Fairbanks Aegis Drum Scales User Manual

Installation Manual

Aegis Drum Scale

© 2008-2010 by Fairbanks Scales, Inc. Revision 2 04/10

All rights reserved

51190

Aegis Stainless Steel Drum Scale, shown

Amendment Record

AEGIS DRUM SCALE

Document 51190

Manufactured by Fairbanks Scales Inc.

821 Locust

Kansas City, Missouri 64106

Created 07/08 Created Document

Revision 1 07/08 Preliminary Release

Revision 2 04/10 Corrected part number on page 29.

04/10 3 51190 Rev. 2

with optional Ramp and Integral Pillar

Disclaimer

Every effort has bee n made to provide com plete and accurate inform ation in this manual. However,

although this manual m ay include a specifically identi fied warranty notice for the product, Fairbanks

Scales makes no representations or warranties with respect to the contents of this manual, and

reserves the right to make changes to this manual without notice when and as improvements are

made.

Fairbanks Scales shal l not be liable f or any loss, damage, c ost of repairs, i ncidental or conseq uential

damages of any kind, whether or not based on express or implied warrant y, contract, negligence, or

strict liability arising in connection with the design, development, installation, or use of the scale.

© Copyright 2008-2010

This document contains proprietary information protected by copyright. All rights are reserved; no part

of this manual may be reproduced, copied, translated or transmitted in any form or by any means

without prior written permission of the manufacturer.

04/10 4 51190 Rev. 2

Table of Contents

TABLE OF CONTENTS ............................................................................................. 5

SECTION 1: GENERAL INFORMATION .................................................................. 7

1.1. Introduction ................................................................................................................ 7

1.1.1. Specifications ....................................................................................................................... 7

1.1.2. Applications.......................................................................................................................... 8

1.1.3. Accessories.......................................................................................................................... 8

1.2. General Service Policy ............................................................................................... 9

1.3. Conferring with Our Client ........................................................................................ 10

1.3.1. Service technician’ s Responsibilies .................................................................................. 10

1.3.2. Users’ Responsibility ......................................................................................................... 10

SECTION 2: SCALE INSTALLATION ...................................................................... 11

2.1. Overview .................................................................................................................. 11

2.1.1. Physical Installation Notes ................................................................................................. 11

2.1.2. Pre-Installation Checklist ................................................................................................... 12

2.1.3. Unpacking .......................................................................................................................... 12

2.1.4. Positioning the Equipment ................................................................................................. 13

2.2. Installation Steps...................................................................................................... 14

2.2.1. Assembling the Scale Platform ...................................................................................... 14

2.2.2. Wheel Kit Assembly Steps ................................................................................................. 15

2.2.2. Wheel Kit Assembly Steps, Continued .............................................................................. 16

2.2.3. Installing the Ramp(s) ........................................................................................................ 17

2.2.4. Installing Ramp(s) With Integral Pillar ............................................................................... 17

SECTION 3: USER OPERATIONS .......................................................................... 18

3.1. Moving the Scale with a Wheel Kit .......................................................................... 18

3.2. Changing Position of Top Plate ............................................................................... 18

SECTION 4: SERVICE & MAINTENANCE .............................................................. 19

4.1. General Troubleshooting .......................................................................................... 19

4.2. Scale Platform Troubleshooting ............................................................................... 20

4.2.1. Scale Platform Testing ....................................................................................................... 20

4.2.2. Load Cell Testing ............................................................................................................... 20

4.2.3. Load Cell Replacement Steps ........................................................................................... 21

4.2.3. Load Cell Replacement Steps, Continued ......................................................................... 22

SECTION 5: PARTS ................................................................................................. 24

5.1. 30 x 30 Mild Steel Parts List (p/n 28374) .................................................................. 24

5.2. 30 x 30 Mild Steel Parts Diagram (p/n 28374) ......................................................... 25

5.3. 30 x 30 Stainless Steel Parts List (p/n 28379) ......................................................... 26

5.4. 30 x 30 Parts Diagram (p/n 28379) ......................................................................... 27

5.5. 38 x 38 Mild Steel Parts List (p/n 28723) ................................................................. 28

5.6. 38 x 38 Mild Steel Parts DIAGRAM (p/n 28723) ...................................................... 29

5.6. 38 x 38 Mild Steel Parts Diagram (p/n 28723) .......................................................... 30

5.7. 38 x 38 Stainless Steel Parts List (p/n 28726) ......................................................... 31

5.9. Accessory Part Numbers ......................................................................................... 32

04/10 5 51190 Rev. 2

Section 1: General Information

Accuracy

Ultra-low profile for easy on- and off-loading.

