Page 1

INSTALLATION MANUAL

GB

®

Page 2

APROLI 280/700 STRONG

INSTRUCTIONS FOR THE INSTALLATION OF THE APROLI 280/700 STRONG SWING

GATE OPERATOR

FOR CORRECT APROLI 280/700 STRONG INSTALLATION AND GOOD PERFORMANCE, PLEASE READ THE INSTRUCTIONS OUTLINED

IN THIS MANUAL CAREFULLY AND KEEP TO THE DIAGRAMS.

IMPORTANT: THE ENTIRE INSTALLATION MUST BE CARRIED OUT BY QUALIFIED TECHNICAL PERSONNEL, WHO ARE ADVISED TO

FOLLOW GOOD INSTALLATION PRACTICE AND KEEP TO CURRENT SAFETY STANDARDS.

GENERAL INFORMATION

- Check that the structure of the gate to be automated is suitable for the application to be installed: make sure that there are no anomalies

in the metal structure, reinforce any weak points and ensure that the leaf hinges are in perfect condition.

- If necessary, reinforce the connection point between the leaf and the bended arm fixing shoe

- The gate’s movement should not be obstructed in any way: excessive rises in the ground, friction in the hinges, ...

- The gate leaves must be installed and levelled on a flat surface

The Aproli 280/700 Strong is an external oil-hydraulic gate operator for swing gates, with two-directional hydraulic locking, suitable

for gates with very large pillars and for heavy gates. It meets all the most demanding installation requirements thanks to the use of a

bended steel arm and “telescopic” end section for leaf fixing.

We recommend using the Aproli 280/700 Strong for leaves of no more than 3.0 metres long and weighing more than 300 kg.

IMPORTANT:

- The Aproli 280/700 Strong should only be installed on gates with leaves up to 3.0 metres long

- An electric lock must always be installed for leaves of over 2.0 metres long.

