Page 1

7

4

PRINT

2

3

1

0

ENTER

8

9

5

6

NET

B/G

MENU

Operator Manual

FB2255 Series Instrument

PC2255

PC Software Utility Program

9

8

7

PRINT

6

4

5

2

1

3

ENTER

0

MENU

B/G

NET

2012-2013 by Fairbanks Scales, Inc.

All rights reserved

51297

Rev. 1 01/2013

Page 2

Page 3

Amendment Record

FB2255

Document 51297

Manufactured by Fairbanks Scales Inc.

821 Locust

Kansas City, Missouri 64106

Created 07/2012

Revision 1 01/2013

Disclaimer

Every effort has been made to provide complete and accurate information in this manual. However,

although this manual may include a specifically identified warranty notice for the product, Fairbanks

Scales makes no representations or warranties with respect to the contents of this manual, and

reserves the right to make changes to this manual without notice when and as improvements are

made.

It is the responsibility of the requesting party to develop, maintain, install, and connect networking

devices and general network connectivity as it applies to the originating party’s network. No warranty

or guarantee, expressed or implied, concerning the network, its design, its installation, or operational

characteristics has been offered by Fairbanks Scales. Fairbanks Scales shall not be liable for any

loss, damage, cost of repairs, incidental or consequential damages of any kind, whether or not based

on express or implied warranty, contract, negligence, or strict liability arising in connection with the

design, development, installation, or use of an intended network.

The Bluetooth® word mark and logos are owned by the Bluetooth SIG, Inc. and any use of such marks

by Fairbanks Scales is under license. Other trademarks and trade names are those of their respective

owners.

© Copyright 2012-2013

This document contains proprietary information protected by copyright. All rights are reserved; no part

of this manual may be reproduced, copied, translated or transmitted in any form or by any means

without prior written permission of the manufacturer.

01/13

3 51297 Rev. 1

Page 4

Table of Contents

SECTION 1: GENERAL INFORMATION ................................................................... 7

1.1.Model Descriptions ................................................................................................... 7

1.2.Main Product Features ............................................................................................. 7

1.3.Specifications ........................................................................................................... 8

1.3.1.Instrument Approvals ................................................................................................... 8

1.3.2.Basic Specifications ..................................................................................................... 8

1.3.3.Standard Settings......................................................................................................... 9

1.3.4.Weight Accumulator ..................................................................................................... 9

1.3.5.Outputs ........................................................................................................................ 9

1.3.6.PC2255 ........................................................................................................................ 9

1.3.7.Power Requirements .................................................................................................... 9

1.3.8.DC Models ................................................................................................................. 10

1.3.9.Out of Range Warnings .............................................................................................. 10

1.3.10.External Printers ........................................................................................................ 10

1.3.11.Environment ............................................................................................................... 10

1.4.Accessories ............................................................................................................ 11

1.5.AC Operation .......................................................................................................... 12

1.6.Powering up the FB2255 ........................................................................................ 12

SECTION 2: USER OPERATIONS ......................................................................... 13

2.1.Front Panel Key Functions ...................................................................................... 13

2.2.Front Panel Programming Parameters .................................................................... 14

2.2.1.Setting the Time ......................................................................................................... 14

2.2.2.Setting the Date ......................................................................................................... 14

2.2.3.Checking Power Supply / Battery Voltage ................................................................... 15

2.2.4.Programming the Sleep Function ............................................................................... 15

2.3.Operating Procedures ............................................................................................ 15

2.4.Gross, Tare and Net Weight ................................................................................... 16

2.5.Basic Weighing ....................................................................................................... 16

2.6.Gross Weighing ...................................................................................................... 17

2.7.Net Weighing .......................................................................................................... 17

2.8.Gross/Tare/Net Weighing ....................................................................................... 17

2.9.Weight Accumulation .............................................................................................. 18

2.10.Number of Accumulations ...................................................................................... 18

2.11.Clearing the Accumulators ...................................................................................... 18

2.12.Piece Counting ....................................................................................................... 19

2.13.Piece Count and Total ............................................................................................ 20

2.14.Peak Weight ........................................................................................................... 21

SECTION 3: SERIAL COMMUNICATION WIRING ................................................. 22

3.1.JP3 Jumper Configuration) ..................................................................................... 22

3.2.TB4 Wiring connections, COM1 (A), COM2 (B), and COM2 (C) ............................. 23

3.3.TB5 Remote Switch Inputs ..................................................................................... 23

3.4. Remote Display Active Keys .................................................................................. 24

01/13

4 51297 Rev. 1

Page 5

Table of Contents

SECTION 4: INPUT / OUTPUT ................................................................................ 25

4.1.3550 Tape Printer ................................................................................................... 25

4.2.Okidata 186 T Form Printer .................................................................................... 25

4.3.Okidata 420 Form Printer........................................................................................ 30

4.4.TM-U295 Ticket Printer ........................................................................................... 33

4.5.TM-U590 Ticket Printer ........................................................................................... 33

4.6.Remote Display ...................................................................................................... 34

4.6.1.Programming the 4-20mA Analog Output mode .......................................................... 35

4.6.2.Programming the 4mA Weight Value .......................................................................... 35

4.6.3.Programming the 20mA Weight Value ........................................................................ 35

SECTION 5: FIELDBUS/BLUETOOTH ................................................................... 36

5.1.Fieldbus Installation ................................................................................................ 36

5.2.Fieldbus Connections ............................................................................................. 37

5.2.1.Overview of Terms ..................................................................................................... 37

5.2.2.DeviceNet (29578) ..................................................................................................... 39

5.2.3.ControlNet (31979) ..................................................................................................... 41

5.2.4.Profibus (29576) ........................................................................................................ 43

5.2.5.Ethernet / IP Diagnostic LEDs .................................................................................... 45

5.3.Bluetooth® Technology Device ................................................................................ 46

SECTION 6: PC2255 UTILITY SOFTWARE ........................................................... 49

6.1.Introduction ............................................................................................................. 49

6.2.Communication Settings ......................................................................................... 49

6.3.Communication Files .............................................................................................. 51

6.4.Menu Bar ................................................................................................................ 51

6.5.Configuration .......................................................................................................... 53

6.6.Calibration .............................................................................................................. 54

6.7.Fieldbus / 4-20 mA .................................................................................................. 54

6.8.Custom Output – Settings ....................................................................................... 58

6.9. Custom Output – Load ............................................................................................. 58

6.10.Custom Output – Build ............................................................................................ 59

6.11.Custom Output – Tokens ........................................................................................ 60

6.12. Custom Output – Weights ...................................................................................... 61

6.13.Formatting Tickets .................................................................................................. 62

6.14.Printed Examples.................................................................................................... 63

SECTION 7: SERVICE AND MAINTENANCE ........................................................ 64

7.1. Troubleshooting the Instrument ................................................................................ 64

7.2.Battery Installation .................................................................................................. 64

01/13

5 51297 Rev. 1

Page 6

Table of Contents

APPENDIX I: DATA OUTPUT FORMATS ............................................................... 65

A.General Notes ........................................................................................................ 65

B.Fairbanks/ Toledo Continuous Output ..................................................................... 65

C.Cardinal 738 Continuous Scoreboard Output .......................................................... 68

D.Weightronics WI-120 Continuous Output ................................................................ 68

E.Condec Continuous Output ..................................................................................... 69

F.Demand Output ...................................................................................................... 69

G.Continuous Output .................................................................................................. 70

H.PLC ........................................................................................................................ 71

I.

UPS ........................................................................................................................ 72

J.P Ship ..................................................................................................................... 73

APPENDIX II: REMOTE PC COMMANDS ............................................................... 75

APPENDIX III: FB2255 REMOTE DISPLAY WIRING .............................................. 77

APPENDIX VI: FB2255 REMOTE DISPLAY ACTIVE KEYS ................................... 78

01/13

6 51297 Rev. 1

Page 7

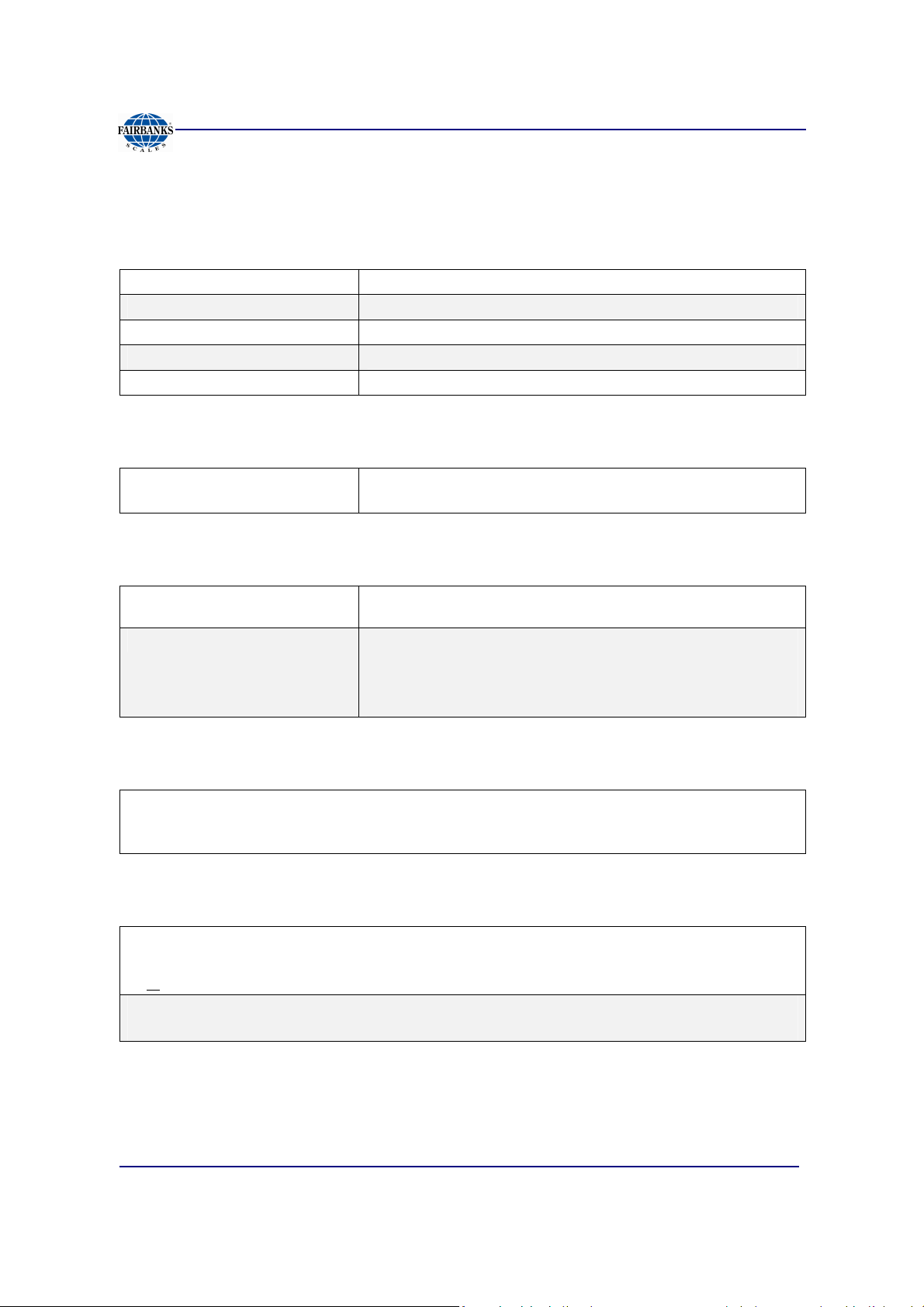

Section 1: General Information

1.1. Model Descriptions

The FB2255 is a general purpose weighing instrument that can be used with a wide

variety of platforms and load receivers, and is available in eight (8) different

configurations.

MODEL PART NO.

• FB2255-1 Series ABS, AC Power

• FB2255 Series ABS, AC/Battery Power with Bracket

• FB2255-2 Series SS, AC Power

• FB2255 Series SS, AC/Battery Power with Bracket

• FB2255 Series SS, AC Power, No Bracket

• FB2255 Series SS, AC/Battery Power, No Bracket

• FB2255 Series SS, AC Power, No Bracket, IP69K

• FB2255-K Series SS, AC Power, IP69K

32351

32449

32352

32450

32451

32452

32453

32352

1.2. Main Product Features

Major features of the Instrument include the following.

• Push-button programming and calibration.

• Program data is stored in battery supported ram and backed up in flash memory.

– The battery should be replaced every twelve (12) months.

• The FB2255 series instrument features a large one inch (1”) green backlit LCD

weight display, which can be tilted up or down to accommodate different lighting

conditions.

– Microprocessor controlled design allows the instrument to be rapidly

programmed at installation to meet the specific requirements of the

application.

• The obtainable accuracy meets Handbook 44 requirements, and the instrument is

approved for commercial application up to 10,000 divisions.

– A maximum of 100,000 displayed divisions can be programmed for non-

commercial applications.

• A computer utility software program PC2255 is available, downloaded from

Fairbanks Intranet for programming using the computer, and is required for

certain features such as custom ticket formatting.

01/13

7 51297 Rev. 1

Page 8

Section 1: General Information

1.2. Main Product Features, Continued

• The PC2255 software utility program can also upload and modify the instruments

set-up, configuration, and calibration.

– Saved information can be downloaded from a computer to the FB2255 Series

in the event of a catastrophic failure.

• The instrument provides two (2) serial communication ports to provide

communication to various types of peripheral devices for RS232, RS422, RS485,

and 20mA data outputs.

• Optional accessories include a 4-20 mA Analog Output, a Bluetooth® serial

adapter, and three different fieldbus devices; Profibus®, DeviceNet™, and

Ethernet/IP.

