Page 1

Operating Manual

H90-5200-A

Digital Instrument

50515

Issue #2 4/04

© 2004 by Fairbanks Scales Inc.

All rights reserved

®

SET POINT

= CENTER OF ZERO

SP1

SP2

SP3

SP4

SET POINT

CONTROL

9

8

7

TEST

PROG

6

5

4

DATE

TIME

3

2

1

4-20mA

SET PT

.

0

CLEAR

lb

kg

NET

TARE

ID

I/O

ENTER

3051

Page 2

Amendment Record

H90-5200-A

Digital Instrument

50515

Manufactured by Fairbanks Scales Inc.

821 Locust

Kansas City, Missouri 64106

Created 3/99

Issue #1 3/99 New Product Release

Issue #2 4/04 Added Printer Information and Computer Modifications

50515 2 Issue #2 4/04

Page 3

Table of Contents

SECTION 1: DESCRIPTION

A. Introduction 4

B. Specifications 4

C. Keypad Description 7

D. Indicator Description 9

E. Back Panel Description 9

F. Basic Weighing Operations 9

G. Power-Up Test 11

SECTION 2: PROGRAMMING

A. Security Code “S.Code” Operation 12

B. Programming Operating Parameters 12

C. Displaying and Setting Time 16

D Displaying and Setting Date 17

E. Test Mode 17

F. SETPOINT Operation And Programming 18

G. Serial Output Operation and Programming 27

H. Computer Commands 30

I. Computer Command Protocol 33

J. Programming the SMART 4-20mA Analog Loop 33

SECTION 3: INSTALLATION

A. Instrument Mounting Options 36

SECTION 4: TROUBLESHOOTING

A. Troubleshooting 37

APPENDIX I: Quick Reference Chart 38

APPENDIX II: Serial Output Installation 39

APPENDIX III: Switch Settings for Selected Printers 42

APPENDIX IV: Wiring Diagram for Serial Outputs 47

APPENDIX V: Serial Output Data Format 49

APPENDIX VI: Wiring Diagram for Smart 4-20 Output Accessory 51

APPENDIX VII: Setpoint Outputs VS. Calibration 52

APPENDIX VIII: Pillar Accessory lnstallation 53

APPENDIX IX: ASCII Character Chart 54

APPENDIX X: Keyboard Schematic / Wiring Diagram 55

APPENDIX XI: Remote Switch 56

APPENDIX XII: Summary of Error Messages 58

APPENDIX XIII: Wall Mounting Bracket 59

APPENDIX XIV: Print Samples 60

DISCLAIMER

Every effort has been made to provide complete and accurate information in this manual. However, although this

manual may include a specifically identified warranty notice for the product, Fairbanks Scales makes no

representations or warranties with respect to the contents of this manual, and reserves the right to make

changes to this manual without notice when and as improvements are made to the product.

50515 3 Issue #2 4/04

Page 4

SECTION 1:

DESCRIPTION

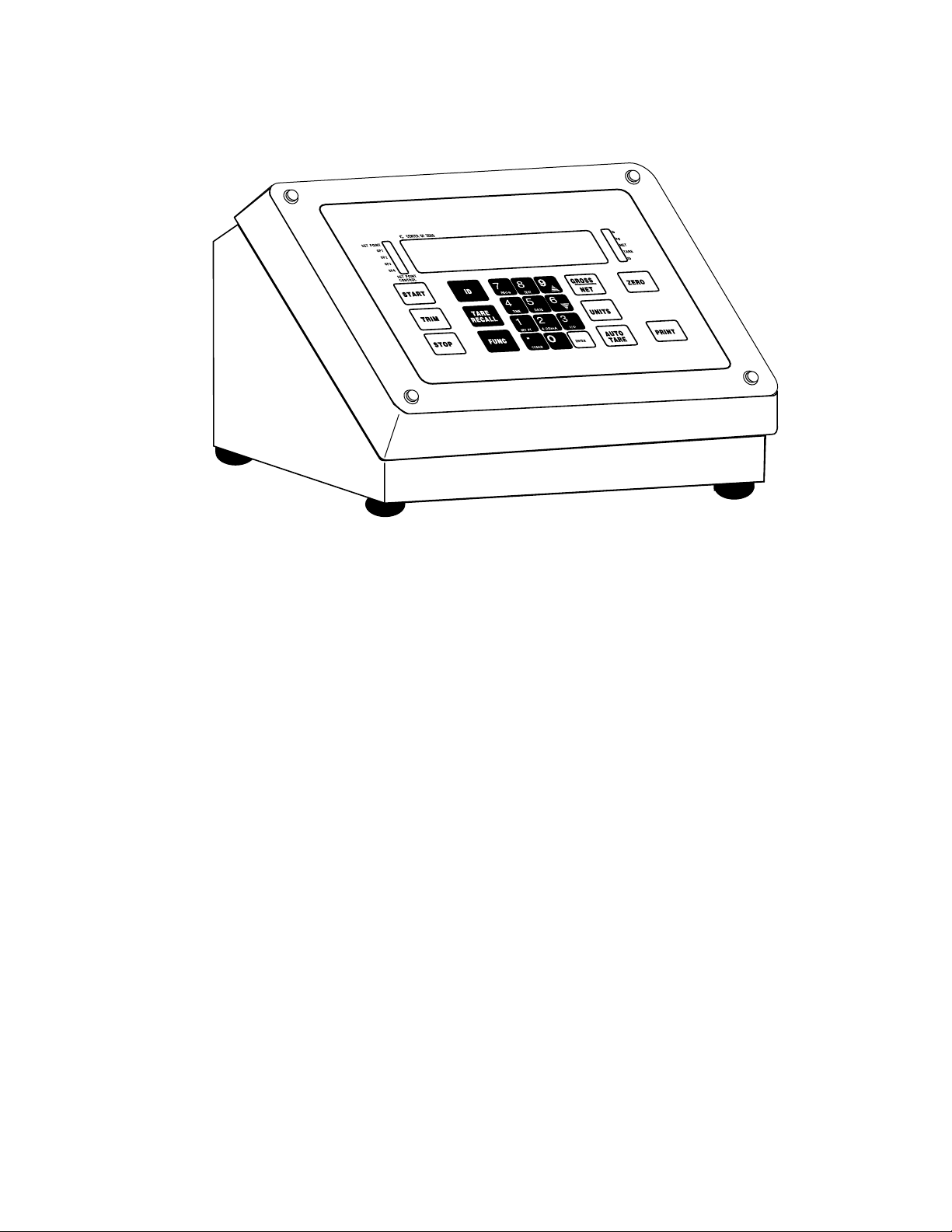

A. Introduction:

The model H90-5200-A indicator is a general purpose indicator that can be used with a wide

variety of Fairbanks platforms. Stainless steel construction makes the instrument well suited

for use in wash-down locations. The standard unit can be bench, wall, or pillar mounted.

The H90-5200-A features a bi-directional serial output and four setpoint outputs. Front panel

programming enables easy setting or changing instrument operation parameters. The

instrument also includes all of the standard weight processing controls, such as digital tare,

tare recall, automatic tare, push button zero, print, and lb/kg conversion.

B. Specifications:

1. Model Number: H90-5200-A

2. Units: lb, kg, lb/kg, or custom (no units indicator)

3. Accuracy: Commercial, 10,000 divisions Non-commercial, 20,000 divisions

4. Load Cells: Up to 4-350 ohm load cells, or 12-1,000 ohm load, Excitation 10VDC

5. Division Size: Programmable from 0.0001 to 50 for both lbs. and kgs.

50515 4 Issue #2 4/04

=

3051

Page 5

6. Display: High visibility, 6 digit LED display, with 0.8 inch digits.

Separate indicators for:

Left Side Display Right Side Display

SP Enable lb

SP 1 kg

SP 2 NET

SP 3 TARE

SP 4 ID

Center-of-Zero Indicator appears in the display.

7. Display update rate: Programmable for 0.1, 0.3, 0.5, 0.8 or 1.0 seconds.

8. Digital Filter: Programmable - 5 levels

9. Tare: 10 key numeric TARE entry or Auto Tare entry, TARE operation(s) may be

disabled in the setup mode.

10. Programmable Features: Primary Units, Scale ID, Time and Date in Military, US,

and International Formats, Security Code, Switch Inhibit, and remote switches.

11. AUTO-ZERO tracking: Programmable OFF, 0.5d, 1 .0d, or 3.0d

12. Auto-Zero Time Delay: Programmable from 1 to 6 seconds.

13. Re-zero Range: Programmable +/- 2% or 100% of capacity

14. Overcapacity Warning: The display will show “—OL—” if the weight exceeds

105% capacity

15. Underload Warning: The display will show “—UL—” if the weight on the platform is

below the A/D input range.

16. Balance/Motion band: Programmable 0.5,1.0, 2.0, 3.0d

17. Controls: 23 key keypad

18. Setpoints: Four setpoints with open collector outputs rated at 60VDC @ 100mA.

Setpoint status is shown by 4 LED indicators, one indicator to show the setpoints

are active, and a separate indicator for each setpoint to show its status.

Setpoint mode available with dribble, preact, discharge and zero band.

Checkweigh modes available with preact, discharge and zero band.

Batch modes available with dribble, preact, discharge, zero band and setpoint

inhibit.

50515 5 Issue #2 4/04

Page 6

Auto Batch mode available with dribble, preact, discharge, zero band, setpoint

inhibit, setpoint auto zero, delay 1, and print.

Auto Batch Repeat mode available with the same features as Auto Batch but

includes delay 2.

19. Serial output: One bi-directional serial port, which may be configured for RS-232 or

20mA current loop. Selectable BAUD rates are 300, 600,1200, 2400, 4800, 9600,

and 19200.

20. Power: 100-130VAC, 50/60 HZ 10 watts standard

200-250 VAC, 50/60 HZ 10 watts optional

Options:

Accessories:

a. Second Serial Output:

Accessory 145 (1-57364-1) - Output configured for 20mA current loop

Accessory 146 (1-57365-1) - Output configured for RS-232

Accessory 147 (1-57401-1) - Output configured for RS-422 or RS-485

b. Accessory 148 (4-57402-1) - SMART 4-20mA analog output. Output can

also be configured for 0-20mA, or 0/1-5VDC, 0-10VDC with customer supplied

resistor.

