Fairbanks Aegis Industrial Stainless User Manual

Aegis

Stainless Steel

Floor Scale

Installation Manual

© 2007 by Fairbanks Scales Inc.

All rights reserved

51103

Revision 1 01/07

51103 2 01/07 -- Rev. 1

Amendment Record

Aegis Stainless Steel Floor Scale

51103

Manufactured by Fairbanks Scales Inc.

821 Locust

Kansas City, Missouri 64106

Revision 0 01/07 Preliminary Release

Revision 1 01/07 Manual Release

Disclaimer

Every effort has been made to provide complete and accurate information in this manual. However, although this manual may

include a specifically identified warranty notice for the product, Fairbanks Scales makes no representations or warranties with

respect to the contents of this manual, and reserves the right to make changes to this manual without notice when and as

improvements are made.

51103 3 01/07 -- Rev. 1

Table of Contents

Section 1: General Information

A. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

B. Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

C.Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Section 2: Installation

A. General Service Policy . . . . . . . . . . . . . . . . . . . . . . . 5

B. Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

C. Pre-Installation Checklist . . . . . . . . . . . . . . . . . . . . . . 6

D. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

E. Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

F. Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

i. Analog Interface (Junction Box 67171) . . . . . . . . 8

ii. Intalogix Technology Interface (QMB 15291) . . . 9

Section 3: Accessories Installation

A. Bolt-Down Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

B. Ramps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

C. Bumper Guards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

D. Pit Frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Section 4: Maintenance and Service

A. Load Cell Replacement . . . . . . . . . . . . . . . . . . . . . . . 14

B. Junction Box/QMB PCB Replacement . . . . . . . . . . . 15

C. Foot Assembly Replacement . . . . . . . . . . . . . . . . . . 16

Section 5: Parts

A. Stainless Steel Platforms . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Diagram: Stainless Steel models . . . . . . . . . . . . . . . . . . 18

