Operator Manual

Fairbanks Access Solutions

Model: AN Series

powered by Titan Technology

2012-2013 by Fairbanks Scales, Inc.

All rights reserved

Rev. 1

51299

01/13

Amendment Record

Fairbanks Access Solutions

Model: AN-Series

Document 51299

Manufactured by Fairbanks Scales Inc.

821 Locust

Kansas City, Missouri 64106

Created 10/2012

Revision 1 01/2013

powered by Titan Technology

01/13 3 51299 Rev. 1

Disclaimer

Every effort has been made to provide complete and accurate information in this manual. However, although this

manual may include a specifically identified warranty notice for the product, Fairbanks Scales makes no

representations or warranties with respect to the contents of this manual, and reserves the right to make changes

to this manual without notice when and as improvements are made.

It is the responsibility of the requesting party to develop, maintain, install, and connect networking devices and

general network connectivity as it applies to the originating party’s network. No warranty or guarantee, expressed

or implied, concerning the network, its design, its installation, or operational characteristics has been offered by

Fairbanks Scales. Fairbanks Scales shall not be liable for any loss, damage, cost of repairs, incidental or

consequential damages of any kind, whether or not based on express or implied warranty, contract, negligence,

or strict liability arising in connection with the design, development, installation, or use of an intended network

.

Trademarks

All other product names mentioned herein are used for identification purpose only and may be

trademarks and/or registered trademarks of their respective companies.

© Copyright 2012-2013

This document contains proprietary information protected by copyright. All rights are reserved; no part of this

manual may be reproduced, copied, translated, or transmitted in any form or by any means without prior written

permission of the manufacturer.

01/13 4 51299 Rev. 1

Table of Contents

Section 1: General Information ................................................................................................................... 7

1.1. Brief Overview ................................................................................................................................ 7

1.2. System Configurations .................................................................................................................... 8

1.3. Features ......................................................................................................................................... 9

1.4. Safety Guidelines .......................................................................................................................... 10

1.5. Recommendations ........................................................................................................................ 11

Section 2: Maintenance ............................................................................................................................ 12

2.1 Securing the Terminal cabinet ........................................................................................................ 12

2.2. Opening Secure Access Entry Unit .................................................................................................. 13

2.3. Loading the Printer Paper .............................................................................................................. 14

2.4. Create Backup From USB Memory Stick ......................................................................................... 17

2.5. Restore From Backup Using USB Memory Stick .............................................................................. 19

2.6. Power Down Terminal ................................................................................................................... 20

2.7. Parts Orientation .......................................................................................................................... 22

2.8. Contact Support ............................................................................................................................ 23

Section 3: Access Terminal Screens Defined .............................................................................................. 25

3.1 Home ............................................................................................................................................ 25

3.1.1. System Status Page ........................................................................................................................... 25

3.1.2. Reports Page ..................................................................................................................................... 27

3.1.3. System Setup Menu ........................................................................................................................... 28

3.1.4. Device Setup ...................................................................................................................................... 29

3.1.5. Diagnostics ........................................................................................................................................ 29

3.1.6. About ................................................................................................................................................. 30

3.2 System Setup ................................................................................................................................. 31

3.2.1. Access Unit Setup .............................................................................................................................. 31

3.2.2. Credit Card Processor Settings ........................................................................................................... 33

3.2.3. Date And Time Setup ......................................................................................................................... 34

3.2.4. Email Setup ........................................................................................................................................ 35

3.2.5. Email Subscriptions ............................................................................................................................ 36

3.2.6. Hours Of Operation Setup ................................................................................................................. 37

3.2.7. Matrex Setup ..................................................................................................................................... 38

3.2.8. Payment Setup .................................................................................................................................. 41

3.2.9. Scale Ticket Setup .............................................................................................................................. 42

3.2.10. Timeout And Delay Setup ................................................................................................................ 45

3.2.11. Traffic Control Setup ........................................................................................................................ 49

3.2.12. Transaction Flow Setup ................................................................................................................... 58

3.2.13. Units Of Measure ............................................................................................................................. 60

3.2.14 User Setup ........................................................................................................................................ 61

3.2.15. Weightment Setup ........................................................................................................................... 64

3.2.16. Welcome Screen .............................................................................................................................. 69

3.3. Device Setup Menu ....................................................................................................................... 73

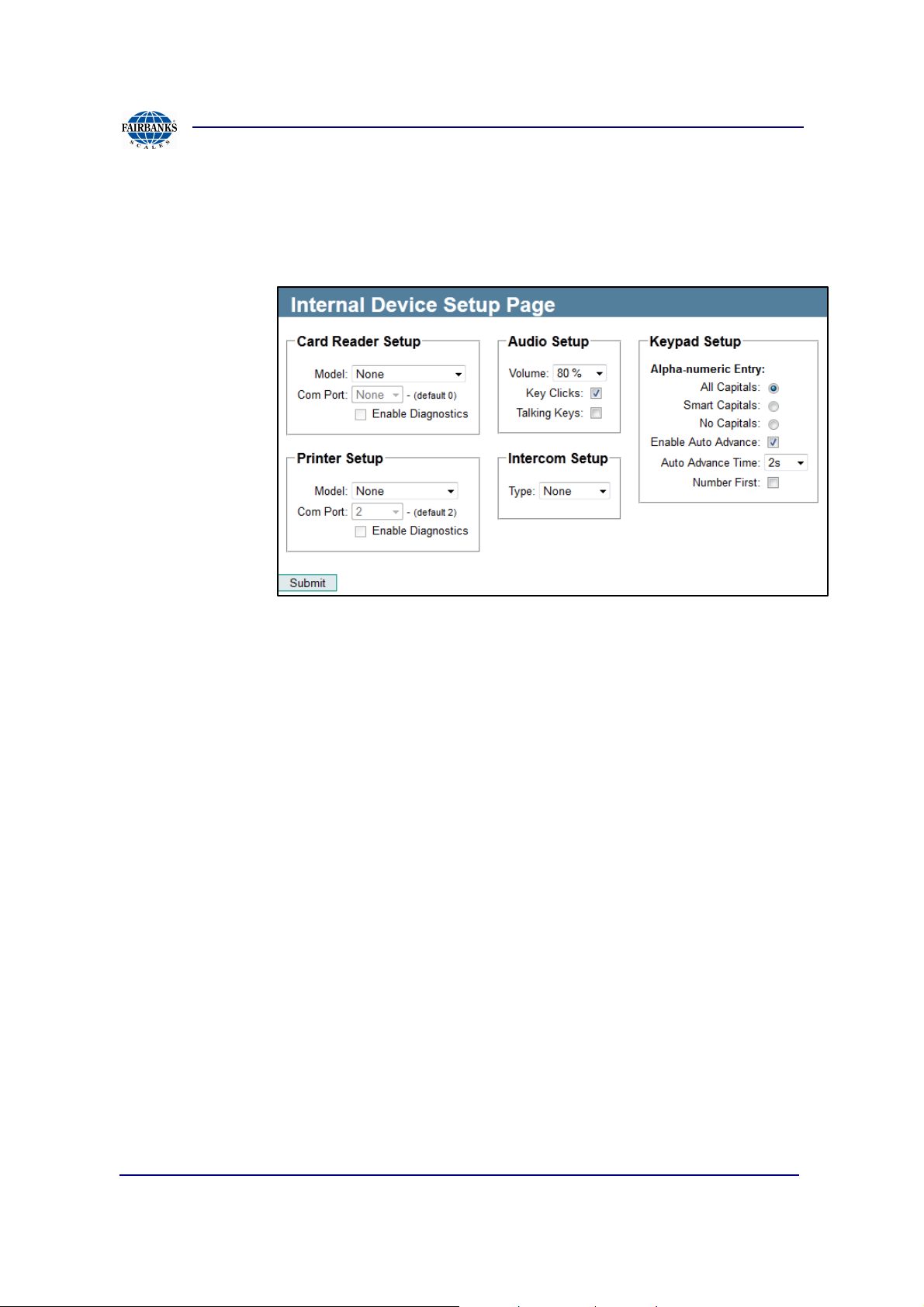

3.3.1. Internal Devices ................................................................................................................................. 74

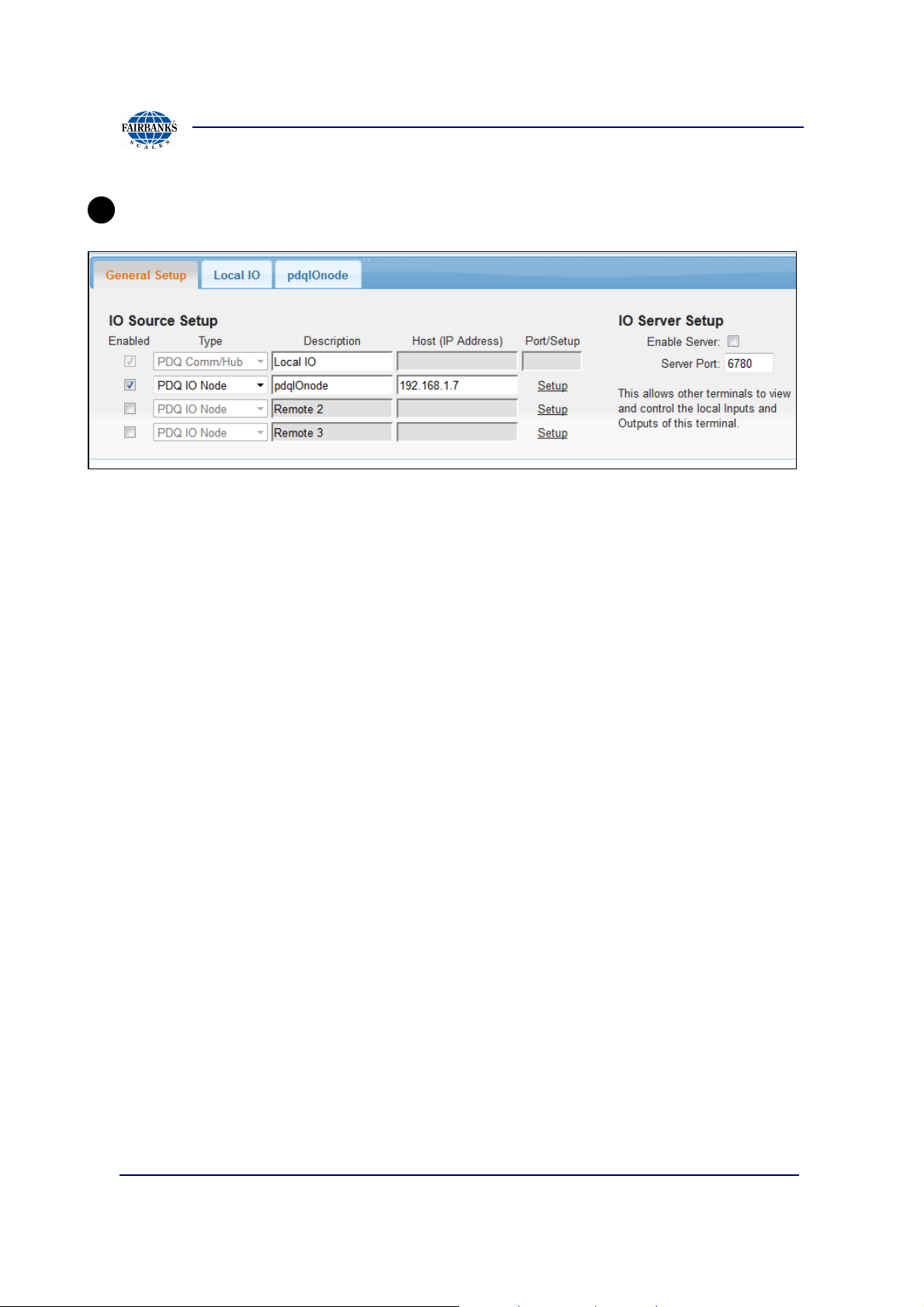

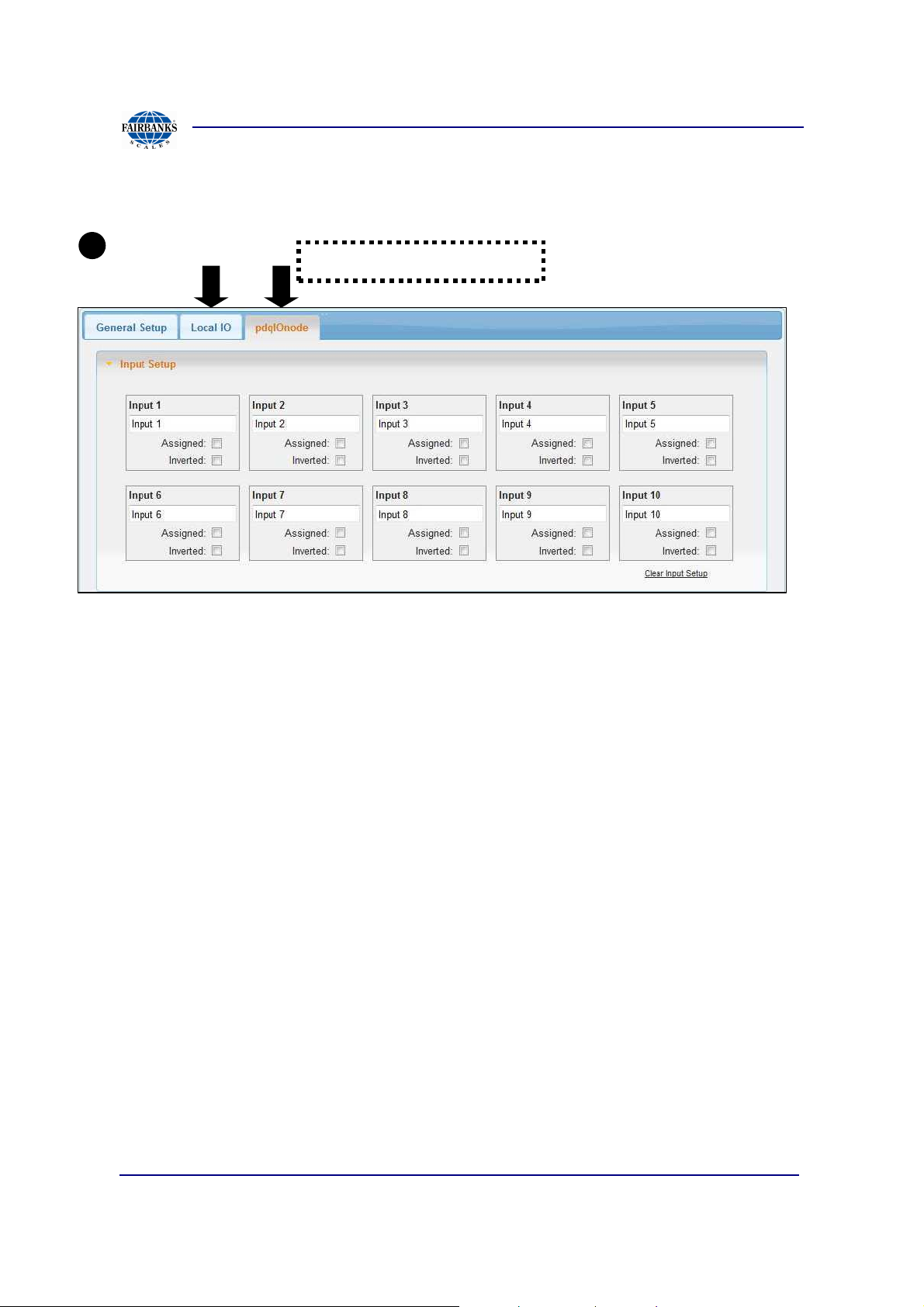

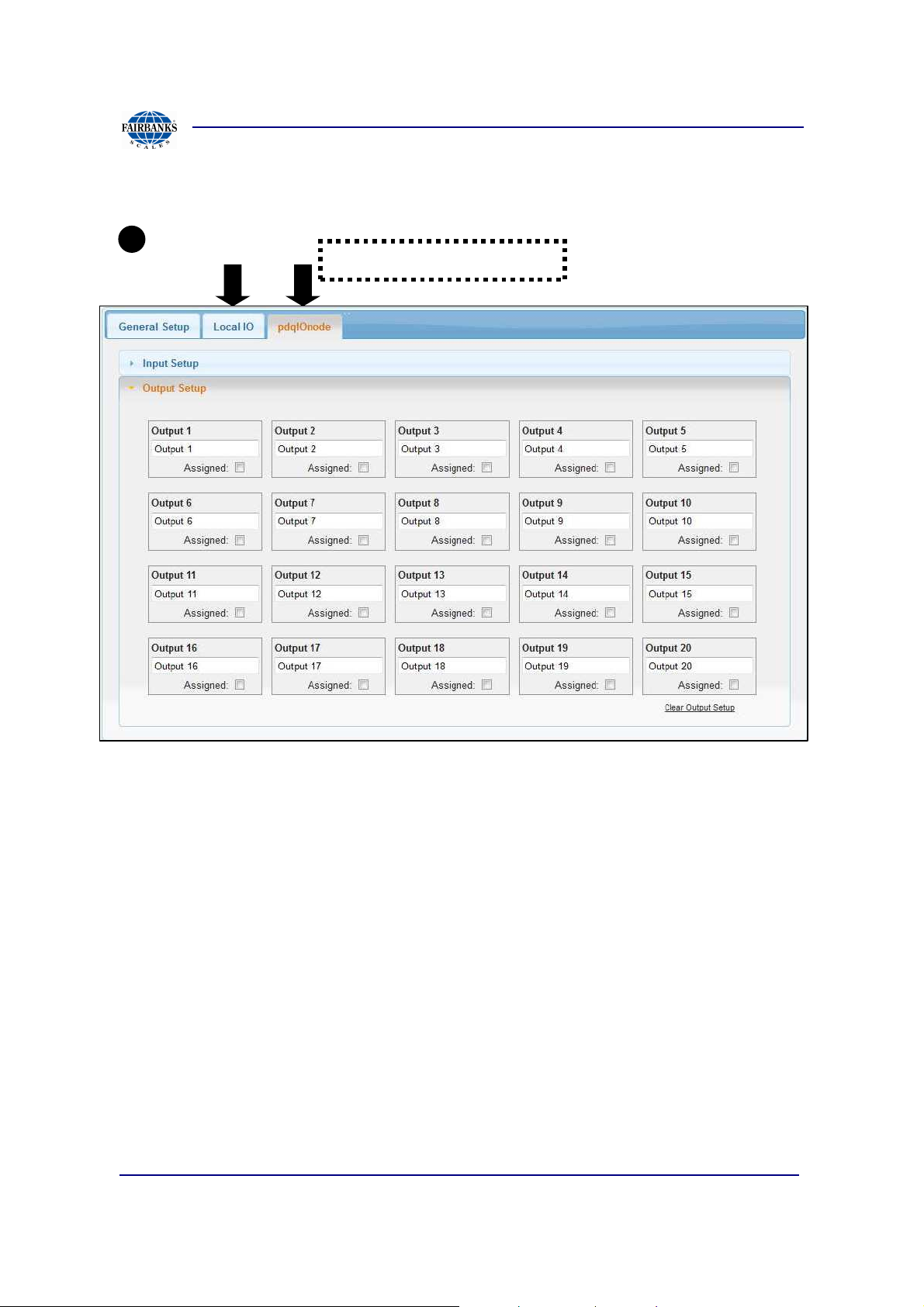

3.3.2. Input/Output Setup ........................................................................................................................... 76

3.3.2 Configurations for PDQ IO node ......................................................................................................... 84

3.3.3. Network Setup ................................................................................................................................... 88

