Page 1

J200 HA

J200 HA

Page 2

CE DECLARATION OF CONFORMITY FOR MACHINES

(DIRECTIVE 2006/42/EC)

Manufacturer: FAAC S.p.A.

Address: Via Calari, 10 - 40069 Zola Predosa BOLOGNA - ITALY

Declares that: the operator mod. J200 HA

is built to be integrated into a machine or to be assembled with other machinery to create a machine under the

provisions of Directive 2006/42/EC;

conforms to the essential safety requirements of the following EEC directives:

2006/95/EC Low Voltage Directive

2004/108/EC Electromagnetic Compatibility Directive

and also declares that it is prohibited to put into service the machinery until the machine in which it will be integrated

or of which it will become a component has been identifi ed and declared as conforming to the conditions of

Directive 2006/42/EEC and subsequent amendments.

Bologna, 01st September 2012

The Managing Director

A. Marcellan

CE DECLARATION OF CONFORMITY FOR MACHINES

Manufacturer: FAAC S.p.A.

Address: Via Calari, 10 - 40069 Zola Predosa BOLOGNA - ITALY

Declares that: the control unit 624BLD

ENGLISH

• conforms to the essential safety requirements of the following EEC directives:

2006/95/EC Low Voltage Directive

2004/108/EC Electromagnetic Compatibility Directive

Additional note:

This product underwent tests in a typical homogenous confi guration

(all products manufactured by FAAC S.p.A.).

Bologna, 01st September 2012

The Managing Director

A. Marcellan

1

Page 3

WARNINGS FOR THE INSTALLER

GENERAL SAFETY OBLIGATIONS

1. A TTENTION! T o ensure the safety of people, it is important that you read all

the following instructions. Incorrect installation or incorrect use of the

product could cause serious harm to people.

2. Carefully read the instructions before beginning to install the product.

3. Do not leave packing materials (plastic, polystyrene, etc.) within reach of children

as such materials are potential sources of danger.

4. Store these instructions for future reference.

5. This product was designed and built strictly for the use indicated in this

documentation. Any other use, not expressly indicated here, could

compromise the good condition/operation of the product and/or be a source

of danger.

6. FAAC declines all liability caused by improper use or use other than that for which

the automated system was intended.

7. Do not install the equipment in an explosive atmosphere: the presence of

inflammable gas or fumes is a serious danger to safety.

8. For non-EU countries, to obtain an adequate level of safety, the Standards

mentioned above must be observed, in addition to national legal regulations.

ENGLISH

9. FAAC is not responsible for failure to observe Good Technique in the construction

of the closing elements to be motorised, or for any deformation that may

occur during use.

10. Installation must be performed in compliance with current Standards.

11. Before attempting any job on the system, cut out electrical power.

12. The mains power supply of the automated system must be fitted with an all-pole

switch with contact opening distance of 3 mm or greater. Use of a 6A thermal

breaker with all-pole circuit break is recommended.

13. Make sure that a differential switch with threshold of 0.03 A is fitted upstream of

the system.

14. Make sure that the earthing system is perfectly constructed and connect metal

parts of the closure to it.

15. The automated system is supplied with an intrinsic anti-crushing safety device

consisting of a torque control. Nevertheless, its tripping threshold must be

checked as specified in the Standards indicated at point 10.

16. The safety devices (EN 12978 standard) protect any danger areas against

mechanical movement Risks, such as crushing, dragging, and shearing.

17. Use of at least one indicator-light (i.e. flashing lamp incorporated in the bollard

head) is recommended for every system, as well as a warning sign adequately

secured to the frame structure, in addition to the devices mentioned at point

“16”.

18. FAAC declines all liability as concerns safety and efficient operation of the

automated system, if system components not produced by FAAC are used.

19. For maintenance, strictly use original parts by FAAC.

20. Do not in any way modify the components of the automated system.

21. The installer shall supply the user with the necessary information for the manual

operation of the system in the event of emergency

22. Do not allow children or adults to stay near the product while it is operating.

23. Keep remote controls or other pulse generators away from children, to prevent the

automated system from being activated involuntarily.

24. Transit on the bollard is permitted only when the device is completely down.

25. The user must not attempt any kind of repair or direct action whatever and contact

qualified personnel only.

