & Features ............................................. |

2 |

Programming ............................................................ |

9 |

Specifications............................................................ |

2 |

Batch Settings....................................................... |

9 |

Requirements........................................................ |

2 |

Temperature Settings ......................................... |

10 |

Weights and Capacities ........................................ |

2 |

Advanced Settings and Diagnostics ................... |

10 |

Electrical Configuration and Brewing Efficiency ... |

3 |

Relay Test........................................................... |

11 |

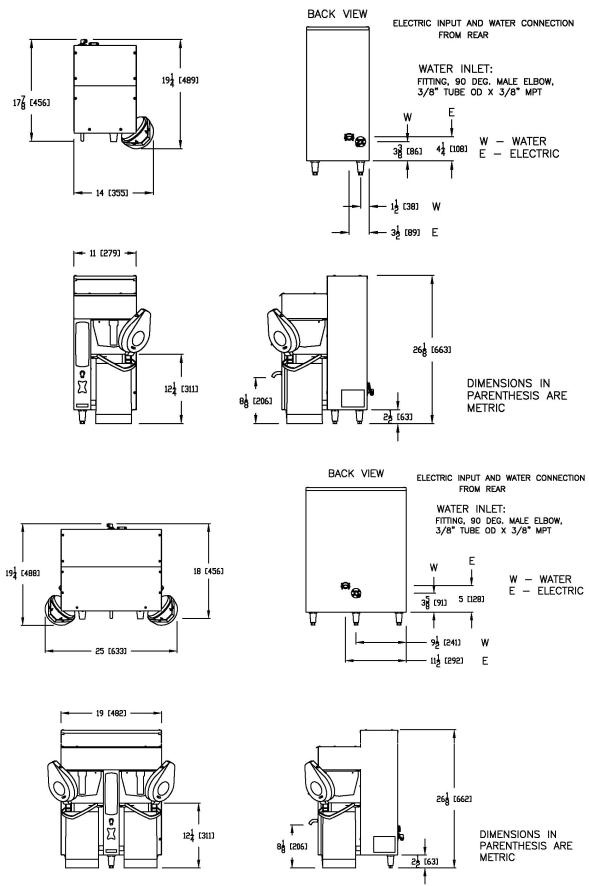

Dimensions & Utility Connections............................. |

4 |

Error Codes ............................................................ |

12 |

Installation................................................................. |

5 |

Parts ....................................................................... |

13 |

FETCO®, LUXUS®, EXTRACTOR® and Driven To Pioneer Innovation™ are trademarks or trade names of Food Equipment Technologies Company.

© 2005 Food Equipment Technologies Company |

Part # P019 August 16, 2005 |

Contact Information

FETCO® |

Phone: (800) 338-2699 (US & Canada) |

Food Equipment Technologies Company |

(847) 719-3000 |

600 Rose Road |

Fax: (847) 719-3001 |

Lake Zurich • IL • 60047-0429 • USA |

Email: sales@fetco.com |

|

|

Internet: www.fetco.com |

techsupport@fetco.com |

Description & Features

The CBS-2030e and CBS-2030s series feature patented intermittent spray over technology, which works like this:

The following variables are programmed for each batch size:

|

Brew volume |

Prewet percent (Percentage of the brew volume) |

|

|

Brew time |

|

Prewet delay (The time between prewetting and the brew cycle.) |

|

Bypass percent |

|

Drip delay (The time between the end of the brew cycle |

|

(CBS-2031s & 2032s only) |

|

and the unlocking of the brew basket.) |

|

(Percentage of the brew volume) |

|

|

Using these variables, the software calculates how much water to use for prewetting and brewing. The total brew time is divided into several 30 second cycles. Within these cycles, the software calculates how long to spray water over the coffee grounds, and how long to pause before the next cycle begins.