NOTE: One Accessory, A or B can be used , NOT BOTH.

c. Accessory 149 (4-57568-1) - NEMA 12 Relay Accessory. Accessory can be

attached to instrument or remote mounted. Accessory is driven by setpoint

outputs and provides (4) Form C contacts rated at 5 Amps @ 250 VAC or 5

Amps @ 30 VDC.

d. Accessory 150 (701138) - Cable for remote mounting of Accessory 149 or

Accessory 151, up to 100 ft from the instrument

e. Accessory 151 (4-57838-1) - NEMA 4 Remote Relay Accessory Accessory

is driven by setpoint outputs and provides (4) Form C contacts rated at 5 Amps

@ 250 VAC or 5 Amps @ 30 VDC.

f. Pillar Accessory - The H90-5200-A is compatible with all Series 7 Pillar

Accessories

50515 6 Issue #2 4/04

Page 7

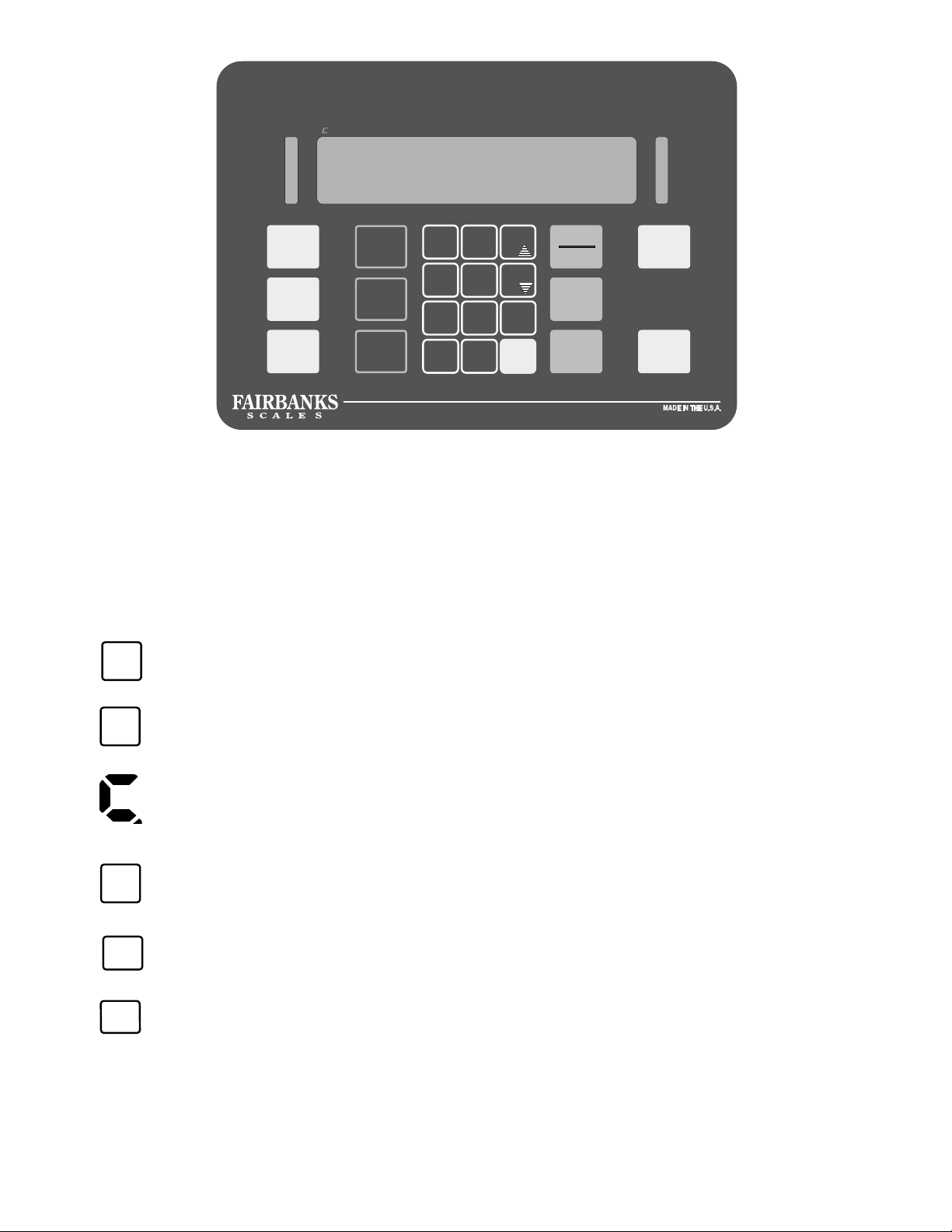

FIGURE 1-2:

C. Keypad Description

The functions of the front panel keys vary depending on the mode in which the

instrument is operated. This Subsection defines the operation of each front panel key.

Refer to Figure 1-2.

START: Initiates setpoint batching operation to pre-selected setpoint weight.

Batching modes only.

TRIM : Overrides setpoint control to add additional weight in touch controlled

increments. Manual batch mode only.

STOP: Overrides setpoint control cycle to turn off all set points, in batching

modes only. During batching it is used to change selected setpoint(s) for

subsequent batching operation.

ID: Up to a 6 - digit product ID for printer/computer print out, not maintained at

power loss.

TARE RECALL: Tare retrieval. Displays current tare for aprox. 5 seconds.

FUNC: Press function key and then one of the following keys to enter special

modes described below. Up to six digit security code is then required (if

security code entered does not equal 0) to change displayed value using

keypad. Refer to Section 2 for further information on all function key

operations.

50515 7 Issue #2 4/04

SET POINTS

ENABLE

SP 1

SP 2

SP 3

SP 4

START

TRIM

STOP

= CENTER OF ZERO

TARE

RECALL

FUNC

ID

8

7

PROG

4

TIME

9

TEST

56

DATE

123

SET PT

.

CLEAR

4-20mA

0

I/O

ENTER

GROSS

NET

UNITS

AUTO

TARE

lb

kg

NET

TARE

ID

ZERO

PRINT

3050

ST ART

TRIM

ID

TARE

RECALL

FUNC

Page 8

a. FUNC 1: Setpoint key will access setpoint setup mode.

b. FUNC 2: 4-20 ma key will access the Smart 4-20 ma current

loop calibration mode.

c. FUNC 3: I/O key access the serial I/O setup mode.

d. FUNC 4: Accesses and displays time. A new time can now be

entered or ENTER can be pressed to keep the current time.

e. FUNC 5: Accesses and displays date. A new date can now be

entered or ENTER can be pressed to keep the current date

f. FUNC 7: Program key accesses and displays the current

operating parameters of the instrument.

g. FUNC 8: Instrument test. Shows security level, flashes A/D

counts, deadload counts, span counts, display test, RAM Test,

EE Prom Test, and Switch Test.

GROSS/NET: Switches weight display mode to Gross or Net, or used to

exit programming menu.

UNITS: Allows the displayed weight to be converted to new weight units

if the option was enabled.

AUTOTARE: Will set Tare memory equal to the Gross weight on the

Platform (which will then force the Net weight to zero). Auto tare must be

enabled and gross weight cannot be negative. Display will automatically

switch to Net mode, not maintained at power loss.

ZERO: Will set the Gross weight equal to zero provided the weight to be

zeroed does not exceed the programmed zero range.

PRINT: Causes the instrument to transmit information to the output

device if enabled.

CLEAR: This is a dual function key. The first time it is pressed it

produces a decimal point. Pressing the key twice “CLEARS” the last

entry made.

KEYPAD: Keys “0” through “9” and “.” and “ENTER” are used to

enter Tare, programming codes, setpoints, etc.

50515 8 Issue #2 4/04

FUNC

1

SET PT

GROSS

NET

FUNC

FUNC

FUNC

FUNC

FUNC

FUNC

2

4-20mA

3

I/O

4

TIME

5

DATE

7

PROG

8

TEST

"

AUTO

TARE

"

O/U

PRINT

CLEAR

789

456

123

0

Page 9

D. Indicator Description

lb, kg : Indicates the units of the displayed weight. If neither indicator is lighted, then

“Custom Units” is enabled.

NET: Indicates the instrument is displaying NET weight.

TARE: Indicates the instrument is displaying TARE weight.

ID: Indicates the instrument is displaying a product ID or date in international date

(day/month/year) format.

ENABLE: Indicates the setpoint outputs are active

SP1, SP2, SP3, SP4: Indicates the particular setpoint output is ON when the SP

Enabled indicator is also ON.

C = Center-of-Zero: A “C” will appear in the left most digit to indicate that the weight is

within a quarter grad of zero.

