Page 1

CORAL 1050

CORAL 1080

Retractable oil-hydraulic

traffic control post

Diameter ø100mm

Stroke 500 mm

Stroke 800 mm

Instruction manual

GB

Page 2

INSTRUCTIONS TO BE FOLLOWED BEFORE INSTALLING THE OPERATOR

FOR OPTIMAL APPLICATION AND USE OF THE OPERATOR PLEASE READ THE INSTRUCTIONS AND CONSULT EXPLANATORY DIAGRAMS.

IMPORTANT: ALL INSTALLATION OPERATIONS MUST BE PERFORMED BY A QUALIFIED TECHNICIAN, IN OBSERVANCE OF THE

EN 12453 - EN 12445 SAFETY REGULATIONS AND MACHINERY DIRECTIVE 98/37/EC. CAREFUL RISK ANALYSIS IS REQUIRED UNDER

APPLICABLE REGULATIONS

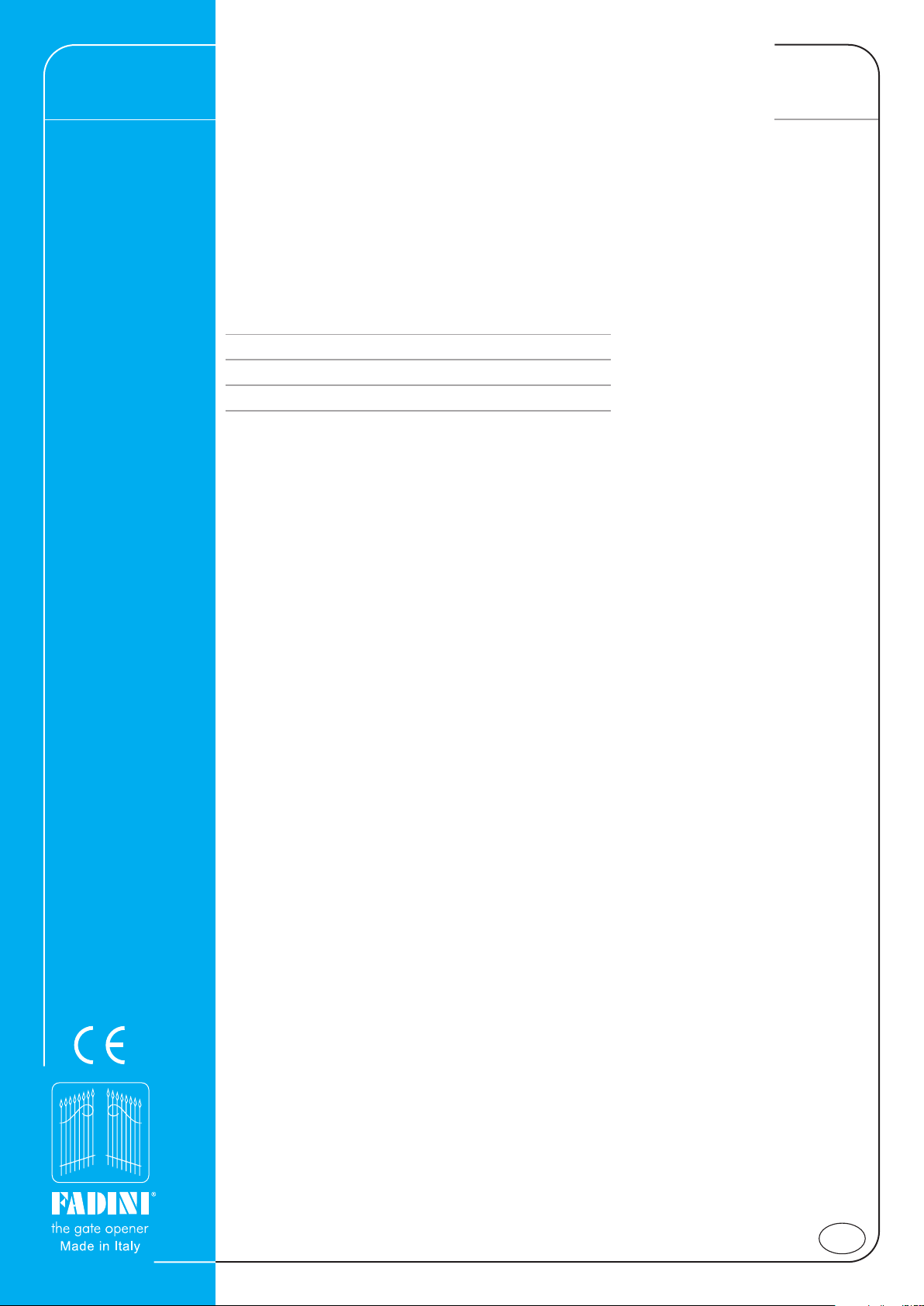

A - Retractable post that moves vertically out of the road paving

Coral 1050

B - Container unit inside the housing to be sunk in a dedicated

trench in the ground

FA

D

IN

I

l

’

