Fairbanks Tundra Series Truck Scale User Manual

© 2008-2012 by Fairbanks Scales, Inc.

INSTALLATION MANUAL

Tundra Series

Truck Scale

All rights reserved

51193

Revision 5 12/12

Disclaimer

Every effort has been made to provide complete and accurate information in this manual. However,

although this manual may include a specifically identified warranty notice for the product, Fairbanks

Scales makes no representations or warranties with respect to the contents of this manual, and reserves

the right to make changes to this manual without notice when and as improvements are made.

Fairbanks Scales shall not be liable for any loss, damage, cost of repairs, incidental or consequential

damages of any kind, whether or not based on express or implied warranty, contract, negligence, or

strict liability arising in connection with the design, development, installation, or use of the scale.

© Copyright 2008-2012

This document contains proprietary information protected by copyright. All rights are reserved; no part

of this manual may be reproduced, copied, translated, or transmitted in any form or by any means

without prior written permission of the manufacturer.

12/12 3 51193 Revision 5

AMENDMENT RECORD

Tundra Series Truck Scale

Installation Manual

Document 51193

Manufactured by Fairbanks Scales, Inc.

821 Locust Street

Kansas City, MO 64106

Created 8/2008

Revision 1 11/2008 Documentation Release

Revision 2 03/2010 Updated parts list to include checking

Revision 3 08/2010 Corrected drawing 51193-4 to 51193-4a

Revision 4 04/2012 Updated drawings and images. Added magnet to parts list.

Revision 5 12/2012 Updated parts list; new images, pages 9, 38, 40, and 47.

12/12 4 51193 Revision 5

Table of Contents

SECTION 1: GENERAL INFORMATION .................................................................................................................................. 7

1.1. Scale Descriptions .................................................................................................... 7

1.2. Scale Applications ..................................................................................................... 7

1.3. Component Descriptions .......................................................................................... 8

1.3.1. Weighbridge ......................................................................................................................... 8

1.3.2. Deck ..................................................................................................................................... 8

1.3.3. Scale Pit ............................................................................................................................... 9

1.3.4. Smart Sectional Controllers (SSCs) .................................................................................... 9

1.3.5. Load Cells .......................................................................................................................... 10

1.4. Component Specs ................................................................................................... 11

1.4.1. Load Cell Specifications .................................................................................................... 11

1.4.2. Platform Specifications ...................................................................................................... 11

1.5. Options ..................................................................................................................... 12

1.6. Accessories ............................................................................................................. 12

SECTION 2: COMPANY SERVICE INFORMATION ......................................................................................................... 13

2.1. General Service Policy ............................................................................................ 13

2.1.1. Service Technician’s Responsibiliti es ................................................................................ 14

2.1.2. Users’ Responsibility.......................................................................................................... 14

SECTION 3: PRE-INSTALLATION ....................................................................................................................................... 15

3.1. Conferring with Our Client ...................................................................................... 15

3.2. Pre-Installation Checklist ........................................................................................ 15

3.3. Unpacking ................................................................................................................ 16

3.3.1. Physical Installation Notes ................................................................................................. 17

3.4. Tools, Equipment and Materials............................................................................. 17

3.4.1. Measuring, Testing & Checking Equipm ent ...................................................................... 17

3.4.2. Assembly Tools .................................................................................................................. 18

3.4.3. Materials ............................................................................................................................ 18

3.5. Precautions .............................................................................................................. 20

3.5.1. Welding .............................................................................................................................. 20

3.5.2. Load Cell Installation Precautions ..................................................................................... 21

3.5.3. Load Cell Handling............................................................................................................. 21

3.6. Site Inspection ......................................................................................................... 22

3.6.1. Pit/ Foundation ................................................................................................................... 22

3.6.2. Scale House ....................................................................................................................... 22

SECTION 4: SCALE INSTALLATION ................................................................................................................................... 23

4.1. Standard Installation Steps .................................................................................... 23

4.2. Inspecting the Contractor’s Pit Construction ....................................................... 24

4.3. Weighbridge Section Assembly ............................................................................. 24

4.3.1. Proper Bolt Torque............................................................................................................. 25

