Page 1

Service / Installation Manual

5000 Series

Bench Scale Platforms

51245

© 2010-2013 by Fairbanks Scales, Inc.

All rights reserved

Revision 3 07/13

Page 2

Page 3

Amendment Record

5000 SERIES

BENCH SCALE PLATFORMS

SERVICE / INSTALLATION MANUAL

Document 51245

Manufactured by Fairbanks Scales, Inc.

821 Locust

Kansas City, Missouri 64106

Created 06/10 Created document

Revision 1 06/10 Document release

Revision 2 02/13 Corrected model numbers included.

Revision 3 07/13 Corrected formatting errors and added part number 14964.

Page 4

Disclaimer

Every effort has been made to provide complete and accurate information in this manual. However,

although this manual may include a specifically identified warranty notice for the product, Fairbanks

Scales makes no representations or warranties with respect to the contents of this manual, and

reserves the right to make changes to this manual without notice when and as improvements are

made.

Fairbanks Scales shall not be liable for any loss, damage, cost of repairs, incidental or consequential

damages of any kind, whether or not based on express or implied warranty, contract, negligence, or

strict liability arising in connection with the design, development, installation, or use of the scale.

© Copyright 2010-2013

This document contains proprietary information protected by copyright. All rights are reserved; no part

of this manual may be reproduced, copied, translated or transmitted in any form or by any means

without prior written permission of the manufacturer.

07/13 4 51245 Rev. 3

Page 5

Table of Contents

SECTION 1: INTRODUCTION & DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . 6

SECTION 2: TECHNICAL SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . 7

SECTION 3: INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

SECTION 4: PARTS REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

SECTION 5: 10” X 10” PLATFORMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

SECTION 6: 12” X 12” PLATFORMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

SECTION 7: 18” X 18” PLATFORMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

SECTION 8: 18” X 24” PLATFORMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

SECTION 9: 24” X 24” PLATFORMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

