Page 1

CAPACITORS

FUSE

630 mA

DWELL TIME

1 A FUSE

MOTOR RUN TIME

OPEN & CLOSE

CUT OFF SWITCH

BY COVER KNOB

2 AMP. FUSE TO PROTECT

THE ELECTRIC LOCK

OUTPUT

TERMINALS

No. 9-10

5 AMP .

FUSE

FUSE

630 mA

COMMON

COMMON

FOR SWING GATES

bpt

240 V SINGLE-PHASE

SUPPLY VOLTAGE

240 V - 25 W max. FLASHING LAMP

SINGLE-PHASE

ELECTRIC MOTORS

Max permitted load:

24 V OUTPUT A.C.

24 V INDICATOR GATE OPEN - 3 W max.

2 pairs photocells

1 radio receiver

23

CEI

NOTE WELL: For special applications, ie. to switch

on lights - CCTV etc., SOLID STATE RELAYS are

recommended to be used only. Standard relays

would affect the micro-processor.

RADIO CONTROL

PLUG-IN CARD SUPPORT

24 V OUTPUT

1st CHANNEL

1 A FUSE TO PROTECT

THE 24 V= OUTPUT

LEAF DELAY

TIMER CLOSE

MICROPROCESSOR

TERMINALS FOR THE

CONNECTIONS TO THE

PUSH BUTTONS PULIN 3

ON

DIP-SWITCH

OFF

VOLTAGE OUTPUT

ELECTRIC LOCK SUPPLY 12V A.C./ 24V D.C.

COMMON

RADIO CONTACT N.O.

STOP SWITCH N.C. CONTACT

CLOSE SWITCH N.O. CONTACT

OPEN SWITCH N.O. CONTACT

COMMON

N.C. CONTACT

PHOTOCELLS

PEDESTRIAN MODE

ONE PULSE OPENS

ONE GATE LEAF ONLY

REVERSE

RADIO CONTACT

ALL OPERATIONS

OPEN, CLOSE AND

PULSE TWICE

BOTH GATE LEAFS

CONSECUTIVELY TO OPEN

GB

Drwg. No.

2125

24 V. D.C.

OUTPUT

Should more pairs of photocells be required than

the recommended quantity, fit an auxiliary

NOTE WELL: THIS PANEL IS TESTED TO

OPERATE GATES ONLY THROUGH FADINI

ACCESSORIES. NO GUARANTEE FOR

ACCESSORIES OF OTHER MAKE OR SPECIAL

APPLICATIONS.

transformer outside the control box.