1.3. Specifications

1.3.1. INSTRUMENT APPROVALS

• CC

• MC

• ETL

• Conforms to ANSI/UL STD 60950-1

• Certified to CAN/CSA C22.2 STD NO. 60950-1-03

09-023

AM-5720

ETL Listed

1.3.2. BASIC SPECIFICATIONS

• ENCLOSURE

• DISPLAY

• FRONT PANEL KEYS

• UNITS

• GRADUATION SIZE

• AD CONVERSION

• LOAD CELL EXCITATION

• SENSITIVITY

• LOAD CELLS

• DISPLAYED DIVISIONS

• CAPACITIES

ABS, Black NEMA 1, Stainless Steel NEMA 4X Desk and Wall

Mount

6-digits, One inch (1”) LCD, Green Backlight

On/Off, Units, Zero, B/G, Net, Tare and Print

lbs., oz, kg, g and lbs/oz, or custom

0.0001 to 50

66 per second

5 Volts DC

1µv/d (microvolt/division)

Eight (8) 350 ohm or Sixteen (16) 1000 ohm

10,000d Commercial and 100,000d Non-Commercial

Programmable to 999999

01/13

8 51297 Rev. 1

Page 9

Section 1: General Information

1.3. Specifications, Continued

1.3.3. STANDARD SETTINGS

• Zero Range

• Auto Zero Tracking

• Balance

• Filter

• Display Update Rate

Off, 2 % or 100%

OFF, 0.5, 1 or 3 divisions

OFF, 0.5, 1 or 3 divisions

Slow, Animal, Standard, and Fast

0.2, 0.4, and 0.8 seconds

1.3.4. WEIGHT ACCUMULATOR

• Capacity

999,999 Weight Units

– Printed or viewed.

1.3.5. OUTPUTS

• PORT 1

• PORT 2

Bidirectional Serial Port. Settings include OFF, RS232, RS422,

and RS485. RS232 has 30+ updates a second

Port 2 is used to interface to the PC2255 program,

OR,

Provide 20 mA passive, RS232, RS422,or RS485.

1.3.6. PC2255

• Computer software utility program is available for your local Fairbanks Representative.

• PC2255 is required for setting certain aspects of programming, such as custom Units and custom

ticket formatting.

1.3.7. POWER REQUIREMENTS

• 117 volts AC +/- 10 %

• 220 volts AC +/- 10 %

• < 0/2 volts AC between Neutral and Ground

• 1.5 watts maximum

• The FB2255 is designed to operate from 80 to 260 volts AC, 50 to 60 Hertz

01/13

9 51297 Rev. 1

Page 10

Section 1: General Information

1.3. Specifications, Continued

1.3.8. DC MODELS

• Batteries

• Battery Life

• Internal Battery

Five (5) Size “D” Alkaline batteries @ 1.5 Volts DC each.

• Up to forty (40) Hours or greater with a maximum load of 4, 350 load

cells and backlighting enabled.

• Battery usage time can be adversely affected by battery storage,

battery capacity and battery brand.

• To maximize battery life, Serial Ports 1 and 2 should be switched

OFF, if not used.

• Should be replaced every 12 months using Panasonic CR 1220 3V or

equivalent.

1.3.9. OUT OF RANGE WARNINGS

• HiCAP

• - - - - - - -

• Sleep Mode

• Time and Date

Scale input is over capacity

Displayed weight exceeds 6 digits

Settings include OFF, 1, 2, 5, 10, 20, and 30 minutes

Battery Maintained

1.3.10. EXTERNAL PRINTERS

• Citizens IDP 3550 Tape Printer

• Okidata 184 & 186 Serial Form Printer

• Okidata 420 Serial Form Printer

• Epson Models TM-U295 and TM-U590 Ticket Printers

1.3.11. ENVIRONMENT

• Temperature

• Storage Temp.

01/13

-10ºC to + 40ºC (+14ºF to + 104ºF)

-40ºC to + 60ºC (-40ºF to + 140ºF)

10 51297 Rev. 1

Page 11

Section 1: General Information

1.4. Accessories

Optional accessories include the following.

FIELDBUS DEVICES

• DeviceNet™ • ControlNet™ • Profibus® • Ethernet/IP

4-20 MA ANALOG CURRENT LOOP OUTPUT

• 16 bit Resolution and Monotonicity • 0.01% Non-Linearity

• Isolated 4mA to 20mA

BLUETOOTH® TECHNOLOGY INTERFACE

• Utilizes either Port 1 or Port 2 Serial Output. RS232 serial Interface to Bluetooth Interface. Range

100 meters (328 feet).

• The Bluetooth option will operate either as a Client or Server depending on which device the

FB2255 is connected.

– If connected to a printer, the FB2255 will be a Server.

– If connected to a PC, the Instrument will be a Client.

• Front Panel Programmable or via PC2255 utility

software program

01/13

11 51297 Rev. 1

Page 12

Section 1: General Information

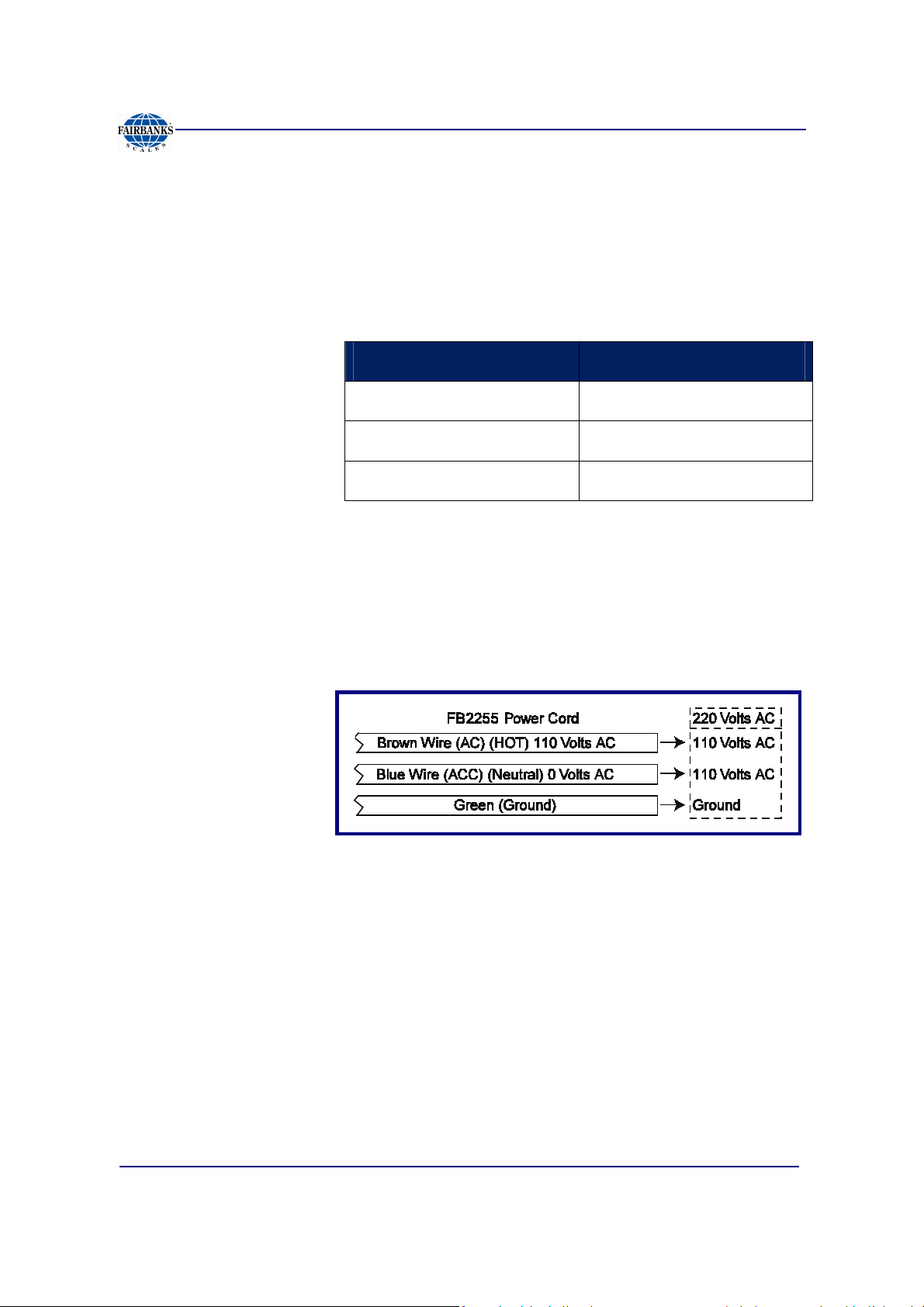

1.5. AC Operation

The FB2255 is designed to operate from 80 to 260 volts AC, 50 to 60 Hertz.

• 117 Volt AC Operation

• FB2255 is factory wired for 117 VAC and requires a three prong grounded outlet.

FB2255 ABS Power Cord Connection

• 220 Volt AC Operation

The FB2255 has Auto Switching capability.

• Rewire the power cord according to the following diagram.

•

Brown/Black AC (Hot) 117 VAC

Blue/White ACC (Neutral) 0 VAC

Green/Green-Yellow Ground

1.6. Powering up the FB2255

1. Press and hold the ON / OFF Key for one to two (1 – 2) seconds.

– The Instrument will display “888888”, then a “1234567890” character display

moving from right to left, followed by the revision of software.

– Upon completing the warm-up, the FB2255 will display the actual weight on

the scale.

2. Press and hold the ON / OFF Key for one to two (1 – 2) seconds to turn off the

FB2255.

01/13

12 51297 Rev. 1

Page 13

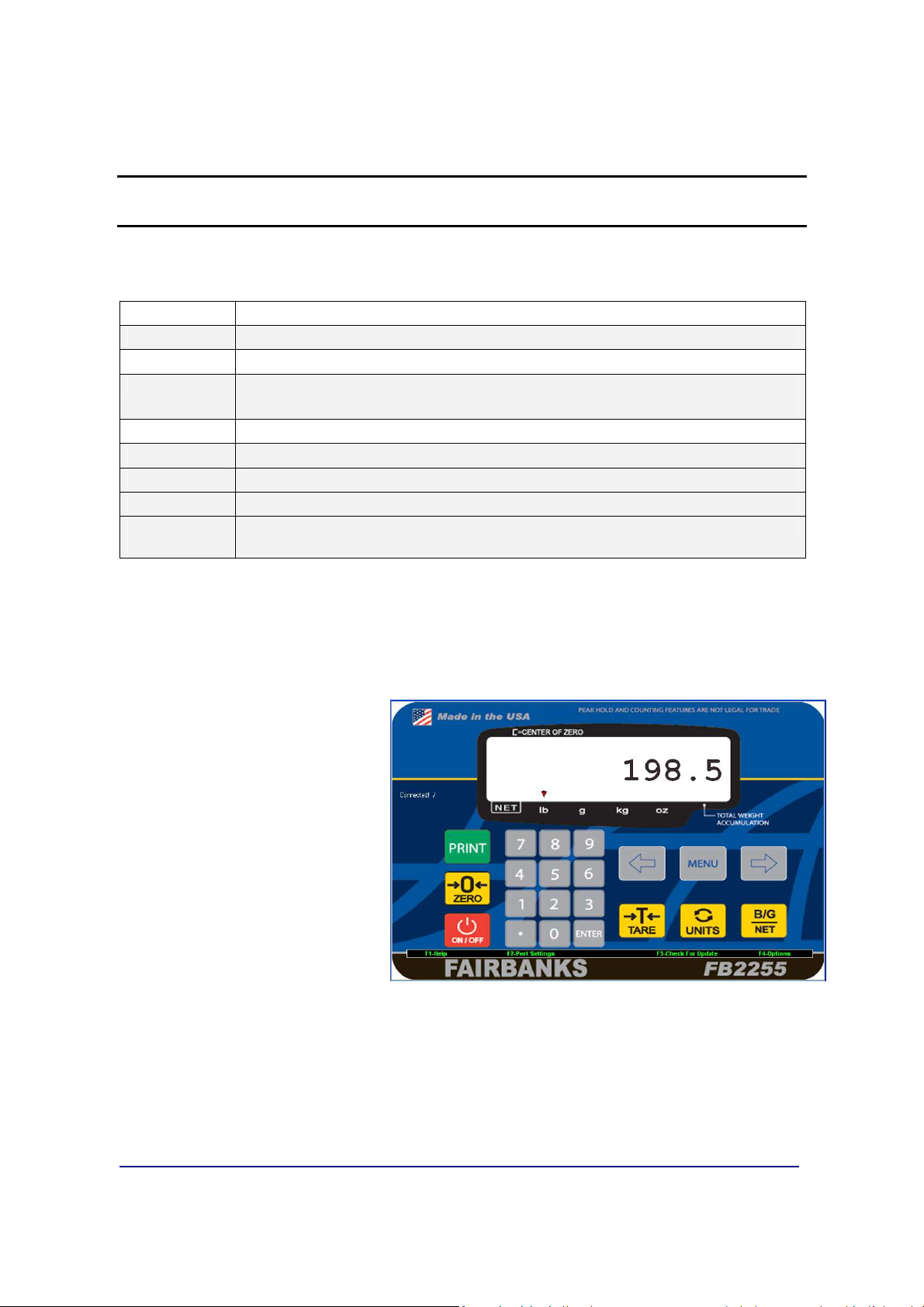

Section 2: User Operations

2.1. Front Panel Key Functions

ON/OFF

UNITS

ZERO

B/G – NET

TARE

PRINT

0-9

MENU Gains access to the sub-menus in the Configuration Mode.

ARROW

KEYS

Turns the Instrument on or off.

Switches between pre-programmed selectable weight units.

Sets the display to zero, programmable: 2% or 100% of capacity.

Toggles between Gross and Net weights

• This apples only if a Tare Value has been entered greater than ZERO.

Automatically tares off displayed weight when key is pressed.

Simple RS232 output when key is pressed.

Used for Programming and inputting manual tares.

Used for scrolling through the menu selections.

