Page 1

Installation Manual

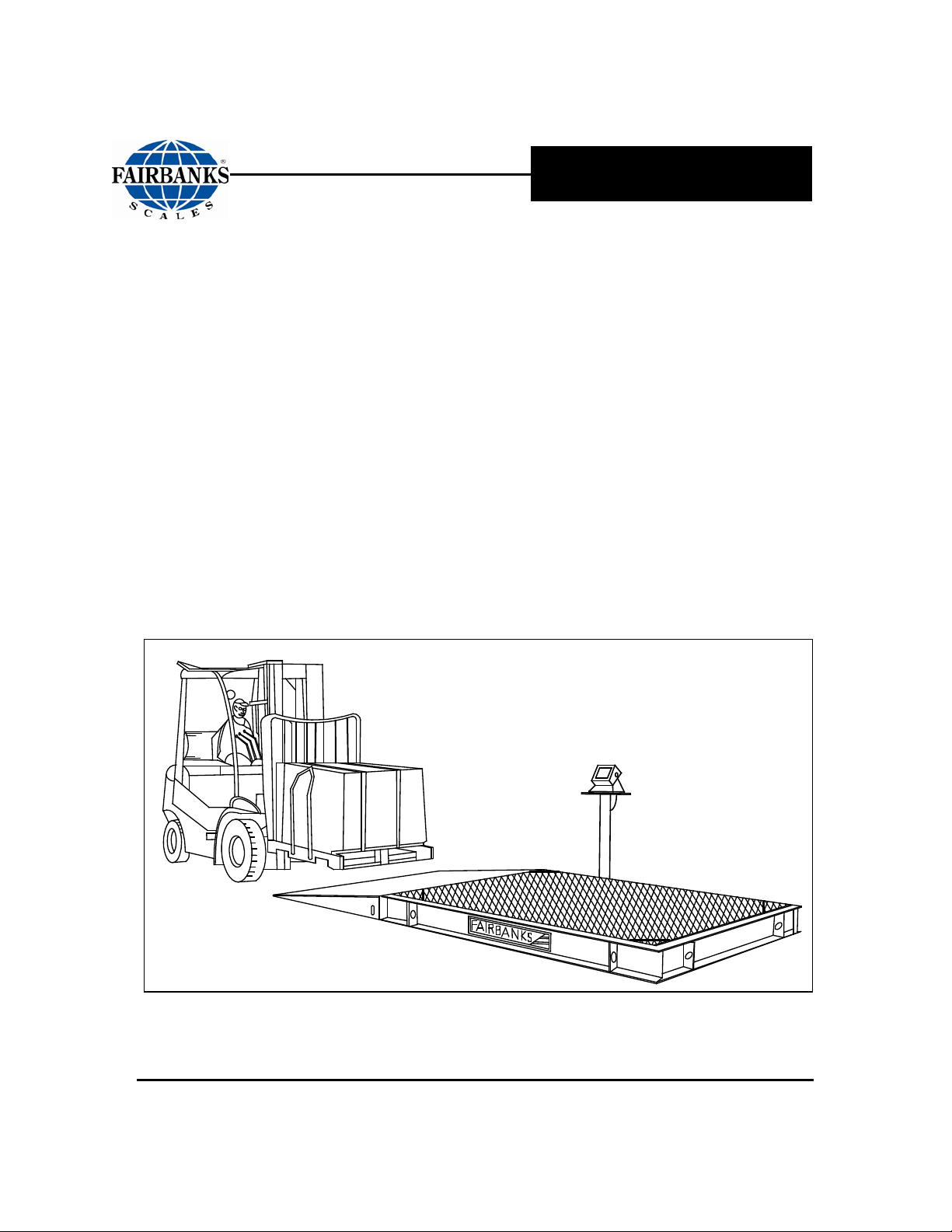

Aegis Xtreme-Duty Floor Scale

© 2008 by Fairbanks Scales, Inc. Revision 1 11/08

All rights reserved

51206

Page 2

Page 3

Amendment Record

AEGIS XTREME-DUTY FLOOR SCALE

Document 51206

Manufactured by Fairbanks Scales Inc.

821 Locust

Kansas City, Missouri 64106

Created 9/08 Created Document

Revision 1 11/08 Document Release

11/08 3 51206 Rev. 1

Page 4

Disclaimer

Every effort has bee n made to provide com plete and accurate inform ation in this manual. However,

although this manual m ay include a specifically identi fied warranty notice for the product, Fairbanks

Scales makes no representations or warranties with respect to the contents of this manual, and

reserves the right to make changes to this manual without notice when and as improvements are

made.

Fairbanks Scales shal l not be liable f or any loss, damage, cost of repairs , incidental or c onsequential

damages of any kind, whether or not based on express or implied warrant y, contract, negligence, or

strict liability arising in connection with the design, development, installation, or use the scale.

© Copyright 2008

This document contains proprietary information protected by copyright. All rights are reserved; no part

of this manual may be reproduced, copied, translated or transmitted in any form or by any means

without prior written permission of the manufacturer.

11/08 4 51206 Rev. 1

Page 5

Table of Contents

SECTION 1: GENERAL INFORMATION .................................................................. 7

1.1. Introduction ................................................................................................................ 7

1.1.1. Specifications ....................................................................................................................... 7

1.1.2. Accessories.......................................................................................................................... 9

SECTION 2: GENERAL SERVICE POLICY............................................................ 10

2.1. General Service Policy ............................................................................................. 10

2.1.1. Service Technician’s Responsibilities ................................................................................ 11

2.1.2. Users’ Responsibility ......................................................................................................... 11

SECTION 3: SCALE INSTALLATION ...................................................................... 12

3.1. Conferring with Our Client ........................................................................................ 12

3.2. Standard Installation Steps ...................................................................................... 14

3.2.1. Unpacking .......................................................................................................................... 15

3.2.2. Positioning the Scale ......................................................................................................... 16

3.2.3. Positioning Steps ............................................................................................................ 17

3.2.4. Installing the Platform ........................................................................................................ 18

3.2.5. Wiring the Junction Box ..................................................................................................... 20

3.3. Installing Accessories .............................................................................................. 21

3.3.1. Ramp Installation ............................................................................................................... 21

3.3.2. Pillar Installation Steps ...................................................................................................... 22

SECTION 4: SERVICE & MAINTENANCE .............................................................. 23

4.1. General Troubleshooting .......................................................................................... 23

4.2. Scale Platform Troubleshooting ............................................................................... 24

4.2.1. Scale Platform Testing ....................................................................................................... 24

4.2.2. Load Cell Testing ............................................................................................................... 24

