Fairbanks FB2550 User Manual

Operators Manual

FB2550 SERIES

INCLUDES:

IN/OUT APPLICATION

NETWORK APPLICATION

2010-2012 by Fairbanks Scales, Inc.

All rights reserved

51254

Rev. 3 07/2012

Amendment Record

FB2550 SERIES INSTRUMENT

DOCUMENT 51254

Manufactured by Fairbanks Scales Inc.

821 Locust

Kansas City, Missouri 64106

Created 10/2010

Revision 1 05/2011 Released document

Revision 2 04/2012 Updated manual to Rev. 3.x Software. Added numerous

feature definitions and specification information.

Revision 3 07/2012 Added Network Application information and update images.

.

Disclaimer

Every effort has been made to provide complete and accurate information in this manual. However, although this

manual may include a specifically identified warranty notice for the product, Fairbanks Scales makes no

representations or warranties with respect to the contents of this manual, and reserves the right to make changes

to this manual without notice when and as improvements are made.

It is the responsibility of the requesting party to develop, maintain, install, and connect networking devices and

general network connectivity as it applies to the originating party’s network. No warranty or guarantee, expressed

or implied, concerning the network, its design, its installation, or operational characteristics has been offered by

Fairbanks Scales. Fairbanks Scales shall not be liable for any loss, damage, cost of repairs, incidental or

consequential damages of any kind, whether or not based on express or implied warranty, contract, negligence,

or strict liability arising in connection with the design, development, installation, or use of an intended network.

Trademarks

Award is a trademark of Award Software International, Inc.

CF and Compact Flash are trademarks of ScanDisk Corporation.

Microsoft, Microsoft Windows XP Pro, Windows XP Pro Embedded, and MS-DOS are either trademarks or

registered trademarks of Microsoft Corporation.

Adobe, the Adobe logo, Acrobat, the Adobe PDF logo, Distiller, and Reader are either registered trademarks or

trademarks of Adobe Systems Incorporated.

All other product names mentioned herein are used for identification purpose only and may be

trademarks and/or registered trademarks of their respective companies.

© Copyright 2010-2012

This document contains proprietary information protected by copyright. All rights are reserved; no part of this

manual may be reproduced, copied, translated, or transmitted in any form or by any means without prior written

permission of the manufacturer.

07/2012 4 51254 Rev. 3

Table of Contents

SECTION 1: GENERAL INFORMATION ................................................................... 8

1.1. Description ................................................................................................................. 8

1.2. Specifications ............................................................................................................. 9

SECTION 2: GETTING STARTED ........................................................................... 11

2.1. Unpacking ................................................................................................................ 11

2.2. Equipment Location ................................................................................................. 11

2.3. Safety ...................................................................................................................... 12

2.4. Users’ Responsibilities ............................................................................................. 12

SECTION 3: OPERATIONS ..................................................................................... 13

3.1. Introduction ............................................................................................................... 13

3.2. Key Functions .......................................................................................................... 14

3.2.1. Front Panel Keypad ...................................................................................................... 14

3.2.2. External Keyboard......................................................................................................... 15

3.3. Proper Shutdown Procedure .................................................................................... 16

3.4. Operational Procedures ........................................................................................... 17

3.4.1. Basic Operations Summary ........................................................................................... 18

3.5. Configuration Menu .................................................................................................. 22

3.6. Operator Menu ......................................................................................................... 23

3.6.1. Time and Date Format .................................................................................................. 23

3.6.2. Set Time and Date ........................................................................................................ 24

3.6.3. Ticket Number .............................................................................................................. 24

3.6.4. Load Cell Diagnostics ................................................................................................... 26

3.6.5. Entering a New Tare Automatically ................................................................................ 27

3.6.6. Entering a New Tare using a Keyboard ......................................................................... 27

3.7. Edit Customers ........................................................................................................ 28

3.7.1. Adding or Editing Customers ......................................................................................... 28

3.8. Editing Products ....................................................................................................... 30

3.8.1. Adding or Editing Products ............................................................................................ 30

3.9. Product Groups ........................................................................................................ 34

3.9.1. Adding or Editing Product Groups ................................................................................. 34

3.10. Editing Tares .......................................................................................................... 35

3.10.1. Adding or Editing Tares ............................................................................................... 36

3.11. Delete Incomplete Transactions ............................................................................. 38

3.12. Reports .................................................................................................................. 40

3.12.1. Master File Reports ..................................................................................................... 40

3.12.2. Transaction Reports .................................................................................................... 43

3.13.3. Summary Reports ....................................................................................................... 47

3.12.4. Email Transaction ....................................................................................................... 49

3.13. External Monitor ..................................................................................................... 50

3.14. Audit Trail............................................................................................................... 51

3.14.1. Calibration Audit Trail .................................................................................................. 51

3.14.2. Configuration Audit Trail .............................................................................................. 51

07/2012 5 51254 Rev. 3

Table of Contents

SECTION 4: FB2550 CUSTOMIZATION ................................................................. 52

4.1. Programmable Legends ........................................................................................... 52

4.2. Programmable Prompts ........................................................................................... 54

4.3. Truck Image Type .................................................................................................... 55

4.4. Entry Sequence Prompts ......................................................................................... 56

SECTION 5: INPUT/ OUTPUT ................................................................................. 57

5.1. Introduction .............................................................................................................. 57

5.2. Instrument Configuration - Printers .......................................................................... 57

5.3. Printer Switch Settings ............................................................................................. 60

5.4. Printer Setup and Programming ............................................................................... 61

5.4.1. OKI ML420 Printer Settings ........................................................................................... 61

5.4.2. HP P2055d Laserjet Printer Settings ............................................................................. 65

5.4.3. iDP3550 Tape Printer Settings ...................................................................................... 70

5.4.4. TM-U590 Ticket Printer Settings .................................................................................... 71

5.4.5. TM-U295 Ticket Printer Settings .................................................................................... 72

5.4.6. SP298 Printer Settings .................................................................................................. 73

5.4.7. SP700 Printer Settings .................................................................................................. 75

5.4.8. SP2000 ......................................................................................................................... 77

5.4.9. SP2200 ......................................................................................................................... 77

5.4.10. TM-U230 ..................................................................................................................... 78

5.5. Format Tickets ......................................................................................................... 79

5.6. Serial Card (30921) .................................................................................................. 83

5.7. Remote Display Setup and Configuration ................................................................ 84

5.7.1. Serial 20mA Configuration (Multi-Function Board) ......................................................... 84

5.7.2. Multi-Function Board 20 mA Wiring (J1) ........................................................................ 86

5.7.3. Serial 20 mA Configuration (Serial Expansion Board) .................................................... 87

5.7.4. Serial Expansion Board 20 mA Wiring (TB1) ................................................................. 88

5.8 Configure Outputs ..................................................................................................... 89

5.8.1. Configuring an Output Data String ................................................................................. 89

5.8.2. Two Methods of Formatting ........................................................................................... 89

5.8.3. Method 1 – Pre-configured Output ................................................................................. 90

5.8.4. Method 2 - Customizing Output Data Strings ................................................................. 97

5.9. Report Printer Configuration .................................................................................. 105

5.10. IP Output Configuration ........................................................................................ 106

5.11. RS-485 Configuration........................................................................................... 108

5.12. Network Parameters Configuration ...................................................................... 110

5.13. 4-20MA Analog Card (30919) ............................................................................... 112

5.14. Fieldbus Protocols and Formats ........................................................................... 113

5.14.1. Transmission Methods ............................................................................................... 113

5.14.2. Communication Format .............................................................................................. 113

5.14.3. Handling Network Traffic ............................................................................................ 113

5.15. Fieldbus Connections .......................................................................................... 114

5.15.1. Overview of Terms ..................................................................................................... 114

5.15.2. DeviceNet (30923) ..................................................................................................... 115

5.15.3. ControlNet (30924) ..................................................................................................... 117

5.15.4. Modbus (30925) ......................................................................................................... 119

5.15.5. Profibus (30922) ........................................................................................................ 121

07/2012 6 51254 Rev. 3

Table of Contents

SECTION 6: TRAFFIC LIGHT CONTROL ............................................................ 123

6.1. Traffic Light Control ................................................................................................ 123

6.2. Threshold Weights ................................................................................................. 128

6.3. Blind Counter ......................................................................................................... 129

SECTION 7: VIDEO CAMERA PROGRAMMING .................................................. 131

7.1. Video Camera Setup ............................................................................................... 131

7.2. Installing the Camera Without Factory Defaults ..................................................... 131

7.2.1. Camera Setup .............................................................................................................. 132

7.2.2. Axis Network Setup ...................................................................................................... 133

7.2.3. Resetting to the Axis Factory Defaults .......................................................................... 135

7.3. Video Camera Programming .................................................................................. 136

SECTION 8: SERVICE AND MAINTENANCE ...................................................... 139

8.1. Database Maintenance ........................................................................................... 139

8.1.1. Database Backup ......................................................................................................... 139

8.1.2. Database Restore ........................................................................................................ 145

8.1.3. Re-Index Database ...................................................................................................... 149

8.1.4. Transaction Data Backup Days Reminder .................................................................... 150

8.2. Troubleshooting – Loopback Test for Serial Ports .................................................. 151

SECTION 9: NETWORK APPLICATION CONFIGURATION ................................ 153

9.1. Introduction ............................................................................................................ 153

