October 2013

FAN54015 — USB-Compliant Single-Cell Li-Ion Switching Charger with USB-OTG Boost Regulator

FAN54015

SW

PGND

C

OUT

L1

VBAT

+

Battery

CSIN

R

SENSE

68m

1H

C

BAT

SYSTEM

LOAD

0.1F

1F

4.7F

SDA

SCL

OTG/USB#

C

REG

1F

VREG

STAT

10F

DISABLE

C

BUS

C

MID

VBUS

PMID

All trademarks are the property of their respective owners.

FAN54015

USB-Compliant Single-Cell Li-Ion Switching Charger with

USB-OTG Boost Regulator

Features

Fully Integrated, High-Efficiency Charger for Single-Cell

Li-Ion and Li-Polymer Battery Packs

Faster Charging than Linear

Charge Voltage Accuracy: 0.5% at 25°C

1% from 0 to 125°C

5% Input Current Regulation Accuracy

5% Charge Current Regulation Accuracy

20 V Absolute Maximum Input Voltage

6 V Maximum Input Operating Voltage

1.45 A Maximum Charge Rate

Programmable through High-Speed I

(3.4 Mb/s) with Fast Mode Plus Compatibility

2

C Interface

– Input Current

– Fast-Charge / Termination Current

– Charger Voltage

– Termination Enable

3 MHz Synchronous Buck PWM Controller with Wide

Duty Cycle Range

Small Footprint 1 H External Inductor

Safety Timer with Reset Control

1.8 V Regulated Output from VBUS for Auxiliary Circuits

Dynamic Input Voltage Control

Low Reverse Leakage to Prevent Battery Drain to VBUS

5 V, 500 mA Boost Mode for USB OTG for 3.0 V to

4.5 V Battery Input

Available in a 1.96 x 1.87 mm, 20-bump, 0.4 mm Pitch

WLCSP Package

Description

The FAN54015 combines a highly integrated switch-mode

charger, to minimize single-cell Lithium-ion (Li-ion) charging

time from a USB power source, and a boost regulator to

power a USB peripheral from the battery.

The charging parameters and operating modes are

programmable through an I2C Interface that operates up to

3.4 Mbps. The charger and boost regulator circuits switch at

3 MHz to minimize the size of external passive components.

The FAN54015 provides battery charging in three phases:

conditioning, constant current and constant voltage.

To ensure USB compliance and minimize charging time, the

input current limit can be changed through the I2C by the

host processor. Charge termination is determined by a

programmable minimum current level. A safety timer with

reset control provides a safety backup for the I2C host.

Charge status is reported to the host through the I2C port.

The integrated circuit (IC) automatically restarts the charge

cycle when the battery falls below an internal threshold. If the

input source is removed, the IC enters a high-impedance

mode, preventing leakage from the battery to the input.

Charge current is reduced when the die temperature reaches

120°C, protecting the device and PCB from damage.

The FAN54015 can operate as a boost regulator on

command from the system. The boost regulator includes a

soft-start that limits inrush current from the battery and uses

the same external components used for charging the battery.

Applications

Cell Phones, Smart Phones, PDAs

Tablet, Portable Media Players

Gaming Device, Digital Cameras

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN54015 • Rev. 1.0.2

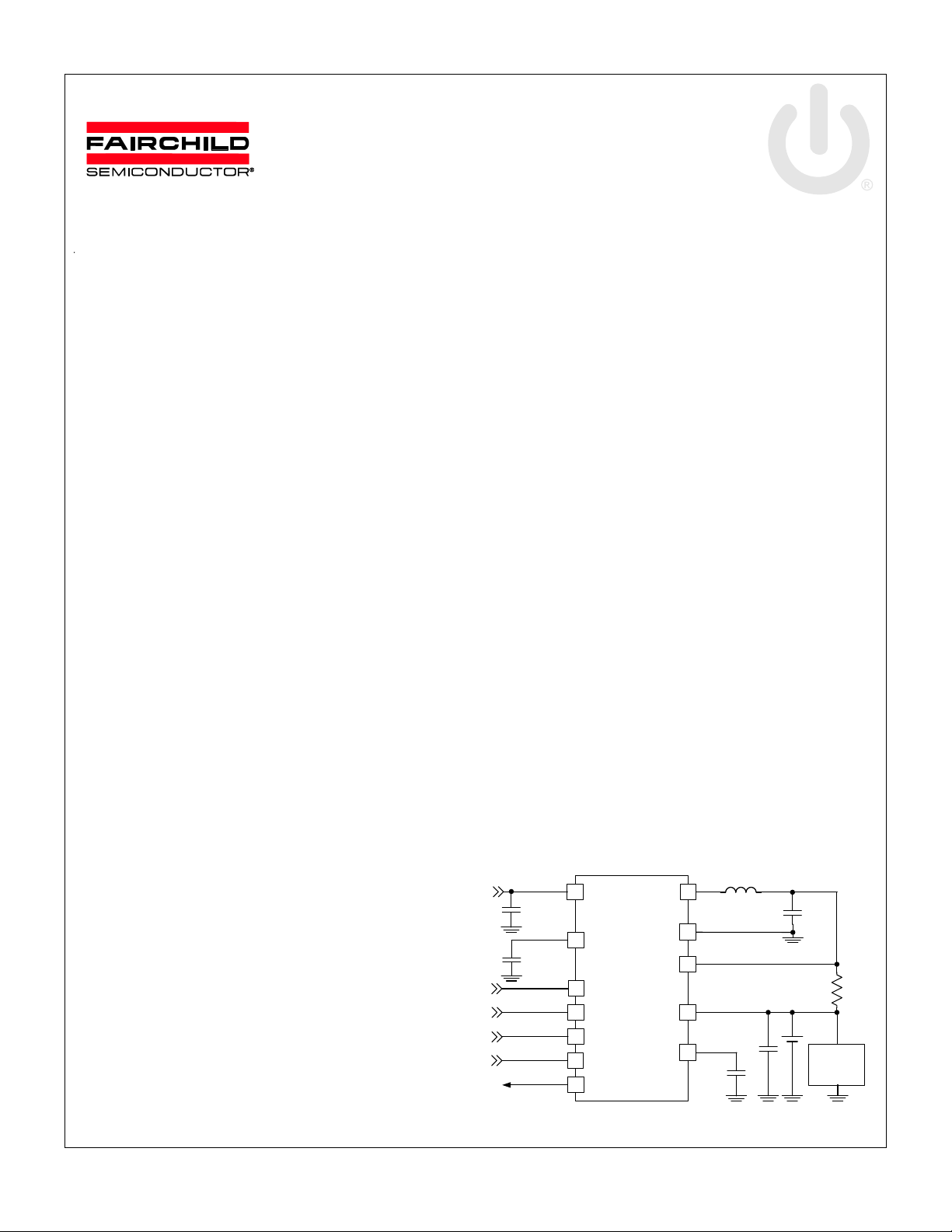

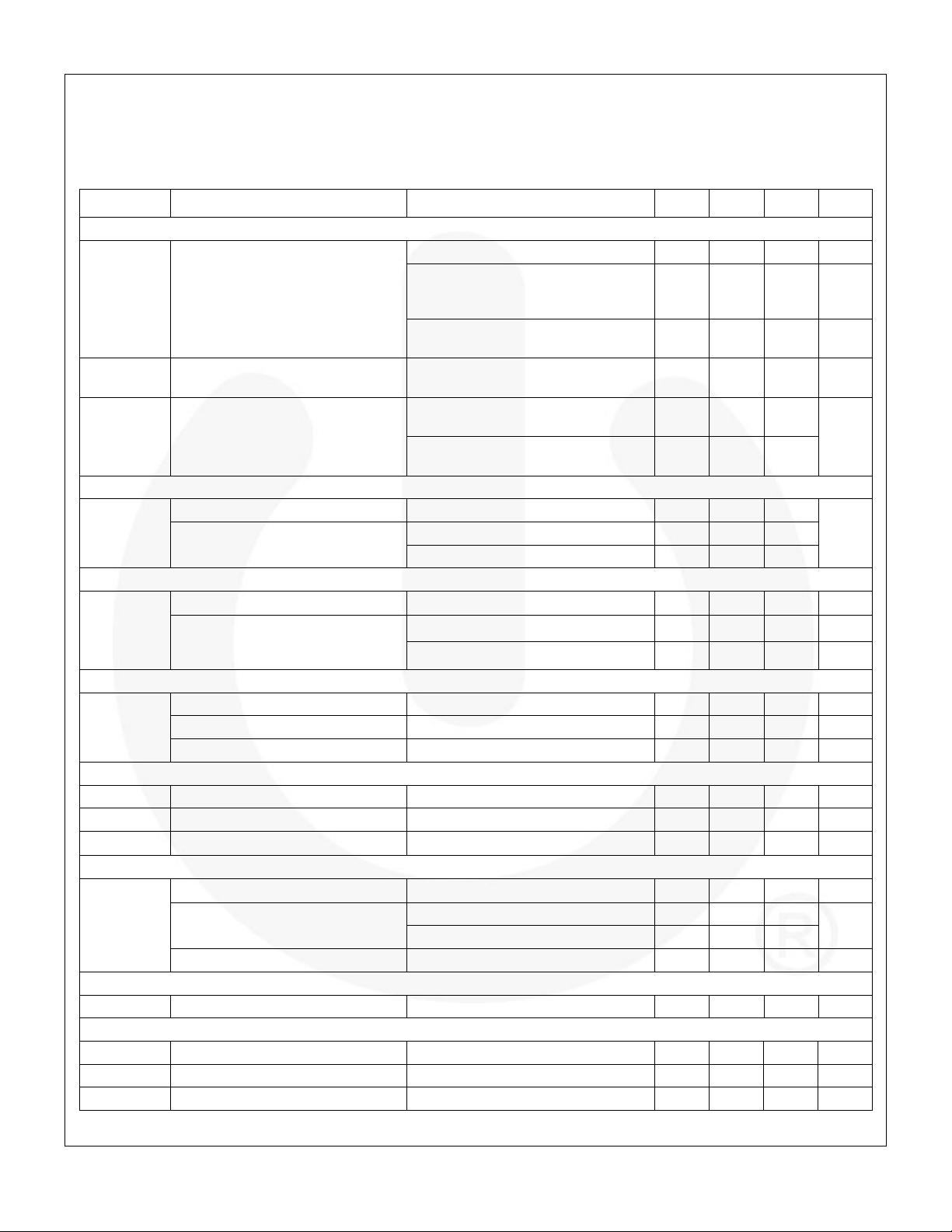

Figure 1. Typical Application

FAN54015 — USB-Compliant Single-Cell Li-Ion Switching Charger with USB-OTG Boost Regulator

Part Number

Temperature

Range

Package

PN Bits:

IC_INFO[4:2]

Packing

Method

FAN54015UCX

-40 to 85°C

20-Bump, Wafer-Level Chip-Scale Package (WLCSP),

0.4 mm Pitch, Estimated Size: 1.96 x 1.87 mm

101

Tape and

Reel

FAN54015BUCX

(1)

Part Number

Slave Address

Automatic

Charge

Special

Charger

(2)

Safety

Limits

Battery Absent

Behavior

E2 Pin

VREG

(E3 Pin)

FAN54015UCX

1101010

Yes

Yes

Yes

ON

DISABLE

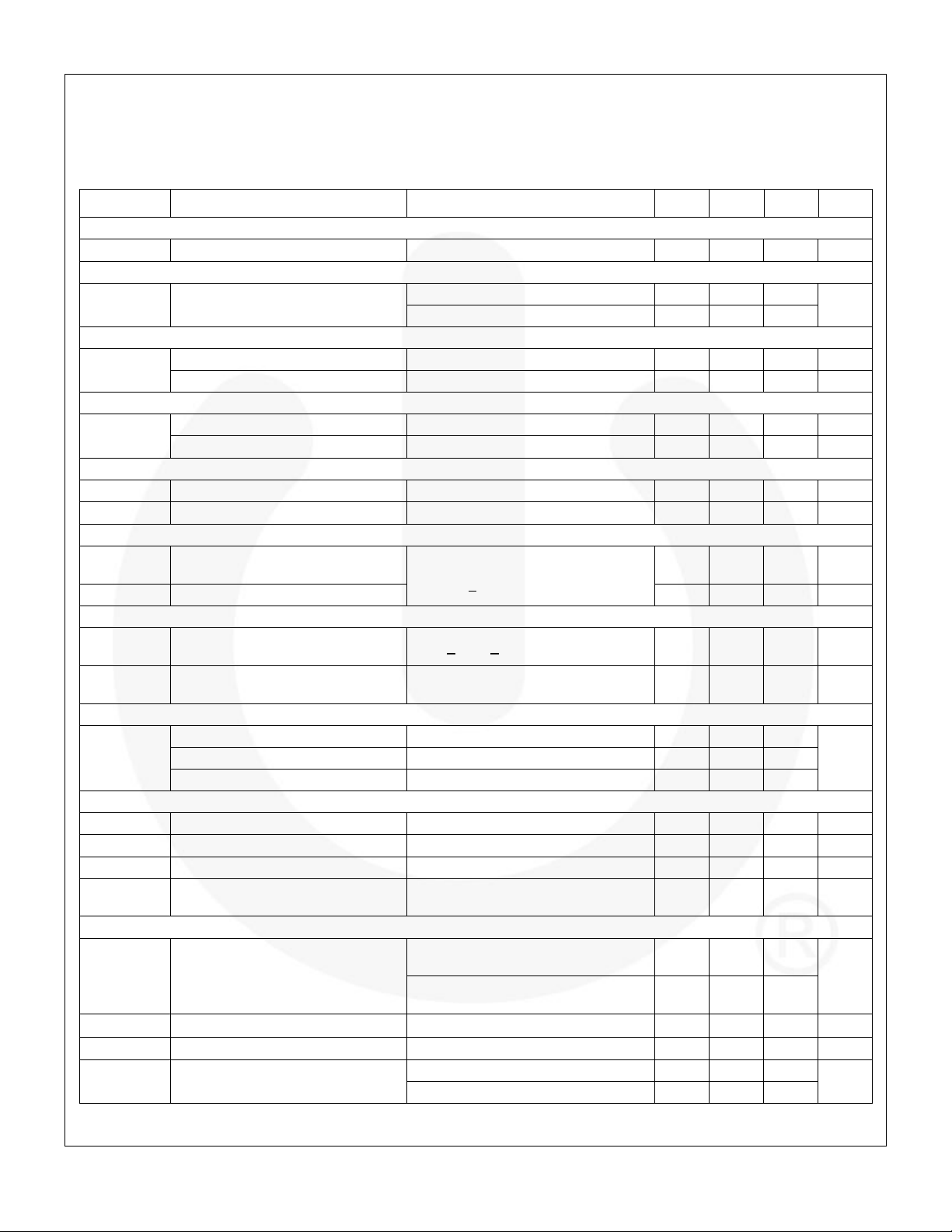

1.8 V

PWM

MODULATOR

PMID

SW

PGND

PMID

L1

VBAT

C

MID

+

Battery

CSIN

1H

4.7F

C

BAT

SYSTEM

LOAD

VREF

SDA

SCL

OTG/USB#

VCC

VBUS

C

BUS

1F

STAT

I2C

INTERFACE

LOGIC

AND

CONTROL

PMID

OSC

30mA

C

OUT

0.1F

R

SENSE

Q3

CHARGE

PUMP

VBUS

OVP

I_IN

CONTROL

VREG

C

REG

1F

DAC

DISABLE

1.8V / PMID REG

Q2

Q1B

Q1A

Q1

Component

Description

Vendor

Parameter

Typ.

