Page 1

pag. 1,2,3

®

I

GB

F

D

LIBRETTO DI ISTRUZIONI

RP

7

PROGRAMMATORE ELETTRONICO PER NUPI 66

CON TECNOLOGIA RADIO PROGRAMMABILE

INSTRUCTIONS

RP

7

ELECTRONIC CONTROL PANEL FOR NUPI 66

WITH PROGRAMMABLE RADIO TECHNOLOGY

NOTICES D'INSTRUCTION

RP

7

PROGRAMMATEUR ELECTRONIQUE POUR NUPI 66

AVEC TECNOLOGIE RADIO PROGRAMMABLE

ANLEITUNG

RP

7

ELEKTRONISCHE STEUERUNG FÜR NUPI 66

MIT PROGRAMMIERBARER TECHNOLOGIE

- APPRENDIMENTO DEI TEMPI CON RADIO-TRASMETTITORE

- FUNZIONE AUTOMATICO-SEMIAUTOMATICO

- FUNZIONE PASSO-PASSO CON BLOCCO INTERMEDIO

- FUNZIONE AD ANTA PEDONALE

- DIP-SWITCH DI PROGRAMMAZIONE

- LEARNING TIMES BY REMOTE CONTROL

- AUTOMATIC/SEMI-AUTOMATIC OPERATING MODES

- STEP BY STEP MODE INTERMIDIATE STOP

- PARTIAL PEDESTRIAN OPENING

- DIP-SWITCH SETTING

page 1,4,5

- AUTOAPPRENTISSANT DES TEMPS PAR TELECOMMANDE

- FONCTION AUTOMATIQUE-SEMIAUTOMATIQUE

- FONCTION PAS-PAS AVEC ARRET INTERMEDIAIRE

- FONCTION VANTAIL PIETONS

- DIP-SWITCH DE PROGRAMMATION

page 1,6,7

- ERLERNUNG DER ZEITEN DURCH FUNKSENDER

- AUTOMATISCHE/HALBAUTOMATISCHE FUNKTION

- SCHRITT-IMPULS-FUNKTION MIT MITTELSTOPP

- GEHTÜRFUNKTION

- DIP-SCHALTER ZUR PROGRAMMIERUNG

Seite 1,8,9

E

NL

Dis. N.

FOLLETO DE INSTRUCCIONES

7

PROGRAMADOR ELECTRONICO PARA NUPI 66

CON TECNOLOGIA DE RADIO PROGRAMABLE

HANDLEIDING

7

RADIOPROGRAMMEERBARE ELEKTRONISCHE

PROGRAMMEEREENHEID VOOR NUPI 66

4153

RP

RP

- APRENDIZAJE DE LOS TIEMPOS POR MEDIO DE RADIOTRANSMISOR

- FUNCION AUTOMATICO-SEMIAUTOMATICO

- FUNCION PASO A PASO CON BLOQUEO INTERMEDIO

- FUNCION DE HOJA PARA PASO DE PEATONES

- “DIP-SWITCH” DE PROGRAMACION

pág. 1,10,11

- TIJDSLERING MET RADIOZENDER

- AUTOMATISCHE-HALFAUTOMATISCHE FUNCTIE

- STAP-VOOR-STAP FUNCTIE MET TUSSENTIJDSE BLOKKERING

- FUNCTIE MET VOETGANGERSPOORT

- PROGRAMMERINGSDIP-SWITCH

pag. 1,12,13

Via Mantova, 177/A - C.P. 126 - 37053 Cerea (Verona) Italy - Tel. +39 0442 330422 r.a.

®

Fax +39 0442 331054 - e-mail: info@fadini.net - www.fadini.net

s.n.c.