4.3.2. Torque Chart ................................................................................................................... 26

4.4. Moving the Assembled Sections............................................................................ 27

4.5. Installing Base Plates, and Locator Tools ............................................................. 28

12/12 5 51193 Revision 5

Table of Contents

SECTION 4: SCALE INSTALLATION, CONTINUED

4.6. Completing Scale Construction ............................................................................. 29

4.7. Concrete Deck Forming and Pouring .................................................................... 32

4.8. Replacing the Locator Tools with Load Cells ....................................................... 34

4.9. Mounting the Weighbridge Components .............................................................. 35

4.9.1. SSC, PPS, or Balance Box Mounting ................................................................................ 35

SECTION 5: ELECTRICAL INSTALLATION .......................................................................................................................36

5.1. Wiring Information ................................................................................................... 36

5.1.1. Maximum Cable Lengths ................................................................................................... 36

5.2. Electronic Component Care ................................................................................... 36

5.2.1. Protection Against Hostile Environments........................................................................... 37

5.2.2. Tightening O-rings ............................................................................................................. 38

5.3. Load Cell Numbering............................................................................................... 39

5.4. Smart Sectional Controller (SSC) to Load Cell Wiring ......................................... 40

5.4.1. RC Load Cell Wiring .......................................................................................................... 40

5.5. Power Supply Wiring ............................................................................................... 41

5.6. Indicator to Pit Power Supply Cable Connection ................................................. 42

5.7. Grounding the Scale ............................................................................................... 43

5.8. Indicator and Accessories. Test and Calibration ................................................. 44

SECTION 6: SERVICE & MAINTENANCE ......................................................................................................................... 45

6.1. Recommended Preventive Maintenance Schedule .............................................. 45

6.1.1. Performed every month .................................................................................................. 45

6.1.2. Performed every six (6) months ......................................................................................... 45

6.2. Component Replacement Steps............................................................................. 46

6.2.1. Rocker Column Load cell replacement .............................................................................. 46

6.2.2. SSC Board Replacement ................................................................................................... 47

6.2.3. Pit Power Supply PC Board Replacement ........................................................................ 47

SECTION 7: PARTS ................................................................................................................................................................ 48

7.1. Scale Parts List ........................................................................................................ 48

7.2. Load Cells and Hardware ........................................................................................ 48

7.3. O-Rings ..................................................................................................................... 49

APPENDIX I: INTALOGIX WIRING .................................................................................................................................. 50

APPENDIX II: FOUNDATION CHECK LIST ........................................................................................................................ 53

APPENDIX III: PIT DRAWING ............................................................................................................................................. 54

