Festool CTL 22 E SG, CTL 33 LE SG, CTL 44 E, CTL 33 E SG, CTL 44 LE Operating & Parts Manual

...Page 1

Festool GmbH

Seen at Ideal Tools.

Wertstraße 20

D-73240 Wendlingen

Telefon: 07024/804-0

Telefax: 07024/804-608

http://www.festool.com

CTL 22 E SG

CTL 33 E SG/CTL 33 LE SG

CTL 44 E/CTL 44 LE

CTL 55 E

Bedienungsanleitung/Ersatzteilliste*) 4 - 8

Operating Instructions/Spare parts list*) 9 - 12

Mode d’emploi/Liste de pièces de rechange*) 13 - 17

Instrucciones de servicio/Lista de piezas de repuesto*) 18 - 22

Istruzioni d’uso/Elenco parti di ricambio*) 23 - 27

Gebruiksaanwijzing/Lijst met reserveonderdelen*) 28 - 32

Bruksanvisning/Reservdelslista*) 33 - 36

Käyttöohje/Varaosaluettelo*) 37 - 40

Driftsvejledning/Reservedelsliste*) 41 - 44

Bruksanvisning/Reservedelsliste*) 45 - 48

Instruções de uso/Lista de peças sobresselentes*) 49 - 53

Руководство по эксплуатации/Перечень запасных частей*) 54 - 58

Návod k obsluze/Seznam náhradních dílù*) 59 - 62

468 032_001

Instrukcja obs³ug/Lista czêœci zamiennych*) 63 - 67

Page 2

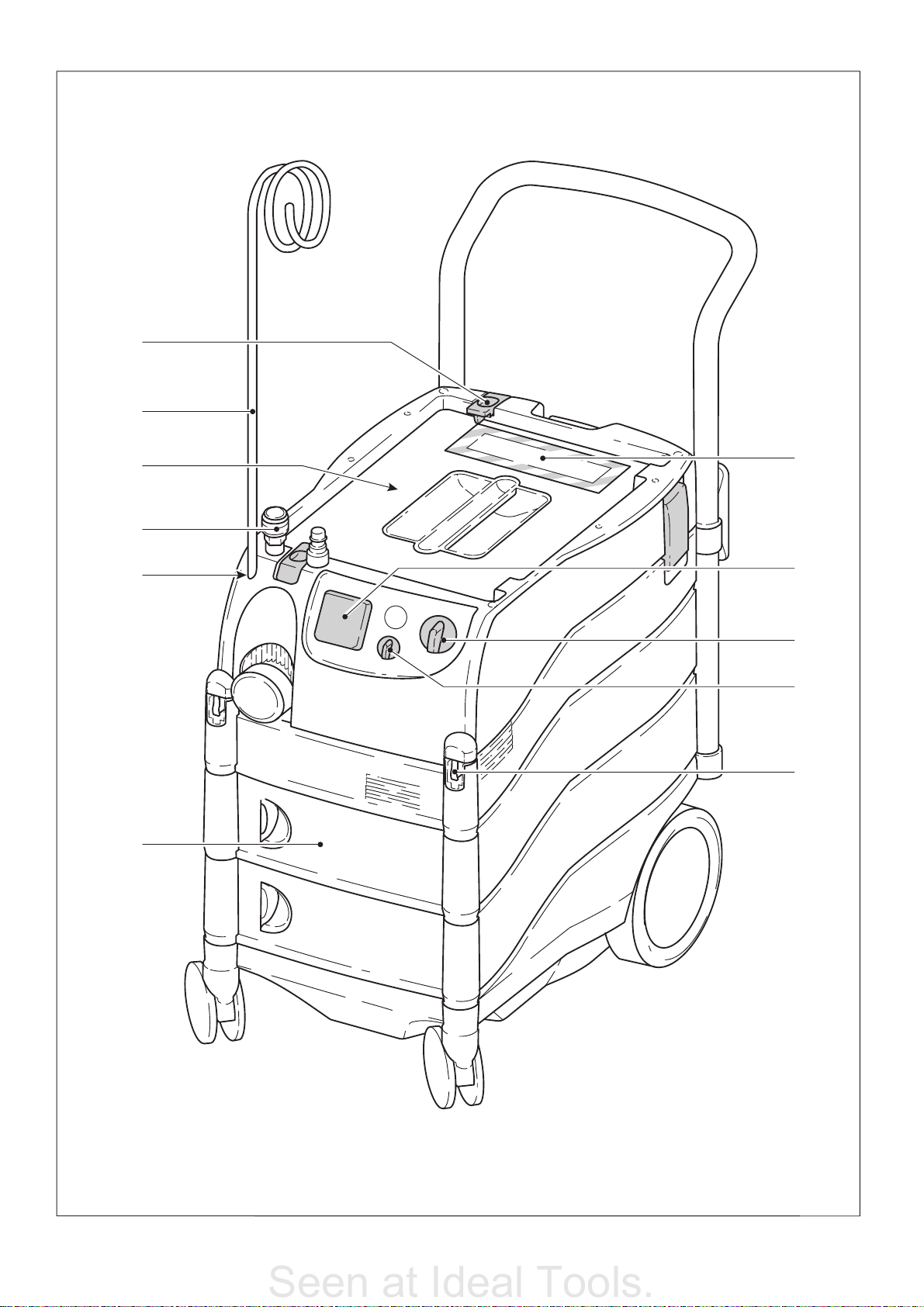

1.11

Seen at Ideal Tools.