Features

All Models: |

CBS-2031s & CBS-2032s Only: |

||

Two fully programmable batch sizes per side |

Magnetic brew basket sensor |

||

|

Adjustable prewetting cycle |

|

Brew basket safety locks |

|

Electronically controlled hot water service |

|

Adjustable bypass |

Brew temperature protection

Specifications

Requirements

Water Requirements: |

|

Electrical: See electrical configuration chart. |

CBS-2031e/2031s: 20-75 psig, ¼ gpm |

|

|

CBS-2032e/2032s: 20-75 psig, ½ gpm |

|

Coffee Filters: 13” X 5 ” FETCO Product # F002 |

Weights and Capacities

Brewer |

Weight |

Water tank |

Weight |

Dispenser |

Dispenser |

Total Weight Brewer |

|

Model |

(empty) |

Capacity & Weight. |

(filled) |

Weight, ea. |

Filled, ea.. |

& Dispensers, Filled |

|

CBS-2031e |

35 lbs. |

3.0 gal. |

25 lbs. |

60 lbs. |

4.4 lbs. |

11 lbs. |

71 lbs. |

CBS-2031s |

|

|

|

|

|

|

|

CBS-2032e |

53 lbs. |

5.4 gal. |

45 lbs. |

98 lbs. |

4.4 lbs. |

11 lbs. |

120 lbs. |

CBS-2032s |

|

|

|

|

|

|

|

2

Electrical Configuration and Brewing Efficiency

US & Canada

CBS-2031e / CBS-2031s

3.0 liters per batch

Electrical |

Heater |

Voltage |

|

|

|

Maximum |

Batches per Hour* (max 11) |

|

Config. Code |

Configuration |

(AC) |

Phase |

Wires |

KW |

Amp draw |

Cold Water |

Hot Water |

E31045 |

1 X 1.5 KW |

120 |

single |

2 + ground |

1.6 |

13.0 |

4.9 |

11.0 |

Can be connected |

2 X 1.5 KW |

120/208 |

single |

3 + ground |

2.4 |

11.3 |

7.3 |

11.0 |

to 120 VAC or |

|

120/220 |

|

|

2.6 |

12.0 |

8.2 |

11.0 |

120/208-240 VAC |

|

120/240 |

|

|

3.1 |

13.0 |

9.7 |

11.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E31035 |

1 X 1.7 KW |

120 |

single |

2 + ground |

1.8 |

14.7 |

5.5 |

11.0 |

Can be connected |

2 X 1.7 KW |

120/208 |

single |

3 + ground |

2.7 |

12.8 |

8.3 |

11.0 |

to 120 VAC or |

|

120/220 |

|

|

3.0 |

13.5 |

9.2 |

11.0 |

120/208-240 VAC |

|

120/240 |

|

|

3.5 |

14.7 |

11.0 |

11.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E31015 |

1 X 2.3 KW |

120 |

single |

2 + ground |

2.4 |

19.7 |

7.4 |

11.0 |

Can be connected |

2 X 2.3 KW |

120/208 |

single |

3 + ground |

3.6 |

17.1 |

11.0 |

11.0 |

to 120 VAC or |

|

120/220 |

|

|

4.1 |

18.1 |

11.0 |

11.0 |

120/208-240 VAC |

|

120/240 |

|

|

4.7 |

19.7 |

11.0 |

11.0 |

CBS-2032e / CBS-2032s |

|

|

|

|

|

3.0 liters per batch |

||

Electrical |

Heater |

Voltage |

|

|

|

Maximum |

Batches per Hour* (max 22) |

|

Config. Code |

Configuration |

(AC) |

Phase |

Wires |

KW |

Amp draw |

Cold Water |

Hot Water |

E32015 |

2 X 3 KW |

120/208 |

single |

3 + ground |

4.6 |

22.4 |

14.6 |

22.0 |

|

|

120/220 |

|

|

5.1 |

23.7 |

16.9 |

22.0 |

|

|

120/240 |

|

|

6.1 |

25.8 |

19.4 |

22.0 |

* Based on standard factory settings: 4.0 minute brew time; 0% prewet; 200 F water.

Export

CBS-2031e / CBS-2031s

3.0 liters per batch

Electrical |

Heater |

Voltage |

|

|

|

Maximum |

Batches per Hour* (max 11) |

|

Config. Code |

Configuration |

(AC) |

Phase |

Wires |

KW |

Amp draw |

Cold Water |

Hot Water |

E31025 |

1 X 3 KW |

220 |

single |

2 + ground |

2.6 |

12.0 |

8.4 |

11..0 |

CBS-2032e / CBS-2032s |

|

|

|

|

|

3.0 liters per batch |

||

Electrical |

Heater |

Voltage |

|

|

|

Maximum |

Batches per Hour* (max 22) |

|

Config. Code |

Configuration |

(AC) |

Phase |

Wires |

KW |

Amp draw |

Cold Water |

Hot Water |

E32025 |

2 X 3 KW |

220 |

single |

2 + ground |

5.1 |

23.7 |

16.9 |

22.0 |

* Based on standard factory settings: 4.0 minute brew time; 0% prewet; 200 F water.

