Page 1

pag. 1,2,3,4

LIBRETTO DI ISTRUZIONI

I

PROGRAMMATORE A MICROPROCESSORE

14

MONOFASE-TRIFASE PER CANCELLI A

DOPPIA ANTA SCORREVOLE

PLUS

- FUNZIONE PASSO PASSO

- UOMO PRESENTE

- APERTURA PEDONALE

- SPIA DI SEGNALAZIONE DELLO STATO DELL'AUTOMAZIONE

- POSSIBILITA' DI ESCLUDERE LAMPEGGIANTE IN PAUSA

- LUCE DI CORTESIA TEMPORIZZATA

- FUNZIONE OROLOGIO

GB

F

D

E

INSTRUCTIONS

14

CONTROL BOARD WITH MICROPROCESSOR

FOR BI-PARTING SLIDING GATES

MANUEL D'INSTRUCTION

14

PROGRAMMATEUR A MICROPROCESSEUR

MONOPHASE-TRIPHASE POUR PORTAILS

14

E-STEUERUNG MIT MICROPROZESSOR,

FÜR DOPPELFLÜGELSCHIEBETORE

FOLLETO DE INSTRUCCIONES

14

PROGRAMADOR DE MICROPROCESADOR

MONOFÁSICO-TRIFÁSICO PARA VERJAS DE

PLUS

SINGLE-/THREE-PHASE

PLUS

DOUBLES COULISSANTS

ANLEITUNG

PLUS

EIN-UND DREIPHASIG,

PLUS

DOBLE HOJA DESLIZANTE

- STEP BY STEP

- DEADMAN CONTROL

- PEDESTRIAN OPENING

- GATE STATUS INDICATION

- FLASHING LAMP ON DWELL TIME MADE SWITCH ABLE

-

TIMED COURTESY LIGHT

- TIME CLOCK FUNCTION

- FONCTION PAS-PAS

- HOMME MORT

- OUVERTURE AUX PIETONS

- LED DE SIGNALISATION POUR L'ETAT DE L'AUTOMATISATION

- EXCLUSION VOYANT CLIGNOTANT EN PAUSE

- LUMIERE DE COURTOISIE

- HORLOGE

- SCHRITT FÜR SCHRITT

- TOTMANNFUNKTION

- GEHTÜRFUNKTION

- AUTOMATION STATUS ANZEIGELAMPE

- AUSSCHALTBARE BLINKLEUCHTE WÄHREND DER PAUSEZEIT

- EINSTELLBARE DECKENLEUCHTE

- SCHALTUHRFUNKTION

- FUNCIÓN PASO-PASO

- HOMBRE PRESENTE

- ABERTURA PEATONAL

- INDICADOR DE SEÑALIZACIÓN ESTADO DE LA AUTOMACIÓN

- POSIBILIDAD DE DESCONECTAR DESTELLADOR EN PAUSA

- LUZ INTERIOR TEMPORIZADA

- FUNCIÓN RELOJ

page 1,5,6,7

page 1,8,9,10

Seite 1,11,12,13

pág. 1,14,15,16

NL

Dis. N.

GEBRUIKERSHANDLEIDING

14

PROGRAMMEERINRICHTING MET MICROPROCESSOR

EENFASE-DRIEFASE VOOR SCHUIFHEKKEN MET

Nyota 115 - n°1

PLUS

TWEE VLEUGELS

4198

- STAP-VOOR-STAP FUNCTIE

- DODEMANSFUNCTIE

- VOETGANGERSDOORGANG

- SIGNALERINGSLAMPJE VAN TOESTAND VAN AUTOMATISERING

- UITSCHAKELBAAR KNIPPERLICHT TIJDENS PAUZETIJD

- GETIMED COURTESY LIGHT

- KLOKFUNCTIE

Nyota 115 - n°2

Via Mantova, 177/A - 37053 Cerea (Verona) Italy - Tel. +39 0442 330422 r.a.

