Page 1

Operator Manual

2800 Series

Intrinsically Safe Instrument

with Intalogix

™

Technology

50647

© 2001-2012 by Fairbanks Scales, Inc. Revision 9 01/12

All rights reserved

Page 2

Page 3

2800 Series

Intrinsically Safe Instrument

With Intalogix™ Technology

Document 50647

Manufactured by Fairbanks Scales Inc.

821 Locust

Kansas City, Missouri 64106

AMENDMENT RECORD

Issue #1 09/01 Created and released manual.

Issue #2 11/01 Updated specifications.

Issue #3 03/02 Updated specifications and procedures

Issue #4 08/02 Updated specifications for 4-20mA

Issue #5 01/03 Updated drawings, note, and caution graphics.

Issue #6 11/06 Updated specifications for 4-20mA.

Revision 7 10/07 Updated format, images, and technical specifications.

Revision 8 07/09 Updated Control Drawings, formatting, added down

weighing information

Revision 9 01/12 Updated Battery Charger revision information and FM

Control Drawings in Appendix II.

01/12 3 50647 Rev. 9

Page 4

Disclaimer

Every effort has been made to provide complete and accurate information in this manual. However,

although this manual may include a specifically identified warranty notice for the product, Fairbanks

Scales makes no representations or warranties with respect to the contents of this manual, and

reserves the right to make changes to this manual without notice when and as improvements are

made.

It is the responsibility of the requesting party to develop, maintain, install, and connect networking

devices and general network connectivity as it applies to the originating party’s network. No warranty

or guarantee, expressed or implied, concerning the network, its design, its installation, or operational

characteristics has been offered by Fairbanks Scales. Fairbanks Scales shall not be liable for any

loss, damage, cost of repairs, incidental or consequential damages of any kind, whether or not based

on express or implied warranty, contract, negligence, or strict liability arising in connection with the

design, development, installation, or use of an intended network.

© Copyright 2001-2012

This document contains proprietary information protected by copyright. All rights are reserved; no part

of this manual may be reproduced, copied, translated or transmitted in any form or by any means

without prior written permission of the manufacturer.

01/12 4 50647 Rev. 9

Page 5

Table of Contents

SECTION 1: GENERAL INFORMATION .................................................................. 7

1.1. Description ................................................................................................................... 7

1.2. Specifications .............................................................................................................. 8

1.3. Accessories ................................................................................................................. 9

1.3.1. Accessory 2802 Intrinsically Safe Controller ....................................................................... 9

1.3.2. Accessory 2825 Safe Area Power Supply ........................................................................... 9

1.3.3. Accessory 2830 Battery (20615) ......................................................................................... 9

1.3.4. Battery Charging ................................................................................................................ 11

1.3.5. Accessory 2845 Battery Charger 110-120 VAC (31354) .................................................. 11

1.3.6. Accessory 2841 Battery Charger 230VAC for Accessory 2830 (21740) ........................... 11

1.3.7. Accessory 2850 Safe Area Relay Setpoint Interface (20570) ........................................... 12

1.3.8. Accessory 2860 Safe Area Data Converter (20523) ......................................................... 13

1.3.9. Accessory 2875 Intrinsically Safe Interconnection Cable (21737) .................................... 13

1.3.10. Accessory 2880 Analog Cell Input (19797) ..................................................................... 14

1.3.11. Accessory 2900 Splice Box (20310) ................................................................................ 14

1.3.12. Accessory 2910 Splice Box Kit w/cables (20199) ........................................................... 14

1.3.13. Accessory 5806 Fiber Optic cable (17229) ..................................................................... 14

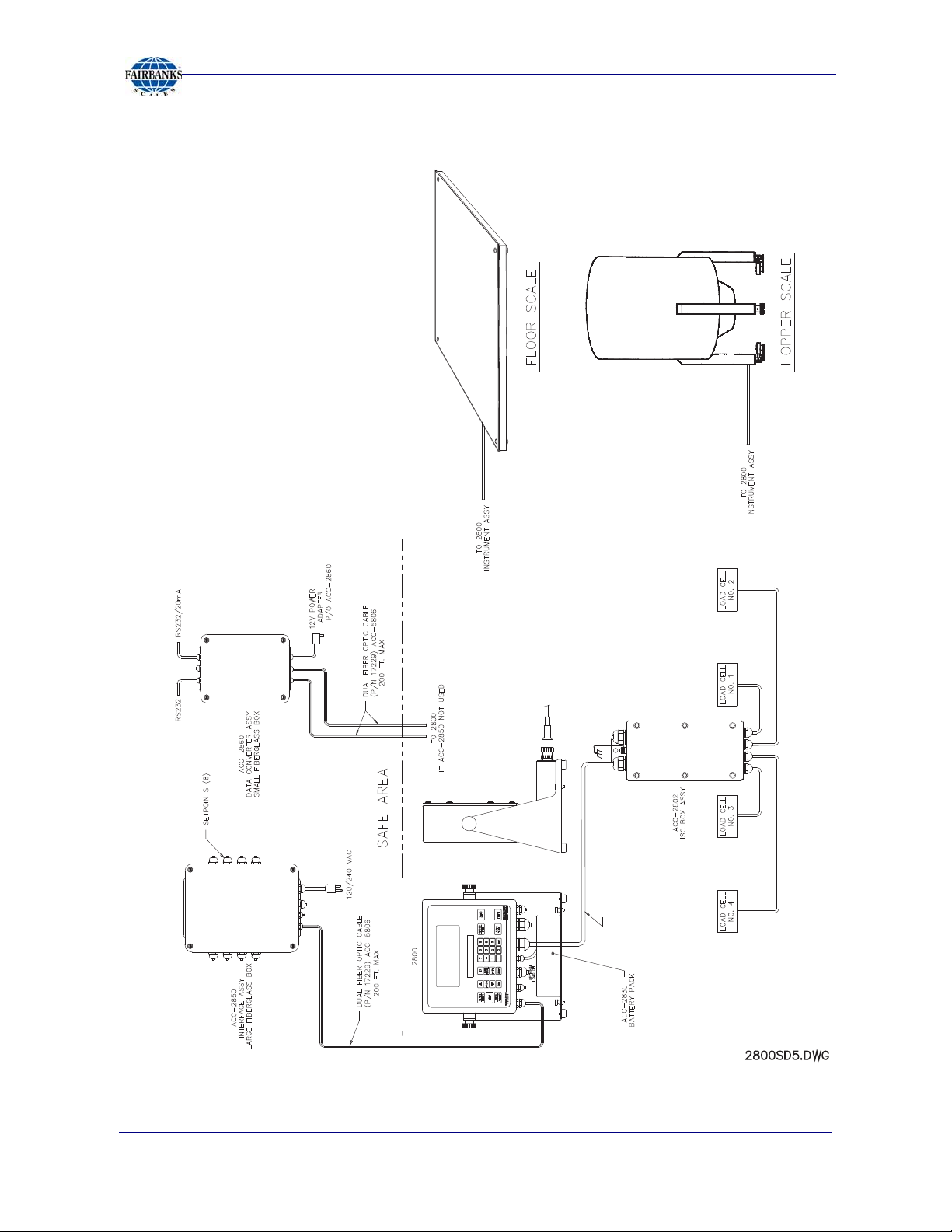

1.4. Typical System Layout #1 ......................................................................................... 15

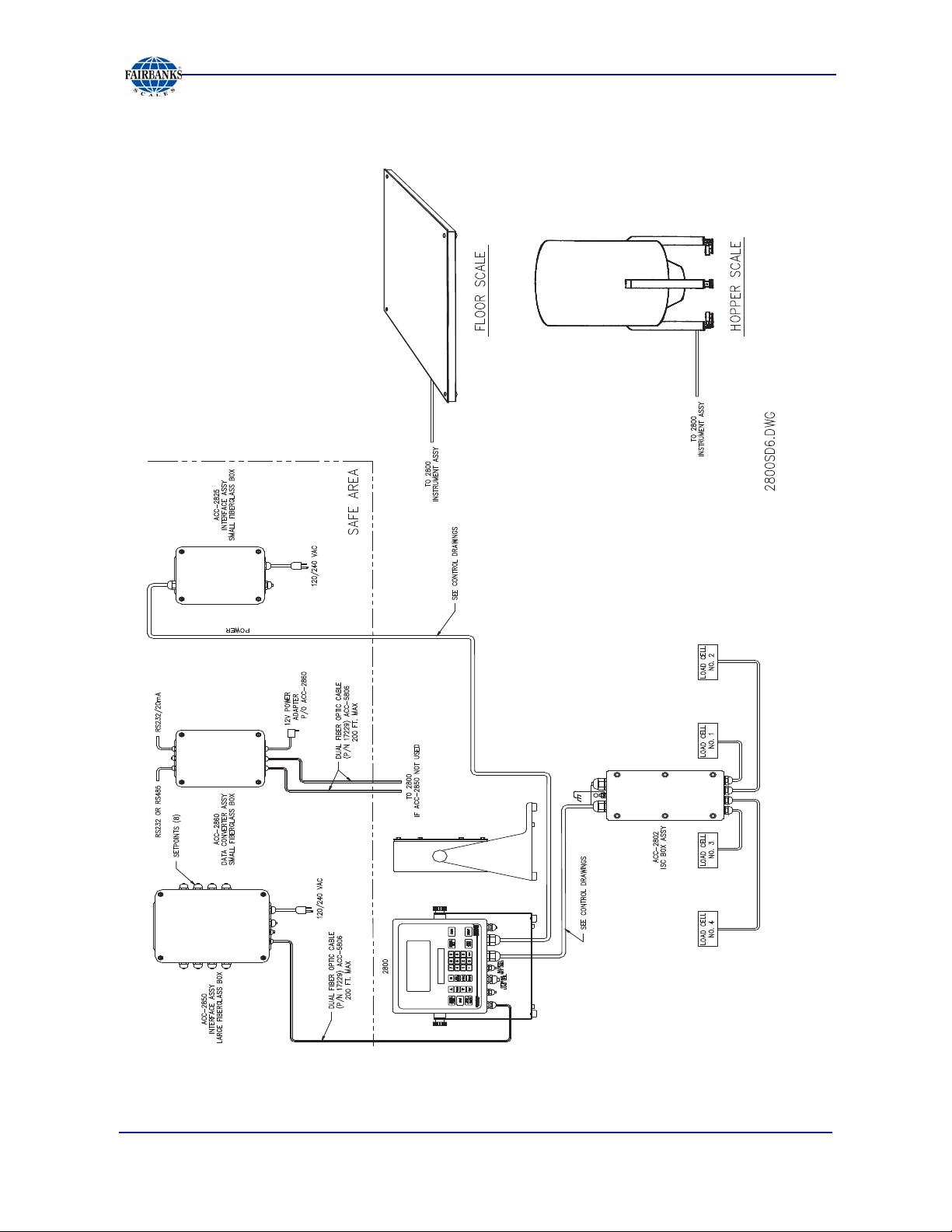

1.5. Typical System Layout #2 ......................................................................................... 16

SECTION 2: OPERATION ........................................................................................ 17

2.1. Customer/ Owner Responsibilities............................................................................. 17

2.2. Safety ........................................................................................................................ 18

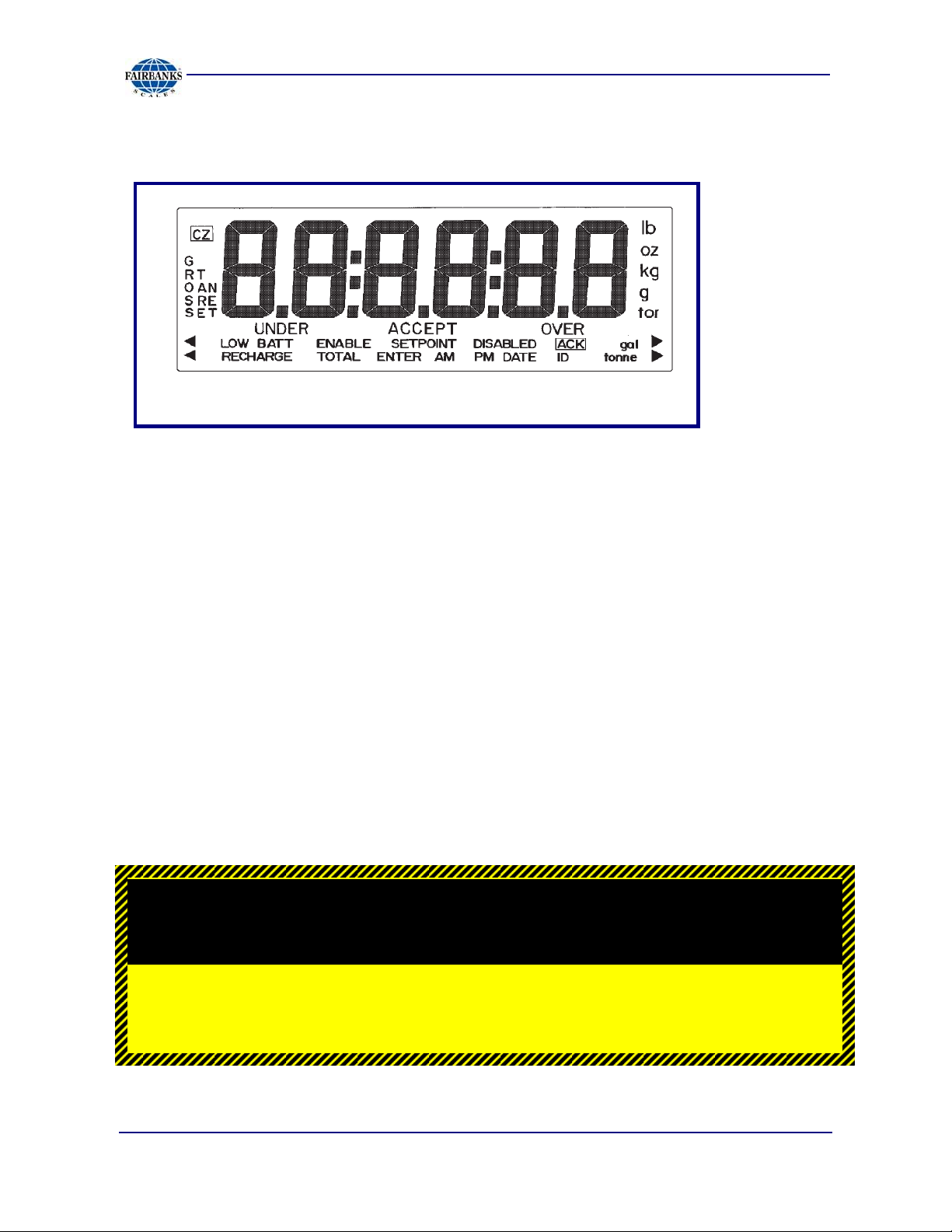

2.3. Front Panel Key Functions ........................................................................................ 19

