Page 1

APROLI 280 BATT

External oil-hydraulic operator for

swinging gates with very large pillars

Oil-hydraulic operator fitted with articulated arm

Hydraulic driving force adjustment

Two-way locking

Instruction manual

GB

Page 2

APROLI 280 BATT

CUTAWAY VIEW OF THE ELECTRIC MOTOR ASSEMBLY AND

HYDRAULIC JACK

AVAILABLE TYPES: NON LOCKING - LOCKING - WITH FLOW REGULATOR

TWO-WAY LOCKING

VALVE ASSEMBLY

PRESSURE SAFETY

VALVE “CLOSE”

GREEN

PRESSURE SAFETY

VALVE “OPEN”

RED

OIL RESERVOIR

TERMINAL PLUG

COVER

“C” “A”

“B”

TERMINAL PLUG

EARTH WIRE

OIL RESERVOIR

REAR CAP

0.25 HP

ELECTRIC MOTOR

HYDRAULIC LOBE

PUMP

JACK END CAP

st

PISTON

1

RACK

RELEASE LEVER

PISTON LINER

SHAFT SUPPORT

SQUARE INDENTED

SHAFT

nd

PISTON

2

PISTON LINER

MAIN ASSEMBLY

BLOCK WITH MOTOR

AND HYDR. JACK

®

PIC. 1

2

Page 3

INSTRUCTIONS FOR THE INSTALLATION OF APROLI 280 BATT TO SWINGING DOUBLE GATES WITH VERY

LARGE PILLARS

it is recommended to follow these instructions to achieve a perfect application of the operator.

BASE AND

FIXING BRACKET

STUD

BOLT

ASSEMBLY ELEC.

MOTOR HYDR. JACK

PROTECTION

COVER

FIXING

SCREWS

Lh

RETAINING

OPEN STOP ASSEMBLY

14 E22 NUT, STUD BOLT,

ADJUSTER COVER.

LEFT-HAND WASHER Ø 8.5

8M E13 NUT

GRUB SCREW

PIC. 2

First loosen the fastening screws to remove the cover. To do this, open the hinged door with the supplied key; one of the two fastening

screws is there. After the removal of the cover, the electro-hydraulic assembly is fully exposed, ie. “electric motor/hydraulic jack” fitted

with the pressure safety valves that control the thrust/pushing power of the operator and the emergency release in events like power

failure. It also includes a bracket, designed to provide fixing facility to a wall or pillar and a suitable outlet for the cables; an articulated

arm, adjustable to meet the most various distance requirements on site applications; and a shoe bracket to be fixed to the gate. The

operator is supplied already pre-filled with special oil to suit both high and low environment temperatures. It allows the correct performance

of APROLI 280 BATT within a temperature range from –20°C to +80°C. APROLI 280 BATT is produced and tested in the workshops of

MECCANICA FADINI which guarantees the long lasting reliability of this product in time.

DRIVING

BENDED

ARM

BENDED ARM

PLUG PROFILE

BOLT AND

NUT

STRAIGHT

ARM COVER

ARTICULATED ARM

LEFT-HANDED

SCREW FOR

ADJUSTMENT

STRAIGHT

ARM.

ADJUSTABLE

BUSH

FIXING

SHOE

®

3

Page 4

HOW TO FIX APROLI 280 BATT TO A PILLAR BY EXPANDING BOLTS OR SCREWS

Before fitting the operator APROLI 280 BATT to the gate, make sure that the gate structure is adequate to be electrically operated and

that is strong enough to bear the mechanical stress of automatic operations and is well built and smooth running.

It is recommended to reinforce the gate and fix the metallic parts which may not work properly, do the necessary to prevent or correct

friction of the gate against the pavement or pillar (this must particularly apply to the gate hinges).

VERY LARGE PILLAR

WHERE THE GATE

HINGE IS FIXED

IN THE MIDDLE

4 EXPANDING

BOLTS

MAINS SUPPLY

ELECTRIC CABLE

FIXING

BRACKET

NUTS WITH

WASHERS

GATE LEAF

LEVEL

PIC. 3

ARTICULATED

ARM

OPERATOR

COVER

Fix the bracket to the pillar and bring the electric cable to the most suitable position so that the fixing of the articulated arm is allowed

to coincide with a solid crossing bar of the gate leaf. The shoe bracket is to be bolted or welded to the gate at a suitable distance which

is set after the first manual tests. (Release lever B page 10)

DISTANCE

The distance from gate pivot center to arm bolt

center is to be calculated through manual

operations of the gate before fixing the shoe

bracket. The distances on page 6-7 are merely

an application example.