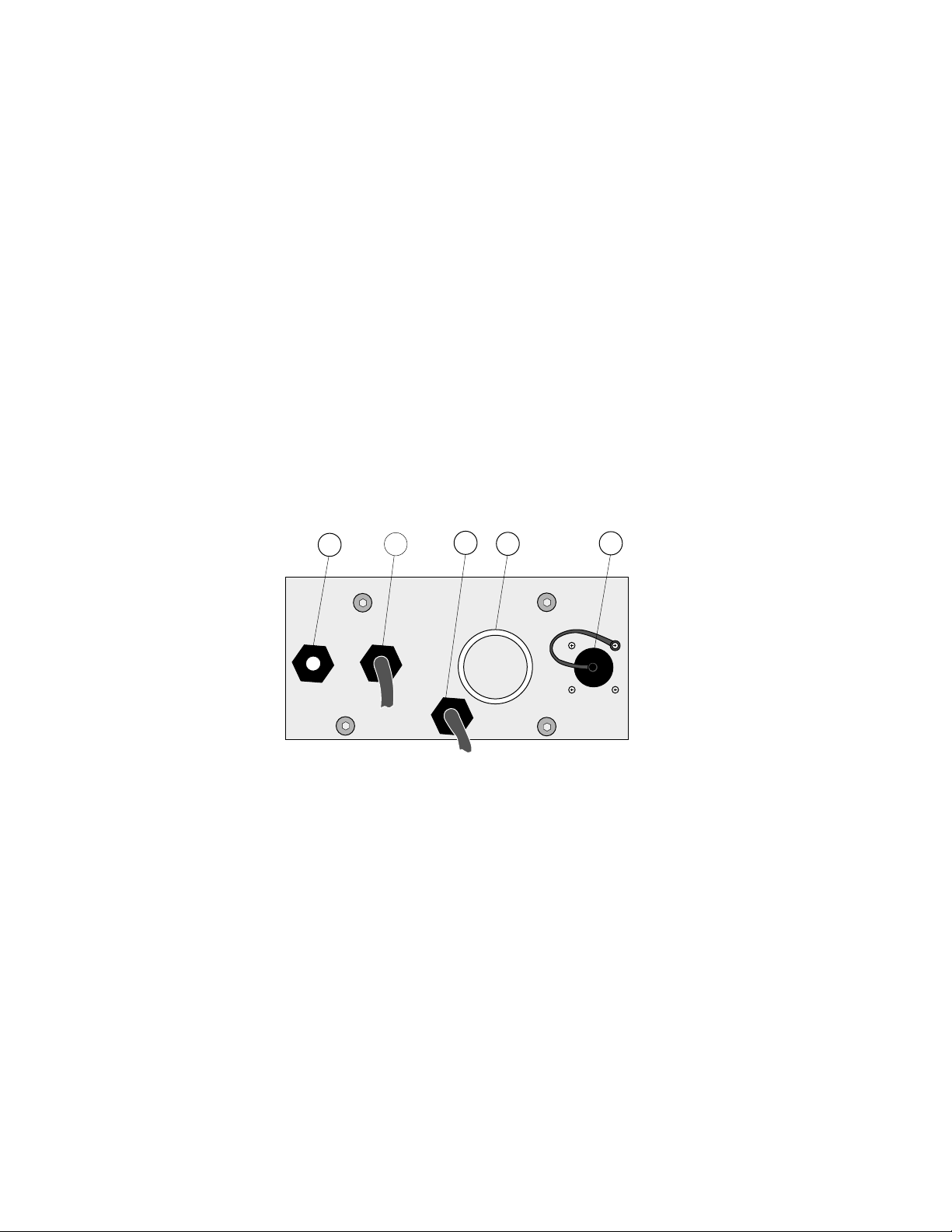

E. Back Panel Description

1. Serial Output Port

2. Accessory Port

3. AC Power cord, water tight gland.

4. Load Cell, water tight gland.

5. Setpoint output, water tight gland.

F. Basic Weighing Operations

1. General Gross Weighing

a. Push GROSS/NET to select Gross. When the instrument is in Gross Mode,

the NET Indicator light will be OFF.

50515 9 Issue #2 4/04

5

3 2 14

2417

Page 10

b. With the platform empty push ZERO, the display will indicate zero.

c. Place the loaded carrier on the platform.

d. Read the Gross weight at the display.

2. Net Weighing Using Keypad Tare

a. Enter the known Tare weight through the keypad.

b. Press ENTER

c. The instrument will display a negative weight value and the NET Indicator will

be ON.

d. Place filled container on platform. The display will show the Net weight of the

material.

3. Net Weighing Using AUTO TARE

a. Place an empty container on the platform.

b. Press the AUTOTARE key.The empty container weight is transferred to tare

memory.

c. The weight display will now be zero and the NET Indicator light will be ON.

d. Place the material in the container and the instrument display will show the

Net weight.

4. Entering Product ID

a. Press lD.

b. Current ID is displayed.

c. Press GROSS/NET to exit and retain displayed ID, or enter new ID (up to 6

digits) using the keypad. Press ENTER.

5. Printing Weight Information

a. In any mode above, Press PRINT when weight on the platform is stable.

6. For Other Operating Features, Refer to Section 2

50515 10 Issue #2 4/04

Page 11

G. Power-UpTest

Upon instrument power-up the H90-5200-A will perform the following tests:

1. RAM Test - The RAM test verifies the operation of the processors external

memory device.

2. Display Test - The display will perform a warm-up sequence. This routine is

designed to test that all display segment lines, digit lines, and annunciator

LEDs, have no defects. This is a passive test and the user must observe the

display throughout the test to check for any anomalies.

3. EEPROM Read -The processor will attempt to retrieve the stored scale

programming data from the EEPROM. This data includes: deadload and span

counts, grad size, capacity, security level, etc.

If the processor detects any out-of-range data, it will repeatedly request data from the

EEPROM until the retrieved data is deemed valid. During this period, the display will

flash “EE Err.”

Very often the problem is with the data itself and not the actual hardware. The two

most common causes are as follows:

a. A replacement board has just be installed in the instrument and this is a

first-time power-up. Thus, the current EEPROM data might not be

appropriate for the software in use.

b.You are using a new (or different) software program or revision level than

used at the previous instrument power down. This result is that the new

software might be trying to access data from the wrong areas of memory.

50515 11 Issue #2 4/04

Page 12

SECTION 2:

PROGRAMMING

A. Security Code “S.Code” Operation

If the security code is programmed with a value other than zero, the display will

indicate “S.COdE” when accessing the front panel programming. The operator must

enter the security code through the keypad and then press ENTER. The entered keys

will then be compared to the security code. If the correct security code has been

entered, the display will enter the appropriate programming routine, otherwise the

instrument will return to the weigh mode.

B. Programming Operating Parameters

When in the program mode, the value displayed at each step is the value currently

stored in the program. When in the programming mode, if a key is not pressed within

one minute, the instrument will time out and return to the weigh mode Some of the

keys and switches have special functions in the program mode.

These functions are defined as follows:

The ENTER key is used to store the displayed value in memory and advance to the

next program step.

The UP or DOWN arrow keys or the numeric keypad (0-9) can be used to change the

displayed value.

The GROSS / NET key can be used to immediately exit from most programming

menus.

To program the operating parameters, press the calibrations switch, SW3, located on

the main PC Board next to the load cell terminal block (standard programming), once,

or press FUNC 7 (front panel programming).

1. Program Steps

NOTE: If the programming mode is entered by pressing the SW3 switch, all of the

following programming steps can be changed. If the programming mode is

entered via the front panel, some steps may not be able to be changed

depending on the scales security level (selected in Step 15).

2. Program Number Display

This display will show the program number and revision level (P294X). This

information should be recorded for reference should any problems arise with the

operation of the scale. This is a nonprogrammable step.

50515 12 Issue #2 4/04

Page 13

3. Weight Units Selection

The display will read “ U “, and one or more of the units indicator lights may be ON.

The lighted indicator(s) show the current selection(s). Units of lb,kg, lb/kg or custom

(no units indicated) can be selected, depending on the operators requirements.

Custom or “no” units are not front panel selectable

a. Primary Weight Unit Selection

This program step will only appear if lb/kg was selected in step 2. The display

will read “ PU “ and ONE of the units indicator lights will be ON. The light

indicates the primary weight unit. The primary weight unit is the weight unit

the scale is calibrated in and the units the scale will start in when it is powered up.

4. Grad Size Selection

This display will read “GSxxxx”, where the “xxxx” is the grad size. The grad size

displayed is for the primary units selected in program step 2a. Grad sizes for other

weight units are dependent on the primary unit grad size and are not independently

programmable.

Grad sizes from 0.0001 to 50 can be selected. If an unacceptable grad size is

selected, an error message “ElL” or “E1H” will be displayed. A grad size is

unacceptable IF The number of divisions for any weight unit is less than 100 or

more than 10,000 (number of divisions = capacity/grad size). These error

messages and inhibits will only be displayed when programming through the front

panel.

5. Balance / Motion Band Selection

The display will read “bALx.x”, where “x.x” is the width of the motion band in

divisions, “0.5,1.0, 2.0 or 3.0”. If the current A/D reading exceeds the digitally

filtered output by more than the motion band for 1/2 second, there is “motion” on

the scale and the instrument will switch to the fast filter mode, where the display

tracks the input.

If there is “motion” on the scale, zero, autotare and print operations are inhibited

until “motion” stops.

6. AUTOZERO Tracking (AZT) Selection

The display will read “AO x.x”, where the “x.x” is the width of the AZT band in

divisions. AZT enables the instrument to automatically zero off small changes in the

zero balance of the scale. For an AZT to occur, the weight must be within the AZT

band for a time defined by AZTD (see 7. Auto Zero Time Delay).

7. Auto Zero Time Delay

The display will read “AOtd x”, where x is 1, 2, 3, 4, 5 or 6. The Auto Zero Time

Delay is the number of seconds that the weight must be stable in the AZT band

before an Auto Zero operation will take place. AZTD will not be offered unless

AZT was enabled in the previous step.

50515 13 Issue #2 4/04

Page 14

8. Zero Limit Selection

The display will read “OL xxx”, where the “xxx” is 100 or 2. The Zero Limit

controls the weight range over which the zero switch will operate. The weight

range is either 100% or +/- 2% of the scale capacity.

9. AUTO TARE Selection

The display will read “AtArEx”, where the “x” will be a 1 or a 0. The “1” indicates

the AUTOTARE key is enabled and the “0” indicates disabled.

10. Keyboard Tare Selection

The display will read “tArE x”, where “x” will be a 1 or a 0. The “1” indicates the

keyboard tare is enabled and the “0” indicates the keyboard tare is disabled.

11. Display Update Rate Selection

The display will read “SECx.x”, where the “x.x” represents the update rate in

seconds. The rates available are 0.1, 0.3, 0.5, 0.8, and 1.0.

12. Digital Filter Selection

The display will read “FF x”, where the “x” is the digital filter factor. The available

values are 0, 1, 2, 3, or 4. A “0” will disable the filter, a “1” will give a minimum

amount of filtering, and a “4” will give the maximum amount of filtering. The

digital filter is used to stabilize the weight display, when it behaves erratically

due to low signal levels or unstable weight on the platform. The more filtering,

the more stable the display will be.

NOTE: When using the remote display accessory, the update rate

must be 0.5 seconds or greater

.