2.3.1. LEGENDS .......................................................................................................................... 22

2.3.2. Instrument Weighing Functions ......................................................................................... 23

2.3.3. Gross Weighing ........................................................................................................ ......... 25

2.3.4. Tare Weights ..................................................................................................................... 25

SECTION 3: PROGRAMMING ................................................................................. 30

3.1. Menu Navigation ........................................................................................................ 30

3.2. tArgEt MENU Description .......................................................................................... 32

3.3. inFo Menu Description ............................................................................................... 33

3.4. Main Menu Descriptions ............................................................................................ 34

3.5. I/O Menu .................................................................................................................... 35

3.5.1. I/O Menu Descriptions ....................................................................................................... 36

SECTION 4: SECURITY ........................................................................................... 48

4.1. Security Codes .......................................................................................................... 48

01/12 5 50647 Rev. 9

Page 6

Table of Contents

APPENDIX I: TROUBLESHOOTING/ERROR CODES ............................................ 49

APPENDIX II: FM CONTROL DRAWINGS .............................................................. 50

APPENDIX III: MATERIAL SAFETY DATA SHEET ................................................ 62

APPENDIX IV: CONTINUOUS OUTPUT DATA STREAMS .................................... 64

A. Format: Fairbanks Computer (FbPutr) ......................................................................... 64

A.2. Status Word B ...................................................................................................................... 65

A.3. Status Word C ...................................................................................................................... 65

B. 4. Format : Consolidated Controls (ConCon) .............................................................. 66

C. Format: Weightronix (tronix) ....................................................................................... 67

APPENDIX V: DEMAND OUTPUT DATA STREAMS ............................................. 68

A. Format : Computer Polled (Poll) ................................................................................... 68

B. Format: Computer Polled with Id (Pollid)...................................................................... 69

APPENDIX VI: ACC 2860 COMMUNICATION WIRING .......................................... 70

A. Port A ........................................................................................................................... 70

B. Port B ........................................................................................................................... 71

APPENDIX VII: ASCII CODES ................................................................................. 72

01/12 6 50647 Rev. 9

Page 7

Section 1: General Information

1.1. DESCRIPTION

The model 2800 series is an Intrinsically Safe instrument utilizing Intalogix™

Technology. It is Factory Mutual (FM) Approved for direct use in hazardous

environments as shown in the FM Approved Control Drawings.

The 2800 series instrument eliminates the need for explosion proof enclosures or

purging systems. Enclosed in a stainless steel, NEMA 4X enclosure, the

instrument is able to withstand both wash down and corrosive environments.

Major features of the Instrument include push-button programming and calibration,

with data storage in nonvolatile ROM for 100% memory retention.

The 2800 series instrument features a large 1.25 inch high LCD weight display

with an additional alphanumeric status display, which can be tilted up or down to

accommodate different lighting conditions. Its microprocessor controlled design

allows the instrument to be rapidly programmed at installation to meet the specific

requirements of the application.

The obtainable accuracy meets Handbook 44 requirements, and the instrument is

approved for commercial application up to 10,000 divisions. A maximum of

30,000 divisions can be achieved for non-commercial applications.

This ultra-low power instrument can interface to analog load cells through an

Intalogix™ intrinsically safe controller or can be connected directly to analog load

cells using an available optional accessory.

The instrument provides fiber optic interfaces from the hazardous area to the

optional accessories located in a safe area. The optional accessories provide

communications to various types of peripheral devices in selectable formats for

RS232, and 20mA data outputs. Other available options include analog interfaces

through programmable setpoints and 4-20 ma analog outputs. The instrument may

be powered by a battery or a continuous power accessory.

01/12 7 50647 Rev. 9

Page 8

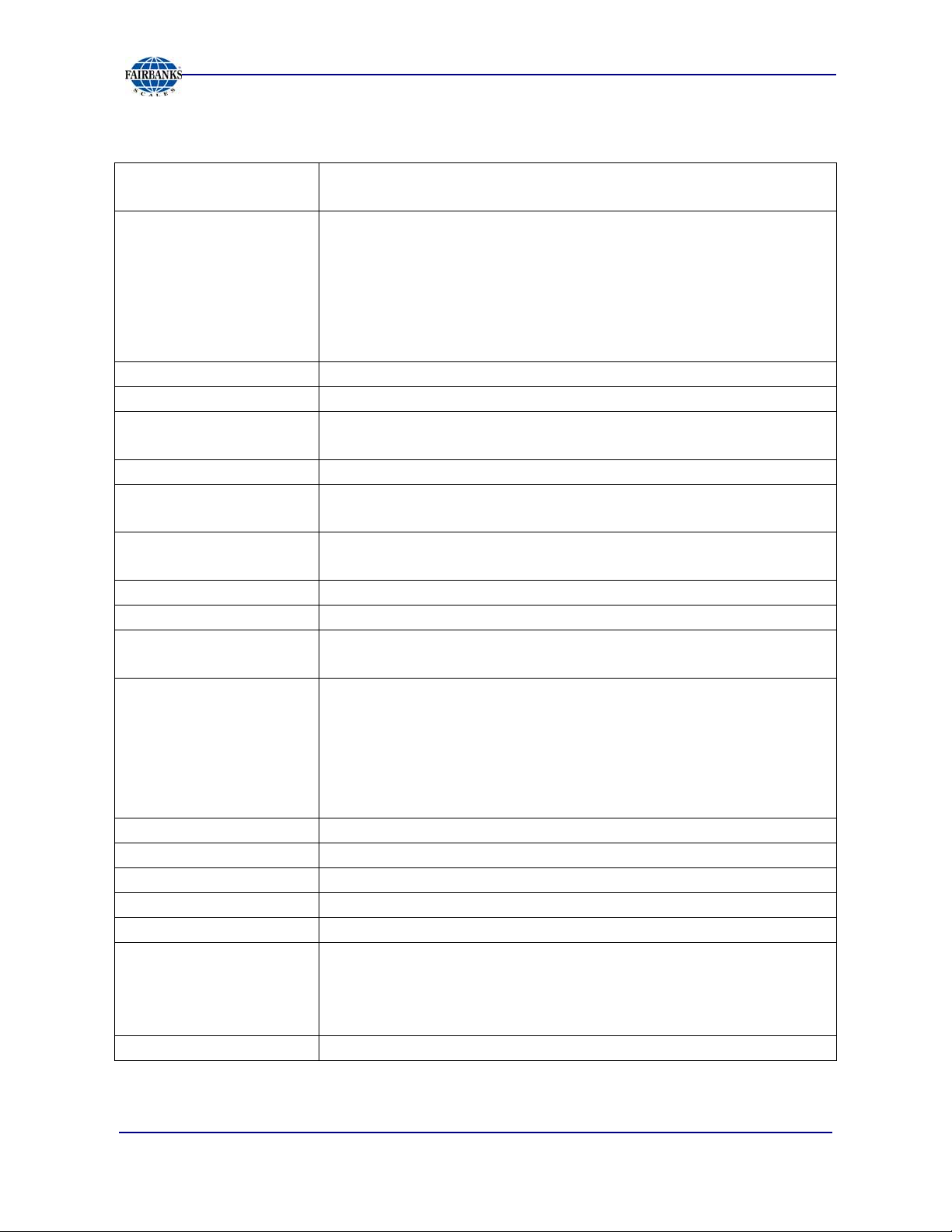

1.2. SPECIFICATIONS

Section 1: General Information

Instrument Approvals

FM Approvals

NTEP: CoC 01-009

CWM: Pending

Class I, II, and III

Division 1

Groups A, B, C, D, E, F, and G

* For more detailed information, see FM Control Drawing 21943.

Appendix II.

see

Physical Dimensions Approximately 13"W x 9"H x 3"D

Material Stainless Steel

Enclosure Rating

Capacities Service programmable up to 999,950 lb, kg, oz, g, tons, lb-oz, or gallons

Division Sizes

Resolution

Sensitivity

Load Cells Up to 16 - 350 or 1000 ohm impedance

Load Cell Cable

Length/Wire Gauge

NEMA 4X

IP65

Service programmable for .0002 to 50

Fixed at one (1) oz. in the lb/oz mode

Commercial - Up to 10,000 divisions maximum

Noncommercial - Up to 30,000 divisions maximum

1µv/d (microvolt/division)

75' maximum

20 AWG maximum

Display Weight Display

1.25" height

7 segment LCD

Status Display

.38" x 3.73" Alphanumeric LCD

16 characters - .38" x .191" character size

Zero Range Service programmable - Disabled, 2, or 100%

Auto-Zero-Tracking Service programmable - Disabled, .5, 1, or 3 divisions

Motion Detection Service programmable - Disabled, .5, 1, or 3 divisions

Digital Filter Service programmable from disabled up to heavy

Display Update Rate Service programmable settings from .1 to .8 seconds.

Environment

Chemical Resistance Resistant to all petroleum derivatives and salts.

Handbook 44 Compliance Tested Operating Environment

Temp -10°C to + 40°C (+14°F to + 104°F)

Storage

Temp -40°C to + 60°C (-40°F to + 140°F)

01/12 8 50647 Rev. 9

Page 9

1.3. ACCESSORIES

1.3.1. ACCESSORY 2802 INTRINSICALLY SAFE CONTROLLER

(22119)

Each controller allows up to four (4) load cells to be interconnected

Communicates to the Model 2800 Series Instrument using Intalogix ™

Technology

Enclosure: NEMA 4X, Stainless steel

1.3.2. ACCESSORY 2825 SAFE AREA POWER SUPPLY (18448)

This accessory will provide continuous power to the Model 2800 Instrument.

The Accessory 2830 cannot be used with this accessory, as this accessory is

installed in a non-hazardous, safe area only.

Section 1: General Information

Enclosure: NEMA 4, Fiberglass

Output: 7 VDC

1.3.3. ACCESSORY 2830 BATTERY (20615)

Supplies battery power to the Model 2800 Series Instrument.

It must be recharged in a non-hazardous, safe area using Accessory 2845 or

2846 only.

Accessory 2830 is the only battery approved to be used with the

Model 2800 Series Instruments for all applications.

CAUTION

Battery surface gets very HOT during recharging!

DO NOT USE Accessory 2830

in conjunction with Accessory 2825.

01/12 9 50647 Rev. 9

Page 10

Section 1: General Information

1.3. ACCESSORIES, CONTINUED

1.3.4. BATTERY CHARGING

Charging time is 16 hours for a fully discharged battery.

The battery requires recharging when the Recharge display appears.

The battery may be recharged 100 - 500 times dependent on depth of

discharge.

Recharge intervals may vary depending upon usage.