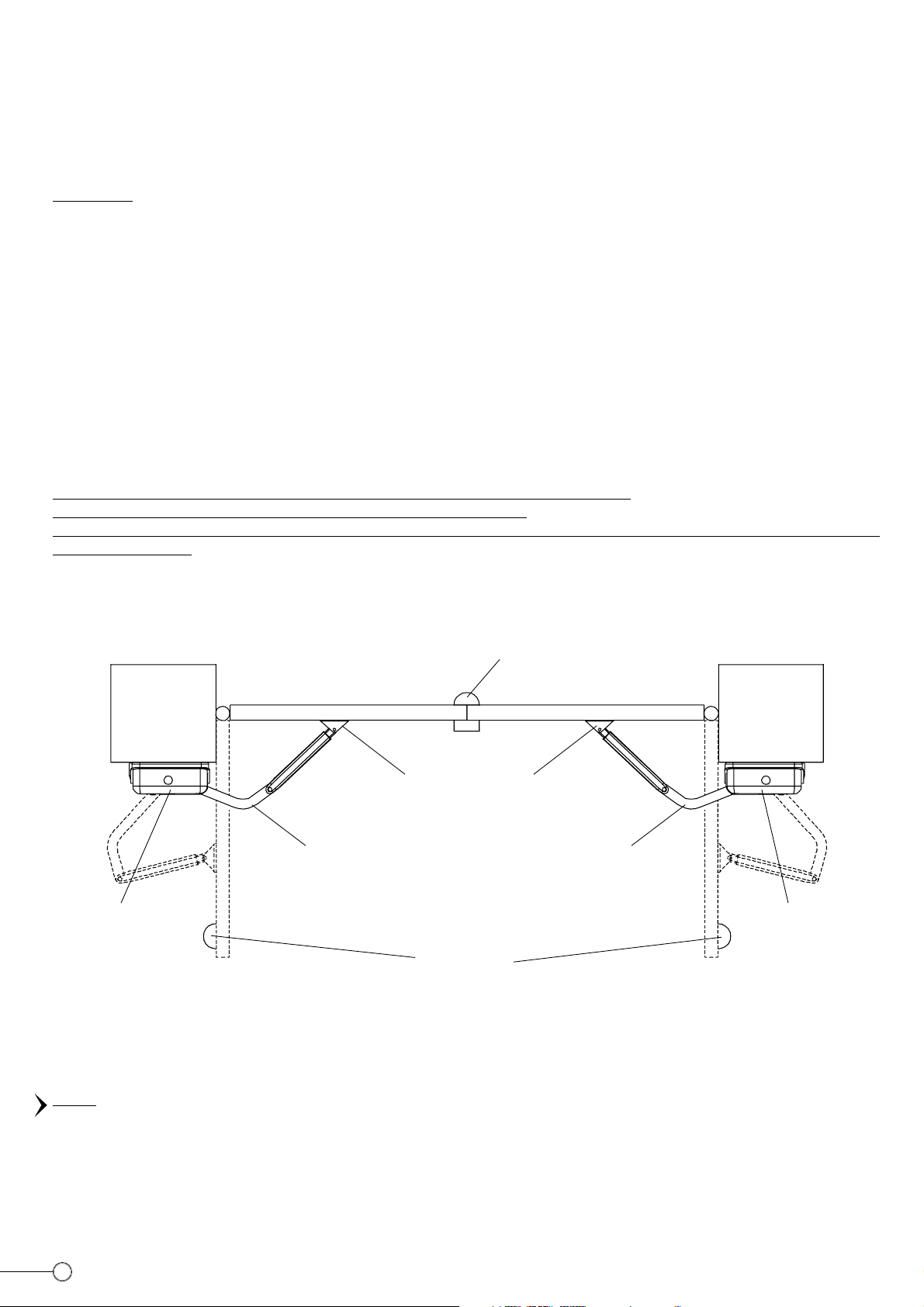

It is advisable to fasten all the open and closed gate stops firmly to the ground, and to check how sturdy they are during the initial gate

operation tests. (Pic.1)

