Page 1

ADDITIONAL INFORMATION

Page 2

FANUC Series 30i –MODEL B

FANUC Series 31i –MODEL B

FANUC Series 32i –MODEL B

Common to Lathe System / Machining Center System

1. Type of applied technical documents

Name

FANUC Series 30i –MODEL B

FANUC Series 31i –MODEL B

FANUC Series 32i –MODEL B

Common to Lathe System / Machining Center System

OPERATOR'S MANUAL

OPERATOR'S MANUAL

Spec.No./Version

B-64484EN/01

2. Summary of change

Group Name / Outline New,

Basic

Function

The description of the maximum number of files of the USB

memory folder screen was corrected. Parameter No.11376 was

added.

The description of “Multiple programs on memory card selection

input function” is added.

The description of “Overwriting confirmation when program is input

Add,

Correct,

Delete

Correct,

Add

Add

Add

Applicable

Date

Immediately

ED

Date

Date

and file is output” is added.

The description about deleting a folder recursively is added.

The description of improvement of folder management is added.

The description of power consumption monitoring screen is added.

Title

Common to Lathe System / Machining Center System

Draw

No.

Design

2010.06.18

Design

Description Page

Approve

Add

Add

Add

FANUC Series 30i / 31i / 32i-MODEL B

OPERATOR'S MANUAL

B-64484EN/01-01

1/2

Page 3

Optional

Function

The description of Rate Feed function is added.

The description of Plane Conversion function is added.

The description of Stored Pitch Error Compensation function is

added and corrected.

The description of High-speed Smooth TCP is added and corrected

The description of Rigid Tapping By Manual Handle is added.

The description of Three-dimensional Rotary Error Compensation is

added and corrected

The description of 5-axis machining configuration selecting function

Add

Add

Add

Correct

Add

Correct

Add

Correct

Add

New

Immediately

is added and corrected.

Unit

Maintenance

parts

Notice - This function is available in the following software.

G301,G311,G321, G331,

G401,G411,G421,G431,G501 : 01.0 or later

Correction

Another

ED

Date

Date

Design

2010.06.18

Design

Title

Draw

No.

Description Page

Approve

FANUC Series 30i / 31i / 32i-MODEL B

Common to Lathe System / Machining Center System

OPERATOR'S MANUAL

B-64484EN/01-01

2/2

Page 4

Replace the NOTE in "8 DATA INPUT/OUTPUT" of "III. OPERATION" with following description.

NOTE

1 If the external input/output device is other than a data server interface or

embedded Ethernet interface, a file name of up to 12 characters can be handled.

NC programs on the memory of the CNC can each be assigned any file name of

up to 32 characters, but the name is restricted to up to 12 characters in the

input/output to and from external I/O devices.

2 If the external input/output device is a data server interface, embedded Ethernet

interface, or USB memory interface, a file name of up to 32 characters can be

handled.

3 When a memory card interface is used as an external I/O device, up to 512 files

can be handled.

ED

Date

Date

Design

2010.06.17

Design

Title

Draw

No.

Description Page

Approve

FANUC Series 30i / 31i / 32i-MODEL B

USB memory folder screen

B-64484EN/01-01

1/4

Page 5

Replace "Limitation" in "11.1.3 Selecting a USB Memory as a Device" with following description.

Limitation

There are the following restrictions on the USB function.

(1) Only one USB memory can be recognized. (No USB hub can be recognized.)

(2) Up to 32 characters can be used for a file or folder name.

If a file or folder name is longer than 32 characters, the 32nd character is replaced with a tilde (~) and the

subsequent characters are omitted when displayed. All operations including management operation and

input/output cannot be performed for a file or folder whose name is omitted with a tilde (~).

(3) The maximum number of folder levels is 6 (excluding the root folder).

(4) In case of setting that is sorted by the file name (parameter SOR(No.3107#4)=1), the maximum number of

files and folders that can be the display in a folder is 512. Do not store more than 512 files in the USB

memory.

(5) If a non-ASCII character (alphanumeric character) is used in a file or folder name, it cannot be displayed

correctly.

For detailed specifications of and restrictions on a USB memory, see the section related to the USB function.

NOTE

1 Remove a USB memory only when “REMOVE OK” is displayed as the USB

memory status, or data may be damaged.

2 When the free space of the USB memory is a little or when a large amount of file

is in the USB memory, it might take time to operate the USB memory. In the

default configuration, warning "TIME-OUT" is displayed after 30 seconds

passed, and the operation of the USB memory stops. When the period of the

time-out is changed, set parameter No.11376 .

- Operation of creation, edition, and management of a program

When “USB memory as a device” is selected, operation of creation, edition, and management of a program is

below (Table 11.1.3 (a)):

Table 11.1.3 (a)

Item Usable

Creation of a program Unusable

Edition prohibition attribute Unusable

Inserting, alteration, and deletion a Word Unusable

Deletion of a block Unusable

Program search Usable

Sequence number search Unusable

Deletion of a program Usable

Editing a custom macro Unusable

Password function Unusable

Editing a program character Unusable

Program copy function Unusable

Key and program encryption Unusable

Selecting a device Usable

Creation of a folder Usable

Renaming of a folder Usable

Changing the attribute of a folder Unusable

ED

Date

Date

Design

2010.06.17

Design

Title

Draw

No.

Description Page

Approve

FANUC Series 30i / 31i / 32i-MODEL B

USB memory folder screen

B-64484EN/01-01

2/4

Page 6

Item Usable

Deletion of a folder Usable

Selecting a default folder Unusable

Renaming of a file Usable

Deletion of a file Usable

Changing the attribute of a file Unusable

Selecting a main program Unusable

Making a program compact Unusable

Input/output of program Usable

ED

Date

Date

Design

2010.06.17

Design

Title

Draw

No.

Description Page

Approve

FANUC Series 30i / 31i / 32i-MODEL B

USB memory folder screen

B-64484EN/01-01

3/4

Page 7

Add the parameter No. 11376 to "A.1 DESCRIPTION OF PARAMETERS" of APPENDIX .

11376 Time-out period of USB memory

[Input type] Parameter input

[Data type] Word

[Unit of data] sec

[Valid data range] 0 to 32767

Set the time-out period of the USB memory. Please adjust this parameter according to the USB

memory.

NOTE

When 0 is set in this parameter, it is assumed to 30.

ED

Date

Date

Design

2010.06.17

Design

Title

Draw

No.

Description Page

Approve

FANUC Series 30i / 31i / 32i-MODEL B

USB memory folder screen

B-64484EN/01-01

4/4

Page 8

App

p

Add the following specification in

Ⅲ Operation,

10.12.2 “Copy of program file with memory card device”

10.12.3 “Deleting files in memory card device”

10.12.2 Copy of program file with memory card device

Overview

In the program list screen, the program file can be input and output between the memory cards connected as

an external input-output device and program memory (CNC MEM) on CNC by the same operation as the copy

of the program file.

NOTE

1 This function targets the memory card by the PCMCIA interface connected as an

external input-output device.

2 Change the following parameter setting to copy the program file between the memory

cards and program memory.

Patameter No.20-23 are set to 4.

・

Bit 0 (IO4) of parameter No.0110 is set to 0.

・

When Bit 0 (IO4) of parameter No.0110 is set to 1, and sets parameter No.20-23 to a

value that means input-output device other than the memory card,

warning " CHANGE EXTERNAL DEVICE TO MEMORYCARD" is occurred,

and the file with the memory card cannot be copied.

Explanation

・Cnc mode when the copy is operated

Change to the EDIT mode when the file is copied between different devices.

In the multi path system, change the entire path to the EDIT mode.

Warning "CHANGE TO EDIT MODE" is occurred excluding the EDIT mode in any mode except EDIT.

・Selection of file

The file is selected according to the program file selection operation that becomes effective because of the bit 3

(PCP) of parameter No.11374 is set to 1.

The file that can be selected as a copy target is only a file in the same folder.

・Copy of program file

When the program file is copied from the program memory to the memory card, the selected program is output

to the memory card.

When the program file is copied from the memory card to the program memory, the selected file is read to the

program memory.

FANUC Series 30i / 31i / 32i-MODEL B

Title

Draw

No.

Date

ED

Date

Design

2010.06.17

Description

rv.Design

Multiple programs on memory card

selection in

ut function

B-64484EN/01-01

Page

1/3

Page 9

App

p

・File that can be copied

The file that can be output to the memory card by the copy operation is only a program file on the CNC-MEM

device. Therefore, the file that exists in other devices except the CNC-MEM and folder cannot be output.

NOTE

Even if the folder has been selected during output operation to the memory card, the

folder is not output.

・Overwrite of program file

The file is overwritten according to the program file overwriting operation by setting the bit 3 (PCP) of

parameter No.11374 to 1.

NOTE

Operation when the file is copied to the memory card depends on the setting of bit 1

(COW) of parameter No.11308.

Operation when the file is copied to the program memory of CNC depends on the

setting of bit 2 (REP) of parameter No.3201.

Restrictions

・File operation restrictions on devices

A copy or movement between the following devices is possible.

・ CNC MEM

・ MEM CARD (binary format)

(However, this device can only be selected as the copy source folder from which a file is read.)

・ Data server

・ Memory card

(However, This device can do only the copy operation with the CNC MEM device.

Moreover, this device cannot be used together with MEM CARD.)

For devices other than the above, a copy or movement between them is impossible.

If an attempt is made to perform a copy or movement, the warning message "CAN NOT COPY/MOVE"

appears.

・Copy of file including some programs

Don’t input anything to the key input buffer when you copy the file including some programs.

When some programs are included in the file of the copy origin, if the character string is input to the key input

buffer, only the program of the head in the file is read to CNC MEM with program name input to the key input

buffer.