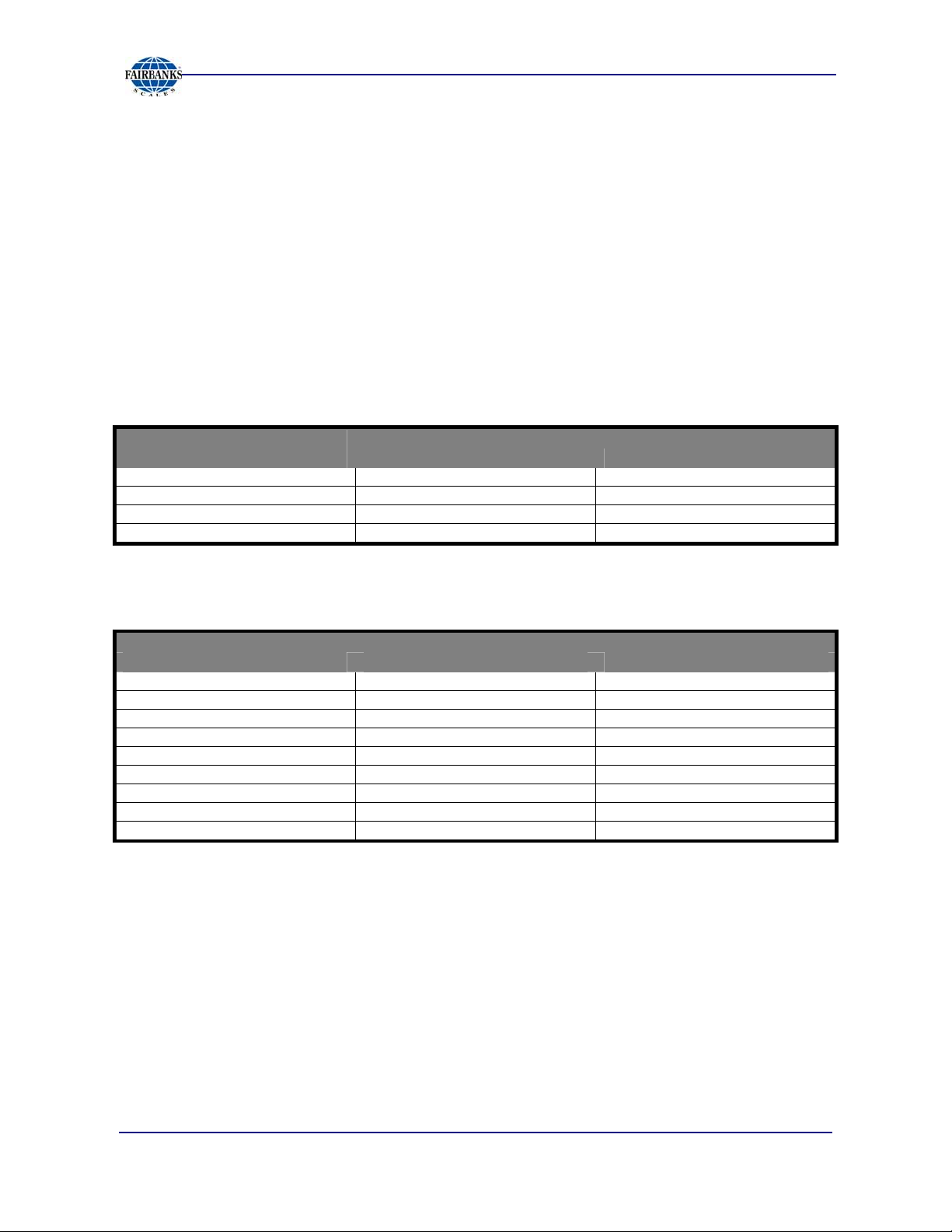

Table 1 – Recharge intervals using Accessory 2802

RECHARGING HOURS

No. of Cells 350 ohm Load Cells 1000 ohm Load Cells

16 6 20

12 20 40

8 45 70

4 100 133

Table 2 – Recharge intervals using Accessory 2830

RECHARGING HOURS

No. of Cells 350 ohm Load Cells 1000 ohm Load Cells

16 85 133

14 90 150

12 95 172

10 100 184

8 117 199

6 133 219

4 175 247

3 194 266

1 269 320

01/12 10 50647 Rev. 9

Page 11

Section 1: General Information

1.3. ACCESSORIES, CONTINUED

1.3.5. Accessory 2845 Battery Charger 110-120 VAC (31354)

(REPLACES ACCESSORY 2840 – 21199)

The Safe Area Smart Recharger uses the Battery Accessory 2830 only.

The 2845 Battery Charger is plugged into a standard outlet.

This accessory is intended for non-hazardous, safe areas only.

Follow these guidelines when charging Battery Accessory 2830.

A charged battery can be left on the charger with no resulting damage to

either the charger or battery pack.

When a discharged battery is first connected to a charger, the status L.E.D. on

the charger will be a constant yellow as it charges.

Once the battery is fully charged, the LED remains a constant green.

CAUTION

Battery surfaces get very HOT during recharging.

1.3.6. ACCESSORY 2846 BATTERY CHARGER 230VAC (31466)

FOR ACCESSORY 2830

Equipped with a European Style 230 VAC plug.

Used with the Battery Accessory 2830 only.

Intended for non-hazardous, safe areas only.

Follow these guidelines when charging Battery Accessory 2830.

A charged battery can be left on the charger with no resulting damage

to either the charger or battery pack.

When a discharged battery is first connected to a charger, the status

L.E.D. on the charger will be a constant yellow as it charges.

Once the battery is fully charged, the LED remains a constant green.

01/12 11 50647 Rev. 9

Page 12

Section 1: General Information

1.3. ACCESSORIES, CONTINUED

1.3.6. ACCESSORY 2846 BATTERY CHARGER 230VAC (31466)

FOR ACCESSORY 2830, CONTINUED

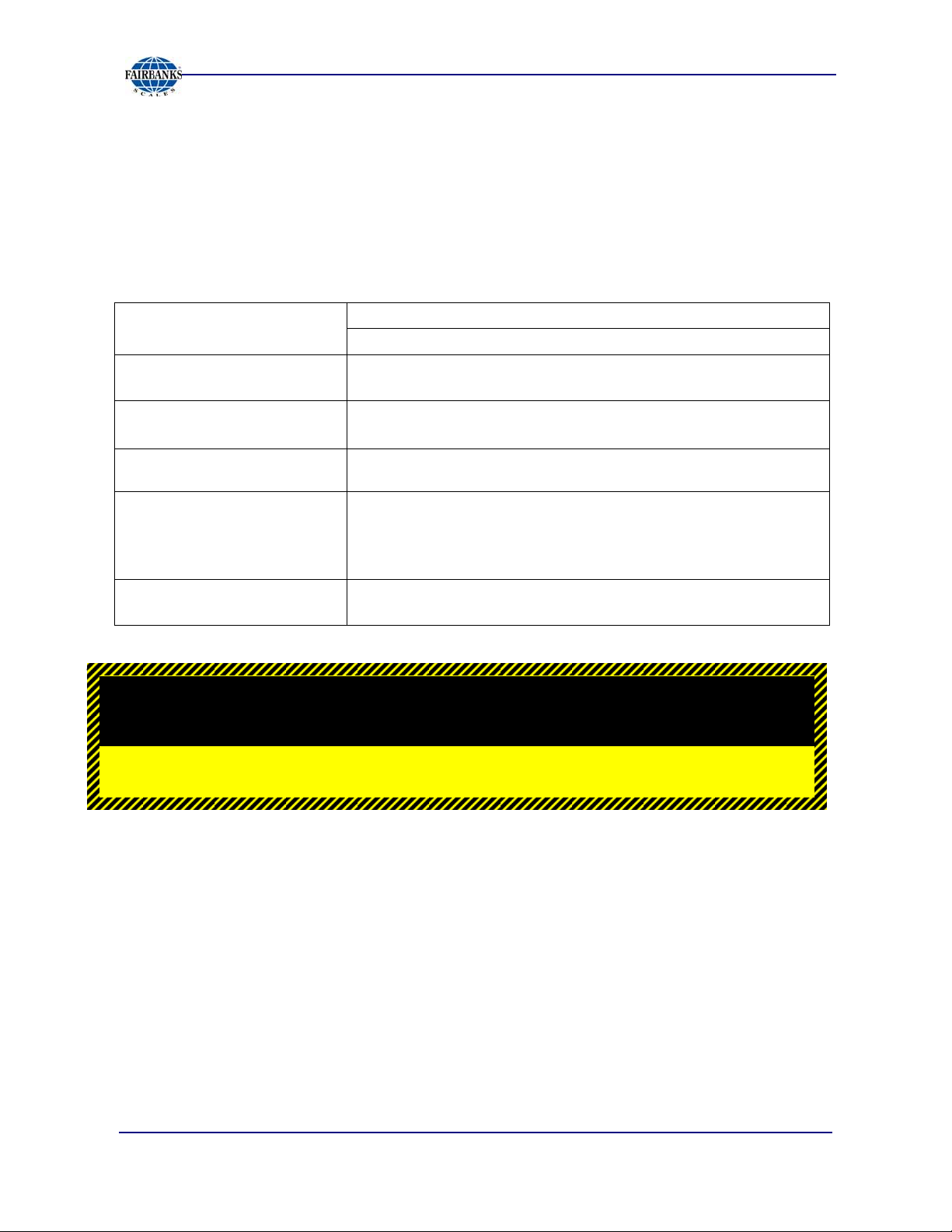

The following chart outlines basic information for both models of battery chargers.

INPUT VOLTAGE

BATTERY OUTPUT

VOLTAGE

LEADS

STATUS L.E.D.

CHARGING TIME

OPERATING

TEMPERATURE RANGE

2845 – 120 VAC, 60 Hz – Standard style plug

2846 – 230 VAC, 50/60 Hz

7.0 VDC +/- 0.2 VDC at the end of charge cycle with battery

connected.

Output leads 18 AWG, approximately three feet (3’).

Extended power cord up to six feet (6’).

Brightness sufficient to discern the charge status under general

office environment lighting.

Sixteen (16) hours maximum for undamaged chargeable battery

(electrolyte not depleted).

Initial unloaded output voltage of 5.0 VDC.

Do not recharge a battery with a voltage below 4.0 VDC.

0°C to +38°C (+32°F to +100°F).

CAUTION

Battery surfaces get very HOT during recharging.

1.3.7. ACCESSORY 2850 SAFE AREA RELAY SETPOINT

INTERFACE (20570)

The setpoint accessory is service programmable for up to eight (8) setpoints.

These setpoints may be configured to one of five different modes of operation.

Enclosure: NEMA 4. Fiberglass

01/12 12 50647 Rev. 9

Page 13

1.3. ACCESSORIES, CONTINUED

1.3.8. ACCESSORY 2860 SAFE AREA DATA CONVERTER

(20523)

This accessory is service programmable and configurable for RS232 or 20mA

data outputs.

This accessory can also be configured to provide a 4-20 ma analog output.

Enclosure: NEMA 4; Fiberglass

4 -20 ma Specifications: 16 bit resolution (+/- .01 integral linearity)

CAUTION

The 4-20ma accessory is a passive device!

Section 1: General Information

The power is to be supplied by others, and MUST

BE

a DEDICATED and an ISOLATEDpower supply.

Current loop voltage compliance: 7vdc minimum to 40vdc maximum (typical

voltage = 24vdc)

Full scale settling time: 8msecs

Output impedance: 25 meg

Alarm current: 3.5 to 24 mA (underload/overload conditions)

─ Offset @ 25 degrees C; +/- .1% of full scale

Offset drift: +/- 25ppm of full scale per degree C

Total output error: 20mA @ 25 degrees C: +/- .2% of full scale max

Total output drift: +/- 50ppm of full scale per degree C-max

1.3.9. ACCESSORY 2875 INTRINSICALLY SAFE

INTERCONNECTION CABLE (21737)

This is the only approved cable for interconnecting the Accessory 2802, and

for connecting to the Model 2800 to the Accessory 2850.

Specifications: 2 pair - 16AWG; 0.48" O.D.

01/12 13 50647 Rev. 9

Page 14

1.3. ACCESSORIES, CONTINUED

1.3.10. ACCESSORY 2880 ANALOG CELL INPUT (19797)

This accessory allows for direct interface to a analog load cell(s).

This accessory is complete, and is supplied with mounting hardware and an

EPROM.

1.3.11. ACCESSORY 2900 SPLICE BOX (20310)

Enclosure: NEMA 4X; Stainless steel

1.3.12. ACCESSORY 2910 SPLICE BOX KIT W/CABLES (20199)

Enclosure: NEMA 4X; Stainless steel

Section 1: General Information

1.3.13. ACCESSORY 5806 FIBER OPTIC CABLE (17229)

This accessory allows a direct connection of the Model 2800 Series

Instrument.

It is located in the hazardous area to the Accessories 2850 and 2860, in the non-

hazardous, safe area for I/O operation. Maximum fiber optic cable distance is 200

feet. Do not place the fiber optic cable within conduits.

01/12 14 50647 Rev. 9

Page 15

1.4. TYPICAL SYSTEM LAYOUT #1

Section 1: General Information

SEE CONTROL DRAWINGS

01/12 15 50647 Rev. 9

Page 16

1.5. TYPICAL SYSTEM LAYOUT #2

Section 1: General Information

01/12 16 50647 Rev. 9

Page 17

Section 2: OPERATION

2.1. CUSTOMER/ OWNER RESPONSIBILITIES

It is the customer/ owners' responsibility to maintain, the platform,

instrument, and peripheral accessories in good order, and to

protect the equipment from accidental or malicious damage.

The installation shall be in accord with the manufacturer's instructions and with the

National Electric Code (ANSI-NFPA 70).

─ Refer to ANSI/ ISA-RP12.6, Installation of Intrinsically Safe Systems for

Hazardous (Classified) Locations for guidance on the installation of

intrinsically safe apparatus and systems.

Please follow these guidelines .

Do not break the seals on the instrument or attempt any internal

adjustments.

Absolutely no physical, electrical, or program modifications other than the

selection of standard options and accessories are to be made to this

equipment.

Electrical connections other than those specified may not be performed,

and no physical alterations (mounting holes and etc.)

are allowed.

No service, repairs, or adjustments, other than those

outlined in this manual, may be performed by untrained

service personnel.

01/12 17 50647 Rev. 9

Page 18

Section 2: Operation

2.2. SAFETY

As is in the case with any material handling equipment, certain safety precautions

must be observed during operation.

Never load the scale platform beyond its rated capacity.