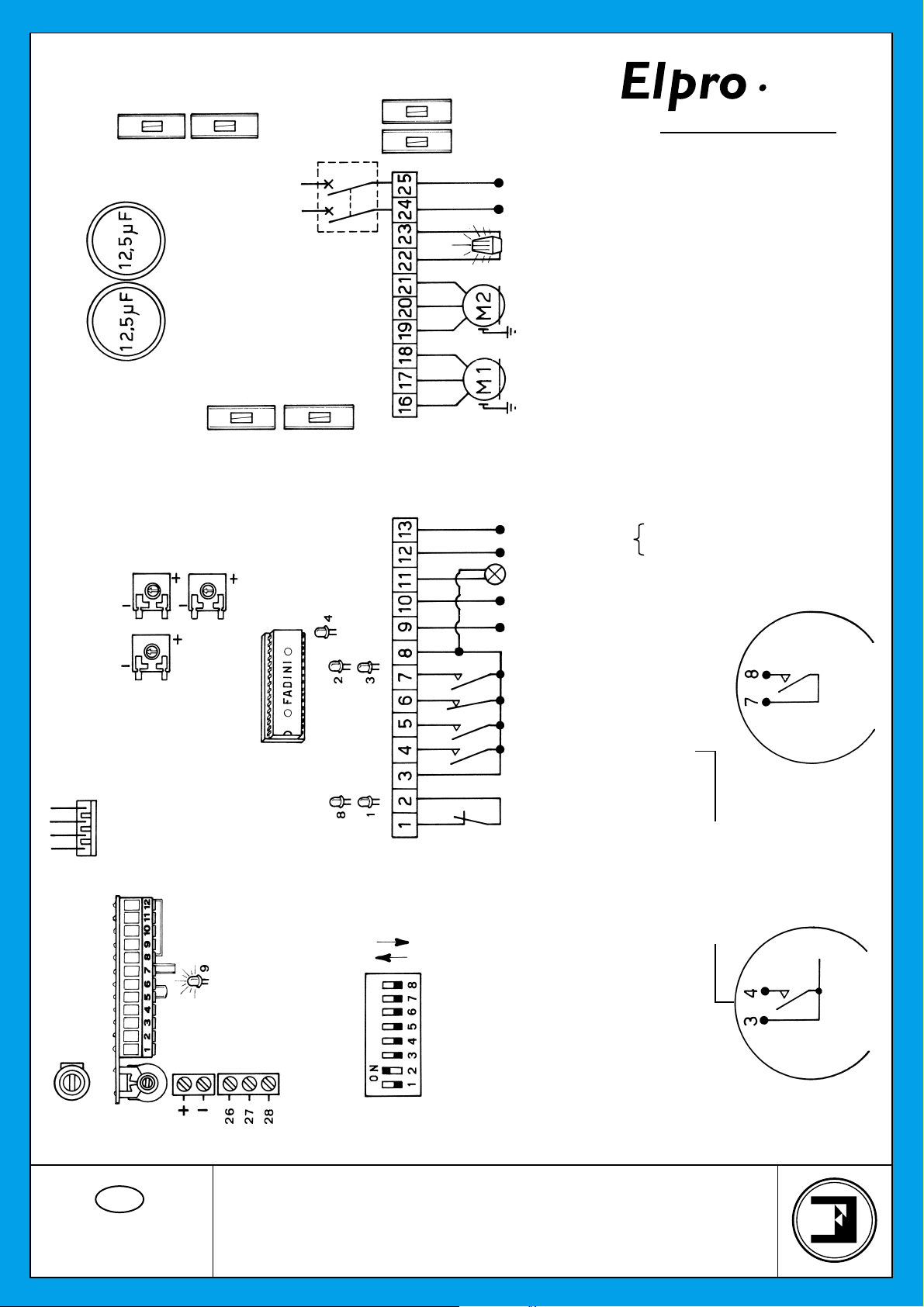

CONNECTION DIAGRAM

ELECTRONIC PROGRAMMER

FOR SINGLE-PHASE SWING GATES

Page 2

23

CEI

bpt

FEATURES OF THE ELECTRONIC PROGRAMMER FOR SWINGING GATES

All the electrical connections are to be made as per the following instructions and diagrams. Supply the terminals 24-25 with 240V- 50 Hz

single-phase voltage. The “Red LED” switches on and stays on as long as the board is properly supplied. Through the timer No. 9 you

can control the running time of the motor in both cycles, OPEN and CLOSE. Set it so that the running time of the motor is longer than the

actual travel of the gate; set the timer No. 8 - DWELL - ie. the interval between open and re-closing, so that you can meet the required

interval of time. The timer No. 7 - LEAF DELAY in "close" cycle - is to be set as follows: on to "-" (less) the delay is out of service; clockwise

on to "+" (more) the delay is operative.

- With the electric motor connected to terminals 19-20-21: the delay is operative in the "open" cycle, with a factory pre-set time.

- With the electric motor connected to 16-17-18: the delay is operative in "close" cycle and can be adjusted through the timer No. 7 on to

"less" or "more".

LOGIC OF THE ELECTRONIC PROGRAMMER: When a pulse is given, the flashing light switches on. After three seconds the motors start .

During the interval before re-closing, the light stays on. When the gates are fully re-closed, the light keeps on flashing for three more seconds

and then switches off automatically.

The 3 second interval (pre-flashing) which precedes the actual start of the motors can be eliminated by means of the DIP-SWITCH “A” No. 4.

LED No. 1: "OPEN". It switches on when the respective switch is activated.

LED No. 2: "CLOSE". It switches on when the respective switch is activated.

LED No. 3: "RADIO". It switches on whenever a pulse is given, either from remote control, keyswitch or push buttons.

LED No. 4: “STOP". Normally on. It switches off when the respective switch is activated.

LED No. 8: "PHOTOCELLS". Normally on. It switches off when the photocells are obstructed.