9.2. Standard Network Setup ........................................................................................ 153

9.2.1. Record Keeping ........................................................................................................... 154

9.2.2. Network Connections ................................................................................................... 155

9.2.3. Testing Connectivity ..................................................................................................... 155

9.3. Network Setup Procedure ...................................................................................... 156

9.3.1. Network Terminal Name ............................................................................................... 156

9.3.2. Synchronizing this Terminal ......................................................................................... 157

APPENDIX I: FIELDBUS INTERFACE REFERENCE DATA ................................ 159

A. Introduction .............................................................................................................. 159

B. Hardware Specifications ........................................................................................... 159

C. Software Specifications ............................................................................................ 160

D. Field Bus Data Representation ................................................................................. 163

E. Status/Command Word Bit Usage ............................................................................ 168

APPENDIX II: DATA OUTPUT ............................................................................... 174

A. Remote Display Output ............................................................................................ 174

B. Configure Output ...................................................................................................... 174

APPENDIX III: SMA PROTOCOL .......................................................................... 180

A. Standard Scale Response Message ......................................................................... 180

B. Examples ................................................................................................................. 181

APPENDIX IV: 20MA CODES ................................................................................ 182

APPENDIX V: REMOTE SWITCHES ..................................................................... 184

APPENDIX VI: REMOTE SERIAL COMMUNICATION COMMANDS ................... 185

07/2012 7 51254 Rev. 3

Section 1: General Information

1.1. DESCRIPTION

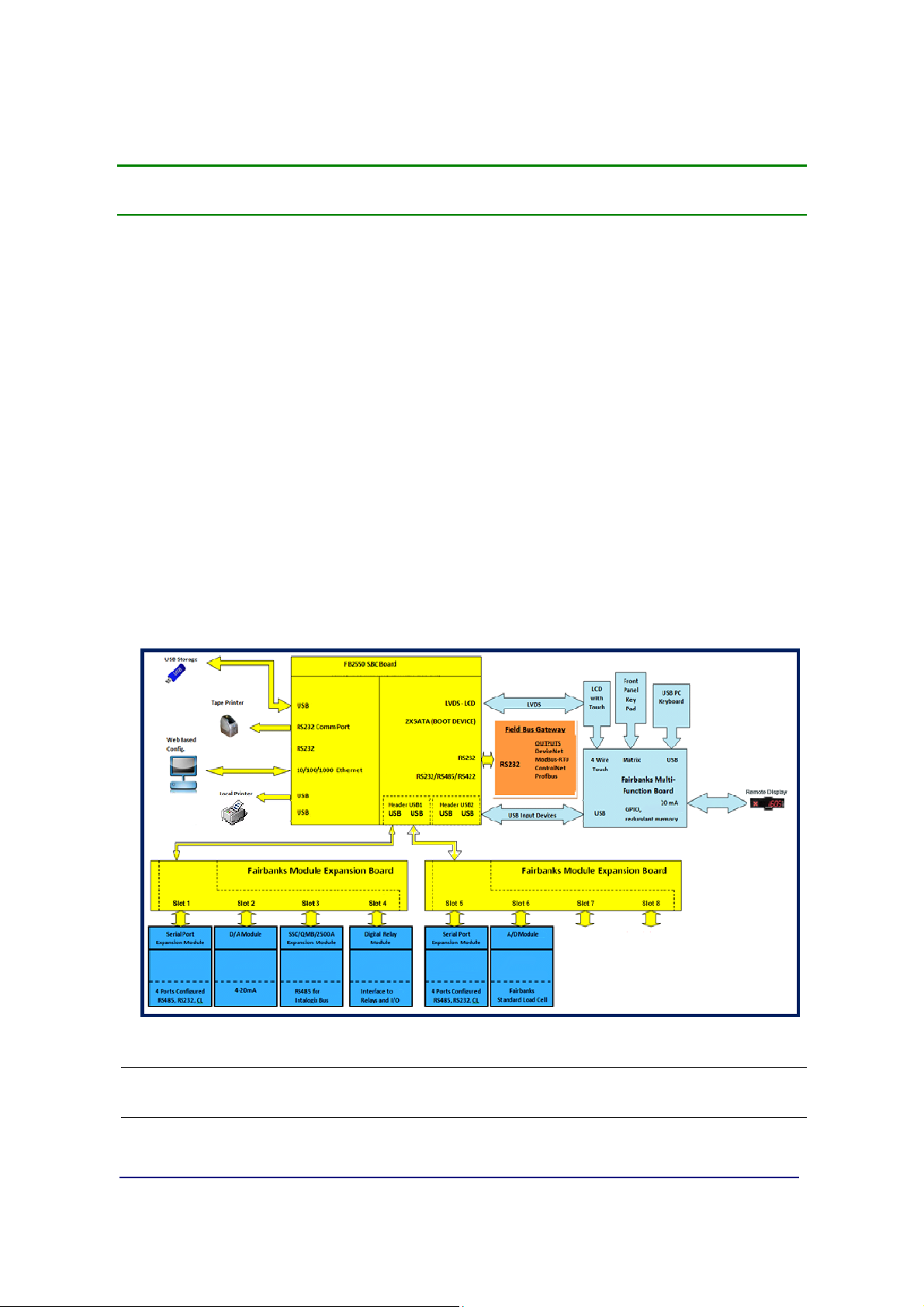

The FB2550 is a modular designed instrument, configurable and upgradable using

Printed Circuit Modules.

• Each module provides a specific scale or I/O functionality to the weighing system.

• The FB2550 instrument has four enclosure styles.

– Desktop – Panel Mount – Rack Mount – NEMA 4

STANDARD FEATURES

•••• 7” full-color display •••• Multiple/ Expandable serial ports

•••• Ethernet •••• Built-in reporting functions

•••• SQL database •••• IP Camera interface with onscreen image

•••• Touch screen operation •••• Stainless steel and aluminum desktop NEMA 12

•••• Integrated web server •••• Programmable F-key Prompts

Figure 1 – FB2550 Block Diagram

NOTE:

maximum number. Possibly even less, depending on the module kit type.

07/2012 8 51254 Rev. 3

Any combination of eight (8) modules can be installed, restricted to this

Section 1: General Information

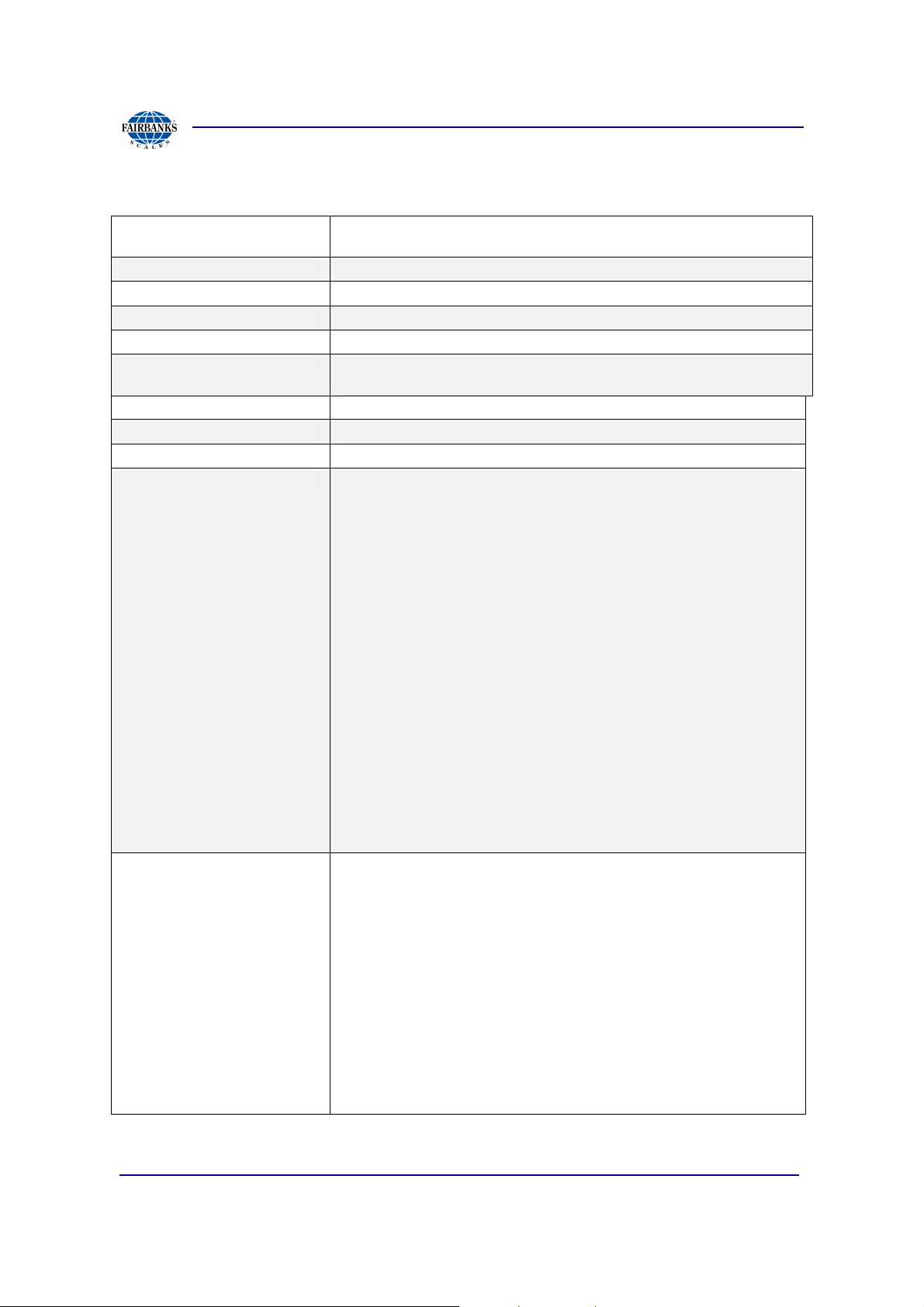

1.2. SPECIFICATIONS

Enclosure Desktop (30770), Panel Mount (31053), Rack Mount (31173),

NEMA 4 (31150)

BIOS

RAM

Disk Storage

Operating System

Serial Outputs

Digital I/O

Ethernet Interface

Display

Scale Interface Options • Intalogix Technology

Accessories • Serial Interface (30921), including:

Award™ Software

1 GB

8 GB

Windows XP Professional Embedded

Up to 12 serial ports and 4 built-in USB ports. The USB port on the

Multi-Function board is dedicated for a keyboard only.