3

Dimensions & Utility Connections

CBS-2031e / CBS-2031s

DWG 201108-000

CBS-2032e / CBS-2032s

DWG 201109-000

4

Installation

(For Qualified Service Technicians Only)

Keys To A Successful Installation

If not installed correctly by qualified personnel, the brewer will not operate properly and damage may result. Damages resulting from improper installation are not covered by the warranty.

Here are the key points to consider before installation:

Electrical:

All FETCO brewers require NEUTRAL. Ground is not an acceptable substitute. Installation without neutral may cause damage to the electronic components.

The electrical diagram is located on the inside of the lower cover.

The installation must comply with applicable federal, state, and local codes having jurisdiction at your location. Check with your local inspectors to determine what codes will apply.

Plumbing:

This equipment is to be installed to comply with the applicable federal, state, or local plumbing codes.

The water line must be flushed thoroughly prior to connecting it to the brewer to prevent debris from contaminating the machine.

Verify that the water line will provide at least ¼ gallon per minute for the CBS-2031, and ½ gallons per minute for the CBS-2032 before connecting it to the brewer.

General:

Utilize only qualified beverage equipment service technicians for installation. A Service Company Directory may be found on our web site, http://www.fetco.com.

Installation Instructions

Brewer Setup

1. Review the Dimensions for the unit you are installing. Verify that the brewer will fit in the space intended for it, and that the counter or table will support the total weight of the brewer and dispensers when filled.

2. The brewer’s legs are shipped inside the brew baskets. Remove the brew basket(s) and the coffee dispenser(s). Place the brewer on its back and screw in the legs.

3. Place the brewer on the counter or stand.

4. When the brewer is in position, level it front to back as well as side to side by adjusting the legs.

5.Remove the lower cover to access the water and electrical connections. Knock-outs are provided in the back and base of the brewer body for the connections.

Water Connection

1.Water inlet is a 3/8 inch male flare fitting.

2.The brewer can be connected to a cold or hot water line. Cold water is preferred for best coffee flavor, but hot water will allow for faster recovery times.

3.Install a water shut off valve near the brewer to facilitate service. If an in-line water filter is used, it should be installed after the water shut off valve and in a position to facilitate filter replacement.

4.Flush the water supply line and filter before connecting it to the brewer.

5.Verify that the water line will provide at least ¼ gallon per minute for the CBS-2031, and ½ gallon per minute for the CBS-2032, and that the water pressure is between 20 and 75 psig.

5

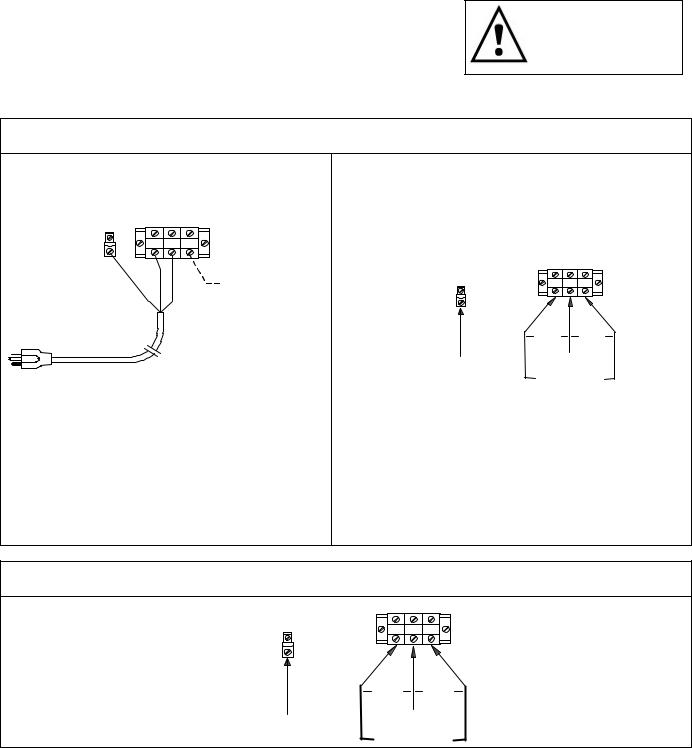

Electrical Connection – US & Canada

1.Verify that the actual voltage at the electrical service connection is compatible with the specifications on the brewer’s serial number label. Make sure the electrical service includes neutral.

2.The temperature and water tank fill level are pre-set at the factory. There is no need to turn off the heaters during the installation process. The heaters are disabled by the control board until the tank is full of water. The heating process will start automatically when the tank has filled.