12/12 6 51193 Revision 5

SECTION 1: GENERAL INFORMATION

1.1. SCALE DESCRIPTIONS

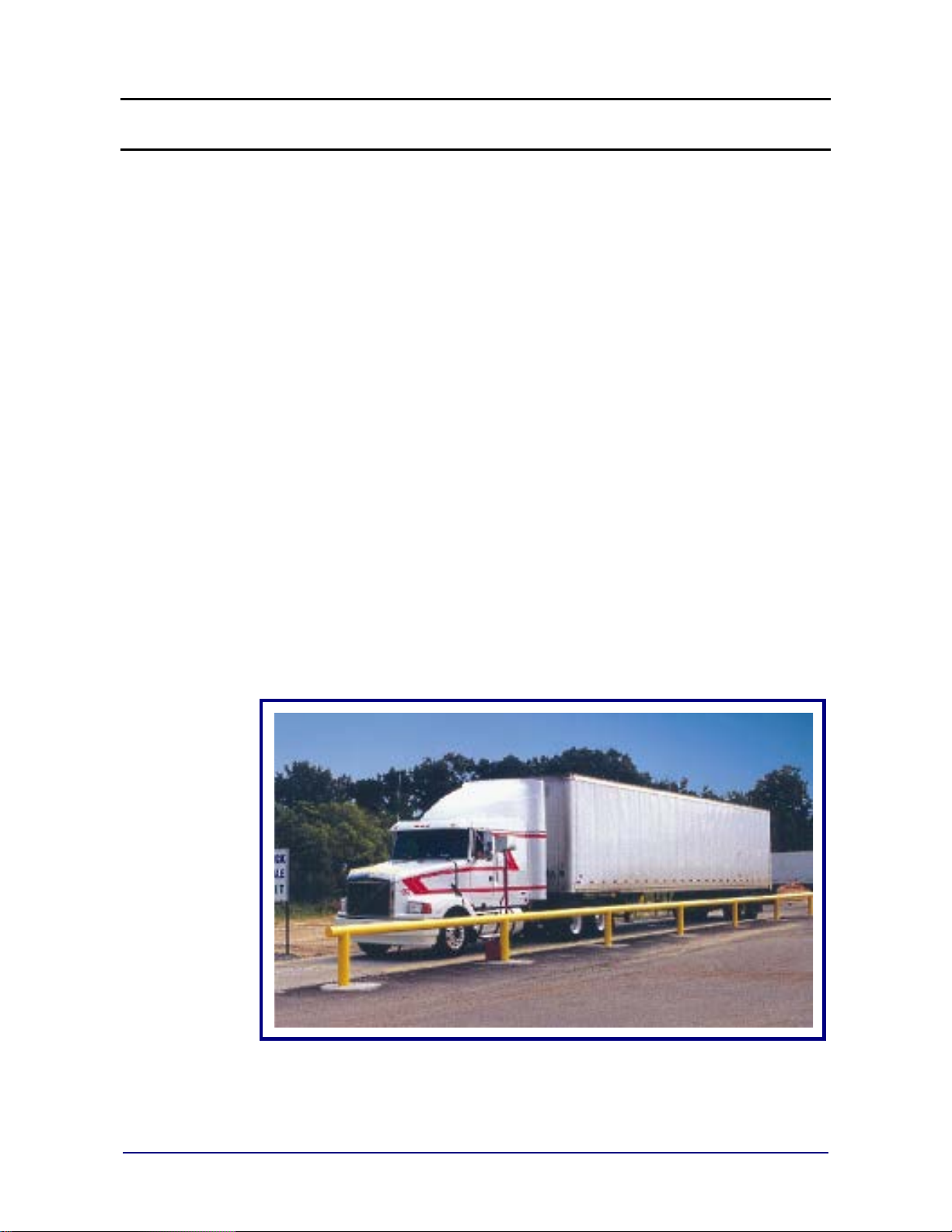

The Tundra Truck Scale is a fully electronic Pit Type Truck Scale.

• This field-assembled unit has a pour-in-place concrete deck.

• Concrete approaches are also required according to H44 Standards.

1.2. SCALE APPLICATIONS

• Asphalt & concrete plants • Aggregate yards • Coal mines

• Dairy farms • Farmer’s markets • Grain plants

• High volume applications • Landfills • Ports of entry

• Timber Mills • Transfer stations • Transportation companies

12/12 7 51193 Revision 5

Section 1: General Information

1.3. COMPONENT DESCRIPTIONS

1.3.1. Weighbridge

The weighbridge is constructed of structural steel beams which bolt together. The

weighbridge is supported by the load cells and bearing plates, and includes checking

devices to limit excessive longitudinal and lateral platform movements.

1.3.2. Deck

The platform deck is constructed of reinforced concrete, as detailed on the

Certified Drawing Specifications.

─ The concrete deck is six inches (6”) thick.

─ Concrete is typically poured over corrugated steel, which rests on the

weighbridge and is contained by a steel channel frame.

─ One or more manholes may be provided for access to the scale pit (optional).

