Fetco CBS-2152XTS Service Manual

® User’s Guide, Operator Instructions and Access

® User’s Guide, Operator Instructions and Access

FETCO Models:

CBS-2151XTS |

CBS-2152XTS |

CBS-2152-2XTS |

6-liter/1 ½ -gallon |

7.3-liter-2gallon |

|

hot beverage brewers

Commercial Hot Beverage Equipment

Table of Contents

Contact Information........................................................ |

2 |

Description & Features .................................................. |

2 |

Factory settings.............................................................. |

2 |

Accessing equipment and control screens .................... |

3 |

Layout of the brewer ...................................................... |

3 |

Accessing batch and programming menu screens........ |

3 |

Operating Instructions.................................................... |

4 |

Programmingoperator access programming ............... |

6 |

Menu Features: Batch Parameters................................ |

7 |

How to calibrate the flow rate....................................... |

11 |

Operator Training ......................................................... |

14 |

Safety Notes ................................................................. |

13 |

Error Codes .................................................................. |

13 |

Service Guide to a Successful Installation ................... |

15 |

Installation Directions ................................................... |

16 |

CBS-2150XTS Dimensions & Utility Connections........ |

18 |

Final Setup for Startup.................................................. |

22 |

Parts and Wiring Diagrams .......................................... |

24 |

NOTICE TO INSTALLER: Please leave this book with the machine.

© 2014-2015 Food Equipment Technologies Company |

May 2015 P129 rev 002 |

|

. |

Contact Information

FETCO® |

Technical Support |

|

Food Equipment Technologies Company |

techsupport@fetco.com |

|

600 Rose Road |

General Inquiries: |

info@fetco.com |

Lake Zurich • IL • 60047-0429 • USA |

||

Phone: (847) 719-3000 |

Sales (North Americas): |

sales@fetco.com |

Toll Free: (800)FETCO.99 or (800) 338-2699 |

Sales (International): |

international@fetco.com |

Internet: www.fetco.com |

|

|

Description & Features

CBS-2150XTS Series coffee brewers feature universal spray over technology from the Cascading Spray Dome™. The following variables are programmed for each batch size:

|

Brew volume |

Prewet percent (Percentage of the brew volume) |

|

|

Brew time |

|

Prewet delay (The time between prewetting and the brew cycle) |

Adjustable number of pulses |

|

Bypass-infinitely variable for strength adjustment |

|

Drip delay (The time between the end of the brew cycle and end of the brewing cycle…to empty the brewbasket)

Operating Principles

Using these variables, the software calculates how much water to use for prewetting and brewing. The total brew time digitally divides into several cycles. Within these cycles, the software calculates how long to spray water over the coffee grounds, and how long to pause before the next cycle begins. If desired, pulse count and length, brew-volume may be adjusted without changing brew time and brew-time may be adjusted without changing volume brewed.

Factory settings

The following are the factory set defaults—all variables in the brew menu are adjustable:

Brew Volume and coffee filter size: |

|

CBS-2150 single and Twin: 1.5 gallon/6 liters per brew |

Coffee Filters: 15” X 5 ½ ” |

CBS-2152-2 Gallon Twin EXPORT ONLY: 2 gallon/7.6 liters per brew Coffee Filters: 15” X 5 ½ Brew Time, all models: Factory set at 5.5 minutes=[4 minute brew time + 1.5 minute drip delay]

Temperature Control: Water temperature is factory set at —93°C/200°F

Features

Touchscreen Operation [XTS: EXtractor Touch Screen]

Cascading Spray Dome-No clog sprayhead

Brew mechanism is digitally adjustable

Intuitive Control Settings for Batch sizing

Infinitely variable bypass for strength adjustment

Four fully programmable batch sizes per side

User programs save-to and load-from SD cards

Recipe copy to SD card

Customizable batch name

Screen logo customizable by user from SD card

SD card firmware program and upgrade installation

Universal wiring – single or 3 phase

Brew water low temperature lockout

ECO mode for tank heater energy savings

Dispenser locator under brew basket

Magnetic flux brew basket sensor

Brewbasket locks (configurable)

Totalizing counters for brewer functions

Optional gourmet stainless steel brewbasket

Demonstration Mode for review & training

Heavier gauge stainless steel cabinet

Configurable for FLOWJET® pump module

SD card Backup for menu items

2

Accessing equipment and control screens

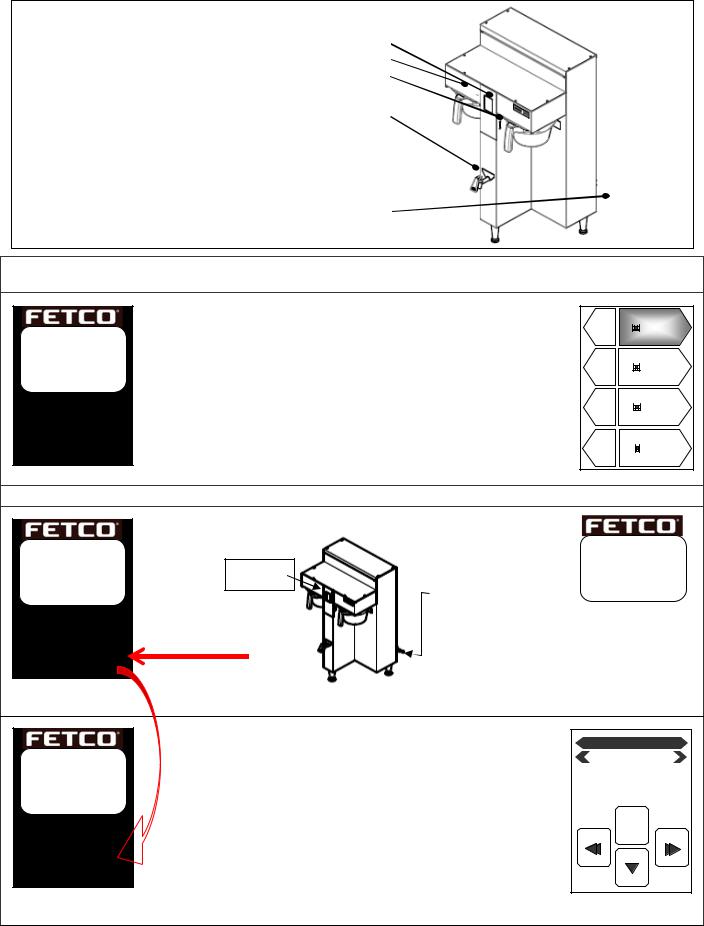

Layout of the brewer

Touch-screen for brewer operation

Brew basket sensor (internal)

SD card interface port (Load & Save)

Hot Water Faucet Airpot or Dispenser Locator

(Two for dual side)

