Page 1

NUPI 66

Oil-hydraulic actuator for double swinging gates

Diameter øStroke 800 mm

Instructions manual

pages 9-16

9

Page 2

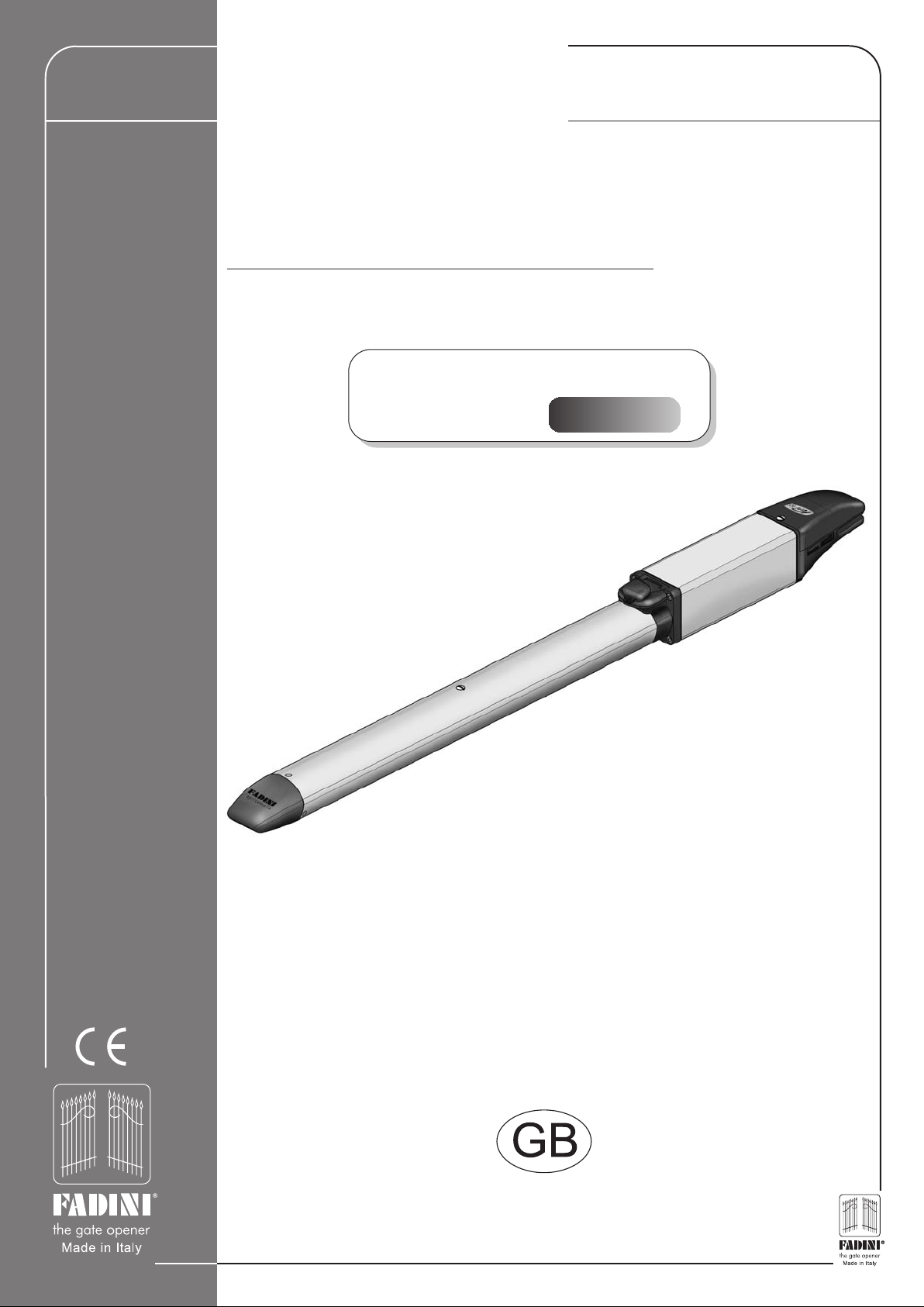

NUPI 66

FITTING INSTRUCTIONS

Important: Keep to the instructions outlined in the pages and diagrams that follow to achieve a perfect installation.