12/12 8 51193 Revision 5

Section 1: General Information

1.3. COMPONENT DESCRIPTIONS, CONTINUED

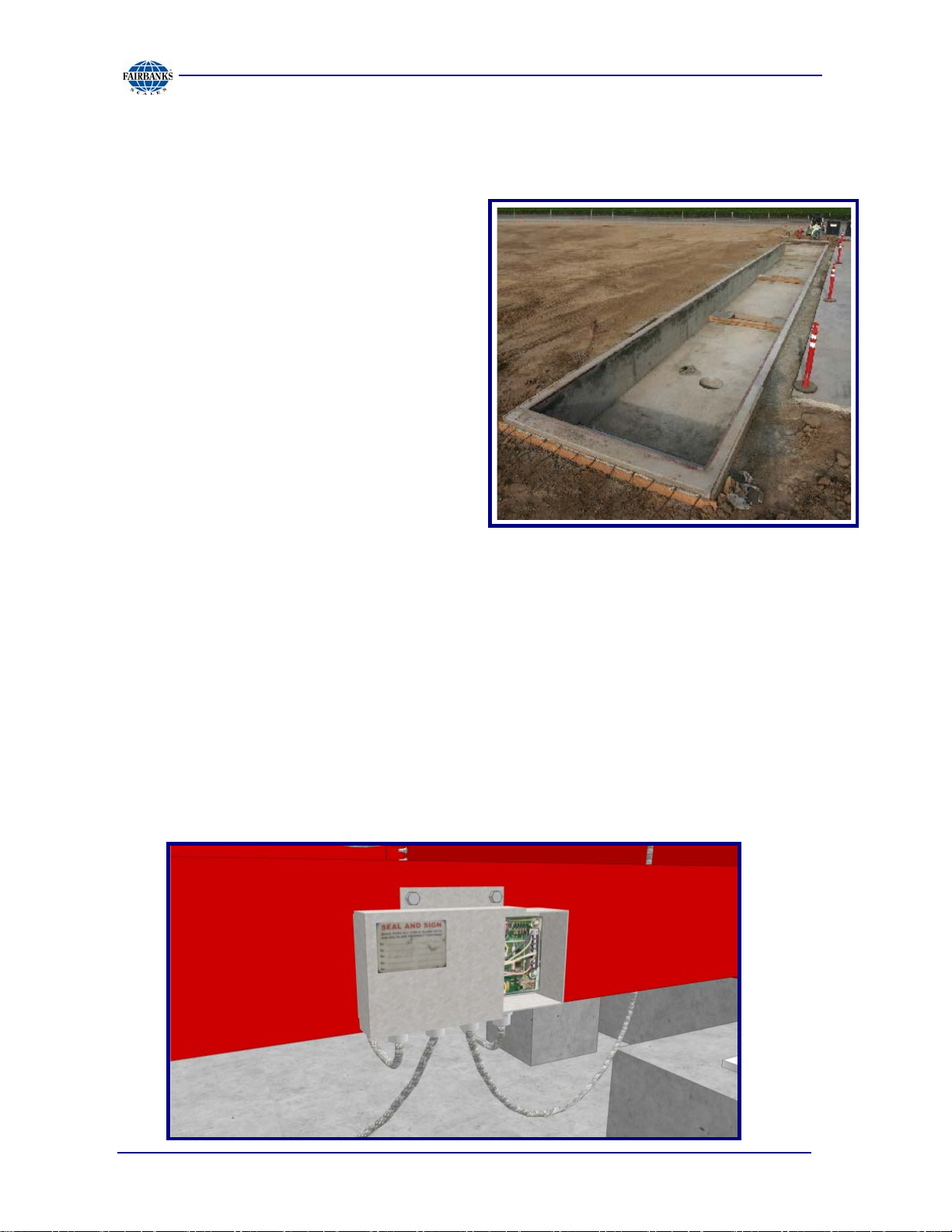

1.3.3. Scale Pit

The scale pit is constructed of reinforced

concrete as detailed on the Certified

Drawing Specifications.

• The Tundra Scale requires a four foot

(4’) or deeper foundation.

─ Some states require a minimum of

four feet (48”) pit depth. Consult

with the local W&M for specifics in

your area.

• The pit includes correctly positioned

piers with level surfaces for RC type

load cell base plates.

• The ground rod(s) should be installed

before the pit floor is poured.