・File name on memory card

When the program with 8 character or more name of the program in the program memory on CNC is output, it

is output on the memory card as follows.

For eight digits O numbers ('O'+ numeric parts)

・The numeric parts are 8 digits or more:

The file name is changed to eight numerical value digits except first 'O'.

Example) O12345678 → 12345678

・The numeric parts are less than 8 digits:

One digit is deleted '0' and program name is changed to seven digits of 'O' + numerical value.

FANUC Series 30i / 31i / 32i-MODEL B

Title

Draw

No.

Date

ED

Date

Design

2010.06.17

Description

rv.Design

Multiple programs on memory card

selection in

ut function

B-64484EN/01-01

Page

2/3

Page 10

App

p

Example) O00012345 → O0012345

For arbitrary program name (9 characters or more)

・Program name is changed to the file name that rounds down since the ninth character.

Example) 123456789 → 12345678

The file name output on the memory card might overlap by the above operation. In this case, it is output

according to the setting of bit 1 (COW) of parameter No.11308.

10.12.3 Deleting files in memory card device

Overview

The file on the memory card can be deleted according to the operation of program file deletion by setting the bit

3 (PCP) of parameter No.11374 to 1.

FANUC Series 30i / 31i / 32i-MODEL B

Title

Draw

No.

Date

ED

Date

Design

2010.06.17

Description

rv.Design

Multiple programs on memory card

selection in

ut function

B-64484EN/01-01

Page

3/3

Page 11

g

App

Add the following specification in

Ⅲ Operation,

10.12.4 “Overwriting confirmation when programs are input”

10.12.5 “Overwriting confirmation when file is output”

10.12.4 Overwriting confirmation when programs are input

Overview

When the program is input and there is already another program whose name is the same as the former, it is

possible to select whether the program is overwritten or not, by the softkey operation.

Inputing a program

Procedure

Operate the following procedures on the ALL IO screen, the program edit screen, and the program list screen.

1 Press the soft key [F INPUT].

2 Specify the input file name, and press the soft key [F SET].

When the file name is not specified, the file of the default file name is input.

3 Specify the input program name, and press the soft key [P SET].

When the program name is not specified, programs in the file are input.

4 Press the soft key [EXEC]. The following softkey is displayed.

Fig.10.12.4 (a) Softkey display during input operation(10.4inch)

5 When the program of the same name is already existed in the destination, the confirmation message

“Overwrite ? ‘input program name’ ” and the following softkey are displayed.

Fig. 10.12.4 (b) Confirmation of overwriting by input operation in program list screen(10.4inch)

・ When the softkey [YES] is pressed, only the same program as the name displayed in the confirmation

message is input by the overwriting.

・ When the softkey [NO] is pressed, the program of the same name displayed in the confirmation message is

skipped, and input from the next file.

When the program of the same name is found again, the above confirmation message is displayed in every

case.

FANUC Series 30i / 31i / 32i-MODEL B

Title

Overwriting confirmation when

program is input and file is output

Draw

No.

Date

ED

Date

Date

Design

2010.06.17

Desi

n

Description

rv.

B-64484EN/01-01

B-64484EN/01-01

Page

1/3

Page 12

g

App

・ When the softkey [YES ALL] is pressed, all programs of the same name displayed in the confirmation

message and programs of the same name after that are input by the overwriting.

・ When the softkey [NO ALL] is pressed, all programs of the same name displayed in the confirmation

message and programs of the same name after that are not input.

・ When the softkey [CANCEL] is pressed, the input is ended. Moreover, when the return menu key is

pressed, the input is similarly ended.

The softkey returns to the display before the softkey [F INPUT] is pressed when the input of all programs ends.

The input operation is canceled when the mode is switched and the screen are switched to another screen while

confirming the overwriting.

NOTE

1 The input is interrupted when there is a protected program.

2 The overwriting confirmation is canceled as well as the switch to another screen, and

the input ends, when switching to full screen display between small screen display or

the path is switched while confirming the overwriting.

3 When the programs are input to effective the overwriting confirmation function on the

background editting (the bit 2 (REP) of parameter No.3201 and bit 3 (PCP) of

parameter No.11374 are set to 1), the program is input at last is selected as a

program for the background editing.

The program for the background editing even if the program is input by the

background editing when the folder to be input has been selected on each screen is

not changed, when the overwriting confirmation function cannot be used (the bit 7

(FLI) of parameter No.11364 is set to 1).

4 The program that input the program of the same name before failing if failing in input

for the reasons such as protecting the program input while editing the background

when the folder to be input is a setting that inputs the overwriting (the bit 2 (REP) of

parameter No.3201 is set to 1, and bit 3 (PCP) of parameter No.11374 is set to 0),

and is foreground or a background folder (bit 7 (FLI) of parameter No.11364 is set to

0) is selected to the program for the background editing. The program of the

background editing is not changed even if failing in the input of the program of the

head when the overwriting confirmation function is available.

5 The overwriting confirmation cannot be used by inputting the background editing.

10.12.5 Overwriting confirmation when file is output

Overview

On the bit 1 (COW) of parameter No.11308 is set to 1, when the file of same name had already exist when the

NC data of the program and the parameter, etc. was output to an external input-output device, it is possible to

select the overwriting or cancel the output to file by the operation.

Operation procedure in normal output

Procedure

Operate the following procedures on the screen where the NC data can be output.

FANUC Series 30i / 31i / 32i-MODEL B

Title

Draw

No.

Date

ED

Date

Date

Design

2010.06.17

Desi

n

Description

rv.

Overwriting confirmation when

program is input and file is output

B-64484EN/01-01

B-64484EN/01-01

Page

2/3

Page 13

g

App

1 Press the soft key [F OUTPUT].

2 Specify the input file name, and press the soft key [F SET].

When the file name is not specified, the file of the default file name is output.

3 Press the soft key [EXEC].

4 Only when the file of the same name exists at the output destination, the confirmation message of

following softkey and "OVERWRITE ?" is displayed.

Fig.10.12.5 (a) Overwriting confirmation by output operation(10.4inch)

・ When the softkey [YES] is pressed, the file of same name is overwritten, and the file is output.

・ When the softkey [CANCEL] is pressed, the output is ended. Moreover, when the return menu key is

pressed, the output is similarly ended.

Operation procedure in all output

Procedure

Operate the following procedures on the ALL IO screen.

1 Press the soft key [ALL OUTPUT].

2 The input file name is specified, and press the soft key [F SET].

When the file name is not specified, the file of the default file name is output.

3 Press the soft key [EXEC].

4 Only when the file of the same name exists at the output destination, the confirmation message of

following softkey and "‘Output file name’ OVERWRITE ? " is displayed.

Fig.10.12.5 (b) Overwriting confirmation by all output operation(For the offset data)(10.4inch)

・ When the softkey [YES] is pressed, the file of the same name displayed in the confirmation message is

overwritten, and the file is output..

・ When the softkey [YES ALL] is pressed, the file of the same name displayed in the confirmation message

and all files of the same name after that are output by the overwriting.

・ When the softkey [CANCEL] is pressed, the output is ended. Moreover, when the return menu key is

pressed, the output is similarly ended.

FANUC Series 30i / 31i / 32i-MODEL B

Title

Draw

No.

Date

ED

Date

Date

Design

2010.06.17

Desi

n

Description

rv.

Overwriting confirmation when

program is input and file is output

B-64484EN/01-01

B-64484EN/01-01

Page

3/3

Page 14

y

Add the following description to III OPERATION 11.5.1 “DELETING A FOLDER RECURSIVELY”.

11.5.1 DELETING A FOLDER RECURSIVELY

This function enables the deletion of the folder that includes programs and folders.

Explanation

When a folder is deleted, all the programs and folders in the folder is deleted.

This function is enabled by setting bit 3 (FDR) of parameter No. 11364.

In the program list screen (CNC built-in memory), this function is available.

Procedure

1. Display the program list screen.

2. Move the cursor to a folder to delete.

3. Press the softkey [DELETE].

4. Press the softkey [EXEC].

5. The folder is deleted. All the programs and folders in the folder are also deleted.

NOTE

Following programs, folders and folders that include them are not deleted.

- The executed programs

- The programs which are selected in foreground

- The current folder

By following function, protected programs, folders and the folders that include them are not

deleted, too.

- Key and program encryption

- NE8/NE9 parameter protection

- Protection of data at eight levels

- Read only attribute

When some programs and folders are not deleted, the warning “PROGRAM IN FOLDER IS

NOT DELETED” is displayed.

ED

Date

Date

Design

2010.06.17

Design

Title

Draw

No.

Description Page

Approve

FANUC Series 30i / 31i / 32i-MODEL B

Deleting a folder recursivel

B-64484EN/01-01

1/2

Page 15

y

Add the following description to APPENDIX A PARAMETERS.

#7 #6 #5 #4 #3 #2 #1 #0

11364 FDR

[Input type] Parameter input

[Data type] Bit

#3 FDR When the folder that includes programs or folders are tried to be deleted,

0: the folder is not deleted.

1: the folder, and the program and the folders in it are deleted.

ED

Date

Date

Design

2010.06.17

Design

Title

Draw

No.

Description Page

Approve

FANUC Series 30i / 31i / 32i-MODEL B

Deleting a folder recursivel

B-64484EN/01-01

2/2

Page 16

g

Add the following as 11.13 “Folder management” of III OPERATION.

11.13 Folder management

This function restricts the folder operation in program management. As a result, operator can manage the

program without the complex folder operation. Following two specifications can be selected by the parameter.

1) The folders under the path folders can be used for program management.

2) Only the path folders can be used for program management.