SECTION 10: TROUBLESHOOTING FLOW CHART . . . . . . . . . . . . . . . . . . . 20

07/13 5 51245 Rev. 3

Page 6

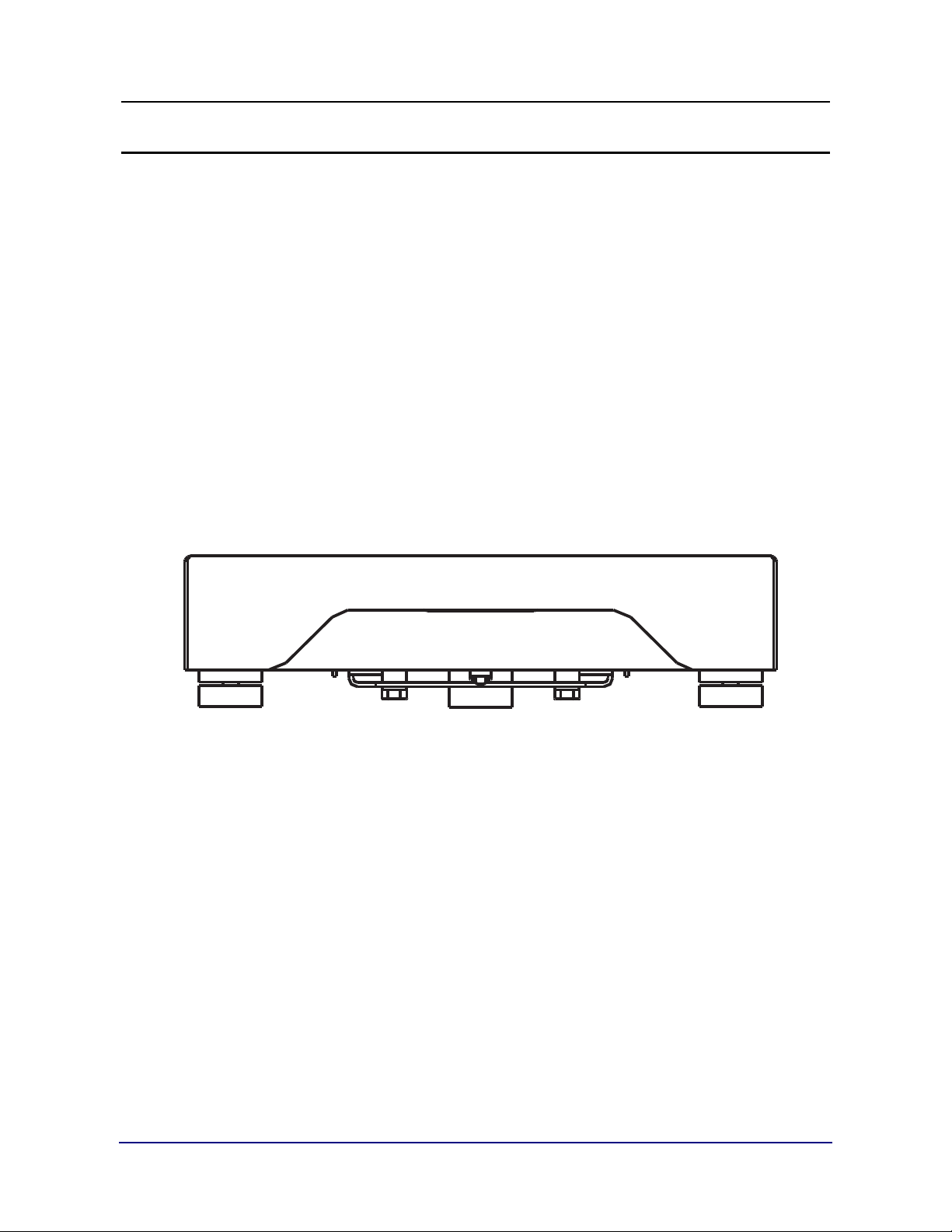

Section 1: Introduction & Description

The 5000 Series analog platforms are constructed of stainless steel. There is a wide

variety of application uses. These bench scales are designed for pharmaceutical,

chemical, and food applications because of their ruggedness and easy-to-clean

construction.

Certifications include:

• NTEP CC: 94-100

• MC: AM5107, AM5279, and AM5573

07/13 6 51245 Rev. 3

Page 7

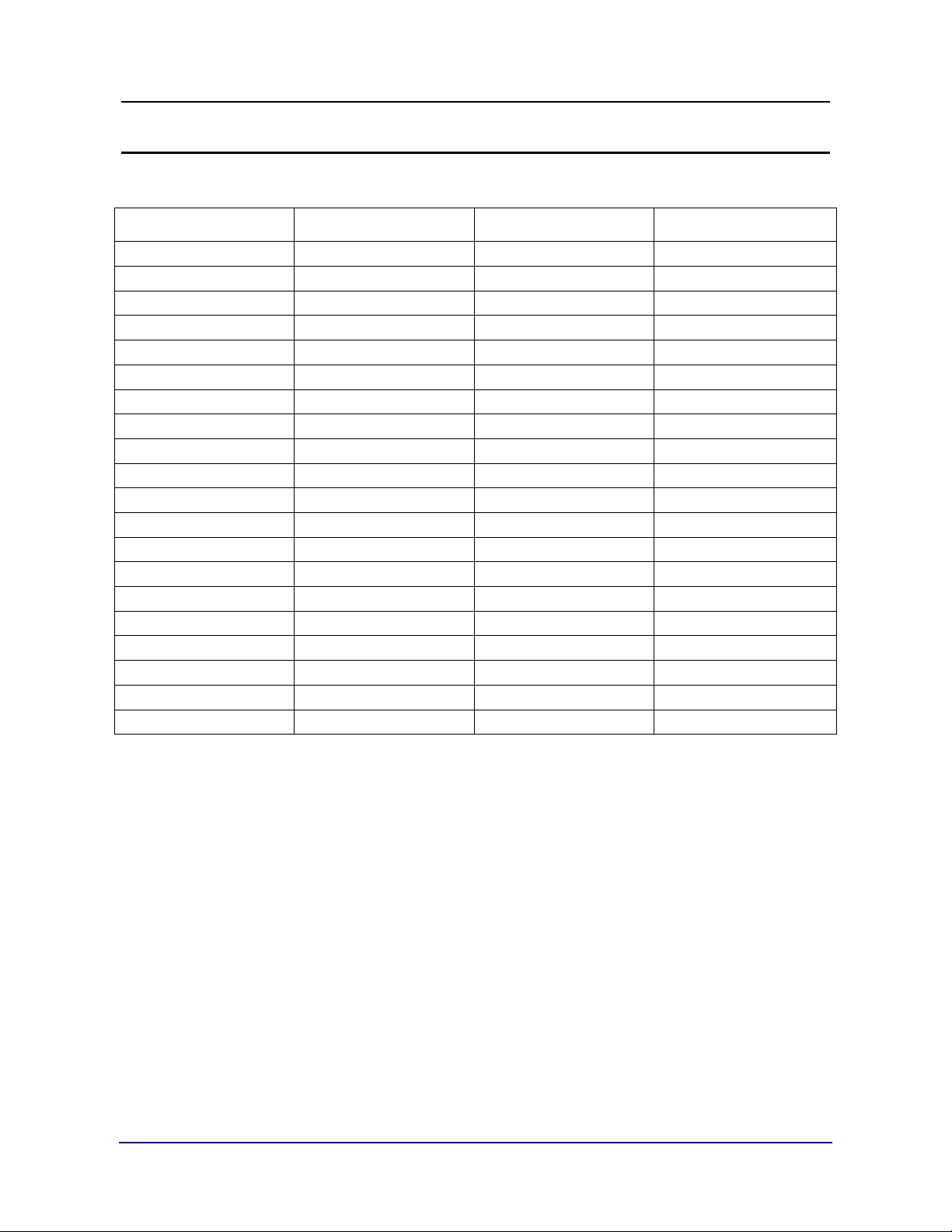

Section 2: Technical Specifications

Division size

lb oz kg g

2 x .0005 32 x .01 .91 x .002 910 x .2

5 x .001 80 x .02 2.26 x .0005 2260 x .5

6 x .002 96 x .05 2.72 x .001 2720 x 1

10 x .002 160 x .05 4.53 x .001 4530 x 1

12 x .005 192 x .1 5.44 x .002 5440 x 2

24 x .01 384 x .2 10.9 x .005 10900 x 5

25 x .005 400 x .1 11.3 x .002 11300 x 2

30 x .01 480 x .2 13.6 x .005 13600 x 5

40 x .01 640 x .2 18.1 x .005 18100 x 5

50 x .01 800 x .2 22.6 x .005 22600 x 5

60 x .02 960 x .5 27.2 x .01 27200 x 10

80 x .02 280 x .5 36.2 x .01 36200 x 10

100 x .02 1600 x .5 45.4 x .01 45400 x 10

120 x .02 1920 x .5 54.4 x .01 54400 x 20

150 x .05 2400 x 1 68 x .02 68000 x 20

200 x .05 3200 x 1 90.7 x .02 90700 x 20

250 x .05 4000 x 1 113 x .02 113000 x 50

300 x .1 4800 x 2 36 x .05 136000 x 50

500 x .1 8000 x 2 227 x .05 227000 x 50

1000 x .2 16000 x 5 454 x .1 454000 x 100

07/13 7 51245 Rev. 3

Page 8

Section 3: Installation

The platforms are shipped ready to interface to an analog instrument. Refer to the

table below for wiring color codes.

1. Place the platform where it will be used.

2. Level the platform using the feet.

3. Connect the interface cable to the instrument. The load cell interface cable is

Platform wiring

identified as follows.

Product

Number

24760

through

24769

and

26029

24862

through

24864

24783

through

24786

24770

through

24776

+

Excitation

--

Excitation

+

Sense

--

Sense

+

Signal

--

Signal

Green Black N/A N/A White Red

Green Black N/A N/A White Red

Green Black N/A N/A White Red

Green Black Blue Brown

Red White

07/13 8 51245 Rev. 3

Page 9

Section 4: Parts Replacement

Load cell replacement

Tools required:

• Open-end wrench

• Side cutter

• Torque wrench

Procedure:

1. Disconnect the instrument from the power supply.

2. Place the platform upright without the cover.

3. Remove the screws holding the load cell and spacer in place.

4. Remove the load cell and cable, and note the cell and cable placement!

5. Install the new load cell and the spacer(s).

6. Tighten the load cell mounting screws to 8 (± 2) INCH/LBS of torque only.

7. Route the load cell cable exactly as the original cable and plug in the connector.

8. Calibrate the instrument.

07/13 9 51245 Rev. 3

Page 10

Section 5: Parts - 10” x 10” Platforms

10” X 10” Platform (2 lb., 6 lb., and 25 lb. capacities)

Item Part No. Description

2 14961 Load cell – 7 kg – for platforms 24760, 24761, and 24762

2 14963 Load cell – 30 kg – for platform 24763

4 14219 Foot assembly (used as a bumper)

5 23664 Spider, platform

6 23669 Cover, platform

7 24779 Shim, load cell (.109 thick)

10 23668 Base, platform

11 24406 Clip, ground

13 11051 Screw, machine, hex head cap, .23 – 20 x .75

16 24408 Screw, set, socket head, cup point, 10 – 32 x .50

17 11103 Nut, hex, 10 – 32

18 11920 Adhesive, screw

19 17613 Tie wire

20 14220 Foot assembly

21 11039 Bull’s eye level

22 13223 Adhesive sealant

24 22963 Nut, nylon, stop

Diagram on next page.

