Page 1

51248 Revision 1 07/10

Page 2

Fairbanks Scales

2

AADI Document W150 H70 001

st

Edition 14th September 2007 Preliminary Edition

1

nd

2

Edition 11th January 2008

page 2

© Copyright: Aanderaa Data Instruments AS

010 Fairbanks Scales

Contact information:

Aanderaa Data Instruments AS

PO BOX 34, Slåtthaug

Fairbanks Scales 821 Locust Kansas City, MO 64106

5851 Bergen, NORWAY

Visiting address:

Nesttunbrekken 97

5221 Nesttun, Norway

TEL: +47 55 604800

FAX: +47 55 604801

E-MAIL: info@aadi.no WEB: http://www.aadi.no

Page 3

OPERATOR’S MANUAL page 3

Table of Contents

CHAPTER 1 Description of LOADTRONIC 3 ............................................................... 5

1.1 Sensors .....................................................................................................................5

1.2 Main Unit .................................................................................................................5

1.3 Calibration Switch ...................................................................................................6

1.4 Printer (Optional).....................................................................................................6

1.5 Remote Wireless Communication (Optional) .........................................................7

1.6 Certified Technical Data ..........................................................................................7

CHAPTER 2 Operator Display and Menu........................................................................8

2.1 Menu Layout............................................................................................................ 9

CHAPTER 3 Operating LOADTRONIC 3..................................................................... 11

3.1 Start –Normal Operation........................................................................................ 11

3.2 Automatic Weighing..............................................................................................11

3.2.1 Tips for best results when weighing................................................................ 14

3.3 Recording............................................................................................................... 15

3.3.1 Job Record....................................................................................................... 15

3.3.2 Unspecified Recording.................................................................................... 16

3.3.3 Specified Recording ........................................................................................ 17

3.3.4 Selecting a Pre-defined Job Record ................................................................19

3.3.5 Multiple Jobs ................................................................................................... 19

3.4 Manual Weighing...................................................................................................20

3.5 Changing and Deleting Attachment....................................................................... 21

3.6 Zeropoint Adjustment ............................................................................................22

3.7 Re-Weighing and Adjusting the Weight................................................................25

3.8 Shakeoff to Truck ..................................................................................................26

3.9 Cancelling/Dumping last Bucket ........................................................................... 27

3.10 Pause mode ..........................................................................................................27

3.11 Adjusting the Display Backlight.......................................................................... 28

3.12 Display Volume of Load...................................................................................... 28

3.13 System Information.............................................................................................. 28

CHAPTER 4 Library and Reports ..................................................................................30

4.1 Library of Customers, Materials, Trucks and Locations ....................................... 30

4.1.1 Search the Library for a Customer, Truck etc.................................................30

4.1.2 Special Characters ........................................................................................... 31

4.1.3 Enter Job Details from the Job List................................................................. 31

4.1.4 Enter Job Details from the Text Editor ...........................................................34

Page 4

Fairbanks Scales

4.2 Reports ...................................................................................................................39

4.2.1 Report Header..................................................................................................39

4.2.2 Total Load Report............................................................................................40

4.2.3 Specified Report ..............................................................................................41

4.2.4 Copy of Receipt ...............................................................................................43

CHAPTER 5 Maintenance ..............................................................................................45

5.1 Load List, Event List and Error List ......................................................................46

5.2 Backup and Restore Logfiles, Database and System Files....................................47

5.3 Copy Calibration Details........................................................................................49

5.4 System Information................................................................................................50

page 4

Page 5

OPERATOR’S MANUAL page 5

CHAPTER 1 Description of LOADTRONIC 3

LOADTRONIC 3 is an automatic and dynamic weighing system for wheel

loaders. It is automatic in the respect that the load in the bucket is weighed

without any involvement from the operator and dynamic as the weighing is

done while the machine operates normally without any interruption for

weighing.

LOADTRONIC 3 is type approved as Automatic Catchweigher according to

MID-directive MI-006 and OIML R51.

1.1 Sensors

LOADTRONIC 3 has two pressure sensors fitted to the hydraulics of the

wheel loader. These sensors measure the forces applied to the lifting arm

system, refer LOADTRONIC 3 Installation Guide.

There are two more sensors in the system:

x One angular sensor (inclinometer) which measures the position of the

lifting arms.

x One acceleration sensor which measures the movement (acceleration,

retardation and the inclination of the machine).

There is one switch in the system:

x One bucket position switch to signal when the bucket is fully retracted.

x In addition, the system is connected to the reverse signal of the machine.

1.2 Main Unit

The main unit is a combined operator’s display and a computer unit. The

main unit is mounted on the right corner post in the cabin, and has the

following functions:

x To read sensor signals.

x To compute and analyze measured data.

x To control the automatic weighing function.

x To record and report the weighing results.

Page 6

Fairbanks Scales

page 6

x To carry out calibration and similar functions when the calibration switch

is set to the enabled position.

x To present measurement results on the LCD display.

x To receive commands from the operator through a keypad and a set of

function keys.

1.3 Calibration Switch

The calibration switch is placed underneath the main unit, refer Figure 1-1.

Calibration is enabled when the switch is in the rightmost position. Ensure

that the switch is in the leftmost position (calibration disabled) during

normal operation of the LOADTRONIC 3.

Figure 1-1 The Calibration Switch is placed underneath the Main Unit.

1.4 Printer (Optional)

The printer is connected to the main unit and positioned as required.

The printer has the following functions:

x Print a load receipt for each truck load.

x Print reports about customer, truck, material, location and load list.

If a printer is connected, you can print a load receipt by pressing the function

key next to the printer symbol (F2). Print/F2 will automatically cancel/zero

the running accumulated total for the current active job.

Page 7

OPERATOR’S MANUAL page 7

1.5 Remote Wireless Communication (Optional)

Wireless communication is used for up- and downloading data between the

wheel loader and a remote location.

1.6 Certified Technical Data

Accuracy class Y(b)

Verification scale interval e t 0.02t

Number of verification scale interval n d 200

Maximum capacity Max t 100e

Max d 200e

Minimum load Min t 10e

Temperature range -25°C to +50°C

Power supply 18 - 36 VDC

Page 8

n,p

Fairbanks Scales

CHAPTER 2 Operator Display and Menu

page 8

Figure 2-1 LOADTRONIC 3 Display.

LOADTRONIC 3 has a set of function keys, F1, F2, F3, F4, #,

on the display unit, refer Figure 2-1 and Figure 2-2. The functionality differs

depending on which sub menu is currently open; a symbolic representation is

shown inside the display, in the rightmost column (next to the function

keys).

The LOADTRONIC 3 display unit has a keypad below the display; the

keypad holds the digits from 0 to 9, and the English alphabet; the layout is

similar to the one used in mobile phones.