Main power switch  Slide out back panel for service access

Slide out back panel for service access

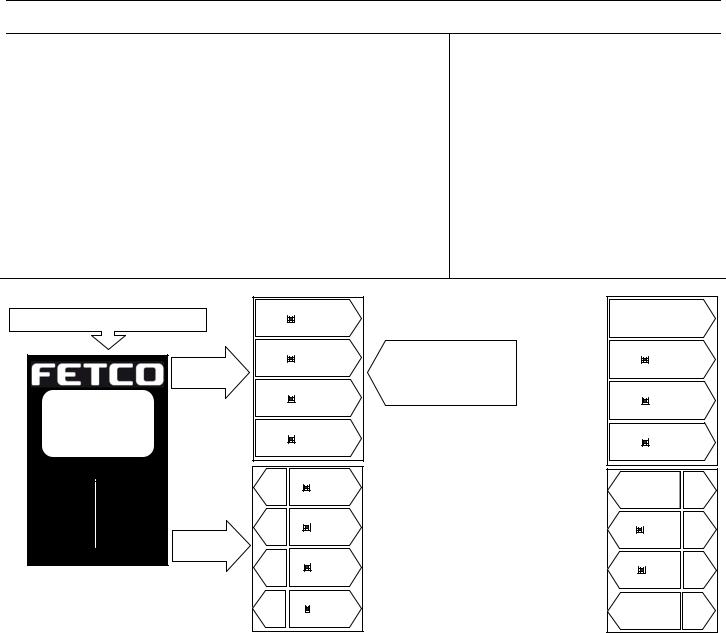

Accessing batch and programming menu screens

XTS™

EXTRACTOR

TOUCHSCREEN

CBS-21XX

Ready |

Touch |

Heating |

screen |

Filling |

to unlock |

CBS-2100 home screen shown

|

Regular |

|

|

1.50 |

|

Å CBS_2100XTS brewer HOME SCREEN: |

05:30 |

|

Regular |

||

Tap to enter batch selection screen. |

1.50 |

|

|

05:30 |

|

ÅTap left or right side batchesÆ |

Decaf |

|

…AND… |

1.50 |

|

Select and hold down a batch selector pennant to begin brew. |

05:30 |

|

Decaf |

||

|

||

|

1.50 |

|

|

05:30 |

|

|

Batch selection screen |

Accessing the menu screens for programming

XTS™

EXTRACTOR

TOUCHSCREEN

CBS-2150XTS

Ready |

Touch |

Heating |

screen |

Filling |

to unlock |

CBS-2100 home screen shown

Touchscreen

Touch/Hold here

to enter “PROGRAMMING”

|

|

XTS™ |

|

MAIN POWER SWITCH |

|

||

|

EXTRACTOR |

||

Located to lower right |

|

TOUCHSCREEN |

|

|

|

|

|

side of back panel |

|

CBS-2150XTS |

|

|

|

ECO |

Touch |

|

|

||

|

|

Heating |

screen |

|

|

Filling |

to unlock |

|

|

|

|

CBS-2100 home screen shown

Shown in optional “ECO” Mode

XTS™

EXTRACTOR

TOUCHSCREEN

|

CBS-2150XTS |

||

|

CBS-21XX |

||

Ready |

Touch |

||

|

Ready |

Touch |

|

Heating |

|||

screen |

|||

|

Heating |

screen |

|

Filling |

|||

to unlock |

|||

|

Filling |

to unlock |

|

|

|

|

|

CBS-2100 home screen shown

ÆFrom power “OFF” ÆTouch screen will briefly illuminate ÆTurn main power switch to “ON”

(Switch located lower right side of back panel) -When Complete: the HOME SCREEN will display

-Immediately touch and hold finger to enter programming -Lower portion of the screen will highlight as shown

-In 5-8 seconds “PROGRAMMING” screen will appearÆ

PROGRAM |

Batch 1 Left |

EXIT |

3

|

ÆQuick brewer setup |

NOTES |

|

|

Install plumbing and electrical utilities |

-See Installation Section in this guide |

|

|

|

|

|

|

Turn rear power switch “ON” |

-Located on back, lower right side |

|

|

|

|

|

|

Brewer hot water tank will fill in 4-8 minutes |

-Ready screen will display ”▪FILLING” |

|

|

|

|

|

|

Heater(s) activate when tank is full |

-Ready screen will display ”▪HEATING” |

|

|

|

|

|

|

Initial heating will be 15-30 minutes |

-Place dispenser under brewbasket(s) |

|

|

|

to collect any overflow and condensate |

|

|

Tank displays “ ▪READY” when filled & 200°F/93°C is reached |

|

|

|

|

|

|

|

|

|

|

|

Brewer is ready to brew when “▪READY” is displayed |

-Best results if brewer remains “ON” |

|

|

|

|

|

Operating Instructions

ÆTo brew a single coffee batch, using default recipe NOTES

All CBS-2150xts series brewers are factory calibrated and preloaded with recipes and are ready to brew.

Place paper filter in brew basket

Add ground coffee

Insert loaded brewbasket into brewer rails Have empty dispenser under brewbasket

Tap “▪ READY” screen to enter the batch selection menu Touch a top batch key for “REGULAR 1”

Brewer will brew and display the icon for the function step it is in

For dual side brewer, touch other side to access and activate the second side batches for brewing

Batch will complete brewing in 5 ½ minutes

-Use any quality pleated filter paper CBS-2150XTS Coffee Filters: 15” X 5 ½ ”

-Brewbasket(s) must be in place -Use the convenient locator guide -A long duration “TAP” with fingertip -Touch batch pennant with fingertip -Icon may be toggled for information