LEFT-HAND

APROLI 280/700

STRONG

GATE STOP IN

CLOSED GATE

POSITION

CLOSED LEAF CLOSED LEAF

PILLAR PILLAR

LEAF FIXING SHOE

LEFT BENDED ARM RIGHT BENDED ARM

OPEN LEAF

GATE STOP IN OPEN

GATE POSITION

PLAN OF GATE WITH TWO APROLI 280/700 STRONG INSTALLED

OPEN LEAF

RIGHT-HAND

APROLI 280/700

STRONG

PIC. 1

2

Page 3

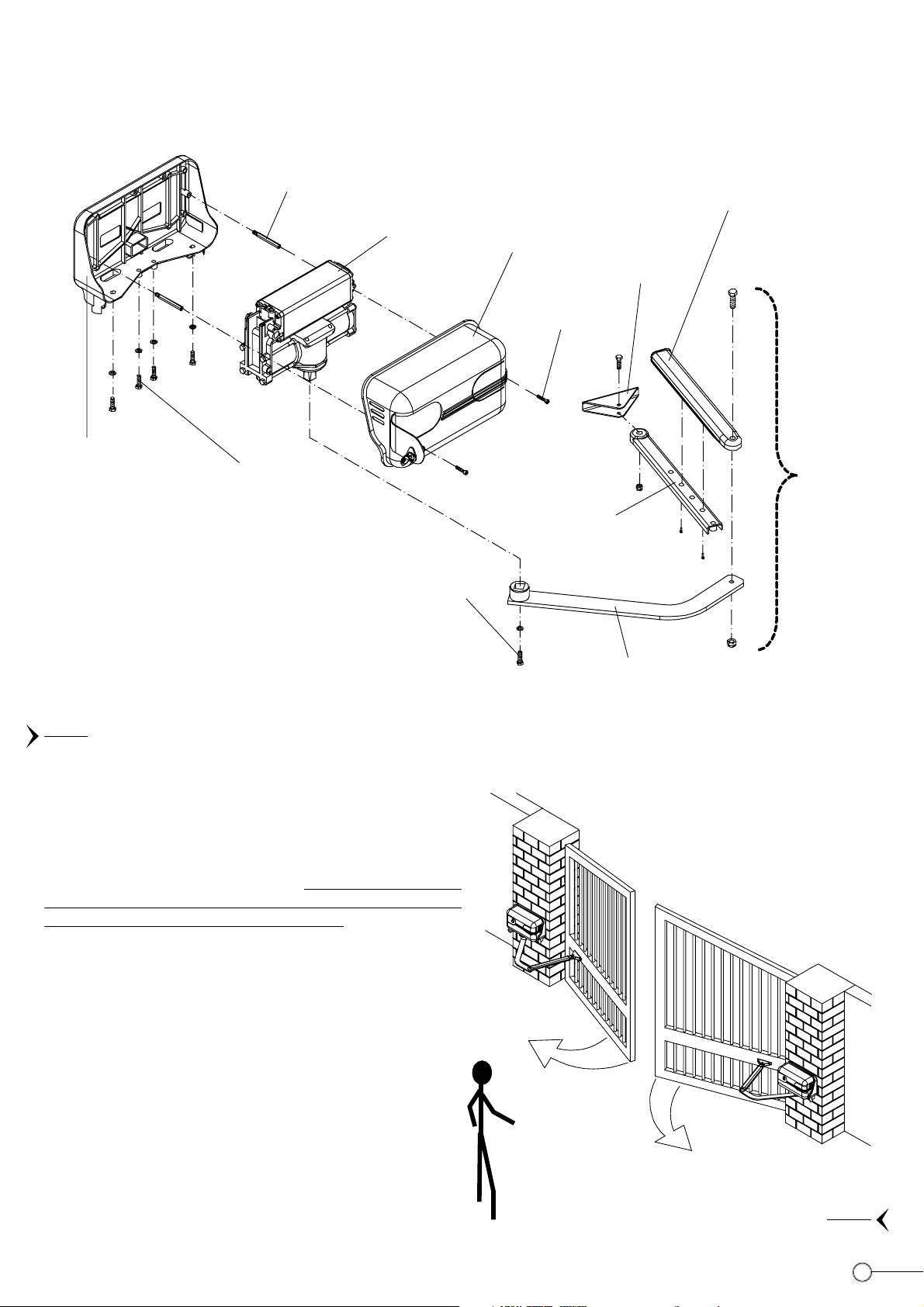

Firstly slide off the whole bended arm by unscrewing the specific screw on the rotation shaft; then remove the protection cover by

unscrewing the 2 fixing screws – A (Pic. 2), one of which is found inside by opening the cover with the customized key. At this point

unscrew the 4 locking screws – B positioned beneath the automation (Pic. 2), thereby making it possible to remove the electric

motor/hydraulic jack assembly, exposing the pillar fixing bracket.

PILLAR FIXING

BASE AND

BRACKET

STUD BOLT

FIXING SCREWS – B

FOR ELECTRIC

MOTOR/HYDRAULIC

JACK ASSEMBLY

LEFT-HAND

ELECTRIC

MOTOR/HYDRAULIC

JACK ASSEMBLY

FIXING SCREWS

FOR ATTACHING

BENDED ARM TO

ROTATION SHAFT

PROTECTION

COVER

COVER FIXING

SCREWS- A

ADJUSTABLE

TELESCOPIC

STRAIGHT

ARM

STRAIGHT ARM

COVER

LEAF FIXING

SHOE

LEFT-HAND

ARTICULATED

ARM

EXPLODED VIEW OF MAIN COMPONENTS OF LEFT-HAND APROLI 280/700 STRONG GATE OPERATOR

PIC. 2

APPLICATION OF TWO APROLI 280/700 STRONG

Before proceeding with the installation and use of the Aproli 280/700

Strong, it is essential to understand the exact position of each operator

in the system. The automations have the abbreviation Sx (left) and

Dx (right) stamped on the hydraulic jack, which can be seen once

the protection cover has been removed:

intended for an observer standing in front of the two gate leaves to

be opened towards the observer himself (Pic. 3).

I.e. if the gate opens inwards the observer will be standing inside

and will see the right-hand Aproli 280/700 Strong on his right; vice

versa, if the gate opens outwards, the observer will be standing

outside and will see the right-hand Aproli 280/700 Strong on his right.

in fact Right and Left are

Lh

LEFT-HAND APROLI 280/700

STRONG

OBSERVER STANDING

IN FRONT – “AGAINST”

THE LEAF OPENING

DIRECTION

ROBUST LEFT-HAND

BENDED ARM

Rh

RIGHT-HAND APROLI

280/700 STRONG

PIC. 3

3

Page 4

SETTING APROLI 280/700 STRONG

In order to install the device, it is firstly necessary to dismantle and expose the individual components; fundamental for both optimal

installation and good performance.

- Swing the lock cover flap placed on the left side of the front protection cover to one side (for both the RH and LH Aproli) and open

the cover with the customized key provided (Pic. 4-A)

- Remove the bended arm by unscrewing the fixing screws positioned on the rotation shaft (for both the RH and LH Aproli) (Pic. 4-B)

- Remove the protection cover by unscrewing the two fixing screws – A on the cover. (Pic. 4-C)

ELECTRIC

MOTOR/HYDRAULIC

JACK ASSEMBLY

COVER FIXING

SCREWS - A

PILLAR FIXING BASE

AND BRACKET

PIC. 4-C

CUSTOMIZED KEY

PIC. 4-A

PROTECTION

LOCK

PROTECTION

COVER

COVER HINGED

DOOR

RIGHT-HAND

BENDED ARM

PROTECTION

COVER

FIXING SCREWS FOR

ATTACHING THE BENDED

ARM TO THE ROTATION

SHAFT

PIC. 4-B

- In order to extract the electric motor/hydraulic jack assembly from the fixing base, unscrew the four fixing screws – B positioned

under the fixing base (Pic. 5)

BENDED ARM AND TELESCOPIC CONNECTION ARM

The straight arm should be bolted to the bended arm. The straight arm offers various different assembly solutions since it has holes

for connection with the telescopic arm cover in 3 different positions (Pic. 6), obtaining a centre distance between the bended arm and

the fixing shoe equivalent to 460 mm, 520 mm or 580 mm. The fixing shoe is attached to a robust gate upright with screws or firmly

welded in place, and is then connected to the adjustable straight arm with one screw.