NUPI 66 is an oil-hydraulic actuator locking in the closed gate position to operate gates that are not wider than 2.0 m. Fìxing to the gate

and gate post is by specially designed brackets. Peculiar with this operator is the absence of the high/low pressure valves, power is set

and controlled by the electronic control box ELPRO 7 RP (See the description as from page 12, Elpro 7 RP wiring diagram).

RELEASE

KEY

END COVER

HEXAGONAL

HEAD PIN

12.5 μF CAPACITOR

REAR PLATE

WITH HOLES

FOR FIXING

ADJUSTMENT

REAR BRACKET

BLOCK

English

FITTING NUPI 66

PIC. 1

This explains how to remove the operator cover and fix the

actuator. The first operation is to unlock the operator: push the

lock flap to one side, insert the key and turn it 90° clockwise. The

locking barrel can be tilted open and the operator is now released

(pic. 2). Unscrew the two screws that fix the operator cover and

remove it. Unscrew the screw that fixes the rear end cover and

remove it. The actuator is so ready for fixing operations.

RELEASE

DEVICE

RELEASE

FLAP COVER

FASTENER

COVER WITH

CAP

FIXING PIN

FRONT

FIXING

BENZING

RING

TERMINALSCABLE

RELEASE VALVE

BLOCK

CLOSED

CYLINDER

HEAD

UNLOCKED GATELOCKED GATE

PISTON

SHAFT

OPEN

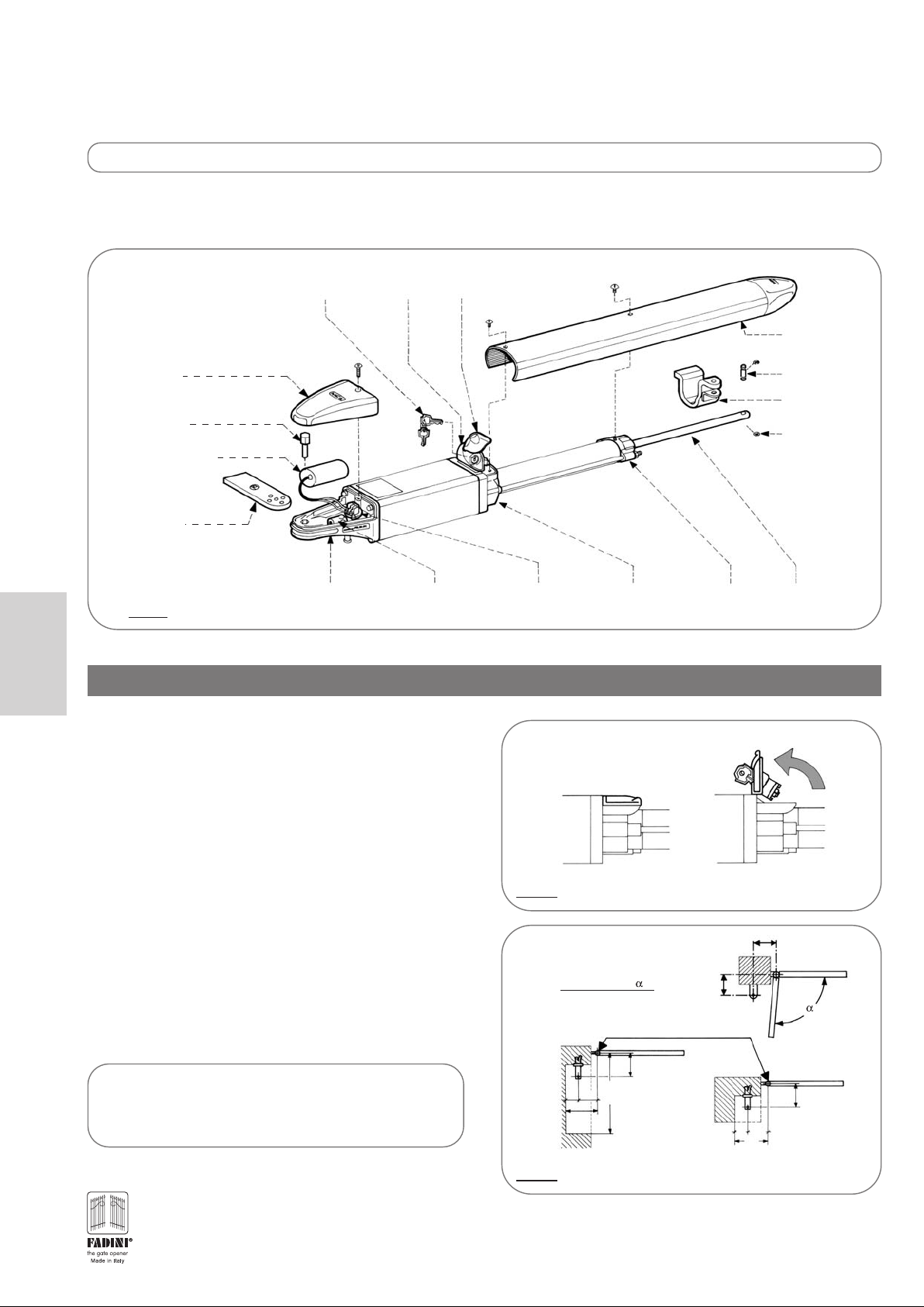

• Special fitting

There can be cases where special fitting requirements are needed

to meet (gate hinges on the post edge line, brickwork to be

indented, special opening,...). NUPI 66 is supplied complete with

an adjustable rear fixing pIate: a pattern of fixing holes makes

the rear fixing extremely versatile to suit any gate. Refer to the

diagram on the right for fixing geometry (pic. 3).