─ Refer to the rating on the serial number plate to be certain.

Ensure that any structure which supports the platform is capable

of withstanding the weight of the platform plus its rated capacity

load.

Do not load the scale platform if there is any evidence of damage

to the platform or supporting structure.

Use safety chains or other suitable restraining devices if there is

any possibility of the load shifting, falling, or rolling from its

position on the load receiver.

01/12 18 50647 Rev. 9

Page 19

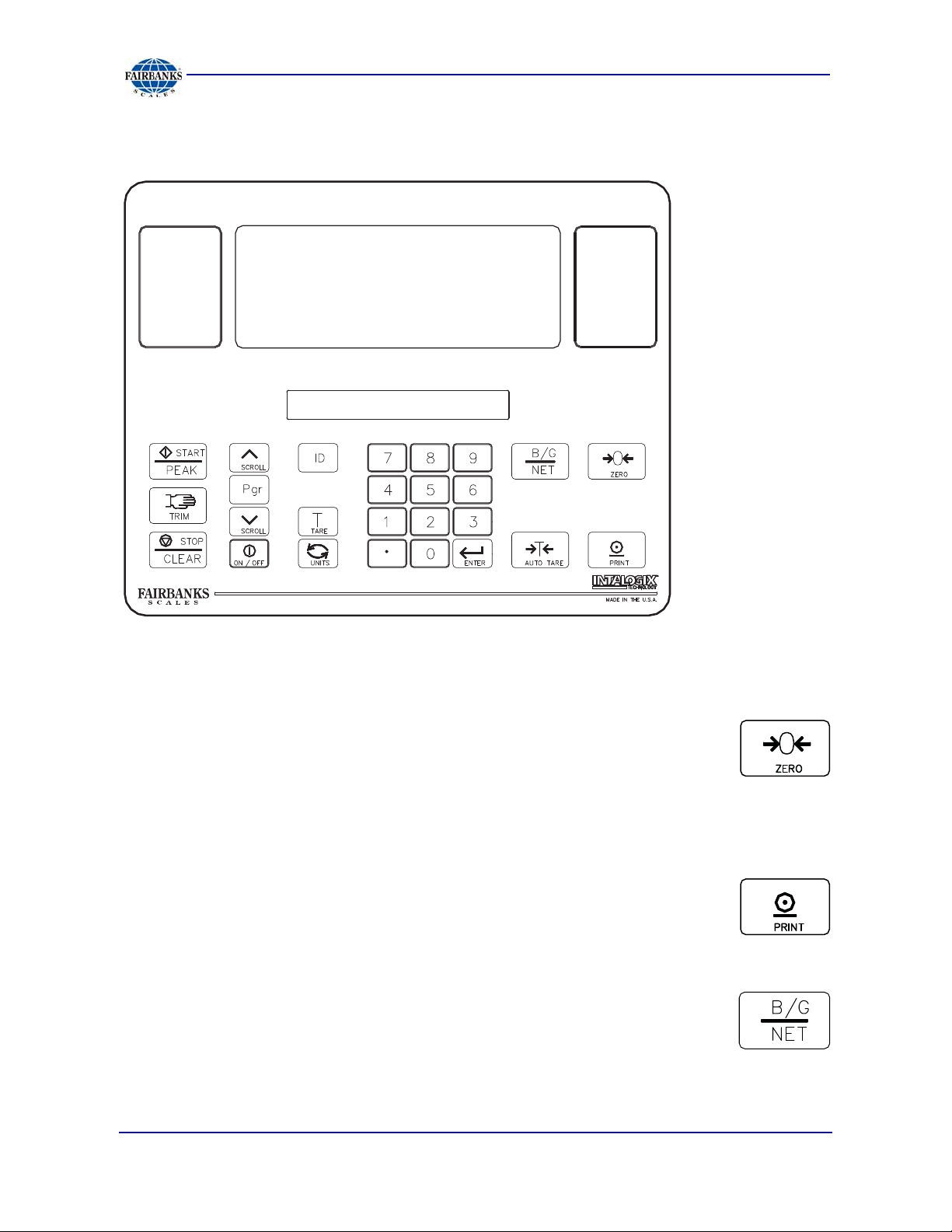

2.3. FRONT PANEL KEY FUNCTIONS

Section 2: Operation

The function of the front panel keys varies depending on the mode in which the

instrument is operated. This Subsection defines the operation of each front panel key

when in the weighing mode.

ZERO KEY

When in the Gross mode, this key sets the Gross Weight to Zero.

─ If motion exists, the ZERO command will not be executed.

─ If the weight on the platform exceeds the zero limit, and the

pressed, the Zero command will not be executed.

ZERO key is

PRINT KEY

Used to transmit weight data to an external device.

GROSS/NET KEY

Toggles between the Gross and Net Weight modes.

─ It is also used to exit programming.

01/12 19 50647 Rev. 9

Page 20

Section 2: Operation

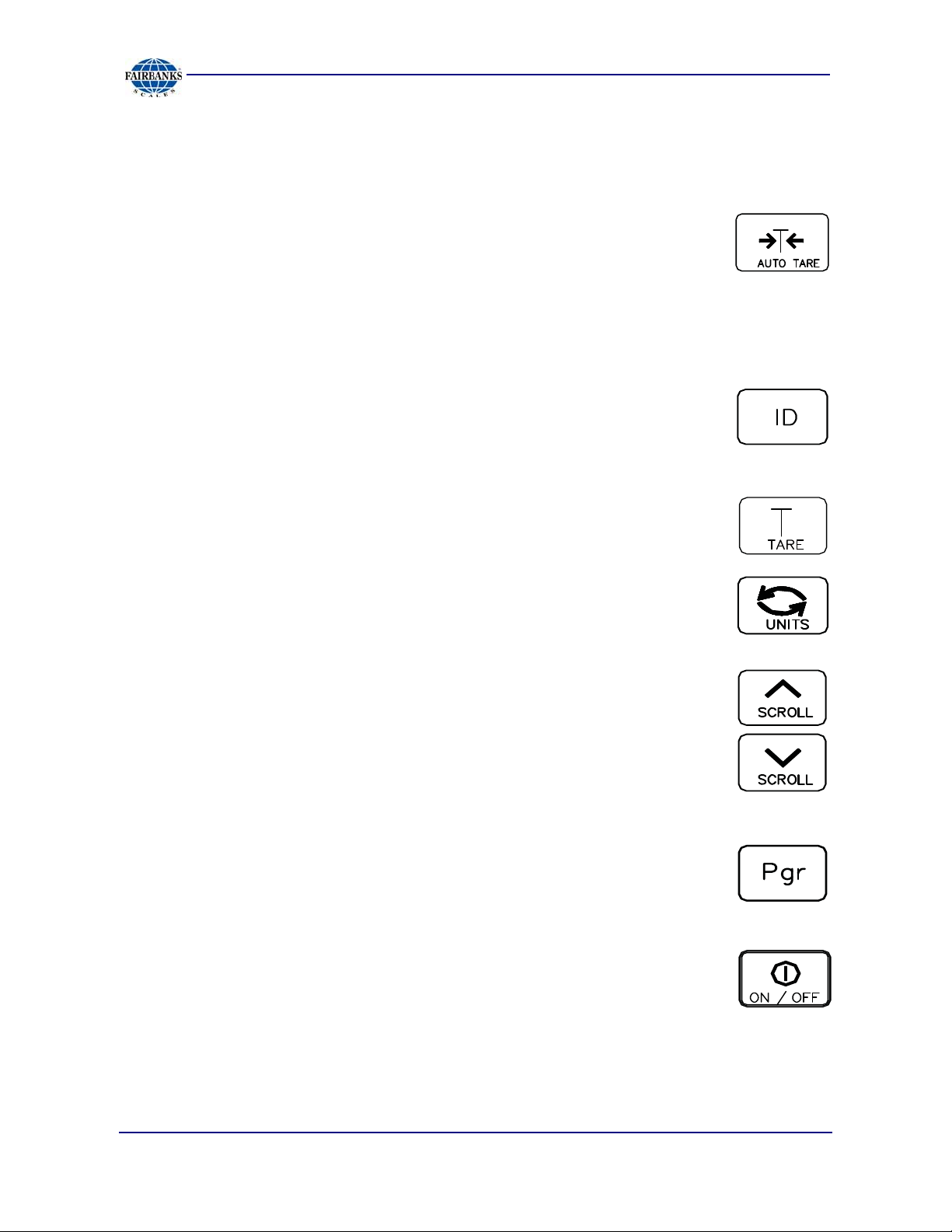

2.3. FRONT PANEL KEY FUNCTIONS, CONTINUED

AUTO TARE

In the Gross or Net mode, this key sets Tare Memory equal to the Gross

Weight on the platform.

─ The instrument displays "0" weight and enters the Net Weigh

mode.

─ The NET Legend displays.

─ Auto Tare only operates if the Gross Weight is positive.

ID KEY

Enters numeric ID for printer or computer printout.

─ A maximum of six digits is available, 0 thru 999999.

TARE KEY

Displays the currently entered Tare Value.

UNITS KEY

Toggles the displayed weight between the units selected in the

Configuration Program (i.e. lb to kg or kg to lb.)

SCROLL KEYS

Moves through the Programming Menu Tree in an UPWARD or

DOWNWARD direction.

PROGRAM KEY

Enters into the instrument's Programming mode.

ON/OFF KEY

Turns instrument ON or OFF.

If the Sleep Function is selected, this key either disables or

enables the Sleep mode.

01/12 20 50647 Rev. 9

Page 21

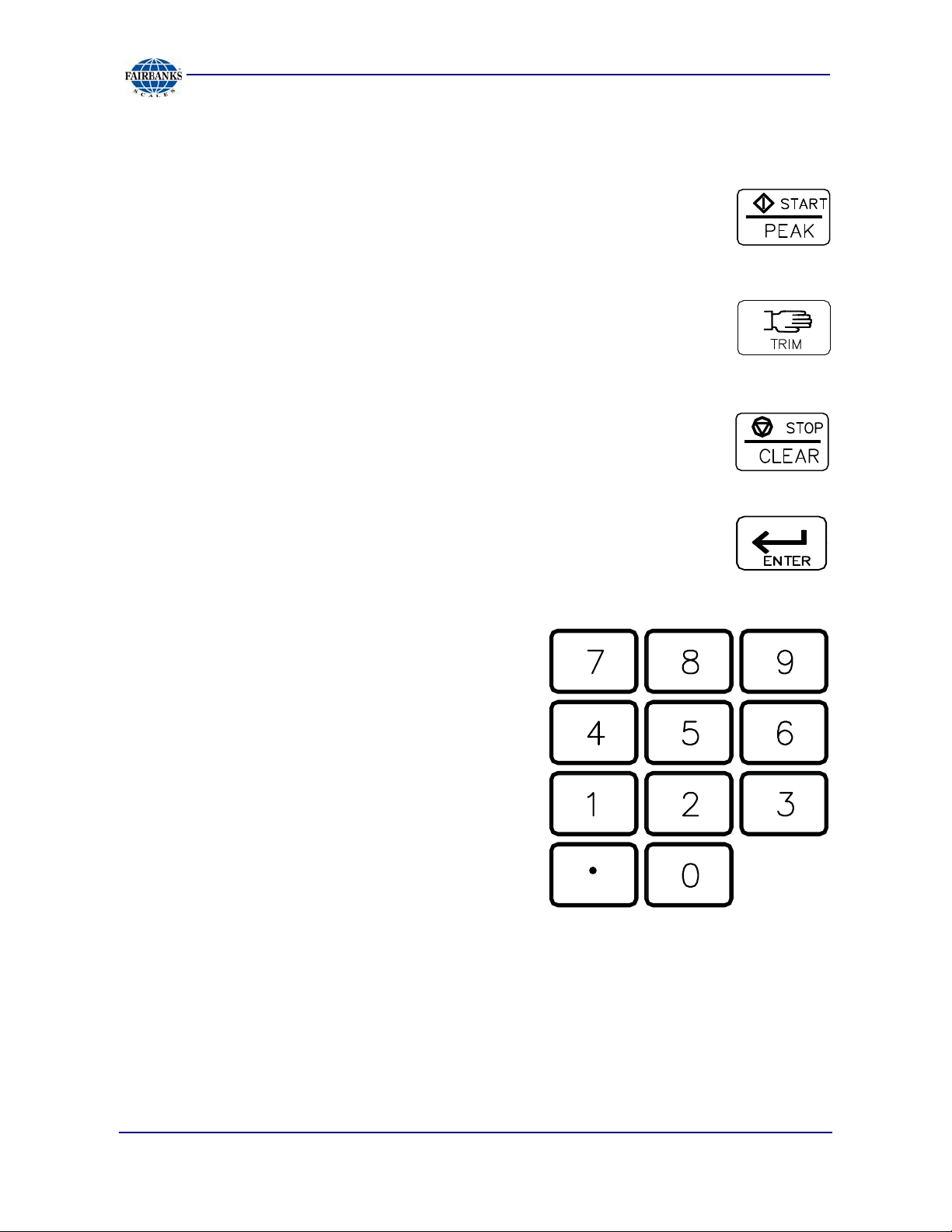

2.3. FRONT PANEL KEY FUNCTIONS, CONTINUED

START/PEAK KEY

Initiates a Setpoint Operation.

Also enables Peak Net Tracking (PNT).