®

Fax +39 0442 331054 - e-mail: info@fadini.net - www.fadini.net

s.n.c.

pag. 1,17,18,19

MEC 200

1

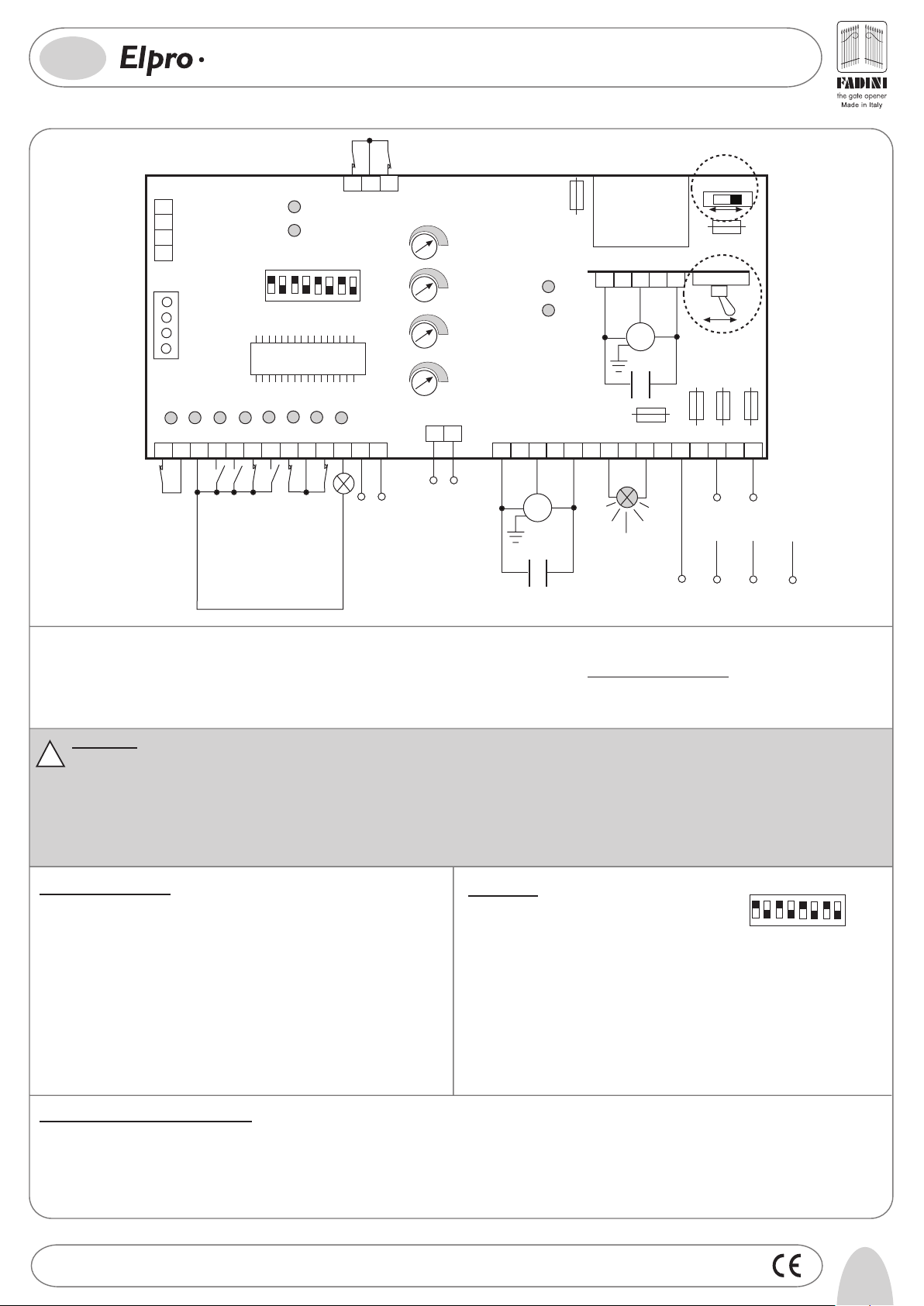

Page 2

GB

14

PLUS

230V-400V SINGLE- /THREE-PHASE CONTROL BOARD

DESIGNED FOR AUTOMATIONS TO OPERATE BI-PARTING SLIDING GATES

®

26

27

PULIN 3

28

3

PLUG-IN

RADIO CARD

CONNECTOR

L3

L2

1

EDGES

L4

2

3

COMMON

CLOSE

OPEN

PHOTOCELLS AND SAFETY

LIMIT SWITCH

CLOSING

M2 MOTOR

D49

D50

DIP-SWITCH

4

2

1

3

5

Elpro 14 Plus vers. 1.4

L5

L8

STOP

L7

L9

74

85

96

RADIO

LIMIT SWITCH COMMON

LIMIT SWITCH CLOSING M1

LIMIT SWITCH

OPENING

M2 MOTOR

35

34 33

-

ON

-

OFF

6

8

7

-

-

L6

13

11

10

12

LIMIT SWITCH OPENING M1

24V max 3W

PILOT LIGHT

1 Radio receiver

2 pairs photocells

24V OUTPUT max load:

T4

EXT TIME (Electric lock and

courtesy light) from 2 to 255s

+

T3

PEDESTRIAN TIME

+

from 3 to 30s

T2

DWELL TIME

+

from 5 to 128s

T1

MOTOR RUN TIME

+

from 5 to 128s

RS

RS

16

W

230V COURTESY LAMP

OR 12V AC RELAY FOR

ELECTRIC LOCK

F6=630mA

24V protection

17

COMMON

V

M1

MOTOR

CAPACITOR

L1

L10

CAPACITOR

F5=1A Flashing

lamp protection

18

U

TRANSFORMER

30

31

W

COMMON

V

M2

MOTOR

ELPRO 14 PLUS

19

20

FLASHING LAMP

230V 25W max

230/400V

F4=630mA

transformer protection

230/400V

32

U

F3=10A Mains

21 22

LIVE

S

SINGLE-PHASE

230V 50Hz

POWER SUPPLY

LIVE

S

T

THREE-PHASE

400V 50Hz

POWER SUPPLY

F2=10A Mains

2322

±10%

R

±10%

F1=10A Mains

NEUTRAL

NEUTRAL

General Description: Elpro 14 Plus is an electronic board incorporating a microprocessor to control single- and three-phase operators for bi-parting sliding gates. Power

supply is 230V/400V ±10% 50Hz single-/ or three-phase. it is built in compliance with BT 93/68/CE Low Voltage norms and EMC 93/68/CE norms for the electro-magnetic

compatibility. Installation is recommended by a qualified technician in observance of the existing regulations.

Incorporated logic functions: automatic or semi-automatic

operating modes, pre-flashing/no pre-flashing options, reversing/non reversing options by remote control, electric lock output, pedestrian mode, hold-on-switched (deadman)

control, gate status indication by leds. The manufacturer declines any responsability for incorrect handling and applications, and reserves the right to update the instructions

and the control board without notice. Failure to observe the installation instructions may result into serious damages to persons and properties.

IMPORTANT:

- The control box is to be fitted in a sheltered, dry place inside a suitable enclosure

!

- Fit the mains to the control box with a 0.03 A high performance, magnetic-thermal circuit breaker

- Make sure that the power supplied to the board is 230V/400V ±10% 50Hz

- For the power supply and the flashing lamp use 1.5 mm

2

wires up to 50 m distance; for the limit switches and the accessories use 1mm

2

wires

- Bridge terminals 1 and 2 if no photocells are required

- Bridge terminals 3 and 6 if no key- or button-switches are required

- N.W: Should other applications be required such as light switching, CCTV, etc. use only solid state relays to prevent disturbances to the microprocessor.

1

DIP-SWI TCH

2

3

ON

OFF

6

8

4

7

5

Led Status Indication:

L1 = Power supply 230V/400V±10% 50Hz alight

L2 = Photocells. If obstructed the led goes off

L3 = Open. It illuminates when an Open pulse is given

L4 = Close. It illuminates when a Close pulse is given

L5 = Stop. It goes off when a Stop pulse is given

L6 = Radio. It illuminates when the remote control is pulsed.

L7 = Gate Status Indication. It flashes while gate is moving

L8 = Limit switch Closing M1 motor. Off when gate is closed

L9 = Limit switch Opening M1 motor. Off when gate is open

Dip-Switch:

1= ON Photocells stop gate on opening

2= ON Radio. No gate reversing on opening

3= ON Automatic Closing

4= ON Pre-flashing in service

5= ON Radio. Step by step, stop in between

6= ON Deadman Control (Dip 4=OFF and Dip 3=OFF)

7= ON Flashing lamp off on dwell time, automatic mode

8= OFF, blank

L10 = It stays alight as long as the time set on T4 Trimmer

D49= Limit switch Closing M2 motor. Off when gate is closed

D50= Limit switch Opening M2 motor. Off when gate is open

In case the automation fails to start:

- Check power supply to be 230V or 400V ±10% 50 Hz

- Check fuses

- Check photocells contacts to be normally closed

- Check all N.C. contacts

- Check that no voltage drop occurs between the board and the electric motor

Drwg. No.

