Fairbanks PC2250 User Manual

Operating Manual

FB2250 Series Instrument

PC2250 Utility Software

2009-2013 by Fairbanks Scales, Inc. 51214

All rights reserved Rev. 8 01/13

Amendment Record

FB2250 Series Instrument

PC2250 Utility Software

Document 51214

Manufactured by Fairbanks Scales Inc.

821 Locust

Kansas City, Missouri 64106

Created 3/2009

Revision 1 03/2009 Released Manual

Revision 2 05/2009 Added CC and ETL Approvals

Revision 3 06/2009 Added MC Approval, IP69K, and Panel Mount Models

Revision 4 07/2009 Added power on/off instruction

Revision 5 03/2010 Updated for Rev 2 Software

Revision 6 05/2011 Added fieldbus information.

Revision 7 06/2012 Added PC2250 information.

Revision 8 01/2013 Corrected grammatical errors and clarification of charts.

.

6/12 2 51214 Rev. 7

Disclaimer

Every effort has bee n made to provide com plete and accurate inform ation in this manual. However,

although this manual m ay include a specifically identi fied warranty notice for the product, Fairbanks

Scales makes no representations or warranties with respect to the contents of this manual, and

reserves the right to make changes to this manual without notice when and as improvements are

made.

It is the responsibility of the requesting party to develop, maintain, install, and connect networking

devices and general net work connect ivity as it applies to the originatin g party’s network . No warranty

or guarantee, expressed or implied, concerning the network , its design, its installation, or operat ional

characteristics has been offered by Fairbanks Scales.

Fairbanks Scales shal l not be liable f or any loss, damage, c ost of repairs, i ncidental or conseq uential

damages of any kind, whether or not based on express or implied warrant y, contract, negligence, or

strict liability arising in connection with the design, development, installation, or use of an intended

network or scale instrument.

The Bluetooth® word mark and logos are owned by the Bluetooth SIG, Inc. and any use of such

marks by Fairbanks Scales is under license. Other trademarks and trade names are those of their

respective owners.

© Copyright 2009-2013

This document contains proprietary information protected by copyright. All rights are reserved; no part

of this manual may be reproduced, copied, translated, or transmitted in any form or by any means

without prior written permission of the manufacturer.

6/12 3 51214 Rev. 7

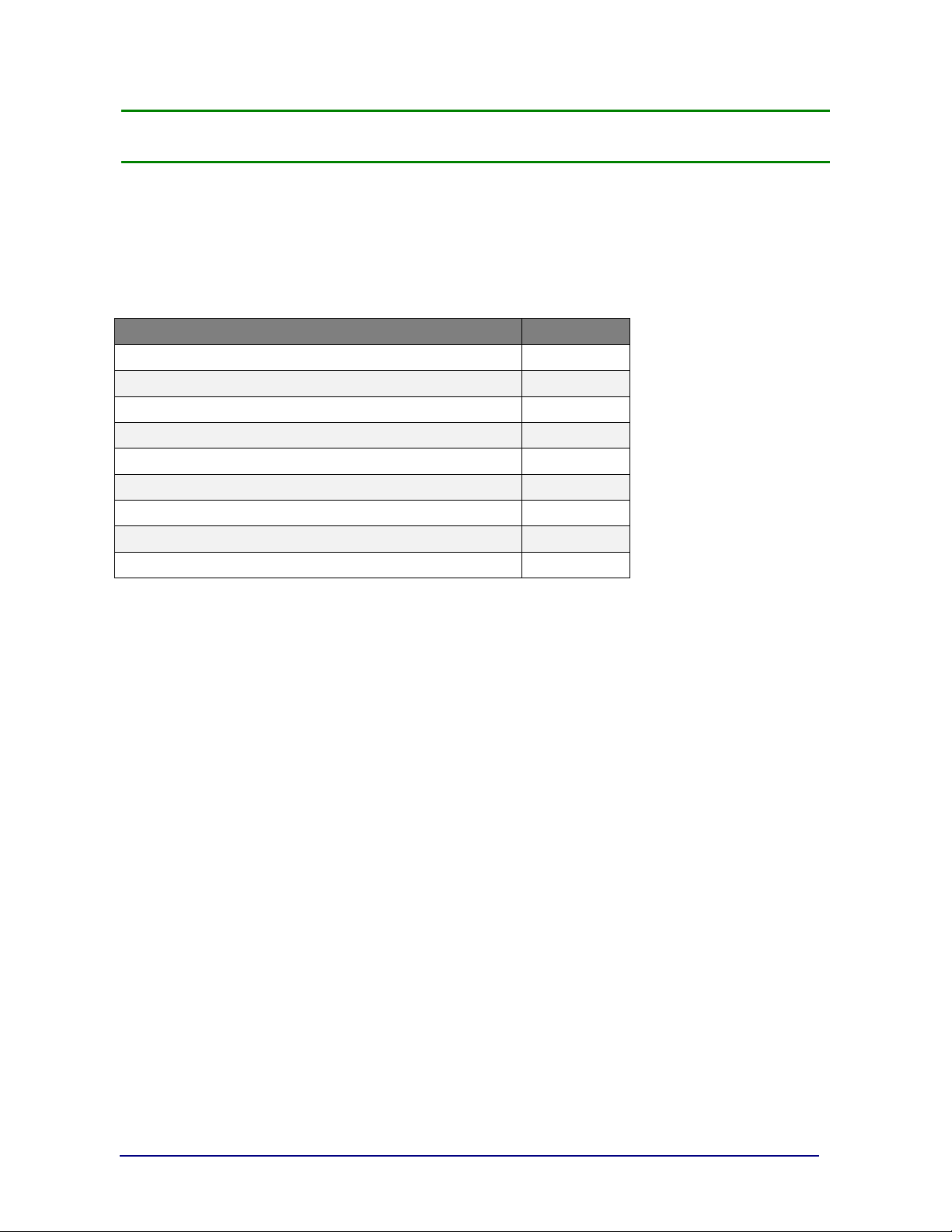

Table of Contents

SECTION 1: GENERAL INFORMATION .................................................................. 6

Model Descriptions ............................................................................................................ 6

Main Product Features ....................................................................................................... 6

Specifications .................................................................................................................... 7

Instrument Approvals ...................................................................................................................... 7

Specifications .................................................................................................................................. 7

Settings .......................................................................................................................................... 8

Weight Accumulator ........................................................................................................................ 8

Outputs .......................................................................................................................................... 8

Power Requirements ...................................................................................................................... 8

DC Models ...................................................................................................................................... 8

Out of Range Warnings .................................................................................................................. 9

External Printers ............................................................................................................................. 9

Environment .................................................................................................................................... 9

PC2250 9

Accessories ..................................................................................................................... 10

Battery Installation ........................................................................................................... 10

Powering up the FB2250 ................................................................................................. 11

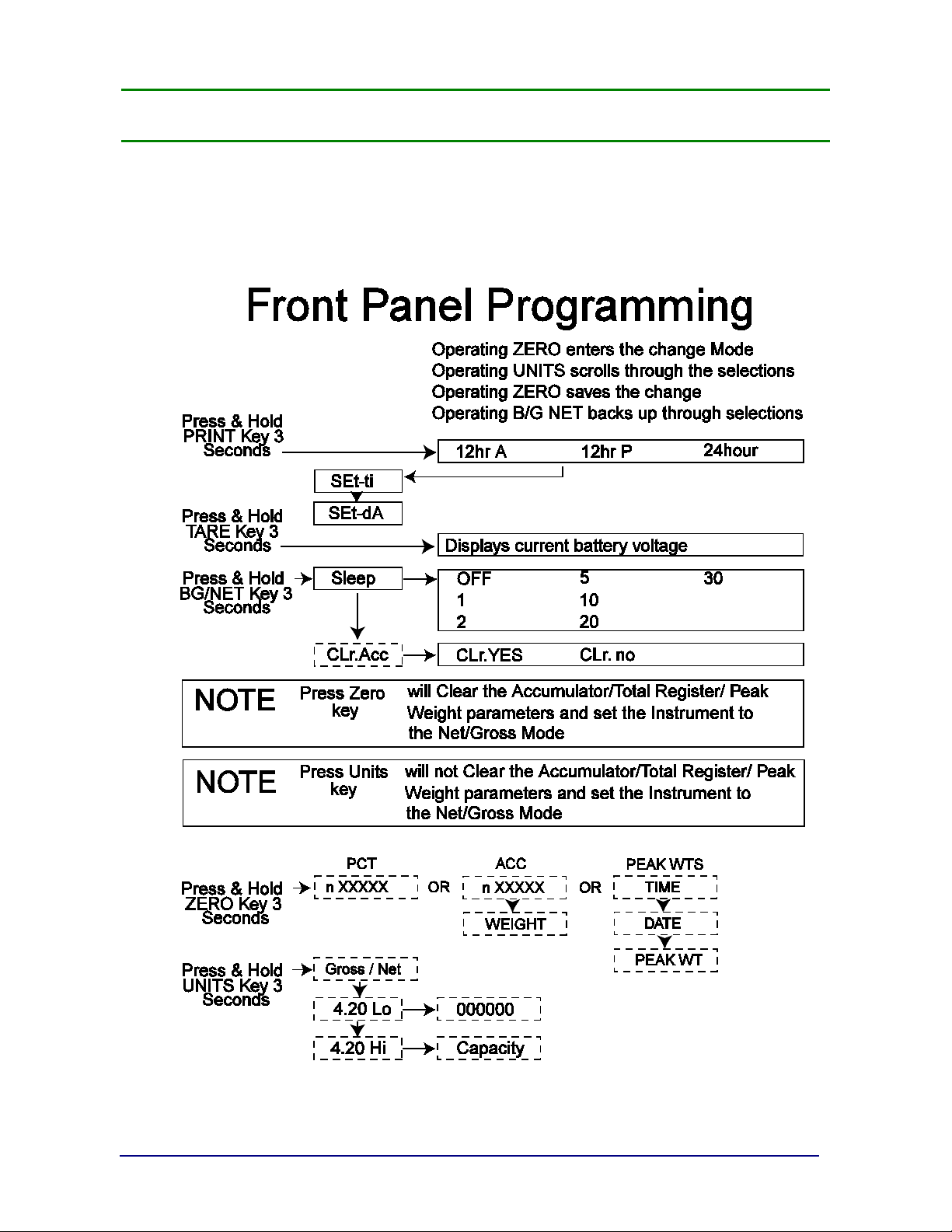

Flow Charts ..................................................................................................................... 11