TRIM KEY

Overrides the Setpoint Cycle.

Adds weight in touch-controlled increments.

STOP/CLEAR

Terminates a Setpoint Cycle.

Resets the memory of the Peak Net Capture to a null value until

a new Peak Net Weight is captured.

Section 2: Operation

ENTER

Inputs commands to the Setpoint Operation.

NUMERIC KEYS (0 THRU 9)

Used for numeric entries, such as Tare, ID,

Setpoint Values, etc.

LCD DISPLAY

Displays weight on the load receiver and applicable prompts.

01/12 21 50647 Rev. 9

Page 22

2.3. FRONT PANEL KEY FUNCTIONS, CONTINUED

Section 2: Operation

2497

2.3.1. LEGENDS

Several different legends display on the LED screen.

While most are self explanatory, the following items are defined.

CZ (Center of Zero).

RECHARGE

Battery power is low and will require recharging soon.

The RECHARGE legend displays when the input voltage from the Battery

Accessory 2830 falls below a threshold of approximately 5.4VDC when using

Accessory 2802, or 5.32VDC when using Accessory 2880.

01/12 22 50647 Rev. 9

CAUTION

Battery surfaces get very HOT during recharging.

Page 23

Section 2: Operation

2.3.1. LEGENDS, CONTINUED

LoBAtt

Battery requires immediate recharging.

The RECHARGE legend disappears and the instrument automatically shuts down

and displays LoBAtt when the voltage from the battery falls below the following:

5.3VDC when using Accessory 2802

5.12VDC with Accessory 2880.

CAUTION

Batteries which measure below 4.0 VDC must not be charged with the ACC

2840 or ACC 2841 chargers, or damage to the charger and/or battery may occur.

2.3.2. INSTRUMENT WEIGHING FUNCTIONS

Three terms which describe the distribution of an object's weight are GROSS

WEIGHT, TARE WEIGHT, and NET WEIGHT.

TARE WEIGHT

Tare weight is the weight of the incidental materials, such as its container.

NET WEIGHT

Net weight is the weight of only the primary materials.

01/12 23 50647 Rev. 9

Page 24

Section 2: Operation

2.3.2. INSTRUMENT WEIGHING FUNCTIONS

GROSS WEIGHT

Gross weight is the total weight of a weighment.

─ This includes any primary and incidental materials comprising the total

weighment.

TARE WEIGHT VALUE + NET WEIGHT VALUE = GROSS WEIGHT

A Working Example

A can of house paint is an object to be weighed. The can is the incidental material

used to hold the primary material, paint, and the label is incidental material used to

identify the paint. All the incidental materials summed together comprise the Tare

weight. All the primary materials weights summed together comprise the Net weight;

in this case pigment, base, and solvent. The object is made up of incidental

materials, can and label, and primary material, paint. Summed together, the complete

object is the Gross weight.

GROSS = NET + TARE

TARE = GROSS – NET

NET = GROSS – TARE

NET = GROSS - TARE is particularly important because it is what a scale uses

to compute net weights in the NET WEIGHING mode.

Gross Weight is a function of the total weight on the platform from the zero reference.

Tare Weight is always an operator defined value.

01/12 24 50647 Rev. 9

Page 25

Section 2: Operation

2.3.3. GROSS WEIGHING

1. Press the key to select Gross as indicated by the legend.

2. With the platform empty, press the key.

─ The display indicates ZERO.

─ The Center-of-Zero (CZ) legend appears.

3. Place the object to be weighed on the scale platform.

─ The weight of the object displays.

─ The instrument is only able to measure the weight on the platform.

─ The instrument can not tell if the weight is from the object to be weighed or

from some other objects left on the platform.

─ The operator must tell the scale when there is nothing on the platform to

weighed by pressing the key.

─ The instrument will assign whatever weight happens to be on the platform a

zero weight value.

─ Starting with an empty platform is not required.

─ The key sets the display to "0", regardless of what is on the platform.

─ Weighing in the Gross mode consists of pressing the key and

placing a weight on the platform.

─ The display shows the Gross Weight of the object.

─ The instrument understands Gross Weight as the total weight placed on the

platform after the key is pressed.

2.3.4. TARE WEIGHTS

Tare weight is operator-defined. There are two methods to input a tare weight value.

Keypad Tare Entry

Assign the tare weight value using the numeric keypad, then press the

key. The instrument will change to the Net Weighing mode, and display the Gross

Weight less the Keypad Tare weight entry.

01/12 25 50647 Rev. 9

Page 26

Section 2: Operation

2.3.4. TARE WEIGHTS, CONTINUED

Auto Tare Entry

Place the item(s) that will comprise the Tare weight onto the scale and press the

key. The instrument will Change to the Net Weighing mode, and display the Gross

Weight less the Auto-tare weight entry. The tare weight value remains unaltered in

the instruments memory until the following occurs.

1. Power is removed.

2. The key is pressed.

3. A new tare weight is entered via the keypad.

4. The Program Menu is accessed.

─ If the value of the tare weight entered using the keypad does not correspond

with an exact division size, the number is first truncated to the correct decimal

location, and then rounded to the nearest division size.

─ For example, for a division size of 0.1, an entered tare of 2.19 is truncated to

2.1. It is then rounded to a final tare of 2.1.

─ For a division size of 20 an entered tare of 511 will be truncated to 510 and

then rounded to a final tare of 520.

5. Correct entry errors by inputting "0's" until a single "0" is displayed

6. Press the key.

Net Weighing Using AUTO TARE

1. Press the key. The display will read "0" and the GROSS Legend will be

displayed.

2. Place the empty container on the platform.

3. Press the key.

─ The scale displays "0" and the NET legend is also displayed. The weight of the

container on the scale will be entered in to the instruments memory as a TARE

weight value.

01/12 26 50647 Rev. 9

Page 27

Section 2: Operation

2.3.4. TARE WEIGHTS, CONTINUED

4. Place the material to be weighed in the container. The display will show the

weight of the material that is in the container. This is the NET weight value.

NOTE:

placing an empty container that is the same weight as the product container on the

platform, and pushing before beginning weighing operations.

Net weighing of pre-packaged containers can be accomplished by first

Batching Using AUTO TARE

1. Select the GROSS Mode and place the empty container on the platform.

─ the TARE Weight of the container is displayed.

2. Push the key.

3. Fill the container with the first item until the desired weight is achieved. Instrument

display indicates the net weight of the first item (in the GROSS mode).

4. Push the key to reset the display to zero.

─ The instrument display indicates zero net weight.

5. Place the next item into the container until the desired weight is reached.

6. Repeat Steps 4 and 5 until all items have been put into the container.

7. Switch to the GROSS Mode and read the total NET weight of the batch.

8. Repeat Steps 1 through 7 for other batches.

Follow these steps to clear the operation.

1. Select the GROSS mode.

2. Remove all materials from the platform.

3. Push the key to zero the display.

4. Push the key to reset the tare memory.

5. Select the GROSS mode.

01/12 27 50647 Rev. 9

Page 28

Section 2: Operation

2.3.4. TARE WEIGHTS, CONTINUED

ENTERING ID Numbers

1. Place the instrument into the Weighing mode.

2. Press the key.

─ The current ID number or id none will be displayed.

3. Use the numeric keypad to assign an ID number.

─ A maximum of six digits, 0 through 999999.

4. Press the key to save the displayed ID number and to return the

instrument to the Weighing mode.

─ The ID number is printed as part of each print cycle if selected in the IO

Output Programming.

Peak Hold Function

The PEAK HOLD (P hoLd) function is used to determine, display, and print the

largest Net weight data achieved during a weighing cycle. A weigh cycle ends when

the Print command is given, or when the peak Net weight is manually cleared by the

CLEAR key. PEAK HOLD tracks only Net weight, and operates independently of the

display. The peak weight can either be a positive or a negative number, determined

by the absolute weight value. This means that if a positive peak is displayed, a

negative weight value of greater absolute value could update the peak information in

the same cycle.

If the P hoLd option is activated in the IO Menu, then pressing the START key

enables this function

─ It allows the viewing of the current peak net weight.

Pressing ENTER returns the display to the Weighing mode.

─ The P hoLd feature works in the Gross or Net Weighing modes.

1. Place a container on the scale.

2. Press the AUTOTARE key, or enter in a known TARE Weight.

3. Press the START/PEAK key to view the current Peak Net Weight.

4. Press the ENTER key to enable the feature and return to the Weighing mode.

5. Perform the desired number of weighment’.

01/12 28 50647 Rev. 9

Page 29

Section 2: Operation

─ At any time, the current Peak Net Weight can be viewed by pressing the

START/PEAK key.

─ Press the ENTER key to return the Weighing mode.

6. If a printer is enabled, pressing the PRINT key will have the Peak Net Weight

transmitted with the printed data.

─ A print command ends the “Peak hoLd” Weighing Cycle.

7. Press the STOP/CLEAR key to reset the current Peak Weight, and press the

START/PEAK key followed by the ENTER key to enable the feature.

01/12 29 50647 Rev. 9

Page 30

Section 3: Programming

3.1. MENU NAVIGATION

The instrument must be programmed before it can be used. The program is arranged

in a menu tree format. Once the Programming mode is entered, menu's may be

accessed in any order by following the flow charts on the following pages.

tArGEt

SEE PAGE 29

inFo

SEE PAGE 30

io

SEE PAGE 32

CAnnEd

ConFig

CAL

LEGEND : :

= CONDITIONAL PROGRAMMING MENU ITEMAbCd

2800navo

The graphic model shows the Main Menu Tree options and several levels of sub-

menu options. On the following pages, menus are displayed graphically starting with

a specific main menu option, its sub-menu's, and ending with the data within each

that can be selected and saved. Each graphic shows lines as the paths to follow

while navigating the menu.

01/12 30 50647 Rev. 9

Page 31

Section 3: Programming

3.1. MENU NAVIGATION, CONTINUED

Keys Used for Navigation

The SCROLL keys are used to navigate through menu options or data in an

UPWARD or DOWNWARD direction. Continually pressing either SCROLL key

cycles through the available options.

The ENTER key accepts and/or stores the displayed option or data entry. Press

ENTER at a menu option to access the sub-menu's and data contained in that option.

In the following flow charts, Enter is expressed as a lateral navigation key.

The B/G NET key exits most programming menu's returning to the previous menu.

Continually pressing the B/G NET key exits programming and returns to the Weight

Screen. In the following flow charts, B/G NET is expressed as a lateral navigation

key.

MAIN MENU DESCRIPTIONS

MENU ITEM DESCRIPTION

tArgEt

info

io

U CodE

(User Code)

CAnnEd

ConFig

CAL

Conditional statement that appears if the setpoints are active.

No password is required.

Allows the operator to set target weights as defined by Setpoint mode.

See page 29 further details.

No password is needed.

Displays instrument data.

Prints Audit Reports.

See page 30 for further details.

"U" Code is required,.

Sets the time and date.

Programs all I/O Ports for printers and other accessory devices.

See page 32 for further details.

Used by an operator to access the IO Menu.

Not operator accessible.

Not operator accessible.

Not operator accessible.

01/12 31 50647 Rev. 9

Page 32

3.2. TARGET MENU DESCRIPTION

This area is for the numeric entry of target

weights by the operator.

─ No sub menu selections are

available.

─ Note that the Status Display

shows the current setpoint being

programmed.

tArGEt

inFo

Section 3: Programming

xxxxxx

xxxxxx

xxxxxx

tArgEt 1

tArgEt 2

tArgEt 3

1. Use the SCROLL keys to select the

setpoint to be programmed.

2. Key in the desired target weight using

the numeric keypad including the

decimal point, if applicable.

3. Press the ENTER key.

4. When all applicable setpoints have

been programmed, press the

B/G NET key.

─ The SToRE displays.

5a. If the ENTER key is pressed, the display will indicate SToRED momentarily and

then TARGET. Pressing B/G NET again will exit to the weigh screen.

5b. If the SCROLL key is depressed, it will toggle between SToRE and CANCEL.

io

CAnnEd

ConFig

CAL

xxxxxx

xxxxxx

xxxxxx

xxxxxx

xxxxxx

tArgEt 4

tArgEt 5

tArgEt 6

tArgEt 7

tArgEt 8

─ The CANCEL prompt gives the operator the option of exiting without saving

changes.

6. Select CANCEL and press the ENTER key, the display will show TARGET.

7. Pressing the B/G NET key will exit to the weigh screen.

01/12 32 50647 Rev. 9

Page 33

Section 3: Programming

3.3. INFO MENU DESCRIPTION

The info menu is user accessible without a security code. This menu may be

checked by Weights & Measures to view the

C Audt entries, or the operator, service technician for diagnostic and

informational purposes. This menu contains the following menu selections.

tArGEt

S Audt, U Audt, or

inFo

io

CAnnEd

ConFig

CAL

CoUntS

rEPort

C SEnS

hoUr

dAtE

C AUdt

S AUdt

CELL 1

Up to

16

hrdCPY

x.xxxx

xx:xx:xx

xx.xx.xx

xxxxx C dAtE xxxxxx hrdCPY

xxxxx

S dAtE

xxxxxx

hrdCPY

U AUdt

bAtt

dEg C

01/12 33 50647 Rev. 9

xxxxx

x.xx dC

xx.x C

U dAtE

xxxxxx

hrdCPY

Page 34

3.4. MAIN MENU DESCRIPTIONS

MENU ITEM DESCRIPTION

CoUntS

dEg C

bAtt

U AUdt

S AUdt

C Audt

dAtE

hoUr

C SEnS

rEPort

hrdCPY

Formatted CELL X, where x represents the load cell currently being

displayed, the load cells are selectable using the SCROLL key.