3.The CBS-2031 is factory equipped with a 120 V cord and plug. The CBS-2032 has only a terminal block for connecting the incoming power wires. Consult local codes to determine if a cord and plug can be installed, or if the unit must be hard wired.

4.A fused disconnect switch or circuit breaker on the incoming power line must be conveniently located near the

brewer, and its location and markings known to the operators.

5. The body of the brewer must be grounded to a suitable building ground. A ground lug is provided in the brewer next to the power terminal block. Use only 10 gauge copper wire for grounding.

6. Electrical connections must be secured in-place within the unit to meet national and local standards.

7. Finally, connect the incoming power wires to the terminal block as shown in accordance with applicable codes.

CBS-2031e / CBS-2031s

Can be connected to 120 VAC or 120/208-240 VAC

Factory Configuration |

Optional Field Conversion* |

|

|

||

120 VAC, 3 wires |

|

120/208-240 VAC, 4 wires |

|

|

|

|

|

Step 1: Remove the factory provided 120 V cord & |

|||

|

|

plug from the terminal block. |

|

||

GROUND |

L1 N L2 |

Step 2: Connect the incoming wires to the terminal |

|||

|

|

block in accordance with applicable codes. |

|||

|

L2 - NOT USED |

|

GROUND LUG |

L1 N |

L2 |

|

|

|

|||

|

CORD WITH |

|

120V |

120V |

|

|

NEMA 5-20P PLUG |

|

|

N |

|

|

|

|

GROUND |

|

|

|

|

|

|

|

|

|

|

|

WIRE |

208-240V |

|

|

|

*This procedure must be performed only by a qualified |

|||

|

|

service technician or electrician. |

|

|

|

|

|

Notice: In order for this product to comply with the |

|||

|

|

requirements of the Underwriters Laboratories listing, |

|||

|

|

the following conditions apply: |

|

|

|

|

|

1.) This unit must be hard wired for 120/208-240 VAC. |

|||

|

|

2.) Once the unit is converted to 120/208-240 VAC |

|||

|

|

operation, it cannot be converted back to 120 |

|||

|

|

VAC operation. |

|

|

|

CBS-2032e / CBS-2032s |

|

|

|

|

|

Can be connected only to 120/208-240 VAC |

|

|

|

|

|

|

GROUND LUG |

L1 |

N L2 |

|

|

|

|

|

|

||

|

|

120V |

120V |

|

|

|

GROUND |

|

N |

|

|

|

|

|

|

|

|

|

WIRE |

208-240V |

|

|

|

6

Final Setup

1.Turn on the incoming water supply line and inspect both inside and outside of the brewer for leaks in all fittings and tubes

2.Turn on the incoming power.

3.Press the brewer’s main power switch, which is hidden behind the front leg of the brewer. The control panel on/off switch will begin flashing. Press this switch.

4.Within 6 seconds, the hot water tank will begin filling until the water is sensed by the probe at the top of the tank. The display will read “FIL”. The heaters will be disabled by the control board until the tank is full.

5.While the water is heating, the display will read “LO” and the actual water temperature will be displayed. After the water has reached the set temperature, the display will be blank. There is no “ready” light.

6.Review the Operating Instructions. Brew one full batch (water only) on each side to confirm proper fill levels. The brewer is factory set with water only (no coffee) to dispense the correct amount of water. If the actual volume is slightly different from the programmed volume, fine tuning the brewer may be necessary. See #60 – 61 in the Advanced Settings & Diagnostics section.

7.Re-attach the covers after one final inspection for leaks. Look closely in the top of the brewer at the dispense fittings during this inspection.

Operator Training

Review the operating procedures with whoever will be using the brewer. Pay particular attention to the following areas:

1.Always pre-heat the dispensers before the first use of each day by filling them half way with hot water, and letting them stand for at least 15 minutes.

2.Don't remove the brew basket until it has stopped dripping.

3.Make sure the dispenser is empty before brewing into it.

4.Show how to attach covers, close, and or secure the thermal dispensers for transporting.

5.Show the location and operation of the water shut off valve as well as the circuit breaker for the brewer.

6.Steam from the tank will form condensation in the vent tubes. This condensation will drip into and then out of the brew baskets. 1/4 cup discharging overnight is possible. Place an appropriate container under each brew basket when not in use.

7.We recommend leaving the power to the brewer on overnight. The water tank is well insulated and will use very little electricity to keep the tank hot. Leaving the brewer in the on position will also avoid delays at the beginning of shifts for the brewer to reach operating temperature.