, and *

Page 9

OPERATOR’S MANUAL page 9

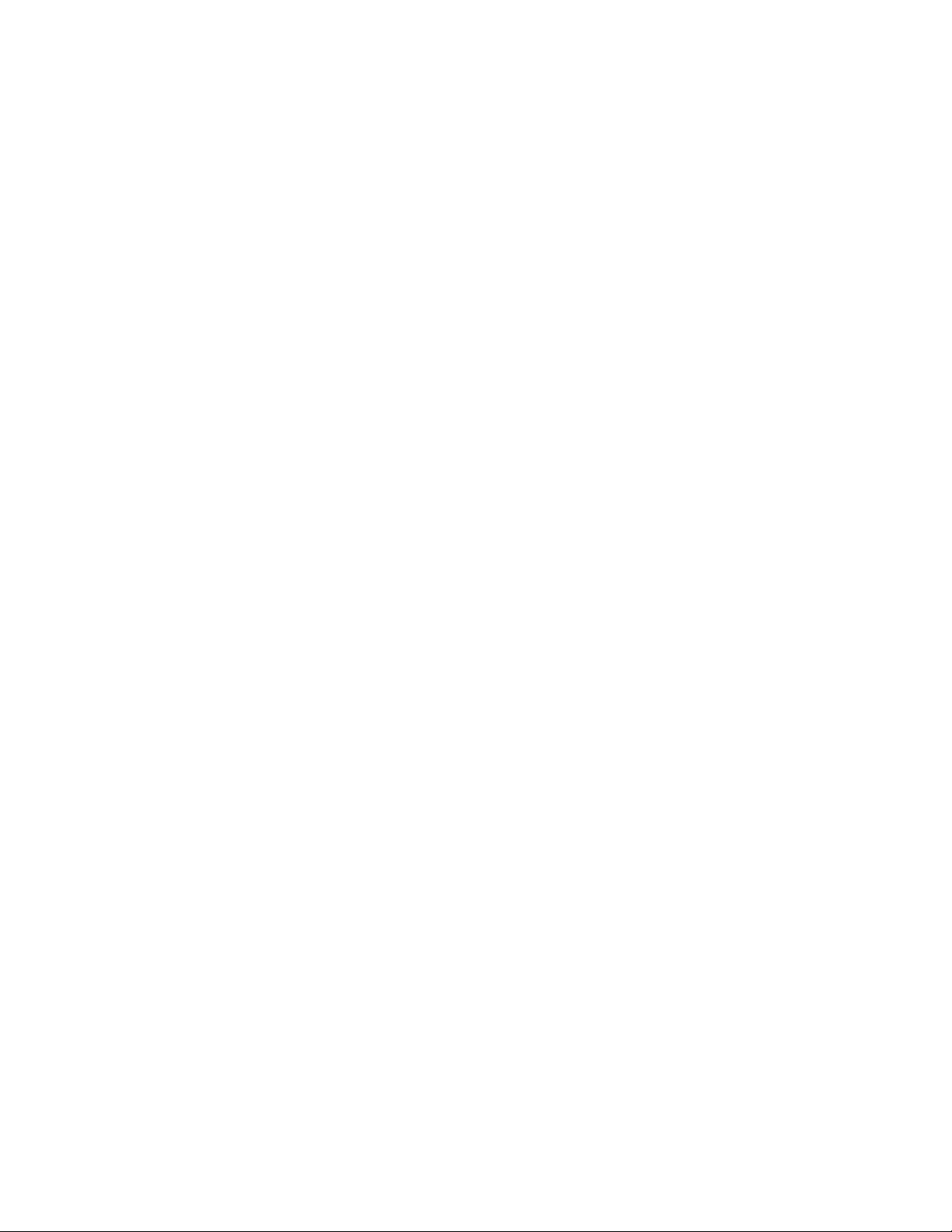

2.1 Menu Layout

Figure 2-2 Illustration of the LOADTRONIC 3 menu.

Page 10

Fairbanks Scales

The LOADTRONIC 3 starts up in automatic weighing mode. Press the down

arrow to open the main menu; press the down- or up arrow to highlight the

sub menus, refer Figure 2-2. Press Enter/# to open the highlighted sub menu,

and Cancel/Exit/* to return to automatic weighing mode without performing

any changes to the settings.

page 10

Figure 2-3 Main menu as shown in the operator’s display.

Page 11

OPERATOR’S MANUAL page 11

CHAPTER 3 Operating LOADTRONIC 3

3.1 Start –Normal Operation

LOADTRONIC 3 starts up as the machine’s ignition key is set in position 1

(running position) and the power switch at the rear of the main unit is

switched ON/1. After a few seconds a start up window is shown in the

display; next the system enters automatic weighing mode.

LOADTRONIC 3 is now ready for automatic weighing, refer chapter 3.2.

The currently active job record is shown in the lower part of the display; if

all records have been cleared (no active record) job record 0 ‘Unspecified

Recording’ is displayed.

Note:

If the instrument is directly connected to the machine battery (optional,

refer the LOADTRONIC 3 Installation Guide), the activation time is less

than 1 seconds if the engine is stalled; normally activation time is

approximately 10 seconds. The direct connection to the battery will also

provide power to the thermostat controlled heating element (optional) for

operations in very cold locations.

If the machine has been idle for more than two hours, LOADTRONIC 3

will block weighing, and request the operator to carry out a manual

zeropoint adjustment, refer chapter 3.6.