ELECTRIC LOCK

An electric lock is recommended in installations where

each gate leaf exceeds 1.8 meters and is subjected to high

winds or are close boarded gates.

10

PIC. 2

GATE POST 150x150mm

AB

130 130 95°

130 120 100°

70 130

PIC. 3

RELEASING SYSTEM. DETAILS.

GATE MOVEMENT CENTRES

CLOSED

130

GATE

1˙210

200

A

B

CLOSED GATE

130

70 130

200

Page 3

IMPORTANT: It is important to temporarily fix the operator rear casting using the center hole in the fixing plate and, once the installation

is completed, move the rear fixing to the inner hole.

IMPORTANT: it is necessary to firmly fix the gate stops to the ground in the open and closed gate positions (See pic. 5 on page 11 and

pic. 7 on page 12, parts 5 and 15) before installing the operator.

- A reinforcement plate (pic. 6) is recommended for the rear fixing, either to be embedded in the gate post, anchoring plates to be welded

to improve holding, or bolted to it so that the operator rear fixing can be welded to it in full respect of the geometry indicated below. See

distances A and B in pic.5 (distances are strictly referred to the center lines of the gate hinge and operator rear fixing)

Pierced

fixing plate

Reinforcement plate

Temporary installation axis to coincide

with center hole

Final installation axis to coincide with

inner hole

=130

B

Rear casting

Ground stop in

open gate

position

A=130

Closed gate

Ground stop in

closed gate position

260

=80

D

95°

PIC. 4 PIC. 5

- By means of a spirit level, make sure that the fixing plates are perfectly levelled, respect distance D for the front fixing, the gate in closed

position, ie. operator shaft driven 260 mm out.