4.2.3. Load Cell Replacement Steps ........................................................................................... 25

SECTION 5: PARTS ................................................................................................. 26

5.1. Parts Lists #107979 – 5’ x 5’ X8”, 20K ..................................................................... 26

5.2. Parts List #106966 – 6’ X 8’ X 8”, 40K ..................................................................... 26

5.4. Parts Diagram .......................................................................................................... 27

5.5. Accessory Part Numbers ......................................................................................... 28

5.5.1. Aegis Xtreme-Duty Ramp Assembly .................................................................................. 28

5.5.2. Aegis Xtreme-Duty Pit Frame Assembly ............................................................................ 28

5.5.3. Mild Steel Stand-alone Instrument Pillar ........................................................................... 28

5.3. PLATFORM MODEL MATRIX .......................................................................... 29

11/08 5 51206 Rev. 1

Page 6

Page 7

Section 1: General Information

• Gene ral Industrial

• Heavy-Duty Industr ial

• Extremely large fork lifts

• Large freight containers

• Warehousing

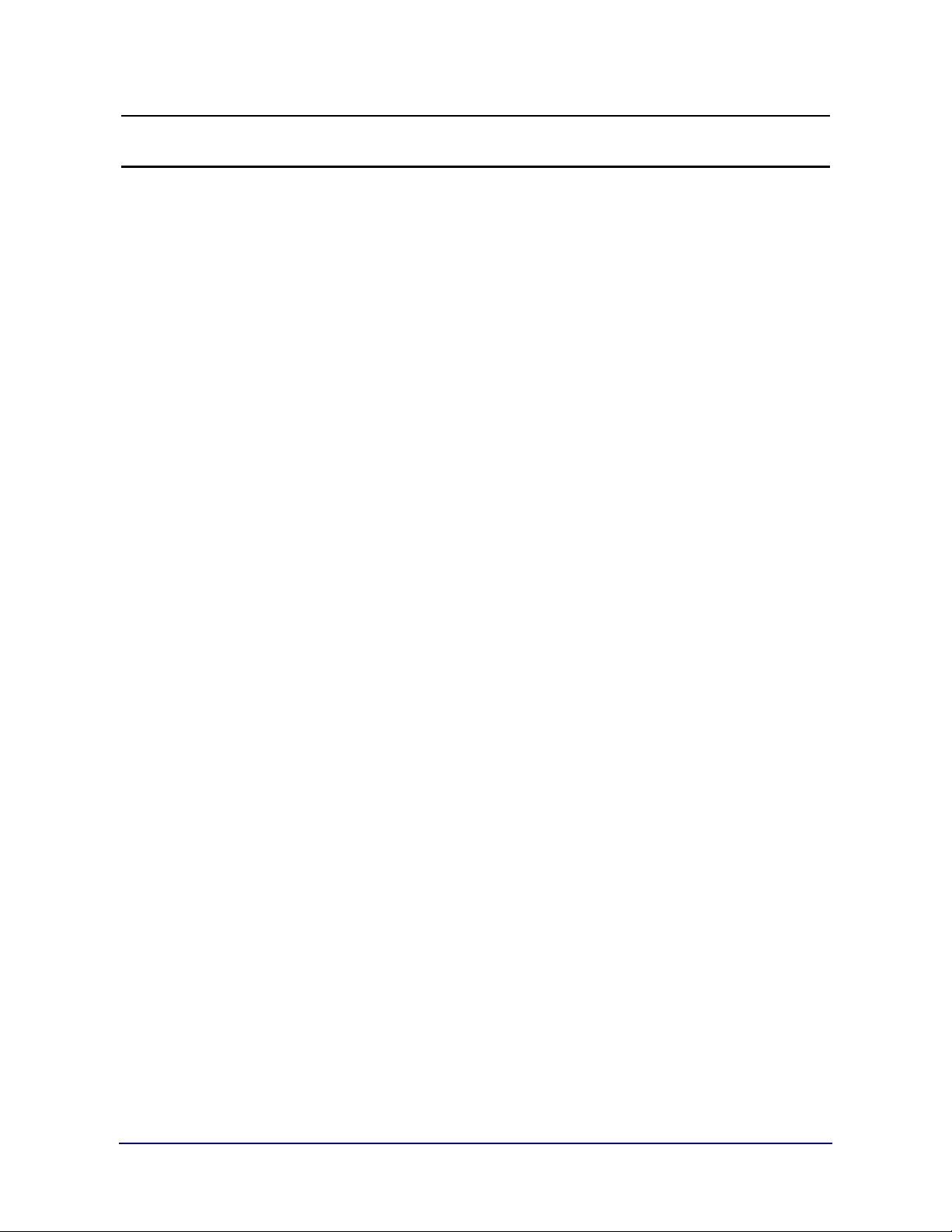

Feature

Description

Standard Platform Sizes

4’ x 4’ thru 6’ x 8’

Custom Platform Sizes

4’ x 2’ thru 12’ x 15’

