Fairbanks Aegis Coil Scales User Manual

Installation Manual

Aegis Coil Scale

© 2008-2010 by Fairbanks Scales, Inc. Revision 2 04/10

All rights reserved

51205

Amendment Record

AEGIS COIL SCALE

Document 51205

Manufactured by Fairbanks Scales Inc.

821 Locust

Kansas City, Missouri 64106

Created 10/08 Created Document

Revision 1 12/08 Documentation Release

Revision 2 04/10 Updated cradle drawings, p arts list, and per ECO 637.

Disclaimer

Every effort has bee n made to provide com plete and accurate inform ation in this manual. However,

although this manual m ay include a specifically iden tified warranty notice for the produc t, Fairbanks

Scales makes no representations or warranties with respect to the contents of this manual, and

reserves the right to make changes to this manual without notice when and as improvements are

made.

Fairbanks Scales shal l not be liable f or any loss, damage, c ost of repairs, inc idental or conseq uential

damages of any kind, whether or not based on express or implied warrant y, contract, negligence, or

strict liability arising in connection with the design, development, installation, or use the scale.

© Copyright 2008-2010

This document contains proprietary information protected by copyright. All rights are reserved; no part

of this manual may be reproduced, copied, translated or transmitted in any form or by any means

without prior written permission of the manufacturer.

Table of Contents

SECTION 1: GENERAL INFORMATION .................................................................. 6

1.1. Introduction ................................................................................................................ 6

SECTION 2: GENERAL SERVICE POLICY.............................................................. 9

2.1. General Service Policy ............................................................................................... 9

SECTION 3: SCALE INSTALLATION ...................................................................... 11

3.1. Conferring with Our Client ........................................................................................ 11

3.2. Standard Installation Steps ...................................................................................... 13

SECTION 4: ELECTRICAL INSTALLATION ........................................................... 22

4.1. Introduction .............................................................................................................. 22

4.2. Wiring the Junction Box ........................................................................................... 24

4.3 Grounding the Scale ................................................................................................. 26

4.4. Installing Accessories .............................................................................................. 27

SECTION 5: SERVICE & MAINTENANCE .............................................................. 29

5.1. Recommended Preventive Maintenance Schedule .................................................. 29

5.2. Troubleshooting ....................................................................................................... 30

5.3. Scale Platform Troubleshooting ............................................................................... 31

SECTION 6: PARTS ................................................................................................. 33

6.1. Platform Model Matrix .............................................................................................. 33

6.2. Parts List .................................................................................................................. 34

6.3. Dimensions Diagram ................................................................................................ 35

6.4. Accessory Part Lists ................................................................................................ 36

6.5. Accessory Part Drawings ......................................................................................... 37