B. Stainless Steel Lift Deck Platforms . . . . . . . . . . . . . . . . . 19

Diagram: Stainless Steel 3’ x 3’ and 4’ x 4’ models . . . 20

Diagram: Stainless Steel 5’ x 5’ models . . . . . . . . . . . . . 21

APPENDIX I: Model Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

APPENDIX II: Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

APPENDIX III: Standard Pit Frame and Installation Drawing . . . 24

APPENDIX IV: Lift Deck Pit Frame Installation Drawing . . . . . . . . 25

A. Introduction:

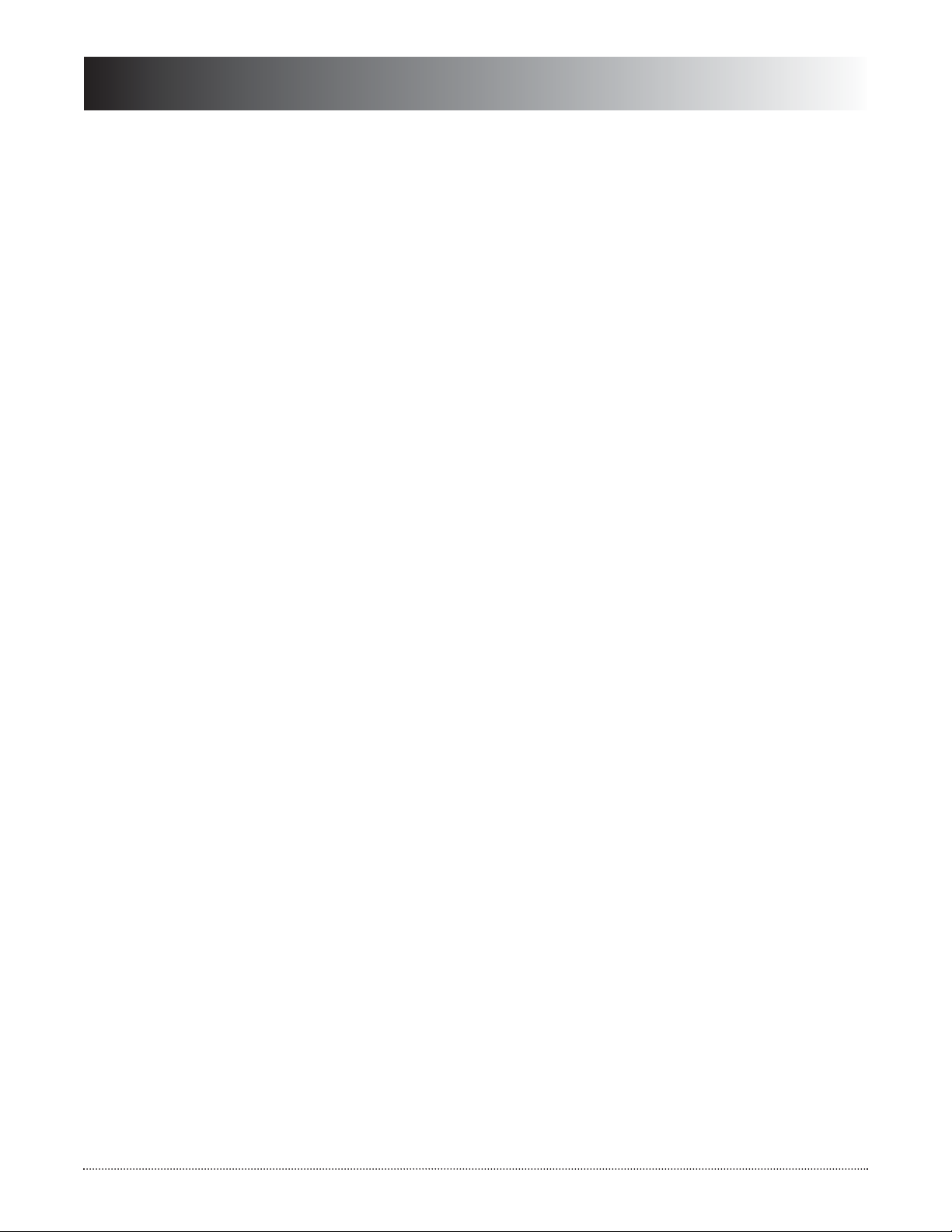

The Aegis Stainless Steel floor scale features a rugged structural rib design and a

nominal height of three inches -- among the lowest in the industry. With a full range of

accessories, these scales can be configured to fit most floor scale applications.

B. Description:

The Aegis Industrial Stainless Steel series floor scale platform is fully assembled and

pre-wired. Aegis stainless steel floor scale sizes range from 30" x 30" to 6' x 8', and

have capacities from 1000 to 10,000 lbs.