Unit

L1

1 H ±20%, 1.6 A, DCR=55 m, 2520

Murata: LQM2HPN1R0

L

1.0

H

1 H ±30%, 1.4 A, DCR=85 m, 2016

Murata: LQM2MPN1R0

C

BAT

10 F, 20%, 6.3 V, X5R, 0603

Murata: GRM188R60J106M

TDK: C1608X5R0J106M

C

10

F

C

MID

4.7 F, 10%, 6.3 V, X5R, 0603

Murata: GRM188R60J475K

TDK: C1608X5R0J475K

C

(3)

4.7

F

C

BUS

1.0 F, 10%, 25 V, X5R, 0603

Murata GRM188R61E105K

TDK:C1608X5R1E105M

C

1.0

F

PMID

Q1A

Q1B

Greater than V

BAT

ON

OFF

Less than V

BAT

OFF

ON

Ordering Information

Note:

1. FAN54015BUCX includes backside lamination.

Table 1. Feature Summary

Note:

2. A “special charger” is a current-limited charger that is not a USB compliant source.

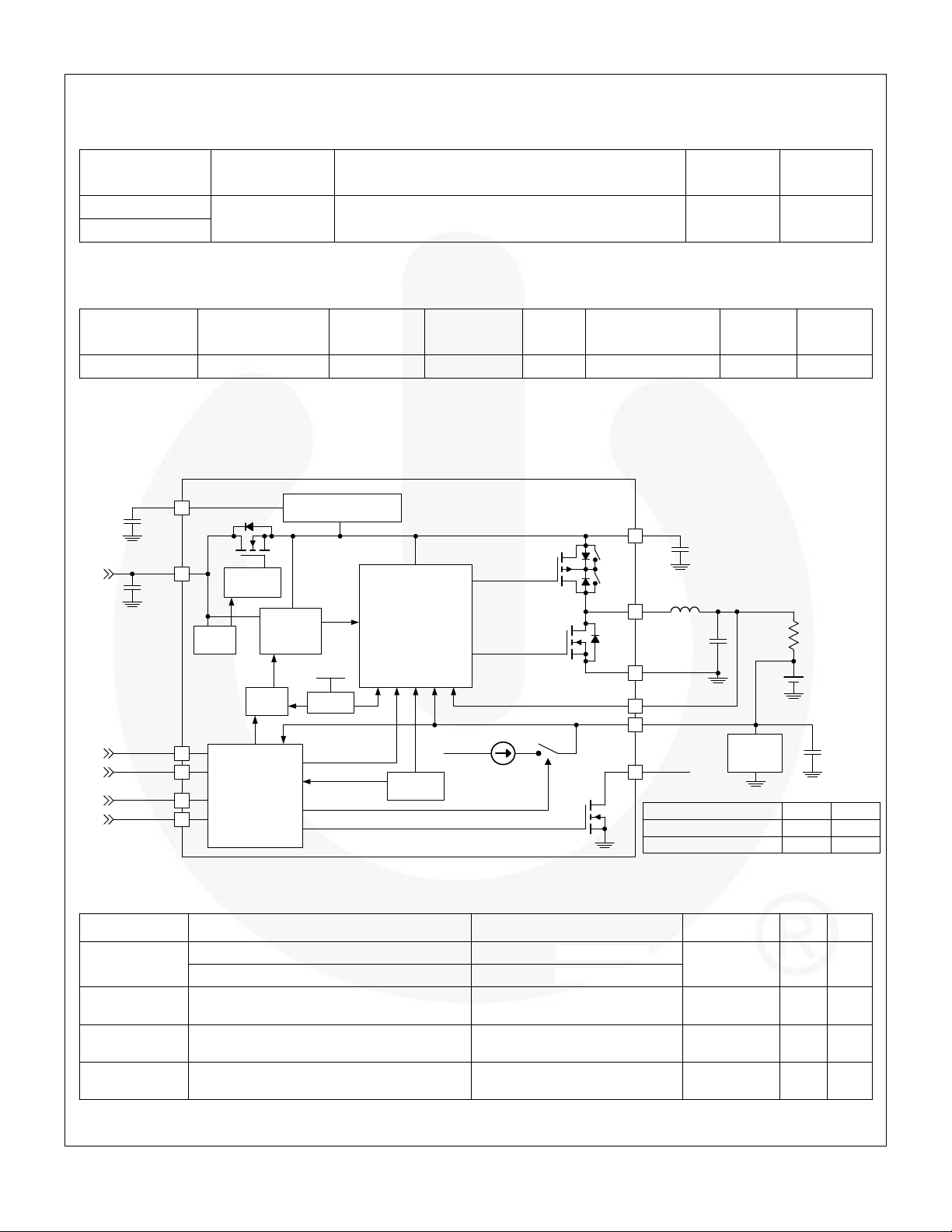

Block Diagram

Table 2. Recommended External Components

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN54015 • Rev. 1.0.2 2

Note:

3. A 6.3 V rating is sufficient for C

because PMID is protected from over-voltage surges on VBUS by Q3 (Figure 2).

MID

Figure 2. IC and System Block Diagram

FAN54015 — USB-Compliant Single-Cell Li-Ion Switching Charger with USB-OTG Boost Regulator

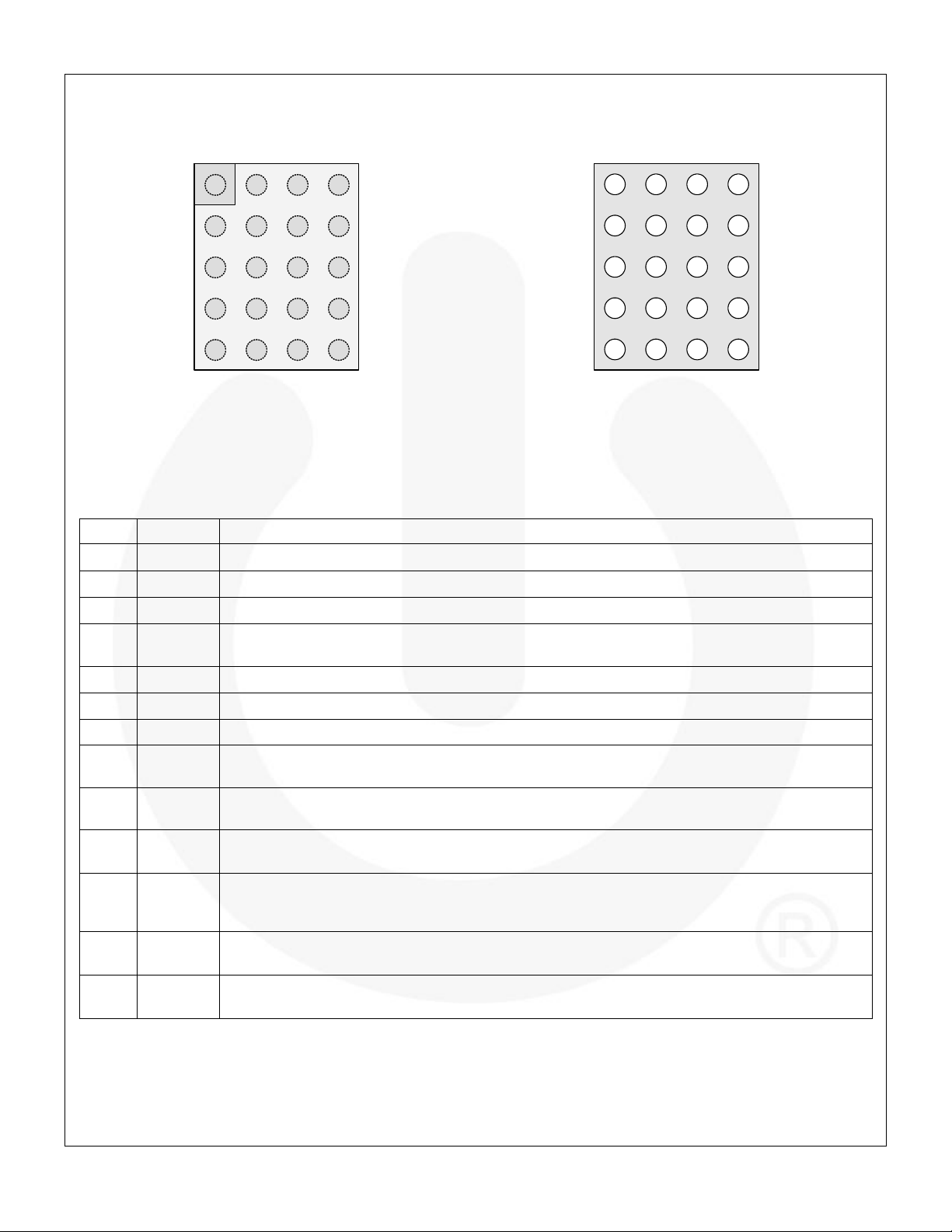

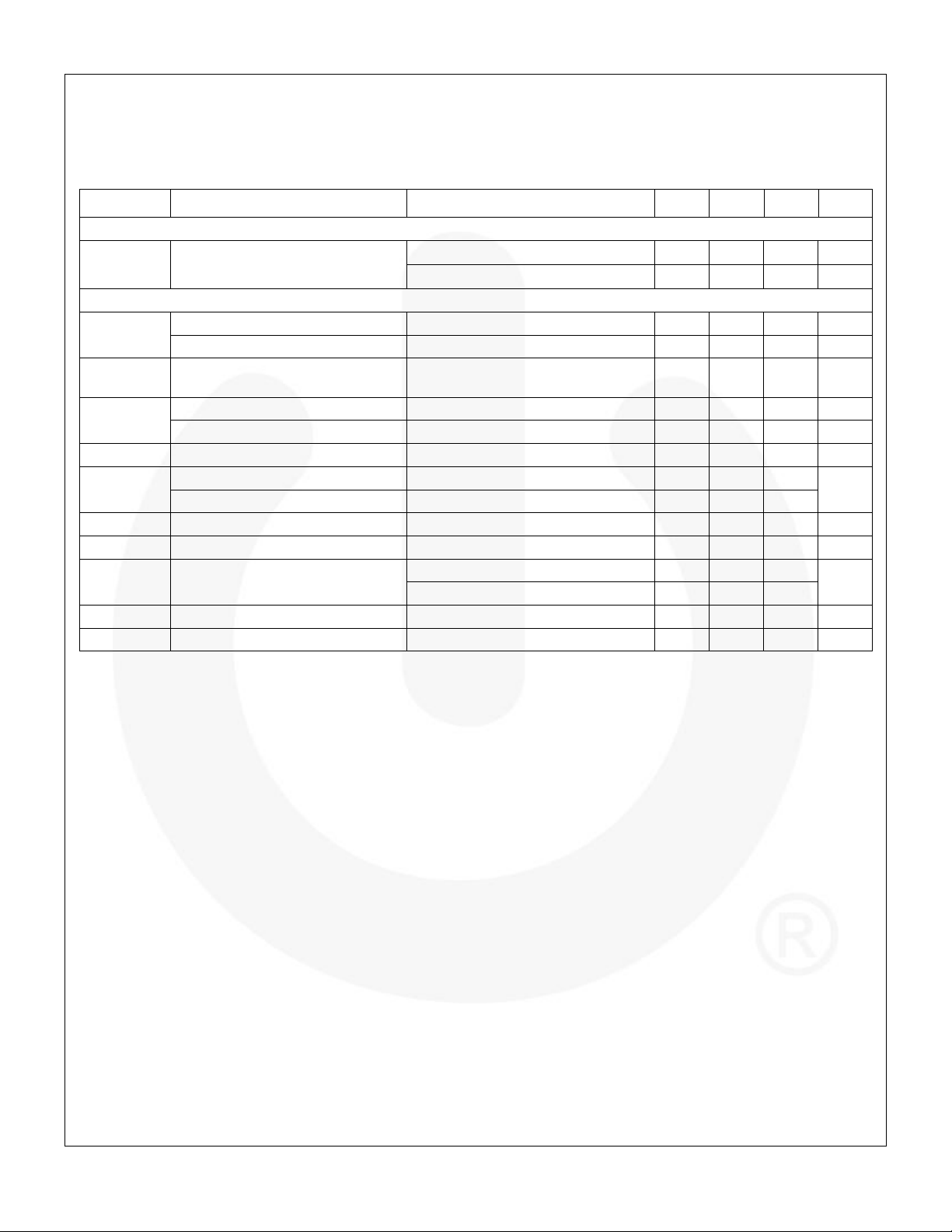

Top View

Bottom View

Figure 3. WLCSP-20 Pin Assignments

Pin #

Name

Description

A1, A2

VBUS

Charger Input Voltage and USB-OTG output voltage. Bypass with a 1 F capacitor to PGND.