SECTION 2: FRONT PANEL PROGRAMMING ...................................................... 12

Front Panel Programming Parameters ............................................................................. 12

SECTION 3: OPERATION ....................................................................................... 15

Front Panel Key Functions ............................................................................................... 15

Operating Procedures ..................................................................................................... 15

Instrument Weighing Functions ........................................................................................ 16

Weight Accumulatio n ....................................................................................................... 17

Clearing the Accumulators ............................................................................................... 17

Parts Counting and Accumulation .................................................................................... 18

Peak Weight .................................................................................................................... 19

SECTION 4: ACCESSORIES .................................................................................. 20

4-20 mA Analog Output ................................................................................................... 20

Ethernet/IP Addressing ................................................................................................................. 22

Fieldbus Connections: ..................................................................................................... 23

Profibus® Diagnostic LED’S: ........................................................................................... 24

DeviceNet™ Diagnostic LED’S: ....................................................................................... 25

Ethernet / IP Diagnostic LED’S: ....................................................................................... 26

SECTION 5: SERIAL COMMUNICATION WIRING ................................................ 27

JP3 Jumper Configuration: .............................................................................................. 27

TB4 Wiring connections ................................................................................................... 27

6/12 4 51214 Rev. 7

Section 1: Gen er al Information

SECTION 6: PRINTER INSTALLATION ................................................................. 28

3550 Tape Printer ............................................................................................................ 28

Okidata 186 T Form Printer ............................................................................................. 29

Okidata 420 Form Printer ................................................................................................. 33

TM-U295 Ticket Printer .................................................................................................... 36

TM-U590 Ticket Printer .................................................................................................... 37

Remote Display ............................................................................................................... 38

SECTION 7: PC2250 UTILITY SOFTWARE ........................................................... 39

Introduction ...................................................................................................................... 39

Wiring .............................................................................................................................. 39

Communication settings ................................................................................................... 39

Menu Bar ......................................................................................................................... 40

Configuration ................................................................................................................... 42

Calibration ....................................................................................................................... 43

Fieldbus / 4-20 mA ........................................................................................................... 44

Custom Output: Settings .................................................................................................. 47

Custom Output: Load ....................................................................................................... 48

Custom Output: Build ....................................................................................................... 49

Custom Output: Tokens ................................................................................................... 50

Custom Output: Weights .................................................................................................. 52

Format tickets .................................................................................................................. 53

APPENDIX I: DATA OUTPUT FORMATS ............................................................... 55

APPENDIX II: ASCII CHART.................................................................................... 62

APPENDIX III: FB2250 REMOTE DISPLAY WIRING .............................................. 63

APPENDIX IV: REMOTE DISPLAY ACTIVE KEYS ................................................. 64

APPENDIX V: REMOTE PC COMMANDS .............................................................. 65

6/12 5 51214 Rev. 7

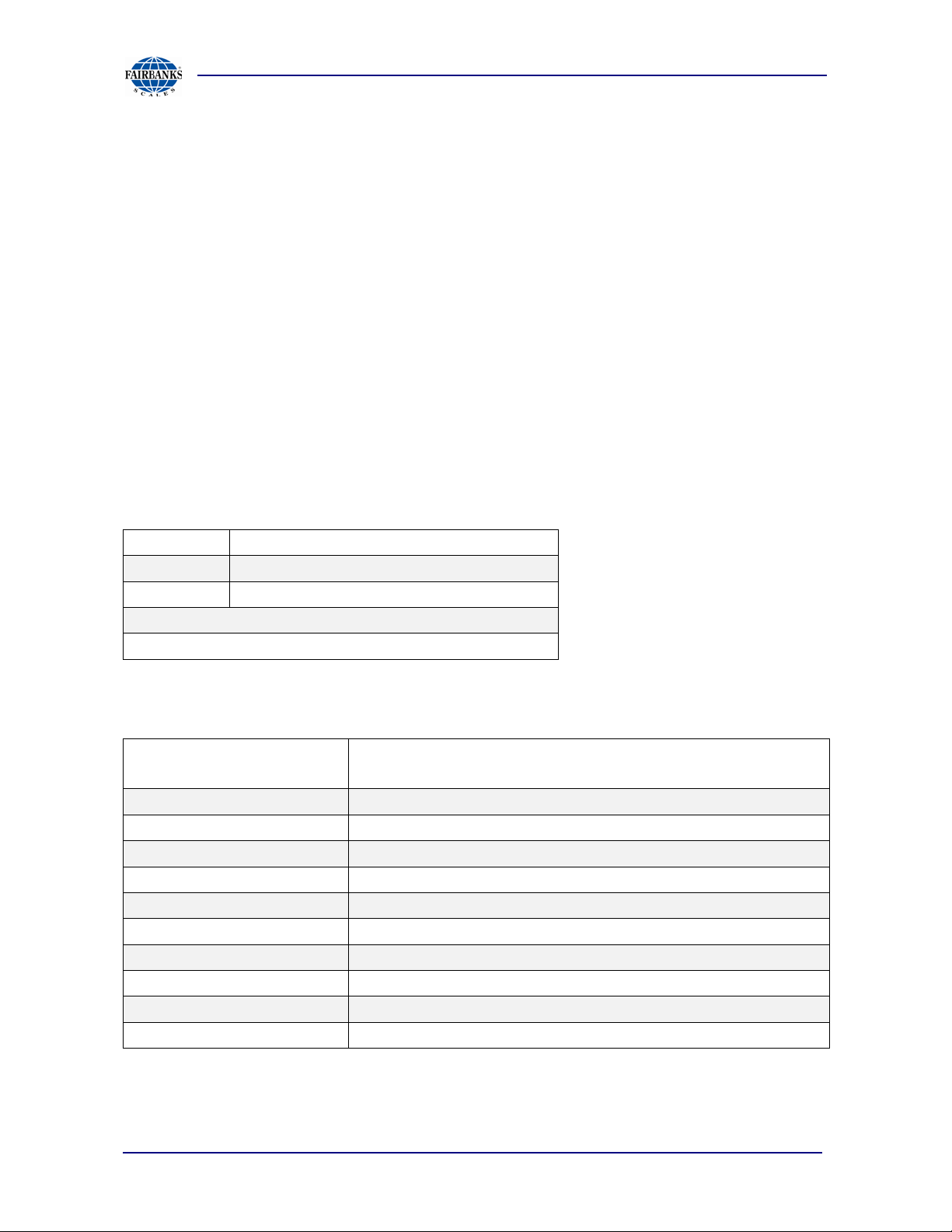

Section 1: General Information

Model Descriptions

The FB2250 is a general purpose weighing instrument that can be used with a wide

variety of platforms and load receivers, and is available in nine (9) different

configurations.

MODEL PAR T NO.

• FB2250 Series ABS, AC P o wer

• FB2250 Series ABS, AC/Battery Power

• FB2250 Series SS, AC Power

• FB2250 Series SS, AC/Battery Power

• FB2250 Series SS, AC Power, No Bracket

• FB2250 Series SS, AC/Battery Power, No Bracket

• FB2250 Series SS, AC Power, No Bracket, IP69K

• FB2250 Series SS, AC Power, IP69K

• FB2250 Series, AC Power, Panel Mount

29250

29561

29251

29562

29563

29564

29013

28990

29803

Main Product Features

Major features of the Instrument include the following.

• Push-button programming and calibration.

• Program data is stored in battery supported ram and backed up in flash memory.

• The battery should be replaced every 12 months.

• The FB2250 series instrument features a large one inch high green backlit LCD

weight display, which can be tilted up or down to accommodate different lighting

conditions. Microprocessor controlled design allows the instrument to be rapidly

programmed at installation to meet the specific requirements of the application.

• The obtainable accuracy meets Handbook 44 requirements, and the instrument is

approved for commercial appl i cati on up to 10,000 divisions. A maximum of

100,000 displayed divisions can be programmed for non-commercial applications.

• A computer utility software program PC2250 is available, via download from

Fairbanks Intranet for programming via computer, and is required for certain

features such as custom ticket formatting.

6/12 6 51214 Rev. 7

Section 1: Gen er al Information

Main Product Features, Continued

• The PC2250 software utility program can also upload and modify the instruments

set-up, configuration, and calibration. Saved information can be downloaded from

a computer to the FB2250 Series in the event of a catastrophic fail ure.

• The instrument provides two (2) serial communication ports to provide

communication to various types of peripheral devices for RS232, RS422, RS485,

and 20mA data outputs.

• Optional accessories include a 4-20 mA analog output, Bluet oot h® serial adapter,

and four different fieldbus devices; Profibus®, DeviceNet™, ControlNet and

Ethernet/IP.