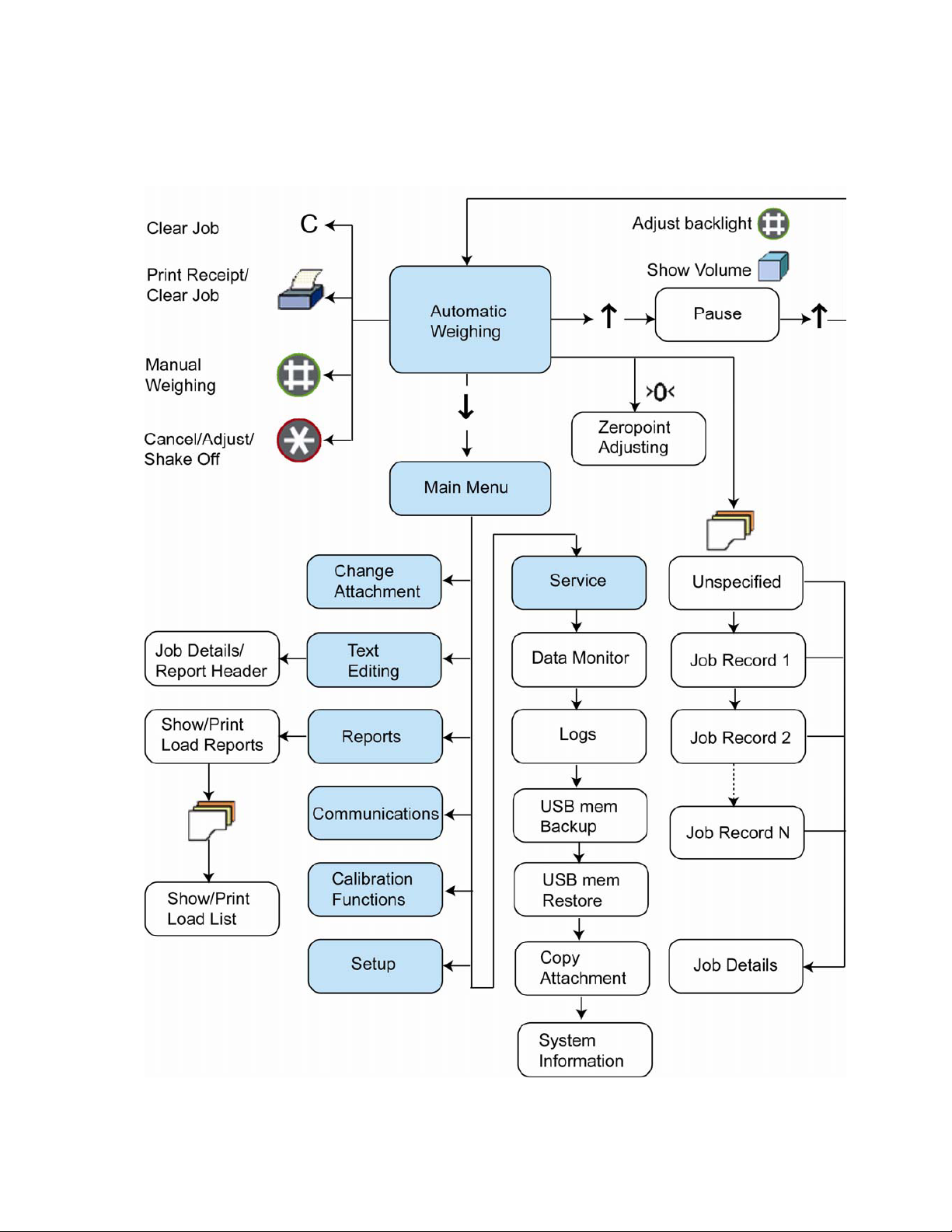

3.2 Automatic Weighing

Normally the LOADTRONIC 3 is in the mode for automatic weighing.

Automatic weighing means that the operator can operate as usual; during

normal operation the weighing sequence is activated automatically when the

wheel loader is reversed out from the material heap after filling the bucket.

Refer Figure 3-1 for an illustration.

The weighing begins as soon as the lifting arms have moved within the

weighing range, providing that other sensor signals are acceptable.

Page 12

q

Fairbanks Scales

page 12

The weight of the bucket is automatically added to the running total weight.

Figure 3-1 Automatic Weighing is connected to the normal working cycle. A: 2 seconds. B:

measurement area -20

to +20q. C: weighing.

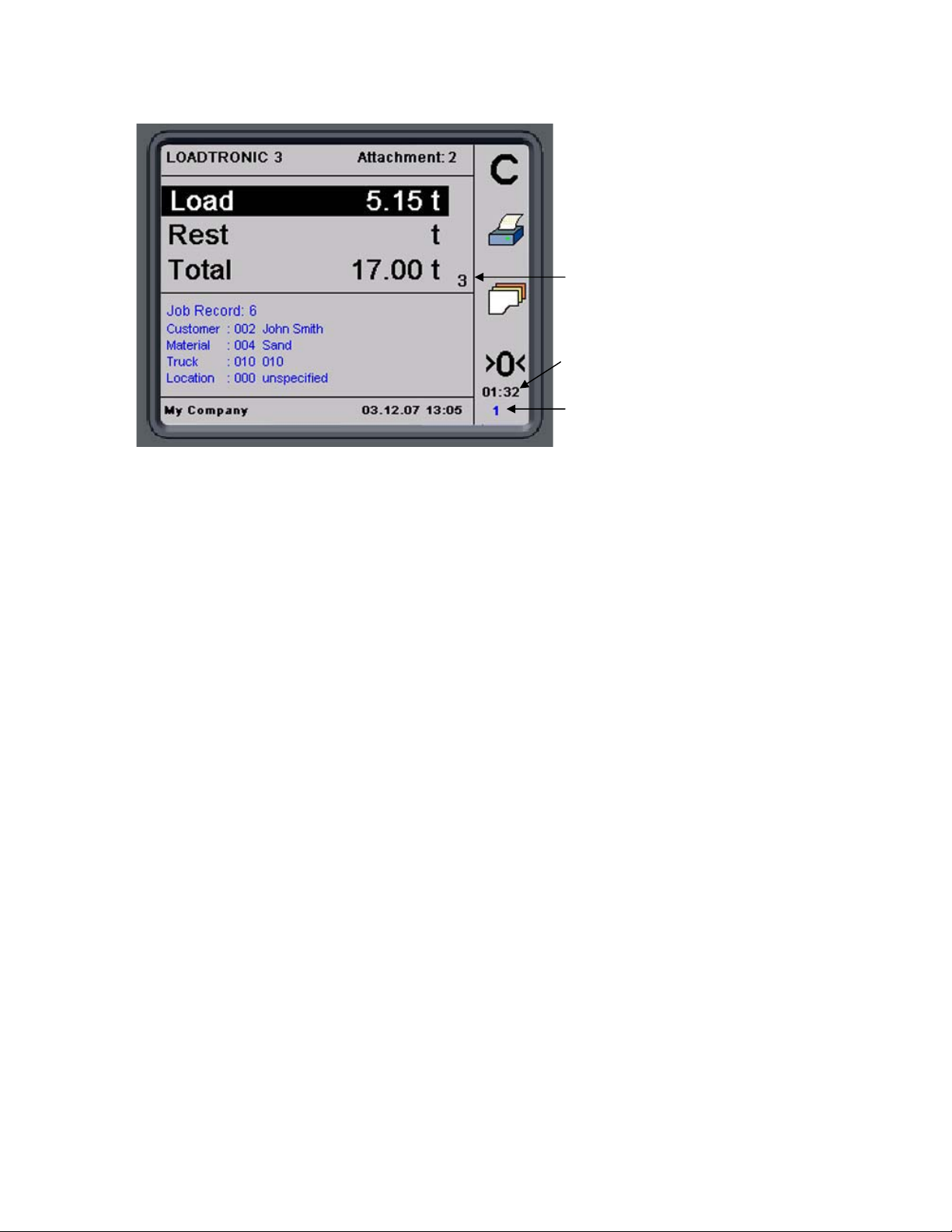

During automatic weighing the display unit shows, refer Figure 3-2:

x Load of the current bucket (Material weight), e.g. 5.15 t.

x Rest (Remaining material to be loaded (the required final weight -

(minus) total load so far).

x Running Total weight loaded so far, e.g. 17.00 t.

x Number of buckets loaded so far, e.g. 3.

x Attachment: ID number of the current attachment.

x Number of Active Jobs.

x Active Job (details).