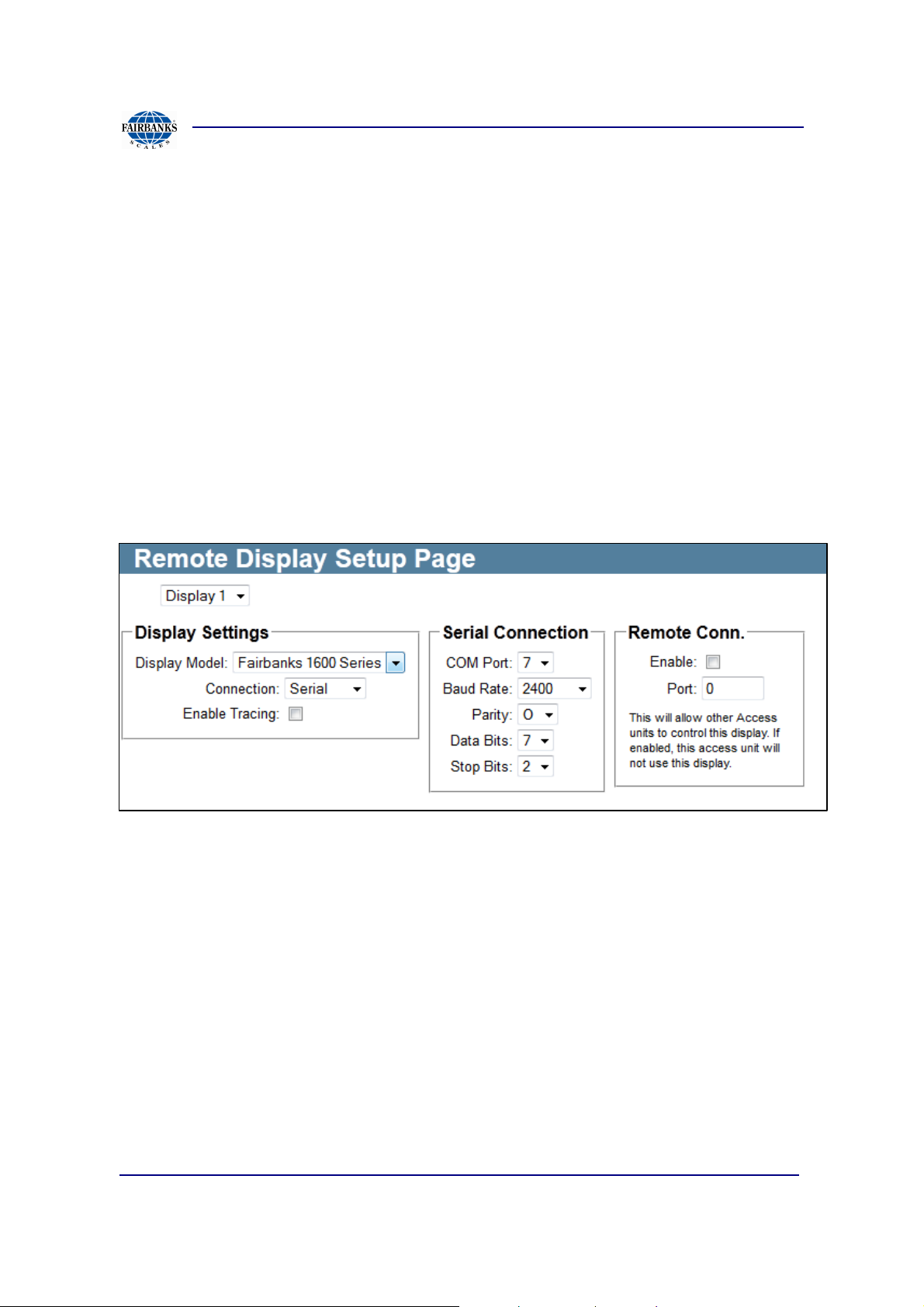

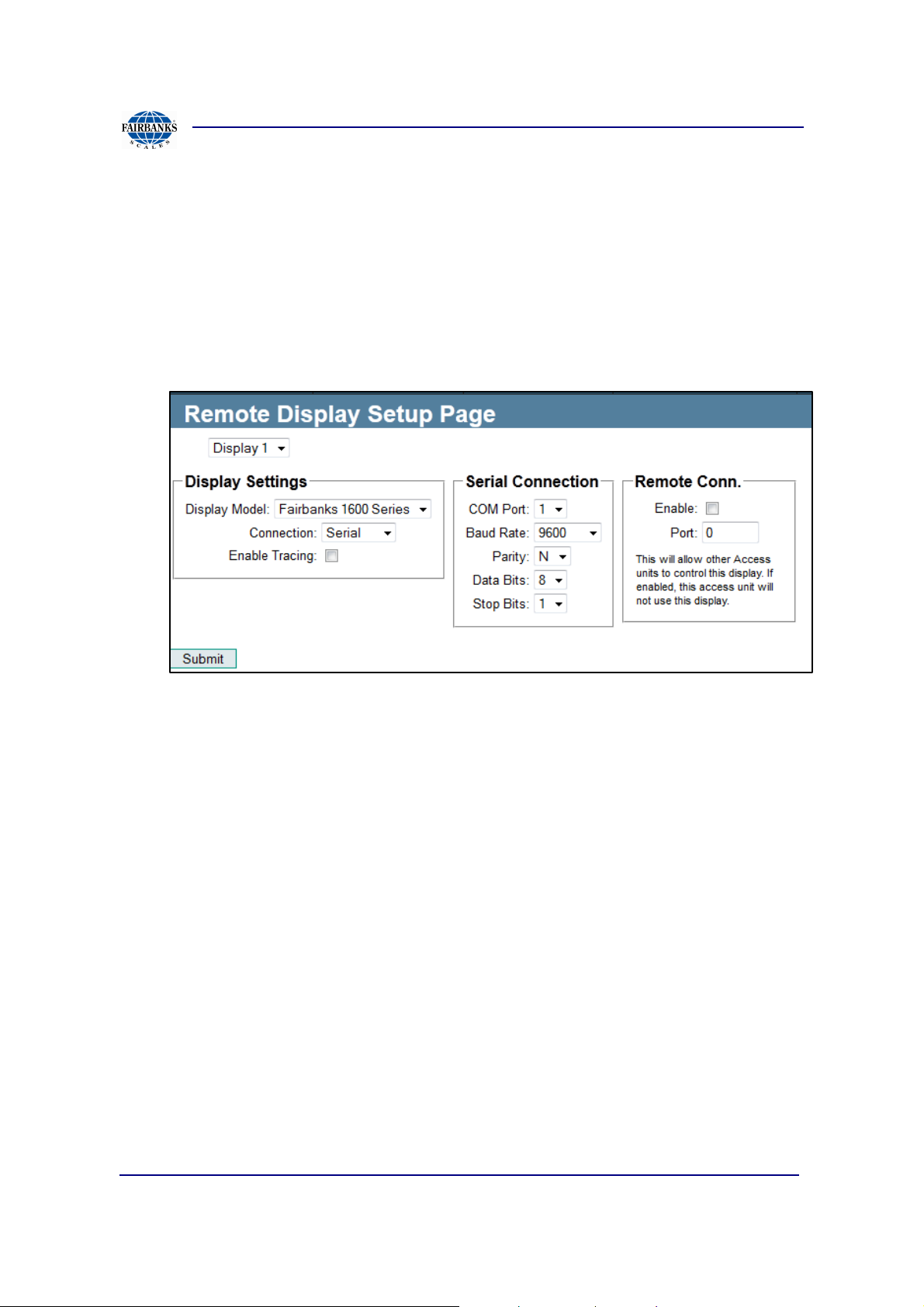

3.3.4. Remote Display Setup ........................................................................................................................ 90

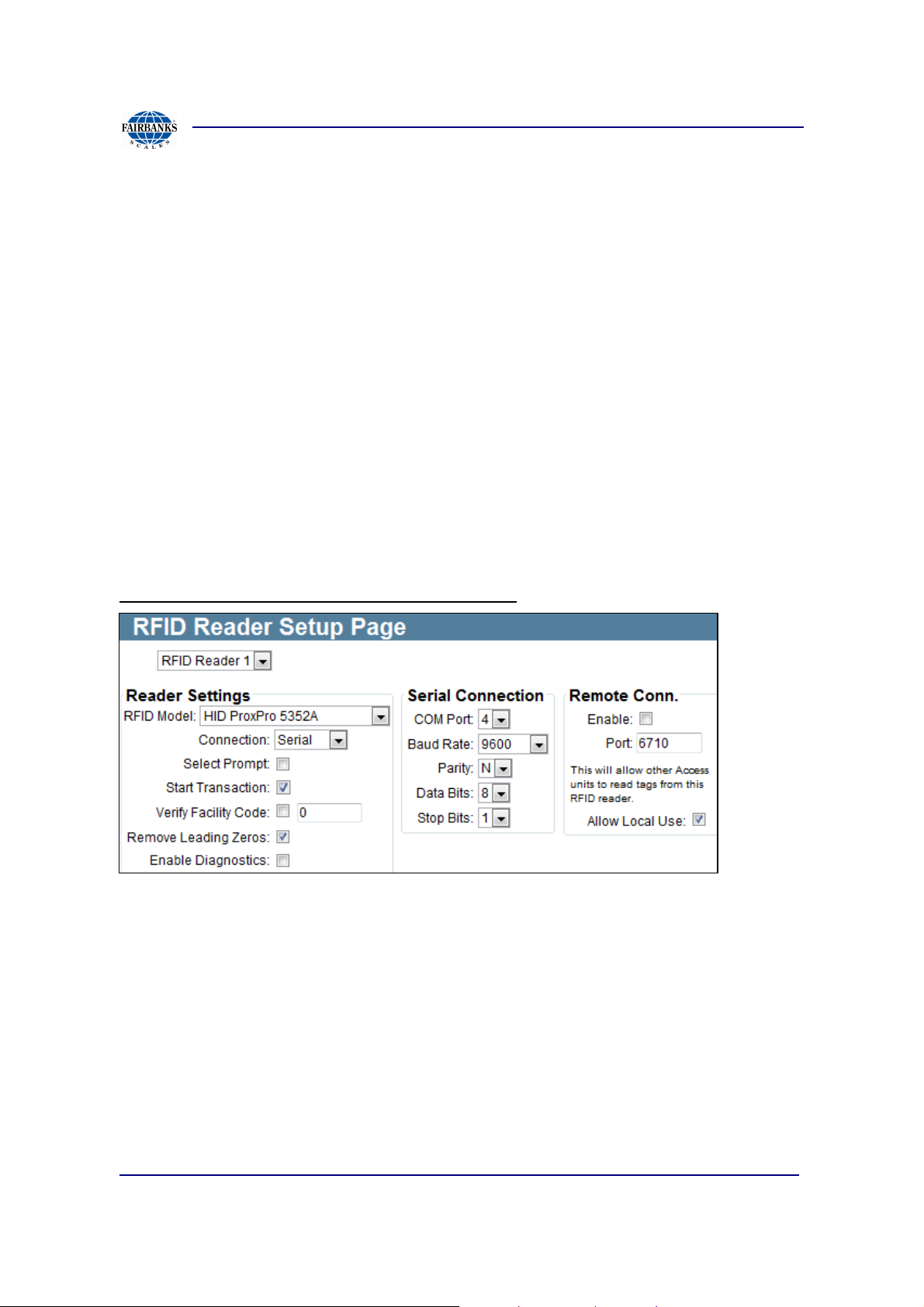

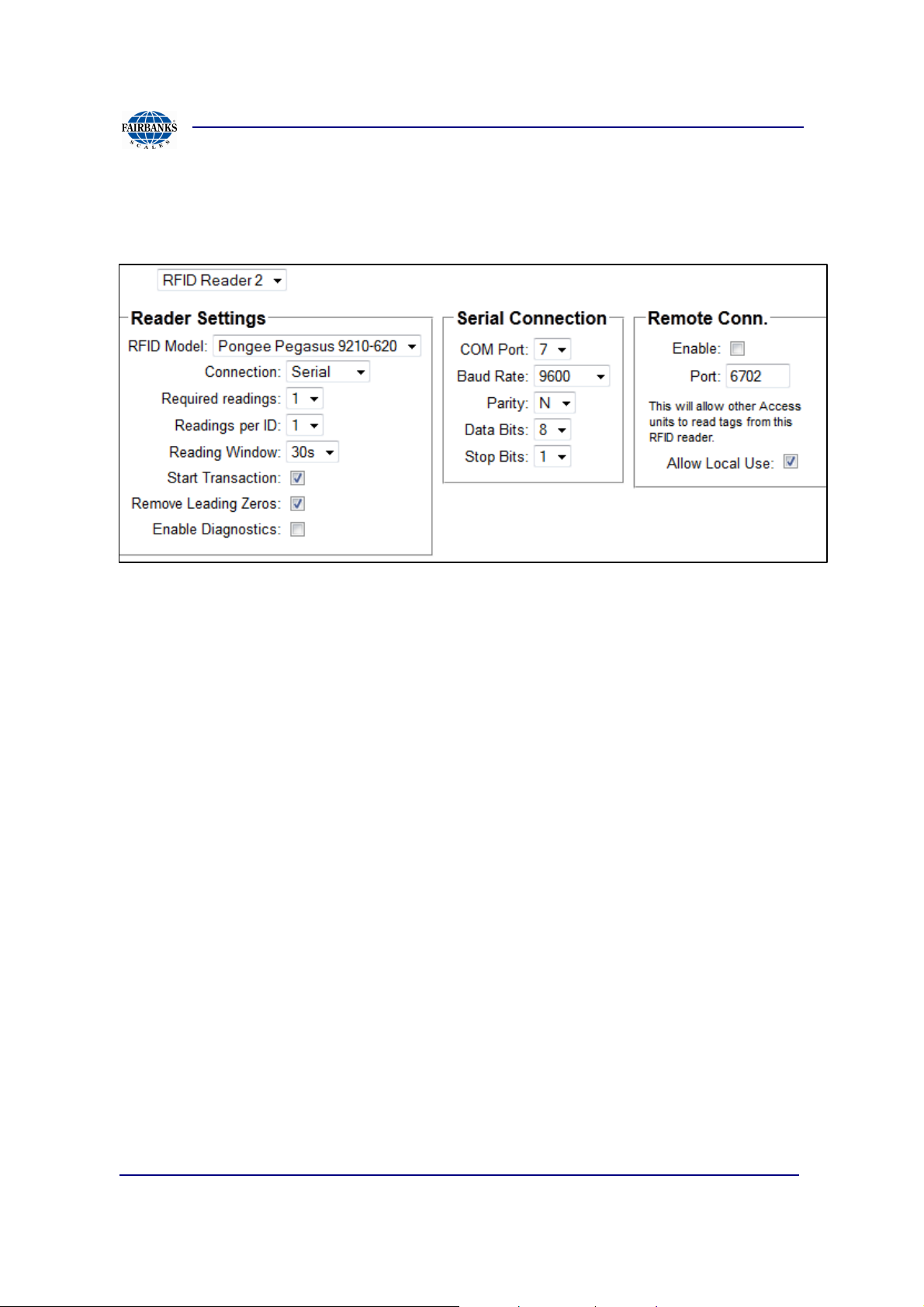

3.3.5. Rfid Reader Setup .............................................................................................................................. 92

3.3.6. Scale Indicator Setup ......................................................................................................................... 98

01/13 5 51299 Rev. 1

Table of Contents

3.3.7. Sign Setup ........................................................................................................................................ 102

3.4. Diagnostics Menu ....................................................................................................................... 104

3.4.1. Audio Diagnostics ............................................................................................................................ 105

3.4.2. Credit Card Logs............................................................................................................................... 106

3.4.3. I/O Diagnostics ................................................................................................................................ 107

3.4.4. Keypad Control ................................................................................................................................ 109

3.4.5. Network Diagnostics........................................................................................................................ 110

3.4.6. Diagnostics Options ......................................................................................................................... 111

3.4.7. Restart Page .................................................................................................................................... 112

3.4.8. Screen File Viewer ............................................................................................................................ 113

3.4.9. System Logs ..................................................................................................................................... 114

3.4.10. System Management .................................................................................................................... 115

3.4.11. Transaction Cache ......................................................................................................................... 115

3.4.12. About Page .................................................................................................................................... 116

01/13 6 51299 Rev. 1

Section 1: General Information

1.1. Brief Overview

Fairbanks Access Solutions system controls entrance/exit of vehicles hauling

materials in/out of a facility. The Access Solutions system contains 1 or more Access

Terminals and a data processing system (i.e. MatreX).

VEHICLE WEIGHING PROCESS ORDER

1. Vehicle drives onto a scale (provided by customer).

2. Vehicle is identified through 1 of 3 options: short/long range RFID reader,

card, or a manual process where the customer enters a code on Access

Terminal.

3. MatreX looks up vehicle information and sends it to the Access Terminal.

4. Vehicle is processed based on specific vehicle weighing process information.

5. Terminal receives vehicle weight from scale indicator (provided by customer).

6. Weight data and customer responses are sent to MatreX.

7. If transaction is complete, customer receives a detailed scale ticket receipt.

SAMPLE TRANSACTION PROCESS SCENARIOS

Fairbanks Access Solutions processes vehicles in multiple ways through weight:

Processing by Weight

• Weigh In and Weigh Out: Truck weighs entering the facility and weighs exiting

the facility, 2 weighments

• Weigh In w/ Stored Tare Weight: Truck weighs entering the facility then exits

facility, 1 weighment

• Weight Out w/ Stored Tare Weight: Truck enters facility then weighs exiting

facility, 1 weighment

• Multiple Weighs: Mixed load vehicles are weighed multiple times while at the

facility

GROSS WEIGHT (full weight) = VEHICLE WEIGHT + MATERIAL

TARE WEIGHT (empty weight) = VEHICLE WEIGHT

NET WEIGHT (material weight) = GROSS WEIGHT (vehicle + material) - TARE

Gross, Tare, & Net Weight Relationships

01/13 7 51299 Rev. 1

Section 1: General Information

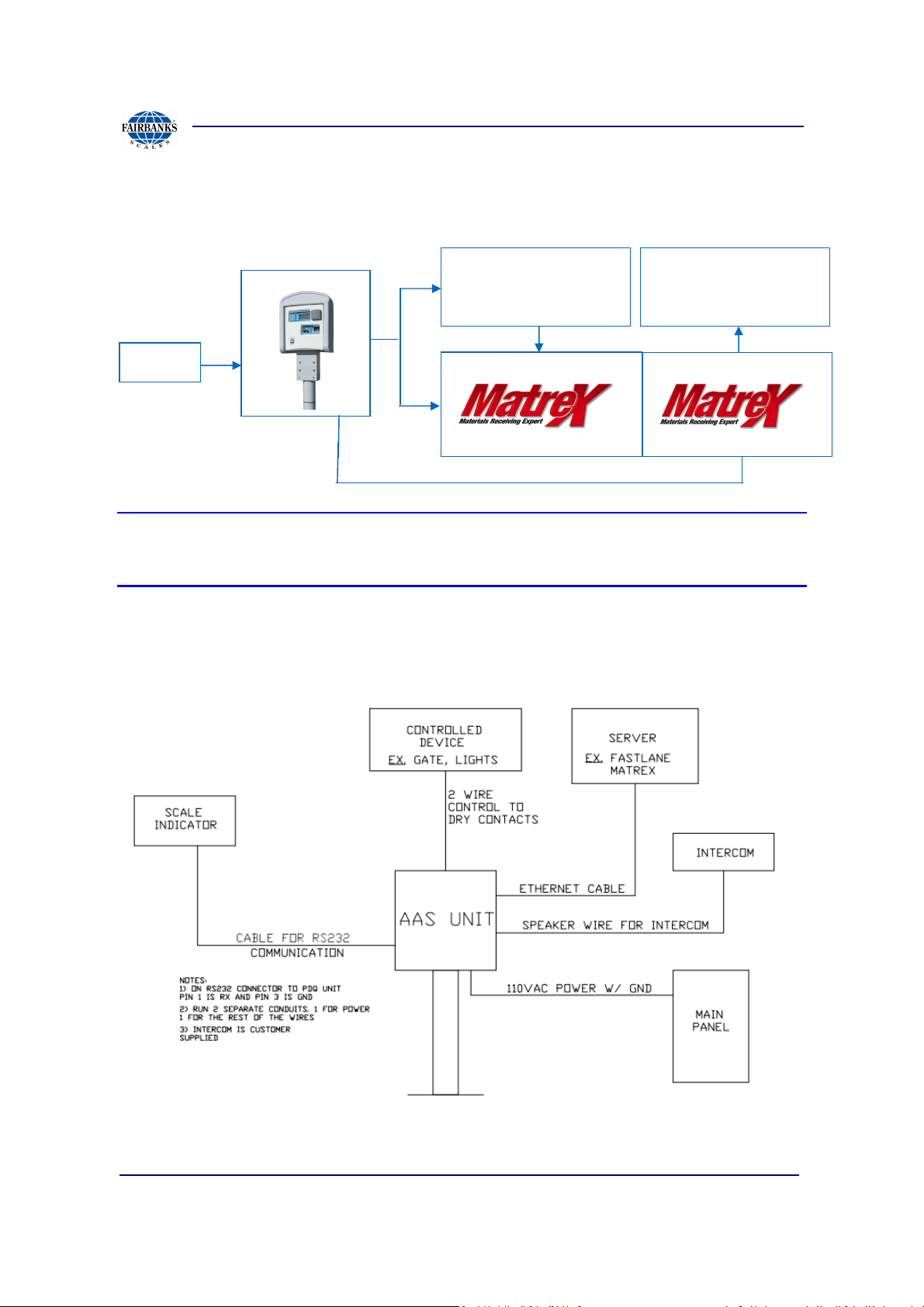

1.2. System Configurations

Fairbanks Access Solutions is configurable in multiple ways:

Data Processing System

3rd Party

Data Processing System

3rd Party

Scale

Note:

If using a 3rd party data processing system custom software integration, additional software

installation will be required.

01/13 8 51299 Rev. 1

Section 1: General Information

1.3. Features

• Various Mounting Options and Contemporary Design

• Easy Maintenance

• Replaceable Keypad

• Short-Range/Long Range RFID Reader

• Custom Inputs (start transaction, detect vehicle)/Outputs (lights, gates)

• Magnetic Card Reader

- Provides users with card success or failure status through audio sounds and

assistance

- Jam proof operation, provides clear and safe path for entering debris and/or

water

• Electrical System

- Modular design allows for multiple component replacements.

- Protects against damage and operational problems during low power

and/or lightning storms.

- Battery Backup System providing 12VDC battery power during power loss.

(2 weeks if fully charged)

- Climate Control System

- Provides continuous air and heat circulation to internal Access Terminal

devices

01/13 9 51299 Rev. 1

Section 1: General Information

1.4. Safety Guidelines

• Any personnel operating or performing maintenance on the equipment must read

and adhere to all safety and machine operating instructions

• When installing or operating a piece of Fairbanks Access Solutions equipment,

adhere to all fire and safety rules/regulations, per local, state, and national

authorities; consult local code authorities for additional information

• The equipment must be maintained and operated only by competent personnel.

The user must operate appropriate tools and understand electrical wiring and

potential hazards. If there is any doubt, contact the Fairbanks Access Solutions

service representative to arrange professional maintenance of the equipment.

• Do not climb or stand on equipment for any reason

• Use appropriate protective gear and tools during installation

• Personnel are to perform lockout/ tag safety requirements, per OSHA regulations

• All personnel should read, be familiar with, and observe all CAUTION, DANGER,

AND WARNING decals/labels placed on equipment

• Follow all maintenance schedules and procedures; it is critical to maintain trouble

free performance of FBAS equipment

• There may be residual voltage in the unit-proceed with caution

• The battery is a high output style that stores a great amount of energy; enlist care

when servicing the battery, power board, or controller

The unit contains a Rechargeable Sealed Lead-Acid Battery. The battery should

NOT be disposed of in normal trash containers, but recycled. In the USA call 1800-SAV-LEAD. The battery is functionally similar to a car battery supplier.

• Read battery markings for additional safety and disposal information

• Ensure all shields, guards, nuts, bolts, and screws are in place and secure.

