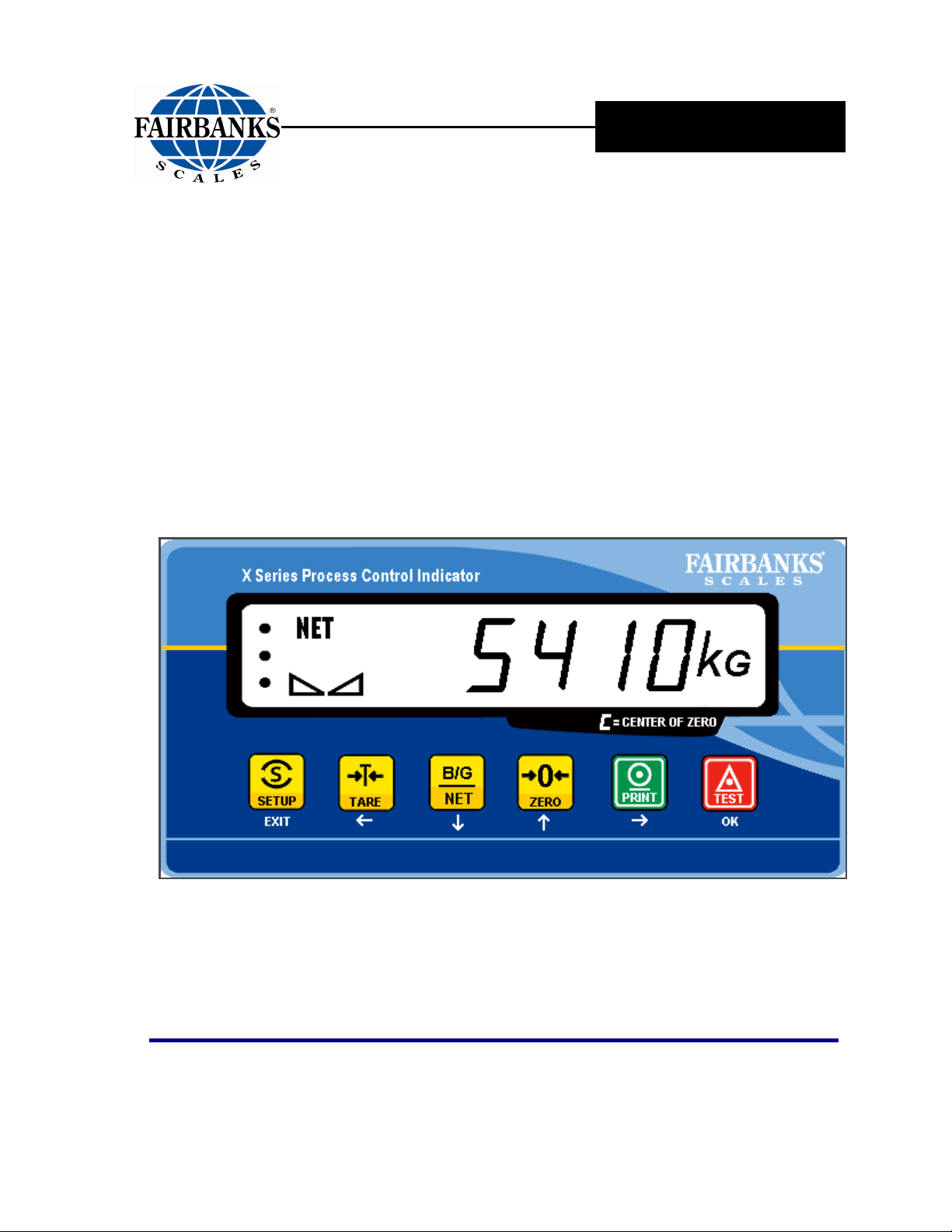

OPERATION MANUAL

X Series

Process Indicator

© 2008 by Fairbanks Scales, Inc.

All rights reserved

PR 5410

51207

Revision 1 10/08

Disclaimer

Every effort has been made to provide complete and accurate information in this

manual. However, although this manual may include a specifically identified

warranty notice for the product, Fairbanks Scales makes no representations or

warranties with respect to the contents of this manual, and reserves the right to make

changes to this manual without notice when and as improvements are made.

Fairbanks Scales shall not be liable for any loss, damage, cost of repairs, incidental

or consequential damages of any kind, whether or not based on express or implied

warranty, contract, negligence, or strict liability arising in connection with the design,

development, installation, or use of the scale.

© Copyright 2008

This document contains proprietary information protected by copyright. All rights are

reserved; no part of this manual may be reproduced, copied, translated or

transmitted in any form or by any means without prior written permission of the

manufacturer.

10/08 2 51207 Revision 1

Table of Contents

Table of Contents

1 Warnings and Safety Precautions............................................................................. 10

1.1 I

NTENDED USE

1.2 I

NITIAL INSPECTION

.........................................................................................................................10

..................................................................................................................10

1.3 B

EFORE COMMISSIONING

1.3.1 Installation 10

1.3.2 Opening the Instrument 10

1.3.3 Grounding and Shock Prevention PR 5410/00 11

1.3.4 Grounding and Shock Prevention PR 5410/01 11

1.3.5 Power Connection and Power Supply PR 5410/00 11

1.3.6 Power Connection 24 VDC PR5410/01 11

1.3.7 Failure and Excessive Stress 11

1.3.8 Important Note 11

.........................................................................................................10

2 Process Indicator ....................................................................................................... 12

2.1 O

2.2 H

2.3 D

VERVIEW OF THE INSTRUMENT

OUSING

ISPLAY AND CONTROLS

2.3.1 Display 14

2.3.2 Front-Panel Keys 14

2.3.3 Selection Using the Navigation Keys (VNC) 15

2.3.4 Tool Tip (VNC) 15

2.3.5 System Messages during Input (VNC) 16

2.3.6 Overview of Accessories 17

2.3.7 Plug-in Cards 18

..................................................................................................................................13

................................................................................................12

..........................................................................................................14

3 Installing the Instrument and Plug-in Cards ............................................................ 19

3.1 M

ECHANICAL PREPARATION

.....................................................................................................19

3.2 H

3.3 M

3.4 A

3.5 C

ARDWARE CONSTRUCTION

AIN BOARD

3.3.1 Network Port 20

3.3.2 Standard RS-232 Interface 20

3.3.3 Optocoupler Inputs 22

3.3.4 Optocoupler Outputs 23

CCESSORIES

3.4.1 Installing Plug-in Cards 24

3.4.2 Cable Connection in the D-Sub Connector Mating Plug 25

3.4.3 PR 5510/02 Serial I/O 26

3.4.4 PR 5510/04 Serial I/O 27

3.4.5 PR 5510/07 Analog Input/Output Card 31

3.4.6 PR 5510/08 BCD Output (Open Emitter) 33

3.4.7 PR 5510/09 BCD Output (Open Collector) 36

3.4.8 PR 5510/12 6 Optocoupler Inputs / 12 Optocoupler Outputs 41

3.4.9 PR 1721/31 Profibus Interface 46

3.4.10 PR 1721/32 Interbus Interface 47

3.4.11 PR 1721/34 DeviceNet Interface 48

3.4.12 PR 1721/37 EtherNet/IP Schnittstelle 49

3.4.13 PR 5510/14 ModBus TCP Interface 51

ONNECTING LOAD CELLS

3.5.1 Connecting a Load Cell with 4-Wire Cable 52

3.5.2 Connecting PR 6221 Load Cells 52

............................................................................................................................19

..........................................................................................................................24

.....................................................................................................19

.......................................................................................................52

10/08 4 51207 Revision 1

Table of Contents

3.5 C

ONNECTING LOAD CELLS, CONTINUED

3.5.3 Connecting up to 8 Load Cells (650 Ohms) Using 6-Wire Connecting Cable 53

3.5.4 Connecting Load Cells with External Supply 54

3.5.5 Connecting Load Cells via Intrinsically Safe Load Cell Interface PR 1626/60 55

3.5.6 Connecting Platforms (CAP...) 56

4 Commissioning...........................................................................................................57

4.1 D

4.2 S

4.3 C

4.4 O

4.5 C

4.6 E

4.7 C

ATA PROTECTION/POWER FAILURE

4.1.1 CAL Switch 57

WITCHING ON THE INSTRUMENT

4.2.1 Display Test 58

4.2.2 Front-Panel Key Test 58

4.2.3 Resetting the Instrument to the Factory Settings 58

4.2.4 Setting the Network Address Using Front-Panel Keys 59

4.2.5 Viewing the Network Address via Front-Panel Keys 59

4.2.6 Searching the Instrument in the Network Using 'IndicatorBrowser' 59

4.2.7 Loading New Software 60

ONFIGURATION AND CALIBRATION USING FRONT KEYS

4.3.1 Meaning of Front Keys 61

4.3.2 Entering Date and Time 61

4.3.3 Parameter Table 62

4.3.4 New Calibration using Front Keys 64

4.3.5 Subsequent Change of Deadload using Front Keys 65

4.3.6 View Calibration Data 65

4.3.7 View Calibration Data for Deadload and Maximum Load 66

4.3.8 PIN Code 66

PERATION USING A

4.4.1 Operation Using the VNC Program 67

4.4.2 Operation Using Internet Browser 68

4.4.3 INFO Function 69

4.4.4 Setup Function (VNC) 70

4.4.5 Setup Menu (VNC): Overview 70

4.4.6 Calibration Menu 71

ALIBRATION

4.5.1 Displaying Calibration Data 72

4.5.2 Selecting the Calibration Mode 73

4.5.3 Determining the Maximum Capacity (Max) 74

4.5.4 Determining the Scale Interval 75

4.5.5 Determining the Dead Load 75

4.5.6 Calibration with Weight (by Load) 76

4.5.7 Calibration with mV/V Value 77

4.5.8 Calibration with Load Cell Data (“Smart Calibration“) 78

4.5.9 Subsequent Dead Load Correction 79

4.5.10 Linearization 80

4.5.11 Test Value Determination / Display 80

4.5.12 Finishing / Saving the Calibration 81

4.5.13 Parameter Input 81

RROR MESSAGES

4.6.1 Measuring Circuit Error Messages 85

4.6.2 General Error Messages 85

ONFIGURING GENERAL PARAMETERS

4.7.1 Date and Time 86

4.7.2 Serial Ports 86

4.7.3 SMA Protocol 88

4.7.4 EW Protocol 88

4.7.5 Operating Parameters 89

4.7.6 Printing Parameters 90

...........................................................................................................................72

PC .......................................................................................................... 67

...................................................................................................................85

........................................................................................57

..............................................................................................58

...........................................................61

.....................................................................................86

10/08 5 51207 Revision 1

Table of Contents

4.7 C

4.8 L

4.9 A

4.10 A

4.11 C

4.12 MODBUS / J-BUS P

ONFIGURING GENERAL PARAMETERS, CONTINUED

4.7.7 Fieldbus Parameters 91

4.7.8 Network Parameters 92

IMIT VALUES, DIGITAL INPUTS AND OUTPUTS

4.8.1 Conditions for Limit Values and Digital Inputs, States for Outputs 93

4.8.2 Configuring Digital Inputs and Outputs 94

4.8.3 Configuring Outputs 94

4.8.4 Configuring Inputs 95

4.8.5 Configuring Limit Values 97

4.8.6 BCD Output 99

NALOG OUTPUT

4.9.1 Adapting the Analog Output 101

LIBI MEMORY

ONFIGUREIT PROFESSIONAL

4.11.1 Installation 103

4.11.2 Program Start 105

4.11.3 107

4.11.4 Transfer Dataset from Instrument to PC 108

4.11.5 Store Current Dataset on PC 108

4.11.6 Store Current Dataset or Selected Parameters in the Instrument 110

4.11.7 Reset the Instrument to Factory Default 110

4.11.8 Exporting a Dataset as Printable File 110

4.11.9 Operation of the Instrument via Browser (VNC) 111

4.11.10 Closing the Program 111

4.12.1 Communication 112

4.12.2 Function 1 or 2: Reading n Bits 113

4.12.3 Function 3 or 4: Reading n Successive Words 113

4.12.4 Function 5: Writing a Bit 114

4.12.5 Function 6: Writing a Word 114

4.12.6 Function 8: Diagnosis 115

4.12.7 Function 15: Writing n Successive Bits 115

4.12.8 Function 16: Writing n Successive Words 116

4.12.9 MODBUS / J-BUS Error Messages 116

4.12.10 MODBUS / J-BUS Word Addresses 117

...................................................................................................................100

.......................................................................................................................102

.................................................................................................103

ROTOCOL

...............................................................................................112

..........................................................................93

5 SMA Protocol............................................................................................................ 118

5.1 G

5.2 D

5.3 SMA C

5.4 SMA R

10/08 6 51207 Revision 1

ENERAL

ESCRIPTION OF USED SYMBOLS

5.3.1 Requesting a Weight 119

5.3.2 Controlling the Scale 120

5.3.3 Scale Diagnosis 121

5.3.4 Scale Data 122

5.3.5 Scale Information 122

5.3.6 Escape Command 122

5.4.1 Standard Reply 123

5.4.2 Reply with Unknown Command 124

5.4.3 Reply in Case of Communication Error 124

5.4.4 Reply with Diagnosis Command 124

5.4.5 Reply with ‘A’ and ‘B’ Command 125

5.4.6 Scale Reply with ‘I’ and ‘N’ Commands 126

5.4.7 Communication Error 126

...............................................................................................................................118

...........................................................................................118

OMMAND SET

EPLY MESSAGES

..............................................................................................................119

.........................................................................................................123

Table of Contents

6 PR 1612 Commands .................................................................................................127

6.1 Main commands for indicator function 127

6.2 Error Messages for PR 1612 Commands 127

7 Fieldbus Interface.....................................................................................................128

7.1 F

IELDBUS INTERFACE PROTOCOL

7.1.1 Write Window (Input Area) 129

7.1.2 Read Window (Output Area) 129

7.1.3 Reading and Writing Data 129

7.2 D

7.3 F

ESCRIPTION OF THE

7.2.1 Input Area 130

7.2.2 Output Area 131

7.2.3 Reading and Writing Register via Fieldbus 132

7.2.4 Example: Reading the Gross Weight 134

IELDBUS REGISTER

7.3.1 Register 0: IO Status Bits for Reading 135

7.3.2 Register 1: Scale Status 135

7.3.3 Register 2: State of State-Controlled Action Bits 136

7.3.4 Register 3: State of Edge-Controlled Action Bits 136

7.3.5 Register 4: Calibration Information, Error Byte 136

7.3.6 Register 5: Device Type and Software Release 137

7.3.7 Register 6: Board Number 137

7.3.8 Register 7: (Reserved) 137

7.3.9 Register 8 ...15: Weight Data 137

7.3.10 Register 20: Weight Data 137

7.3.11 Register 22 ... 27: Limit Values (Read/Write) 137

7.3.12 Register 30, 31: Fixed Values (Read/Write) 138

7.3.13 Register 80 ... 89: State-Controlled Action Bits (Write) 138

7.3.14 Register 112 ... 121: Transition-Controlled Action Bits (Write) 138

I/O A

...........................................................................................................................135

...........................................................................................128

REA (READ / WRITE WINDOW

).......................................................130

8 Global SPM Variables...............................................................................................139

9 Configuration print-out.............................................................................................141

10 Repairs and Maintenance.........................................................................................142

10.1 B

ATTERY FOR DATE/TIME

10.1.1 Battery Replacement 142

10.1.2 Solder Work 142

10.1.3 Cleaning 142

....................................................................................................... 142

11 Disposal.....................................................................................................................143

12 Specifications ...........................................................................................................144

12.1 I

NSTRUCTIONS FOR USE OF 'FREE SOFTWARE

12.2 G

12.3 E

ENERAL DATA

12.2.1 Backup Battery for Time/Date 144

12.2.2 Power Supply PR 5410/00 144

12.2.3 Power Supply PR 5410/01 144

FFECT OF AMBIENT CONDITIONS

12.3.1 Environmental Conditions 145

12.3.2 Electromagnetic Compatibility (EMC) 145

12.3.3 RF Interference Suppression 145

.....................................................................................................................144

..........................................................................................145

'.......................................................................144

10/08 7 51207 Revision 1

Table of Contents

12.4 W

12.5 M

12.6 U

EIGHING ELECTRONICS

12.4.1 Load Cells 145

12.4.2 Principle 146

12.4.3 Accuracy and Stability 146

12.4.4 Sensitivity 146

ECHANICAL DATA

12.5.1 Construction 146

12.5.2 Dimensions 146

12.5.3 Weight 146

SE IN LEGAL-FOR-TRADE MODE

12.6.1 Documentation for Verification on the Enclosed CD 147

12.6.2 Additional Instructions 147

........................................................................................................145

................................................................................................................146

...........................................................................................146

13 Index.......................................................................................................................... 148

10/08 8 51207 Revision 1

Section 1: Warnings and Safety Precautions

1 Warnings and Safety Precautions

This instrument has been built and tested in compliance with the safety

regulations for measuring and control instrumentation for protective class I

(protective earth connection) according to IEC 1010/ EN61010 or VDE 0411. The

instrument was in perfect condition with regard to safety features when it left the

factory. To maintain this condition and to ensure safe operation, the operator

must follow the instructions and observe the warnings in this manual.