1.10

1.9

1.8

L

L

1.1

1.7

1.6

1.2

1.3

1.4

1.5

1

Page 3

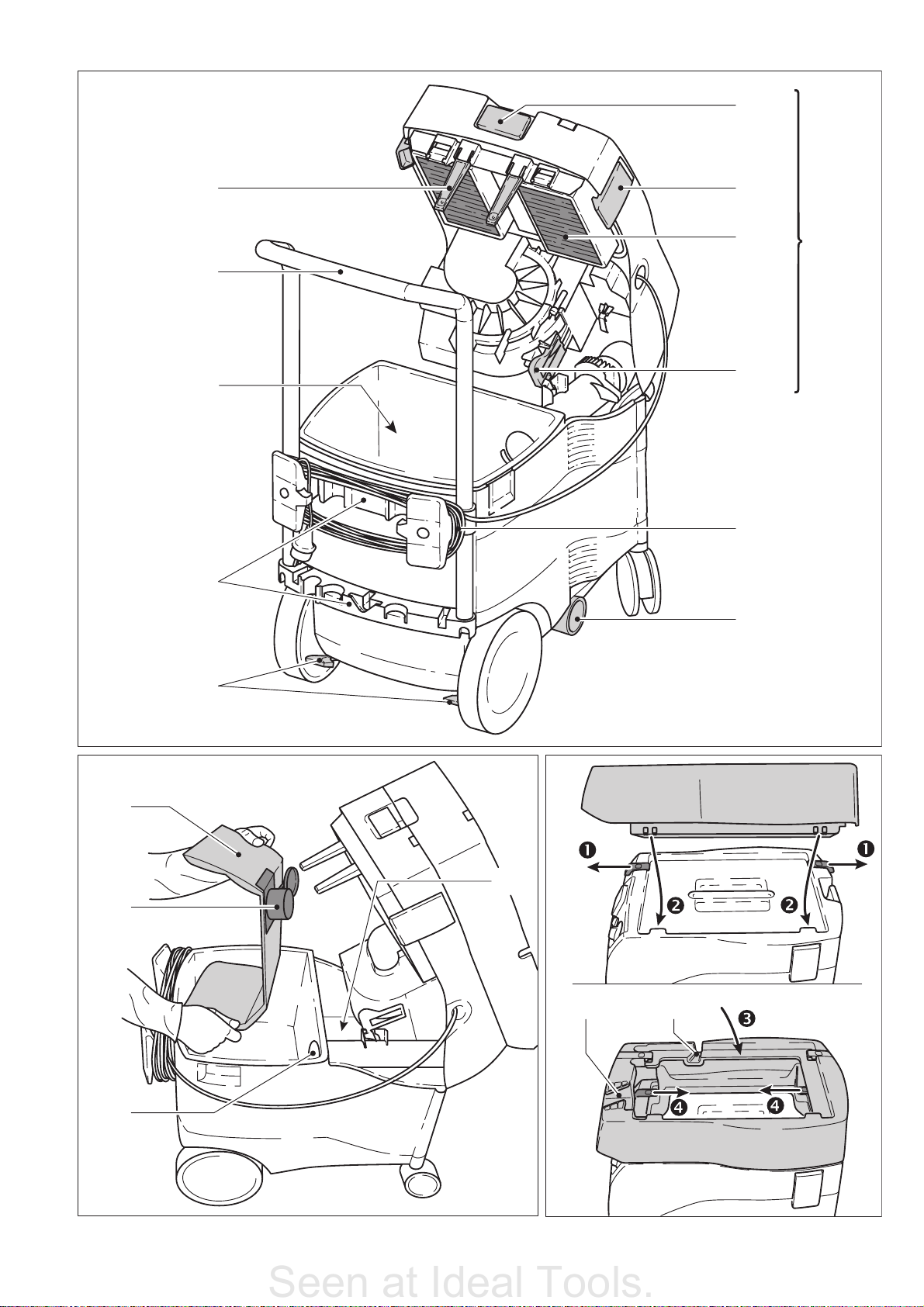

2.1

Seen at Ideal Tools.

2.12

2.11

2.10

2.9

2.2

2.3

2.5

2.6

2.7

2.4

2

3.4

3.3

3.2

2.8

3.1

4.1 4.2

3

4

Page 4

Technical data

Seen at Ideal Tools.

Power consumption 350 - 1200 W

Connected load to appliance plug socket max.:

EC 2400 W

CH, DK 1100 W

GB 240 V/110 V 1800 W/500 W

AUS 1200 W

Volume fl ow (air) max., turbine 228 m³/h

Vacuum max., turbine 23000 Pa

Filter surface 14000 cm2

Suction hose Ø 27 mm x 3.5 m

Sound pressure level in compliance

with DIN 60704-1 72 dB(A)

Power cable length 7.5 m

Protection type IP X4

Container capacity

CTL 22 E SG 22 l

CTL 33 E SG/CTL 33 LE SG 33 l

CTL 44 E/CTL 44 LE 44 l

CTL 55 E 55 l

Dimensions L x W x H

CTL 22 E SG 625 x 380 x 550 mm

CTL 33 E SG/CTL 33 LE SG 625 x 380 x 660 mm

CTL 44 E/CTL 44 LE 710 x 380 x 935 mm

CTL 55 E 710 x 380 x 935 mm

Weight CTL 22 E SG 13.1 kg

CTL 33 E SG/CTL 33 LE SG 15.6 kg

CTL 44 E/CTL 44 LE 20 kg

CTL 55 E 22 kg

The specifi ed illustrations can be found at the beginning of the operating instructions.

Pictograms

Note, Danger! Manual, read the instructions.

1 Intended use

The vacuum cleaners are designed as specifi ed for the aspiration and evacuation

of noxious dusts industrial threshold limit

values (LTL-values) up to 1 mg/m³ and of

wood dusts corresponding to dust class ‘L’

in accordance with IEC 60335-2-69. The

vacuum cleaner is designed as specifi ed

for extracting water. The vacuum cleaner

is designed in accordance with EN 60335-1

and EN 60335-2-69 for a higher loading in

industrial use.

2 Safety instructions

- Only use original Festool accessories.