A3

NC

No Connect. No external connection is made between this pin and the IC’s internal circuitry.

A4

SCL

I2C Interface Serial Clock. This pin should not be left floating.

B1-B3

PMID

Power Input Voltage. Power input to the charger regulator, bypass point for the input current sense,

and high-voltage input switch. Bypass with a minimum of 4.7 F, 6.3 V capacitor to PGND.

B4

SDA

I2C Interface Serial Data. This pin should not be left floating.

C1-C3

SW

Switching Node. Connect to output inductor.

C4

STAT

Status. Open-drain output indicating charge status. The IC pulls this pin LOW when charging.

D1-D3

PGND

Power Ground. Power return for gate drive and power transistors. The connection from this pin to the

bottom of C

MID

should be as short as possible.

D4

OTG

On-The-Go. Enables boost regulator in conjunction with OTG_EN and OTG_PL bits (see Table 16). On

VBUS Power-On Reset (POR), this pin sets the input current limit for t

15MIN

charging.

E1

CSIN

Current-Sense Input. Connect to the sense resistor in series with the battery. The IC uses this node to

sense current into the battery. Bypass this pin with a 0.1 F capacitor to PGND.

E2

DISABLE

Charge Disable. If this pin is HIGH, charging is disabled. When LOW, charging is controlled by the

I2C registers. When this pin is HIGH, the 15-minute timer is reset. This pin does not affect the

32-second timer.

E3

VREG

Regulator Output. Connect to a 1 F capacitor to PGND. This pin can supply up to 2mA of DC load

current. The output voltage is PMID, which is limited to 1.8 V.

E4

VBAT

Battery Voltage. Connect to the positive (+) terminal of the battery pack. Bypass with a 0.1 F

capacitor to PGND if the battery is connected through long leads.

C1

B1

A1 A2

C3

B3

A3

C2

D1 D3D2

B2

C4

B4

A4

D4

E1 E3E2 E4

C1

B1

A1

C3

B3

A3 A2

C2

D1D3 D2

B2

C4

B4

A4

D4

E1E3 E2E4

Pin Configuration

Pin Definitions

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN54015 • Rev. 1.0.2 3

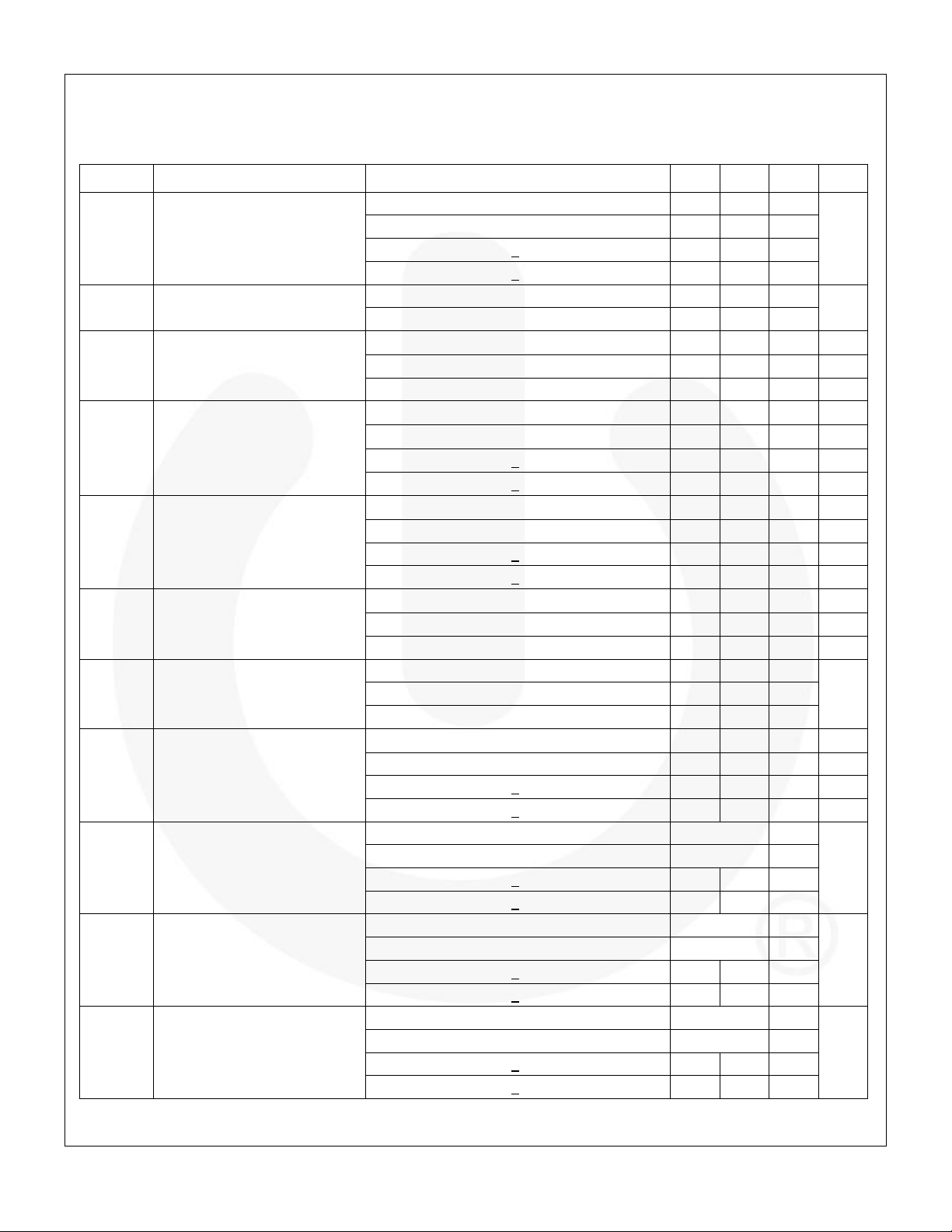

FAN54015 — USB-Compliant Single-Cell Li-Ion Switching Charger with USB-OTG Boost Regulator

Symbol

Parameter

Min.

Max.

Unit

V

BUS

VBUS Voltage

Continuous

–1.4

20.0

V

Pulsed, 100 ms Maximum Non-Repetitive

–2.0

V

STAT

STAT Voltage

–0.3

16.0

V

VI

PMID Voltage

7.0

V

SW, CSIN, VBAT, DISABLE Voltage

–0.3

7.0

VO

Voltage on Other Pins

–0.3

6.5

(4)

V

dt

dV

BUS

Maximum V

BUS

Slope above 5.5 V when Boost or Charger are Active

4

V/s

ESD

Electrostatic Discharge

Protection Level

Human Body Model per JESD22-A114

2000

V

Charged Device Model per JESD22-C101

500

TJ

Junction Temperature

–40

+150

°C

T

STG

Storage Temperature

–65

+150

°C

TL

Lead Soldering Temperature, 10 Seconds

+260

°C

Symbol

Parameter

Min.

Max.

Unit

V

BUS

Supply Voltage

4 6 V

V

BAT(MAX)

Maximum Battery Voltage when Boost enabled

4.5

V

dt

dV

BUS

Negative VBUS Slew Rate during VBUS Short Circuit,

C

MID

< 4.7 F (see VBUS Short While Charging)

TA < 60°C

4

V/s

TA > 60°C

2 TA

Ambient Temperature

–30

+85

°C

TJ

Junction Temperature (see Thermal Regulation and Protection section)

–30

+120

°C

Symbol

Parameter

Typical

Unit

JA

Junction-to-Ambient Thermal Resistance

60

°C/W

JB

Junction-to-PCB Thermal Resistance

20

°C/W

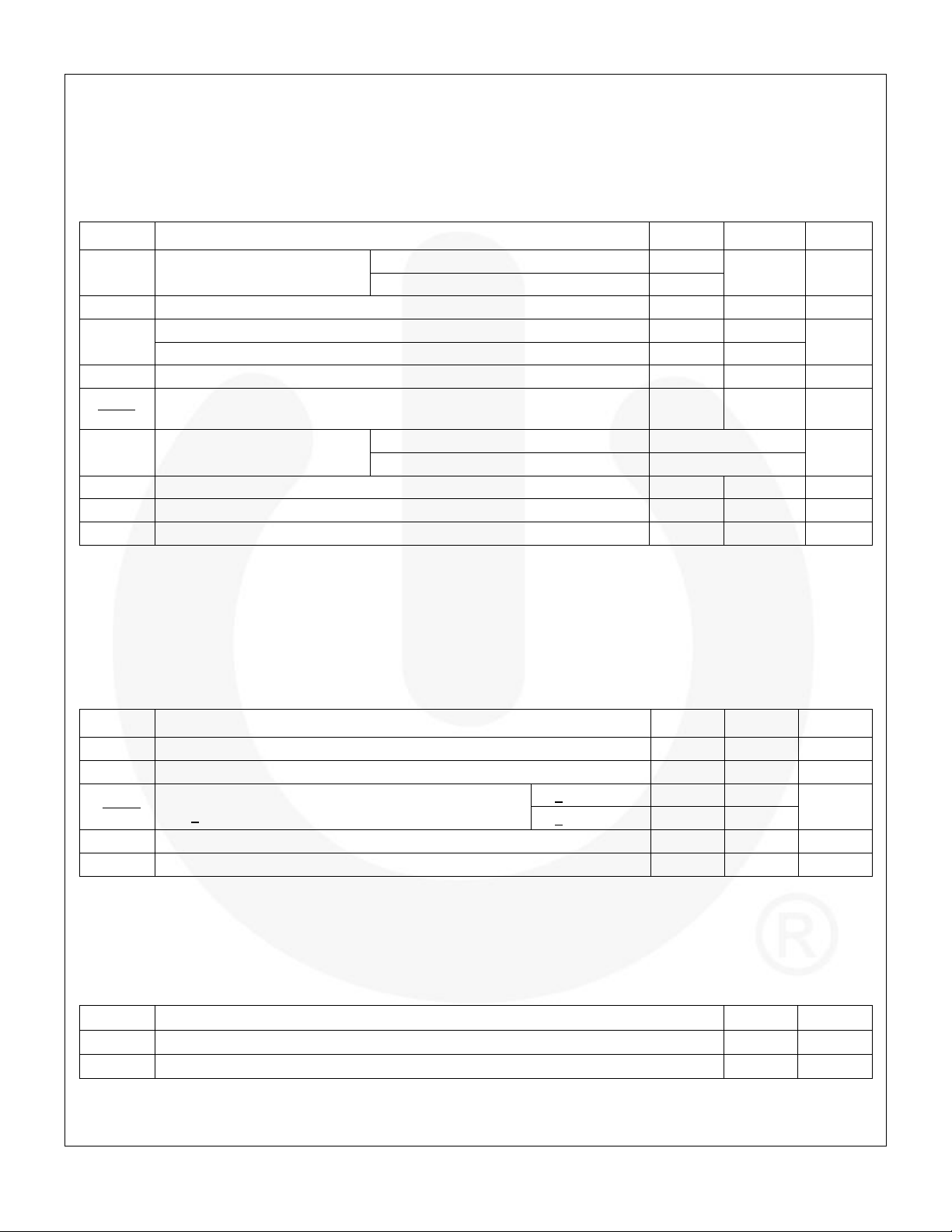

Absolute Maximum Ratings

Stresses exceeding the absolute maximum ratings may damage the device. The device may not function or be operable above

the recommended operating conditions and stressing the parts to these levels is not recommended. In addition, extended

exposure to stresses above the recommended operating conditions may affect device reliability. The absolute maximum

ratings are stress ratings only.

Note:

4. Lesser of 6.5 V or VI + 0.3 V.

Recommended Operating Conditions

The Recommended Operating Conditions table defines the conditions for actual device operation. Recommended operating

conditions are specified to ensure optimal performance to the datasheet specifications. Fairchild does not recommend

exceeding them or designing to absolute maximum ratings.

Thermal Properties

Junction-to-ambient thermal resistance is a function of application and board layout. This data is measured with four-layer

2s2p boards in accordance to JEDEC standard JESD51. Special attention must be paid not to exceed junction temperature

T

at a given ambient temperature TA. For measured data, see Table 11.

J(max)

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN54015 • Rev. 1.0.2 4

FAN54015 — USB-Compliant Single-Cell Li-Ion Switching Charger with USB-OTG Boost Regulator

Electrical Specifications

Unless otherwise specified: according to the circuit of Figure 1; recommended operating temperature range for TJ and TA;

V

BUS

=5.0 V; HZ_MODE; OPA_MODE=0; (Charge Mode); SCL, SDA, OTG=0 or 1.8 V; and typical values are for TJ=25°C.