1.1 I

NTENDED USE

The instrument is intended for use as an indicator for weighing functions. Product operation,

commissioning and maintenance must be performed by trained and qualified personnel who are

aware of and able to deal with the related hazards and take suitable measures for self-protection.

The instrument reflects the state of the art. The manufacturer does not accept any liability for

damage caused by other system components or due to incorrect use of the product.

1.2 I

NITIAL INSPECTION

Check the content of the consignment for completeness and inspect it visually for signs of damage

that may have occurred during transport. If there are grounds for rejection of the goods, a claim must

be filed with the carrier immediately and the sales or service organization must be notified.

1.3 B

EFORE COMMISSIONING

Visual inspection:

Before commissioning and after and storage or transport, inspect the instrument

visually for signs of mechanical damage.

1.3.1 Installation

The front panel of the instrument housing meets IP65. It is suitable for mounting in any position. To

ensure proper cooling of the instrument, make sure air circulation around the instrument is not

blocked. Avoid exposing the instrument to excessive heat; e.g., from direct sunlight. Ambient

conditions must be taken into account at all times. The instrument is suitable for control

cabinet/panel mounting.

1.3.2 Opening the Instrument

Working on the instrument while it is switched on may have life-threatening

consequences.

Disconnect the instrument from the supply voltage. Any time covers or parts are

removed, live parts or terminals may be exposed.

CAUTION:

DANGER OF

Capacitors in the unit may still be charged also after disconnecting the unit from

all voltage sources.

DEATH

This instrument contains electrostatic sensitive components. For this reason, an equipotential

bonding conductor must be connected when working on the open instrument (antistatic protection).

10/08 10 51207 Revision 1

Section 1: Warnings and Safety Precautions

1.3.3 Grounding and Shock Prevention PR 5410/00

The instrument must be connected to protective earth via a protective earth conductor (PE) in the

power connector. The power cable contains a protective earth conductor which must not be

interrupted inside or outside the unit (e.g., by using an extension cable that does not have a

protective earth connection). The PE conductor is connected to the back panel of the housing inside

the instrument.

1.3.4 Grounding and Shock Prevention PR 5410/01

The back panel of the housing must be connected to protective earth.

1.3.5 Power Connection and Power Supply PR 5410/00

The unit does not have a power switch and is ready for operation immediately after connecting the

supply voltage. Safe interruption of both supply voltage conductors must be provided for, either by

disconnecting the power connector or using a separate switch. The unit is equipped with a wide

range power supply and covers AC systems with a frequency of 50 Hz/60 Hz and a voltage range of

100 VAC to 240 VAC +10%/-15% automatically (without manual selection). The power supply is

protected against short circuits and overload, and switches off automatically in the event of failure.

When the electronic protection is triggered:

• Disconnect the unit from all voltage sources and wait at least one minute.

• Determine and eliminate the source of error.

• Re-connect the unit to the supply voltage.

1.3.6 Power Connection 24 VDC PR5410/01

The version PR5410/01 is designed for 24 V direct current.

The supply is done with two screw terminals (- 24V +), the instrument is protected

against wrong polarity.

The instrument is protected by a fuse in the + conductor on the back panel of the

housing.

1.3.7 Failure and Excessive Stress

If there is any reason to assume that safe operation of the instrument is no longer ensured, shut it

down and make sure it cannot be used. Safe operation is no longer ensured if any of the following is

true:

- The instrument is physically damaged

- The instrument does not function

- The instrument has been subjected to stresses beyond the tolerance limits (e.g., during storage

or transport).

1.3.8 Important Note

Make sure that the construction of the instrument is not altered to the detriment of safety. In

particular, leakage paths, air gaps (of live parts) and insulating layers must not be reduced. cannot

be held responsible for personal injury or property damage caused by an instrument repaired

incorrectly by a user or installer.

10/08 11 51207 Revision 1

Section 2: Process Indicator

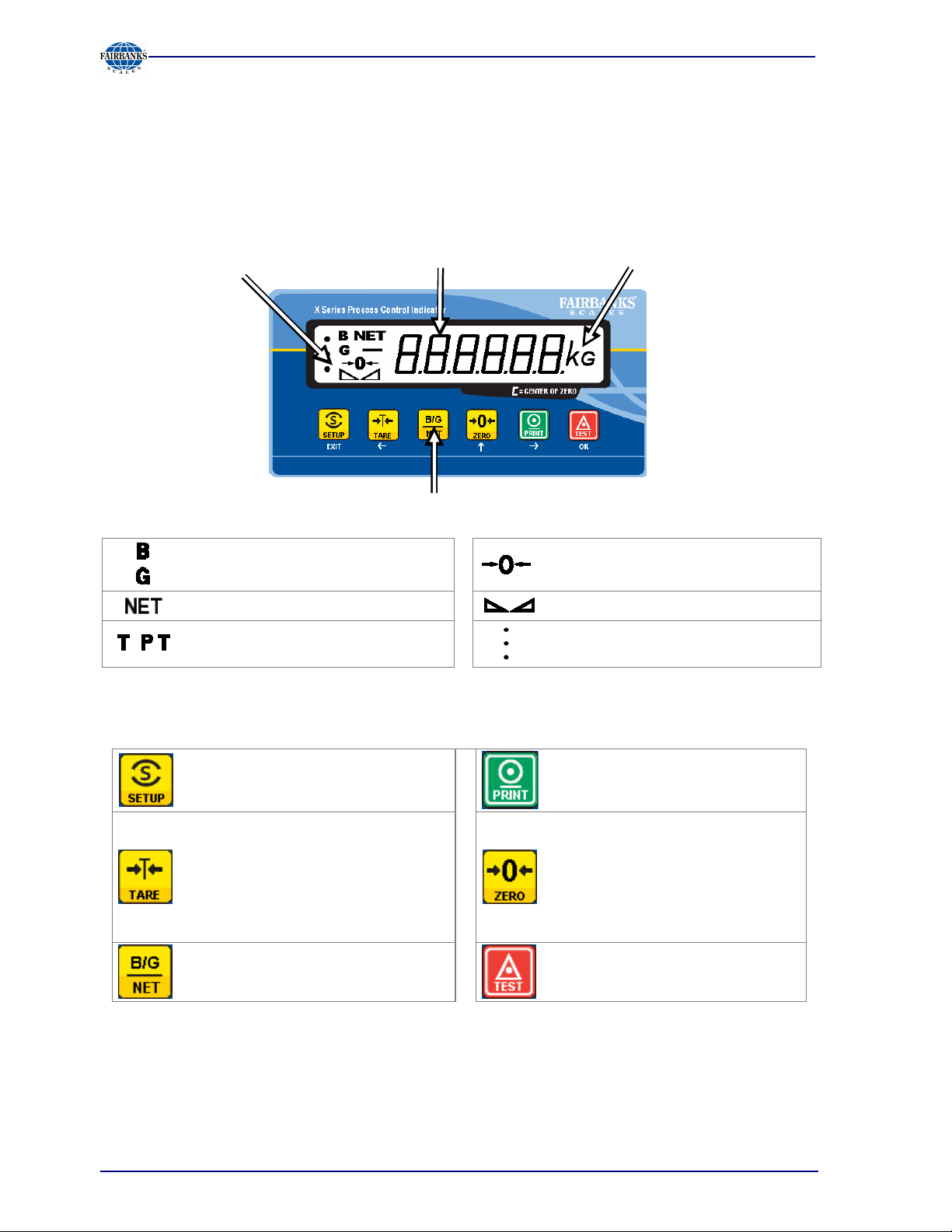

2 Process Indicator

The instrument is equipped with a six-digit 7-segment display and additional status indication. Local

operation is performed using 6 double-function keys.

2.1 O

- Accuracy 10,000 e (Class III) for the weighing electronics

- High-speed conversion with response times from 10 Msec

- Weight indication with status by transflective 6-digit 7-segment display

- 6 function keys for front-panel operation

- Front panel rated to IP 65, back panel to IP30

- LAN adapter with 10/100 Mbit/sec (built-in)

- RS-232 interface, built-in; for connecting e.g. a printer or a remote indicator

- Expansion possible by addition of plug-in circuit boards (2 slots)

- Galvanically isolated interfaces (except RS-232, analog input and BCD output)

- Wide range power supply for 100 to 240 V AC, protection class I (protective earth)

- Version PR 5410/01 for 24 VDC direct current

- Plug-in connections on the back panel for load cells, inputs/outputs, LAN adaptor

- Suitable for mounting in a panel cut-out or a control cabinet

- Calibration using front keys or PC tool (Browser/VNC)

- Calibration using weights, by entering mV/V values,

- Software configuration of the interface cards, e.g. for remote display or printer

- Analog test for the weighing electronics

Communication protocols:

For the internal RS-232 or RS-232/-485 (see Accessories):

- Remote display

- Printer, standard or legal for trade

- JBUS/MODBUS (slave)

- SMA

- Asycom

Fieldbus slave with PR 1721/3x (see Accessories):

- Profibus-DP

- Interbus-S

- DeviceNet

- EtherNet/IP

or PR 5510/14 Ethernet for Modbus TCP/IP

VERVIEW OF THE INSTRUMENT

or directly, using load cell data ("smart calibration")

10/08 12 51207 Revision 1

Section 2: Process Indicator

2.2 H

The instrument has aluminium housing and a front panel compliant with IP 65. It is suitable for

installation in a control cabinet. Keypad, display and display board form a unit with the front panel. A

square cut-out is required for installation. The cable connectors are on the back panel of the

housing. A 6-pin plug-in terminal block is provided for connection of the load cells. The built-in serial

interface has a 9-contact D-Sub female connector. Network connection is possible via the built-in

RJ-45 LAN socket. 3 Optocoupler inputs and 3 Optocoupler outputs can be connected using plug-in

terminals.

The cut-outs for up to 2 plug-in cards are covered by dummy plates.

The power cable plugs into the built-in power connector (with fuse socket).

OUSING

Front view Side view

View from the back Panel cut-out

10/08 13 51207 Revision 1

Section 2: Process Indicator

2.3 D

The display permits indication of 6-digit weight values (digit height 18 mm) with decimal point and

polarity sign.

Possible units of mass are t, kg, g or lb.

ISPLAY AND CONTROLS

2.3.1 Display

Status indication Weight value Mass unit

Front keys (Indicator / navigation)

Gross weight display

(G with NTEP or NSC mode)

Net weight display Stability of the weight value

,

2.3.2 Front-Panel Keys

Indicator keys

Tare weight or fixtare display

Instrument settings, set-up Start printing

Taring, the current gross weight is

stored in the tare memory, provided

that:

- weight value is stable

- indicator not in error status

(function dependent on configuration)

The weight value is within +/- ¼ d of

zero

Range indication

Set gross weight to zero, provided

that:

- weight value is stable

- weight within zero setting range

(function dependent on

configuration)

Selection of display mode:

gross – net – tare weight

Calibration and parameter input using front keys is described in chapter 4.3 .

10/08 14 51207 Revision 1

Analog test, weighing function

Section 2: Process Indicator

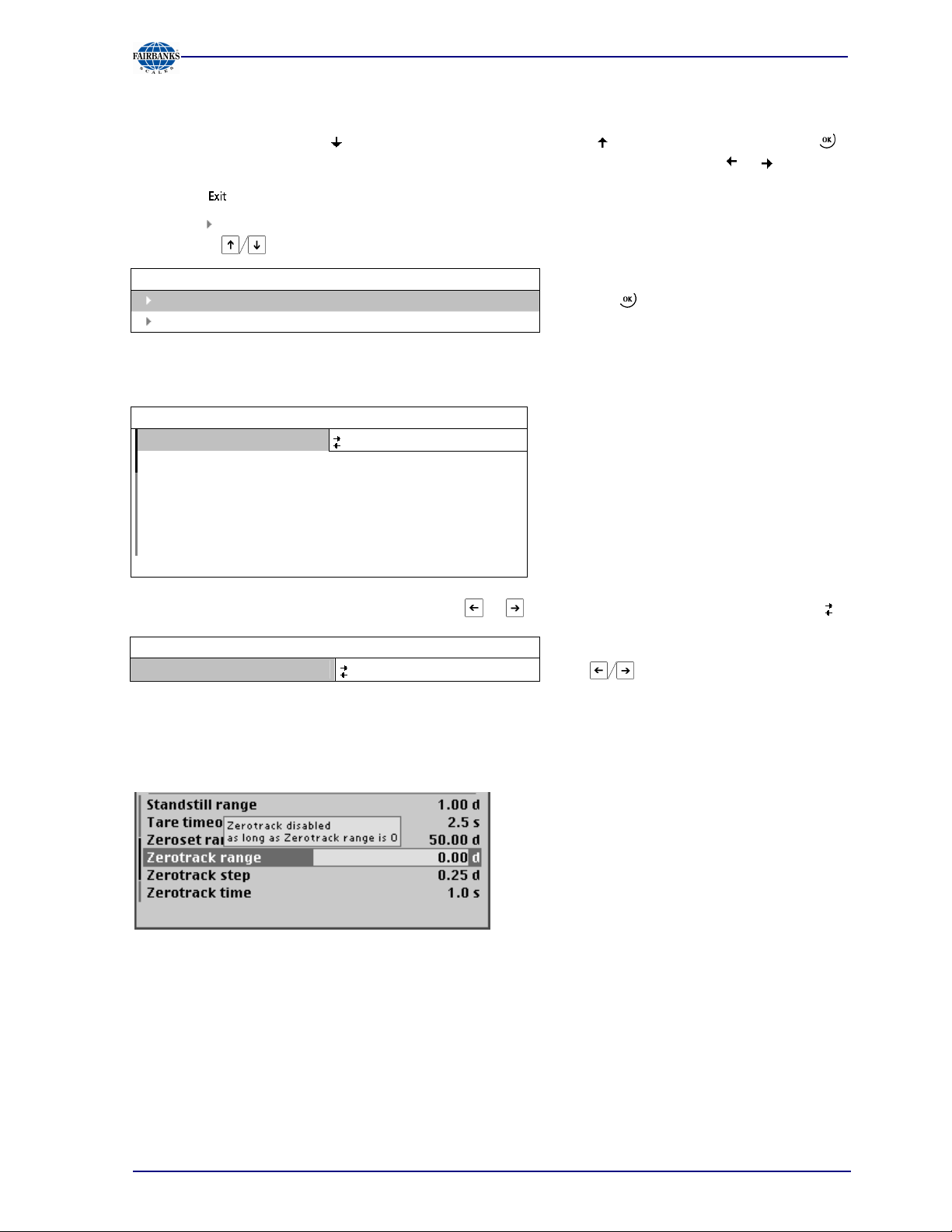

2.3.3 Selection Using the Navigation Keys (VNC)

Press the down arrow key to scroll down, or the up arrow key to scroll up in a menu. Press

to select a menu item. To choose the desired setting for the selected menu, press or .

Press the key to exit a menu and continue the operation on the next higher level.

An arrow in front of a menu item indicates that there are menu sublevels. The menu item selected

by pressing is shown inversely.

Info

Show version

Show status

If the list of menu items is long, a vertical bar graph on the left (black and gray) shows which part of

the list is displayed.

WP A/Calibration

Measuretime

320 ms

Digital filter off

Test mode absolute

W & M

none

Standstill time 0.50 s

Standstill range 1.00 d

Availability of settings options (selectable with or ) is indicated by preceding double arrows .

WP A/Calibration

Measuretime

640 ms Press to select the measuring time.

2.3.4 Tool Tip (VNC)

The 'tool tip' indicates valid value ranges or important properties in a pop-up window, see example:

Press the key to select an item.

This is a warning, that the zero tracking is not activated, if the Zerotrack time is set to 0.