13. Scale ID Selection

The display will read “id xxx” where “xxx” is the scale ID number used for polled

computer serial interface. If the computer polled with ID option is not used, ID

should be set to “0”. If the computer polled with ID option is used, any number

from 1 to 255 may be entered.

14. Time/Date Format Selection

The display will read “tdxxyy”, where “xxyy” is the format used to display and

print time (xx) and date (yy). The options available are “12” or “24” hour clock

for time and “US” (mo/day/yr) or “id” International date (day/mo/yr).

15. Security Code Selection

The display will read “S.COdE” to indicate the security code selection step. The

current security code is not shown. The security code is used to limit access to

front panel programming. A security code up to 6 digits long may be used. A

security code of “0” enables free access to all front panel programming.

50515 14 Issue #2 4/04

Page 15

16. Security Level Selection

The display will read “SL x”, where “x” is a “0”, “1”, or “2”. The “0” enables full

programming capability from the front panel for non-commercial applications.

The “1” enables limited front panel programming for commercial applications.

The “2” disables all front panel programming for commercial applications.

CAUTION:

a. If Security Level “1”, or “2 “ is selected at this step, Security Level “0”

CANNOT be selected at a later time from the front panel. Be sure of your selection

before you continue

b. If Security Level “1” is selected, program steps 3, 4, 5, 6, 7, 14 and 15 cannot

be changed from the front panel.

c. If Security Level “2” is selected, NO parameters can be changed from the front

panel

d. Security Level must be set to “1” or “2 “for commercial applications. If the

Security Level is set for “0”, the instrument is NOT considered “LEGAL FOR

TRADE”, therefore the Security Level should be set for “1 “ or “2” for any

commercial application.

17. Inhibit Switch Selection

The display will read “inhS x”, where x will be a “1” or a “0”. If “1” is selected then one

or more front panel switches may be inhibited from operating. If “0” is selected then

all switches are operational. All keys except the ENTER key may be inhibited. If “1” is

selected, the display will show which switches are inhibited upon re-entering

programming mode. If no switches are inhibited the display will be blank.

a. If the displayed list is acceptable, press the ENTER key.

b. If a new key inhibit list is wanted

1) Press the keys that are to be inhibited

2) When the list is complete, press the ENTER key

If there are more switches inhibited than the display can show at one time, the display

can be shifted over one switch at a time by pressing the FUNC key. Pressing the

ENTER key will retain the current list. If any other key is pressed the current list will be

cleared and a new one started. The new list will end when the ENTER key is pressed.

Some examples of this feature are:

a. The instrument is monitoring the weight of a hopper and the user is

afraid someone will accidentally ZERO the indicator and lose the weight

readings. By inhibiting the ZERO switch this can be prevented.

b. The supervisor feels the instrument is too complicated and the operator

could accidentally change the desired setup. Inhibit all the switches

except ZERO and that is the only key the operator can use.

c. Instrument is hooked to a remote computer and user doesn’t want

anyone to interfere with the computer control. Inhibit all the switches once

the indicator is setup.

50515 15 Issue #2 4/04

Page 16

NOTE: When a switch that has been disabled/inhibited is pressed,

the display will momentarily flash “Error”.

18. Remote Switch Enable

Three (3) remote or external switches can be used to emulate only the following keys,

ZERO, START, PRINT, AUTO TARE,TRIM, TARE RECALL, UNITS, STOP. All remote

switches must be momentary dry contact type (without power), and are hard wired to

the optically isolated 10 position connector, TB3 on the main board. See Appendix XI

for wiring diagram.

a. Display will read: “rS 0” where rS means remote switch and 0=OFF. By

pressing”1”then “enter” the display will read”rS 1 “and enable this function.

b. The display will read “rS1 ” which means remote switch 1 is enabled for

the ZERO function.( See chart of key symbols in APPENDIX XII). To

change, press the key you wish to be remotely controlled and press “enter”.

c. The display will advance to show “rS2 A” meaning remote switch 2 is set

to function as an AUTO-TARE key. Change as required by pressing the

key you want to emulate, then press “enter”.

d. The display will advance to show “rS3 P” meaning remote switch 3 is set

to function as a PRINT key. Change as required by pressing the key you

want to emulate, then press “enter”.

e. After “enter” is pressed for “rS3 X”, the display will return to the weigh

mode

C. Displaying and Setting Time

1. From a gross or net weight display, press FUNC, the display will indicate

“Func”.

2. Press the 4 key.

3. The display will indicate the current time where “A” stands for AM and “P”

stands for PM (e.g. “11:36 AM will be shown as “1136 A”).

If the time was set in 24 hour military format (00:00 thru 23:59), the AM or

PM legends will not be shown.

4. Press ENTER if time is correct The display will return to the weigh mode or

enter the correct time by pressing the numeric keys “0” through “9” .Enter the

hours first and then the minutes (see example).

The time must be entered in 24 hour military format (0000 through 2359).

Example: Military Time Setting

To set the time to 8:49AM, enter “849”. To set 8:49 PM, enter “2049”.

Do not enter leading 0’s.

5. When the correct time is entered, press the ENTER key to store the

displayed time.

50515 16 Issue #2 4/04

Page 17

D. Displaying and Setting Date

1. From a gross or net weight display, press FUNC, the display will indicate

“Func “.

2. Press the 5 key. The display will show the current date e.g. 121598.

If ID LED is ON - the date is in International format. Standard Format - MM

DD:YY International Format - DD MM:YY

3. Press ENTER if the date is correct. The display will return to the weight

display.

4. Enter the date by pressing the numeric keys “0” through “9” (omitting leading

zeroes).

Enter the date as day/month/year or month/day/year format (see examples).

When entering days 1 - 9 the digits must be preceded by a zero (e.g. 06 for the

sixth day). Entering only a 6 will cause the entry to be interpreted as the 60th

day of the month ).

Examples: 1. To set the date to January 16, 1999 in month/day/year format, the key

sequence would be as follows: 11699 enter. (US format).

2. To set the date to 16 January 1999 in day/month/year format, the key

sequence would be as follows 160199. (International format).

5. Press the ENTER key to store the displayed date. The time and date format

is set when programming operating parameters.

E. Test Mode

The 8 key is used by the operator to verify proper operation of the instrument.

1. Select the Gross or Net Mode.

2. Push the FUNC key, then the 8 key.

The instrument will show the security level “SLx and then a blinking internal counts

display, which is equivalent to the weight on the platform This function can be used to

verify that the A/D is operating properly.

Press ENTER to continue.

3. Instrument will display in the following sequence:

a. The deadload counts, “0 xxxx”.

b. The span counts, “S xxxx”.

c. All segments and legends are lit to verify display operation.

d. A RAM and EEPROM test are done. A summary of error messages

may be found in Appendix XII.

4. A switch test can be done by the operator or ENTER can be pressed to exit.

When a particular switch pressed, it’s corresponding display may be found in

Appendix XII.

50515 17 Issue #2 4/04

Page 18

F. SETPOINT Operation And Programming

1. General Description, SETPOINT Modes

The Setpoints are used to control alarms, gate controls etc. that are furnished by the

customer. Setpoint operation is dependent on Gross or Net weight. The setpoint

outputs can only change state when the instrument is displaying Gross or Net weight.

If the instrument is not displaying Gross or Net weight, the setpoint outputs will revert

to their OFF state.

A setpoint output is ON if the Setpoint “Enable” LED is lighted AND the individual

Setpoint LED is ON.

Setpoint Mode Summary

Refer to Appendix VII for more information.

a. Individual (Single Feed) Setpoints Fast Feed Cutoff = SP - P

b. Paired (Dual Feed) Setpoints

Fast Feed Cutoff = SP - D - P Dribble Cutoff = SP - P

SP (Setpoint) = weight value desired at end of weighing operation

D (Dribble) = weight range at end of setpoint over which material flow

changes, usually from “fast” to “slow” feed

P (Preact) = weight value which is used to compensate for material in

suspension or other delays in control loop

There are six operating modes. “Mode 0” turns the setpoint option “OFF”. Two modes

are for setpoints only and three modes are for batching operations. In addition, a

zeroband operation in the Gross Mode only, up to capacity, is available in all modes, if

Setpoint 4 is available. The following sections explain each of the modes.

MODE 0- SETPOINTS OFF

The display shows “SP OFF”. The setpoint outputs are disabled.

MODE 1- SETPOINT MODE

The display shows “SP SP”. The setpoint mode is used for simple operations Where

the setpoint outputs are not directly controlling valves or gates and it is not desirable or

necessary to manually “start” and “stop” the setpoints.

Setpoint mode configures the outputs as simple “dumb” setpoints. When the absolute

value of the weight is less than the setpoint, the setpoint output is ON and when the

absolute value of the weight exceeds the setpoint, the setpoint output is OFF. The

setpoints are always active when the instrument is monitoring weight and the START,

TRIM, and STOP keys are not functional.

Up to 4 setpoints may be enabled and dribble, preact, discharge and zeroband options

are available. Some application examples are:

a. turning on a light to signal that a box has been filled to the proper weight.

50515 18 Issue #2 4/04

Page 19

b. providing inputs to a process controller that is controlling an automatic

batching process, where the batching controller is providing the intelligence

to control the valves or gates.

MODE 2- CHECKWEIGH MODE

Display shows “SP CH”.

The checkweigh mode is used to determine if a weight is under, within or over a

programmed weight range.

The setpoint outputs operate as follows:

SP1 = Overrange(On when weight> Setpoint 1)

SP2 = Accept range(On when Setpoint2 <= weight <=Setpoint 1)

SP3 = Under range(On when weight < Setpoint 2)

Checkweigh outputs are active immediately upon startup and are always on except for

any programming which interrupts the weight monitoring process.

START, TRIM, and STOP keys are not functional in this mode. Preact, discharge and

zeroband options are available.

MODE 3- MANUAL BATCH MODE

Display shows “SP bA”.

The batch mode is used to control simple filling operations where gates or valves are

controlled by the setpoint outputs and an operator is manually controlling the sequence

of operation. The setpoint outputs are controlled by the START, TRIM, and STOP keys.

In the batch mode, the setpoints may be set up as one to four FAST FEED outputs

with optional PREACT, or one or two paired setpoints with FAST FEED and DRIBBLE

outputs, with optional PREACT.