Up to 28 I/O

PCI 10/100 Mbps Ethernet Complies with IEEE 802.3x Standards

7” Diagonal Touch Screen LCD Color

─ Intalogix Power Supply and Communications (30916)

─ Scale Interface Controller (30918)

─ External QMB Interface (30433)

─ External Intalogix Communication Board (28330)

Maximum of twenty (20) 1000 Ω or twelve (12) 350 Ω

cells

─ External Dual Intalogix Communication Board (28333).

Up to forty (40) 1000 Ω or twenty-four (24) 350 Ω cells.

• Analog Technology.

─ A/D Convertor Load Cell Interface (31079)

Up to sixteen (16) 1000 Ω or eight (8) 350 Ω cells.

─ External Analog Load Cell Interface (29646).

Up to sixteen (16) 1000 Ω or ten (10) 350 Ω cells.

─ External Dual Analog Load Cell Interface (30124).

Up to sixteen (16 x 2 = 32) 1000 Ω, or ten (10 X 2 = 20)

350 Ω cells.

Maximum of two (2) per FB2550.

– RS232 – RS-485 – 20mA

• 4-20mA (30919)

• Mini keyboard (25498)

─ USB – 87 key

• Keyboard (31036)

─ USB – 104 key

• SVP/ Uninterruptible Power Supply (UPS) (15892)

─ 500 VA Rating

• Field Bus Gateway

– ProfiBus (30922) – DeviceNet (30923)

– ControlNet (30924) – ModBus (30925)

07/2012 9 51254 Rev. 3

Section 1: General Information

1.2. SPECIFICATIONS, CONTINUED

Power Requirements

ETL Listed

Approvals

100 - 130 VAC @ 12A @ 60 Hz +/- 2 Hz

– Separate and dedicated circuit.

– Neutral to Ground voltage should be < 0.2 VAC

– One Amp (1A) is typical. Twelve Amps (12A) is a fully equipped

model.

• Conforms to UL STD 60950-1.

• CAN/CSA C 22.2 NO.60950-1-03.

• CC# 10-089

• MC# AM-5805

07/2012 10 51254 Rev. 3

Section 2: Getting Started

2.1. UNPACKING

Follow these guidelines when unpacking all equipment:

Check in all components and accessories according to the customer's order.

Remove all components from their packing material, checking against the

invoice that they are accounted for and not damaged.

• Advise the shipper immediately, if damage has occurred.

• Order any parts necessary to replace those which

have been damaged.

• Keep the shipping container and packing material for

future use.

• Check the packing list.

Collect all necessary installation manuals for the

equipment and accessories.

Open the equipment and perform an inspection, making

certain that all hardware, electrical connections, and

printed circuit assemblies are secure.

Do not reinstall the cover if the final installation is to be

performed after the pre-installation checkout.

2.2. EQUIPMENT LOCATION

Position the equipment with these points in mind:

Intense direct sunlight can harm the display.

Airborne particles can activate the touch screen.

Work areas should be relatively free from drafts and

vibrations.

Do not locate near magnetic material or equipment/instruments which use

magnets in their design.

Avoid areas which have extreme variations in room temperatures.

Temperatures outside the instrument’s specifications will affect the weighing

accuracy of this product.

07/2012 11 51254 Rev. 3

Section 2: Getting Started

2.3. SAFETY

Follow these safety precautions during operation:

Properly shut down the equipment and

remove power before any cables or

hardware is disconnected.

Unplug the power cord to the equipment

after a proper shut down before servicing

the equipment.

2.4. USERS’ RESPONSIBILITIES

All electronic and mechanical calibrations and/or adjustments required for

making this equipment perform to accuracy and operational specifications

should be performed by trained service personnel.

Absolutely no physical, electrical or program modifications other than selection

of standard options and accessories are to be made to this equipment.

─

Electrical connections other than those specified may not be

performed, and physical alterations (holes, etc.) are not allowed.

The equipment consists of printed circuit assemblies which must be handled

using ESD handling procedures, and must be replaced as units.

─

Replacement of individual components is not allowed.

07/2012 12 51254 Rev. 3

Section 3: Operations

3.1. INTRODUCTION

Listed below are the options available for weighing.

• Gross Weighing Only

• Gross-Tare-Net Weighing

• Gross Weighing or Gross-Tare-Net Weighing

• Inbound / Outbound Weighing

• Inbound / Outbound Weighing or Gross Weighing Only

• Inbound / Outbound Weighing or Gross-Tare-Net Weighing.

• Inbound / Outbound Weighing or Gross Weighing or Gross-Tare-Net

Weighing.

07/2012 13 51254 Rev. 3

Section 3: Operations

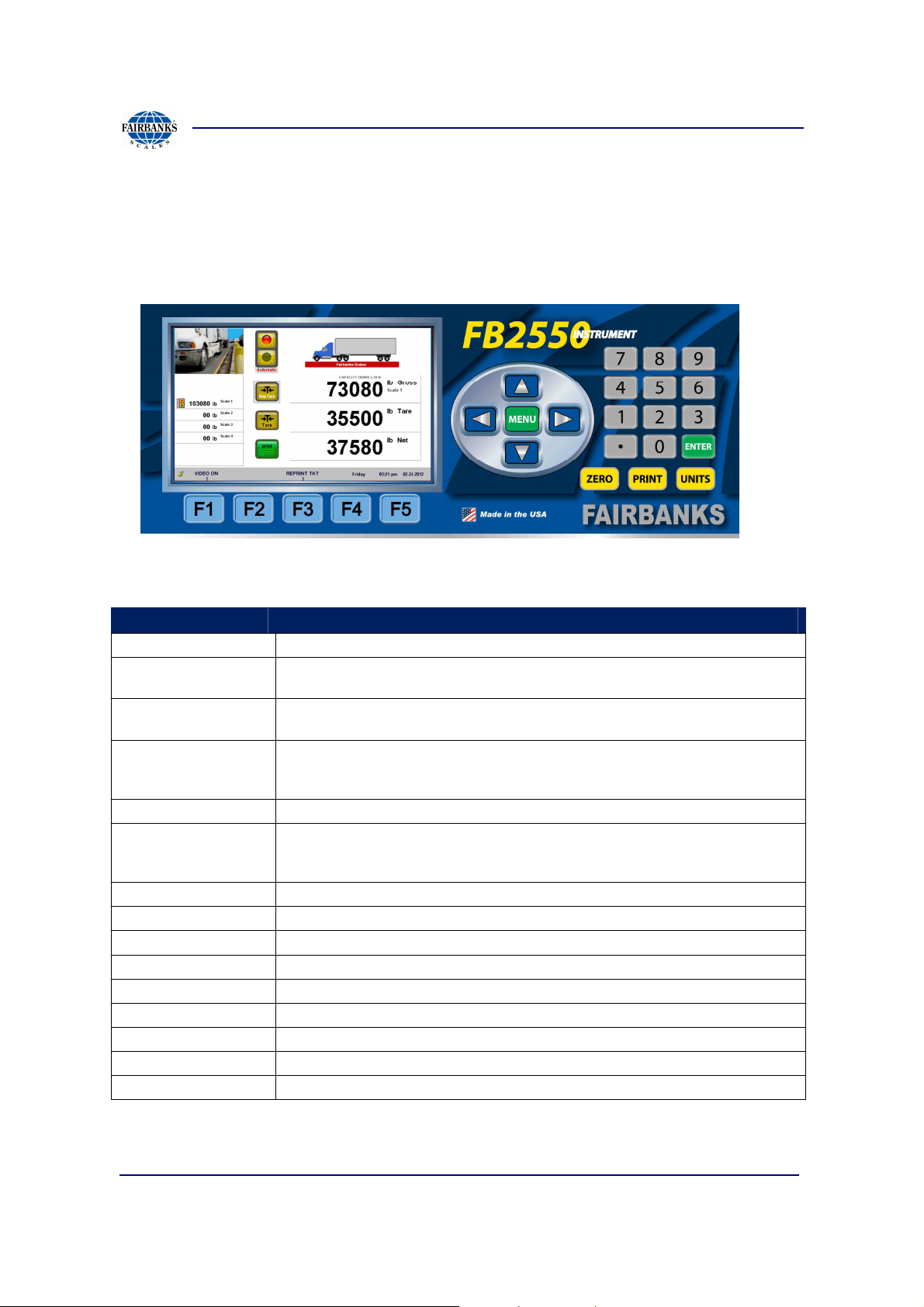

3.2. KEY FUNCTIONS

3.2.1. FRONT PANEL KEYPAD

Key(s) Function

0-9

F1

F2

F3

F4

F5

Enter

Zero

Units

Print

Menu

Up Arrow

Down Arrow

Left Arrow

Right Arrow

Used to enter numeric data such as tares and IDs.