COMPLETELY INSTALLED

UNIT. LEFT-HANDED

MODEL

ANTI-CRUSH DESIGN

ARTICULATED ARM

FOR SAFETY

APROLI 280 BATT is easy to install. It can be supplied either fitted with hydraulic locking device for gates up to 2 m width, or without

hydraulic locking with an electric lock for gates up to 5 m.

®

4

PIC. 4

Page 5

APPLICATION OF TWO APROLI 280 BATT ON TO A DOUBLE SWINGING GATE. 90° OPENING.

The recommended maximum gate width with APROLI 280 is 5 m. The locking type operator is recommended up to 2 m gate width. Beyond

2 m a lock is required to be fitted to the gate and the non locking type operator is advisable.

2 m 2 m

LEFT-HAND

GATE STOP IN

OPEN GATE

POSITION

PIC. 5

LEFT-HAND

ARTICULATED

ARM

GATE STOP

IN CLOSE GATE

90° 90°

POSITION

RIGHT-HAND

ARTICULATED

ARM

It is recommended that suitable gate stops are always fitted to

the system both in open and close gate positions.

OVERTURN

RIGHT-HAND

GATE STOP IN

OPEN GATE

POSITION

BOTH

Rh Lh

RIGHT-HAND

ARTICULATED

ARM

GRUB

SCREW

ELECTRIC MOTOR/HYDRAULIC

JACK ASSEMBLY

Rh AND Lh

LEFT-HAND

ARTICULATED

ARM

GRUB

SCREW

SQUARE

SECTION

SHAFT

REFERENCE

SEAT

PIC. 6

Both right-hand and left-hand applications are possible just by turning over the articulated arm and fitting it to the square section shaft

of the operator. Tighten the retaining pin in its seat to fix the arm to the shaft. The assembly ie. motor/jack, fixing bracket and cover are

designed to suit both right and left-hand applications with the same method of installation.

Important: the articulated arm must be fixed so that it pushes against the gates and keeps them well pressed on to the close

position gate stop.