10/08 15 51207 Revision 1

Section 2: Process Indicator

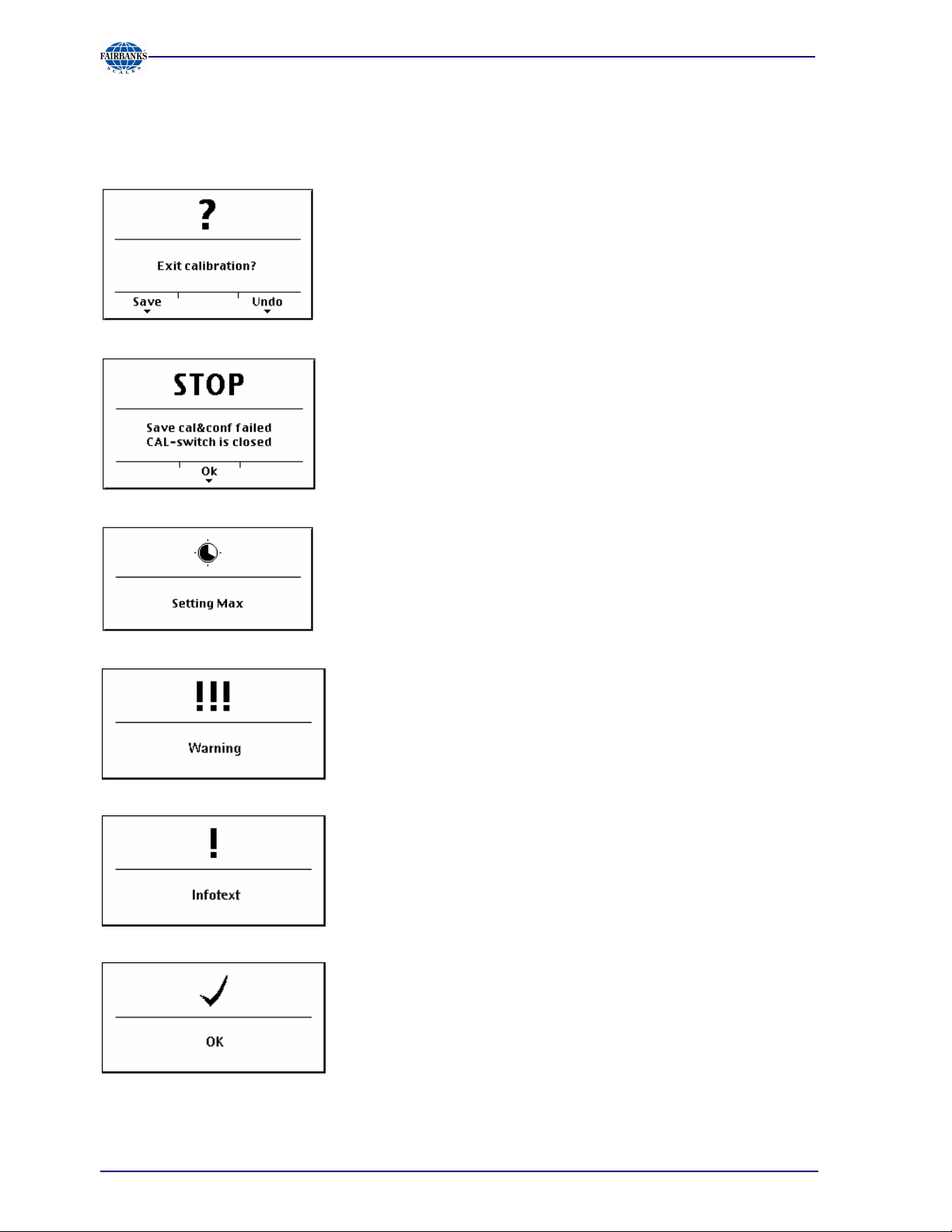

2.3.5 System Messages during Input (VNC)

The following types of messages are displayed as confirmation prompts / warnings during input:

Question mark

A question mark indicates that a choice of options (e.g. [Save] for

saving or [Undo] for cancelling) is available.

“Stop“

Processing is in progress

Warning

An important indication that an action cannot be executed (e.g., if

saving is not possible because the CAL switch is closed). Read

the description and press [OK] to continue:

If an action takes a long time (e.g., Max for setting the full scale

deflection), a clock symbol is shown.

A warning is marked by three exclamation points.

Informational text

Execution message

The graphics are not always included when system messages are depicted in this manual.

10/08 16 51207 Revision 1

An informational text is marked by one exclamation point.

Successful execution of an action is indicated by a checkmark.

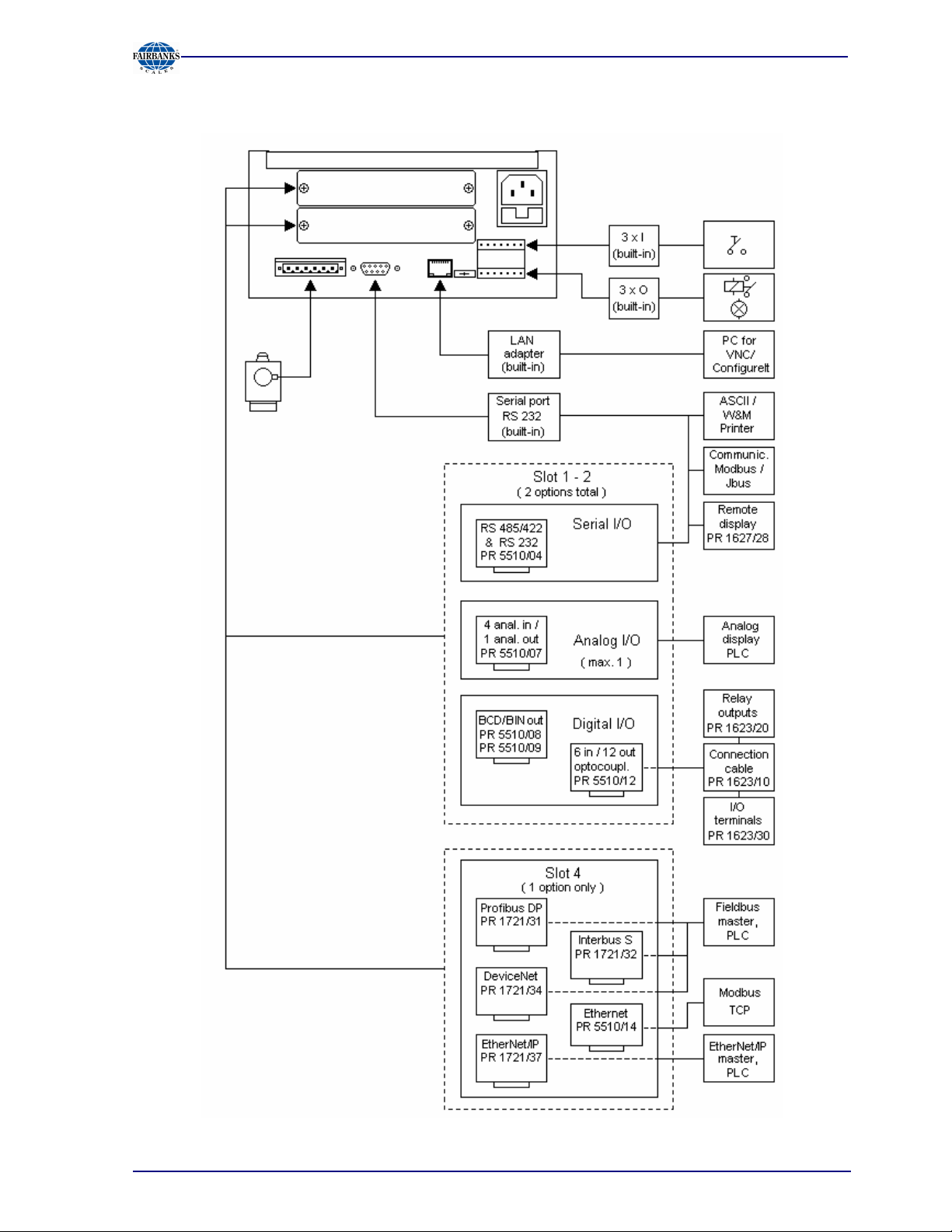

2.3.6 Overview of Accessories

Section 2: Process Indicator

10/08 17 51207 Revision 1

Section 2: Process Indicator

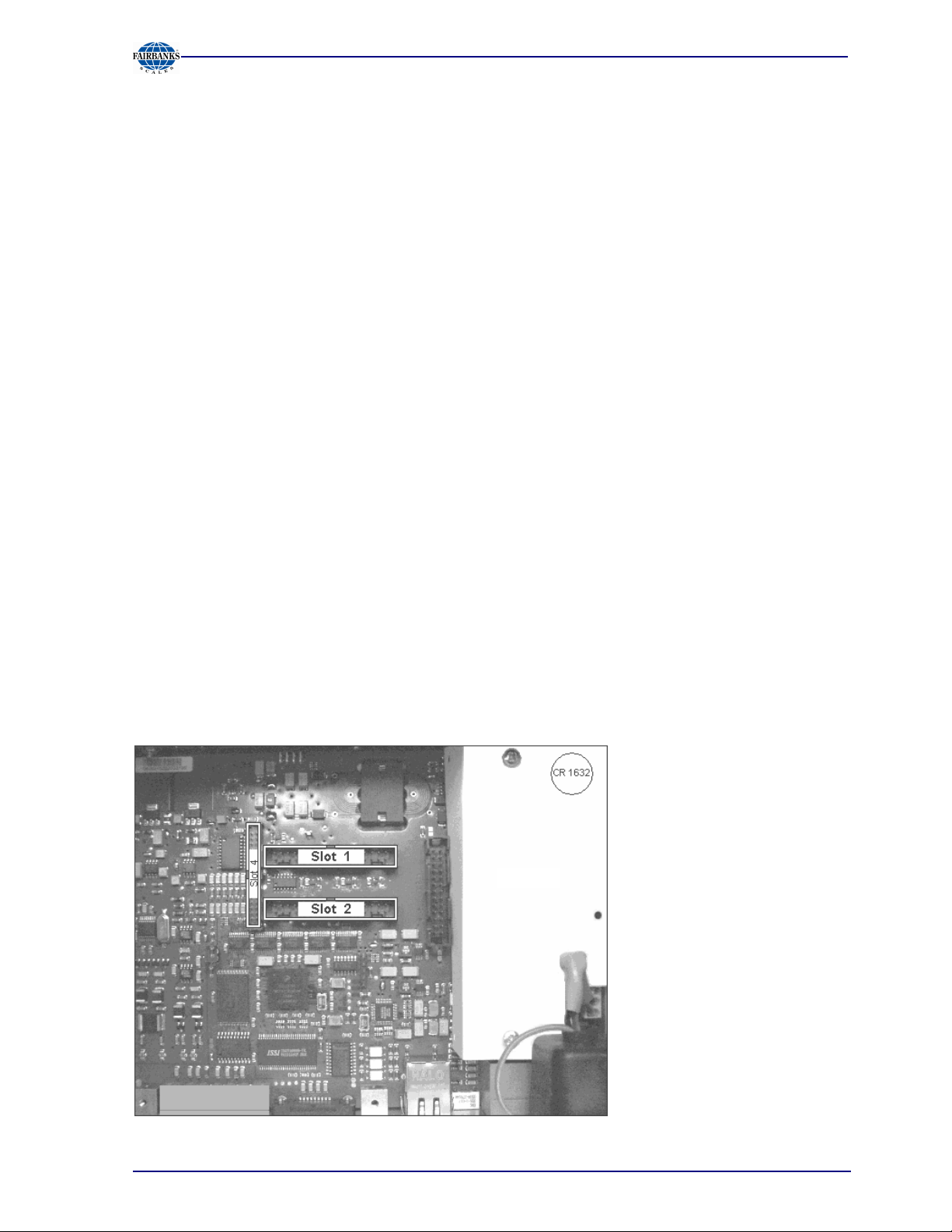

2.3.7 Plug-in Cards

On the main board, the PR 5410 Process Indicator can be fitted with up to 2 plug-in cards. Mounting

different types of cards on Slots 1 and 2 is mandatory (exception: PR 5510/04)!

If a card is fitted on Slot 4, only one more card may be mounted on Slots 1 or 2.

Product Function Position

PR 5510/02

2 serial RS-232 interfaces

PR 5510/04

1 serial RS-232 interface and

1 serial RS-485/RS-422 interface.

PR 5510/07

1 analog output,

4 analog inputs

PR 5510/08

BCD output

PR 5510/09

BCD output

PR 5510/12

6 optocoupler inputs and

12 optocoupler outputs

PR 5510/14

Ethernet

PR 1721/31

Profibus-DP slave

PR 1721/32

Interbus-S slave

PR 1721/34

DeviceNet slave

PR 1721/37

EtherNet/IP

For product details, see chapter 3.3.3 .

Protocols and parameters are adjustable

via software.

The serial RS-485/-422 interface is

configurable using DIL switches on the

card. Protocols can be selected via

software.

16-bit analog output, 0/4 - 20 mA.

Input: 4 channels with common ground,

3000 d resolution (max. 1 card)

Output: 5 decades + plus or minus sign or

3 bytes binary, open emitter. 1 input

Output: 5 decades + plus or minus sign,

or 3 bytes binary, open collector. 1 input

Digital interfaces electrically isolated via

optocouplers. Passive inputs and outputs.

10 / 100 Mbit/s Modbus TCP Slot 4

Profibus-DP to IEC 61158 with

max. 12 Mbit/s

Interbus-S slave with up to 2 Mbit/s Slot 4

DeviceNet slave with max. 500 kbit/s Slot 4

10 / 100 Mbit/s EtherNet/IP Slot 4

Slot 1 or 2

Slot 1 and/or

2

Slot 1 or 2

Slot 1 or 2

Slot 1 or 2

Slot 1 or 2

Slot 4

10/08 18 51207 Revision 1

Section 3: Installing the Instrument and Plug-In Cards

3 Installing the Instrument and Plug-in Cards

Before starting work, please read Chapter 1 and follow all instructions.

Further procedures:

• Check the consignment: unpack the components specific to the application.

• Safety check: inspect all components for damage.

• Make sure the on-site installation is correct and complete including cables, e.g. power cable fuse

protection, load cells, cable junction box, data cable, console/cabinet, etc.

• Follow the instructions for installation of the unit relating to application, safety, ventilation, sealing

and environmental influences).

• If necessary, mount the plug-in cards (instrument must be disconnected from all voltage

sources).

• Connect the cable from cable junction box or platform/load cell.

• If applicable: connect other data cables, power cable, etc.

• Connect the instrument power cable.

• Check the installation.

3.1 M

For cabinet or panel mounting, a corresponding cut-out for the housing must be provided (see

Chapter 2.2).

Have all required parts, technical documents and tools at hand for mounting. Secure the cable at

the place of installation; e.g., using cable ties. Remove the insulation from the cable ends, keep the

strands short and fit them with ferrules.

3.2 H

The electronics are contained on two printed circuit boards: the main board and the display board.

The display board is connected to the main board by a plug.

3.3 M

ECHANICAL PREPARATION

ARDWARE CONSTRUCTION

AIN BOARD

The lithium battery (under the

cover for the power supply) is

always activated and energizes

the calendar/clock module.

The main board holds the power

supply and Slots 1, 2 and 4 for

additional cards.

Load cell connector, serial

interface, LAN adaptor, CAL

switch as well as 3 inputs and

outputs are accessible on the

back panel.

Load cell

connector

10/08 19 51207 Revision 1

RS-232

LAN

CAL

3 inputs

3 outputs

45 socket on back panel of housing

Section 3: Installing the Instrument and Plug-In Cards

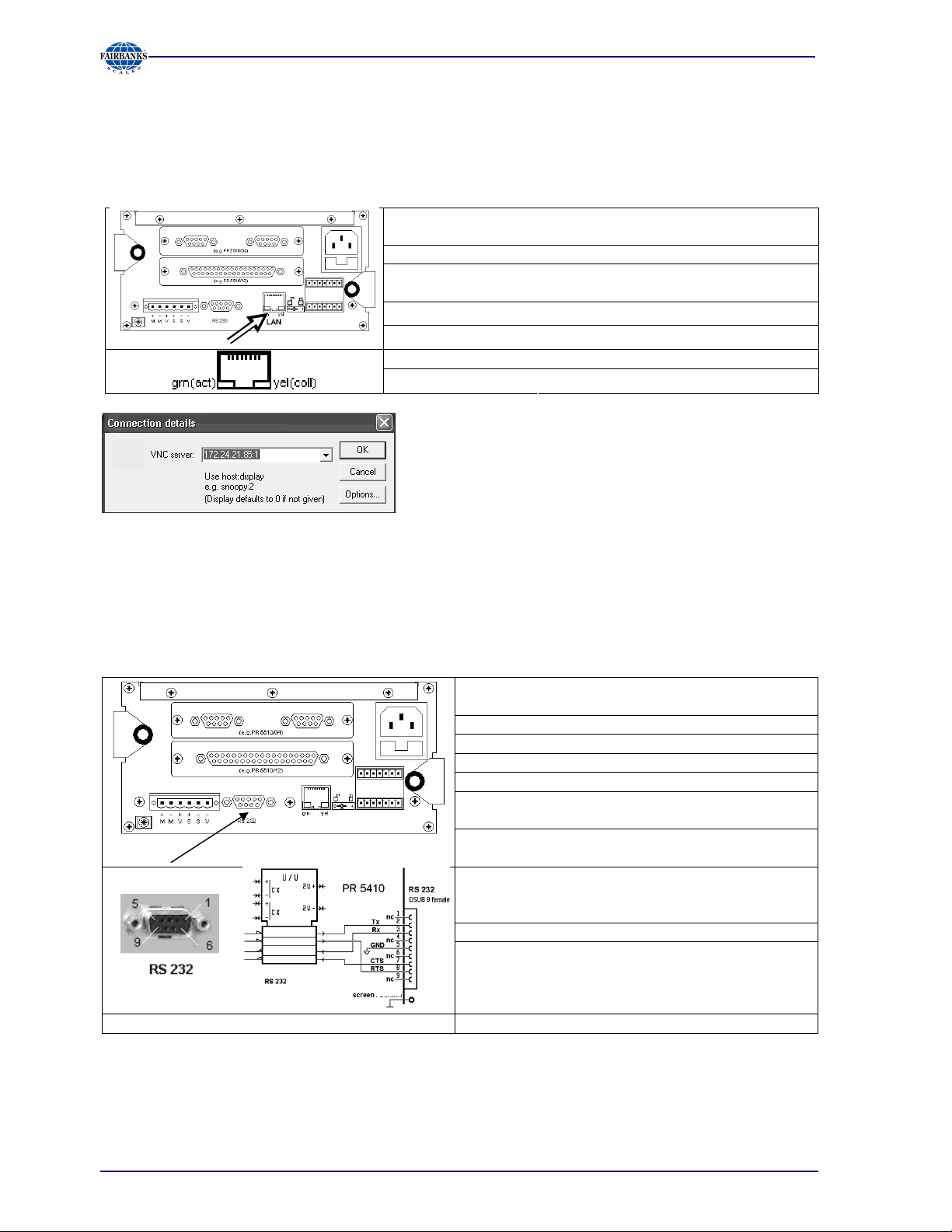

3.3.1 Network Port

The network port is built in as standard equipment. The port contains powerful TCP/IP connection

circuitry with transfer rates of 10 or 100 Mbit/sec. The LEDs on the connector indicate whether the

port is functioning.