1.1. INTRODUCTION

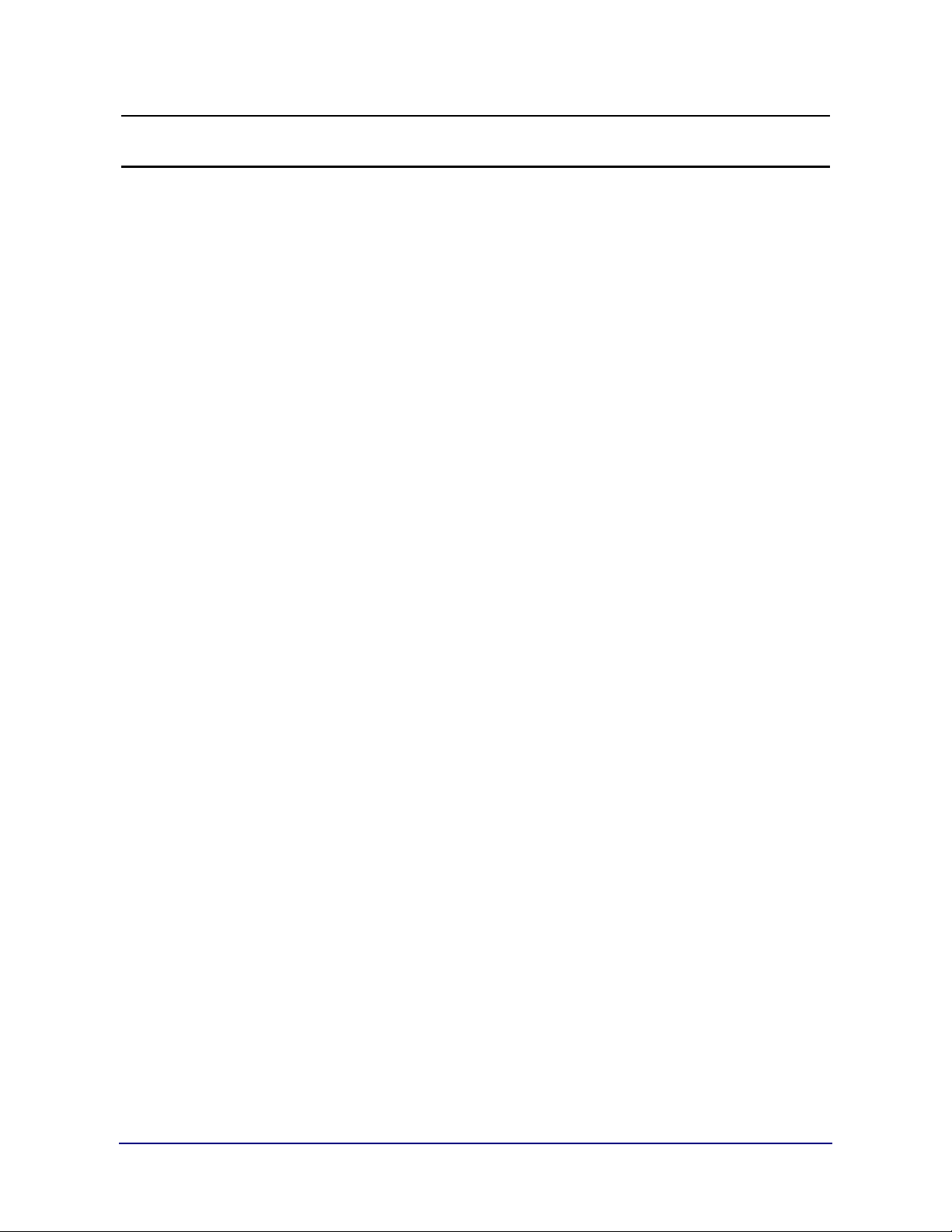

The Aegis Drum Scale has a one-anda-half inch (1½”) low profile for easy onand off-loading.

• Threaded half-inch (½”) holes for

inserting Eyebolts, to make the Platform

easy to move.

• Available in Mild Steel and Stainless

Steel.

• Stainless Steel Load Cells are used on all models.

