Page 1

Installation Manual

Omnicell

Models: 9111

© 2008 by Fairbanks Scales Inc.

All rights reserved

50767

Revision 2 01/08

Page 2

50767 2 01/08 Rev. 2

Amendment Record

Omnicell

9111

50767

Manufactured by Fairbanks Scales Inc.

821 Locust

Kansas City, Missouri 64106

Issue #1 New Product

Revision 2 Inserted Load Cell Wiring Chart

Disclaimer

Every effort has been made to provide complete and accurate information in this manual. However, although this manual may include

a specifically identified warranty notice for the product, Fairbanks Scales makes no representations or warranties with respect to the contents of this manual, and reserves the right to make changes to this manual without notice when and as improvements are made.

Page 3

50767 3 01/08 Rev. 2

Table of Contents

Section 1: General Information

A. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

B. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

C. Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Section 2: Installation

A. General Service Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

B. Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

C. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

D. Installation Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Section 3: Parts List

A. Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

B. Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Appendix 1: Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Page 4

50767 4 01/08 Rev. 2

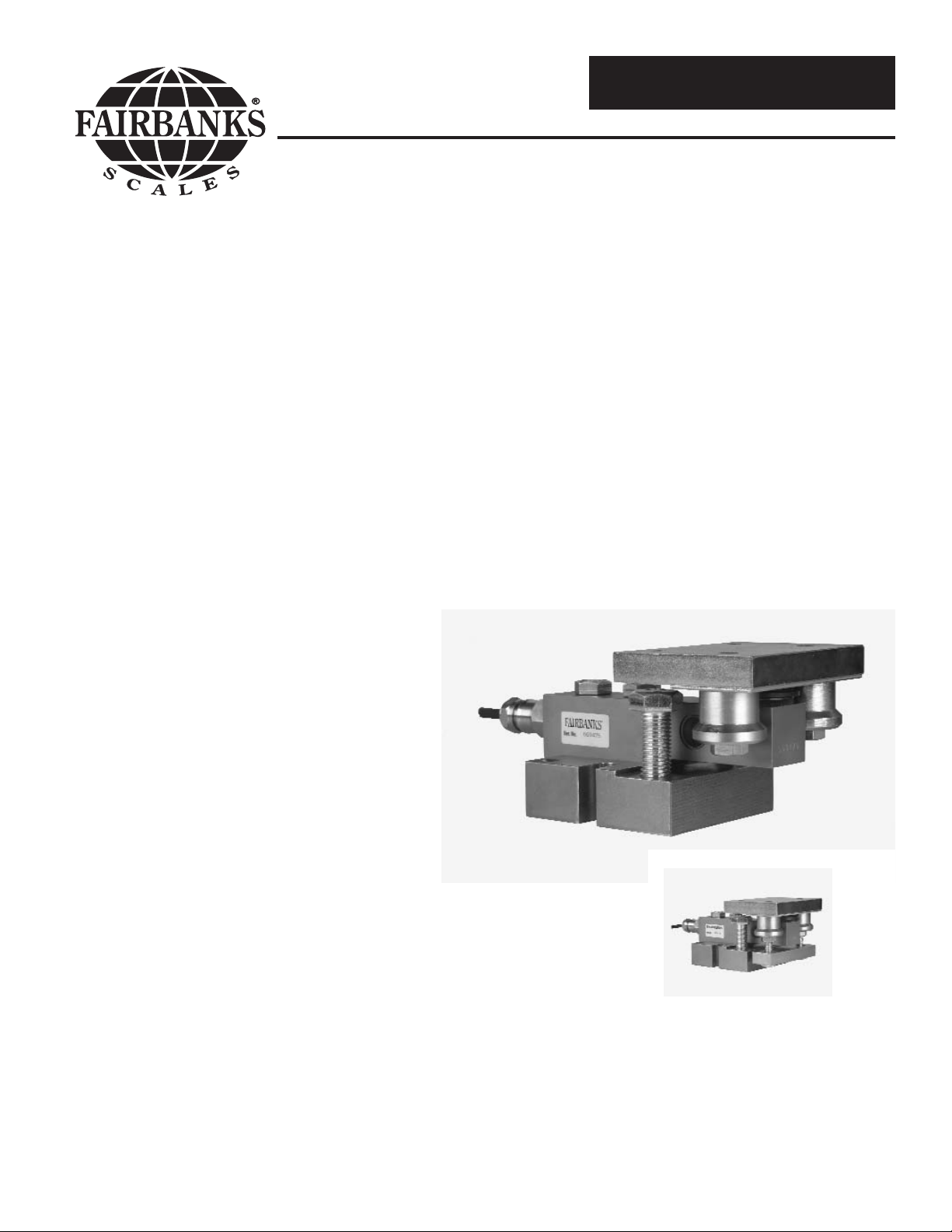

A. Introduction

Fairbanks’ Omnicell 9111 Series’ tank weighing assembly is a compact, low profile weighing

assembly designed for superior performance in light to medium weight ranges commercial and noncommercial.

OMNICELL® 9111 SERIES TANK WEIGHING ASSEMBLY FEATURES

• Capacities available from 500 lbs to 10,000 lbs.

• Slider plate compensates for thermal expansion.

• Mount assembly has built-in, two-directional bumpers.

• Low profile design for easy installation.

• Load cells sealed to industry’s highest standard for environmental protection.

• Load cell constructed of 17-4 stainless steel for high caustic protection.

• Mounts available in 304 stainless and zinc plated steel.

