Page 1

pag. 1,2,3,4

®

I

GB

F

D

LIBRETTO DI ISTRUZIONI

12

12

NYOTA 115 SLIDING GATE OPERATOR

NOTICES D’INSTRUCTION

12

OUVRE-PORTAIL COULISSANT NYOTA 115

12

SCHIEBETORANTRIEBE NYOTA 115

PLUS

MONOFASE PER

SCORREVOLE NYOTA 115

INSTRUCTIONS

PLUS

SINGLE-PHASE FOR

PLUS

MONOPHASE POUR

ANLEITUNG

PLUS

EINPHASIG FÜR

- FUNZIONE PASSO PASSO - UOMO PRESENTE

- APERTURA PEDONALE - LUCE DI CORTESIA

- DIAGNOSTICA A LED LUMINOSI

- SPIA DI SEGNALAZIONE DELLO STATO DELL’AUTOMAZIONE

- FUNZIONE OROLOGIO

- STEP BY STEP OPERATIONS - HOLD-ON SWITCHED (DEADMAN) CONTROL

- PEDESTRIAN OPENING - COURTESY LIGHT

- FAULT INDICATION BY LEDs

- GATE STATUS INDICATION

- TIME CLOCK OPTION

page 1,5,6,7

- FONCTION PAS-PAS - HOMME MORT

- OUVERTURE PIETON - LAMPE D’ECLAIRAGE

- DIAGNOSE A LED VOYANT A DIODE

- SIGNALISATION DE L’ETAT DE L’AUTOMATION PAR LED

- FONCTION HORLOGE

page 1,8,9,10

- SCHRITT-IMPULS-FUNKTION - TOTMANN-BEDIENUNG

- GEHTÜRFUNKTION - DECKENLEUCHTE

- DIAGNOSE-LED

- AUTOMATION-STATUS ANZEIGELAMPE

- UHR-FUNKTION

Seite 1,11,12,13

E

NL

Dis. N.

4086

FOLLETO DE INSTRUCCIONES

12

VERJAS DESLIZANTES NYOTA 115

12

SCHUIFHEKKEN NYOTA 115

PLUS

MONOFASICO PARA

HANDLEIDING

PLUS

EENFASE VOOR

- FUNCIONAMIENTO PASO A PASO - HOMBRE PRESENTE

- ABERTURA PARA PASO DE PEATONES - LUZ AUXILIAR

- DIAGNOSTICO POR MEDIO DE LED LUMINOSOS

- LÁMPARA TESTIGO QUE SEÑALA ELE ESTADO DEL AUTOMATISMO

- FUNCIÓN RELOJ

- STAP-VOOR-STAP FUNCTIE - DODEMANSFUNCTIE

- VOETGANGERSDOORGANG - SIGNALERINGSLAMP

- DIAGNOSTIEK MET LICHTGEVENDE LEDS

- SIGNALERINGSLAMP AUTOMATISERINGSSTATUS

- KLOKFUNCTIE

Via Mantova, 177/A - C.P. 126 - 37053 Cerea (Verona) Italy - Tel. +39 0442 330422 r.a.

®

Fax +39 0442 331054 - e-mail: info@fadini.net - www.fadini.net

s.n.c.