Path folders are the one of the initial folders. The folder exists under //CNC_MEM/USER, and the number is

same to the system path. Please refer to USER’S MANUAL (B-64484EN, II 12 PROGRAM

MANAGEMENT) for details.

ED

Date

Date

Design

2010.06.17

Design

Title

Draw

No.

Description Page

Approve

FANUC Series 30i / 31i / 32i-MODEL B

Folder mana

ement

B-64484EN/01-01

1/6

Page 17

g

//CNC_MEM

/

SYSTEM/

MTB1/

MTB2/

USER/

1)

PATH1/

CYLINDER/

2)

PISTON/

Fig.11.13 (a) Folder that can be used by each setting

PATH2/

LIBRARY/

User created folder

GEAR1/

GEAR2/

ED

Date

Date

Design

2010.06.17

Design

Title

Draw

No.

Description Page

Approve

FANUC Series 30i / 31i / 32i-MODEL B

Folder mana

ement

B-64484EN/01-01

2/6

Page 18

g

11.13.1 Program management under the path folder

If parameter FPF (No.11302#6) is set to “1”, the operation on the program folder screen becomes as follows. At

this time, it is necessary to set parameter CFP (No.11304#7) to “0”.

Table 11.13.1 (a) Restriction of operation

Operation Working

Moving of the folder

Creating of user folder Possible

Changing of foreground default folder Possible

Changing of background default folder Possible

Display on program folder screen

Only the folder under the path folder corresponding to selected path can be displayed.

Warning message “CAN’T MOVE TO FOLDER” is displayed and cannot move when the folder is operated to

move upper from the path folder.

Setting of foreground/background default folder

Only the folder under the path folder corresponding to selected path can be set to foreground/background

default folder.

Under the path folder Possible

Upper from the path folder Impossible

ED

Date

Date

Design

2010.06.17

Design

Title

Draw

No.

Description Page

Approve

FANUC Series 30i / 31i / 32i-MODEL B

Folder mana

ement

B-64484EN/01-01

3/6

Page 19

g

)3)

11.13.2 Program management only in the path folder

If Parameter CFP (No.11304#7) is set to 1, the operation on the program folder screen becomes as follows. At

this time, the setting of parameter FPF (No.11302#6) is invalid.

Table 11.13.2 (a) Restriction of operation

Operation Working

Moving of the folder

Creating of user folder Impossible

Changing of foreground default folder Impossible

Changing of background default folder Impossible

Display on program folder screen

Only the path folder corresponding to selected path can be displayed. “RETURN TO UPPER FOLDER” is

not displayed. (Refer to “1)” in Fig. 11.13.2 (a) and Fig. 11.13.2 (b).)

The subfolder that has already been made under the path folder before the parameter CFP(No.11304#7) is made

effective can be displayed. But it is impossible to move to the subfolder.

Under the path folder Impossible

Upper from the path folder Impossible

2)

1

Fig.11.13.2 (a) Program folder screen(parameter CFP(No.11304#7)=0)

Title

Draw

No.

Date

ED

Date

Design

2010.06.17

Design

Description Page

Approve

FANUC Series 30i / 31i / 32i-MODEL B

Folder mana

ement

B-64484EN/01-01

4/6

Page 20

g

)

)3)

3)

2)

1)

Fig.11.13.2 (b) Program folder screen(parameter CFP(No.11304#7)=1)

Display of device name and current folder

The current folder name is not displayed though the device name is displayed so far. (Refer to “2)” in Fig.

11.13.2 (a) and Fig. 11.13.2 (b).)

Display and setting of foreground/background default folder

Foreground/background default folders are not displayed. (Refer to “3)” in Fig. 11.13.2 (a) and Fig. 11.13.2

(b).)

Moreover, foreground/background default folders cannot be set.

Note

Set foreground/background default folder to each path folder before the

parameter CFP(No.11304#7) is made effective.

Softkey that is not displayed

The following soft key is not displayed, and cannot be operated.

・ CREATE FOLDER 1)

・ FORE CHANGE 2)

・ BACK CHANGE 3)

1

2

Fig11.13.2 (c) Softkey display for CNC_MEM device

Title

Draw

No.

Date

ED

Date

Design

2010.06.17

Design

Description Page

Approve

FANUC Series 30i / 31i / 32i-MODEL B

Folder mana

ement

B-64484EN/01-01

5/6

Page 21

g

11.13.3 Folder for subprogram/macro calls

In the following subprogram call/macro call, the folder /USER/LIBRARY, /MTB12, /MTB2 and /SYSTEM are

searched before the folder where there is the main program are searched.

There is a possibility being executed for the subprogram that the operator doesn't intend if the subprogram is

registered to the above-mentioned folder even if the display and the operation are limited by this function.

-Subprogram call based on an M code

-Subprogram call based on a particular address

-Subprogram call based on a second auxiliary function code

-Macro call based on a S code

-Macro call based on a G code

-Macro call based on an M code

-Macro call based on a T code

-One-touch macro call

By setting 1 to the parameter SCC (No.3457#6), the folder where there is the main program is added to the top

of search order.

1) Folder where the main program is stored. ← Added.

2) Common program folder of initial folder

3) MTB-dedicated folder 2 of initial folder

4) MTB-dedicated folder 1 of initial folder

5) System folder of initial folder

The folders of 2) though 5) can be excluded from search target folders by setting the parameters

LIB(No.3457#0), MC2(No.3457#1), MC1(No.3457 #2), and SYS(No.3457#3).

ED

Date

Date

Design

2010.06.17

Design

Title

Draw

No.

Description Page

Approve

FANUC Series 30i / 31i / 32i-MODEL B

Folder mana

ement

B-64484EN/01-01

6/6

Page 22

Insert the following descriptions as 12.4.15 "Power consumption monitoring screen" of III OPERATION. And move

the following item numbers one by one.

12.4.15 Power consumption monitoring screen

The electric power data of servo axis and spindle axis consumption and regeneration can be displayed.

Display of power consumption monitoring screen

1. Press function key .

2. Press continuous menu key

3. Press soft key [POWER MONIT].

several times until soft key [POWER MONIT] appears.

Fig. 12.4.15 Power consumption monitoring screen for 10.4-inch display unit

Procedure for 8.4-inch display unit

1. Press function key

2. Press continuous menu key

3. Press soft key [POWMON].

Press soft key [TOTAL] to display value of integral power consumption.

4.

Press soft key [GRAPH] to display bar-graph.

Ed. Date Design Description

Date Design. Apprv.

.

several times until soft key [POWMON] appears.

Title

Draw

No.

FANUC Series 30i / 31i / 32i-MODEL B

Power consumption monitoring screen

B-64484EN/01-01

page

1 / 5

Page 23

Fig. 12.4.15 (a) Power consumption monitoring screen (TOTAL) for 8.4-inch display unit

Fig. 12.4.15 (b) Power consumption monitoring screen (Bar-graph) for 8.4-inch display unit

Operation of power consumption monitoring screen

Switch of display axis

When information on all axes is not displayed, the page is switched with the MDI key <PageUp> or <PageDown>.

Explanation

TIME

Integrating time of power consumption is displayed.

FANUC Series 30i / 31i / 32i-MODEL B

Power consumption monitoring screen

B-64484EN/01-01

Ed. Date Design Description

Date Design. Apprv.

Title

Draw

No.

page

2 / 5

Page 24

Axis name

Axis name of servo and spindle is displayed. "ALL" means the total amount of power consumption.

CONSUMP

Integral power consumption is displayed.

REGEN

Integral power regeneration is displayed.

NET

Integral net amount of power consumption is displayed.

The net amount of power consumption = power consumption – power regeneration.

PRESENT

Present net power consumption is displayed. A negative value is displayed about the net power consumption while the power is

regenerating like the axis is decelerating, etc.

Bar-graph

Current net power consumption is displayed as a bar-graph.

The scale of bar-graph is selected automatically by the parameter (No.4541#1 and #2 in case of the servo, No.2281#0 and #1 in case

of the spindle).

The scale of the entire power consumption bar-graph can be specified in the parameter (No.11371).

The bar expands from the center to right while consuming the electric power. The bar expands from the center to left while

regenerating the electric power.

Ed. Date Design Description

Date Design. Apprv.

Title

Draw

No.

FANUC Series 30i / 31i / 32i-MODEL B

Power consumption monitoring screen

B-64484EN/01-01

page

3 / 5

Page 25

Add the following descriptions as 12.4.30 "Power consumption monitoring screen (15/19-inch display unit)" of III

OPERATION.

12.4.30 Power consumption monitoring screen (15/19-inch display unit)

The electric power data of servo axis and spindle axis consumption and regeneration can be displayed.

Display of power consumption monitoring screen

1. Press function key .

2. Press continuous menu key

3. Press soft key [POWER MONIT].

several times until soft key [POWER MONIT] appears.

Fig. 12.4.30 Power consumption monitoring screen for 15” display unit

Operation of power consumption monitoring screen

Switch of display axis

When information on all axes is not displayed, the page is switched with the MDI key <PageUp> or <PageDown>.

Explanation

TIME

Integrating time of power consumption is displayed.

Axis name

Axis name of servo and spindle is displayed. "ALL" means the total of all servo and spindle axes.

FANUC Series 30i / 31i / 32i-MODEL B

Power consumption monitoring screen

B-64484EN/01-01

Ed. Date Design Description

Date Design. Apprv.

Title

Draw

No.

page

4 / 5

Page 26

CONSUMP

Integral power consumption is displayed.

REGEN

Integral power regeneration is displayed.

NET

Integral net amount of power consumption is displayed.

The net amount of power consumption = power consumption – power regeneration.

PRESENT

Present net power consumption is displayed. A negative value is displayed about the net power consumption while the power is

regenerating like the axis is decelerating, etc.