Page 13

OPERATOR’S MANUAL page 13

j

Number of buckets

Time until next zero

ad

ustment

Number of active

jobs

Figure 3-2 Operator’s display during automatic weighing.

Note: If the bucket is not fully tilted rearward, the message:‘BUCKET’

will be shown in place of the bucket weight (no weighing performed).

Comments:

x When weighing begins, the Load-field starts to flash, and the value is

updated.

x Weighing is completed when the weight of the current load is added to the

running total. The buzzer will give a sound signal if activated in

Parameter Setup II, refer Figure 3-6 and LOADTRONIC 3 Installation

Guide.

x The total weight and the rest weight to be loaded will be updated.

x The weight of the last bucket remains displayed until the load has been

dumped.

x Press Print/F2 to clear the job and print a receipt (if a printer has been

installed), or press C/F1 to clear the job (no report).

Page 14

Fairbanks Scales

page 14

3.2.1 Tips for best results when weighing

Maximum function and accuracy is achieved by avoiding substantial

deviations from the usual work cycle, while at the same time noting the

following points:

x The LOADTRONIC 3 is activated/made ready for weighing 2 seconds

after the gear selector has been moved into reverse. During this time the

bucket should be pulled out from the material heap so that no friction

forces between the heap and the bucket will affect the weighing result.

This particularly applies if the bucket has been raised fairly high while

filling it.

x The lifting arms must be moving upward to initiate the weighing.

x If it should happen that the LOADTRONIC 3 does not become activated /

begin weighing, it is possible to activate manual weighing by pressing #,

refer chapter 3.4.

x The bucket must be tilted rearward to its end-stop when weighing,

otherwise the message ‘BUCKET’ will appear on the display.

x The lifting arms must be lifted into the measurement area, refer Figure

3-1.

x The lifting arms must not touch against the front frame or the machine

body when the weighing begins. This could cause false readings. This

means that:

o It is possible to control at which point in the work cycle the

weighing should be done by awaiting raising the lifting arms until

the machine has reached a suitable destination.

o When loading, transporting and dumping the load at a low height,

e.g. down a slope, it is necessary to raise the bucket before

emptying it to allow weighing to take place.

x When weighing on ground which is inclined more than 5 %, it is

recommended that weighing should be avoided at low lifting angles

particularly when the machine is pointing downhill. The system will only

weigh when the tilt is less than 10 %.

x If the operator wants to weigh the load under controlled conditions, he can

cancel the current weight and re-weigh the load, refer chapter 3.7 and 3.9.

If the bucket has been emptied, the cancel function must be used. At

manual activation a new weighing sequence starts immediately. When

canceling before dumping, the system must also be activated for a

Page 15

OPERATOR’S MANUAL page 15

renewed weighing by moving the gear selector from forward or neutral to

reverse.

3.3 Recording

LOADTRONIC 3 records each operation when the system is active

(LOADTRONIC 3 is not active in pause mode, refer chapter 3.10). The

recording is linked to a specific job record, with or without reference to a

specific type of truck, material, customer or location. Data are stored

internally in the main unit; data can be inspected and printed for a customer

receipt. The current active job record is shown in the lower part of the

display.

3.3.1 Job Record

The LOADTRONIC 3 system can hold job details for as many as 999 job

records. A specific job record can be activated by e.g. pressing the job record

number directly on the keypad. The operator can receive a set of job records

to perform prior to the working day, and/or the operator can assign details

during the day.

Job record 0 is for unspecified recordings. The operator can temporarily

type/set job details for job identification in the records list for reporting etc,

but the details are not stored in job record 0 for later use; the job details are

unspecified the next time job record 0 is opened.

Job records 1 to 999 are for specified recordings. The job details that are

assigned to a specific job record are stored until changed by the operator.

A job record is active until the operator:

x Press Print/F2 to print a report.

x Press C/F1 to clear (no report).

Refer chapter 4.1 for a description of managing a library of customers,

materials, trucks and location.

Page 16

page 16

Fairbanks Scales

3.3.2 Unspecified Recording

LOADTRONIC 3 allows the operator to perform an unspecified recording; a

recording of material weight without any specification of the material type,

truck, customer or location.

The operator can specify the target load before the job starts; either to set the

maximum permitted load limit for the truck or hauler, or to set a pre-defined

amount of material requested by the customer, refer Figure 3-4.

After each weighing LOADTRONIC 3 will display the weight of the current

bucket, the running total weight and the remaining weight to be loaded, refer

Figure 3-3.

If the operator does not specify the target load for the job, the field for the

remaining weight will be blank. The current weight of the bucket and the

running total weight will be displayed.

Figure 3-3 Job record with specified target load.

Page 17

OPERATOR’S MANUAL page 17

n

Procedure to start an unspecified job record with a specified target

load:

1. Press 0 on the keypad to open job record no. 0.

2. Press job record/F3 to set the target load (recommended):

- Press Next/F4 repeatedly to highlight the Load-field at the end.

- Type the target load using the keypad, or press the up arrow/

to

adjust the load in step of 0.01t. Press and hold the arrow to adjust

the load in step of 0.1t.

3. Press Enter/# to activate the job, or press Cancel/* to abort the

operation. LOADTRONIC 3 returns to automatic weighing mode.

When the job is complete, the operator can press Print/F2 for a customer

receipt (requires a printer), or simply C/F1(no report), refer chapter 4.2 for

more detail about customer reports.

Figure 3-4 Setting the target load.

3.3.3 Specified Recording

LOADTRONIC 3 allows the operator to assign job details in the job record:

details about customer, material, truck and/or location. By adding job details

the operator can easily identify a specific job record later. The job details are

printed on the load receipt. The job details of the current job are shown in

the display, refer e.g. Figure 3-5.

Page 18

n

Fairbanks Scales

page 18

Figure 3-5 Job details.

Procedure to specify job details for a job record:

1. Press a job record number directly using the keypad; job record 0 will

not store the details for later use.

2. Press job record/F3 to edit the job record; you may also change the job

record number in the job list: press the keypad directly, or press the up-

or down arrows.

3. Press Next/F4 to highlight the Customer-field. Search for/type

customer details, refer chapter 4.1 for a description about searching for

a description/typing a description. Press Next/F4 to enter material

details and other job details until the job has been specified according

to your requirements.

4. Press Next/F4 to highlight the Load-field. Type the target load using

the keypad, or press the up arrow/

Press and hold the arrow to adjust the load in step of 0.1t.

to adjust the load in step of 0.01t.

5. Press Enter/# to activate the job, or press Cancel/* to abort the

operation. LOADTRONIC 3 returns to automatic weighing mode.

When the job is complete, the operator can press Print/F2 for a customer

receipt (requires a printer), or C/F1 (no report) to start a new unspecified job,

refer chapter 4.2 for more detail about customer reports.

Page 19

OPERATOR’S MANUAL page 19

3.3.4 Selecting a Pre-defined Job Record

If the operator has a set of pre-defined jobs to perform, the assigned job

record including details can be selected from the job record.