Video On/ Video Off. This key will turn the camera image on or off if

cameras are enabled.

Expand image. This will enlarge the camera image to a full display image.

Pressing it again will return the image to its normal size.

Reprint Ticket. This key will permit the reprinting of a previously printed

ticket. This key will also function to pull up a list of items such as Loop,

Customer, or Product during the weighing process.

Void ticket(s). Available at the Initial Weigh Screen when scale is at Zero.

Power Off. This key turns the instrument off. The power cord must be

unplugged and plugged back in to power up the instrument. This key, while

in the configuration menu, performs a backup to the previous screen.

Will store or accept a data entry item.

Will Zero the scale

Will toggle the Units

Will initiate a print cycle.

Will open the Menu for the Configuration Home

Navigate up.

Navigate down.

Navigate left.

Navigate right.

07/2012 14 51254 Rev. 3

Section 3: Operations

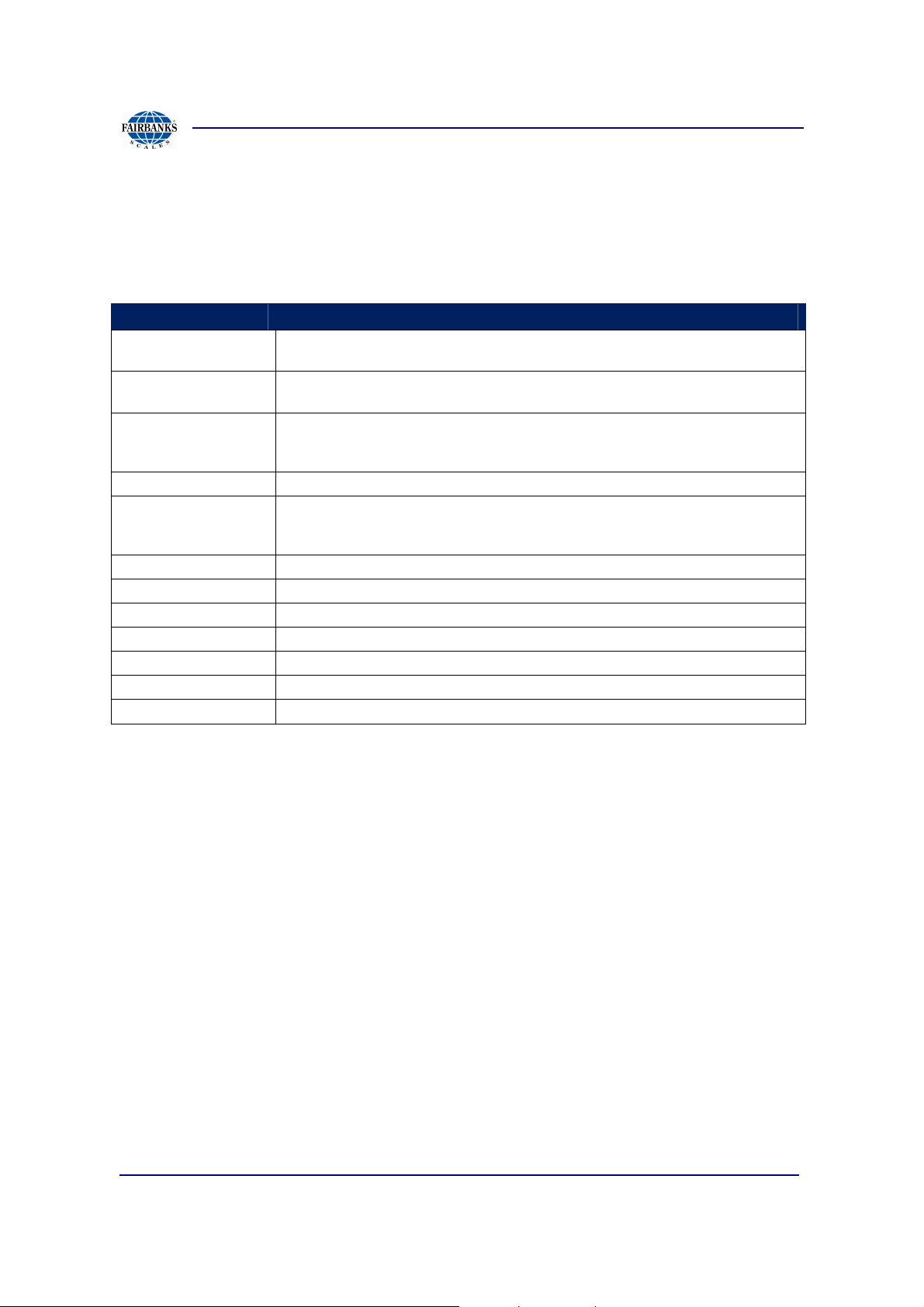

3.2. KEY FUNCTIONS, CONTINUED

3.2.2. EXTERNAL KEYBOARD

Key(s) Function

F1

F2

F3

F4

F5

Pause Break

Scroll Lock

PrtSc SysRq

Home

ESC

Ctrl + Shift + H

Alphanumeric keys

Video On/ Video Off. This key will turn the camera image on or off if

cameras are enabled.

Expand image. This will enlarge the camera image to a full display image.

Pressing it again will return the image to its normal size.

Reprint Ticket. This key will permit the reprinting of a previously printed

ticket. This key will also function to pull up a list of items such as Loop,

Customer, or Product during the weighing process.

Void ticket(s). Available at the Initial Weigh Screen when scale is at Zero.

Power Off. This key turns the instrument off. The power cord must be

unplugged and plugged back in to power up the instrument. This key, while

in the configuration menu, performs a backup to the previous screen.

Will Zero the scale

Will toggle the Units

Will initiate a print cycle.

Will open the Menu for the Configuration Home

Clear or restart, shrink or expand image

System Information

Used to enter various data. i.e. – truck id’s, products

07/2012 15 51254 Rev. 3

Section 3: Operations

C A U T I O N

3.3. PROPER SHUTDOWN PROCEDURE

FB2550 must be shut down properly!

Failure to shut down properly can result in corrupting essential

software files necessary for proper operation, and may require

The FB2550 Instrument is best shut down when

there is no weight on the scale. The instrument can

also be shut down when there is weight on the scale.

• When there is no weight on the scale, the

POWER OFF (F5)

replacement of the 8GB Flash Drive.

notification displays.

– There is no shut off notification for this.

• Whenever there is weight on the scale, the F5

button is still active, but hidden.

– A

Shut Off Warning

F5

is pushed and there is weight on the scale.

• The

POWER OFF (F5)

Service Programming is being completed.

1. Press the F5 key to begin the shut-down process.

2.

After proper shut-down is complete, ALWAYS unplug the

Instrument from AC power.

– Until the FB2550 is unplugged from AC power, it will continue to supply

operating voltage to the instrument circuits.

appears whenever

is inactive when any

07/2012 16 51254 Rev. 3

Section 3: Operations

DO NOT CONNECT OR DISCONNECT WIRING FROM SCALE

SVP/ Uninterruptible Power Supply (UPS) (

15892

), 500 VA Ra

ting

3.3. PROPER SHUTDOWN PROCEDURE, CONTINUED

A T T E N T I O N !

After proper shut-down is complete, ALWAYS

unplug the Instrument from AC power.

Until the FB2550 is unplugged from AC power,

the Instrument is still powered.

W A R N I N G !

COMPONENTS WHILE THE FB2550 IS ENERGIZED.

FAIRBANKS SCALES

STRONGLY RECOMMENDS USING A SUITABLY SIZED UPS.