Depending on programmed selection, Tare Weight amount will do one of the

following.

• Be retained for reuse until changed, or if power is removed.

OR…

• Automatically clear when

Gross Weight returns to

ZERO

.

01/13

13 51297 Rev. 1

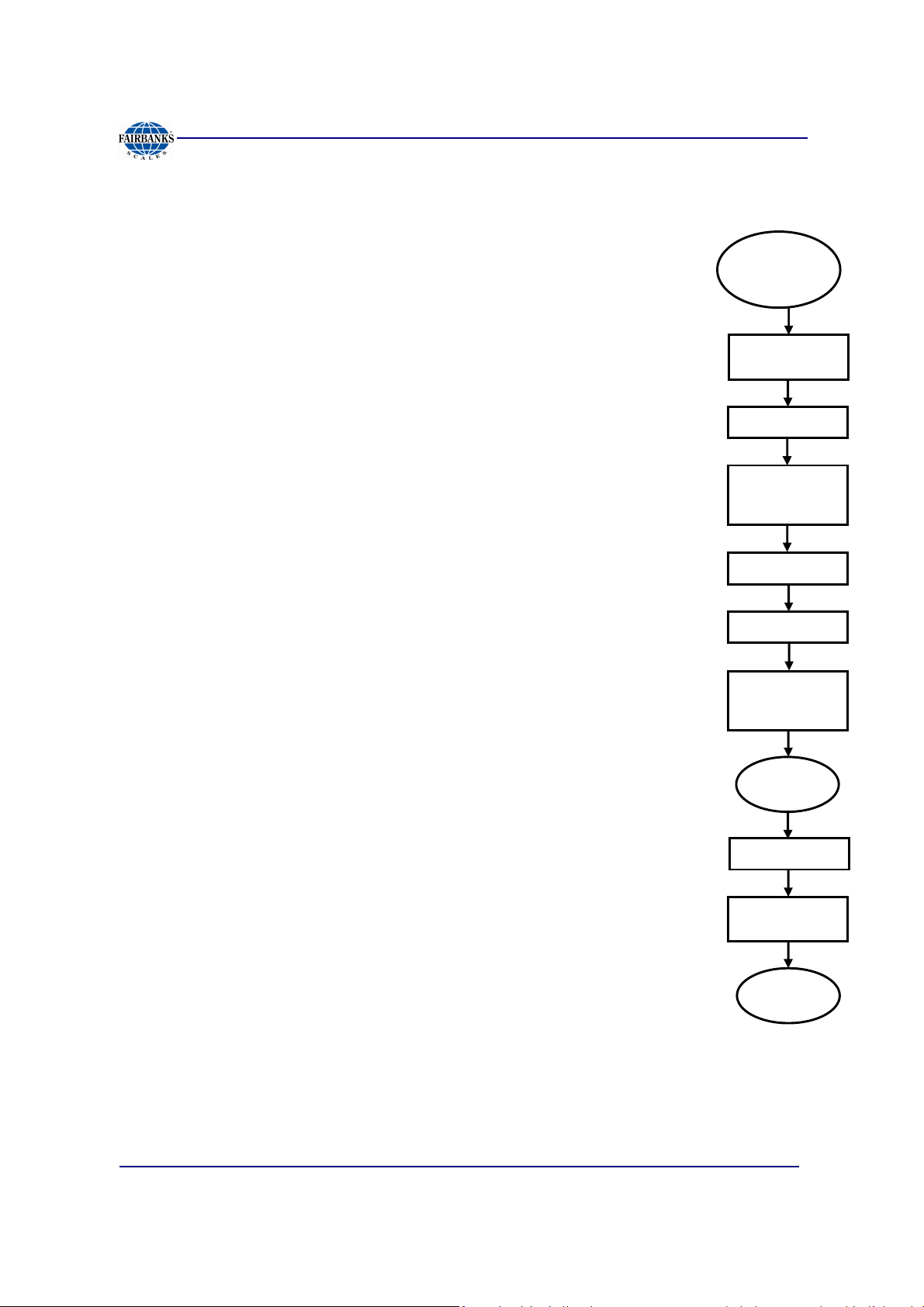

Page 14

Section 3: Serial Communication Wiring

3 seconds

AM, PM,

ARROW Keys

ENTER

RIGHT

Time

0-9 Keys

ENTER

Date

2.2. Front Panel Programming Parameters

Follow these steps to program the Instrument.

2.2.1. SETTING THE TIME

Press, hold

PRINT for

1. Press and hold the

– The display momentarily displays

time in

2. Press the

dA”,

and then back to Weigh Menu.

HHMMSS

RIGHT ARROW

PRINT

.

key for three (3) seconds.

Set-ti

key will scroll to

, then shows the current

“12hr A”, “Set-

3. When the current time setting is displayed, press the

– The most significant digit will erase.

4. Key the new time setting with the

5. Press

ENTER

.

6. At the “12hr A” prompt, press the

7. Use the

•

12hr A

•

12hr P

•

24 hour

ARROW KEYS

to toggle through the option noted below.

– 12 hour clock, currently AM.

– 12 hour clock, currently PM.

– Military time (1:00 PM = 1300 hours).

0-9

keys.

MENU

key.

MENU

key.

Press

ARROW

Press MENU

Enter

Press ENTER

Press MENU

Enter

Mil. Time with

with

8. Press

ENTER

to save the setting.

2.2.2. SETTING THE DATE

•

Set-dA displays

• Date is entered in the MM-DD-YY format.

1. Press

2. Key the new time setting with the

3. Press

01/13

Menu

– The first two digits will blink.

– The most significant digit will erase.

ENTER

, followed by the current date setting.

.

0-9

keys.

.

14 51297 Rev. 1

Press

Press MENU

Enter

0-9 Keys

Press

with

Page 15

Section 3: Serial Communication Wiring

2.2.3. CHECKING POWER SUPPLY / BATTERY VOLTAGE

1. Press the

– The battery current or power supply voltage displays

– 8.3 VDC nominal.

TARE

key for three (3) seconds.

2.2.4. PROGRAMMING THE SLEEP FUNCTION

1. Press and hold the

– The display will indicate

– This function serves to prolong battery life by turning off the Instrument.

– When there is no activity, the Sleep Mode activates according to the

programmed time frame.

– Activity is when weight is applied to the scale exceeding the balance setting,

pressing a key, and receiving a polling request on a communication port.

2. Press

3. Use the

MENU

Arrow Keys

– Selections in minutes include

.

BG/Net

key for three (3) seconds.

SLEEP

to toggle between the available options.

, and then display the current setting.

OFF, 1, 2, 5, 10, 20, 30.

4. Press

ENTER

to save the setting.

2.3. Operating Procedures

1. Press and hold the

– The Instrument will display “888888”, followed by “1234567890” character

display moving from right-to-left, then the revision of software.

– Once the warm-up is complete, the FB2255 displays the actual weight on the

scale.

2. To turn the FB2255 off, press the

• The Zero. Tare and the AZT functions require the displayed weight to be stable

before these functions will operate.

• The weight reading is stable if the variation in weight is less than the programmed

BAL RANGE

ON / OFF

.

Key for two (2) seconds.

ON / OFF

key for two (2) seconds.

01/13

15 51297 Rev. 1

Page 16

Section 3: Serial Communication Wiring

T

G

2.4. Gross, Tare and Net Weight

There are three terms used when weighing an object’s or

load’s amount.

The

NET WEIGHT

WEIGHT

(container only).

(total amount) minus the

NET WEIGHT

(product only) is the

GROSS

TARE WEIGHT

= Gross Weight – Tare Weight

WORKING EXAMPLE

A

R

E

NET

R

O

S

S

A full can of house paint is an object to be weighed. The empty can is the

weight. The paint is the

NET

2.5. Basic Weighing

Follow these steps for Basic Weighing.

1. Empty the platform.

2. Turn the scale

3. Press

– When the display indicates “0”, it is ready for use.

ZERO

.

ON

.

weight. Together they equal the

GROSS

TARE

weight.

01/13

16 51297 Rev. 1

Page 17

Section 3: Serial Communication Wiring

2.6. Gross Weighing

Follow these steps for Gross Weighing.

1. Press the

2. Press the

3. Place container/object on scale (Tare weight).

4. Read the Gross Weight on the display.

GROSS/NET

ZERO

key, if required, to set scale to “0”.

key, if required, to set display to GR (gross).

2.7. Net Weighing

Follow these steps for Net Weighing.

1. Press the

2. Press the

3. Place container/object on scale (Tare weight).

4. Press the

5. Place material in container or add objects (Net weight).

6. Read the Net Weight on the display.

GROSS/NET

ZERO

TARE

key, if required, to set scale to “0”.

key.

key, if required, to set display to GR (gross).

2.8. Gross/Tare/Net Weighing

1. Press the

2. Press the

3. Place container/object on scale, noting the weight.

4. Press

5. Place material in container or add objects.

6. Note the Net Weight on the display.

7. Press the

8. Read the Gross Weight on the display.

01/13

GROSS/NET

ZERO

TARE

.

GROSS/NET

key to display GR (Gross).

key, if required, to set scale to “0”.

key to switch to Gross.

17 51297 Rev. 1

Page 18

Section 3: Serial Communication Wiring

2.9. Weight Accumulation

1. Place a weight on the Scale Platform.

2. After the weight is stable, press the

between the number of Accumulations "n" and the Accumulated weight.

3. Press the

“ACCEPt”, or press the

4. The scale must return to “0” Gross Mode before another accumulation can

occur.

5. Repeat steps 1 through 4 for additional accumulations.

UNITS

key to accept the weight, (display will momentarily indicate

B/G NET

B/G NET

key to skip and return to the weigh screen.

key until the display alternates

2.10. Number of Accumulations

1. Press and hold

– The display will alternate between the Accumulated Piece Count and the

Accumulated Weight for thirty (30) seconds, then return to the Weigh

Mode.

2. Press

UNITS

– Pressing the

ZERO

and exit immediately to the Weigh Mode.

for three (3) seconds.

UNITS

key will not clear the accumulator.

2.11. Clearing the Accumulators

1. Press and hold the

– The display will indicate “Sleep” and then display the current setting.

2. Press

3. Press the

settings.

Available selections include the following settings.

Clr.YES

4. Press

01/13

Right Arrow

– “CLr.ACC” will display.

MENU

(Clear the Accumulator)

ENTER

BG/Net

key.

key, then the

to enter the selection.

key for three (3) seconds.

Right Arrow

key to toggle the available

CLr. NO

18 51297 Rev. 1

(Do not Clear the Accumulator)

Page 19

Section 3: Serial Communication Wiring

on Scale

TARE

Tare stored.

NET

UNITS

to Exit

2.12. Piece Counting

5. Place the empty weighing container on the Scale Platform.

6. Press

7. Press

8. Pressing the

"Add 1", "Add 5", "Add 10", "Add 25", Add 50", or "Add 100"

parts.

9. Add the required sample to the container, then press

10. Add the remaining parts to the container.

TARE.

– This stores the container weight the only, placing the scale

in the Net Mode.

– “0 Net Weight” should display on the indicator.

B/G NET

.

– The Display prompts to "Add" a number of sample parts to

the container.

B/G NET

key repeatedly prompt the user to;

– The Display alternates between indicating the weight and

the number of pieces.

UNITS

Place

Container

Press

. Scale in

MODE

Press B/G

Select sample

size

.

Add sample.

Press

– The display will update and continue to alternate between

the Weight and Number of Pieces, including the original

sample.

11. Press

– Pressing the

B/G NET

.

B/G NET

key will skip adding the Current

Piece to the Total Register and return to the Weigh Mode.

See the Print Example below.

NOTES:

The operating mode must be set to

If the prompts do not occur, clear the

PIECE COUNT & TOTAL

Accumulator

Add remaining

parts

Press

B/G NET

and start over.

to function.

01/13

19 51297 Rev. 1

Page 20

Section 3: Serial Communication Wiring

2.13. Piece Count and Total

This feature enables the FB2255 to count and display the Net Weight of the counted

items, and to display the total amount of those items.

1. Place the container on the scale platform.

2. Press

3. The Display should indicate

4. Press the

5. When the display prompts to "Add", add a number of sample parts to the

Container.

6. Press

10", "Add 25", Add 50", or "Add 100" parts.

7. Add the required sample to the container.

8. Add the remaining parts to the container.

9. Press

TARE

B/G NET

– The Display will alternate between the Weight and Number of Pieces,

including the original sample.

– The Display will update and continue to alternate between the Weight and

Number of Pieces, including the original sample.

B/G NET

– The Display will alternate between the "Total" legend and the Total Number

of Pieces Accumulated.

to calculate the container weight.

0 NET WEIGHT

B/G NET

key.

repeatedly until the display reads to; "Add 1", "Add 5", "Add

.

.

10. Press

NOTE:

The Operating Mode must be set to

To reset Piece Count – see “CLEARING THE ACCUMULATOR”.

01/13

UNITS

If the prompts do not occur, clear the

to return to the Weigh Mode.

ACCUMULATOR

Piece Count & Total

20 51297 Rev. 1

and start over.

to function.

Page 21

Section 3: Serial Communication Wiring

2.14. Peak Weight

The Peak Weight feature records the heaviest stable or unstable load t placed on the

scale, and its time and date.

1. Press and hold

– The display will alternate between the Peak Weight Value, the time and date

for thirty (30) seconds, then return to the Weigh Mode.

2. Press

• Conditional upon programming the Operating Mode to

UNITS

– Pressing the

PIECE COUNT, OR PIECE COUNT

• The FB2255 will display total number of Pieces, Weight, and Time-out [thirty

(30) seconds].

• Conditional upon programming the Operating Mode to

STABLE

• The FB2255 will display Time, Date, Peak Weight, and Time Out [thirty (30)

seconds].

ZERO

to end the process. and exit to the Weigh Mode.

for three (3) seconds.

UNITS

key will not clear the accumulator.

ACCUMULATION,

and

TOTAL.