01/13 10 51299 Rev. 1

Section 1: General Information

DO

Follow all maintenance schedules for trouble

-

free performance of

Fairbanks

Access S

olutions

DO NOT

1.5. Recommendations

Read all manuals completely.

Follow all instructions completely.

equipment.

Ensure backup battery remains connected during controller unit service to prevent incorrect date, time,

or possible data loss when power is restored.

Verify high voltage is disconnected by checking the voltage with a volt meter on each circuit.

Ensure the following devices are fully operational: card reader, receipt printer, Ethernet gateway, and

internet account with email.

Monitor emails and transactions, possible errors will be indicated in Email error message; frequently

check.

Properly recycle batteries.

Change codes regularly and remove past users from list to maintain security.

Use care when setting operational procedures and user security levels.

Turn off main circuit breaker and wait 60 seconds prior to disconnecting battery or main power

controller box.

Enlist care when handling battery; it stores abundant energy and remains active after main power is

turned off.

Test all common transactions prior to processing customer transactions AND opening business.

Save the initial setup account configuration for future reference.

For transactions, completely insert card into reader and quickly withdraw.

DO NOT operate the system until all safety features are tested.

DO NOT attempt to add or retrofit components to equipment without first contacting FBAS.

01/13 11 51299 Rev. 1

Section 2: Maintenance

2.1. Securing the Terminal cabinet

The Access terminal comes with a padlock when inserted, locks and prevents

opening the housing. For record keeping have the key tag # written down and stored.

If one or both keys are

lost the key tag# can be

used to reorder keys for the exact lock. Contact a local Fairbanks distributor or tech

services at toll free 800-451-4581, press 2, press 1.

01/13 12 51299 Rev. 1

Section 2: Maintenance

2.2. Opening Secure Access Entry Unit

By default the Access Terminal is configured to sound an alarm from

unauthorized users when a service and user code is not entered. To change

paper or further maintenance enter the below steps.

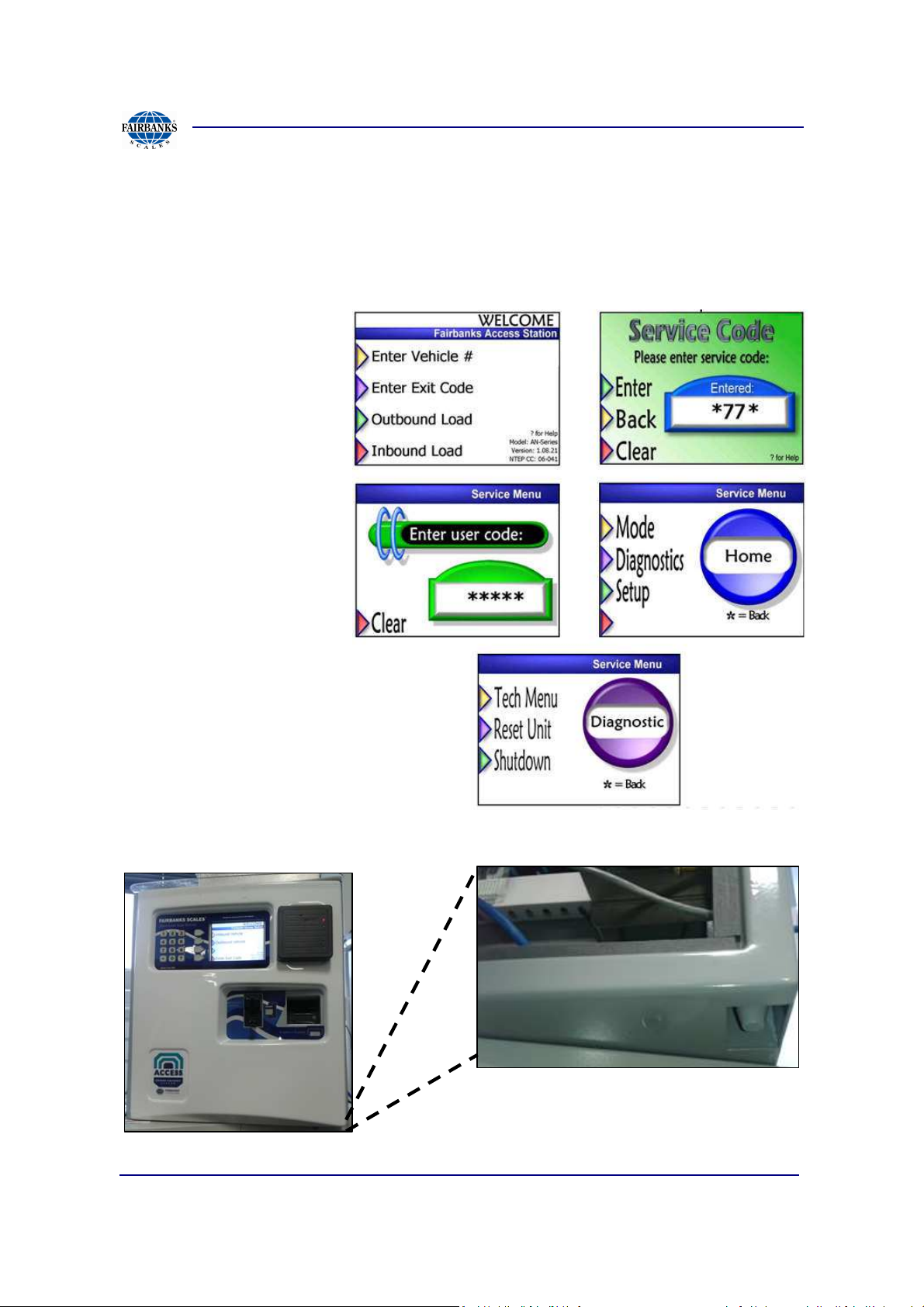

STEPS IN DISABLING ALARM

From keypad, type:

*77*

12345

From the Service Menu

Home screen the door

alarm will be disabled.

Open cabinet door by pressing up on release lever, located in bottom right of unit.

.

01/13 13 51299 Rev. 1

Section 2: Maintenance

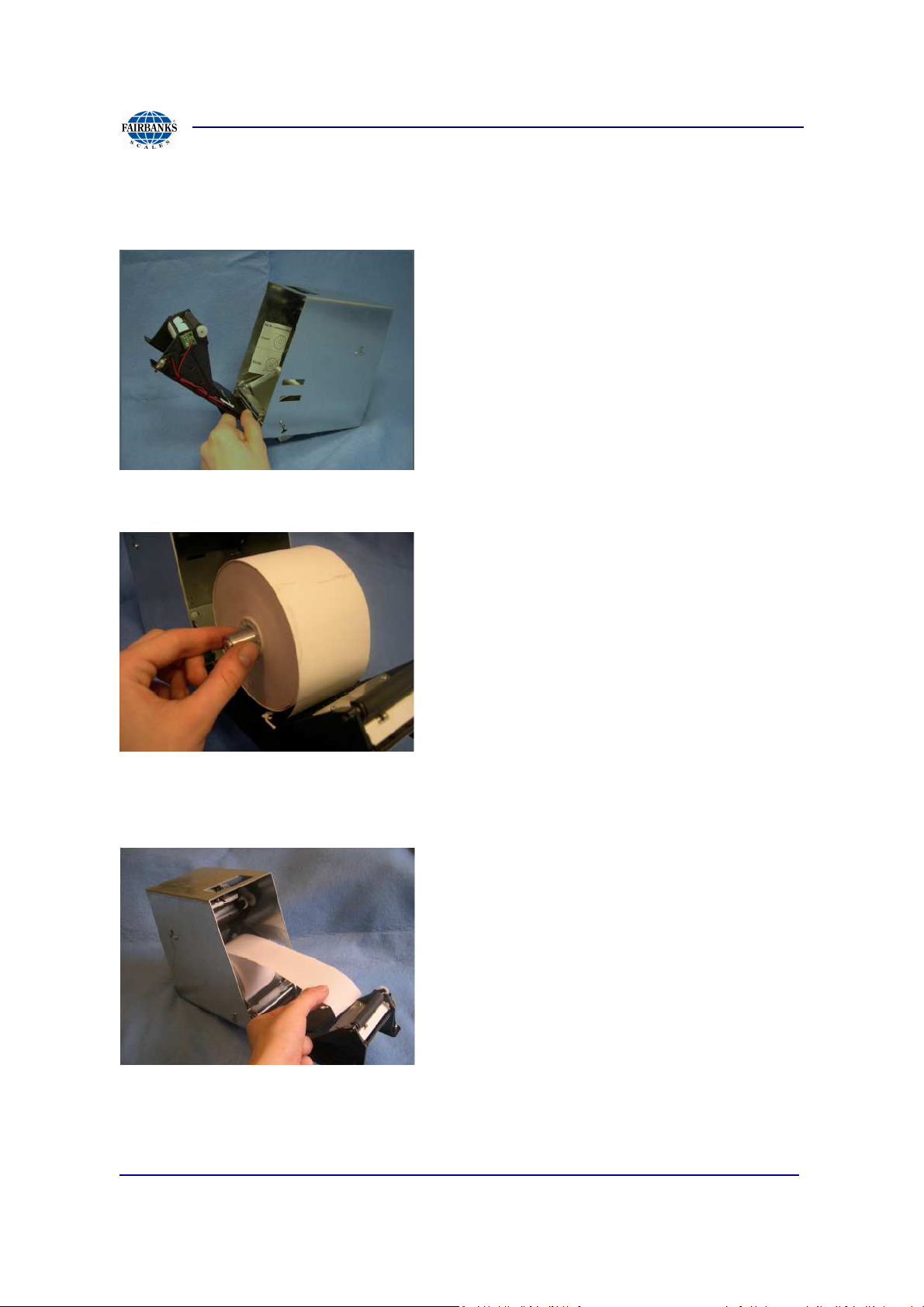

2.3. Loading the Printer Paper

1. Open the front door assembly, picture shown without printer paper loaded.

2. Place paper roll inside of printer assembly, picture shown with metal core

inside of roll.

3. Verify receipt paper is pulling from top down, note position is pulled close to

feed roller.

01/13 14 51299 Rev. 1

Section 2: Maintenance

2.3. Loading the Printer Paper, Continued

4. Feed paper through slot in front of white plastic hinge, note ,” white feed here”

sticker position.

5. Side view of printer assembly loaded without front door hinge open, note

paper is in the feed area.

01/13 15 51299 Rev. 1

Section 2: Maintenance

2.3. Loading the Printer Paper, Continued

6. After successfully loading paper and closing the printer door, a configuration

page will print.

If paper fails to print, press the button on the top right quadrant of the printer

door, this should manually feed paper through.

If no paper is printing or feeding through the printer, verify the previous 5 steps

again; possible causes could be pinched paper in printer assembly door or the

paper has been fed improperly.

01/13 16 51299 Rev. 1

Section 2: Maintenance

2.4. Create Backup From USB Memory Stick

After successful installation and configuration of the site it is good practice to back up

the Access Terminal to lessen future down time.

Note(s):

Using the navigation prompts will create a directory with the units’ serial number then

the data is stored inside it. This procedure allows multiple units to be backed up to a

single USB jump drive. Restoration of files reflects on the serial number assigned to

the unit.

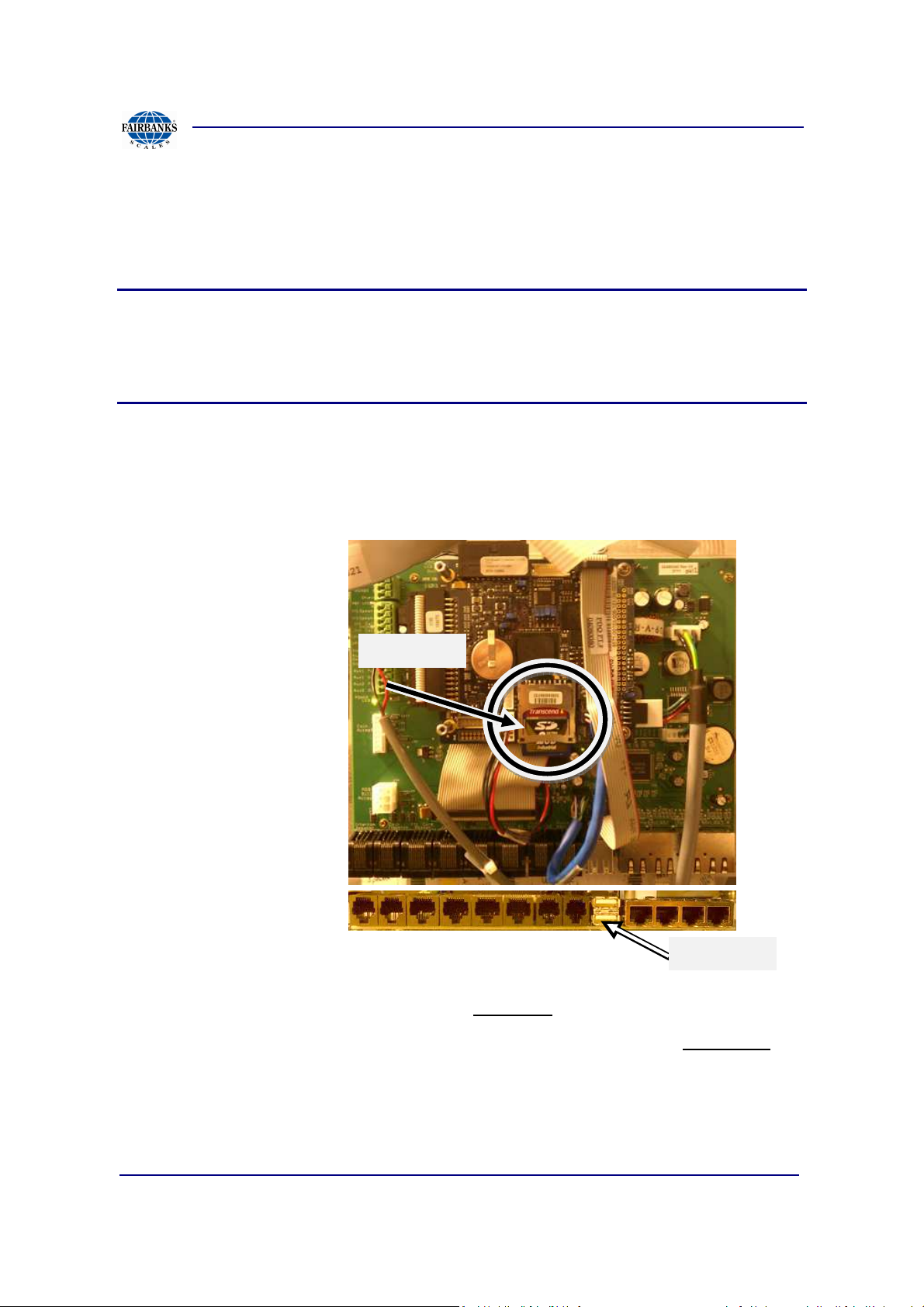

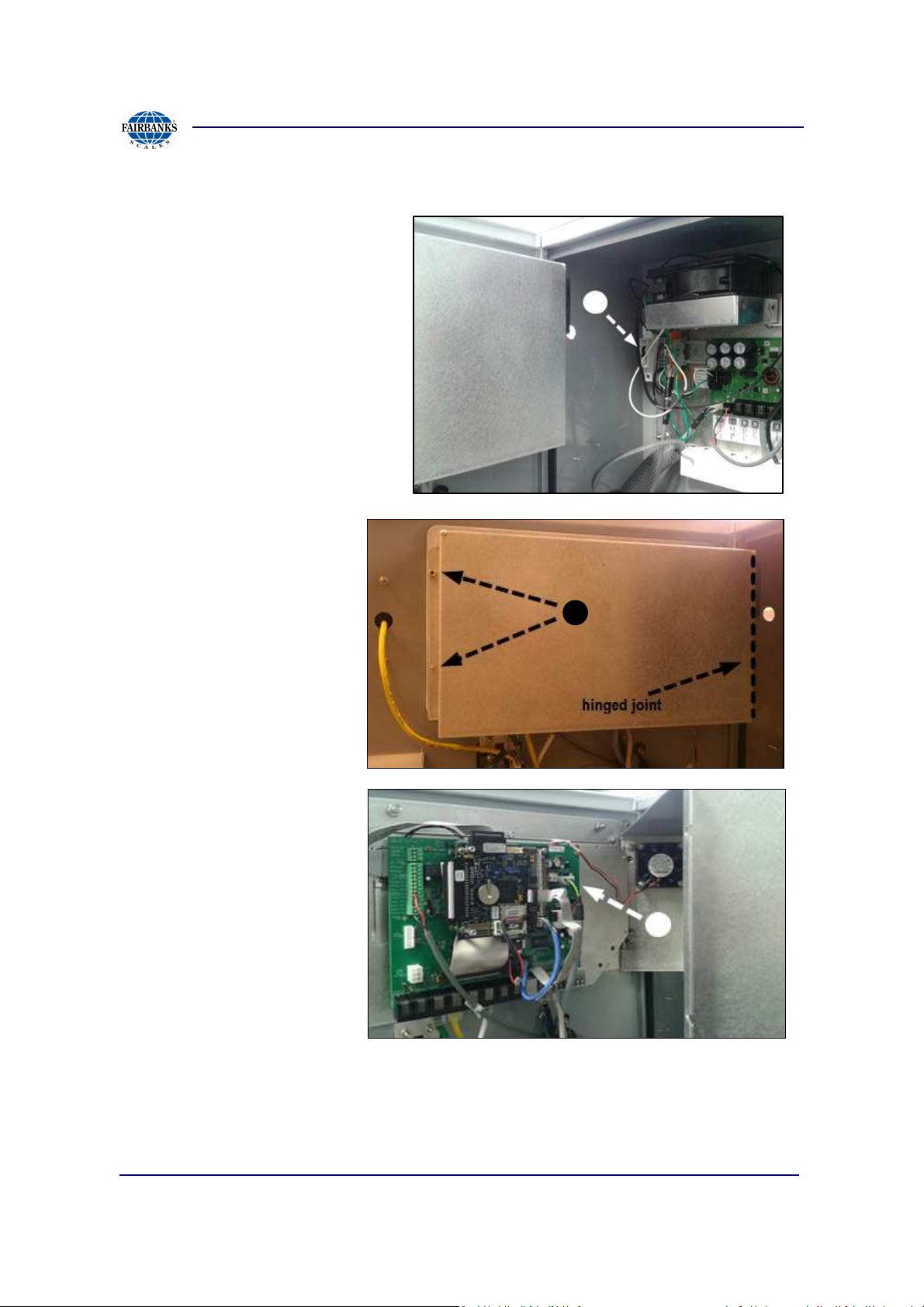

To backup, place a USB drive in the USB connector on the communication board,

located in region (a) then follow the screen prompts to backup files.

If the Titan board requires replacement, remove the existing SD card (region b) and

insert into the replaced

board. If the SD card is

undamaged the version

and configuration

information will transfer

over to the new board. If

the SD card is damaged a

preloaded Titan card can

be installed and updated

using the USB drive.

region (b)

.

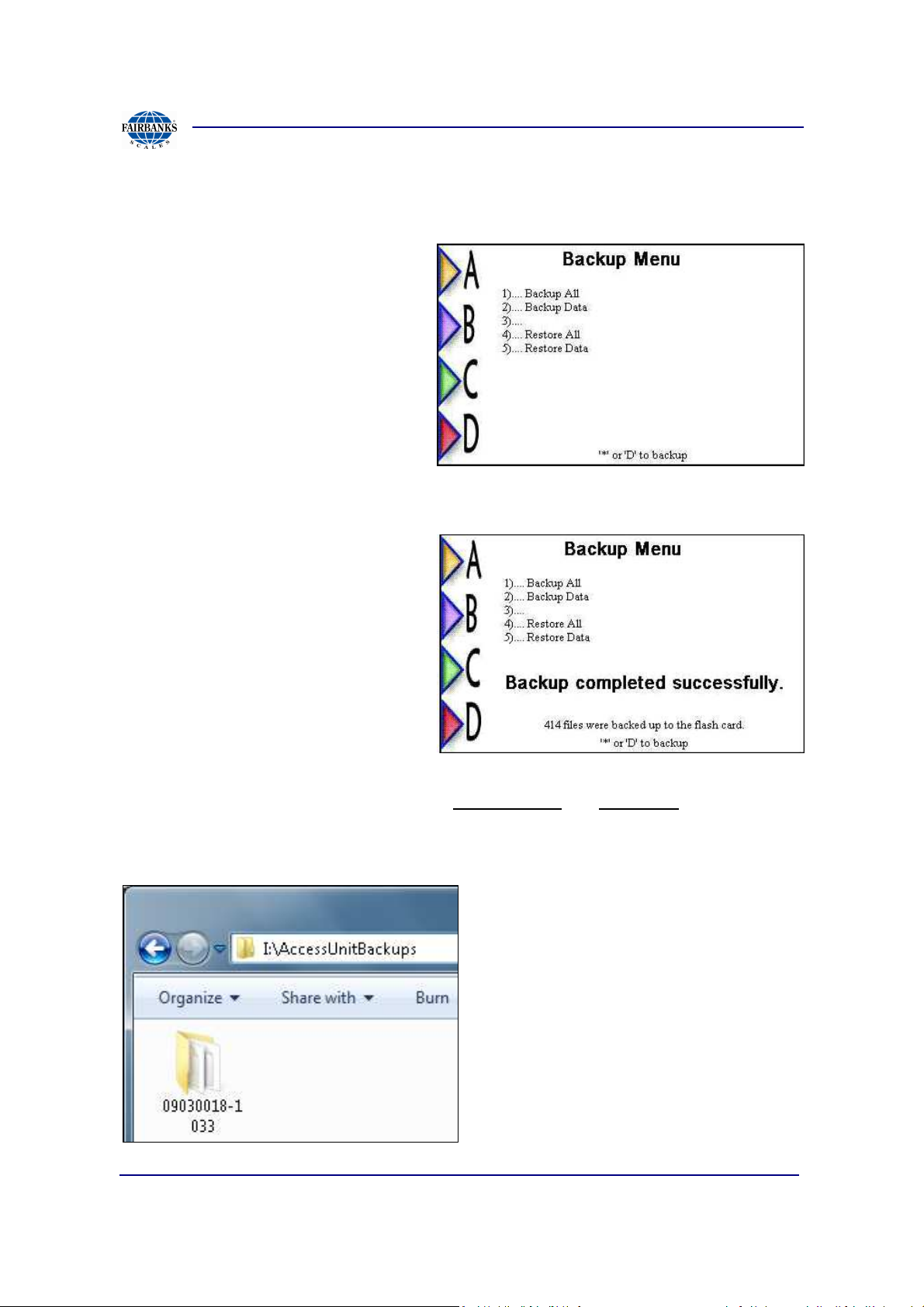

Follow the navigation steps below from the “Welcome”, location.