Symbol

Parameter

Conditions

Min.

Typ.

Max.

Unit

Power Supplies

I

VBUS

VBUS Current

V

BUS

> V

BUS(min)

, PWM Switching

10 mA

V

BUS

> V

BUS(min)

; PWM Enabled,

Not Switching (Battery OVP

Condition); I_IN Setting=100 mA

2.5 mA

0°C < TJ < 85°C, HZ_MODE=1

V

BAT

< V

LOWV

, 32S Mode

63

90

A

I

LKG

VBAT to VBUS Leakage Current

0°C < TJ < 85°C, HZ_MODE=1,

V

BAT

=4.2 V, V

BUS

=0 V

0.2

5.0

A

I

BAT

Battery Discharge Current in HighImpedance Mode

0°C < TJ < 85°C, HZ_MODE=1,

V

BAT

=4.2 V

20

A

DISABLE=1, 0°C < TJ < 85°C,

V

BAT

=4.2 V

10

Charger Voltage Regulation

V

OREG

Charge Voltage Range

3.5 4.4

V

Charge Voltage Accuracy

TA=25°C

–0.5%

+0.5%

TJ=0 to 125°C

–1%

+1%

Charging Current Regulation

I

OCHRG

Output Charge Current Range

V

LOWV

< V

BAT

< V

OREG

, R

SENSE

=68 m

550

1450

mA

Charge Current Accuracy Across

R

SENSE

20 mV ≤ V

IREG

≤ 40 mV

92

97

102

%

V

IREG

> 40 mV

94

97

100

%

Weak Battery Detection

V

LOWV

Weak Battery Threshold Range

3.4 3.7

V

Weak Battery Threshold Accuracy

–5 +5

%

Weak Battery Deglitch Time

Rising Voltage

30 ms

Logic Levels: DISABLE, SDA, SCL, OTG

VIH

High-Level Input Voltage

1.05 V VIL

Low-Level Input Voltage

0.4

V

IIN

Input Bias Current

Input Tied to GND or VIN

0.01

1.00

A

Charge Termination Detection

I

(TERM)

Termination Current Range

V

BAT

> V

OREG

– V

RCH

, R

SENSE

=68 m

50 400

mA

Termination Current Accuracy

[V

CSIN

– V

BAT

] from 3 mV to 20 mV

–25 +25

%

[V

CSIN

– V

BAT

] from 20 mV to 40 mV

–5 +5

Termination Current Deglitch Time

2 mV Overdrive

30 ms

1.8V Linear Regulator

V

REG

1.8V Regulator Output

I

REG

from 0 to 2 mA

1.7

1.8

1.9

V

Input Power Source Detection

V

IN(MIN)1

VBUS Input Voltage Rising

To Initiate and Pass VBUS Validation

4.29

4.42

V

V

IN(MIN)2

Minimum VBUS During Charge

During Charging

3.71

3.94

V

t

VBUS_VALID

VBUS Validation Time

30 ms

Continued on the following page…

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN54015 • Rev. 1.0.2 5

FAN54015 — USB-Compliant Single-Cell Li-Ion Switching Charger with USB-OTG Boost Regulator

Electrical Specifications

Unless otherwise specified: according to the circuit of Figure 1; recommended operating temperature range for TJ and TA;

V

BUS

=5.0 V; HZ_MODE; OPA_MODE=0; (Charge Mode); SCL, SDA, OTG=0 or 1.8 V; and typical values are for TJ=25°C.

Symbol

Parameter

Conditions

Min.

Typ.

Max.

Unit

Special Charger (V

BUS

)

VSP

Special Charger Setpoint Accuracy

–3 +3

%

Input Current Limit

I

INLIM

Input Current Limit Threshold

IIN Set to 100 mA

88

93

98

mA

IIN Set to 500 mA

450

475

500

V

REF

Bias Generator

V

REF

Bias Regulator Voltage

V

BUS

> V

IN(MIN)

or V

BAT

> V

BAT(MIN)

6.5

V

Short-Circuit Current Limit

20 mA

Battery Recharge Threshold

V

RCH

Recharge Threshold

Below V

(OREG)

100

120

150

mV

Deglitch Time

V

BAT

Falling Below V

RCH

Threshold

130 ms

STAT Output

V

STAT(OL)

STAT Output Low

I

STAT

=10 mA

0.4

V

I

STAT(OH)

STAT High Leakage Current

V

STAT

=5 V

1

A

Battery Detection

I

DETECT

Battery Detection Current before

Charge Done (Sink Current)

(5)

Begins after Termination Detected

and V

BAT

< V

OREG

–V

RCH

–0.80 mA

t

DETECT

Battery Detection Time

262 ms

Sleep Comparator

V

SLP

Sleep-Mode Entry Threshold,

V

BUS

– V

BAT

2.3 V < V

BAT

< V

OREG

, V

BUS

Falling

0

0.04

0.10 V t

SLP_EXIT

Deglitch Time for VBUS Rising

Above V

BAT

by V

SLP

Rising Voltage

30 ms

Power Switches (see Figure 2)

R

DS(ON)

Q3 On Resistance (VBUS to PMID)

I

IN(LIMIT)

=500 mA

180

250

mΩ

Q1 On Resistance (PMID to SW)

130

225

Q2 On Resistance (SW to GND)

150

225

Charger PWM Modulator

fSW

Oscillator Frequency

2.7

3.0

3.3

MHz

D

MAX

Maximum Duty Cycle

100

%

D

MIN

Minimum Duty Cycle

0 %

I

SYNC

Synchronous to Non-Synchronous

Current Cut-Off Threshold

(6)

Low-Side MOSFET (Q2) Cycle-byCycle Current Limit

140 mA

Boost Mode Operation (OPA_MODE=1, HZ_MODE=0)

V

BOOST

Boost Output Voltage at VBUS

2.5 V < V

BAT

< 4.5 V, I

LOAD

from 0 to

200 mA

4.80

5.07

5.17

V

3.0 V < V

BAT

< 4.5 V, I

LOAD

from 0 to

500 mA

4.77

5.07

5.17

I

BAT(BOOST)

Boost Mode Quiescent Current

PFM Mode, V

BAT

=3.6 V, I

OUT

=0

140

300

A

I

LIMPK(BST)

Q2 Peak Current Limit

1272

1590

1908

mA

UVLO

BST

Minimum Battery Voltage for Boost

Operation

While Boost Active

2.42

V

To Start Boost Regulator

2.58

2.70

Continued on the following page…

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN54015 • Rev. 1.0.2 6

FAN54015 — USB-Compliant Single-Cell Li-Ion Switching Charger with USB-OTG Boost Regulator

Electrical Specifications

Unless otherwise specified: according to the circuit of Figure 1; recommended operating temperature range for TJ and TA;

V

BUS

=5.0 V; HZ_MODE; OPA_MODE=0; (Charge Mode); SCL, SDA, OTG=0 or 1.8 V; and typical values are for TJ=25°C.

Symbol

Parameter

Conditions

Min.

Typ.

Max.

Unit

VBUS Load Resistance

R

VBUS

VBUS to PGND Resistance

Normal Operation

1500

k

Charger Validation

100

Protection and Timers

VBUS

OVP

VBUS Over-Voltage Shutdown

V

BUS

Rising

6.09

6.29

6.49

V

Hysteresis

V

BUS

Falling

100 mV

I

LIMPK(CHG)

Q1 Cycle-by-Cycle Peak Current

Limit

Charge Mode

2.3

A

V

SHORT

Battery Short-Circuit Threshold

V

BAT

Rising

1.95

2.00

2.05

V

Hysteresis

V

BAT

Falling

100 mV

I

SHORT

Linear Charging Current

V

BAT

< V

SHORT

20

30

40

mA

T

SHUTDWN

Thermal Shutdown Threshold

(7)

TJ Rising

145

°C

Hysteresis

(7)

TJ Falling

10

TCF

Thermal Regulation Threshold

(7)

Charge Current Reduction Begins

120 °C

t

INT

Detection Interval

2.1 s

t

32S

32-Second Timer

(8)

Charger Enabled

20.5

25.2

28.0

s

Charger Disabled

18.0

25.2

34.0

t

15MIN

15-Minute Timer

15-Minute Mode

12.0

13.5

15.0

min

∆tLF

Low-Frequency Timer Accuracy

Charger Inactive

–25 25

%

Notes:

5. Negative current is current flowing from the battery to VBUS (discharging the battery).

6. Q2 always turns on for 60 ns, then turns off if current is below I

SYNC

.

7. Guaranteed by design; not tested in production.

8. This tolerance (%) applies to all timers on the IC, including soft-start and deglitching timers.

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN54015 • Rev. 1.0.2 7

FAN54015 — USB-Compliant Single-Cell Li-Ion Switching Charger with USB-OTG Boost Regulator

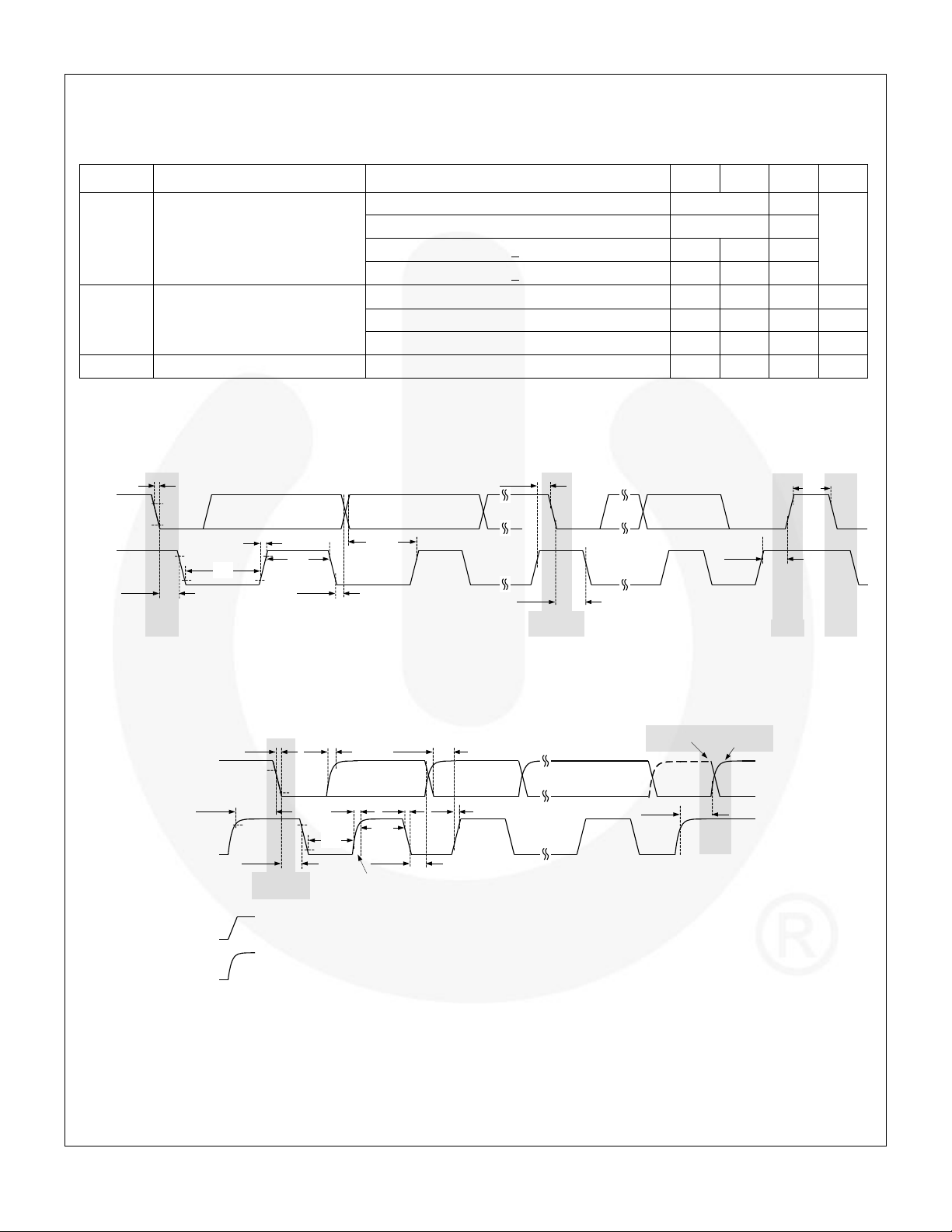

I2C Timing Specifications

Guaranteed by design.

Symbol

Parameter

Conditions

Min.

Typ.

Max.