• This System uses Intalogix™

Technology, and requires two (2) pit ground rods.

1.3.4. Smart Sectional Controllers (SSCs)

The Smart Sectional Controllers (SSCs) used on Intalogix™ Applications are mounted

at each section using the supplied self-tapping screws and should be placed on the

cross members at installation.

• Each Sectional Controller has four (4) water-tight gland bushings for cables.

• The Pit Power Supply(ies) are mounted in the same manor.

─ Wiring diagrams for Sectional Controller(s) and Pit Power Supply(ies) are

in Appendix I.

12/12 9 51193 Revision 5

Section 1: General Information

1.3. COMPONENT DESCRIPTIONS, CONTINUED

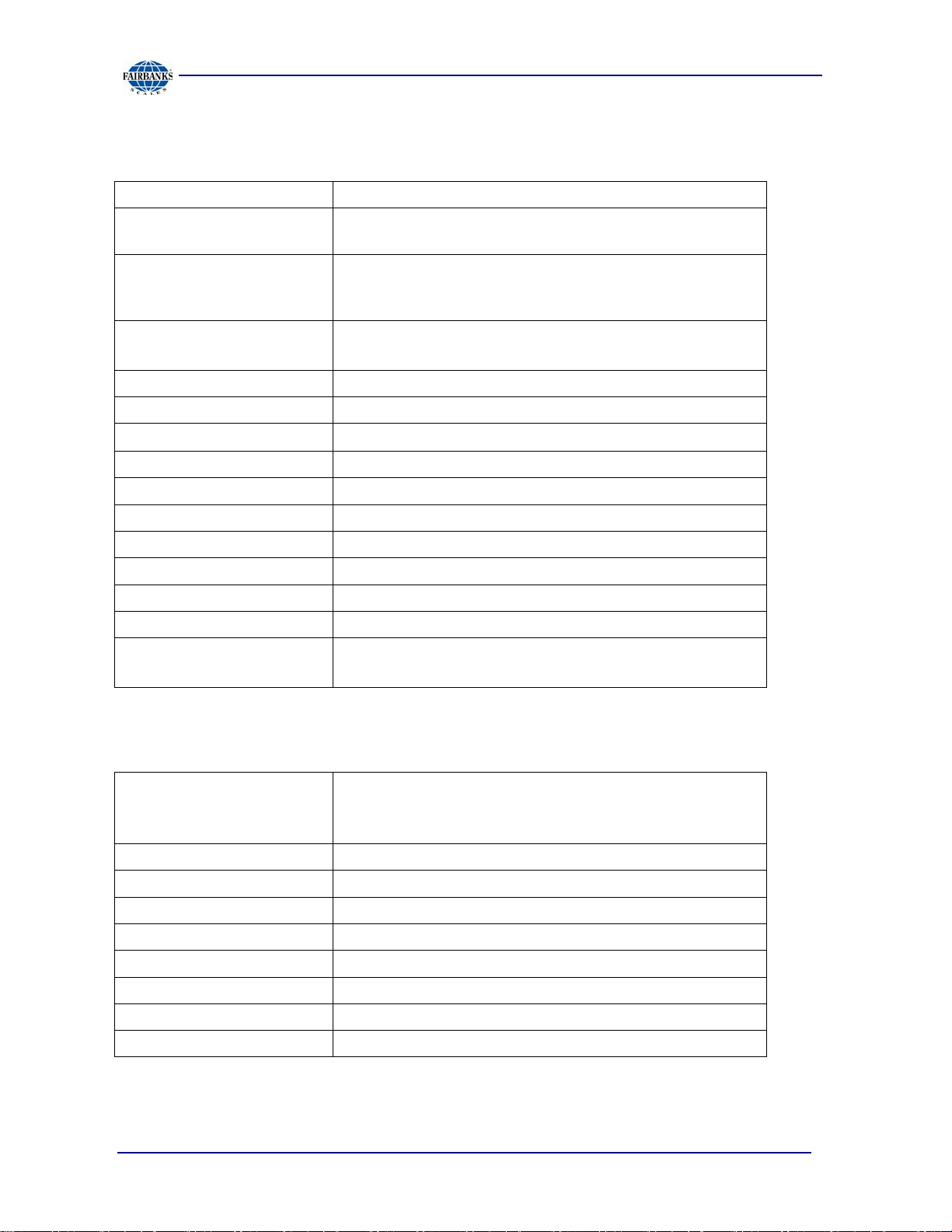

1.3.5. Load Cells

The load cells directly support the weighbridge. The Tundra Truck Scale uses the

Rocker Column (RC) type Load Cell.