A=130B=130

English

Spirit level

Never weld the front fixing

Spirit level

This distance to allow

1cm clearance between the cover

and the gate in open position

D=80

bracket directly to the gate. Use

a reinforcement plate. Remove

the operator before welding

Spirit level

PIC. 6

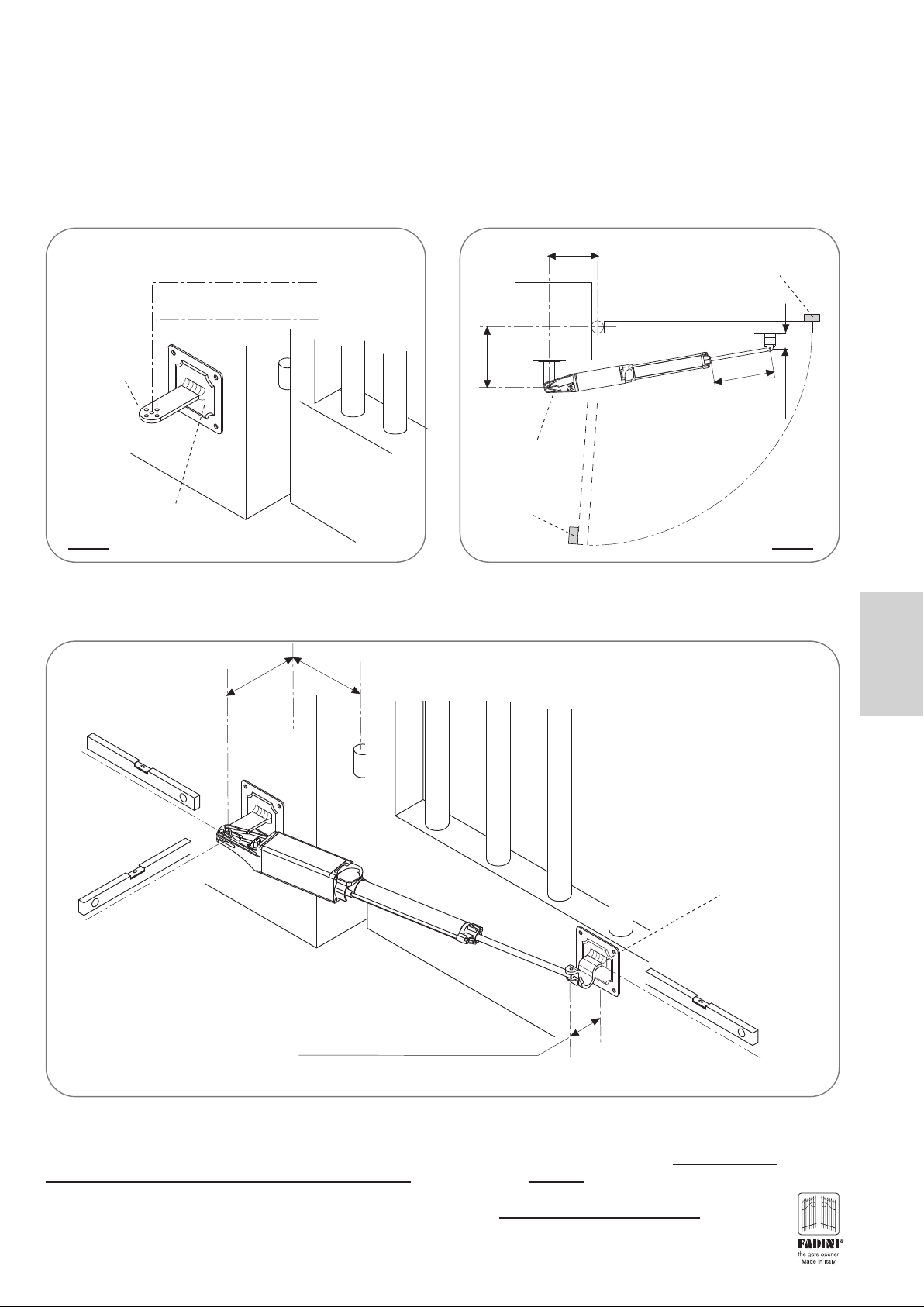

- At this stage NUPI 66 is fixed to the gate leaf. Note that it is locking when the release lid is closed; with the lid in the open

position the locking device is overridden and the gate can be pushed open by hand (pic.2 on page 10). The electrical connections

of the power supply cable to the terminal board are the next step. Remove the cable fastener. Connect

central terminal and the two live wires to the lateral terminals (pic. 9 on page 12) in parallel with the capacitor. Put back the

cable fastener.