04/10 5 51205 Rev. 2

Section 1: General Information

1.1. INTRODUCTION

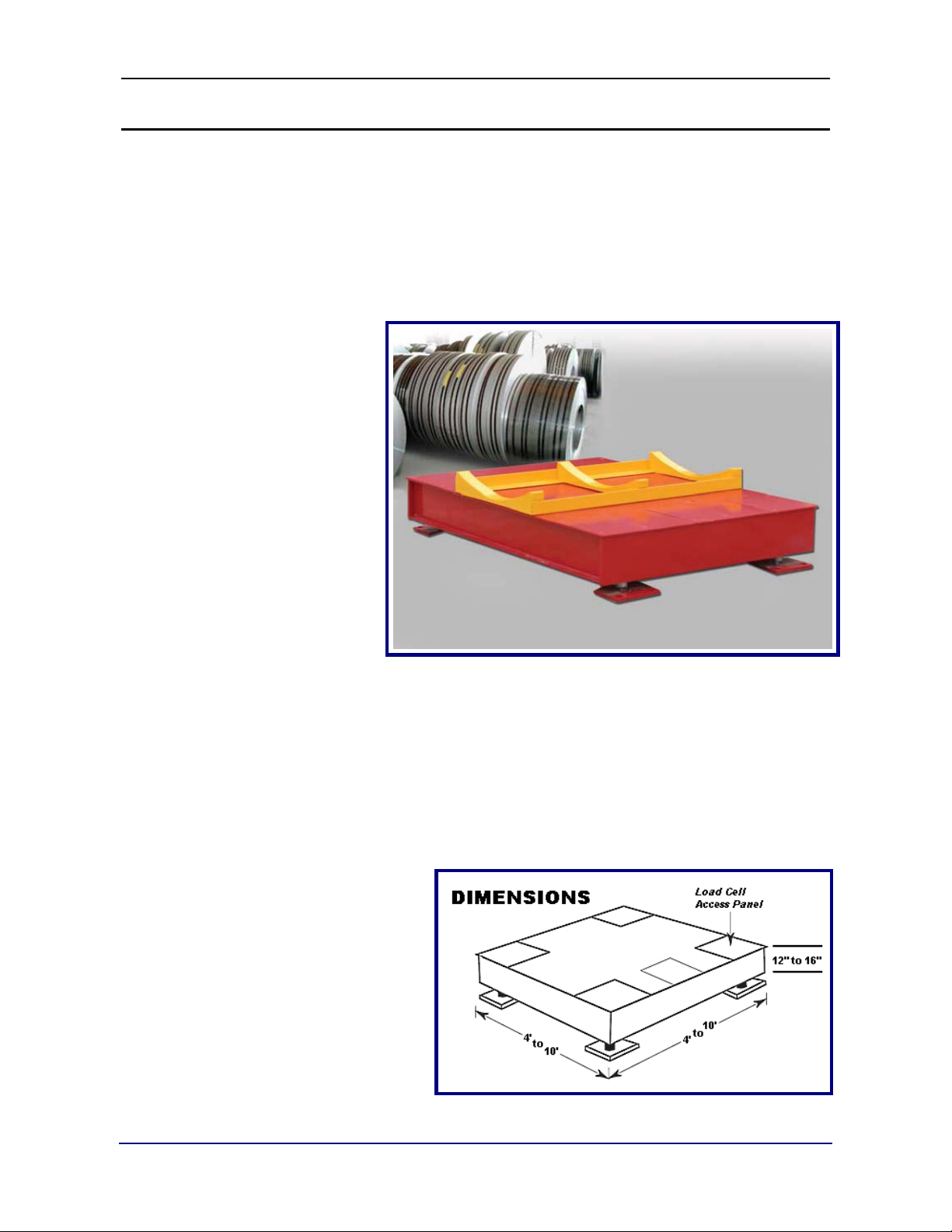

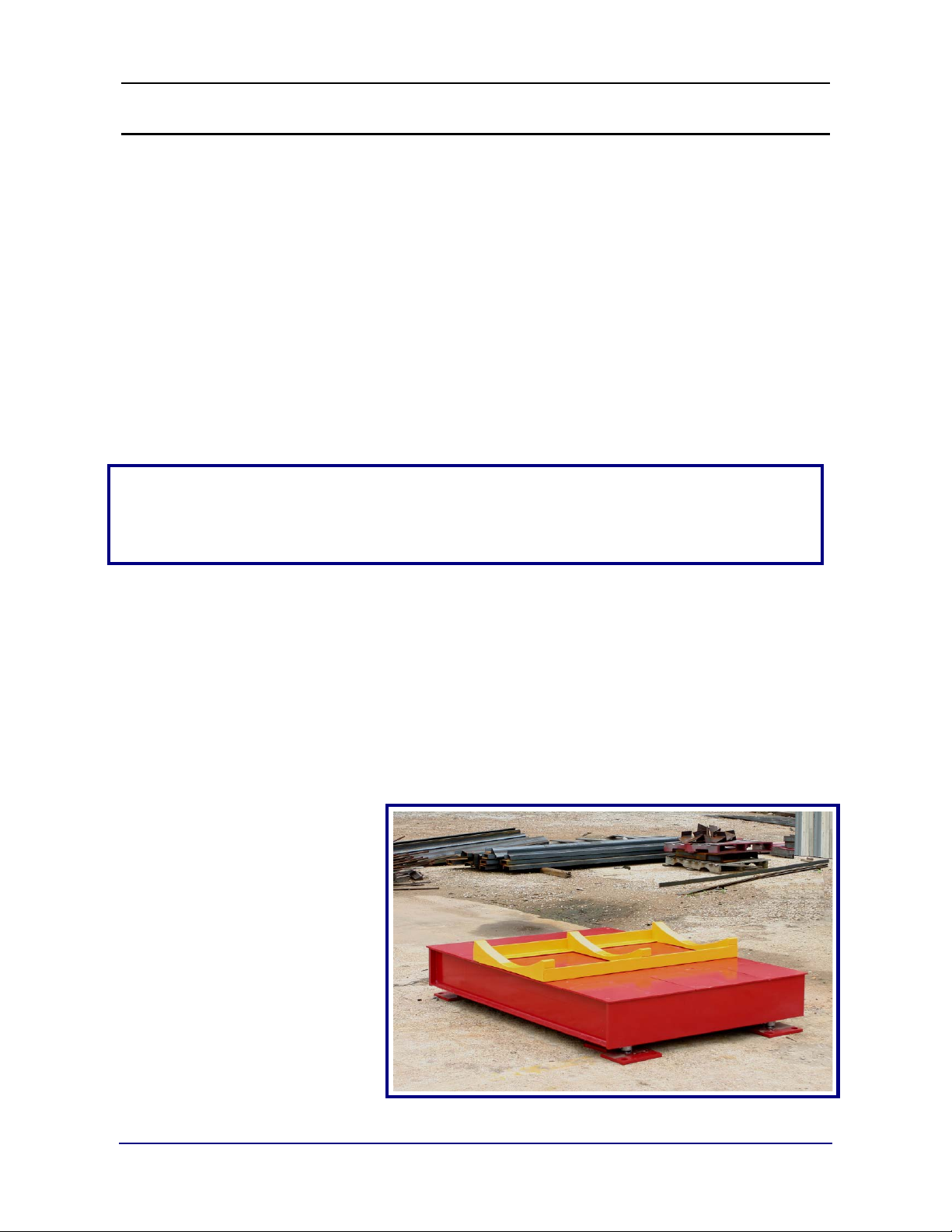

The Aegis Coil Scale is an extremely rugged floor scale, designed for high

capacities and a wide variation of dimensional sizes.

• The Aegis Coil Scale was designed for weighing coils (steel, copper, aluminum,

etc.).

• It features a free-floating

platform and rocker

column load cell design.

• Its smooth deck platform

is designed for

concentrated loads an d

harsh working

environments found at

steel mills and

manufacturing plants.

• It is designed for

applications 12” to 16”

above grade.

Aegis Coil Scale is designed for applications with high load concentrations.

The

• General Industrial • Heavy-Duty Industrial • Warehousing

• Extremely Heavy Point

Loading that bends or

dimples normal platforms

• When Impact Loading is

necessary, dropping the

product onto the scale

• Weighing steel, aluminum, or

copper coil, as well as billets,

castings and cable spools

04/10 6 51205 Rev. 2