When the START key is pressed, the outputs will be enabled (“Setpoint Enabled” LED

is lighted) assuming the setpoint inhibit function is satisfied or disabled. The active

setpoint output(s) will be ON if the absolute value of the weight is less than the

CUTOFF VALUE. When the absolute value of the weight exceeds the CUTOFF

VALUE, or the STOP key is pressed, the setpoint output will turn OFF. If all setpoints

are OFF, the “Setpoint Enabled” LED will turn OFF and the active setpoint indicators

will light. The TRIM key can be used to momentarily turn ON an individual setpoint

output. If outputs are paired, the TRIM key will only operate on the dribble setpoint of

the selected pair. When the TRIM key is released, all setpoint outputs will turn OFF.

Another batch of the same ingredient can be released by pressing the START key

again.

A new ingredient can be batched by pressing the STOP key until the SP indicator for

that ingredient is lit and then pressing the START button.

50515 19 Issue #2 4/04

Page 20

If individual setpoints are used, the cutoff value is equal to the Setpoint entered minus

the PREACT value. If paired (Dual Feed) setpoints are used, the FAST FEED cutoff

(SP1&3) is equal to Setpoint - Dribble -Preact and the Dribble cutoff (SP2&4) is equal

to Setpoint - Preact.

With paired setpoints, setpoint outputs 1 and 3 are the FAST FEED outputs and

setpoint outputs 2 and 4 are the DRIBBLE outputs. Setpoint 1 is paired with Setpoint 2,

and Setpoint 3 is paired with Setpoint 4.

IMPORTANT NOTES

I. The front panel STOP key should never be used as the primary STOP control

(EMERGENCY STOP) in a critical batching operation.

2. The batch cycle will automatically stop if any operation interrupts the weight

monitoring process. For example, if print, zero or tare operations are initiated

during weight operations.

Up to 4 setpoints may be enabled and dribble, preact, discharge, zeroband

and setpoint inhibit options are available.

MODE 4- AUTO BATCH MODE

Display shows “SP AbA”:

The Auto batch mode is used to control simple filling operations where gates or valves

are controlled by the setpoint outputs and the operator desires to batch one set of

ingredients automatically after the START button is pressed. The Auto Batching mode

operates the same as the batch mode except that instead of requiring the operator to

press the START key to turn each setpoint ON and the STOP key to change setpoints,

the instrument will automatically sequence from the first setpoint to last setpoint. When

the last enabled setpoint has been reached, the instrument will automatically return to

the first setpoint and then turn OFF. The amount of delay, DELAY 1, between each

setpoint, or setpoint pairs, is programmable.

When the START button is pressed, if the instrument is not inhibited from operating by

the setpoint inhibit (refer to setpoint operation), the following sequence will occur:

a. If the Setpoint 1 (SP1) is enabled, and the Setpoint Autozero feature is

enabled, then the scale will be zeroed.

b. An autotare will occur and the indicator will switch to NET mode.

c. The first ingredient output(s) will turn on until the setpoint is reached.

d. The “ENABLED” indicator will start to flash and the delay time out will start. (If

the DELAY 1 = 0 an infinite delay will occur and START must be pressed.)

e. At the end of the delay, a print operation will occur if the batch print mode is

enabled.

f. The instrument will switch to the next ingredient setpoint.

g. The “ENABLED” indicator stops flashing and an autotare will occur.

h. The setpoint is enabled.

i. When the displayed weight reaches the setpoint, the output will turn off. If

print mode is enabled, the currently displayed weight is printed, “AA BB SX”.

50515 20 Issue #2 4/04

Page 21

AA is the weight, BB is the weight unit, and X is the corresponding setpoint

number.

j. Steps d - i will be repeated until the last setpoint has been reached. If batch

print mode is enabled, a weight total will be printed.

k. The instrument will switch back to the first ingredient setpoint.

I. The setpoint outputs will remain OFF and the unit will return to normal

operation in the GROSS mode.

If the batching is stopped in the middle of the cycle, it may be restarted where it left off

(Step h) by pressing the FUNC, START keys or started at the beginning of the current

ingredient setpoint (Step g) by pressing the START key. The current setpoint can be

changed by pressing the STOP key until the desired setpoint indicator is lit. The TRIM

Key is not functional in this mode.

IMPORTANT NOTES

1. The front panel STOP key should never be used as the primary STOP control

(EMERGENCY STOP) in a critical batching operation.

2. The batch cycle will automatically stop if any operation interrupts the weight

monitoring process. For example, if print, zero or tare operations are initiated

during weight operations.

Up to 4 setpoints may be enabled depending on settings of : dribble, preact, discharge,

zeroband, setpoint inhibit, SP auto zero, delay 1 and print options.

MODE 5- AUTO BATCH REPEAT MODE

Display shows “SP Abr”:

The Auto Batching with Repeat mode operates the same as the Auto Batch mode

except that instead of stopping after each batching cycle is complete the unit will

automatically return to the first setpoint and start a new cycle after a delay of length

DELAY2. When the START button is pressed, if the instrument is not inhibited from

operating by the setpoint inhibit (refer to setpoint operation), the following sequence

will occur:

a. If Setpoint 1 (SP 1) is enabled and the Setpoint Autozero feature is enabled,

then the scale will be zeroed.

b. An autotare will occur and the indicator will switch to NET mode.

c. The first ingredient output(s) will turn on until the setpoint is reached.

d. The “ENABLED” indicator will start to flash and the delay time out will start. (If

the DELAY 1 = 0, an infinite delay will occur and START must be pressed.)

e. At the end of the delay, a print operation will occur if the batch print mode is

enabled.

f. The instrument will switch to the next ingredient setpoint.

g. The “ENABLE” indicator stops flashing and an autotare will occur.

h. The setpoint is enabled.

i. When the displayed weight reaches the setpoint, the output will turn off.

50515 21 Issue #2 4/04

Page 22

j. Steps d - i will be repeated until the last setpoint has been reached. If batch

print mode is enabled, a weight total will be printed.

k. The instrument will switch back to the first ingredient setpoint(s).

l. The setpoint outputs will remain OFF and the unit will return to the GROSS

mode.

m. A time out of the second delay will now start. (If the DELAY2 = 0, an infinite

delay will occur and START must be pressed.)

n. If the instrument is inhibited by the setpoint inhibit (refer to setpoint

operation), the instrument will respond as though delay 2 was set to 0

(infinite). All setpoints will be disabled and the “enabled” indicator will blink

until the inhibit condition is removed.

o. Steps a through o will be repeated until the batching cycle is stopped by

pressing the STOP key. If the batching is stopped in the middle of the cycle,

it may be restarted where it left off (Step h) by pressing the FUNC, START

keys, or started at the beginning of the current ingredient setpoint (Step 9) by

pressing the START key. The current setpoint can be changed by pressing

the STOP key until the desired setpoint indicator is lit. The TRIM key is not

functional in this mode.

IMPORTANT NOTES

1. The front panel STOP button should never be used as the primary STOP

control (EMERGENCY STOP) in a critical batching operation.

2. The batch cycle will automatically stop if any operation interrupts the weight

monitoring process. For example, if print, zero or tare operations are initiated

during weight operations.

Up to 4 setpoints may be enabled depending on settings of : dribble, preact, discharge,

zeroband, setpoint inhibit, SP auto zero, delay 1 and print options.

DISCHARGE (DUMP) OPERATION

The discharge output is an optional output that is used to discharge or dump a

completed batch. It is available in modes AbA and Abr only. If enabled, the discharge

output will automatically turn on after the last ingredient of an auto-batch or autobatch

repeat mode has been added. It will then turn off automatically “delay 2” seconds

after the cause of any software inhibit is removed. In the other setpoint modes, the

discharge output is manually turned on by pressing STOP. In all setpoint modes, an

active discharge operation may be turned off by pressing STOP.

The discharge function will operate on Setpoint 3 if that setpoint is available. If Setpoint

3 is not available, but Setpoint 4 is unused, the discharge feature will be offered on

Setpoint 4. Discharge maintains a higher precedence than zeroband. So, if Setpoint 4

is the only setpoint available, the first option offered is the discharge feature. If

discharge is unused, zeroband will be offered.

50515 22 Issue #2 4/04

Page 23

ZEROBAND OPERATION - Optional

The Zeroband output is an optional output that will turn ON only when the absolute

value of the GROSS weight is within the zeroband setpoint. The Zeroband can be

used as an inhibit signal, to disable the set-points from operating if the weight is less

than the Zeroband. The Zeroband output always uses SP4, and the value of Setpoint 4

determines the Zeroband. The Zeroband is always operational unless the setpoints

are disabled. The START button does not have to be pressed.

A hardware inhibit may be obtained by connecting the Zeroband (SP4) output to

external control circuits or, if Accessory 149/151 is used, by connecting the SP4 relay

contacts in series with the other contacts.

SETPOINT INHIBIT

The setpoint software inhibit (SPi) is available to prevent the start or restart of a

batching cycle. The inhibit is active when the weight on the scale is above or below (as

defined by the user) a preset gross weight value. This gross weight is programmed as

Setpoint 5. However, the user must recognize that the Setpoint 5 value is strictly a

software parameter and it does NOT represent a fifth setpoint output.

Within Setpoint programming:

* If SPi is programmed to “OFF”, the inhibit feature is disabled.

* If SPi is programmed to “LO”, the batch cycle will not start if the gross weight on

the scale is less than the setpoint 5 weight.

* If SPi is programmed to “HI”, the batch cycle will not start if the gross weight on the

scale is equal to or exceeds the Setpoint 5 weight.

Examples using Zeroband and Setpoint Inhibit:

1. In the Manual Batch Mode, to prevent fill operations from occurring when no

container is on the scale:

* Enable Zeroband, set Setpoint 4 equal to slightly less than the minimum

container tare weight, and disable the Setpoint Autozero feature.

* If setpoint software inhibit is used, program it for “SPi LO” and set Setpoint 5

to the same weight as Setpoint 4.