• Factory Mutual approved for hazardous applications.

• Patented MV/V/Ohm calibration for ease of installation.

• NTEP approval pending.

B. Specifications

Mount Construction . . . . . . . . . . . . . . . . . . . 304 stainless steel;

zinc plated mild steel

Capacities (in lbs) . . . . . . . . . . . . . . . . . . . . 500, 1K, 2.5K, 5K and 10K

Full Scale Output (FSO) . . . . . . . . . . . . . . . 2.0mV/v ± 0.05%

Combined Error (FSO) . . . . . . . . . . . . . . . . <

0.03%

Non-Linearity (FSO) . . . . . . . . . . . . . . . . . . 0.02%

Hysteresis (FSO). . . . . . . . . . . . . . . . . . . . . 0.02%

Creep Error (30 min.) . . . . . . . . . . . . . . . . . <

0.05%

Compensated Temperature . . . . . . . . . . . . . 14° F to 104° F (-10° C to 40° C)

Operating Temperature . . . . . . . . . . . . . . . . -40° F to 176° F (-40° C to 80° C)

Excitation Voltage . . . . . . . . . . . . . . . . . . . . 5-15 VDC

Overload . . . . . . . . . . . . . . . . . . . . . . . . . . . Safe = 150%; ultimate = 300%

Sideload . . . . . . . . . . . . . . . . . . . . . . . . . . . Safe = 100%

Bridge Resistance . . . . . . . . . . . . . . . . . . . . 1000 ohms nominal

Load Cell Construction . . . . . . . . . . . . . . . . Stainless Steel 17-4 PH

Sealing . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hermetic seal;

cable entry sealed by glass to metal header

Load Cell Cable. . . . . . . . . . . . . . . . . . . . . . 20 ft., polyurethane

Protection . . . . . . . . . . . . . . . . . . . . . . . . . . IP 68

Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . Factory Mutual; NTEP pending

C. Accessories

Mild Steel Uplift Protection with bolts. . . . . . .25460 (500-5k); 25462 (10k)

Stainless Steel Uplift Protection with bolts. . .25461 (500-5k); 25463 (10k)

Section 1: General Information

Page 5

50767 5 01/08 Rev. 2

A. General Service Policy

Prior to installation, it must be verified that the equipment will satisfy the customer's require-

ments as supplied, and as described in this manual. If the equipment cannot satisfy the application

and the application cannot be modified to meet the design parameters of the equipment, the installation should not be attempted.