Bar-graph of PRESENT

Present net power consumption is displayed as a bar-graph.

The scale of bar-graph is selected automatically by the parameter (No.4541#1 and #2 in case of the servo, No.2281#0 and #1 in case

of the spindle).

The scale of the entire power consumption bar-graph can be specified in the parameter (No.11371).

The bar expands from the center to right while consuming the electric power. The bar expands from the center to left while

regenerating the electric power.

Ed. Date Design Description

Date Design. Apprv.

Title

Draw

No.

FANUC Series 30i / 31i / 32i-MODEL B

Power consumption monitoring screen

B-64484EN/01-01

page

5 / 5

Page 27

Add the following descriptions as 5.7 "Rate Feed" of II Programming.

5.7 Rate Feed

M

Outline

Specify the rate feed mode with G93.2, and directly specify a tool end feedrate as a numeric value after F. By using the value of F in

the previous block as the initial value, a machine is accelerated or decelerated linearly. The unit of the value of F is mm/min or

inch/min. G93.2 is modal. G93.2, once specified, remains to be valid until G93 (inverse time feed) or G94 (feed per minute) or G95

(feed per revolution) is specified.

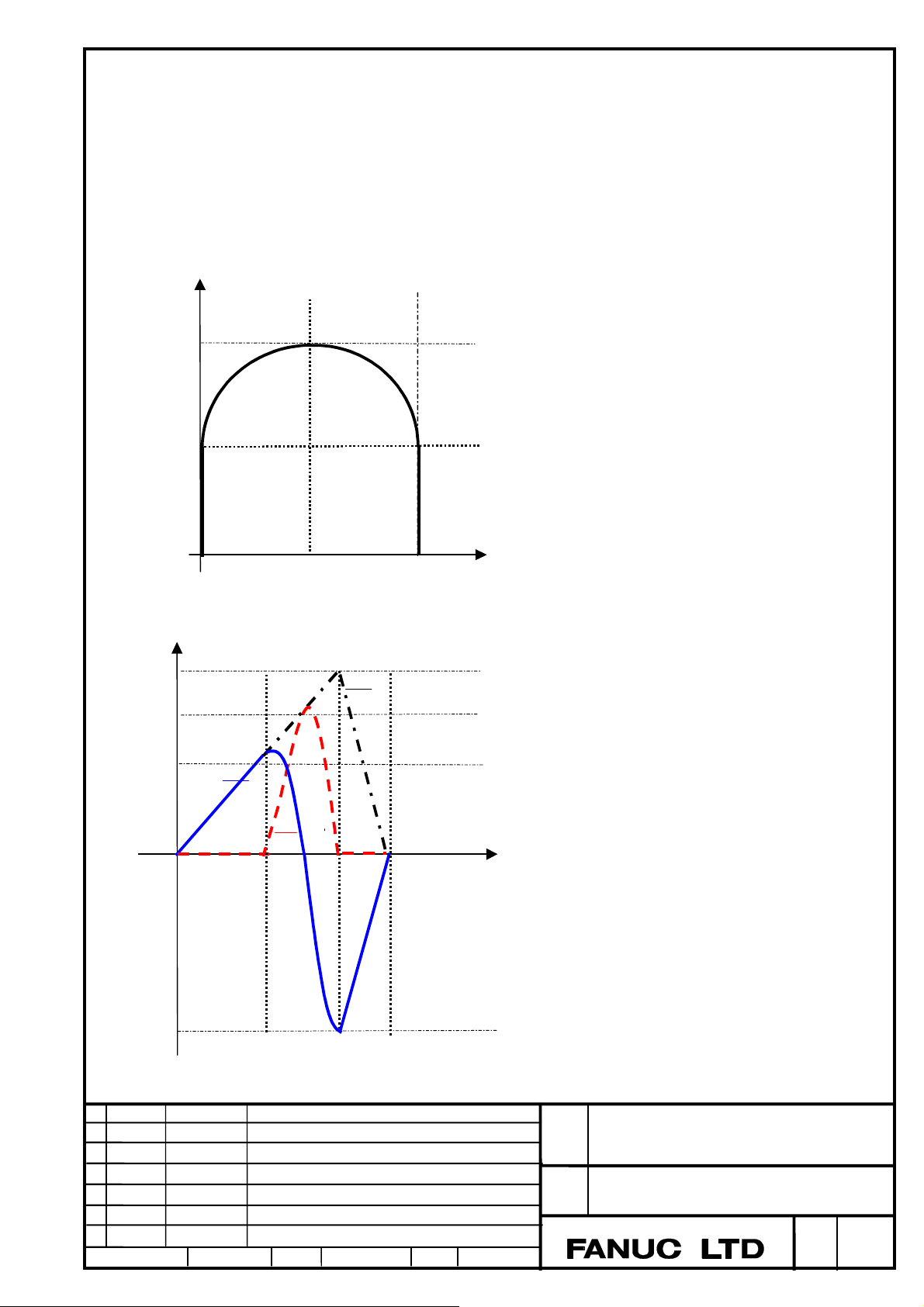

F

f0

x0

f1

x1 x2 x3

N10 G01 Xx0 Ff0 ;

N20 G93.2 Xx1 Ff1 ;

N30 Xx2 Ff2 ;

N40 Xx3 Ff3 ;

f2

f3

t

Note

1. When axes are accelerated, a feedrate is limited by the parameter No. 1430 (FEDMX) used

to specify an ordinary upper feedrate limit.

2. When the interpolation except the linear interpolation or circular interpolation is specified, an

alarm PS0522 is generated.

Format

G93.2 IP_F_; Rate feed command

IP_:

F_ :Speed in the end point

Ed. Date Design Description

Date Design. E.Tanosaki Apprv.

For an absolute programming, the coordinates of an end point, and for an

incremental programming, the distance of the tool move

.

Title

Draw

No.

FANUC Series 30i / 31i / 32i-MODEL B

Rate feed function

B-64484EN/01-01

page

1 / 6

Page 28

Explanation

About the initial speed

The initial speed of the rate feed of each block is decided depending on the speed of the previous block, and the initial speed becomes

0 if the feed type of the previous block is specified excluding a cutting feed (feed per minute) or the rate feed.

About the movement during the rate feed

During the rate feed, when each signal such as single block or override is operated, the feed rate is changed as (1) to (3).

(1) When the feedrate override is change during the rate feed.

(the feedrate override, the second feedrate override, override cancel signal etc.)

When the speed is changed by the feedrate override, acceleration/deceleration is changed according to it, because present speed and

speed at the end point are changed. Speed in the end point becomes a speed after the override is multiplied.

(Example) When the feedrate override is changed from 100% to 70% and to 90%.

(Feedrate) F

Speed in the

end point

100%

90%

70%

100%→70%

Change of the feed override

*Note) The feedrate in the figure shows the command feedrate exclusive of acceleration/deceleration after interpolation.

70%→90%

Next

block

(Time) t

Ed. Date Design Description

Date Design. E.Tanosaki Apprv.

Title

Draw

No.

FANUC Series 30i / 31i / 32i-MODEL B

Rate feed function

B-64484EN/01-01

page

2 / 6

Page 29

(2) When the speed is changed during the rate feed (Dry run signal, External deceleration signal)

A machine is accelerated or decelerated from present speed to the dry run speed when the dry run speed is selected. A machine is

accelerated or decelerated to the former end speed when the dry run speed is released.

(Example) When the dry run speed is selected and released.

F

Speed in the

end point

Dry run

speed

Changing to the

dry run speed

Releasing of the

dry run speed

Next

block

t

(3) When the operation is stopping and restarting during the rate feed. (By feed hold, Interlock signal, Single block operation)

When the feed hold operation is executed during automatic operation and the operation is restarted, the speed at the interrupted point

is applied as restarting feedrate.

(Example) When the feed hold stop is operated and restarted during automatic operation

F

Speed in the

end point

Speed when

interrupted

Operation

stop

Operation

restart

Ed. Date Design Description

Date Design. E.Tanosaki Apprv.

Next

block

t

Title

Draw

No.

FANUC Series 30i / 31i / 32i-MODEL B

Rate feed function

B-64484EN/01-01

page

3 / 6

Page 30

Y

(4) When the axes more than two are interpolated(linear interpolation, circular interpolation)

Tangential speed becomes a speed of the rate feed at the start point and the end point

between blocks, in which linear interpolation was commanded with multi axes.

In case that the movement direction is changed between blocks, the speed of each axis at the end point of previous block does not

correspond with the speed of each axis at the start point of current block.

(Example1) When the continuous blocks of linear interpolation and circular interpolation are commanded with two axes X and Y

N0001 G93.2 G91 G01 Y30. F100;

N0002 G02 X60. R30. F200;

N0003 G01 Y-30. F0;

60.000

30.000

(2)

200

100

F

0

0

Y axis

Tool path of X and Y axis

Tang e ntial Speed

X axis

60.00030.000

X

t

-200

Speed change of X and Y axis

Ed. Date Design Description

Date Design. E.Tanosaki Apprv.

Title

Draw

No.

FANUC Series 30i / 31i / 32i-MODEL B

Rate feed function

B-64484EN/01-01

page

4 / 6

Page 31

Y

X

(Example2) When the continuous blocks of linear interpolation are commanded with two axes X and Y

N0001 G93.2 G91 G01 X30. Y20. F100;

N0002 X10. Y30. F200;

50.000

20.000

0

X axis speed

at the end

point of N1

block

Y axis speed

at the end

point of N1

block

Tool path of X and Y axis

F

0

30.000

Y axis

40.000

X axis

X

Tangential

speed

Y axis

X axis

Y axis speed

at the start

point of N2

block

axis speed

at the start

point of N2

block

t

Title

Ed. Date Design Description

Date Design. E.Tanosaki Apprv.