a

p

r

i

c

a

n

c

e

l

l

o

Ø100

A

stroke

500mm

B

Length of

electrical cables

10 metres

FA

D

IN

I

l

’

a

p

r

i

c

a

n

c

e

l

l

Ø100

A

B

o

stroke

800mm

Coral 1080

F

A

D

I

N

I

l

’a

p

r

ic

a

n

c

e

ll

o

Coral 1050 and Coral 1080

with raised post

access prohibited

Coral 1050 and Coral 1080

with lowered post

access free

PIC. 1

OVERVIEW

This product belongs to our range of retractable traffic control posts. It is quick and easy to install, as it does not need to be adjusted or

calibrated and has been designed to regulate and prohibit vehicular access.

Both the CORAL 1050 and CORAL 1080 oil-hydraulic operators have anti-corrosion treated steel posts with a diameter of Ø100mm and

ranges of 500mm (Coral 1050) and 800mm (Coral 1080).

The product’s hallmark is its ease of installation: once the housing has been secured, the operator can be introduced ready for operation,

as soon as the wiring has been completed.

As soon as the retractable post receives a command (from a key switch or radio transmitter), it rises from its interred position. The post

is clearly visible at nighttime thanks to a reflective strip and the possibility of connecting a flashing light or traffic light. Using the electronic

microprocessor programmer, the operator can also be customised with presence indicator accessories (magnetic coils, presence

indicator photocells).

PRELIMINARY OPERATIONS

Before starting installation operations, it is important to follow the indications given below:

- Before digging the trench to house the housing, check that there are no pipes or other utilities that could interfere with

the preparatory operations.

- Check the firmness and consistency of the ground.

®

- Remove any obstacles hindering the post’s movement.