Transfer rate: 10 Mbit/s, 100Mbit/s,

full / half duplex, auto-detection

Connection method: Point to point

Cable: CAT 5 patch cable, shielded twisted

pair

Cable impedance: 150 ohms

Electrical isolation: Yes

Cable length : Max. 115 m

Connection : RJ-

Remote operation of the PR 5410 indicator from the PC

is possible; install version 3.3.7 VNC program on the

PC. For setting the network address, see Chapter

4.2.4.

3.3.2 Standard RS-232 Interface

The instrument is provided with a built-in RS-232 interface that is accessible on the back panel of

the housing. This interface is configurable, and can be used, for example, for data transmission to

a remote display or a printer.

Number of

1

channels:

Type: RS-232, full duplex

Transfer rate: 300 to 115K2 bit/s

Parity: none, odd, even

Data bits: 7 / 8 bits

Input signal level: logic 1 (high) - 3 ... - 15 V

logic 0 (low) + 3 ... + 15 V

Output signal level: logic 1 (high) - 5 ... - 15 V

logic 0 (low) + 5 ... + 15 V

Number of signals: 2 output signals (TXD,

RTS)

2 input signals (RXD, CTS)

Electrical isolation: none

Cable type: shielded twisted pair

(e.g. LifYCY 3x2x0,20),

1 pair of wires for GND

Connection: 9-pin D-Sub socket (female) Cable length: max. 15 m

10/08 20 51207 Revision 1

Section 3: Installing the Instrument and Plug-In Cards

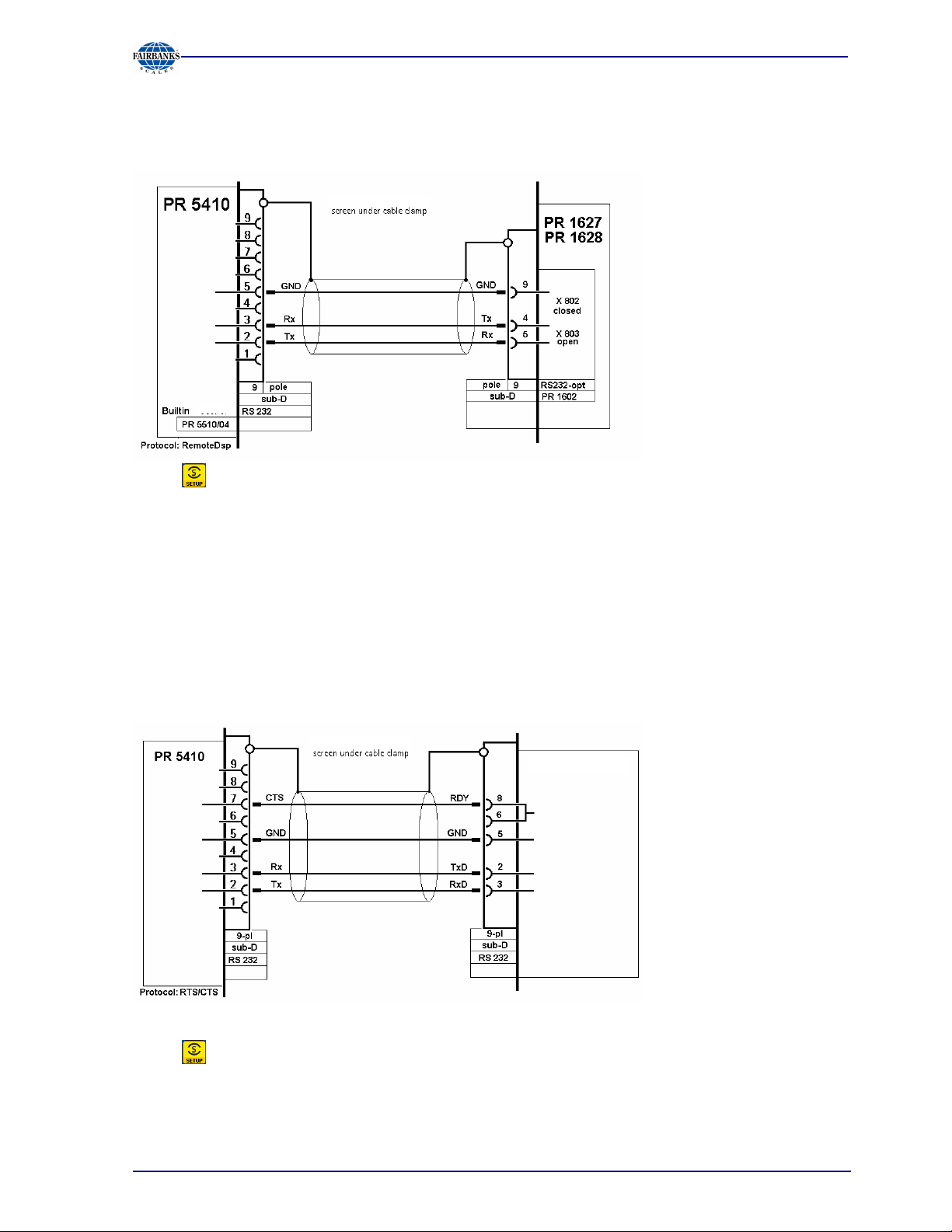

Connecting a Remote Display / Remote Terminal

A PR 1627 remote display or a PR 1628 remote terminal can be connected to the built-in RS-232

interface [Builtin RS232] or to the PR 5510/04 card.

Press -[Serial ports parameters]-[Remote display]-[Builtin RS232]-[Param] and select

[Baudrate] 4800. The baud rate now corresponds to the default settings of PR 1627 or PR 1628.

The following settings cannot be changed: [Bits] 7, [Parity] even and [Stopbits] 1.

If only one instrument is connected to a PR1627/8, [Mode] must be [single transmitter].

When connecting several instruments to a PR 1628 via an RS-232/RS-485 converter, selection for

display on PR 1628 is possible using addresses. For this purpose, select [multiple transmitters] as

[Mode] in all instruments, enter the instrument address under [Device Id] and the address of the

subsequent instrument under [Next Device Id].

Connecting a YDP12IS or YDP04IS Ticket Printer

The ticket printer YDP12IS-OCEUV or YDP04IS-OCEUV can be connected via [Builtin RS232]

interface or the RS-232 on card PR 5510/04.

If the printer is connected to the [Builtin RS232] port:

Press -[Serial ports parameter]-[Printer]-[Builtin RS232]-[Param] and configure the following

settings under [Protocol]: [RTS/CTS], [Baudrate]: 9600, [Bits]: 8, [Parity]: [none], [Stopbits]: 1 and

[Output mode]: [Raw].

The printer must be set to Line Mode (factory setting: Page Mode). Press the 'FEED' button to

change modes; please refer to the installation instructions delivered with the printer.

10/08 21 51207 Revision 1

Section 3: Installing the Instrument and Plug-In Cards

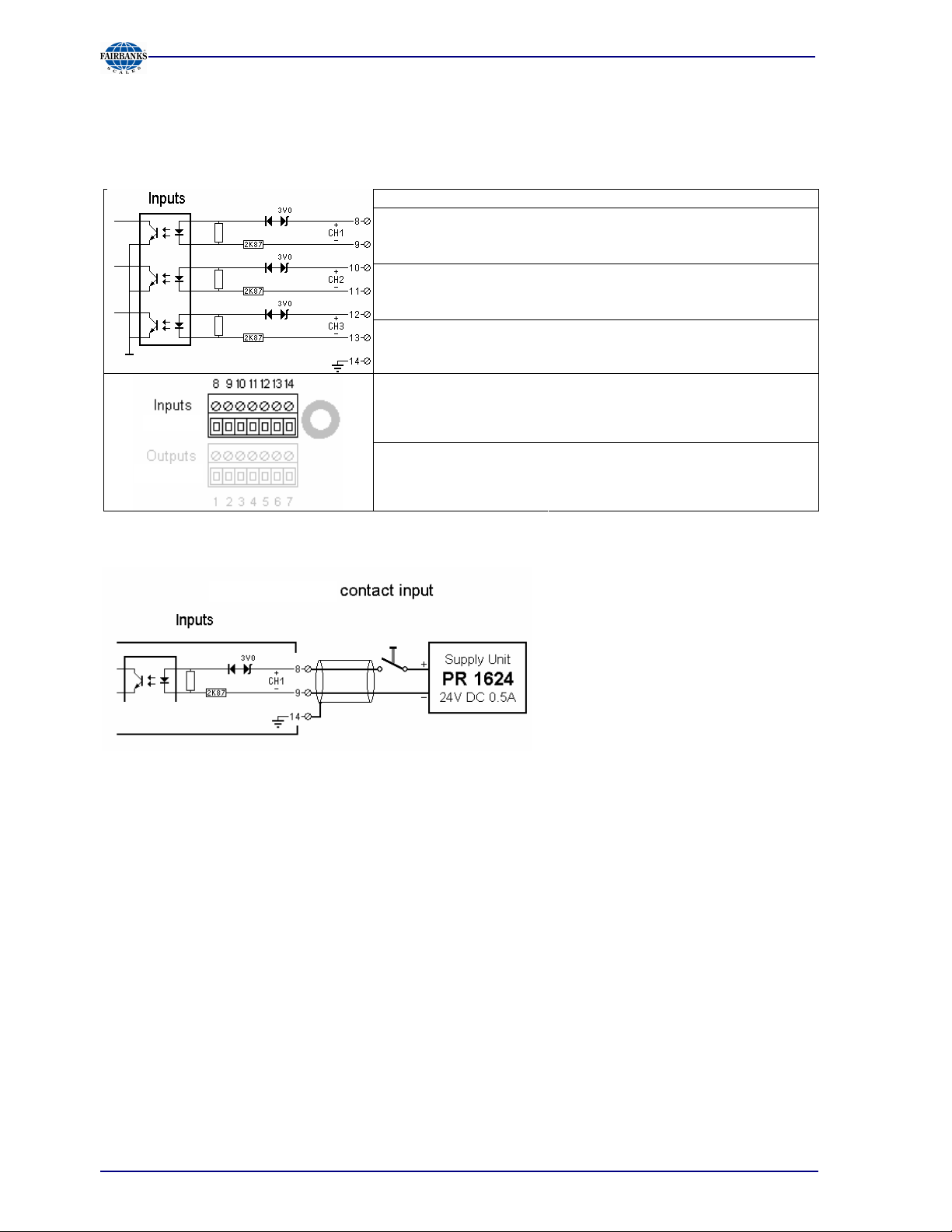

3.3.3 Optocoupler Inputs

The main board has 3 digital inputs for process control, electrically isolated by optocouplers, each

bipolar potential-free.

Number of inputs: 3 ( CH1, CH2, CH3 )

Input signal: Logic 0: 0 to 5 VDC or open

Logic 1: 10 to 31 VDC

Passive, external supply required

Input current: < 7 mA @ 24 V

< 3 mA @ 12 V

Protected against incorrect polarity

Electrical isolation: Yes, via optocoupler

Plug-in 7-pin screw terminal block,

Connection:

Cable: Shielded, max. 50 m

cable shield connected to housing

(terminal 14), max. 1.5 mm² cable.

Example: connection of a contact input

10/08 22 51207 Revision 1

Section 3: Installing the Instrument and Plug-In Cards

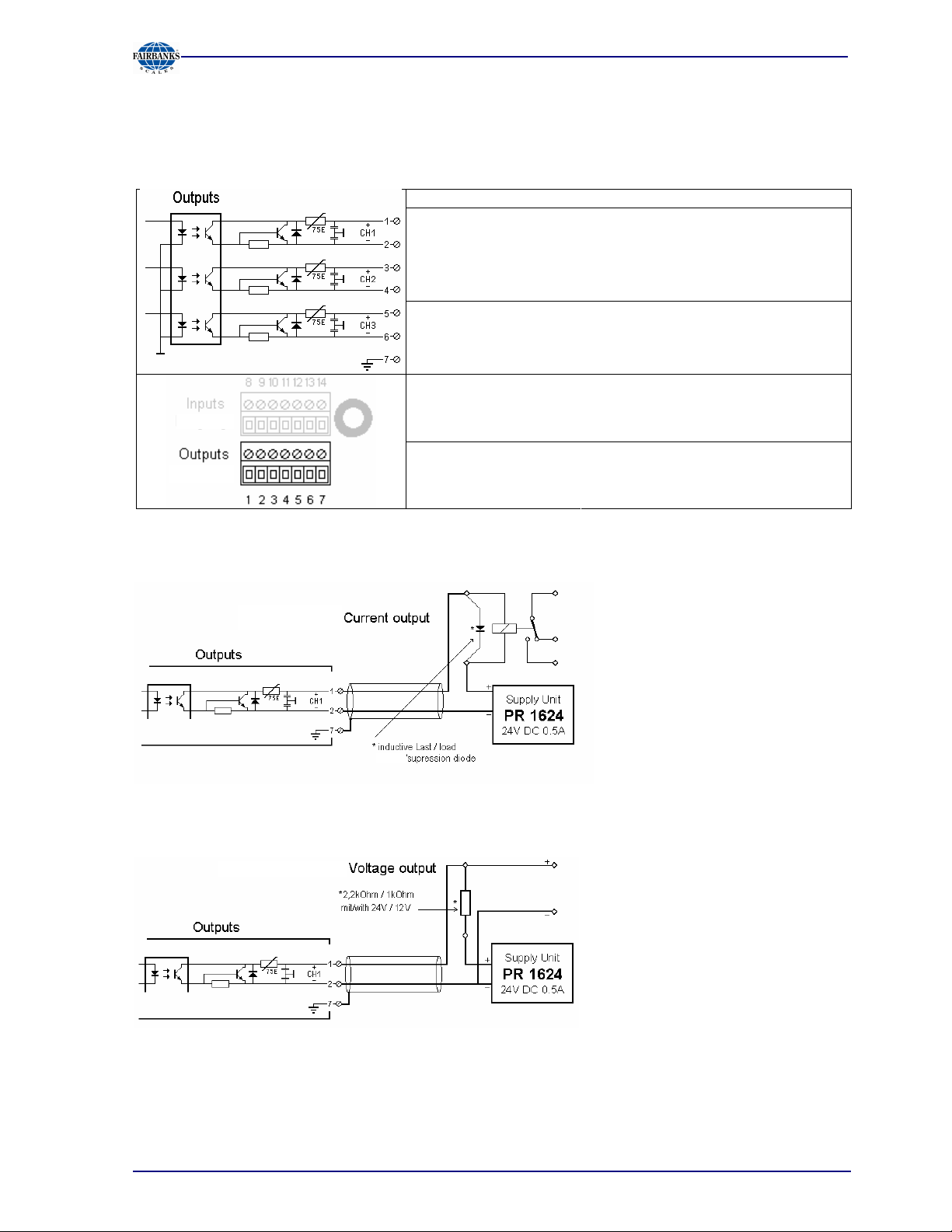

3.3.4 Optocoupler Outputs

The main board has 3 digital outputs for process control, electrically isolated by optocouplers, each

bipolar potential-free.

