Page 1

Installation Manual

PALS

Portable Axle Load Scale

50784

Issue 1 04/05

© 2005 by Fairbanks Scales

All rights reserved

Page 2

Amendment Record

PALS

Portable Axle Load Scale

50784

Manufactured by Fairbanks scales

821 Locust

Kansas City, Missouri 64106

Created 04/05

Issue 1 04/05 New Product

Disclaimer

Every effort has been made to provide complete and accurate information in this manual. However, although this manual

may include a specifically identified warranty notice for the product, Fairbanks Scales makes no representations or warranties

with respect to the contents of this manual, and reserves the right to make changes to this manual without notice when and

as improvements are made.

04/05 2 50784 Issue 1

Page 3

Table of Contents

Section 1: General Information

A. Introduction . . . . . . . . . . . . . . . . . . . . . . . 4

B. Specifications . . . . . . . . . . . . . . . . . . . . . 4

C. Accessories . . . . . . . . . . . . . . . . . . . . . . . 5

Section 2: Installation

A. Introduction . . . . . . . . . . . . . . . . . . . . . . . 6

B. Site Selection . . . . . . . . . . . . . . . . . . . . . 6

C. Standard Platform Installation . . . . . . . . . . 6

D. Ramp Installation . . . . . . . . . . . . . . . . . . . 8

E. Instrument Installation . . . . . . . . . . . . . . . 8

Section 3: Calibration

A. Platform Cornering . . . . . . . . . . . . . . . . . . 9

Section 4: Service and Maintenance

A. Load Cell Replacement . . . . . . . . . . . . . . 11

B. Junction Box/ PCB Replacement . . . . . . . 12

Section 5: Parts

A. Parts List . . . . . . . . . . . . . . . . . . . . . . . . . 13

04/05 3 50784 Issue 1

Page 4

A. Introduction and Description

Fairbanks’ Portable Axle Load Scales (PALS) is an ideal choice for a cost-effective

weighing solution for non-commercial vehicle axle weights.

The scale is constructed in a subframe which eliminates the need for a pier or slab

foundation. Aflat surface such as asphalt or concrete is required to install the complete

unit. By eliminating the foundation, installation and relocation of this scale require minimal

effort. As an example, if a change in process, traffic flow or location occurs, the Fairbanks

Portable Axle Load Scale offers the ultimate in weighing flexibility.

The Fairbanks Portable Axle Load Scale is fabricated from USA extruded structural steel

members. This heavy-duty scale is designed to produce a minimum deflection at its rated

60,000 pound Dual Tandem Axle Capacity (DTAC). The ramps are constructed to the

same standards as the weighbridge. The ramp size comes standard in a full-width design

that will accommodate any wheel base for most highway vehicles.

The PALS is equipped with 50,000 pound rocker column load cells. These load cells are

constructed of stainless steel and are hermetically sealed. They are installed at the

factory to ensure proper alignment which eliminates potential weighing errors.

The Portable Axle Load Scales come standard with an analog junction box, but Intalogix

®

Technology may be used if desired.

B. Specifications

Product Number . . . . . . . . . . .83306

Platform Size . . . . . . . . . . . . .10’ x 7’

DTAC. . . . . . . . . . . . . . . . . . . 60,000 lbs

Deck Dimensions . . . . . . . . . .10’ x 7’

Deck Plate . . . . . . . . . . . . . . .1/4”

Subframe. . . . . . . . . . . . . . . . 6” channel

Full Scale Capacity . . . . . . . . 60,000 lbs x 20 lbs

Shipping Weight . . . . . . . . . . .3,500 lbs

Grade and Location . . . . . . . . Relatively level and solid surface.

Platform must be supported on all corners.

04/05 4 50784 Issue 1

Section 11:

General Infor mation

Page 5

B. Specifications continued

Load cell . . . . . . . . . . . . . . . . . . . . . .50k lbs

Rated Output (=RO) . . . . . . . . . .2 mv/v +/- .1%

Calibration (% RO) . . . . . . . . . . .<

+/- 0.05 (< +/- 0.005)

Zero Balance % RO . . . . . . . . . .<

+/- 1.0

Insulation Resistance . . . . . . . . . >

5000 Meg ohms

Input Resistance . . . . . . . . . . . . .1150 ohms +/- 10

Output Resistance . . . . . . . . . . .1000 ohms +/- 1

Maximum Excitation Voltage . . . .15 vdc

Safe load limit %Emax . . . . . . . . .200

Ultimate overload %Emax . . . . . .300

Approvals . . . . . . . . . . . . . . . . . .NTEP; FM

Sealing . . . . . . . . . . . . . . . . . . . .Complete hermetic seal; cable entry sealed by