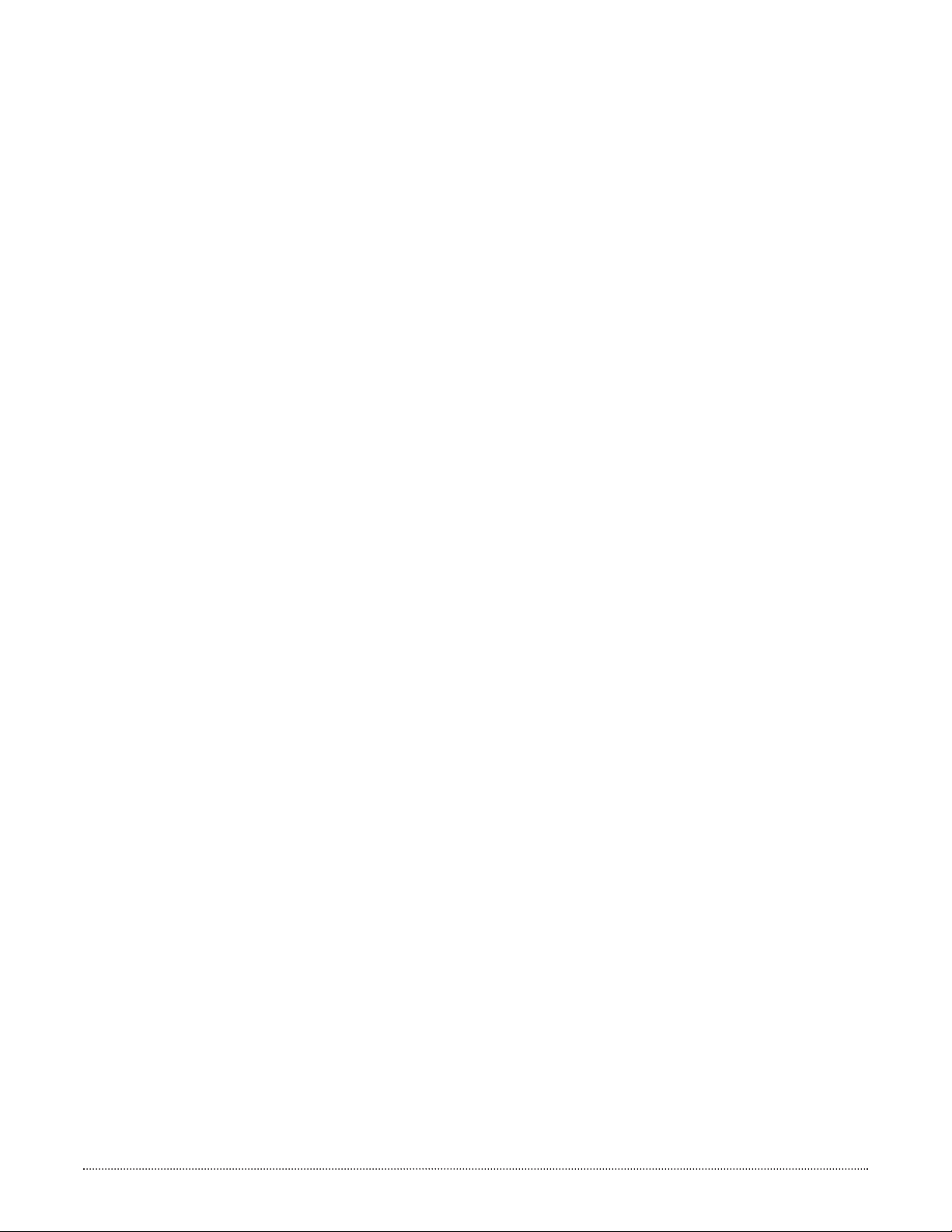

The Aegis Lift Deck Floor Scale is another addition to Fairbanks’ Aegis line of floor

scales. It is designed to offer a safe and convenient way to lift the deck of the scale to

facilitate cleaning. The Aegis Lift Deck Floor Scale is for pit installation only.

The Aegis floor scales use a standard summing junction box to interface with analog

indicators, and is equipped with a 25' interface cable. Junction boxes are constructed

of stainless steel, and all models have threaded holes in the decks for attaching

eyebolts to facilitate installation and cleaning.

C. Specifications:

Models and sizes are included in a chart in Appendix II.

Description Aegis Stainless Steel

Platform deck plate 0.25”

Platform height 3.0”

Operating temperature 15º to 104º F

-10º to 40º C

Humidity 100% suitable for water washdown

Overload capacity 150% of rated capacity

Endloading capacity 100% of rated capacity

Construction Type 304 stainless steel

Grade level Within 3º of level

Section 1: General Information

51103 4 01/07 -- Rev. 1

A. General Service Policy:

Prior to installation, it must be verified that the equipment will satisfy the customer's

requirements as supplied, and as described in this manual. If the equipment cannot

satisfy the application, and the application cannot be modified to meet the design

parameters of the equipment, the installation should not be attempted.

It is the customer / operator’s responsibility to ensure the equipment provided by

Fairbanks is operated within the parameters of the equipment's specifications and

protected from accidental or malicious damage. Other than the procedures authorized

in the Operating manual, no service, repair, or adjustments may be performed by

unauthorized / untrained service personnel. Any unauthorized repairs will void any

verbal, implied, or written warranties.

B. Overview:

1. These instructions apply to the floor scale and its specific installation procedures.

The instructions include a pre-installation checkout, which must be performed either

at the service center before the technician goes to the site, or at the site before he

places the equipment in service.

2. All electronic and mechanical calibrations and / or adjustments required to make this

equipment perform to accuracy and operational specifications are considered to be

part of the installation, and are included in the installation charge. Only those

charges which are incurred as a result of the equipment's inability to be adjusted or

calibrated to performance specifications may be charged to warranty.

