Instructi

on

Ma

nual

Portable Platform

Models BPP1000 & BPP2000

©

Copyright 1990-2013 Fancor Inc.

Scale

50699 Revision 4 ‒ 03-13

Portable Platform

Models BPP1000 &

03/13 50699 Rev 4

Scale

BPP2000

©

Copyright 1990-2013

This document contains proprietary information protected by copyright. All rights are reserved; no part

of this manual may be reproduced, copied, translated or transmitted in any form or by any means

without prior written permission of the manufacturer.

Disclaimer

Every effort has been made to provide complete and accurate information in this manual.

However, although this manual may include a specifically identified warranty notice for the product,

Fancor Inc. makes no representations or warranties with respect to the contents of this manual,

and reserves the right to make changes to this manual without notice when and as improvements

are made.

Fancor Inc. shall not be liable for any loss, damage, cost of repairs, incidental or consequential

damages of any kind, whether or not based on express or implied warranty, contract, negligence,

or strict liability arising in connection with the design, development, installation, or use of a scale.

Amendment Record

Portable Platform Scale

Models BPP1000 & BPP2000

Document 50699

Manufactured by Fancor Inc.

821 Locust St.

Kansas City, MO 64106

Created 08/1990

Rev. 1 8/1990 Released Manual

Rev. 2 11/2006

Rev. 3 04/2012 Corrected parts list description

Rev 4 03/2013 Misc. revisions

Updates made to include BPP2000;

Revisions in text formatting, illustration updates,

Descriptions, and processes

03/13 5 50699 Rev. 4

T

able of Contents

SECTION 1: INTRODUCTION ........................................ 9

Scope of This Manual ................................................ 9

Modifications ....................................................... 9

Customer/Operator Responsibilities .................................... 9

Repair Restrictions .................................................. 9

Service Responsibility ................................................ 9

Operating Requirements .............................................. 9

Description ........................................................ 10

Specifications ...................................................... 10

SECTION 2: INSTALLATION ......................................... 11

Unpacking ......................................................... 11

Tools Required for Assembly ......................................... 11

Base Assembly .................................................... 12

Pillar and Beam Assembly ........................................... 14

Zeroing the Beam .................................................. 16

Troubleshooting .................................................... 17

SECTION 3: PARTS ................................................ 18

Parts List .......................................................... 18

Parts Diagram ..................................................... 20

03/13 7 50699 Rev. 4

03/13 8 50699 Rev. 4

Section 1: Introduction

Scope of This Manual

This manual provides instructions for the Portable P

BPP1000

•

Please read this manual carefully before assembling.

•

Untrained personnel should not attempt to make any adjustments not specified in

and

B

PP2000

latfor

.

m

Scale Models

these instructions.

Modifications

Absolutely NO PHYSICAL ALTERATIONS (mounting holes, etc.) are to be made to

this equipment.

Customer/Operator Responsibilities

It is the customer/operator’s responsibility to maintain and protect the scale from

accidental or malicious damage.

Repair Restrictions

The Portable Platform Scale must be repaired following specific current

warranty policies for this product.

Service Responsibility

The Portable Platform Scale is factory calibrated, and supplied to the

customer ready to be unpacked, assembled and placed into operation.

Operating Requirements

•

The scale must be operated on a firm, level surface.

•

A bubble level is provided for checking the level condition of the scale.

03/13 9 50699 Rev. 4

y

(

g)

g)

Section 1:

Description

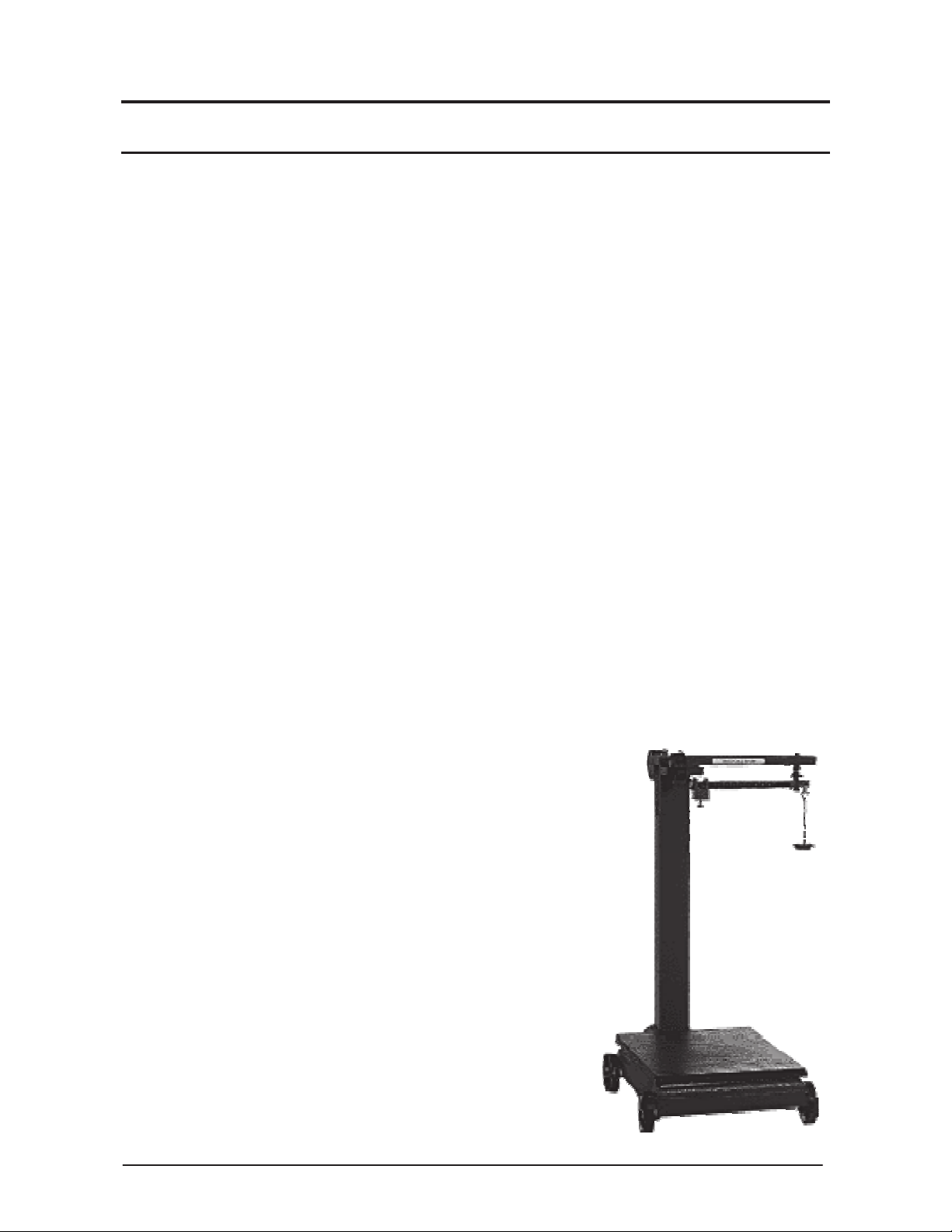

The Portable Platform Scale is a compact portable unit designed for light to

medium operation. It requires no external power connections and will operate in a

wide variety of environmental conditions.

Specifications

Introduction

Specificati

Capacit

Division Size

on

s

1000 lbs.

BPP 1000

1/2lb

454.5 k

BP 2000

2000 lbs. (909 k

.

1 lb

.

Platform Cast iron base Cast iron base

Platform Size 21" x 23½" 24" x 31"

Overall Height 42¾" 42¾"

Platform Height About 7" About 7"

Cast Iron Lever

Cast Iron

Weighing System

t

em

Sys

03/13 10 50699 Rev. 4

Lever Sys

t

em

Section 2: Installation

Unpacking

•

Check the packing materials for loose parts or hardware before disposal.

•

Check that all parts are included using the packing list.

•

Check for component damage that may have occurred during shipping

•

The scale platform under-structure arrives fully assembled, with the levers in their

proper positions.

Tools Required for Assembly

•

Needle nose pliers

•

Flat head and Phillips head screwdrivers

•

An adjustable wrench

03/13 11 50699 Rev. 4

Section 2:

Installation

Base Assembly

NOTE: The following descriptions refer to “Key#” (#4, etc.) to describe parts. Use the

parts list and Key# in the list to identify all such parts.

1. Place the Platform Sub

blocks to raise it up off the floor, if possible.

Assembly

on the floor

upside-down,

preferably on 2x4

2. Remove the cotter pins and washers from one side of the Axle Rod (#19).

•

Axle assembly includes an affixed cotter pin (#17), a 5”

3. Insert the Axle Rod

a flat washer (#18).

Assembly

through the two axle rod holes, side-to-side.

4. Place one flat washer (#18), then a wheel (#16) over the other end.

03/13 12 50699 Rev. 4

wheel (#16), and then

Section 2:

Installation

Base Assembly, Continued

5. Insert a cotter pin (#17) through the

Axle Rod.