On connecting the electronic control panel Elpro 7 RP, it is advised to set the

torque control switch to position 3

(pic. 10 on page 13 and pic. 11 on page 14).

the neutral to the

11

Page 4

ELECTRICAL WIRING DIAGRAM

The diagram here below shows the electrical connections of all the accessories that are available for the system:

13

1

9

English

10

12

11

n°2x1

n°2x1

5

.

n°3x1

n°4x1.5

14

2

IMPORTANT: All the system must be properly earthed

1 - PHOTOCELL RECEIVER TRIFO 11

2 - JUNCTION BOX

3 - POST WITH PHOTOCELL PROJECTOR TRIFO 11

4 - OIL-HYDRAULIC ACTUATORS NUPI 66

5 - CLOSED GATE STOP REQUIRED

6 - RADIO TRANSMITTER ASTRO 43/2 TR SMALL

7 - POST WITH PHOTOCELL RECEIVER TRIFO 11

8 - PHOTOCELL PROJECTOR TRIFO 11

8

cable RG58

n°4x1

n°4x1

4

5

4

n°4x1.5

15

n°2x1

3

15

n°4x1

6

7

9 - KEYSWITCH CHIS 37 SURFACE MOUNT

10 - FLASHING LAMP MIRI 4

11 - PLUG-IN RADIO RECEIVER CARD ASTRO 43/2 R

12 - ELECTRONIC CONTROL PANEL ELPRO 7 RP

13 - AERIAL BIRIO A8

14 - 0.03A MAGNETIC-THERMAL CIRCUIT BREAKER

(BEYOND 100m 2.5mm

2

Ø CABLE TO BE USED )

15 - OPEN GATE STOP REQUIRED

PIC. 7

PIC. 8 PIC. 9

LIVE 1

NEUTRAL - BLUE

LIVE 2

NOTE: BY EXCHANGING THE POSITION OF L1 WITH L2 THE ELECTRIC

MOTOR ROTATION IS REVERSED.

TERMINALS FITTED ON TO

THE OPERATOR BRACKET BLOCK

12.5 μF CAPACITOR

SUPPLY CABLE

230V - 50 Hz

– FLEXIBLE

– FLAME-PROOF NPI

– 450/750 - 4x1.5 mm

– CEI STANDARD 20-52

THE NEUTRAL BLUE WIRE

TO BE CONNECTED TO THE

CENTRAL TERMINAL

THE TWO LIVE WIRES TO

BE CONNECTED TO THE

LATERAL TERMINALS

PARALLEL TO THE

CAPACITOR

2

IT IS IMPORTANT TO AVOID

ANY SHARP BENDS WITH

THE CABLE. IT MUST

DANGLE IN A WIDE LOOP

12

Page 5

WIRING DIAGRAM CONTROL PANEL ELPRO 7 RP

IMPORTANT: Elpro 7 RP is specifically designed to suit NUPI 66 only. The manufacturer declines any responsibility for damages caused by

incorrect use, or applications with accessories that are not FADINI.

2

For the electrical connections to the motor of NUPI 66 and mains use 1.5 mm

For the photo cells, keyswitches, flashing lamp, and other accessories you can use 1 mm

Make sure that all the electrical connections are done in compliance with this diagram.

Once the terminals 19 - 20 are supplied with 230V - 50Hz power, the neutral and live properly connected, the red led No. 1 (L1) illuminates

to confirm that the board has voltage.

Read the instructions contained in the ELPRO 7 RP box.

cables.

2

wires.

GB

L7

Elpro 7 RP

L1

L2

1

2

3

COMMON

PHOTOCELLS NC

RP

7

PLUG-IN RADIO

CARD SUPPORT

PROGRAMMING “P”

BUTTON

L3

L4

74

RADIO

CLOSE

STOP NC

OPEN

L5

24V max 3W

ELECTRONIC CONTROL PANEL FOR NUPI 66

WITH PROGRAMMABLE RADIO TECHNOLOGY

DIP-SWITCH

6

4

2

1

3

L6

85

96

INDICATOR

1 No. Radio receiver

2 Pairs photocells

7

5

10

24V OUTPUT max load:

- LEARNING TIMES BY REMOTE CONTROL

- AUTOMATIC/SEMI-AUTOMATIC OPERATING MODES

- STEP BY STEP MODE INTERMIDIATE STOP

- PARTIAL PEDESTRIAN OPENING

- DIP-SWITCH SETTING

ON

OFF

8

COURTESY LIGHT

OR 12V AC RELAY FOR

ELECTRIC LOCK

SINGLE-PHASE

electric lock if

12345

ELECTRONIC TORQUE

11

12

COMMON

M1

MOTOR M1

(actuator and

required)

TRANSFORMER

CONTROL

13

1514

COMMON

M2

SINGLE-

PHASE

MOTOR M2

2A 24V low

voltage fuse

19

20

181617

NEUTRAL

PHASE

POWER SUPPLY

230V 50Hz SINGLE-PHASE

25W max

FLASHING LAMP 230V

5 A line

fuse

5 A line

fuse

English

PIC. 10

Drwg. No.