Unit

f

SCL

SCL Clock Frequency

Standard Mode

100

kHz

Fast Mode

400

High-Speed Mode, CB < 100 pF

3400

High-Speed Mode, CB < 400 pF

1700

t

BUF

Bus-Free Time between STOP

and START Conditions

Standard Mode

4.7

s

Fast Mode

1.3

t

HD;STA

START or Repeated START

Hold Time

Standard Mode

4

s

Fast Mode

600 ns

High-Speed Mode

160 ns

t

LOW

SCL LOW Period

Standard Mode

4.7

s

Fast Mode

1.3

s

High-Speed Mode, CB < 100 pF

160 ns

High-Speed Mode, CB < 400 pF

320 ns

t

HIGH

SCL HIGH Period

Standard Mode

4

s

Fast Mode

600 ns

High-Speed Mode, CB < 100 pF

60 ns

High-Speed Mode, CB < 400 pF

120 ns

t

SU;STA

Repeated START Setup Time

Standard Mode

4.7

s

Fast Mode

600 ns

High-Speed Mode

160 ns

t

SU;DAT

Data Setup Time

Standard Mode

250

ns

Fast Mode

100

High-Speed Mode

10

t

HD;DAT

Data Hold Time

Standard Mode

0 3.45

s

Fast Mode

0 900

ns

High-Speed Mode, CB < 100 pF

0 70

ns

High-Speed Mode, CB < 400 pF

0 150

ns

t

RCL

SCL Rise Time

Standard Mode

20+0.1CB

1000

ns

Fast Mode

20+0.1CB

300

High-Speed Mode, CB < 100 pF

10

80

High-Speed Mode, CB < 400 pF

20

160

t

FCL

SCL Fall Time

Standard Mode

20+0.1CB

300

ns

Fast Mode

20+0.1CB

300

High-Speed Mode, CB < 100 pF

10

40

High-Speed Mode, CB < 400 pF

20

80

t

RDA

t

RCL1

SDA Rise Time

Rise Time of SCL after a

Repeated START Condition

and after ACK Bit

Standard Mode

20+0.1CB

1000

ns

Fast Mode

20+0.1CB

300

High-Speed Mode, CB < 100 pF

10

80

High-Speed Mode, CB < 400 pF

20

160

Continued on the following page…

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN54015 • Rev. 1.0.2 8

FAN54015 — USB-Compliant Single-Cell Li-Ion Switching Charger with USB-OTG Boost Regulator

I2C Timing Specifications

Guaranteed by design.

Symbol

Parameter

Conditions

Min.

Typ.

Max.

Unit

t

FDA

SDA Fall Time

Standard Mode

20+0.1CB

300

ns

Fast Mode

20+0.1CB

300

High-Speed Mode, CB < 100 pF

10

80

High-Speed Mode, CB < 400 pF

20

160

t

SU;STO

Stop Condition Setup Time

Standard Mode

4

s

Fast Mode

600 ns

High-Speed Mode

160 ns

CB

Capacitive Load for SDA, SCL

400

pF

START

REPEATED

START

SCL

SDA

t

F

t

HD;STA

t

LOW

t

R

t

HD;DAT

t

HIGH

T

SU;DAT

t

SU;STA

t

HD;STO

t

BUF

START STOP

t

HD;STA

REPEATED

START

SCLH

SDAH

t

FDA

t

LOW

t

RCL1

t

HD;DAT

t

HIGH

t

SU;STO

REPEATED

START

t

RDA

t

FCL

t

SU;DAT

t

RCL

STOP

= MCS Current Source Pull-up

= RP Resistor Pull-up

note A

Note A: First rising edge of SCLH after Repeated Start and after each ACK bit.

t

HD;STA

t

SU;STA

Timing Diagrams

Figure 4. I2C Interface Timing for Fast and Slow Modes

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN54015 • Rev. 1.0.2 9

Figure 5. I2C Interface Timing for High-Speed Mode

FAN54015 — USB-Compliant Single-Cell Li-Ion Switching Charger with USB-OTG Boost Regulator

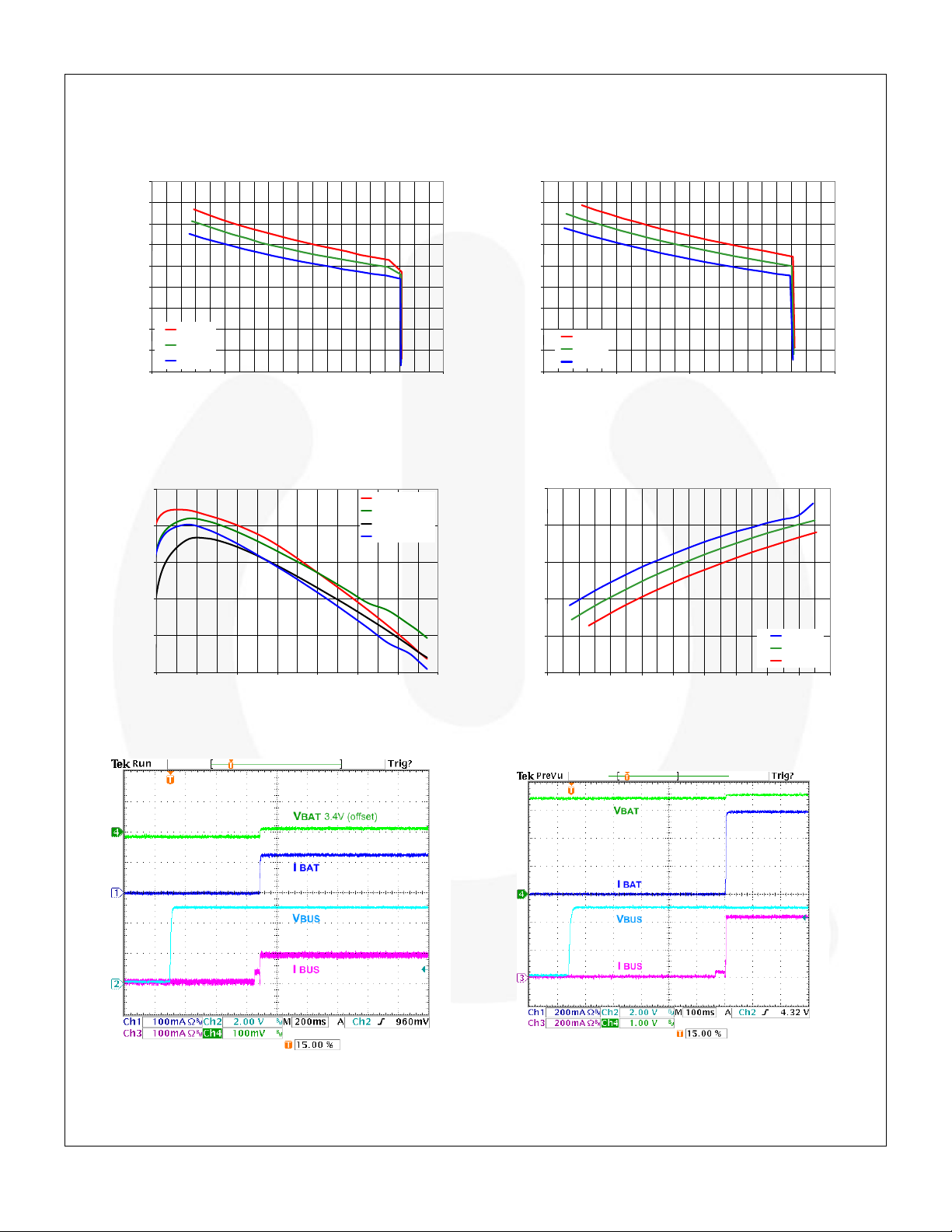

Charge Mode Typical Characteristics

Unless otherwise specified, circuit of Figure 1, V

OREG

=4.2 V, V

BUS

=5.0 V, and TA=25°C.

Figure 6. Battery Charge Current vs. V

BUS

with

I

INLIM

=100 mA

Figure 7. Battery Charge Current vs. V

BUS

with

I

INLIM

=500 mA

Figure 8. Charger Efficiency, No I

INLIM

, I

OCHARGE

=1450 mA

Figure 9. Charger Efficiency vs. V

BUS

, I

INLIM

=500 mA

Figure 10. Auto-Charge Startup at VBUS Plug-in,

I

INLIM

=100 mA, OTG=1, V

BAT

=3.4 V

Figure 11. Auto-Charge Startup at VBUS Plug-in,

I

INLIM

=500 mA, OTG=1, V

BAT

=3.4 V

-

20

40

60

80

100

120

140

160

180

2.5 3 3.5 4 4.5

Battery Charge Current (mA)

Battery Voltage, VBAT (V)

5.5VBUS

5.0VBUS

4.5VBUS

-

100

200

300

400

500

600

700

800

900

2.5 3 3.5 4 4.5

Battery Charge Current (mA)

Battery Voltage, VBAT (V)

5.5VBUS

5.0VBUS

4.5VBUS

82%

85%

88%

91%

94%

97%

100 300 500 700 900 1100 1300 1500

Efficiency

Battery Charge Current (mA)

4.20VBAT, 4.5VBUS

4.20VBAT, 5.0VBUS

3.54VBAT, 5.0VBUS

3.54VBAT, 4.5VBUS

84%

86%

88%

90%

92%

94%

2.5 2.7 2.9 3.1 3.3 3.5 3.7 3.9 4.1 4.3

Efficiency

Battery Voltage, VBAT (V)

4.5VBUS

5.0VBUS

5.5VBUS

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN54015 • Rev. 1.0.2 10

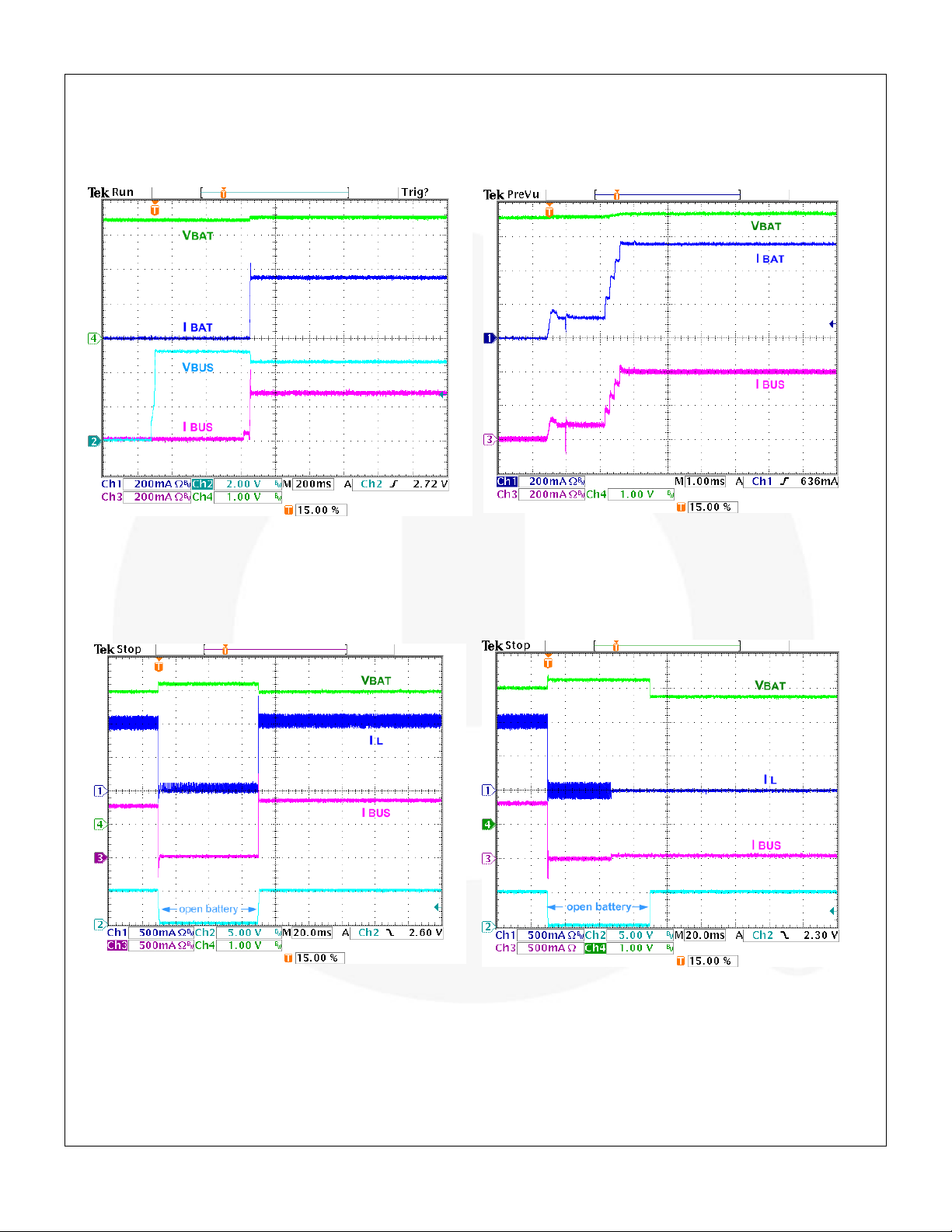

FAN54015 — USB-Compliant Single-Cell Li-Ion Switching Charger with USB-OTG Boost Regulator

Charge Mode Typical Characteristics

Unless otherwise specified, circuit of Figure 1, V

OREG

=4.2 V, V

BUS

=5.0 V, and TA=25°C.

Figure 12. AutoCharge Startup with 300mA Limited

Charger / Adaptor, I

INLIM

=500 mA, OTG=1, V

BAT

=3.4 V

Figure 13. Charger Startup with HZ_MODE Bit Reset,

I

INLIM

=500 mA, I

OCHARGE

=1050 mA, OREG=4.2 V, V

BAT

=3.6 V

Figure 14. Battery Removal / Insertion During Charging,

V

BAT

=3.9 V, I

OCHARGE

=1050 mA, No I

INLIM,

TE=0

Figure 15. Battery Removal / Insertion During Charging,

V

BAT

=3.9 V, I

OCHARGE

=1050 mA, No I

INLIM,

TE=1

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN54015 • Rev. 1.0.2 11

FAN54015 — USB-Compliant Single-Cell Li-Ion Switching Charger with USB-OTG Boost Regulator

Charge Mode Typical Characteristics

Unless otherwise specified, circuit of Figure 1, V

OREG

=4.2 V, V

BUS

=5.0 V, and TA=25°C.