®

5

Page 6

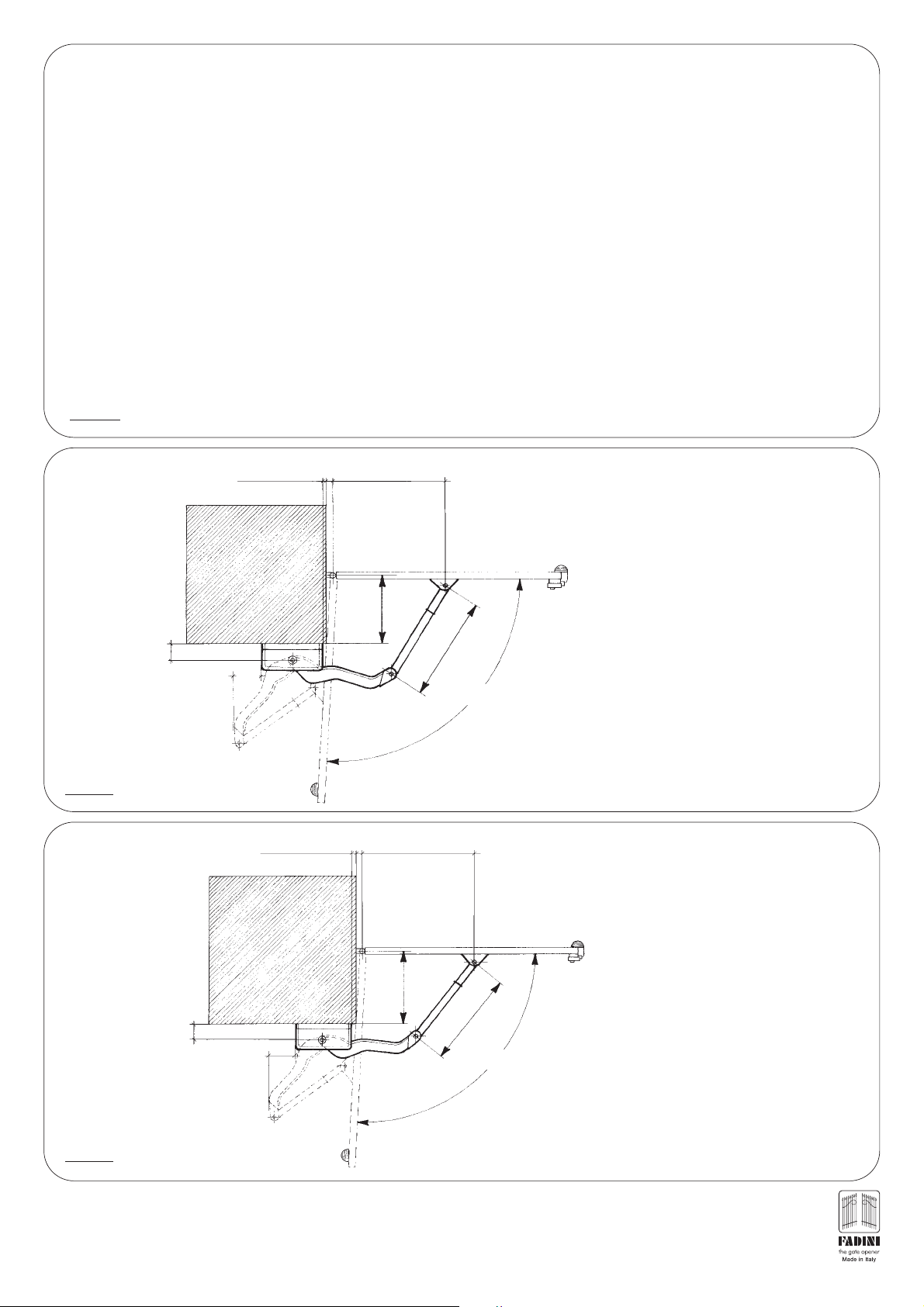

EXAMPLE OF APPLICATIONS TO PILLARS OF VARIOUS DIMENSIONS. DISTANCES ARE NOT BINDING AND

ARE QUOTED FOR REFERENCE ONLY

PIC. 7

20 mm FROM PILLAR

SURFACE LINE

400x400

90

40

GATE STOP

IN OPEN GATE

POSITION

20 mm FROM PILLAR

SURFACE LINE

500x500

40

OPEN GATE LEAF

510

GATE STOP

IN CLOSED

CLOSED GATE LEAF

200

460

100°

POSITION

APPLICATION EXAMPLE

400x400 mm PILLAR

2 m GATE LEAF - 110 Kg

40

250

560

CLOSED GATE LEAF

GATE STOP

IN CLOSED

POSITION

PIC. 8

90

GATE STOP

IN OPEN GATE

POSITION

20 mm FROM PILLAR

SURFACE LINE

600x600

90

60

40

460

APPLICATION EXAMPLE

500x500 mm PILLAR

3 m GATE LEAF - 100 Kg

100°

OPEN GATE LEAF

40

300

560

CLOSED GATE LEAF

460

GATE STOP

IN CLOSED

POSITION

ELECTRIC

LOCK

PIC. 9

6

100°

APPLICATION EXAMPLE

600x600 mm PILLAR

1.8 m GATE LEAF - 140 Kg

GATE STOP

®

IN OPEN GATE

POSITION

OPEN GATE LEAF

Page 7

20 mm FROM PILLAR

SURFACE LINE

700X700

40 580

350

CLOSED GATE LEAF

GATE STOP

IN CLOSED

POSITION

ELECTRIC

LOCK

APPLICATION EXAMPLE

700x700 mm PILLAR

3 m GATE LEAF - 130 Kg

PIC. 10

90

170

OPEN GATE LEAF

40 620

170

800x800

90

GATE STOP

IN OPEN GATE

POSITION

20 mm FROM PILLAR

SURFACE LINE

400

580

100°

CLOSED GATE LEAF

580

GATE STOP

IN CLOSED

POSITION

ELECTRIC

LOCK

APPLICATION EXAMPLE

800x800 mm PILLAR

4 m GATE LEAF - 140 Kg

100°

PIC. 11

PIC. 12

90

900x900

GATE STOP

IN OPEN GATE

POSITION

20 mm FROM PILLAR

SURFACE LINE

GATE STOP

IN OPEN GATE

POSITION

170

OPEN GATE LEAF

40 650

F

ATE LEA

G

PEN

O

450

CLOSED GATE

LEAF

580

100°

GATE STOP

IN CLOSED

POSITION

ELECTRIC

LOCK

APPLICATION EXAMPLE

900x900 mm PILLAR

5 m GATE LEAF - 150 Kg

It is recommended that all gates are provided with adequate gate stops both in open and closed gate positions. When a 5 m

gate is involved the weight must not be greater than 200 Kg and it is required to fit the gate with an electric lock, the operator

must be non locking type. With gates up to 2 m width, it is possible to install the locking type without electric lock.

See the examples and drawings on pages 6 - 7.

®