1

Page 2

®

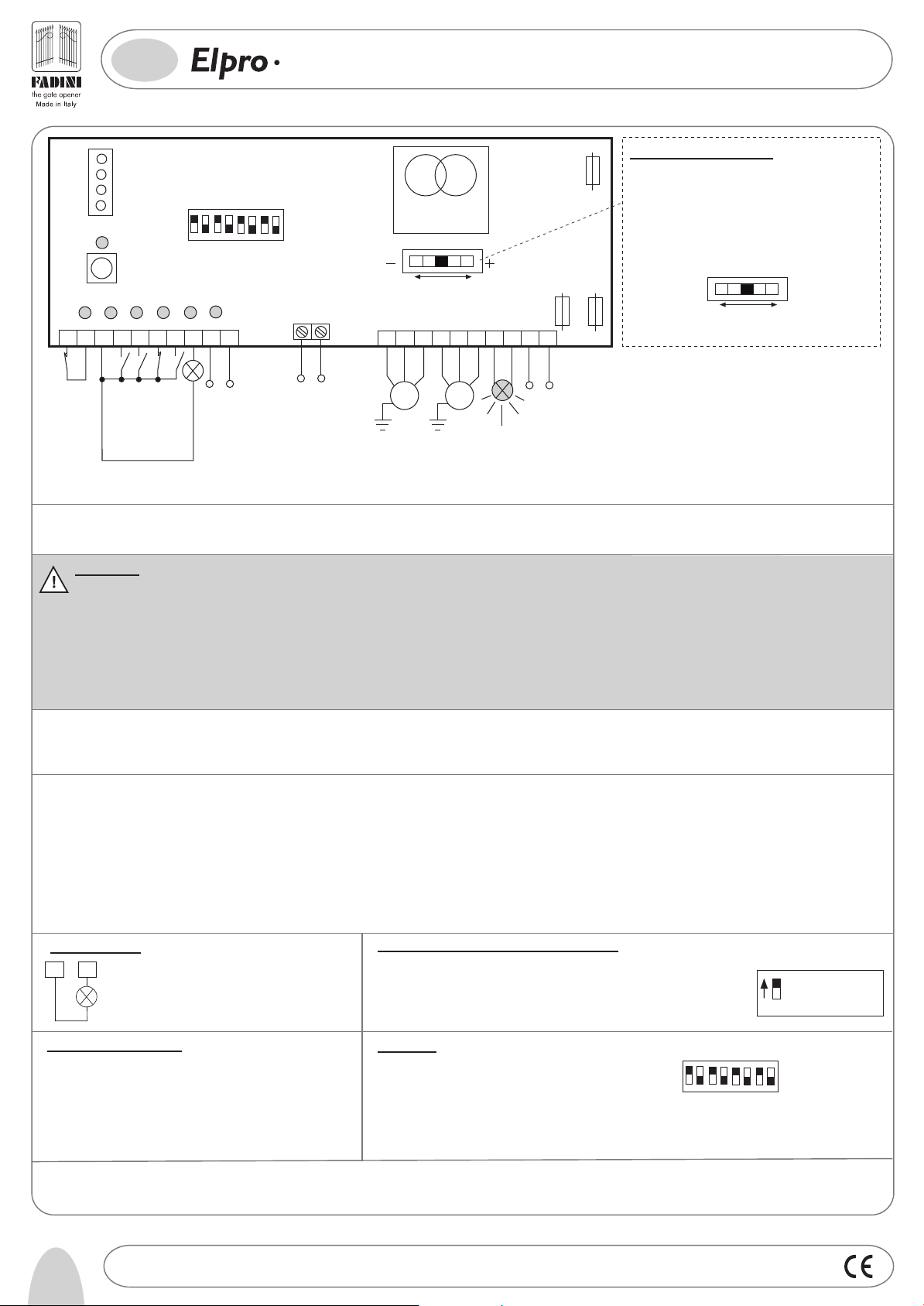

GB

7

RP

ELECTRONIC CONTROL PANEL FOR NUPI 66

WITH PROGRAMMABLE RADIO TECHNOLOGY

2A 24V low

voltage fuse

19

181617

N

E

U

TR

AL

PHASE POWER SUPPL

230V 25W max

FLASHING LAMP

Y

5 A line

fuse

20

LIVE

230V

±10% 50Hz SINGLE-

L7

Elpro 7 RP

L1

L2

1

2

3

COMMON

PHOTOCELLS NC

PLUG-IN RADIO

CARD SUPPORT

PROGRAMMING "P"

BUTTON

L3

L4

74

RADIO

CLOSE

STOP NC

OPEN

DIP-SWITCH

2

1

3

L5

L6

85

96

10

24V max 3W

INDICATOR

1 No. Radio receiver

2 Nos. photocells

ON

OFF

6

8

4

7

5

24 V OUTPUT max load:

COURTESY LIGHT

OR 12V AC RELAY FOR

ELECTRIC LOCK

ELECTRONIC TORQUE

11

12

C

O

M

M

O

N

M1

SINGLE-PHASE

MOTOR M1

(actuator and

electric lock if

required)

TRANSFORMER

12 453

CONTROL

13

1514

C

O

M

M

O

N

M2

SINGLE-

PHASE

MOTOR M2

General description: Elpro 7 RP is an electronic control panel developed for Nupi 66. The main feature of this unit is the capability to learn the required working times

during operation (gate delay in open and close cycles, dwell time). It is recommended to carry out the installation in strict compliance with the rules of good technique and

fit the system with ground stops in the Open and Closed positions.

IMPORTANT:

- The control panel must be installed in a sheltered, dry place, inside the box provided with it.