8” to 9” Diamond Tread

150%

100%

100%

10 to 100%

Meets or exceeds Handbook 44 tolerances

5 to 15 VDC

Less than 3 Ohms to True Earth Ground

1.1. INTRODUCTION

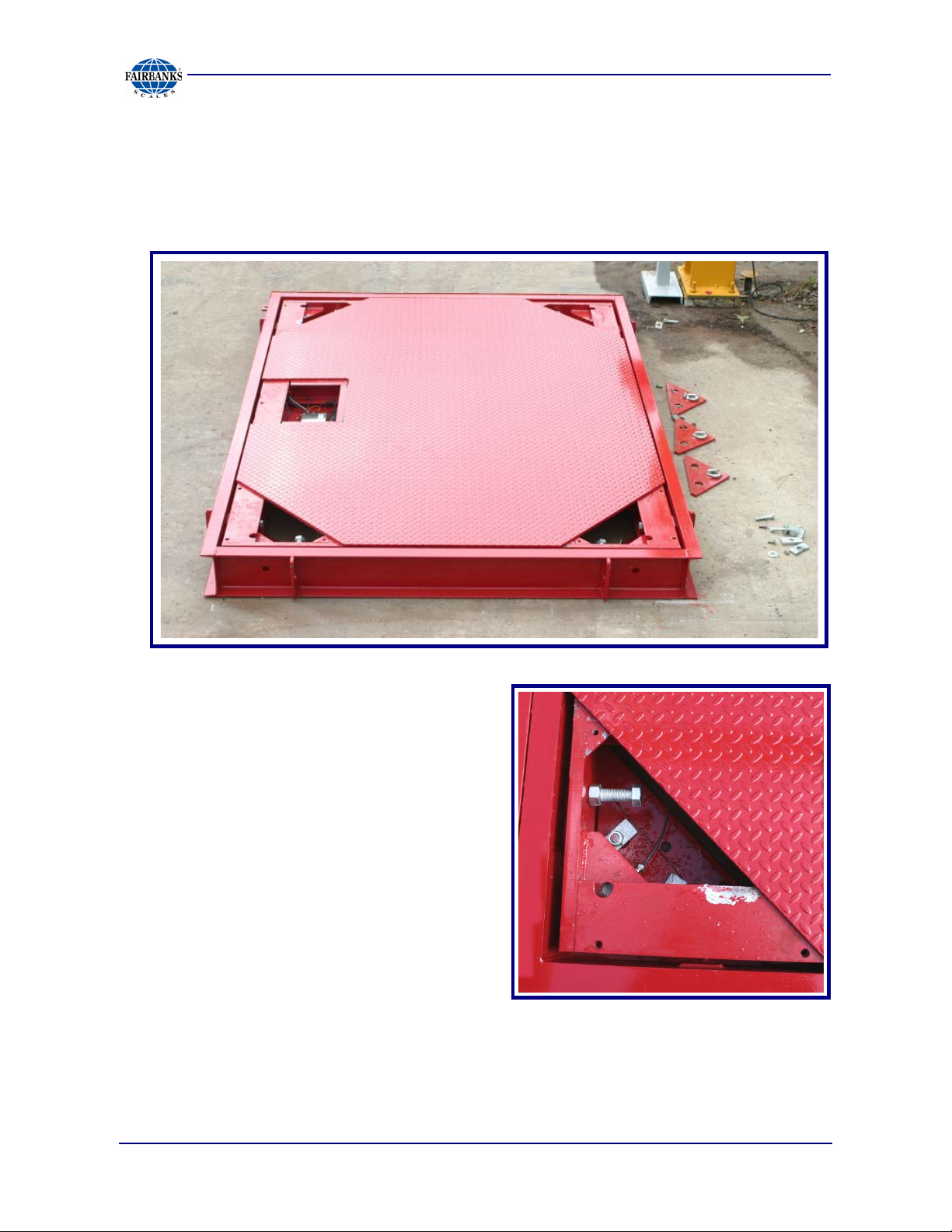

The Aegis Xtreme-duty Scale is an extremely rugged floor scale, designed for

high capacities and a wide variation of dimensional sizes. This is because of the

additional I-beam supports under the platform that run both along the scale’s “X” and

“Y” axis.

It has an extremely low-profile design. The scale’s floor height is 8 or 9 inches,

depending on the capacity.

The Aegis Xtreme-duty Scale is designed for applications with high load

concentrations.

1.1.1. Specifications

Platform Height

Scale Capacities

Overload Capacity

Point Loading

Endloading

Temperatures

Humidity

Accuracy

Load Cell Excitation

Grounding

• 20,000, 40,000, and 60,000

• 2,500 up to 95,000

• Operating: 10°C to 40°C (14°F to 104°F)

• Storage: -20°C to 70°C (14°F to 158°F)

11/08 7 51206 Rev. 1

Page 8

1.1.1. Specifications, Continued

Feature

Description

Interface Cable

31’ PVC Jacketed

Standard Platform dimensions: 4’ x 4’ thru 6’ x 8. Height: 8” or 9”.

Section 1: Gen er al Information

Scale Construction

Junction Box

Load Cells

Approvals

• Type A36 carbon steel

• Deck plate – ¼” to ½”

• Full I-beam support

• Diamond Tread

• Watertight Analog

• Stainless Steel

• NEMA 4X

• Four (4) Rocker Column Design

• IP69K “True” Hermetically Sealed

• 17-4 ph Stainless Steel

• 15,000 to 50,000 Capacity

• Combined Error -- +/< 0.02% of Rated Capacity

• FM Approved

• NTEP Approval CC# 07-097 (for 6,000 divisions)

• Load Cell NTEP Approval CC# 07-037

Scale Capacities: 20K, 40K & 60K. Steel Deck: ¼” – ½”. J-Box: NEMA 4X.

11/08 8 51206 Rev. 1

Page 9

Section 1: Gen er al Information

• Aegis Xtreme-Duty Ramp

• Stand-alone Instrument Pillar

• Flush-Grade Pit Frame

1.1.2. Accessories

Available modifications and accessories include the following:

11/08 9 51206 Rev. 1

Page 10

Absolutely NO physical, electrical or program modifications other

Section 2: General Service Policy

2.1. GENERAL SERVICE POLICY

Prior to installation, always verify that the

equipment satisfies the customer's

requirements as supplied, and as described

in this manual.

If the equipment cannot satisfy the application and the application cannot be

modified to meet the design parameters of the equipment, the installation

should NOT be attempted.

It is the customer/operator's responsibility to ensure the

equipment provided by Fairbanks is operated within the par a m e ters

of the equipment's speci fi c a ti ons and pr ot ec t e d fr om ac c idental or

malicious damage.

than selection of standard options and accessories can be made

by customers to this equipment

Repairs are performed by Fairbanks Scales Service Technicians

and Authorized Distri but or P er s onne l ONLY!

WARNING!

Failure to comply with this poli c y voids al l im pli e d a nd/or written

warranties

11/08 10 51206 Rev. 1

Page 11

Section 2: General Servic e P olicy

2.1.1. Service Technician’s Responsibilities

All electronic and mechanical calibrations and/or

adjustments required for making this equipment

perform to accuracy and operational specifications

are considered to be part of the original installation.

─ They are included in the installation charge.

─ Only those charges which are incurred as a result

of the equipment's inabi lity to be adjusted or

calibrated to per for ma nc e spec ifications may be

charged to warranty.

The equipment consists of printed circuit assemblies

which must be handled using ESD handling procedures, and must be replaced as

units.

─ Replacement of individual components is not allowed.

─ The assemblies must be properly packaged in ESD protective material and

returned intact for replacement credit per normal procedures.

2.1.2. Users’ Responsibility

Absolutely no physical, electrical or program modifi cations ot he r

than selection of standard options and accessories are to be

made to this equipment.

11/08 11 51206 Rev. 1

Page 12

Section 3: Scale Installation

3.1. CONFERRING WITH OUR CLIENT

• The technician must be prepared to recommend the arrangement of components

which provide the most efficient layout, utilizing the equipment to the best possible

advantage.

• Assist the customer in selecting a site which allows easy access to and from the

scale, ensuring enough area for straight and level approaches, if applicable.