07/13 10 51245 Rev. 3

Page 11

W

OUTPUTLC (+)SIG

SHIELD

LC (-)SIG

LC SHIELD

Y

R

OUTPUT

INPUTLC (+)EX

LC (-)EX

G

BK

INPUT

10

20

24

22

16 17

2

21

1813

11

13 18

7

6

4

7

5

19

(.205)

51245-1

PARTS DIAGRAM – 10” X 10” PLATFORM

07/13 11 51245 Rev. 3

Page 12

Section 6: Parts - 12” x 12” Platforms

12” x 12” Platform (30 lb, 50 lb, and 100 lb capacities)

Item Part No. Description

2 14963 Load cell – 30 kg – for platform 24763, 24764, 24765

2 14964 Load cell – 60 kg – for platform 26029.

4 14219 Foot assembly (used as a bumper)

5 23971 Spider, platform

6 23977 Cover, platform

7 24780 Shim, load cell (.185 thick)

10 23976 Base, platform

11 24406 Clip, ground

13 11051 Screw, machine, hex head cap, .23 – 20 x .75

16 24408 Screw, set, socket head, cup point, 10 – 32 x .50

17 11103 Nut, hex, 10 – 32

18 11920 Adhesive, screw

19 17613 Tie wire

20 14220 Foot assembly (used as a bumper)

21 11039 Bull’s eye level

22 13223 Adhesive sealant

24 22963 Nut, nylon, stop

Diagram on next page.

07/13 12 51245 Rev. 3

Page 13

20

24

16 17

2

10

7

11

6

5

4

13 18

13 182122

7

19

(.357)

51245-2

W

OUTPUTLC (+)SIG

SHIELD

LC (-)SIG

LC SHIELD

Y

R

OUTPUT

INPUTLC (+)EX

LC (-)EX

G

BK

INPUT

PARTS DIAGRAM – 12” X 12” PLATFORM

07/13 13 51245 Rev. 3

Page 14

Section 7: Parts - 18” x 18” Platforms

18” x 18” Platform (50 lb., 100 lb., 150 lb., and 300 lb. capacities)

Item Part No. Description

2 14965 Load cell – 100 kg – for platforms 24766, 24767 and 24768

2 14966 Load cell – 150 kg – for platform 24769

4 14219 Foot assembly (used as a bumper)

5 23538 Spider, platform

6 23548 Cover, platform

8 24843 Shim, load cell (.750 thick) for platform 24769

9 24781 Shim, load cell (.500 thick)

10 23547 Base, platform

11 24406 Clip, ground

12 24844 Screw, machine, hex head cap, ⅜ – 16 x 1.50 for platform 24769

13 11047 Screw, machine, hex head cap, ⅜ – 16 x 1.25

16 24782 Screw, set, socket head, cup point, ¼ – 20 x .88

17 11131 Nut, hex, jam, ¼ – 20

18 11920 Adhesive, screw

19 17613 Tie wire

20 14220 Foot assembly

24 22963 Nut, nylon, stop

34 11039 Bull’s eye level

35 13223 Adhesive sealant

Diagram on next page.

07/13 14 51245 Rev. 3

Page 15

34

35

13

18

20

4

2

5

1716

6

24

10

13

18

9

9

19

24766 50 LB. CAPACITY

24767 100 LB. CAPACITY

24768 150 LB. CAPACITY

24769 300 LB. CAPACITY

1716

13

35

2

34

18

9

10

6

8

12

18

11

5

20

24

19

4

11

LC (+)SIG

LC SHIELD

LC (-)SIG

R

Y

SHIELD

OUTPUT

BK

LC (+)EX

LC (-)EX

G

W

OUTPUT

INPUT

INPUT

(.580)

(.830)

W

BK

R

Y

LC SHIELD

LC (-)EX

LC (+)SIG

LC (-)SIG

LC (+)EX

G

SHIELD

OUTPUT

OUTPUT

INPUT

INPUT

51245-3

PARTS DIAGRAM – 18” X 18” PLATFORM

07/13 15 51245 Rev. 3

Page 16

Section 8: Parts - 18” x 24” Platforms

18” x 24” Platform (50 lb., 100 lb., and 300 lb. capacities)

Item Part no. Description

2 15835 Load cell - 150 kg – for platforms 24770, 24771 & 24772

2 21350

4 14219 Foot assembly (used as a bumper)

5 24430 Spider, platform

6 24429 Cover, platform

9 15831 Spacer, load cell (.250 thick)

10 24428 Base, platform

11 24406 Clip, ground

13 11050 Screw, machine, hex head cap, 5/16 - 18 x 1.00

18 11920 Adhesive, screw

19 17613 Tie wire

20 14220 Foot assembly

24 22963 Nut, nylon, stop

34 11039 Bull’s eye level

35 13223 Adhesive sealant

Load cell (hermetically sealed) - 100 kg – for platforms 24862, 24863 & 24864)

Diagram on next page.