4153

Elpro 7 RP is an electronic control panel developed for Nupi 66. The main feature of this unit is the capability to learn the required working

times during operation (gate delay in open and close cycles, dwell time). It is recommended to carry out the installation in strict compliance

with the rules of good technique and fit the system with ground stops in the Open and Closed positions.

Elpro 7RP is to be powered with 230 V single-phase voltage. It is manufactured in conformity to 2006/95 CE Low Voltage Safety Norms

and 2004/108/CE and 92/31 CEE Norms for the Electro Magnetic Compatibility. Installation is to be carried out by qualified technicians in

compliance with the existing safety regulations. The manufacturer is not liable for incorrect use of the equipment and reserves the right

to do changes to the unit and this manual any time.

13

Page 6

GB

7

RP

ELECTRONIC CONTROL PANEL FOR NUPI 66

WITH PROGRAMMABLE RADIO TECHNOLOGY

DESCRIPTION OF FUNCTIONS OF THE CONTROL PANEL FOR SWINGING GATES

ELECTRICAL CONNECTIONS:

- The control panel must be installed in a sheltered, dry place, inside the box provided with it.

- Fit the mains to the control panel with a 0.03A high performance circuit breaker.

- Use 1.5mm2 section wires for voltage supply and electric motor. Maximum recommended distance 50m.

- Use 1mm

- Bridge terminals 1 and 2 if no photocells are required.

- Bridge terminals 3 and 6 if no key- or push-button switches are required.

N.W.: To fit extra accessories such as lights, CCTV etc. use only solid state relays to prevent damages to the microprocessor

LOGIC: Elpro 7 RP is supplied with pre-set working times to allow the first installation:

- Working time is about 20 s

- Gate Delay Times: - Opening=2 s

- Closing=6 s

- Dwell on automatic Mode=15 s

Once satisfied that the system is working all right, new working times can be programmed to meet the user's needs or the installation requirements.

Elpro 7RP functions can be set by Dip-switches, both before and after the times have been stored by the unit.

LEARNING THE TIMES: ELPRO 7 RP learning operation is quite easy and can be achieved either by the P button on the PCB or by the remote

control after entering setting mode, see point 1).

Starting the unit to learn the required times: with the gate in closed position pulse the equipment to one complete cycle, ie. open-dwell-close.

Important:

1) In order to avoid setting times which are not suitable to the correct gate functioning, some time limits are pre-set. Beyond these values the

M1 and M2 Motor Run time: max.55s Dwell time on Automatic Mode: maximum 90s

2) During the learning operation, no other functions can be activated, the Photocells and the Stop button are out of service

3) If the new setting operation is interrupted (for example: mains cut off), the times in the previous setting are memorized.

4) Normally, not on programming mode, the P button has the same function as a remote control button and it is possible to test the system by

2

section wires for limit switches, photocells, push-buttons/key-switch and accessories.

automation will start with the maximum pre-set time:

pulsing it; the Led 7 becomes a simple indicator, the same as the indicator to terminal 8.

English

Led Status Indication:

L1=230V 50Hz power supply. Alight

L2=Photocells, if obstructed light goes off

L3=Open. Alight whenever an Open pulse is given

L4=Close. Alight whenever a Close pulse is given

L5=Stop. It goes off on pulsing Stop

L6=Radio. It goes on by pressing a transmitter button

L7=Gate Status; and programming led

24V 3W Indicator:

8

3

COMMON

IMPORTANT: The Elpro 7 RP control panel is supplied with open/close time memory.