LED No. 9: It switches on when voltage is supplied.

DIP-SWITCH SETTING IN ELPRO 23 type "A"

N° 1 OFF = PHOTOCELLS. NO STOP IN OPEN CYCLE. REVERSE/CLOSE

N° 2 OFF = REMOTE CONTROL. REVERSE

N° 3 OFF = NO AUTOMATIC RECLOSING

N° 4 OFF = NO PRE-FLASHING

N° 5 OFF = REMOTE CONTROL. NO STOP AND HOLD AS LONG

AS BUTTON DOWN. IT OPENS STRAIGHT AWAY

N° 6 OFF = BOTH LEAFS ARE OPERATED

N° 7 OFF = S. R. P. OUT OF SERVICE

N° 8 OFF = LEAF DELAY OPEN CYCLE.

ONE STARTS BEFORE THE OTHER

LAMP ON = GATE OPEN

LAMP FLASHES SLOWLY = GATE OPENING

LAMP FLASHES FAST = GATE CLOSING

LAMP OFF = GATE CLOSED

1) It is advisable not to expose the control box directly to weather conditions; if mounted outside, a suitable enclosure is recommended to

protect it from sunshine and rain.

2) Bridge terminals 1 - 2 if you do not require any photocells.

3) Should two sets of photocells be required, these are to be series connected to terminals 1 - 2, contact normally closed.

N° 1 ON = STOP DURING OPEN CYCLE

N° 2 ON = NO REVERSE DURING OPEN CYCLE

N° 3 ON = AUTOMATIC RECLOSING

N° 4 ON = PRE-FLASHING

N° 5 ON = STOP AND HOLD AS LONG AS

THE BUTTON IS KEPT DOWN

N° 6 ON = PEDESTRIAN. ONE LEAF ONLY

GATES IN CLOSE POSITION

N° 7 ON = S. R. P. IN SERVICE

GATES IN CLOSE POSITION

N° 8 ON = NO LEAF DELAY

BOTH MOTORS START TOGETHER

4) Bridge terminals 6 - 8 if you do not require any keyswitch or push buttons.

5) Fit the mains to the control box with a high sensitivity, differential, magnetic-thermal switch, 0.03 Amps.

6) NOTE WELL

FAULT FINDING:

- Check supply voltage with a tester: it must be 240V, single-phase

- Check the high voltage fuses

- Check if the photocells contacts are normally closed

- Check voltage from the control box to the electric motor(s): power might have dropped

- Check the low voltage fuse

- The section of the electric cables to the motor(s) must not be less than 1.5 mm

* 24 V ~ output. Terminals 12-13. It can supply power for 2 pairs of photocells plus 1 radio receiver. Terminal 11 provides a power output

for a lamp. 24 V - 3 W max. Flashing lamp output. Terminals 22-23. Maximum available power 25 W max.

2

®

Page 3

23

CEI

bpt

FEA TURES AND TECHNICAL SPECIFICATIONS

"ELPRO 23” represents the latest state of the art technology for control panels. It is extremely versatile and can meet the most various

requirements.

It has the same functions as ELPRO 9 and incorporates additional advantages as follows: Stroke Reversing Pulse, Pedestrian Operating

Mode (where one leaf only can be operated allowing people to walk in/out), STOP and HOLD function by keeping the remote control button

pressed down).

Further improvements can be noted in the "ELPRO 23" panel:

- Addition of a 1 A fuse to the 24 V circuit as a protection for the accessories (remote control - photocells - etc.) which are connected to

the terminals 12 - 13 and for the panel itself in that it can prevent short circuit during installation.

- The pulse to the electric lock has an adjustable time so that the electric lock can be released with an anticipation of 100 mS before the

gate starts moving.

- A 24V 3W lamp indicates gate operations (Gate CLOSED = Lamp OFF - Gate in OPEN cycle = Lamp flashes slowly - Gate OPEN = Lamp

stays ON without flashing - Gate in CLOSE cycle = Lamp flashes fast).

- It provides a better switching intelligence design to enhance the reliability of the relays.

- The Motor Run Time is independent from the Leaf Delay Time in close cycle (the delay time is automatically added to the duration of the

opening time).