From a successful power up the first screen or state is the main state, “Welcome”.

Welcome >> Press *77* >> Press 12345 >> Press 2nd Key down >> Press 1st Key

>> Press 7 >> Press 1 for backup all data

01/13 17 51299 Rev. 1

region (a)

Section 2: Maintenance

2.4. Create Backup From USB Memory Stick, Continued

To create a full backup chose option

1.

Screen update after backup

completed successfully.

When viewing the USB thumb drive on a Windows operating system, the drive should

mount as an additional drive letter under, My Computer OR Computer location.

Each Access Terminal backup creates a folder with the terminals serial number. This

allows storing multiple units due to the unique folder naming/serial number reference.

01/13 18 51299 Rev. 1

Section 2: Maintenance

2.5. Restore From Backup Using USB Memory Stick

Note(s):

The USB memory sticks restore is only necessary if the SD card or software has

been damaged. Otherwise all files pertaining to Access Terminal operations are

contained on the SD card.

If the SD card and software is intact but a hardware replacement of the Titan board is

necessary then only move the existing SD card to the new board.

With the USB memory stick inserted on the communications board, go to below

navigation points.

From a successful power up the first screen or state is the main state, “Welcome”.

Follow the navigation steps below from the “Welcome”, location.

First verify the serial number on the unit is correct, if not the restore will not have

correct reference to locate the previous backup.

1.) Login to the service home screen: Press *77* >> Press 12345 >>

2.) Select Setup: Press 3dnd arrow button

3.) Set Serial Number: Press 2nd arrow button

4.) View Serial Number, if correct press ‘*’ otherwise modify and save.

5.) Back out to the main Welcome Screen by continually pressing * till the

Welcome Screen is seen.

Restore after serial number confirmed.

1.) Login to the service home screen: Press *77* >> Press 12345 >>

2.) Select Diagnostics: Press 2nd arrow button

3.) Tech Menu: Press 1st arrow button

4.) Backup Menu: Press key 7

5.) Restore All: Press key 4

01/13 19 51299 Rev. 1

Section 2: Maintenance

2.6. Power Down Terminal

To properly power down the unit, follow the below instructions.

Steps In Complete Power

Down

From keypad, type:

*77*

12345

Choose option shutdown

unit from the Diagnostics

Service Menu.

Open cabinet door by pressing up on release lever, located in bottom right of unit.

.

01/13 20 51299 Rev. 1

Section 2: Maintenance

B

C

A

2.6. Power Down Terminal, continued

Locate breaker labeled A, and

power down by pressing the

switch downward.

Next locate and remove

standoffs labeled B from left

edge of door and open.

Locate and press in tab

connector labeled (C) to

remove power controller

cable. Gently pull away from

soldered connector.

*TIP

Powering off the unit in the

above manner then

reconnecting first C, waiting

15 seconds and turning

power back on to A;

produces a cold boot in which the unit fully reboots with all power discharged prior to

booting. A stuck screen with no feedback from the keypad indicates the same

symptom of a frozen mouse cursor on a typical pc system. With the system

responding from a reboot, further trouble shooting can take place.

01/13 21 51299 Rev. 1

Section 2: Maintenance

B

B

C

B

D

G

F

E

A

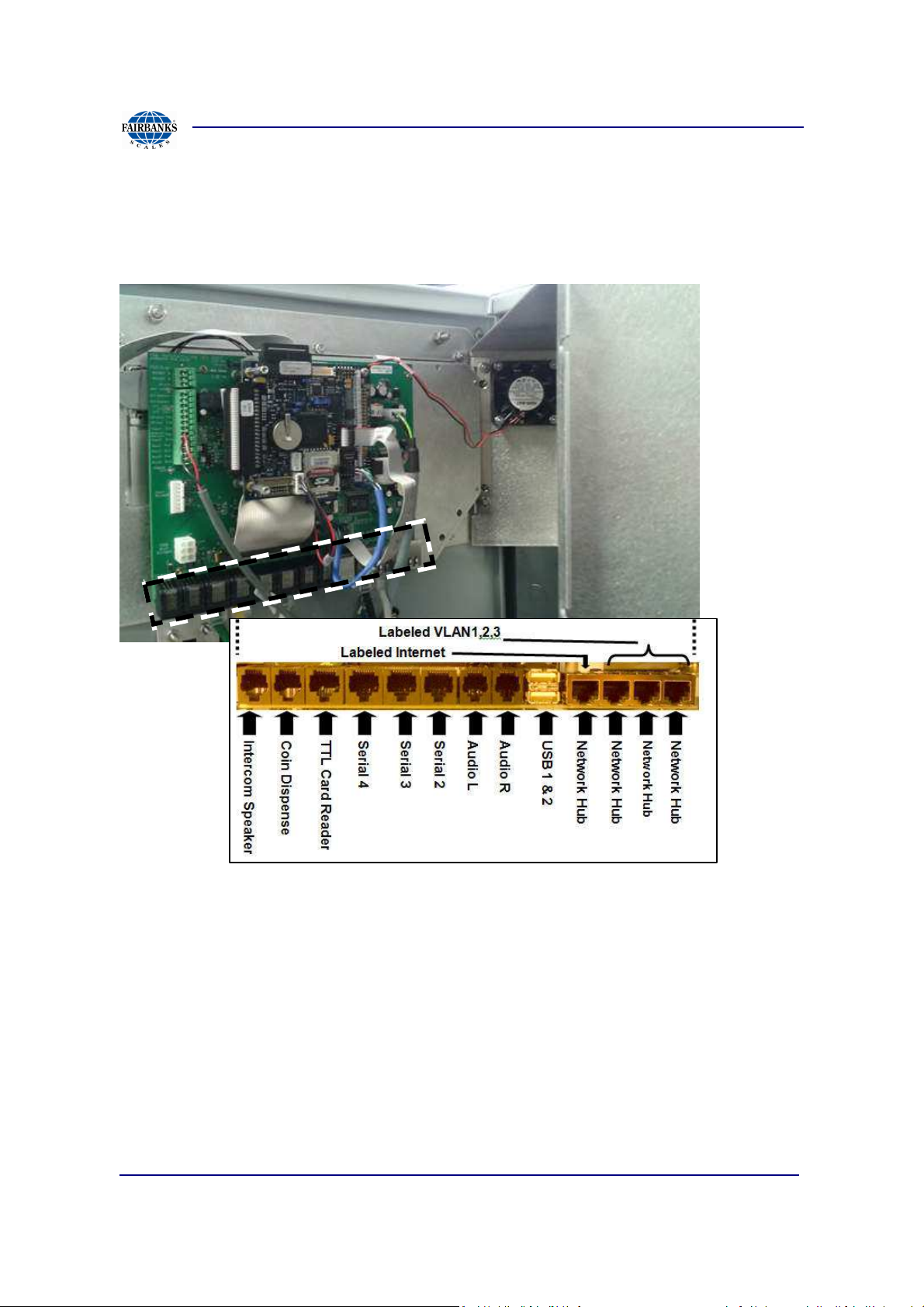

2.7. Parts Orientation

To help assist a Fairbanks technician in description the below items are listed in

order of possible connection.

Label Description

A Communication Board and Titan Board

B Heater and Blower Assembly

C Power Breaker

D AC Board

E IO Node

F Receipt Printer

G Network Filter

01/13 22 51299 Rev. 1

Section 2: Maintenance

B

B

2.7. Parts Orientation, Continued

The below image shows the communications and Titan board along with the possible

connection ports from the bottom of the board.

01/13 23 51299 Rev. 1

Section 2: Maintenance

2.8. Contact Support

If service is needed beyond the scope of initial install or for questions

contact a service technician. The toll free line is (800) 451-4581, at the

prompt press 2 for the Automated Access Solutions then 1 for a

technician.

01/13 24 51299 Rev. 1

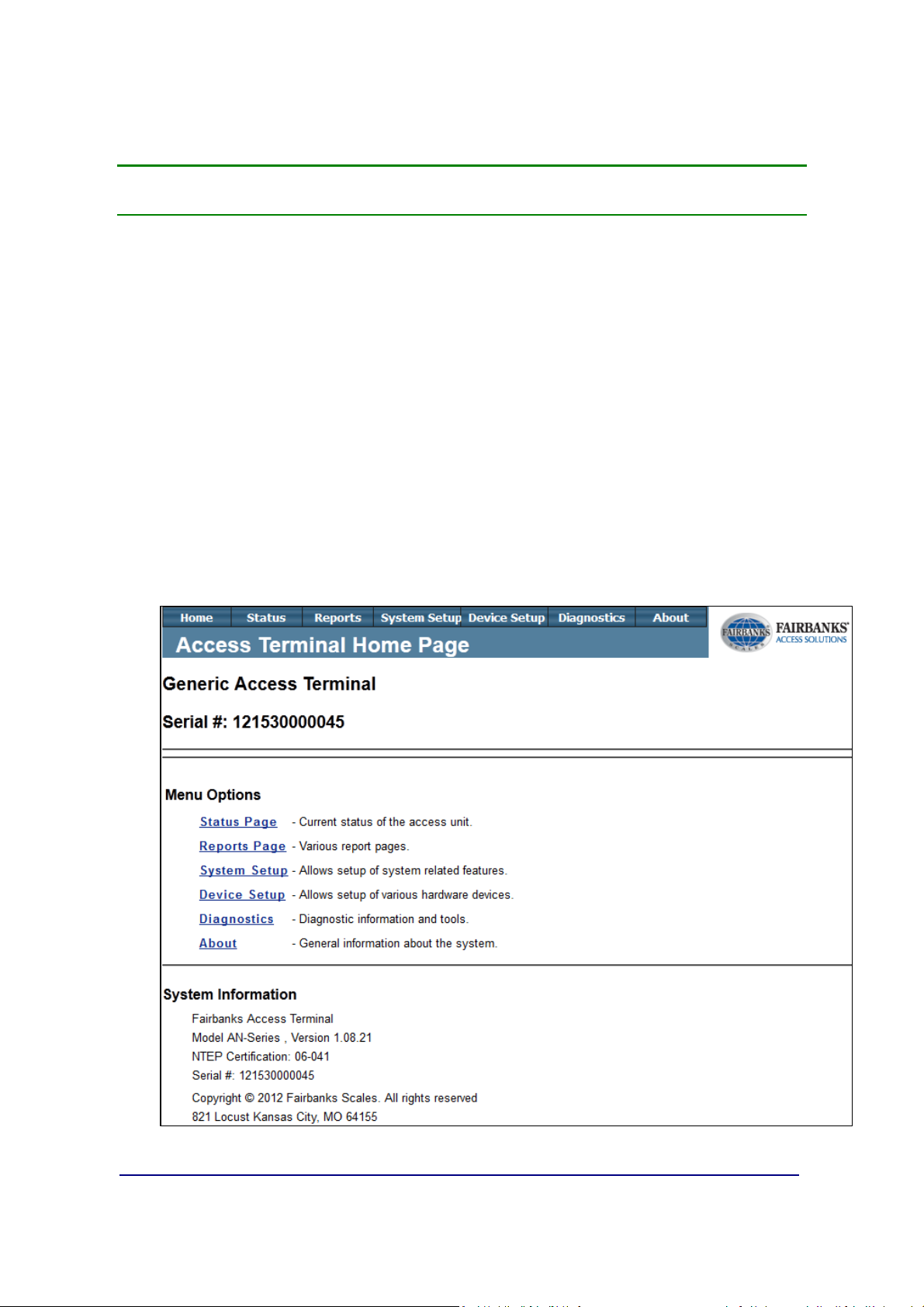

Section 3: Access Terminal Screens Defined

This section shows captures of the navigation screens contained in the Access

Terminal web configuration area, grouped by navigation top menu, containing submenu items. The home page screen shown here also contains the units name, and

serial number.

It is recommended to only view items in the Home and Status location unless a

Fairbanks authorized technician advises otherwise. Changing these setting

may report false data or shutdown automated scale usage.

3.1. Home

Containing submenu items: Status Page, Reports Page, System Setup,

Device Setup, NTEP Setup, Diagnostics

01/13 25 51299 Rev. 1

Section 3: Access Terminal Screens Defined

A

B

C

D

B

C

D

A

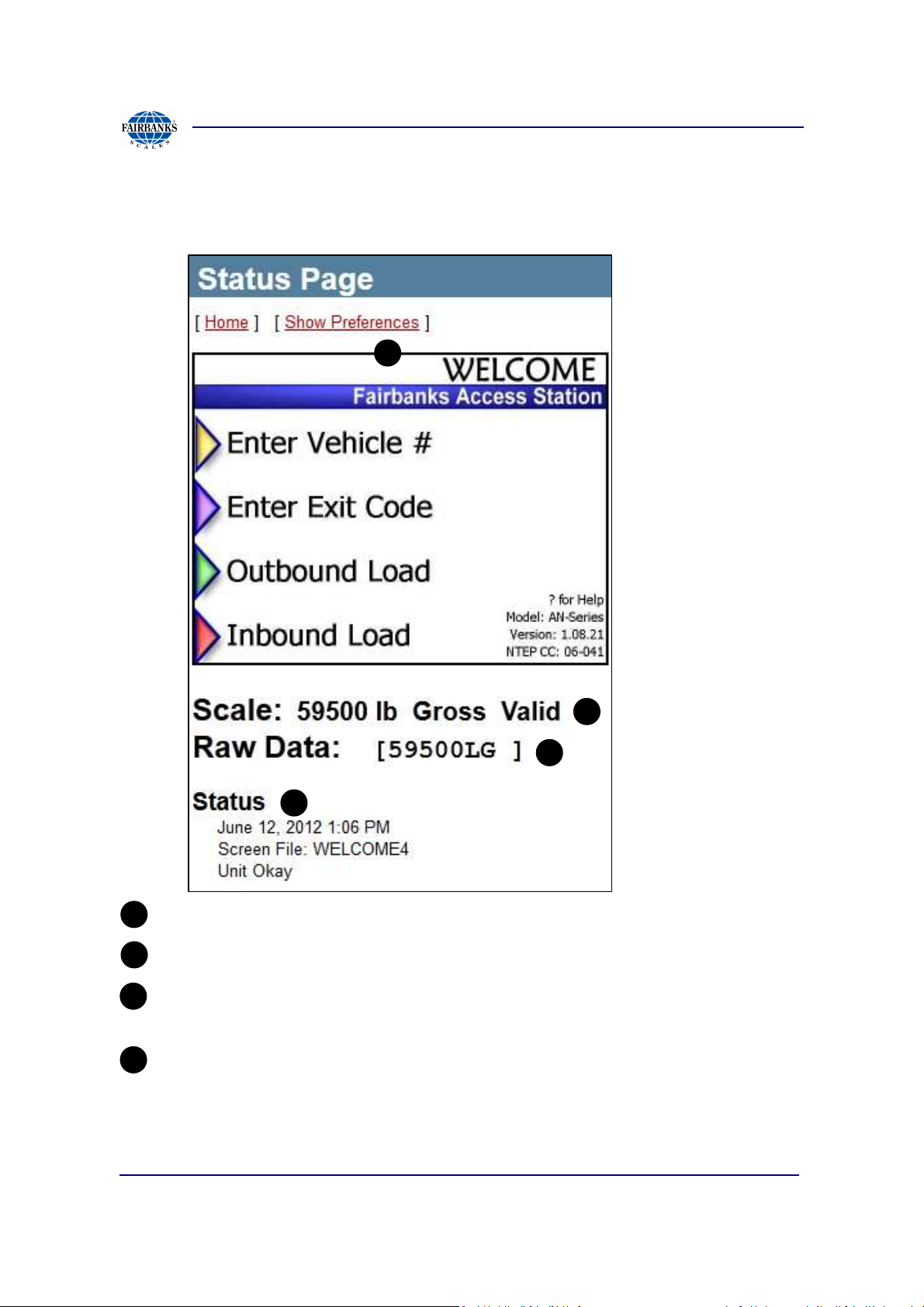

3.1.1. System Status Page

System Status Page displays Access Terminal information

Driver Screen “Welcome Screen”, shown

Scale status shown when Scale Indicator is configured.

Raw Data, shown if tracing enabled is checked under Scale Indicator

Setup (see section 3.3.6).

Status of Terminal: Unit Ok shown but can also be a starting place for

troubleshooting errors.

01/13 26 51299 Rev. 1

Section 3: Access Terminal Screens Defined

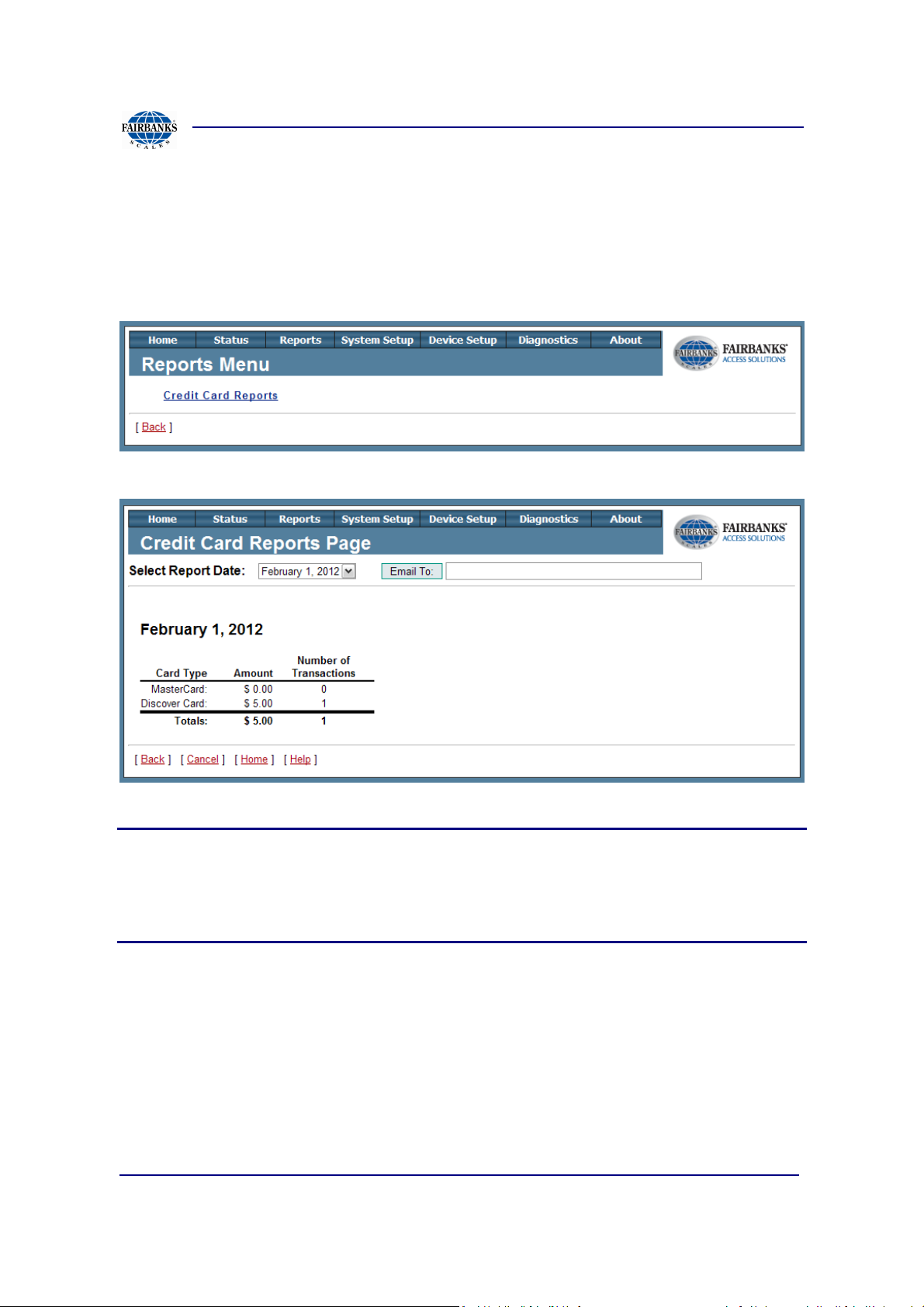

3.1.2. Reports Page

The credit card report is a daily report that includes the number and type of credit

card transactions that have occurred on individual terminals.

Note(s):

Credit Card Reports page only reflects each individual Access terminals transactions.

If there are multiple Access terminals then a better practice is using the credit card

reports from the credit card processing agent Authorize Net or running custom

reports from MatreX.