PEAK HOLD

or

PEAK HOLD UNSTABLE

.

01/13

21 51297 Rev. 1

Page 22

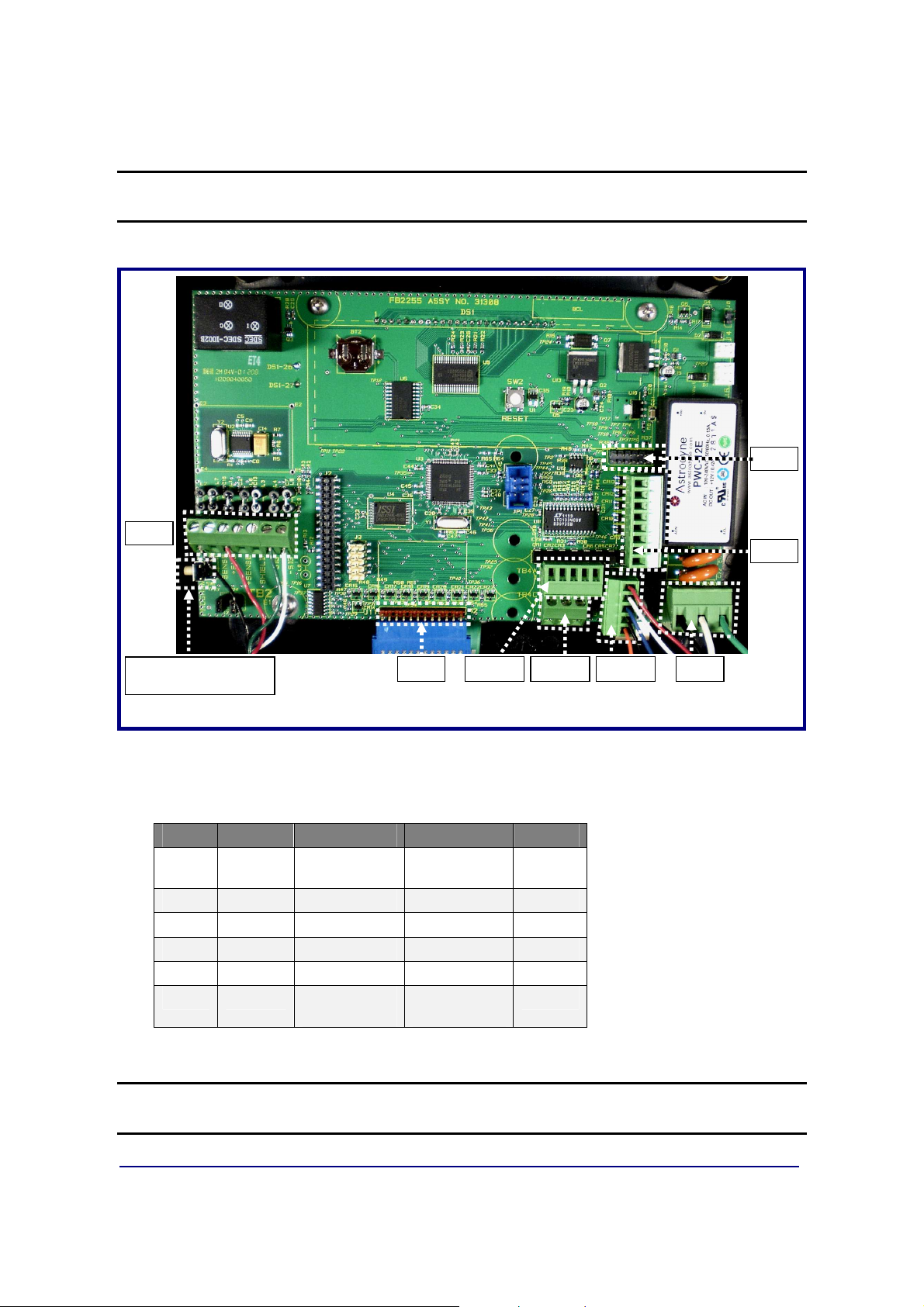

TB2

J11 TB4-A TB4-C TB4-B TB3

SWITCH

TB5

JP3

Section 3: Serial Communication Wiring

INTERNAL PROGRAM

Printed Circuit Board (31308)

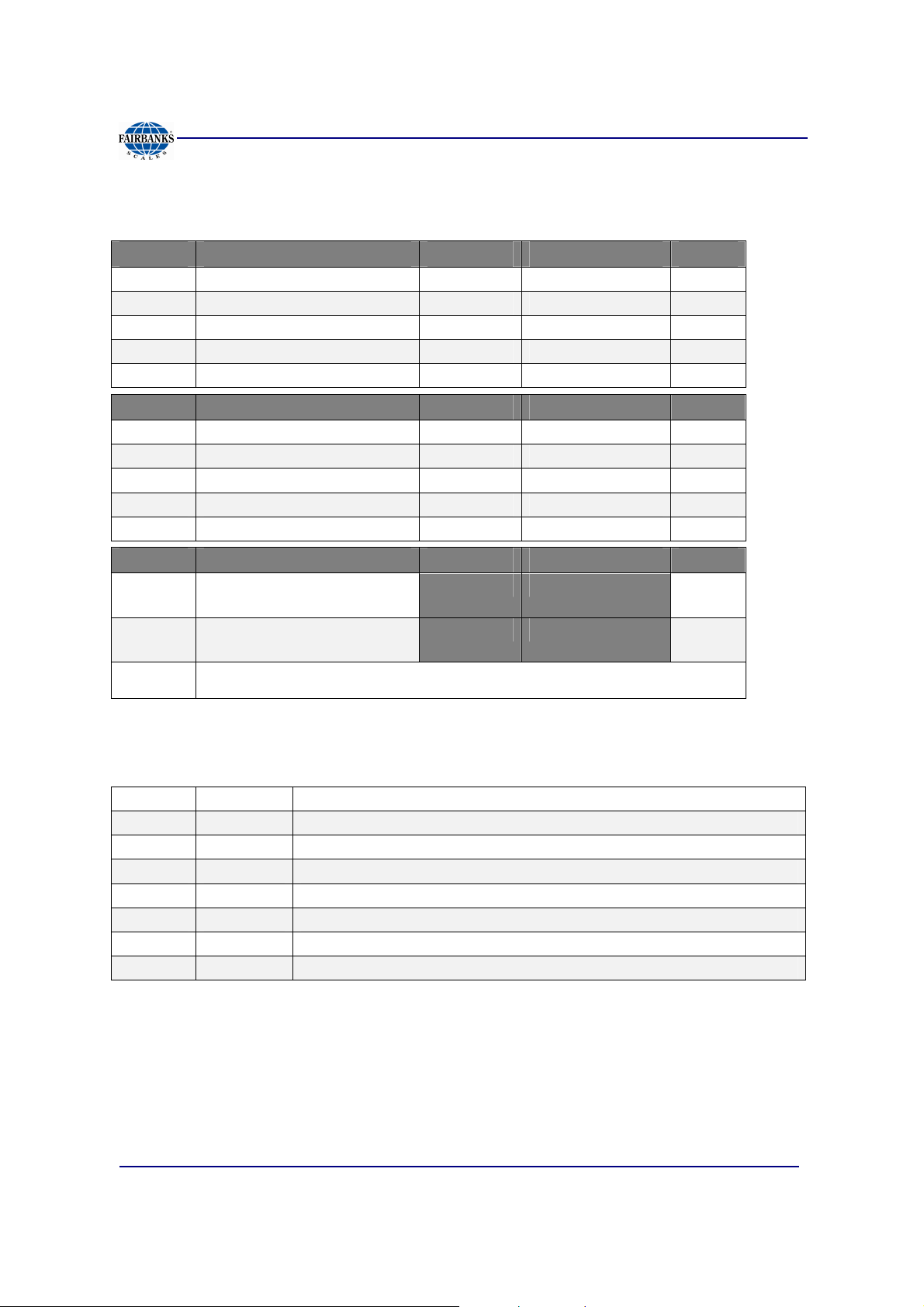

3.1. JP3 Jumper Configuration)

JP3 RS232 RS485 RS422* PORT

1-2

3-4

5-6

7-8

9-10

11-12

*Port should be set to RS485.

Out 120 Ohm

Out In Out COM1

Out In Out COM1

Out In Out COM2

Out In Out COM2

Out 120 Ohm

Resistor

Resistor

120 Ohm

Resistor

120 Ohm

Resistor

COM1

COM2

NOTE: 120 ohm Termination Resistors

last node on the network.

01/13

22 51297 Rev. 1

are required if the receiver is the

Page 23

Section 3: Serial Communication Wiring

3.2. TB4 Wiring connections, COM1 (A), COM2 (B), and COM2 (C)

TB4 (A) RS232 RS485 RS422* PORT

1 Rx – Receive Data (–) RS485 RS422 (–) Rx COM1

2 Tx – Transmit Data (–) RS485 RS422 (–) Tx COM1

3 CTS – Clear-to-Send (+) RS485 RS422 (+) RX COM1

4 GND -- Ground GND GND COM1

5 RTS – Ready-to-Send (+) RS485 RS422 (+) Tx COM1

TB4 (B) RS232 RS485 RS422* PORT

1 Rx – Receive Data (–) RS485 RS422 (–) Rx COM2

2 TX – Transmit Data (–) RS485 RS422 (–) Tx COM2

3 CTS – Clear-to-Send (+) RS485 RS422 (+) Rx COM2

4 GND – Ground GND GND COM2

5 RTS – Ready-to-Send RS485 RS422 (+) Tx COM2

TB4 (C) 20 MA RS485 RS422 PORT

1 (+) TX – Remote Display

Passive, 20 mA Output

2 (–) TX – Remote Display

Passive, 20 mA Output

3

*Port should be set to RS485.

(+) 7.5V Bluetooth® Technology Supply

COM2

COM2

3.3. TB5 Remote Switch Inputs

1 Ground

2 Ground

3 Ground

4 Print Connect to ground to perform programmed Print function

5 Tare Connect to ground to Tare off Gross weight

6 B/G Net Connect to ground to Select Gross/Tare displays

7 Zero Connect to ground to Zero Platform Weight

8 Units Connect to ground to change to alternate weight units

01/13

23 51297 Rev. 1

Page 24

Section 3: Serial Communication Wiring

3.4. Remote Display Active Keys

INSTRUMENT FB2255 ACTIVE FRONT PANEL KEYS

FB2200

FB2255

FB2255

2300

2500

2800

5200A

01/13

24 51297 Rev. 1

Page 25

1

2

3

4

5

6

7

8

X

X

X

X

X

X

X

X

DS2 ON

OFF

1

2

3

4

5

6

7

8

9

10

X

X

X

X

X

X

X

X

X

X

DS1 ON

OFF

Section 4: Input / Output

4.1. 3550 Tape Printer

Transmission

Baud Rate

Data Bits

Stop Bit

OUTPUT

RS232

9600

8

1

“BUTTON” for Print Key

4.2. Okidata 186 T Form Printer

FB

Printer Cable (

15599

) is used for both printers.

Transmission

Baud Rate

Data Bits

Stop Bit

OUTPUT

RS232

9600

8

1

“BUTTON” for Print Key

Switch 7 (SW2)

** Space after power on ON

Space when printer is selected

Switch 8 (SW2)

01/13

DTR Signal

OFF

Not Used

25 51297 Rev. 1

Page 26

Section 4: Input / Output

4.2. Okidata 186 T Form Printer, Continued

Follow these steps to change Menu Settings.

1. To enter MENU MODE, press and hold

– The “12” and “UTILITY” LEDs will blink.

2. With the printer in the Menu Mode, press

– The current default settings print out.

– It is recommended to use tractor fed paper.

NOTE:

3. Press

4. Press

5. Press

6. To continue making changes: press

The Printed Menu selections are different for each

LINE FEED

– The group is the left-hand column on the Menu Printout.

FORM FEED

– The Item is the center column on the Menu Printout.

TOF SET

– The settings are the right-hand column on the Menu Printout.

FORM FEED

to select the relevant group to be changed.

to select the relevant item within the selected group.

to cycle through the settings available for the item to change.

for the next item.

SELECT

SELECT

LINE FEED

while turning on the printer.

to print the complete menu.

Emulation Mode.

for the next group or press

– Repeat as needed until finished changing settings.

7. Press

Mode.

NOTES:

changed settings.

01/13

PITCH

Exiting the

and

MODE

together to save the changes and exit the Menu

Menu Mode

by turning off the printer will cancel any

26 51297 Rev. 1

Page 27

Section 4: Input / Output

4.2. Okidata 186 T Form Printer, Continued

• Printed menu’s changes according to the Printer Emulation Mode.

• If printer emulation mode is not set to ML, set this first, then reprint the menu.