ELECTRIC MOTOR/

HYDRAULIC JACK

ASSEMBLY

PIC. 5

PILLAR FIXING BASE AND

BRACKET

FIXING SCREWS – B

ELECTRIC MOTOR/

HYDRAULIC JACK ASSEMBLY

LEFT-HAND

BENDED ARM

STRAIGHT

ARM COVER

LEAF FIXING

SHOE

ADJUSTABLE

TELESCOPIC

STRAIGHT

ARM

CENTRE DISTANCE

460 mm, 520 mm, 580 mm

PIC. 6

4

Page 5

FIXTURE TO THE PILLAR

Using a spirit level, fix the fixing base in position with

plugs depending on the type of pillar (Pic. 7) (not provided). When

suitable fixing

PILLAR

deciding the height at which to fix it to the pillar, consider at what

point the articulated arm will be connected to the gate leaf: preferably

on a strong upright. The fixing shoe (Pic. 6) must be bolted or welded

FIXING PLUGS

into position at a distance established after the initial manual leaf

opening and closing tests, following the indicated installation heights

(Pic. 8).

LEVEL

Once the fixing base has been installed, insert and fix the electric

motor/hydraulic jack assembly into position using the 4 fixing screws

– B (Pic. 5).

The following table indicates some installation distances. These are

not obligatory and are for reference purposes only (Pic. 8).

The distances indicated must be used to obtain an automation that

is able to close the leaf decisively.

FIXING BASE

AND BRACKET

POWER CABLE ALREADY

INSERTED INSIDE A TUBE

PREPARED BEFORE

INSTALLATION INSIDE THE

PILLAR

Pillar dimensions A (mm) B (mm) C (mm) D (mm) G° Gate leaf

400 x 400 (mm) 510 200 460 50 100° 2,0 m

500 x 500 (mm) 560 250 460 60 100° 3,0 m

600 x 600 (mm) 560 300 460 / 95° 1,80 m

700 x 700 (mm) 580 350 580 140 95° 3,0 m

800 x 800 (mm) 620 400 580 135 90° 4,0 m

900 x 900 (mm) 650 450 580 50 90° 5,0 m

PIC. 7

PILLAR

20 mm from the pillar edge

110

D

GATE STOP IN

OPEN GATE

POSITION

40

B

OPEN LEAF

GATE STOP IN

A

CLOSED LEAF

C

G°

CLOSED GATE

POSITION

PIC. 8

5

Page 6

ELECTRICAL CONNECTIONS TO THE ELPRO 13 CEI PROGRAMMER

Before making any connections, study the enclosed electrical diagrams carefully.

IMPORTANT: The whole electrical system must be earthed (Pic. 9); DO NOT CUT the electric cable for installation requirements; CUT

OFF the 230 V power supply (line switch not connected. (Pic. 9), during the electric wiring installation and connection phase.

- Power supply, electric motor and flashing light connections are made with electric cables with a section of 1.5 mm2 for a maximum

distance of 50 m. For distances of over 50 metres, we recommend using electric cables with a section of 2 mm2.

- For limit switches, photocells, pushbuttons and accessories use cables with 1 mm2 wires (Pic. 9)

IMPORTANT: PERFORM A RISK ANALYSIS IN COMPLIANCE WITH EN 12445 AND EN 12453 STANDARDS AND INSTALL THE NECESSARY

SAFETY DEVICES. THE FOLLOWING FIGURE PROVIDES AN INDICATION OF THE ESSENTIAL ACCESSORIES FOR THE SYSTEM OPERATION.

THE SYSTEM SHOULD BE CUSTOMIZED AT THE INSTALLER AND USER’S DISCRETION DEPENDING ON THE VARIOUS REQUIREMENTS

AND CHARACTERISTICS OF THE ENVIRONMENT.