It is the customer / operator's responsibility to ensure the equipment provided by Fairbanks is

operated within the parameters of the equipment's specifications and protected from accidental or

malicious damage. Other than the procedures authorized in the Operating manual, no service,

repair, or adjustments may be performed by unauthorized / untrained service personnel. Any unauthorized repairs will void any verbal, implied, or written warranties.

B. Overview

1. These instructions apply to the specific installation procedures. The procedures for instruments, printers and other peripherals are given in manuals specifically provided for those units.

2. All electronic and mechanical calibrations and or adjustments required to make this equipment perform to accuracy and operational specifications are considered to be part of the installation,

and are included in the installation charge. Only those charges which are incurred as a result of the

equipment's inability to be adjusted or calibrated to performance specifications may be charged to

warranty.

3. Absolutely no physical or electrical modifications are to be made to this equipment. Electrical

connections other than those specified may not be performed, and physical alterations are not

allowed.

4. Before the installation is considered complete, the equipment is to be installed to meet or

exceed any applicable weights and measures requirements, if applicable. The installing technician is

responsible to make certain customer personnel are fully trained and familiar with the capabilities

and limitations of the equipment. Be prepared to recommend the arrangement of components which

will provide the most efficient layout, utilizing the equipment to the best possible advantage. The

warranty policy must be explained and reviewed with the customer.

C. Unpacking

1. Check that all components are on hand, and agree with the customer's order.

2. Remove all components from their packing material, checking to make certain that all parts

are accounted for and no parts are damaged. Advise the shipper immediately, if damage has

occurred. Order any parts necessary to replace those which have been damaged. Keep the shipping

container and packing material for future use. Check the packing list.

Section 2: Installation

Page 6

50767 6 01/08 Rev. 2

D. Installation Instruction

1. Items not Supplied

a. 3/8-16 UNC bolts- 4 required for each 500 lb, 1k lb, 2.5k and 5k lb assembly.

1/2-13 UNC bolts- 4 required for each 10k lb assembly.

b. 1/2-13 UNC Anchors/ bolts - 2 required for each 500 lb, 1k lb, 2.5k and 5k lb assembly.

5/8-11 UNC Anchors/ bolts - 2 required for each 10k lb assembly.

2. Raise the vessel to be supported by the Omnicell® assemblies and secure by safely

blocking the vessel to the required height. See Figure 50767-1.

3. Place each Omnicell® assembly onto a level surface under each support leg.

4. Set the assemblies for the correct orientation as per Figure 50767-2.

5. Adjust the load lifting/ support bolt until it is against the top plate. Insert the four (4)

top mounting plate bolts and loosely tighten the bolts to the support leg for each assembly.

6. Mark the location of the anchor bolt locations. Slide the assembly back and drill the anchor

hole locations. Re-position the load cell assembly, level, and anchor all assemblies.

7. Lower the vessel onto the top plate of each Omnicell® assembly. Tighten the bolts securing

the load plates to each support leg of the vessel. Remove all cribbing blocks. Lower the load

lifting/ support bolts on each assembly until the bolt has approximately 1/4” clearance and the

load cell is bearing the vessel’s weight.

8. Route the cables to the junction box and indicator. Wire the Omnicell® assemblies according

to the appropriate junction box and indicator service manual. Calibrate as required.

WARNING:

The Omnicell® assemblies MUST be orientated as per Figure 50767-2 or severe damage could

occur to the vessel or assemblies.

Load Cell Wiring

+ EXC = Green

- EXC = Black

+ SIG = White

- SIG = Red

Page 7

50767 7 01/08 Rev. 2

JACKING SCREW JACKING SCREW

GROUNDING CABLEGROUNDING CABLE

TOP PLATETOP PLATE

BASE PLATEBASE PLATE

5/8"-11 UNC (2x) (10K )5/8"-11 UNC (2x) (10K )

1/2"-13 UNC (2x) (5K & under)1/2"-13 UNC (2x) (5K & under)

(Bolts not provided)

3/8"-16 UNC (4x) (5K & under)3/8"-16 UNC (4x) (5K & under)

UPLIFT PROTECTIONUPLIFT PROTECTION

1/2"-13 UNC (4x) (10K )1/2"-13 UNC (4x) (10K )

(Bolts not provided)

C

DE

F

H

I

J

K

L

M

N

G

A

B

(Optional)

50767-1

DIMENSIONS (in inches) Corresponds to drawing above.