- Warning: The appliance contains dust

hazardous to health. Emptying and maintenance operations, including removal of

the dust collection means, must only be

carried out by authorised personnel wearing suitable personal protection. Do not

operate without the full fi ltration system

fi tted.

- The appliance may be operated only in

an adequately ventilated space (in compliance with national industrial safety

provisions).

- Do not suck in any sparks or hot chippings.

- With the exception of wood dust, do not

suck in any fl ammable or explosive dusts

such as magnesium, aluminium etc. - Risk

of explosion!

- Do not use to extract fl ammable or explosive liquids (e.g. petrol, thinners) - Risk

of explosion!

9

Page 5

- Do not use to extract aggressive liquids/

Seen at Ideal Tools.

dry materials (e.g. acids, alkalis, solvents).

- Remove plug from mains socket when not

in use and before maintenance work.

- Do not pull plug out of mains socket by

its cable.

- Protect the cable against heat, oil and

sharp edges.

- Check the plugs and cables regularly and

have them replaced by an expert if damaged.

- Do not leave devices out in the rain.

- Do not lift or carry the devices by their

handles using a crane hook or lifting gear.

- The device may only be used by persons

who have been trained in its use and who

are authorised to do so.

- If noxious dusts have been extracted, the

vacuum cleaner and all accessories must

be completely cleaned (inside and outside)

by suction and wiping, before removal

from the contaminated area. Parts that

cannot be completely cleaned are to be

packed for transport in a plastic bag with

an airtight seal.

- For safety reasons, only operate the machine using a totally earthed socket.

3 Appliance preparation and initial

operation

Stick the enclosed sticker in your national

language on the text area of the warning

plate (1.1). The accessories are delivered

horizontal in the container (2.10), and must

be removed prior to initial operation.

3.1 Power supply

The line voltage and frequency must

correspond with the data on the ra-

tings plate!

Make sure that the vacuum cleaner is switched off when you plug the power cable in.

The antistatic system (AS)

Friction in the suction hose causes electrostatic charges which can result in unpleasant electric shocks for the operator.

In order to conduct these static charges to

earth, the extraction units are provided with

an antistatic system as a standard feature.

However, antistatic hoses and accessories

have to be used in this case. The antistatic

function will only work if the plug is plugged

into a totally earthed socket.

3.2 On/off switch (1.3)

In position 0 the vacuum cleaner is switched

off and the appliance plug socket (1.2) is

dead.

Two modes of operation are possible:

a) Switch position „MAN“

The appliance plug socket is dead.

The cleaner motor starts immediately.

b) Switch position „Auto“

The appliance plug socket is live.

The cleaner motor starts only when the tool

connected to the appliance plug socket is

switched on.

3.3 Suction force regulator (1.4)

The suction force regulator can be used to

vary the suction capacity. This permits a

precise adaptation to different substances

to be picked up.

3.4 Temperature control

A temperature fuse switches the dust extractor off before this reaches a critical

temperature to protect against overheating

- switch dust extractor off and leave for

around 5 minutes to cool down.

If the dust extractor still cannot be switched

back on, please consult a Festool-service

centre.

3.5 Connecting an electric tool

Connect the electric tool to the appliance

plug socket (1.2).

3.6 Connecting pneumatic tools

When the compressed-air module (1.8)

(452829; supplied ready with CTL 33 LE

SG and CTL 44 LE) is fi tted, the automatic

cut-in of the appliance also operates in

conjunction with compressed-air tools. We

also recommend fi tting of the VE supply

Before turning the switch to the

„Auto“ position, ensure that the tool

connected to the appliance plug socket is switched off.

Observe the maximum connected

load on the appliance plug socket

(see “Technical Data“)!

Make sure that the electric tool is

switched off when plugging it in and

unplugging it.

Make sure that the pneumatic tool

is switched off when plugging it in

and unplugging it.