─ However on the Stainless Steel Platform Models, the Lo ad Cell s have a

“true” hermetically sealed (IP69K) rating (optional on Mild Steel Models).

• The Aegis Drum Scale is used with either analog or digital weight indicators.

• Three inch (3”) high Side Rails for pallet weighing.

• The Platform is supported by four (4) 17-4ph Stainless Steel Shear Beam Load

Cells.

• Bubble Level for platform leveling confirmation.

− Shown with optional Ramp.

1.1.1. Specifications

Feature Description

Platform Sizes

Overall Dimensions

Scale Capacities

Endloading

Load Cell Excitation

Instrument Signal

Temperatures

Humidity 10 to 100%, Wash-down (Stainless Steel models only)

Power Cable

Adjustment Limits

Construction

Approvals

30” x 30” x 1-½” and 38” x 38” x 1-½”

41” x 30” x 3” and 49” x 38” x 3”

500, 1000, 2000 and 2500 l bs .

100% of capacity all models except 2,500 lb model which is rated at 80%.

5 to15 VDC

Analog or Digital

Operating: -10°C to 40°C (14°F to 104°F)

Storage: -20°C to 70°C (14°F to 158°F)

Platform Accuracy up to 0.02%

Thirty cable feet (30’) of four (4) conductor interface cable; PVC jacketed.

• Scale must be level within three degrees (3°).

• Height adjustment allows for up to one-quarter inch (¼”) per foot.

Mild steel with black enamel finish; Type 304 PH stainless steel, brushed.

Both Stainless Steel and Mild Steel have

NTEP and CWM approvals PENDING.

FM Approved Load Cells.