Specifications

Instrument Approval s

• CC

• MC

• ETL

• Conforms to ANSI/UL STD 60950-1

• Certified to CAN/CSA C22.2 STD NO. 60950-1-03

09-023

AM-5720

ETL Listed

Specifications

• ENCLOSURE

• DISPLAY

• FRONT PANEL KEYS

• UNITS

• GRADUATION SIZE

• AD CONVERSION

• LOAD CELL EXCITATION

• SENSITIVITY

• LOAD CELLS

• DISPLAYED DIVISIONS

• CAPACITIES

ABS, Black NEMA 1, Stainless Steel NEMA 4X Desk

and Wall Mount

6 digits, 1 inch LCD, Green Backlight

On/Off, Units, Zero, B/G, Net, Tare and Print

lbs, oz, kg, g and lbs/oz, or custom

0.0001 to 50

66 per second

5 Volts DC

1µv/d (microvolt/division)

Eight (8) 350 ohm or Sixteen (16) 1000 ohm

10,000d Commercial and 100,0 00d Non-Commercial

Programmable to 999999

6/12 7 51214 Rev. 7

Section 1: Gen er al Information

Specifications, Continued

Settings

• Zero Range

• Auto Zero Tracking

• Balance

• Filter

• Display Update Rate

2 % or 100%

OFF, 0.5, 1 or 3 divisions

OFF, 0.5, 1 or 3 divisions

Slow, Cattle, Standard, and Fast

0.2, 0.4, and 0.8 seconds

Weight Accumulator

• Capacity

999,999 Weight Units

– Printed or viewed

Outputs

• PORT 1

• PORT 2

*Port should be set to RS485. Note jumper and wiring connections listed in Section 5:Serial Communication

Wiring.

Bidirectional Serial Port. Settings include OFF, RS232, RS422,

and RS485. RS232 has 30+ updates a second

Port 2 is used to interface to the PC2250 program, OR to

provide 20 mA passive, RS232, RS422*, or RS485.

Power Requirements

• 117 volts AC +/- 10 %

< 0.2VAC between Neutral and Grou nd.

• 220 volts AC +/- 10 %

• 1.5 watts maximum

• The FB2250 is designed to operate from 80 to 260 volts AC, 50 to 60 Hertz

DC Models

• Batteries

• Battery Life

• Internal Battery

Five (5) Size “D” Alkaline batteries @ 1.5 Volts DC each.

Up to 40 Hours or greater with a maximum load of 4, 350 load cells and

backlighting enabled.

Battery usage time can be adversely affected by battery storage, battery

capacity and battery brand.

To maximize battery life, serial Ports 1 and 2 should be switched OFF, if

not used.

• Should be replaced every 12 months using Panasonic CR 1220 3V or

equivalent.

6/12 8 51214 Rev. 7

Section 1: Gen er al Information

Specifications, Continued

Out of Range Warnings

• HiCAP

• - - - - - - -

• Sleep Mode

• Time and Date

Scale input is over capacity

Displayed weight exceeds 6 digits

Settings include OFF, 1, 2, 5, 10, 20, and 30 minutes

Battery Maintained

External Printers

• Citizens IDP 3550 Tape Printer

• Okidata 184 & 186 Serial Form Printer

• Okidata 420 Serial Form Printer

• Epson Models TM-U295 and TM-U590 Ticket Printers

Environment

• Temperature

• Storage Temp.

-10ºC to + 40ºC (+14ºF to + 104ºF)

-40ºC to + 60ºC (-40ºF to + 140ºF)

PC2250

• Computer software utility program is available for download using the Fairbanks Intranet.

• PC2250 is required for setting certain aspects of programming, such as custom Units and custom

ticket formatting.

6/12 9 51214 Rev. 7

Section 1: Gen er al Information

FIELDBUS DEVICES

4-20 MA ANALOG CURRENT LOOP OUTPUT

BLUETOOTH® TECHNOLOGY INTERFACE

Accessories

Optional accessories include the following.

• DeviceNet™ • ControlNet™ • Profibus® • Ethernet/IP

• 16 bit Resolution and Monotonicity • 0.01% Non-Linearity

• Isolated 4mA to 20m A

• Utilizes either Port 1 or Port 2 Serial Output. RS232 serial Interface to Bluetooth Interface. Range

100 meters (328 feet).

• The Bluetooth option will operate either as a Client or Server depending on which device the

FB2250 is connected.

– If connected to a printer, the FB2250 will be a Server.

– If connected to a PC, the In str um ent will be a Client.

• Front Panel Programmable or via PC2250 utilit y

software program

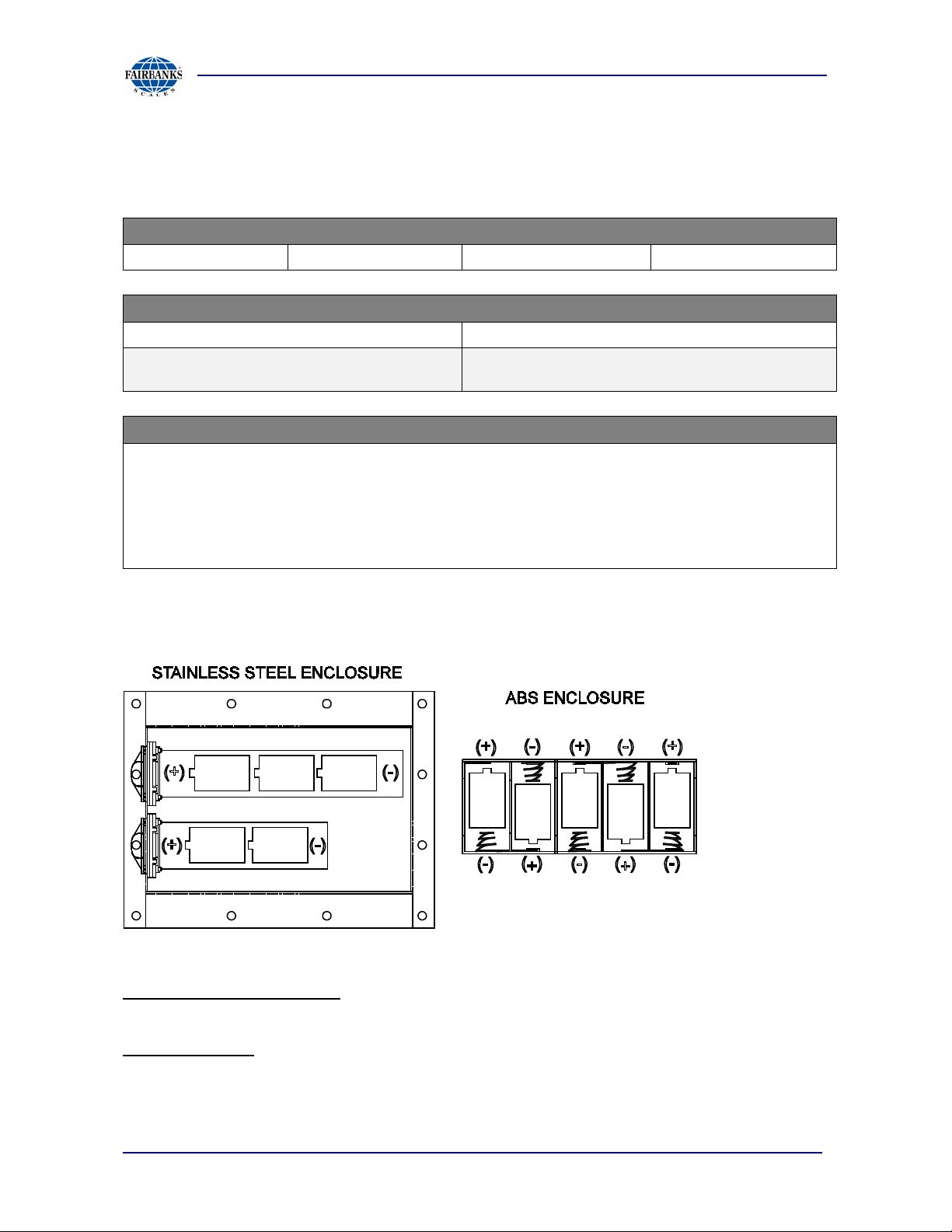

Battery Installation

Stainless Steel Instr um ent: Unscrew the black plastic end caps and insert 5 alkaline

“D” cells as shown above.

ABS Instrument: Unscrew the two large knurled screws on the back of the Instrument

and remove the battery cover. Insert 5 alkaline “D” cells as shown above.

Industrial ‘D’ Size battery Energizer EN95 or equivalent is recommended for

maximum operating time.

6/12 10 51214 Rev. 7

Section 1: Gen er al Information

Powering up the FB2250

Press the ON / OFF Key for 1 to 2 seconds. The Instrument will display “888888”

followed by a “1234567890” character display moving from right to left, followed by

the revision of sof tware. Upon completing the warm-up, the FB2250 will display the

actual weight on the scale.

To turn the FB2250 off, press the ON / OFF key for 1 to 2 seconds.

