Page 1

Installation Manual

™

Ultegra Junior

Bench Scale

USB Interface

2011-2013 by Fairbanks Scales, Inc.

All rights reserved

51119

Revision 4 07/13

Page 2

Page 3

Amendment Record

Ultegra Junior Bench Scale – USB Interface

Document 51119

Manufactured by Fairbanks Scales Inc.

821 Locust St.

Kansas City, Missouri 64106

Created 01/2006

Revision 1 02/2006 Released Manual

Revision 2 05/2007 Updated and added corrections for product specifications

Revision 3 01/2011 Revisions to format.

Revision 4 07/2013 Corrected formatting and parts list.

.

Page 4

Disclaimer

Every effort has been made to provide complete and accurate information in this manual. However,

although this manual may include a specifically identified warranty notice for the product, Fairbanks

Scales makes no representations or warranties with respect to the contents of this manual, and reserves

the right to make changes to this manual without notice when and as improvements are made.

© Copyright 2011-2013

This document contains proprietary information protected by copyright. All rights are reserved; no part

of this manual may be reproduced, copied, translated or transmitted in any form or by any means

without prior written permission of the manufacturer.

Page 5

Table of Contents

SECTION 1: GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1. Introduction

1.2 Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2: SERVICE POLICY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1. General Service Policy

2.2. Conferring with Our Client

2.2.1. Service Technician’s Responsibilities

2.2.2. Users’ Responsibility

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3: INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1. Prior to installation

3.1.1. Pre-Installation Checklist

3.1.2. Unpacking

3.1.3. Finding the Best Location

3.2. Powering up the scale

3.3. Computer Interface

3.3.1 Connections:

3.3.2 Computer Interface Driver

3.3.3 USB Data Output

3.4. Weighing

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10

11

11

11

11

11

11

6

6

7

8

8

8

9

9

9

SECTION 4: PROGRAMMING CONFIGURATION. . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1: Gaining Access to the Program Mode:

4.2: Keys in Programming/Calibration Mode

4.3. Programming Steps

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13

13

13

SECTION 5: PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1. Diagrams and Parts List