2

Page 3

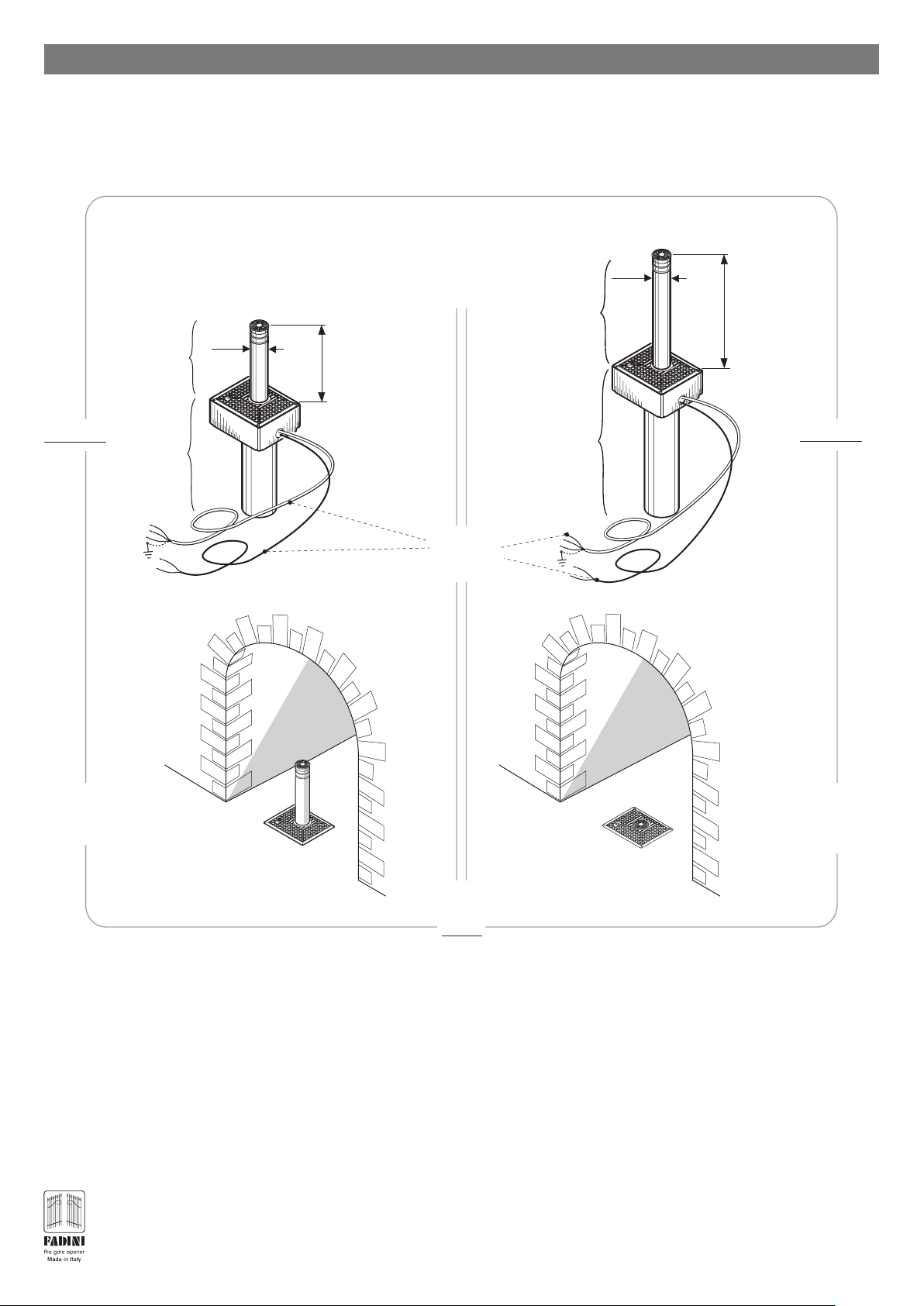

PRELIMINARY OPENING OF ALL FUNCTIONAL COMPONENTS

Eyebolt

Post cover

Rubber buffer

Cover plate

Electric motor cable,

10 metres

Detail of retractable post

with hoisting connection

Housing to be cemented

Cylindrical container for oilhydraulic piston

Hydraulic

main unit

Cable for opening limit

switch (post lowered),

10 metres

into the ground

Electric motor cable,

10 metres

PIC. 2

Start by removing the cover plate to reveal the operator and separate the individual components, with the aid of a hoist. Pic.2: this makes it

easy to extract the internal piston and hydraulic main unit container unit.

IMPORTANT: take care not to tear or cut wires.