GROUP ITEM SET

(Press

to change) to change) to change)

Printer Control Emulation Mode ML

Font Print Mode Utility

Font DRAFT Mode SSD

Font Pitch 10 CPI

Font Proportional Spacing No

Font Style Normal

Font Size Single

Symbol Sets Character Set Standard

Symbol Sets Language Set American

Symbol Sets Zero Character Slashed

Symbol Sets Code Page USA

Vertical Control Line Spacing 6 LPI

Vertical Control Skip Over Perforation No

Vertical Control Page Length 11”

Set-Up Graphics Bi-directional

Set-Up 7 or 8 Bits Graphics 7

Set-Up Receive Buffer Size 128K

Set-Up Paper Out Override No

Set-Up Paper Registration 0

Set-Up 7 or 8 Bits Data Word 8

Set-Up Operator Panel Function Full Operation

Set-Up Reset Inhibit No

Set-Up Print Suppress Effective Yes

Set-Up Auto LF No

Set-Up Print DEL Code Yes

Set-Up Time Out Print Invalid

Set-Up Auto Select No

Set-Up Impact Mode Normal

LINE FEED

(Press

FORM FEED

(Press

TOF SET

01/13

27 51297 Rev. 1

Page 28

Section 4: Input / Output

4.2. Okidata 186 T Form Printer, Continued

GROUP ITEM SET

Parallel I/F I-Prime Buffer Print

Parallel I/F Pin 18 +5v

Parallel I/F Bi-Direction Enable

Serial PCB Assy Switch Settings: (SW1) (** indicates typical Fairbanks setting)

Parity Type Switch 1 (SW1)

** Odd parity ON

Even parity OFF

Parity Switch 2 (SW1)

** No parity ON

With parity OFF

Data Bits Switch 3 (SW1)

** 8 Bits ON

7 Bits OFF

Protocol Switch 4 (SW1)

Ready/Busy ON

** X-ON, X-OFF OFF

Test Select Switch 5 (SW1)

** Circuit ON

Monitor OFF

Mode Select Switch 6 (SW1)

** Print mode ON

Test mode OFF

Busy Line Selection Switch 7, 8 (SW1)

SSD- Pin 11 OFF, ON

SSD+ Pin 11 OFF, OFF

** DTR- Pin 20 ON, ON

RTS- Pin 4 ON, OFF

(SW2) (** indicates typical Fairbanks setting)

01/13

28 51297 Rev. 1

Page 29

Section 4: Input / Output

4.2. Okidata 186 T Form Printer, Continued

Transmission Speed Switches 1, 2, 3 (SW2)

19,200 bps ON, ON, ON

** 9,600 bps OFF, ON, ON

4,800 bps ON, OFF, ON

2,400 bps OFF, OFF, ON

1,200 bps ON, ON, OFF

600 bps OFF, ON, OFF

300 bps ON, OFF, OFF

110 bps OFF, OFF, OFF

DSR Input Signal Switch 4 (SW2)

Active ON

** Inactive OFF

Buffer Threshold Switch 5 (SW2)

32 bytes ON

** 256 bytes OFF

Busy Signal Timing Switch 6 (SW2)

** 200 ms minimum ON

1 second minimum OFF

01/13

29 51297 Rev. 1

Page 30

Section 4: Input / Output

4.3. Okidata 420 Form Printer

Program the FB2255 the following settings.

Transmission

Baud Rate

Data Bits

Stop Bit

OUTPUT

NOTE:

Always restart the printer after making any switch changes.

SEL

SEL

MENU

EXIT

POWER

1. To enter MENU MODE, press and hold the

SELECT

RS232

9600

8

1

“BUTTON” for Print Key

SHIFT

ALARM

LF

Micro Feed

Down

GROUP

FF/LOAD

Micro Feed

ITEM

key.

Up

MENU

TEAR

SET

FB

Printer Cable (

PARK

PRINT

SHIFT

key while pressing the

QUIET

TOF

15599

) is used for this printer.

– The MENU legend will be illuminated while in the Menu Mode.

2. With the printer in the Menu Mode, press

PRINT

to print the complete menu.

– The current default settings print out.

– It is recommended to use tractor fed paper.

NOTE:

3. Press

The Printed Menu selections are different for each Emulation Mode.

GROUP

to select the relevant group that needs to be changed.

– Found on the left-hand column on the Menu Printout.

4. Press

ITEM

to select the relevant item within the selected group.

– Found on the Item is the center column on the Menu Printout.

5. Press

SET

to cycle through the settings available for the item to change.

– The settings are the right-hand column on the Menu Printout.

6. Press and hold the

SHIFT

key while pressing the

SELECT

Menu Mode.

key to exit the

01/13

30 51297 Rev. 1

Page 31

Section 4: Input / Output

4.3. Okidata 420 Form Printer, Continued

NOTE:

be lost.

If the printer is turned off before exiting the

MENU MODE

, all changes will

GROUP ITEM SET

(Press

to change) to change) to change)

Printer Control Emulation Mode IBM PPR

Font Print Mode Utility

Font DRAFT Mode HSD

Font Pitch 10 CPI

Font Proportional Spacing No

Font Style Normal

Font Size Single

Symbol Sets Character Set Set 1

Symbol Sets Language Set American

Symbol Sets Zero Character Slashed

Symbol Sets Code Page USA

Rear Feed Line Spacing 6 LPI

Rear Feed Form Tear-off Off

Rear Feed Skip Over Perforation No

Rear Feed Page Length 11”

Bottom Feed Line Spacing 6 LPI

Bottom Feed Form Tear-off Off

Bottom Feed Skip Over Perforation No

Bottom Feed Page Length 11”

Top Feed Line Spacing 6 LPI

Top Feed Form Tear-off Off

Top Feed Skip Over Perforation No

Top Feed Page Length 11”

LINE FEED

(Press

FORM FEED

(Press

TOF SET

01/13

31 51297 Rev. 1

Page 32

Section 4: Input / Output

4.3. Okidata 420 Form Printer, Continued

GROUP ITEM SET

Set-Up Graphics Uni-directional

Set-Up Receive Buffer Size 64K

Set-Up Paper Out Override No

Set-Up Print Registration 0

Set-Up Operator Panel Function Full Operation

Set-Up Reset Inhibit No

Set-Up Print Suppress Effective Yes

Set-Up Auto LF No

Set-Up Auto Select No

Set-Up SI Select Pitch (10CP) 17.1 CPI

Set-Up SI Select Pitch (12CPI) 12 CPI

Set-Up Time Out Print valid

Set-Up Auto Select No

Set-Up Centering Position DEFAULT

Set-Up ESC SI Pitch 17.1 CPI

Set-Up Power Saving Enable

Set-Up Power Save Time 5 Min

Parallel I/F I-Prime Buffer Print

Parallel I/F Pin 18 +5v

Parallel I/F Bi-Direction Enable

Serial I/F Parity None

Serial I/F Serial Data 7/8 Bits 8 Bits

Serial I/F Protocol X-On/X-Off

Serial I/F Diagnostic Test No

Serial I/F Busy Line SSDSerial I/F Baud Rate 9600 BPS

Serial I/F DSR Signal Invalid

Serial I/F DTR Signal Ready on Pwr up

Serial I/F Busy Time 200 ms

01/13

32 51297 Rev. 1

Page 33

Section 4: Input / Output

4.4. TM-U295 Ticket Printer

Transmission

Baud Rate

Data Bits

Stop Bit

OUTPUT

RS232

9600

8

1

“BUTTON” for Print Key

Set the dip switches to the following.

• 1 and 3 are ON.

• The rest are

OFF

.

NOTE:

Always restart the printer after making any switch changes.

FB

Printer Cable (

15599

) is used for both printers.

4.5. TM-U590 Ticket Printer

Transmission

Baud Rate

Data Bits

Stop Bit

OUTPUT

Set the dip switches to the following.

• DSW 1

• DSW 2

RS232

9600

8

1

“BUTTON” for Print Key

• 1, 3 and 7 are

• All are

OFF

.

ON

only.

01/13

33 51297 Rev. 1

Page 34

Section 4: Input / Output

4.6. Remote Display

=CENTER OF ZERO

Part #

20903

Using the

20 mA Serial Current Loop Output

distances up to 1000 cable feet.

– Interface Cable (

20903

) is recommended.

Port

Baud Rate

Parity

Stop Bit

Current

2

C-Loop

2400

Odd

1

Passive

will allow transmission

The remote display must be wired for

20 mA Active

, and programmed to match

the FB2255.

– Wiring to the FB2255:

1 Tx + Passive 20 mA Output

2 Tx – Passive 20 mA Output

TB4 (C)

to the Remote Display.

Wire the Remote Display to the FB2255 as shown in this diagram.

(C)

(C)

01/13

34 51297 Rev. 1

Page 35

Section 4: Input / Output

4.6.1. PROGRAMMING THE 4-20MA ANALOG OUTPUT MODE

Access to this features is conditional, and depends upon whether it is enabled in the

FB2255 Internal Programming.

1. Press and hold the

NOTE

to

analog output continues to operate.

2. Select

3. Press

4. Press the

5. Press

Available selections include the following.

• Gross • Net

: If 4-20mA Analog Output has been installed and programmed, setting 4-20

NO

in the APPS Menu will prevent access to it from the front panel while the

GROSS

– The 4-20 mA Analog Output will continue to track the selection regardless of

the currently selected Weigh Mode.

MENU

right arrow

ENTER

UNITS

or

NET

.

to select an option.

key for three (3) seconds

.

key to toggle the available settings.

4.6.2. PROGRAMMING THE 4mA WEIGHT VALUE

4.20 Lo displays, followed by the current setting.

1. Key in the correct Weight Value with the

2. Press

This weight entry results in a

ENTER.

4mA Output

0-9

.

keys.

4.6.3. PROGRAMMING THE 20mA WEIGHT VALUE

4.20 Hi displays, followed by the current setting.

3. Key in the correct Weight Value with the

4. Press

This weight entry results in a

01/13

ENTER.

20mA Output

0-9

keys.

.

35 51297 Rev. 1

Page 36

Section 5: Fieldbus/Bluetooth

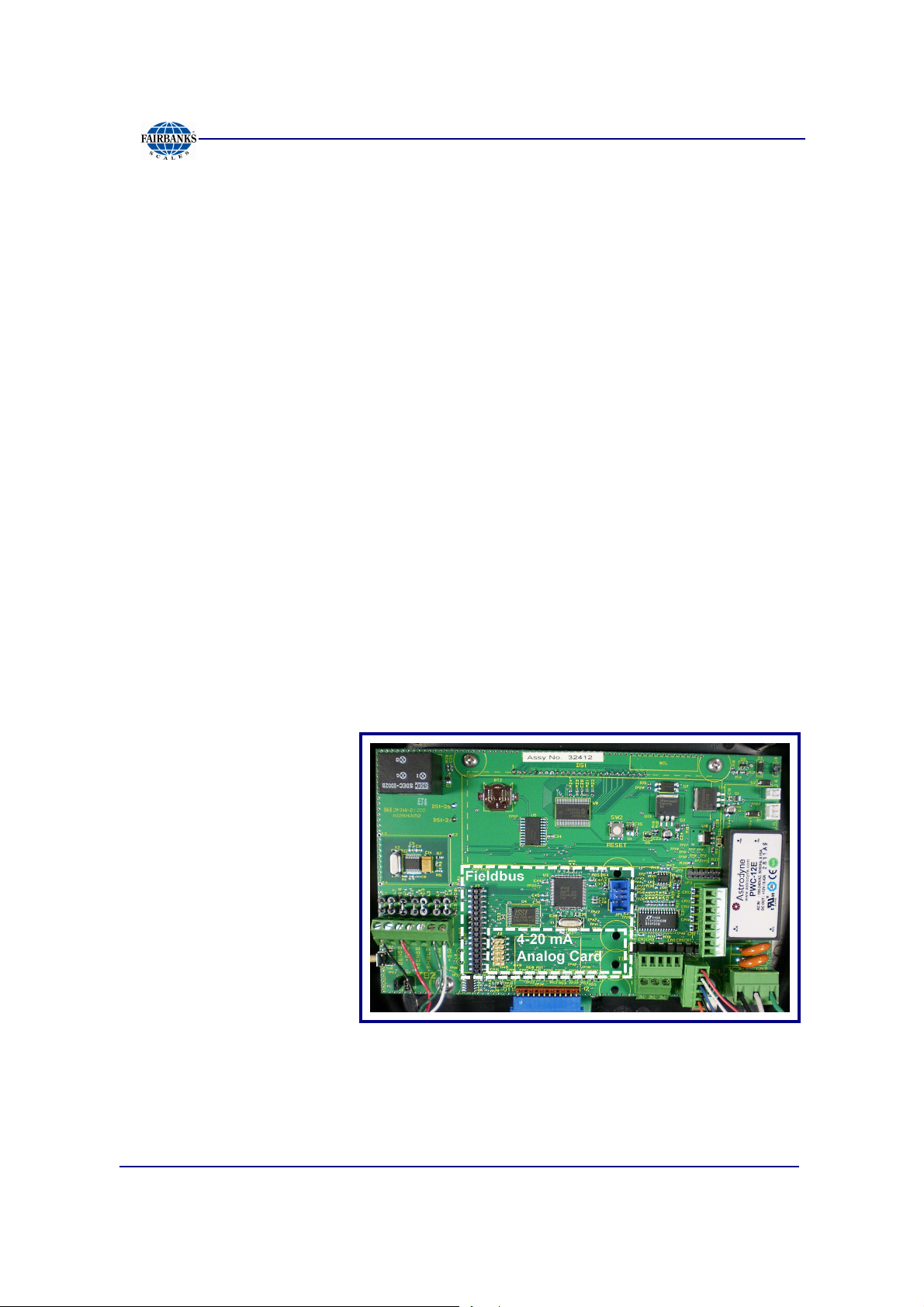

5.1. Fieldbus Installation

Fieldbus

system that interconnects measurement and control equipment such as sensors,

actuators and controllers.

– Fieldbus traces its beginnings in the automotive industry, where efforts to

For example, many cars have multiple controls on the door, such as power-window,

power-mirror, power-lock and power-seat controls.

– To eliminate the thick bundle of wires of the older method, a driver's-door

– If the driver presses the window switch, the door module closes a relay that

– If the driver presses the switch to adjust the passenger-side mirror, the

– This packet tells a different module to energize one of the power-mirror

As time has progressed, many different Fieldbus types have been developed, each

with different characteristics and specifications.

is a general term that describes an all-digital two-way communications

simplify and reduce wiring resulted in a multiplexed Controller Area Network

(CAN) system of modules installed at various points of a car

module monitors all of the switches.

provides power to the window motor.

driver's door module sends a packet of data onto the communication bus of

the car.

motors. In this way, most of the signals that leave the driver's door are

consolidated onto the two wires that form the communication bus.

– Very simply, they serve as a Local Area Network (LAN) for instrumentation

used in automatic process control and manufacturing applications.

– The LAN is a digital, bi-directional, multi-drop, serial-bus communications

network used to link field devices (often referred to as “Nodes”), such as

controllers, transducers, actuators and sensors.