Led On = the Gate is Open

Led Off = the Gate is Closed

Fast Flash = closing movement

Slow Flash = opening movement

Pedestrian Opening (M1 Motor by Open pulse):

Partial opening for pedestrians is only allowed in

closed gate position by pulsing to Open (the gate

closes after the dwell time if set to Automatic

Dip-Switch 3=ON)

-the first pulse operates 1 gate leaf (M1)

-the second pulse operates the second gate leaf

Dip-Switch:

1= ON Photocells, Stop during opening

2= ON Radio no reversing during Opening

3= ON Automatic Closing

4= ON Pre-flashing in service

5= ON Radio step by step. Stop in between

6= ON No delay on opening

7= ON Additional pushing on the gate leaf after closing

8= ON Pedestrian opening by Open button

MORE POWER

DIP-SWITCH

1 45 6782

3

ON: 1 gate leaf for

OFF: Standard

8

operation

ON

OFF

pedestrian opening

+

TORQUE CONTROL SETTING: Adjust torque from lower level (step 1) up

to the required amount of power step by step to achieve a correct

performance of the system so that the gates are operated as required

and any injuring hazard is prevented.

Please note, torque is to be adjusted by a technician.

TORQUE ADJUSTING WHEN LIGHT GATES ARE INVOLVED: (made of timbers, PVC or aluminium etc. ...) replace the existing capacitor with a

8 μF one and adjust torque accordingly starting from step one (lowest setting).

ELECTRONIC

TORQUE

CONTROL

_

12 45

LESS POWER

PIC. 11

14

Page 7

GB

7

RP

ELECTRONIC CONTROL PANEL FOR NUPI 66

WITH PROGRAMMABLE RADIO TECHNOLOGY

DESCRIPTION OF FUNCTIONS OF THE CONTROL PANEL FOR SWINGING GATES

Preliminary notes to Learning Mode:

- Make sure that the gate is closed

- Make sure that the gate stops in the respective open and closed gate positions

are firmly fixed to the ground

1°

1°

st

1

Operation:

Cut off power supply to Elpro 7 RP by removing the 2A 24V Low

Voltage white Fuse, which is on the right upper side of the PCB

2°

2°

2nd

Operation:

Hold the button “P” pressed and re-power the PCB by inserting

the 24V Low Voltage Fuse back into its holder.

3°

3rd

Operation:

When the Led L7 illuminates, release button “P”: Led L7 will flash

5 times and the flashing lamp will illuminate: the program “learning

working times” has been entered.

IMPORTANT: at this stage two options are allowed to go on with setting

ie. learning the required operating times: by the “P” button or by remote

!

control. The last option allows the installation agent to have direct visual

control of the

by the gates.

operation being performed

L7

L7

L7

L7

7°

Birio

7th

Operation:

A pulse stops M2 motor

(second gate wide open on open gate stop)

The time passing from 7th to 8th operation is stored by the system as

“Dwell Time”, in service on AUTOMATIC MODE (Dip No.3=ON) or out of

!

service (Dip No.3=OFF, dwell time still in the system memory but not applicable).

M2

8°

M2

th

Operation:

8

A Pulse to close starts M2 motor

(M2 gate starts closing)

The time between the 8

!

as “Gate Delay Time on Closing Cycle”

Birio

th

and 9th operations is stored by the system

9°

M2

9th

Operation:

A pulse to close starts M1 motor

(M1 gate starts closing)

Birio

M1

M1

M1

English

Birio

4°

Birio

4th

Operation:

A pulse to open starts M1 motor

(the first gate starts opening)

The time passing from 4th to 5th operations is stored by the system as the

Gate Delay Time in Open Cycle, with the options in service (Dip No.6 =ON)

!

or out of service (Dip No. 6=OFF, the time is stored but no delay will occur).

M2

5°

M2

Birio

5th

Operation:

A pulse to open starts M2 motor

(second gate starts opening)

6°

6th

Operation:

A pulse stops M1 motor

(first gate wide open on open gate stop)

Birio

M2

M1

M1

M1

10°

M1

M2

Birio

10th

Operation:

A pulse stops M2 motor (M2 gate on closed gate position)

In order to ensure that the gate is securely held in stop position, it is advised

to pulse the actuator ie. gate to stop approx. 3-4 seconds after the gate has

reached the end of the permitted stroke on the closed gate stop position.

11°

M1

M2

Birio

11th

Operation:

A pulse stops M1 motor (M1 gate on closed gate position)

In order to ensure that the gate is securely held in stop position, it is advised

to pulse the actuator ie. gate to stop approx. 3-4 seconds after the gate has

reached the end of the permitted stroke on the closed gate stop position.