The small display shows two numeric values.

─ The first value is the Initial Deadload or Zero Counts.

─ The second is the Current Liveload Count(s).

Formatted XX.X°C.

Displays the current internal temperature of the instrument in Centigrade.

Displays XX.XdC.

The current battery voltage.

User Audit.

Service Audit.

Calibration Audit.

Displays MM.DD.YY.

The current system date.

Displays HH.MM.SS.

The current system time.

For viewing purposes only.

Refer to the IO Section for programming.

mV/V of cell(s) currently selected.

All cells may be viewed using the SCROLL key.

For printing a configuration report to an installed printer.

A conditional statement appearing only when a printer is installed on IO Ports

A or B.

Section 3: Programming

01/12 34 50647 Rev. 9

Page 35

3.5. I/O MENU

tArGEt

inFo

io

CAnnEd

ConFig

tArGEt

Port b

dAtE

hoUr

SdELAY

xxxxxx

xx.xx.xx

xx:xx:xx

x.x

UnUSEd

SEtPoint

PoLL

PoLLid

Printr

Contin

Up to 8

entries

SEtPoint

PoLL

PoLLid

rS232

rS485

rS232

rS485

Section 3: Programming

SPhAnd

SPAUto

SPnonE

SPALrt

SPChEC

SPCont

id xxx

CAL

SLEEP

gALCon

0ShiFt

tArEoP

PhoLd

FodiSt

PrtLoC

PtroPt

4-20

ConoPt

ProtoA

Port A

Protob

x.xxhr

0-20%

Short

Long

grLooP

ntLooP

nogAL

gAL

nonE

both

tA Ent

AUto

nohoLd

hoLd

bUSYLo

buSYhi

P3550

P3921

P3960

P3950

P610

LoSEt xxxxx hiSEt xxxxx 4 AdJ xxxxx Agtest

3052r

FbStd

FbPutr

troniC

ConCon

bAUd

UnUSEd

Printr

Contin

bAUd

300

600

1200

2400

4800

9600

19200

300

600

1200

2400

4800

9600

19200

gL1

gC1

nL3

nC1

tL2

tC1

iL4

iC1

hL5

hC1

dL6

dC1

PL7

PC1

Ln15

ChAr

noALog

AnALog

ChAr

20 AdJ

7

PAritY

8

7

PAritY

8

nonE

EVEn

odd

nonE

EVEn

odd

xxxxx

01/12 35 50647 Rev. 9

Page 36

Section 3: Programming

3.5.1. I/O MENU DESCRIPTIONS

The IO (Input/Output) Menu sets up communications for sending data to devices,

such as computers, printers, or remote displays. It also contains a menu for setting

the time & date.

MENU ITEM DESCRIPTION

Port b

dAtE

Steps for Setting the Date

1. With dAtE displayed, press the ENTER key.

─ The present date in memory displays with a small legend date flashing .

2. Using the numeric keypad, enter the current date.

─ Use the MM/DD/YY (month/day/year) format.

Programs Setpoint modes, remote displays, printer, and computer outputs.

Adjusts the date.

3. Press ENTER.

─ Once complete, the display returns to the dAtE.

MENU ITEM DESCRIPTION

hoUr

Adjusts the time.

Steps for Setting the Time

─ With hoUr displayed, press the ENTER key.

─ The present time in memory displays with a small legend time flashing.

─ Using the numeric keypad, enter the current date.

─ Use the HH/MM/SS (hour/minute/second) format.

─ When entering the time of 08:35am for example, press the numeric keys

3,

5, followed by the AUTOTARE key.

─ The time 08:35A.

─ The AUTOTARE key is used to enter an A for AM.

─ The

PRINT key is used to enter P for PM.

─ For military time (24 hour format), enter the current time using the numeric

keypad and press the ENTER key.

0, 8,

01/12 36 50647 Rev. 9

Page 37

3.5.1. I/O MENU DESCRIPTIONS, CONTINUED

MENU ITEM DESCRIPTION

SdELAY

SLEEP

Activates the Sleep Delay mode in minutes and/or seconds between ingredients

in a batch file of selected setpoints if the Auto Batch mode is on.

The Sleep Delay adjusts the length of time the instrument is inactive before

going to sleep.

─ 0.00 hr or X.XX hr (hrs & min) is displayed.

─ Use the SCROLL keys to adjust as required.

─ A setting of 0.00 hr disables the Sleep Function.

Section 3: Programming

NOTE:

The Sleep mode will not activate if Recharge displays. The Sleep

mode will also not occur when in the SPAUto or SPhAnd modes if relays are

energized.

EXAMPLE

MENU ITEM DESCRIPTION

gALCon

4. In the Gross Weigh mode, note the displayed amount.

5. Press the UNITS key to toggle to the Gallons (GaL) display.

─ The number of gallons displays.

6. Press the

─ The amount displays (

7. Press any numeric key.

Weight-to-Gallons Conversion Option.

When Gallon is selected, the

gallon units.

UNITS key toggles the display from weight unit to

TARE key to adjust the number of gallons.

Gallons Factor).

─ A UCoDE window displays.

8. Enter the code using the numeric keypad.

9. Press ENTER.

─ The current date flashes in the display.

─ “Entering Gallons” also displays.

01/12 37 50647 Rev. 9

Page 38

Section 3: Programming

3.5.1. I/O MENU DESCRIPTIONS, CONTINUED

10. Press ENTER again.

─ The current gallon per weight displays.

11. Clear the display by pressing the numeric ZERO key until it is blank.

12. Key in the correct number of gallons.

13. Press

ENTER.

─ The amount of gallons displays.

14. Press the UNITS key to toggle from weight to Gallons and confirm the correct

weight to gallons ratio.

NOTE: The Tare Mode is unavailable in Gallon Conversion Mode.

MENU ITEM DESCRIPTION

0ShiFt

tArEoP

tA Ent

P hoLd

FodiSt

PrtLoC

Sets the Capacity Percentage of the Positive Weight Shift on the scale.

─ Zeros the scale before an error code (i.e. lc error) displays in the small

window display.

─ Press the

weighing.

Tare options include AUto (Using the

Using the numeric keypad, enter a known Tare Weight.

Peak Weight options are Hold and No-Hold.

─ If enabled, this holds the highest recorded NET Weight Reading.

─ Not used while in the Setpoint mode.

If a Device Output is selected, there are two fiber optic distance options.

─ 0-99 ft. = Short

─ 100+ ft. = Long

Formats all available printer locations, if a ticket printer is selected in either port.

The following prompts apply when formatting the printer.

ZERO key a second time zeros the scale and continues its

AUTOTARE key).

01/12 38 50647 Rev. 9

Page 39

Section 3: Programming

3.5.1. I/O MENU DESCRIPTIONS, CONTINUED

NOTE:

The references to Line are as seen from the top of page down, and the

Column is equal to one character space width.

PROMPT COMMENT CHOICES

bUSYh

gL 1

gC 1

nL 3

nC 1

tL 2

tC 1

iL 4

iC 1

hL 5

hC 1

6

dC 1

PL 7

PC 1

Ln 15

no Leg

Busy Line bUSYhi, bUSYLo

Gross Line

Gross Column

Net Line

Net Column

Tare Line

Tare Column

ID Line

ID Column

Hour (Time) Line

Hour (Time) Column

Date Line

Date Column

'Peak' Line (if enabled)

'Peak' Column (if enabled)

Length (Total Lines Printed)

Legend/No Legend no LEg, grtAnt

EXAMPLE

Using the basic format below, to place time and date on the same line requires the

following settings.

hL5

hC1

dL5

C15

NOTE: Peak Net Weight must be printed to a GTN format.

3.5.1. I/O MENU DESCRIPTIONS, CONTINUED

MENU ITEM DESCRIPTION

PtroPt

4-20

Selects the printer type.

─ Options include P3550, P3921, P3960, P3950, P610, P3921.

Sets the 4-20 Analog Output.

01/12 39 50647 Rev. 9

Page 40

Section 3: Programming

NOTE: The 4-20mA Output is enabled by selecting AnALog in Port A.

CAUTION

The 4-20ma accessory is a passive device!

The power is to be supplied by others, and MUST

BE

a DEDICATED and an ISOLATEDpower supply.

MENU ITEM DESCRIPTION

4-20

─

─ grLooP: Tracks the GROSS Weight.

─ ntLooP: Tracks the NET Weight.

PROM Version 6.2+ Notes

The 4-20mA output remains locked on the last reading at the time the PGR

was pressed.

An Overload (oL) condition produces a reading of 24mA.

An Underload (UL) condition produces a reading of 3.5mA.

While in the Sleep mode, the 4-20mA produces a reading of 3.5mA, and it is

not tracked until the instrument is re-activated.

01/12 40 50647 Rev. 9

Page 41

3.5.1. I/O MENU DESCRIPTIONS, CONTINUED

PROMPT COMMENT(S)

LoSEt

hiSEt

4 AdJ

20 AdJ

AgtESt

Sets the weight value associated with 4mA.

Usually "0".

1. At the LoSEt prompt, press ENTER.

2. Use the numeric keypad to enter desired weight value.

3. Press ENTER.

Associated weight value of 20MA.

Usually the capacity of the scale.

1. Press ENTER at the hiSEt prompt.

2. Use the numeric keypad to enter the desired weight value.

3. Press ENTER.

Press ENTER to display a current number representing the 4mA Output.

─ See note on key functions.

Press ENTER to display a current number representing the 20mA

Output.

─ See note on key functions.

LP4 - TO - LP22.

Press ENTER to perform an analog test.

4mA thru 22mA will be output momentarily in 2mA steps.

When adjusting either 4mA or 20mA, the following numeric keys increase

or decrease the reference value in the fashion that follows.

Increased by: Decreased by:

9 10,000 4 10,000

8 1,000 3 1,000

7 100 2 100

6 10 1 10

5 1 0 1

Section 3: Programming

ConoPt

Used for Continuous Output.

Choices include the following:

3052r FbStd FbPUtr troniC ConCon

ProtoA

Protocol setting for Port A choices include selections for the following:

bAUd 9600, 600, 1200, 2400, and 4800

ChAr 8 and 7

PAritY nonE, odd, and EuEn

01/12 41 50647 Rev. 9

Page 42

3.5.1. I/O MENU DESCRIPTIONS, CONTINUED

PROMPT COMMENT(S)

Port A

noALog, AnALog

Protob

tArgEt

Port b

Poll

Poll id

Port A has available selections of the following:

UnUSEd - no outputs

Printr - printer output

Contin - continuous output

Used to turn on or off the 4 - 20MA output.

noALog = Off

AnALog = On

Protocol setting for Port A choices include the following:

bAUd 9600, 600, 1200, 2400, and 4800

ChAr 8 and 7

PAritY nonE, odd, and EuEn

Conditional, if setpoints are selected in Port B.

1. Press

2. Enter a new Target Weight Value with the numeric keypad.

3. Press

Port b can be configured for the following:

UnUSEd - no outputs

* SEtPnt - Setpoint modes

* PoLL or PoLL id - computer output

Printr – printer

Contin - continuous output

Used for Demand Output to a computer.

When the instrument receives an upper-case "W" followed by a

carriage return ("W", "Cr") from the PC, a data stream transmits.

See Appendix VII for ASCII Chart.

Use this demand mode when a specific instrument ID is required.

Setup by entering the required ID's decimal equivalent.

See Appendix VII for ASCII Chart.

ENTER to adjust the Setpoint Target Weight Menu.

─ The large display shows the Current Target Weight Value

associated with the Target Number, as shown in the small

display.

─ The

SCROLL key toggles through available Setpoint Relays

(Targets).

ENTER to accept the new weight value and advance to the

next available target.

Section 3: Programming

01/12 42 50647 Rev. 9

Page 43

Section 3: Programming

3.5.1. I/O MENU DESCRIPTIONS, CONTINUED

EXAMPLE

The required ID is 3 (decimal equivalent is 51).

1. Press the ID key.

─ Either idnonE or the current ID shows in the large display.

2. Using the numeric keypad, enter 51.

3. Press ENTER.

─ When the PC sends ID 3, then a upper case W followed by a C carriage

return (

transmission.

3, W, Cr), the instrument with that ID responds with a data

SEtPnt

The operation of Setpoint requires that accessories 5806 (Fiber Optic Cable)

and 2850 (Safe Area Relay Box) be installed. There are five modes of setpoint

operation that may be selected from during the installation and programming by your

local Fairbanks Service Center or Authorized Factory trained Distributor.

SEtPnt Modes

PROMPT CHOICE(S)

SPCont

SPChEC

SPALrt

SPAUto

SPhAnd

Continuous operation of setpoints, ON at entered target weight.

MUST press START to begin function.

Check weighing, such as UNDER/ACCEPT/OVER, with setpoint

Relays 1 and 2 active for alarms.

Setpoint Relay 8 is active, used as both LOW and HIGH alarms in

SoLo mode.

Or Relays 4 and 8 if in Paired mode.

Automatic batching, a range of materials can be added one at a time to

complete a batch.

SPAUto will not function when in the Gallons mode.