•

Using needle nose pliers, bend

back both haves of the cotter pin

to secure the wheel assembly.

6. Repeat steps two through four (2-4)

for the second axle.

7. Center the axles in the base, and then

insert the four

locking

screws (#15)

into each of the tapped holes in the

bottom of the base.

•

Located directly under the axle

holes

8. Tighten the locking screws, and then

secure the Lock Nuts (#14).

9. Turn the platform over so it sets on

the wheels.

After inserting the four Cotter Pins, center

axles, tighten the Locking Screws, and

secure the Lock

Nuts.

the

then

03/13 13 50699 Rev. 4

Section 2:

Installation

Pillar and Beam

Assembly

1. Thread the two (2) Pillar Support Rods (#1) into the tapped holes provided in the base.

•

The end with the longer thread should fit into the platform (about 1⁄2 inch).

2. Place the Pillar (#2) down over the support

rods with the pillar cut-outs facing the right and

left of the platform.

3. Insert the Steelyard Rod (#35) down through

the pillar.

•

The bent hook on top; the loose Swivel

4. Hook the Steelyard Rod (#35) to the

03/13 14 50699 Rev. 4

Hook on the bottom.

•

The hook opening should be toward the

platform when properly placed.

•

DO NOT remove the washers from the

Steelyard Rod.

Long

Lever Tip Pivot (

•

Temporarily, hook the upper end of

#34).

Steelyard Rod on the pillar

cut-out.

the

Hook the Steelyard Rod to

Long Lever Tip

Pivot.

the

y

Section 2:

Installation

Pillar and Beam Assembly, Continued

5. Place the cast iron Beam Support (#39) over the Steelyard Rod with the hook

facing to the right (when facing the scale platform).

6. Insert the Beam Cap (#45) onto the pillar rods.

•

The long side will be to the right.

7. Place Washers over the pillar rods, and then screw on the

two (2) Acorn Nuts (#44).

•

Hand-tighten only, at this time.

8. On the butt end on Beam

Load Loop to the Steelyard

•

See image to the right.

Assembly,

Rod.

hook the bottom

9. Pulling the Beam up, hook the top Fulcrum Loop (of the

Beam

•

10.

Insert the Beam Lock (#43) onto the front end of the

Beam Assembly.

•

11.

Slide t he Beam Lock (#43) over the

Beam and align it with the two (2) holes

in the Beam Cap (#45).

12.

Fasten the Beam Lock to the Beam Cap

with the two (2) Hex Bolts (#46).

•

13.

Hang the

(

14.

Set the Sliding Poise (#52) to zero and

hand tighten the screw on its under-side.

•

•

Assembly)

to the hook on the Beam Support

(#39).

The beam should hang loosely from the two hooks.

See image to the right.

The handle faces the scale platform.

Counterpoise Assembly

#54) from the Beam Tip

Check that the beam is straight and does

not touch the sides of the Beam Lock.

Shift the Cap if necessary to straighten,

and then tighten the acorn nuts securely

Loop.

Insert the Beam Lock onto the end of the

Assembly, then align the Beam Lock under the

with an adjustable wrench.

Hook the bottom Load

to the Steelyard Rod.

the Beam up, hook the

Fulcrum

two

holes in the Beam Cap. Fasten this

assembl

with

the two Hex

Loop.

Bolts.

Loop

Pulling

top

Beam

03/13 15 50699 Rev. 4

Section 2:

Installation

Zeroing the Beam

Note:

1. Unlock the Beam Lock Loop to allow the beam to balance.

2. Balance the beam by adjusting the balance ball at the butt end of the beam, using a

The scale is now assembled.

03/13 16 50699 Rev. 4

Check that the weighing platform "floats" on the levers' pivots and bearings and

does not bind or set to one side. The platform should return to a centered position if

moved to any position then released.

•

The beam should move up and down freely coming to rest in the center of the trig

lock opening.

screwdriver.

•

Turning the screw CW (Clock-Wise) raises the beam

•

Turning the screw CCW (Counter Clock-Wise) lowers the beam.

Section 2:

Installation

Troubleshooting

If the beam will not balance using the balance ball, check the

•

Is the poise is at 0 (zero), and is the poise screw is snug?

•

Is the platform free and “floating”?

•

Is the beam load rod connected properly on both ends?

•

Is something under the platform inhibiting the levers (floor debris)?

•

Are there any weights on the counterpoise hanger, and is it on the Tip

•

Is the beam hanging from the middle loop?