14

1

13

2

12

3

4

5

6

8

7

1) “ELPRO 13 CEI” PROGRAMMER WITH PLUG-IN JUBI 433 RADIO RECEIVER

2) 0.03 A MAGNETO-THERMAL DIFFERENTIAL SWITCH

3) JUNCTION BOX

4) LEFT-HAND APROLI 280/700 STRONG

5) PHOTOCELL TRANSMITTER POLO 44 ON POST

6) GATE STOP IN OPEN GATE POSITION

7) JUBI SMALL 433 TRANSMITTER

8) ELECTRIC LOCK

9) PHOTOCELL RECEIVER POLO 44 ON POST

10) RIGHT-HAND APROLI 280/700 STRONG

11) ENCODED KEYSWITCH PRIT 19

12) MIRI 4 FLASHING LIGHT FITTED WITH BIRIO ANTENNA

13) PHOTOCELL TRANSMITTER POLO 44

14) PHOTOCELL RECEIVER POLO 44

11

9

LEFT-HAND APROLI ELECTRIC

MOTOR TERMINAL BOX

10

6

PIC. 9

6

Page 7

Once all the electrical connections have been made, carry out the initial operation tests, adjust the motor run timer 09 for a period of

4-5 seconds more than the real gate opening time; the dwell timer 08, and the leaf closure delay 07 (Pic. 10)

In order to set automatic or semiautomatic operation, flick the Dip-switch B:

- Automatic Operation: with dip-switch lever No. 3 in the ON position, once the opening pulse has been given (contact 4 and 8 on the

Elpro 13 CEI programmer terminal box), the gate opens and dwells for the time set by the potentiometer 08, then closes automatically.

- Semiautomatic Operation: with dip-switch lever No. 3 in the OFF position, once the opening pulse has been given, the gate opens,

while a closing pulse must be given in order to close in (contact 5 and 8 on the Elpro 13 CEI programmer terminal box).

- Radio Contact: contact 7 and 8 on the Elpro 13 CEI electronic programmer terminal box (Pic. 10), the automation reverses the movement

that it is carrying out upon every pulse from the keyswitch, the transmitter or the wall push buttons (it is advisable to read the instructions

leaflet enclosed with the electronic programmer carefully).

WARNING: If the electric motors have insufficient drive power due to shortage of electric current, add two 12 µF capacitors (one for

each electric motor), connecting them in parallel to the individual electric motor phases.

13

CEI

FOR SWING GATES - SINGLE-PHASE

RADIO CONTROL

PLUG-IN CARD SUPPORT

1° CHANNEL

26

27

28

TERMINALS FOR THE

CONNECTION OF THE

PUSH BUTTONS PULIN 3

DIP-SWITCH

ON

B

12 435678

Should more pairs of photocells be required

than the recommended quantity, fit an

auxiliary transformer outside the control box.

ON

OFF

PEDESTRIAN MODE

ONE PULSE OPENS

ONE GATE LEAF ONLY

34

PULSE TWICE

CONSECUTIVELY TO OPEN

BOTH GATE LEAFS

24 V OUTPUT

MICROPROCESSOR

1234 5 6

PAIR-

nd

-PHOTOCELLS 2

INSIDE PHOTOCELLS N.C. contact. If

obstructed, they prevent the gates from

PHOTOCELLS

N.C. CONTACT.

opening, reverse gate direction during

close cycle.

ON TO “0” THE DELAY

IS OUT OF SERVICE

FADINI

43211312111098765

COMMON

OPEN SWITCH N.O. CONTACT

CLOSE SWITCH N.O. CONTACT

78

ALL OPERATIONS

OPEN, CLOSE & REVERSE

RADIO CONTACT

STOP SWITCH N.C. CONTACT

COMMON

RADIO CONTACT N.O.

7

8

9

VOLTAGE OUTPUT

ELECTRIC LOCK SUPPLY

0

24 Vac OUTPUT

24 V - 3 W max. INDICATOR

2 pairs photocells

Max. permitted load:

LEAF DELAY

TIMER

+

CLOSE

DWELL TIME

+

MOTOR RUN

TIME OPEN

+

& CLOSE

F5

1 Amp. FUSE:

24 V OUTPUT

TERMINALS 12 - 13

CAPACITORS

CUT OFF SWITCH

BY COVER KNOB

12,5 µF 12,5 µF

16 252423222120191817

COMMON

LED 1: LIGHTS UP WHEN THE CARD IS POWERED

1 radio receiver

LED 2: SWITCHES OFF WHEN THERE IS AN OBSTACLE IN FRONT

LED 3: OPEN. LIGHTS UP UPON OPENING PULSE

LED 4: CLOSE. LIGHTS UP UPON CLOSE PULSE

LED 5: STOP, SWITCHES OFF UPON STOP PULSE

LED 6: RADIO, LIGHTS UP UPON EVERY RADIO PULSE

N. W.: for special applications, ie. to switch on lights - CCTV etc…, SOLID

STATE RELAYS are recommended to be used only.

Standard relays would affect the micro-processor.