2. To prevent an amount to be emptied from a hopper when there is insufficient

material in the hopper to complete the batch:

* Enable Zeroband, set Setpoint 4 equal to slightly more than the amount to be

emptied from the hopper, and disable the Setpoint Autozero feature.

* If setpoint software inhibit is used, program it for “SPi LO” and set Setpoint 5

to the same weight as Setpoint 4.

50515 23 Issue #2 4/04

Page 24

3. In Auto Batch or Auto Batch Repeat Mode, to prevent a fill operation from

occurring when no container is on the scale:

* Enable Zeroband, set Setpoint 4 equal to slightly more than the

maximum difference in tare weights between containers, and enable the

Setpoint Autozero feature.

* If setpoint software inhibit is used, program it for “SPi HI” and set

Setpoint 5 to the same weight as Setpoint 4.

* Manually zero off the very first container’s tare weight before starting.

Programming Setpoint Mode Of Operation

1. Press FUNC, 1. The display will show “CAL SP”. Press the Prog / 7 key to

program setpoint mode and other operating parameters

2. The display will now show the current setpoint mode of operation Use the 9

and 6 arrow keys until the desired mode is displayed and then press ENTER.

3. The display will now show “SPon x”, where x = 0 or 1. Use the arrow keys to

select the desired setpoint ON state, either 0 (LOW) or 1 (HI). Select “0” if

you are using Relay Accessory 149/151. Press ENTER

If “0” is selected, the setpoint outputs turn on and provide a Low state.

If “1” is selected, the setpoint outputs turn on and provide a High impedance.

4. The display will now show “ni x”, where x represents the number of

ingredients which are to be batched. Enter the number of ingredients from 1

to 4. If the number of ingredients is 3 or 4, continue with Step 6.

NOTE: If setpoints are to be “paired”, that is a fast feed and dribble are used, the

maximum number of ingredients is 2.

5. If the number of ingredients is 1 or 2, the display will show “dr x”, where x = 0

or 1. Enter 1 to enable or 0 to disable dribble (paired setpoint) operation.

If dribble is enabled, setpoint 1 (Fast feed) will be paired with setpoint 2

(Dribble), and setpoint 3 (Fast feed) will be paired with setpoint 4 (Dribble).

The second setpoint pair (3 and 4) will only be available if the number of

ingredients selected in step 4, is 2.

6.The display will now show “Pr x”, where x = 0 or 1 Enter 1 to enable or 0 to

disable preact.

7. If Setpoint 3 or 4 is available, the display will show “dc x”, where “x” equals 0

or 1. Enter 1 to enable or 0 to disable the discharge output.

50515 24 Issue #2 4/04

Page 25

NOTE: “Discharge” will normally use the Setpoint 3 output. If Setpoint 3 is

unavailable, discharge will use the Setpoint 4 output

8. If Setpoint 4 is unused, the display will show “Zb x” where x = 0 or 1. Enter 1

to enable or 0 to disable Zeroband.

9. If “SP bA” , “SP AbA” or “SP Abr” was selected, the display will show

“SPi xxx”, where “xxx” is OFF, LO or HI. Enter OFF to disable the setpoint

software inhibit, LO to enable the software inhibit when the gross weight is

less than Setpoint 5, or HI to enable the software inhibit when the gross

weight is greater than or equal to Setpoint 5.

NOTE: Unlike Setpoint 1 through 4, Setpoint 5 does not have an output. The Setpoint 5

value is the Setpoint Software Inhibit reference. A batch, auto batch, or autobatch with

repeat cycle will be inhibited from starting if the weight on the scale is less than or

greater than (as defined by the user) the Setpoint 5 value.

10. If “SP AbA” or “SP Abr” is selected, the display will show “SPA2 x” where x

equals 0 or 1. Enter 1 to enable the Setpoint Autozero feature or 0 to

disable. If enabled, the instrument will automatically perform a zero

operation before starting an auto batch cycle. Enable if the application uses

a platform, disable if the application uses a hopper.

11. If “SP AbA” (Auto Batch mode) or “SP Abr” (Auto Batch with Repeat mode)

was selected, the instrument will now prompt the user for the amount of

time to delay between each ingredient, “d1” (DELAY 1), before starting the

next batch.

Enter the amount of time (from 0-99 seconds).

12. In all but the checkweigh setpoint mode, the display will now show “d2 xx”,

where “xx” is the delay 2 in seconds. The discharge output will turn off 2

seconds after the cause of any software inhibit is removed. If delay 2 is set

to 0, the discharge output will turnoff when the STOP key is pressed. Enter

the desired amount of delay, from 0 to 99 seconds.

NOTE: If 0 is selected, the instrument will wait for the next setpoint to be manually

started by the operator pressing the START ‘’ button.

13. If “SP Aba” or “SP Abr” was selected, then the display will show “print x”,

where x is a 0 or 1.

0 = No print function is enabled.

1 = Print function enabled and the printer will automatically print at the

end of the delay period.

14. The unit will return to the normal weight display.

50515 25 Issue #2 4/04

Page 26

Programming Setpoint Values

1. Press FUNC, 1. The display will show “SP CAL” Enter the number of the setpoint

you wish to program, 1 – 5. If paired setpoints are used (dribble is enabled), then

enter 1 or 3 to program the setpoint value and 2 or 4 to program the dribble value.

Always enter 5 to program Setpoint Software Inhibit.

2. The selected setpoint indicator will turn ON and the display will alternately flash

between a legend and the current value programmed. The legend will be “SP” for

setpoint, “DR” for dribble, or “SPi” for setpoint software inhibit, or “2b” for zeroband.

3. Enter a new value from the keypad or press ENTER to store the current value in

memory.

4. If Preact is enabled, the instrument will now prompt the user to enter the Preact

value to be used. There is a separate preact available for each output.

5. The unit will now return to normal weigh mode.

SETPOINT Outputs

The setpoint output terminal block, is located in the bottom of the instrument. The

setpoint output cable is connected to J3 (pins 10-16) on the main PC Board, near the

AC power connector.

The setpoint control cable will exit the instrument through the waterproof gland on the

back (see Figure 2417, page 11). Refer to Appendix VII to identify setpoint outputs at

TB3.

50515 26 Issue #2 4/04

JP6

JP7

1

14

1

Load Cell

Connector

8

7

12

1 2 3 4 5

RS232 C. Loop

1

2413

Power

Supply

1

1

J3

6 7 8 9 11 12 13 14 15 16

Set Points

JP1

JP2

1

JP3

50514-2

Page 27

The setpoint terminal block is marked Setpoints 1, 2, 3, and 4, as well as a ground

terminal. The open collector relay driver output is capable of driving DC loads up to a

maximum of 60VDC @ 100mA.

FIGURE 2-1

G. Serial Output Operation and Programming

Each instrument has a serial output as a standard feature which may be configured for

RS-232 or a 20mA current loop. The connector, located on the back of the instrument,

is a water-proof, 9 pin circular connector. The connector is covered with a screw cap.

1. Programming Serial IO Interface

Refer to Appendix III for selected printer switch settings. Program the instrument to

match the selected printer.

a. To program the serial channel baud rate, etc., press FUNC, 3 to enter

the IO calibration mode The display will show “CAL I0”. Press the 7 key.

b. The display will show “SELCH x”, where x is the channel number. Enter the

channel number you wish to setup, i.e., 1, 2, or 3.

Channel 1 is the first serial output channel (RS-232 or current loop). Channel 2

is the optional serial output channel (RS-232 or current loop). Channel 3 is the

optional serial output channel (RS-485). To use the standard output, select

channel 1. With the proper accessory installed, select channel 2 or 3.

c. The display will show “b xxxx”. This is the output baud rate. Using the UP or

DOWN arrows, scroll through the baud rate choices, 300, 600,1200,

2400, 4800, 9600, or 19200 When the desired baud rate is displayed, press

the ENTER key.

d. The display will show “StOP x , where “x” is 1 or 2. This is the number of stop

bits. Scroll through the choices with the UP or DOWN arrows and press

ENTER when the desired choice is displayed.

e. The display will show the parity, “odd”, “EUEN” or “NONE”. Scroll through the

choices with the UP or DOWN arrows and Press ENTER when the desired

choice is displayed.

f. The display will now show” CHAr x ,where x is 7 or 8 This is the number of

data bits per character. Scroll through the choice with the Up and Down arrow

keys and press ENTER at the desired value.

g. If Channel 1 is selected, the display will show “CtS x”, where x = 0 or 1. Enter

0 if you wish the instrument to transmit when the CTS (Clear To Send) line is

LOW (example: printer busy, active high), or if the CTS line is not used. Enter

1 if you wish the instrument to transmit when the CTS line is HIGH (example:

50515 27 Issue #2 4/04

Page 28

standard CTS operation or printer with busy, active low).

Serial Output Operation and Programming:

Clear

to Send (CTS) Selection

Port 1 Only CTS Value

50-3710 1

50-3715 1

50-3920 (Oki 182) 0

50-3921 (Oki 184T) 1

50-3925/SP2000/SP2200 0

PTR-3950/610 0

50-3960/295/590 0

Computer with CTS Handshake 1

Remote Display 0

20mA Current Loop 0

W

ith ACC 146 Installed

Port 1 & Port 2 CTS Value

50-3715 50-3921 1

50-3715 PTR-3950 1

50-3715 50-3960 1

SP-2000 1

50-3960 50-3715 0

50-3960 50-3921 0

50-3960 PTR-3950 0

50-3921 50-3715 1

50-3921 50-3960 1

50-3921 PTR-3950 1

PTR-3950 50-3715 0

PTR-3950 50-3921 0

PTR-3950 50-3960 0

Switch settings on ACC-146: 1, 3, 5, and 8 ON.

h. The instrument will now return to the normal weigh mode.

2. Programming the Serial IO Format

There are 3 channels available

Channel 1 - Standard Serial Port

Channel 2 - RS232 / 20mA CL

Channel 3 - RS422/485 Output

a. Press FUNC, 3 to enter IO calibration mode. The display will show ‘CAL IO”.

Press the number of the IO channel you wish to format.

50515 28 Issue #2 4/04

Page 29

b. The display will show “ENA x”. This is the ENABLE or DISABLE function.