Draw

No.

FANUC Series 30i / 31i / 32i-MODEL B

Rate feed function

B-64484EN/01-01

page

5 / 6

Page 32

(3)

(3)

(5) When the interpolations except G01 liner interpolation, G02/G03 circular interpolation are specified

(Helical interpolation, Hypothetical axis interpolation, Exponential interpolation, Involute interpolation, Spiral interpolation, and

Conical interpolation, Cylindrical interpolation etc.)

An alarm (PS0522) will be issued.

(6) When AI contour control is executed.

An alarm (PS0522) will be issued.

(7) When retrace is executed

The rate feed cannot be retraced. When the rate feed is commanded during reverse, retrace is finished then and displayed ‘RVED’.

But, when the parameter No.11630#4 sets to be ‘1’, the rate feed can be retraced.

In this case the reverse execution is as follows.

1 In the block of the rate feed mode, reverse execution and forward reexecution are executed at per minute feedrate (G94) (a speed

of F command).

2 In the forward execution from the start point of reverse execution to the end point on the block of the rate feed mode, the rate

feed is executed with the speed at the forward execution interruption as the initial speed.

(8) Other functions

- 3D interference check with Open CNC cannot be used.

- Do not specify Coordinate system rotation, Three-dimensional coordinate system conversion or Tilted working plane command

during the rate feed mode.

Parameter

#7 #6 #5 #4 #3 #2 #1 #0

11630 RTR

[Input type] Parameter input

[Data Type] Bit path

#4 RTR Reverse execution in the rate feed

0: is ineffective(end of reverse execution‘RVED’is displayed)

1: is effective.

Alarm

Number Message Description

PS0522 ILLEGAL CMD. IN RATE

FEED(G93.2)

During AI contour control mode or the

interpolation except linear interpolation, circular

interpolation is commanded in the rate feed.

Ed. Date Design Description

Date Design. E.Tanosaki Apprv.

Title

Draw

No.

FANUC Series 30i / 31i / 32i-MODEL B

Rate feed function

B-64484EN/01-01

page

6 / 6

Page 33

Please add “Ⅱprogramming 7.5 Plane Conversion Function ”.

7.5 Plane Conversion Function

Outline

This function converts a machining program created on the G17 plane in the right-hand Cartesian coordinate

system to programs for other planes specified by G17.1Px commands, so that the same figure appears on each

plane when viewed from the directions indicated by arrows shown in Fig.7.5 (a)

Z

G17.1P4 G17.1P1(G17)

Y

G17.1P2

G17.1P3 G17.1P5

X

Fig.7.5 (a) Planes specified by G17.1Px commands

ED

Date

Date

Design

2010.06.17

Design

Title

Draw

No.

Description Page

Approve

FANUC Series 30i / 31i / 32i-MODEL B

Plane conversion function

B-64484EN/01-01

1/7

Page 34

Format

G17.1 P_ ;

P_ : P1 to P5 Plane conversion specification

G17.1P1 is the same as G17.

Explanation

The plane conversion for a machining figure on the G17 plane shown in Fig.7.5 (b) is performed as Fig.7.5 (c),

Fig.7.5 (d), Fig.7.5 (e), Fig.7.5 (f) or Fig.7.5 (g).

Y

X

Z

G17

plane

Fig.7.5 (b) G17

The circle at the origin indicates that the positive direction of the axis perpendicular to this page is the direction

coming out of the page (in this case, the Z-axis is perpendicular to the XY plane).

Y

Z

G17

plane

Fig.7.5 (c) G17.1P1

X

ED

Date

Date

Design

2010.06.17

Design

Description

Approve

Title

Draw

No.

FANUC Series 30i / 31i / 32i-MODEL B

Plane conversion function

B-64484EN/01-01

Page

2/7

Page 35

Z

X

Y

G18

plane

Fig.7.5 (d) G17.1P2

The cross at the origin indicates that the negative direction of the axis perpendicular to this page is the direction

coming out the page (in this case, the Y-axis is perpendicular to the XZ plane).

Z

X

G19

plane

Fig.7.5 (e) G17.1P3

Y

Z

ED

Date

Date

Design

2010.06.17

Design

X

Y

Description

Approve

G18

plane

Fig.7.5 (f) G17.1P4

Title

Draw

No.

FANUC Series 30i / 31i / 32i-MODEL B

Plane conversion function

B-64484EN/01-01

Page

3/7

Page 36

Y

Z

X

G19

plane

Fig.7.5 (g) G17.1P5

Program commands on the G17 plane are converted to the following commands by plane conversion:

Table 7.5 (a) Program commands converted by plane conversion

Command

X X X Y -X -Y

Y Y Z Z Z Z

Z Z -Y -X Y -X

G02 G02 G03 G02 G02 G03

G03 G03 G02 G03 G03 G02

I I I J -I -J

J J K K K K

K K -J I J -I

G41 G41 G42 G41 G41 G42

G42 G42 G41 G42 G42 G41

Tool length

compensation

Direction of coordinate

rotation

Direction of drilling axis + - + + -

Plane G17 G18 G19 G18 G19

G17.1P1 G17.1P2 G17.1P3 G17.1P4 G17.1P5

+ - + + -

+ - + + -

Plane conversion

The modal information displayed in plane conversion function is as follows.

Table 7.5 (b) The displayed modal information

Command Displayed modal

G17.1P1 G17

G17.1P2 G17.1

G17.1P3 G17.1

G17.1P4 G17.1

G17.1P5 G17.1

ED

Date

Date

Design

2010.06.17

Design

Description

Approve

Title

Draw

No.

FANUC Series 30i / 31i / 32i-MODEL B

Plane conversion function

B-64484EN/01-01

Page

4/7

Page 37

Example

The machining program created on the G17 plane in the right-hand Cartesian coordinate system is converted to

appear the same figure when viewed from the direction indicated by G17.1P2 command.

Z

Y

Y

Y

Z

Y

G17.1P2

O1000 (MAIN PROGRAM)

N10 G91 G28 X0 Y0 Z0

N20 G54

N30 G17

N40 M98 P2000

N50 G55

N60 G17.1 P2

N70 M98 P2000

N80 G91 G28 X0 Y0 Z0

N90 M30

Y

X

-Z

X

G17

G54

Machine coordinate system

Z

X

Machine coordinate system

Y

G54

-Z

O2000(SUB PROGRAM)

N2010 G90 G00 Z0

N2020 G00 X0 Y0

N2030 G00 X30.0 Y20.0

N2040 G01 Z-50.0 F200

N2050 Y90.0 F500

N2060 X60.0 Y70.0

N2070 G02 Y20.0 J-25.0

N2080 G01 X30.0

N2090 G00 Z0

N2100 M99

X

X

X

X

Limitations

1 Plane conversion can be performed only for commands for the X-, Y-, or Z-axis.

2 Plane conversion cannot be performed for manual operation.

FANUC Series 30i / 31i / 32i-MODEL B

Plane conversion function

ED

Date

Date

Design

2010.06.17

Design

Title

Draw

No.

Description

Approve

B-64484EN/01-01

Page

5/7

Page 38

3 Plane conversion cannot be performed for the following commands for moving the tool to a specified

position, commands related to the machine coordinate system, and commands for setting a coordinate

system:

(1) Automatic reference position return (G28 and G30)

(2) Floating reference position return (G30.1)

(3) Return from the reference position (G29)

(4) Selecting the machine coordinate system (G53)

(5) Stored stroke limit (G22)

(6) Setting the coordinate system (G54 to G59 and G92)

(7) Presetting the workpiece coordinate system (G92.1)

(8) Setting the offset (G10)

4 The current position display shows the coordinates after plane conversion. (Table 7.5 (c))

Table 7.5 (c) Current Position Indication

Absolute coordinates Command

X Y Z

G90 G00 X0 Y0 Z0 0.0 0.0 0.0

G17.1 P3 0.0 0.0 0.0

G00 X10.0 Y20.0 0.0 10.0 20.0

G01 Z-50.0 F200 -50.0 10.0 20.0

G02 X50.0 Y60.0 I40.0 -50.0 50.0 60.0

5 Plane conversion cannot be performed together with the axis switching function.

6 Specify plane conversion commands after canceling the following modes.

(1) Cutter compensation

(2) Tool length compensation

(3) Canned cycle

(4) Three-dimensional coordinate conversion

(5) Coordinate rotation

(6) Scaling

(7) Programmable mirror image

7 Plane conversion cannot be performed for the following commands that control a rotation axis together with

the X-, Y-, or Z-axis:

(1) Polar coordinate interpolation

(2) Cylindrical interpolation

(3) Control in normal directions

(4) Exponential interpolation

(5) Circular threading B

8 If a G17, G18, or G19 command is executed during plane conversion, the conversion is disabled and the

plane specified by the command is selected.

Please add to G code list in ⅡProgramming 3.1 G CODE LIST IN THE MACHINING CENTER

SYSTEM

G code Group Function

G17.1 02 Plane conversion function

FANUC Series 30i / 31i / 32i-MODEL B

Plane conversion function

B-64484EN/01-01

ED

Date

Date

Design

2010.06.17

Design

Title

Draw

No.

Description

Approve

Page

6/7

Page 39

Please add to G code list in ⅡProgramming 3.2 G CODE LIST IN THE LATHE SYSTEM

G code system

A B C

G17.1 G17.1 G17.1 16 Plane conversion function

Group Function

ED

Date

Date

Design

2010.06.17

Design

Description

Approve

Title

Draw

No.