There are a number of different manufacturers that produce Fieldbus devices.

– Each produces different hardware interfaces, wiring and connector types,

speed, and the amount of bytes of data that can be exchanged on the

network, among other things.

01/13

36 51297 Rev. 1

Page 37

Section 6: Fieldbus/Bluetooth

Additionally, the current Fieldbus communications network is replacing the older 420mA Analog Signal.

– The older 4-20 mA analog signal requires each device to have its own set of

wires and its own connection points.

– A Fieldbus eliminates this need as, generally, twisted pair wiring is used.

– All devices on the network are now connected together.

Fairbanks Scales currently offers three different Fieldbus Devices: DeviceNet™,

ControlNet™, Profibus®, and Ethernet/IP.

For more information and EDS files, see http://www.hms.se/default.shtml.

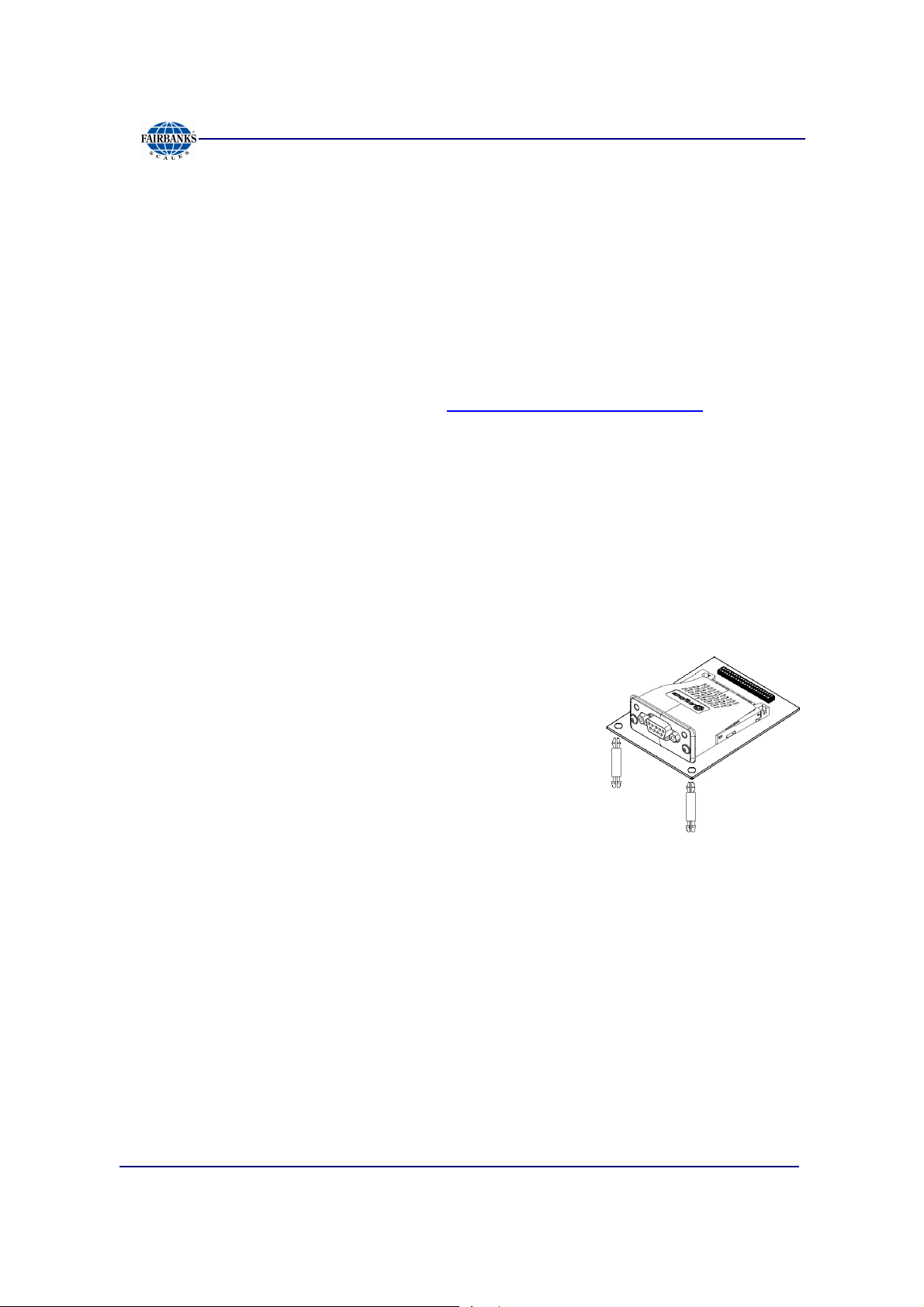

5.2. Fieldbus Connections

The term

system that interconnects measurement and control equipment such as sensors,

actuators and controllers.

The Fieldbus assembly connects to the 32-pin header on the FB2255 main PCB

Assembly.

It is provided with two (2) standoffs which support the

right side of the card.

FIELDBUS

usually describes an all-digital two-way communications

5.2.1. OVERVIEW OF TERMS

There are currently four (4) different of Fieldbus Interfaces listed as standard

accessories for the FB2550 Instrument.

• DEVICE NET™ (29578)

– A network system to interconnect control devices for data exchange.

– It uses a differential serial bus, called Controller Area Network (CAN), as

the backbone technology and defines an application layer to cover a range of

device profiles.

• CONTROL NET® (31979)

– An open control network in real-time, for high-throughput applications.

01/13

37 51297 Rev. 1

Page 38

Section 6: Fieldbus/Bluetooth

5.2.1. OVERVIEW OF TERMS, CONTINUED

• PROFIBUS® (29576)

– Non-powered two-wire (RS485) network, with up to 126 nodes, transferring a

maximum of 244 data bytes per node per cycle.

• ETHERNET/IP (29873)

– Dynamic Host Configuration Protocol (DHCP) is used for address requests.

– The data is transmitted continuously from this module.

– The IP address may be made static by downloading the IP Configuration

Tool Software.

ETHERNET/IP

the Internet Protocol. Instead, it is an Industrial Application Layer Protocol used

for communication between industrial control systems and their components.

– Such components include Programmable Automation Controller, Logic

Controller, or an I/O System.

The “IP” in EtherNet/IP is not an abbreviation for “Internet Protocol”, but instead, it

stands for “Industrial Protocol”.

can be easily confused as a simple combination of EtherNet and

01/13

38 51297 Rev. 1

Page 39

Section 6: Fieldbus/Bluetooth

5.2.2. DEVICENET (29578)

DEVICENET

is a low-cost communications link that connects industrial devices to

a network, eliminating expensive hardwiring.

– It is based on a broadcast-oriented, communications protocol the CAN.

– The CAN Protocol was originally developed by BOSCH for the European

automotive market for replacing expensive wire harnesses with low-cost

network cable.

– The CAN Protocol has fast response and high reliability for applications like

anti-lock brakes and air bags.

DEVICENET

also provides power to the network. This allows devices with limited

power requirements to be powered directly from the network.

– This reduces connection points and physical size.

– The maximum network size is up to 64 Nodes, with message data packets up

to 8 bytes.

Wire

1

2

3

4

5

SIGNAL DESCRIPTION

V

CAN_L

SHIELD

CAN_H

V+

Negative bus supply voltage

CAN low bus line

Cable shield

CAN high bus line

Positive bus supply voltage

NOTE:

Additional information and

EDS files

are available at the following website.

http://www.hms.se/products/devicenet.shtml.

01/13

39 51297 Rev. 1

Page 40

Section 6: Fieldbus/Bluetooth

5.2.2. DEVICENET (29578), CONTINUED

NETWORK STATUS LED

STATE INDICATION

OFF

GREEN

FLASHING GREEN (1 Hz)

Red

Flashing Red (1 Hz)

Alternating Red/Green

Not online/ No power

Online, one or more connection established

Online, no corrections established

Critical link failure

One or more connections timed out

Self-test

1 NS = Operation Mode LED

2 MS = Mode Status LED

3 Connection = DeviceNet Connector

MODULE STATUS LED

STATE INDICATION

OFF

GREEN

FLASHING GREEN (1 Hz)

Red

Flashing Red (1 Hz)

Alternating Red/Green

No power

Operating in normal condition

Missing/Incomplete configuration/ Device needs commissioning

Unrecovrerable fault(s)

Recoverale fault(s)

Self-test

01/13

40 51297 Rev. 1

Page 41

Section 6: Fieldbus/Bluetooth

5.2.3. CONTROLNET (31979)

CONTROLNET

running in “real-time”, for high-throughput

applications.

– It uses a Control and Information Protocol

(CIP), combining the functionality of an I/O

Network and a Peer-to-Peer Network.

–

CONTROLNET

Producer/Consumer Model, permitting all

nodes on the network to simultaneously

access the same data from a single source.

– Maximum of 99 nodes, with no minimum

distance between nodes

– The Control net card uses BNC connectors.

is an open control network

is based on the

SPECIAL NOTES

For signal redundancy, both connectors should be used.

– If not, use either Connector A or B.

Network Status LED A and Module Status LED correspond to LED 1 and LED 2 in

the instance attributes of the Anybus Object.

– They are available in the application interface, but the LED placement on the

front does not conform to the standard Anybus CompactCom placement of

LED 1 and LED 2.

01/13

41 51297 Rev. 1

Page 42

Section 6: Fieldbus/Bluetooth

5.2.3. CONTROLNET (31979), CONTINUED

NETWORK STATUS

LED STATE INDICATION

A and B

A or B

OFF

Flashing Red (1 Hz)

Alternating Red/Green

Red

OFF

Alternating Red/Green

Flashing Green (1 Hz)

Green

Flashing Red (1 Hz)

Not online / No power

Incorrect node configuration, duplicate MAC ID etc.

Self test of bus controller

Fatal event or faulty unit

Channel is disabled

Invalid link configuration

Temporary errors (node self-corrects) or node is not

configured to go online.

Normal operation

Media fault or no other nodes on the Network

MODULE STATUS

STATE INDICATION

OFF

GREEN Operating in normal condition, controlled by a Scanner in RUN state.

FLASHING GREEN

(1 Hz)

Red

Flashing Red (1

Hz)

No power

The module has not been configured or the Scanner is in the Idle state.

Unrecovrerable fault(s), EXCEPTION,

Media fault or no other nodes on the Network

No.

1

2 Module Status LED

3

4

5

DESCRIPTION

Network Status LED A

Network Status LED B

ControlNet Connector A

ControlNet Connector B

01/13

42 51297 Rev. 1

Page 43

Section 6: Fieldbus/Bluetooth

5.2.4. PROFIBUS (29576)

PROFIBUS

is one of the best-known industrial

fieldBus protocols from Europe.

– It is an established standard, used in a wide

range of applications as a multi-application

communications link for industrial devices.

– The ProfiBus protocol was originally

developed by a committee founded by the

German government.

PROFIBUS

utilizes a non-powered two-wire (RS-485) Network.

– A ProfiBus Network may have up to 126 nodes, transferring a maximum of

244 bytes data per node/ per cycle.

– Baud (Communication) Rates are selectable, and overall end-to-end network

distance varies with speed.

– The maximum standard Baud Rate is 12Mbps, with a maximum distance of

100M (328ft), and 1200M (3936 ft.) at 93.75Kbps without repeaters.

–

PROFIBUS

connects to a wide variety of field devices including the

following:

▪ Discrete and analog I/O Drives.

▪ Robots.

▪ HMI/MMI products.

▪ Pneumatic valves.

▪ Barcode readers.

▪ Weigh scales.

▪ Transducers.

▪ Flow measuring equipment.

PIN SIGNAL DESCRIPTION

3

4

5

6

8

B-Line

RTS

GND

+5 Bus

Output

A-Line

Positive RxxD/TxD, Rs485 level

Request to Send

Ground (Isolated)

+5V termination power (Isolated,

short circuit protected)

Negative RXD/TxD, RS485 level

01/13

43 51297 Rev. 1

Page 44

Section 6: Fieldbus/Bluetooth

5.2.4. PROFIBUS (29576), CONTINUED

OPERATION MODE LED

LED STATE DESCRIPTION

OFF

Green

Flashing Green

Flashing Red (1 flash)

Flashing Red (2 flashes)

Not online or No power

Online/ Data Exchange

Online, clear

Parameterization error

Profibus configuration error

MODULAR STATUS LED

LED STATE DESCRIPTION COMMENTS

OFF

Green

Flashing Green

Red

No power - OR – not initialized

Initialized

Initialized, diagnostic events(s) present Extended diagnostic bit is set

Exception error

Module state = “SETUP” OR NW-INIT”

Module has left the NW_INIT state

Module state = EXCEPTION

NO. DESCRIPTION

1 Communication

LED

2 Device Status LED

3 Profibus Interface

NOTE:

Additional information and

EDS files

http://www.hms.se/default.shtm.

01/13

are available at the following website.

44 51297 Rev. 1

Page 45

Section 6: Fieldbus/Bluetooth

5.2.5. ETHERNET / IP DIAGNOSTIC LEDS

The Ethernet/IP module uses Dynamic Addressing.

– Dynamic Host Configuration Protocol

(DHCP) is used for address requests.

– The data is transmitted continuously from this

module.

– The IP address may be made static by

downloading the IP Configuration Tool

Software from the following site:

http://www.hms.se/support/support.asp?PID=368&Product

Type=Anybus-CompactCom.

• Using this download, it is possible to change the IP, Sub Net and Gateway

addresses of an Ethernet/IP Module.

• To change an address, double click on the IP address field and enter the

changes.

Shown below is the Network Status LED Chart

1. Network Status LED

2. Module Status LED

3. Link/Activity

4. Ethernet Interface (RJ-45)

(Standard Cat 5 Cable)

STATE DESCRIPTION

Off Not online / No power

Green Online, one or more connections established.