─ The site needs good drainage away from the scale, elevated enough so the

surrounding areas drain away from the scale.

─ Obtain all the necessary permits and licenses prior to beginning construction.

• Explain and review the warranty policy with the customer.

The installing technician is responsible that all per sonnel a re fully

trained and familiar wit h the equipment's capabilities and

limitations before the installation is considered complete.

• All electrical assemblies must be returned intact for replacement credit using the

standard procedures.

• At the time of installation, all electr o ni c and mech ani cal adj ustments are

considered to be part of the installation, and are included in the installation

charge(s).

• The AC receptacle/outlet shall be located near the Indicator and easily accessible.

• Electrical connections other than those specified may not be performed.

11/08 12 51206 Rev. 1

Page 13

Section 3: Scale Installation

• All load cells, load cell cables and interconnecting cables used to connect all

scale components shall be located a minimum of thirty-six (36”) inches

distance away

electric current carrying conductors.

• This includes digital weight indicators, junction boxes, sectional

controllers, and power supplies.

• This includes any peripheral devices, such as printers, remote

displays, relay boxes, remote terminals, card readers, and

auxiliary data entry devices.

• Also included is the scale components themselves, such as

120 volt AC, 240 volt AC, 480 volt AC and electric supply of

higher voltage wiring runs and stations, AC power transformers,

overhead or buried cables, electric distribution panels, electric

motors, florescent and high intensity lighting which utilize

ballast assemblies, electric heating equipment, traffic light

wiring and power, and relay boxes.

IMPORTANT INSTALLATION NOTICE

from all single and multiple phase high energy circuits and

• All scale components, including digital weight indicators and

peripheral devices are not des igned to operate on internal combustion engine

driven electric generators and other similar equipment.

Electric arc weld i ng can severely damage scale components such as digital

•

weight indicators, junction boxes, sectional controllers, power supplies, and load

cells.

NOTE: For additional information, please contact your Fairbanks Scales

Service Representative.

11/08 13 51206 Rev. 1

Page 14

Section 3: Scale Installation

3.2. STANDARD INSTALLATION STEPS

The Aegis Xtreme-Duty Scale Platform is shipped fully assembled and

wired. The standard scale installation consists of the following steps.

• Unpack the Scale, and any components.

• Selecting the best Platform Site Location.

• Connect lifting straps or chains to the lifting lugs on the sides of the platform,

then move it to the designated site using a crane.

• Install the Ramps (if applicable).

• Level the Platform.

• Install and wire the Instrument to the Platform.

• Adjust and Calibrate the Scale according to the appropriate Indicator Service

Manual.

11/08 14 51206 Rev. 1

Page 15

Section 3: Scale Installation

3.2.1. Unpacking

Follow these guidelines when unpacking all equipment.

Check in all components and accessories according to the customer's order.

Remove all components from their packing material, checking against the invoice

that they are accounted for and not damag e d .

Advise the shipper immediately, if damage has occurred.

Keep the shipping container and packing material for future use.

Order any parts necessary to replace those which have been damaged.

Check the packing list.

The CUSTOMER is the receiving party if the equipment was shipped to

the Customer’s address.

FAIRBANKS is the receiving party if the equipment was shipped to the

Fairbanks Service Center.

Collect all necessary installation manuals for the

equipment and accessor i es.

Open the equipment and perform an inspection, m aking

certain that all hardware, electrical connections and printed

circuit assemblies are secure.

Do not reinstall the cover if the final installation is to be

performed after the pre-installation checkout.

Do not load the platform if there is any evidence of damage

to the platform or supporting structure.

NOTE: It is the owner's responsibilit y to document, notify, and follow-up

regarding shipping damage with the carrier.

11/08 15 51206 Rev. 1

Page 16

Section 3: Scale Installation

3.2.2. Positioning the Scale

Position the Scale with these points in mind:

Use the proper lifting equipment to position and place the scale.

The scale is to be placed on a flat, solid, level surface, one that fully supports the

weight of the platform plus a full capacity load.

The smooth surface must be within 1/8”, and on a level plane, within ¼” across

both the length and width of the platform.

The four corners of the Platform must rest solidly on the surface, and not rock.

Irregular bumps and foreign material under the Platform can cause an “out-oflevel” condition, which will affect the weight accuracy.

Platform vibrations ma y also affect the weighing accuracy. Wherever possible,

locate the platform as far away from heavy, low frequency vibrations as much as

possible.

Do not load the platform if there is any evidence of damage to the platform or

supporting structure.

Ease of access is very important. Allow plenty of room for maneuvering a fork lift.

Reading the Indicator is also important to workers, so place it in a very visib le

position.

When installing the Scale and Indicator in an outdoor location, set it up so the

snow, ice accumulation, rain and other conditions do not affect the platform

operations.

11/08 16 51206 Rev. 1

Page 17

Section 3: Scale Installation

To lift and move the Platform, place strap hooks into brackets

3.2.3. Positioning Steps

1. Position the Scale into its final location.

2. Place the hooks of the straps or chains into the specific lifting points of the Scale.

─ The straps or chains should be long enough to f orm a minimum 45° angle

with the platform while lifting.

on each side of it, and also into each hole of the ramp.

3. Place the platform in the desired location.

─ The platform should be made stable and level.

─ Shims are not included with the platform and must be supplied locally as

needed.