3

®

Page 4

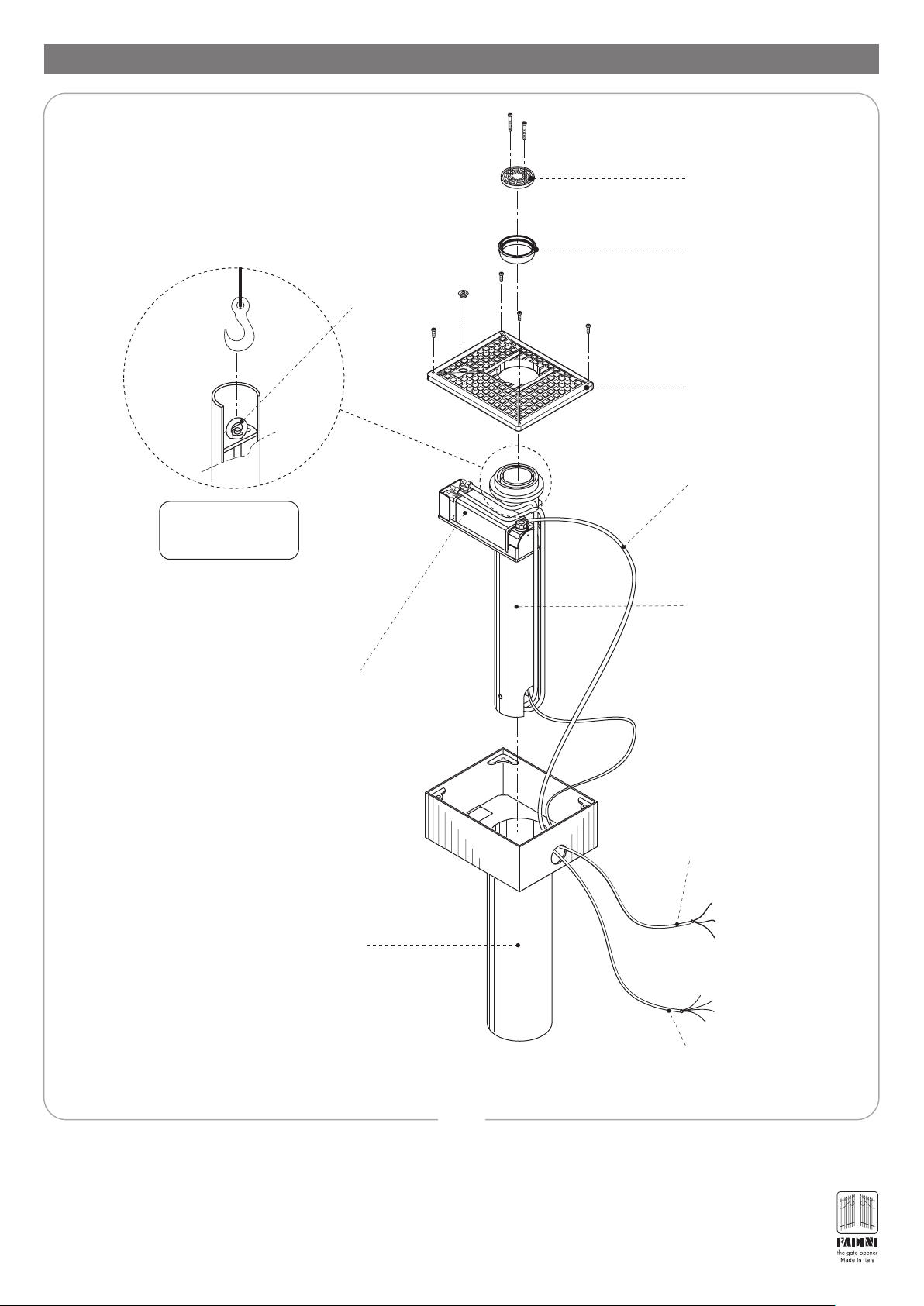

ARRANGING THE HOUSING

CORAL 1050

CORAL 1080

845

675 170

330

200

FRONT SIDE

Ø195

Coral 1050 Housing

PIC. 3 PIC. 4

200

130

400

200

165

120

165

Side

Front

120

Side view

330

165

200

top part

housing

165

130

ø 60

Side

Back

1140

330

170

970

Ø195

Coral 1080 Housing

200

FRONT SIDE

200

400

200

130

120

165

165

The Housing is the component inside which the operator is installed. It is therefore essential, when securing it in the ground to check

that the top edge is level with the ground.

IMPORTANT: the top recess of the Housing (inside which the hydraulic main unit is placed), is not central to the tube below inside which

the oil-hydraulic piston unit is placed: the latter is 13cm from the “Back side” of the Housing (Pic.3 and Pic.4).

Piping

Ø50 mm

for passage

of electric wires

12 cm

Depth

Piping centre

Housing

15 cm

Loose pebble

drainage layer

1.30 m

800 mm

BACK SIDE

FRONT SIDE

200 mm

Buried Coral 1080 Housing

395 mm

790 mm

230 mm

395 mm

Piping

Ø50 mm

for passage

of electric wires

12 cm

Depth

Piping centre

Housing

15 cm

Loose pebble

drainage layer

1.0 m

395 mm

800 mm

BACK SIDE

FRONT SIDE

200 mm

Buried Coral 1050 Housing

790 mm

395 mm

230 mm

PIC. 5 PIC. 6

- Dig a trench in the ground in the point at which the Coral 1050 or Coral 1080 operator is to be installed, according to the

measurements shown in Pic.5 and Pic.6, and connect a Ø50 mm pipe leading to the Elpro S40 electronic programmer (10 metres

®

of cable are provided).

Place a 15 cm deep layer of loose gravel and pebbles on the bottom.

4

Page 5

Spirit

level

Concrete

cast

- Once the housing has been positioned and installation

completed, it is important for the top edge to be level

with the ground (Pic. 7 and Pic. 8)

IMPORTANT: The top edge of the

housing must be level with the ground

!

when installation has been completed

Concrete

cast

FRONT SIDE

cover with about 30 cm

of concrete

30 cm

Cover rest of housing with earth

Housing CORAL 1050

Housing CORAL 1080

PIC. 7

PLACING THE TRAFFIC CONTROL POST INSIDE THE HOUSING

Hoisting

hook

Piston

container unit

CORAL 1050

CORAL 1080

CORAL 1050

CORAL 1080

Electric motor and limit switch

cables,

10 metres

3

4

1

2

Elpro S40 electronic

programmer wall-mounted

in a protected place

51

50

Housing

Buried piping

Ø50 mm

PIC. 8

Before performing this operation, wait for the housing to be secured firmly in place. Do not commence until the concrete has set and

the electric wire pipe has been secured and covered with soil.

- Use a hoisting hook to lift the piston unit with the post and main unit (using the eyebolt) and place on top of the housing.

- The subsequent phase of this operation consists in threading the motor and limit switch electric wires through the piping and simultaneously

starting to delicately place the operator inside the housing.

IMPORTANT: Pass the motor and limit switch electric wires through the piping without tearing or cutting the cables. Pic.8.

5

®

Page 6

ELECTRIC CONNECTIONS WITH THE ELECTRONIC PROGRAMMER

Traffic lights card 230V

power supply

RED

YELLOW

GREEN

60 61

63 64 65 66

External three-light

traffic lights

51 52 53

S40

230V input ±10% 50 Hz

Siti 63 Plug-in

radio receiver

Programmer

Important: Place a jumper

between the Common and

the Closing limit switch

(terminals 12 and 13)

S40

20µF

Siti

20 µF

Capacitor

1 2 3 4 5 6 7 8 9

26 27 28 29 30

11 12 13 14 15

31 32 33 34 35 36

22 23 24 25

16 17 18 19 20 21

70/1

M1

OPENING LIMIT SWITCH M1

(Post lowered)

CLOSING LIMIT SWITCH

(Post raised)

11

Brown

14 15!16 17 18

13

12

Black

LIMIT SWITCH

COMMON

Common

MOTOR COMMON

MOTOR PHASE

MOTOR PHASE

Connect all yellow-green

wires to the grounding in this

!

terminal.