Feature

Description

Standard Platform Sizes

4’ x 4’ thru 10’ x 10’

Platform Height

12” to 16” Smooth Tread

Deck Thickness

¼” to ½” Plate

Scale Capacities

30,000 to 80,000 lbs.

Overload Capacity

300%

Sideload Protection Rating

100%

Humidity

10 to 100%

Accuracy

Platform Accuracy up to 0.02%

Load Cell Excitation

5 to 15 VDC

Grounding

Less than 3 Ohms to True Earth Ground

1.1.1. Specifications

Section 1: Gen er al Information

Temperatures

Scale Construction

Junction Box

Load Cells

Interface Cable

Approvals

• Operating: -10°C to 40°C (14°F to 104°F)

• Storage: -20°C to 70°C (-4°F to 158°F)

• Type A36 carbon steel

• Deck plate – ¼”,

• Analog

• Stainless Steel

• NEMA 4X

• Four (4) Rocker Column Design

• IP69K – “True” Hermetically Sealed, with the highest ingress

protection available

• 17-4 PH Stainless Steel

• 15,000 to 50,000 Capacity

• Combined Error -- ≤ ±0.02% of Rated Capacity

31’ PVC Jacketed

• FM Approved

• NTEP Approval CC# 07-097 (for 6,000 divisions)

• Load Cell NTEP Appro val CC# 07-037

3

/8”, ½”