─ The RC cells are 5 1/2” tall.

─ The Load Receiver is free-floating design.

─ The platform is free to move within the clearances provided by adjustable

checking.

─ With weight applied or empty, the platform must stay in, or return to the

original position.

─ The load cells are calibrated with the cable attached, and therefore the cable

should NOT be cut.

─ Load cells and sections are adjusted within the Intalogix™ Equipment

Indicator.

12/12 10 51193 Revision 5

Section 1: General Information

66,000 lbs.

Rocker Column (RC Cells)

water-tight gland bushings

17-4 PH (1.3448)

NEMA 6P (IP68)

≤0.02%

1.0%

5 to 15 VDC

300%

15’

Factory Mutual (FM) Approved

Custom sizes also available.

45 tons to 135 tons

60,000 and 90,000 CLC

66,000 lbs

Field Pour Concrete

Structural Steel

6” thick

NTEP CC #06-112

1.4. COMPONENT SPECS

1.4.1. Load Cell Specifications

Capacity

Type

Sealing

Material

Rating

Resistance

Operating Temperature

Output

Combined Error

Zero Balance (FSO)

Excitation

Ultimate Overload

Cable Length

Cable Protection

Approvals

5.5” Electrochemically Polished Stainless Steel

Glass-to-Metal Connection Points, complete

hermetic sealing; cable entry sealed by four (4)

Stainless Steel

1,000 Ohms

-10 to +40°C (-14 to 104°F)

2.0 mv/v

Stainless Steel Sheathing

NTEP CC# 97-078

1.4.2. Platform Specifications

Deck Dimensions

Scale Capacity

CLC

Load Cell Capacity

Sections

Deck Construction

Module Construction

Deck Thickness

Approval

Widths: 10’, 11’ and 12’ Standard

Lengths: 10’ to 120’ Standard

─

2 thru 7

12/12 11 51193 Revision 5

Section 1: General Information

1.5. OPTIONS

• Dump through deck • CLC up to 100,000

• Factory assembled with factory

poured concrete deck

• Steel deck • Galvanized weighbridge

• Structural grating

• Custom design to fit existing

foundations

1.6. ACCESSORIES

• Remote weight displays • Instrumentation

• Intrinsically safe electronics • Remote terminal

• Ticket printers • Traffic signals

• Manholes

12/12 12 51193 Revision 5

Absolutely NO physical, electrical or program modifications other

SECTION 2: COMPANY SERVICE INFORMATION

2.1. GENERAL SERVICE POLICY

Prior to installation, always verify that the

equipment satisfies the customer's

requirements as supplied, and as described

in this manual.

If the equipment cannot satisfy the application and the application cannot be

modified to meet the design parameters of the equipment, the installation

should NOT be attempted.

It is the customer/operator's responsibility to ensure the

equipment provided by Fairbanks is operated within the parameters

of the equipment's specifications and protected from accidental or

malicious damage.

than selection of standard options and accessories can be made

by customers to this equipment

Repairs are performed by Fairbanks Scales Service Technicians

and Authorized Distributor Personnel ONLY!

WARNING!

warranties

12/12 13 51193 Revision 5

Failure to comply with this policy voids all implied and/or written

Section 2: Company Service Information

2.1.1. Service Technician’s Responsibilities

All electronic and mechanical calibrations and/or adjustments required for making

this equipment perform to accuracy and operational specifications are considered

to be part of the original installation.

─ They are included in the installation charge.