. . . . . . . . . . . . . . . . . . . . . . . . . .glass to metal header. IP 68

Material . . . . . . . . . . . . . . . . . . .Stainless Steel 17-4 PH (1.4548)

Wiring . . . . . . . . . . . . . . . . . . . .Function

Color

. . . . . . . . . . . . . . . . . . . . . . . . . .Excitation + Green

. . . . . . . . . . . . . . . . . . . . . . . . . .Excitation - Black

. . . . . . . . . . . . . . . . . . . . . . . . . .Output + White

. . . . . . . . . . . . . . . . . . . . . . . . . .Output - Red

C. Accessories

Ramp Product Number . . . . . . . .83558

Ramp Dimensions . . . . . . . . . . . .10’ x 30” x 6”

04/05 5 50784 Issue 1

Page 6

A. Introduction

The standard installation of the Portable Axle Load Scale consists of locating the platform,

leveling the platform, installing the ramps, interfacing the platform to an instrument, and

calibrating/ adjusting the system.

B. Site Selection

The following points should be considered when selecting a location for the platform.

1. Locate the platform to allow convenient maneuvering of vehicles over the

platform.

2. The location should provide a solid base to support the platform and be level.

3. The location must be able to support the platform plus the weight that will be

placed upon it.

C. Standard Platform Installation

1. The platform is shipped fully assembled and wired. Remove the platform from

the packing materials.

2. Connect lifting straps or chains to the lifting lugs on the sides of the platform.

The lifting straps/chains should be long enough to form a 45-degree angle with

the platform during the lifting process.

3. Place the platform in the desired location.

4. The platform should be made stable and level. Shims are not included with the

platform and must be supplied locally as needed.

5. Remove the four (4) cover plates.

6. Drill and anchor the platform using the supplied ¾” wedge anchors.

04/05 6 50784 Issue 1

Section 22:

Installation

~ Caution ~

Absolutely no arc welding operations are to be performed on or near this scale while the

load cells are in place and/or connected. All load cells must be disconnected and removed

during welding.

Page 7

7. Remove the shipping bolts in each corner.

8. Adjust the checking bolts to a 1/16” to 1/8” clearance.

9. Verify all of the load cells are plumb, square and level. Correct if necessary.

10. If ramps are part of the installation, they should be located and installed at this

time.

04/05 7 50784 Issue 1

50784-2

"

TOP VIEW OF COVER PLATE

UPPER CUP

HOLD DOWN BOLT

FOR SHIPPING

ADJUST BUMPER BOLT TO 1/16" - 1/8

LOAD CELL

LOWER BASE PLATE

LOAD CELL

ASSEMBLY DETAIL

50784-1

O-RING IN EACH

RECEIVER CUP

Page 8

D. Ramp Installation

The ramps are used in combinations in specific applications.

1. Each ramp has two (2) bolt down tabs as part of the ramp.

2. Place the ramp against the the platform frame.

3. The ramp should be made stable and level.

Shims are not included with the ramps and must be supplied.

4. Bolt the ramps to scale frame using

3

/4” hardware.

5. Drill and anchor the ramp(s) using the supplied

3

/4” wedge anchors.

6. No more than two (2) ramps, located on opposite sides of the platform, may

be installed.

E. Instrument Installation

The platform is shipped fully assembled and wired. The interface cable to the

indicator is as follows:

L/C W

ire Color Function Analog Instrument

Black (-) Excitation (-) Excitation

Green (+) Excitation (+) Excitation

Yellow Shield Shield

White (+) Signal (+) Signal

Red (-) Signal (-) Signal

Refer to the proper indicator service manual for proper installation, programming, and

calibration of the indicator.