- Make sure that the power supply to the electronic programmer is 230V ±10%

- Make sure that the power supply to the Electric Motor is 230V ±10%

- For distances of over 50 metres we recommend using electric cables with bigger sections

- Fit the mains to the control panel with a 0.03A high performance circuit breaker.

- Use 1.5mm2 section wires for voltage supply, electric motor and flashing lamp. Maximum recommended distance 50m.

- Use 1mm

2

section wires for limit switches, photocells, push-buttons/key-switch and accessories.

- Bridge terminals 1 and 2 if no photocells are required.

- Bridge terminals 3 and 6 if no key- or push-button switches are required.

N.W.: To fit extra accessories such as lights, CCTV etc. use only solid state relays to prevent damages to the microprocessor

WORKING LOGIC: Elpro 7 RP is supplied with pre-set working times so that to allow the first installation: Working time is about 20 s

Gate Delay Times: - Opening=2 s - Closing=6 s - Dwell on automatic Mode=15 s

Once satisfied that the system is working all right, new working times can be programmed to meet the user's needs or the installation requirements.

Elpro 7RP functions can be set by Dip-switches, both before and after the times have been stored by the unit.

Adjust torque from lower level (step 1) up to the

required amount of power step by step to achieve

a correct performance of the system so that the

gates are operated as required and any injuring

hazard is prevented.

Please note, torque is to be adjusted by a technician.

5 A line

fuse

LESS POWER

12 453

ELECTRONIC

TORQUE CONTROL

MORE POWER

Torque control setting:

LEARNING THE TIMES: ELPRO 7 RP learning operation is quite easy and can be achieved either by the P button on the PBC or by the remote control after entering setting

mode, see point 1).

Starting the unit to learn the required times: with the gate in closed position pulse the equipment to one complete cycle, ie. open-stop/dwell-close

Important:

1) In order to avoid setting times which are not suitable with the correct gate functioning, some time limits were pre-set. Beyond these values the automation will start

with the maximum pre-set time:

M1 and M2 Motor Run time: max.55s Dwell time on Automatic Mode: maximum 90s

2) During the learning operation, no other functions can be activated, the Photocells and the Stop button are out of service

3) If the new setting operation is interrupted (for example: mains cut off), the times in the previous setting are memorized.

4) Normally, not on programming mode, the P button has the same function as a remote control button and it is possible to test the system by pulsing it;

the Led 7 becomes a simple indicator, the same as the indicator to terminal 8.

24V 3W Indicator:

3

8

COMMON

Led On = the Gate is Open

Led Off = the Gate is Closed

Fast Flash = closing movement

Slow Flash = opening movement

Led Status Indication:

L1=230V 50Hz power supply. Alight

L2=Photocells, if obstructed light goes off

L3=Open. Alight whenever an Open pulse is given

L4=Close. Alight whenever a Close pulse is given

L5=Stop. It goes off on pulsing Stop

L6=Radio. It goes on by pressing a transmitter button

L7=Gate Status; and programming led

Pedestrian Opening ( M1 Motor by Open pulse):

Partial opening for pedestrians is only allowed in closed gate position by

pulsing to Open (the gate closes after the dwell time if set to Automatic

Dip-Switch 3=ON)

-the first pulse operates 1 gate leaf (M1)

-the second pulse operates the second gate leaf

Dip-Switch:

1= ON Photocells, Stop during opening

DIP-SWITCH

2= ON Radio no reversing during Opening

3= ON Automatic Closing

4= ON Pre-flashing in service

5= ON Radio step by step

4

2

1

3

6= ON No delay on opening

7= ON No Additional pushing on the gate leaf after closing

8= ON Pedestrian opening by Open button

ON: 1 gate leaf for

pedestrian opening

OFF: Standard

operation

8

ON

OFF

6

8

7

5

Elpro 7 RP is to be powered with 230 V single-phase voltage. It is manufactured in conformity to 2006/95 CE Low Voltage Safety Norms and 2004/108/CE & 92/31 CEE Norms for the

Electro Magnetic Compatibility. Installation is to be carried out by qualified technicians in compliance with the existing safety regulations. The manufacturer is not liable for incorrect use

of the equipment and reserves the right to do changes to the unit and this manual any time.

Failure to follow installation regalations may result in serious damage to property and persons.

4

Drwg. No.

4153

Page 3

GB

7

RP

ELECTRONIC CONTROL PANEL FOR NUPI 66

WITH PROGRAMMABLE RADIO TECHNOLOGY

®

Preliminary notes to Learning Mode:

- Make sure that the gate is closed

- Make sure that the gate stops in the respective open and closed gate positions

are firmly fixed to the ground

1°

1°

st

1

Operation:

Cut off power supply to Elpro 7 RP by removing the 2A 24V Low

Voltage white Fuse, which is on the right upper side of the PCB

2°

2°

2nd

Operation:

Hold the button "P" pressed and re-power the PCB by inserting

the 24V Low Voltage Fuse back into its holder.