─ Only those charges which are incurred as a result of the equipment's inability to

be adjusted or calibrated to performance specifications may be charged to

warranty.

The equipment consists of printed circuit

assemblies which must be handled using ESD

handling procedures, and must be replaced as

units.

─ Replacement of individual components is not

allowed.

─ The assemblies must be properly packaged in

ESD protective material and returned intact for

replacement credit per normal procedures.

2.1.2. Users’ Responsibility

Absolutely no physical,

electrical or program

modifications other than

selection of standard options

and accessories are to be

made to this equipment.

12/12 14 51193 Revision 5

SECTION 3: PRE-INSTALLATION

3.1. CONFERRING WITH OUR CLIENT

• The technician must be prepared to recommend the arrangement of components

which provide the most efficient layout, utilizing the equipment to the best possible

advantage.

• Assist the customer in selecting a site which allows easy access to and from the

scale, ensuring enough area for straight and level approaches, and to meet all

State and Local Weights and Measures Regulations.

─ Smooth and level approaches are required at each end of the platform to

reduce loading shock, and to facilitate testing of the scale.

─ The site needs good drainage away from the scale, elevated enough so the

surrounding areas drain away from the scale.

─ Obtain all the necessary permits and licenses prior to beginning construction.

─ In the absence of such laws, the approaches must conform to paragraph

UR.2.6 of the National Institute of Standards and Technology Handbook

44, which states that the first 10 feet must be level and on the same plane as

the scale platform.

• The platform should be visible from the instrument location.

─ Surface water must drain easily, and not collect, under the scale.

• Explain and review the warranty policy with the customer.

3.2. PRE-INSTALLATION CHECKLIST

The following points should be checked and discussed with the Area Sales Manager

and/or customer, if necessary, before the technician goes to the site and installs the

equipment.

Check the customer's application to make certain it is

within the capabilities and design parameters of the

equipment.

If the installation process might disrupt normal business

operations, tell the customer and ask that they make

ample arrangements.

The service technician reviews the recommended setup

with the Area Sales Manager or Area Service Manager,

and together they identify all necessary variations to

satisfy the customer's particular application.