Press the job record number directly from the keypad, or open the job list:

1. Press job record/F3.

2. Press the up- and down arrows to set the desired job record number, or

type the number directly on the keypad.

3. Press Enter/# to activate the job, or press Cancel/* to abort the

operation. LOADTRONIC 3 returns to automatic weighing mode.

When the job is complete, the operator can press Print/F2 for a customer

receipt (requires a printer), or C/F1 (no report), refer chapter 4.2 for more

detail about customer reports.

3.3.5 Multiple Jobs

LOADTRONIC 3 can manage multiple active jobs. The operator can

maintain multiple active jobs by selecting a new job record without clearing

the current record; the operator can switch between different jobs in the

same time period. All active jobs will be handled individually regarding

running total, number of buckets and the remaining weight to be loaded.

The number of active jobs is shown in the lower right corner of the display.

The operator can keep up to 9 active jobs at a time; the maximum number of

allowed active jobs can be set in Parameter Setup II, refer Figure 3-6 and

LOADTRONIC 3 Installation Guide.

Page 20

page 20

Fairbanks Scales

Figure 3-6 Open Main Menu – Setup – Parameter Setup II to set the maximum number of active

jobs.

Job record 1-9 can be active jobs. A job becomes active once the first bucket

of material is delivered; the operator can easily see that a job is active since

the running total is different from zero.

An active job is accessed by pressing the job record number (1-9) on the

keypad.

Note! A job is active until the operator presses the function key Print/F2,

or C/F1.

3.4 Manual Weighing

Weighing can be activated manually:

x Press # to activate manual weighing. The machine does not have to be

moved.

x Raise the bucket evenly from below the horizontal level. The load is now

weighed.

x The running total weigh is updated as the bucket is dumped.

Page 21

OPERATOR’S MANUAL page 21

3.5 Changing and Deleting Attachment

10 different attachments can be used with LOADTRONIC 3. The current

attachments ID number (1-10) is shown in the upper right corner of the

display, refer Figure 3-7.

Figure 3-7 Changing Attachment.

The attachments that are listed in blue color have been calibrated on the

wheel loader and are available, refer LOADTRONIC 3 Installation Guide.

Attachments that are not calibrated on the wheel loader are listed in red

color; you can not select the attachment before it has been calibrated.

Taring and basic calibration must be performed for every attachment to be

used with LOADTRONIC 3, refer LOADTRONIC 3 Installation Guide.

Procedure for changing attachment:

1. Fit the attachment to the machine.

2. Open Main Menu - Change Attachment, refer chapter 2.1.

3. Press the arrows to highlight the attachment identification number and

description. Press Select/# to select the correct attachment (or press

Cancel/* to return to automatic weighing mode without changing the

setting).

4. Ensure that the attachment is empty.

LOADTRONIC 3 requires a zeropoint adjustment, refer chapter 3.6.

Page 22

page 22

Fairbanks Scales

Note! The system will block the automatic weighing function and indicate

the requirement with the message ‘Adjust Zeropoint’ until the zeropoint

adjustment has been performed.

Procedure for deleting attachment calibration data:

x Enable the calibration switch, refer Figure 1-1.

x Open Main Menu - Change Attachment, refer chapter 2.1.

x Highlight the correct attachment.

x Press and hold Clear/F3 for 3 seconds; the entry will change to

“Unspecified” (red font).

3.6 Zeropoint Adjustment

A zeropoint adjustment must be carried out each time the machine has been

idle for a while, or at least every 2 hour. During normal operation, the

zeropoint can be adjusted up to r 4% of max load.

The LOADTRONIC 3 display shows a request for the operator to perform a

new zero point adjustment 10 minutes before the system is blocked (the load

will show ‘

****’ when the system is blocked).

Procedure for a zeropoint adjustment:

1. Ensure that the attachment is empty.

2. Position the machine on level ground. The attachment must be fully

retracted.

3. Press >0</F4 to enter the zero point adjustment sub menu.

4. Press Start/# to start the adjustment.

Note! If the bucket is not fully retracted, an error message appears on the

screen: ‘Bucket’, refer Figure 3-8. Retract the bucket and press Start.

Page 23

OPERATOR’S MANUAL page 23

Figure 3-8 Retract the bucket before a zeropoint adjustment.

Figure 3-9 Zeropoint adjustment.

5. Operate the lifting arm at a slow and even speed according to the

instructions on the display: Lower – Lift – Lower, refer Figure 3-10.

Page 24

Fairbanks Scales

Figure 3-10 Operation of the lifting arms during zeropoint adjustment.

page 24

Lifting arm

Horizontal

6. When the zeropoint adjusting is OK and completed, the

LOADTRONIC 3 automatically returns to automatic weighing after

showing the adjustment in kg. Accumulated load will be continued.

When the zeropoint adjusting is not OK an error message appears

in the display, refer Figure 3-11.

Figure 3-11 Error message when the zero point adjustment has failed.

Page 25

OPERATOR’S MANUAL page 25

Probable cause:

x Uneven movements of the lifting arm mechanism during taring.

x The adjustment was more than r 4% of max load. The information

indicates that the zero point of the sensors have moved significantly

relative to the tare curve.

This can happen if the machine has not been used for a while, if the

machine has been given maintenance recently, or if the bucket is not

completely empty due to material build-up, presence of ice etc.

x There is a mismatch between the actual attachment mounted to the

machine, and the selected calibration data.

Necessary action:

x Ensure that the selected calibration data are valid for the actual

attachment; select the correct calibration data/attachment.

x The zeropoint adjustment can be initiated (allowing adjustment up

to r 20% of max load by pressing >0</F4 twice. Follow the

instructions given on screen, refer Figure 3-11. Repeat the zeropoint

adjustment.

x If the zeropoint adjustment still fails, contact service personnel.

3.7 Re-Weighing and Adjusting the Weight

The operator can easily re-weigh the material in the bucket; this is typically

necessary if

x Part of the load falls off while moving the machine.

x The operator must adjust (remove) the loaded amount of material.

Procedure to re-weigh the material in the bucket:

1. Press # or move the gear selector to forward drive and then back to

reverse to initiate the weighing. The machine does not have to be

moved.

2. Raise the bucket evenly from below the horizontal level. The load is

now re-weighed.

Page 26

Fairbanks Scales

Procedure to adjust the material in the bucket:

1. Press and hold * for at least 1 second to cancel the bucket weight from

the running total weight. The current approximate weight is shown in

the display.

2. Move the machine to a place where the surplus material can be

dumped.

3. Shake off the material until the display shows the approximate desired

weight.

Note: The weight shown is slightly different from the actual weight,

since the bucket is not tilted rearward.

4. Retract the bucket and lower the arm when complete.

5. Press # or move the gear selector to forward drive and then back to

reverse to initiate the weighing. The machine does not have to be

page 26

moved.