The 11th operation concludes the procedure for the control panel to learn the

required working times.

After the learning procedure, it is possible to set the operating modes either

ON/OFF as required by means the Dip-switches on the PCB.

Drwg. No.

4153

15

Page 8

NUPI 66 TECHNICAL SPECIFICATIONS

OIL-HYDRAULIC ACTUATOR

Pump flow rate - P5 ..............................................................1.4

/min.

Working pressure......................................................2 MPa (20 Bars)

Working temperature....................................................–20°C +80°C

Shaft travelling time.................................................................21 sec.

Power oil................................................................................Oil Fadini

Piston stroke ............................................................................280 mm

Piston diametre..........................................................................45 mm

Shaft diametre ............................................................................16 mm

Pushing power open................................................................2˙720 N

Pulling power close..................................................................3˙120 N

Weight of NUPI 66 complete........................................................8 Kg

Protection standards..................................................................IP 553

Overall dimensions (LxWxH)...................................1˙240x86x86 mm

ELECTRIC MOTOR

Power output...........................................................0.18 KW (0.25 HP)

Supply voltage ..............................................................................230 V

Frequency......................................................................................50 Hz

Absorbed current..........................................................................1.2 A

Absorbed power ........................................................................250 W

Capacitor.....................................................................................12.5 μF

Motor rotation speed..........................................................1˙350 rpm

Intermittent service .........................................................................S 3

Flexible electric cable..............................CEI 20-52 FROR 450-750 V

Class......................................................................................................H

Gate height and width (mm) ..................................H 1˙200, W 1˙600

Max. weight per gate leaf up to 2m ........................................150 Kg

60

86

70

160 230 47 803

1˙240

86

48

1˙240

83

l'apricancello

FADINI

PIC. 12

SERVICE

Duty cycle ...19 sec. Opening - 30 sec. Stop - 21 sec. Closing - 30 sec. Stop

Time of one complete cycle........................................................100 s

No. of complete cycles Opening - Stop - Closing - Stop.........36/h

No. of cycles a year, 8 hours’ service a day........................105˙000

WARNINGS

- Before installing the equipment carry out a Risk Analysis and fit any required device in compliance with EN 12445 and EN 12453 Safety Norms.

- It is recommended to keep to the instructions here outlined - check the specifications on the motor sticker with your mains supply.

- Dispose properly of the packaging: cardboard, nylon, polystyrene, through specialized companies.

- Should the operator be removed, do not cut the electric cables. These must be properly removed from the terminal board in the junction box.

- Switch off the mains switch before removing the junction box cover where the electric cables are terminated.

- All the system must be earthed by using the yellow/green wire.

English

- It is recommended to read the regulations, suggestions and remarks quoted in the booklet “Safety Norms”.

CHECKS AND MAINTENANCE:

To achieve an optimum performance and longer life of the equipment and in observance of the safety regulations, it is recommended that inspections and proper

maintenance are made by qualified technicians to the whole installation ie. both the mechanical and electronic parts, as well as wiring.

- Mechanical parts: maintenance every 6 months approx.

- Electronic apparatus and safety equipment: maintenance inspection monthly.

- Ordinary and extraordinary maintenance to be agreed between buyer and installation agent.

The growth of MECCANICA FADINI has always been based on the development of guaranteed products thanks to our “TOTAL QUALITY CONTROL” system

which ensures constant quality standards, updated knowledge of the European Standards and compliance with their requirements, in view of an ever

increasing process of improvement.

2003/108/CE Directive

for waste electrical and

GB

electronic equipments

DISPOSE OF PROPERLY

ENVIRONMENT-NOXIOUS MATERIALS

¤

s.n.c.

AUTOMATIC GATE MANUFACTURERS

Via Mantova, 177/A - C.P.126 - 37053 Cerea (Verona) Italy

Tel. +39 0442 330422 r.a. - Fax +39 0442 331054

e-mail: info@fadini.net - www.fadini.net

16

The manufacturer reserves the right to make amendments to this manual without prior

notice and declines all responsibility for any errors, personal injury or damage to property.

Loading...

Loading...