11/08 17 51206 Rev. 1

Page 18

Section 3: Scale Installation

3.2.4. Installing the Platform

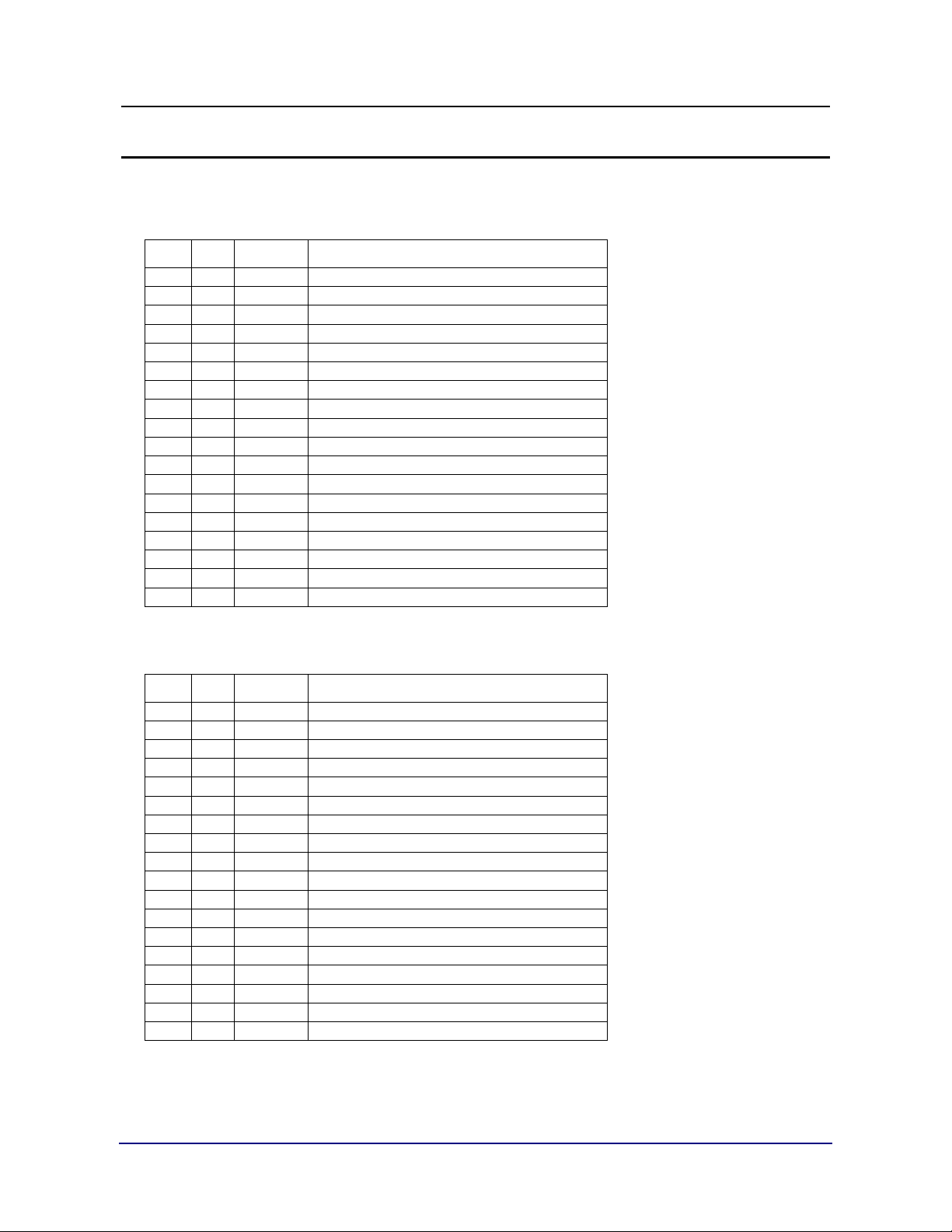

1. Remove the four (4) triangular cover plates, found on each corner.

2. Remove the nut from the shipping bolts in each corner.

3. Drill and secure the platform using the

supplied ¾” wedge anchors.

4. Adjust the checking bolts to a 1/16” to

1/8” clearance.

11/08 18 51206 Rev. 1

Page 19

Section 3: Scale Installation

Bolts

Anchor

3.2.4. Installing the Scales,

Continued

5. Verify that the platform is plumb, square

and level.

─ If Ramps are to be installed, do it at

this time.

6. Replace the nut on the shipping bolt, then

loosen it two (2) full threads.

7. Replace the four (4) triangular cover

plates, found on each corner .

8. Calibrate the unit according to the appropriate indicator service manual.

Checking

Shipping Bolts

Wedge

11/08 19 51206 Rev. 1

Page 20

Section 3: Scale Installation

WIRE COLOR

FUNCTION

3.2.5. Wiring the Junction Box

Load Cells are preinstall ed, pl um be d, and pr e-wired to the Junction Box at the

factory, prior to shipping.

─ Dip Switches are not set.

─ Interconnecting cables are not installed.

1. Open the platform access cover, then the junction box cover.

2. Loosen all gland bushing nuts.

3. Wire the Indicator to Junction Box according to the chart below.

4. Follow the indicator installation manual to properly connect it with the platform.

5. Tighten all gland bushing nuts.

IMPORTANT NOTE: Leave the Junction Box Cover off until all corner

adjustments are completed.

Red

White (+) Signal

Black

Green (+) Excitation

Yellow Ground

(−) Signal

(−) Excitation

11/08 20 51206 Rev. 1

Page 21

Sect ion 3: Scale I ns ta llation

CAUTION

• Aegis Xtreme-Duty Ramp

• Stand-alone Instrument Pillar

• Intrinsically Safe Controllers

• Smart Sectional Controllers

• Flush-Grade Pit Frame

• Intalogix Technology (QMB)

3.3. INSTALLING ACCESSORIES/MODIFICATIONS

Listed below are the standard Aegis Xtreme-Duty Scale Accessories.

Absolutely NO ARC WELDING i s t o be perform e d on, or ne ar

this scale while the Load Cells are in pl a c e and/ or c onne c t e d.

Disconnected and removed ALL the Loa d Ce lls during ANY

welding.