04/10 7 51205 Rev. 2

Section 1: Gen er al Information

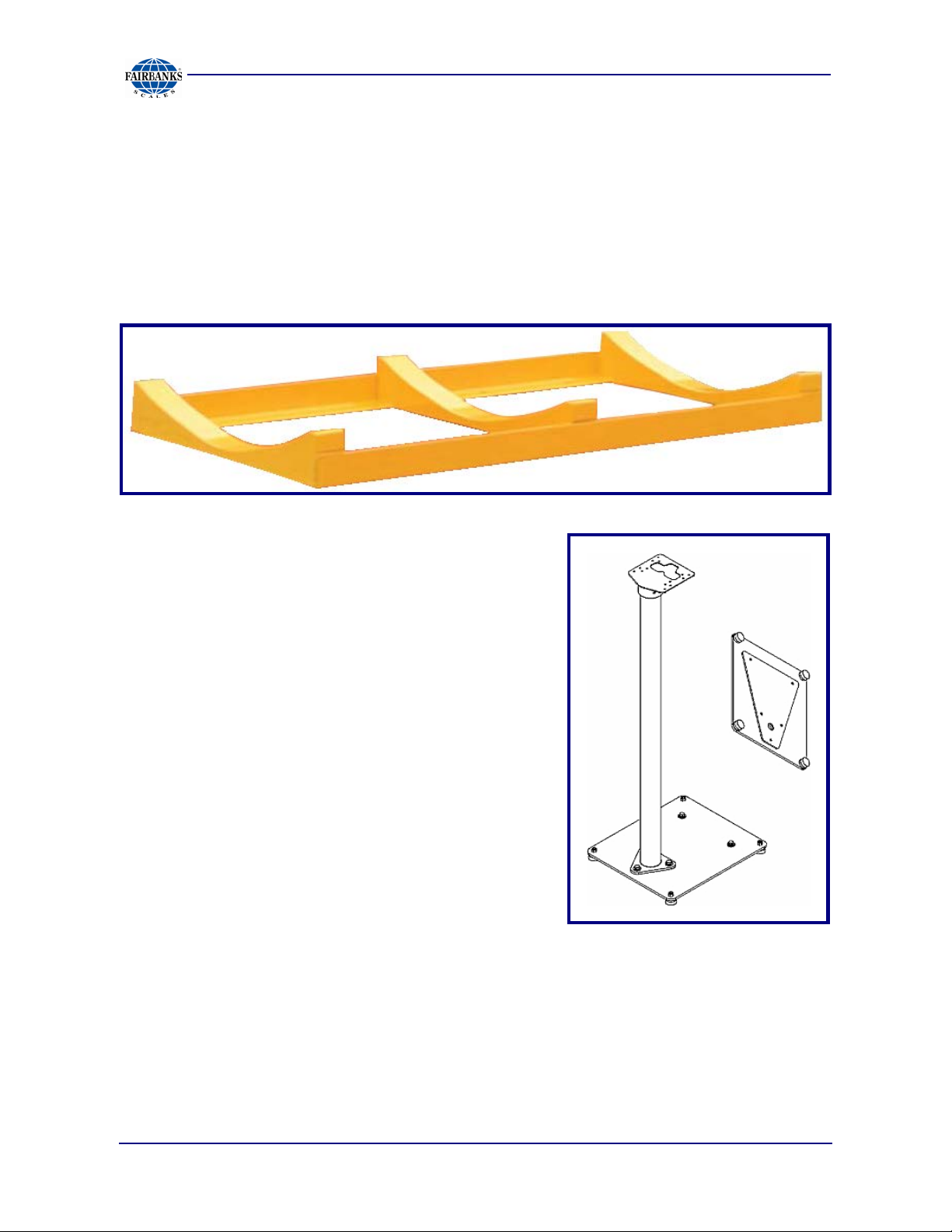

• Coil Cradle

• Intrinsically Safe Controller

• Stand-alone Instrument Pillar

• Smart Sectional Controller

• QMB

1.1.2. Accessories

Available modifications and accessories include the following:

04/10 8 51205 Rev. 2

Absolutely NO physical, electrical or program modifications other

Section 2: General Service Policy

2.1. GENERAL SERVICE POLICY

Prior to installation, always verify that the

equipment satisfies the customer's

requirements as supplied, and as described

in this manual.

If the equipment cannot satisfy the application and the application cannot be

modified to meet the design parameters of the equipment, the installation

should NOT be attempted.