7

Operating Instructions

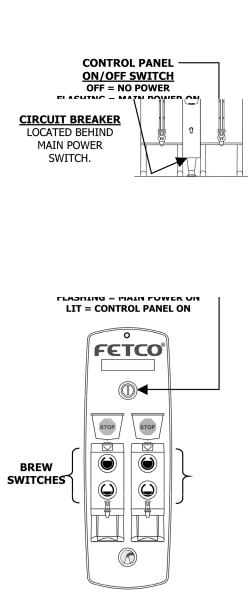

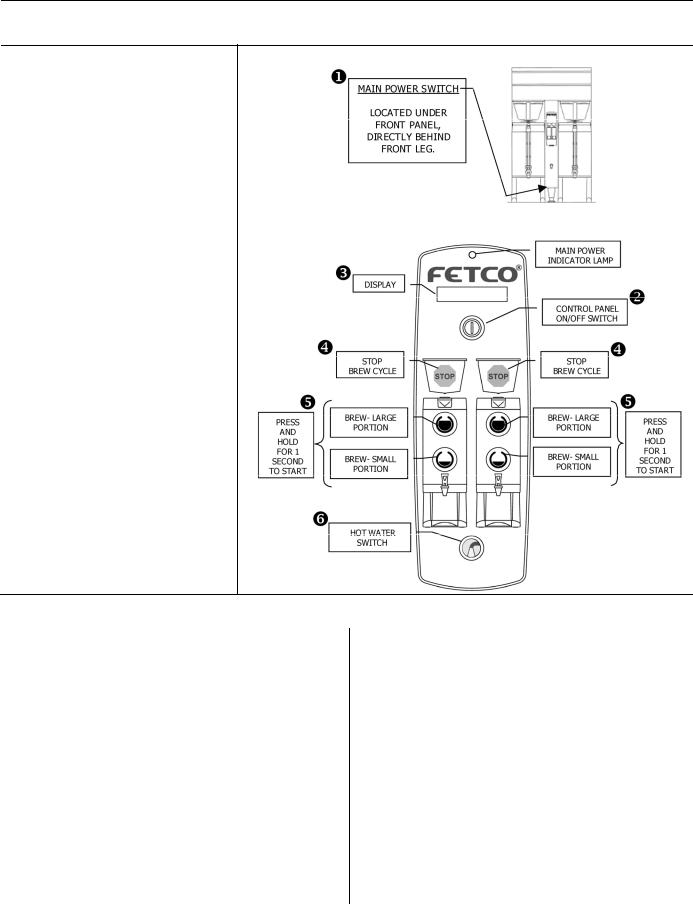

Control Panel Functions

Only switches that are active are illuminated.

Switches that are inactive or disabled are invisible.

XMain Power Switch

Controls all power to brewer

Indicator lamp at top of panel.

YControl Panel On/Off Switch

Affects only control panel. Does not disconnect main power.

Flashing = Off

Lit = On

Invisible = Main Power Off

Z Display

”FILL” = Water tank is filling.

”LO XXX” = Unit is heating, not ready to brew. (XXX = actual temperature.)

Blank = Ready to brew.

Also displays error messages.

[ Stop Switches

Stops brew cycle

Lit = Brew cycle in progress

Invisible = Not brewing, or dripping in progress

\ Brew Switches

Starts brew cycle

Must be held in for 1 second

Flashing = Brew cycle in progress

Lit = Ready to brew

Invisible – Not ready to brew, or batch disabled

(See Programming Section)

] Hot Water Switch

Dispenses hot water from faucet

Hold in to dispense

Brewing

1.Turn the main power switch and control panel switch on.

2.Prepare a brew basket with the correct size filter and appropriate amount of coffee.

3.Slide the brew basket completely into the rails.

4.Place a clean, empty, preheated dispenser under the brew basket.

5.Select a batch from the available choices, and hold the corresponding BREW button in for 1 second to start the brew cycle.

6.The STOP button will illuminate, and the selected BREW button will flash, indicating that brewing is in progress. All other BREW buttons will extinguish.

7.When the brew cycle is finished, the STOP button will extinguish and the BREW button will continue flashing, indicating that coffee may still be dripping from the bottom of the brew basket.

8.Before removing the brew basket or dispenser, visually verify that dripping has stopped.

Notes:

Preheat dispenser by filling at least ½ full with water at brewing temperature. Allow it to sit for at least 15 minutes before draining.

8

Loading...

Loading...