•

Is the Beam Lock Loop (#43) open?

following:

Loop?

Apply a slight pressure to the scale platform and see if the beam tip rises.

•

If it does, continue onto balancing step.

•

If it does not, recheck mechanical assembly.

If the scale beam

still does not balance (beam rises with slight pressure),

perform the following:

1. Use a screwdriver to 'center' the balance ball at the butt end of the beam.

2. If the beam is up, apply small amounts of weight (BBs) to the top of the

C

ounterpoise.

3. If the beam is low, remove the

Counterpoise

hanger (#54), loosen the hanger rod

by turning and holding the bottom nut, and remove a small amount of lead shot.

4. Add or remove small amounts of weight until beam balances.

5. Secure the counterpoise hanger with added or removed weight.

03/13 17 50699 Rev. 4

Section 3: Parts

Parts List

Key #

Part #

B

PP1000

55017

B

PP2000

Part

#

Description

BPP1000

Series, 24" x 21",

1K x .5, NTEP,

Portable Beam

55789*

1 71622 78796* Set of Pillar

2 58933 77228*

3 95847 Cover Assembly,

4 95848

5 95855 Cotter

6 58937 Bearing,

7 95856 Screw, Phillips

8 95857 Screw,

9 95858 Level,

10 95859 Pin, Corner

11 71623 Loop,

12 71624 Bearing, Corner

13 71625 Cotter

11, 12, 13 58938 Corner Loop

14 95867 Nut,

15 95868 Bolt, Hex

16 95869 Wheel, 5"

17 71628 Cotter

18 71629 Washer,

19 71630

24 95861

25 72948 Lever Assembly,

26 58939 Center Connection Assembly (26, 27, 28, 29,

27 Clip, Center

28 Link, Center

29 Cotter

30 95862

31 95863

32 75712* Upper Bearing, Center

33 72947 75713* Long Lever

34 95864 Long Lever Tip

35 58934 Steelyard Rod

BPP2000

Pillar

Frame

Axle

Pivot

Pivot

Pivot

Series, 24" x 31",

Rods

Pin

Platform

Head

Allen

Bubble

Loop

Corner

Pin

Assembly

Hex

Head

Diameter

Pin

Flat

Connection

Connection

Pin

Assembly

Pivot

Assembly

Platform

Loop

Short

2K x 1, NTEP,

Connection

Portable Beam

32)

xxxxx* Indicates a part number for the BPP2000.

03/13 18 50699 Rev. 4

p

A

y

A

t

Section 3:

Parts

Parts List, Continued

B

Key #

36, 37, 38 71594 Loo

37

38

39

95839 77229* Support Beam

40

71591

40, 41, 42 71595

41

42

43

95840

44

71592

45

95841 77227* Cap, Beam

46

71593

47

48

47, 48, 49 95843

PP1000

Part #

55017

50

71632

51

51, 52, 53 95842

53

54, 58,

60

55, 56, 57

55, 56, 57

55

56

57

58

59

60

61

62

N/S

N/S

59,

58935

58936

95853

95854

95865

95866

71586

71587

B

PP2000

Part #

71633* BPP2000 2000 lb. Portable Beam

75711* BPP2000 BPP2000 Beam Inser

Description

ssembl

Cotter Pin

Bearing

Loop

LoopAssembly

Cotter Pin

Bearing

LockAssembly, Beam

corn Nut (2)

Hex Bolt (2)

Screw, Balance WeightAdjustment

Weight, Balance

BeamAssembly (100 x 0.5 lb)

BPP1000 1K x 0.5 NON-NTEP Beam

Pivot

Pivot

PoiseAssembly

Loop

Counterpoise Stem Assembly

71598* Set of SE Weights

74392* Set of Metric Weights

1 lb. Counterpoise Weights

2 lb. Counterpoise Weights

4 lb. Counterpoise Weights

Top, Counterpoise

Cup, Counterpoise

Nut, Hex

Pin

Cotter Pin

Set of Corner Loops

Set of Bearing Corner Loops

xxxxx*

03/13 19 50699 Rev. 4

Indicates a part number for the BPP2000.

Section 3:

Parts

Parts Diagram

45

44

39

40

49

1

35

8

7

9

34

2

46

43

52

55

56

25

14

54

31

26

15

24

57

3

61

62

33

6

5

10

12

13

11

17

18

16

19

03/13 20 50699 Rev. 4

4

Portable Platform Scale

Models BPP1000 & BPP2000

Document 50699

Loading...

Loading...