- The 8 DIP-switches can be arranged into any of the possible patterns to achieve the required operating modes without any risk of

interference with one another.

"STROKE REVERSING PULSE" and "S.1A.P.":

Set DIP switch No. 7 to ON. The "Stroke Reversing Pulse" (S.R.P.) is activated only with the gate in the CLOSE position. The pulse operates

the gate in the CLOSE direction first and then immediately reverses into OPEN (this will help the gate lock to release). All the other operations

will be performed in the standard way. No danger comes from the Stroke Reversing Pulse. This function remains in service with the panel

set to "Pedestrian Mode".

Set DIP switch No. 6 to ON for "Pedestrian Mode" (S.1A.P.), terminals 3-4. Only one leaf is operated when the OPEN button is pressed

down. Automatic reclosing. If the OPEN button is pressed twice in a row, both leafs are opened. The S.1A.P. function is activated only when

the gate is in the fully CLOSE position. The remote control always operates both gates, contact 7 - 8.

DIP-SWITCH SETTING IN ELPRO 23 type "A"

N° 1 OFF = PHOTOCELLS. NO STOP IN OPEN CYCLE. REVERSE/CLOSE

N° 2 OFF = REMOTE CONTROL. REVERSE

N° 3 OFF = NO AUTOMATIC RECLOSING

N° 4 OFF = NO PRE-FLASHING

N° 5 OFF = REMOTE CONTROL. NO STOP AND HOLD AS LONG

AS BUTTON DOWN. IT OPENS STRAIGHT AWAY

N° 6 OFF = BOTH LEAFS ARE OPERATED

N° 7 OFF = S. R. P. OUT OF SERVICE

N° 8 OFF = LEAF DELAY OPEN CYCLE.

ONE STARTS BEFORE THE OTHER

ADDITIONAL FEATURES:

- OPEN and CLOSE pulses to allow one cycle only in case a button is stuck down.

- “HOLD OPEN GATES” feature. The panel set on automatic reclosing mode; it is possible to connect a switch or timeclock to the OPEN

terminal to hold the gate open for the required period of time.

- Auxiliary 24 V D.C. 150 mA max. OUTPUT.

- In addition to the features which you already know and the LED indication outputs that are standard with the existing panel, the following

additional features have been included with the new unit:

1 No. 5A-150 mA change-over contact. This can be used to connect signal lights such as traffic lights (for instance you can connect

two external lamps 1 red, 1 green).

4 Nos. N.O. solid state switch outputs designed to allow the connection of 24 V D.C. relay coils without protecting diodes.

The 4 switches are excited individually to indicate the following gate status: OPENING - OPEN - CLOSING - CLOSED.

12 V A.C. / 24 V D.C. electric lock output. The duration of the pulse to the lock can be adjusted by means of a potentiometer.

12 V D.C./A.C. relay with N.O. contacts for the connection of an Intercom Entry System.

N° 1 ON = STOP DURING OPEN CYCLE

N° 2 ON = NO REVERSE DURING OPEN CYCLE

N° 3 ON = AUTOMATIC RECLOSING

N° 4 ON = PRE-FLASHING

N° 5 ON = STOP AND HOLD AS LONG AS

THE BUTTON IS KEPT DOWN

N° 6 ON = PEDESTRIAN. ONE LEAF ONLY

GATES IN CLOSE POSITION

N° 7 ON = S. R. P. IN SERVICE

GATES IN CLOSE POSITION

N° 8 ON = NO LEAF DELAY

BOTH MOTORS START TOGETHER

®

Page 4

200

23

FOR SWING GATES

CEI

280

260

182

®

ADDITIONAL

CARD

bpt

140

COVER KNOB

CUT OFF SWITCH

8 WAY

DIP-SWITCH

TECHNICAL DATA

- Supply Voltage 240 V - 50 Hz

- Voltage Output 240 V - 25 Hz

- Low Voltage Output 24 V - 10 W

- E.M. Power Output 1˙100 W

- Line Fuses 5 A

- Secondary Fuses 0.5 A

- Command Open - Stop - Close Other functions

- Dimensions of the Container 280x200x140 mm

- IP Standards IP 437

Open Contact Relay

Approval Mark IMQ - -S-S-10 A - 240 V

- Capacitor 12 µF - 400 V

Transformer

- Power 20 VA

- Magnetic Core 1.5 W / Thickness 0.50

- Supply Voltage 0 - 240 V

- Output 0 - 18 - 24 V

- Working Frequency 50 - 60 Hz

- Insulation 4 Kv x 1’

+

CUT OFF SWITCH

BY COVER KNOB

GB

Drwg. No.