-Right to left side switching by touch

-Brew time: 4 minutes+1½ min. drip out

Touch the “Ready” screen |

to activate |

Regular 1 |

||||

0.80 |

||||||

|

|

|

|

|

05:30 |

|

|

|

|

|

|

Regular 2 |

|

|

|

|

|

|

0.80 |

|

|

|

|

|

CBS-2151XTS |

05:30 |

|

XTS |

|

|

|

Decaf 1 |

||

|

|

|

1.50 |

|||

|

|

|

Decaf 2 |

|||

CBS_2132 3L |

|

|

05:30 |

|||

|

|

™ |

|

|

|

|

EXTRACTOR |

|

|

|

1.00 |

||

TOUCHSCREEN |

|

|

05:30 |

|||

|

|

|

|

|

||

Ready |

Touch |

|

|

Regular |

||

|

|

1.50 |

||||

Heating |

screen |

|

|

05:30 |

||

|

|

Regular |

||||

Filling |

to unlock™ |

|

1.50 |

|||

CBS-2152XTS |

05:30 |

|||||

EXTRACTOR |

||||||

Decaf |

||||||

Example shown is CBS-2152 XTS Dual |

1.50 |

|||||

05:30 |

||||||

|

|

|

|

|

Decaf |

|

|

|

|

|

|

1.50 |

|

|

|

|

|

|

05:30 |

|

|

|

|

|

|

4 |

|

Touch and hold finger |

|

on selection pennant |

Æ |

for about two seconds |

|

to start brew |

Touch |

|

batch |

|

pennant |

|

to access |

CB SMenu selection |

menu |

|

|

for brewing on right, |

|

left or both sides. |

|

Touch batch pennant |

|

to access menu |

|

Regular 1 |

0.80 |

05:30 |

Regular 2 |

0.80 |

05:30 |

Decaf 1 |

1.50 |

05:30 |

Decaf 2 |

1.00 |

05:30 |

Regular |

1.50 |

05:30 |

Regular |

1.50 |

05:30 |

Decaf |

1.50 |

05:30 |

Decaf

1.5005:30

1.5005:30

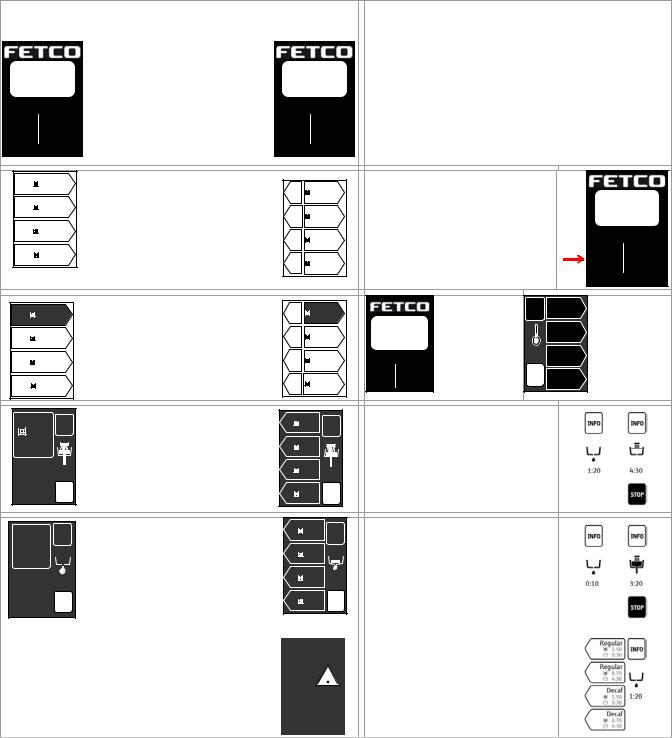

Brewing-shown by touchscreen

|

Brewer screens displayed for brewing |

|

NOTES |

||

CBS-2151XTS |

|

CBS-2152XTS |

|

||

SINGLE SIDE |

|

TWIN SIDE |

|

||

XTS™ |

|

XTS™ |

Note: There are three |

||

EXTRACTOR |

“READY SCREEN” |

EXTRACTOR |

“BREW AT TEMPERATURE DEFINITONS”. |

||

TOUCHSCREEN |

TOUCHSCREEN |

||||

CBS_2131 3L |

Tap screen to display menus |

CBS_2132 3L |

The “Brew At Temperature ”—“ON” default routine |

||

Ready |

Touch |

Ready |

Touch |

||

Heating |

screen |

|

Heating |

screen |

is used for the illustration below.. |

Filling |

to unlock |

|

Filling |

to unlock |

|

XTS™ |

|

XTS™ |

|

||

Regular 1 |

|

|

|

|

|

|

|

|

|

|

|

1:50 |

|

Unit displays four |

Regular 1 |

Brew at tempertaure “ON” |

|

|

|

||||

Regular 2 |

05:30 |

|

|

|

|

||||||

05:30 |

|

|

1.50 |

|

|

|

|

|

|

XTS |

|

|

|

preprogrammed batch buttons |

|

enabled: if this feature is |

|

||||||

05:30 |

|

Regular 2 |

|

||||||||

1:50 |

|

|

|

|

|

|

|

|

|

|

™ |

Decaf 1 |

|

per side. |

1.50 |

|

enabled:brew start will be |

|

EXTRACTOR |

||||

|

05:30 |

|

|

TOUCHSCREEN |

|||||||

1:50 |

|

CBS-2152XTS has right and left |

Decaf 1 |

enabled when tank temperature |

CBS_2132 3L |

||||||

05:30 |

|

1.50 |

|

Ready |

Tank Temp °F |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

Decaf 2 |

ÅCBS-2151XTS single side |

05:30 |

|

reaches the temperature set |

|

|

197 |

||||

1:50 |

|

Decaf 2 |

|

Heating |

|||||||

05:30 |

|

CBS-2152XTS dual sideÆ |

|

||||||||

|

|

05:30 |

|

|

|

point |

|

|

Filling |

|

|

|

|

|

1.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

If pressed in ON: |

|

|

XTS |

|

Regular 1 |

|

Regular 1 |

|

|

INFO |

Regular 1 |

If pressed in “AUTO” |

||||

|

|

|

Brew activation |

1.50 |

Brew At |

|

|||||

1:50 |

|

|

1.50 |

|

|

|

|

05:30 |

|

||

05:30 |

|

|

05:30 |

|

|

|

screen “locks out” |

|

Regular 2 |

Temperature |

|

Regular 2 |

|

Regular 2 |

|

™ |

|

||||||

|

|

|

1.50 |

|

|

||||||

Select and hold one button |

XTS |

until tank is at set |

|

Setting, a WAIT |

|||||||

1:50 |

|

1.50 |

|

TOUCHSCREEN |

|

05:30 |

|||||

05:30 |

|

05:30 |

|

|

|

|

|

||||

|

|

|

|

|

EXTRACTOR |

|

|

|

|

|

|

Decaf 1 |

|

for 2 seconds |

Decaf 1 |

CBS_2132 3L |

temp. |

92°C |

Decaf 1 |

sceen with |

|||

|

1.50 |

temperature icon |

|||||||||

1:50 |

|

|

1.50 |

|

Ready |

Tank Temp °F |

|

|

05:30 |

||

05:30 |

|

|

05:30 |

|

Heating |

197 |

|

STOP |

1.00 |

appears . Brew will |

|

Decaf 2 |

|

|

Decaf 2 |

|

|||||||

|

|

|

|

|

|

|

|

|

Decaf 2 |

start when tank is at |

|

1:50 |

|

|

1.00 |

|

Filling |

|

|

|

05:30 |

||

05:30 |

|

|

05:30 |

|

|

|

|

|

|

set temperature |

|

|

|

|

|

|

|

|

|

|

|

||

Regular 1 |

INFO |

|

Regular 1.. |

|

|

|

|

|

|

|

|

|

|

1.50.… |

INFO |

Both sides of a dual side |

|

|

|

||||

…0.80.. |

|

Brewing |

05:30…. |

|

|

|

|||||

.…..05:30.. |

|

Regular 2.. |

|

|

CBS-2152XTS brewing |

|

|

|

|||

F°……..200.. |

|

|

1.50.… |

|

|

|

|

|

|||

|

|

|

05:30…. |

|

simaltanously, brewer sides will |

|

|

||||

|

3:12 |

ÅCBS-2151XTS single side |

Decaf 1.. |

|

|

|

|||||

|

1.50.… |

3:30 |

also operate indepentently or |

|

|

||||||

|

|

CBS-2152XTS dual sideÆ |

05:30…. |

|

|

||||||

|

STOP |

1.50.… |

STOP |

|

|

alone |

|

|

|

|

|

|

|

|

Decaf 2.. |

|

|

|

|

|

|

|

|

|

|

|

05:30…. |

|

|

|

|

|

|

|

|

Regular 1 |

|

|

Regular 1.. |

|

|

|

|

|

|

|

|

INFO |

|

1.50.… |

INFO |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

…0.80.. |

|

|

05:30…. |

|

Both sides of a dual side |

|

|

|

|||

|

Brew completed |

1.50.… |

|

|

|

|

|||||

.…..05:30.. |

|

|

|

|

|

||||||

|

|

|

Regular 2.. |

|

|

|

|

|

|

|

|

°F……..200.. |

|

(in drip delay) |

05:30…. |

|

|

CBS-2152XTS brewing |

|

|

|

||

|

1:30 |

Decaf 1.. |

1:30 |

|

|

|

|

||||

|

ÅCBS-2151XTS single side |

05:30…. |

simaltanously. Left side |

|

|

|

|||||

|

|

|

1.50.… |

|

|

|

|

|

|

|

|

|

STOP |

CBS-2152XTS dual sideÆ |

Decaf 2.. |

STOP |

|

completing drip delay |

|

|

|

|

|

|

|

1.50.… |

|

|

|

|

|

||||

|

|

|

05:30…. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Brew basket sensor enabled. |

|

|

|

CBS-2152XTS dual side right |

|

|

|

|

|||

Unit is brewable only when brebasket is in |

|

|

|

||

|

|

|

side completing drip delay, left |

||

|

|

|

|||

|

place. |

|

|

|

|

|

|

INSERT |

side ready for next brew |

||

(option may be disabled by user) |

|

BREW |

|||

|

BASKET |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

5

Programmingoperator access programming

-The FETCO CBS-2150XTS brewers have four brew batch menus per side.

Menus are preprogrammed by the factory with basic settings that will operate the equipment as purchased. There are two batches each marked “Regular” and two marked “Decaf”

-Most operators prefer a full batch and half batch setting for regular and decaf or specialty coffees. The half batch setting will need to be programmed by the operator to match the dispenser.

-Settings are adjustable and the name of the menu can be changed. -Batch 1 & 4 cannot be disabled.