FANUC Series 30i / 31i / 32i-MODEL B

Plane conversion function

B-64484EN/01-01

Page

7/7

Page 40

Correct the following description in Ⅱ.PROGRAMMING 18 “PROGRAMMABLE PARAMETER INPUT

(G10)”.

18 PROGRAMMABLE PARAMETER INPUT (G10)

Overview

The values of parameters and pitch error compensation data can be entered in a program. This function is used

for setting pitch error compensation data when attachments are changed or the maximum cutting feedrate or

cutting time constants are changed to meet changing machining conditions.

The input format of pitch error compensation data is changed depending on bit 0 (APE) of parameter No. 3602.

Format

- Parameter entry mode

G10L52 ; Parameter entry mode setting

N_(Q_)R_ ; For parameters other than the axis type or spindle type

N_P_(Q_)R_ ; For axis type or spindle type parameters

:

:

G11 ; Parameter entry mode cancel

N_ : Parameter number

R_ : Parameter setting value (Leading zeros can be omitted.)

(Q_) : Bit number 0 to 7 (to be set when a bit type parameter is input)

(Enabled when bit 4 (G1B) of parameter No.3454 = 1.)

P_ : Axis number 1 to maximum controlled axis number (to be specified when an axis

type parameter or spindle type parameter is specified)

NOTE

G10L52 cannot be used to enter pitch error compensation data.

- Pitch error compensation data entry mode

G10L50 ; Pitch error compensation data entry mode setting

N_(L1)R_ ; Pitch error compensation data entry

:

G11 ; Pitch error compensation data entry mode cancel

N_ : Compensation position number for pitch errors compensation +10,000

L1 : Input format of pitch error compensation data (total value type)

R_ : Pitch error compensation data

NOTE

G10L50 cannot be used to enter parameter.

ED

Date

Date

Design

2010.06.17

Design

Description Page

Approve

Title

Draw

No.

FANUC Series 30i / 31i / 32i-MODEL B

Stored pitch error compensation total compensating

value input function

B-64484EN/01-01

1/11

Page 41

Explanation

- Parameter number(N_)

Programmable parameter input (G10L52) enables writing to a parameter for a specific path by adding that path

number to the parameter number to be specified (N_). The format for the parameter number is as follows:

Nppxxxxxxx : Add a path number to the high-order 8th and 9th digits of a parameter number.

For pp, set a path number, and for xxxxxxx, set a parameter number. If a path number is omitted

or if 0 is set, writing to a parameter for the local path is assumed, as usual.

NOTE

1 If a path number out of the range is specified, alarm PS0115 is issued.

2 To read and write data for the 10th path, set bit 0 (F16) of parameter No. 6008 to

0.

If parameter bit F16 is 1, the calculation precision is up to the 8th digit. Thus, if a

parameter number is determined with a calculation command such as #100=

PRM[100000000 +#1] when the data for the 10th path is read or written, the

correct number may not be determined.

3 Pitch error compensation data entry does not enable selection of a path.

- Setting value (R_)

Do not use a decimal point in the setting (R_) of a parameter or pitch error compensation data. To change a bit

type parameter if bit 4 (G1B) of parameter No. 3454 is 1, specify 0 or 1. If a value other than 0 and 1 is

specified, alarm PS1144, "G10 FORMAT ERROR", is issued.

As the value of R, a custom macro variable can be used.

When a parameter of real type is used, set an integer value in (R_) according to the increment system of the

parameter.

- Bit number (Q_)

Bit number (Q_) is effective if bit 4 (G1B) of parameter No. 3454 is 1. To set a bit type parameter, set a number

in the range of 0 to 7.

A custom macro variable can be used as the value of Q.

- Axis number (P_)

As the axis number (P_), specify the order of a controlled axis to be displayed on the CNC display screen, by

using an axis type parameter.

For example, specify P2 for the control axis which is displayed second.

For a spindle type also, specify the order of an axis to be display on the CNC display screen.

A custom macro variable can be used as the value of P.

- Input format of pitch error compensation data (L1)

When the input format of pitch error compensation data is incremental value type (bit 0 (APE) of parameter No.

3602 is set to 0), L1 is not to be specified.

When the input format of pitch error compensation data is total value type (bit 0 (APE) of parameter No. 3602 is

set to 1), L1 needs to be specified.

If the data with L1 is input when bit 0 (APE) of parameter No. 3602 is set to 0, or the data without L1 is input

when bit 0 (APE) of parameter No. 3602 is set to 1, alarm PS1300 “ILLEGAL ADDRESS” is caused.

ED

Date

Date

Design

2010.06.17

Design

Title

Draw

No.

Description Page

Approve

FANUC Series 30i / 31i / 32i-MODEL B

Stored pitch error compensation total compensating

value input function

B-64484EN/01-01

2/11

Page 42

WARNING

1 Do not fail to perform reference position return manually after changing the pitch

error compensation data or backlash compensation data. Without this, the

machine position can deviate from the correct position.

2 If the compensation data is changed when the input format is total value type(bit

0 (APE) of parameter No. 3602 is set to 1), power must be turned off before

operation is continued.

3 The canned cycle mode must be cancelled before entering of parameters. When

not cancelled, the drilling motion may be activated.

CAUTION

Compatibility with the Series 16i/18i/21i:

This model has parameters that are not compatible with the Series 16i/18i/21i.

So, before using this function, make a check according to the Parameter Manual

(B-64490EN) of this model.

NOTE

Other NC statements cannot be specified while in parameter input mode.

- Writing to a parameter for another path

Programmable parameter input (G10L52) enables writing to a parameter for another path by specifying that path

number in either of the following ways:

• Adding a path number to a parameter number (example 3)

• Specifying a path number using system variable #3018 (example 4)

ED

Date

Date

Design

2010.06.17

Design

Title

Draw

No.

Description Page

Approve

FANUC Series 30i / 31i / 32i-MODEL B

Stored pitch error compensation total compensating

value input function

B-64484EN/01-01

3/11

Page 43

CAUTION

If changing a parameter for another path by using this function, be sure to take

appropriate measures such as combining the function with an inter-path wait, so

that the function is executed while the axis for which to change the parameter is

stopped.

[Example]

The following shows an example of changing a parameter for path 2 from path 1,

using M100 and M101 as wait M codes.

Path 1 program

O0100;

:

:

M100P12 ...............(1)

G10L52;

N200xxxxxP_R_ (A)

G11;

M101P12................(2)

G10L52;

NxxxxxP_R_ (B)

G11;

:

M30;

Path 2 program

O0200;

:

M100P12.... (1)

M101P12.... (2)

:

:

M30;

(1): Waits for the start of writing to a

parameter from 1st path

(2): Waits for the end of writing to a

parameter from the 1st path

(Subsequently, operation is performed

with the parameter changed in (A).)

(A):Change to a parameter for another path

Must be made after it is checked that the axis on the path for which to

→

change the parameter is stopped.

(B):Change to a parameter for the local path

Example

1. Set bit 2 (SBP) of bit type parameter No. 3404 (when the bit 4 (G1B) of parameter No. 3454 is set to 0)

G10L52 ; Parameter entry mode

N3404 R 00000100 ; SBP setting

G11 ; Cancel parameter entry mode

2. Set bit 2 (SBP) of bit type parameter No. 3404 (when the bit 4 (G1B) of parameter No. 3454 is set to 1)

G10L52 ; Parameter entry mode

N3404 Q2 R 1 ; SBP setting

G11 ; Cancel parameter entry mode

3. Change the values for the Z-axis (3rd axis) and A-axis (4th axis) in axis type parameter No. 1322 (the

coordinates of stored stroke limit 2 in the positive direction for each axis).

(When the increment systems for the 3rd and 4th axes are IS-B and millimeter machine, respectively)

G10L52 ; Parameter entry mode

N1322P3R4500 ; Change the value for the Z-axis to 4.500

N1322PP4R12000 ; Change the value for the A-axis to 12.000

G11 ; Cancel parameter entry mode

ED

Date

Date

Design

2010.06.17

Design

Title

Draw

No.

Description Page

Approve

FANUC Series 30i / 31i / 32i-MODEL B

Stored pitch error compensation total compensating

value input function

B-64484EN/01-01

4/11

Page 44

4. Of axis type parameter No. 01322 for the 2nd path, change the values for the 3rd and 4th axes.

(When the increment systems for the 3rd and 4th axes are IS-B and metric input, respectively)

G10L52; Parameter entry mode

N20001322P3R4500; Change the value for the 3rd axis in 2nd path to 4.500

N20001322P4R12000; Change the value for the 4th axis in 2nd path to 12.000

G11; Cancel parameter entry mode

5. Write to the 4th axis of parameter No. 01322 for the 2nd path

#3018=2; Set the path subject to parameter writing to the 2nd path

G10L52; Parameter entry mode

N1322P4R12000; Change the value for the 4th axis in 2nd path to 12.000

G11; Cancel parameter entry mode

#3018= 0 ; Return to the local path

6. Change compensation point numbers 10 and 20 of pitch error compensation. ( bit 0 (APE) of parameter No.

3602 is set to 0)

G10L50 ; Pitch error compensation data entry mode

N10010R1 ; Change the compensation point number from 10 to 1

N10020R5 ; Change the compensation point number from 20 to 5

G11 ; Pitch error compensation data entry mode

7. Change compensation point numbers 10 and 20 of pitch error compensation. ( bit 0 (APE) of parameter No.

3602 is set to 1)

G10L50 ; Pitch error compensation data entry mode

N10010L1R1 ; Change the compensation point number from 10 to 1

N10020L1R5 ; Change the compensation point number from 20 to 5

G11 ; Pitch error compensation data entry mode

ED

Date

Date

Design

2010.06.17

Design

Title

Draw

No.