SOLENOID VALVE

POWER SUPPLY

(OPTIONAL)

22 23

Apply a 0.03A

high-sensitivity

differential

thermomagnetic

circuit breaker

Earthing

Dark blue wire

NO contact

not used

®

6

Earthing

Limit switch cable

cable

Electric motor

Solenoid valve cable

(Optional on request)

CORAL 1050

CORAL 1080

Buried

PIC. 9

Two electric cables are provided with Coral 1050 and Coral 1080 traffic control posts: one to connect the 230V 50Hz

electric motor to terminals 16, 17 and 18 and another one to connect to the terminal of the opening limit switch 11

and the common 13 (Pic.9).

Place a jumper between terminals 12 and 13 of the closing limit switch

Page 7

WIRING DIAGRAM SHOWING CONNECTIONS WITH THE ELECTRONIC PROGRAMMER

F

A

D

IN

I

S40

+-

55 56

-

T2

DWELL TIME

1s - 180s

9101112

24V DC OUTPUT

+

ON

OFF

L12 L13 L14 L15

26 27 28 29 30

(Post lowered)

M3 OPENING LIMIT SWITCH

(Post raised)

CONNECTOR FOR 3 LIGHT

TRAFFIC LIGHTS,

MAX 100W PER BULB

-

+

Siti

T1

OPERATING TIME

1s - 22s

14567823

SUPPORT FOR

PLUG-IN RADIO

CARD

DIP-SWITCH

Elpro S40

L3

L2

L1

Input P

17410285396

57 58

Traffic control post motor M1

Pedestrian passage

magnetic coil

Contact terminal

Photoelectric cell or

Common

Open

L4

Close

Stop

L5

L6

Indicator light 24V 3W max

Radio

- 1 Radio receiver

- 2 pairs of photoelectric cells

L7

Output 24V 250mA for max. load:

FIRST OPERATION MANOEUVRES

Secondary Fuse

Transformer

F4= 2A

M3O M3C M4O M4C

Capacitor

C

O

M

M

O

N

(Post lowered)

M4 OPENING LIMIT SWITCH

(Post raised)

M4 CLOSING LIMIT SWITCH

M3 CLOSING LIMIT SWITCH

3

L8

L9

L10 L11

11 12 13

14 15

C

O

M

M

(Post lowered)

M1 opening limit switch

O

N

(Post raised)

M1 closing limit switch

(Post lowered)

M2 opening limit switch

CORAL 1050

CORAL 1080

20VA 50/60Hz

TRANSFORMER

Capacitor

20µF M4

20µF M3

AA

BB

34

36

35

333132

C

C

O

O

M

M

M

M

O

O

N

N

M4

M3

M3 MOTOR

Traffic control post no. 3

Traffic control

post no. 4

4

Capacitor

20µF M1

A

C

O

M

(Post raised)

M2 closing limit switch

M

O

N

control post no. 1

12

Fuse

Motor M4

F6= 5A

Fuse

Motor M3

F7= 5A

M4 MOTOR

Capacitor

20µF M2

A

B

1816 17

21

19 20

C

O

M

M

O

N

M1

M2

M2 MOTOR Traffic

control post no. 2

M1 MOTOR Traffic

Primary Fuse

Transformer

F3= 630mA

51 52 53

COMMON

Fuse for Solenoid Valve,

Buzzer, Flashing Light

and LED F5=1A

Fuse Motor M2

Fuse Motor M1

Anti-disturbance filter

B

2322 24 25

power supply

230V 50Hz

F2= 5A

F1= 5A

P

H

A

N

F

S

E

Panel power supply

Solenoid valve

230V ±10% 50Hz

Single-phase

FLASHING LIGHT

230V 100W max

l’a

p

r

ic

a

n

c

e

l

lo

N

E

U

T

R

A

L

Ref. Drwg. No.

4555

PIC. 10

ATTENTION: it is important to establish the exact position

of the traffic control post, open or closed, according to

!

whether it allows or prohibits vehicular access (Pic. 11)

Traffic control post

FADINI

l’apricanc

ello

Having terminated installation of the traffic control post and all the

safety and control accessories and the respective connections with

the Elpro S40 programmer, and having completed thorough risk analysis,

the first operation manoeuvres can be performed. If you have a radio

Post in raised position:

Access prohibited

transmitter, encode the radio receiver according to the relative

instructions before giving the command to raise the retractable post,

or give the manoeuvre command using a key switch. Pic.11.

Phase

Phase

During first use, it is important to check whether the wiring of the

Common

Switch over phases

electric motor phases corresponds to the "open" and "closed" positions

of the traffic control post, with the post raised limit switch (access

prohibited), if this is not the case, switch over the two “phase” wires,

16 17 18 16 17 18

leaving the common fixed (Pic. 12).