01/13 27 51299 Rev. 1

Section 3: Access Terminal Screens Defined

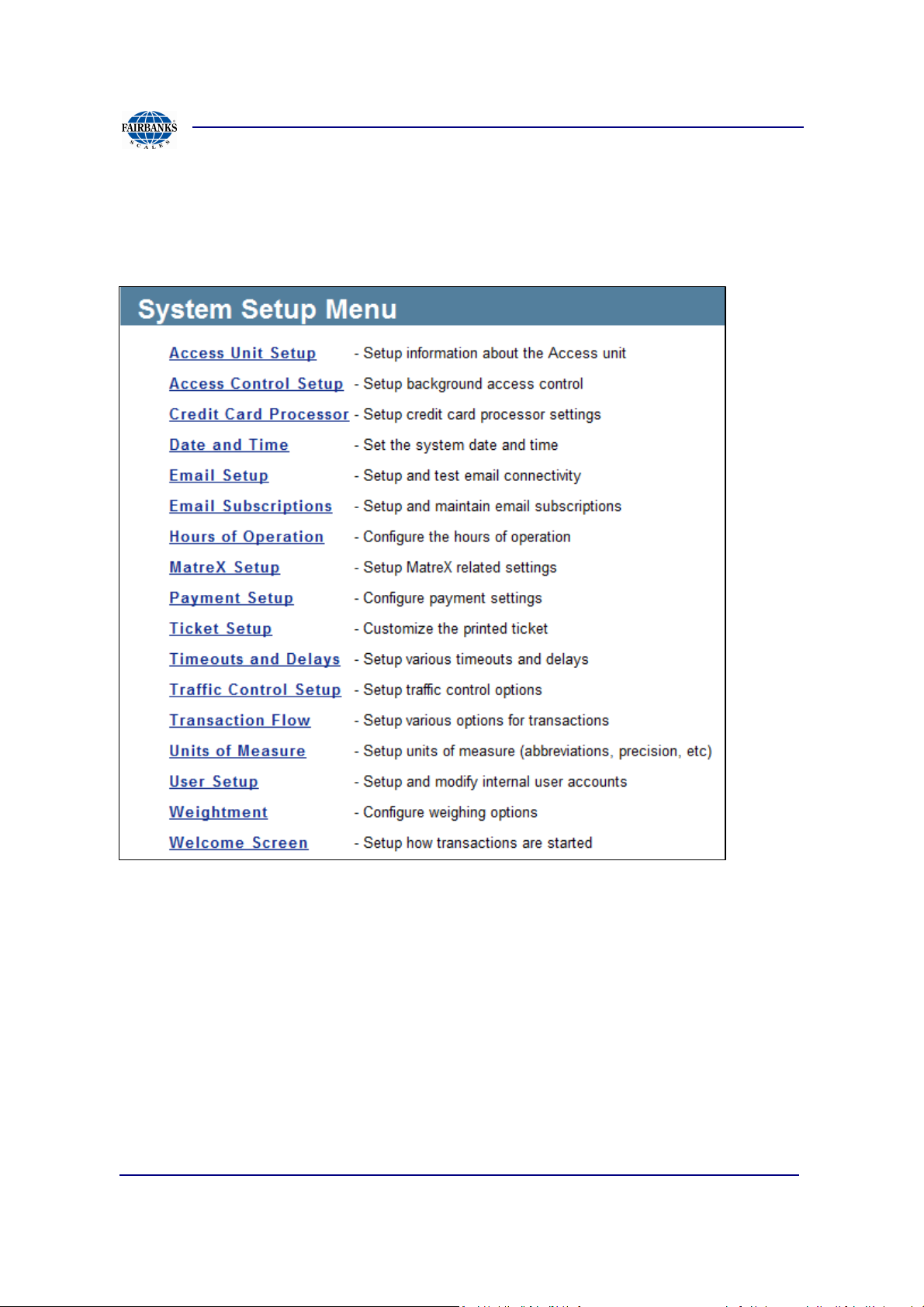

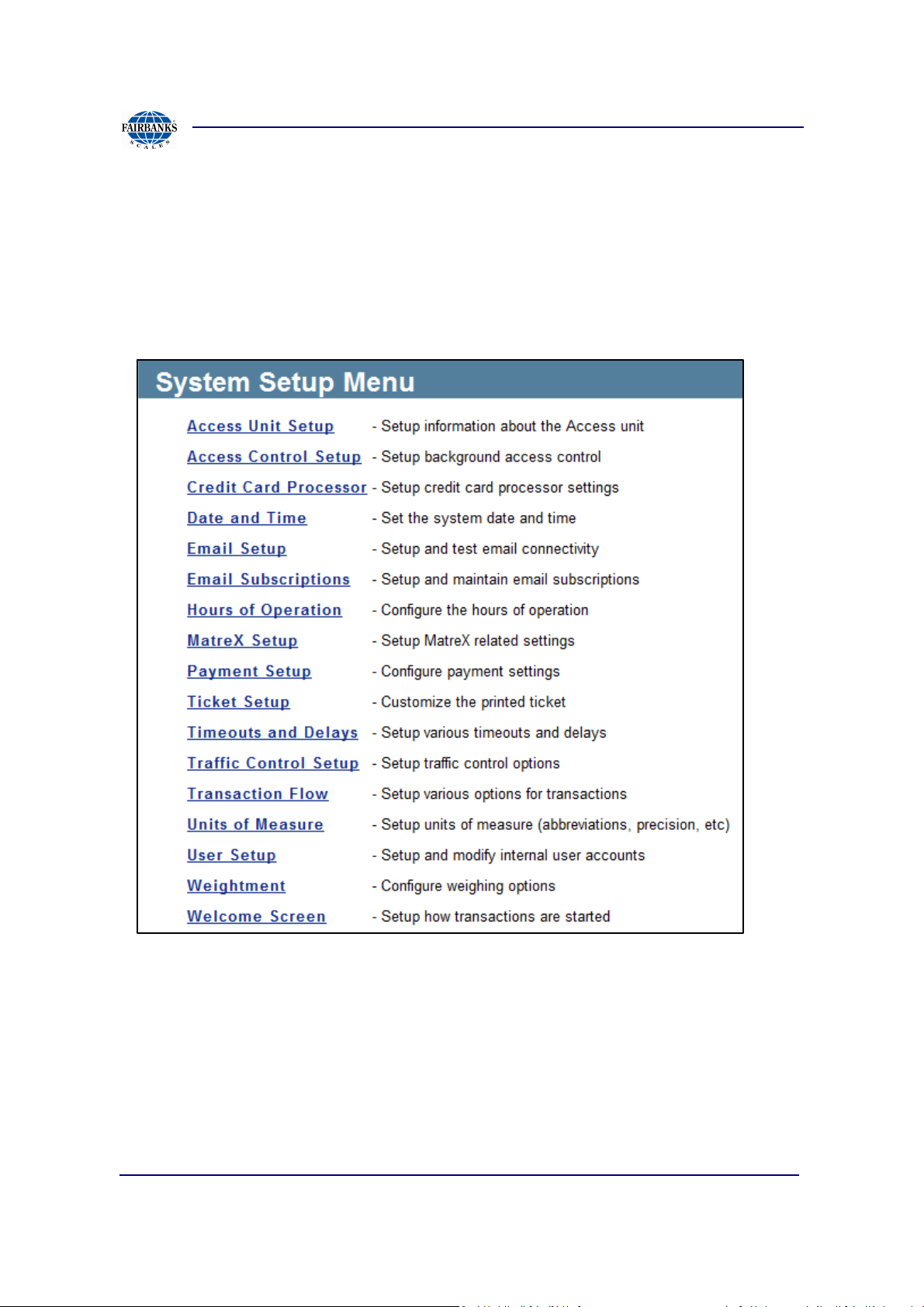

3.1.3. System Setup Menu

The below page contains the System Setup menu of the FBAS unit. The subsection

describes all of the contents currently on the Access Terminal software.

01/13 28 51299 Rev. 1

Section 3: Access Terminal Screens Defined

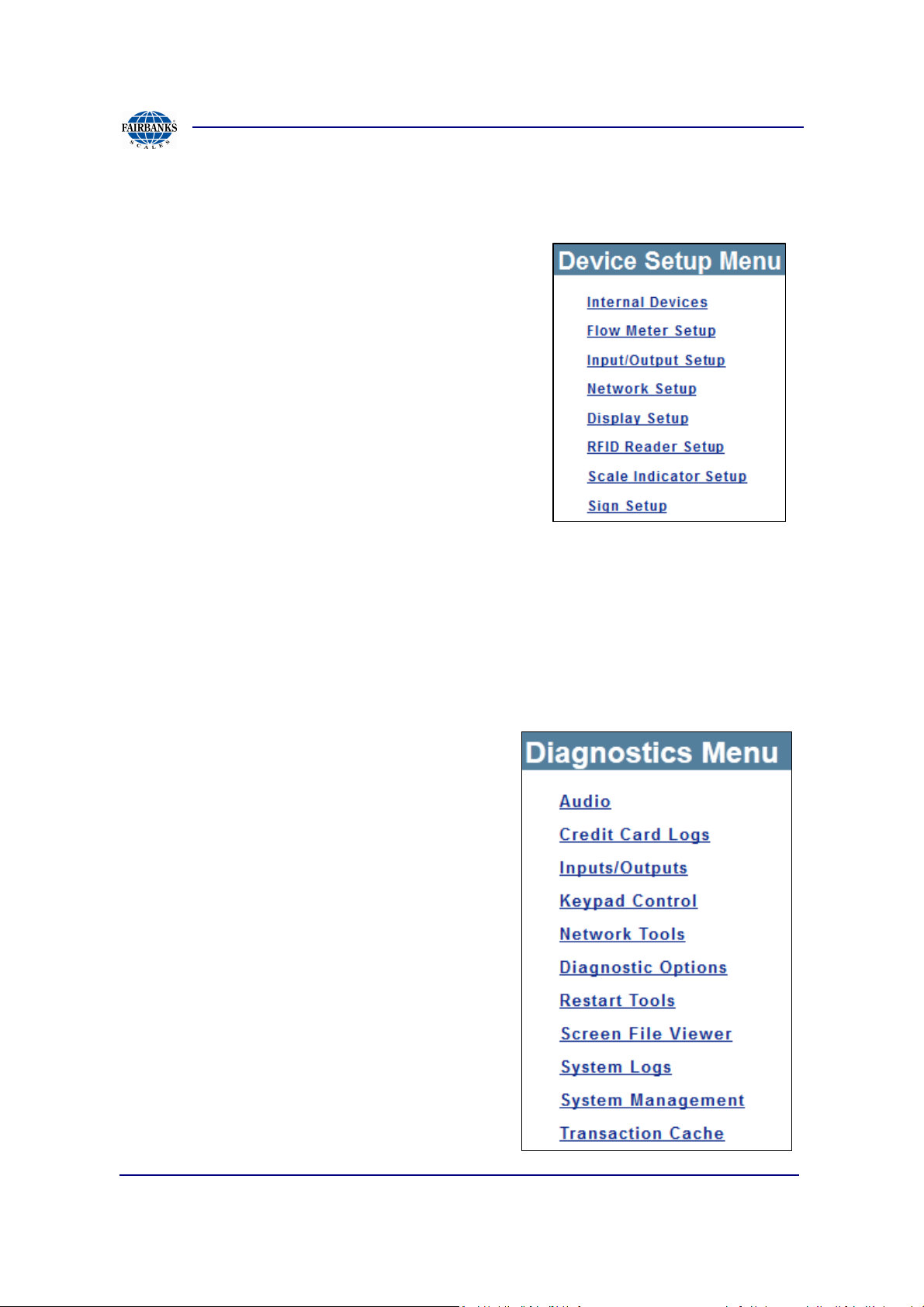

3.1.4. Device Setup

The Device Setup Menu contains multiple

information setup links. This menu’s main focus is

configuring installed devices, if any.

3.1.5. Diagnostics

The Diagnostics Menu contains viewing, event

controlling, and certain command tools to the

Access Terminal.

01/13 29 51299 Rev. 1

Section 3: Access Terminal Screens Defined

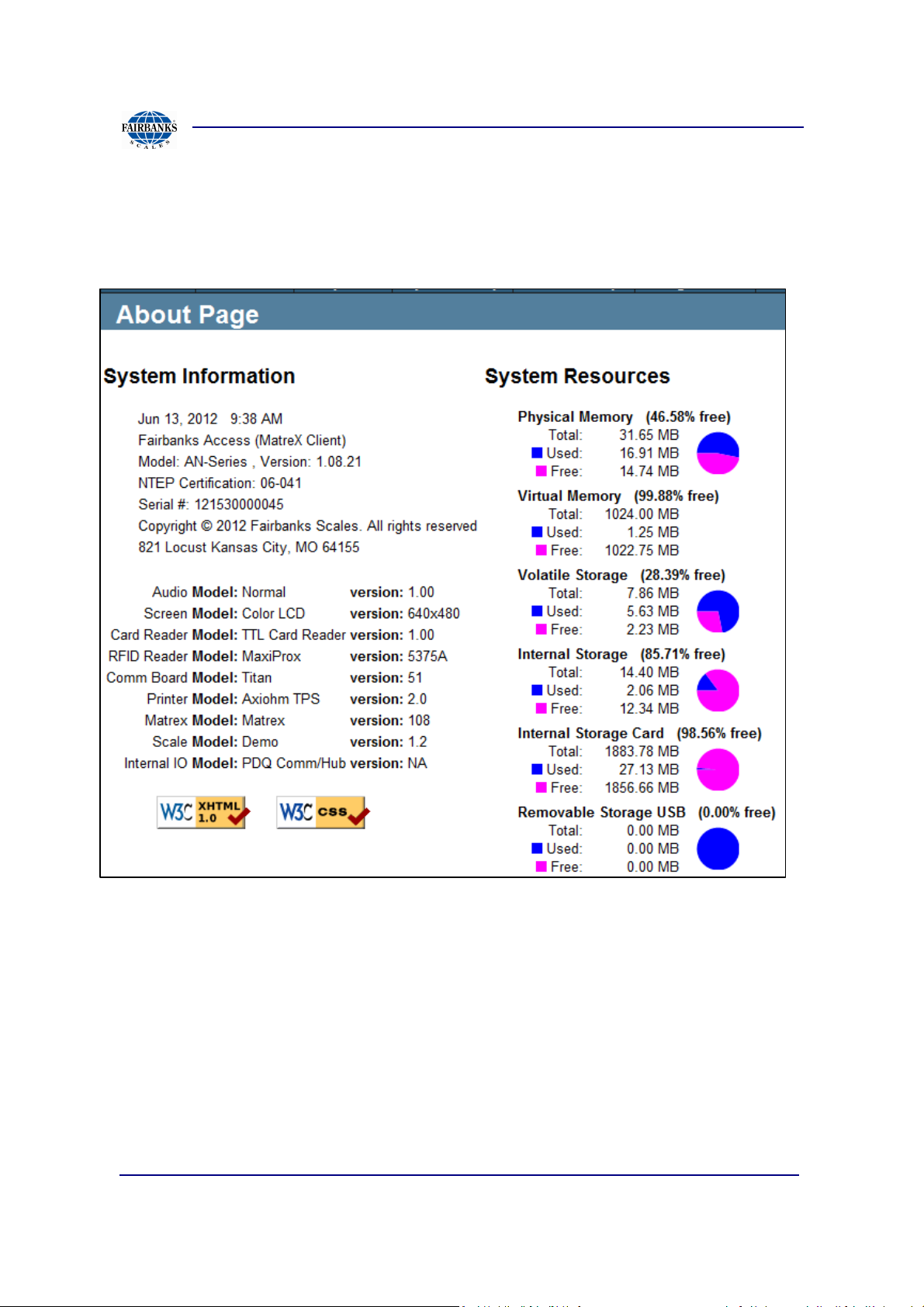

3.1.6. About

About contains system information including: installed version, enabled features, and

model/ software versions for various devices

01/13 30 51299 Rev. 1

Section 3: Access Terminal Screens Defined

3.2. System Setup

System Setup menu of the FBAS terminal controls the software specific settings.

The subsection contains usage and definitions for site specific use.

01/13 31 51299 Rev. 1

Section 3: Access Terminal Screens Defined

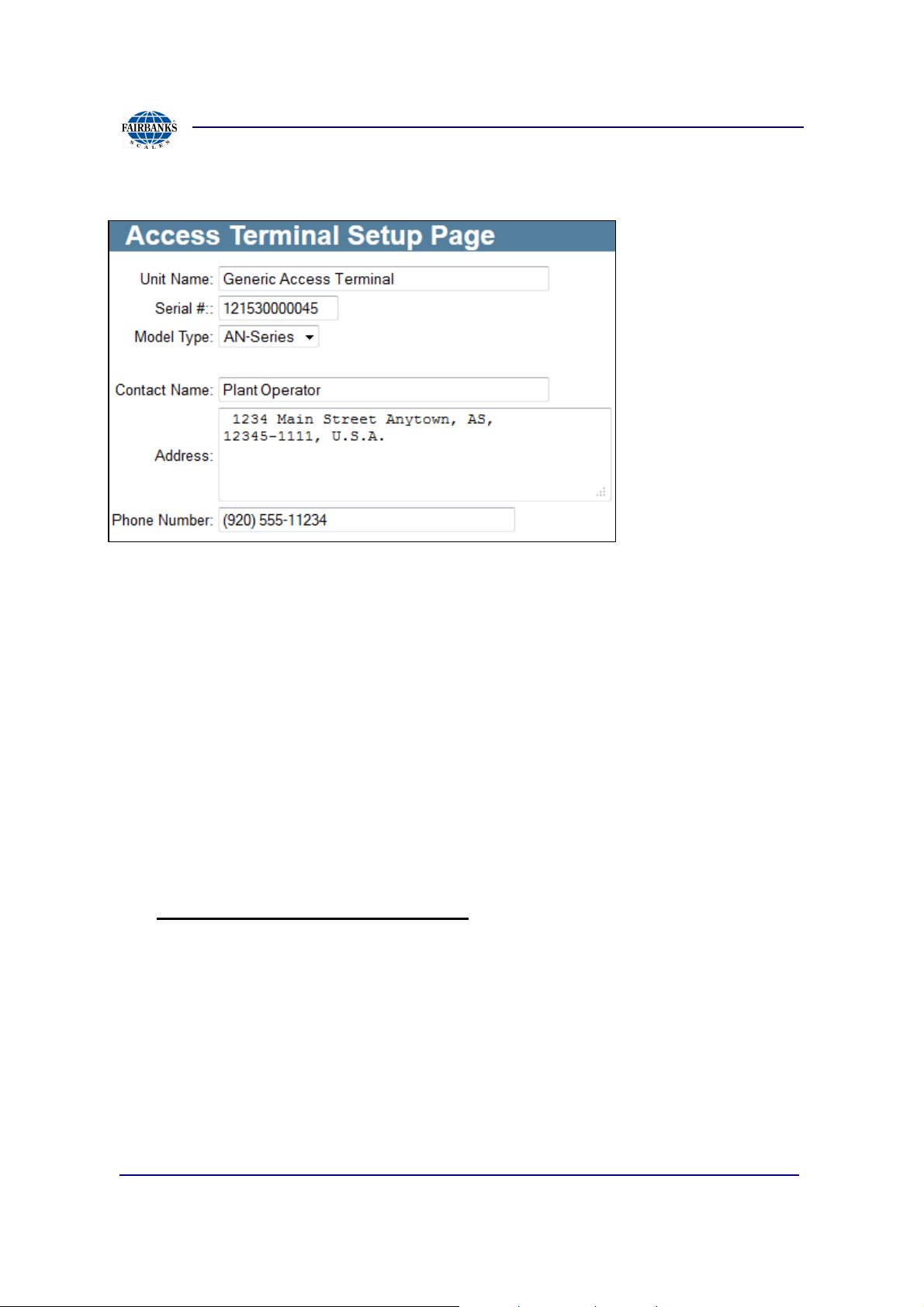

3.2.1. Access Unit Setup

The Access Terminal Setup display contains important information regarding the

access terminal. The terminal name, serial number, and model are programmed

here. The contact information for the site can also be entered to help provide a point

of contact if service is needed.

• Site Name: Labels each Access Terminal, to help identify location or purpose.

Serial #: Identifies each Access Terminal uniquely to MatreX server

• Model Type: Verify as AN Series

• Contact Name: Optional contact information for site

• Address: Address Optional contact information for site

• Phone Number: Optional contact information for site

Required entry for proper operation.

01/13 32 51299 Rev. 1

Section 3: Access Terminal Screens Defined

1

2

3

d

a

b

c

3.2.2. Credit Card Processor Settings

To allow charges for transactions at an individual terminal an account with Authroize

Net is required along with known sections 2,3 and a.

The below items are required to be set if using Authorize Net, otherwise set to none

and transactions will not be charged.

1. Select Authorize Net for processor

2. Check the accepted cards from Merchant supported range

3. Merchant Info:

a. Login will be setup from the Authorize Net account web page.

b. Transaction key will be setup from the Authorize Net account web page.

c. MD5 Value will be setup if used on the Authorize Net account web page.

d. Device type is set to Unattended Terminal

e. Market Type is set to Retail.

e

01/13 33 51299 Rev. 1

Section 3: Access Terminal Screens Defined

A B

C

A

B

C

3.2.3. Date And Time Setup

Date and Time Setup Page allow for selecting the server name and IP address

specific to the time zone.

The terminal uses the SNTP protocol to get time from the time servers.

The system will always try to use the first server in the list. If that one fails it will try

the next in the list until one works or the list runs out.

If the terminal is not keeping time correctly, an internal time server may need to be

added to the list. Contact the sites IT dept. to get the name or IP address of the time

server and replace the first entry in the list.

Date and Time

• Set manually by drop down: Current time, Set Date, Set Time, Set Time Zone

Time Servers

• Server Name- required host name of NTP time server

• IP Address- if DNS isn’t used then it is required, otherwise use for robustness

• Port- default NTP service is on 123

• Location- optional, describes location

• Status- after clicking Test it will show the state of the server test

• Show More- shows more time servers to choose from

• Set Default- sets the current time servers as the new default list

• Test- runs test against all time servers in list

Update Time

• Update time will correct any current time drift that may be in the status

01/13 34 51299 Rev. 1

Section 3: Access Terminal Screens Defined

A

B

A

B

3.2.4. Email Setup

Email Configuration

• Enable Email: If checked unit sends status of unit dependent on subscription

Test Email

Screen Capture of a failed email transmission:

Possible causes to this specific error:

• Incorrect entry in SMTP server

• If SMTP server is by name, verify DNS is working under Network Setup Page

type.