7

Page 8

GB

13

exp

CONNECTION DIAGRAM FOR SWING GATES

RADIO CONTROL

PLUG-IN CARD SUPPORT

26

27

28

TERMINAL FOR

CONNECTIONS TO

PUSH BUTTONS PULIN 3

DIP-SWITCH

ON

1 2 3 4 5 6 7 8

Should more pairs of photocells be required

than the recommended quantity, fit an auxiliary

transformer outside the control box.

3 4

PULSE TWICE CONSECUTIVELY

TO OPEN BOTH GATE LEAFS

24 V OUTPUT

1

st

CHANNEL

ON

OFF

ON TO “0” THE DELAY

IS OUT OF SERVICE

MICROPROCESSOR

123456

123456789

= PHOTOCELLS 2

Inside photocells N.C. contact

If obstructed they prevent the gates from opening

reverse gate direction during close cycle

N.C. CONTACT

PHOTOCELLS

nd

PAIR =

PEDESTRIAN MODE

ONE PULSE OPENS

ONE GATE LEAF ONLY

COMMON

OPEN SWITCH N.O. CONTACT

TIMER SWITCHES

FUSE

–

7

0

8

9

LEAF DELAY

TIMER CLOSE

+

DWELL TIME

+

MOTOR RUN

+

OPEN & CLOSE TIME

1 AMP. FUSE

24 V OUTPUT

TERMINALS 12-13

CAPACITORS

FLASHING LAMP

630 mA FUSE

FUSE 5 AMPS

630 mA

12,5μF12,5μF

10 11 12 13 14 15 16 17 18

CLOSE SWITCH N.O. CONTACT

STOP SWITCH N.C. CONTACT

RADIO CONTACT N.O.

COMMON

VOLTAGE OUTPUT

ELECTRIC LOCK SUPPLY

24 V INDICATOR - 3 W max.

OUTPUT A.C.

24 V

Max permitted load:

2 pairs photocells

1 radio receiver

7 8

ALL OPERATIONS

OPEN, CLOSE AND

REVERSE

RADIO CONTACT

COMMON

SAFETY CONTACT N.C.

NOTE WELL: For special applications, ie. to switch on lights CCTV etc., SOLID STATE RELAYS are recommended to be used

only. Standard relays would affect the micro-processor.

NOTE WELL: THIS PANEL IS TESTED TO OPERATE GATES ONLY

THROUGH FADINI ACCESSORIES. NO WARRANTY IS

ACKNOWLEDGED BY THE MANUFACTURER IN CASE THAT

OTHER ACCESSORIES ARE USED OR NON CONFORMING

APPLICATIONS ARE MADE WITHOUT THE MANUFACTURER’S

APPROVAL.

19 20 21 22 23 24 25

COMMON

M1 M2

ELECTRIC MOTORS

SINGLE-PHASE

230 V FLASHING LAMP

25 W max.

230 V SINGLE-PHASE

SUPPLY VOLTAGE

LED No. 1 - It switches on when voltage is supplied

26 27 28 3

CONNECTION TO THE “PULIN 3” PUSH

BUTTONS WITH STATUS INDICATION LEDS.

PIC. 13

1234 5678910111213

RADIO CONTACT

CLOSE N.O. CONTACT

OPEN N.O. CONTACT

COMMON

STOP N.C. CONTACT

PIC. 14

345 6

N.O. N.C. N.O.