07/2012 17 51254 Rev. 3

Section 3: Operations

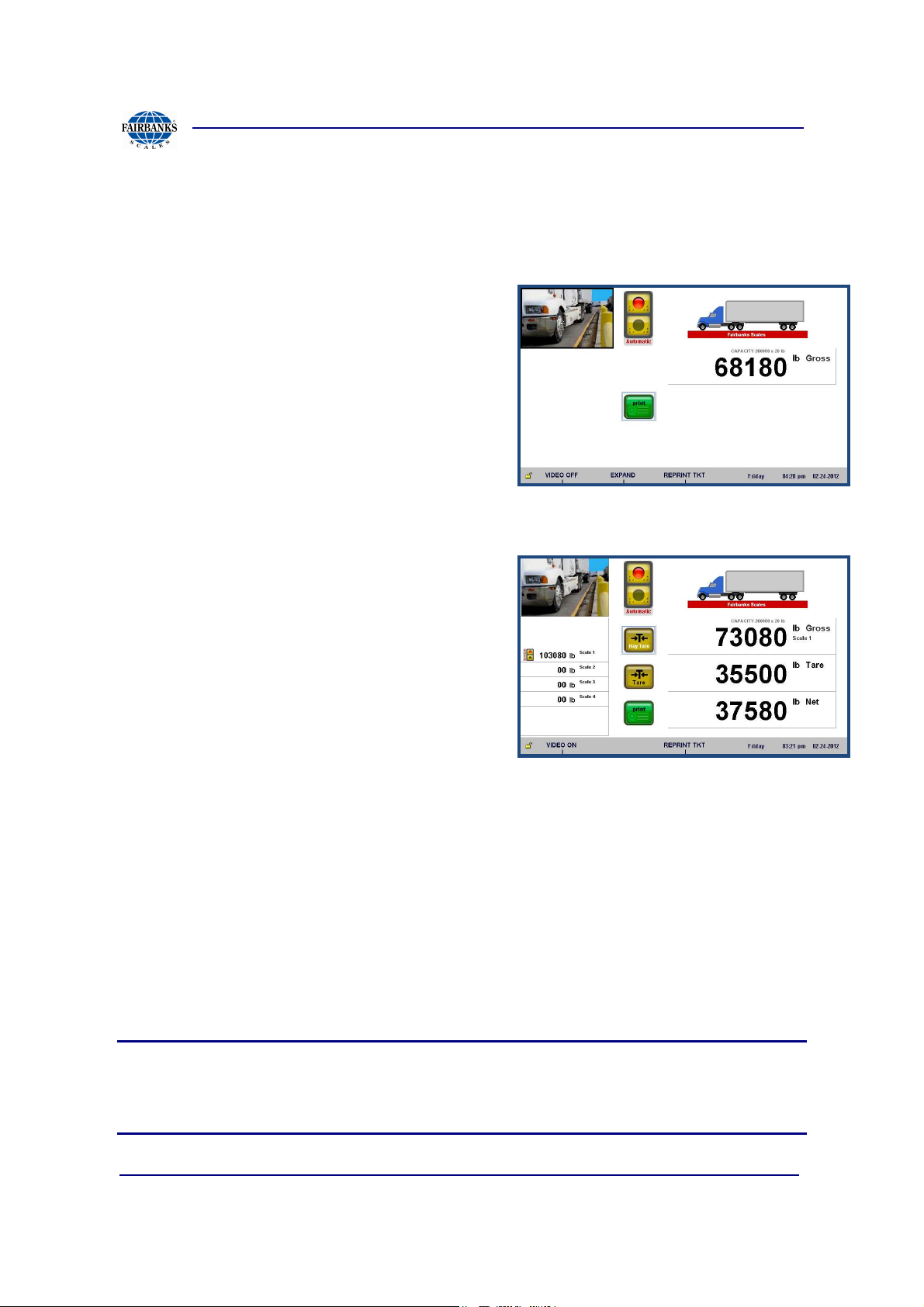

3.4. OPERATIONAL PROCEDURES

3.4.1. BASIC OPERATIONS SUMMARY

GROSS WEIGHING

1. Press the

2. Drive the vehicle to be weighed on

the platform.

3. Once the display stabilizes, press the

PRINT

– A Gross Weight ticket prints.

ZERO

key.

key.

GROSS-TARE-NET WEIGHING

1. Press the

2. Drive the vehicle to be weighed on

the platform.

a. Press either the

button.

b. If

KEY TARE

known Tare Weight on the keypad.

c. If

TARE

display is captured as a Tare Weight.

ZERO

is selected, enter the

is selected, the weight on the

key.

KEY TARE

or

TARE

3. Load the vehicle with product.

4. Press the

– Mode Change – When a

automatically switches from the Gross Weighing Mode to the Gross-Tare-

Net Mode.

5. To change the scale from the Gross-Tare-Net Mode back to the Gross

Weighing Mode, press

keypad.

NOTE:

Check the platform for equipment, debris, or other materials and remove them. If this

does not resolve the condition, call for service.

07/2012 18 51254 Rev. 3

If the display shows cell(s) failure, this indicates an error on the platform.

PRINT

key and a Gross-Tare-Net Ticket will be printed.

KEY TARE

KEY TARE

or

TARE

and enter a

button is pressed, the scale

zero (0)

from the

Section 3: Operations

3.4.1. BASIC OPERATIONS SUMMARY, CONTINUED

INBOUND/OUTBOUND WEIGHING

The INBOUND/OUTBOUND Mode follows

these steps.

1. With the indicator powered up, press

the

ZERO

2. Drive the vehicle onto the platform,

whether it is either full or empty.

key.

3. Press the

– The Indicator displays the LOOP ID

NUMBER on the screen, then also prints

it on the Transaction Ticket.

4. Drive off the scale and process the

trailer, by either filling up or emptying

it.

5. The same vehicle returns to the scale,

either full or empty.

6. Press the

7a. If it is known, enter the

ENTER

7b. If the Loop ID Number is not known, press the F3 key to open the full

INBOUND LIST.

.

OR

– The Inbound, Outbound and the Tare weighment amounts together make a

COMPLETE TRANSACTION

STORED TARE

is an

INCOMPLETE TRANSACTION

INBOUND

OUTBOUND

. An Inbound Weighment without an Outboud Weighment

key.

button.

LOOP ID Number

. Weighment of the empty vehicle is the

with the keypad, then press

.

– The list of Incomplete Transactions displays.

7. Select the correct

07/2012 19 51254 Rev. 3

LOOP ID

number.

Section 3: Operations

3.4.1. BASIC OPERATIONS SUMMARY, CONTINUED

If any input fields are empty, information can

be added from this window.

– An external keyboard is necessary to

edit these windows.

9. Place the cursor in the empty field,

then while in either the Customer

or Product field, press

the keyboard.

If a window box appears, indicating the value

entered does not currently exist follow steps

10-14 otherwise select

your entry.

ENTER

ENTER

to accept

on

10. To add it, select

11. Input the

SUPERVISOR

Service PASSWORD

prompted.

12. Click the

13. Input the correct information in fields.

14. Press the

EDIT

ENTER

YES

.

or

when

button to change Customer or Product input fields.

key.

07/2012 20 51254 Rev. 3

Section 3: Operations

3.4.1. BASIC OPERATIONS SUMMARY, CONTINUED

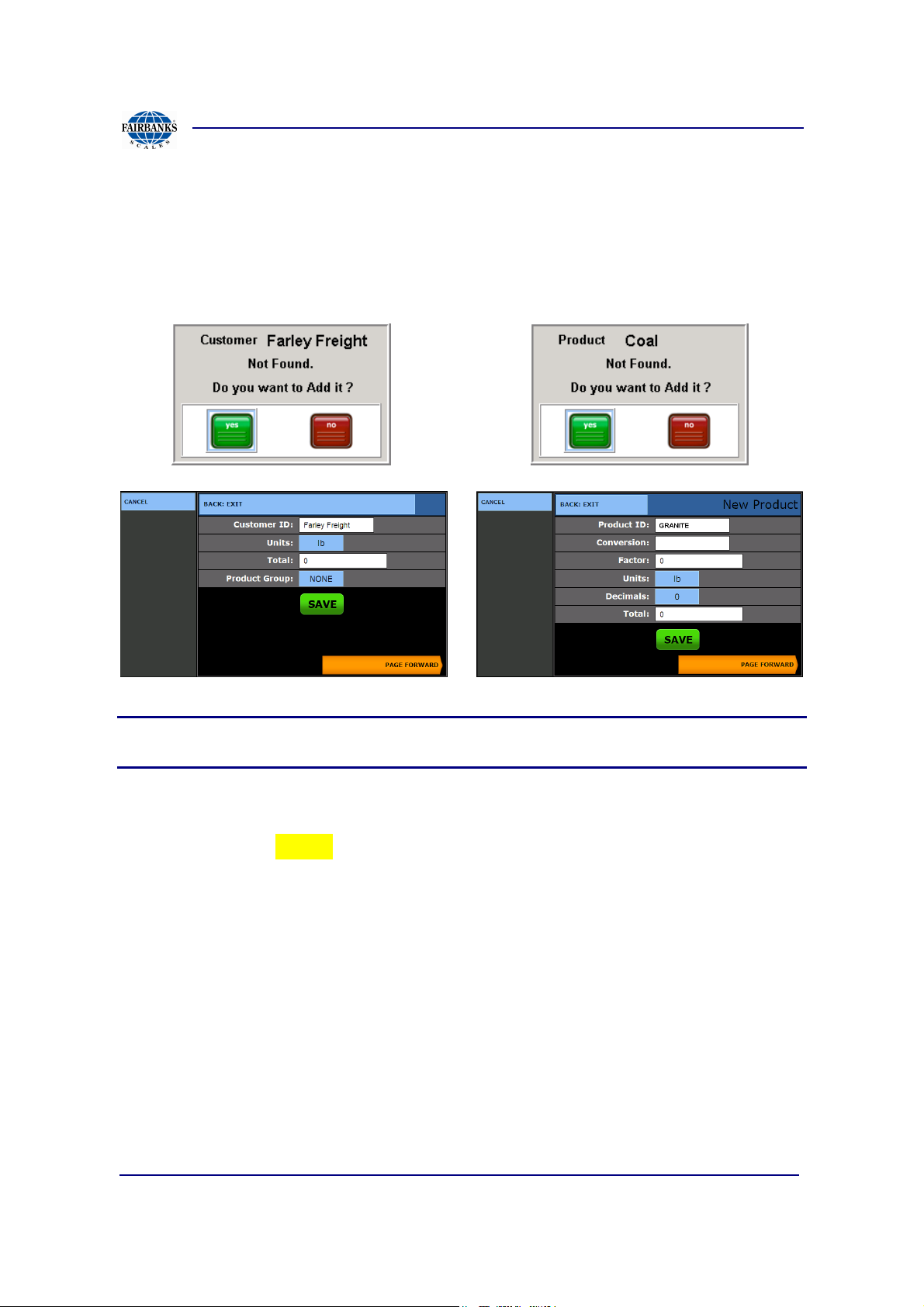

15. A pop-up message asks “Do you want to Add it?” [In the Instrument

database].