Menu screen displayed |

Accessing |

Menu screen displayed |

Accessing |

|

Programming |

Programming menu screens |

|||

|

|

|

|

Turn unit “OFF” |

|

ÅTop line is programming category |

|

|

|

After 10 second delay: |

PROGRAM |

||

|

|

ÅSecond line displays items for |

|||

XTS™ |

Batch 1 Left |

||||

|

programming |

||||

Turn unit “ON” |

|

||||

|

|

||||

CBS_2132 3L |

|

|

|

||

EXTRACTOR |

Å “HOME" Screen on left will |

|

Right and left hand arrows will scroll |

||

TOUCHSCREEN |

|

||||

|

|

|

|||

Ready |

Touch |

appear |

EXIT |

to the screens that display |

|

Immediately place finger on |

“Program, General, Inputs, |

||||

|

|||||

Heating screen |

screen and “HOLD” |

|

Outputs and Other” |

||

|

|

||||

Filling |

to unlock |

Screen on right will appear |

|

The down arrow enters the |

|

|

|

Æ |

|

||

|

|

(Programming menu screen) |

individual programming items |

||

|

|

|

|||

(Brewer “HOME” screen) |

|

shown below |

|||

|

|

||||

|

|

|

|||

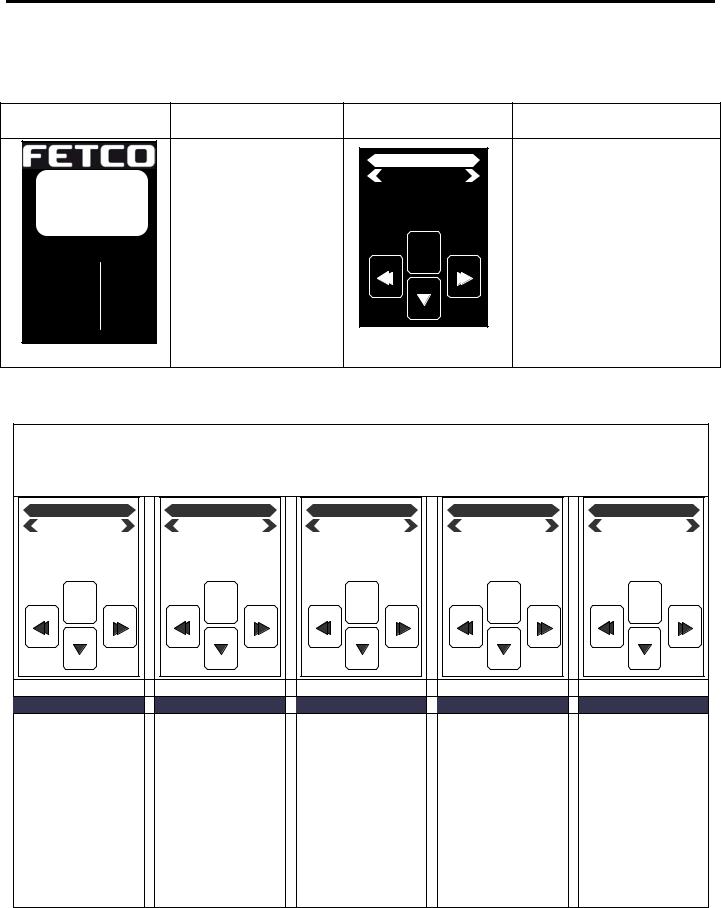

Programming-category screens: Menu Tree

Programming category screens

To enter: Turn unit “OFF”, After 10 second delay, turn unit “ON”, (Home Screen will appear), Immediately place finger on screen and “HOLD”—“PROGRAM” Screen (first below) will appear. Use right/left and down arrows to travel through programming. “EXIT” saves settings

PROGRAM |

GENERAL |

INPUTS |

OUTPUTS |

OTHER |

Batch 1 Left |

Tank Temp |

Display Inputs |

Show Summary |

Error Codes |

EXIT |

EXIT |

EXIT |

EXIT |

EXIT |

Programming Category |

Programming Category |

Programming Category |

Programming Category |

Programming Category |

PROGRAM |

GENERAL |

INPUTS |

OUTPUTS |

OTHER |

Items for Programming |

Items for Programming |

Items for Programming |

Items for Programming |

Items for Programming |

|

|

|

|

|

|

|

Batch 1 Left* |

Tank Temp |

Display Inputs |

Show Summary |

Error Codes |

|

Batch 2 Left** |

Brew At Temp |

Calib Touch Scr |

Left Valve |

Copy Program |

|

Batch 3 Left ** |

Units of Meas. |

|

L. Bypass Valve |

Upload Logo |

|

Batch 4 |

Left ** |

ECO Mode |

|

Right Valve |

Res to Factory |

Batch 1 RIGHT* |

Logo Timeout |

|

R. Bypass Valve |

Counters |

|

Batch 2 |

Right ** |

Brew B.Sensor |

|

Fill Valve |

Firmware |

Batch 3 |

Right ** |

Use Flojet |

|

Left Basket Lk |

DEMO Mode |

Batch 4 |

Right ** |

LLC Sensitivity |

|

Right Basket Lk |

|

Batch Copy |

|

|

Heater |

|

|

|

|

|

|

Screen |

|

6

Menu Features: Batch Parameters

PROGRAM |

Programming Items |

Factory set Default |

Programming Range |

Notes |

||

Batch 1 LEFT* |

• |

Batch Summary |

Display Summary |

|

|

|

|

• |

Batch Name |

Regular 1(-16) |

Choose from list: |

(Regular 1-16) |

|

|

Regular1 |

|

-OR- Write: any name |

|||

CBS-2151& 2152XTS |

• |

Batch Volume |

1.50 gal |

1.5 gal |

|

|

|_________[]________| |

|

|||||

1 ½ Gallon |

|

|

[ 0.50-2.00] |

0.50 |

2.00 |

|

CBS-2152XTS |

• |

Batch Volume |

2.00 gal |

2.5 gal |

|

|

2 Gallon |

[ 0.50-2.25] |

|_____________[]____| |

|

|||

|

|

0.50 |

2.25 |

|

||

|

• |

Brew Time |

4:00 mm:ss |

4:00 mm:ss |

|

|

|

[ 2:00-10.00] |

|_____[]___________| |

|

|||

|

|

|

2:00 |

10:00 |

|

|

|

• |

Nr Of Pulses |

8 |

8 |

|

|

|

|_____[]___________| |

|

||||

|

|

|

|

1 |

30 |

|

|

• |

Prewet Perc. |

0% |

0 % |

|

|

|

|_[]_______________| |

|

||||

|

|

|

|

0 |

15 |

|

|

• |

Bypass Perc. |

0% |

0 % |

|

|

|

|_[]_______________| |

|

||||

|

|

|

|

0 |

40 |

|

|

• |

Drip Delay |

1:30 mm:ss |

1:30 mm:ss |

|

|

|

|_____[]___________| |

|

||||

|

|

|

|

0:30 |

5:00 |

|

|

|

|

|

|

|

|

Batch 2 Left** |

|

**Batch 2-4—Right |

and Batch2-4—Left |

may be individually selected |

-or-entirely deleted |

|

|

• |

Batch ON/OFF |

ON |

ON |

|

|

|

|_________[]________| |

|

||||

|

|

|

|

ON |

OFF |

|

|

• |

Batch Summary |

Display Summary |

|

|

|

|

• |

Batch Name |

Regular 1 |

Regular 1-16;Write own name |

|

|

CBS-2151& 2152XTS |

• |

Batch Volume |

1.50 gal |

1.5 gal |

|

|

|_________[]________| |

|

|||||

1 ½ Gallon |

|

|

[ 0.50-2.00] |

0.50 |

2.00 |

|

CBS-2152XTS |

• |

Batch Volume |

2.00 gal |

2.5 gal |

|

|

2 Gallon |

[ 0.50-2.25] |

|_____________[]____| |

|

|||

|

|

0.50 |

2.25 |

|

||

|

• |

Brew Time |

4:00 mm:ss |

4:00 mm:ss |

|

|

|

[ 2:00-10.00] |

|_____[]___________| |

|

|||

|

|

|

2:00 |

10:00 |

|

|

|

• |

Nr Of Pulses |

8 |

8 |

|

|

|

|_____[]___________| |

|

||||

|

|

|

|

1 |

30 |

|

|

• |

Prewet Perc. |

0% |

0 % |

|

|

|

|_[]_______________| |

|

||||

|

|

|

|

0 |

15 |

|

|

• |

Bypass Perc. |

0% |

0 % |

|

|

|

|_[]_______________| |

|

||||

|

|

|

|

0 |

40 |

|

|

• |

Drip Delay |

1:30 mm:ss |

1:30 mm:ss |

|

|

|

|_____[]_________| |

|

||||

|

|

|

|

0:30 |

5:00 |

|

Batch 3 Left ** |

(See Batch 2-Left) |

|

|

|

|

|

Batch 4 Left ** |

(See Batch 2-Left) |

|

|

|

|

|

Batch 1 Right * |

(See Batch 1-Left) |

|

|

|

|

|

Batch 2 Right ** |

(See Batch 2-Left) |

|

|

|

|

|

Batch 3 Right ** |

(See Batch 2-Left) |

|

|

|

|

|

Batch 4 Right ** |

(See Batch 2-Left) |

|

|

|

|

|

Batch Copy |

Copy From Batch |

L1 |

L1-L4;R1-R4 |

|

||

|

Copy To Batch |

L1 |

L1-L4;R1-R4 |

|

||

|

Copy? |

L1ÆL2? |

NO |

|

|

|

|

(example) |

|_______________[]__| |

|

|||

|

|

|

YES |

NO |

|

|

*Batch 1&4 cannot be disabled. (CBS-2152XTS); *Batch 1 cannot be disabled. (CBS-2151XTS) **Batch can be disabled, and removed from display