Figure 16. VBUS Current in High-Impedance Mode

with Battery Open

Figure 17. V

REG

1.8 V Output Regulation

Figure 18. No Battery, V

BUS

at Power Up

0

50

100

150

200

4.0 4.5 5.0 5.5 6.0

High-Z Mode Current (A)

Input Voltage, VBUS (V)

-30C

+25C

+85C

1.77

1.78

1.79

1.80

1.81

1.82

0 1 2 3 4 5

VREG (V)

1.8V Regulator Load Current (mA)

-10C, 5.0VBUS

+25C, 5.0VBUS

+85C, 5.0VBUS

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN54015 • Rev. 1.0.2 12

FAN54015 — USB-Compliant Single-Cell Li-Ion Switching Charger with USB-OTG Boost Regulator

Boost Mode Typical Characteristics

Unless otherwise specified, using circuit of Figure 1, V

BAT

=3.6 V, TA=25°C.

Figure 19. Efficiency vs. V

BAT

Figure 20. Efficiency Over Temperature

Figure 21. Output Regulation vs. V

BAT

Figure 22. Output Regulation Over Temperature

Figure 23. Quiescent Current

Figure 24. High-Impedance Mode Battery Current

75

80

85

90

95

100

0 100 200 300 400 500

Efficiency (%)

VBUS Load Current (mA)

3.0 VBAT

3.6 VBAT

4.2 VBAT

75

80

85

90

95

100

0 100 200 300 400 500

Efficiency (%)

VBUS Load Current (mA)

-10C, 3.6VBAT

+25C, 3.6VBAT

+85C, 3.6VBAT

4.80

4.85

4.90

4.95

5.00

5.05

5.10

0 100 200 300 400 500

VBUS (V)

VBUS Load Current (mA)

3.0 VBAT

3.6 VBAT

4.2 VBAT

4.80

4.85

4.90

4.95

5.00

5.05

5.10

0 100 200 300 400 500

VBUS (V)

VBUS Load Current (mA)

-10C, 3.6VBAT

+25C, 3.6VBAT

+85C, 3.6VBAT

50

100

150

200

250

2 2.5 3 3.5 4 4.5 5

Quiescent Current (µA)

Battery Voltage, VBAT (V)

-30C

+25C

+85C

0

5

10

15

20

2 2.5 3 3.5 4 4.5 5

High-Z Mode Current (µA)

Battery Voltage, VBAT (V)

-30C

+25C

+85C

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN54015 • Rev. 1.0.2 13

FAN54015 — USB-Compliant Single-Cell Li-Ion Switching Charger with USB-OTG Boost Regulator

Boost Mode Typical Characteristics

Unless otherwise specified, using circuit of Figure 1, V

BAT

=3.6 V, TA=25°C.

Figure 25. Boost PWM Waveform

Figure 26. Boost PFM Waveform

Figure 27. Output Ripple vs. V

BAT

Figure 28. Output Ripple vs. Temperature

0

5

10

15

20

25

30

0 100 200 300 400 500

VBUS Ripple (mVpp)

VBUS Load Current (mA)

2.7 VBAT

3.6 VBAT

4.2 VBAT

4.5 VBAT

0

5

10

15

20

25

30

0 100 200 300 400 500

VBUS Ripple (mVpp)

VBUS Load Current (mA)

-30C, 3.6VBAT

+25C, 3.6VBAT

+85C, 3.6VBAT

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN54015 • Rev. 1.0.2 14

FAN54015 — USB-Compliant Single-Cell Li-Ion Switching Charger with USB-OTG Boost Regulator

Boost Mode Typical Characteristics

Unless otherwise specified, using circuit of Figure 1, V

BAT

=3.6 V, TA=25°C.

Figure 29. Startup, 3.6 V

BAT

, 44 Load, Additional 10 µF,

X5R Across V

BUS

Figure 30. V

BUS

Fault Response, 3.6 V

BAT

Figure 31. Load Transient, 5-155-5 mA, tR=tF=100 ns

Figure 32. Load Transient, 5-255-5 mA, tR=tF=100 ns

IBAT

I

L

V

BUS

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN54015 • Rev. 1.0.2 15

FAN54015 — USB-Compliant Single-Cell Li-Ion Switching Charger with USB-OTG Boost Regulator

V

OREG

V

BAT

I

SHORT

I

CHARGE

PRE-

CHARGE

CONSTANT CURRENT

(CC)

CONSTANT

VOLTAGE (CV)

V

SHORT

I

TERM

I

SHORT

V

SHORT

V

OREG

V

OREG

I

SHORT

I

C

H

A

R

G

E

PRE-

CHARGE

CURRENT REGULATION

VOLTAGE

REGULATION

V

SHORT

I

TERM

V

B

A

T

Circuit Description / Overview

When charging batteries with a current-limited input source,

such as USB, a switching charger’s high efficiency over a

wide range of output voltages minimizes charging time.

FAN54015 combines a highly integrated synchronous buck

regulator for charging with a synchronous boost regulator,

which can supply 5 V to USB On-The-Go (OTG) peripherals.

The regulator employs synchronous rectification for both the

charger and boost regulators to maintain high efficiency over

a wide range of battery voltages and charge states.

The FAN54015 has three operating modes:

1. Charge Mode:

Charges a single-cell Li-ion or Li-polymer battery.

2. Boost Mode:

Provides 5 V power to USB-OTG with an integrated

synchronous rectification boost regulator using the

battery as input.

3. High-Impedance Mode:

Both the boost and charging circuits are OFF in this

mode. Current flow from VBUS to the battery or from the

battery to VBUS is blocked in this mode. This mode

consumes very little current from VBUS or the battery.

Note: Default settings are denoted by bold typeface.

The FAN54015 is designed to work with a current-limited

input source at VBUS. During the current regulation phase

of charging, I

or the programmed charging current

INLIM

limits the amount of current available to charge the battery

and power the system. The effect of I

INLIM

on I

CHARGE

can be

seen in Figure 34.

Figure 33. Charge Curve, I

Not Limited by I

CHARGE

INLIM

Charge Mode

In Charge Mode, FAN54015 employs four regulation loops:

1. Input Current: Limits the amount of current drawn from

VBUS. This current is sensed internally and can be

programmed through the I2C interface.

2. Charging Current: Limits the maximum charging current.

This current is sensed using an external R

3. Charge Voltage: The regulator is restricted from

exceeding this voltage. As the internal battery voltage

rises, the battery’s internal impedance and R

in conjunction with the charge voltage regulation to

decrease the amount of current flowing to the battery.

Battery charging is completed when the voltage across

R

drops below the I

SENSE

4. Temperature: If the IC’s junction temperature reaches

120°C, charge current is reduced until the IC’s

temperature stabilizes at 120°C.

5. An additional loop limits the amount of drop on VBUS to

a programmable voltage (VSP) to accommodate “special

chargers” that limit current to a lower current than might

be available from a “normal” USB wall charger.

Battery Charging Curve

If the battery voltage is below V

pre-charges the battery until V

charging circuit is then started and the battery is charged

with a constant current if sufficient input power is available.

The current slew rate is limited to prevent overshoot.

threshold.

TERM

SHORT

reaches V

BAT

, a linear current source

SHORT

resistor.

SENSE

SENSE

. The PWM

work

Figure 34. Charge Curve, I

INLIM

Limits I

CHARGE

Assuming that V

is programmed to the cell’s fully

OREG

charged “float” voltage, the current that the battery accepts

with the PWM regulator limiting its output (sensed at VBAT)

to V

declines, and the charger enters the voltage

OREG

regulation phase of charging. When the current declines to

the programmed I

value, the charge cycle is complete.

TERM

Charge current termination can be disabled by resetting the

TE bit (REG1[3]).

The charger output or “float” voltage can be programmed by

the OREG bits from 3.5 V to 4.44 V in 2 0mV increments, as

shown in Table 3.

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN54015 • Rev. 1.0.2 16

FAN54015 — USB-Compliant Single-Cell Li-Ion Switching Charger with USB-OTG Boost Regulator

Decimal

Hex

VOREG

Decimal

Hex

VOREG

0

00

3.50 32

20

4.14

1

01

3.52 33

21

4.16

2

02

3.54

34

22

4.18

3

03

3.56 35

23

4.20

4

04

3.58 36

24

4.22

5

05

3.60 37

25

4.24

6

06

3.62 38

26

4.26

7

07

3.64 39

27

4.28

8

08

3.66 40

28

4.30

9

09

3.68 41

29

4.32

10

0A

3.70 42

2A

4.34

11

0B

3.72 43

2B

4.36

12

0C

3.74 44

2C

4.38

13

0D

3.76 45

2D

4.40

14

0E

3.78 46

2E

4.42

15

0F

3.80 47

2F

4.44

16

10

3.82 48

30

4.44

17

11

3.84 49

31

4.44

18

12

3.86 50

32

4.44

19

13

3.88 51

33

4.44

20

14

3.90 52

34

4.44

21

15

3.92 53

35

4.44

22

16

3.94 54

36

4.44

23

17

3.96 55

37

4.44

24

18

3.98 56

38

4.44

25

19

4.00 57

39

4.44

26

1A

4.02 58

3A

4.44

27

1B

4.04 59

3B

4.44

28

1C

4.06 60

3C

4.44

29

1D

4.08 61

3D

4.44

30

1E

4.10 62

3E

4.44

Parameter

Name

Register

Output Voltage Regulation

V

OREG

REG2[7:2]

Battery Charging Current Limit

I

OCHRG

REG4[6:4]

Input Current Limit

I

INLIM

REG1[7:6]

Charge Termination Limit

I

TERM

REG4[2:0]

Weak Battery Voltage

V

LOWV

REG1[5:4]

DEC

BIN

HEX

V

RSENSE

(mV)

I

OCHARGE

(mA)

68 m

100 m

0

000

00

37.4

550

374

1

001

01

44.2

650

442 2 010

02

51.0

750

510

3

011

03

57.8

850

578

4

100

04

71.4

1050

714

5

101

05

78.2

1150

782

6

110

06

91.8

1350

918

7

111

07

98.6

1450

986

I

TERM

V

RSENSE

(mV)

I

TERM

(mA)

68 m

100 m

0

3.3

49

33

1

6.6

97

66

2

9.9

146

99 3 13.2

194

132 4 16.5

243

165 5 19.8

291

198 6 23.1

340

231 7 26.4

388

264

CE

Table 3. OREG Bits (OREG[7:2]) vs. Charger V

(V

) Float Voltage

OREG

OUT

A new charge cycle begins when one of the following occurs:

The battery voltage falls below V

OREG

- V

RCH

VBUS Power on Reset (POR) clears and the battery

voltage is below the weak battery threshold (V

LOWV

).

or HZ_MODE is reset through I2C write to

CONTROL1 (R1) register.

Charge Current Limit (I

Table 5. I

of I

OCHARGE

OCHARGE

Bits and R

(REG4 [6:4]) Current as Function

SENSE

OCHARGE

Resistor Values

)

Termination Current Limit

Current charge termination is enabled when TE (REG1[3])=1.

Typical termination current values are given in Table 6.

Table 6. I

(REG4[2:0]) and R

Current as Function of I

TERM

Resistor Values

SENSE

TERM

Bits

The following charging parameters can be programmed by

the host through I2C:

Table 4. Programmable Charging Parameters

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN54015 • Rev. 1.0.2 17

When the charge current falls below I

, PWM charging

TERM

stops and the STAT bits change to READY (00) for about

500 ms while the IC determines whether the battery and

charging source are still connected. STAT then changes to

CHARGE DONE (10), provided the battery and charger are

still connected.

FAN54015 — USB-Compliant Single-Cell Li-Ion Switching Charger with USB-OTG Boost Regulator

I

INLIM

REG1[7:6]

Input Current Limit

00

100 mA

01

500 mA

10

800 mA

11

No limit

CE

PWM Controller in Charge Mode

The IC uses a current-mode PWM controller to regulate the

output voltage and battery charge currents. The synchronous

rectifier (Q2) has a current limit that which off the FET when

the current is negative by more than 140mA peak. This

prevents current flow from the battery.

Safety Timer

Section references Figure 39.

At the beginning of charging, the IC starts a 15-minute timer

(t

). When this times out, charging is terminated. Writing

15MIN

to any register through I2C stops and resets the t

which in turn starts a 32-second timer (t

TMR_RST bit (REG0[7]) resets the t

timer. If the t

32S

). Setting the

32S

times out; charging is terminated, the registers are set to

their default values, and charging resumes using the default

values with the t

timer running.

15MIN

Normal charging is controlled by the host with the t

running to ensure that the host is alive. Charging with the

t

timer running is used for charging that is unattended by

15MIN

the host. If the t

timer expires; the IC turns off the

15MIN

charger, sets the bit, and indicates a timer fault (110) on

the FAULT bits (REG0[2:0]). This sequence prevents

overcharge if the host fails to reset the t

V

POR / Non-Compliant Charger Rejection

BUS

When the IC detects that V

has risen above V

BUS

32S

timer.

15MIN

32S

timer,

timer

32S

timer

IN(MIN)1

USB-Friendly Boot Sequence

At VBUS POR, when the battery voltage is above the weak

battery threshold (V

its I2C register settings. If V

), the IC operates in accordance with

LOWV

BAT

< V

, the IC sets all

LOWV

registers to their default values and enables the charger

using an input current limit controlled by the OTG pin

(100mA if OTG is LOW and 500 mA if OTG is HIGH). This

feature can revive a battery whose voltage is too low to

ensure reliable host operation. Charging continues in the

absence of host communication even after the battery has

reached V

charger remains active until t

, whose default value is 3.54 V, and the

OREG

times out. Once the host

15MIN

processor begins writing to the IC, charging parameters are

set by the host, which must continually reset the t

32S

continue charging using the programmed charging

parameters. If t

.times out, the register defaults are loaded,

32S

the FAULT bits are set to 110, STAT is pulsed HIGH, and

charging continues with default charge parameters.