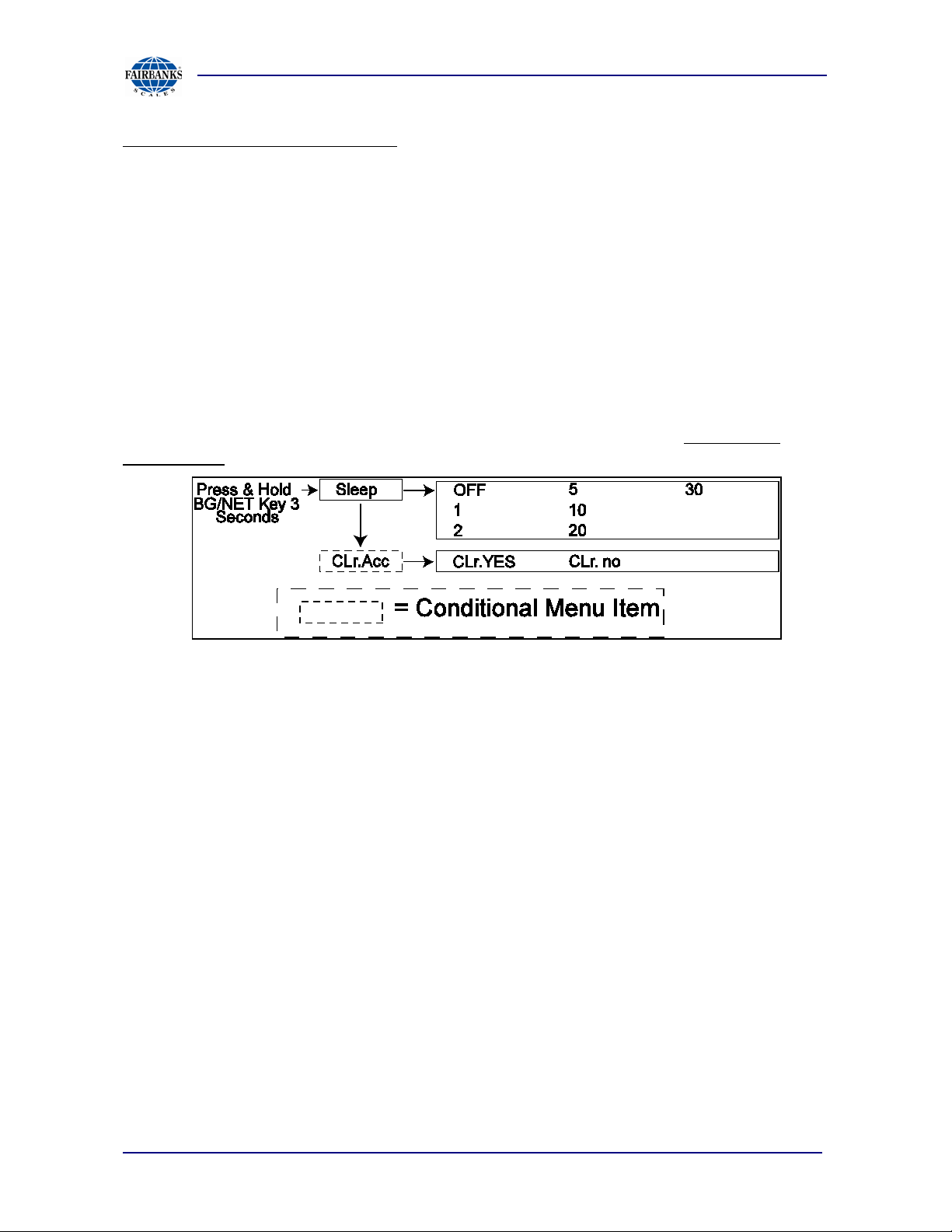

Flow Charts

Dashed line boxes used in the flowchart indicate that the menu item availability is

dependant upon programming performed elsewhere. For example, “clearing the

accumulator” will not be available if accumulation has not been enabled.

6/12 11 51214 Rev. 7

Section 2: Front Panel Programming

Front Panel Programming P aram eters

6/12 12 51214 Rev. 7

Section 2: Front Panel programming

Press the Print key for 3 seconds.

Programming Time Format: Press the ZERO key. Pressing the UNITS key will

toggle through the available selections. Press the ZERO key to enter the selection.

Available selections are:

12hr A: 12 hour clock, currently AM.

12hr P: 12 hour clock, currently PM.

24 hour: Military time, (1:00 PM = 1300 hours)

Set-ti: Programming the Time: Time is set as HHMMSS. The display will indicate

Set-ti and then display the current time. Press the ZERO key, the first two digits will

blink. Press the UNITS key to increment to the desired minute setting and press the

ZERO key. The second set of digits will blink. Press the UNITS key to increment to

the desired seconds setting, and press t he ZERO key. The third set of digits will

blink. Press the UNITS key to increm ent to the desired seconds setting, and press

the ZERO key to enter the time settings.

Set-dA: Programming the date: The display will indicate Set-dA and then display the

current date setting. Date is entered in the MM-DD-YY format. Press the ZERO key

and the first two digits will blink. Press the UNITS key to increment to the desired

month then press the ZERO key. The second set of digits will blink, press the UNITS

key to increment to the desired day and press the ZERO key. The third set of digits

will blink. Press the UNITS key to increment to the desired year setting, then press

the ZERO key to enter the date settings.

Press the TARE key for 3 seconds.

The current battery / power supply voltage is displayed (8.3 volts DC nominal).

Press the BG/Net key for 3 seconds

Sleep: Programming the Sleep Function: The display will indicate Sleep and then

display the current setting. This function serves to prolong battery life by turning off

the Instrument. Sleep mode will commence in the time programmed provided there is

no activity detected for the duration of the programmed sleep time setting. Activity is

defined as weight applied to the scale exceeding the balance setting, the pressing of

a key, and the receiving of a polling request on a communication port. Press the

ZERO key, then the UNITS key to scroll through available settings. Press the ZERO

key to enter the selection. Available selections are:

OFF 1 2 5 10 20 30 (selections indicate mi nutes )

6/12 13 51214 Rev. 7

Section 2: Front Panel programming

CLr.ACC: Clearing the Accumulator:

Conditional upon programming the operating mode to accumulation, peak hold, piece

count, or piece count & total. The display will indicate CLr.ACC. Press the ZERO key,

then the UNITS key to toggle the available settings. Press the ZERO key to enter the

selection. Available selections are:

Clr.YES (Clear the Accumulator) CLr.NO (Do NOT Clear the Accumulator)

Note:

Pressing ZERO will clear the Accumulator and retur n to the Net/Gross mode.

Pressing UNITS will NOT clear the Accumulator and return to the Net/Gross mode.

Press the Zero key for 3 seconds

Conditional upon programming the operating mode to accumulation.

The FB2250 will display total number of pieces and weight, then time out (30 sec).

Conditional upon programming the operating mode to piece count, or piece count &

total. The FB2250 will display total number of pieces, then time out (30 sec).

Conditional upon programming the operating mode to peak hold stable or peak hold

unstable. The FB2250 will display time, date, peak weight, and time out (30 sec).

Note: Pressing the UNITS key will skip time out and immediately exit to the weigh

mode.

4.20: Setting the 4-20 mA.

Press the Units key for 3 seconds

Conditional upon enabling 4-20 mA.

Gross / Net: Programming the weigh mode the output will track: Select Gross or Net.

The 4-20 mA analog output will track the selection. It will continue to track the

selection regardless of the currently selected weigh mode of the FB2250.

Press the ZERO key, then the UNITS key to toggle the available settings. Press the

ZERO key to enter the selection. Available selections are Gross or Net.

4.20 Lo: Programming the weight value associated with 4 mA: The display will

indicate 4.20 Lo: Press the ZERO key. The display will indicate the zero weight

“XXXXXX”. Press the UNITS key to increment the blinking digit, press the ZERO key

to advance to the next digit, repeat until entry is complete. After entering the least

significant digit, press the ZERO key. This weight entry will result in a 4 mA output.

4.20 Hi: Programming the weight value associated with 20 mA: The display will

indicate 4.20 Hi: Press the ZERO key. The display will indicate the maximum weight

“XXXXXX”. Press the UNITS key to increment the blinking digit, press the ZERO key

to advance to the next digit, repeat until entry is complete. After entering the least

significant digit, press the ZERO key. This weight entry will result in a 20 mA output.

6/12 14 51214 Rev. 7

Section 3: Operation

Front Panel Key Functions

ON/OFF Turns the Instrument on or off.

UNITS Switches between pre-programmed selectable weight units.

ZERO Sets the display to zero, programmable: 2% or 100% of capacity.

B/G – NET Toggles between Gross and Net weights

(only if a tare value has been entered greater than zero)

TARE automatically tares off displayed weight when key is pressed.

Depending on programmed selection, Tare weight will either:

A. Be retained for reuse until changed or power is removed, or

B. Automatically clear when Gross weight returns to Zero.

PRINT Simple RS232 output when key is pressed.

Operating Procedures

Press the ON / OFF Key for one to two (1 – 2) seconds. The Instrument will display

“888888” followed by a “1234567890” character display moving from right to left,

followed by the revision of software. Upon completing the warm-up, the FB2250 will

either display zero, or it will display the actual weight on the scale.

The Zero function, Tare function, and AZT require the displayed weight to be stable

before these functions will operate. The weight reading is stable if the variation in

weight is less than the programmed bAL range.

6/12 15 51214 Rev. 7

Section 3: Oper a t ion

Instrument Weighing Functions

The industry uses three terms to describe the apportionment of an object’s weight.

These terms are GROSS WEIGHT, TARE WEIGHT, and NET WEIGHT.

Example: A can of house paint is an object to be weighed.

The empty can is the 'TARE' weight,

the paint is the 'NET' weight, and

together they equal the 'GROSS' weight.

GROSS = NET + TARE

GROSS – NET = TARE

GROSS – TARE = NET

Basic Weighing

Ensure platform is empty, turn the scale ON, press the ZERO key and the display

indicates “0” and is ready for use.

Gross Weighing

1. Press the GROSS/NET key, if required, to set the display to GR (gross).

2. Press the ZERO key, if required, to set scale to “0”.

3. Place container/object on scale platform.

4. Read the gross weight on the display.

Net Weighing

1. Press the GROSS/NET key, if required, to set display to GR (gross).

2. Press the ZERO key, if required, to set scale to “0”.

3. Place container/object on scale (Tare weight).

4. Press the TARE key.

5. Place material in container or add objects (Net weight).

6. Read the net weight on the display.

Gross/Tare/Net Weighin g

1. Press the GROSS/NET key, if required, to set display to GR (gross).

2. Press the ZERO key, if required, to set scale to “0”.

3. Place container/object on scale (Tare weight).

4. Press the TARE key.

5. Place material in container or add objects (Net weight).

6. Read the net weight on the display.

7. Press the GROSS/NET key to switch to Gross and view Gross weight.

6/12 16 51214 Rev. 7

Section 3: Oper a t ion

Weight Accumulation

1. Place a weight on the Scale Platform

2. After the weight has settled. Press the B/G NET key until the display alternates

between the number of Accumulations "n" and the Accumulated weight.