N.W.: THIS PANEL IS TESTED TO OPERATE GATES ONLY THROUGH FADINI

ACCESSORIES. NO GUARANTEE FOR ACCESSORIES OF OTHER MAKE OR

SPECIAL APPLICATIONS.

COMMON

M1

ELECTRIC MOTORS

SINGLE-PHASE

OF THE PHOTOCELLS

M2

230 V SINGLE-PHASE

SUPPLY VOLTAGE

230 V - 25 W max

FLASHING LAMP

F3 F1

630 mA

FUSE

FLASHING

LAMP

F4

630 mA

FUSE

F2

5 Amp.

FUSE

5 Amp.

FUSE

Drwg. No. 2014

7

Page 8

FEATURES OF THE ELECTRONIC PROGRAMMER ELPRO 13 CEI FOR

SWINGING GATES

All the electrical connections are to be made as per the following instructions and diagrams. Supply the terminals 24-25 with 230V 50 Hz single phase voltage. The “red LED” switches on and stays on as long as the board is properly supplied. Through the timer No. 9

you can control the running time of the motor in both cycles, OPEN and CLOSE.

Set it so that the running time of the motor is longer than the actual travel of the gate: set the timer No. 8 -DWELL- ie. the interval between

open and re-closing, so that you can meet the required interval of time. The timer No. 7 -LEAF DELAY in “close” cycle- is to be set as

follows: on to “–” (less) the delay is out of service; clockwise on to “+” (more) the delay is operative.

- With the electric motor connected to terminals 19 - 20 - 21: the delay is operative in the “open” cycle, with a factory pre-set time.

- With the electric motor connected to terminals 16 - 17 - 18: the delay is operative in “close” cycle and can be adjusted through the

timer No. 7 on to “less” or “more”.

LOGIC OF THE ELECTRONIC PROGRAMMER: When a pulse is given, the flashing light switches on. After three seconds the motors start.

During the interval before re-closing, the light stays on. When the gates are fully re-closed, the light keeps on flashing for three more

seconds and then switches off automatically.

The 3 second interval (pre-flashing) which precedes the actual start of the motors can be eliminated by means of the DIP-SWITCH “B” No.4.

LED No. 1: It switches on when voltage is supplied.

LED No. 2: “PHOTOCELLS”. Normally on. It switches off when the photocells are obstructed.

LED No. 3: “OPEN”. It switches on when the respective switch is activated.

LED No. 4: “CLOSE”. It switches on when the respective switch is activated.

LED No. 5: “STOP”. Normally on. It switches off when the respective switch is activated.

LED No. 6: “RADIO”. It switches on whenever a pulse is given, either from remote control, keyswitch or push buttons.

DIP-SWITCH B SETTING IN ELPRO 13 CEI

N° 1 OFF = PHOTOCELLS. NO STOP IN OPEN CYCLE. REVERSE/CLOSE

N° 2 OFF = REMOTE CONTROL. REVERSE

N° 3 OFF = NO AUTOMATIC RECLOSING

N° 4 OFF = NO PRE-FLASHING

N° 5 OFF = REMOTE CONTROL. NO STOP AND HOLD AS LONG

AS BUTTON DOWN. IT OPENS STRAIGHT AWAY

N° 6 OFF = BOTH LEAFS ARE OPERATED

N° 7 OFF = S. R. P. OUT OF SERVICE

N° 8 OFF = LEAF DELAY OPEN CYCLE.

ONE STARTS BEFORE THE OTHER

N° 1 ON = STOP DURING OPEN CYCLE

N° 2 ON = NO REVERSE DURING OPEN CYCLE

N° 3 ON = AUTOMATIC RECLOSING

N° 4 ON = PRE-FLASHING

N° 5 ON = STOP AND HOLD AS LONG AS

THE BUTTON IS KEPT DOWN

N° 6 ON = PEDESTRIAN. ONE LEAF ONLY

GATES IN CLOSE POSITION

N° 7 ON = S. R. P. IN SERVICE

GATES IN CLOSE POSITION

N° 8 ON = NO LEAF DELAY

BOTH MOTORS START TOGETHER

LAMP ON = GATE OPEN

LAMP FLASHES SLOWLY = GATE OPENING

LAMP FLASHES FAST = GATE CLOSING

LAMP OFF = GATE CLOSED

1) It is advisable not to expose the control box directly to weather conditions; if mounted outside, a suitable enclosure is recommended

to protect it from sunshine and rain.

2) Bridge terminals 1 - 2 if you do not require any photocells.

3) Should two sets of photocells be required, these are to be series connected to terminals 1 - 2, contact normally closed.

4) Bridge terminals 6 - 8 if you do not require any keyswitch or push buttons.

5) Fit the mains to the control box with a high sensitivity, differential, magnetic-thermal switch, 0.03 Amps.