OPEN STOP

ELECTRICAL CONNECTIONS

KEYSWITCH PRIT 19

STOP

OPEN

CLOSE

COMMON

TERMINAL BOARD

TERMINAL BOARD

1234

PRIT 19

CLOSE

ELECTRICAL WIRING DIAGRAM OF THE ELECTRONIC

PROGRAMMER

Once the connections have been made, do the first switching

test through the control panel. Set the motor run timer so that

the motor is allowed to run 4 - 5 seconds more than the gates.

Set the other timers to meet the site requirements. Set DIP

switch B No. 3 to automatic (ON): on pulsing to 4 - 8 the gates

must be operated as pre-set, ie. opening and only after the

dwell time, closing. Adjust the times through the respective

timers. (See No. 7, 8 and 9 drwg. No. 1643).

With DIP switch “B” No. 3 to semiautomatic (OFF) one pulse

opens the gates, a second pulse to 5 - 9 is needed to close

the gates. Any one pulse to 7 - 8 will open, close or reverse

the gates independently from the operation being performed.

It is recommended to carefully read the instructions in the

control box to have all the functions performed correctly.

The 6 LEDs on the P.C. board indicate the following:

Led No. 1 It switches on when voltage is supplied

Led No. 2 Photocells - Normally on. It switches off when the

photocells are obstructed

Led No. 3 Open - It switches on when the respective switch

is activated

Led No. 4 Close - It switches on when the respective switch

it activated

Led No. 5 Stop - Normally on. It switches off when the

respective switch is activated

Led No. 6 Radio - It switches on whenever a pulse is given,

either from remote control, keyswitch or push

buttons.

®

Drwg. No.

1643

P.C. BOARD

8

Page 9

The below diagram is general for an application of the operator and the complementary accessories which are supplied with the unit.

4

3

2

4x1.5mm

4x1m

2x1mm

2

m

2

230V

±1

50 H

0%

z

1

2

4x1.5mm

2

12

N.W. All the equipment must be properly earthed.

11

10

2x1mm

2x1m

13

5

RG58

4x1.5m

4x1mm

2

2

m

4x1mm

2

6

7

16

2

m

2x1m

2

8

9

2

m

14

2

4x1mm

15

14

17

1) 230V - 50Hz magnetic-thermal differential 0.03 A

circuit breaker (not provided by the manufacturer)

2) Control board

3) Flashing lamp

4) Aerial

Birio A8

5) External radio receiver

6) Surface mount Key-switch

7) Oil-hydraulic operator

8) Photocell projector

Elpro 13 exp

Miri 4

Astro 43/1 R M.Q.B.

Aproli 280 Batt

Polo 44

Prit 19

- Right-hand

9) Electric lock with closed position gate stop

10) Oil-hydraulic operator

11) Photocell receiver

Aproli 280 Batt

Polo 44

- Left-hand

12) Junction box (not provided by the manufacturer)

13) Photocell projector

Polo 44

post mounted

14) Opened position gate stop (not provided)

Polo 44

15) Photocell receiver

16) Digital push button switch

17) Transmitter

Astro 43/2 TR Small

post mounted

Radi 12

PIC. 15

To perform the electrical work, connections are as per diagrams on pages 8-9. Once the connections have been made, adjust the switches

in the control box so that the sequence of operations occurs as pre-set. Set DIP switch 3 on automatic and check if the working times

meet your requirements. On semiautomatic mode, one pulse opens the gates, a second pulse is needed to close the gates.

Sx 2° Dx 1°

PLEASE NOTE: Should the electric

motors fail to start properly because of

power shortage, connect some extra

12.5 μF capacitors to the phase and

common terminals as shown in pic. 16.

COMMON

COMMON M1

PHASE M1

PHASE M1

COMMON M2

PHASE M2

16 17 18 19 20 21 22 23

PHASE M2

Terminal board

Elpro 13

Drwg. No. 1643

exp

PIC. 16

COMMON

12.5 μF

12.5 μF

®

9

Page 10

The two safety pressure valves are identified by colours: “A” open is red; “C” close is green. They are located in the front of the motor/pump

unit, easy to reach for setting operations in order to meet the power requirements Pic. 17.

Once the valves are set, you can fit the cover and the other accessories.