3. Press the UNITS key to return to the Gross/Net Mode and add the Weight to the

Accumulator.

The display will momentarily indicate ACCEPt then return to the Weigh Mode.

Press the B/G NET key to skip adding the Weight to the Accumulator and return to

the Weigh Mode.

The scale must return to “0” Gross mode before another accumulation can occur.

4. To continue, add the next load, press the B/G NET key until the display alternates

between the number of Accumulations "n" and the Accumulated weight.

5. Press the UNITS key to return to the Gross/Net Mode and add the Weight to the

Accumulator. The display will momentarily indicate ACCEPt then return to the Weigh

Mode.

Clearing the Accumulators

Press the BG/Net key for 3 seconds

The display will indicate “Sleep” and then display the current setting. Press the

UNITS key, and the display will indicate CLr.ACC. Press the ZERO key, then the

UNITS key to toggle the available settings. Press the ZERO key to enter the

selection. Available selections are:

Clr.YES (Clear the Accumulator) CLr. NO (Do NOT Clear the Accumulator)

NOTE:

Pressing the ZERO key will clear the Accumulator and return to the Net/Gross mode.

Pressing the UNITS key will NOT clear the Accumulator and return to the Net/Gross

mode.

Clears Peak Weight data and Piece Count Data if selected .

6/12 17 51214 Rev. 7

Section 3: Oper a t ion

Parts Counting and Accu mulation

1. Place the Container on the Scale Platform.

2. Press the TARE key to Tare off the container weight and set the scale in the Net

Mode. The Display should indicate 0 Net Weight.

3. Press the B/G NET key. The Display prompts to "Add" a number of sample parts

to the Container. Pressing the B/G NET key repeatedly will Prom pt to; "Add 1", "Add

5", "Add 10", "Add 25", Add 50", or "Add 100" parts.

4. Add the required sample to the container, then press t he UNITS key. The Display

will alternate between indicating the weight and the Number of pieces.

5. Add the remaining parts to the Container.

6. The Display will update and continue to alternate between the Weight and Number

of Pieces including the original sample.

7. Press the B/G NET key. The Display will alternate between the "Total" legend and

the Total number of pieces accumulated.

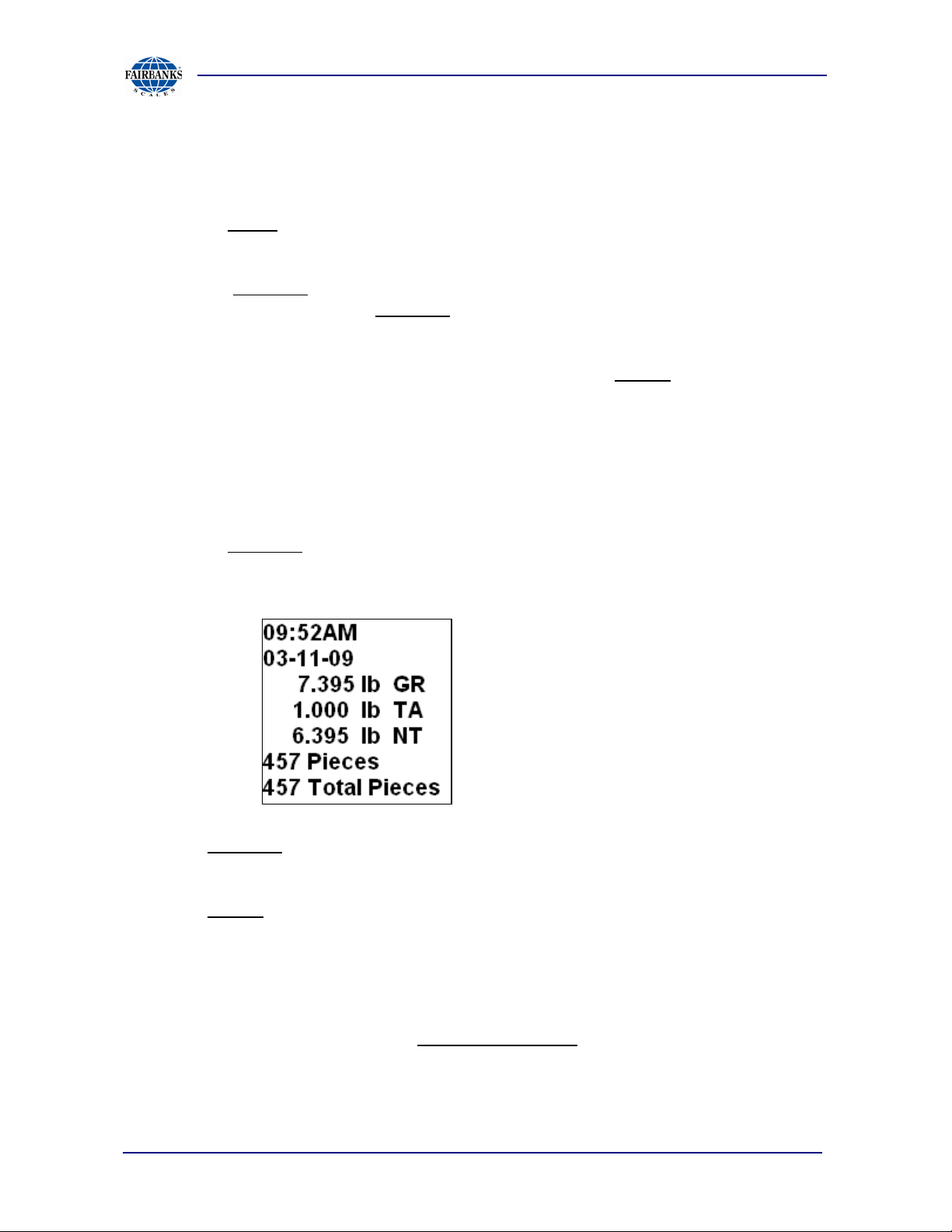

Print Example:

Press the B/G NET key to skip adding the Current Piece to the Total Register and

return to the Weigh Mode

Press the UNITS key to complete the Accumulation

Notes:

If the prompts do not occur, clear the accumulator and start over.

The operating mode must be set to Piece Count & total to function.

6/12 18 51214 Rev. 7

Section 3: Oper a t ion

Peak Weight

Either the Maximum Unstable or Maximum Stable Peak Weights, are stored along

with the time and date that the condition occurred. This data can be printed or viewed

at the FB2250.

To view, press the ZERO key for 3 seconds to alternately display the peak weight,

time, and date. This will time out 30 seconds and return to the weigh mode, otherwise

press the UNITS key to end.

Press the Zero key for 3 seconds

Conditional upon programming the operating mode to accumulation, piece count, or

piece count & total.

The FB2250 will display total number of pieces, weight, and time out (30 sec).

Conditional upon programming the operating mode to peak hold stable or peak hold

unstable.

The FB2250 will display time, date, peak weight, and time out (30 sec).

6/12 19 51214 Rev. 7

Section 4: Accessories

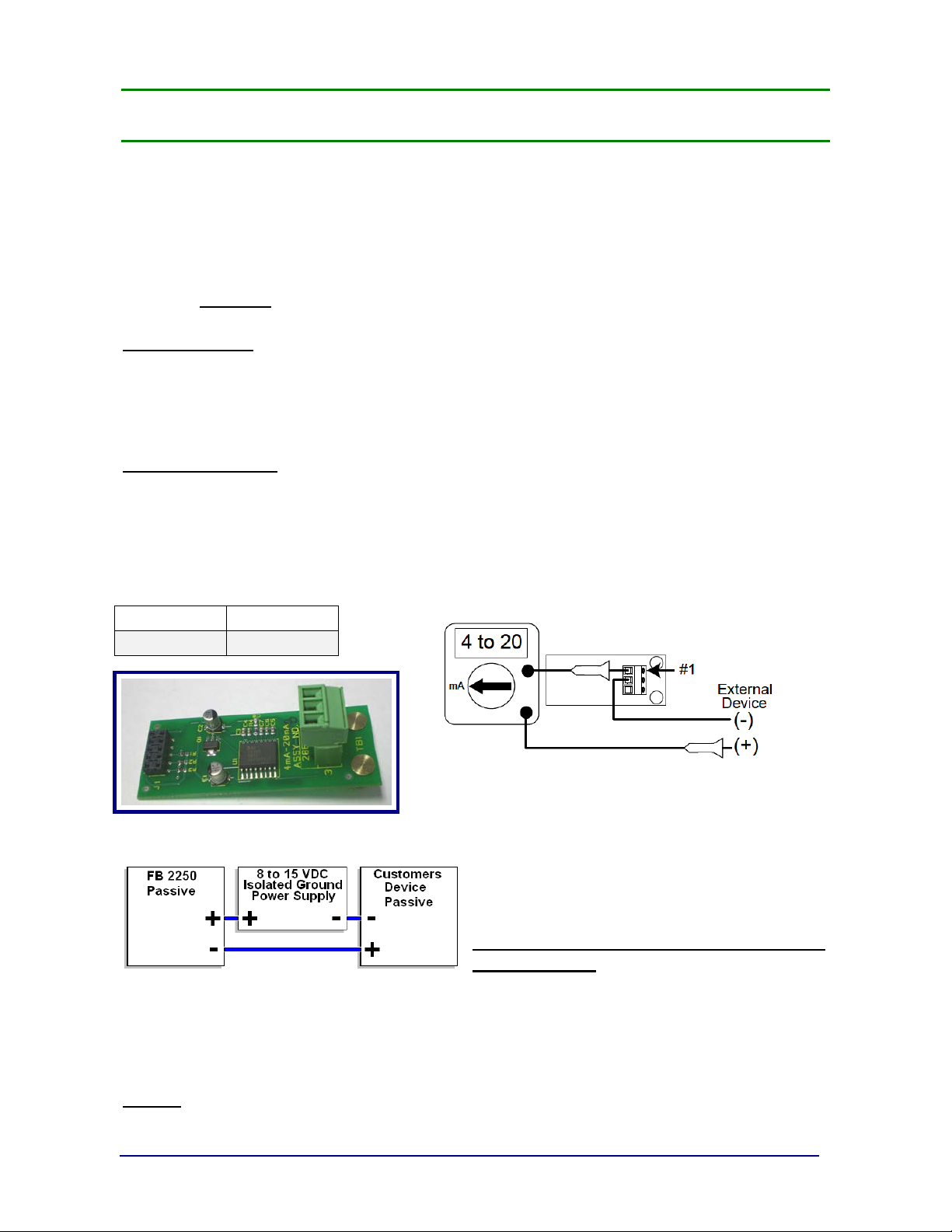

4-20 mA Analog Output

16 bit Resolution and Monoto ni ci ty

0.01% Non-Linearity

Front Panel Programmabl e or via PC2250 utility software program

Passive (does not supply the voltage for the current loop)

Requirements:

External device must fur nis h 7 VDC to 40 VDC

The negative of the supply MUST be isolated from chassis ground

A separate power supply must be furnished for each FB2250

Wiring & Testing:

Follow these steps to text the 4-20 mA Analog Component.