26. Anything not expressly specified in these instructions is not permitted.

INDEX

1 GENERAL NOTES ......................................................................................................................................... 3

2 DESCRIPTION AND TECHNICAL SPECIFICATIONS................................................................................... 3

3 DIMENSIONS .................................................................................................................................................. 4

4 FACILITIES ..................................................................................................................................................... 4

5 ELECTRIC WIRING ........................................................................................................................................ 6

6 MANUAL OPERATION ................................................................................................................................... 9

7 AUTOMATIC OPERATION ............................................................................................................................. 9

8 MAINTENANCE .............................................................................................................................................. 9

9 ELECTRICAL CONNECTIONS .................................................................................................................... 10

10 PRE-SETTING SELECTION ..........................................................................................................................11

11 POSITIONING THE LOOPS ..........................................................................................................................11

12 CONNECTING MORE BOLLARDS ............................................................................................................. 12

12.1 CONNECTION OF UP TO 4 BOLLARDS ON A SINGLE BOARD .................................................................... 12

12.2 CONNECTION OF UP TO 8 BOLLARDS ON TWO 624BLD MASTER – SLAVE CONNECTION .................12

12.3 WIRING OF UP TO 4 BOLLARDS ON A SINGLE BOARD ..............................................................................13

12.4 WIRING OF UP TO 8 BOLLARDS ON TWO 624BLD IN MASTER – SLAVE CONNECTION .......................14

13 TROUBLESHOOTING .................................................................................................................................. 15

14 CLEANING / UNMOUNTING PROCEDURE ................................................................................................ 15