6) OPERATING MODE WITH TWO PAIRS OF PHOTOCELLS, INDEPENDENT FROM EACH OTHER

Dip-switch No. 1 set to OFF, connect the pair of photocells that are inside the property to the terminals marked “2

The second pair always stops the gate in open cycle in case of an obstacle.

During close cycle the second pair reverses the gate direction.

7) NOTE WELL

FAULT FINDING:

- Check supply voltage with a tester: it must be 230 V, single-phase.

- Check the high voltage fuses.

- Check the low voltage fuses.

- Check if the photocell contacts are normally closed.

- Check voltage from the control box to the electric motor(s): power might have dropped.

- The section of the electric cables to the motor(s) must not be less than 1.5 mm

- Connect the other pair to the terminals 1 - 2

This pair performs in the standard pre-set mode, ie:

no stop during open cycle, REVERSING GATE DIRECTION DURING CLOSE CYCLE.

Terminals to stay linked out should the second pair of photocells not be used, and set the desired operating mode through Dip-switch No. 1.

* 24 V ~ output. Terminals 12 - 13. It can supply power for 2 pairs of photocells plus 1 radio receiver.

Terminal 11 provides a power output for a lamp. 24 V - 3 W max.

Flashing lamp output. Terminals 22 - 23. Maximun available power 25 W max.

8

2

.

nd

pair”.

Page 9

FEATURES AND TECHNICAL SPECIFICATIONS

“Elpro 13 CEI” represents the latest state of the art technology for control panels. It is extremely versatile and can meet the most various

requirements. It is fitted with the “Cut Off Switch” by cover knob.

It has the same functions as “Elpro 9” and incorporates additional advantages as follows: Stroke Reversing Pulse, Pedestrian Operating

Mode (where one leaf only can be operated allowing people to walk in/out), STOP and HOLD function by keeping the remote control

button pressed down. Further improvements can be noted in the “Elpro 13 CEI”:

- Addition of a 1 Amp. fuse to the 24 V circuit as a protection for the accessories (remote control - photocells -etc.) which are connected

to the terminals 12 - 13 and for the panel itself in that it can prevent short circuit during installation.

- The pulse to the electric lock is increased to 2 seconds. Releasing is so much easier as the electric lock is released with an anticipation

of 100 msec. before the gate starts moving.

- A 24 V - 3 W lamp indicates gate operations (Gate CLOSED = Lamp OFF - Gate in OPEN cycle = Lamp flashes slowly - Gate OPEN =

Lamp stays ON without flashing - Gate in CLOSE cycle = Lamp flashes fast).

- It provides a better switching intelligence design to enhance the reliability of the relays.

- The Motor Run Time is independent from the Leaf Delay Time in close cycle (the delay time is automatically added to the duration of

the -opening time).

- The 8 Dip-switches can be arranged into any of the possible patterns to achieve the required operating modes without any risk of

interference with one another.

“STROKE REVERSING PULSE” and “S.1A.P.”

Set Dip-switch No. 7 to ON The ”Stroke Reversing Pulse” (S.R.P.) is activated only with the gate in the CLOSE position. The pulse operates

the gate in the CLOSE direction first and then immediately reverses into OPEN (This will help the gate lock to release). All the other

operations will be performed in the standard way. No danger comes from the Stroke Reversing Pulse. This function remains in service

with the panel set to “Pedestrian Mode”. Set Dip-switch No. 6 to ON for “Pedestrian Mode” (S.1A.P.), terminals 3 - 4. Only one leaf is

operated when the OPEN button is pressed down. Automatic reclosing. If the OPEN button is pressed twice in a row, both leafs are

opened. The S.1A.P. function is activated only when the gate is in the fully CLOSE position. The remote control always operates both

gates, terminals 7 - 8.

The box of ELPRO 13 CEI and its cover are made of weather-proof, shock-resistant plastic material which has a degree of protection

equalling IP 437. The cover is fitted with a knob of quick response in case of an emergency by cutting off the voltage supply.

MANUAL RELEASE

The Aproli 280/700 Strong manual release makes it possible to move the gate manually, in the case of a power failure or during the initial

manual opening and closing tests. The manual release lever – S can be accessed by opening the protection cover with the customized

key. Lower the lever in order to release the gate (Pic. 11).

PROTECTION

COVER

MANUAL RELEASE

LEVER – S INSIDE

LOWER THE

MANUAL RELEASE

LEVER – S TO

RELEASE

PIC. 11

MANUAL RELEASE

LEVER - S

9

Page 10

ADJUSTING THE LEAF DRIVE FORCE

During the initial manoeuvre operations it will be necessary to calibrate the opening and closing drive force that each individual Aproli

280/700 Strong exercises on the leaves; it is therefore necessary to remove the protection cover (Pic. 12), firstly using the customized

key on the cover, thereby exposing the automation and the individual pressure regulators that can be adjusted using a flat screwdriver.