Description Page

Approve

FANUC Series 30i / 31i / 32i-MODEL B

Stored pitch error compensation total compensating

value input function

B-64484EN/01-01

5/11

Page 45

Correct the following description in Ⅲ .OPERATION 8.2.4.3 “Input/output format of pitch error

compensation data”.

Input/output format of pitch error compensation data

Pitch error compensation data is input and output in the following input and output formats.

- Keywords

The following alphabets are used as keywords.

The numeric value following each keyword has the meaning listed below:

Table 8.2.4.3 (a)

Keyword Meaning of the following numeric value

N Pitch error compensation data number + 10000

Q Data identification (1 : Parameter data, 0 : Pitch error compensation data )

L Input / Output format of pitch error compensation data (Without L : Incremental value type, L1 :

Total value type)

P Pitch error compensation data value

- Format

The input / output format of pitch error compensation data is changed depending on bit 0 (APE) of parameter

No. 3602.

In case of incremental value type (bit 0 (APE) of parameter No. 3602 is set to 0).

N ***** Q0 P **** ;

In case of total value type (bit 0 (APE) of parameter No. 3602 is set to 1).

N ***** Q0 L1 P **** ;

The 5-digit numeric value following N indicates a pitch error compensation data number to which a value of

10000 is added.

If the Bi-directional pitch error compensation is valid, the 5-digit numeric value following N indicates a pitch

error compensation data number to which a value of 20000 is added.

Q0 indicates pitch error compensation data

L1 indicates that the input / output format of pitch error compensation data is total value type. When the input /

output format is incremental type (bit 0 (APE) of parameter No. 3602 is set to 0), L1 is not to be specified. If the

data with L1 is input when bit 0 (APE) of parameter No. 3602 is set to 0, or the data without L1 is input when

bit 0 (APE) of parameter No. 3602 is set to 1, alarm SR1300 “ILLEGAL ADDRESS” is caused.

The numeric value following P indicates the value (integer value) of pitch error compensation data between

-128 and 127.

The semicolon (;) indicates the end of block (LF in the ISO code or CR in the EIA code).

ED

Date

Date

Design

2010.06.17

Design

Title

Draw

No.

Description Page

Approve

FANUC Series 30i / 31i / 32i-MODEL B

Stored pitch error compensation total compensating

value input function

B-64484EN/01-01

6/11

Page 46

Example1 (bit 0 (APE) of parameter No.3602 is set to 0)

N10001Q0P100;

Pitch error compensation data number 1

Pitch error compensation data value 100

Example2 (bit 0 (APE) of parameter No.3602 is set to 1)

N10001Q0L1P100;

Pitch error compensation data number 1

Pitch error compensation data value 100

- Beginning and end of a record

A pitch error compensation data record begins with % and ends with %.

Example

% ; ................................................................Beginning of record

N10000Q0P10;

N10001Q0P100;

:

N11279Q0P0;

% ..................................................................End of record

When parameters and pitch error compensation data are integrated into one file, % is added to the beginning and

end of the file.

WARNING

1 Do not fail to perform reference position return manually after changing the pitch

error compensation data or backlash compensation data. Without this, the

machine position can deviate from the correct position.

2 If the compensation data is changed when the input format is total value type(bit

0 (APE) of parameter No. 3602 is set to 1), power must be turned off before

operation is continued.

ED

Date

Date

Design

2010.06.17

Design

Title

Draw

No.

Description Page

Approve

FANUC Series 30i / 31i / 32i-MODEL B

Stored pitch error compensation total compensating

value input function

B-64484EN/01-01

7/11

Page 47

Add the following description in Ⅲ .OPERATION 12.4.2 “Displaying and Setting Pitch Error

Compensation Data” after the description of “

Bi-directional pitch error compensation”.

- Stored Pitch Error Compensation Total Value Input function

When bit 0 (APE) of parameter No. 3602 is set to 1, stored pitch error compensation data can be input by a total

value. About details, please refer to “Stored Pitch Error Compensation Total Value Input function” in the

CONNECTION MANUAL (FUNCTION).

ED

Date

Date

Design

2010.06.17

Design

Title

Draw

No.

Description Page

Approve

FANUC Series 30i / 31i / 32i-MODEL B

Stored pitch error compensation total compensating

value input function

B-64484EN/01-01

8/11

Page 48

Correct the following description in Ⅲ .OPERATION 12.4.16 “Displaying and Setting Pitch Error

Compensation Data (15/19-inch Display Unit)” after the description of “

compensation”..

Bi-directional pitch error

- Stored Pitch Error Compensation Total Compensating Value Input function

When bit 0 (APE) of parameter No. 3602 is set to 1, stored pitch error compensation data can be input by a total

value. About details, please refer to “Stored Pitch Error Compensation Total Value Input function” in the

CONNECTION MANUAL (FUNCTION).

ED

Date

Date

Design

2010.06.17

Design

Title

Draw

No.

Description Page

Approve

FANUC Series 30i / 31i / 32i-MODEL B

Stored pitch error compensation total compensating

value input function

B-64484EN/01-01

9/11

Page 49

Add the following parameter to APPENDIX. A.1 “DESCRIPTION OF PARAMETERS”.

#7 #6 #5 #4 #3 #2 #1 #0

3602 APE

[Input type] Parameter input

[Data type] Bit

NOTE

When this parameter is set, the power must be turned off before

operation is continued.

# 0 APE The input type of stored pitch error compensation data is

0: An incremental value.

1: A total value.

This function is effective to the following functions.

- Stored Pitch Error Compensation

- Bi-directional Pitch Error Compensation

- Interpolation Type Pitch Error Compensation

-

Periodical Secondary Pitch Error Compensation

-

Interpolation Type Straightness Compensation

-

Simple Spindle Synchronous Control Independent Pitch Error Compensation

NOTE

If this parameter is changed, the data of stored pitch error

compensation is cleared automatically at next power on.

ED

Date

Date

Design

2010.06.17

Design

Title

Draw

No.

Description Page

Approve

FANUC Series 30i / 31i / 32i-MODEL B

Stored pitch error compensation total compensating

value input function

B-64484EN/01-01

10/11

Page 50

Add the following alarm to APPENDIX. H “ALARM LIST”.

Number Massage

PS0527 ILLEGAL DATA IN PITCH ERROR In the effective pitch error compensation points that is

decided by considering the setting of the parameters,

the difference between two consecutive data exceeds

the range of -128~+127.

Please correct the pitch error compensation data or

change the parameter.

Description

ED

Date

Date

Design

2010.06.17

Design

Title

Draw

No.

Description Page

Approve

FANUC Series 30i / 31i / 32i-MODEL B

Stored pitch error compensation total compensating

value input function

B-64484EN/01-01

11/11

Page 51

Replace II PROGRAMMING 22.2 "Smooth TCP" with the following content as "High-speed Smooth

TCP".

22.2 High-speed Smooth TCP

22.2.1 High-speed Smooth TCP

General

Tool center point control (referred to as TCP in the remainder of this manual) is a 5-axis machining function

whereby the tool center point moves along a specified path even if the tool posture varies in relation to the

object being machined.

High-speed smooth TCP enables smooth tool center point cutting and tool side cutting while TCP.

High-speed smooth TCP has below two functions.

・ Rotation axes compensation (G43.4L1) :

G43.4L1 smoothes the movement of machine compensating the rotation axes to reduce the unevenness in

rotation axes commands.

・ Smooth control (G43.4P3) :

G43.4P3 interpolates the tool center points and tool postures smoothly.

This function is an option function.

- Rotation axes compensation (G43.4 L1)

Depending on the machining program, there may be unevenness in tool posture between blocks. In such a case,

the position of the control point varies in relation to the position of the tool center point, so that

acceleration/deceleration frequently occurs, and the control point does not move smoothly. As a result, there

occur increases in machining time, as well as the degradation of the quality of the machined surface (as

exemplified by streaks).

High-speed Smooth TCP is a function that compensates rotation axes to reduce the unevenness in tool posture in

relation to the tool center path for a machining program for TCP, thereby smoothing the movement of rotation

axes.

This is effective to reducing machining time and improving the quality of the machined surface if there is

unevenness in tool posture between blocks.

This function is optional.