16. Click the

YES

button, and the editing window displays.

NOTE:

for complete details about how to set these up.

• Select

See

3.7. EDITING CUSTOMERS

17. Enter or edit any of the current information within these fields.

18. Click the

BACK: EXIT

19. Proceed with weighing

SAVE

button

to return to the Weight Window.

thru

3.8. EDITING PRODUCTS

07/2012 21 51254 Rev. 3

Section 3: Operations

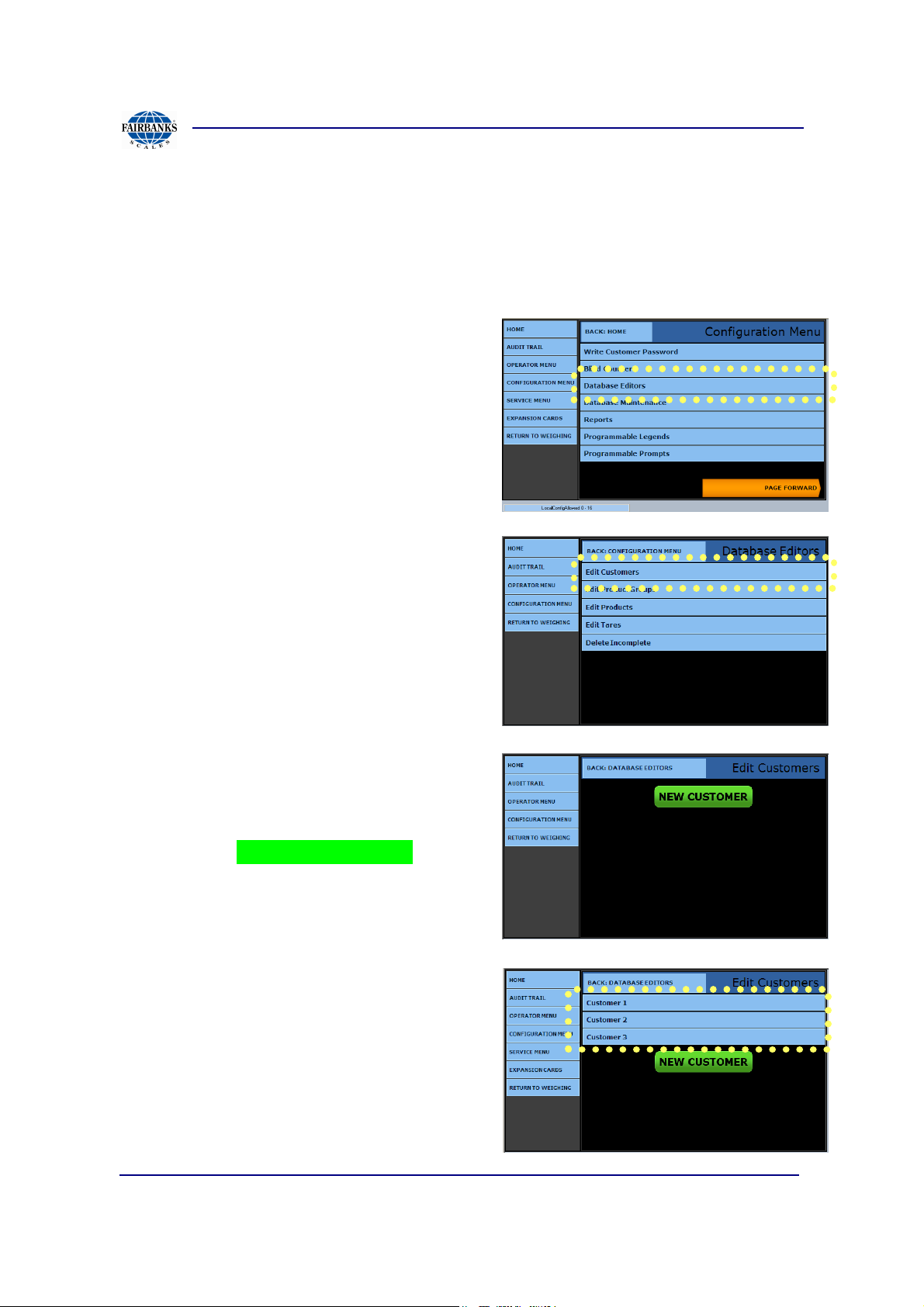

3.5. CONFIGURATION MENU

The FFB2550 Instrument Program provides an intuitive means for configuration and

programming.

Remote configuration of the instrument using a Network interface is also possible.

There are three levels of access: Standard Users, Supervisors, and Service

Technicians.

– No

– Supervisors and Service personnel must

HOME

AUDIT TRAIL

OPERATOR MENU

CONFIGURATION MENU

LOGIN

CONFIGURATION menu.

is required for standard Scale Operators.

Returns the operator to the Configuration Home page

Identifies how many times and when changes have

been made to the scale’s Calibration or Configuration

settings.

User access for Time/Date, Ticket Number, Load Cell

Diagnostics, and Keyboard Tare entries.

Supervisor access to communications programming and

functions, ticket formats, programmable legends and

prompts, camera inputs and weight threshold.

LOGIN

to gain access to the

RETURN TO WEIGHING

07/2012 22 51254 Rev. 3

Returns the user to the Weighing Display Screen.

Section 3: Operations

3.6. OPERATOR MENU

The

OPERATOR MENU

operations of the instrument.

– Allows access to change the time, date,

ticket number, and the formatting of the

time and date.

– Allows basic diagnostics of the load

cells in the scale(s), with beneficial

information for scale operations.

allows basic

Selecting

BACK: HOME

returns to the Configuration Home Menu.

3.6.1. TIME AND DATE FORMAT

1. Select

choices noted below.

• H:M • H:M:S

• HH:MM • HH:MM:SS

2. Open the

permits 12 hour or 24 hour format.

3. Touch the

then select best one for the

company’s needs.

4. Select one available

SEPERATOR

include(

TIME FORMAT

AM/PM

option, which

DATE FORMAT

DATE

formats

SPACE

),

/,

and

from the

, and

–.

5. Press the

they will be lost.

• Select

07/2012 23 51254 Rev. 3

BACK: OPERATOR MENU

SAVE CHANGES

button when any changes are made, or

to return to the Operator Menu.