3. Absolutely no physical or electrical modifications other than selection of standard

options and accessories are to be made to this equipment. Electrical connections

other than those specified may not be performed, and physical alterations (holes,

etc.) are not allowed.

4. Before the installation is considered complete, the equipment is to be installed to

satisfy any applicable Weights and Measures requirements. The installing

technician is responsible to make certain that personnel are fully trained and

familiar with the capabilities and limitations of the equipment. Be prepared to

recommend the arrangement of components which will provide the most efficient

layout, utilizing the equipment to the best possible advantage. The warranty policy

must be explained and reviewed with the customer.

51103 5 01/07 -- Rev. 1

Section 2: Installation

The complete installation consists of:

1. Verifying the application

2. Unpacking

3. Floor scale checkout

4. Customer and site readiness:

a. Is the Location ready?

b. Is the customer aware there may be work disruptions?

c. Are the operators available for training?

5. Floor scale connections

6. Adjustments

7. Customer training

C. Pre-Installation Checklist:

The following points should be checked and discussed with the Area Sales Manager

and/or the customer, if necessary, before the technician goes to the site to install the

equipment.

1. Has the customer's application been checked to make certain that it is within the

capabilities and design parameters of the equipment?

2. If the installation will disrupt the customer's normal operations, is he aware and has

he made arrangements?

3. Is properly grounded power available at the installation location?

4. Will the equipment operator(s) be available for training?

5. Has the service technician thoroughly reviewed the installation procedures?

6. Has the service technician reviewed the recommended setup with the Area Sales

Manager or Area Service Manager, and identified all necessary variations to satisfy

the customer's specific application?

51103 6 01/07 -- Rev. 1

NOTE: It is the owner’s responsibility to document, notify, and follow-up with the carrier if

there is shipping damage.

NOTE: Above ground installations require the scale platform be protected from mobile

machinery that may be present in the area. Fairbanks Scales is not responsible for

damages to unprotected platforms in above ground installations.

D. Unpacking:

1. Check that all components are on hand, and agree with the customer's order.

2. Remove all components from their packing material, checking to make certain that

all parts are accounted for and no parts are damaged. Advise the shipper

immediately if damage has occurred. Order any parts necessary to replace those

which have been damaged. Keep the shipping container and packing material for

future use. Check the packing list.

3. Collect all necessary installation manuals for the floor scale.

4. Examine the floor scale and perform an inspection, making certain that all

hardware, electrical, and PC connections are secure.

E. Safety:

As is the case with any equipment, certain safety precautions should

be observed during operation:

1. Ensure that any structure which supports the floor scale is capable

of withstanding the weight of the scale and its rated capacity.

2. Beware of pinch points on the lift deck models. Severe personal

injury could occur if safety precautions are not observed.

3. Use proper lifting technics when raising the lift deck platforms.

F. Setup:

The setup of the floor scale consists of installing the scale on a level surface and

wiring the scale to the indicator. Consult the appropriate indicator manual for further

information regarding the indicator and its setup.

1. Select a location that is level and will fully support the weight of the platform plus a

full capacity load.

2. Remove the top of the crate and all packing/banding material.

51103 7 01/07 -- Rev. 1

3. Screw two (2) eyebolts into the threaded adapters in the platform top and use a

forklift or other lifting means along with chains, cables, or nylon straps to remove

the scale from the crate.

4. Set the scale so that the interface cable exits in a direction where it can be

protected. If possible, use a cable protector to reduce 'trip' hazards and to protect

the interface cable from being damaged.

5. Level the scale by turning the foot pads.

6. Wire the scale cable to the proper type indicator as follows:

i. Analog Interface (Junction Box 67171):

L/C Wire Color Function Analog Instrument

Black (-) Excitation (-) Excitation

Green (+) Excitation (+) Excitation

Yellow Shield Shield

White (+) Signal (+) Signal

Red (-) Signal (-) Signal

51103 8 01/07 -- Rev. 1

NOTE: The analog junction box and the QMB interface box on the Lift Deck models are

mounted remotely on a wall location. The boxes must be located above the splash

line and in a secure area away from material handling traffic.

CAUTION: Do NOT use grab or slip hooks to lift the scale. Failure to use the proper

lifting tools may result in personal injury.

Loading...

Loading...