07/13 16 51245 Rev. 3

Page 17

13

18

11

2

10

13

18

9

24

19

20

35

34

4

9

6

5

(.800)

24770, 24771, AND 24772

SHIELD

(+)

(-)

(-) EX

(+) SIG

(-) SIG

(+) EX

SENSE

SENSE

INPUT

OUTPUT

OUTPUT

INPUT

BL

BR

BK

R

W

G

24862, 24863, AND 24864

(+) SIG

(-) EX

(-) SIG

SHIELD

(+) EX

OUTPUT

INPUT

OUTPUT

INPUT

W

BK

R

Y

G

51245-4

PARTS DIAGRAM – 18” X 24” PLATFORM

07/13 17 51245 Rev. 3

Page 18

Section 9: Parts - 24” x 24” Platforms

24” x 24” Platform (50 lb, 100 lb, and 300 lb capacities)

Item Part no. Description

1 24447 Base, platform

3 21350 Load cell (hermetically sealed) - 100 kg (24783 and 24784)

3 15835 Load cell - 150 kg (24773 and 24774)

3 21353 Load cell (hermetically sealed) - 500 kg (24785)

3 15836 Load cell - 300 kg (24775)

3 15837 Load cell - 500 kg (24776)

3 21353 Load cell (hermetically sealed) - 500 kg (24786)

4 15831 Spacer, load cell (.250 thick)

7 15827 Plate support (24773, 24774, 24783 and 24784)

7 15828 Plate support (24775, 24776, 24785 and 24786)

8 15826 Spider, platform

9 24448 Cover, platform

12 11480 Foot assembly

13 11101 Nut, hex, ½ - 13

15 11060 Screw, machine, hex head cap, ¼ - 20 x .50

16 11049 Screw, machine, hex head cap, 5/16 - 18 x 1.25

17 11050 Screw, mach. hex hd cap 5/16 - 18 x 1.00 (24773, 24774, 24783 & 24784)

19 11920 Adhesive, screw

24 17613 Tie wire

30 15017 Clip, ground

34 11039 Bull’s eye level

35 13223 Adhesive sealant

Diagram on next page.

07/13 18 51245 Rev. 3

Page 19

WIRING FOR 24773, 24774, 24775 & 24776

WIRING FOR 24783, 24784, 24785, AND 24786

(-) EX

(-) SIG

(+) SIG

(+) EX

SHIELD

SHIELD

(+)

(+) EX

(-)

(-) EX

(+)

(-) SIG

VIEW A - SHOWN WITH COVER REMOVED

1

8

3534

24773, 24783 ASSY, 100 LB. CAPACITY

24774, 24784 ASSY, 250 LB. CAPACITY

1915

1915

1915

1916

13

30

7

19

9

8

4

24

4

3

17

12

1

INPUT

OUTPUT

OUTPUT

INPUT

BK

R

W

G

Y

SENSE

INPUT

SENSE

INPUT

OUTPUT

OUTPUT

BL

G

BR

BK

R

W

51245-5

PARTS DIAGRAM – 24” X 24” PLATFORM

07/13 19 51245 Rev. 3

Page 20

Scale

not

working

Perform a visual inspection and

begin asking specific questions

to identify the cause and/or

symptoms BASICS

Place instrument

on simulator

Does it work?

Repair the

instrument

Check wiring at load cell,

perform load cell tests,

and/or replace load cell

Problem resolved;

finalize all repairs

Does it work?

YES

NO

YES

NO

Call

Technical

Support

51245-6

Section 10: Troubleshooting Flow Chart

07/13 20 51245 Rev. 3

Page 21

Page 22

5000 Series Platforms

SERVICE/INSTALLATION MANUAL

Manufactured by Fairbanks Scales, Inc

821 Locust St.

Kansas City, MO 64106

www.fairbanks.com

.

DOCUMENT 51245

Loading...

Loading...