Section 3: Operations

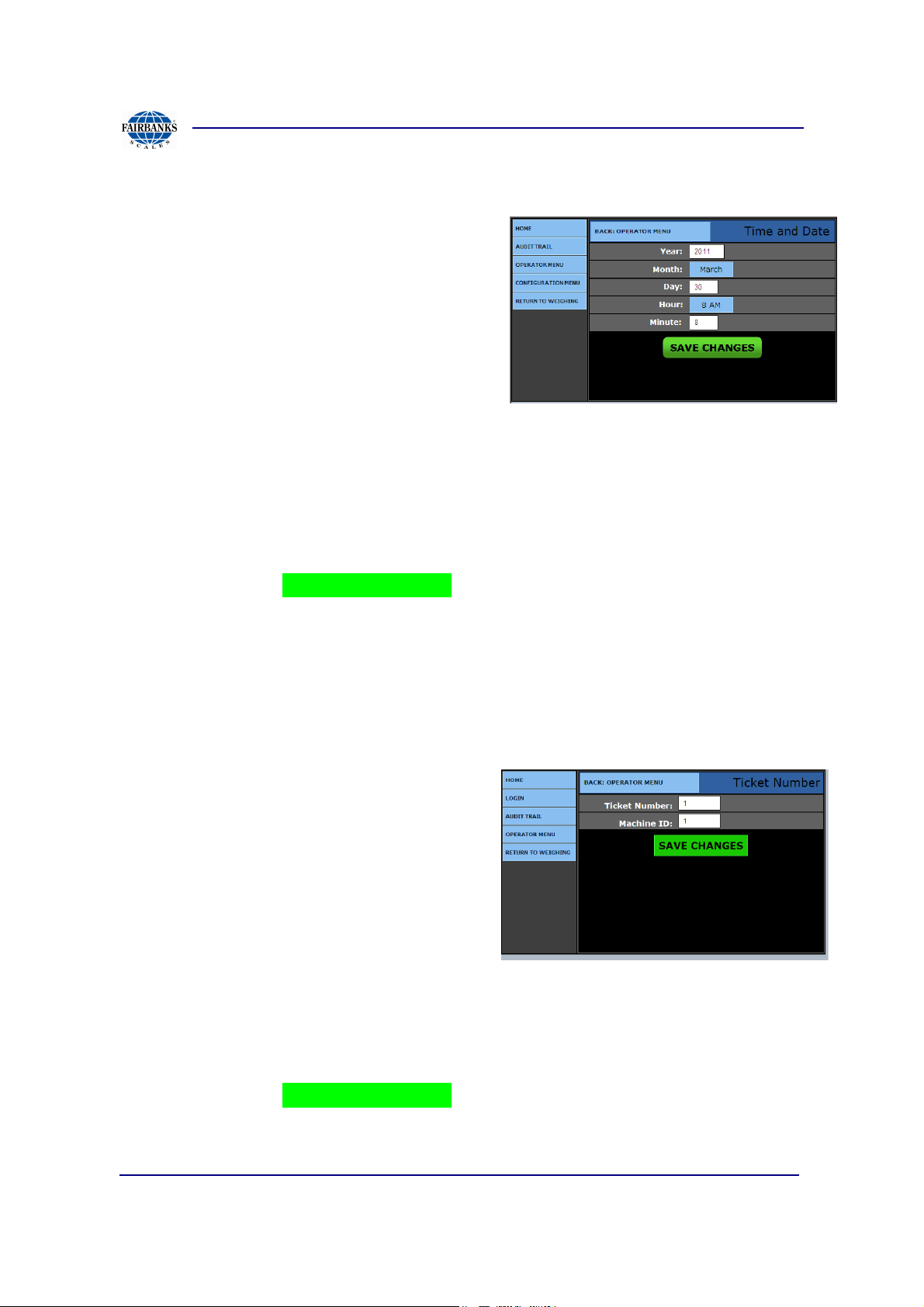

3.6.2. SET TIME AND DATE

1. Enter the

2. Enter the

3. Enter the

4. Enter the

5. Enter the

6. Press the

• Select

YEAR

the correct year into the box next to

the legend.

MONTH

the correct year into the box next to

the legend.

DAY

the correct year into the box next to

the legend.

HOUR

legend.

MINUTE

the legend.

SAVE CHANGES

they will be lost.

BACK: OPERATOR MENU

option by typing

option by typing

option by typing

option by typing the correct year into the box next to the

option by typing the correct year into the box next to

button when any changes are made, or

to return to the Operator Menu.

3.6.3. TICKET NUMBER

1. Enter the

typing the correct value into the box

next to the legend.

– Allows a maximum entry of six (6)

digits.

2. Enter the

the correct value into the box next

to the legend.

– This value is used for customer

identification purposes if required.

Default = 1

3. Press the

they will be lost.

TICKET NUMBER

MACHINE ID

SAVE CHANGES

by

by typing

button when any changes are made, or

07/2012 24 51254 Rev. 3

Section 3: Operations

• Select

BACK: OPERATOR MENU

to return to the Operator Menu.

07/2012 25 51254 Rev. 3

Section 3: Operations

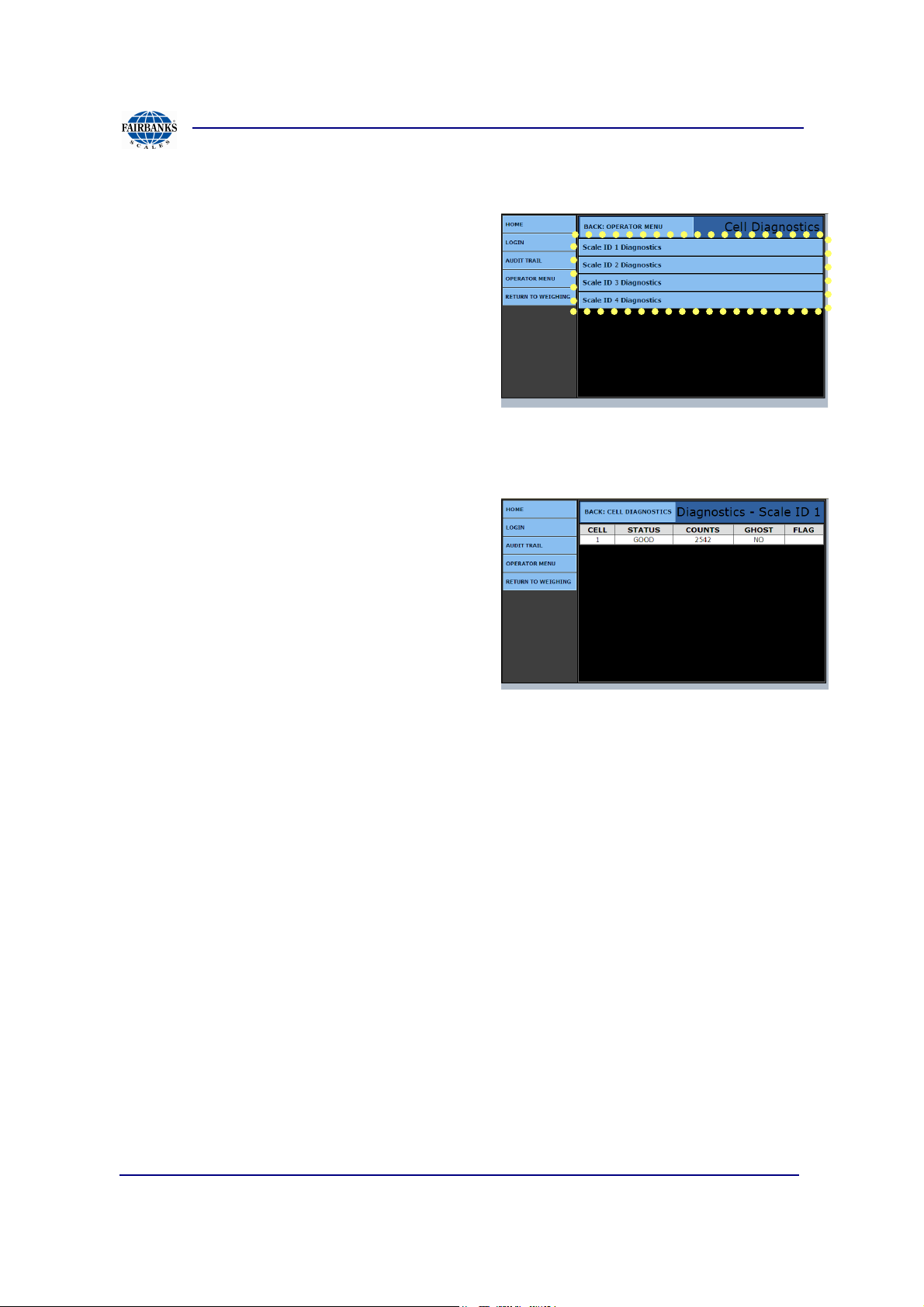

3.6.4. LOAD CELL DIAGNOSTICS

Instruments equipped with Intalogix®

technology have load cell diagnostics

features for easier troubleshooting

capabilities.

1. To view the diagnostic information,

select the correct scale.

• Select

return to the Operator Menu.

BACK: OPERATOR MENU

to

A. Scale ID x Diagnostics

The diagnostic screen gives a quick snapshot

of how each load cell is performing.

–

CELL:

scale platform.

–

STATUS:

output to stored calibration values and

posts a GOOD or BAD condition.

–

COUNTS:

current counts.

–

GHOST:

with an Intalogix™ Interface for load cell communications (preventing system

failure and/or shutdown).

Identifies the load cell in the

Compares the load cell

Displays the load cell’s

Ability to electronically “mimic” or duplicate a load cell if equipped

–

FLAG:

screen until flag is manually cleared This improves the ability to identify

intermittent issues.

• Select

Menu.