1. Remove the four (4) screws fastening the back of the Indicator and open it.

2. Connect the Multimeter in series with the 4-20 mA Analog Output Loop, as noted

below.

TB1-1 (+) Power

TB1-2 (–) Power

If the device is passive, an auxiliary power supply must be used to supply the voltage

for the current loop. Wire it as shown.

FB2250 Condition 4-20 mA

analog output

FB2250 behind zero 3.5 mA

Weight below 4.20 LO 3.5 mA

Weight above 4.20 HI 24 mA

Program Mode Locked on last 4-20 mA reading

Notes:

Loop power should be turned off whenever the FB2250 is turned off.

6/12 20 51214 Rev. 7

Section 4: Accessories

4-20 mA Instrument Setup

Press the Units key for 3 seconds

NOTE:

Conditional upon service programming.

Gross / Net: Programming the weigh mode the output will track:

Select Gross or Net. The 4-20 mA analog output will track the selection. It will

continue to track the selection regardless of the currently selected weigh mode o f the

FB2250. Press the ZERO key, then the UNITS key to toggle the available settings.

Press the ZERO key to enter the selection. Available selections are Gross or Net.

4.20 Lo: Programming the weight value associated with 4 mA: The display will

indicate 4.20 Lo: Press the ZERO key. The display will indicate the zero weight

“XXXXXX”. Press the UNITS key to increment the blinking digit, press the ZERO key

to advance to the next digit, repeat until entry is complete. After entering the least

significant digit, press the ZERO key. This weight entry will result in a 4 mA output.

4.20 Hi: Programming the weight value associated with 20 mA: The display will

indicate 4.20 Hi: Press the ZERO key. The display will indicate the maximum weight

“XXXXXX”. Press the UNITS key to increment the blinking digit, press the ZERO key

to advance to the next digit, repeat until entry is complete. After entering the least

significant digit, press the ZERO key. This weight entry will result in a 20 mA output.

6/12 21 51214 Rev. 7

Section 4: Accessories

Fieldbus

Fairbanks Scales o ffer s three different fieldbus devices modules; Profibus®,

DeviceNet™, and Ethernet/IP.

The fieldbus card is factory installed onto an

adapter.

.

Ethernet/IP Addressing

The Ethernet/IP module uses Dynamic addressing using DHCP for address requests

as the default. The data is transmitted continuously from this module. The IP

address may be made static by downloading the IP Configuration Tool software from

http://www.hms.se/support/support.asp?PID=368&ProductType=AnybusCompactCom.

With this utility, it is possible to change the IP, Sub Net and Gateway addresses of an

Ethernet/IP Module. To change an address, double click on the IP address field and

enter the changes.

EtherNet/IP can be easily confused as a simple combination of EtherNet and the

Internet Protocol. Instead, it is an Industrial Application Layer Protocol used for

communication between industrial control systems and their components.

Such components include Programmable Automation Controller, Logic

Controller, or an I/O System.

The “IP” in EtherNet/IP is not an abbreviation for “Internet Protocol”, but instead, it

stands for “Industrial Protocol”.

6/12 22 51214 Rev. 7

Section 4: Accessories

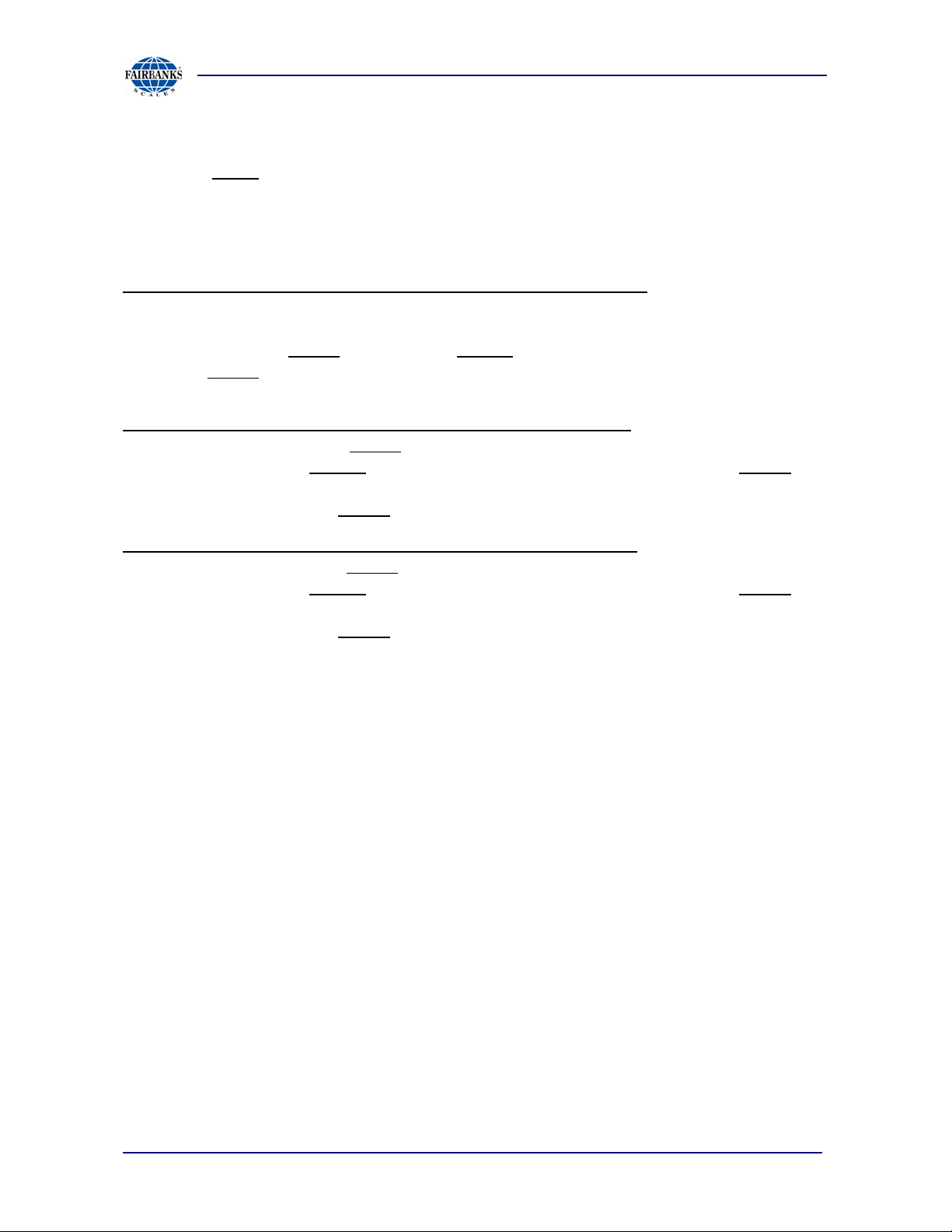

Fieldbus Connecti on s:

Profibus®

Pin Signal Description

3 B Line Positive RxD/TxD, RS485 level

4 RTS Request to Send

5 GND Ground (Isolated)

6 +5 Bus Output +5V termination power (Isolated, short circuit protected)

8 A Line Negative RxD/TxD, RS485 level

DeviceNet™

Pin Signal Description

1 V- Negative bus supply voltage

2 CAN_L CAN low bus line

3 SHIEL D Cable shield

4 CAN_H CAN high bus line

5 V+ Positive bus supply voltage

Eth ernet / IP

Use standard Cat 5 cable

(RJ45)

Output data can be verified using the PC2250 utility.