04/10 7 51190 Rev. 2

Section 1: Genera l Information

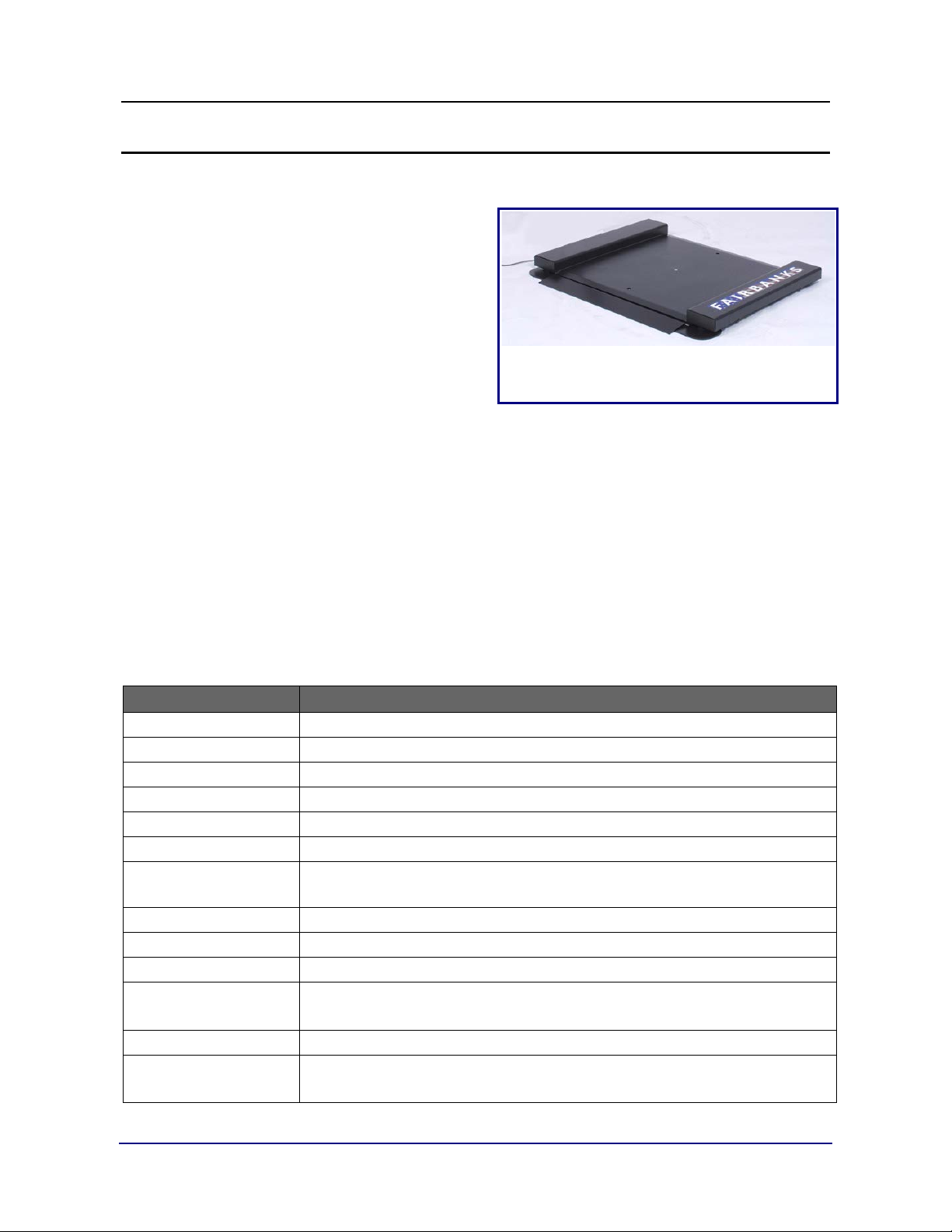

−

SHOCKLOAD

Example of Load Cell from a Mild Steel Scale

1.1.2. Applications

─ Manufacturing ─ Food & Beverage

─ Chemical ─ Textile

─ Scrap or Recycling ─ Pharmaceutical

1.1.3. Accessories

Available modifications and accessories include the following:

─ Loading Ramp ─ Stand-alone Pillar

─ Ramp with Pillar ─ Intrinsically Safe Controller

─ Wheel Kit ─ Quad-multiplexer Board

─ Factory Calibration and Quick Disconnect (not available for Intrinsically Safe Instrument)

DO NOT

THE SCALE!

.

04/10 8 51190 Rev. 2

“True” Hermetically Sealed Load

Cells

used on both the Stainless and

Mild Steel

Prevents problems with accidental

models.

spills and washdown.

Section 1: Genera l Information

Absolutely NO physical, electrical or program modifications other than

warranties.

WARNING!

1.2. GENERAL SERVICE POLICY

Prior to installation, always verify

that the equipment satisfies the

customer's requirements as

supplied, and as described in this

manual.

If the equipment cannot satisfy

the application and the

application cannot be modified to

meet the design parameters of the

equipment, the installati on

should NOT be attempted.

It is the customer/operator's responsibility to ensure the

equipment provided by Fairbanks is operated within the parameters

of the equipment's speci fi c a ti ons and pr ot ec t e d fr om ac c idental or

malicious damage.

selection of standard options and accessories can be made by

customers to this equipment

Repairs are performed by Fairbanks Scales Service Technicians and

Authorized Distributor Personnel ONLY!

Failure to comply with this policy voids all implied and/or written

04/10 9 51190 Rev. 2

Section 1: Genera l Information

1.3. CONFERRING WITH OUR CLIENT

• The technician must be prepared to recommend the arrangement of components

which provide the most efficient layout, using the equipment to the best possible

advantage.

• The warranty policy must be explained and reviewed with the customer.

• Refer to Instrument Manual for power requirements.

1.3.1. Service technician’ s Responsibilies

All electronic and mechanical calibrations and/or adjustments required for making

this equipment perform to accuracy and operational specifications are considered

to be part of the installation.

─ They are included in the installation charge.

─ Only those charges which are incurred as a result of the equipment's inability

to be adjusted or calibrated to performance specifications may be charged to

warranty.

If the equipm ent consists of printed circuit assemblies, they must be handled

using ESD handling procedures, and must be replaced as units.

─ Replacement of individual components is not permitted.

─ The assemblies must be properly packaged in ESD protective material and

returned intact for replacement credit per normal procedures.

1.3.2. Users’

Responsibility

Absolutely no physical, electrical

or program modifications other

than selection of standard

options and accessories are to

be made to this equipment.