Select 0 to disable output or 1 to enable output. Press ENTER when the

desired choice is displayed.

c. Selecting Output Device

Use the UP and DOWN arrow keys to scroll through the available devices

and press ENTER when the Appropriate devices is displayed. The available

device are:

1) “Pntr” = Printer

Data will be transmitted when the PRINT key is pressed or a remote

print command is received. Computer commands without ID may be

received in this mode. Refer to computer command section for further

details.

2) CPtr P” = Computer - Polled

Computer commands without ID may be received in this mode. Refer

to computer command section for further details.

3) “CPtrPi” = Computer Polled with ID

Computer commands with ID may be received in this mode. Refer to

computer command section for further details.

4) “CPtr A” = Computer - Automatic

Data will be transmitted every display update. Computer

commands with or without ID may be received in this mode. Refer to

computer command section for further details.

5) “dISPLY” = Remote Display

Data will automatically be transmitted every display update. Only

commands that are specific to the Remote Display may be received

over the serial port in this mode.

6.) “P 2642” = PTR 2242 /2642/2742/2844 Label Barcode Printer.

NOTE: If amount of data transmitted exceeds the time available between display

updates, display updates will be lost and the system will appear to slow down. This

can be corrected by decreasing the amount of data transmitted, increasing the baud

rate, or slowing down the display update rate.

d. Select Output Format

If data is being output to a computer or printer, you will be prompted to select

what information to transmit. The display will show “tdi” for time, date and ID.

Any combination of these three items may be selected.

Display

meaning

“tdi” time, date, and ID

50515 29 Issue #2 4/04

Page 30

“di” date and ID

‘ti” time and ID

“I” ID only

“td” time and date

“d” date only

“t” time only

“no tdi” no time, date, or ID

Use the UP or DOWN arrows to scroll through the selections, Press ENTER to select.

The display will show “nEt” or Gtn’ If “nEt” is selected, the instrument will output NET

weight only in the Net weigh mode If “Gtn” is selected, the instrument will output

GROSS, TARE and NET weight in the Net weigh mode. The instrument only outputs

GROSS weight in the Gross mode. Use UP or DOWN arrows to toggle between the

choices. Press ENTER to select.

The display will show “CrLF” for carriage return and line feed or “Cr” for carriage return

only at the end of each line. Use UP or DOWN arrows to toggle between the choices .

Press ENTER to select.

For Label Printer ONLY ,select “bar” / “no bar”. (bar = code 128 label, no bar = human readable

label)

e. When a computer format is chosen (at step C) , an option of enabling <STX>

and <ETX> for computer commands must be set. The display prompt will

show” St Etx”, where x is a “1” or a “0”.

Select “1” to enable <STX> and <ETX> for computer commands.

This completes the output programming and the display will return to the weigh mode.

All serial outputs are programmed the same. Switching from RS-232 to the current

loop or RS-485 is controlled by hardware. Refer to Appendix II.

3. Serial Output Data Format

Refer to Appendix V.

4. Wiring Diagram For Data Output

Refer to Appendix IV.

H. Computer Commands

Note: The option of eliminating the <STX> and <ETX> can be selected. This is

useful in “backwards compatibility” with the 5200 instruments. It is strongly

recommended to use the <STX> and <ETX> when using RS485.

1. * The COMMAND FORMAT is <STX>[ID]CMD<CR><ETX> where:

[ ] = Optional parameters

ID = 1-3 Digit ID (1-255)

CMD = Command

<STX> = Start of Text char

<ETX> = End of Text char

50515 30 Issue #2 4/04

Page 31

* All commands must be terminated by a <CR> and <ETX>. Upon receipt, the

command will be executed.

* The Command String (including the <CR> and <ETX>, and ID if required) may not

be longer than 20 characters. IF the string is longer than 20 characters, the extra

characters will be lost.

* If a Scale ID other than 0 (Section 2, B-13) has been entered, the Command

must be preceded by a 1-3 digit Scale ID or it will be ignored. If a Scale ID other than

0 has been entered and weight is outputted, the weight output string will be preceded

by a Scale ID String.

* Buffer will be cleared after command is executed.

* Computer commands may be echoed and /or acknowledged. Refer to Subsection I,

of this section for further information.

Example Command : <STX>12P<CR><ETX>

Response : SCALE 12 <CR><LF>

Weight is output to all printer channels The following computer commands are

supported. Refer to Appendix V (Data Format) for output string information.

PRINT <STX>P<CR><ETX>

Weight is output to all printer channels

WEIGHT <STX>W[L/K]<CR><ETX>

Weight is output to computer channel requesting data only L(LB)

OR K(KG) can be used to request output in specific weight unit

ZERO <STX>Z<CR><ETX>

Scale is zeroed IF no motion

NET <STX>N<CR><ETX>

Scale is switched to net mode IF tare is enabled

GROSS <STX>G<CR><ETX>

Scale is switched to gross mode

AUTOTARE <STX>A<CR><ETX>

Scale is Autotare IF Autotare is enabled

START <STX>B<CR><ETX>

Batch cycle is started

STOP <STX>S<CR><ETX.

Batch cycle is stopped

DISCHARGE <STX>D<CR><ETX>

50515 31 Issue #2 4/04

Page 32

Discharge cycle starts IF enabled

ENTER ID <STX>EIXXXXXX<CR><ETX>

Product ID is entered into memory (XXXX =ID is desired)

RECALL ID <STX>RI<CR><ETX>

ID is output

ENTER TARE <STX>ETXXXXXX{L / K}<CR><ETX>

Tare is entered into memory. IF an illegal tare is used, it will be

cleared. L(LB) OR K(KG) can be used to request output in a

specific weight unit

RECALL TARE <STX>RT{L/K}<CR><ETX>

Tare is output.

L(LB) OR K(KG) can be used to request output in a specific

weight unit

RECALL CONFIG <STX>RC<CR><ETX>

Config/Calibration parameters are output

ENTER SETPOINT <STX>ESM[x][NI][Dy][Py][Cy][Zy][lz][Ay][T1xx][T2xx][Oy]<CR><ETX>

RECALL CONFIG <STX>RC<CR><ETX>

Model, Progam Rev,Time, Date, Cap, Cal Data: Current

Zero______S________ Diag Test 1_______2_______

Note: ONLY 7 variables can be entered at one time

C =Discharge/Dump

I =Setpoint Inhibit

A =Auto zero at batch start

O =Output (Autoprint)

T1 =Delay Timer1

T2 =Delay Timer2

M =Mode

x =0 (Setpoints disabled)

x =1 (Setpoint mode)

x =2 (Checkweigh mode)

x =3 (Batch mode)

x =4 (Autobatch mode)

x =5 (Autobatch repeat mode)

x =Anything else (Setpoints disabled)

N =number of ingredients

I =1,2,3,4

D =Dribble

P =Preact

Z =Zeroband

50515 32 Issue #2 4/04

Page 33

W =0(OFF) L(LOW) H(HIGH)

y =0(disable) 1(enable)

RECALL SETPOINT <STX>RSM<CR><ETX>

The setpoint mode is output

ENTER SETPOINT# <STX>ESN#<CR><ETX>

Where # =1,2,3,4, enables setpoint number

RECALL SETPOINT# <STX>RSN<CR><ETX>

The currently enabled setpoint is output

ENTER SETPOINT <STX>ES#xxxxxx[L/K]<CD><ETX>

Where # = 1,2,3,4

RECALL SETPOINT <STX>RS#[L/K]<CR><ETX>

IF # =A, the setpoint and preact information for all outputs isgiven.

IF # =1,2,3,4 the setpoint value is output. L(LB) OR K(KG) can

be used to request output in specific weight units.

ENTER PREACT <STX>EP#xxxxxx[L/K]<CR><ETX>

Where # =1,2,3,4 . The preact is entered in current weight

units. Any decimal point must be entered. L(LB) OR K(KG) can

be used to select specific weight units.

RECALL PREACT <STX>RP#[L/K]<CR><ETX>

IF # = 1,2,3,4, the preact value is given. L(LB) OR K(KG) can

be used to request output in specific weight units.

ENTER UNITS <STX>EUxx<CR><ETX>

xx=LB or KG

I. Computer Command Protocol

1. To program the Computer command protocol, press FUNC 3. The

display will show “CAL IO” Press 0, ENTER.

2. The display will show “ECHO x”, where x is 0 or 1. Select 0/1 to

disable/enable retransmission of each command after CR is received. If

the instrument is configured as Computer - Polled with ID, it will not

retransmit the command unless the ID is valid.

3. The display will show “AC x”, where x is 0 or 1. Select 0/1 to

disable/enable transmission of acknowledgement that command was

or was not successfully executed. If the command was carried out

successfully, a “>” character will be transmitted as acknowledgement.

If the command was not executed for whatever reason, a “?” will be

transmitted as a failure indication.

4. The display will return to the normal weight display.

50515 33 Issue #2 4/04

Page 34

J. Programming the SMART 4-20mA

1. Install Accessory 148. See Appendix VI for instructions.

2. Place a 100 ohm, 0.1% sense resistor (Part #510381) in series with the loop.

Place a DVM across the shunt resistor to monitor the current.

(4-20mA = 0.400 to 2.000V)

NOTE: The Accessory can be configured for voltage outputs by placing a shunt

resistor at the output terminal block.

Example: To convert 4-20mA to 1-5VDC use a 250 Ohm resistor. To convert 0-

20mA to 0- 10 VDC use a 500 Ohm resistor.

3. Press FUNC, 2 keys to enter the 4-20mA setup menu. The display will read 4-20

x’,where x equals 0,1, or 2. Select “0” to disable the 4-20mA output. Select “1” to set

the 4-20mA output to correspond to GROSS weight. Select “2’ to set the 4-20mA

output to correspond to NET weight. Press the ENTER key.

4. The display will now flash “LoLooP” for 1 second and then show “ACxxxx” (Analog

Count), where “xxxx” is a number between 0 and 4095. This number corresponds to

the Low Loop current calibration point, typically 4mA. Use the arrow keys to scroll

UP or DOWN until the Analog output reaches the low loop current output equal to

the desired value as monitored on the DVM. Press ENTER to store the value.