pág. 1,14,15,16

pag. 1,17,18,19

1

Page 2

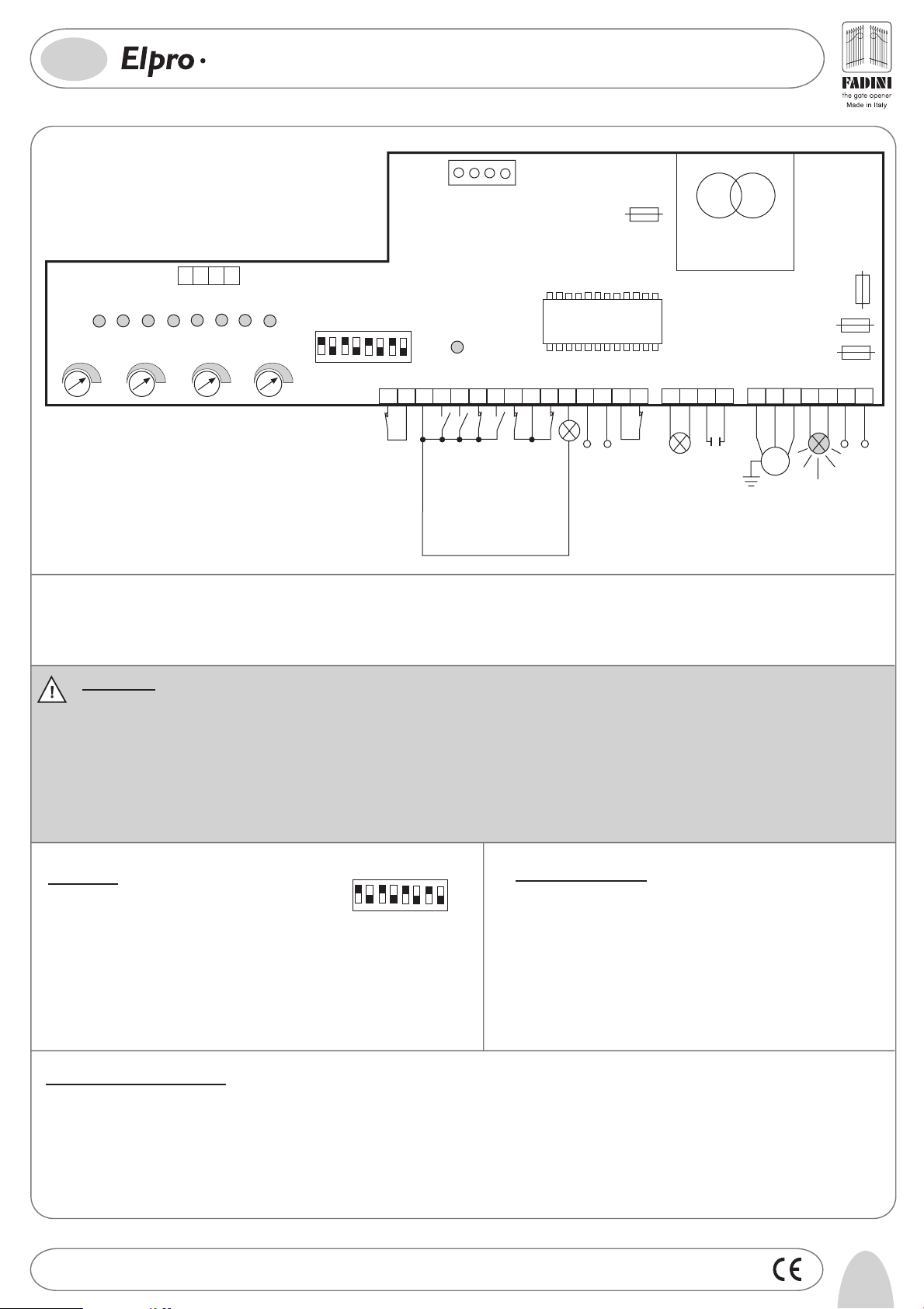

GB

PULIN 3

L3

L2

+

-

R65 R64 R63 R62

MOTOR RUN TIME

OPEN/CLOSE

from 2 up to 128s

L4

-

DWELL TIME

from 2 up to 128s

3

L5

TRIMMER

+

-

12

28

26

27

L6

L7

+

COURTESY LIGHT

from 2 up to 255s

L8

PLUS

L9

+

-

PEDESTRIAN OPENING

from 3 up to 30s

SINGLE-PHASE FOR NYOTA 115 SLIDING GATE OPERATOR

RADIO

14567823

PLUG-IN

CARD

CONNECTOR

ELPRO 12 PLUS

DIP-SWITCH

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

SAFETY EDGES

PHOTOCELLS

L1

ON

OFF

PUSH BUTTONS

COMMON

CLOSE

OPEN

STOP

RADIO CONTACT

LIMIT SWITCH CLOSE

F4 Fuse = 1A

24V Transformer

Protection

E 12 plus

MICROPROCESSOR

LIMIT SWITCH COMMON

LIMIT SWITCH OPEN

24V max. 3W

INDICATION LAMP

1 RADIO RECEIVER)

2 PAIRS PHOTOCELLS

24V OUTPUT (max. load:

SAFETY CONTACT

100W max.

TRANSFORMER

292324

30

CAPACITOR

COURTESY LIGHT

F3 Fuse = 630mA

Transformer Protection

F2 Fuse = 8A

F1 Fuse = 8A

181617

COMMON

M

SINGLE-PHASE

ELECTRIC

MOTOR 230V

Mains

Mains

19 20 21 22

VOLTAGE SUPPLY

FLASHING LAMP

230V 25W max.