6. Raise the bucket evenly from below the horizontal level. The load is

now re-weighed.

3.8 Shakeoff to Truck

If shakeoff to truck has been set in Parameter Setup II, refer Figure 3-6, the

operator can shake off part of the load onto the truck; the material delivered

to the truck is added to the running total.

Procedure for shakeoff to truck:

1. Press and hold * for at least 1 second to cancel the bucket weight from

the running total weight. The current weight of the material delivered

to the truck is 0 kg.

2. Shake off material until the display shows the approximate desired

weight delivered to the truck.

Note: The weight shown is slightly different from the actual weight,

since the bucket is not tilted rearward.

3. Retract the bucket and lower the arm when complete.

4. Press # or move the gear selector to forward drive and then back to

reverse to initiate the weighing. The machine does not have to be

moved.

Page 27

OPERATOR’S MANUAL page 27

n

n

5. Raise the bucket evenly from below the horizontal level. The

remaining load in the bucket is weighed, and the weight of the load

delivered to the truck is displayed in the Load-field.

Note! The weight of the remaining load must be equal or greater than

the Min Load specified in Parameter Setup I.

Repeat the procedure until the correct weight has been shaked off to the

truck.

3.9 Cancelling/Dumping last Bucket

The operator can easily cancel the last weighing if the load in the bucket has

been dumped back to the material bank:

x Empty the bucket. Press and hold Cancel/* for at least 1 second.

Note: The weight is subtracted from the total weight.

3.10 Pause mode

LOADTRONIC 3 can be set in pause mode when the machine performs

actions that are not to be recorded, e.g. tidying the work place.

Pause is selected by:

1. Pressing the up-arrow/

from automatic weighing mode. When the

LOADTRONIC 3 is in the pause mode no buckets will be weighed or

recorded. The display will show a row of ‘–‘ signs, refer Figure 3-12.

The pause mode is ended by:

2. Pressing up-arrow/

(in pause mode). The LOADTRONIC 3 returns to

automatic weighing.

Page 28

Fairbanks Scales

Figure 3-12 Pause mode.

page 28

3.11 Adjusting the Display Backlight

When LOADTRONIC 3 is in pause mode, the intensity of the background

light of the display can be adjusted by pressing # once or several times.

3.12 Display Volume of Load

The volume of the load can be displayed if the density of the material has

been specified, refer chapter 4.1. Enter pause mode and press Volume/# to

display the volume of the total material delivered.

3.13 System Information

In case of a fault/error LOADTRONIC 3 displays a message in red text font

in the top line, refer Figure 3-13.

If serious faults arise during start up, LOADTRONIC 3 will not start the

automatic weighing mode; the main menu will be opened.

Page 29

OPERATOR’S MANUAL page 29

Figure 3-13 Example of an error message.

Page 30

page 30

Fairbanks Scales

CHAPTER 4 Library and Reports

This chapter describes how to add customers, materials, trucks and location

in a library for repeated use (refer chapter 4.1), and how to print reports

based on specifications of job details (refer chapter 4.2).

4.1 Library of Customers, Materials, Trucks and Locations

LOADTRONIC 3 allows you to build a library of customers, material, trucks

and locations for repeated use; up to 1000 entries can be added for each

category. The customer/material/truck/location identification number can be

described with a 30 character text string, refer Figure 4-2.

There are two ways of adding new details to the library:

x Specify job details for a job record. The details are stored in the library for

later use, refer chapter 4.1.3

x Add customers, materials, location etc. independently of the job list, refer

chapter 4.1.4.

An ID number that has been described with a customized text string will

hold its description until the text is changed by the operator.

Job details are job record number, Customer name, type and density of the

Material, type of Truck and PayLoad, and operating Location.

4.1.1 Search the Library for a Customer, Truck etc.

Use the keypad to search for a customer name, truck- and material

description, and locations that have been entered into the library:

1. Open job record/F3.

2. Highlight the text field of the customer/truck/material/location.

3. Press the number-key holding the first character of your search

description repeatedly until the character is visible in the display, refer

Figure 4-1.

Page 31

OPERATOR’S MANUAL page 31

Index-field

Text-field

Letter visible in

search mode

Figure 4-1 Search for customer.

4. If the library contains a description starting with this character, the

description is shown in the Description-field. Press the up arrow to

view more descriptions starting with the same character.

5. Press 0 to exit search mode.

4.1.2 Special Characters

The keypad also holds special characters similar to the mobile phone.

Punctuation, commas, explanation mark etc are found by pressing digit 1,

other characters are found by pressing the other digits 2-9 repeatedly. The

digit 0 does not hold any special characters.

4.1.3 Enter Job Details from the Job List

Press job record/F3 to enter the job list from the automatic weighing mode.

By default, the active job record is visible on the screen. Press the job record

number directly using the keypad, or use the arrows to specify a desired job

number.

Page 32

Fairbanks Scales

Figure 4-2 Example of a job record.

page 32

Customer Description:

Press job record/F3 and open the correct record number. Press Next/F4 until

the Customer ID/description is highlighted.

Press the arrows repeatedly to open the desired customer number. If the

number is assigned to a customer, the customer name will show in the text

field else the text reads ‘unspecified’. Press l/F3 to toggle between the

index field and the text field. Press Edit/F2 to edit the name. Use the keypad

to type the customer name.

- Press F2 to toggle between capital and small letters.

- Press F3 to clear the last letter.

- Press F4 to clear all letters.

Press Save/# to store the customer name with the customer number in the

library.

Material Description:

Press job record/F3 and open the correct record number. Press Next/F4 until

the Material ID/description is highlighted.

Press the arrows repeatedly to open the desired material number. If the

number is assigned to a specific material, the material description will show

Page 33

OPERATOR’S MANUAL page 33

in the text field else the text reads ‘unspecified’. Press l/F3 to toggle

between the index field and the text field. Press Edit/F2 to edit the

description. Use the keypad to type the material description.

- Press F2 to toggle between capital and small letters.

- Press F3 to clear the last letter.

- Press F4 to clear all letters.

Press Save/# to store the material description with the material number in the

library.

Truck Description:

Press job record/F3 and open the correct record number. Press Next/F4 until

the Truck ID/description is highlighted.

Press the arrows repeatedly to open the desired truck number. If the number

is assigned to a specific truck, the truck description will show in the text

field else the text reads ‘unspecified’. Press l/F3 to toggle between the

index field and the text field. Press Edit/F2 to edit the description. Use the

keypad to type the truck description.

- Press F2 to toggle between capital and small letters.

- Press F3 to clear the last letter.

- Press F4 to clear all letters.

Press Save/# to store the truck description with the truck number in the

library.

Location Details

Press job record/F3 and open the correct record number. Press Next/F4 until

the Location ID/description is highlighted.

Press the arrows repeatedly to open the desired location number. If the

number is assigned to a specific location, the place will show in the text field

else the text reads ‘unspecified’. Press l/F3 to toggle between the index

field and the text field. Press Edit/F2 to edit the location. Use the keypad to

type the location.