7

GENERAL |

Programming Items |

Factory set Default |

Programming Range (display) |

Notes |

||||

Tank Temp. |

|

|

200°F |

200 °F |

Chart to correct for |

|||

|

|

|______________[]___| |

||||||

|

|

high altitude below |

||||||

|

|

|

|

170 |

|

207 |

||

Brew at Temp. |

“OFF” allows |

“ON” |

|

ON |

|

SEE NOTE BELOW! |

||

brewing at any |

|________[]_______| |

|||||||

|

temperature. |

|

OFF |

ON |

AUTO |

|

||

Units of Meas. |

• |

Temperature |

°C or °F |

|

°F |

|

[Switchable Units] |

|

|___[]____________| |

||||||||

|

|

|

|

°F |

|

°C |

|

|

|

• |

Volume |

Gallons [Liters] |

Gallons |

[Switchable Units] |

|||

|

|___[]____________| |

|||||||

|

|

|

|

Gallons |

Liters |

|

||

|

|

Energy Saving |

|

ECO Mode |

If Selected: Lowers hot |

|||

ECO Mode |

|

OFF |

water tank temperature to |

|||||

|

_______________[]_____ |

|||||||

|

Mode |

170°F after 1 hour of |

||||||

|

|

|

ON |

|

OFF |

|||

|

|

|

|

|

inactivity |

|||

|

|

|

|

|

|

|

||

Logo Timeout |

|

|

0:30 mm:ss |

0:30 mm:ss |

|

|||

|

|

|__[]___________| |

|

|||||

|

|

|

|

0:15 |

|

5:00 |

|

|

Brew B. Sensor |

|

|

NORMAL |

NORMAL |

Factory or service use for |

|||

|

|

|__[]____________| |

servicing. “NORMAL” is |

|||||

|

|

(SEE WARNINGS) |

||||||

|

|

|

NORMAL |

OVERRIDE |

recommended for safety. |

|||

Use Flowjet |

|

|

NO |

|

NO |

|

Trims water handling |

|

|

|

____[]_______________ |

||||||

|

|

system for Flowjet |

||||||

|

|

|

|

NO |

|

YES |

||

|

|

|

|

|

|

|||

|

|

|

|

|

|

|||

LLC Sensitivity* |

Normal for most water |

NORMAL |

NORMAL |

Liquid level control sensitivity. |

||||

____[]______________ |

High is for reverse osmosis |

|||||||

“HIGH” for R.O. |

||||||||

|

|

|

|

NORMAL |

|

HIGH |

water or very pure water. |

|

Most water has sufficent mineral content for proper brewer refill cycling. If refill is erratic, inspect all wiring and if “ERROR CODE 107” displays, or if water is tested to be very pure (<100 TDS or 5.5 grain), :set LLC to “HIGH”.

|

|

BREW AT TEMPERATURE DEFINITONS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

-------------------------------------------------------------------------------- |

|

|

|

|

|

|

|

|

|

|

|

Chart to correct for altitude for boiling point |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

BREW AT TEMP: “ON” |

|

|

|

|

|

|

|

|

|

|

|

|

in tank water temperature. |

|

|

|||||||||

|

(DEFAULT: FACTORY PROGRAMMED INTO BREWER) |

|

|

|

XTS™ |

|

|

[ft] |

[m] |

|

Suggested |

Boiling |

Suggested |

|

Boiling |

||||||||||

|

|

|

|

|

|

Setting[°F] |

point[°F] |

Setting[°C] |

|

point [°C] |

|||||||||||||||

|

“BREW START” Batch Section Buttons will not be accessible |

EXTRACTOR |

|

|

|

|

|

|

|||||||||||||||||

|

until tank temperature is at set point. |

|

|

TOUCHSCREEN |

|

|

0 |

0 |

|

205 |

212.0 |

96 |

|

100.0 |

|

||||||||||

|

The “BREW START” screens with the Batch Section Buttons |

CBS |

2100 |

|

|

500 |

152 |

|

205 |

211.0 |

96 |

|

99.5 |

|

|||||||||||

|

become accessible when hot water tank is at the selected |

|

|

■Ready |

|

|

Tank Temp |

|

|

1000 |

305 |

|

200 |

210.1 |

93 |

|

98.9 |

|

|||||||

|

temperature. A screen (example to the right) will display showing |

Heating |

|

92 °C |

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

2000 |

610 |

|

200 |

208.1 |

93 |

|

97.8 |

|

||||||||||||||

|

“BREW AT TEMP” is selected. Æ |

|

|

Filling |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

2500 |

762 |

|

200 |

207.2 |

93 |

|

97.3 |

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

-------------------------------------------------------------------------------- |

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

3000 |

914 |

|

200 |

206.2 |

93 |

|

96.8 |

|

|||||||||||

|

BREW AT TEMP: AUTO |

USER SELECTABLE |

|

|

|

Regular 1 |

|

|

|

|

|

||||||||||||||

|

|

|

INFO |

|

|

3500 |

1067 |

|

197 |

205.3 |

92 |

|

96.3 |

|

|||||||||||

|

“BREW START” will pause if the hot water tank is not at the |

|

|■| 3:00 |

|

|

|

|

|

|||||||||||||||||

|

|

|

6:00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

4000 |

1219 |

|

195 |

204.3 |

91 |

|

95.7 |

|

||||||||||||||||

|

selected temperature—and automatically start when it is at the |

|

|

Regular 2 |

|

|

|

|

|

||||||||||||||||

|

set temperature. |

|

|

|

|

|

|■| 3:00 |

|

|

4500 |

1372 |

|

194 |

203.4 |

90 |

|

95.2 |

|

|||||||

|

If the temperature is too low, the brewer will wait until the proper |

|

|

6:00 |

|

|

5000 |

1524 |

|

194 |

202.4 |

90 |

|

94.7 |

|

||||||||||

|

|

|

Decaf 1 |

|

|

|

|

|

|||||||||||||||||

|

temperature is reached. A screen (example to the right) will |

|

|

92°C |

|■| 3:00 |

|

|

5500 |

1676 |

|

193 |

201.5 |

89 |

|

94.2 |

|

|||||||||

|

display showing a thermometer icon and the tank temperatureÆ. |

|

|

6:00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

6000 |

1829 |

|

192 |

200.6 |

89 |

|

93.6 |

|

||||||||||||||

|

|

|

|

Decaf 2 |

|

|

|

|

|

||||||||||||||||

|

IMPORTANT: ALWAYS have dispenser(s) under the brewer |

|

STOP |

|

|■| 3:00 |

|

|

6500 |

1981 |

|

191 |

199.6 |

88 |

|

93.1 |

|

|||||||||

|

when in the BREW AT TEMP mode |

|

|

|

6:00 |

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

7000 |

2134 |

|

190 |

198.7 |

87 |

|

92.6 |

|

||||||||||

---------------------------------------------------------------------------------------------------------- |

|

|

|

|

|

||||||||||||||||||||

|

|

7500 |

2286 |

|

188 |

197.8 |

86 |

|

92.1 |

|

|||||||||||||||

|

BREW AT TEMP: OFF |

USER SELECTABLE |

(Not recommended) |

|

|

|

|

||||||||||||||||||

|

|

8000 |

2438 |

|

187 |

196.9 |

86 |

|

91.6 |

|

|||||||||||||||

|

|

Allows brewing at any temperature above 170°F/77°C. |

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

8500 |

2591 |

|

185 |

196.0 |

85 |

|

91.1 |

|

|||||||

|

|

May NOT apply for two sided brewer if one side is in brew cycle |

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ECO MODE-Energy saving mode DEFINITONS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