NOTE: Always… “CALL BEFORE YOU DIG”. 1-888-258-0808

12/12 15 51193 Revision 5

Section 3: Pre-Installation

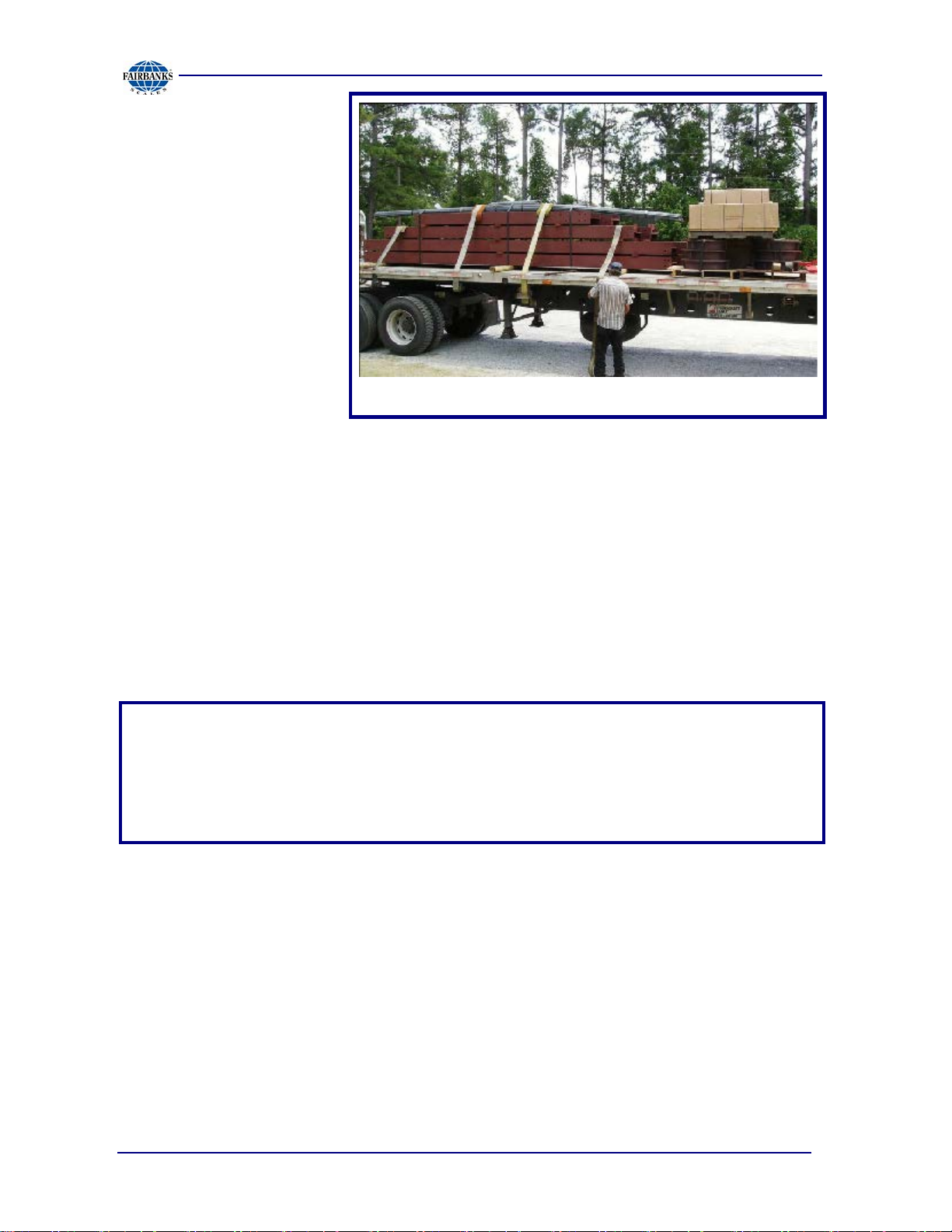

All beams and channels come in banded bundles.

3.3. UNPACKING

Follow these guidelines when unpacking all equipment.

Check in all components and accessories according to the customer's order.

Remove all components from their packing material, checking against the invoice

that they are accounted for and not damaged.

▪ Advise the shipper immediately, if damage has occurred.

▪ Keep the shipping container and packing material for future use.

▪ Order any parts necessary to replace those which have been damaged.

▪ Check the packing list.

The CUSTOMER is the receiving party if the equipment was shipped to

the Customer’s address.

FAIRBANKS is the receiving party if the equipment was shipped to the

Fairbanks Service Center.

Collect all necessary installation manuals for the equipment and accessories.

Open the equipment and perform an inspection, making certain that all hardware,

electrical connections and printed circuit assemblies are secure.

Do not reinstall the cover if the final installation is to be performed after the pre-

installation checkout.

Do not load the platform if there is any evidence of damage to the platform or

supporting structure.

12/12 16 51193 Revision 5

Section 3: Pre-Installation

3.3.1. Physical Installation Notes

• Before installation, check that all components are in good condition.

─ If damage occurs due to shipping, order the new part or component

immediately.

• Only those charges which are incurred as a result of the equipment's

inability to be adjusted to performance specifications may be charged to

warranty.

• No physical alterations (mounting holes, etc.) are allowed during installation.

IMPORTANT NOTE: The installing technician is responsible that all personnel

are fully trained and familiar with the equipment's capabilities and limitations bef or e

the installation is considered complete.

3.4. TOOLS, EQUIPMENT AND MATERIALS

The following tools, equipment and materials are suggested to be on hand

before the installation begins.

Certified Project Drawing Specifications

3.4.1. Measuring, Testing & Checking

Equipment

• Surveyor's Transit and Rod

• Plumb Bob

• Stringline and a chalkline

• 50 to100' steel tape measure.

• Machinist’s Levels (Starrett #134 & 132-6)

• Carpenter's Level

• Multimeter

12/12 17 51193 Revision 5

Loading...

Loading...