Capacity A B C D E F G H I J K L M N

5000 lb and under

3.54 0.59 1.38 6.30 5.12 1.57 0.98 6.50 3.15 0.47(4x) 0.51 2.75 1.97 3.94

10,000 lbs 5.12 0.98 1.97 7.87 6.69 1.97 1.38 8.27 4.13 0.57(4x) 0.63 3.94 2.76 4.72

Note:

a. The load cell mounting bolts for the 500 - 2.5k assemblies must be torqued to 66 ft-lbs.

b. The load cell mounting bolts for the 5k assemblies must be torqued to 88 ft-lbs.

c. The load cell mounting bolts for the 10k assemblies must be torqued to 295 ft-lbs.

Page 8

50767 8 01/08 Rev. 2

Figure 1

2-directional

bumper module

Figure 5

Figure 9

Figure 2

Figure 6 Figure 7

Figure 3

Figure 8

Figure 4

1. Each individual "2-directional bumper module" can be installed rotated 180

around it’s loading point.

2. For scales with 3 modules, distances to center of gravity should be chosen with

ratio 1:2, as shown in figure 1, which gives even load distribution.

3. For best stability, the loading points of the modules should be as far from one

another as the scale structure allows.

gravity

Center of

Load carrier symbol

2 x

120

L

L

50767-2

Page 9

50767 9 01/08 Rev. 2

This page was intentionally left blank.

Page 10

50767 10 01/08 Rev. 2

A. Parts List

Item Part Number Description Capacities

1 25524 Load cell, SS Hermetically Sealed 500 lb

25525 Load cell, SS Hermetically Sealed 1,000 lb

25526 Load cell, SS Hermetically Sealed 2,500 lb

25527 Load cell, SS Hermetically Sealed 5,000 lb

25528 Load cell, SS Hermetically Sealed 10,000 lb

2 3-6856-A Grounding cable w/ bolts ALL

3 4-6851-2 Sliding plate 500 - 5,000 lb

4-6851-3 Sliding plate 10,000 lb

4 4-6843-1 Sliding loading pin 500 - 5,000 lb

4-6845-1 Sliding loading pin 10,000 lb

B. Accessories

Item Part Number Description Capacities

5 25460 Mild Steel Uplift w/ bolts 500 - 5000 lb

25461 Stainless Steel Uplift w/ bolts 500 - 5000 lb

25462 Mild Steel Uplift w/ bolts 10,000 lb

25463 Stainless Steel Uplift w/ bolts 10,000 lb

Section 3: Parts List

Page 11

50767 11 01/08 Rev. 2

50767-3

1

2

3

4

5

Page 12

50767 12 01/08 Rev. 2

A. Mild Steel

Product Number Description

25438 Omnicell, w/ Zinc plated mild steel, ss hermetic load cell, 500 lb capacity

25439 Omnicell, w/ Zinc plated mild steel, ss hermetic load cell, 1k lb capacity

25440 Omnicell, w/ Zinc plated mild steel, ss hermetic load cell, 2.5k lb capacity

25441 Omnicell, w/ Zinc plated mild steel, ss hermetic load cell, 5k lb capacity

25442 Omnicell, w/ Zinc plated mild steel, ss hermetic load cell, 10k lb capacity

B. Stainless Steel

Product Number Description

25443 Omnicell, stainless steel mount, ss hermetic load cell, 500 lb capacity

25444 Omnicell, stainless steel mount, ss hermetic load cell, 1k lb capacity

25445 Omnicell, stainless steel mount, ss hermetic load cell, 2.5k lb capacity

25446 Omnicell, stainless steel mount, ss hermetic load cell, 5k lb capacity

25447 Omnicell, stainless steel mount, ss hermetic load cell, 10k lb capacity

Appendix I : Models

Loading...

Loading...