If Selected: Turns heaters off after 1 hour of inactivity. |

|

|

|

|

|

|

|

|

|

|

|

|

|

XTS™ |

|

|

|||||||

|

|

The hot water tank temperature will slowly decline to no lower than 60°C/170°F |

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

A screen (example to the right) will display showing “ECO Mode” is activated. Æ |

|

|

|

|

|

|

EXTRACTOR |

|

|||||||||||||||

|

|

To return from ECO-Mode |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TOUCHSCREEN |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CBS_2100XTS |

|

||||||||

|

|

Tap the screen, ECO Mode turns off, and the brewer will heat to set temperature. |

|

|

|

|

|

|

|||||||||||||||||

|

|

It takes approximately 7-15 minutes to return from 60°C/170°F to factory default 93°C/200°F |

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

■ECO |

|

|

|

|

|

||||||||||||||||

|

|

All FETCO commercial hot beverage equipment have well insulated hot water tanks and |

|

|

|

89°C |

|

||||||||||||||||||

|

|

have engineered mechanical features to limit energy consumption. |

|

|

|

|

|

|

Heating |

|

|||||||||||||||

|

|

Effective construction and insulation increases equipment life and lowers building HVAC costs. |

|

|

Filling |

|

|

|

|

||||||||||||||||

|

|

FETCO hot beverage equipment have the best energy savings of all major suppliers. |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8

|

INPUTS |

Programming |

Factory set |

Programming Range |

|

Notes |

|

|

Items |

Default |

(display) |

|

|||

|

|

|

|

||||

|

|

|

|

R. Brew Basket Sens. [ single/dual] |

|

|

|

|

|

|

|

L. Brew Basket Sens. |

|

|

|

|

Display Inputs |

• Input Summery |

|

H. Liquid Level probe |

|

|

|

|

|

H. Tank Temperature Probe |

|

|

|||

|

|

|

|

L. Tank Temperature Probe |

|

|

|

|

|

|

|

SD Card Recognized |

|

|

|

|

|

|

|

Tank Temp. 200 |

|

|

|

|

Cal. Touch Scr |

|

Calibrate |

Calibrate |

|

If Yes: |

|

|

|

________________[]____ |

|

Follow directions on the |

|||

|

|

|

|

YES |

NO |

|

touch screen |

INPUT SUMMARY SCREEN

|

Brew Basket Sensor |

Display Inputs |

High Liquid Level Probe |

Low Liquid Level Probe |

|

(See “INPUTS” |

Tank Temp. Probe |

Service Screen) |

|

|

SD Card present |

|

Tank Temperature205F |

|

|

Use DISPLY INPUTS screen to assist in error code fault correction. There are two liquid level probes shown as High and Low High is the fill volume of the hot water tank Low probe is the level when the heaters are sufficiently covered by water to start.

9

|

|

OUTPUTS |

Programming |

Factory set |

Programming Range |

Notes |

|

|

|

Items |

Default |

(display) |

|

||

|

|

|

|

|

|||

|

|

|

|

|

Left Brew FR |

3400 |

|

|

|

|

|

|

Left Bypass FR |

2400 |

|

|

Show Summary |

|

|

Right Brew FR |

3400 |

FR=Flow Rate ml/min |

|

|

• Output Summary |

|

Right Bypass FR |

2400 |

|||

|

|

|

|

|

Screen Contrast |

8 |

|

|

|

|

|

|

Screen Brightness |

8 |

|

|

|

|

|

|

Touch To Return |

|

|

|

Left Valve |

|

|

TEST |

|

Runs valve to verify |

|

|

• Left Valve Test |

(Press to test) |

Press To Test |

TEST |

flow. Have container |

||

|

Test OR Calibrate |

|

|

|

|

under brewbasket! |

|

|

|

|

|

|

|

|

|

|

’’ ’’ |

’’ ’’ |

• L. Valve Calib |

Calibrate |

3400 ml p m |

|

Factory or service use |

|

*Flow Rate |

|_________[]________| |

for flow rate |

||||

|

|

|

|

3000 |

3800 |

||

|

L. Bypass Valve |

• Left Bypass |

(Press to test) |

TEST |

TEST |

Runs valve to verify |

|

|

Test OR Calibrate |

Valve Test |

Press To Test |

flow. Have container |

|||

|

|

|

|

under brewbasket! |

|||

|

Not on CBS 2130XTS |

|

|

|

|

||

|

’’ ’’ |

’’ ’’ |

• L. Bypass |

Calibrate |

2400 ml p m |

|

Factory or service use |

|

Valve Calib |

*Flow Rate |

|_________[]________| |

for flow rate |

|||

|

|

|

2100 |

2800 |

|||

|

|

Left Valve display is only for BCB Seriesdual station brewer. BCB Single series |

displays RIGHT SIDE only |

||||

|

Right Valve |

|

|

TEST |

|

Runs Valve to verify flow. |

|

|

• Right Valve Test |

(Press to test) |

Press To Test |

TEST |

Have container under |

||

|

Test OR Calibrate |

|

|

|

|

brewbasket! |

|

|

|

|

|

|

|

|

|

|

’’ ’’ |

’’ ’’ |

• R. Valve Calib |

Calibrate |

3400 ml p m |

|

Factory or service use |

|

*Flow Rate |

|_________[]________| |

for flow rate |

||||

|

|

|

|

3000 |

3800 |

||

|

R. Bypass Valve |

• Right Bypass |

(Press to test) |

TEST |

TEST |

Runs valve to verify |

|

|

Test OR Calibrate |

Valve Test |

Press To Test |

flow. Have container |

|||

|

|

|

|

under brewbasket! |

|||

|

Not on CBS 2130XTS |

|

|

|

|

||

|

’’ ’’ |

’’ ’’ |

• R. Bypass |

Calibrate |

2400 ml p m |

|

Factory or service use |

|

Valve Calib |

*Flow Rate |

|_________[]________| |

for flow rate |

|||

|

|

|

2100 |

2800 |

|||

|

Fill Valve |

|

(Press to test) |

TEST |

|

Operates fill valve. |

|

|

• Fill Valve Test |

Press To Test |

TEST |

Have container under |

|||

|

|

|

|

|

|

|

both brewbaskets! |

|

Left Basket Lk. |

• Left brew basket |

(Press to test) |

TEST |

|

Energizes brew basket |

|

|

Press To Test |

TEST |

lock. For factory or |

||||

|

Not on CBS 2130XTS |

lock test |

|||||

|

|

|

|

service use |

|||

|

|

|

|

|

|

|

|

|

Right Basket Lk. |

• Right brew |

(Press to test) |

TEST |

|

Energizes brew basket |

|

|

Press To Test |

TEST |

lock. For factory or |

||||

|

Not on CBS 2130XTS |

basket lock test |

|

|

|

service use |

|

|

|

|

|

|

|

|

|

|

Heater |

|

|

TEST |

|

Energizes Heater(s) |

|

|

• Heater Test |

(Press to test) |

Press To Test |

TEST |

|||

|

Use for servicing. |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Screen |

• Screen Contrast |

Contrast |

8 |

|

|

|

|

|____________[]____| |

|

|||||

|

Brightness OR Contrast |

|

|

1 |

10 |

|

|

|

|

|

• S. Brightness |

Brightness |

8 |

|

|

|

|

|

|____________[]____| |

|

|||

|

|

|

|

|

1 |

10 |

|

10

For factory or qualified service professional use only

How to calibrate the flow rate

Set the flow rates of components to adjust for taste profile and for over or under potting.