Press F2 to toggle between capital and small letters.

-

- Press F3 to clear the last letter.

Page 34

page 34

Fairbanks Scales

- Press F4 to clear all letters.

Press Save/# to store the location with the location number in the library.

4.1.4 Enter Job Details from the Text Editor

Job details can be entered from the text editor: Open Main Menu - Text

Editing, refer chapter 2.1.

Figure 4-3 Text editing menu.

The text editor menu consists of 6 sub menus: Customers, Trucks, Locations,

Materials, Report Header and Attachments, refer Figure 4-3.

Press the arrows repeatedly to highlight each sub menu; press Enter/# to

open the sub menu.

Refer page 35 to page 38 for a description of editing a customer, a truck, a

material, a location, and an attachment.

Page 35

OPERATOR’S MANUAL page 35

Edit the Customer:

1. Open Main Menu - Text Editing – Customers, refer chapter 2.1.

2. Type the Customer ID number directly using the keypad, or set the

number by pressing the arrows repeatedly.

3. Press Next/F4 to highlight the text field, refer Figure 4-4.

4. Press Edit/F2 to edit the text description, refer Figure 4-5. Use the

keypad to type the description.

- Press F2 to toggle between capital and small letters.

- Press F3 to clear the last letter.

- Press F4 to clear all letters.

5. Press Save/# to store the description with the identification number in

the library.

6. Press Exit/* to return to the Text Editing menu.

Figure 4-4 Edit the customer description

Page 36

Fairbanks Scales

Figure 4-5 Type the customer description.

page 36

Edit the Truck:

1. Open Main Menu - Text Editing – Truck, refer chapter 2.1.

2. Type the Truck ID number directly using the keypad, or set the number

by pressing the arrows repeatedly.

3. Press Next/F4 to highlight the text field.

4. Press Edit/F2 to edit the text description. Use the keypad to type the

description.

- Press F2 to toggle between capital and small letters.

- Press F3 to clear the last letter.

- Press F4 to clear all letters.

5. Set the PayLoad, refer Figure 4-6:

- Press Next/F4 to highlight the PayLoad-field.

- Press Edit/F2 to edit the value.

- Type the weight using the keypad or adjust the weight in steps using

the arrows. Press Exit/* to clear the field.

6. Press Save/# to store the description with the identification number in

the library.

7. Press Exit/* to return to the Text Editing menu.

Page 37

OPERATOR’S MANUAL page 37

Figure 4-6 Edit the trucks description and PayLoad.

Edit Location:

1. Open Main Menu - Text Editing – Location, refer chapter 2.1.

2. Type the Location ID number directly using the keypad, or set the

number by pressing the arrows repeatedly.

3. Press Next/F4 to highlight the text field.

4. Press Edit/F2 to edit the text description. Use the keypad to type the

description.

- Press F2 to toggle between capital and small letters.

- Press F3 to clear the last letter.

- Press F4 to clear all letters.

5. Press Save/# to store the description with the identification number in

the library.

6. Press Exit/* to return to the Text Editing menu.

Edit the Material:

1. Open Main Menu - Text Editing – Materials, refer chapter 2.1.

2. Type the Material ID number directly using the keypad or set the

number by pressing the arrows repeatedly.

3. Press Next/F4 to highlight the text field.

4. Press Edit/F2 to edit the text description. Use the keypad to type the

description.

Page 38

Fairbanks Scales

- Press F2 to toggle between capital and small letters.

- Press F3 to clear the last letter.

- Press F4 to clear all letters.

5. Set the material Density, refer Figure 4-7:

- Press Next/F4 to highlight the Density-field.

- Press Edit/F2 to edit the value.

- Type the weight using the keypad or adjust the weight in steps using

the arrows. Press Exit/* to clear the field.

6. Press Save/# to store the description with the identification number in

the library.

7. Press Exit/* to return to the Text Editing menu.

page 38

Figure 4-7 Edit the material description and density.

Edit the Attachment:

1. Open Main Menu - Text Editing – Attachment, refer chapter 2.1.

2. Type the Attachment ID number directly using the keypad, or set the

number by pressing the arrows repeatedly.

3. Press Next/F4 to highlight the text field.

4. Press Edit/F2 to edit the text description. Use the keypad to type the

description.

- Press F2 to toggle between capital and small letters.

Page 39

OPERATOR’S MANUAL page 39

- Press F3 to clear the last letter.

- Press F4 to clear all letters.

5. Press Save/# to store the description with the identification number in

the library.

6. Press Exit/* to return to the Text Editing menu.

4.2 Reports

LOADTRONIC 3 keeps track of the latest 30000 jobs. The oldest jobs will

be overwritten by the latest jobs as the number of jobs pasts 30000; refer

chapter 5.2 for backup of the loadlist. You can ask for a report for jobs that

has been performed in a specific time period. You can build up the report to

provide a single value of the total weight loaded, the total weight delivered

to a specific customer, the total load of a specific material delivered to a

specific customer etc, or simply to make a copy of a single job. Refer

chapters 4.2.2, 4.2.3 and 4.2.4 for description of how to specify your report.

4.2.1 Report Header

The report header, e.g. your company details, is added from the Text Editing

menu; open Main Menu - Text Editing - Report Header, refer chapter 2.1.

5 lines can be edited, refer Figure 4-8; the text in the first line will show in

the lower left corner of the display.

Highlight a line, press Edit/F2 to enter text editing. Type your text using the

keypad.

- Press F2 to toggle between capital and small letters.

- Press F3 to clear the last letter.

- Press F4 to clear all letters.

Press Save/# to store the text.

Page 40

Fairbanks Scales

Figure 4-8 Edit the report header.

page 40

4.2.2 Total Load Report

The default setting is to make a report of the total weight loaded during a

certain time period without specifying Customers, Material, Truck or

Location. An example of such a report is given in Figure 4-9.

Figure 4-9 Example of the total load delivered by the wheel loader.

Procedure to build a total load report:

1. Open Main Menu - Reports, refer chapter 2.1.

2. Set the time period: The default date is the current date in both the

‘Date From’-field and the To-field. Press the arrows to set the ‘From’

Page 41

OPERATOR’S MANUAL page 41

date. Press and hold the arrow to step one month at a time. Press

Next/F4 to highlight the ‘To’ date, and the arrows to set the correct

date.

3. The default report type is Total. Press Select/# to view the total weight

loaded, refer Figure 4-10.

4. Press Print/F2 to print the report (requires a printer).

Figure 4-10 Generate the report shown in Figure 4-9.

4.2.3 Specified Report

You can specify the report based on one or more of the following criteria:

Customer, Material, Truck and Location. An example of such a report is

given in Figure 4-11, illustrating that customer John Smith has received 4

different types of material. The report also presents the weight of the

material, and the total weight delivered based on the specification.