4198

5

Page 3

GB

®

14

LOW VOLTAGE ELECTRICAL CONNECTIONS

Photocells and Safety Edge:

PLUS

230V-400V SINGLE- /THREE-PHASE CONTROL BOARD

DESIGNED FOR AUTOMATIONS TO OPERATE BI-PARTING SLIDING GATES

1

2

3

74

85

96

10

13

11

12

2

1

CONTACT FOR

PHOTOCELLS AND

SAFETY EDGE

Keyswitch:

Limit switch:

Radio Contact:

12 13

24V OUTPUT (MAX LOAD:

2 PAIRS PHOTOCELLS

1 RADIO RECEIVER)

4

3

5

OPEN NO

CLOSE NO

9

COMMON

10

6

STOP NC

LIMIT SWITCH

OPENING M1

COMMON

8

LIMIT SWITCH

CLOSING M1

- Open/Close (standard)

- Any new pulse reverses gate travel

- Step by step

DIP-SWITCH 1:

ON: Photocells stop gate on Opening and

reverse it on Closing once obstacle is removed

1

OFF: Photocells do not stop gate on Opening

and reverse it on Closing if obstructed

COMMON

LIMIT SWITCH

3

COMMON

CLOSING M2

35 34 33

LIMIT SWITCH

OPENING M2

7

RADIO NO

DIP-SWITCHES 2 & 5

(NEVER set both of them on to ON at the same time):

ON: No reversing on Opening

OFF: Reversing by any new pulse

2

ON: Step by step. Stop in between

OFF: Standard operating mode

5

Electric Lock:

Mechanical device to hold the gate in closed gate position.

Trimmer T4 to the lowest

Working Time: 2 seconds anticipation of 100ms on gate starting.

24V 3W Pilot Light for gate

movement indication:

Push Button unit Pulin3:

Courtesy light:

Connect a 12VAC relay (Trimmer T4 from 2s

to 255s) to operate a 230V lamp

RS

8

COMMON

Leds signalling the

commands Open-

Stop -Close

RS

RS

11

COMMON

RS

PILOT LIGHT 24V

3W max

12V AC, 15VA OUTPUT

ELECTRIC LOCK

POWER SUPPLY

Light On= Gate Open. Passage allowed

Light Off= Gate Closed. Passage not allowed

Flashing 0.5s (fast)= Gate Closing

Flashing 1s (normal)= Gate Opening

With external clock: 2 short flashes followed by a longer stop

3

28

27

26

-

+

Trimmer T4

EXT TIME (Electric lock and Courtesy Light)

from 2 to 255s

-

+

Trimmer T4

EXT TIME (Electric lock and Courtesy

Light) from 2 to 255s

to the lowest

6

Drwg. No.

4198

Page 4

GB

10

PLUS

230V-400V SINGLE- /THREE-PHASE CONTROL BOARD

DESIGNED FOR AUTOMATIONS TO OPERATE BI-PARTING SLIDING GATES

®

ELECTRIC POWER CONNECTIONS

Single- and three-phase motors:

Important:

Dipending on the site voltage requirements

it is absolutely necessary to set both

switches accordingly

230/400V

230V

400V

16

W

CAPACITOR

Flashing light:

Pre-flashing (Dip-Switch 4=ON): Once an Open

pulse is given, after 3 seconds M1 motor starts

Once the gate is fully closed, the lamp goes on

flashing for 3 more seconds.

Control board power supply:

Fit the mains to the control board with a 0.03A high

sensitivity, magnetic-thermal, differential circuit breaker

The board can be supplied 230V 50Hz ±10% Single-phase or

400V ±10% Three-phase. Both switches are to be set to the

required voltage.

17

COMMON

V

M1

MOTOR

18

U

Motor for

pedestrian

opening

19 20

230V

230/400V

FLASHING LIGHT

230V - 25W max

400V

211816 17 19 22 2320

30

W

31

V

COMMON

32

U

-

Trimmer T1

M2

MOTOR

CAPACITOR

DIP-SWITCH 4 and 7:

ON: Pre-flashing

OFF: No pre-flashing

4

ON: No flashing with the lamp on

Dwell time. Automatic mode

OFF: Flashing on Dwell time in Automatic mode option

7

21 22

LIVE

S

230V 50Hz ±10%

SINGLE-PHASE

MOTOR RUN TIME OPEN /

CLOSE FROM 5 TO 128s

2322

NEUTRAL

21 22

T

400V 50Hz

THREE-PHASE

T1

+

T2

+

-

Trimmer T2

DWELL TIME

from 5 to 128s

FADINI

l'apricancello

2322

LIVE

S

R

±10%

230 VOLT

400 VOLT

FUNCTIONS

Automatic / Semi-automatic:

Automatic cycle: On pulsing to Open the gate is operated to open, stops for a time equal

to the dwell time as pre-set with T2 trimmer, after this time the gate is automatically

operated to Close.