• Unit Name: Unique name to identify the specific unit in email.

• Reply To: Recipients will send to this email if replying back to email.

• SMTP Server: Email server address used for the unit to pass thru.

• SMTP Port: The default port is 25 but can be altered if necessary.

• Subject Prefix: Title of the email going to the sender

• Test Address: After successful configuration, test by sending to a test email

address

01/13 35 51299 Rev. 1

Section 3: Access Terminal Screens Defined

3.2.5. Email Subscriptions

Email Subscriptions provides a way for users to setup email notifications for various

types of events that can occur at the terminal.

To add a new email subscription, first enter the email address to include, then click

subscribe. Otherwise select an existing email address from the list.

Below shows the multiple options the subscribed user has.

After completion click on submit. To select from different subscribers click on the

drop down next to “Subscriptions for:”

01/13 36 51299 Rev. 1

Section 3: Access Terminal Screens Defined

3.2.6. Hours Of Operation Setup

Hours of operation controls when the Access Terminal is available for transactions.

Below are four options that can be toggled.

Open: The terminal is always open and allows transactions. This is the default state.

Closed: The terminal is always closed and does not allow transaction.

Maintenance: The terminal is closed and any traffic gates (configured on Traffic

Control page) are opened. No transactions are allowed.

Auto Open-Close: When in this mode the terminal can automatically close down

each night and open up each morning. When turned on, user may setup system to

automatically close (not allow transactions) and open (always allow transactions).

01/13 37 51299 Rev. 1

Section 3: Access Terminal Screens Defined

3.2.7. Matrex Setup

The terminal supports multiple server configurations which can be toggled from the

home page, and new server configurations can be created by clicking on the link Add

Another Server. Normally only one server is needed so this is a more advanced

feature.

This page only allows configuration of the servers. The actual toggling of the active

server is done from the home page of the terminal’s web interface.

01/13 38 51299 Rev. 1

Section 3: Access Terminal Screens Defined

3.2.7. Matrex Setup,Continued

SERVER CONNECTION

• Server Label: Distinguish between server connections.

• Description: Additional information about server connection.

• Server Name: Name or IP address of the MatreX server; once functioning, DO

NOT change setting. It is always recommended to use the name of the server

instead of the IP address.

• HTTP Address: Allows user to install MatreX in a different location of

processing server (non default website). Once functioning, DO NOT change

setting.

• Server URL: Shows full web address the unit connects to.

• Use Type: (previously located on Access Terminal Setup)

see Section. 3.1.3.1. ACCESS UNIT SETUP

• Company Number: The serial number of the Access Terminal. This should be

set to match the serial number on the label located inside the Access unit. This

number can affect communications with MatreX and the ability to back up and

restore.

ADVANCED SETTINGS

• HTTP Verb: DEFAULT IS POST Allows for different types of HTTP request,

do not change unless also changed in the MatreX server settings.

• HTTP Port: DEFAULT PORT IS 80

• Read Buffer Size: DEFAULT 1024

• Network Timeout: Value used to communicate with MatreX processing

server. Calls typically fail prior to value.

• Network Attempts: Attempts to connect to the MatreX server before failing.

• Retry Interval: Delay between each retry attempt.

01/13 39 51299 Rev. 1

Section 3: Access Terminal Screens Defined

3.2.7. Matrex Setup,Continued

• TRANSACTION CACHE: Cache Size: Number of transactions stored locally

on Terminal; includes completed and off-line transactions.

• Flush to Disk: How often the transaction cache is flushed to file.

• Offline Retry: Number of times the Terminal attempts connecting to the

MatreX server before failing and continuing with an off-line transaction.

• Allow Offline Trx: Select the check box for a yes response. This permits

transactions to be performed when the server is off line. The transactions are

stored in the terminal memory until the server is back online.

MESSAGES:

• Send Camera Requests: When enabled, the terminal will send additional

messages to MatreX at various stages during the transaction. These

messages allow MatreX to capture an image from any cameras

associated with this terminal for the particular stage of the transaction. If not

enabled, MatreX will only capture camera images during the Authorizing and

Processing states.

• Tracing Verbosity: Default 0; allows for additional diagnostic data. When

greater than zero, it can significantly slow down the system.

• Enable Profiling: Enables performance profiling on the messages sent to

the server.

MISCELLANEOUS:

• Maximum Item Count: This is the maximum number of items for a single

prompt that the terminal will accept. For example, if a customer has more than

1024 materials, then this count must be increased.

• Account Code Length: Maximum number of digits in an account number.

The Keypad Number (previously labeled as “cardless” number) for a vehicle

account can be less than this maximum, but the user will need to push the

enter button. Otherwise when the last digit (based on this setting) is entered,

that number is automatically looked up.

01/13 40 51299 Rev. 1

Section 3: Access Terminal Screens Defined

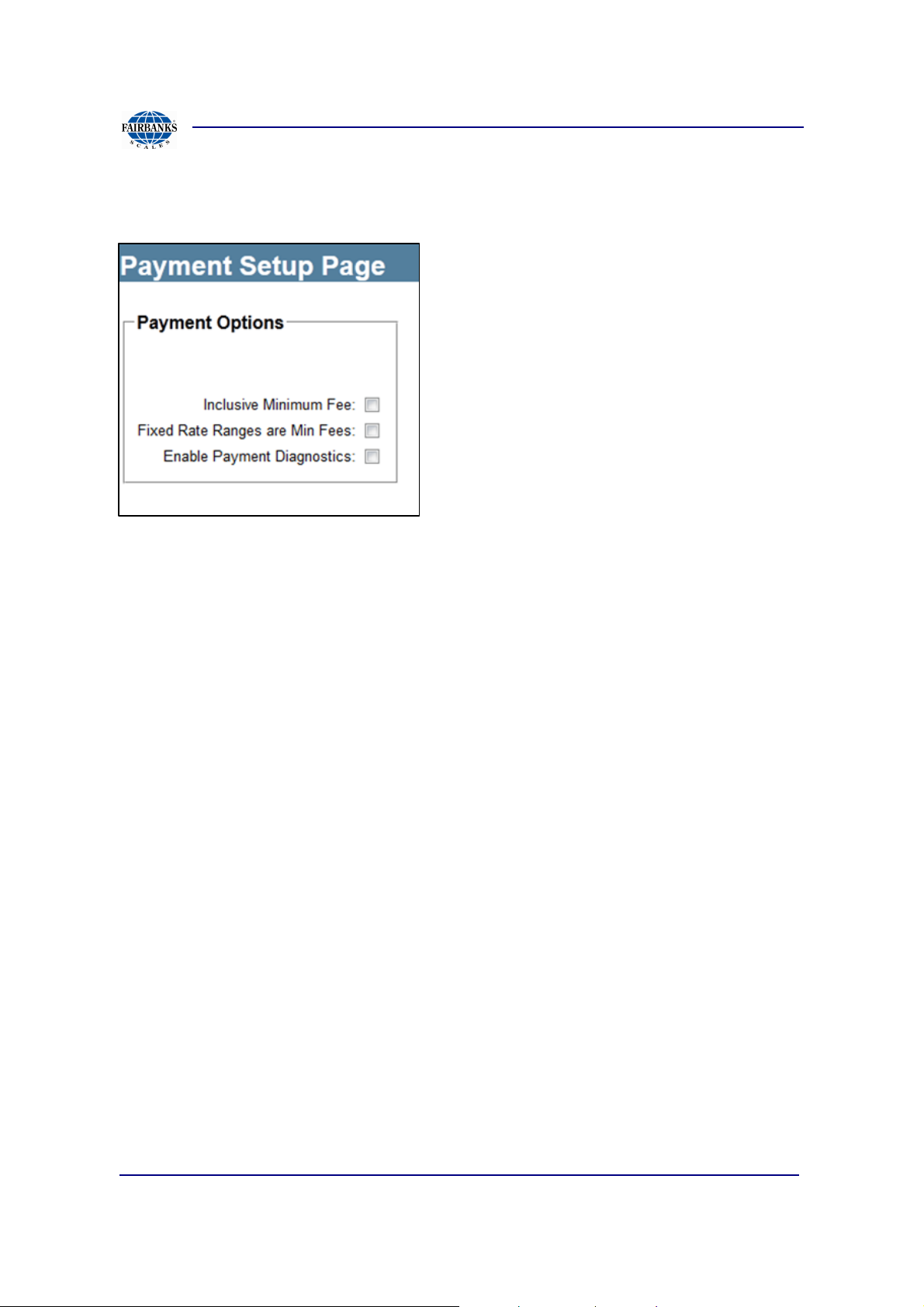

3.2.8. Payment Setup

Inclusive Minimum Fee: Normally, any additional surcharges are added onto a

minimum fee. If this option is enabled, the minimum fee is reduced to so that the

additional surcharges and the reduced minimum fee will equal the desired minimum

fee.

Fixed Rate Ranges are Minimum Fees: When this option is enabled, rate ranges

that are have on a fixed rate, the fixed rate will be treated as a minimum fee.

Enable Payment Diagnostics: This option should only be on when troubleshooting

payment calculations.

01/13 41 51299 Rev. 1

Section 3: Access Terminal Screens Defined

3.2.9. Scale Ticket Setup

Scale Ticket Setup determines when a scale ticket prints and what information to

contain.

Print Account Ticket: Controls when a scale ticket will be printed for vehicles that

have an account in MatreX. Options are Never, Always, and On Completion (default).

On Completion means that for a vehicle that weighs in and out, a scale ticket is only

printed on the weigh out stage (when the transaction is completed).

Print Off-line Ticket: Controls when a scale ticket will be printed for transactions that

are off-line. Options are Never, Always (default), and On Completion. On Completion

means that for a vehicle that weighs in and out, a scale ticket is only printed on the

weigh out stage (when the transaction is completed).

Print Cash Ticket: Controls when a scale ticket will be printed for transactions that

were paid for in cash. Options are Never, Always (default), and On Completion. On

Completion means that for a vehicle that weighs in and out, a scale ticket is only

printed on the weigh out stage (when the transaction is completed).

01/13 42 51299 Rev. 1

Section 3: Access Terminal Screens Defined

3.2.9. Scale Ticket Setup, Continued

Print Credit Card Ticket: Controls when a scale ticket will be printed for transactions

that are paid for with a credit card. Options are Never , Always (default), and On

Completion. On Completion means that for a vehicle that weighs in and out, a scale

ticket is only printed on the weigh out stage (when the transaction is completed).

Transaction / Ticket Number Label: The user can customize the label used for the

transaction or ticket number printed on the ticket. The default value is Ticket#.

Print Hauler: If checked, the name of the hauler name (owner of the vehicle) will be

printed on the scale ticket

Print Vehicle: If checked, the vehicle ID will be printed on the scale ticket. This is the

Vehicle ID in MatreX, not the ID that the driver used to start the transaction.

Print Selected Items: If checked, the names of all of the selected items from the

prompts will be printed on the scale ticket.

Print Transfer ID: The transfer ID is a number generated by the terminal based on

the serial number and the current date/time.

Print CC Pre Auth Data: When enabled, any pre-authentication data ( amount,

authorization code, transaction id) will be printed for credit card transactions. This

only applies to the pre-authentication phase of the transactions (weigh in stage).

Print Signature Line: When enabled, a line on the ticket will be printed to allow the

driver to sign the ticket.

Print Rate Details: When rate information is printed it is normally just the finally

charges, taxes and total charges. With this option enabled, additional rate information

for any selected item will be printed as well.

Print Net Weight in Both: If enabled, the net weight will be printed in both units

(pounds and tons or kilograms and metric tons).

01/13 43 51299 Rev. 1

Section 3: Access Terminal Screens Defined

3.2.9. Scale Ticket Setup, Continued

Print MatreX Units: Requires additional setup on Units of Measure Setup, see

section (3.2.13), and additional MatreX manual

#51227.

• Allows printing up to 4 custom units specific to

a material type.

These units are user defined units of measure from

MatreX. Be sure to setup the precision to use when

printing values in these units.

The ID’s for the units from MatreX will be needed.

Ticket Header: There is approximately 22 characters per line limit and allows for 4

lines. Each printed at the top of the scale ticket.

Ticket Footer: There is approximately 22 characters per line limit and allows for 4

lines. Each printed at the bottom of the scale ticket.

Off-line Note: Printed at the bottom (before the footer) of the scale ticket when the

transaction was offline.

Refund Note: Printed at the bottom (before the footer) of the scale ticket when a

cash refund could not be given.

01/13 44 51299 Rev. 1

Section 3: Access Terminal Screens Defined

3.2.10. Timeout And Delay Setup

Input Screen Timeouts:

• Enter Number: Timeout value for states that enter numbers

• Item Selection: Timeout value for states that allow selection of information

• Payment Selection: Timeout value for the select payment screen (Not Used)

• Insert Card: Timeout value for states with account or (credit cards-Not Used)

• Insert Money: Timeout value for states that accept cash (Not Used)

• Read Message: Timeout value for messages displayed to customer

• Empty Load: Timeout value for empty load (tare weight) prompt

• Empty Mixed Load: Timeout value for empty mixed prompt

• Confirm Weight: Timeout value for confirm weight screen, 0 sets an indefinite

amount of time up to 5min.

• Prompt for Start of Transaction: Timeout value for the screen that prompts the

driver if he wants to start another transaction. This screen is associated with

detecting the last long range RFID tag after a transaction was completed with

that tag. See the Long Range RFID Tag Detection section for more details.

01/13 45 51299 Rev. 1

Section 3: Access Terminal Screens Defined

3.2.10. Timeout And Delay Setup, Continued

Non-Input Screen Delays

• Get Weight: Timeout for the get weight screen. Normally as soon as the

weight is read from the scale data, the system will advance to the next screen.

This timeout will only be used if there is an issue with the scale data. The most

often cause of delay is motion on the scale. There will be a message on the

screen when motion is detected. To speed this process up you can reduce the

required readings setting in the Scale Setup page on the Device Setup menu.

Confirm there is a motion status if the require readings is set to 1 (the default

is 3).

• Display Weight: Timeout for the display weight screen. This timeout is only

used when displaying the weight not confirming the weight.

• Print Ticket: Timeout for the printing scale ticket screen. This screen will

advance to the next state once printed is completed. A longer timeout is only a

safety net or for displaying an error.

• Take Ticket: Timeout for the take scale ticket screen. This screen can be

skipped by setting the timeout to Off.

• Pull Forward: This timeout only applies if the Traffic Control feature is not

enabled. If Traffic Control is enabled, this screen is displayed for as long as a

vehicle is detected on the scale (detected by weight and possibly sensors if

configured). View Pull Forward settings under Input/Output section (3.1.4.3)

for more information.

• Cancel: Timeout value for ‘cancel’ screen

• Take Refund: Timeout value for ‘take refund’ screen

• Take Change: Timeout value for ‘take change’ screen

01/13 46 51299 Rev. 1

Section 3: Access Terminal Screens Defined

3.2.10. Timeout And Delay Setup, Continued

Long Range RFID Tag Detection-These settings control how the system handles

detecting the same long range RFID tag just after a transaction was completed

successfully with that tag.

Ignore Last Long Range RFID Tag: Duration for which the system will ignore a long

range RFID tag that matches the long range RFID tag that was used on the last

transaction. This duration starts just after the transaction ends. See the timeline

below. For example, when a vehicle with an RFID tag completes a transaction, the

vehicle will start to drive off the scale. But while driving off, the RFID tag might still be

read by the reader. In this case, the ID should be ignored, because the vehicle just

completed its transaction. But if the vehicle remains on the scale for some time, that

may indicate that the driver wishes to start the transaction again. This setting will

determine the amount of time the system will ignore the same long range RFID tag

after the end of the transaction.

Prompt for Transaction Start: Duration for which the system will prompt the driver if

another transaction should be started. So if the last long range RFID tag is detected

again during this duration, the driver will have the option of starting a transaction.

This duration starts after the duration of ignoring the tag ends

01/13 47 51299 Rev. 1

Section 3: Access Terminal Screens Defined

3.2.10. Timeout And Delay Setup, Continued

Flow Meter Timeouts

Cancel Timeout: When the volume screen is displayed an no volume was recored by

the flow meter, the transaction will be canceled after this timeout expires. Default is

off. Be sure to allow enough time for the driver to possible move the truck and

connect hoses if this timeout is enabled.

Done Pumping Timeout: Once flow is detected by the meter, the system will not

allow the driver to complete the transaction as long as there is flow. Often at the end

of pumping the flow will go to zero and then start up again. This timeout will keep the

system in this state for the configured number of seconds. Default is 15 seconds.

Auto Complete Timeout: After the flow as stopped and the Done Pumping Timeout

has expired, the driver can then complete the transaction. If the transaction is not

completed, it will be automatically completed when this timeout expires. Default is

None.

01/13 48 51299 Rev. 1

Section 3: Access Terminal Screens Defined

2

5

3 4

6

7

1

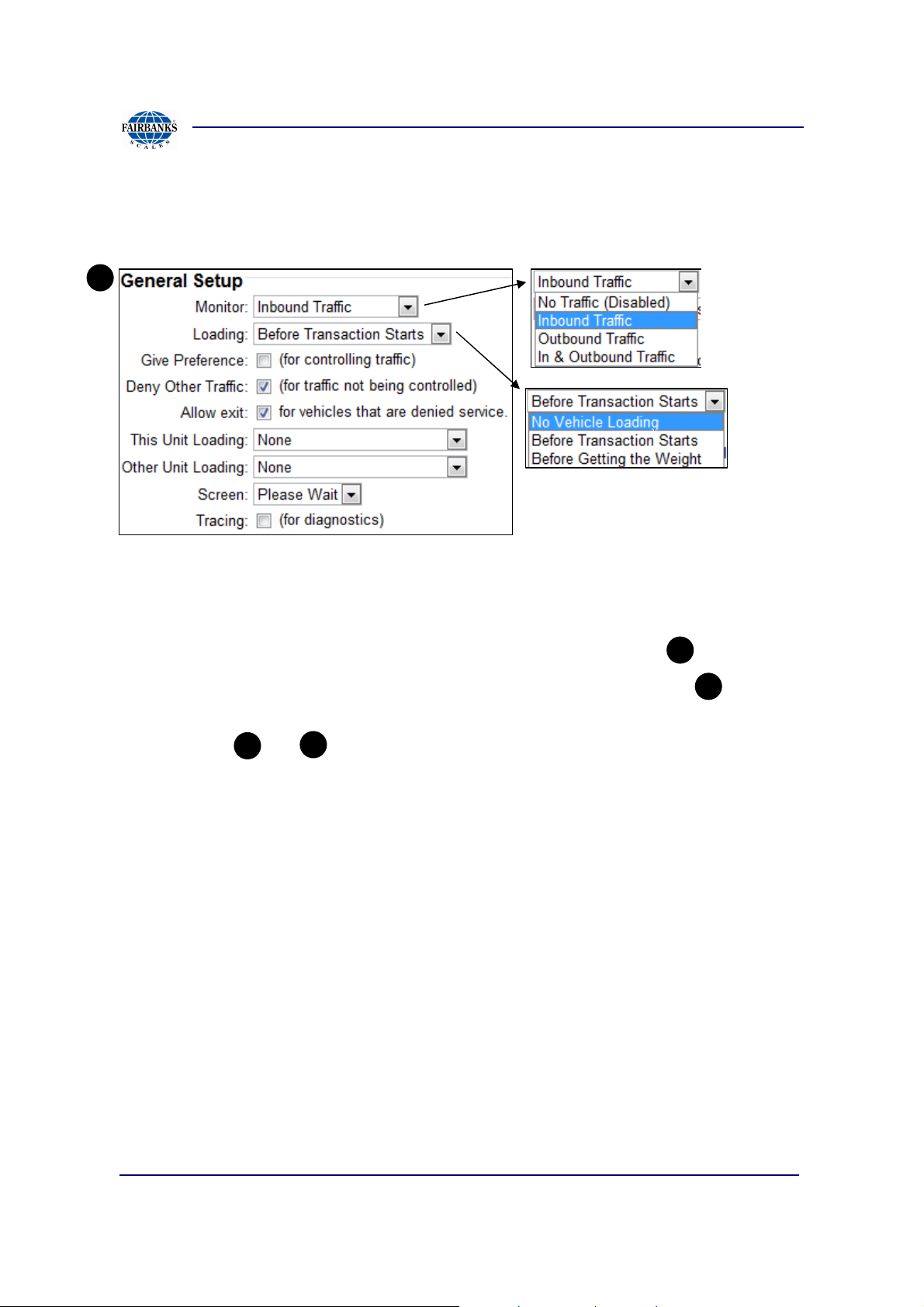

3.2.11. Traffic Control Setup

Traffic Control has two main purposes:

a) Ensure the vehicle is on the scale and that any optional conditions (i.e.

radiation detection) are met before a transaction is allowed to be started at the

terminal.

b) Control varioius traffic devices (e.g. signs, gates, lights) to properly control the

flow of traffic across the scale.

Sections of entire screen traffic control setup are displayed below. The next set of

pages describes the purpose behind each option.

01/13 49 51299 Rev. 1

Section 3: Access Terminal Screens Defined

3.2.11. Traffic Control Setup, Continued

SCREEN PORTION 1 General Setup –

1

Monitor:

• No Traffic – simple in and out weighing without need to stage scale devices.

• Inbound Traffic – Enables inbound Traffic Devices, or section only.

• Outbound Traffic – Enables outbound Traffic Devices, or section only.

3

4

• In & Outbound Traffic – Enables Outbound and Inbound Traffic

or both and

3

4

Loading: Determines when the system will guide and check for vehicle on the scale.