2125

AUTOMATIC GATE MANUFACTURERS

Via Mantova, 177/A - 37053 Cerea (Verona) Italy

®

Tel. 0442 330422 r.a. - Fax 0442 331054

s.n.c.

e-mail: info@fadini.net - www.fadini.net

®

Made in Italy

Page 5

23

CEI

FOR SWING GATES

bpt

CONNECTION DIAGRAM AND FEATURES OF THE ADDITIONAL CARD

COMMON +24 V

2 AMP. FUSE

CLOSING

CLOSE

OPEN

RED

SUPPLY VOLTAGE

240 V - 50 Hz

OPENING

RELAYS FITTED WITH 24 V D.C.

150 mA max. COILS ARE RECOMMENDED

10) ELECTRIC LOCK TIME ADJUSTMENT

CLOCKWISE = MORE

ANTI-CLOCKWISE = LESS

11) GATE STATUS INDICATION LEDs

1-LED OPENING / 2-LED OPEN / 3-LED CLOSE / 4-LED CLOSING / 5-LED TRAFFIC LIGHTS

12) 12V RELAY TO CONNECT ONE INTERCOM UNIT

13) CONNECTORS

14) SWITCH TO CHANGE VOLTAGE TO ELEC.LOCK FROM 12 V A.C. - TO 24V D.C.

15) LINK DOWN, PULSE TO THE 12 V A.C. ELECTRIC LOCK

LINK UP, PULSE TO THE 24V D.C. ELECTRIC LOCK

16) RELAY FOR THE GATE LOCK

17) RELAY FOR THE TRAFFIC LIGHTS

PURE CONTACT N.O. 1 AMP.

12 V DC/AC COIL

GREEN

COMMON

N.O.

N.C.

The green lamp is

on only with open

gates and motors off

PIN TO PREVENT WRONG

FITTING OF THE CARD

ON TO THE PC BOARD

AUDIO/VIDEO

CONNECTION

For audio/video connection 12 V AC Lock Output connect to terminals 8 & 9 plug in additional card. Connect to main terminals

7 & 8 radio/common from additional card 6 & 7 relay contact.

GB

CONNECTION DIAGRAM

AND FEATURES OF THE

Drwg. No.

2125

ADDITIONAL DIAGRAM

®

Page 6

ADDITIONAL FEATURES:

- OPEN and CLOSE pulses to allow one cycle only in case a button is stuck down.

- “HOLD OPEN GA TES ” feature. The panel set on automatic reclosing mode; it is possible

to connect a switch or timeclock to the OPEN terminal to hold the gate open for the required

period of time.

- Auxiliary 24 V D.C. 150 mA max. OUTPUT.

- In addition to the features which you already know and the LED indication outputs that

are standard with the existing panel, the following additional features have been included

with the new unit:

1 No. 5A-150 mA change-over contact. This can be used to connect signal lights such

as traffic lights (for instance you can connect two external lamps 1 red, 1 green).

4 Nos. N.O. solid state switch outputs designed to allow the connection of 24 V D.C.

relay coils without protecting diodes.

The 4 switches are excited individually to indicate the following gate status: OPENING OPEN - CLOSING - CLOSED.

12 V A.C. / 24 V D.C. electric lock output. The duration of the pulse to the lock can be

adjusted by means of a potentiometer.

12 V D.C./A.C. relay with N.O. contacts for the connection of an Intercom Entry System.

23

FOR SWING GATES

bpt

CEI

ADDITIONAL

CARD

1A

1A

240 Volts

50 Hz

5A

630 mA

CUT OFF SWITCH

BY COVER KNOB

GB

Drwg. No.

2125

2A

1716 191813121110987654321 2120 2322 2524

VIEW OF THE P.C. BOARD

WITH COMPONENTS

630 mA

5A

®

Loading...

Loading...