Number of outputs: 3 ( CH1, CH2, CH3 )

Output: Max. switching voltage: 31 VDC,

Protected against incorrect polarity

Max. switching current: 25 mA

Voltage drop @ 25 mA: 3 V

Passive, external supply required

Electrical isolation: Yes, via optocouplers

Plug-in 7-pin terminal block, cable

Connection:

Cable: Shielded, max. 50 m

shield connected to housing

(terminal 7), max 1.5 mm² cable

Example: connection of relay control

Example: connection of voltage output

The relay switches, when the

output is active (true). For

protection of the output circuit,

relays with free-wheel diode must

be provided.

When the output is active (true),

the output voltage goes from 24 V /

12 V to < 3 V . The load resistance

must be 2.2 kohms / 1 kohm.

10/08 23 51207 Revision 1

Section 3: Installing the Instrument and Plug-In Cards

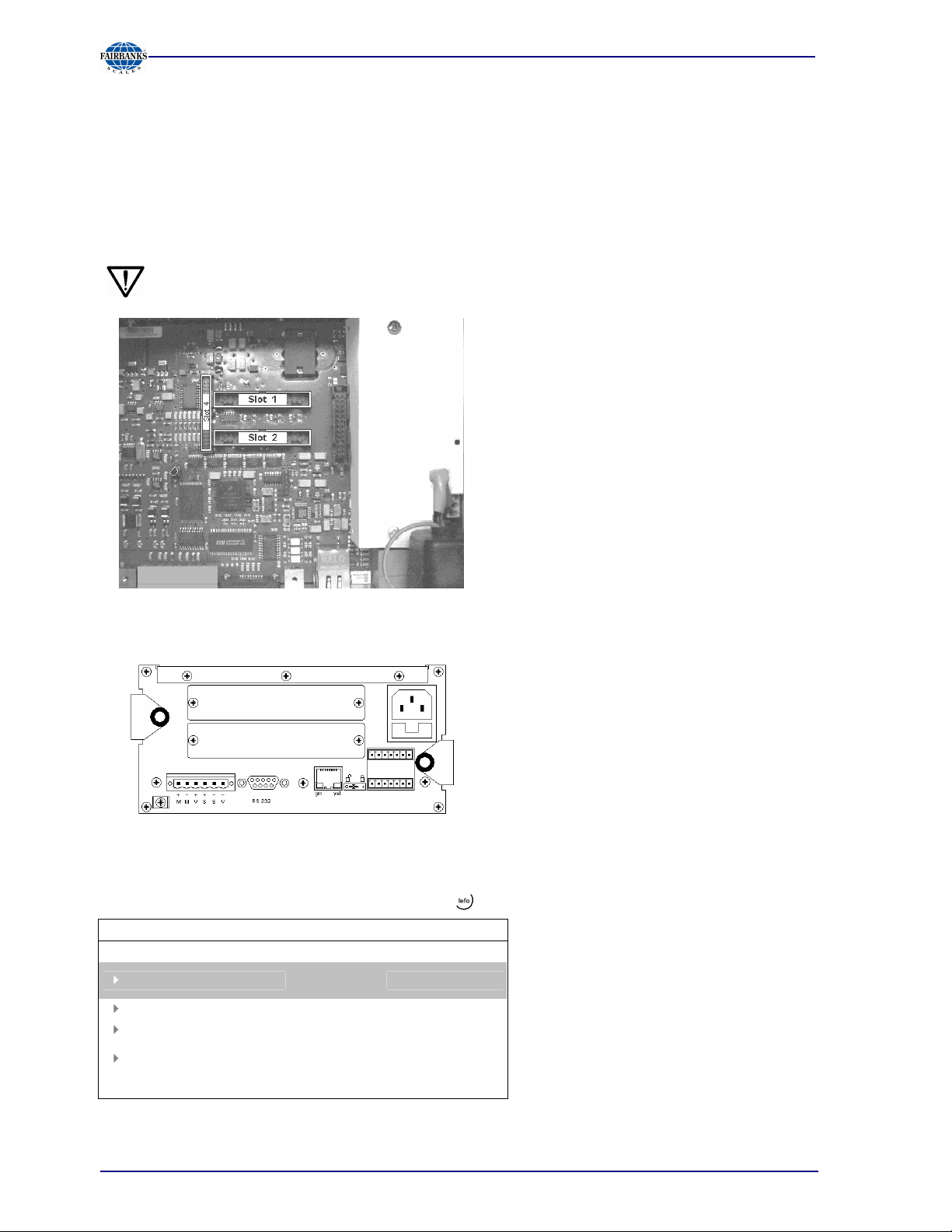

3.4 A

The main board has two slots with identical pin allocation (34 contact pins in two rows of 17) and

another slot (34 contact pins in two rows of 17) for plug-in cards. The slot designations are “Slot 1 ...

2" and "Slot 4" (left). Up to 2 cards can be mounted. Accordingly, the back panel is provided with

two cut-outs for the retainer plates of the cards.

CCESSORIES

3.4.1 Installing Plug-in Cards

Before installing or removing a plug-in card, disconnect the instrument from all voltage

sources.

Installation (Slots 1-2, 4):

The flat cables plug into connectors (Slots 1

... 2, 4) on the main board. The cables are

polarized; i.e. incorrect polarity is precluded.

A description and examples of the various

cards and connections are given in Chapter

3.3.3 .

View from above, back panel connectors at the

bottom

Remove the dummies from the back panel (2

screws; M3) and replace them with the

retainer plates for the plug-in cards.

The flat-cable connectors must be inserted

into the corresponding slots on the main

board.

View from the back

After installation/modification, the plug-in cards are detected automatically.

To view a list of the installed plug-in cards, select -[Show HW-slots]:

Info/HW-Slots

Builtin RS 232 Built-in serial interface

Slot 1

Slot 2 -empty-

Slot 3 Builtin Digital I/O

Slot 4

PR

5510/04

PR

1721/31

RS 485/232 Slots (Slot 1 and 2) are identical

Profibus-DP

Built-in digital I/Os

Only Fieldbus cards

10/08 24 51207 Revision 1

Section 3: Installing the Instrument and Plug-In Cards

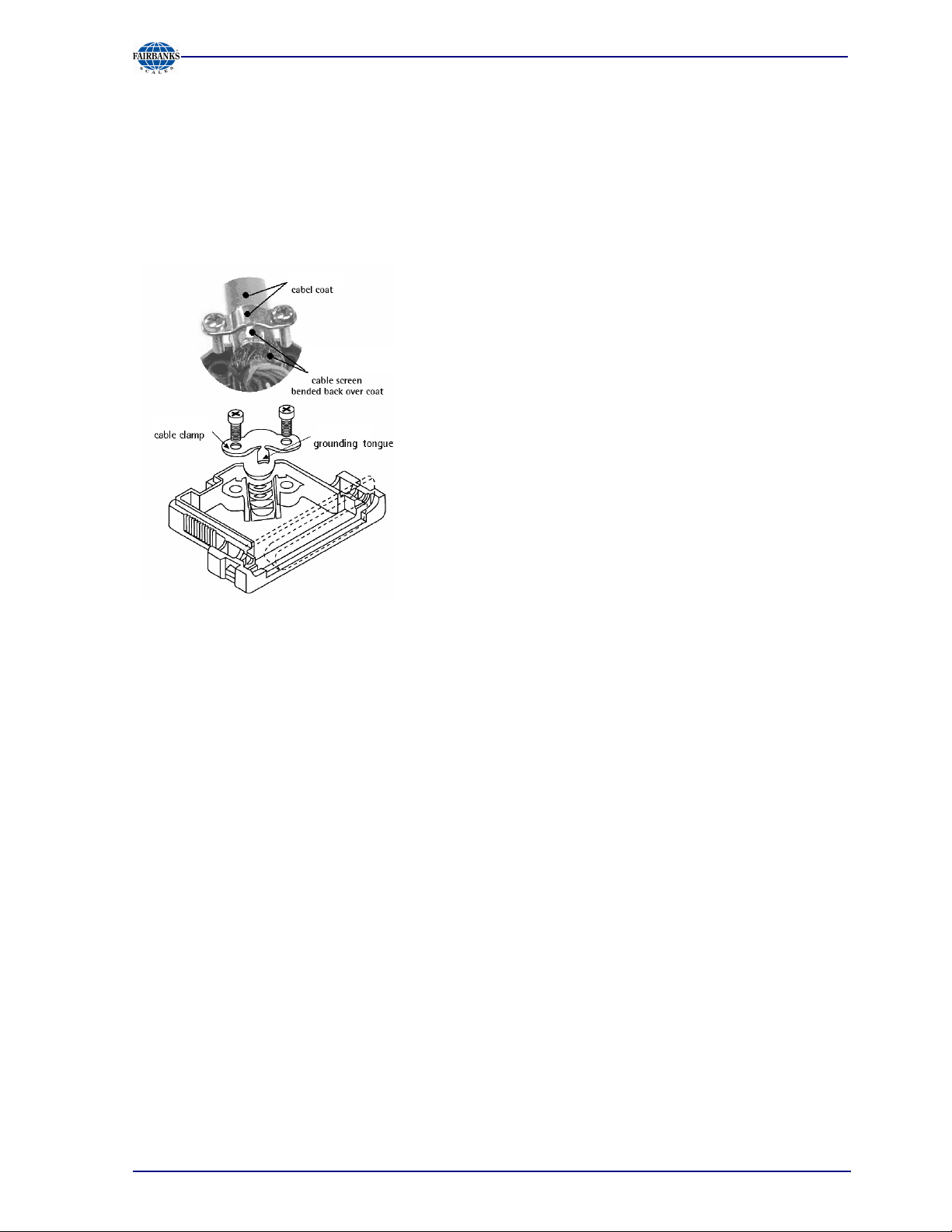

3.4.2 Cable Connection in the D-Sub Connector Mating Plug

The connections on the back panel are plug-in type. Keep the conductors as short as possible and

connect them to the terminals. The connector housings are conductive (metallized), i.e., part of the

shield, and must be fastened to the back panel by screws.

Mounting a cable:

• Open the connector housing (catches)

• Release and open the cable clamp

• Remove approx. 50-60 mm of the cable insulation

• Shorten the shield to 5 mm and bend it over the cable

sheath

• Remove 3mm wire insulation and connect it by soldering

• Insert the pin unit

• Put the cable under the cable clamp

The grounding tongue presses on the shield bent

backwards; the clamp presses on the cable sheath

• Close and tighten the cable clamp

• Check the strain relief

• Insert the mounting screws on both sides

• Close the connector housing (catches)

The shields must be connected to the metal housings on

both ends of the cable.

10/08 25 51207 Revision 1

Section 3: Installing the Instrument and Plug-In Cards

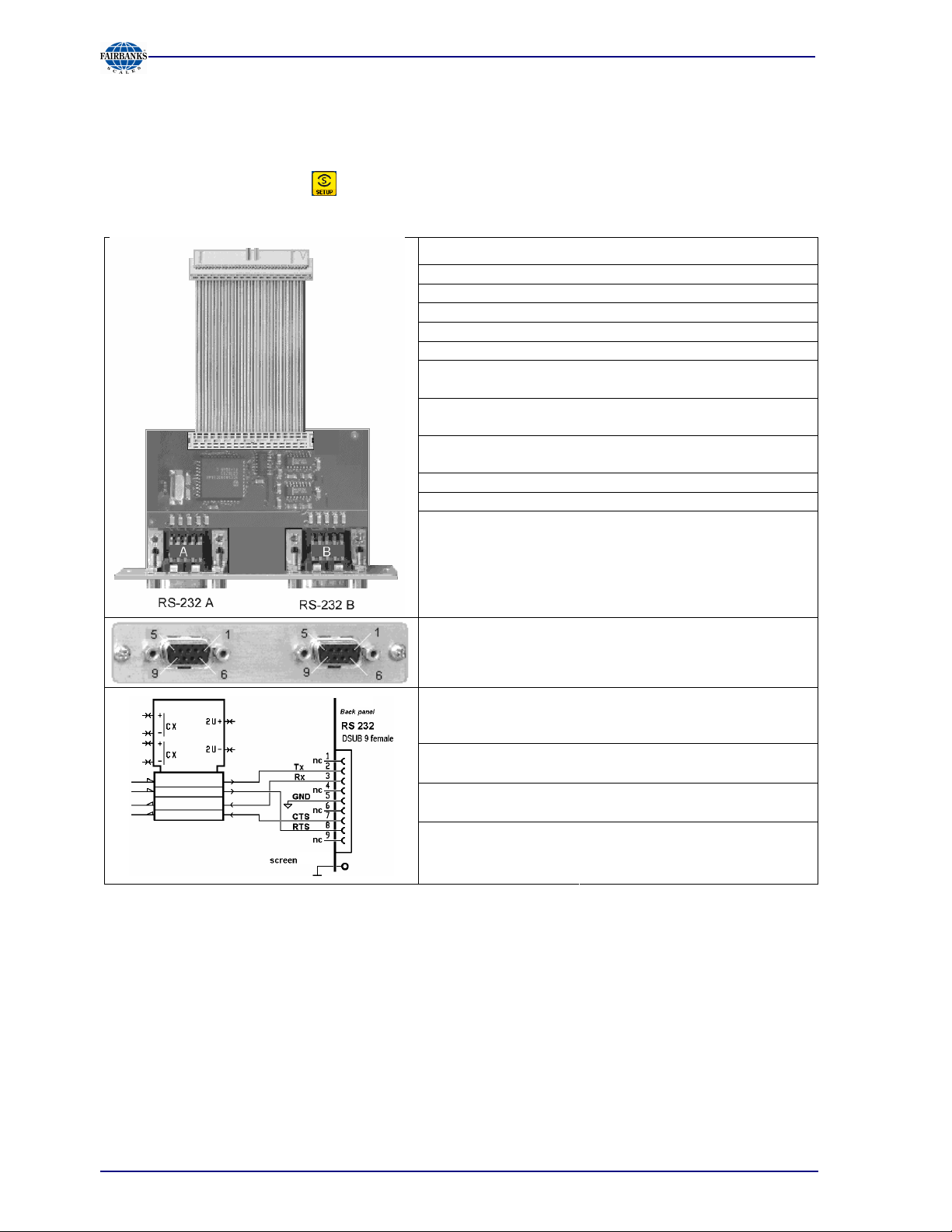

3.4.3 PR 5510/02 Serial I/O

The plug-in card contains two RS-232 channels (A and B), which can be used simultaneously and

independently. Max. 2 PR 5510/02 cards can be plugged in (Slot 1 ... 2). The relevant interface

parameters are adjustable in - [Serial ports parameter], no additional settings on the card are

required.

Internal connection:

Number of channels: 2

Type: RS 232, full duplex

Transfer rate: 300 to 19k2 bits/sec

Parity: No, odd, even

Data bits: 7 / 8 Bit

Signals RS 232:

Input signal level: logic 1 (high) - 3 ... - 15 V

Output signal level: logic 1 (high) - 5 ... - 15 V

Potential isolation: No

Cable length: max. 15m

Cable type:

34-pole connector socket

Output: TX, RTS

Input: RX, CTS

logic 0 (low) + 3 ... + 15 V

logic 0 (low) + 5 ... + 15 V

twisted pairs, screened

(e.g. LifYCY 3x2x0,20),

1 conductor pair for GND.

External connection:

2x D-Sub 9-pole socket

(female)

Accessories

(delivered with the

unit):

Dimensions:

(LxWxH):

Weight: appr. 30 g

The RS-232 can only be used as point to point connection. A max. cable length of 10-15m must not

be exceeded.

The PR5510/02 and the 'Builtin' comply with the standard pin allocation, i.e. they are equal in the

connecting diagrams. Accordingly, the RS232 connections are described only for the Builtin

Interface in this manual (see chapter 3.3.2 ).