• No Vehicle Loading

• Before Transaction Starts- Always use when Access Unit is located on Scale

• Before Getting the Weight- When Access Unit is positioned before scale

Give Preference: Used when two terminals are controlling traffic across the scale.

Each terminal is controlling traffic from one direction (inbound / outbound). Checking

one of the two will give one of the terminals a preference.

Deny Other Traffic: Generally both inbound and outbound transactions can be done

at the same Access Unit, when enabled this is not allowed. The inbound unit can

only start a transaction and the outbound can only complete it, otherwise a service

denied error will appear.

01/13 50 51299 Rev. 1

Section 3: Access Terminal Screens Defined

3.2.11. Traffic Control Setup, Continued

Allow Exit: Associated with Deny Other Traffic, allows a service denied error to be

followed with this option and will turn on any traffic devices (lights, gates). This is

recommended for unattended sites to allow the rest of the vehicles to be processed.

This Unit Loading: Used when two terminals are controlling traffic across the scale.

When the unit is in the process of loading a vehicle on the scale it will turn this output

on. This allows the other unit to know that it cannot be process a transaction.

Other Unit Loading: Used when two terminals are controlling traffic across the

scale. This unit will only read this output. The other terminal will turn this output on

when it is loading a vehicle. That tells this unit that it cannot process a transaction.

Screen: Determines what screen is displayed on the screen when the vehicle is

being loaded. In most cases Instructional should be used, and if the Access Unit is

not on the scale then None or Please Wait should be used.

Tracing: Turns on additional diagnostic data when terminal is ready or loading a

vehicle on the scale. This should not be left on unless troubleshooting an issue.

2

SCREEN PORTION 2 Detect Weight on Scale - These settings determines how a

vehicle is detected to be fully on the scale.

By weight with ##### lb/kg threshold

- If weight does not equal or exceed

set ####, then vehicle not present.

Stable after ###### readings

(change)

- Number of consecutive and

identical reads to determine if

weight is stable.

By sensors (such as photo eyes)

- Inbound and Outbound both have a

input selection and latch time in “s”.

01/13 51 51299 Rev. 1

Section 3: Access Terminal Screens Defined

3.2.11. Traffic Control Setup, Continued

Screen Capture shows Input selections

and latch times. Not shown but latch

goes from 0-30 seconds.

Timeouts –

- Timeout with no weight

If a vehicle is detected but then there is no

weight on the scale this timeout will

determine how long the system will wait

before going back to waiting for a vehicle

to arrive.

3

SCREEN PORTION 3 Inbound Traffic Devices

- Timeout with weight

If there is weight on the scale this timeout

will apply. Generally this should be set to

“None” to allow the driver all the time he

needs to start the transaction.

01/13 52 51299 Rev. 1

Section 3: Access Terminal Screens Defined

3.2.11. Traffic Control Setup, Continued

Gate: Select an output that will

be connected to a gate. Also

specify how long to keep the

output on.

Close gate: When enabled, the Access terminal will close the gate when the

selected input is detected. The input should be a sensor near the gate that will detect

the vehicle. The duration time is then used to make sure the gate is open for at least

the specified number of seconds. It also keeps the gate open until the vehicle is

detected by the sensors near the gate.

Sign: This is a sign (configured

on the Device Setup menu),

that will direct the vehicle onto

and off of the scale.

Display: This is a remote

display (configured on the

Device Setup menu), that will

direct the vehicle onto and off

of the scale.

Exit only: When enabled, the

exit only option on the sign or

display will change the device

to only direct a vehicle off of the

scale.

Staging Sign: This is a sign

(configured on the Device

Setup menu) located in the

staging area that will indicator

to any waiting drivers that the

scale is available to be used.

Staging Input: Associated with a sensor (usually a ground loop) that will detect a

vehicle in the stage area. A latching time can also be applied to the input. This is

often necessary and should be set based on the distance from the sensor to the

scale. The longer the distance the longer the latch time should be.

01/13 53 51299 Rev. 1

Section 3: Access Terminal Screens Defined

3.2.11. Traffic Control Setup, Continued

On Exit: When a vehicle is

directed to exit the scale an

additional output can be

activated. This output can be

turned on for a set duration or

until the vehicle is gone (based

on the settings in the Detect

Vehicle on Scale).

4

SCREEN PORTION 4 Outbound Traffic Devices

Options are identical to the Inbound Traffic Devices on Region but controlling

3

the opposite flow of traffic.

01/13 54 51299 Rev. 1

Section 3: Access Terminal Screens Defined

6

3.2.11. Traffic Control Setup, Continued

5

SCREEN PORTION 5 Drive By and Drive Off Alerts

These alerts occur when a transaction is not

started (Drive By) or started and not

completed (Drive Off). Each alert has the

same configuration options.

Output: When the alert occurs an output can

be turned on for the specified number of

seconds.

Alarm: The system alarm can be sounded

for a few seconds.

Attendant: If an intercom is connected with

a call option, the attendant can be alerted

through the intercom.

Email: An email will be sent to anyone

subscribed for this email.

SCREEN PORTION 6 Traffic Control Alerts

Traffic control alerts are general inputs to the terminal that will prevent a transaction

from starting and optionally from completing once started. They should be used when

the Loading setting is set to Before Transaction Starts. Up to 4 alerts can be

configured.

01/13 55 51299 Rev. 1

Section 3: Access Terminal Screens Defined

3.2.11. Traffic Control Setup, Continued

Each one will have the following options:

Input & Latch Time: This is the input that will trigger

the alert. An optional latching time can be configured

on the input as well. A latching input will remain on

for the set duration after the actual input turns off.

Error/Warning Message: This message will be displayed to the driver on the screen.

The screen option in the general settings must be set to Instructional for these

messages to be displayed to the driver. This message will also be included in the

notification if email subscription is set to monitor Traffic Control Alerts.

Output & Duration: An output can be

turned on when an alert occurs. It can be

turned on for a set duration or for the entire

duration of the input including the latch

time.

Cancel transaction on traffic alert:

This option allows correction to bad staging of equipment and positioning of input

devices such as down range or sensitive long range reader equipment.

Example Site:

• Radiation positioning was directly on the approach of the scale.

• Long Range reader was positioned down range of scale to start transaction

• Truck crept onto the scale slowly to verify tag reads.

• Threshold weight was reached so Welcome Screen, appeared to allow start of

transaction.

• Radiation detector completed scanning and found radiation but only after

transaction started. Checking this option will check after transaction starts as

well.

01/13 56 51299 Rev. 1

Section 3: Access Terminal Screens Defined

3.2.11. Traffic Control Setup, Continued

7

SCREEN PORTION 7 Loading Instructions, only applies if selection for Instructional

was selected from screen portion

1

No Vehicle on Scale: This instruction will be displayed when there is no vehicle on

the scale and no vehicle detected near the scale.

Entering, Drive On: This instruction will be displayed when a vehicle is detected

entering the scale but it is not fully on the scale yet. This can only be detected if there

are sensors to detect the vehicle, not just a weight on the scale.

Over Scale, Backup: This instruction will be displayed when a vehicle has driven

onto the scale too far. This can only be detected if there are sensors to detect the

vehicle, not just a weight on the scale.

Stop, Fully On Scale: This instruction will be displayed when the vehicle is fully on

the scale and not been by the sensors at either end of the scale.

Exiting, Drive Off: This instruction will be displayed when the transaction is complete

and the vehicle should pull forward off of the scale. This will remain until the vehicle is

gone.

Drive Off Detected: This warning will be displayed when a Drive Off/By is detected.

01/13 57 51299 Rev. 1

Section 3: Access Terminal Screens Defined

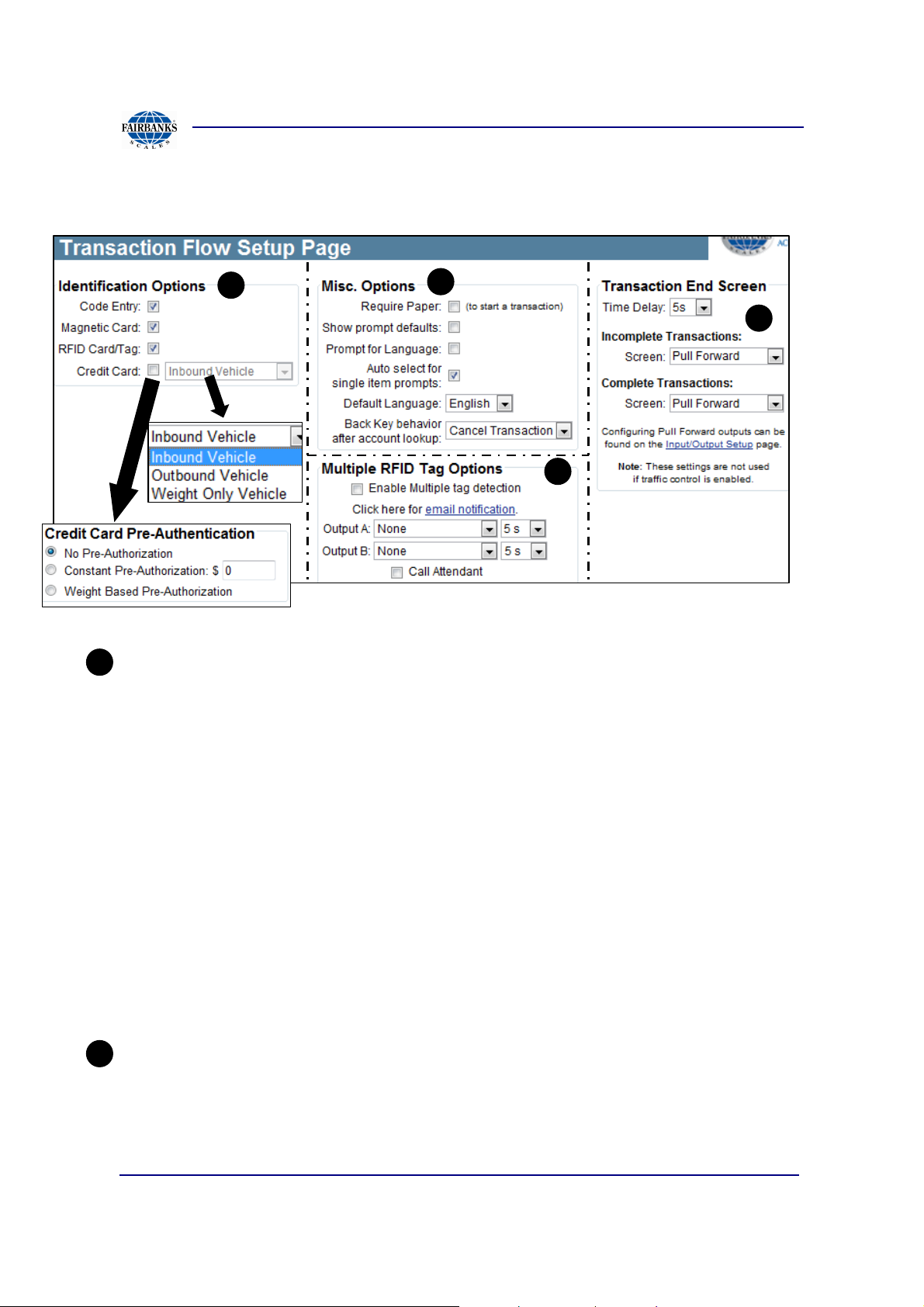

3.2.12. Transaction Flow Setup

A

B

C

A

Identification Options: Enable or disable how the driver can start transactions on an

Access Terminal.

• Code Entry: Use a specific account code to start the transaction.

D

• Magnetic Card: Allow a configured magnetic key card to start transactions.

• RFID Card/Tag: Allow short and long range RFID to start transactions.

• Credit Card:If selected a credit card will start a transaction with below options:

• Credit Card Pre-Authorization: Transactions started with a credit card must be

associated with one of the Unknown Vehicles in MatreX.

No Pre-Authorization- starts transaction, without charging preauthorization

Constant Pre-Authorization- starts with set preauthorization amount

Weight Based Pre-Authorization- starts with amount based on weight

B

Misc. Options:

• Require Paper: Transaction will not occur without printer loaded and working.

Show prompt defaults: Shows stage of transactions that are assumed

otherwise.

01/13 58 51299 Rev. 1

Section 3: Access Terminal Screens Defined

C

3.2.12. Transaction Flow Setup, Continued

• Prompt for language: Forces manual entry customers to select a language.

• Auto select for single item defaults: Less button presses when only one item to

choose.

• Default language: Forces one of three programmed languages (English,

Spanish, and French).

• Back key behavior after account lookup: sets functionality of back key on

Access Unit.

Multiple RFID tag options:

• Enable multiple tag options: Enables this detection feature. This feature should

only be used for RFID readers that broadcast multiple tags that are detected

(Pegasus).

• Email Notifications: When multiple tags are detected, an email can be sent.

Setup this notification via the Email Setup page.

• Outputs: When multiple tags are detected, two outputs can be turned on for a

specified duration.

• Call attendant: When multiple tags are detected, an attendant can be notified

via an integrated intercom.

D

Transaction End Screen:

These settings allow the last screen of a successful transaction to be changed. The

options are None, Pull Forward, and Remain on Scale. There are separate settings

for incomplete and complete transactions. Note that the pull forward outputs will only

work when Pull Forward screen is used. Also these settings are not used when

Traffic Control is enabled (Pull Forward is always used for Traffic Control).

• Time Delay: Set the delay for the end screen. This is the same timeout value

that is labeled Pull Forward on the Timeout and Delays page.

• Incomplete Transactions: Set the end screen for incomplete transaction. i.e.

the weigh in stage of a weight in/out transaction.

• Complete Transactions: Set the end screen for complete transactions.

01/13 59 51299 Rev. 1

Section 3: Access Terminal Screens Defined

3.2.13. Units Of Measure

Page configures the name, abbreviation, and precision of weight types.

The MatreX unit feature allows multiple custom units of measure to be used reflected

upon the settings in MatreX.

The Unit ID is specific to the ‘id’ given

from the MatreX web application.

Captured from the MatreX application, the predefined ID#, is shown. This ID is the

reference for the access unit

to print on scale ticket the

converted unit of measure.

References section (4.3.6)

of MatreX manual #51227

01/13 60 51299 Rev. 1

Section 3: Access Terminal Screens Defined

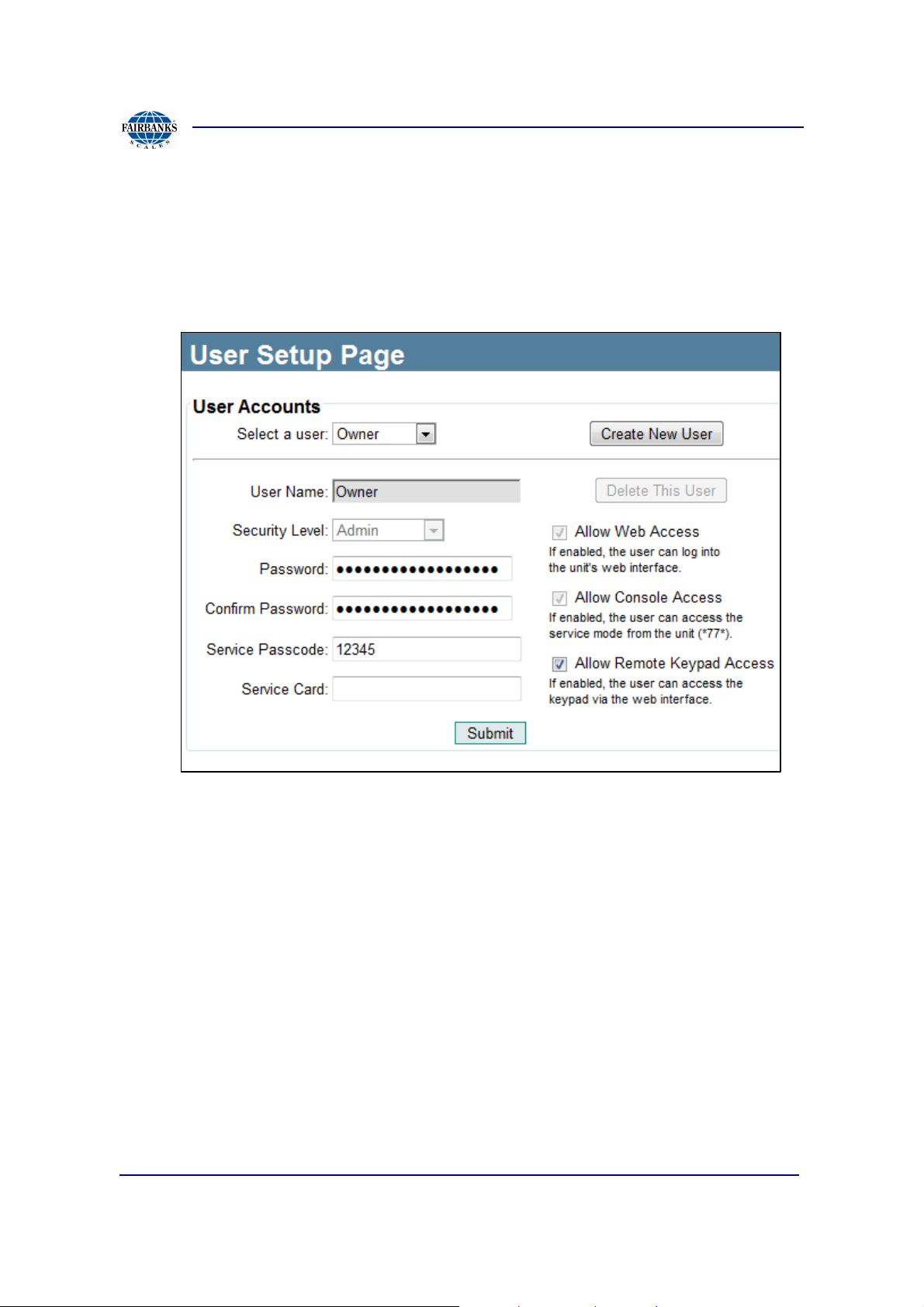

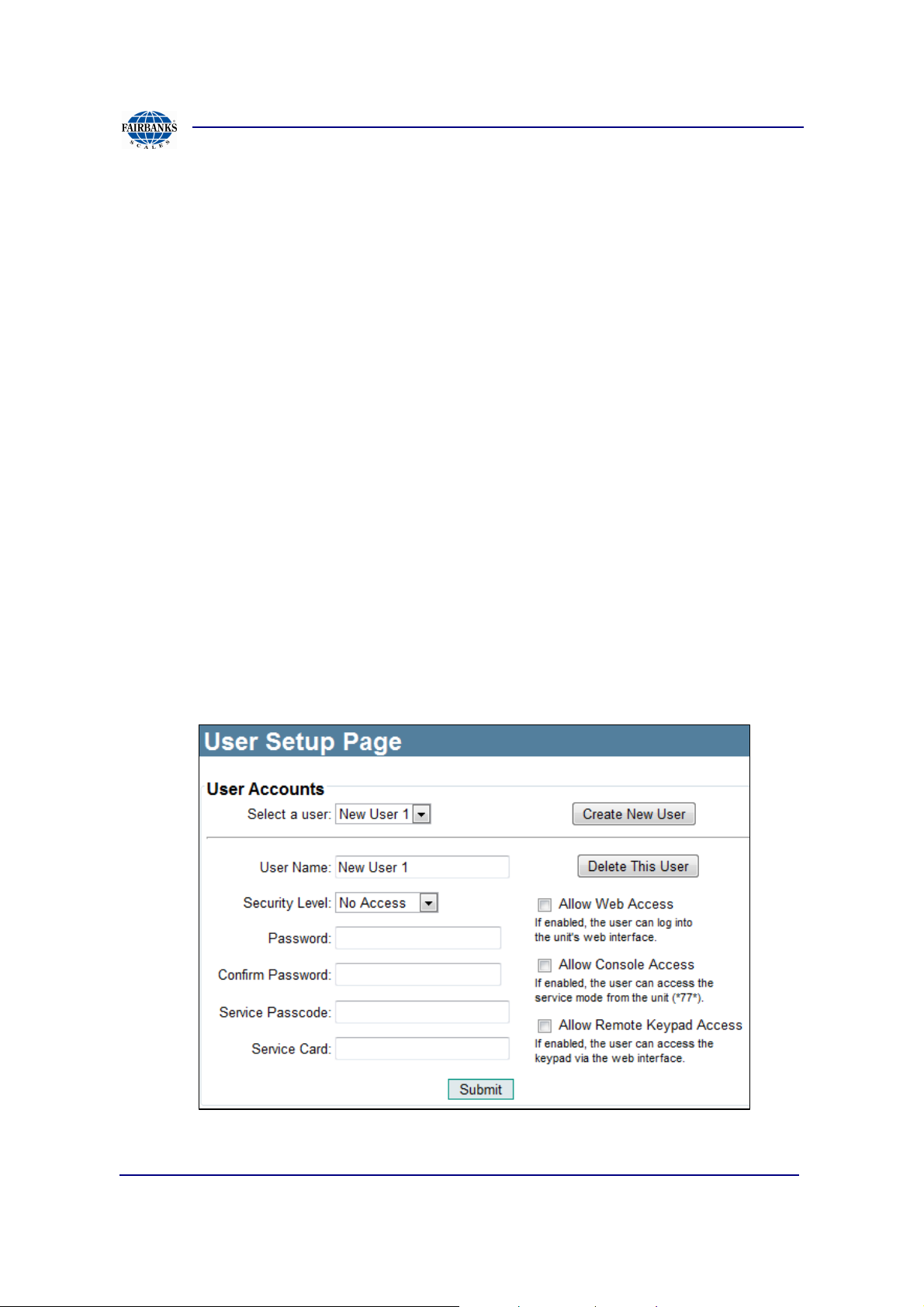

3.2.14. User Setup

User Setup allows user to create, edit, and delete user accounts for Access Terminal.