Flashing Online, no connections established

Red Duplicate IP address, FATAL error

Flashing Red One or more connections timed out

Shown below is the Module Status LED Chart

STATE DESCRIPTION

Off No power

Green Controlled by a scanner in Run state

Flashing Green Not configures, or Scanner in idle state

Red Major fault (EXCEPTION-state, FATAL error, etc.)

Flashing Red Recoverable fault(s)

Shown below is the Link / Activity LED Chart

STATE DESCRIPTION

Off No link, no activity

Green Link established

Flickering Green Activity

For more information and EDS files, see http://www.hms.se/default.shtml.

01/13

45 51297 Rev. 1

Page 46

Section 6: Fieldbus/Bluetooth

5.3. Bluetooth® Technology Device

The Bluetooth® Option replaces direct wiring

between two devices.

– The Bluetooth® Interface uses either

Port 1

– RS232 Serial Interface to Bluetooth®

Interface with a range of 100 meters

(328 feet).

The Bluetooth® Option operates either as a

Client or Server, depending on its

connecting device.

If its connected to a printer, the FB2255 will

be a Server. If connected to a PC, it is a

Client.

or

Port 2 Serial Output

.

Shown below are some Bluetooth® products with their features.

MODEL NO. MODEL NAME DESCRIPTION

29515 Bluetooth® Accessory, Class I, for

non-FB2255 device

29639

29516 Bluetooth® Accessory, Class I,

AC Power adapter for Bluetooth

Accessory 29215

FB2255

• Power source required for non-FB2255

side of the connection.

• 5 - 12 VDC, USB power cable provided.

• PC interfacing software provided.

®

• For use if USB power cable not

applicable.

• FB2255 provides power

• RoHS compliant

• Includes cable

29402

The Bluetooth® device is supplied with a DB-9 female connector.

Shown below is the wiring code / color code to connect the FB2255 and the

Bluetooth® Device.

FB2255 TB 4

Pin 1 Pin 2 Red

Pin 2 Pin 3 White

Pin 4 Pin 5 Black

Pin 13 Pin 9 Green

BLUETOOTH®

DEVICE

FB SUPPLIED

CABLE

01/13

46 51297 Rev. 1

Page 47

Section 6: Fieldbus/Bluetooth

5.3. Bluetooth® Technology Device, Continued

Set the 4-position Dip Switch on each device as shown below.

1,2,3

4

ON

OFF

Follow these steps to installing the Bluetooth® Devices.

5. Turn on both Bluetooth® Devices with the

SLIDE SWITCH

6. Press the

7. Press the

RESET BUTTON

PAIRING BUTTON

on their sides.

on each one.

of Device #1

for two (2) seconds

– The Standby LED turns

OFF

.

– The Connect LED blinks three (3) times

every two (2) seconds.

– Keep the power

8. Press the

PAIRING BUTTON

ON

.

of Device #2

for two (2) seconds.

Baud Rate

Data Bits

Parity

Stop Bit

9600

8

None

1

– The Standby LED turns

OFF.

– The Connect LED blinks three (3) times every two (2) seconds.

9. Press the Pairing Button again for two (2) seconds until the Connect LED blinks

every half (½) second.

• Wait for Devices #1 and #2 to connect to

each other.

– The Connect LEDs of both will be

solid green.

– This connection process takes about

ten (10) seconds.

– If any other Bluetooth® devices are

nearby, it may take longer.

01/13

47 51297 Rev. 1

Page 48

Section 6: Fieldbus/Bluetooth

5.3. Bluetooth® Technology Device, Continued

10. Turn Device #1

– The Connect LED light blinks green twice every three (3) seconds.

11. Turn Device #2

12. The Connect LED light blinks green once every second.

Configuration is now complete. Both devices are configured to make automatic

connection to each other whenever they are powered on.

OFF,

OFF,

and then back

and then back

ON

ON

.

.

01/13

48 51297 Rev. 1

Page 49

Section 6: PC2255 Utility Software

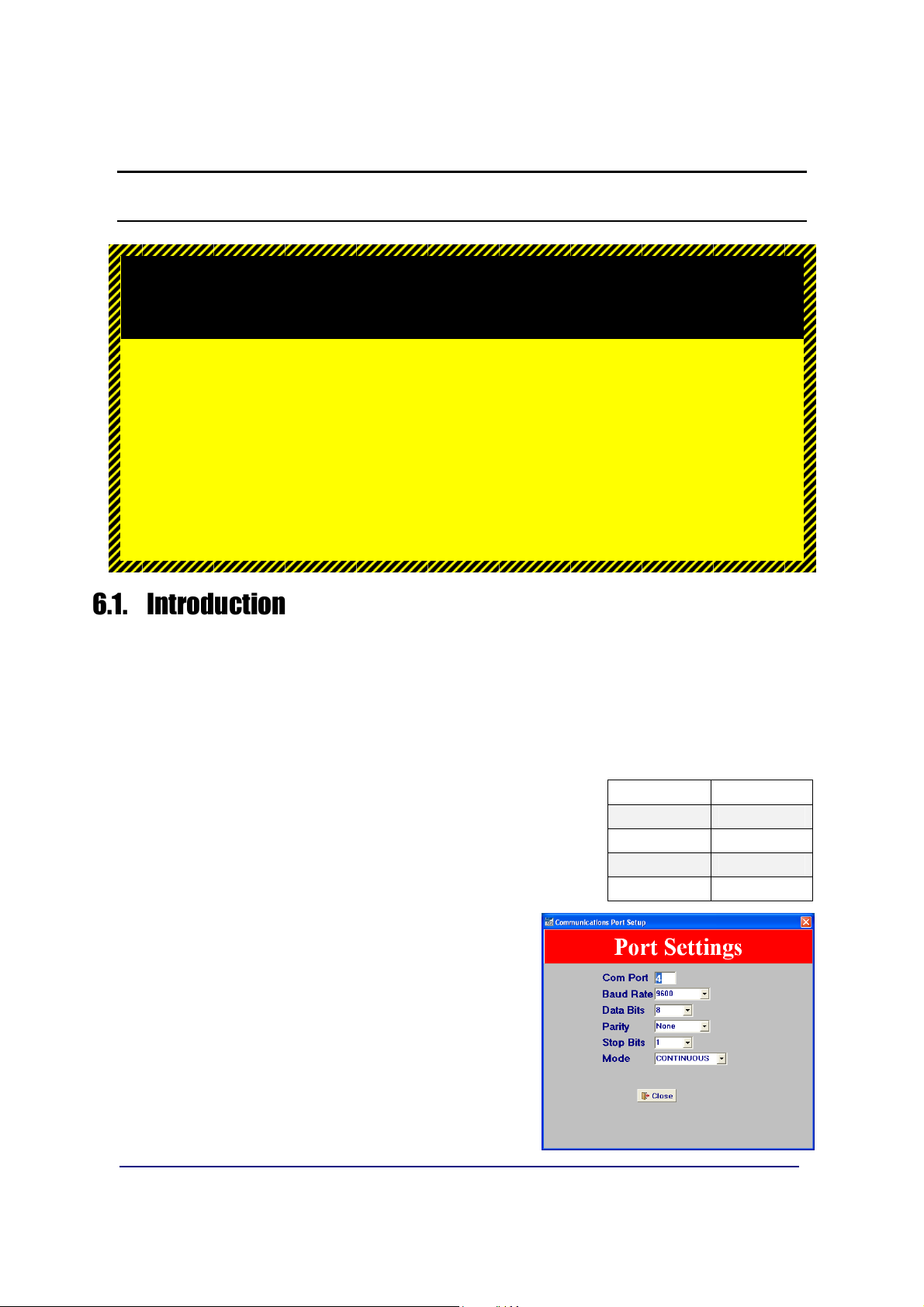

C A U T I O N

USING THIS PC2255 UTILITY PROGRAM CAN ALTER

PROPER CALIBRATION AND USER FUNCTIONS.

OWNER ASSUMES ALL RISKS WHILE USING THIS PROGRAM!

THE CUSTOMER WILL BE RESPONSIBLE FOR ALL

SERVICE DEPARTMENT COSTS TO RESTORE THE

INSTRUMENT TO ITS PROPER OPERATIONS.

6.1. Introduction

• The PC2255 utility software program can be used to set up and configure the

FB2255.

• It is required in order to program certain features, such as custom units and

custom ticket vector programming.

• The FB2255 uses

6.2. Communication Settings

1. Access the COM Port Settings of the computer by

pressing F2.

The Standard Defaults are noted in the chart to

the right.

Port 2

to communicate to the computer.

Baud Rate

Data Bits

Parity

Stop Bit

Mode

9600

8

None

1

Continuous

2. Set

3. Set the FB2255 Port 2 to the same settings,

01/13

VERSION

– It displays at the warm-up screen of the

Instrument.

and then exit from program mode.

setting to match the FB2255.

49 51297 Rev. 1

Page 50

Section 6: PC2255 Utility Software

6.2. Communication Settings, Continued

1. Launch the

– An image of the FB2255 will display on the computer monitor.

– The legend “CONNECTED” with a rotating baton will displayed.

– The weight display will duplicate what is shown on the FB2255.

2. Left-clicking the mouse on any key to transmit that command to the FB2255.

– This excludes the

– The legend “COMMAND SENT!” will display at the right.

– Mouse-clicking the

program.

PC2255.exe

PRINT key.

ON/OFF

file.

key will terminate the PC2255 software

01/13

50 51297 Rev. 1

Page 51

Section 6: PC2255 Utility Software

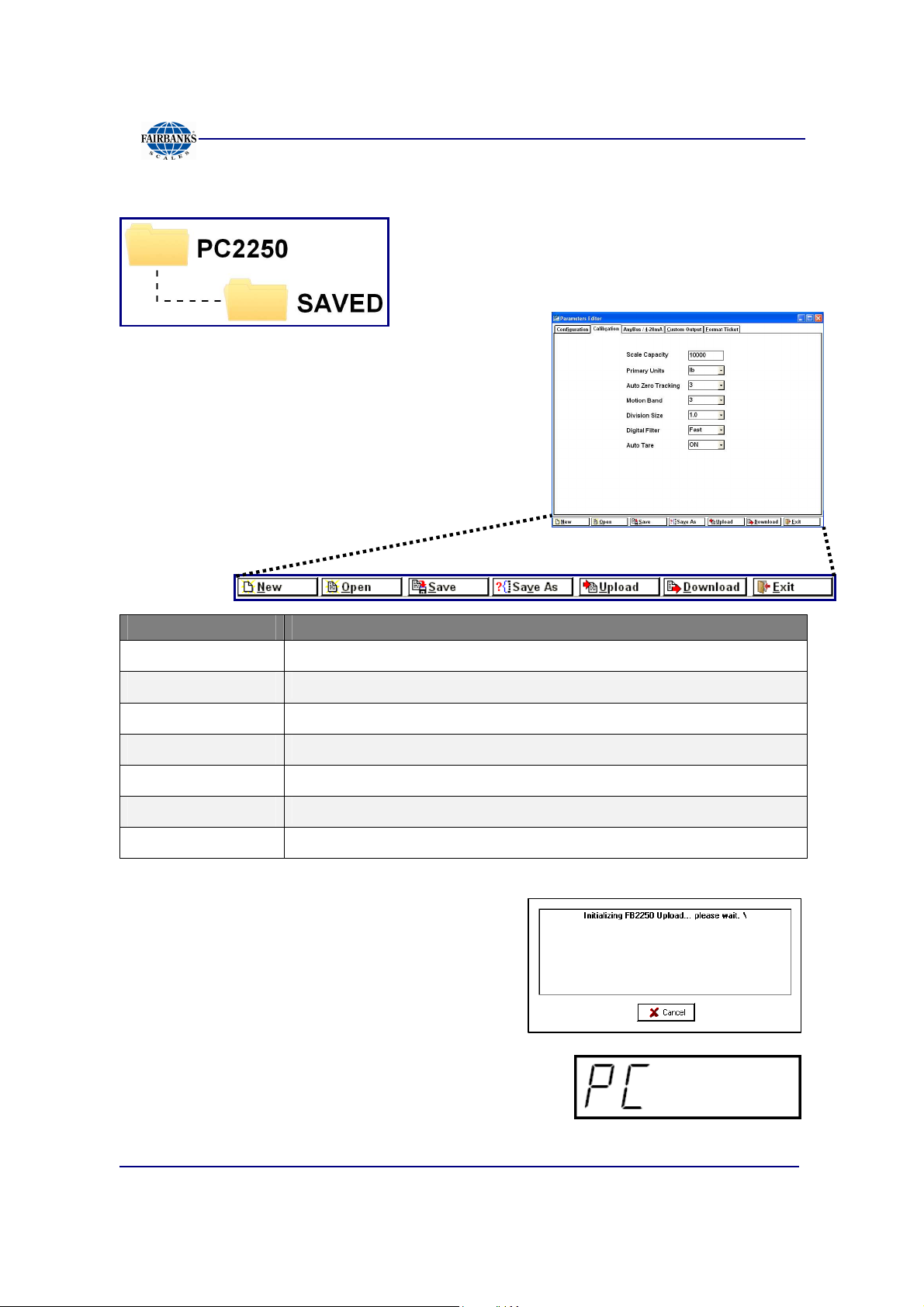

6.3. Communication Files

The default folder for all saved/uploaded

parameter files is

6.4. Menu Bar

The PC2255 menu bar is located at the bottom of

the display.