2x connector counterpart D-Sub

9-pin (male)

incl. screening hoods

86 x 52 x 15 mm

10/08 26 51207 Revision 1

Section 3: Installing the Instrument and Plug-In Cards

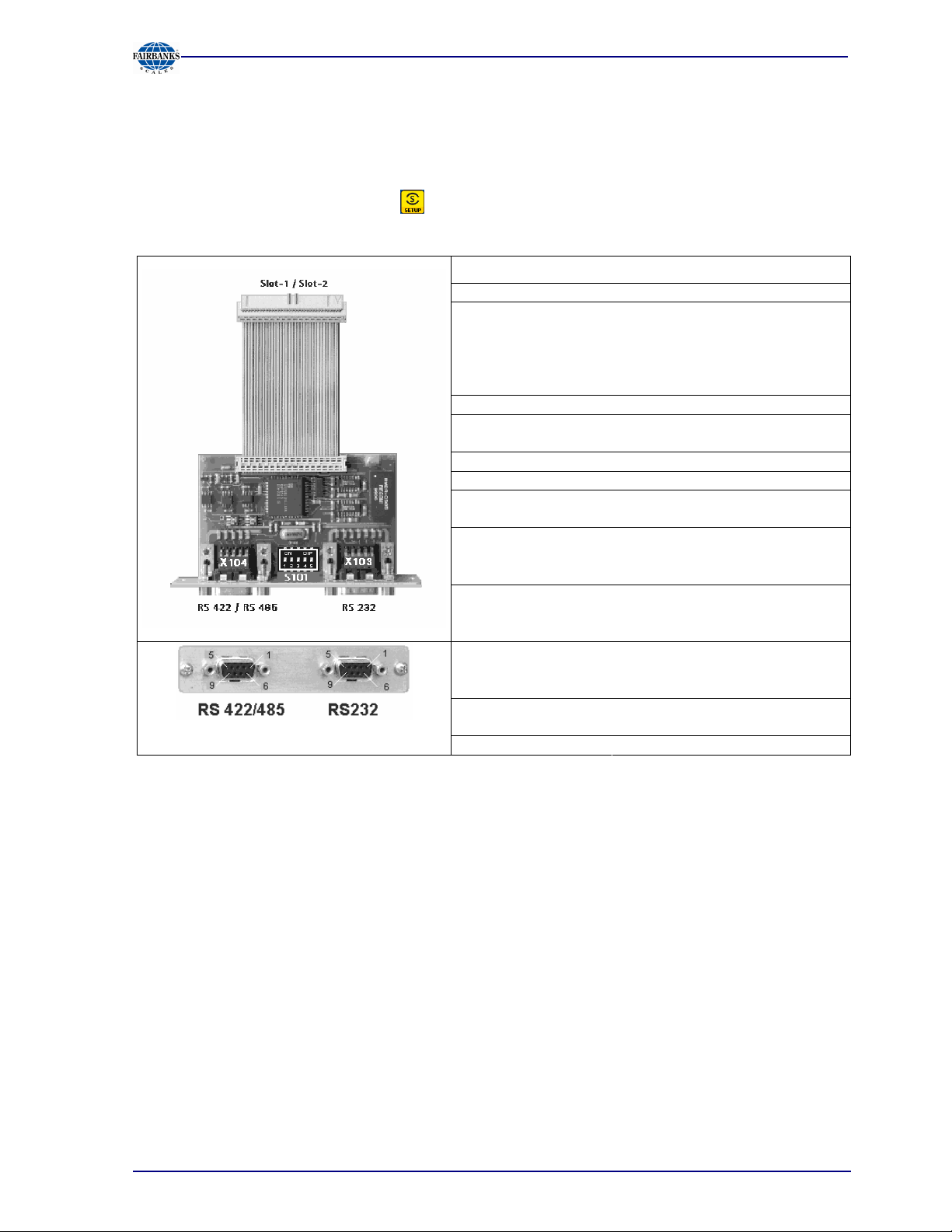

3.4.4 PR 5510/04 Serial I/O

The plug-in card has two channels (1x RS-232 and 1x RS-422/485), which can be used

simultaneously and to a great extent independently. The RS-422/485 interface is electrically

isolated. Up to 2 PR 5510/04 cards (Slot 1 and 2) can be plugged in. The relevant interface

parameters can be configured under -[Serial ports parameter]; the DIL switch S101 must be set

for RS-422/485 additionally.

Internal connection:

Number of channels: 1x RS-232, 1x RS-422/485

Type: RS-232 full duplex

Transfer rate: 300 to 19k2 bit/s

RS-232C (V24)

signals:

RS-422/485 signals: TxA, RxA, TxB, RxB

Electrical isolation: RS-232: no, RS-422 / 485: yes

Cable length:

Cable type:

External connection:

34-contact socket terminal strip

RS-422/485 full duplex (4-wire)

*

RS-485 half duplex (2-wire)

*

Output: TXD, RTS, DTR

Input: RXD, CTS, DCD, RI

Max. 15m with RS-232

Max. 1000 m with RS-422 / 485

Shielded twisted pair

(e.g., LifYCY 3x2x0,20),

1 conductor pair for GND.

2 D-Sub 9-contact female

connectors

Accessories

(delivered with the

unit):

Dimensions:

(LxWxH):

Weight: 33 g

PR 5510/04 RS-232

The RS-232 interface is independent of the S101 switch settings.

It can be used only for point-to-point connection.

PR 5510/04 is provided as an equivalent to the [Builtin RS-232] interface in the RS-232 channel with

additional signals: DCD, DTR, RI.

The built-in and PR 5510/04 interfaces comply with the standard pin allocation; i.e., they are

equivalent in the following connecting diagrams. Thus only the RS-232 connections for the built-in

interface are described in this manual (see Chapter 3.3.2).

2 D-Sub 9-pin mating plugs

(male)

incl. shielded housing

86 x 52 x 15 mm

10/08 27 51207 Revision 1

Section 3: Installing the Instrument and Plug-In Cards

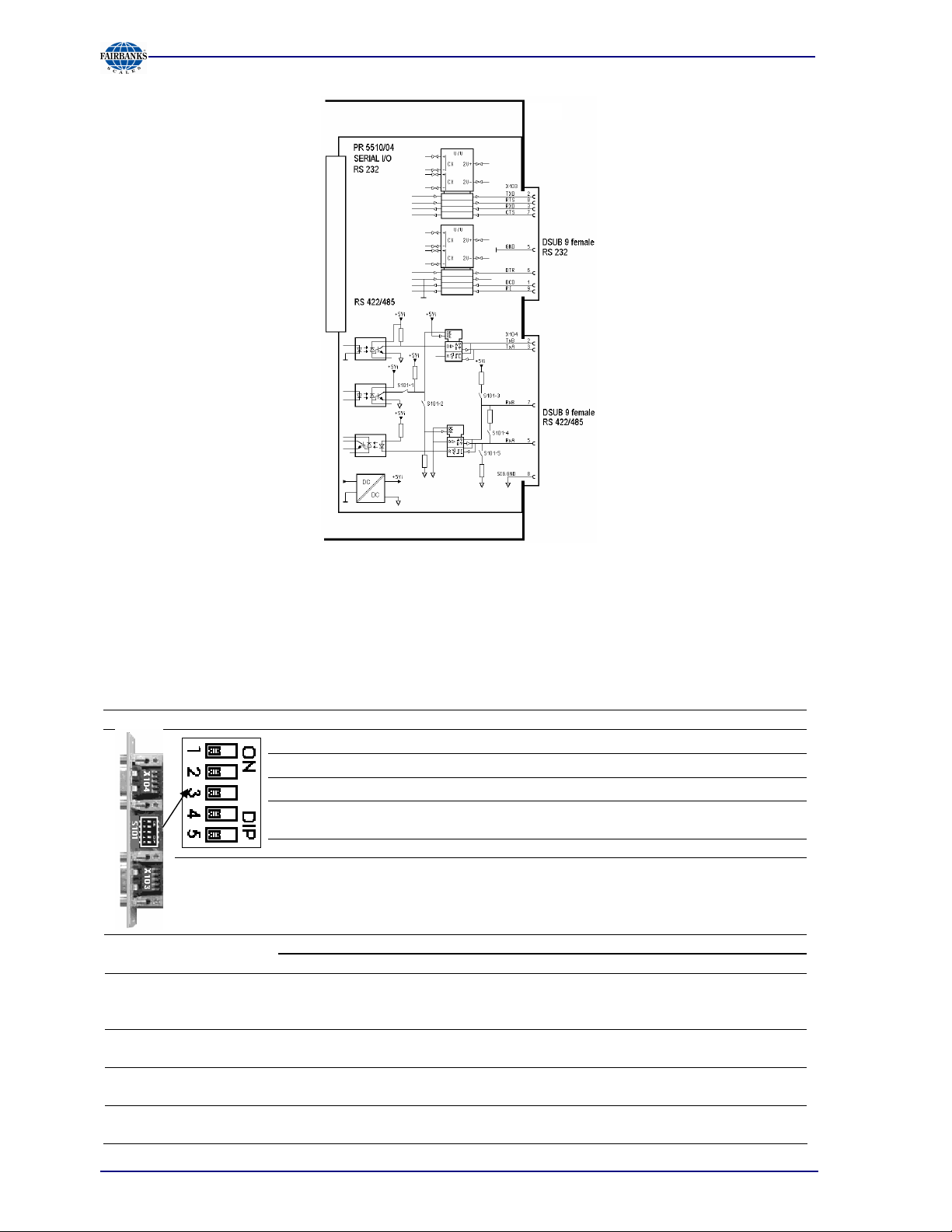

PR 5510/04 RS-422/485

When mounting, the RS-485/422 interface must be configured by DIL switch S101 on the card.

Using RS-485 is compulsory with a multi-point connection (tristate status). The RS-485 interface

can be used also for point-to-point connection. Like 2-wire or 4-wire connections, this is dependent

on the other communicating units.

A 2-wire connection is half-duplex and cannot send and receive simultaneously. It requires

corresponding driver programming (see relevant instrument manual).

Factory setting Switch S101 Settings for RS-422/ 485

1: Tristate enable: OFF – RS-422 ON – RS-485

2: Rx enable OFF – 4-wire ON – 2-wire

3: Rx pull-up resistor: OFF – not connected ON - (RxB 1k54 +V)

4: Rx bus termination: OFF – not connected ON - (RxA 205E

5: Rx pull-down resistor: OFF – not connected ON - (RxA 1k54 -V)

Overview of which switches must be closed (ON) for which mode:

S101

Master RS-485

Individual slave RS-485

Other slaves - RS-485

Last slave - RS-485

Two-wire system Four-wire system

Point to point Bus Point to point Bus

RS-485

1, 2, 3, 4, 5 =

on

1, 2 = on

1, 2, 3, 4, 5 = on

- RS-422

1, 2 = on

1, 2, 3, 4, 5 = on

RxB)

RS-422

4 = on

4 = on

- RS-485

- RS-485

RS-422

3, 4, 5 = on

-

1 = on (default)

1, 3, 4, 5 = on

10/08 28 51207 Revision 1

Section 3: Installing the Instrument and Plug-In Cards

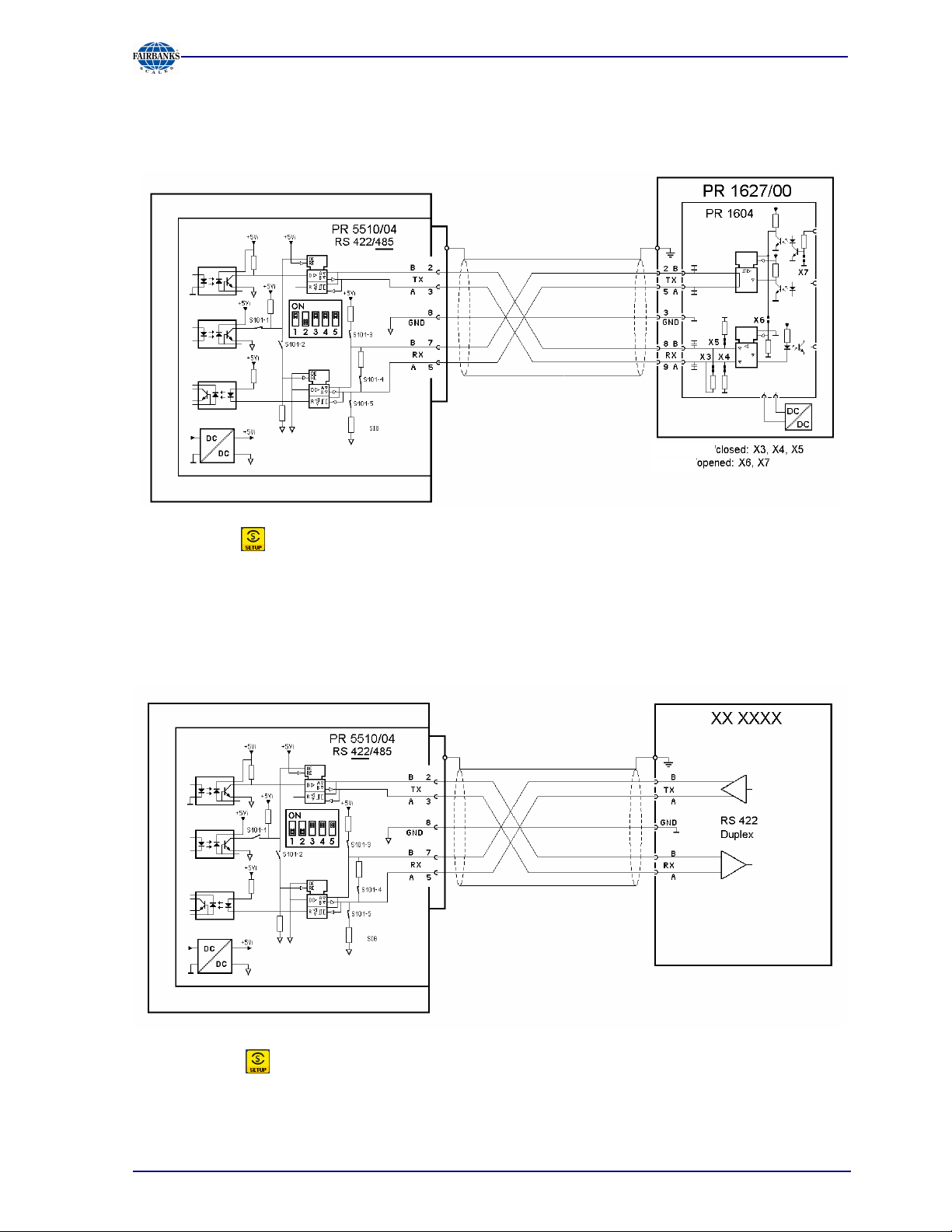

Connecting a PR 1627 Remote Display over RS-485

Four-wire transmission, point to point, full duplex (simultaneous sending and receiving possible)

with PR 1627/00 remote display.

Configuration: -[Serial ports parameter]-[Remote display]-[Slot1/2-RS-485]

RS-422 Point-to-Point Connection (Four-Wire)

Four-wire transmission: full duplex (simultaneous sending and receiving possible)

RS-422 can be used only for point-to-point connection.

Configuration: -[Serial ports parameter]-[.........]-[Slot1/2-RS-485]

10/08 29 51207 Revision 1

Section 3: Installing the Instrument and Plug-In Cards

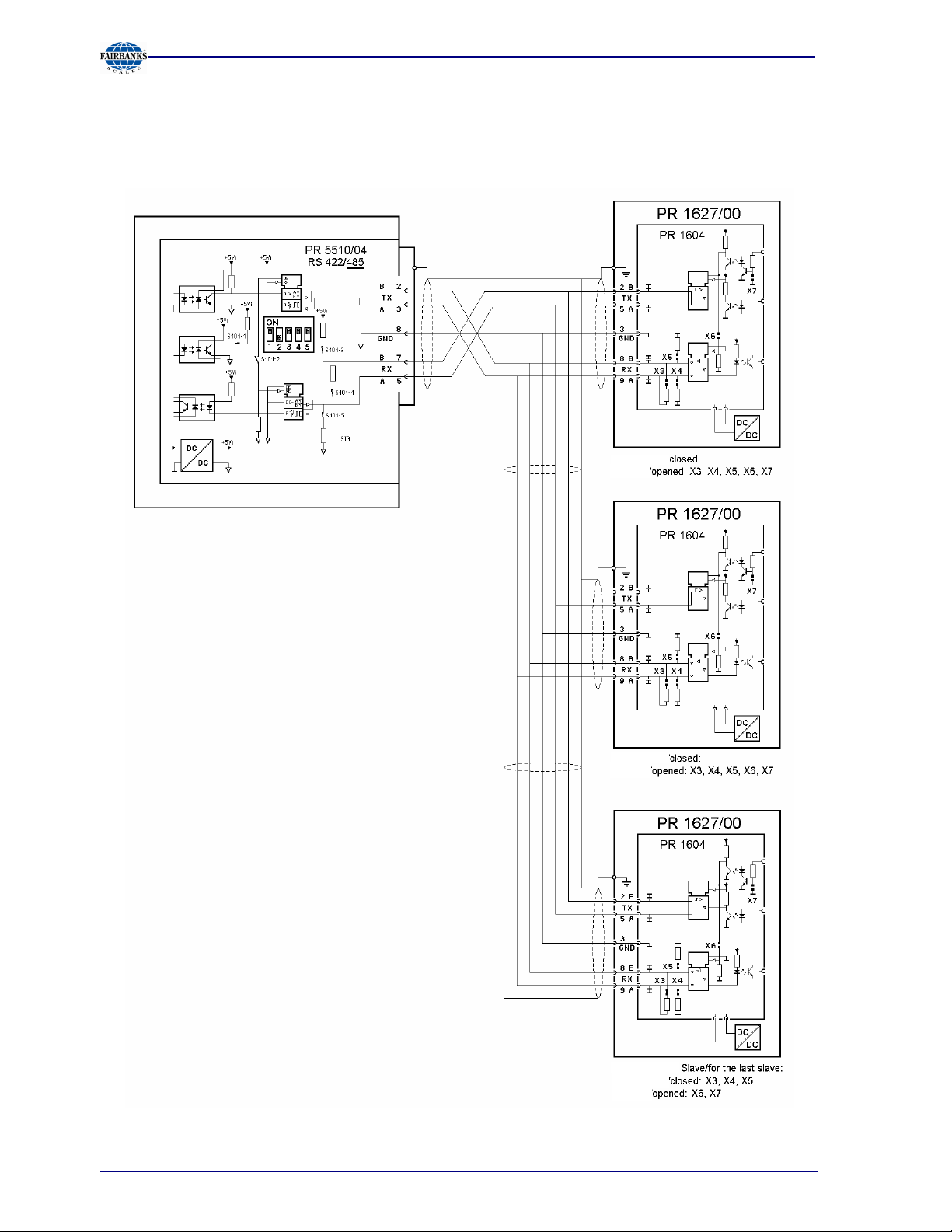

Connecting Several PR 1627 Remote Displays over RS-485

Connection of several PR 1627 remote displays over RS-485, four-wire, full-duplex (simultaneous

sending and receiving possible):

10/08 30 51207 Revision 1

Section 3: Installing the Instrument and Plug-In Cards

3.4.5 PR 5510/07 Analog Input/Output Card

The plug-in card with 15-contact D-Sub socket for the analog channels is configured as 1 analog

output (active) and 4 analog inputs. The analog inputs are not supported by the standard

instrument.