2

Page 4

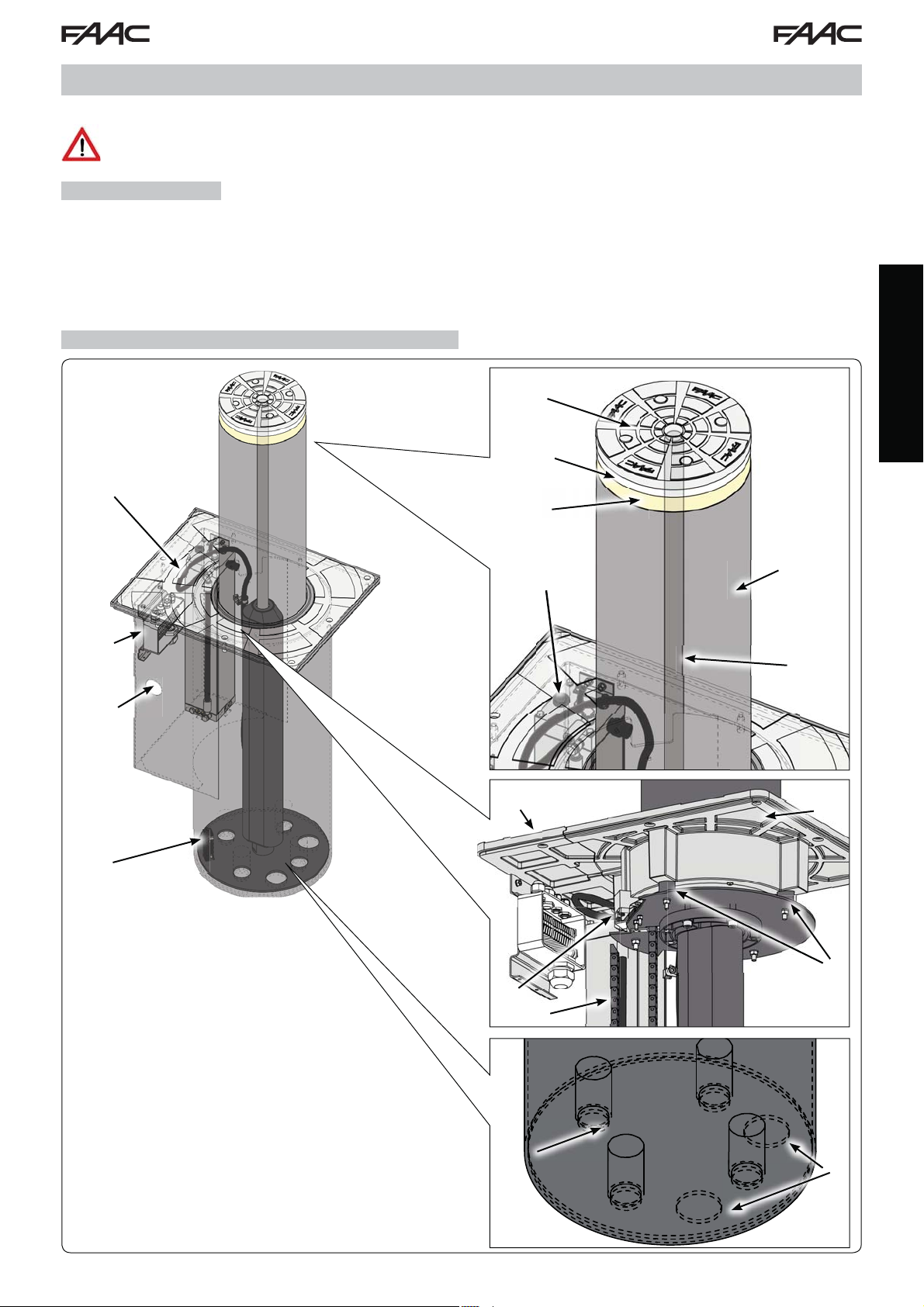

J200 HA BOLLARD

Please read with the utmost care this manual supplied with the product, since it contains important indications

about safety, installation, use and maintenance.

1 GENERAL NOTES

J200HA is an automatic hydraulic traffic bollard. The cylinder is moved by an hydraulic unit located inside the cylinder. The hydraulic

release occurs by direct action on the hydraulic unit. As an alternative, if the optional solenoid valve is present, the release occurs

automatically in the event of a power cut.