RELEASE BY 1 TURN

TO LET THE AIR OUT

OF OIL RESERVOIR

MORE

POWER

MAXIMUM

PRESSURE VALVE

“CLOSE”

GREEN IN COLOUR

MAXIMUM

PRESSURE VALVE

“OPEN”

RED IN COLOUR

PIC. 17

“C”

“O”

LESS

POWER

“S”

AIR BLEED

THIS STICKER IS FITTED ON

THE OIL RESERVOIR

Via Mantova, 177/A - 37053 Cerea (VR) Italy - Tel. 0442 330422 r.a. - Fax 0442 331054

MOTOR

W

VOLTS

r.p.m.

Nm

Degree of protection IP 555

Working pressure max. 3 MPa (30 Bars)

OIL FADINI

MADE IN ITALY

RELEASE LEVER

“B”

PULL THE LEVER DOWNWARDS TO RELEASE

IMPORTANT

AFTER INSTALLING

APROLI 280 BATT

OIL FADINI

®

s.n.c.

2 PHASE

250

230

1˙350

196.2

HP

A

Hz

μF

RELEASE

BY 1 TURN

“S”

OIL-HYDRAULIC

0.25

1.2

50

12.5

BATT

The setting of the safety pressure valves is to be done so to achieve the exact amount of power required to safely operate the gate. The

more you turn the screw clockwise, the more you increase the power of the operator.

Please note, once APROLI 280 has been fixed, unscrew the air bleed screw by one turn. This screw is fitted on the cap of the oil reservoir,

where the mains cable is led to the motor.

Should the operator “APROLI 280” be removed for maintenance or repairing, tighten the screw “S” to prevent oil from coming out during

handling.

In case of power failure, to open the two leafs fitted with APROLI 280 BATT non-loking type, you have to release the electric lock with

the key and push the gate leafs open by hand in a very smooth way. Should the operator be fitted with the locking device, first pull the

release lever “B” downwards and then push open (Pic. 17). Open the hinged door to have access to the lever.

NEVER CUT THE ELECTRIC CABLES

- Please note that the electric cables must be removed from their terminals by loosening the fastening screws. Never cut the electric

cables. Also make sure that the 230V mains switch No. 3 is off before removing the cables. See page 9, pic. 15.

- Only by keeping to these fitting instructions it can be achieved a reliable installation and the best performance of the operator.

The installation is fully under the responsability of the installation agent, even if it consists entirelly of Fadini products as listed in this

booklet. It is advisable that the system is installed in full compliance with these instructions and in observance of the existing laws

which rule automatic doors.

- All the information, specifications and drawings contained herein are subject to any change that is considered appropriate by the

manufacturer without any previous notice.

®

10

Page 11

APROLI 280 BATT SPECIAL VERSION CODE 287

The flow regulator has the purpose of maintaining

constant the rotation speed of the shaft that operates

the articulated arm.

PIC. 18

FLOW

REGULATOR

OPEN

SPEED

SPEED

SPEED

FLOW

REGULATOR

CLOSE

APROLI 280 BATT TECHNICAL SPECIFICATIONS

FIXING

BRACKET

ELECTRIC MOTOR/

JACK ASSEMBLY

PROTECTION

COVER

139

407

100

190

20x20

260

218

345

570

SPEED

35

190

CONSTANT

SPEED

404

402

290

106

EARTH

240

50

580

520

460

LEFT-HAND ARTICULATED ARM

WITH RETAINING SCREW AND SHOE

RIGHT-HAND ARTICULATED ARM

WITH RETAINING SCREW AND SHOE

580

520

460

PIC. 19

ELECTRIC MOTOR

Power output ...........................................................0.18 KW (0.25 HP)

Supply voltage / Frequency............................................230 V - 50 Hz

Absorbed current ..........................................................................1.2 A

Absorbed power..........................................................................250 W

Capacitor .....................................................................................12.5 μF

Motor rotation speed.........................................................1˙350 r.p.m.

Intermittent service ..........................................................................S 3

PERFORMANCE

Service cycle ..23 sec. Opening - 30 sec. Dwell - 23 sec. Closing - 30 sec. Dwell

Complete cycle time .....................................................................106 s

Complete Opening - Dwell - Closing - Dwell cycles ....No. 34/hour

Annual cycles (with 8 hours of use per day) ..........................99˙000

570

Lh

TURN IT OVER TO

MAKE IT RIGHT-HAND

Rh

HYDRAULIC UNIT

P3 - Hydraulic pump capacity ...........................................0.85 l/min.