Built-in algorithms in Brewer controller software corrects brew parameter to customer preferences or to trim variations in flow control components

NOTICE: This operation requires operator hold finger on keypad position for one minute—without lifting it.

1) MEASURE THE FLOW RATE:

-Enter programming mode, scroll left to “OUTPUTS” -Scroll down to “Left(or)Right Valve Test”

-Place 5 liter/2gal measuring container under empty brewbasket.

One good way to measure is to weigh the test water. Use a scale for at least 5 kg/12lb

-Press To Test the Brew Valve. Æ! Keep finger on touchpad for one minute! !!DO NOT STOP!!

It is very important for this test to keep finger in place for the entire minute.

Measure the results of the flow in the 5-liter measuring container and hold the number. 2) AUTOMATIC Built-in CALIBRATE THE FLOW RATE

-Enter this number, in milliliters, into the calibration slider for the Valve tested in the OUTPUT MENU. -Use milliliters. If measured in fluid ounces (fl.oz) multiply by 29.57 to convert to milliliters

-After entering the measured volume, exit PROGRAMMING and return to the normal screens 3) MANUAL METHOD Operator input: CALIBRATE THE FLOW RATE

Use the amount measured, in milliliters, divided by programmed value and multiply by the current setting

3400 ml p m

|_________[]________| 3000 3800

Å Example of CBS-2150 brew valve slider

Actual Volume |

CURRENT |

= |

NEW |

|

|

X |

|||

|

SETTING |

SETTING |

||

|

||||

Programmed Volume |

|

|

|

|

Enter new setting on the slider shown and EXIT to save

Obtain programmed volume from “PROGRAM” Menu under “Batch Summary”.

Note—match correct batch number to correct side, if two sided.

By entering the new flow rate number into the brewer, the software automatically corrects the valve flow discrepancy

Hot water convenience tap

1.The XTS_Series coffee brewers include a hot water convenience tap for single cup beverage purposes.

2.Single use delivery volume should not exceed maximum 16fl.oz/473cc.

3.Water dispensed from this faucet is very hot, up to 205°F/96°C

11

|

OTHER |

Programming |

Factory set |

Programming Range |

|

|

|

Notes |

||||

|

|

Items |

Default |

(display) |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

||||

|

Error Codes |

• Display Errors |

(Codes) |

1: |

|

|

|

See Error Code Chart |

||||

|

2: |

|

|

|

|

for references |

||||||

|

|

|

|

|

3: |

|

|

|

|

|||

|

|

• Reset Errors |

(Reset) |

Reset |

|

|

|

|

!!Errors must be |

|||

|

|

|_______________[]____| |

|

|

|

|||||||

|

|

|

corrected and cleared!! |

|||||||||

|

|

|

|

|

YES |

NO |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

SDÆ Brewer |

|

|

|

Setup upload |

|||

|

Copy Program |

• |

From SD to B. |

SDÆ Brewer |

|

--------------------------------------------------------------------------- |

||||||

|

|

[] |

|

|

Please insert SD card with |

|||||||

|

|

|

|________________ ____ |

|

- |

|

|

|||||

|

|

|

|

|

YES |

NO |

|

|

|

the setup data! |

||

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

BrewerÆ SD |

|

|

|

Setup download |

|||

|

|

• From B to SD |

BrewerÆ SD |

|

--------------------------------------------------------------------------- |

|||||||

|

|

|________________[]____| |

|

|

Please insert SD card with |

|||||||

|

|

|

|

|

|

|

|

- |

|

|

||

|

|

|

|

|

YES |

NO |

|

|

|

sufficient space (≥2GB) |

||

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

UPLOAD LOGO |

|

|

Please insert SD card |

||||

|

Upload Logo |

|

|

Upload Logo |

Are you sure |

|

|

|||||

|

|

|

|________________[]____| |

|

|

|

with logo file! |

|||||

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

YES |

NO |

|

|

|

|

|

|

|

Res to Factory |

See next line: |

|

Reset to Default |

|

|

Completely overwrites |

|||||

|

& Select |

“Select Brewer |

Reset to default |

Are you sure |

|

|

|

all user setup, incl. |

||||

|

|________________[]____| |

|

|

|

||||||||

|

Brewer Type |

Configuration” |

|

|

|

|

user logo. |

|||||

|

|

YES |

NO |

|

|

|

||||||

|

Select Brewer |

CBS_2131 3L; CBS_2131 1G |

Screen appears |

Select Model |

|

|

|

Scroll to your |

||||

|

CBS_2132 3L; CBS_2132 1G |

|

|

brewer and tap ENTER |

||||||||

|

Configuration |

|

CBS_2141; CBS_2142 |

after pressing “Res |

CBS [2131-2152]Series |

|

|

|||||

|

|

CBS_2151; CBS_2152 |

to Factory” [Above] |

|________________[]____| |

|

|

|

ENTER tab |

||||

|

|

|

|

|

Total Counters |

|

|

|

|

|

|

|

|

|

|

|

|

Left Brews |

|

0 |

|

|

|

|

|

|

|

|

|

|

Left Brew activated |

|

0 |

|

Identical screen for |

|

||

|

|

|

|

|

Left Brew [gal] |

|

0 |

|

|

|||

|

|

|

|

|

|

|

Resettable Counters |

|||||

|

|

|

|

|

Left Bypass activated |

|

0 |

|

|

|||

|

|

• Display Counters |

|

Left Bypass [gal] |

|

0 |

|

Will display when |

||||

|

|

Counters |

Right Brews |

|

0 |

|

selected. See next |

|||||

|

|

|

-OR- |

|

0 |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Counters |

• Display |

Display Total |

Right Brew activated |

|

0 |

|

line to reset to zero |

||||

|

Right Brew [gal] |

|

|

|||||||||

|

|

Resettable |

Counters |

|

0 |

|

|

|

|

|

||

|

|

Right Bypass activated |

|

|

|

|

|

|

||||

|

|

Counters |

|

|

0 |

|

|

NOTE: |

||||

|

|

|

Right Bypass [gal] |

|

|

|

||||||

|

|

|

|

|

Fill valve Activated |

|

0 |

|

“ |

Total Counters |

” is |

|

|

|

|

|

|

|

0 |

|

|||||

|

|

|

|

|

Fill Valve [gal] |

|

0 |

|

|

not user resettable |

|

|

|

|

|

|

|

Heater Activated |

|

0 |

|

|

|

|

|

|

|

|

|

|

Heater “ON” time |

|

0:00 |

|

|

|

|

|

|

|

|

|

|

Touch To Return |

|

|

|

|

|

|

|

|

|

• Resets |

Reset All |

Reset All Counters |

|

|

|

Resetting will restart |

||||

|

Reset Counters |

Are you sure |

|

|

|

|||||||

|

Counters |

Counters |

|________________[]____| |

|

|

|

counter from zero |

|||||

|

|

|

|

|

||||||||

|

|

|

|

|

YES |

NO |

|

|

|

|

|

|

|

|

• Firmware |

Display Firmware |

CBS_2152 [or model type] |

|

|

|

Displays firmware |

||||

|

Firmware |

SW ver 2.1.0Z |

|

|

|

|||||||

|

Version |

|

|

|

||||||||

|

Version |

HW ver 1.1.3 |

|

|

|

version |

||||||

|

|

-Software type |

|

|

|

|||||||

|

|

|

QP ver. 4.5.01 |

|

|

|

|

|

|

|||

|

|

• Update |

|

UPDATE |

|

|

|

Firmware upload |

||||

|

|

UPDATE |

|

--------------------------------------------------------------------------- |

||||||||

|

|

|________________ ____| |

|

- |

|

|

||||||

|

|

Firmware |

|

|

[] |

|

|

Please insert SD card with |

||||

|

|

|

YES |

NO |

|

|

|

the firmware file! |

||||

|

|

|

|

|

|

|

|

|||||

|

DEMO Mode |

DEMO ON/OFF |

|

OFF |

|

|

Demonstrates the controls for |

|||||

|

|

|

[] |

|

|

|

training. Disables all |

|||||

|

|

|

|________________ ____| |

|

|

|

||||||

|

|

|

|

|

ON |

OFF |

|

|

components in demo mode. |

|||

12

Safety Notes

1.Professional installation is required. This appliance is manufactured only for commercial use.