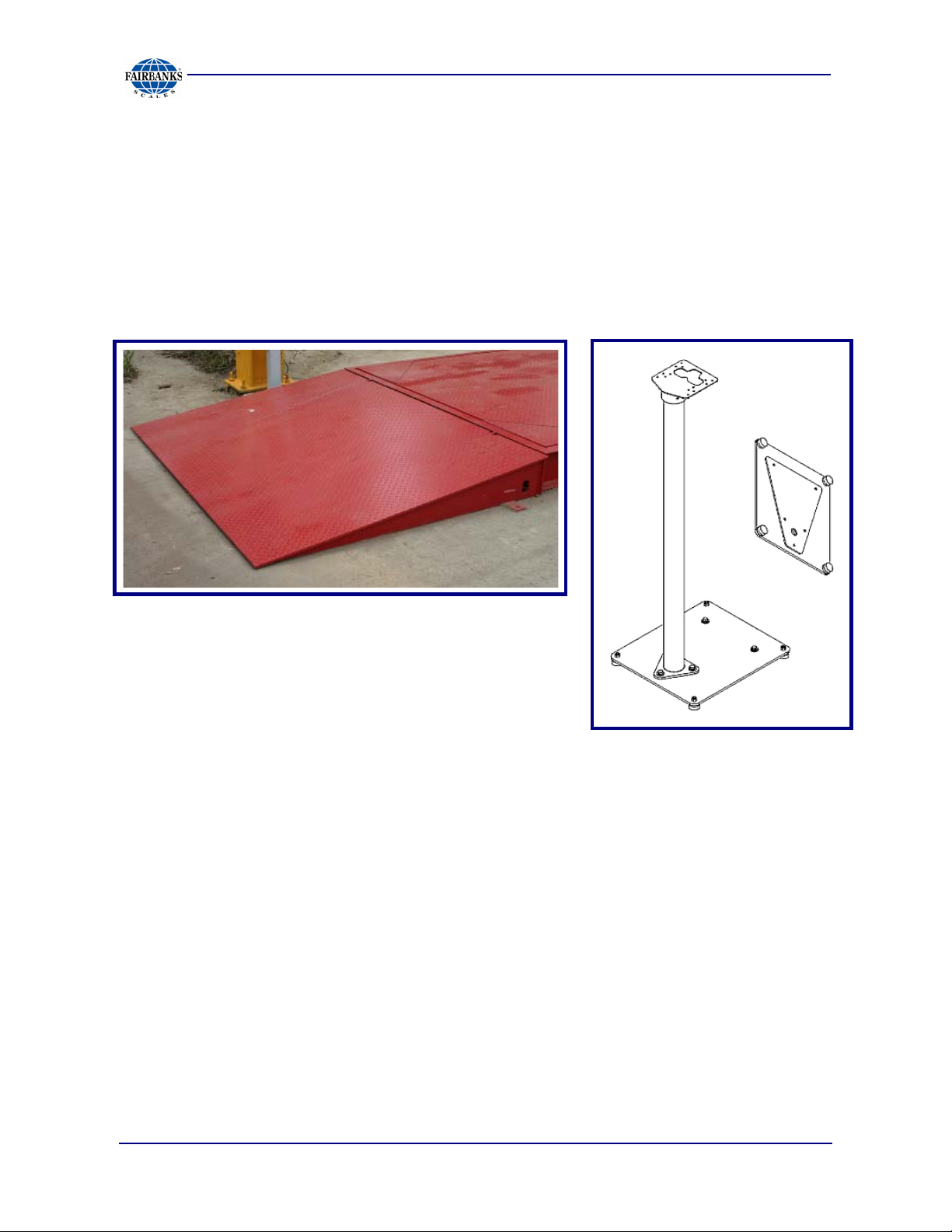

3.3.1. Ramp Installation

The ramps are optional, and used different

ways in varied applications.

• Each ramp has two (2) bolt down tabs, one

on each side.

1. Place the ramp against the platform frame

─ The ramp’s slot is fits inside the scale’s

lifting point.

─ Level and stabilize the ramp against the platform.

─ Shims are not included with the ramps and must be

supplied.

2. Drill and anchor the ramp(s) using the supplied 3/4” wedge

anchors.

─ Up to four (4) ramps can be installed on the

Xtreme-duty Scale

, one on each side.

Aegis

11/08 21 51206 Rev. 1

Page 22

3.3.2. Pillar Installation Steps

1. To remove the Top Plate, loosen the three (3)

one quarter inch (¼”) Allen Screws.

2. Carefully run the Interface Cable into the bottom

Access Hole, up through the Pillar, and then

thread it out through the top Access Hole.

─ Allow extra cable slack to accommodate the

Instrument wiring.

3. Replace the Top Plate, then secure it into

position using the one eighth inch (1/8”)

Allen Wrench

4. Install the Instrument Top Bracket, secure it with

the supplied hardware

.

Section 4: Servi ce & Maintenance

5. Connect the Interface Cable to the Indicator.

─ Refer to the appropriate instrument service

manual for correct wiring information.

11/08 22 51206 Rev. 1

Page 23

Section 4: Service & Maintenance

4.1. GENERAL TROUBLESHOOTING

From the following chart, identify the symptom(s) and cause(s) of each malfunctio n,

solving each issue with an appropriate solution.

SYMPTOM CAUSE SOLUTION

Displays stay at

zero

Erratic Weights

Inaccurate

Weights

1. Load Cell connections faulty.

2. Instrument faulty.

3. Faulty/bad Load Cell(s).

1. Foreign object around load cells,

ramps, or under platform.

2. Excessive vibration near platform.

3. Instrument faulty.

4. Platform not level wit h in ¼ ” (3 .0°).

5. Surface not smooth enough

(within 1/8”).

6. Faulty/bad Load Cell(s).

1. Instrument out of span.

2. Instrument not properly adjusted

to zero.

3. Faulty/bad Load Cell(s).

1. Cable replacement.

2. Service Instrument.

3. Test and replace the Load Cell(s) as

shown in

1. Clear the area.

2. Remove the vibration source.

3. Service Instrument.

4. Level the platform surfac e.

5. Find a smoother surface for the

platform.

6. Test and replace the Load Cell(s) as

shown in

1. Check and alter per the Instrument

Service Manual.

2. Zero the instrument according to

normal operation procedures.

3. Test and replace the Load Cell(s) as

shown in

Section 4.2.3.

Section 4.2.3.

Section 4.2.3.

11/08 23 51206 Rev. 1

Page 24

Section 4: Servi ce & Maintenance

4.2. SCALE PLATFORM TROUBLESHOOTING

Except for severe structural damages, most

Platform Assembly problems can be traced to

the following causes.

• Material under or around the Platform.

• Broken Load Cell receiver cups..

• Faulty Load Cells.

4.2.1. Scale Platform Testing

1. Inspect the Interface Cable from the Platform to the Instrument f or visible breaks

or cracks.

2. ZERO the Instrument Display.

3. Apply a test load of

25% of the Load Cell capacity to one corner.

─ The Instrument should display a weight reading within 0.1% of the applied

weight, or One Instrument Division, whichever is greater.

4. Repeat Step 3 for all the corners, placing the same Test Load on each corner.

4.2.2. Load Cell Testing

When corners do not match the correct tolerances, unsolder each Load Cell Cable,

then test each Load Cell for the settings on the following chart.

TEST READING REMARKS

Green to Black (Input) 1106 Ohms (+5 / -2 Ohms) Input Resistance

Red to White (Output) 1000 Ohms (+5 / -2 Ohms) Output / Bridge Resistance

Yellow (Shield) to Load Cell Case

Input and Output Leads to Shield

Input and Output Leads to Case

More than 1,000 megohms Insulation Resistance

.

11/08 24 51206 Rev. 1

Page 25

Section 4: Servi ce & Maintenance

4.2.3. Load Cell Replacement Steps

1. Cycle-down the power to the indicator, then unplug the unit.

2. Remove the platform and junction box access covers.

3. Loosen the gland bushing, and tie a string or wire to the end of the cable to act as

a pull wire.

4. Place wire markers on the cable ends.

─ Masking tape is an effective alternative

5. Disconnect the faulty load cells wires from the terminal block.

6. Lift the platform end with a forklift or heavy pry bar, using wood blocks for safety.

7. Remove the load cell, pull i ng the cable through the scale while leaving the pull

string/wire in the scale.