2 DESCRIPTION AND TECHNICAL SPECIFICATIONS

ENGLISH

1. Hydraulic unit

2. Junction box

3. Cable routing hole

4. Magnetic contact, down (NC polarity)

5. Crown

6. LED flashing lamp

7. Reflective stripe

8. Oil filler plug

9. Piston

10. Cylinder

11. Magnetic contact, up (NC polarity)

12. Cable routing chain

13. Upper plate (bollard)

14. Upper plate (Hydraulic unit)

15. 4 stop points, up

16. stoppers, down

17. Water drainage holes

Fig. 1

3

Page 5

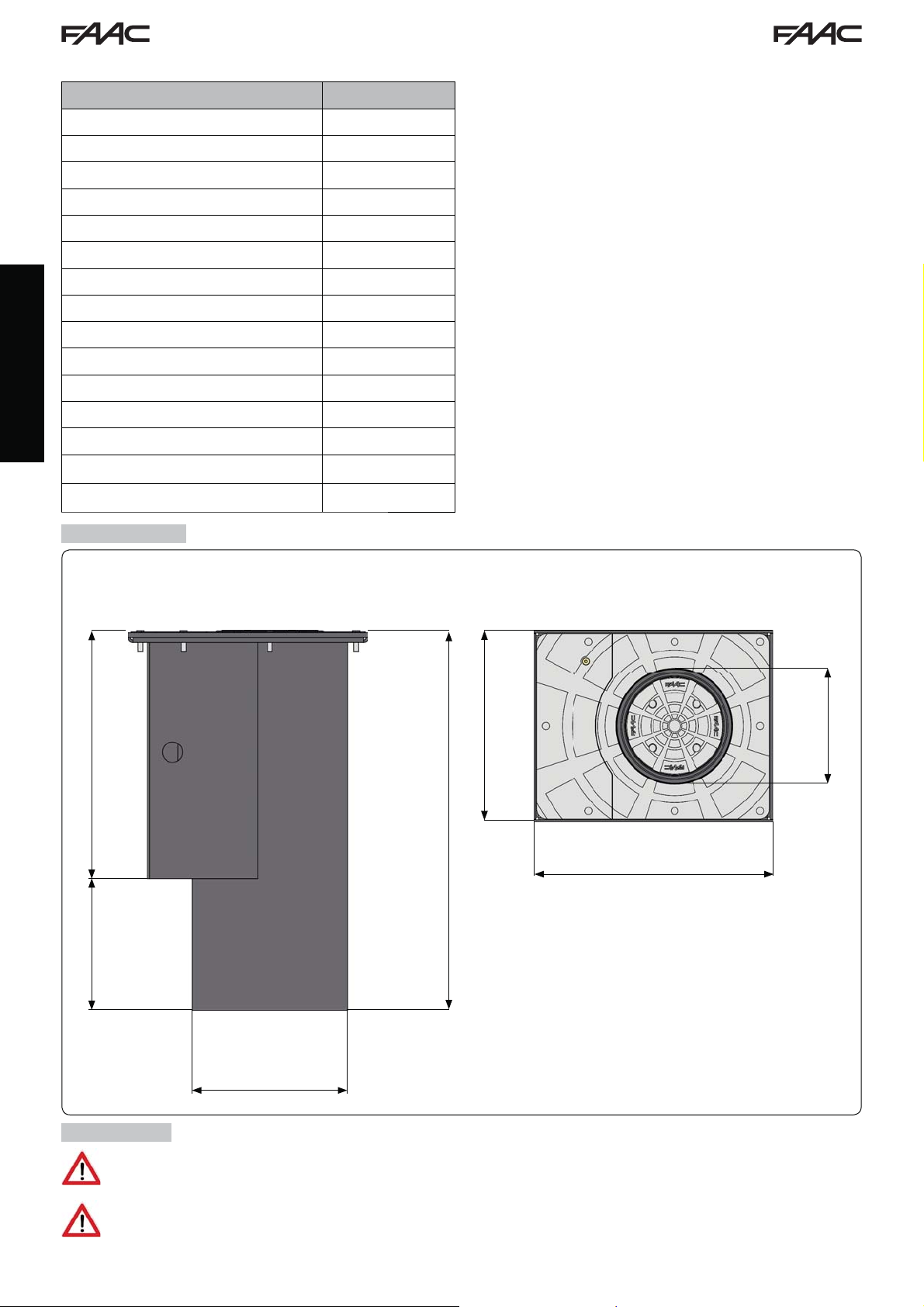

Tab. A - Technical Specifi cations

MODEL J200

Power supply 230 V~ 50 Hz

Max. absorbed power (W) 220

Max. force (N) 1800

Max. pump delivery (lpm)

Minimum lifting time (sec) 7

Minimum lowering time (sec) 7

ENGLISH

3 DIMENSIONS

Dimensions in mm

3

Use temperature (°C) -15 +55

Weight (Kg) 100

Oil quantity (l) 2,6

Protection class IP56

Overall dimensions See Fig.2

Capacitor

Use frequency Semi-Intensive use

R.O.T. at 55°C (min) 40

R.O.T. at 23°C (min) 100

(3) 16μF - 400V

400

790

500

275 515

322

4 FACILITIES

Make sure that the place where the bollard is to be installed is not a cavity; if this is the case, partially protect

the bollard with a drainage channel equipped with covering grid.