Average working pressure .........................................1 MPa (10 bar)

Maximum supplied pump pressure...........................3 MPa (30 bar)

Working temperature ......................................................–20°C +80°C

Opening time ....................................................................................23 s

Rated torque ...........................................................................196.2 Nm

Hydraulic oil type................................................................OIL FADINI

Maximum shaft rotation ................................................................205°

Static weight of operator ............................................................11 Kg

Maximum gate weight ...............................................................100 Kg

Protection standards ..................................................................IP 555

®

11

Page 12

APROLI 280 BATT

WARNINGS

- It is recommended to keep to the instructions here outlined - check the specifications on the motor sticker with your mains

supply.

- Dispose properly of the packaging: cardboard, nylon, polystyrene, through specializing companies.

- Should the operator be removed, do not cut the electric cable. This must be properly removed from the terminal board in the

junction box.

- Switch off the mains switch before removing the junction box cover where the electric cable of APROLI 280 BATT is terminated.

- All the system must be earthed by using the yellow/green wire, marked by its specific symbol.

- It is recommended to read the regulations, suggestions and remarks quoted in the booklet “Safety Norms”.

- Should APROLI 280 BATT be removed for maintenance, servicing or repair, tighten the air bleeding screw (Pic. 17 - Page 10)

to prevent oil coming out of the reservoir during transport.

09-2008

Meccanica Fadini recommends the control panel ELPRO 13 CEI to

achieve an installation that is in conformity to the existing safety

standards as illustrated in our chart.

The electronic programmer ELPRO 13 incorporates and can provide

all the functions which are required by the most demanding

applications with swinging gates.

In addition to the standard features of ELPRO 9 the following

requirements can be provided: “stroke reversing pulse”, pedestrian

mode, stop in any gate position by holding down the remote control

button. Among the added features and improvements of ELPRO 13

in conformity to the European safety standards, there is the mains

rotary switch: it is fitted to the box cover and switches off the mains

voltage whenever the cover is removed.

13

CEI

SINGLE-PHASE

l’apricancello

CUT OFF MAINS SWITCH

The “CE” mark certifies that the operator conforms to the essential

requirements of the European Directive art. 10 EEC 73/23, in relation

to the manufacturer’s declaration for the supplied items, in

compliance with the body of the regulations ISO 9000=UNI EN 29000.

Automation in conformity to EN 12453, EN 12445 safety standards.

CHECKING AND MAINTENANCE:

To achieve an optimum performance and longer life of the

equipment and in observance of the safety regulations, it

is recommended that inspections and proper maintenance

are made by qualified technicians to the whole installation

ie. both the mechanical and electronic parts, as well as

wiring.

- Mechanical parts: maintenance every 6 months approx.

- Electronic apparatus and safety equipment: maintenance

inspection monthly.

EUROPEAN MARK CERTIFYING CONFORMITY TO

THE ESSENTIAL REQUIREMENTS OF THE

STANDARDS 98/37/EC

• DECLARATION OF CONFORMITY

• SAFETY NORMS

• EN 12453, EN 12445 STANDARDS

• CEI EN 60204-1 STANDARDS

• WARRANTY CERTIFICATE ON THE CUSTOMER’S REQUEST

2003/108/CE Directive for

waste electrical and

GB

electronic equipments

DISPOSE OF PROPERLY

ENVIRONMENT-NOXIOUS MATERIALS

®

s.n.c.

AUTOMATIC GATE MANUFACTURERS

Via Mantova, 177/A - 37053 Cerea (Verona) Italy

Tel. +39 0442 330422 r.a. - Fax +39 0442 331054

e-mail: info@fadini.net - www.fadini.net

The growth of MECCANICA FADINI has always been based

on the development of guaranteed products thanks to our

“TOTAL QUALITY CONTROL” system which ensures constant

quality standards, updated knowledge of the European

Standards and compliance with their requirements, in view

of an ever increasing process of improvement.

Distributor’s box

The manufacturers reserve the right to change the products without any previous notice

Loading...

Loading...