CORAL 1050

GROUND-LEVEL CLOSURE OF COVER PLATE

- Use the four screws to close the Cover Plate (Pic.13)

- Lift the retractable post for facilitate closure of the post cover with

the buffer, give the command (by encoding a transmitter with the

radio receiver or a key switch Pic.12) to lift the retractable post (Pic.13).

CORAL 1080

Cover

Buffer

PIC. 11

PIC. 12

GREASE

Post lowered:

Access open

Phase

Phase

Common

IMPORTANT:

WE RECOMMEND GREASING

ALL CLAMPING SCREWS

Stop

Cover plate

Retractable

post

F

A

D

IN

I

l’apricancello

®

PIC. 13

7

Page 8

INSTALLATION WIRING

CORAL 1050

CORAL 1080

1

10

11

8

4x1,5mm

2

9

2

3

4

4x1mm

2

7

FADINI

l

’a

p

r

ic

a

n

c

e

llo

2x1mm2RGB cable

4x1mm

2x1mm

2

4x1mm

230V ±10%

2

2

50 Hz

Earthing

6

2

2x1mm

4x1m

- M

2

m

otor

2x1m

itch

it sw

2

- Lim

m

4x1mm

2

5

6

Components

1 - MIRI 4 flashing light with built-in aerial

2 - Wall-mounted Astro 43 radio receiver

3 - Elpro S40 Electronic programmer

4 - Differential circuit breaker switch

(sensitivity 30mA, protection 6-10A)

5 - Junction box, electric wires

6 - Polo 44 photoelectric cell projector

7 - Polo 44 photoelectric cell receiver

8- Prit 19 key switch

9- Two-light 230V traffic light

10 - Coral 1050 or Coral 1080 retractable traffic control post

11 - Astro 43/2 Piccolo transmitter

IMPORTANT:

The whole electric system must be earthed (Pic. 15).

7

PIC. 14

Before making electric connections, carefully read the wiring diagrams attached: Elpro S40 electronic programmer instruction booklet

- Drwg. 4555.

- Power supply, electric motor and flashing light wiring must be made using cables with 1.5 mm2 sections, for a maximum distance of

50 m. For distances of over 50 metres, we recommend using electric wires with sections of 2 mm

- For the Photoelectric cells, button switches and accessories, electric wires with 1 mm

2

sections may be used.

2

.

- The whole electrics system must be earthed.

ARRANGING THE SAFETY AND SIGNALLING ACCESSORIES

CORAL 1050

CORAL 1080

All safety and control accessories must be installed at certain

distances from the operator in order to obtain effective

installation. Connect to earth.

FADINI

l’a

p

ric

a

n

c

e

.

llo

0 m

ARRANGEMENT OF THE PHOTOELECTRIC CELLS

The photoelectric cells must be installed at a minimum

working distance as indicated in Pic. 15.

Prit 19

min 1

ARRANGING VISUAL 344

The 2 or 3-module Visual 344 cabinet is a metal accessory

used to house the Elpro S40 in exposed positions, in those

installation situations in which the programmer cannot be

wall- or recess-mounted. It has also been designed for the

S40

installation of possible control accessories such as intercom

systems or key switches, in the immediate vicinity of the

Coral 1050 or Coral 1080 (pic. 15).

PIC. 15

®

8

Page 9

WIRING 4 TRAFFIC CONTROL POSTS TO THE ELECTRONIC PROGRAMMER

RED

Three-light

traffic lights

Siti 63 Plug-in

radio receiver

YELLOW

GREEN

1

°

R

63 64 65 66

Siti

2

°

R

60 61

26 27 28 29 30 31 32 33 34 35 36

20 µF

3

20 µF

4

S40

230V ±10%

50Hz

High sensitivity

differential circuit-

breaker, type 0.03 A

Earthing

Capacitors sold

loose

separately

Prit 19 key

switch with

STOP

1

20 µF

1 2 3 4 5 6 7 8 9

1 2 3 4 5 6 7 8 9 10

1

11 12 13 14 15

FA

D

IN

I

l’apric

ancel

lo

16 17 18 19 20 21

FA

DI

N

I

l’ap

rica

ncello

2

22 23 24 25

11 12 13 14 15

F1

11 12 13

F2

13 14 15

FA

D

IN

I

l’apr

ic

an

ce

llo

16 17 18 19 20 21

M1

16 17 18

M2

19 20 21

FA

D

IN

I

l’a

pric

an

ce

llo

20 µF

26 27 28 29 30

F3

26 27 28

F4

28 29 30

2

31 32 33 34 35 36

M3

31 32 33

M4

34 35 36

Pull-out

terminals

Polo 44

photoelectric cells

Projector

CORAL 1050

CORAL 1080

3

4

1 - 2 - 3 - 4 - Retractable post

F1 - F2 - Retractable post limit switch 1 and 2

F3 - F4 - Retractable post limit switch 3 and 4

Connecting 4 traffic control posts

to the electronic programmer

S40

Polo 44

photoelectric cells

Projector

PIC. 16

®

9

Page 10

MANUAL RELEASE OPERATIONS

CORAL 1050

CORAL 1080

1) - Unscrew protection cap

12

1

11

2

10

9

3

8

4

567

3) - Release the hydraulic circuit by

turning the release key one turn

anti-clockwise

Release

key

2) - Insert the release key

in the release key

recess

F

ADINI

l’apr

ic

an

cello

12

1

11

2

10

9

3

8

4

567

FADINI

l

’