Internal

connection:

Number of outputs: 1 active current output: 20mA, 10V

Output

assignment:

Output range: 0/4 ... 20mA, configurable

Output resolution: 16 bits binary,

Output linearity

error:

Output

temperature effect:

Output zero error: 0.05 %

Max. output error: < 0.1 %

Load: Max. 0 ... 500 ohms

34-contact connector socket on flat

cable for Slot 1, 2

output voltage via external 500 ohm

resistor

Gross / net / display following,

configurable

20,000 internal counts @ 20 mA

@ 0 - 20mA: 0.04 %

@ 4 - 20 mA: 0.02 %

< 100 ppm/K

Dimensions:

(LxWxH):

Weight: 40g

86x53x16mm

External

connection:

Accessories: 15-pin D-Sub male connector

Inputs: 4 channels current or voltage input

Input resolution: 3,000 internal counts corresponding

Input accuracy: 0.2 %

Input,

linearity error:

Input

temperature effect:

Input, reserve: +- 15%, i.e. –1.5V ... +11.5V

Electrical isolation: Output: yes, inputs: no

15-contact D-Sub female connector

0 ... 20 mA, input resistance

250 ohms

0 ... 10 V, input resistance

100 kohms

0 ... 5 V, input resistance >10

Mohms

to e.g. 0 - 20 mA / 0 ... 10 V

< 0.03 %

< 50 ppm/K

10/08 31 51207 Revision 1

Section 3: Installing the Instrument and Plug-In Cards

Analog input

Signal selection

S201

S202

Channel

CH1

CH2

CH3

CH4

---CH1

CH2

CH3

CH4

----

Current

0...+ 20mA DC

ON

ON

ON

ON

---OFF

OFF

OFF

OFF

----

Voltage

0...+ 10V DC

OFF

OFF

OFF

OFF

---ON

ON

ON

ON

----

Voltage

0...+ 5V DC

OFF

OFF

OFF

OFF

---OFF

OFF

OFF

OFF

----

Input resistance 250 ohms 100 kohms > 10 Mohms

Pin allocation of rear socket (for installation, see Chapter 3.4.1)

D-Sub 15

Input (PIN) 2 9 3 10 4 11 5 12

4 channels + CH1 GND + CH2 GND + CH3 GND + CH4 GND

Output (PIN) 13 14

1 channel + 0/4 ... 20

Sig GND

mA

10/08 32 51207 Revision 1

Section 3: Installing the Instrument and Plug-In Cards

3.4.6 PR 5510/08 BCD Output (Open Emitter)

The plug-in card is used for BCD-coded output of a 5-decade weight value.

Cyclical output of the weight value with 4-bit (plus or minus sign, stability, error). The value is

intrinsically consistent and can be output continuously or the digital input DATA_IN control can be

used to freeze (hold) the value.

Internal connection: 34-contact female connector on

flat cable for Slot 1, 2

Number of outputs: 5 digits BCD + plus or minus sign

Number of inputs: Input: 1 bit (DATA IN)

Output stage: Common collector at +Uext.,

open emitter

External supply: +5 V ... +24 VDC

Voltage drop: Approx. 1.7 V

Output current: Max. 50 mA

Enable input: 5 V / 24 V adjustable via S101

@ 5 V high > 3.1 V, low < 1.5 V

@ 24 V high > 16 V, low < 10V

protected against incorrect polarity

Cable: Shielded, max. 50 m

Electrical isolation:

No

External connection:

X102

Dimensions

(LxWxH):

Weight:

Before installing the card, set switches S101 and S102; see Chapter 0.

60x106x22 Accessories (delivered

with the unit):

55 g

26-contact D-Sub connector

(female)

26-pin D-Sub mating plug (male)

incl. shielded housing

10/08 33 51207 Revision 1

Section 3: Installing the Instrument and Plug-In Cards

External supply voltage required: pin 1 - Uext, reference potential pin 26 – GND

10/08 34 51207 Revision 1

Section 3: Installing the Instrument and Plug-In Cards

Outputs

The PR 5510/08 outputs (pins 2 - 24) use common supply voltage at the collector as reference

potential and open emitter outputs. A non-activated output has high impedance, and an active

output has a voltage by approximately 1.7 V lower than the supply voltage.

The load to be connected is applied between the output (pins 2 … 24, 25*) and GND (pin 26).

Input

When using as DATA_IN, the input (pin 25) can control the 23 outputs. As an output, data is

“continuous/hold/tristate“ and its signal can be configured (TTL/24V active (high/low). It is applied to

pin 25 – DATA_IN of the 26-pin connector and is effective only with DIL switch S101-1 = OFF and

S101-2 = ON.

The meaning of switches is given in the table in Chapter 0.

PR 5510/08 connector pin allocation:

BCD output for the weight value

Output circuitry

Output Modes

The output modes are identical with the PR 5510/09 card; see Chapter 0

10/08 35 51207 Revision 1

Section 3: Installing the Instrument and Plug-In Cards

3.4.7 PR 5510/09 BCD Output (Open Collector)

The plug-in card is used for BCD-coded output of a 5-decade weight value.

Cyclical output of the weight value is with 4-bit corresponding status (polarity sign, stability, error).

The value is intrinsically consistent and can be output continuously or the digital input DATA_IN

control can be used to freeze (hold) the value.

Internal connection: 34-contact female connector on

flat cable for Slot 1, 2

Number of outputs: 5 digits BCD + plus or minus sign

Number of inputs: Input: 1 bit (DATA IN)

Output stage: Common emitter at GND,

open collector

External supply: +5 V ... +24 VDC

Voltage drop: Approx. 0.9 V

Output current: Max. 50 mA

Enable input: 5 V / 24 V adjustable via S101

@ 5 V high > 3.1 V, low < 1.5 V

@ 24 V high > 16 V, low < 10V

protected against incorrect polarity

Cable: Shielded, max. 50 m

Electrical isolation:

No

External connection:

X102

Dimensions:

(LxWxH):

Weight: 55 g

Before installation, set the switches S101 and S102 as given in Chapter 0.

60x106x22 Accessories (delivered

with the unit):

26-contact D-Sub connector

(female)

26-pin D-Sub mating connector

(male)

incl. shielded housing

10/08 36 51207 Revision 1

Section 3: Installing the Instrument and Plug-In Cards

External supply voltage is required : pin 1 - Uext, reference potential pin 26 – GND

10/08 37 51207 Revision 1

DATA IN

Logic level

I input

Section 3: Installing the Instrument and Plug-In Cards

Outputs

PR 5510/09 outputs (pins 2 ... 24) use common GND as a reference potential and open collectors.

A non-activated output has high impedance, and an active output has a voltage by approximately

0.9 V higher than GND.

The load to be connected is applied between the collector [pins 2 … 24,(25*)] and Uext [PIN 1].

Input

When using as DATA_IN, the input (pin 25) can control the 23 outputs. As an output, data is

“continuous/hold/tristate“ and its signal can be configured (TTL/24V active (high/low). It is applied to

pin 25 – DATA_IN of the 26-pin connector and is effective only with DIL switch S101-1 = OFF and

S101-2 = ON.

Meaning of Switches S101 and S102

Fact. sett. S101 -1 -2 -3 -4 -5

for: OU IN

Level Level Diod

e

As INPUT DATA_IN

As INPUT DATA_IN

As INPUT DATA_IN 24V Active

As INPUT DATA_IN 24V Active LOW Pin 25 OFF ON OFF OFF x

Free-wheel

diode*

Free-wheel

diode*

Fact. sett. S102 -1 -2 -3 -4 -5

Pin25 INPUT DATA_IN follow hold Pin

DATA_IN tristate follow Pin

DATA_IN tristate hold Pin

Signal level:

internal ON

internal OFF

5V Active

HIGH

5V Active LOW Pin 25 OFF ON ON OFF x

HIGH

Pin 25 OFF ON ON ON x

Pin 25 OFF ON OFF ON x

for:

2…24

2…24

2…24

Func

OFF OFF ON x x

Func

tion

ON ON OFF x x

ON ON ON x x

tion

Func

tion

-

-

high 5 V mode > 3.1 V 0.5 mA

low 5 V mode < 1.5 V 0.3 mA

high 24 V mode > 16 V 1.0 mA

low 24 V mode < 10 V 0.5 mA

10/08 38 51207 Revision 1

PR 5510/09 connector, pin allocation:

Section 3: Installing the Instrument and Plug-In Cards

BCD output for weight value

Output circuitry

10/08 39 51207 Revision 1

Section 3: Installing the Instrument and Plug-In Cards

Output Modes

In all modes, data is output with each internal PLC cycle.

Mode 1 : Continuous data output (follow), no DATA_IN:

Continuous output of consistent data without request, e.g. for remote display.

- The driver modules are always enabled.

- PIN25 is output.

Mode 2: Data output on external request DATA_IN (hold):

Output of consistent data in "held" condition on request, otherwise continuous.

- As long as DATA_IN is active, the last output value remains held.

- The driver modules are always enabled.

- PIN25 DATA_IN is data-hold (level S101-3, polarity S101-4).

Note:

Data might be transferred internally (data modification) in the output memory at the same time the

external request signal changes from "Data hold" to "Data valid". In this case, the reading instrument

must wait 100 µs, until the data is considered valid.

Mode 3 : Parallel bus system (tristate), external request DATA_IN (hold):

Parallel connection of n PR 5510/09 cards, controlled via the DATA_IN (tristate/hold) input.

Output of the consistent data in "held" condition on request, otherwise tristate (high-impedance).

- As long as DATA_IN is active, the last output value remains held.

- The driver modules are enabled (not tristate) only, when DATA_In

(hold) is active.

- PIN25 DATA_IN is data-enable+hold (level S101-3, polarity S101-

4).

Mode 4 : Continuous single-bit output (23xDA), DATA_IN (1xDE):

Continuous bit output, continuous, without request (1xIN, 23xOUT, configurable).

- The driver modules are always enabled.

- PIN25 is input.

Mode 5 : Continuous single-bit output (24xDA), no DATA_IN:

Continuous bit output without request (24xOUT, configurable).

- The driver modules are always enabled.

- PIN25 is output.

10/08 40 51207 Revision 1

Section 3: Installing the Instrument and Plug-In Cards

3.4.8 PR 5510/12 6 Optocoupler Inputs / 12 Optocoupler Outputs

The card converts external binary process signals to internal signal levels and vice versa.

12 digital outputs for process control, electrically isolated with passive optocoupler outputs, each

bipolar potential-free.

6 digital inputs for process control, electrically isolated via optocouplers, each bipolar potential-free.

The input signal is logical "0" with open input.

Internal connection: 34-contact female connector for Slot

1, 2

Number of

inputs/outputs:

Input signal: Low: 0 ... 5 VDC or open

Input current: < 7 mA @ 24 V

Output: Max. switching voltage: 32 VDC

Electrical isolation: Yes, via optocoupler

Cable: Shielded, max. 50 m

Accessories (delivered

with the unit):

External connection:

Inputs: 6 , outputs: 12

High: 10 ... 31 VDC

Passive, external supply required

< 3 mA @ 12 V

Protected against incorrect polarity

Max. switching current : 25 mA

Voltage drop @ 25 mA: 3 V

Protected against wrong polarity

Passive, external supply required

1 DB37 mating plug (male)

incl. shielded housing

26-contact D-Sub connector

(female)

Dimensions

(LxWxH):

Weight:

The card has independently from the slot position a fixed signal allocation.

Output, bit 1 DIMM (Weight below zero or above Max)

Output, bit 2 Weight within zero set range

Output, bit 3 Output limit 1

Output, bit 4 Output limit 2

Output, bit 5 Weight within 1/4 around zero

Output, bit 6 Scale error (ADC Error)

Output, bit 7 - 12 Not used

Input, bit 1 Set tare / reset tare, positive edge

Input, bit 2 Print command, positive edge

Input, bit 3 - 6 Not used

60 x 106 x 22

70 g

Accessories: PR 1623/10 4m connecting cable

PR 1623/20 relay output terminal

unit

PR 1623/30 terminal I/O module

10/08 41 51207 Revision 1

Section 3: Installing the Instrument and Plug-In Cards

Passive; external supply voltage required (I/O channels potential-free, no common reference)

10/08 42 51207 Revision 1

Section 3: Installing the Instrument and Plug-In Cards

Output circuitry

Input circuitry

10/08 43 51207 Revision 1

Section 3: Installing the Instrument and Plug-In Cards

Circuit diagram: PR 5510/12 – PR 1623/10 – PR 1623/20

10/08 44 51207 Revision 1

Section 3: Installing the Instrument and Plug-In Cards

Circuit diagram: PR 5510/12 – PR 1623/10 – PR 1623/30

10/08 45 51207 Revision 1

Section 3: Installing the Instrument and Plug-In Cards

3.4.9 PR 1721/31 Profibus Interface

Profibus interface PR 1721/31 is a plug-in card for mounting in Slot 4; see Chapter 3.4.1.

Communication protocols and syntax comply with the Profibus-DP standard to IEC 61158, with

transfer rates up to 12 Mbit/s.

Internal

connection:

External

connection:

Transfer rate: 9.6 kbit/s to 12 Mbit/s,

Connection mode: Profibus network,

Protocol: PROFIBUS-DP-V0 slave

Transport: EIA RS-485 , Profibus DIN 19245

Cable: Special Profibus color: violet

Cable impedance: 150 ohms

Bus termination Can be activated externally via DILCertificates: Profibus test center Comdec in

Dimensions

(LxWxH):

Weight: 125 g Cable length: Max. distances 200m can be

Make sure the two rotary switches are set to position 0.

The terminating resistors can be switched on and off by pressing switch .

Connecting diagram for a master with three slaves

87 x 55 x 15 mm Electrical isolation: Optocoupler in lines A and B (RS-

34-pin connector on flat cable for Slot

4

9-contact D-Sub socket in retainer

plate

baud rate auto-detection

connections can be made/released

without affecting other stations

to EN 50 170 (DIN 19245),

mono or multi-master systems

are supported. Master and slave

devices, max. 126 nodes possible.

Watchdog timer

Part 1

Shielded twisted pair cable

switch

Germany and PNO (Profibus User

Organization). Suitable for industrial

applications to CE, UL and cUL

485)

extended with 1.5 Mbit/s by means of

additional repeater.

10/08 46 51207 Revision 1

Section 3: Installing the Instrument and Plug-In Cards

3.4.10 PR 1721/32 Interbus Interface

The Interbus interface PR 1721/32 is a plug-in card for installation in Slot 4; see Chapter 3.4.1.

The interface is based on the Interbus chip technology and enables transfer rates of 500 kbit/s and

2 Mbit/s.

Internal

connection:

External

connection:

Transfer rate: 500 kbit/s or 2 Mbit/s, selectable

Topology: Bus as a closed ring

Protocol: INTERBUS-S master-slave

Transport: EIA RS-422, cable-bound

Cable: Interbus, color: green

Cable impedance: 150 ohms

Lead termination: Not required, due to active ring

Certificates: From Interbus Club e.V.:

Dimensions

(LxWxH):

Weight: 125 g Cable length: 400m (between two remote bus

87 x 55 x 15 mm Electrical isolation: Yes, optocoupler and DC/DC

34-pin connector on flat cable, only

for Slot 4

Standard IBS 9-contact D-Sub

socket OUT and D-Sub plug IN in

retainer plate

Bus In Bus Out

fixed telegram length, deterministic

cyclical process data transmission

with max. 10 words I/O.