2.Operation requirements and maintenance for commercial cooking appliances differ from household appliances.

3.Operators must be trained for this equipment and must understand the use, maintenance and hazards.

4.Access to the service area is restricted to persons having safety/hygiene knowledge and practical experience of the coffee brewer. This appliance must be installed in locations where it can be overseen by adult trained personnel.

5.Do not attempt to move hot beverage equipment once it is filled. Drain equipment before moving.

6.FETCO commercial coffee brewers prepare large amounts of coffee or tea in a single batch using very hot water

7.Commercial coffee brewers provides very hot water from the sprayhead, brewbasket and faucet when it is pulled.

8.Coffee brewers may continue to dispense very hot water from the mechanically operated faucet after the electronic touchpad is completely disabled by turning off the power switch on the lower back of the unit, or unplugging the unit.

9.For safety, the brewer control locks the brew basket for 5.5 minutes after starting the brew.

10. Never attempt to defeat the factory set (default) time that the brew basket is locked for safety from start of brew. Keep these instructions for training and future reference

Error Codes

ÆContact specialized personnel for error codes

Code |

Description |

Possible Cause |

Corrective Action |

How to Clear |

|

Error Codes |

|||||

|

|

|

|

||

001 |

Software error-error on start |

Improper start-up or |

Restart , if still fault: reload |

|

|

up or corrupted software |

shutdown |

software |

|

||

|

|

||||

050 |

Shorted temperature probe |

Probe failure. |

Replace probe. |

|

|

051 |

|

Bad probe |

Check all connections. |

TO CLEAR FAULT, |

|

Open temperature probe. |

connection, or probe |

Replace probe if necessary. |

Make repairs as |

||

|

|

failure. |

|

required |

|

|

Initial Fill Error. Initial fill |

Water supply flow |

Watch for short potting during |

||

|

|

||||

100 |

brew cycle. Investigate cause |

Below is the only way |

|||

time was more than 4 |

|||||

rate is too low. |

of low flow rate. (Clogged |

||||

|

minutes after power up. |

to clear error codes |

|||

|

|

water filter...) |

|||

|

|

|

1) Enter |

||

|

Error on refill |

|

Watch for short potting during |

||

|

Water supply flow |

“PROGRAMMING” |

|||

101 |

brew cycle. Investigate cause |

||||

Tank did not refill within 3 |

|

||||

rate is too low. |

of low flow rate. (Clogged |

|

|||

|

minutes. |

2)Scroll left to |

|||

|

|

water filter…) |

|||

|

|

|

|

“OTHER” |

|

102 |

Unwanted fill; |

Possible leak in tank, |

Check inside of machine for |

||

fitting, or valve. |

leaks. |

|

|||

|

|

3)Scroll down to |

|||

103 |

Liquid level probe fault |

Probe fouled or |

Clean, check all connections. |

||

shorts |

Replace probe if necessary. |

“ERROR CODES” |

|||

|

|

||||

|

|

-Tank not filling |

Occurs after prefill |

4)Scroll down to |

|

|

Lower liquid level probe |

-Orange wire to |

-Low probe is uncovered |

||

107 |

temperature probe |

-Wires are reversed |

“Display Errors” |

||

Fault |

|||||

|

disconnected |

-Set LLC sensitivity to HIGH |

|

||

|

|

|

|||

|

|

-Very pure water |

see MENU—GENERAL-LLC |

5)Scroll left to “Reset |

|

201 |

Heater open, high limit |

Failure of: heating |

Check and replace heating |

Errors” |

|

thermostat, or Solid State |

element,SSR,high |

|

|||

elements if necessary. |

|

||||

|

Relay (SSR) fault |

Limit or low voltage |

6)Scroll down to |

||

|

|

||||

|

|

Usually from longer |

Restart , if still fault: reload |

“Reset” |

|

255 |

Touch pad error |

than 2 min touch |

|

||

contact. Or faulty |

software. If mechanical: |

7)Follow directions |

|||

|

|

reassembly after |

reassemble correctly |

||

|

|

shown on screen. |

|||

|

|

service |

|

||

|

|

|

|

|

|

Regular 1 |

|

|

Merely toggling |

|

|

1.50 |

|

|

ON/OFF switch will not |

|

|

05:30 |

|

|

|

|

|

Regular 2 |

|

|

clear error codes. |

|

|

1.50 |

Brewbasket must be |

|

Error codes must be |

|

INSERT |

05:30 |

Insert brewbasket |

||

|

Decaf 1 |

in place |

cleared by entering |

||

INSERT |

BREW |

|

|||

BASKET |

1.50 |

|

|

PROGRAMMING and |

|

BREW |

05:30 |

|

|

||

|

Decaf 2 |

|

|

using the menus! |

|

BASKET |

|

|

|

|

|

|

|

1.50 |

|

|

|

|

|

05:30 |

|

|

|

! Æ Never attempt to defeat or override a brew basket-locking feature.

13

Operator Training

Review the operating procedures with whoever will be using the brewer.

Pay particular attention to the following areas:

1.Always pre-heat the dispensers before the first use of each day by filling them half way with hot water, and letting them stand for at least 5 minutes.

2.Do not remove the brew basket from a coffee brewer until it has stopped dripping.

3.Make sure the dispenser is empty before brewing into it.

4.Show how to attach covers, close, and or secure the dispensers for transporting.

5.Show the location and operation of the water shut off valve as well as the circuit breaker for the brewer.

6.Steam from the tank will form condensation in the vent tubes. This condensation will drip into and then out of the brew baskets. Up to 1/4 cup/118cc discharging overnight is possible. Place an appropriate container under each brew basket when not in use.

7.We recommend leaving the power to the brewer on overnight. The water tank is well insulated and very little electricity is used to keep the tank hot. Leaving the brewer in the “ON” position will also avoid delays at the beginning of shifts for the brewer to reach operating temperature.

Cleaning & Maintenance

After Each Brew:

1.Dispose of grounds and rinse brew basket.

2.Never strike a brewbasket or hit it against a hard surface.

This will damage the brew cone, and may damage the brewbasket support rails 3. Rinse dispensers before reuse.

Every Day:

1.Wash brew basket with hot sudsy water.

2.Pull CSD from the spray head, it is magnetically attached. Use gloves or a heavy towel. Æ Wash off any film and reattach. Use vinegar if limescale filming is present.

3.Clean dispensers with hot suds water and a brush, rinse and air dry.

4.Use only a soft cloth and hot suds on the outside to avoid scratches. Never use abrasives that will scratch surface.

Weekly

1.Use a commercial coffee dispenser cleaner such as URNEX™, TABZ™, DIP-IT™ or Squeak 'n Clean™.

2.Carefully Follow the instructions supplied with the cleaning product

3.Never use spray cleaners, solvent, solvent based cleaner or petroleum based polish anywhere on dispensers

Warning

1.Turn off power before any cleaning procedure, including wiping the exterior for appearance reasons.

2.Dry the exterior, especially the face panel, before turning on power.

3.Do not apply any type of spray cleaner on the face panel of this equipment.

4.Never use solvent or solvent-based cleaner or petroleum based polish anywhere on this equipment.

5.Dry the face of the touch pad before turning on power

6.Do not electrically energize this equipment or attempt operation without all covers in place and all screws fastened.

7.Unplug machine before disassembly or servicing.

14

Loading...

Loading...