When configuring SdELAY, to perform the delay in minutes and

seconds between ingredients, the setting is located in the main I/O

Menu.

This operation requires a manual START at each setpoint.

01/12 43 50647 Rev. 9

Page 44

3.5.1. I/O MENU DESCRIPTIONS, CONTINUED

TARGET MENU

PROMPT CHOICE(S)

tArgEt

Used for programming weight values associated with setpoint-relays.

Target 1 = relay 1 and Target 2 = relay 2, through rest of programmed

setpoints.

The number of targets will vary depending on number selected during

initial setup. Modifications should be performed with caution.

The Setpoint mode determines the target function, and targets should

be programmed accordingly.

SEtPnt MODE

Target Assignment

PROMPT CHOICE(S)

SPCont

SPChEC

Target 1 thru X (where X is the total number of setpoints) are the

programmed number of setpoint relays.

Single-value relays that energize when their assigned weight value is

reached or exceeded.

These relays, as a group, are manually controlled by the START and

STOP front panel keys.

No Autoprint available in this mode.

In the Check Weigh mode, Target 1 is the UNDER range setpoint-

Relay 1.

It is on-active if the weight is equal to or below its assigned weight

value.

Target 2 is the OVER range setpoint-Relay 2.

It is Active when the weight is equal to or above its assigned weight

value.

The ACCEPT range is the weight between UNDER and OVER.

It is selected to operate either the Gross or Net modes.

Section 3: Programming

NOTE:

The legends for UNDER, ACCEPT, and OVER show on the large display

when its associated weight value is active.

There is not a relay output for the ACCEPT range.

When using the

absolute value displayed (+/-) in the Gross mode and to the positive value

displayed in the

01/12 44 50647 Rev. 9

SPCont or SPChEC modes the relays respond to the

Net mode.

Page 45

Section 3: Programming

3.5.1. I/O MENU DESCRIPTIONS, CONTINUED

PROMPT CHOICE(S)

SPALrt

─ The following applies to either of the Setpoint Batch modes, whenever the

weight on the scale is below or above the Alert Value, and the Alert is

enabled. The alert relay(s) toggle On/Off when the following occurs.

The front panel keys are pressed.

The instrument comes out of its Sleep mode.

Used for ALARM purposes.

In the SoLo mode only Relay 8 is used, for both the LOW and HIGH

alarm.

In the paired mode, Relays 4 and 8 are used.

The setpoint-relay will be active when the GROSS weight is equal to or

below the programmed LOW ALARM weight value or equal to or

above the programmed HIGH ALARM weight value.

The SPALrt targets are only programmable in the IO Port B Menu.

The SPALrt may be used with all other setpoint modes except whenever

four (4) paired setpoints are programmed.

If SPALrt is enables in conjunction with any other setpoint option, the

instrument prompts for Alarm low wgt, causing an Alarm high wgt.

Alarm IO must be set to a value other than zero.

01/12 45 50647 Rev. 9

Page 46

3.5.1. I/O MENU DESCRIPTIONS, CONTINUED

PROMPT CHOICE(S)

SPAUto

A Batching mode, allowing the operator to press the START key once to

add multiple materials automatically

─ It allows SoLo (single setpoint-relay) or PAIRED (dual setpoint-

relays) setpoint(s).

─ In the SoLo mode. Targets 1 thru X represent the required

weight of each individual material.

─ In the PAIRED mode, Targets 1 thru 4 represent the Bulk or

Fast-Fill Relays

─ Targets 5 through 8 are the slow or target.

─ Note the association of paired setpoints-relay:

1-5 2-6 3-7 4-8

Always program the Bulk-Fast Fill Setpoint-Relays to a lesser weight

value than the complete material weight value

─ Configure the Target-Slow Fill Setpoint-Relays assigned to the

complete material weight value.

─ When using multiple materials, set the SdELAY (timer for start of

next material relays) in the IO Menu.

─ If a printer has been selected, an auto print occurs when target

value is reached.

─ SPAUto is not available in the gallons mode.

SPAUto EXAMPLE

Below is an example of a simple, two (2) material batch with PAIRED

relays.

FUNCTION TARGET NUMBER

─ Material 1 bulk - fast fill

relay (1)

─ Material 2 bulk - fast fill

relay (2

─ Not used ─ 3

─ Not used ─ 4

─ Material 1 target - slow fill

relay (5)

─ Material 2 target - slow fill

relay (6)

─

Section 3: Programming

─ 1

─ 2

─ 5

─ 6

01/12 46 50647 Rev. 9

Page 47

3.5.1. I/O MENU DESCRIPTIONS, CONTINUED

PROMPT CHOICE(S)

SPhAnd

SPhAnd SPALrt

EXITING MENUS

The Manual mode of a batching process.

─ Each separate material is operator-selected by using the

SCROLL key, and then pressing START.

─ This sequence must be continued until the batch is complete.

─ If a printer is selected, an auto print occurs when target value is

reached.

─ Further detailed programming includes the following in order to

define this modes operation.

Gross (groSS) Net (nEt) Single relays (SoLo)

Dual relays (PAirEd) Upweighing (UP)

Downweighing (not UP)

Down weighing is a net mode function and requires an

─ initial weight of zero. The instrument must have an auto tare

performed prior to beginning the setpoint operation.

─ SPhAnd is not available in the Gallons mode.

Used for ALARM purposes.

Only setpoint-relay (8) is used for both the LOW and HIGH alarms.

The setpoint-relay actives when the GROSS weight is equal to or

below the programmed LOW ALARM weight value, or equal to or

above the programmed HIGH ALARM weight value.

Set the LAST to the following value, if Paired is selected:

PAIRED LAST

1 5

2 6

3 7

4 8

Relays (4) and (8) are conditional on selection of the SPALrt feature.

When exiting the TARGET or IO menus, either store or canceling the

changes.

─ When prompted to SToRE, press ENTER to save the changes.

─ The display momentarily reads SToRED, and then returns to the

root menu prompt.

─ With SToRE displayed, press the SCROLL key to select the

CANCEL option

─ Press ENTER and no changes are saved.

Section 3: Programming

01/12 47 50647 Rev. 9

Page 48

Section 4: Security

4.1. SECURITY CODES

PROMPT CHOICE(S)

UCodE

DISPLAYED PROMPTS REQUIRED ACTIONS

UCodE

P

PU

PUC

PUCi

PUCin

PUCini

noSEAL

nUPASS

CLrFin

XX.XX.XX

User Code

Provides access for the operator /supervisor to the user programmable options.

USE CAUTION when making changes to the system.

1. Press the

2. Press the UNITS key.

3. Press the

4. Press the ID key.

5. Press the hidden key (between) ID and TARE.

6. Press the ID key.

7. Press the

8. Use the SCROLL key to choose either noSEAL.

(noncommercial) or SEAL (commercial) set, depending on

the

local jurisdiction.

9. Press the ENTER key.

10. Using the numeric keypad, enter the new user code.

11. Press the

12. Use the SCROLL key to choose either CLrFin

(password

needed upon menu re-entry) and CLrPon (password

needed

after power-up).

13. Current date. If correct, proceed by pressing the

key, or enter correct date using the numeric keypad.

PRINT key.

Pgr key.

ENTER key.

ENTER key.

ENTER

Follow these steps to create or change a

UCodE.

Follow the standard exiting procedures as noted in the Menu Navigation section

of this manual.

01/12 48 50647 Rev. 9

Page 49

Appendix I: Troubleshooting/Error Codes

FAULT CAUSE SOLUTION

-UL-- LOADCELL FAILURE

--oL-- LOADCELL

FAILURE

RECHARGE

LoBAtt

err 069

likely lc error

Scale restricted.

Debris under scale.

Scale behind 0.

Load Cell failure.

Overloaded Scale.

Load Cell failure.

Battery voltage low

between 5.4 to 5.32VDC.

Battery voltage low, between

5.3 to 5.12VDC

Programming input error.

0shift out of range

Load Cell Failure.

Correct the bind or restriction.

Remove debris under the

scale/cells.

Replace items removed from

the scale.

Call Fairbanks service.

Remove weight from the scale.

Call Fairbanks service.

Recharge the battery.

Recharge the battery

IMMEDIATELY.

Recycle the power to

instrument.

Remove weight from the scale.

Re-zero the scale.

Call Fairbanks service.

01/12 49 50647 Rev. 9

Page 50

Appendix II: FM Control Drawings

MJQ06-26-04

APP

06-14-01

01-17-01

1

----------- REVISIONS -----------

Rev Sheets 4 and 8

1

2

REV DESCRIPTION DATE

GAL6-9-09

07-02-03 MJQ

07-04-01

Rev Sheets 4 and 8

3

2-2-11 GAL

REV SHEETS 4 & 8 PER ECO 13552

ADDED SHEETS 11 & 12 PER ECO 14036

REV SHEETS 9 & 10 PER ECO 14187

Add Sheets 9 & 10 per ECO 13469

4

5

6

7

It(Io) = 190 ma

Vt(Vo) = 7.02v

FOR TB3, TB4, TB5 or TB6:

ENTITY OUTPUT PARAMETERS

Po = 0.38 w

La(Lo) GP A,B 2.3 mH

Ca(Co) GP A,B 14 uF

Ca(Co) GP C,E 42 uF

Ca(Co) GP D,F,G 84 uF

La(Lo) GP C,E 9.2 mH

TO TRANSDUCERS

La(Lo) GP D,F,G 18.4 mH

HAZARDOUS AREAS:

CL I, DIV 1 & 2, GP A, B, C & D

CL II, DIV 1 & 2, GP E, F & G

CL III

1 12Tuesday, July 03, 2001

21943

CONTROL/INSTALLATION DRAWING FOR 2800 INDICATOR

FAIRBANKS SCALES

2176 PORTLAND ST.

B

SUITE 1

ST,JOHNSBURY VT. 05819

Title

Size Document Number

Date: Sheet of

1

CL I Zones 0, 1, 2 GP IIC, IIB, IIA

2

FM approval) or CSA certified (for installations requiring CSA approval) for the

hazardous locations where they are installed and have appropriate

or between ACC-2802s shall not exceed wire size 16AWG.

and ANSI/ISA-RP12.6 "Installation of Intrinsically Safe Instrument Systems

in Class I Hazardous (Classified) Locations."

1. Installation shall be in accordance with the National Electrical Code(ANSI/NFPA 70)

2. Size of wires in cable between ACC-2825 and 2800 or between 2800 and ACC-2802

3. Strain gage based transducers must be FM approved (for installations requiring

NOTES:

entity parameters.

5. SEE SHEET 6 FOR 2800 GLAND SEAL LOCATIONS AND CABLE FUNCTIONS.

4. ALL UNUSED GLAND SEALS ARE PLUGGED.

B B

GLAND SEAL

TB3

ACC-2802

SECTIONAL CONTROLLER

PCB ASSY 18720

(PN 21234)

2800 INDICATOR

GLAND SEAL

TB2

PCB ASSY 18725

TB4

PCB ASSY 18468

GLAND SEAL

TB5

JP1

GLAND SEALS

GLAND SEAL

GLAND SEAL

TB6

16 AWG CABLE

20 FEET MAXIMUM

TB1 TB1

TB2

GS5

GS4

(SEE SHEET 5)

BATTERY PACK

PN 20615

ACC-2830

GLAND SEAL

A A

GROUPS A, B, C, D, E, F & G

GROUPS IIC, IIB & IIA

NO CHANGE MAY BE MADE TO THIS DRAWING OR RELATED

COMPONENTS WITHOUT PRIOR WRITTEN APPROVAL OF FACTORY MUTUAL!!!!

2

01/12 50 50647 Rev. 9

Page 51

Appendix II: FM Control Drawings

GAL

GAL

MJQ

APP

6-9-09

07-02-03

01-17-01

1

----------- REVISIONS -----------

REV DESCRIPTION DATE

ADDED SHEETS 11 & 12 PER ECO 14036

REV PER ECO 13469

1

6

4

GLAND SEAL

TB3

CONTROLLER

SECTIONAL

PCB ASSY 18720

ACC-2802

2-2-11

REV SHEETS 9 & 10 PER ECO 14187

7

GLAND SEAL

TB2

GROUPS C, D, E, F & G

GROUPS IIB & IIA

TO TRANSDUCERS

GLAND SEAL

GLAND SEAL

TB5

TB4

PCB ASSY 18468

TB6

JP1

TB1

GLAND SEAL

GLAND SEAL

TB3

CONTROLLER

PCB ASSY 18720

SECTIONAL

TB2

ACC-2802

Vt(Vo) = 7.02v

FOR TB3, TB4, TB5 or TB6:

ENTITY OUTPUT PARAMETERS

GLAND SEAL

GLAND SEAL

TB4

TB5

JP1

PCB ASSY 18468

It(Io) = 190 ma

Po = 0.38 w

TO TRANSDUCERS

TB6

SECTIONAL CONTROLLER

ACC-2802

TB1

Ca(Co) GP D,F,G 84 uF

Ca(Co) GP C,E 42 uF

La(Lo) GP C,E 9.2 mH

GLAND SEAL

GLAND SEAL

TB3

PCB ASSY 18720

TB2

La(Lo) GP D,F,G 18.4 mH

HAZARDOUS AREAS:

GLAND SEAL

TB4

TB5

JP1

PCB ASSY 18468

CL I, DIV 1 & 2, GP C & D

TO TRANSDUCERS

GLAND SEAL

TB6

TB1

CL II, DIV 1 & 2, GP E, F & G

CL III

CL I Zones 0, 1, 2 GP IIB & IIA

GLAND SEAL

GLAND SEAL

TB3

SECTIONAL CONTROLLER

PCB ASSY 18720

TB2

ACC-2802

SUITE 1

FAIRBANKS SCALES

GLAND SEAL

TB4

PCB ASSY 18468

2176 PORTLAND ST.

TB5

JP1

ST,JOHNSBURY VT. 05819

Title

GLAND SEAL

21943

CONTROL/INSTALLATION DRAWING FOR 2800 INDICATOR

B

Size Document Number Rev

TO TRANSDUCERS

TB6

TB1

2Tuesday, July 03, 2001

Date: Sheet

1

(SEE SHEET 5)

GLAND SEALS

2

16 AWG CABLE

50 FEET MAXIMUM

GLAND SEAL

TB1

GS5

TB2

BATTERY PACK

ACC-2830

GS4

PN 20615

GLAND SEAL

2

NO CHANGE MAY BE MADE TO THIS DRAWING OR RELATED

COMPONENTS WITHOUT PRIOR WRITTEN APPROVAL OF FACTORY MUTUAL!!!!