04/10 10 51190 Rev. 2

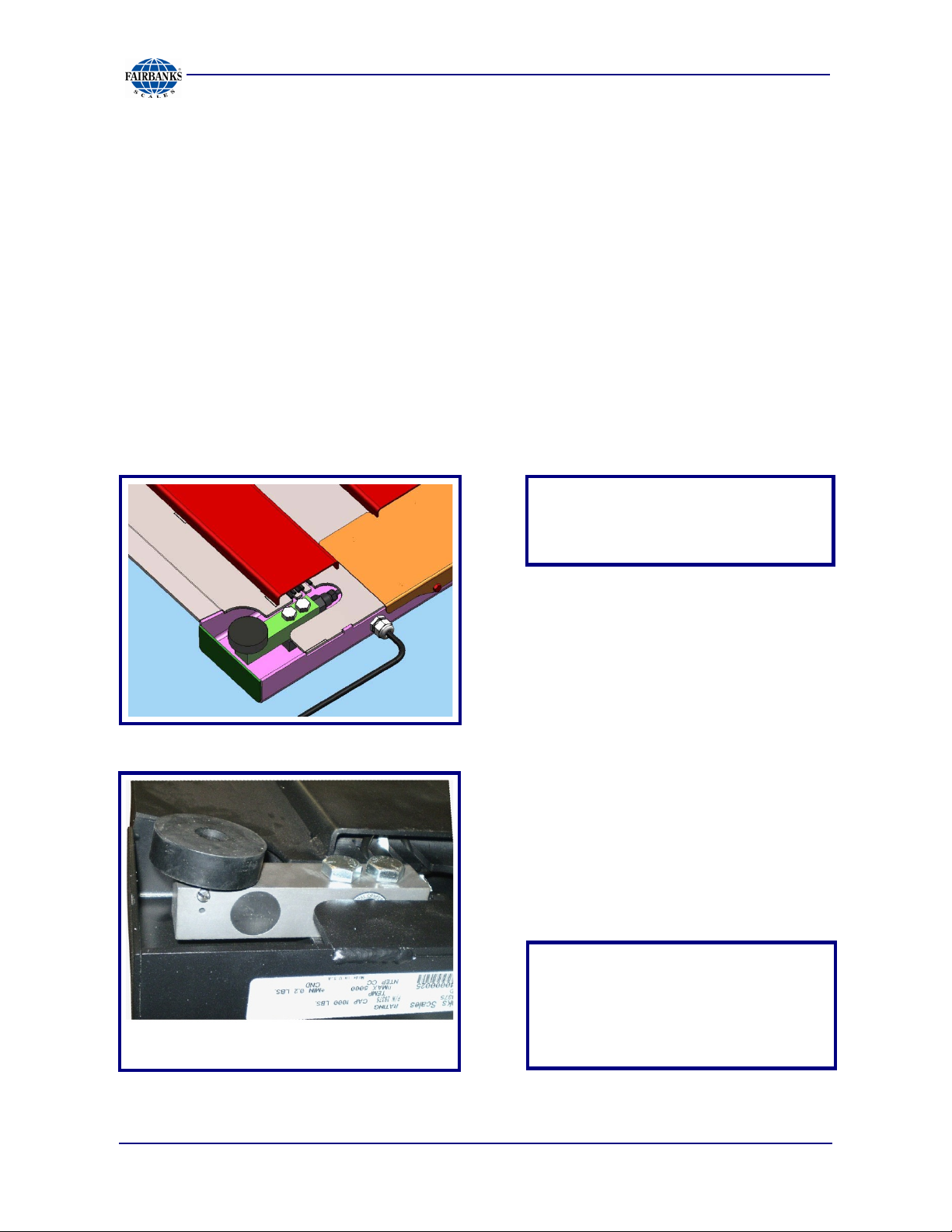

Aegis Drum Scale shown with FB 2200 Indicator

Wheel Kit.

Section 2: Scale Installation

2.1. OVERVIEW

2.1.1. Physical Installation Notes

• Only those charges which are incurred as a result of the equipment's

inability to be adjusted to performance specifications may be charged to

warranty.

• No physical alterations (mounting holes, etc.) are permitted during installation.

The installing technici a n is res pons ible that all personnel are fully

trained and familiar with the equipment's capa bilities and

limitations before the installation is considered com plete.

• All electrical assemblies must be replaced as assemblies or units.

─ Replacement of individual components is not permitted.

─ These components must be returned intact for replacement credit using the

standard procedures.

• At the time of installation, all

electronic and mechan i cal

adjustments are considered to be

part of the installation, and are

included in the installation

charge(s).

• The AC receptacle/outlet shall be

located near the Indicator and

easily accessible.

• Electrical connections other than

those specified may not be

performed.

04/10 11 51190 Rev. 2

and optional

Loading...

Loading...