10

Page 6

unit (452797). The supply unit fi lters and

Seen at Ideal Tools.

oils the compressed air and allows the air

pressure to be regulated. An IAS connecting

piece (454757) is available for connecting

Festool compressed-air tools with the IAS

system. To ensure trouble-free functioning

of the automatic cut-in, the operating pressure of the tool must be 6 bar.

4 Operation

4.1 Opening/closing the vacuum

cleaner

- Open retaining clamps (2.2),

- Raise upper part (2.4) until support catch

(2.5) engages.

Follow the reverse order to close the appliance. You must raise the upper part

slightly before depressing or disengaging

the support.

4.2 Changing the fi lter

During the following procedure, take

care not to raise dust more than is

unavoidable.

Wear a P2 breathing protection mask

with health-hazardous dusts!

a) Changin the fi lter bag (3.4)

Order no.:

CTL 22 E SG 452970

CTL 33 E SG/CTL 33 LE SG 452971

CTL 44 E/CTL 44 LE 452972

CTL 55 E 452973

- Open the vacuum cleaner,

- Remove the used fi lter bag (see printed

text on fi lter bag),

- Dispose of the used fi lter bag in accor-

dance with statutory requirements,

- Thoroughly clean the dirt container (2.10)

and the space (3.1) for suction turbine

(wipe down with a damp cloth),

- Insert new fi lter bag (see printed text on

fi lter bag). Important: Press the fi lter

bag sleeve (3.3) fi rmly onto the dust ex-

traction fi tting (3.2)!

- Close the vacuum cleaner.

b) Changing the filter element

(2.3)

Order no.: 452923

Do not operate machine without a

fi lter element. This may damage the

motor.

- Open the vacuum cleaner,

- Remove the used filter element (see

11

printed text on the fi lter element packaging),

- Dispose of the used fi lter element in a

sealed, dust-tight bag in accordance with

statutory requirements,

- Thoroughly clean dirt container (2.10) and

space (3.1) for the suction turbine (wipe

down with a damp cloth),

- Fit a new fi lter element (see printed text

on the fi lter element packaging),

- Close vacuum cleaner.

4.3 Cleaning the fi lter element

To clean, move the handle (2.1) to and fro

about 10 times. N.B.: You need to clean the

fi lter element only if you use the vacuum

cleaner without a fi lter bag.

4.4 Emptying the dirt trap (2.10)

Always remove the upper part of the vacuum cleaner before emptying the dirt

container!

- Open the vacuum cleaner,

- Raise the upper part slightly, depress the

support (2.5),

- Raise the upper part to the stop (vertical

position),

- Remove the upper part by moving it forwards horizontally,

- Empty the dirt container,

- Replace the upper part. Warning: Make

sure that both upper-part pins are fully

inserted in the recesses (1.5)!

- Close the vacuum cleaner.

4.5 Stand/Brake

The wheels can be blocked by the brakes

(2.8), thus preventing the vacuum cleaner

from rolling away unexpectedly.

4.6 Hose depot (partly in scope of

delivery)

Securing the hose depot on the dust extractor: see Fig. 4. When work is complete, you

can guide the extractor hose through the

opening (4.1) and deposit the hose in the

depot. Similarly, the mains cable can also

be guided through the opening (4.2) and

deposited in the hose depot.

5 Application

- A systainer can be fi xed to the storage

area (1.9) with the two clamps (1.11).

Tools or accessories can also be stowed

on the storage area and in the storage

Page 7

compartments (1.6, not with CTL 22).

Seen at Ideal Tools.

- A hose coupling (1.10) (487072) can be

plugged into the opening (1.7). The suction hose is connected to the tool from

above with the hose coupling. Alternatively, a hose clip (452998) can be fi tted

for coiling the suction hose.

- The push handle (2.11) (452921; supplied

ready with CTL 44 and CTL 55) makes the

vacuum cleaner easier to move. Accessories (e.g. vacuum accessories) can be

fi xed to the push handle batten (2.9).

- An air blast is obtained by inserting a

suction hose in the blast opening (2.7).