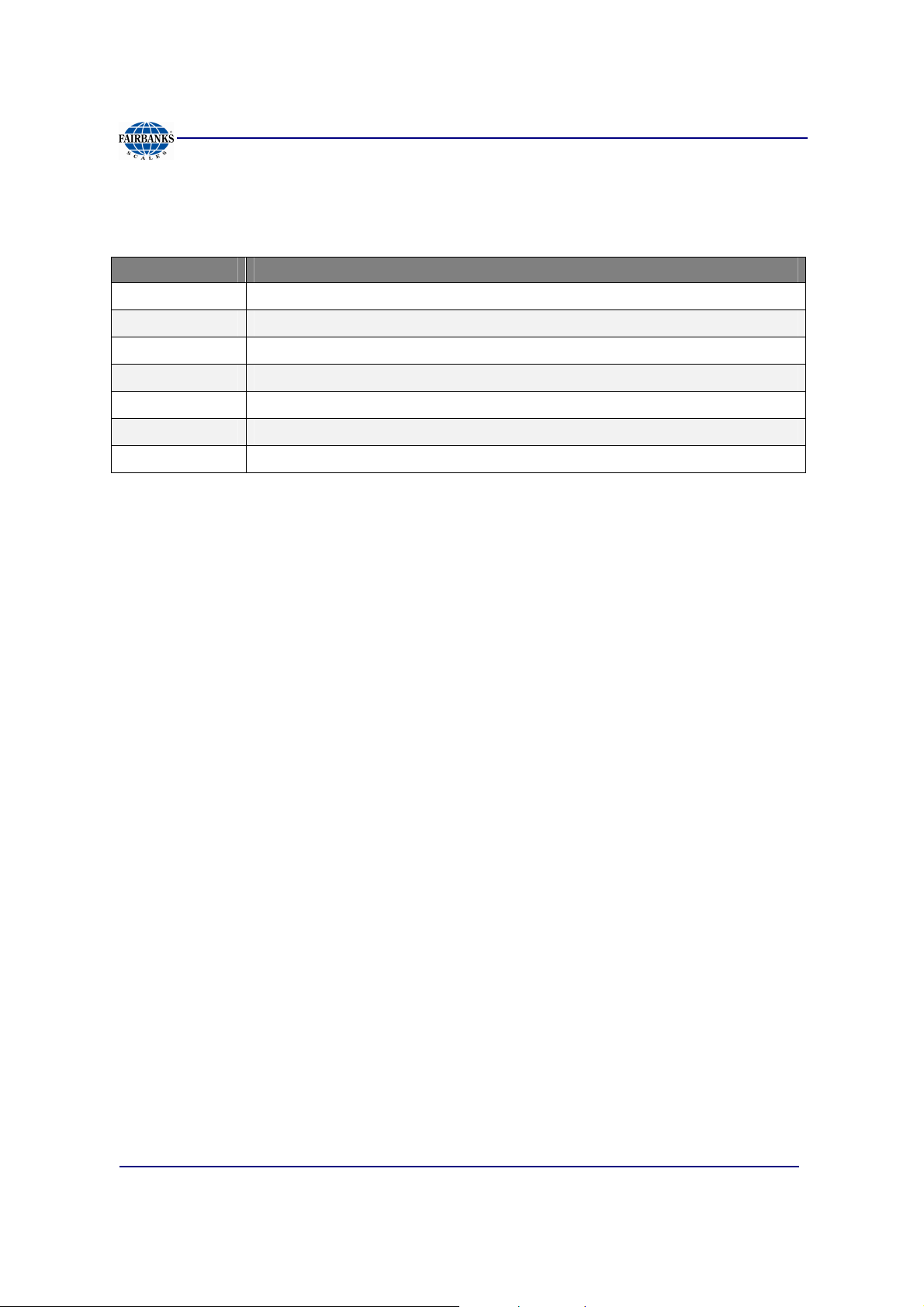

BUTTON FUNCTION

NEW

OPEN

SAVE

Loads the Parameters Menu with FB2255 default settings.

Opens the SAVED folder to select a file.

Saves the currently named file.

PC2255\SAVED.

SAVE AS

UPLOAD

DOWNLOAD

EXIT

1. Press the

current FB2255settings to the PC2255.

– The FB2255 displays “PC”.

2. Press the

SWITCH

01/13

UPLOAD

INTERNAL PROGRAMMING

.

Saves the current file and prompts for a file name.

Uploads the current FB2255 settings to the PC2255.

Downloads the current PC2255 settings to the FB2255.

Exits the program.

button to retrieve the

51 51297 Rev. 1

Page 52

Section 6: PC2255 Utility Software

6.4. Menu Bar, Continued

3. When the process is complete, click

4. Click the

the current PC2255 settings to the FB2255.

The FB2255 displays “PC”.

5. Press the

PROGRAMMING SWITCH.

DOWNLOAD

INTERNAL

button to retrieve

OK

.

6. When complete, click

7. Press

EXIT

to close the Parameter Editor.

OK

.

01/13

52 51297 Rev. 1

Page 53

Section 6: PC2255 Utility Software

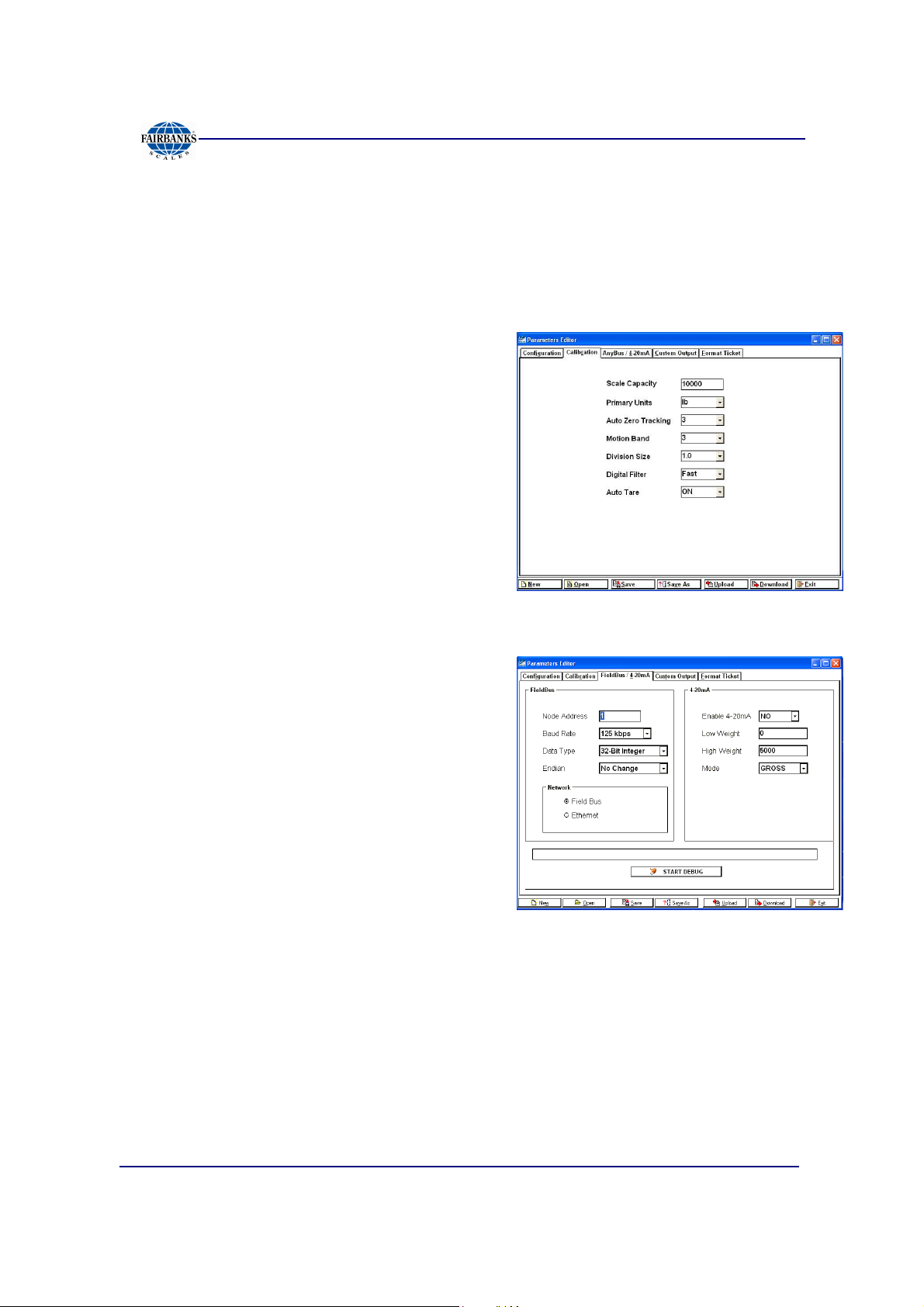

6.5. Configuration

1. Press

Use one of the following methods that apply to programming the features.

• Click on the data item to highlight it, then type in the replacement data.

• Click the drop down arrow and selecting an available item.

F4

to enter the Parameters Editor.

• Click on the checkmark to select the option(s).

• Input the custom unit factor to set the conversion factor of the current primary

weight data.

CUSTOM UNIT PROGRAMMING EXAMPLE

To convert pounds to dry barrel units, enter the conversion factor, resolution and

custom legend. The current primary weight will be multiplied by the conversion

factor, rounded off to the custom resolution and printed with a custom legend.

01/13

53 51297 Rev. 1

Page 54

Section 6: PC2255 Utility Software

6.6. Calibration

Settings from this window include the following options.

• Scale capacity • Primary Units • Auto Zero Tracking (AZT) • Motion Band (BAL)

• Division Size • Digital Filter • Auto Tare settings

Actual test weight calibration is performed with

the FB2255 front panel keys.

6.7. Fieldbus / 4-20 mA

The Anybus or DeviceNet Module is set up

using the

supported by the following parameters.

NODE ADDRESS

• Enter the Node Address of the Module.

• This is typically furnished by the customer.

BAUD RATE

• Most Anybus Modules can automatically detect the network speed by using the

Auto Baud feature.

• Device Net uses 125K bps, 250K bps or 500K bps.

PC2255 Program

and is

01/13

54 51297 Rev. 1

Page 55

Section 6: PC2255 Utility Software

6.7. Fieldbus / 4-20 mA, Continued

DATA TYPE

Data can be setup to output a 32 bit Integer

word or a 32 bit floating point value.

ENDIAN

The Endianess of a module is determined by

the network type, but can be changed from

Little Endian to Big Endian, or vice versa by

using the

LITTLE ENDIAN FORMAT OR INTEL ORDER

In Little Endian Format, the least significant byte is stored first, followed by the

next three more significant bytes.

"CHANGE ORDER"

setting.

For example, a 32bit value of

0x12345678

would be stored in memory in

LITTLE ENDIAN as shown below.

• Address + 0 0x78

• Address + 1 0x56

• Address + 2 0x34

• Address + 3 0x12

BIG ENDIAN FORMAT OR MOTOROLA ORDER

In Big Endian Format, the most significant byte is stored first, followed by the next

three least significant bytes.

For example, a 32bit value of

BIG ENDIAN as shown below.

• Address + 0 0x12

• Address + 1 0x34

0x12345678

would be stored in memory in

• Address + 2 0x56

• Address + 3 0x78

01/13

55 51297 Rev. 1

Page 56

Section 6: PC2255 Utility Software

6.7. Fieldbus / 4-20 mA, Continued

OUTPUT

Data from the FB2255 comprises of three (3) 32-bit words.

• Gross Weight

• Tare Weight

• A 32bit Status Word

• Gross and Tare weights can be selected as either a 32-bit Integer or a 32-bit

Floating Point Word.

• The Most significant Byte indicates the Weigh Mode

for Net.

• The Next Order Byte indicates

command received. (See INPUT Commands)

The next order byte indicates the weight units.

•

"l"

•

"k"

pounds

kilograms

"O"

Overcapacity,

"G"

for Gross, and

"M"

Motion of the last

"N"

•

"o"

ounces

•

"g"

grams.

The Least Significant Byte indicates the number of decimal places, if the weight

output is selected to be a 32-bit Integer word.

– If a Floating point word is selected, this byte will be

“0”.

INPUT

Single Byte Commands can be sent from the network.

– Although the input is read as a 32-bit word, only the Least Significant Byte is

used in this process.

– When the command is sent and recognized, it is entered into the 32 -bit status

byte in the Least Significant Command Byte location.

– New commands can be transmitted after transmitting a

NULL

command.

01/13

56 51297 Rev. 1

Page 57

Section 6: PC2255 Utility Software

6.7. Fieldbus / 4-20 mA, Continued

RECOGNIZED COMMANDS

COMMAND DESCRIPTION

Print Steam

Print Format Stream CR, SPACE, STX, ENQ or Defined Poll

Tare “A”

Print Ticket “p” or “P”

Zero “Z”

Change Gross Net

Weight Mode

Change Units “U”

See Custom Format PC2255.

Character

“G”

DEBUG

• Data in the Anybus Module can be examined by clicking the

button.

• It is stopped by clicking the

STOP DEBUG

button.

START DEBUG

• The

WRITE BUFFER

contains three 32-bit words.

– Gross Weight, Tare Weight and the Status Word is the data sent to the

Network.

• The Contents of the

READ BUFFER,

which is the data received from the

network, is displayed as a 32-bit word.

01/13

57 51297 Rev. 1

Page 58

Section 6: PC2255 Utility Software

6.8. Custom Output – Settings

CHECKSUM

• This setting determines whether a

Checksum Character is enabled or not.

• Checksum is an error detection method

that checks the integrity of the entire string

of data that is transmitted.

DELIMITED

This setting determines if a comma is added

to the output string to separate data fields

contained within the output string.

HARDWARE HAND SHAKING

No current function. Set up for future use.

6.9. Custom Output – Load

A variety of pre-packaged Output Strings is

available.

1. Click the radio button that applies.

Default = Fairbanks

2. Click

OK

Cancel

– See

Formats

to download the settings, or

.

Appendix 1: Data Output

.

IMPORTANT NOTE:

Customized Outputs use

The power must be cycled to the FB2255 Instrument whenever custom outputs are

programmed in order for them to take effect.

Port 1

only.

01/13

58 51297 Rev. 1

Page 59

Section 6: PC2255 Utility Software

6.10. Custom Output – Build

1. Customize the Data Output String to suit

the application requirements.

– The current structure of the output