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15

APPENDIX I: ULTEGRA JUNIOR CABLING DETAIL . . . . . . . . . . . . . . . . . . . . 17

07/2013

5

51119 Rev. 4

Page 6

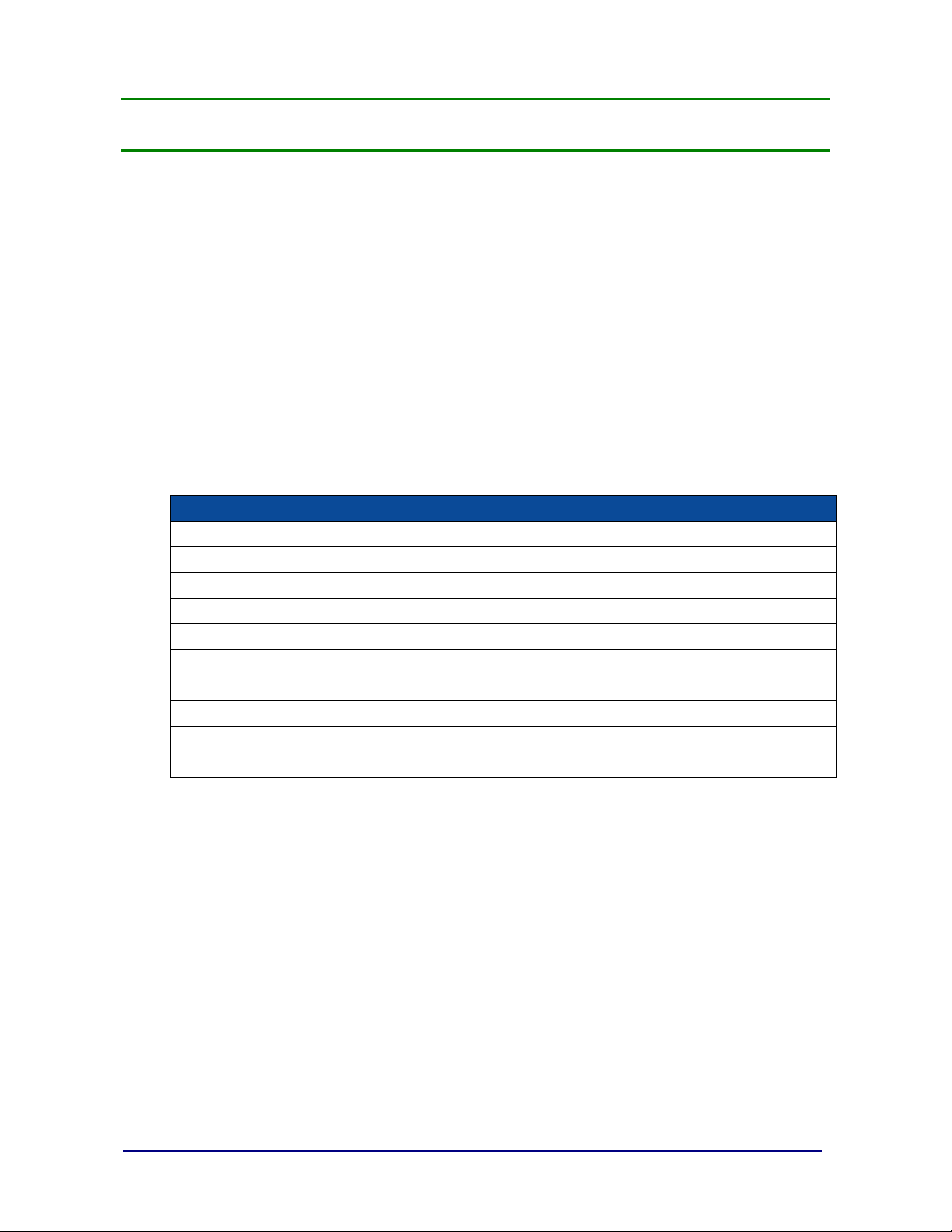

Feature

Description

Display

4-

digit, LCD, 0.5” tall

Capacity

70 lbs / 32 kg

Division Size

0.05 lbs / 0.02 kg

Load Cell

1 – 350 Ohm

Power Requirement

117

VAC, Wall Transformer

– Output 9 VDC, 20mA (min)

Dimensions

11” x 11” x 1.5”

Interfaces

USB for computer (HID

-

10 protocol)

Other RJ-

45 for remote display

Units

Pounds and Kilograms

Approvals

ROHS compliant

Section 1: General Information

1.1. Introduction

The Ultegra Junior Parcel / Shipping scale is a fully electronic, low profile scale that is

designed for shipping and general industrial weighing applications.

• General weighing, non-washdown environments

• Pound and kilogram annunciators

• USB Interface to computers

• RoHS Compliant

1.2 Specifications

07/2013

6

51119 Rev. 4

Page 7

Section 2: Service Policy Information

2.1. General Service Policy

Prior to installation, always verify that the equipment

satisfies the customer's requirements as supplied,

and as described in this manual.

If the equipment cannot satisfy the application and the application

cannot be modified to meet the design parameters of the

equipment, the installation should NOT be attempted.

It is the customer/operator's responsibility to ensure the equipment

provided by Fairbanks is operated within the parameters of the

equipment's specifications and protected from accidental or

malicious damage.

Absolutely NO physical, electrical or program modifications other

than selection of standard options and accessories can be made

by customers to this equipment

Repairs are performed by Fairbanks Scales Service Technicians

and Authorized Distributor Personnel ONLY!

Failure to comply with this policy voids all implied and/or written

warranties.

W A R N I N G !

07/2013

7

51119 Rev. 4

Page 8

Section 2: Service P olicy Information

2.2. Conferring with Our Client

• The technician must be prepared to recommend the arrangement of components which

provides the most efficient layout, utilizing the equipment to the best possible advantage.

• Explain and review the warranty policy with the customer.

The

installing technician

fully trained and familiar with the equipment's capabilities and

limitations before the installation is considered complete.

• All electrical assemblies must be returned intact for replacement credit using the

standard procedures.

• At the time of installation, all electronic and mechanical adjustments are considered to

be part of the installation, and are included in the installation charge(s).

is responsible that all personnel are

• The AC receptacle/outlet shall be located near the Indicator and easily accessible.

• Electrical connections other than those specified may not be performed.

2.2.1. Service technician’s responsibilities

• All electronic and mechanical calibrations and/or

adjustments required for making this equipment perform

to accuracy and operational specifications are considered

to be part of the installation.

They are included in the installation charge.

Only those charges which are incurred as a result of the

equipment's inability to be adjusted or calibrated to

performance specifications may be charged to warranty.

• The equipment consists of printed circuit assemblies which

must be handled using ESD handling procedures, and must be replaced as units.

Replacement of individual components is not allowed.

The assemblies must be properly packaged in ESD

protective material and returned intact for replacement

credit per normal procedures.

2.2.2. Users’ responsibility

Absolutely no physical, electrical or program modifications other

than selection of standard options and accessories are to be

made to this equipment.

07/2013

8

51119 Rev. 4

Page 9

Section 3: Installation

3.1. Prior to installation

1. Pre-Installation checklist

2. Powering up the scale

3. Computer interface

4. Weighing

3.1.1. Pre-installation checklist

The following points should be checked and discussed with the Area Sales Manager

and/or customer, if necessary, before the technician goes to the site and installs the

equipment.