Input Current Limiting

To minimize charging time without overloading VBUS current

limitations, the IC’s input current limit can be programmed by

the I

Table 7. Input Current Limit

bits (REG1[7:6]).

INLIM

timer to

(4.4 V), the IC applies a 100 load from VBUS to GND. To

clear the VBUS POR (Power-On-Reset) and begin charging,

VBUS must remain above V

t

VBUS_VALID

(30 ms) before the IC initiates charging. The

VBUS validation sequence always occurs before charging is

initiated or re-initiated (for example, after a VBUS OVP fault

or a V

t

VBUS_VALID

recharge initiation).

RCH

ensures that unfiltered 50 / 60 Hz chargers and

and below VBUS

IN(MIN)1

OVP

for

The OTG pin establishes the input current limit when t

running.

15MIN

is

other non-compliant chargers are rejected.

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN54015 • Rev. 1.0.2 18

FAN54015 — USB-Compliant Single-Cell Li-Ion Switching Charger with USB-OTG Boost Regulator

VBUS POR

V

BAT

> V

LOWV

YES

Charge

Configuration

State

T15Min Timer?

NO

NO

YES

NO

Reset all registers

Start T

15MIN

NO

YES

HZ State

YES

Charge State

NO

YES

HZ State

NO

YES

T32Sec

Armed?

NO

YES

T32Sec

Armed?

HZ, CE# or

DISABLE Pin

set?

CE

HZ, CE# or

DISABLE Pin

set?

CE

HZ, CE# or

DISABLE Pin

set?

CE

Flow Charts

Figure 35. Charger VBUS POR

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN54015 • Rev. 1.0.2 19

FAN54015 — USB-Compliant Single-Cell Li-Ion Switching Charger with USB-OTG Boost Regulator

CHARGE STATE

YES

YES

Disable Charging

Indicate

VBUS Fault

NO

T

15MIN

Timeout?

NO

Enable I

SHORT

,

Reset Safety reg

Indicate Charging

PWM Charging

Indicate Charging

NO

YES

VBUS OK?

YES

Indicate timer fault

Set CE

HIGHZ mode

Indicate Charge

Complete

NO

V

BAT

< V

OREG–VRCH

NO

YES

VBUS OK?

Charge

Configuration

State

YES

NO

Disable Charging

Indicate

VBUS Fault

NO

YES

T

15MIN

Timeout?

NO

I

OUT

< I

TERM

Termination enabled

V

BAT

> V

OREG–VRCH

V

BAT

< V

SHORT

YES

Battery Removed

Reset charge

parameters

V

BAT

< V

OREG–VRCH

Reset Safety reg

Delay t

INT

Stop Charging

Enable IDET for T

DETECT

Flow Charts (Continued)

Figure 36. Charge Mode

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN54015 • Rev. 1.0.2 20

FAN54015 — USB-Compliant Single-Cell Li-Ion Switching Charger with USB-OTG Boost Regulator

Charge

Configuration

State

T32Sec

ARMED AND

CE# = 0?

Charge State

YES

NO

VBAT < VOREG

for 262ms?

NO

YES

NO

YES

START T15Min

Has T15Min

and CE# = 0

CE

CE

Stop T32Sec

HZ State

NO

Charge State

VBAT > VLOWV?

YES

YES

RUN

T32Sec

Reset T15min

if running

DISABLE

PIN

HIGH

LOW

LOW

HIGH

NO

HZ or CE# set?

CE

DISABLE

PIN

Flow Charts (Continued)

Figure 37. Charge Configuration

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN54015 • Rev. 1.0.2 21

Figure 38. HZ-State

FAN54015 — USB-Compliant Single-Cell Li-Ion Switching Charger with USB-OTG Boost Regulator

Charge Start

Start T

15MIN

T

15MIN

Active?

Reset Registers

YES

NO

Start T

32SEC

Stop T

15MIN

I2C Write

received?

YES

T

15MIN

Expired?

NO

Continue

Charging

T

32SEC

Expired?

YES

NO

NO

YES

Timer Fault :

Set CE

CE

Flow Charts (Continued)

Figure 39. Timer Flow Chart

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN54015 • Rev. 1.0.2 22

FAN54015 — USB-Compliant Single-Cell Li-Ion Switching Charger with USB-OTG Boost Regulator

SP (REG5[2:0])

DEC

BIN

HEX

VSP

0

000

00

4.213

1

001

01

4.293

2

010

02

4.373

3

011

03

4.453

4

100

04

4.533

5

101

05

4.613

6

110

06

4.693

7

111

07

4.773

ISAFE (REG6[6:4])

DEC

BIN

HEX

V

RSENSE

(mV)

I

SAFE

(mA)

68 m

100 m

0

000

00

37.4

550

374

1

001

01

44.2

650

442

2

010

02

51.0

750

510

3

011

03

57.8

850

578

4

100

04

71.4

1050

714

5

101

05

78.2

1150

782

6

110

06

91.8

1350

918

7

111

07

98.6

1450

986

VSAFE (REG6[3:0])

DEC

BIN

HEX

Max. OREG

(REG2[7:2])

VOREG

Max.

0

0000

00

100011

4.20

1

0001

01

100100

4.22

2

0010

02

100101

4.24

3

0011

03

100110

4.26

4

0100

04

100111

4.28

5

0101

05

101000

4.30

6

0110

06

101001

4.32

7

0111

07

101010

4.34

8

1000

08

101011

4.36

9

1001

09

101100

4.38

10

1010

0A

101101

4.40

11

1011

0B

101110

4.42

12

1100

0C

101111

4.44

13

1101

0D

110000

4.44

14

1110

0E

110001

4.44

15

1111

0F

110010

4.44

Special Charger

The FAN54015 has additional functionality to limit input

current in case a current-limited “special charger” is

supplying VBUS. These slowly increase the charging current

Table 9. I

Bits (REG6[6:4])

SAFE

(I

OCHARGE

Limit) as Function of ISAFE

until either:

I

INLIM

or I

OCHARGE

is reached

or

V

If V

BUS

BUS=VSP

.

collapses to VSP when the current is ramping up, the

FAN54015 charge with an input current that keeps

V

BUS=VSP

. When the VSP control loop is limiting the charge

current, the SP bit (REG5[4]) is set.

Table 8. VSP as Function of SP Bits (REG5[2:0])

Safety Settings

FAN54015 contain a SAFETY register (REG6) that prevents

the values in OREG (REG2[7:2]) and IOCHARGE

(REG4[6:4]) from exceeding the values of the VSAFE and

ISAFE values.

After V

with its default value and may be written only before any

other register is written. The entire desired Safety register

value should be written twice to ensure the register bits are

set. After writing to any other register, the SAFETY register

is locked until V

The ISAFE (REG6[6:4]) and VSAFE (REG6[3:0]) registers

establish values that limit the maximum values of I

and V

write a value higher than VSAFE or ISAFE to OREG or

IOCHARGE, respectively; the VSAFE, ISAFE value appears

as the OREG, IOCHARGE register value, respectively.

exceeds V

BAT

falls below V

BAT

used by the control logic. If the host attempts to

OREG

, the SAFETY register is loaded

SHORT

.

SHORT

OCHARGE

Table 10. V

SAFE

(V

Limit) as Function of VSAFE

OREG

Bits (REG6[3:0])

Thermal Regulation and Protection

When the IC’s junction temperature reaches T

120°C), the charger reduces its output current to 550 mA to

prevent overheating. If the temperature increases beyond

T

SHUTDOWN

to 101, and STAT is pulsed HIGH. In Suspend Mode, all

timers stop and the state of the IC’s logic is preserved.

Charging resumes at programmed current after the die

cools to about 120°C.

; charging is suspended, the FAULT bits are set

(about

CF

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN54015 • Rev. 1.0.2 23

FAN54015 — USB-Compliant Single-Cell Li-Ion Switching Charger with USB-OTG Boost Regulator

Power (W)

JA

0.504

54°C/W

0.844

50°C/W

1.506

46°C/W

EN_STAT

Charge State

STAT Pin

0 X OPEN

X

Normal Conditions

OPEN

1

Charging

LOW

X

Fault (Charging or Boost)

128s Pulse,

then OPEN

Additional JA data points, measured using the FAN54015

evaluation board, are given in Table 11 (measured with

TA=25°C). Note that as power dissipation increases, the

effective JA decreases due to the larger difference between

the die temperature and ambient.

Battery Detection During Charging

The IC can detect the presence, absence, or removal of a

battery if the termination bit (TE) is set. During normal

charging, once V

is close to V

BAT

and the termination

OREG

charge current is detected, the IC terminates charging and

sets the STAT bits to 10. It then turns on a discharge current,

Table 11. Evaluation Board Measured JA

I

DETECT

, for t

DETECT

. If V

is still above V

BAT

OREG

– V

RCH

, the

battery is present and the IC sets the FAULT bits to 000. If

V

is below V

BAT

OREG

– V

, the battery is absent and the IC:

RCH

1. Sets the registers to their default values.

2. Sets the FAULT bits to 111.

Charge Mode Input Supply Protection

Sleep Mode

When V

V

IN(MIN),

draining into VBUS. During Sleep Mode, reverse current is

falls below V

BUS

BAT

+ V

, and V

SLP

is above

BUS

the IC enters Sleep Mode to prevent the battery from

3. Resumes charging with default values after t

Battery Short-Circuit Protection

If the battery voltage is below the short-circuit threshold

(V

); a linear current source, I

SHORT

V

BAT

> V

SHORT

.

SHORT

, supplies V

System Operation with No Battery

INT

.

until

BAT

disabled by body switching Q1.

The FAN54015 continues charging after VBUS POR with the

Input Supply Low-Voltage Detection

The IC continuously monitors VBUS during charging. If V

falls below V

IN(MIN)

, the IC:

BUS

1. Terminates charging

2. Pulses the STAT pin, sets the STAT bits to 11, and sets

the FAULT bits to 011.

If V

recovers above the V

BUS

t

(about two seconds), the charging process is repeated.

INT

rising threshold after time

IN(MIN)

This function prevents the USB power bus from collapsing or

oscillating when the IC is connected to a suspended USB

port or a low-current-capable OTG device.

Input Over-Voltage Detection

When the V

exceeds VBUS

BUS

, the IC:

OVP

1. Turns off Q3

2. Suspends charging

3. Sets the FAULT bits to 001, sets the STAT bits to 11,

and pulses the STAT pin.

When V

cleared and charging resumes after V

falls about 150 mV below VBUS

BUS

, the fault is

OVP

is revalidated (see

BUS

VBUS POR / Non-Compliant Charger Rejection).

VBUS Short While Charging

If VBUS is shorted with a very low impedance while the IC is

charging with I

=100 mA, the IC may not meet

INLIMIT

datasheet specifications until power is removed. To trigger

this condition, V

must be driven from 5 V to GND with a

BUS

high slew rate. Achieving this slew rate requires a 0 short

to the USB cable less than 10cm from the connector.

Charge Mode Battery Detection & Protection

VBAT Over-Voltage Protection

The OREG voltage regulation loop prevents V

BAT

from

default parameters, regulating the V

the host processor issues commands or the 15-minute timer

line to 3.54 V until

BAT

expires. In this way, the FAN54015 can start the system

without a battery.

The FAN54015 soft-start function can interfere with the

system supply with battery absent. The soft-start activates

whenever V

OREG

, I

INLIM

, or I

OCHARGE

are set from a lower to

higher value. During soft-start, the IIN limit drops to 100 mA

for about 1ms unless I

is set to 11 (no limit). This could

INLIM

cause the system processor to fail to start. To avoid this

behavior, use the following sequence.

1. Set the OTG pin HIGH. When VBUS is plugged in, I

is set to 500 mA until the system processor powers up

and can set parameters through I2C.

2. Program the Safety Register.

3. Set I

to 11 (no limit).

INLIM

4. Set OREG to the desired value (typically 4.18).

5. Reset the IO_LEVEL bit, then set IOCHARGE.

6. Set I

to 500mA if a USB source is connected.

INLIM

During the initial system startup, while the charger IC is

being programmed, the system current is limited to 500mA

for 1ms during steps 4 and 5. This is the value of the softstart ICHARGE current used when I

is set to No Limit.

INLIM

If the system is powered up without a battery present, the

CV bit should be set. When a battery is inserted, the CV bit

is cleared.

Charger Status / Fault Status

The STAT pin indicates the operating condition of the IC and

provides a fault indicator for interrupt driven systems.

Table 12. STAT Pin Function

INLIM

overshooting the OREG voltage by more than 50 mV when

the battery is removed. When the PWM charger runs with no

battery, the TE bit is not set and a battery is inserted that is

charged to a voltage higher than V

; PWM pulses stop. If

OREG

no further pulses occur for 30 ms, the IC sets the FAULT bits

to 100, sets the STAT bits to 11, and pulses the STAT pin.