3°

3rd

Operation:

When the Led L7 illuminates, release button "P": Led L7 will flash

5 times and the flashing lamp will illuminate: the program "learning

working times" has been entered.

IMPORTANT: at this stage two options are allowed to go on with setting

ie. learning the required operating times: by the "P" button or by remote

!

control. The last option allows the installation agent to have direct visual

control of the operation being performed

by the gates.

L7

L7

L7

L7

7°

Birio

7th

Operation:

A pulse stops M2 motor

(second gate wide open on open gate stop)

The time passing from 7th to 8th operation is stored by the system as

"Dwell Time", in service on AUTOMATIC MODE (Dip No.3=ON) or out of service

!

(Dip No.3=OFF, dwell time still in the system memory but not applicable ).

M2

8°

Birio

th

Operation:

8

A Pulse to close starts M2 motor

(M2 gate starts closing)

The time between the 8th and 9th operations is stored by the system

!

as "Gate Delay Time on Closing Cycle"

M2

9°

M2

9th

Operation:

A pulse to close starts M1 motor

(M1 gate starts closing)

Birio

M1

M1

M1

Birio

4°

Birio

4th

Operation:

A pulse to open starts M1 motor

(the first gate starts opening)

The time passing from 4th to 5th operations is stored by the system as the

Gate Delay Time in Open Cycle, with the options in service (Dip No.6 =ON)

!

or out of service (Dip No. 6=OFF, the time is stored but no delay will occur).

M2

5°

M2

Birio

5th

Operation:

A pulse to open starts M2 motor

(second gate starts opening)

6°

6th

Operation:

A pulse stops M1 motor

(first gate wide open on open gate stop)

Birio

M2

M1

M1

M1

10°

M1

M2

Birio

10th

Operation:

A pulse stops M2 motor (M2 gate on closed gate position)

In order to ensure that the gate is securely held in stop position, it is advised to

pulse the actuator ie. gate to stop approx. 3-4 seconds after the gate has reached

the end of the permitted stroke on the closed gate stop position.

11°

M1

M2

Birio

11th

Operation:

A pulse stops M1 motor (M1 gate on closed gate position)

In order to ensure that the gate is securely held in stop position, it is advised to

pulse the actuator ie. gate to stop approx. 3-4 seconds after the gate has reached

the end of the permitted stroke on the closed gate stop position.

The 11th operation concludes the procedure for the control panel to learn the

required working times.

After the learning procedure it is possible to set the operating modes either ON/OFF

as required by means the Dip-switches on the PCB

Drwg. No.

4153

5

Page 4

200

182

06-2010

260 280

110

I -

Prima dell'installazione da parte di personale tecnico qualificato, si consiglia di prendere visione del

Libretto Normative di Sicurezza che la Meccanica Fadini mette a disposizione.

GB -

Please note that installation must be carried out by qualified technicians following Meccanica Fadini's

Safety Norms Manual.

F -

L'installation doit être effectuée par un technicien qualifié suivant le manuel des Normes de Sécurité

de Meccanica Fadini.

D -

Vor der Montage durch einen Fachmann, wird es empfohlen die Anleitung zur Sicherheitsnormen, die

Meccanica Fadini zur Verfügung stellt, nachzulesen.

E -

Antes de la instalación por el personal técnico calificado, se recomienda leer detenidamente el Folleto

de la Reglamentación de Seguridad que la empresa Meccanica Fadini pone a su disposición.

NL -

Voordat de installatie door gekwalificeerd technisch personeel wordt uitgevoerd, wordt geadviseerd

om het boekje met veiligheidsvoorschriften dat Meccanica Fadini ter beschikking stelt door te lezen.

Direttiva 2003/108/CE

Smaltimento dei materiali

I

elettrici ed elettronici

VIETATO GETTARE NEI RIFIUTI

MATERIALI NOCIVI PER L’AMBIENTE

2003/108/CE Directive

for waste electrical and

GB

electronic equipments

DISPOSE OF PROPERLY

ENVIRONMENT-NOXIOUS MATERIALS

®

s.n.c.

Via Mantova, 177/A - C.P. 126 - 37053 Cerea (Verona) Italy - Tel. +39 0442 330422 r.a. - Fax +39 0442 331054

e-mail: info@fadini.net - www.fadini.net

La ditta costruttrice si riserva di apportare modifiche al presente libretto senza preavviso

Loading...

Loading...