Additional informati on and ED S fil es ar e av ail abl e at: http://www.hms.se/default.shtml

6/12 23 51214 Rev. 7

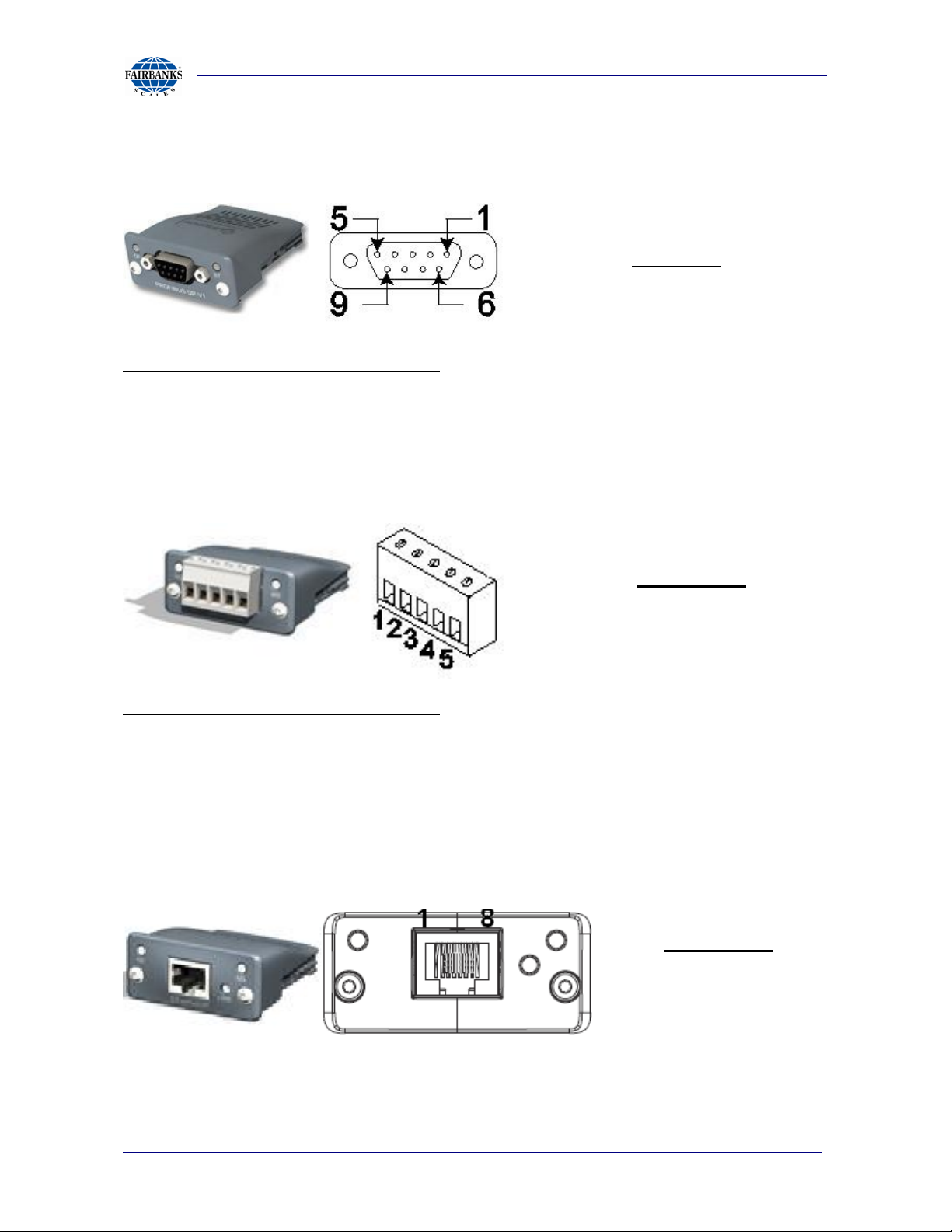

Section 4: Accessories

Profibus® Diagnostic LED’S:

1: Operation Mode LED

2: Module Status LED

Operation Mode LED

State Description Comments

Off Not online / No power Green Online / Data exchange Flashing Green Online, clear Flashing Red (1 flash) Parameterization error See Parameterization data handli ng

Flashing Red (2 flashes) Profibus configuration error See Configuration data handling

Module Status LED

State Description Comments

Off No power or not initialized Module state=“SETUP” or NW_INIT”

Green Initialized Module has lef t the NW_INIT state

Flashing Green Initialized, diagnostic event(s) present Extended diagnostic bit is set

Red Exception error Module state = EXCEPTIO N

Additional informati on and ED S fil es ar e av ail abl e at: http://www.hms.se/default.shtml

6/12 24 51214 Rev. 7

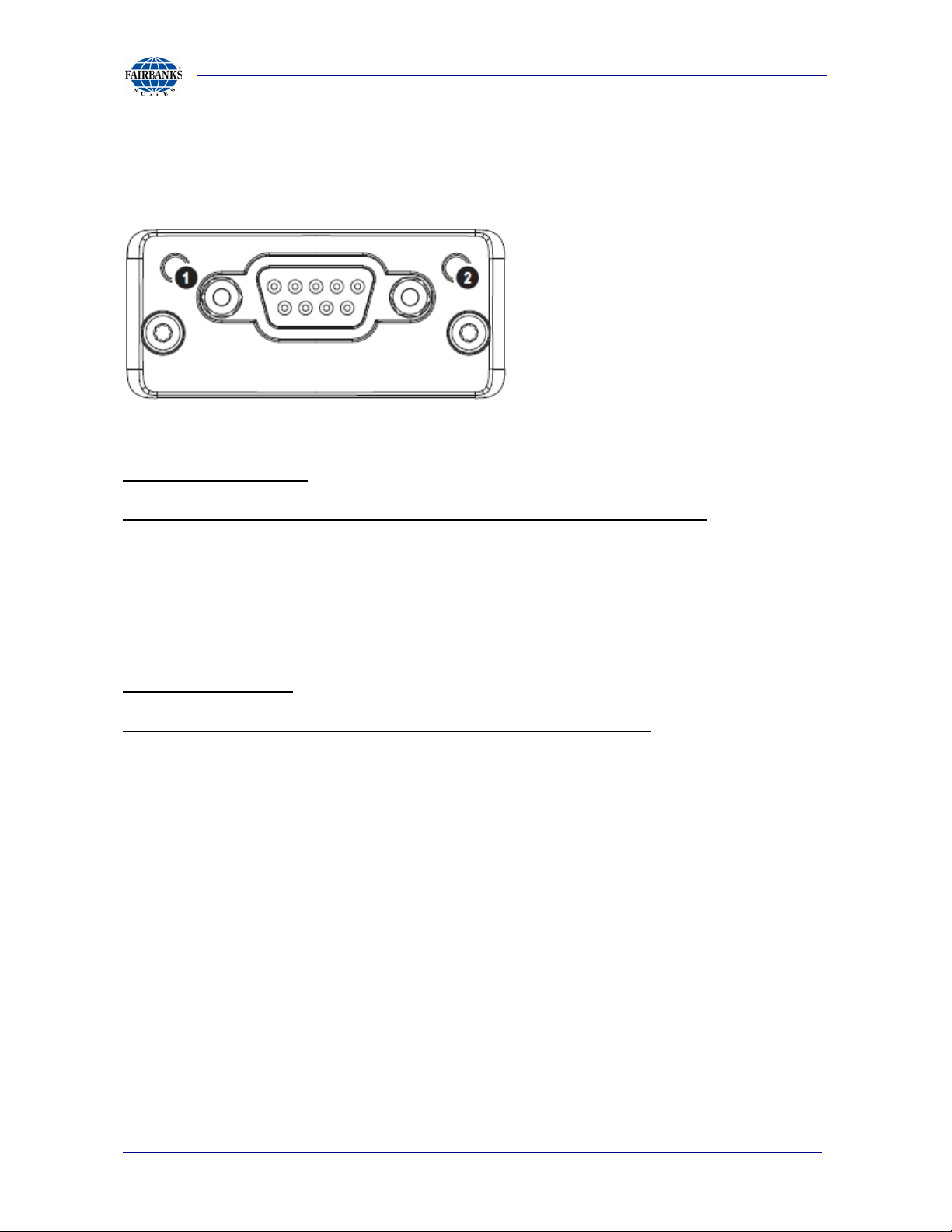

Section 4: Accessories

DeviceNet™ Diagnostic LE D ’ S:

1: Network Status LED

2: Module Status LED

3: DeviceNet™ connector

Network Status LED

State Description

Off Not online / No power

Green Online, one or more connections established

Flashing Green (1 Hz) Online, no connections established

Red Critical link failure

Flashing Red (1 Hz) One or more connections timed out

Alternating Red/Green Self-test

Module Status LED

State Description

Off No power

Green Operating in normal condition

Flashing Green (1 Hz) Missing/incomplete configuration / Device needs commissioning

Red Unrecoverable fault(s)

Flashing Red (1 Hz) Recoverable fault(s)

Alternating Red/Green Self-test

Additional informati on and ED S fil es ar e av ail abl e at: http://www.hms.se/default.shtml

6/12 25 51214 Rev. 7

Section 4: Accessories

Ethernet / IP Diagnostic L ED’S:

1: Network Status LED

2: Module Status LED

3: Link/Activity

4: Ethernet Interf ace (RJ 45) (Standard Cat 5 cable)

Network Status LED

State Description

Off Not online / No power

Green Online, one or more connections established

Flashing Green Online, no connections established

Red Duplicate IP address, FATAL error

Flashing Red One or more connections timed out

Module Status LED

State Description

Off No power

Green Controlled by a scanner in Run state

Flashing Green Not configures, or Scanner in idle state

Red Major fault (EXCEPTION-state, FATAL error, etc.)