5.1 Vacuuming dry materials

A fi lter bag must be used without

exception when evacuating noxious

substances!

Before using the vacuum cleaner to evacuate dry substances, a fi lter bag must

always be inserted in the container. Then

the evacuated material can be disposed of

easily. The fi lter element becomes damp

after evacuating liquids. A damp fi lter element suffers more wear and tear if it is used

for dry materials. Accordingly, the fi lter

element should be dried or replaced with a

dry one before dry operation.

5.2 Vacuuming liquids

Do not evacuate combustible liquids!

If foam or liquid escapes, stop work

immediately and empty the dirt con-

tainer.

The fi lter bag has to be removed before

evacuating liquids. We recommend use of a

special wet fi lter. When the maximum fi lling

level is reached, a bag-full indicator (2.12)

automatically interrupts extraction.

6 After fi nishing work

- Switch off the cleaner and pull the Plug of

the mains lead out of the Plug socket.

- Wind up the mains lead (2.6).

- Empty dirt tank.

- Clean the vacuum cleaner inside and out-

side by suction and wiping.

- Deposit the appliance in a dry room, safe

from unauthorised use.

7 Maintenance and care

Always remove the power supply

plug from the socket before carrying

out any work on the machine.

All maintenance and repair work

which requires the motor casing to

be opened may only be carried out

by an authorised service centre.

A safety test is to be carried out at least

once a year by the manufacturer or an instructed person, e.g. for possible damage

to the fi lter and leaks in the appliance,

and to ensure that the control devices are

functioning.

If the user services the appliance, it must be

dismantled, cleaned and serviced, as far as

possible without any danger to the maintenance staff and other persons. Appropriate

measures include decontamination before

dismantling, locally fi ltered forced ventilation on the dismantling site, cleaning the

service area, and suitable personal safety

equipment.

8 Accessories, fi lter

The accessory and fi lter order number can

be found in your Festool catalogue or on the

Internet under “www.festool.com”.

9 Warranty

Our equipment is under warranty for at

least 12 months with regard to material or

production faults in accordance with national legislation. In the EU countries, the

warranty period for exclusively private use

is 24 months (an invoice or delivery note

is required as proof of purchase). Damage

resulting from, in particular, normal wear

and tear, overloading, improper handling, or

caused by the user or other damage caused

by not following the operating instructions,

or any fault acknowledged at the time of

purchase, is not covered by the warranty.

Complaints will only be acknowledged if

the equipment has not been dismantled

before being sent back to the suppliers or

to an authorised Festool customer support

workshop. Store the operating instructions,

safety notes, spare parts list and proof of

purchase in a safe place. In addition, the

manufacturer’s current warranty conditions

apply.

Note

We reserve the right to make changes to

the technical data contained in this information as a result of ongoing research and

development work.

12

Page 8

EG-Konformitätserklärung. Wir erklären in alleini-

Seen at Ideal Tools.

ger Verantwortung, dass dieses Produkt mit den

folgenden Normen oder normativen Dokumenten

übereinstimmt: EN 60335-1, EN 60335-2-69, EN 55 014,

EN 61 000 gemäß den Bestimmungen der Richtlinien 73/23/

EWG, 89/336/EWG.

CE-Konformitetserklæring. Vi erklærer på eget ansvar at dette produktet er i overensstemmelse med

følgende normer eller normative dokumenter:

EN 60335-1, EN 60335-2-69, EN 55 014, EN 60 555 i henhold

til bestemmelsene i direktivene 73/23/EØF, 89/336/EØF.

EC-Declaration of Conformity: We declare at our sole

responsibility that this product is in conformity with

the following standards or standardised documents:

EN 60335-1, EN 60335-2-69, EN 55 014, EN 61 000,

in accordance with the regulations 73/23/EEC,

89/336/EEC.