04/05 8 50784 Issue 1

Page 9

A. Platfor m Cor nering

Analog Interface (Junction Box 67171):

1. Adjust the analog indicator to the platform. First, ensure all corners are within

one (1) division of each other at 25% of rated capacity. Follow the appropriate

indicator service manual for indicator calibration.

a. Perform a course platform calibration close to the actual weight.

b. Identify the platform corner numbers.

c. Place a concentrated weight (25% of platform capacity) on corner 1. Move it

to corner 2, corner 3 and corner 4, noting the displayed reading on each

corner.

d. If corners require adjustment

: Place the concentrated weight on the corner

displaying the lowest weight and use the appropriate potentiometer to

change the displayed weight to read the same as the highest reading by

turning the potentiometer clockwise (CW). Repeat this procedure while

rechecking all corners until there are no errors. Perform a zero reference

check with a unloaded platform, then repeat the corner test to ensure all

readings are the same before proceeding.

04/05 9 50784 Issue 1

Section 33:

Calibration

1

+E -E SH -S +S

2

+E -E SH -S +S

3

+E -E SH -S +S +E -E SH -S +S

4

1

2

- SIG

+ SIG

SHLD

- SEN

- EXC

+ SEN

- EXC

3

4

96141

Page 10

e. When the corners are the same in reference to each other:

1. Remove all weights.

2. Zero the indicator.

3. Perform a final calibration with test weights.

4. Follow the appropriate indicator service manual for indicator calibration.

04/05 10 50784 Issue 1

Note:

Junction box assembly 67171 has four (4) extended range, multi-turn potentiometers, one

for each load cell. If you have difficulty cornering the platform, turn all potentiometers to the

fully counter clockwise (CCW) position until a clicking is heard when turned. With the weight

on the lowest reading corner, turn the corresponding potentiometer clockwise (CW) to read

the same as the highest reading corner. Repeat this procedure for each corner until the

platform is properly calibrated.

Note:

As you move the weight(s) from corner to corner, do NOT zero the scale. Remember at this

time you are only adjusting the corners to be the same, not performing a correct calibration.

Page 11

A. Load Cell Replacement

1. Remove power to the indicator.

2. Remove the platform access cover, then the junction box cover, and disconnect

the failed load cell cable at the junction box. Loosen the gland bushing and tie a

string or wire to the end of the cable to act as a pull wire. (Check that all cells

have wire markers on the cable ends. If not, identify cells with wire markers or

other means.) Disconnect the faulty load cell’s wires from the terminal block.

3. Lift the platform and use wood blocks for safety.

4. Remove the load cell pulling the load cell cable through the scale while leaving

the pull string/wire in the scale.

5. Install on the new cell.

6. Disconnect the pull string/wire from the old cell's cable and attach to the new

load cell's cable end. Pull the cable of the new cell through to the junction box.

7. Lower the scale onto the new load cell, removing the safety blocks.

8. Connect the load cell wires into the junction box and tighten the box gland

bushing(s).

9. Recalibrate as necessary.

10. Replace the box cover and torque all screws to 10-12 in/lbs. Replace the

platform access covers.

04/05 11 50784 Issue 1

Section 44: SService aand

Maintenance

Page 12

B. Junction Box/PCB Replacement

1. Remove power to the indicator

2. Open the platform access cover, then the box cover.

3. Loosen all gland bushing nuts.

4. Check that all load cells have wire markers on the cable ends. If not, identify

load cells with wire markers or other means, then disconnect the load cell wires

from the terminal blocks. Disconnect the main interface cable wires.

5. Remove the junction box/PCB, then install the new junction box/ PCB.

6. Reconnect all load cell and main interface cable wires to the new junction

box/PCB.

7. Tighten all gland bushing nuts.

8. Recalibrate as necessary.

9. Replace the box cover and torque all screws to 10-12 in/lbs. Replace the

platform access cover.

04/05 12 50784 Issue 1

Note:

Leave the box cover OFF until all calibration adjustments are completed.