®

230V ±10% SINGLE-PHASE

General description: the electronic control panel Elpro 12 Plus, new generation, is designed to operate the sliding gate operator Nyota 115. Power supply is 230V 50Hz

single-phase. Built in full compliance with 2006/95 CE Low Voltage and 2004/108/CEE & 92/31 CEE Electro-Magnetic Compatibility Regulations.

Fitting operations are recommended by a qualified technician in conformity to the existing safety standards.

The manufacturing company declines any responsability for incorrect handling and application; also, it reserves the right to change or update the control panel any time.

Failure to follow installation regulations may result into serious damage to property and persons.

PLEASE NOTE:

- The control panel must be installed in a sheltered, dry place, inside the box provided with it.

- Make sure that the power supply to the electronic programmer is 230V ±10%

- Make sure that the power supply to the Electric Motor is 230V ±10%

- For distances of over 50 metres we recommend using electric cables with bigger sections.

- Fit the mains to the control panel with a 0.03A high performance circuit breaker.

- Use 1.5mm2 section wires for voltage supply, electric motor and flashing lamp. Maximum recommended distance 50m.

Use 1mm2 section wires for limit switches, photocells, push-buttons/key-switch and accessories.

- Bridge terminals 1 and 2 if no photocells are required.

- Bridge terminals 3 and 6 if no key- or push-button switches are required.

N.W: To fit extra accessories such as lights, CCTV etc. use only solid state relays to prevent damages to the microprocessor.

Dip-Switch:

1= ON. Photocells. Stop while opening

2= ON. Radio. No reversing while opening

3= ON. Automatic closing

4= ON. Preflashing activated

5= ON. Radio. Step by step. Stop in between

6= ON. Dead Man Control (Dip 4=OFF and Dip 3=OFF)

7= ON. No lamp on during dwell time

8= OFF

. No function

1456782

DIP-SWI TCH

3

ON

OFF

Led Status Indication:

L1= 230V 50Hz power supply. Alight

L2= Photocells, if obstructed light goes off

L3= Open. Alight whenever an Open pulse is given

L4= Close. Alight whenever a Close pulse is given

L5= Stop. It goes off on pulsing Stop

L6= Radio. It goes on by pressing a transmitter button

L7= Gate Status; it flashes on gate opening

L8= Limit switch Close; off when gate is closed

L9= Limit switch Open; off when gate is open

In case of failure of the panel:

- Make sure that the power supply to the electronic programmer is 230V ±10%

- Make sure that the power supply to the Electric Motor is 230V ±10%

- For distances of over 50 metres we recommend using electric cables with bigger sections.

- Check fuses

- Check photocells if contacts are normally closed

- Check all NC contacts

- Check that no voltage drop has occurred from the control panel to the electric motor

Drwg. No.

4086

5

Page 3

®

GB

LOW VOLTAGE ELECTRICAL CONNECTIONS

Photocells and Safety Edge:

2

1

PHOTOCELLS

AND SAFETY EDGE

12 13

12

24V OUTPUT (500 mA) (MAX. LOAD:

2 PAIRS PHOTOCELLS

1 RADIO RECEIVER)

PLUS

SINGLE-PHASE FOR NYOTA 115 SLIDING GATE OPERATOR

DIP-SWITCH 1:

ON: Photocells stop gate while opening,

reverse it on closing once obstacle is removed

OFF: Photocells do not stop gate while opening,

1

reverse it on closing in case of an obstacle

Button switch:

Radio Contact:

- Open/Close (Standard)

- Travel reversing on

pulsing

- Step by step

Push Button Switch Pulin 3:

24V 3W Indication Light:

Light ON = Open gate

Light OFF = Closed gate

Flashing (fast) 0.5s= Closing gate

Flashing (normally) 1s= Opening gate

Flashing (slowly) 2s= gate is stopped

3

COMMON

3

COMMON

4

OPEN

5

CLOSE

7

RADIO

CONTACT

COMMON

3

6

STOP

28

26

27

Led to indicate status of

Open - Stop - Close

switches

3

11

Limit switch:

DIP-SWITCH 2 and 5 (NEVER set BOTH of them ON

at the same time):

ON: Gate is not reversed while opening

OFF: Any pulse reverses the gate

2

ON: Step by step. Stop in between

OFF: Standard operating mode

5

Safety Contact:

CLOSE

14

8

LIMIT SWITCH

15

10

9

LIMIT SWITCH

OPEN

COMMON

This contact must be

N.C. for the control

panel to be allowed to

work

ELECTRICAL POWER CONNECTIONS

Capacitor and Single-phase Motor (230V):

Flashing lamp:

19

20

ON: Pre-flashing

OFF: No pre-flashing

4

ON: Lamp is not operating during

Dwell time. Automatic mode.