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN54015 • Rev. 1.0.2 24

FAN54015 — USB-Compliant Single-Cell Li-Ion Switching Charger with USB-OTG Boost Regulator

Fault Bit

Fault Description

B2

B1

B0

0 0 0

Normal (No Fault)

0 0 1

VBUS OVP

0 1 0

Sleep Mode

0 1 1

Poor Input Source

1 0 0

Battery OVP

1 0 1

Thermal Shutdown

1 1 0

Timer Fault

1 1 1

No Battery

Charging

DISABLE Pin

HZ_MODE

ENABLE

0 0 0

DISABLE

X 1 X

DISABLE

X X 1

DISABLE

1 X X

HZ_MODE

OPA_MODE

FAULT

Operation Mode

0 0 0

Charge 0 X

1

Charge Configure

0 1 0

Boost 1 X

X

High Impedance

OTG_EN

OTG

Pin

HZ_

MODE

OPA_

MODE

BOOST

1 X X Enabled

X X 0 1 Enabled

X X

0

Disabled

0 X 1 X Disabled

1 1 1 Disabled

0 0 0 Disabled

CECECE

CE

CE

CE

ACTIVE

ACTIVE

ACTIVE

ACTIVE

The FAULT bits (R0[2:0]) indicate the type of fault in Charge

Mode (see Table 13).

Table 15. Operation Mode Control

Table 13. Fault Status Bits During Charge Mode

The IC resets the OPA_MODE bit whenever the boost is

deactivated, whether due to a fault or being disabled by

setting the HZ_MODE bit.

Boost Mode

Boost Mode can be enabled if the IC is in 32-Second Mode

with the OTG pin and OPA_MODE bits as indicated in Table

16. The OTG pin ACTIVE state is 1 if OTG_PL=1 and 0

when OTG_PL=0.

Charge Mode Control Bits

Setting either HZ_MODE or through I2C disables the

charger and puts the IC into High-Impedance Mode and

resets t

t

32S

(except SAFETY) reset, which enables t

versions with the 15-minute timer.

When t

enters High-Impedance Mode. If was set by t

overflow, a new charge cycle can only be initiated through

I2C or VBUS POR.

Setting the RESET bit clears all registers. If HZ_MODE or

also cleared, but the t

remains in High-Impedance Mode.

Table 14. DISABLE Pin and Bit Functionality

32S

. If V

BAT

< V

while in High-Impedance Mode,

LOWV

begins running and, when it overflows, all registers

charging on

15MIN

overflows, the IC sets the bit and the IC

15MIN

15MIN

bits were set when the RESET bit is set, these bits are

timer is not started, and the IC

32S

If boost is active using the OTG pin, Boost Mode is initiated

even if the HZ_MODE=1. The HZ_MODE bit overrides the

OPA_MODE bit.

Table 16. Enabling Boost

To remain in Boost Mode, the TMR_RST must be set by the

host before the t

Mode; the IC resets all registers, pulses the STAT pin, sets

the FAULT bits to 110, and resets the BOOST bit. VBUS

POR or reading R0 clears the fault condition.

timer times out. If t

32S

times out in Boost

32S

Raising the DISABLE pin stops t

does not reset it. If the DISABLE pin is raised during t

charging, the t

Operational Mode Control

OPA_MODE (REG1[0]) and the HZ_MODE (REG1[1]) bits in

conjunction with the FAULT state define the operational

mode of the charger.

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN54015 • Rev. 1.0.2 25

timer is reset.

15MIN

from advancing, but

32S

15MIN

Boost PWM Control

The IC uses a minimum on-time and computed minimum offtime to regulate VBUS. The regulator achieves excellent

transient response by employing current-mode modulation.

This technique causes the regulator to exhibit a load line.

During PWM Mode, the output voltage drops slightly as the

input current rises. With a constant V

constant output resistance.

The “droop” caused by the output resistance when a load is

applied allows the regulator to respond smoothly to load

transients with no undershoot from the load line. This can be

seen in Figure 31 and Figure 40.

, this appears as a

BAT

FAN54015 — USB-Compliant Single-Cell Li-Ion Switching Charger with USB-OTG Boost Regulator

LOADOUTOUT

IR07.5V

EQ. 1

V018.52.026.007.5V

OUT

EQ. 1A

V005.52.0327.007.5V

OUT

EQ. 1B

Mode

Description

Invoked When

LIN

Linear Startup

V

BAT

> V

BUS

SS

Boost Soft-Start

V

BUS

< V

BST

BST

Boost Operating Mode

V

BAT

> UVLO

BST

and

SS Completed

Fault Bit

Fault Description

B2

B1

B0

0 0 0

Normal (no fault)

0 0 1

V

BUS

> VBUS

OVP

0 1 0

V

BUS

fails to achieve the voltage required to

advance to the next state during soft-start

or sustained (>50 s) current limit during the

BST state.

0 1 1

V

BAT

< UVLO

BST

1 0 0

N/A: This code does not appear.

1 0 1

Thermal shutdown

1 1 0

Timer fault; all registers reset.

1 1 1

N/A: This code does not appear.

200

225

250

275

300

325

350

2.0 2.5 3.0 3.5 4.0 4.5 5.0

Battery Voltage, VBAT (V)

Output Resistance (m

W

)

OUT

IN

V

V

SS State

When PMID > V

switching with a reduced peak current limit of about 50% of

its normal current limit. The output slews up until V

within 5% of its setpoint; at which time, the regulation loop is

closed and the current limit is set to 100%.

If the output fails to achieve 95% of its setpoint (V

128 s, the current limit is increased to 100%. If the output

fails to achieve 95% of its setpoint after this second 384s

period, a fault state is initiated.

– 400 mV, the boost regulator begins

BAT

BST

is

BUS

) within

BST State

This is the normal operating mode of the regulator. The

Figure 40. Output Resistance (R

OUT

)

V

as a function of I

BUS

can be computed when the

LOAD

regulator is in PWM Mode (continuous conduction) as:

At V

=3.3 V, and I

BAT

=200 mA, V

LOAD

would drop to:

BUS

regulator uses a minimum t

scheme. The minimum t

OFF

keeps the regulator’s switching frequency reasonably

constant in CCM. t

ON(MIN)

higher value if the inductor current reached 0 before t

in the prior cycle.

To ensure the VBUS does not pump significantly above the

regulation point, the boost switch remains off as long as

FB > V

REF

.

-minimum tON modulation

OFF

is proportional to , which

is proportional to V

and is a

BAT

OFF(MIN)

At V

=2.7 V, and I

BAT

=200 mA, V

LOAD

would drop to:

BUS

PFM Mode

If V

> VREF

BUS

(nominally 5.07 V) when the minimum

BOOST

off-time has ended, the regulator enters PFM Mode. Boost

pulses are inhibited until V

< VREF

BUS

. The minimum

BOOST

on-time is increased to enable the output to pump up

sufficiently with each PFM boost pulse. Therefore the

regulator behaves like a constant on-time regulator, with the

bottom of its output voltage ripple at 5.07 V in PFM Mode.

Table 17. Boost PWM Operating States

Startup

When the boost regulator is shut down, current flow is

prevented from V

V

BUS

to V

BAT

.

BAT

to V

, as well as reverse flow from

BUS

Boost Faults

If a BOOST fault occurs:

1. The STAT pin pulses.

2. OPA_MODE bit is reset.

3. The power stage is in High-Impedance Mode.

4. The FAULT bits (REG0[2:0]) are set per Table 18.

Restart After Boost Faults

If boost was enabled with the OPA_MODE bit and

OTG_EN=0, Boost Mode can only be enabled through

subsequent I2C commands since OPA_MODE is reset on

boost faults. If OTG_EN=1 and the OTG pin is still ACTIVE

(see Table 16), the boost restarts after a 5.2 ms delay, as

shown in Figure 41. If the fault condition persists, restart is

attempted every 5ms until the fault clears or an I2C

command disables the boost.

Table 18. Fault Bits During Boost Mode

LIN State

When EN rises, if V

attempts to bring PMID within 400 mV of V

internal 450 mA current source from VBAT (LIN State). If

PMID has not achieved V

FAULT state is initiated.

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN54015 • Rev. 1.0.2 26

BAT

> UVLO

BAT

, the regulator first

BST

using an

BAT

– 400 mV after 560 s, a

FAN54015 — USB-Compliant Single-Cell Li-Ion Switching Charger with USB-OTG Boost Regulator

BIT#

NAME

STATE

Active When

0

1

MONITOR Address 10H

7

ITERM_CMP

V

CSIN

– V

BAT

< V

ITERM

V

CSIN

– V

BAT

> V

ITERM

Charging with TE=1

V

CSIN

– V

BAT

< 1 mV

V

CSIN

– V

BAT

> 1mV

Charging with TE=0

6

VBAT_CMP

V

BAT

< V

SHORT

V

BAT

> V

SHORT

Charging

V

BAT

< V

LOWV

V

BAT

> V

LOWV

High-Impedance Mode

V

BAT

< UVLO

BST

V

BAT

> UVLO

BST

Boosting

5

LINCHG

Linear Charging Not Enabled

Linear Charging Enabled

Charging

4

T_120

TJ < 120°C

TJ > 120°C

3

ICHG

Charging Current Controlled by

I

CHARGE

Control Loop

Charging Current Not Controlled by

I

CHARGE

Control Loop

Charging

2

IBUS

I

BUS

Limiting Charging Current

Charge Current Not Limited by I

BUS

Charging

1

VBUS_VALID

V

BUS

Not Valid

V

BUS

is Valid

V

BUS

> V

BAT

0

CV

Constant Current Charging

Constant Voltage Charging

Charging

450mA

VBUS

BATTERY

CURRENT

0

560

BOOST

0

64

5200

can supply up to 2 mA. This circuit, which is powered from

PMID, is enabled only when PMID > V

current from the battery. During boost, V

off when the HZ_MODE bit (REG1[1])=1.

and does not drain

BAT

is off. It is also

REG

Monitor Register (Reg10H)

Additional status monitoring bits enable the host processor

Figure 41. Boost Response Attempting to Start into V

BUS

Short Circuit (Times in s)

VREG Pin

The 1.8 V regulated output on this pin can be disabled

through I2C by setting the DIS_VREG bit (REG5[6]). VREG

Table 19. MONITOR Register Bit Definitions

to have more visibility into the status of the IC. The monitor

bits are real-time status indicators and are not internally

debounced or otherwise time qualified.

The state of the MONITOR register bits listed in HighImpedance Mode is only valid when V

is valid.

BUS

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN54015 • Rev. 1.0.2 27

FAN54015 — USB-Compliant Single-Cell Li-Ion Switching Charger with USB-OTG Boost Regulator

Part Type

7 6 5 4 3 2 1

0

FAN54015

1 1 0 1 0 1 0

Symbol

Definition

S

START, see Figure 43

A

ACK. The slave drives SDA to 0 to acknowledge

the preceding packet.

NACK. The slave sends a 1 to NACK the

preceding packet.

R

Repeated START, see Figure 45

P

STOP, see Figure 44. Figure 44

WR/

SCL

T

SU

T

H

SDA

Data change allowed

SCL

T

HD;STA

SDA

Slave Address

MS Bit

SCL

SDA

Slave Releases Master Drives

ACK(0) or

NACK(1)

t

HD;STO

SCL

SDA

ACK(0) or

NACK(1)

Slave Releases

SLADDR

MS Bit

t

HD;STA

t

SU;STA

Master Drives Bus

Slave Drives Bus

A

I2C Interface

The FAN54015’s serial interface is compatible with

Standard, Fast, Fast Plus, and High-Speed Mode I2C-Bus®

specifications. The SCL line is an input and the SDA line is a

bi-directional open-drain output; it can only pull down the bus

when active. The SDA line only pulls LOW during data reads

and signaling ACK. All data is shifted in MSB (bit 7) first.

Slave Address

Table 20. I2C Slave Address Byte

In hex notation, the slave address assumes a 0 LSB. The

hex slave address for the FAN54015 is D4H and is D6H for

all other parts in the family.

Bus Timing

As shown in Figure 42, data is normally transferred when

SCL is LOW. Data is clocked in on the rising edge of SCL.

Typically, data transitions shortly at or after the falling edge

of SCL to allow ample time for the data to set up before the

next SCL rising edge.

During a read from the FAN54015 (Figure 46, Figure 47), the

master issues a Repeated Start after sending the register

address and before resending the slave address. The

Repeated Start is a 1-to-0 transition on SDA while SCL is

HIGH, as shown in Figure 45.

High-Speed (HS) Mode

The protocols for High-Speed (HS), Low-Speed (LS), and

Fast-Speed (FS) Modes are identical except the bus speed for

HS Mode is 3.4 MHz. HS Mode is entered when the bus

master sends the HS master code 00001XXX after a start

condition. The master code is sent in Fast or Fast Plus Mode

(less than 1 MHz clock); slaves do not ACK this transmission.

The master then generates a repeated start condition

(Figure 45) that causes all slaves on the bus to switch to HS

Mode. The master then sends I2C packets, as described

above, using the HS Mode clock rate and timing.

The bus remains in HS Mode until a stop bit (Figure 44) is

sent by the master. While in HS Mode, packets are

separated by repeated start conditions (Figure 45).

Figure 42. Data Transfer Timing

Each bus transaction begins and ends with SDA and SCL

HIGH. A transaction begins with a START condition, which is

defined as SDA transitioning from 1 to 0 with SCL HIGH, as

shown in Figure 43.

Figure 43. Start Bit

A transaction ends with a STOP condition, which is defined

as SDA transitioning from 0 to 1 with SCL HIGH, as shown

in Figure 44.

Figure 44. Stop Bit

Figure 45. Repeated Start Timing

Read and Write Transactions

The figures below outline the sequences for data read and

write. Bus control is signified by the shading of the packet,

defined as and .

All addresses and data are MSB first.

Table 21. Bit Definitions for Figure 46, Figure 47,

and Figure 48

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN54015 • Rev. 1.0.2 28

FAN54015 — USB-Compliant Single-Cell Li-Ion Switching Charger with USB-OTG Boost Regulator

Register

Address Bits

Name

REG#

7 6 5 4 3 2 1

0

CONTROL0

0

0 0 0 0 0 0 0

0

CONTROL1

1