Page 13

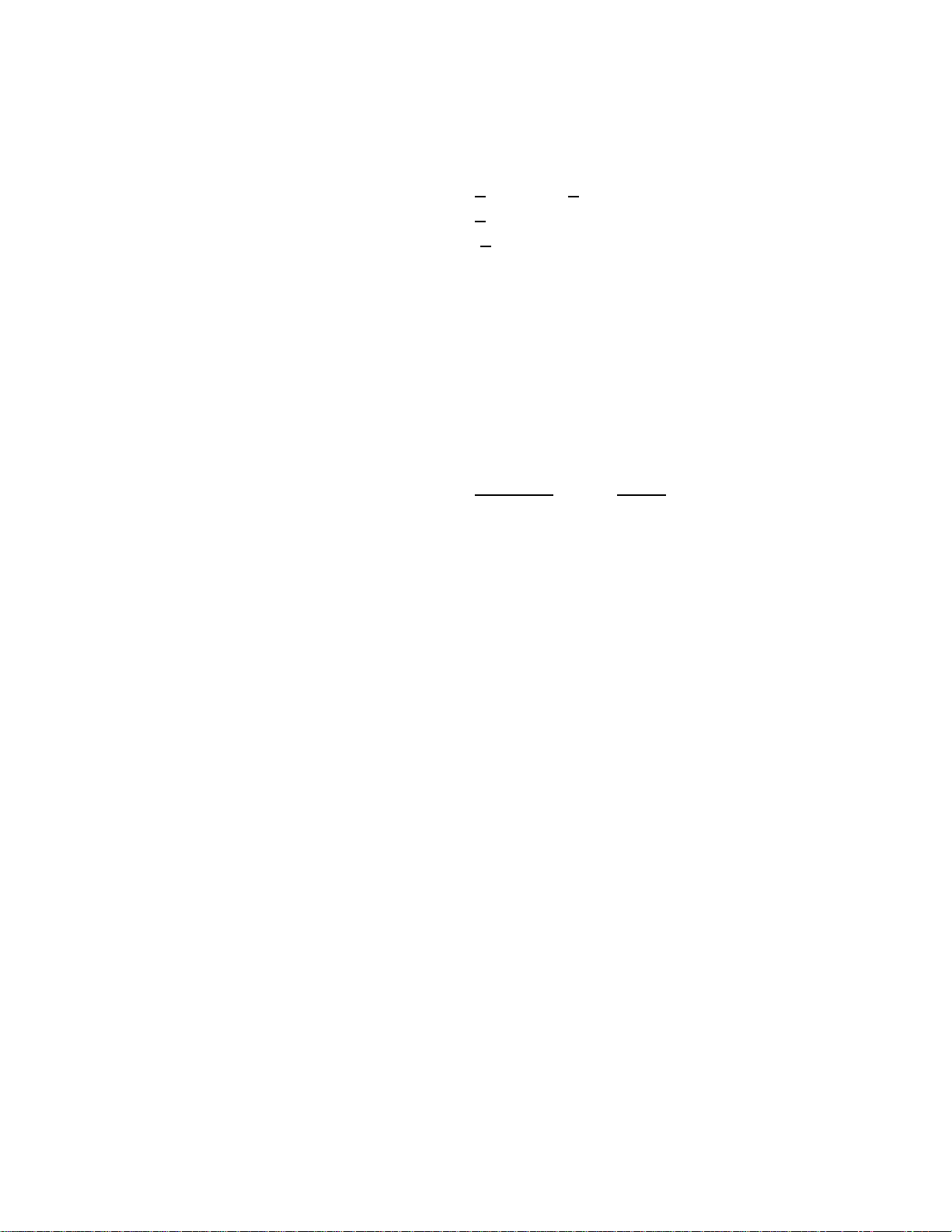

A. Par ts List

Item No. Part Number Description

1 83307 Platform Weldment

2 83313 Frame

3 83353 Base Plate w/ Lower Cup

4 54517 ¾”-10 x 2” HHCS

5 67171 Junction Box Assembly

6 54203 Hex Nut SS 10-24

* 14721 Velcro Loop

* 14722 Velcro Hook

9 83669 Load Cell 50k lb 3½” RC3 1000 ohm

* 73542 Upper Cup w/o Anti-rotation

* 73732 O Ring 28.24 x 2.62 ( Inside of each cup)

12 54264 Hex Nut ¾”-10

13 66979 SS ½”-13 x 1” FHSS

14 61743 Clamp Bar

* 83942 ¾” PVC Pipe, 4’-3”

* 83883 ¾” PVC Elbow

17 Fairbanks PALS Sticker

* 83884 Clamp for ¾” PVC Pipe

* 73378 Wedge Anchor , ¾” x 7”

21 72967 ¾”-10 x 5”, Hex HD Cap Screw

22 60237 1”-8 x 5” LG. Hex HD Cap Screw

23 54277 1”-8 Hex Nut

* = Not Shown

04/05 13 50784 Issue 1

Section 55:

Parts

Page 14

04/05 14 50784 Issue 1

13

FAIRBANKS

PALS SCALES

17

4

9

1

2

50784-3

21

12

23

22

14

12

6

5

3

Loading...

Loading...