UP TO 4 ACC-2802s

PLUG SEAL FOR TB2 ON LAST ACC-2802

GLAND SEALS

B B

31 FEET MAXIMUM

16 AWG CABLE

GLAND SEALS

16 AWG CABLE

31 FEET MAXIMUM

GLAND SEALS

2800 INDICATOR

(PN 21234)

PCB ASSY 18725

A A

16 AWG CABLE

31 FEET MAXIMUM

01/12 51 50647 Rev. 9

Page 52

Appendix II: FM Control Drawings

GAL6-9-09

GAL2-2-11

MJQ07-02-03

APP

3Tuesday, July 03, 2001

01-17-01

1

----------- REVISIONS -----------

REV PER ECO 13469

ADDED SHEETS 11 & 12 PER ECO 14036

REV SHEETS 9 & 10 PER ECO 14187

1

6

7

4

REV DESCRIPTION DATE

GLAND SEAL

TB3

CONTROLLER

SECTIONAL

PCB ASSY 18720

TB2

ACC-2802

uF

21943

CONTROL/INSTALLATION DRAWING FOR 2800 INDICATOR

B

SUITE 1

ST,JOHNSBURY VT. 05819

FAIRBANKS SCALES

2176 PORTLAND ST.

Title

Size Document Number Rev

Date: Sheet

1

GROUPS C, D, E, F & G

GROUPS IIB & IIA

TO TRANSDUCERS

GLAND SEAL

GLAND SEAL

GLAND SEAL

GLAND SEAL

GLAND SEAL

It(Io) = 213 ma

FOR TB3, TB4, TB5 or TB6:

ENTITY OUTPUT PARAMETERS

Vt(Vo) = 7.875v

TO TRANSDUCERS

GLAND SEAL

GLAND SEAL

Po = 0.42 w

Ca(Co) GP C,E 5.6

Ca(Co) GP D,F,G 19 uF

La(Lo) GP C,E 2.4 mH

GLAND SEAL

GLAND SEAL

La(Lo) GP D,F,G 7.64 mH

HAZARDOUS AREAS:

GLAND SEAL

GLAND SEAL

CL II, DIV 1 & 2, GP E, F & G

CL I, DIV 1 & 2, GP C & D

TO TRANSDUCERS

CL III

CL I Zones 0, 1, 2 GP IIB & IIA

TO TRANSDUCERS

GLAND SEAL

GLAND SEAL

GLAND SEAL

GLAND SEAL

(SEE SHEET 5)

TB5

PCB ASSY 18468

TB6

JP1

TB1

TB3

SECTIONAL CONTROLLER

PCB ASSY 18720

TB2

ACC-2802

TB4

TB5

PCB ASSY 18468

TB6

JP1

TB1

TB3

SECTIONAL CONTROLLER

PCB ASSY 18720

ACC-2802

TB2

TB4

TB5

TB6

JP1

PCB ASSY 18468

TB1

TB5

TB4

PCB ASSY 18468

TB6

JP1

TB1

TB3

CONTROLLER

PCB ASSY 18720

SECTIONAL

TB2

ACC-2802

TB4

31 FEET MAXIMUM

GLAND SEAL

GLAND SEALS

16 AWG CABLE

50 FEET MAXIMUM

GS5

TB1

2

GLAND SEAL

UP TO 4 ACC-2802s

2

PLUG SEAL FOR TB2 ON LAST ACC-2802

GLAND SEALS

16 AWG CABLE

PN 18448

PCB ASSY 18414

ACC-2825

(SAFE AREA INTERFACE)

31 FEET MAXIMUM

TB3

TB1

GLAND SEALS

TB2

16 AWG CABLE

31 FEET MAXIMUM

SAFE AREA

GLAND SEAL

GLAND SEALS

16 AWG CABLE

HAZARDOUS AREA

(PN 21234)

PCB ASSY 18725

2800 INDICATOR

CONTROL

CERTIFIED EQUIPMENT.

REQUIREMENTS MUST USE CSA

CONNECTING EQUIPMENT MUST NOT

GENERATE OR BE CONNECTED TO

EQUIPMENT GENERATING MORE THAN

250 VOLTS.

INSTALLATIONS CONFORMING TO CSA

EQUIPMENT

TO COMPUTER

OR PROCESS

B B

120/240VAC

16 AWG CABLE

200 FEET MAXIMUM

A A

TB2

GS6

COMPONENTS WITHOUT PRIOR WRITTEN APPROVAL OF FACTORY MUTUAL!!!!

NO CHANGE MAY BE MADE TO THIS DRAWING OR RELATED

01/12 52 50647 Rev. 9

Page 53

Appendix II: FM Control Drawings

GAL6-9-09

APP

MJQ07-02-03

1

----------- REVISIONS -----------

1 01-17-01

REV DESCRIPTION DATE

2

06-14-012

22075 changed to 21912

REV PER ECO 13469

Added Sum Jct Box 67171

3 07-04-01

4

06-26-04 MJQ

REV PER ECO 13552

ADDED SHEETS 11 & 12 PER ECO 14036

5

6

2-2-11 GAL

REV SHEETS 9 & 10 PER ECO 14187

7

EXC+

SIG+ SIG-

CABLE

TRANSDUCER TRANSDUCER TRANSDUCER

TRANSDUCER

4Tuesday, July 03, 2001

EXC-

TYPICAL TRANSDUCER

FAIRBANKS SCALES

SUITE 1

Ca(Co) GP D,F,G 84 uF

Ca(Co) GP C,E 42 uF

It(Io) = 250 ma

Vt(Vo) = 7.02v

FOR TB1 ACC-2880:

75 FT MAX

ENTITY OUTPUT PARAMETERS

Po = 0.88 w

La(Lo) GP A,B 2.3 mH

Ca(Co) GP A,B 14 uF

La(Lo) GP D,F,G 18.4 mH

La(Lo) GP C,E 9.2 mH

HAZARDOUS AREAS:

CL III

CL II, DIV 1 & 2, GP E, F & G

CL I, DIV 1 & 2, GP A, B, C & D

CL I Zones 0, 1, 2 GP IIC, IIB, IIA

21943

CONTROL/INSTALLATION DRAWING FOR 2800 INDICATOR

2176 PORTLAND ST.

B

ST,JOHNSBURY VT. 05819

Title

Size Document Number Rev

Date: Sheet

1

TB1

TB4

TB2

TB3

PN 21912

TB1

TB4

TB3

TB3

TB1

PN 21912 PN 21912

TB2

TB2

TB4

TB2

TB1

OR

P/N 67171

TB3

P/N 67171M

TB5

TB4

WITH SUITABLE PARAMETERS

FM APPROVED/CSA CERTIFIED

STRAIN GAGE BASED TRANSDUCERS

FOR CLASS, ZONE/DIVISION AND GROUP.

TRANSDUCER TRANSDUCER TRANSDUCER

TRANSDUCER TRANSDUCER

18AWG MAX 18AWG MAX 18AWG MAX

TRANSDUCER TRANSDUCER

TB1

TB4

TB2

TB3

PN 21912

TRANSDUCER

OR

OR

18 AWG MAX

100 FT MAX

2

18 AWG MAX

NOTES:

100 FT MAX

(PN 21234)

& ACC-2880

2800 INDICATOR

1. ALL UNUSED GLAND SEALS ARE PLUGGED.

3. TWO TRANSDUCERS MAY PARALLELED REDUCING THE NUMBER OF PN 21912 BY HALF.

2. MAXIMUM TRANSDUCER CABLE LENGTH/WIRE GAGE 75 FT/20AWG.

PCB ASSY 18725

B B

GLAND

PCB ASSY 19797

GS3

SEAL

TB1

GLAND SEAL

BATTERY PACK

PN 20615

ACC-2830

NO CHANGE MAY BE MADE TO THIS DRAWING OR RELATED

GROUPS A, B, C, D, E, F & G

GROUPS IIC, IIB & IIA

A A

COMPONENTS WITHOUT PRIOR WRITTEN APPROVAL OF FACTORY MUTUAL!!!!

JP1

ACC-2880

(ANALOG INTERFACE)

GS4

TB2

01/12 53 50647 Rev. 9

Page 54

Appendix II: FM Control Drawings

GAL

MJQ07-02-03

GAL

APP

1

----------- REVISIONS -----------

REV DESCRIPTION DATE

REV PER ECO 13469

1 01-17-01

4

6-9-09

2-2-11

ADDED SHEETS 11 & 12 PER ECO 14036

REV SHEETS 9 & 10 PER ECO 14187

6

7

5Tuesday, July 03, 2001

21943

CONTROL/INSTALLATION DRAWING FOR 2800 INDICATOR

FAIRBANKS SCALES

2176 PORTLAND ST.

B

SUITE 1

ST,JOHNSBURY VT. 05819

Title

Size Document Number Rev

Date: Sheet

Ca(Co) GP D,F,G 84 uF

Ca(Co) GP C,E 42 uF

La(Lo) GP D,F,G 18.4 mH

FOR TB1 ACC-2880:

ENTITY OUTPUT PARAMETERS

It(Io) = 213 ma

Vt(Vo) = 7.875v

SIG-SIG+

EXC-

EXC+

SIG+ SIG-

EXC+

GLAND SEAL

Po = 0.42 w

EXC-

La(Lo) GP C,E 9.2 mH

HAZARDOUS AREAS:

CL II, DIV 1 & 2, GP E, F & G

CL I, DIV 1 & 2, GP C & D

SIG-SIG+

EXC+

EXC-

GLAND SEAL

CL III

CL I Zones 0, 1, 2 GP IIB, IIA

SIG-

EXC-

EXC+

SIG+

WITH SUITABLE PARAMETERS

FM APPROVRD/CSA CERTIFIED

STRAIN GAGE BASED TRANSDUCERS

FOR CLASS, ZONE/DIVISION AND GROUP.

1

OPTIONAL SUMMING/JUNCTION BOX

POWER DISSIPATING COMPONENTS)

(CONTAINS NO ENERGY STORING OR

GLAND SEAL

NO CHANGE MAY BE MADE TO THIS DRAWING OR RELATED

NOTES:

1. ALL UNUSED GLAND SEALS ARE PLUGGED.

2. MAXIMUM TRANSDUCER CABLE LENGTH/WIRE GAGE 75 FT/20AWG.

2

SAFE AREA

PN 18448

ACC-2825

(SAFE AREA INTERFACE)

PCB ASSY 18414

TB3

TB2

TB1

GLAND SEAL

(PN 21234)

& ACC-2880

PCB ASSY 18725

PCB ASSY 19797

(ANALOG INTERFACE)

2800 INDICATOR

16 AWG CABLE

CONTROL

CONNECTING EQUIPMENT MUST NOT

GENERATE OR BE CONNECTED TO

EQUIPMENT GENERATING MORE THAN

250 VOLTS.

TO COMPUTER

OR PROCESS

EQUIPMENT

120/240VAC

B B

200 FEET MAXIMUM

GROUPS C, D, E, F & G

50 FEET MAX/18AWG MAX

TB1

GROUPS IIB & IIA

GS3

JP1

ACC-2880

TB2

A A

COMPONENTS WITHOUT PRIOR WRITTEN APPROVAL OF FACTORY MUTUAL!!!!

2

GS6

GLAND SEAL

01/12 54 50647 Rev. 9

Page 55

Appendix II: FM Control Drawings

APP

GAL6-9-09

GAL2-2-11

MJQ07-02-03

6Tuesday, July 03, 2001

21943

1

----------- REVISIONS -----------

REV PER ECO 13469

ADDED SHEETS 11 & 12 PER ECO 14036

REV SHEETS 9 & 10 PER ECO 14187

1 01-17-01

4

6

REV DESCRIPTION DATE

7

ENCLOSURE

U17

PCB ASSEMBLY 18725

U16

SMALL DISPLAY WINDOW

BIG DISPLAY WINDOW

PCB ASSY 19797

KEYPAD/OVERLAY

CONTROL/INSTALLATION DRAWING FOR 2800 INDICATOR

B

SUITE 1

ST,JOHNSBURY VT. 05819

FAIRBANKS SCALES

2176 PORTLAND ST.

Title

Size Document Number Rev

Date: Sheet

1