Accounts are then used to access service and diagnostic menus of Access Terminal.

USER ACCOUNTS

• Select a user: Use the drop down menu to select a current user.

• Create New User Button: Press the Create New User button to create a new

user.

User Setup Create New User/Edit User

User Setup allows users to edit previously created users or add new users.

01/13 61 51299 Rev. 1

Section 3: Access Terminal Screens Defined

3.2.14. User Setup, Continued

USER ACCOUNTS

• Select a user: Uses the drop down menu item selected from the previous

screen.

• Username: User name of account; used when logging into Access Terminal

web interface.

• Security Level: Access level granted to user.

• No Access – A user with this security will be denied access to both the

terminal console and the terminal’s web interface. Use this level to “disable” a

user without having to permanently remove the user.

• Maintenance – A maintenance user can quickly place the terminal into

Maintenance mode. When entering into service mode at the console of the

terminal either via a *77* code or a service card, the terminal will not go into

service mode, but instead automatically toggle to or out of Maintenance mode.

It is recommended to not allow this user access to the web interface.

01/13 62 51299 Rev. 1

Section 3: Access Terminal Screens Defined

3.2.14. User Setup, Continued

• Service – A user that has full access to the service menus at the console of

the terminal and almost full access to the terminal’s web interface. This user

will be denied access to the following areas:

♦ Credit Card Reports

♦ User Setup

• Admin – A user that has full access to the service menus at the console of the

terminal and full access to the terminal’s web interface.

• Password: Only available in Edit Users Setup screen and used when logging

into Access Terminal local web interface.

• Confirm Password: A pass code used to enter service and diagnostic menus

of Access Terminal; it must be 5 numerical digits.

•

•

•

•

Allow Web Access: If enabled, user is granted web browser access to

the Access Terminal.

Allow Console Access: If enabled, the user is granted web browser access

to the service mode of the Access Terminal (*77*).

Allow Remote Keypad Access: If enabled, user is granted keyboard access

to Access Terminal.

•

01/13 63 51299 Rev. 1

Delete This User: If user selects Delete, the user selected from drop-down

menu upon pressing the Submit button will be deleted.

Section 3: Access Terminal Screens Defined

A

B

C

D

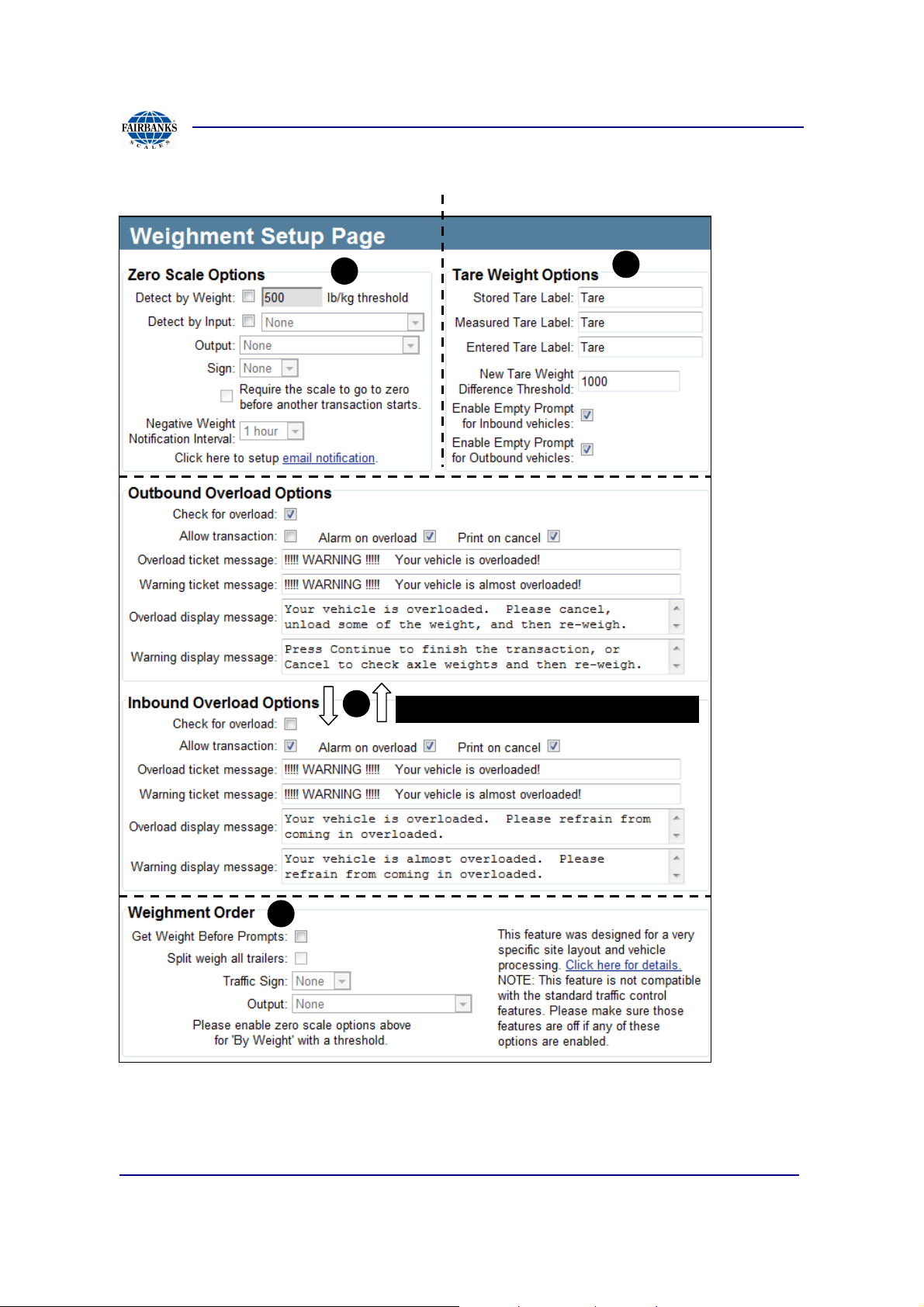

3.2.15. Weightment Setup

OVERLOAD OPTIONS SIMILAR ON BOTH

01/13 64 51299 Rev. 1

Section 3: Access Terminal Screens Defined

A

3.2.15. Weightment Setup, Continued

Zero Scale Options

The zero scale option has 3 main features:

1. Control an output or sign based on the scale being zero (or close to zero).

2. Ensures the system goes back to zero (or close to zero) before the next

transaction can start. This capability is also available by enabling Traffic

Control and vehicle loading as well. But for less complicated sites this one

could be used instead.

3. Send email notifications when the scale weight goes negative (beyond the

negative value of the threshold).

A zero scale can be detected in one of two ways by weight with a threshold. The

scale is considered zero of the weigh is greater than or equal to the negative of the

threshold weight and less than or equal to the positive threshold weight. The second

way is based on an input from the scale indicator. When the input is on, the scale will

be considered zero.

Detect By Weight: Detect a zero scale based on the weight from the scale indicator.

A weight threshold can also be set such that if the absolute value of the weight is less

then this threshold, then the scale is considered to be zero. That means if the scale

weight is negative and greater than the negative value of the threshold, the scale is

not zero.

Detect by Input: Detect a zero scale based on an input. This input is usually from the

scale indicator.

Output: An output can be turned on when the scale is zero. The output will remain on

the entire duration that the scale is zero.

Sign: Control a sign based on when the scale is zero. The sign will use the stop

signal when the scale is not zero and the go signal when the scale is zero.

Require the scale to go to zero before another transaction starts: In order to

meet NTEP requirements, the scale must go to zero before the next transaction is

allowed to start. Enabling this feature will ensure those checks are made.

Negative Weight Notification Interval: An email notification can be sent every so

often when the scale is reading a negative weight. This can be done through the

email subscripts on the Email Setup page. The frequency of the email is set here.

The default is every hour.

01/13 65 51299 Rev. 1

Section 3: Access Terminal Screens Defined

B

C

3.2.15. Weightment Setup, Continued

Tare Weight Options

Stored Tare Label: Set the text label to use for a tare weight that is stored with the

vehicle

Measured Tare Label: Set the text label to use for a tare weight that is measured or

read from the scale.

Entered Tare Label: Set the text label to use for a tare weight that is entered by the

driver.

New Tare Weight Difference Threshold: This threshold is used when a driver is

getting a new stored tare weight for a vehicle. If the new tare weight is within (+/-)

this threshold of the old stored tare weight no confirmation is needed. Otherwise if

the difference of the new and old weights is greater than this threshold, then the

driver must confirm the use of the new stored tare weight.

Enable Empty Prompt for Inbound vehicles: This setting enables the “Empty

Load” prompt. Basically this setting enables the ability for a driver to get a new

stored tare weight for the vehicle. This setting applies to only vehicles that use

stored tare weights and for vehicles that are marked as inbound vehicles in MatreX.

Enable Empty Prompt for Outbound vehicles: This setting is the same as above

but for only vehicles that are marked as outbound vehicles in MatreX.

Inbound and Outbound Overload Options

These two sections allow the terminal to check for and act on vehicles that weigh

more than their maximum gross weight. The maximum gross weight of the vehicle is

setup in MatreX on the Vehicle View/Edit page for each vehicle. The inbound and

outbound does not refer to the vehicle inbound/outbound flag. In this case it refers to

when the vehicle is arriving at the facility (inbound) or when the vehicle is leaving the

tacitly (outbound).

Check for overload: Enable this option to check for vehicles that are over their

maximum allowed weight. This maximum weight is assigned to each vehicle in

MatreX. There are separate but identical settings for vehicles that are entering

(inbound) or exiting (outbound) the facility.

Allow transaction: If enabled, the transaction will be allowed to complete. The driver

will still be warned and have the option to not complete the transaction.

Alarm on Overload: Sound Alarm

01/13 66 51299 Rev. 1

Section 3: Access Terminal Screens Defined

D

3.2.15. Weightment Setup, Continued

Overload ticket message: This is a message that will be printed on the scale ticket if

the vehicle is overloaded.

Warning ticket message: This is a message that will be displayed on the screen if

the vehicle is close to being overloaded. This requires a threshold weight to be set

along with the maximum weight in MatreX for the vehicle.

Overload display message: This is a message that will be displayed on the screen

if the vehicle is overloaded.

Warning display message: This is a message that will be displayed on the screen if

the vehicle is close to being overloaded. This requires a threshold weight to be set

along with the maximum weight in MatreX for the vehicle.

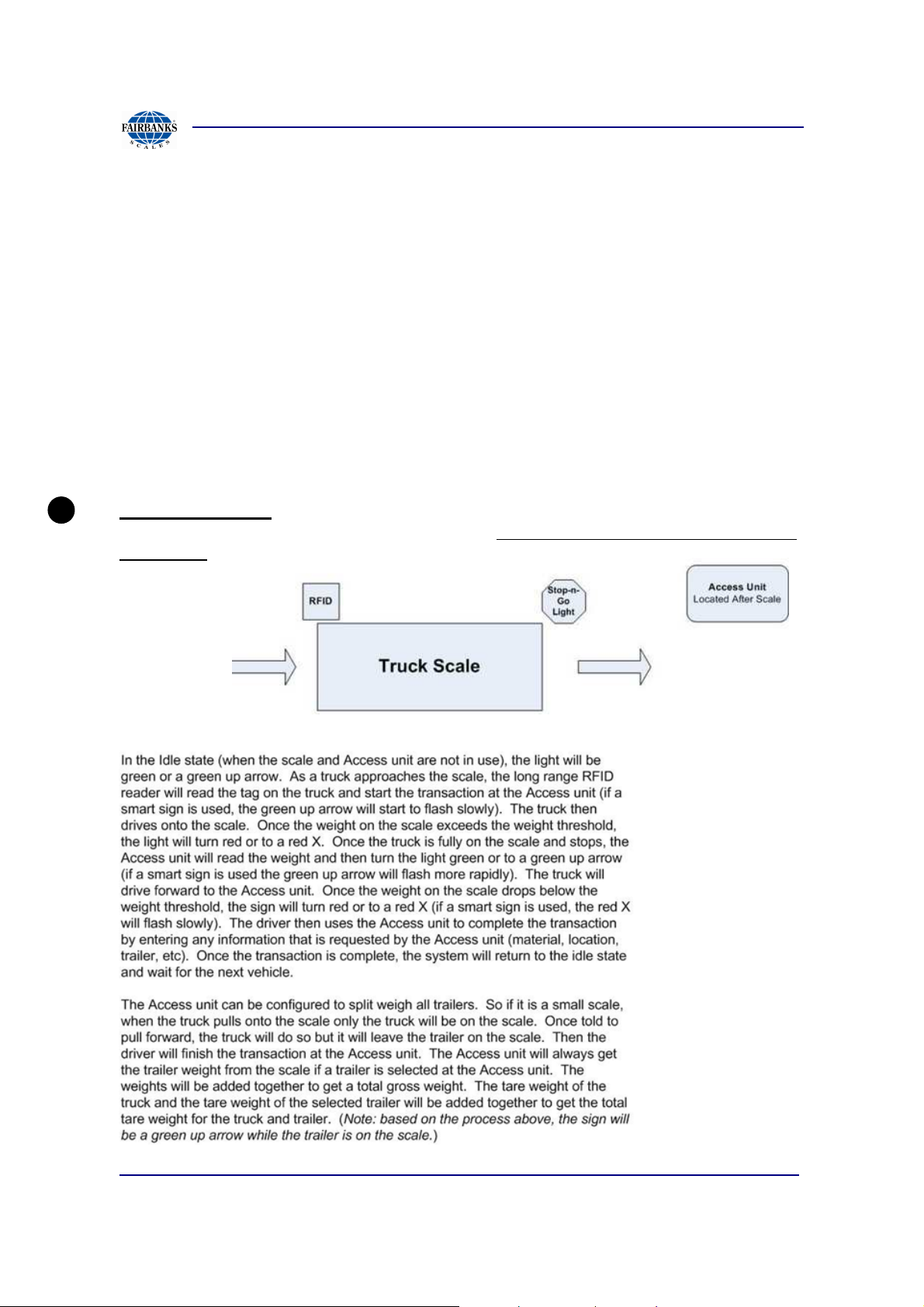

Weighment Order- Designed for a very specific site layout and vehicle processing.

The Access Unit is located ahead of the scale. View the diagram and process before

continuing.

Process:

01/13 67 51299 Rev. 1

Section 3: Access Terminal Screens Defined

3.2.15. Weightment Setup, Continued

NOTE:

Not compatible with the standard traffic control features. Please make sure those

features are off if any of these options are enabled.

Get Weight Before Prompts: Enable this option to have the terminal get the weight

before the prompts are displayed to the driver

Split weigh all trailers: This requires a trailer that does has no or little tongue weight

on the vehicle. The vehicle will pull onto the scale (but not the trailer) and start the

transaction. The system will get the vehicles weight. Then the vehicle will pull ahead

so that only the trailer is on the scale. The driver will then answer prompts at the

terminal. The terminal will then get the weight of the trailer and finish the transaction.

Traffic Sign: Select a sign to guide the driver across the scale.

Output: Select an output to control a light or gate to guide the driver across the

scale.

01/13 68 51299 Rev. 1

Section 3: Access Terminal Screens Defined

B

B

A

B A

3.2.16. Welcome Screen

Simple Mode

The above capture shows the default 4 scenarios. In Simple mode each scenario

has only 2 items, a message to appear to the driver and a behavior.

Line message visible on the display screen

Behavior selected when key pressed in line with line message

Capture shows items in Behavior

dropdown

01/13 69 51299 Rev. 1

Section 3: Access Terminal Screens Defined

A

C

A

B

3.2.16. Welcome Screen, Continued

ADVANCED OPTION

Captured shows the Welcome Screen using advanced options. Note previous simple

mode only had 2 items being the on screen text and the behavior. The advanced

mode has the type of action, text, and a behavior as a final result.

• Any chosen scenario requires at least one of the 4 steps to be populated with

a type of action and a behavior. Example Scenario 1, shows each action type

except for the “none” item, with a final outcome “behavior being Vehicle

Lookup Numeric”.

• Scenario 2 uses the Acquire ID Option, with all other steps set to none and a

behavior of “Exit Code Lookup”. If the types of actions used are only for

acquiring an ID and no other steps are used then a better approach would

have been the simple mode for this site.

Type has 5 options that scenario 1 shows in steps 1,2,3,4 and

“None” in Scenario 2.

• None: no action is taken

• Custom Input: This condition will wait for the specified

input to turn on (or off) before going on to

the next step.

• Button Press: This condition will wait for the button associated with the

scenario (selection key) before going on to the next step.

• Scale Weight:

Checks for a certain amount of

weight to be on the scale before

going on to the next step.

01/13 70 51299 Rev. 1

Section 3: Access Terminal Screens Defined

B

C

3.2.16. Welcome Screen, Continued

• Acquire ID: This is the final step after all other conditions are met. At this point

the driver can enter or present vehicle identification.

Type is text and limited to the characters used on a single

line on the display

Behavior list shown below, this is the expected

outcome of the staging area.

Vehicle Lookup (Numeric) / (Alpha) / (Card): With this option the driver identifies

the vehicle via the keypad (numeric or alpha-numeric) or a card (magnetic swipe or

RFID card). The transaction will be based on how the vehicle is configured in MatreX.

NOTE: Any time a number is keyed in or a card is swiped without making a selection

at the welcome screen this option will be used.

(Inbound) / (outbound) Load Weigh In/Out: When using MatreX, this option is used

for vehicles that do not have an account. Transactions started by selecting this option

will be associated with the Unknown Inbound Vehicle or the Unknown Outbound

Vehicle in MatreX. This type of transaction will also generate an exit code that is used

during the weigh out stage of the transaction. When integrated with Soft-Pak, this will

generate a list of vehicles for the driver to choose from. When integrated with

Paradigm, this will be associated with Paradigm's cash customer.

Vehicle Weigh Only: When using Matrex, this option is used for vehicles that do not

have an account and are not doing a typical transaction. This case the vehicle is just

getting a weight from the scale. Depending on how MatreX is configured, the driver

may need pay before getting this weight.

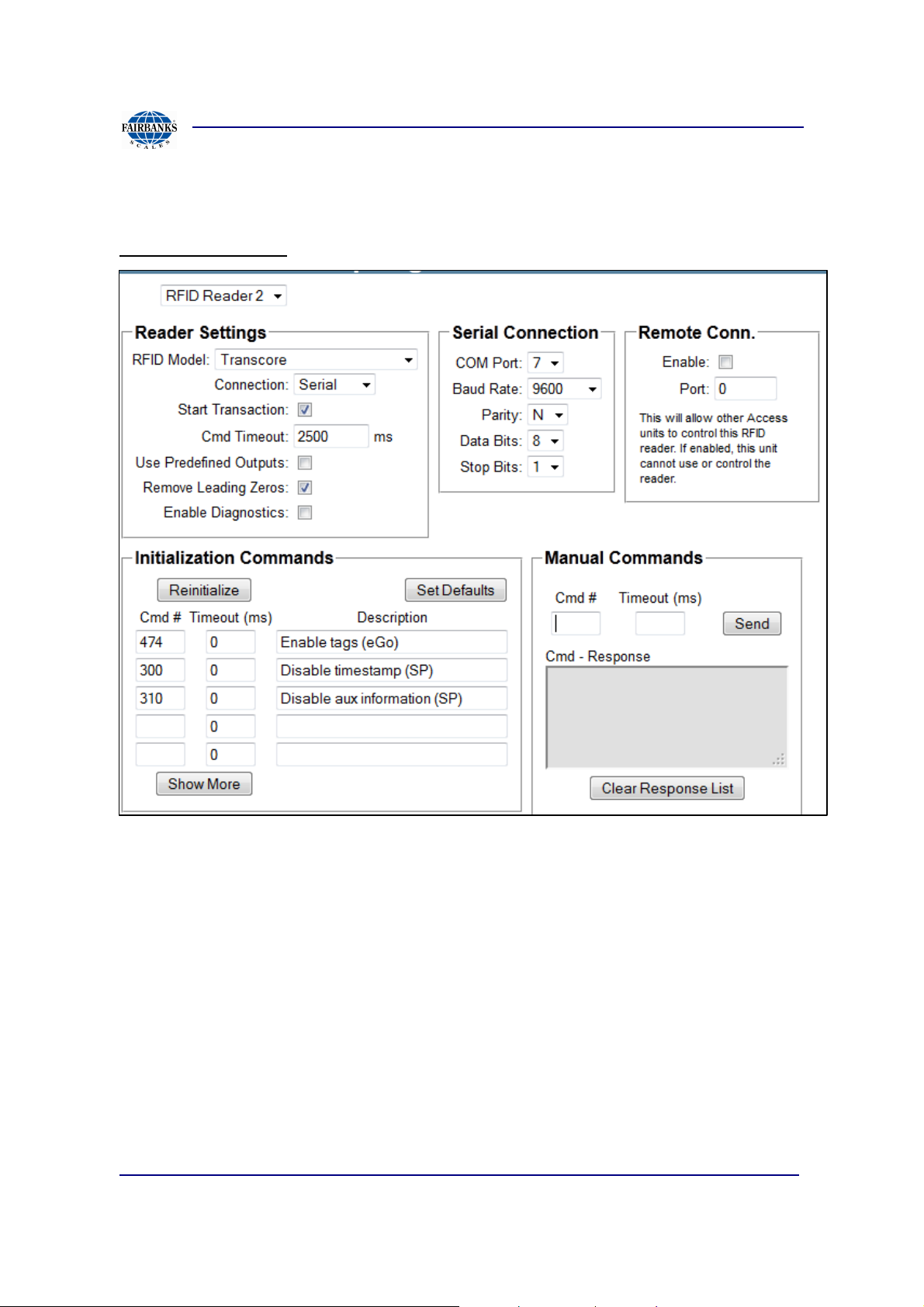

Exit Code Lookup: When this option is select, the terminal will prompt for an exit