Page 42

Fairbanks Scales

Figure 4-11 Specified report of the material delivered to customer John Smith.

page 42

Procedure to build a specified report:

1. Open Main Menu - Reports, refer chapter 2.1.

2. Set the time period: The default date is the current date in both the

‘Date From’-field and the To-field. Press the arrows to set the ‘From’

date. Press and hold the arrow to step one month at a time. Press

Next/F4 to highlight the ‘To’ date, and the arrows to set the correct

date.

3. The default report type is Total. Press the arrows to specify the report

either on Customer, Material, Truck or Location. Press Select/# to view

the total weight loaded.

4. Optionally, you can specify the report even more detailed by selecting

Customer and/or Material and/or Truck and/or Location, refer Figure

4-11 and Figure 4-12:

- Press Next/F4 to highlight the Customer-field in the upper part of

the screen.

- Either:

a. Press the customer ID number from the keypad.

b. Press the arrows to set the number.

c. Press Next/F4 to highlight the Description-field and specify

the customer by e.g. pressing the arrows or search the name

using the keypad etc.

Page 43

OPERATOR’S MANUAL page 43

Perform similar for the Material-, Truck- and Location-field to set all

your criteria.

5. Press Print/F2 to print the report (requires a printer).

Figure 4-12 Build the specified report as presented in Figure 4-11.

4.2.4 Copy of Receipt

You can build a report to get a copy of a job record performed earlier, refer

Figure 4-13.

Figure 4-13 Copy of receipt.

Page 44

page 44

Fairbanks Scales

Procedure to make a copy of a receipt:

1. Open Main Menu - Reports, refer chapter 2.1.

2. Specify the report, refer chapter 4.2.3. Press Select/# to update the total

load weight.

3. Press job record/F3 to view the load lists of the jobs according to your

specification. Press Next Day/F4 to view the next record.

4. Press Print/F2 to print a copy of the job record shown on the screen.

In the Reports sub menu, you can press job record/F3 to view the load

list, refer Figure 4-14. Press Next Day/F4 or the arrows to see job details,

number of buckets and the weight of the total load for each job. You can

also see the time and date for when the job was complete.

Figure 4-14 Example of Load List.

Page 45

OPERATOR’S MANUAL page 45

CHAPTER 5 Maintenance

Open Main Menu – Service, refer chapter 2.1.

Service Functions holds submenus for sensor test, log files, backup and

restore log files/database, copy attachment calibration, and system

information.

Figure 5-1 Service functions.

Data Monitor is for sensor test after e.g. installation and service. Data

monitor and sensor readings are described in the LOADTRONIC 3

Installation Guide.

Logs holds a complete history of the LOADTRONIC 3 operations: LoadList,

Event list, Error list, and a combined list of these three lists. These files are

used for e.g. analysis of system errors.

USB MEM Backup is used to store backup of logs, database, calibration

details and other system files.

USB MEM Restore is used for retrieving logs, database, calibration details

and other system files after service and software upgrade of the system.

Copy Attachment is used to copy calibration details between attachments.

Page 46

page 46

Fairbanks Scales

System Information holds information about e.g. software versions and legal

system files.

5.1 Load List, Event List and Error List

There are 4 lists available: Loadlist, Event list, Error list and a Combined list

of these three lists. Press Next/F4 to toggle between the lists. Press /F2 and

/F3 to page up and -down in the list. Press the up- and down arrows to

move up and down a single entry. Errors/failures are listed in a red font. For

backup of the logfiles, refer chapter 5.2.

The Loadlist is a list of each recording, holding information about the total

load, number of buckets delivered, and date/time of the recording, refer

Figure 5-2. Loadlist is a compressed list of the information given in the

customer report, refer chapter 4.2.2.

LOADTRONIC 3 gives a warning in the top line at system start up when the

Loadlist is more than 95% full, refer chapter 3.13 and chapter 4.2.

Figure 5-2 Loadlist.

The Event list holds information about every event performed by the system:

calibration, backup, changing of legal system parameters etc.

Page 47

OPERATOR’S MANUAL page 47

The Error list states system error, e.g. missing sensor, zeropoint failure etc.

Figure 5-3 Event List.

5.2 Backup and Restore Logfiles, Database and System Files

We recommend that you perform a backup of log files (refer chapter 5.1),

database (all editable text fields) and system files (calibration and

configuration details) regularly, and that you store a backup after a

calibration of the attachment. The database and system files can be retrieved

using the restore function. The function is useful for e.g. retrieving the

original calibration after a service/software upgrade of the system.

When performing backup to a USM MEM device files will be copied to a

directory called \Loadtronic\ID_NNN; NNN is the LOADTRONIC ID

number given in Parameter Setup I. If the LOADTRONIC ID number is 001

(default number), the directory name will be \Loadtronic\ID_001.

By using different ID numbers for each LOADTRONIC 3, the same USB

MEM device can be used to backup several LOADTRONIC 3 systems

without loosing data.

The Restore function will only copy files from the USB MEM device with

the corresponding directory name, hence backup from a LOADTRONIC 3

Page 48

page 48

Fairbanks Scales

device with ID number 001 will only restore files from the \Loadtronic

\ID_001 directory.

Perform a backup:

1. Open Main Menu – Service – USB MEM Backup, refer chapter 2.1.

2. Select which files to backup: Logs, Database and/or System files, refer

Figure 5-4.

3. Press Enter/# to perform the backup.

Figure 5-4 Backup.

Retrieve details:

1. Open Main Menu – Service – USB MEM Restore, refer chapter 2.1.

2. Select which files to restore: Database or System Files, refer Figure

5-5.

Note! To restore calibration data, enable the calibration switch, refer

Figure 1-1.

3. Press Enter/# to perform the restore function.

Page 49

OPERATOR’S MANUAL page 49

Figure 5-5 Restore.

5.3 Copy Calibration Details

The attachment descriptions are stored in ID number 1 to 10; calibration

details are stored in corresponding A1 to A10. Calibration details stored in

e.g. A1 can be copied to e.g. A2 for backup, refer Figure 5-6.

Procedure for copying attachment:

1. Open Main Menu – Service – Copy Attachment, refer chapter 2.1.

2. Use the up- and down arrows to select the desired attachment ID from

which calibration details are copied from.

3. Press Next/F4 to toggle between the attachment source and destination

4. Use the up- and down arrows to select the desired attachment ID to

which calibration details are copied to.

5. Press Enter/# to copy. The calibration switch must be enabled, refer

Figure 1-1.

Page 50

Fairbanks Scales

Figure 5-6 Copy attachment.

page 50

5.4 System Information

System information holds two pages displaying information about software

version, main unit serial number, OIML requirements, power supply,

operating ranges, and checksum information on legal system files, refer

Figure 5-7 and Figure 5-8. Press Next/F4 to toggle between the two pages.

Figure 5-7 System Information, page 1.

Page 51

OPERATOR’S MANUAL page 51

Figure 5-8 System Information, page 2.

Loading...

Loading...