a

p

ri

c

a

n

c

e

l

lo

5) - Block the hydraulic circuit by

4) - Press to lower the post

manually

turning the release key

clockwise

PIC. 17

In the case of a blackout, the post can be lowered manually following the instructions show in Pic.17. Unscrew the Protection cap (1),

insert the release key into the recess (2) and turn once anti-clockwise to release the hydraulic circuit (3). Press down manually to lower

the column (4) and then block the hydraulic circuit, by turning the release key clockwise (5).

= To raise the post, first “Block” by turning the key clockwise, then give command =

PACKAGING DETAILS

Oil-hydraulic traffic control post CORAL 1050

0.50 m

0.45 m

CORAL 1050

CORAL 1080

0.85 m

0.40 m

R

Oil-hydraulic traffic control post

CORAL 1080

R

0.40 m

0.50 m

0.45 m

1.20 m

Individually packed

on wooden pallet

Total weight of Coral 1050: 91 Kg

PIC. 18 PIC. 19

®

Important: discarded material should be disposed of using the dedicated containers by specialised firms.

10

Individually packed

on wooden pallet

Total weight of Coral 1080: 109 Kg

Page 11

MANUFACTURER'S DECLARATION OF CONFORMITY

CORAL 1050

CORAL 1080

1

s.n.c.

®

R

MANUFACTURER'S

CORAL 1050

Via Mantova 177/A - 37053 Cerea (VR) Italy

Tel. +39 0442 330422 - Fax +39 0442 331054

e-mail: info@fadini.net - www.fadini.net

HEREBY DECLARES UNDER ITS OWN RESPONSIBILITY THAT:

DECLARATION OF CONFORMITY

Manufacturer:

Address:

Model:

retractable traffic control post

2

3

EN 12445 & EN 12453

and that:

IS CONFORMING TO MACHINERY DIRECTIVE .........98/37/CE

- Low Voltage directive 2006/95 CE

Coral 1050 is sold for installation as an automated system, with original accessories and components indicated by the

Manufacturer.

Pursuant to legal provisions, the operator is a ‘machine’ and consequently, the Installer must comply with all applicable

safety regulations. The Installer is obliged to issue his/her own Declaration of Conformity.

The Manufacturer declines all responsibility for improper use of the product

- Electromagnetic Compatibility Directive 2004/108/CEE & 92/31 CEE

The product is conforming to the following specific regulations:

- Risk analysis and subsequent operations to eliminate them:

®

EN 13241-1

Supervisor

Supervising Manager

Meccanica Fadini s.n.c.

PRODUCT STANDARD .........................

09-06-08

In order to certify the product, the Manufacturer declares under its own responsibility that it complies with

Date:

GB

1

s.n.c.

®

R

MANUFACTURER'S

CORAL 1080

Via Mantova 177/A - 37053 Cerea (VR) Italy

Tel. +39 0442 330422 - Fax +39 0442 331054

e-mail: info@fadini.net - www.fadini.net

HEREBY DECLARES UNDER ITS OWN RESPONSIBILITY THAT:

DECLARATION OF CONFORMITY

Manufacturer:

Address:

Model:

retractable traffic control post

2

3

EN 12445 & EN 12453

and that:

IS CONFORMING TO MACHINERY DIRECTIVE .........98/37/CE

Coral 1080 is sold for installation as an automated system, with original accessories and components indicated by the

Manufacturer.

Pursuant to legal provisions, the operator is a ‘machine’ and consequently, the Installer must comply with all applicable

safety regulations. The Installer is obliged to issue his/her own Declaration of Conformity.

The Manufacturer declines all responsibility for improper use of the product

The product is conforming to the following specific regulations:

- Risk analysis and subsequent operations to eliminate them:

- Low Voltage directive 2006/95 CE

- Electromagnetic Compatibility Directive 2004/108/CEE & 92/31 CEE

®

EN 13241-1

Supervisor

Supervising Manager

Meccanica Fadini s.n.c.

PRODUCT STANDARD .........................