Flashing Red Recoverable fault(s)

LINK / Activity LED

State Description

Off No link, no activity

Green Link established

Green, flickering Activity

Additional informati on and ED S fil es ar e av ail abl e at: http://www.hms.se/default.shtml

6/12 26 51214 Rev. 7

Section 5: Serial Communication Wiring

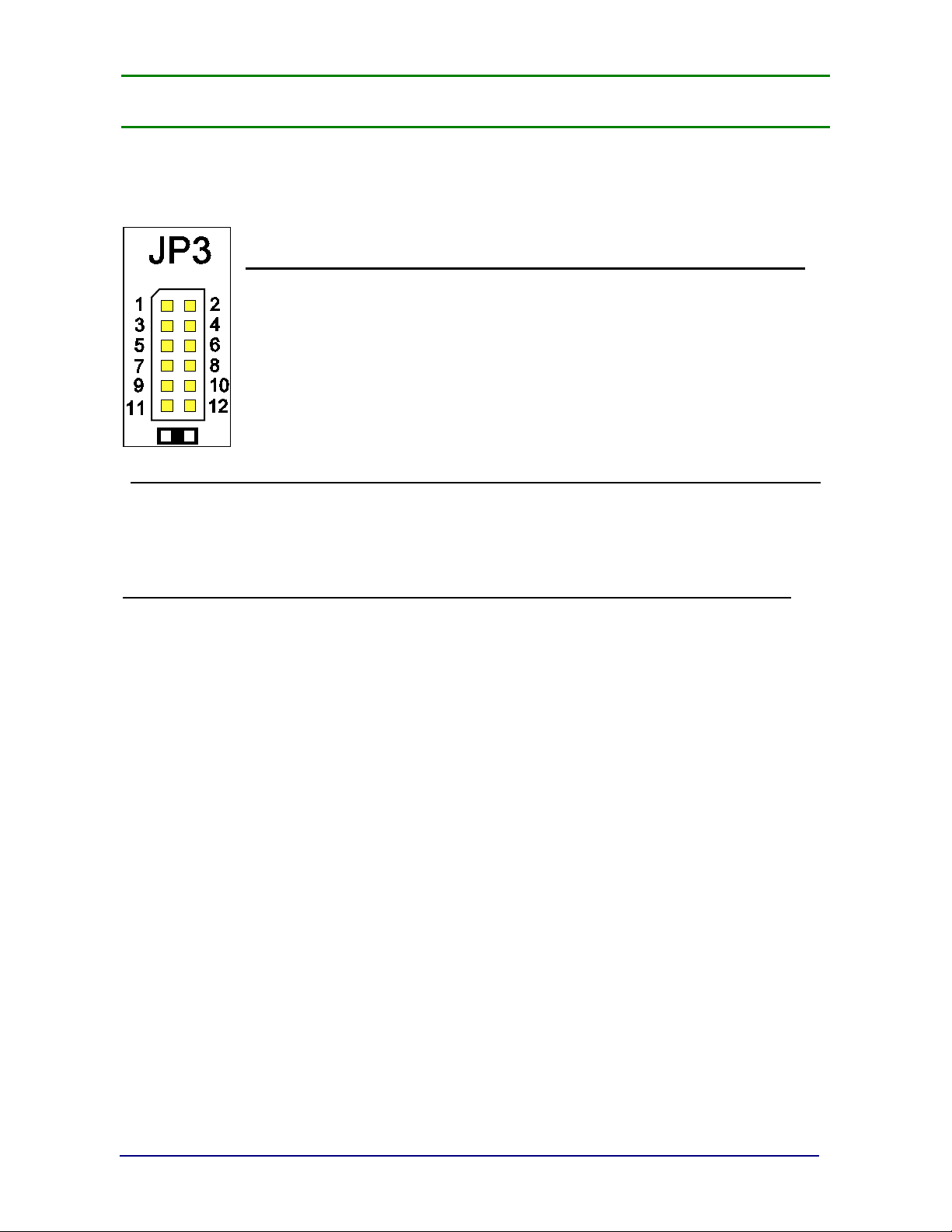

JP3 Jumper Configuration:

JP3 RS232 RS485 RS422* Port

1-2 out 120 Ω resistor 120 Ω resistor Com1

3-4 out in out Com1

5-6 out in out Com1

7-8 out in out Com2

9-10 out in out Com2

11-12 out 120 Ω resistor 120 Ω resistor Com2

120 ohm termination resistors required if the receiver is the last node of the network

TB4 Wiring connections

RS232 RS485 RS422* Port #

TB4 (A)

1 Rx Receive Data RS485 - RS422 Rx - Com 1

2 Tx Transmit Data RS485 - RS422 Tx - Com 1

3 CTS Clear to Send RS485 + RS422 Rx + Com 1

4 GND GND GND Com 1

5 RTS Ready to Send RS485 + RS422 Tx + Com 1

TB4 (B)

1 Rx Receive Data RS485 - RS422 Rx - Com 2

2 Tx Transmit Data RS485 - RS422 Tx - Com 2

3 CTS Clear to Send RS485 + RS422 Rx + Com 2

4 GND GND GND Com 2

5 RTS Ready to Send RS485 + RS422 Tx + Com 2

TB4 (C)

1 Tx + Passive 20 mA Output Com 2

2 Tx – Passive 20 mA Output Com 2

3 +7.5 V Bluetooth® Technology Supply

*Port should be set to RS485.

6/12 27 51214 Rev. 7

Section 6: Printer Installation

3550 Tape Printer

The FB2250 should be programmed for RS 232, 9600 baud, 8 data bits, and 1 stop

bit. The OUTPUT setting should be “BUTTON” for the Print key.

6/12 28 51214 Rev. 7

Section 6: Printers

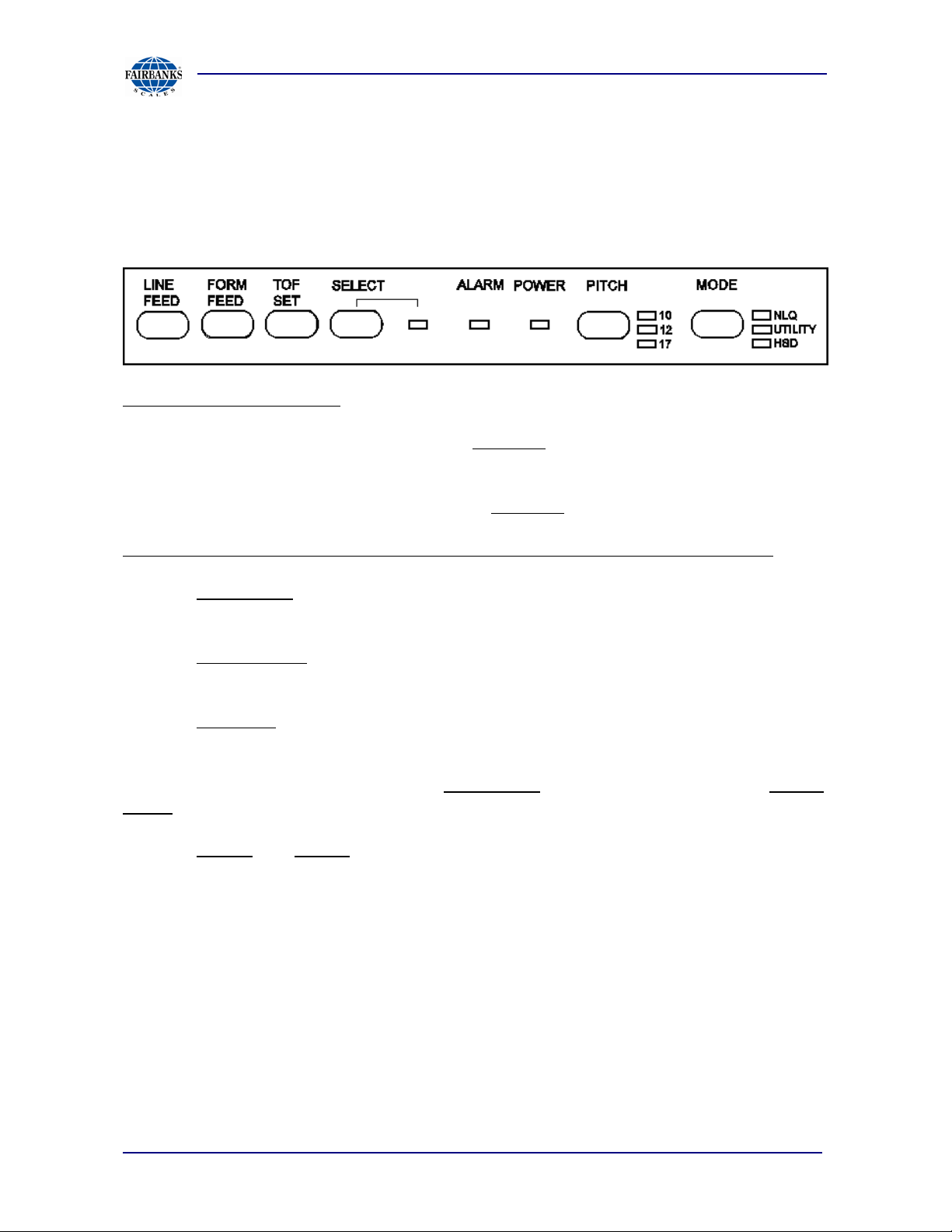

Okidata 186 T Form Printer

The FB2250 should be programmed for RS 232, 9600 baud , 8 data bi ts , and 1 stop

bit. The OUTPUT setting should be “BUTTON” for the Print key.

To change Menu Settings:

1. To enter MENU MODE, press and hold SELECT while turning on the printer. The

“12” and “UTILITY” LEDs will blink.

2. With the printer in the Menu Mode, press SELECT to print the complete menu.

The current default settings print out. It is recommended to use tractor fed paper.

NOTE: The printed menu selec ti ons ar e different for each emulation mode.

3. Press LINE FEED to select the relevant group that needs to be changed (the

group is the left-hand column on the Menu printout).

4. Press FORM FEED to select the relevant item within the selected group (the Item

is the center column on the Menu printout).

5. Press TOF SET to cycle through the settings available for the item you want to

change (the settings are the right-hand column on the Menu printout).

6. To continue making changes: pres s LINE FEED for the next group or press FORM

FEED for the next item. Repeat as needed until you are finished changing settings.

7. Press PITCH and MODE together to save the changes and exit the Menu Mode.

NOTES:

Exiting the Menu Mode by turning off the printer will cancel any changed settings.

Printed menu’s changes per Printer Emulation Mode. If printer em ulation mode is

NOT set to ML, set this first, then reprint the menu. Then set menu as follows:

6/12 29 51214 Rev. 7

Loading...

Loading...