It is the customer/operator's responsibility to ensure the

equipment provided by Fairbanks is operated within the para m e ters

of the equipment's specifications and protected from accidental or

malicious damage.

than selection of standard options and accessories can be made

by customers to this equipment

Repairs are performed by Fairbanks Scales Service Technicians

and Authorized Distri but or P er s onne l ONLY!

WARNING!

Failure to comply with this poli c y voids al l im pli e d a nd/or written

warranties

04/10 9 51205 Rev. 2

Section 2: General Servic e P olicy

2.1.1. Service Technician’s Responsibilities

• All electronic and mechanical calibrations and/or

adjustments required for making this equipment

perform to accuracy and operational specifications

are considered to be part of the original installation.

─ They are included in the installation charge.

─ Only those charges which are incurred as a result

of the equipment's inabil ity to be adjusted or

calibrated to per for ma nc e spec ifications may be

charged to warranty.

• The equipment consists of printed circuit assemblies which must be handled

using ESD handling procedures, and must be replaced as units.

─ Replacement of individual components is not allowed.

─ The assemblies must be properly packaged in ESD protective material and

returned intact for replacement credit per normal procedures.

2.1.2. Users’ Responsibility

Absolutely no physical, electrical or program modifications ot he r

than selection of standard options and accessories are to be

made to this equipment.

04/10 10 51205 Rev. 2

Section 3: Scale Installation

3.1. CONFERRING WITH OUR CLIENT

• The technician must be prepared to recommend the arrangement of components

which provide the most efficient layout, utilizing the equipment to the best possible

advantage.

• Assist the customer in selecting a site which allows easy access to and from the

scale.

─ The site needs good drainage away from the scale, elevated enough so the

surrounding areas drain away from the scale.

• Explain and review the warranty policy with the customer.

The installing technician is responsi ble that all personnel are

fully trained and familiar wi t h the e quipme nt 's capa bilities and

limitations before the installation is considered com plete.

• All electrical assemblies must be returned intact for replacement credit using the

standard procedures.

• At the time of installation, all electronic and mechanical adjus t m ents are

considered to be part of the installation, and are included in the installation

charge(s).

• The AC receptacle/outlet shall be located near the Indicator and easily accessible.

• Electrical connections other than those specified may not be perf ormed.

04/10 11 51205 Rev. 2

Section 3: Scale I ns tallation

• All load cells, load cell cables and interconnecting cables used to connect all

scale components shall be located a minimum of thirty-six (36”) inches

distance away

electric current carrying conductors.

• This includes digital weight indicators, junction boxes, sectional

controllers, and power supplies.

• This includes any peripheral devices, such as printers, remote

displays, relay boxes, remote terminals, card readers, and

auxiliary data entry devices.

• Also included is the scale components themselves, such as

120 volt AC, 240 volt AC, 480 volt AC and electric supply of

higher voltage wiring runs and stations, AC power transformers,

overhead or buried cables, electric distribution panels, electric

motors, florescent and high intensity lighting which utilize

ballast assemblies, el e ct r ic heating equipment, traffic light

wiring and power, and relay boxes.

IMPORTANT INSTALLATION NOTICE

from all single and multiple phase high energy circuits and

• All scale components, including digital weight indicators and

peripheral devices are not des igned to operate on internal combustion engine

driven electric generators and other similar equipment.

Electric arc welding can severely damage scale

components such as digital wei ght indi c a t ors, junction

boxes, sectional control lers, power supplies, and load

cells.

NOTE: For additional information, please contact your Fairbanks Scales

Service Representative.

04/10 12 51205 Rev. 2

Section 3: Scale I ns tallation

3.2. STANDARD INSTALLATION STEPS

The Aegis Coil Scale Platform standard installation consists of the following

steps.

A. Unpack scale, and check off all components.

B. Prepare tools, materials and documentation.

C. Select site location.

D. Foundation check, layout, and base plate setting.

E. Set up deck.

F. Set deck on load cells.

G. Level platform.

H. Install and wire instrument to platform.

I. Adjust and calibrate scale according to appropriate indicator service

manual.

J. Install coil cradle (if applicable).

3.2.1. Standard Components

The Aegis Coil Scale Platform is shipped with these standard components:

• The Weighbridge Platform

• Load Cells

• Load Cell Base Plates

• Side Checking Assemblies

• Mounting Hardware

• Analog Junction Box

04/10 13 51205 Rev. 2

Loading...

Loading...