09-06-08

In order to certify the product, the Manufacturer declares under its own responsibility that it complies with

Date:

GB

11

®

Page 12

TECHNICAL DATA AND DIMENSIONS

HYDRAULIC MAIN UNIT

Hydraulic pump ......................................................................................................................................P10

Hydraulic pump flow rate ..........................................................................................................4.45 l /min

Mean operating pressure .................................................................................................2 MPa (20 bar)

Maximum pump pressure .................................................................................................4 MPa (40 bar)

Operating temperature......................................................................................................... –20°C + 80°C

Hydraulic oil type .........................................................................................................................Oil Fadini

Main unit static weight ......................................................................................................................10 Kg

Main unit protection class .................................................................................................................IP 54

ELECTRIC MOTOR

Output ..............................................................................................................................0.25 KW (0.33 HP)

Supply voltage .....................................................................................................................................230 V

Absorbed current ................................................................................................................................1.8 A

Frequency ............................................................................................................................................50 Hz

Consumption power ..........................................................................................................................330 W

Capacitor ..............................................................................................................................................20 µF

Motor rotation speed ..................................................................................................................2˙800 rpm

Service mode ...........................................................................................................................................S 3

CORAL 1050

OIL-HYDRAULIC PISTON

Rod exit time..............................................................................................................................4s

Net rod stroke..................................................................................................................500 mm

Rod diameter......................................................................................................................16 mm

Plunger diameter...............................................................................................................30 mm

Thrust force.......................................................................................................................15 daN

Complete protection class ...............................................................................................IP 557

PERFORMANCE CORAL 1050 (STROKE 500mm)

Service cycle......................................4 secs Opening - 30s Dwell - 4s Closing - 30s Dwell

Complete cycle time..............................................................................................................68s

Complete Opening - Dwell - Closing - Dwell cycles:..........................................53 per hour

Annual cycles (considering 8-hour working day): ....................................................154˙000

Packaging Pic.18

(See Pic. 20)

CORAL 1050

CORAL 1080

PIC. 20

10 metres of cable

Electric motor and

limit switch

Ø100

400

Ø195

CORAL 1050 - weight 86 Kg

Ø100

330

170

800

stroke

500

stroke

1350

850

housing

11-2008

CORAL 1080

OIL-HYDRAULIC PISTON

Rod exit time..............................................................................................................................6s

Net rod stroke..................................................................................................................800 mm

Rod diameter......................................................................................................................16 mm

Plunger diameter...............................................................................................................30 mm

Thrust force.......................................................................................................................15 daN

Complete protection class ...............................................................................................IP 557

PERFORMANCE CORAL 1080 (STROKE 800mm)

Service cycle......................................6 secs Opening - 30s Dwell - 6s Closing - 30s Dwell

Complete cycle time..............................................................................................................72s

Complete Opening - Dwell - Closing - Dwell cycles:..........................................50 per hour

Annual cycles (considering 8-hour working day): ....................................................146˙000

Packaging Pic.19

(See PIC. 21)

PIC. 21

10 metres of cable

Electric motor and

limit switch

400

Ø195

CORAL 1080 - weight 104 Kg

330

WARNINGS

- Before performing installation, conduct Risk Analysis and operate using devices compliant with EN 12445 and EN 12453 safety regulations.

- Packaging materials such as cardboard, nylon, polystyrene, etc. should be disposed of using specialised waste collection firms.

- If the operator is removed, do not cut the electric wires, rather remove them from the terminal board loosening the clamping screws inside the dividing box.

- Disconnect the main switch before opening the lid of the electric cable junction box.

- The whole operator must be earthed using the yellow/green electric cable.

- GUARANTEE CERTIFICATE ON REQUEST BY CUSTOMER

We recommend reading the standards, suggestions and observations contained in the “Safety Regulations booklet” thoroughly.

CHECKS AND MAINTENANCE:

For optimal performance of the system over time and operation in compliance with safety

regulations, correct maintenance and checks must be performed on the operator, the electronic

equipment constituting the installation and on wiring performed by qualified technicians:

- Oil-hydraulic operator: maintenance check every 6 months.

- Electronic equipment and safety systems: a monthly maintenance check.

EUROPEAN MARK CERTIFYING CONFORMITY

TO THE ESSENTIAL REQUIREMENTS OF THE

STANDARDS 98/37/EC

The growth of MECCANICA FADINI has always been based on the development of guaranteed

products thanks to our “TOTAL QUALITY CONTROL” system which ensures constant quality standards,

updated knowledge of the European Standards and compliance with their requirements, in view of

an ever increasing process of improvement.

170

1940

1140

housing

®

s.n.c.

AUTOMATIC GATE MANUFACTURERS

Via Mantova, 177/A - 37053 Cerea (Verona) Italy

Tel. +39 0442 330422 r .a. - Fax +39 0442 331054

e-mail: info@fadini.net - www.fadini.net

2003/108/CE Directive

for waste electrical and

GB

electronic equipments

DISPOSE OF PROPERLY

ENVIRONMENT-NOXIOUS MATERIALS

Distributor’s box

The manufacturer reserves the right to make amendments to this manual without prior

notice and declines all responsibility for any errors, personal injury or damage to property.

Loading...

Loading...