Check the customer's application to make certain it is within the capabilities and

design parameters of the equipment.

If the installation process might disrupt normal business operations, tell the

customer and ask that they make ample arrangements.

Be sure that the equipment operator(s) are available for training.

The service technician reviews the recommended setup with the

Area Sales Manager or Area Service Manager, and together

they identify all necessary variations to satisfy the customer's

particular application.

3.1.2. Unpacking

Follow these guidelines when unpacking all equipment:

• Check in all components and accessories according to the customer's order.

• Remove all components from their packing material, checking against the invoice

that they are accounted for and not damaged.

Advise the shipper immediately, if damage has occurred.

Order any parts necessary to replace those which have been damaged.

Keep the shipping container and packing material for future use.

Check the packing list.

• Collect all necessary installation manuals for the equipment and

accessories.

• Open the equipment and perform an inspection, making certain that

all hardware, electrical connections and printed circuit assemblies

are secure.

• Do not reinstall the cover if the final installation is to be performed

after the pre-installation checkout.

07/2013

9

51119 Rev. 4

Page 10

Section 3: Installa tion

3.1.3. Finding the best location

Position the equipment with these points in mind:

• Intense direct sunlight can harm the display.

• Do not locate near magnetic material or equipment/Indicators which use magnets

in their design.

• Avoid areas which have extreme variations in room temperatures. Temperatures

outside the Indicator’s specifications will affect the weighing accuracy of this product.

• Do not open the Indicator if there is any evidence of damage to it or any other

scale component or supporting structure.

• When selecting the right location for the Indicator and the scale, keep the

components completely away from all high water, such as low-lying areas that

may flood, and away from any drain pipes.

IMPORTANT INSTALLATION NOTICE

• All load cells, load cell cables and interconnecting cables used to connect all

scale components shall be located

away

carrying conductors.

• This includes digital weight indicators, junction boxes, sectional

controllers, and power supplies.

• This includes any peripheral devices, such as printers, remote

displays, relay boxes, remote terminals, card readers, and auxiliary

data entry devices.

• Also included is the scale components themselves, such as 120 volt

AC, 240 volt AC, 480 volt AC and electric supply of higher voltage

wiring runs and stations, AC power transformers, overhead or buried

cables, electric distribution panels, electric motors, florescent and

high intensity lighting which utilize ballast assemblies, electric heating

equipment, traffic light wiring and power, and relay boxes.

• All scale components, including digital weight indicators and peripheral

devices are not designed to operate on internal combustion engine

driven electric generators and other similar equipment.

from all single and multiple phase high energy circuits and electric current

Electric arc welding can severely damage scale components such as

digital weight indicators, junction boxes, sectional controllers, power

supplies, and load cells.

a minimum distance of 36” inches

NOTE:

07/2013

For additional information, please contact your

Service Representative.

10

Fairbanks Scales

51119 Rev. 4

Page 11

Section 3: Installa tion

3.2. Powering up the scale

The scale performs a warm-up cycle. During the warm-up cycle . . .

• The display scrolls from 1 to 9 in sequential order using all available digits

while toggling between the available annunciators.

• The program number will display briefly (PXXXXX), followed by the software revision.

• Then “” scrolls across the display.

• “-----” for a few seconds

• “”, Scale is ready to weigh

• After approximately 30 seconds with no weight on the scale it will go into a

sleep mode. The display will continuously scroll “”.

Simply applying any weight to the platform will wake-up the scale.

3.3. Computer interface

3.3.1 Connections:

The USB Type A port is a hard-wired connection inside the scale. Connect the

other end of the USB cable to an unused USB port on your computer. Use the

configuration procedure supplied with your freight provider’s computer software.

3.3.2 Computer interface driver

The USB port will only function with a computer running Windows 2000 or

higher operating system. When the scale’s USB cable is connected to the

computer’s USB port, the computer will prompt “a device has been found” and

it will automatically install the driver. Check with your software manufacturer or

freight provider for compatible computer software.

3.3.3 USB data output

The Ultegra Junior uses the HID-10 USB protocol.

3.4. Weighing

With the platform empty, press the [ZERO] key.

The display will indicate zero.

Note:

The “C” to the left of the “0.00” indicates true center of zero.

07/2013

11

51119 Rev. 4

Page 12

Section 3: Installa tion

Check that the correct units are indicated; press the [UNITS] key to change

to "lb" or "kg".

Place the item to be weighed centered on the platform.

Read the Gross weight from the display.

07/2013

12

51119 Rev. 4

Page 13

Section 4: Programming Configuration

4.1. Gaining Access to the program mode:

There is a pushbutton installed on the internal printed circuit board assembly.