8. Remove the defective load cell from the receiver cups , then install the new load

cell.

─ Use a lubricant on the O-rings.

9. Disconnect the pull string/wire from the defective load cell's cable, then attach to

the replacement load cell's cable end.

10. Pull the cable from the new cell through to the junction box.

11. Lower the scale to the surface removing the saf ety blocks.

12. Distribute the scale’s weight evenly on all four (4) load cells..

13. Connect the load cell wires into the junction box, then tighten the box gland

bushing(s).

14. Replace the platform ac ces s cov er .

11/08 25 51206 Rev. 1

Page 26

PART No.

1 1 107972

PLATFORM WELDMENT, X-TREME

2 1 107978

FRAME WELDMENT

3 2 107701

BASE PLATE W/LOWER CUP

4 2 107702

BASE PLATE W/LOWER CUP

5 4 105718

UPPER CUP W/O ANTI-ROTATION

6 1 67171M

J- BOX ASSY. SS

7 4 108120

3 ½” RC L/C /, 15k

8

12

61743

CLAMP BAR

9 4 54555

¾”–10 x 3 ½” HEX HEAD CAP SCREW

10

16

54264

¾” HEX NUT

11 1 83861

WEDGE ANCHOR BOX

12

STICKER, FAIRBANKS SCALES

13

13

54406

½”-13 x ¾” LG FLAT HEAD SOCKET

14 4 54233

¾” FLAT WASHER

15 4 107797

SHIM, .01 x 1 ½” ID x 2 1/8” OD

16 4 107798

SHIM, .03 x 1 ½” ID x 2 1/8” OD

17 4 72967

FULL THD BOLT, ¾”- 10 x 5” LG

18 4 54218

FULL THD BOLT, ¾”- 10 x 3” LG

PART No.

1 1 106975

PLATFORM WELDMENT, X-TREME

2 1 107976

FRAME WELDMENT

3 2 107701

BASE PLATE W/LOWER CUP

4 2 107702

BASE PLATE W/LOWER CUP

5 4 105718

UPPER CUP W/O ANTI-ROTATION

6 1 67171M

J- BOX ASSY. SS

7 4 108121

3 ½” RC L/C /, 30k

8

12

61743

CLAMP BAR

9 4 54555

¾”–10 x 3 ½” HEX HEAD CAP SCREW

10

16

54264

¾” HEX NUT

11 1 83861

WEDGE ANCHOR BOX

12

STICKER, FAIRBANKS SCALES

13

13

66979

½”-13 x 1” LG FLAT HEAD SOCKET

14 4 54233

¾” FLAT WASHER

15 4 107797

SHIM, .01 x 1 ½” ID x 2 1/8” OD

16 4 107798

SHIM, .03 x 1 ½” ID x 2 1/8” OD

17 4 72967

FULL THD BOLT, ¾”- 10 x 5” LG

18 4 54218

FULL THD BOLT, ¾”- 10 x 3” LG

Section 5: Parts

5.1. PARTS LISTS #107979 – 5’ X 5’ X 8”, 20 K

ITEM QTY

DESCRIPTION

5.2. PARTS LIST #106966 – 6’ X 8’ X 8”, 40K

ITEM QTY

DESCRIPTION

11/08 26 51206 Rev. 1

Page 27

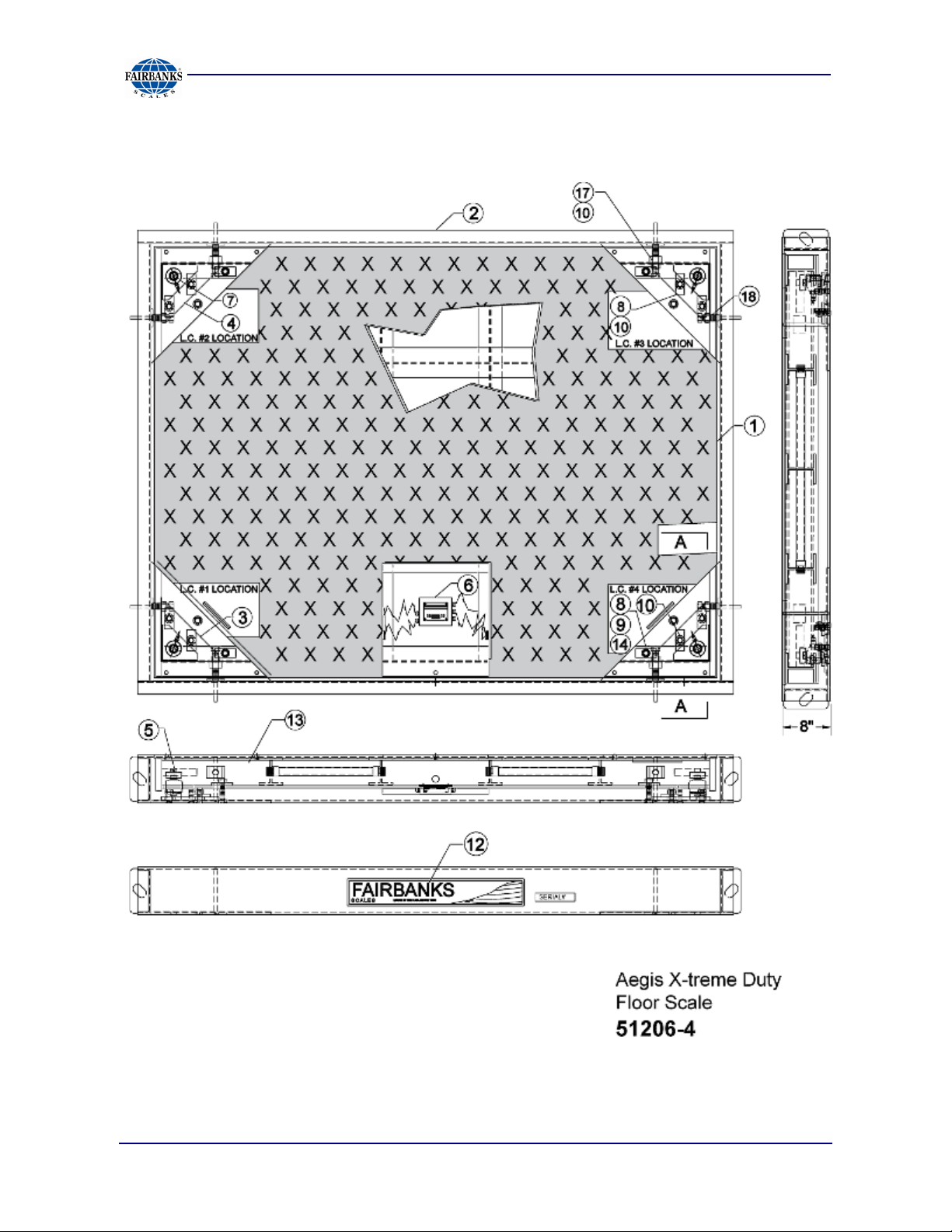

5.4. PARTS DIAGRAM

Section 5: Parts

11/08 27 51206 Rev. 1

Page 28

108440

Aegis Xtreme-Duty Pit Frame, 4’ x 4’