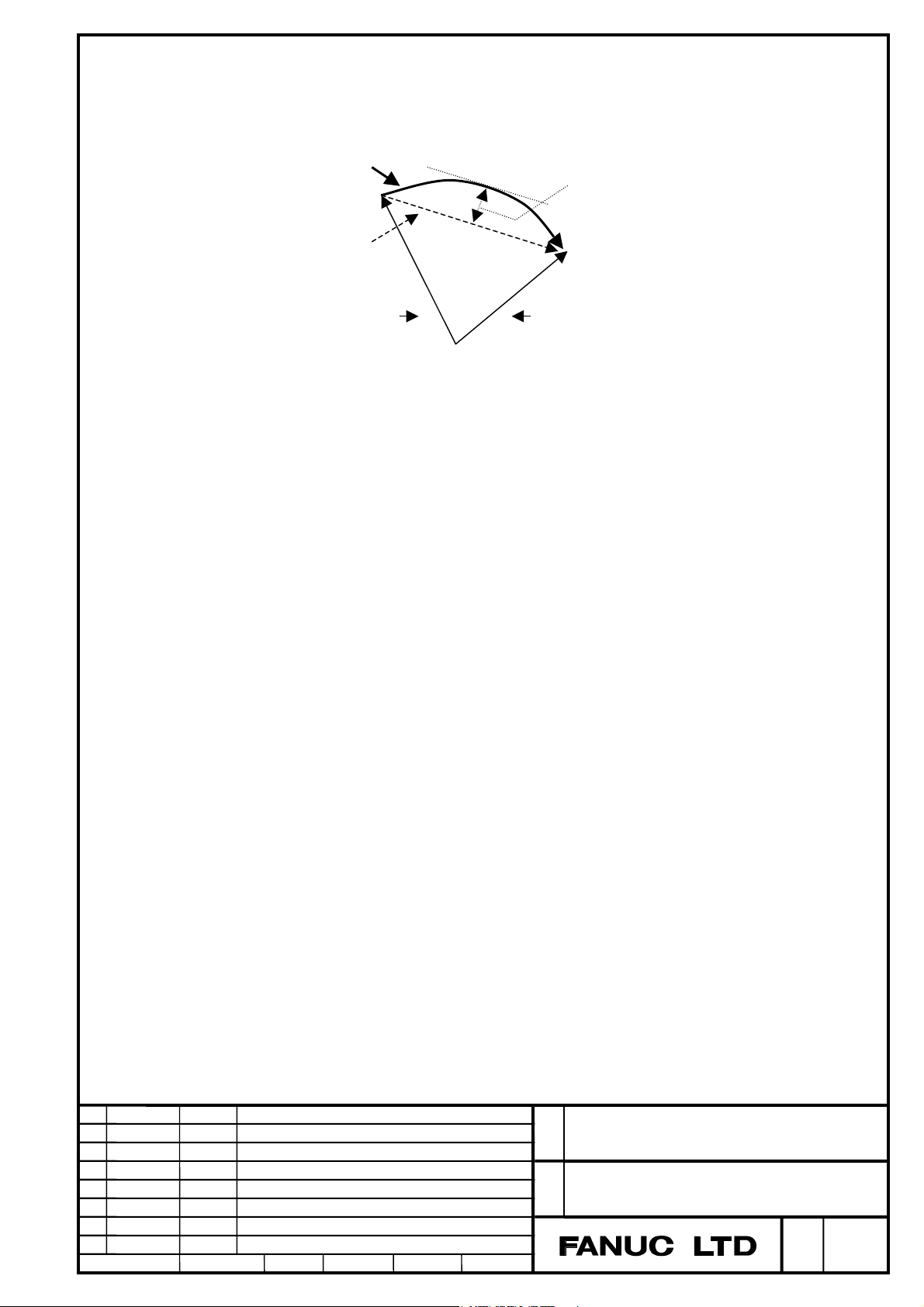

Path of control point

The command is compensated.

ED

Date

Date

Tool posture

Tool center point path

Design

2010.06.17

Command with the rotation

axes compensated

Before compensation

Fig.222.1 (a) Compensation with High-speed Smooth TCP

Description Page

Design

Approve

After compensation

Title

Draw

No.

FANUC Series 30i / 31i / 32i-MODEL B

High-speed Smooth TCP

B-64484EN/01-01

1/30

Page 52

NOTE

1 The option of "Smooth TCP" or "High-speed Smooth TCP" is necessary to use

Rotation axes compensation (G43.4 L1). It can be used in Series 30i /31i -B,

31i -B5.

2 This function may not be effective to programs and so on that do not involve

unevenness in tool posture.

3 In case of tool side cutting which must follow the specified tool posture, this

function may not be suitable because the tool posture vector is compensated.

4 Each rotation axis is compensated from the original value within the

compensation tolerance. The tolerance can be specified by the parameters (No.

10486, 10487) or the G code (G10.8L1).

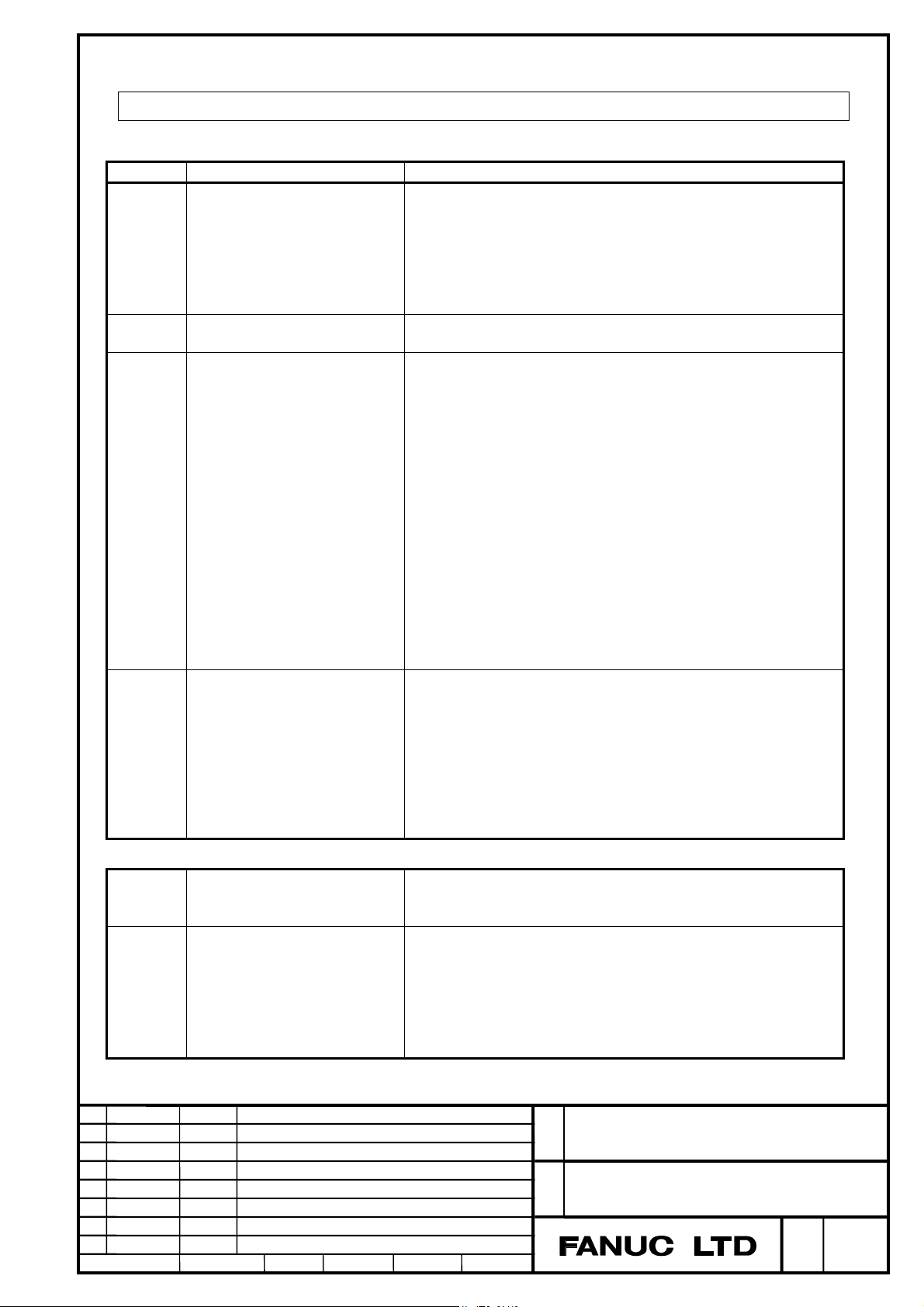

- Smooth control (G43.4 P3)

Under tool posture control, the tool posture is controlled every moment for operation on the plane formed by the

tool postures (tool length compensation vectors) at the start point and the and point of a block. (Fig.2.1 (b))

This control method is suitable for machining a plane with the side of a tool using the tool center point control.

Tool posture control

Tool length compensation

vector Vs at block start point

Plane formed by Vs and Ve

Programmed path

Fig.2.1 (b) Tool posture control

Tool length compensation

vector Ve at block end point

Adding to the tool posture control, this feature (High-speed Smooth TCP) generates and interpolates smooth

surfaces from commanded tool center points and tool postures.

Traditionally, when a free surface is machined by Tool posture control, the free surface is approximated by

polyhedrons. (Fig.2.1 (c)) But, by this feature, the free surface can be machined with smooth surfaces and the

machining quality can be improved. (Fig.2.1 (d))

This feature is suitable for machining that the tool posture is needed to move smoothly using Tool center point

control.

ED

Date

Date

Design

2010.06.17

Design

Title

Draw

No.

Description Page

Approve

FANUC Series 30i / 31i / 32i-MODEL B

High-speed Smooth TCP

B-64484EN/01-01

2/30

Page 53

Fig.2.1 (c) Polyhedron approximation of free surface Fig.2.1 (d) Free surface machined with this feature

NOTE

The option of "High-speed Smooth TCP" is necessary to use Smooth control

(G43.4 P3). It can be used in Series 30i -B/31i -B5.

Explanation

This feature is available for TCP type 1 (G43.4). (TCP type 2 (G43.5) is planned to be available.)

AI contour control is also turned on with the command G43.4 P3. Automatic speed control of AI contour

control reduces shocks on the machine tool system.

ED

Date

Date

Design

2010.06.17

Design

Title

Draw

No.

Description Page

Approve

FANUC Series 30i / 31i / 32i-MODEL B

High-speed Smooth TCP

B-64484EN/01-01

3/30

Page 54

Format

G43.4 L_ P_ IP_ α_ β_ H_ ; (M series) TCP mode is turned ON.

G43.4 L_ P_ IP_ α_ β_ D_ ; (T series) TCP mode is turned ON.

G49 ; TCP mode is turned OFF.

L: 0 : Rotation axes compensation is not effective

1 : Rotation axes compensation is effective

Using bit 0 (STC) of setting parameter No.10485, the state in which the address "L"

command is absent can be selected. (Note 1)

P: Selection of Tool posture control mode

0 : Tool posture control is not effective.