Semi-automatic Cycle: On pulsing to Open the gate is operated to Open and held in open

position. A new pulse is needed for the gate to close.

Deadman Control:

Open and Close operations are by "hold on switched" control ( no

relay self-holding is involved). The automation is to be attended and

the command unit is required to be held switched to achieve gate

operation. Any operation is stopped on releasing the button or key.

DIP-SWITCH 6

ON= Deadman Control Dip-switch 4=OFF

and Dip-switch 3=OFF

OFF= Normal operating mode

6

Pedestrian Opening:

With the gate in fully closed position, it is possible to open the gate for pedestrians by

pulsing to Open with Dip-Switch No.6=ON terminals 3-4:

- a first Open pulse operates Motor 1 to open

- a second pulse operates the other gate to Open

A pulse given to terminals 7 - 8 (Radio Contact) by the remote control always operates both gates.

Radio out of service on Dwell time in

Automatic Mode option:

ON: No gate travel reversing on Opening

OFF: Any new pulse reverses gate travel

2

In this Mode, any pulse given by Radio remote control during the dwell time in Automatic mode option does

not allow any operation with the system . DIP-SWITCH No.2=ON, No.3=ON and No.5=ON

ON= Automatic Closing

OFF= No Automatic Closing

3

+

-

Trimmer T2

DWELL TIME

from 5 to 128s

+

-

Trimmer T3

From 3 to 30 s activated by any

commanding pulse (even by remote

control), superior to 2s to M1 Motor

ON: Step by step Stop in between

OFF: Standard operating mode

5

DIP-SWITCH 3

ON= Automatic Closing

OFF= No automatic closing

Semi-automatic mode

3

Time clock:

Drwg. No.

How it works: Set the clock to the required time. On the set time the gate is operated to open and held open. No

other operations can be achieved (not even by remote control) until the time set on the clock has expired. On

expiring of the clock time and after the dwell time of the system, the gate is automatically operated to to close.

Trimmer T3 is to be set on to zero, Dip-Switch No. 3=ON

+

-

Trimmer T3

T3 Trimmer. Pedestrian

to zero value

DIP-SWITCH No.3=ON Automatic Closing

ON= Automatic Closing

OFF= No automatic closing.

3

Semi-automatic option

4198

COMMON

43

OPEN

NO

COMMON

7

Page 5

200

182

3-2007

260 280

110

I -

Prima dell'installazione da parte di personale tecnico qualificato, si consiglia di prendere visione del

Libretto Normative di Sicurezza che la Meccanica Fadini mette a disposizione.

GB -

Please note that installation must be carried out by qualified technicians following Meccanica Fadini's

Safety Norms Manual.

F -

L'installation doit être effectuée par un technicien qualifié suivant le manuel des Normes de Sécurité

de Meccanica Fadini.

D -

Vor der Montage durch einen Fachmann, wird es empfohlen die Anleitung zur Sicherheitsnormen, die

Meccanica Fadini zur Verfügung stellt, nachzulesen.

E -

Antes de la instalación por el personal técnico calificado, se recomienda leer detenidamente el Folleto

de la Reglamentación de Seguridad que la empresa Meccanica Fadini pone a su disposición.

NL -

Voordat de installatie door gekwalificeerd technisch personeel wordt uitgevoerd, wordt geadviseerd

om het boekje met veiligheidsvoorschriften dat Meccanica Fadini ter beschikking stelt door te lezen.

Direttiva 2003/108/CE

Smaltimento dei materiali

I

elettrici ed elettronici

VIETATO GETTARE NEI RIFIUTI

MATERIALI NOCIVI PER L’AMBIENTE

2003/108/CE Directive

for waste electrical and

GB

electronic equipments

DISPOSE OF PROPERLY

ENVIRONMENT-NOXIOUS MATERIALS

®

s.n.c.

Via Mantova, 177/A - 37053 Cerea (Verona) Italy - Tel. +39 0442 330422 r.a. - Fax +39 0442 331054

e-mail: info@fadini.net - www.fadini.net

La ditta costruttrice si riserva di apportare modifiche al presente libretto senza preavviso

Loading...

Loading...