108441

Aegis Xtreme-Duty Pit Frame, 4’ x 8’

108442

Aegis Xtreme-Duty Pit Frame, 5’ x 5’

108443

Aegis Xtreme-Duty Pit Frame, 6’ x 6’

108444

Aegis Xtreme-Duty Pit Frame, 6’ x 8’

5.5. ACCESSORY PART NUMBERS

5.5.1. Aegis Xtreme-Duty Ramp Assembly

Part No. Description

108413 Aegis Xtreme-Duty Ramp Assembly, 4’ ramp

107988 Aegis Xtreme-Duty Ramp Assembly, 5’ ramp

107307 Aegis Xtreme-Duty Ramp Assembly, 6’ ramp

108415 Aegis Xtreme-Duty Ramp Assembly, 8’ ramp

5.5.2. Aegis Xtreme-Duty Pit Frame Assembly

Part No. Description

Section 5: Parts

5.5.3. Mild Steel Stand-alone Instrument Pillar

Part No. Description

28396 Stand-alone Pillar Assembly, Mild Steel

28392 MS Base Plate

28561 MS Base Plate Su ppor t

28760 MS Top Plate As sy

27787 MS Pillar Weldment

12777 Foot

11/08 28 51206 Rev. 1

Page 29

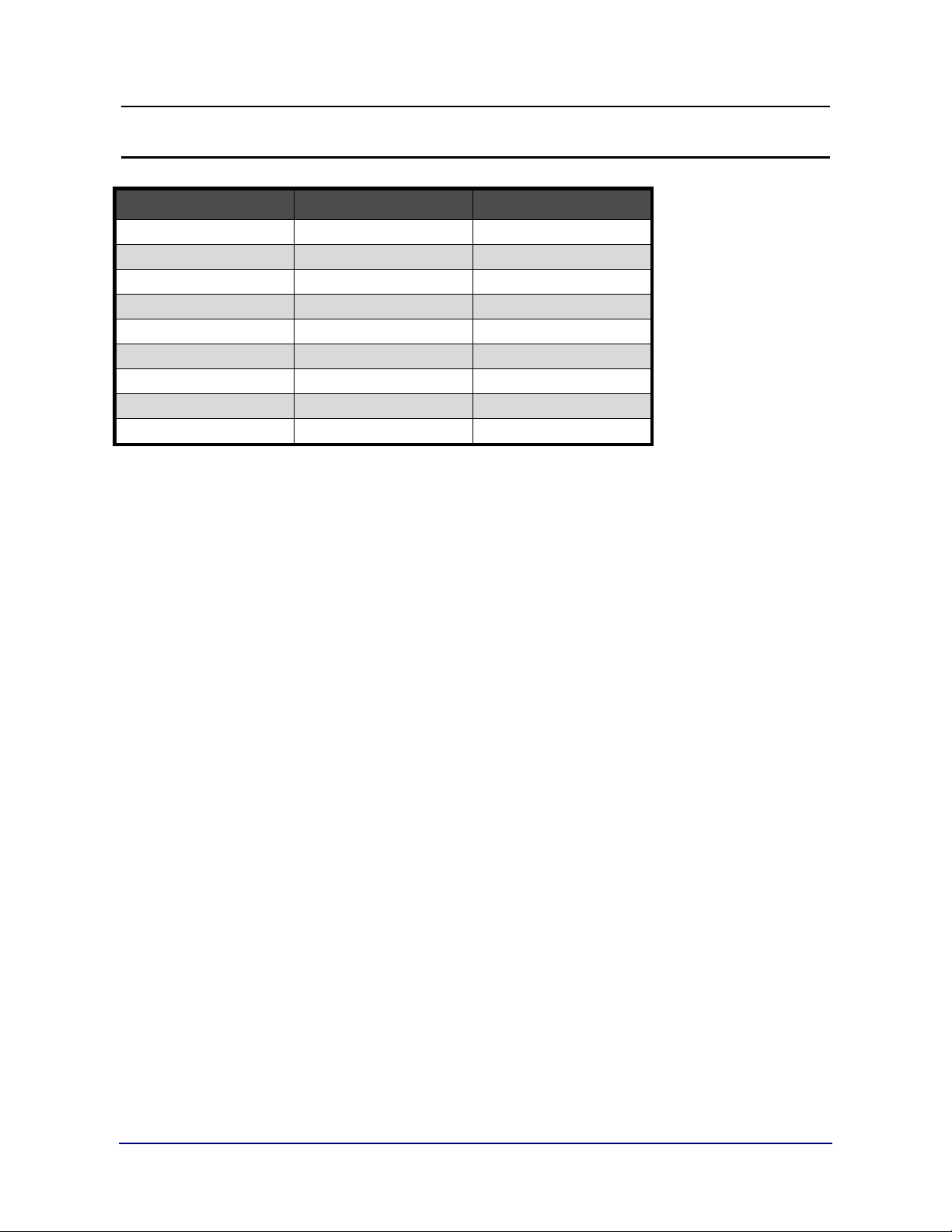

108400

4’ x 4’

108401

4’ x 8’

107979

5’ x 5’

20,000 lbs

108402

6’ x 6’

108403

6’ x 8’

108404

6’ x 6’

40,000 lbs

106966

6’ x 8’

108409

6’ x 6’

5.3. Platform Model Matrix

PRODUCT NO. SIZE CAPACITY

20,000 lbs

20,000 lbs

20,000 lbs

20,000 lbs

40,000 lbs

60,000 lbs

108410 6’ x 8’

60,000 lbs

11/08 29 51206 Rev. 1

Page 30

Page 31

Page 32

Manufactured by Fairbanks Scales, Inc.

Aegis Xtreme-Duty Floor Scale

821 Locust

Kansas City, MO 64106

www.fairbanks.com

INSTALLATION MANUAL

DOCUMENT 51206

Loading...

Loading...