3x2 twisted pairs, common shield

topology

Compatibility with Interbus standard

IEC 61158 (Parts 3 to 6)

EN 50254 (DIN 19258)

Suitable for industrial applications

CE, UL & cUL

converter

sharing units). Overall length: 13 km

With Bus OUT , 5 and 9 must be bridged if another slave follows.

Connecting diagram for a master with three slaves.

10/08 47 51207 Revision 1

Suitable for industrial applications CE,

Section 3: Installing the Instrument and Plug-In Cards

3.4.11 PR 1721/34 DeviceNet Interface

DeviceNet interface PR 1721/34 is a plug-in card for installation in Slot 4; see Chapter 3.4.1. It is a

complete DeviceNet adaptor (slave) with CAN controller and transfer rates of up to 500 kbit/s.

Internal connection: 34-pin connector on flat cable, only

for Slot 4

External connection: 5-pin screw terminal block (plug-

in) in retainer plate

Transfer rates: 125, 250 and 500kbit/s

Topology: Parallel bus

Protocol: DeviceNet master-slave

Polling method (polled IO)

CRC error detection

to IEC 62026 (EN50325)

Max. 64 station nodes

Max. data width 512 bytes

input&output

Transport: EIA RS-485

Configuration: EDS file (PR 1721/34-specific)

MAC-ID (1…62)

Certificates/

conformity:

Compatible with DeviceNet

specification

Vol. 1: 2.0, vol. 2: 2.0

ODVA certificate in accordance with

conformity test software version A-12

UL & cUL

Cable: DeviceNet, color: petrol-green

2x2 shielded twisted pair

Cable impedance: 150 ohms

Bus termination: 120 ohms at the cable ends

Dimensions

(LxWxH):

Weight: 125 g Electrical isolation: Yes, optocoupler and DC/DC

Connecting diagram for a master with three slaves

87 x 55 x 15 mm Bus load: 33mA

converter

Make sure DIP switches 1- 8 are set to ON.

10/08 48 51207 Revision 1

Section 3: Installing the Instrument and Plug-In Cards

3.4.12 PR 1721/37 EtherNet/IP Schnittstelle

The EtherNet/IP interface is a plug-in card for installation in Slot 4, see chapter 3.4.1. The card is

fitted with a standard RJ-45 socket for Ethernet connection and contains a powerful TCP/IP and

EtherNet/IP connecting circuitry with transfer rates of 10 and 100Mbits/s.

Internal connection: 34-pin connector on flat cable for

Slot-4

External connection: RJ-45 connecting socket in holding

plate

Transfer rate: 10Mbit/sec and 100Mbit/sec

Autodetection (10/100,

HalfDX/FullDX)

Connection mode: Network

Protocol: EtherNet/IP

Transport: TCP/IP oder UDP/IP

Cable: Twisted pairs, screened

e.g. patch cable CAT5

Autolink (straight oder crossover)

Cable impedance: 150 Ohm

Cable length to HUB: Max. 115 m

Certificates: EtherNet/IP Specification

ODVA File No. 10286

Test Date: 06.09.2005

Vendor ID 90

See also: www.odva.org

Tested according to: CE, UL & cUL

Potential isolation: Yes

Dimensions (LxWxH): 87 x 55 x 15mm

Weight: 125 g

The EtherNet/IP card is supported from PR 5410 Firmware Release 1.30 onwards. The IP-Address

and the Subnet-Mask are set at Fieldbus parameter FP 96 und 97 (see chapter 4.7.7 and Error!

Reference source not found.).

Take care, that switches 1 - 8 are set to (OFF)

LED 1 LED 2 LED 3 LED 4

Off

On green Connection (HW) Controlled by a

On red Major unrecoverable

Flasching green Not configured o.

Flashing red Minor recoverable

Alternat.

red/green

No connection (HW) No power No power o.

No IP Address

Online,

scanner

fault

scanner in idle state

fault

Self test in progress Self test in progress

connection

established

IP Address double,

fatal error

Online, no connection

established

Connection timeout

packet is received or

transmitted

Flashing 1Hz

green

10/08 49 51207 Revision 1

Watchdog LED

Modul initialized and running without problems

Flashing 2Hz

green

Flashing red

Modul not initialized

RAM, ROM or ASIC test error

Section 3: Installing the Instrument and Plug-In Cards

10/08 50 51207 Revision 1

Section 3: Installing the Instrument and Plug-In Cards

3.4.13 PR 5510/14 ModBus TCP Interface

The Ethernet interface PR 5510/14 is a plug-in card for installation in Slot 4, Chapter 3.4.1. The card

is fitted with a standard RJ-45 socket for Ethernet connection.

It contains powerful TCP/IP and ModBus TCP connecting circuitry with transfer rates of 10 and

100Mbits/s.

Internal connection: 34-pin connector on flat cable

for Slot-4

External

connection:

Transfer rate: 10Mbits/sec (10BaseT , Ethernet) and

Connection mode: Network

Protocol: ModBus-TCP

Transport: TCP/IP or UDP/IP

Certificates: Compatible with ModBus-TCP standard

Cable: Twisted pairs, screened

Cable impedance: 150 Ohm

Cable length to

HUB:

Dimensions

(LxWxH):

Weight: 125 g

Application: ModBus TCP as a Fieldbus interface

The IP-Address and the Subnet-Mask are set at Fieldbus parameter FP 96 und 97. (see chapter

4.7.7 and Error! Reference source not found.).

87 x 55 x 15mm Potential isolation: Yes

RJ-45 connecting socket in holding

plate

100Mbits/sec (100BaseTx, Fast

Ethernet)

Auto-detection (10/100, HalfDX/FullDX)

of ModBus organization

suitable for industrial applications CE,

UL, cUL

e.g. patch cable CAT5

Autolink (straight or crossover)

Max. 115 m

Take care, that switches 1 - 8 are set to (OFF)

10/08 51 51207 Revision 1

Section 3: Installing the Instrument and Plug-In Cards

3.5 C

Load cells or analog platforms (e.g., from the CAPP series) can be connected.

The supply voltage is protected from short circuit and overload.

The card is fitted with a solder link (factory setting: closed; see Chapter 3.5.5), which should be

opened only when the supply voltage and thus also the sense voltage are reduced to below approx.

+/- 4 VDC.

ONNECTING LOAD CELLS

Terminal block Connection Description

+M + meas. + signal/LC output

- M - meas. - signal/LC output

+V + supply + supply/excitation

+S + sense + sense

- S - sense - sense

- V - supply - supply/excitation

Housing GND shield/ground

3.5.1 Connecting a Load Cell with 4-Wire Cable

Provide links

between + supply and + sense and

between – supply and - sense

directly at the terminal block.

The cable colors shown above are applicable to the PR 62.. series load cells.

Before connecting, check the assignment of cable colors in the load cell manual.

3.5.2 Connecting PR 6221 Load Cells

See PR 6021/08, -/68 operating manual.

10/08 52 51207 Revision 1

Section 3: Installing the Instrument and Plug-In Cards

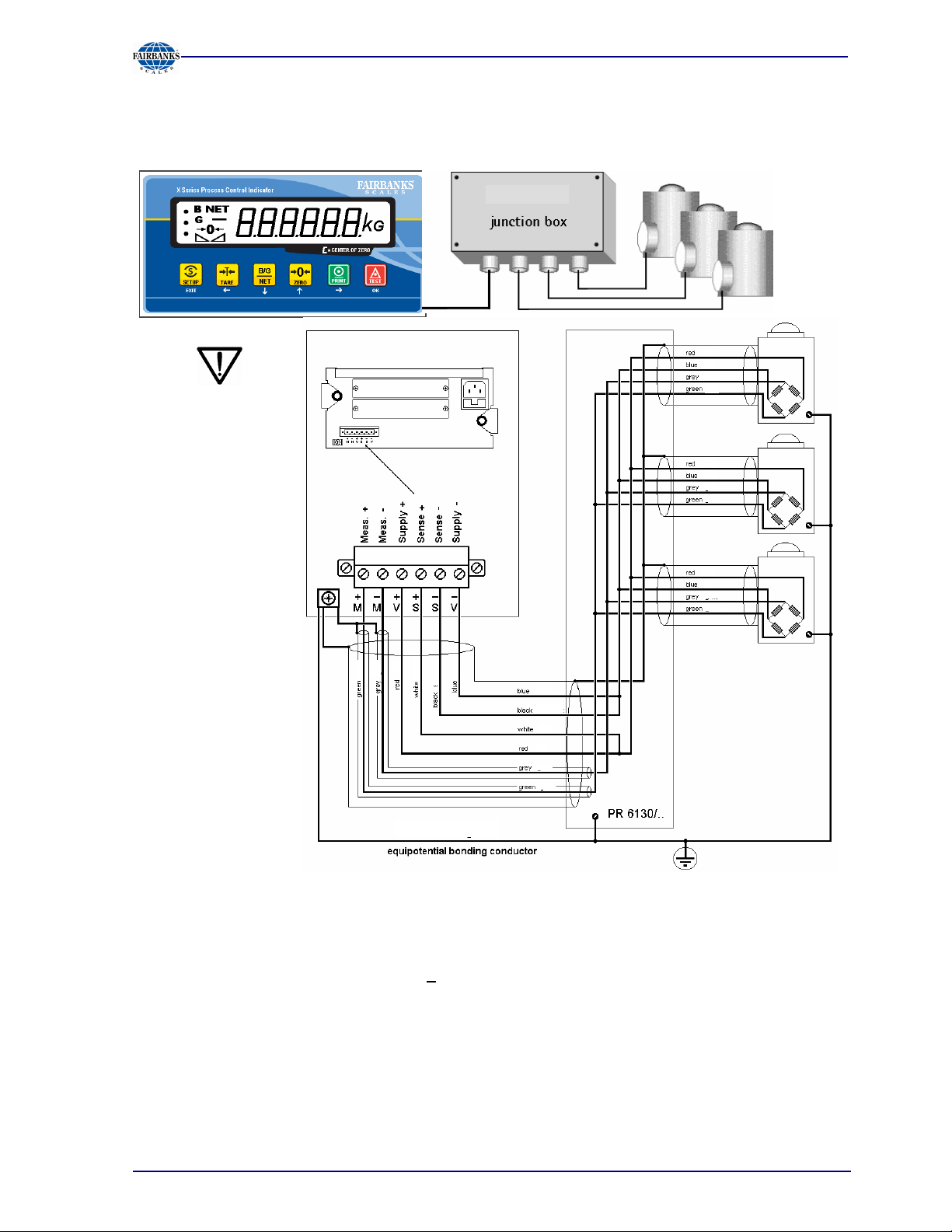

3.5.3 Connecting up to 8 Load Cells (650 Ohms) Using 6-Wire Connecting Cable

Via cable junction box PR6130/.. using PR 6135 or PR6136 connecting cable:

The cable colors

shown here are valid

for PR 62 . . series

load cells and for the

PR 6135 connecting

cable.

When using different

load cells, the cable

colors may have

different

assignments.

For this reason,

consult the relevant

manual or data sheet

for the assignments

of cable colors

before connecting.

Recommendations: - Install cable in steel pipe connected to earth potential.

- Min. distance to high-voltage cables: 1m

Load cell supply circuit:

Load resistance of load cell circuit > 75 ohms, e.g. 8 load cells of 650 ohms each,

supply voltage is 12 V DC; for further data, see Chapter 12.4.

10/08 53 51207 Revision 1

Section 3: Installing the Instrument and Plug-In Cards

3.5.4 Connecting Load Cells with External Supply

When the load of the load cells is < 75 ohms (e.g. more than 4 load cells with 350 ohms), external

load cell supply is required. In this case, the internal supply is replaced by a potential-free external

supply. The neutral wire of the external supply voltage (0 ext. supply) must be connected to the

instrument housing to ensure that the voltage is symmetrical to 0. The internal supply is not

connected.

The cable colors indicated

above are valid for connecting

cable PR 6135.

When using other load

cells/cables, the assignment of

colors may differ.

For this reason, the relevant

manual or data sheet should be

consulted for assignments of cable

colors before connecting.

10/08 54 51207 Revision 1

Section 3: Installing the Instrument and Plug-In Cards

3.5.5 Connecting Load Cells via Intrinsically Safe Load Cell Interface PR 1626/60

The cable colors shown here are

valid for the PR 62.. series load cells

and for PR 6135 and PR 6136

connecting cables.

When using other load cells, the

assignments of cable colors may differ.

For this reason, the relevant manual or

data sheet should be consulted for

assignments of cable colors before

connecting.

When using the PR 1626/60 intrinsically

safe load cell interface with 7.5 VDC

(MX 8 closed), open the solder link on

the main board of PR5410 to switch the

sense voltage detection.

The PR5410 load cell supply must not

be connected.

10/08 55 51207 Revision 1

Section 3: Installing the Instrument and Plug-In Cards

3.5.6 Connecting Platforms (CAP...)

One Combics analog platform (CAP... series) can be connected to the instrument.

The following example shows a platform with 6-wire connection and another one with 4-wire

connection.

Platforms with

4-wire connection require

links between +V and +S and

between –V and –S.

The cable colors shown above are valid for a CAPP4 500 x 400 and a CAPP1 320 x 420, as

an example.

The assignments of cable colors are given in the platform operating manual.

The cable shields must be connected to the GND terminal of the instrument. If the measuring lines

(+M, -M) are shielded individually, these shields must be connected to the GND terminal as well.

10/08 56 51207 Revision 1

Section 4: Commissioning

4 Commissioning

Front panel key assignment and operating concept are described in Chapter 2.3.

4.1 D

The calibration data and parameters as well as all configuration and interface data are stored in

non-volatile (EAROM) memory. Unauthorized data changing can be prevented by an access code;

the front panel keys can be disabled. Additional write protection is provided for calibration data and

parameters (CAL switch, see Chapter 4.1.1). Clock and calendar continue running in the event of a

power failure.

The CAL switch is located on the instrument back panel. Generally, we recommend setting the

switch into the closed position after calibration to prevent accidental overwriting/data loss.

The built-in alibi memory is protected against erasure, as long as the CAL switch is closed.

With legal-for-trade applications, the CAL switch must be sealed in the closed position.

ATA PROTECTION/POWER FAILURE

4.1.1 CAL Switch

With operation via front keys with under Cd 000 'CAL.CLS' is shown if the CAL switch is closed,

the calibration data and - parameter can be viewed but not altered.

To view the position of the CAL switch with VNC, select -[Show status]:

Info/Status

Free system RAM 1904 of 13136 kb

Clock battery ok

Cal-Switch opened

[opened] = opened; no write protection

[closed] = closed; write protection is active.

10/08 57 51207 Revision 1

Section 4: Commissioning

4.2 S

The instrument can be put into operation and calibrated using a PC with the VNC program (on the

enclosed CD), an Internet browser or the ConfigureIt program.

On initial start-up, the date and time must be set.

When the supply voltage is applied to the instrument, the following information is displayed:

xPR5410w

xB,10,00,0w

xF,10,00,0w

z,8,8,8,8,8,8y

m135,050b

xERROR6

Press to access the front panel key menu: xDS,PTS,Tx.

WITCHING ON THE INSTRUMENT

Instrument type: PR5410 = X3

BIOS release

Firmware release

Automatic display test

Weight display

Error message if no load cells are connected, see Chapter 4.6.1.

4.2.1 Display Test

Press to activate all display items. After approx. 5 s,

z,8,8,8,8,8,8y

4.2.2 Front-Panel Key Test

Press and hold , then press as well.

x,0,0,0,0,0,0w

x,0,0,0,1,0,0w

x-8023-w

If no key is pressed for 5 s, the test is finished automatically and the weight is displayed again.

4.2.3 Resetting the Instrument to the Factory Settings

Reset to the factory settings is possible only, when the CAL switch is open.

DS,PTS,Tw

BIOS w

BIO,S..w

FLASH w

DE,LEA,Rw

ERA,S 0w It is asked, whether resetting should be done

ERA,S 1w

DONE w

One digit per key is displayed. Each time a key is pressed, the corresponding digit is

incremented by 1

Display, if is pressed once

Display, if several keys (2 and 3) are triggered simultaneously

Press Setup at the instrument

Press to reach the BIOS menu

Press

Is displayed, followed by

Press

Press

Alter with the '0' to '1' for resetting and confirm with

Is displayed to indicate the execution

to go to menu

the menu is closed automatically.

10/08 58 51207 Revision 1

Section 4: Commissioning

4.2.4 Setting the Network Address Using Front-Panel Keys

DS,PTS,Tw

BIOS w

BIO,S..w

FLASH w

NET w

I,PADDRw

00,000,0

00,000,0

MASK w

22525,0w

24,000,0w

SAVE 0w

SAVE 1w

DONEw

ERR31w

For DHCP (Assignment by server) the address has to be set to 00,000,0w 00,000,0w .

4.2.5 Viewing the Network Address via Front-Panel Keys

DS,PTS,Tw

BIOS w

BIO,S..w

FLASH w

ETHERw

DHC,P..w

17,202,4w

2,108,1w

FLASH?w