Press the CAL button, S1 on the PCB, accessed through hole in back.

&

REMOTE

DISPLAY

PORT

AC ADAPTER

USB

OUTPUT

CABLE

REAR VIEW

PROGRAMMING

CALIBRATION

PUSHBUTTON

4.2. Keys in Programming/Calibration Mode

Each program step has more than one choice. The [UNITS] key will toggle the

displayed value, the [ZERO] key will accept the current displayed value, and move

to the next step.

4.3. Programming Steps

4.3.1. First program step: Zero range -- The display will show USA or CAn.

• The zero range is set at 2% or 1.4 lbs when programmed for Canadian use

• The zero range is set at 100% or 70 lbs when programmed for USA use

Press the [UNITS] key to change, [ZERO] key to accept.

4.3.2. Second program step: Active Units -- Diamonds on the bottom of the display

will point to the currently enabled units. Selections available are lb only, kg only, or

lb/kg selectable.

Press the [UNITS] key to change, [ZERO] key to accept.

07/2013

13

51119 Rev. 4

Page 14

Section 4: Programming Configuration

4.3.3. Third program step: Weighing Mode: Display will show rAngE or 2000d.

2000d will set the weighing mode to 70 lb capacity by 0.05 lb / 31.75 kg by 0.01 kg.

rAngE will set the weighing mode to automatically change its increment size as

follows:

Scale will weigh from 0 lb to 28 lb by 0.02 lb increment (0-14 kg by 0.01 kg)

Scale will weigh from 28 lb to 70 lb by 0.05 lb increment (14 kg to 31.75 kg by 0.02

kg)

Press the [UNITS] key to change, [ZERO] key to accept.

4.3.4. Fourth program step: Output mode: The display will show COnt or POLLEd.

COnt will establish a continuous output stream to the computer.

POLLEd will establish a demand output to the computer.

Press the [UNITS] key to change, [ZERO] key to accept.

NOTE: The following steps will calibrate the scale. If you do not wish to alter the

calibration, press the CAL button to leave the programming area.

4.3.5 . Fifth program step:: Zero reference: The display will show -----. Ensure the

scale is empty of any objects and press the [ZERO] key. A “0: digital count will now

be displayed. If necessary, the [ZERO] key can be pressed repeatedly to establish

clean zero reference.

4.3.6 . Sixth program step: Test Weights: Apply a known test weight value that

matches one of the following choices. When the test weight(s) are applied, the

displayed digital counts value will increase in relation to the applied load. Press the

[UNITS] key repeatedly until the correct Test weight value is displayed,

5,10,15,20,30,40,50,60,70 lbs; 10,20,30, KG . You can continue to press the

[UNITS] key to cycle through the choices again if required.

4.3.7. Seventh program step: Calibration: Press the [ZERO] key or the CAL switch to

complete scale calibration. The display will show good if the calibration is

successful, and error if not. The scale will then return to weight mode.

07/2013

14

51119 Rev. 4

Page 15

1

1

2

3

4

5

6

6

7

8

9

Section 5: Parts

5.1. Diagrams and Parts List

07/2013

15

51119 Rev. 4

Page 16

Section 5: Parts

UNITS ZERO

FRONT VIEW

=CENTER OF ZERO

lb

kg

MADE IN THE U.S.A.

Product Number: 25701C

Key # Part # Description

___________________________

1 25709 Socket cap screw, flat head, M6 x 25

2 20190 Foot

3 25697 Base frame

4 25706C Display assembly (Complete assy, includes pushbuttons and overlay.)

5 26783CB Main PCB assembly

6 25695 Plates, upper and lower

7 25698C Load cell

8 25696 Weigh platter

9 25699 Top mat

24532 Remote Display

Not Pictured

15805 Cable assembly, display to main PCB assembly

29827C Cable assembly with connector, USB output

28182C A/C power adapter

07/2013

16

51119 Rev. 4

Page 17

ZERO

=CENTER OF ZERO

lb

kg

Fairbanks Scales

UNITS

1

5

DISPLAY

P3

DISPLAY

P2

S4

J1

P4

P5

S1

51

REMOTE

DISPLAY

AC ADAPTER

USB

OUTPUT

CABLE

CALIBRATION

PROGRAMMING

&

PUSHBUTTON

REAR VIEW

TOP VIEW

MAIN PCB

LOADCELL

Appendix I: Ultegra Junior Cabling Detail

07/2013

17

51119 Rev. 4

Page 18

Ultegra Junior Bench Scale

Manufactured by Fairbanks Scale, Inc

821 Locust Street

Kansas City, MO 64106

www.fairbanks.com

.

USB Interface

Document 51119

Loading...

Loading...