Visual flags “ * ” are used to identify problem load cell(s) on diagnostic

BACK: CELL DIAGNOSTICS

to return to the Cell Diagnostics

07/2012 26 51254 Rev. 3

Section 3: Operations

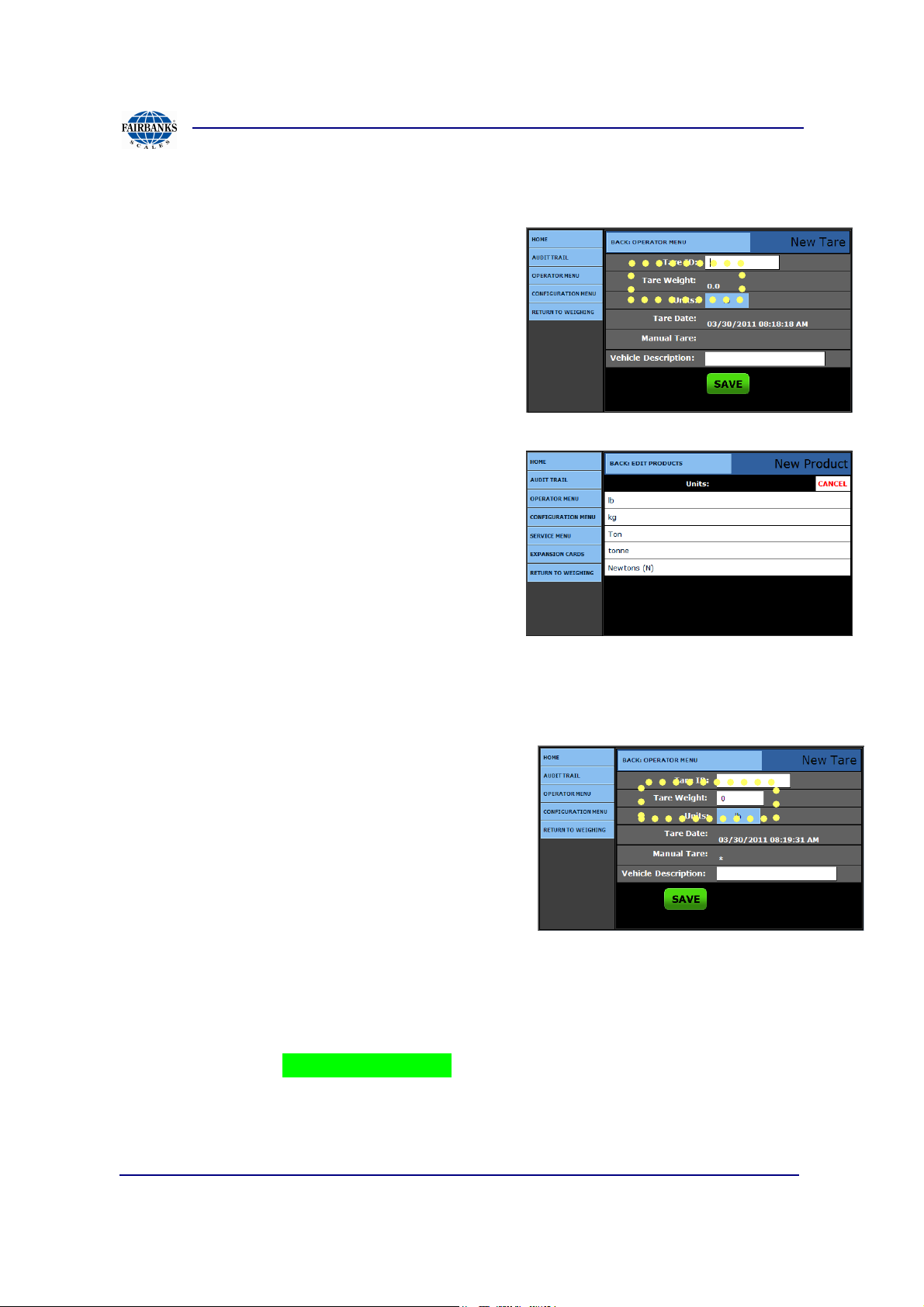

3.6.5. ENTERING A NEW TARE AUTOMATICALLY

1. Enter the

store and recall a tare weight saved.

– The Tare Weight value is either what is

currently on the scale, or was entered

previously.

– This value cannot be edited.

2. Select the correct

• A Tare Date generates automatically when

the Tare is entered.

• The Manual Tare option is not used in this

programming menu.

3. Enter the

DESCRIPTION

– This is a unique description or label for

the tare weight, and how it is associated.

TARE ID

numeric value to

UNITS value.

VEHICLE

.

3.6.6. ENTERING A NEW TARE USING A KEYBOARD

1. Enter a new

to save and recall the tare Weight.

2. Enter the

using the keyboard.

3. Select the

– The Tare Date records the date and time

the tare generates automatically.

– The Manual Tare is a flag designating the

tare is manually entered.

4. Enter the

– This is a unique description or label for the tare weight, and how it is

associated.

5. Press the

they will be lost.

• Select

BACK: OPERATOR MENU

TARE ID

TARE WEIGHT

UNITS

numeric value

manually

for the new Tare.

VEHICLE DESCRIPTION

SAVE CHANGES

button when any changes are made, or

to return to the Operator Menu.

.

07/2012 27 51254 Rev. 3

Section 3: Operations

3.7. EDIT CUSTOMERS

The FB2550 Instrument stores customer’s name and address, as well as information

used for reporting accumulated weights.

3.7.1. ADDING OR EDITING CUSTOMERS

1. Select

2. Enter the Supervisor Password or

Service Password.

3. Select the

MENU

4. Press

5. Select

The first time a customer will be entered, the

screen will appear as shown.

LOGIN.

CONFIGURATION

DATABASE EDITORS.

EDIT CUSTOMERS

.

6a. Press the

NEW CUSTOMER

button.

OR…

6b. Select the existing customer record

which needs editing or updating.

07/2012 28 51254 Rev. 3

Section 3: Operations

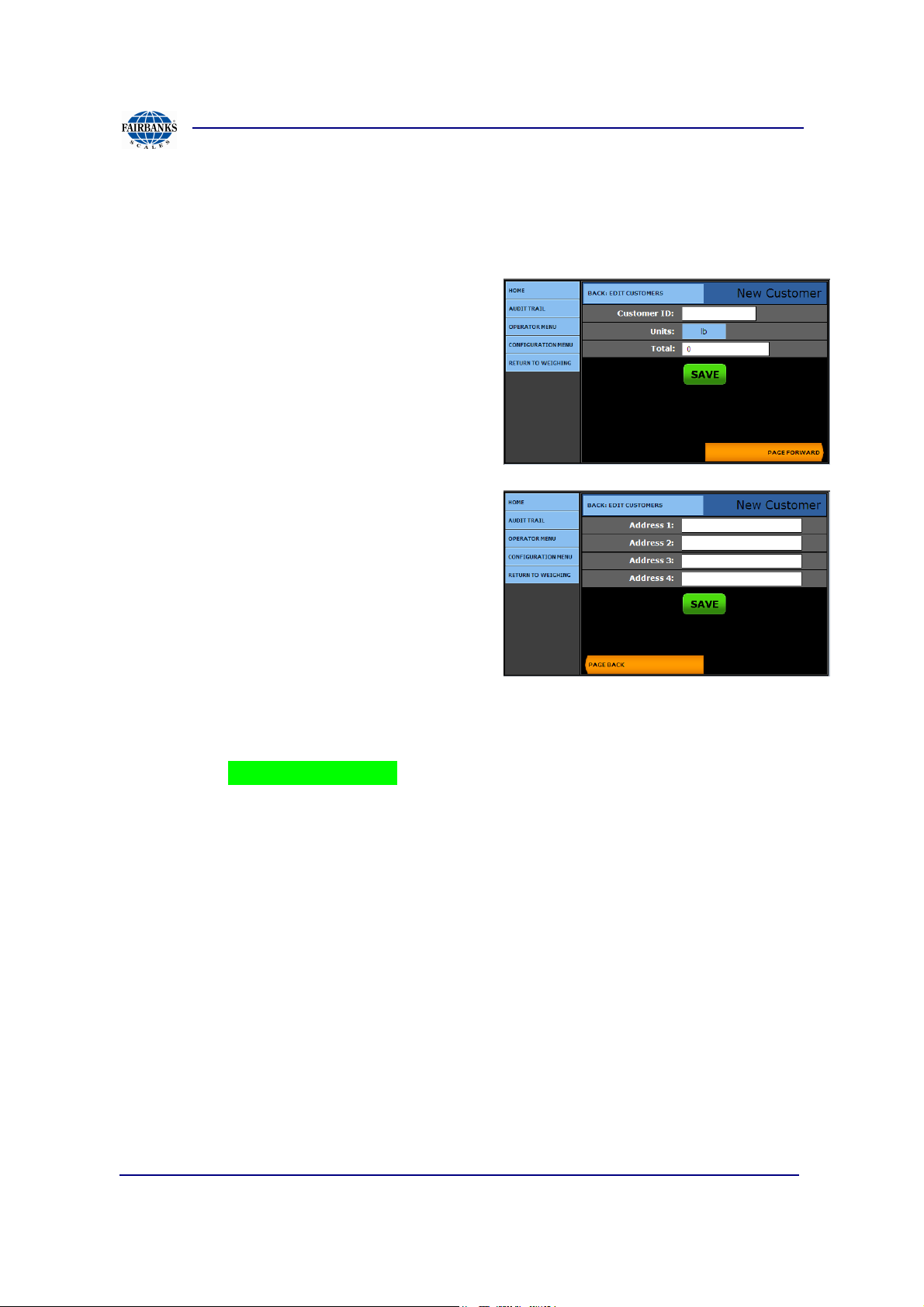

3.7.1. ADDING OR EDITING CUSTOMERS, CONTINUED

7. Enter the unique customer number in the

box.

– When selecting a preexisting

Customer, the Customer ID will

generate automatically.

• The

TOTAL

automatically populated and updated at

every weighment that uses the Customer

ID Value.

– This provides a running total of Net

weight for each customer.

8. Input any pertinent company

information in the

THRU 4

– Include customer names, addresses,

telephone numbers, fax numbers, and

point-of-contact names.

data entry box is

ADDRESS 1

data entry boxes.

CUSTOMER ID

data entry

• Press the

be lost. Select

Editors menu.

• Select

menu.

BACK: EDIT CUSTOMERS

SAVE CHANGES

button when any changes are made, or they will

BACK: DATABASE EDITORS

OR

to return to the the Edit Customers

to return to the Database

07/2012 29 51254 Rev. 3

Section 3: Operations

3.8. EDITING PRODUCTS

The FB2550 Instrument can store a great deal of information about products.

The product id, conversion factor, conversion factor units, and number of decimal

places are entered as information used for reporting such as accumulated weights.

This menu adds new product or edits existing product.

A Supervisor or Service level access is required to add or edit the products.

3.8.1. ADDING OR EDITING PRODUCTS

1. Select

2. Enter the Supervisor Password or

Service Password.

3. Select the

MENU.

4. Click on the

EDITORS

5. Select

LOGIN

.

CONFIGURATION

DATABASE

button.

EDIT PRODUCTS

.

07/2012 30 51254 Rev. 3

Loading...

Loading...