5. The display will now flash the weight that corresponds to the low loop current

calibration. Enter a new weight with the keypad if desired, and then press ENTER.

6. Repeat steps 4 and 5 for the Hi Loop, typically 20mA calibration.

7. The display will now return to the normal weigh mode. As long as the instrument is

monitoring the weight, the 4-20mA output will be updated every A/D cycle.

EXAMPLES:

a. To calibrate the 4-20mA loop to correspond to 0-130 lb NET, a typical

50515 34 Issue #2 4/04

mA

▲

20mA

OUTPUT

4mA

▲

LBS NET

0

130

2431

Page 35

calibration would be:

at Step 3 - “4-20, 2” (Net Mode)

at Step 4 - flash “LoLooP” then “AC 750” (4mA on DVM)

at Step 5 - “LO Ld” “0 lb”

at Step 4A - flash “HiLooP” then “AC 3800” (20 mA on DVM)

at Step 5B - “Hi Ld” “130 lb”

b. To calibrate the 4-20mA loop to correspond to 10000 to 1500 lbs GROSS,

a typical calibration would be:

at Step 3 - “4-20 1” (Gross Mode)

at Step 4A - flash “LoLooP” then “AC 750” (4mA on DVM)

at Step 5A - “LO Ld” “10000 lb”

at Step 4B - flash “HiLooP” then “AC 3800” (20 mA on DVM)

at Step 5B - “Hi Ld” “1500 lb”

NOTE: If the instrument is not monitoring weight (Example: Entering a keyboard Tare)

The 4-20mA will hold at the last update until it returns to displaying weight.

50515 35 Issue #2 4/04

mA

▲

20mA

OUTPUT

4mA

▲

LBS GROSS

0

1500

10,000

Page 36

SECTION 3:

INSTALLATION

A. Instrument Mounting Options

The H90-5200-A instrument is designed for bench mounting, wall mounting, or pillar

mounting. Wall mounting plates are provided with each instrument.

1. Wall Mount

a. Remove the four feet from the bottom of the instrument.

b. Rotate the wall mounting plates 180 degrees, so they extend out to the sides

of the instrument.

c. Reinstall the foot screws through the mounting plates, into the bottom of the

instrument and tighten.

d. Mount the instrument on the wall with fasteners through the mounting plates

into the wall. It is recommended that the water proof glands face downward

when the instrument is wall mounted.

e. Place the instrument front panel in the appropriate position, rotated 180

degrees from the normal bench mounting position.

2. Pillar Mount

The instrument can be mounted on a pillar attached to the platform. See Appendix VIII

for more information.

50515 36 Issue #2 4/04

Page 37

SECTION 4:

TROUBLESHOOTING

A. Troubleshooting

Use Appendix XII for viewing error codes. Should a problem occur, first unplug the

H90-5200-A indicator. Wait a few seconds then repower while observing display. If

problem is not resolved, call your local Fairbanks Service representative.

1. Perform a power-up test. Upon instrument power-up the H90-5200-A will

perform the following tests:

a. RAM Test - The RAM test verifies the operation of the processors external

memory device.

b. Display Test - The display will perform a warm-up sequence. This routine is

designed to test that all display segment lines, digit lines, and annunciator

LEDs, have no defects. This is a passive test and the user must observe the

display throughout the test to check for any anomalies.

c. EEPROM Read -The processor will attempt to retrieve the stored scale

programming data from the EEPROM. This data includes: deadload and span

counts, grad size, capacity, security level, etc.

If the processor detects any out-of-range data, it will repeatedly request data from the

EEPROM until the retrieved data is deemed valid. During this period, the display will

flash “EE Err.”

Very often the problem is with the data itself and not the actual hardware. The two

most common causes are as follows:

1). A replacement board has just be installed in the instrument and this is a

first-time power-up. Thus, the current EEPROM data might not be

appropriate for the software in use.

2)

. You are using a new (or different) software program or revision level than

used at the previous instrument power down. This result is that the new

software might be trying to access data from the wrong areas of memory.

50515 37 Issue #2 4/04

Page 38

APPENDIX I: QUICK REFERENCE CHART

Front Panel Program Steps Factory Setting Prompt

1. Displays Program Revision Number “P294-x”

2. Weight Units Selection lb/kg “U”

lb, kg, lb/kg, or custom (no display unit)

2a. Primary Weight Units Selection lb “PU”

(if lb/kg are selected in step 2)

3. Grad Size Selection 0.01 “GSxxxx”

0.0001 to 50

4. Balance/Motion Selection 2.0 “bALx.x”

0.5,1.0,2.0,3.0 divisions

5. AUTO ZERO TRACKING Selection 1.0 divisions “AO x.x”

OFF, 0.5,1.0, 3.0 divisions

6. Auto Zero Time Delay 1 sec “AOtd x”

1 to 6 sec

7. ZERO LIMIT Selection 100% “OL xxx”

+/- 2% or 100% of capacity

8. AUTO TARE Selection 1 “AtArEx”

0 = disabled 1 = enabled

9. KEYBOARD TARE Selection 1 “tArE x”

0 =disabled 1 enabled

10. Display Update Rate Selection 0.5 “SEC x.x”

0.1,0.3,0.5,0.8, 1.0 seconds

11. Digital Filter Selection 2 “FF x”

0 (No filter), 1, 2, 3 or 4 (Mm to Max filter)

12. Scale ID for Polled Serial Communications 0 “id xxx”

0 to 255

13. Time/Date Format Selection: 12 US ‘td xxxx”

12/24 Hours and US/International Date

14. Security Code Selection 0 “S.CodE”

Any number up to 6 digits

0 =disabled

15. Security Level Selection 0 “SL x”

0 = all front panel programming enabled *

1 = limited front panel programming enabled

2 = no front panel programming enabled

* Non-commercial applications only

16. Inhibit Switch Selection 0 “inhS x”

0 = all switches are enabled

1 = one or more front panel switches are disabled

17. Remote Switch 0 “rS 0”

0 = disable, 1 = enable

18, Remote Switch “rS 1”

19. Remote Switch A “rS 2”

20. Remote Switch P “rS3”

50515 38 Issue #2 4/04

Page 39

50515 39 Issue #2 4/04

APPENDIX II: Serial Output Installation

The Standard Serial RS-232 output is factory installed at J3, pins 1-5 on the main PC board,

with a shunt jumper placed on pins 8 and 9. To configure the instrument for 20mA current

loop output, move the connector at J3 to pins 5-9 and move the shunt jumper from pins 8

and 9 to pins 2 and 3 (see Section 3, Figure 3-2).

Accessory 145: I/O board configured for 20mA current loop, serial output, used to

output to a remote display or computer.

Accessory 146: I/O Board configured for RS-232 output to a printer or computer.

Accessory 147: I/O Board configured for RS-485 output to a computer.

The second serial output accessory (145,146,147) is mounted in the bottom of the

instrument. Four weld-studs are provided for mounting the accessory board.

To install the accessory:

1. Unplug the AC power cord from its outlet.

2. Remove the four bolts holding the front panel to the instrument.

3. Lift the instrument front panel and carefully remove all cables from the main

PC Board. Set the front panel aside.

4. Remove the hole plug from the accessory port on the back of the instrument.

5. Install the 9 pin accessory connector in the accessory port.

R10

R8

R6

R7

R4

SW1

J1

J2

I/O ASSY

Page 40

6. Install the four hex spacers on the four weld-studs in the bottom of the

instrument.

7. Place the accessory PC Board on the weld-studs. The 24 pin connector

should be toward the center of the instrument.

8. Install the four nuts on top of the weld-studs to hold the PC Board in place.

9. Connect the 24 pin ribbon cable from the accessory PC Board to J4 on

the main PC Board.

NOTE: Pin 1 on the cable must go to pin 1 on the accessory board and on the

instrument or damage will result. Make sure the cable exits towards

the center of the main PCB.

10. Connect the Accessory output cable from the 9 pin connector to J1 on the

I/O Accessory.

11. On the I/O Output board, set the slide switches at SW1 for the output

desired. If the I/O Accessory is installed,the following switch settings on SW1

must be made to operate various pieces of equipment.

ACC 146 Settings ( channel 2 )

Switch

Device

1 2 3 4 5 6 7 8 Remarks

Printer1 1 0 1 0 1 0 0 1 50-3925, PTR-3950, 50-3921

RS-232 1 0 1 0 0 1 0 1 Citizens, 50-3960, 50-3715

Computer

RS-232 1 0 1 0 0 1 0 1

ACC 146 Settings ( channel 2 )

Remote Display or

Computer 0 0 1 1 0 0 0 1

Current Loop

Computer

RS-485 0 0 1 0 0 0 0 1

ACC 147

0=OFF 1=ON

Accessory Switch Configuration Chart

50515 40 Issue #2 4/04

Page 41

12. Re-connect all of the cables to the main PC Board.

13. Apply power and program the serial channel from the front panel. Verify

output is functioning properly.

14. Re-install the front panel screws.

50515 41 Issue #2 4/04

ACC 145

J2

ACC 146

J2

4

5

8

3

6

7

20 mA Output

6

5

4

8

+TXD

-TXD

+RXD

-RXD

RS-232

TXD

RXD

GND

Frame GND

BUSY

ACC 147

J2

3

1

2

ACC 148

J2

1

2

3

485/422 Output

GND

485+

485-

4-20 mA Analog Output

+Output

-Output

GND (Chassis) (Shi eld)

2427b

Page 42

APPENDIX III: Switch Settings for Selected Printers

The following printers are not manufactured by Fairbanks, but may be interfaced to the

H90-5200-A series instrument. The switch settings are furnished to aid in setting-up

these printers.

1. Interface to Okidata Model 182 Serial Printer (Fairbanks Model 50-3920)

Using the Printer Handbook included with the Printer, set the Printer internal switches

per the following tables:

Switch on Printer Controller PCB

Function

1 2 3 4

5 6 7

8

ASCII - US ON OFF OFF

11” Form OFF ON

Length

No Auto LF OFF

8 Bit Data ON

Not Used* OFF

*Must remain in the OFF Position

Switch on Printer Serial Interface PCB

Function