NOTE: during factory production, the two hydraulic pressure regulators on each individual Aproli 280/700 Strong are distinguished by

different colours: on the Right Aproli and the Left Aproli, the red regulator adjusts the drive force of the leaf during closing, while the

green regulator adjusts the drive force of the leaf during opening (Pic.12)

LEFT-HAND APROLI 280/700 STRONG RIGHT-HAND APROLI 280/700 STRONG

DRIVE FORCE

ADJUSTMENT

VALVES

LEFT-HAND APROLI 280/700 STRONG

RED REGULATOR = DRIVE

DURING CLOSING

GREEN REGULATOR =

DRIVE DURING OPENING

PROTECTION

COVER

COVER FIXING

SCREWS - A

DRIVE FORCE

ADJUSTMENT

VALVES

RIGHT-HAND APROLI 280/700 STRONG

GREEN REGULATOR =

DRIVE DURING OPENING

RED REGULATOR =

DRIVE DURING

CLOSING

PIC. 12

10

MANUAL RELEASE

LEVER – S

CLOCKWISE=

MORE DRIVE

FORCE

ANTICLOCKWISE=

LESS DRIVE FORCE

MANUAL RELEASE

LEVER – S

Page 11

TECHNICAL DATA

ELECTRIC MOTOR

Power output...........................................................0.18 KW (0.25 HP)

Supply voltage / Frequency....................................230 V c.a. / 50 Hz

Absorbed current........................................................................250 W

Absorbed power............................................................................1.2 A

Capacitor........................................................................................12 µF

Motor rotation speed ...........................................................1˙350 rpm

Intermittent service...........................................................................S3

SERVICE

Duty cycle......................... 23 s Opening - 30 s Dwell - 23 s Closing

Time of one complete cycle..........................................................76 s

No. of complete cycles: Open - Dwell - Close ........47 cycles/hour

No. of cycles a year, 8 hours a day........................................137˙000

OVERALL DIMENSIONS

OIL-HYDRAULIC PUMP

Pump flow rate - P3 ............................................................0.85 l /min.

Average working pressure.......................................1 MPa (10 bars)

Max. pump pressure .................................................3 MPa (30 bars)

Working temperature.....................................................–20°C +80°C

Hydraulic oil................................................OIL A 15 FADINI by AGIP

Static weight of operator with arm ...........................................20 Kg

Opening time....................................................................................23 s

Rated torque..............................................................................137 Nm

260

400

105

190

240

580

10

SX

570

520

460

150

345

150

220

580

30

520

460

407

570

DX

140

10

50

52

52

50

11

Page 12

CHECKING AND MAINTENANCE:

To achieve an optimum performance and longer life of the equipment and in observance of the safety regulations, it is recommended

that inspetions and proper maintenance are made by qualified technicians to the whole installation ie. both the mechanical and

electronic parts, as well as wiring.

- Mechanical parts: maintenance every 6 months approx.

- Electronic apparatus and safety equipment: maintenance every month.

Lineagrafica

12-2003

The “CE” mark certifies that the operator conforms to the essential

requirements of the European Directive art. 10 EEC 73/23, in relation

to the manufacturer’s declaration for the supplied items, in

compliance with the body of the regulations ISO 9000-UNI EN 29000.

Automation in conformity to EN 12453, EN 12445 safety standards.

EUROPEAN MARK CERTIFYING CONFORMITY TO

THE ESSENTIAL REQUIREMENTS OF THE

STANDARDS 98/37/EC

• DECLARATION OF CONFORMITY

• GENERAL WARNINGS

• EN 12453, EN 12445 STANDARDS

• CEI EN 60204-1 STANDARDS

• WARRANTY CERTIFICATE ON THE CUSTOMER'S REQUEST

®

s.n.c.

AUTOMATIC GATE MANUFACTURERS

The growth of MECCANICA FADINI has always been based

on the development of guaranteed products thanks to our

“TOTAL QUALITY CONTROL” system which ensures

constant quality standards, updated knowledge of the

European Standards and compliance with their

requirements, in view of an ever increasing process of

improvement.

®

the gate opener

Made in Italy

Distributor’s box

The manufacturers reserve the right to change the products without any previous notice

Via Mantova, 177/A - 37053 Cerea (Verona) Italy - Tel. 0442 330422 r.a. - Fax 0442 331054 - e-mail: info@fadini.net - www.fadini.net

Loading...

Loading...