OFF: It flashes during Dwell Time.

230V MAX 25W

7

Automatic Mode.

Courtesy light:

Connect a 24VAC Modular Relay

R63 Trimmer Time from 2s to 255s)

(

to operate a 230V lamp

6

Drwg. No.

4086

DIP-SWITCH 4 and 7:

23 24

29

30

Capacitor

20μF for 0.5HP

40μF for 1.0HP

Trimmer R63

-

COURTESY LIGHT

FROM 2 UP TO 255s

181617

COMMON

M

FROM 2 UP TO 128s

R65

-

MOTOR RUN

TIME

OPEN/CLOSE

+

R64

+

-

DWELL TIME

FROM 2 UP TO 128s

Power supply:

21 22

POWER SUPPLY

230V ±10% 50Hz

SINGLE-PHASE

+

Page 4

GB

OPERATING MODES

12

PLUS

SINGLE-PHASE FOR NYOTA 115 SLIDING GATE OPERATOR

®

Automatic / Semiautomatic:

Automatic Operation: any pulse opens the gate, the gate stays open as long as the Dwell time expires

as set by R64 trimmer, then it closes automatically, no pulsing is required.

Semi-automatic Operation: any pulse opens the gate that stays open. A second pulse to Close is required

for the gate to close.

Pedestrian Opening:

Gate in fully closed position; an Open pulse opens the gate a span equals to the time set

by Pedestrian Trimmer

Hold on switched (Deadman) control:

Open and Close operations are achieved “by holding a switch on” (no relay self-holding

is involved) therefore a phisical attendance is required to keep the gate opening or

closing until either the button or key is released.

Time Clock Installation (Optional):

How it works: Set the clock to the required times. On the pre-set time the gate is automatically

opened and held open. Any further pulsing (even by remote control) is not accepted by

the system until the time pre-set by the clock has expired. On expiring and after the preset dwell time the gate is closed automatically.

R62 trimmer on to zero, Dip-Switch 3=ON.

COMMON

Trimmer R64

-

Dwell Time

from 2 to 128s

3

COMMON

DIP-SWITCH 6

ON= Deadman Control. Dip-switch 4=OFF

and Dip-switch 3=OFF

OFF= Standard Operations

6

4

OPEN

External Time Clock

43

OPEN

NO

+

COMMON

DIP-SWITCH 3

ON= Automatic Closing

OFF= No Automatic. Semi-automatic

3

closing by pulse

Trimmer R62

+

-

Trimmer R62 at minimum

disactivates Pedestrian Opening

from 3 to 30s. It can be activated

by any pulse superior to 2s

DIP-SWITCH No.3=ON Automatic Closing

ON= Automatic Closing

OFF= No Automatic. Semi-automatic

3

closing by pulse

+

-

Pedestrian Trimmer R62

set on to zero

Drwg. No.

4086

7

Page 5

04-2010

I -

Prima dell’installazione da parte di personale tecnico qualificato, si consiglia di prendere visione del

Libretto Normative di Sicurezza che la Meccanica Fadini mette a disposizione.

GB -

Please note that installation must be carried out by qualified technicians following Meccanica Fadini’s

Safety Norms Manual.

F -

’installation doit être effectuée par un technicien qualifié suivant le manuel des Normes de Sécurité

L

de Meccanica Fadini.

D -

Vor der Montage von einem Fachmann, wird es empfohlen die Anleitung zur Sicherheitsnormen, die

Meccanica Fadini zur Verfügung stellt, nachzulesen.

E -

Antes de la instalación por el personal técnico calificado, se recomienda leer detenidamente el Folleto

de la Reglamentación de Seguridad que la empresa Meccanica Fadini pone a su disposición.

Voordat de installatie door gekwalificeerd technisch personeel wordt uitgevoerd, wordt geadviseerd

NL -

om het boekje met veiligheidsvoorschriften dat Meccanica Fadini ter beschikking stelt door te lezen.

®

®

s.n.c.

s.n.c.

Via Mantova, 177/A - C.P. 126 - 37053 Cerea (Verona) Italy - Tel. +39 0442 330422 r.a. - Fax +39 0442 331054

e-mail: info@fadini.net - www.fadini.net

La ditta costruttrice si riserva di apportare modifiche al presente libretto senza preavviso

Loading...

Loading...