CE-Déclaration de conformité communautaire. Nous

déclarons sous notre propre responsabilité que ce

produit est conforme aux normes ou documents

de normalisation suivants: EN 60335-1, EN 60335-2-69,

EN 55 014, EN 61 000, conformément aux prescriptions des

directives 73/23/CEE, 89/336/CEE.

CE-Declaración de conformidad. Declaramos bajo

nuestra exclusiva responsabilidad que este producto

corresponde a las siguientes normas o documentos normalizados: EN 60335-1, EN 60335-2-69, EN 55 014,

EN 61 000, conforme a las prescripciones estipuladas en las

directrices 73/23/CEE, 89/336/CEE.

CE-Dichiarazione di conformità CE. Dichiariamo sot-

to la nostra esclusiva responsabilità che il presente

prodotto è conforme alle norme e ai documenti

normativi seguenti: EN 60335-1, EN 60335-2-69, EN 55 014,

EN 61 000, conformemente alle normative delle direttive

73/23/CEE, 89/336/CEE.

CE-Declaração de conformidade: Declaramos, sob

a nossa exclusiva responsabilidade, que este pro-

duto corresponde às normas ou aos documentos

normativos citados a seguir: EN 60335-1, EN 60335-2-69,

EN 55 014, EN 61 000 segundo as disposições das directivas

73/23/CEE, 89/336/CEE.

Заявление о конформности СЕ. Мы заявляем в

единоличной ответственности, что данное изделие

соответствует требованиям следующих стандартов

или нормативов: EN 60335-1, EN 60335-2-69, EN 55 014,

EN 61 000 в соответствии с постановлениями директив

ЕЭС 73/23, ЕЭС 89/336.

Prohlášení o souladu s normami CE. Prohlašujeme

na vlastní zodpovìdnost, že tento výrobek od-

povídá následujícím normám nebo normativním

dokumentùm:

EN 60335-1, EN 60335-2-69, EN 55 014, EN 61 000 v souladu

s ustanoveními smìrnic 73/23/EHS, 89/336/EHS.

Oœwiadczenie o zgodnoœci CE. Niniejszym oœwiadcz-

amy z ca³¹ odpowiedzialnoœci¹, ¿e wyrób ten odpo-

wiada nastêpuj¹cym normom wzglêdnie dokumentom normatywnym : EN 60335-1, EN 60335-2-69, EN 55 014,

EN 61 000 zgodnie z postanowieniami wytycznych 73/23/

EWG, 89/336/EWG.

EG-conformiteitsverklaring. Wij verklaren op eigen

verantwoordelijkheid dat dit produkt voldoet aan de

volgende normen of normatieve documenten.

EN 60335-1, EN 60335-2-69, EN 55 014, EN 61 000, conform

de richtlijnen 73/23/EEG, 89/336/EEG.

EG-konformitetsförklaring. Vi förklarar i eget ansvar,

att denna produkt stämmer överens med följande

normer och normativa dokument:

EN 60335-1, EN 60335-2-69, EN 55 014,EN 61 000 enligt

bestämmelserna i direktiven 73/23/EEG, 89/336/EEG.

EY-standardinmukaisuusvakuutus. Vakuutamme yksinvastuullisina, että tuote on seuraavien standardien

ja normatiivisten ohjeiden mukainen:

EN 60335-1, EN 60335-2-69, EN 55 014, EN 61 000 direktiivien 73/23/EY, 89/336/EY määräysten mukaan.

EF-konformitetserklæring: Vi erklærer at have alene

ansvaret for, at dette produkt er i overensstemmelse

med de følgende normer eller normative dokumenter:

EN 60335-1, EN 60335-2-69, EN 55 014, EN 61 000 i henhold

til bestemmelserne af direktiverne 73/23/EØF, 89/336/EØF.

Leiter Forschung und Entwicklung

Manager Research and Development

Directeur de recherce et développement

Festool GmbH

Wertstr. 20

D-73240 Wendlingen

Dr. Johannes Steimel

450 589 /03.06

Loading...

Loading...