200

Fig. 2

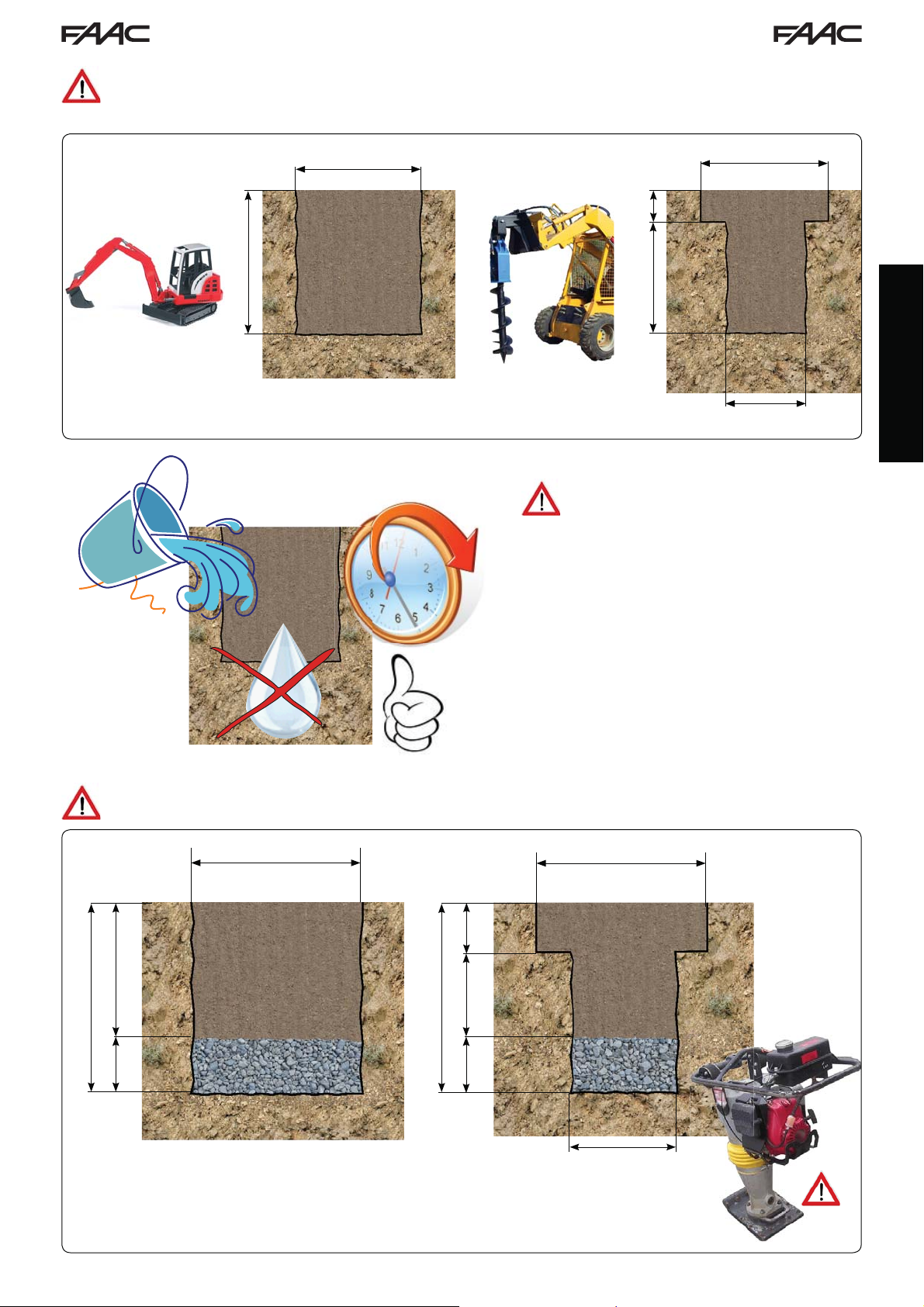

Dig up to a depth of about 1.1 m

4

Page 6

The dig can be square and have a side of about 1 m (fig. 3). Otherwise it can be carried out using an earth

drill with a diameter of 50 cm up to the depth mentioned above and widened in the last 30 cm giving a square

shape of 1 m per side

Dimensions in mm

1100

30’40lt

1000

1000

800 300

500

Make sure that the ground

is able to absorb water: pour

about 40 l water and evaluate if

draining requires less than 30

minutes. If this is not the case,

discharge rain water by means

of a pipeline with a diameter of

60mm connected to the drainage

system or, as an alternative,

connected to a pit, equipped

with a drainage system (such

as a motor pump), having a

depth greater than the pit for the

collection and drainage of rain

water

Fig. 3

ENGLISH

Introduce gravel (grain diameter: approx. 20 mm.) to obtain a thickness of about 30 cm, taking care to compact

it well to avoid future settlements

1000

1000

300

800

1100

300

1100

500

300

500

Fig. 4

5

Page 7

IPlace the two included grub screws on the threaded holes indicated in the following reference, then tighten

the two eyebolts and use them to lift and position the frame.

ENGLISH

Place the bollard taking care to position it

plumb. The top level of the frame must be

approx. 10 mm higher than the floor surface

(to limit the inlet of rainwater in the pit).

To reduce any stumble risk, level the pit to the

street surface.

Respect the direction of transit as shown in fig.5.

10

Fig. 5

With the bollard in place, enter additional 35mm of gravel, then lay a flexible sheat (external diameter = 40mm)

from the bollard to the control unit.

6

Page 8

GRAVEL

CONCRETE

FLEXIBLE SHEATH

STREET SURFACE

ø 40mm

Fig. 6

350300

Cast concrete, type RCK25, all around the pit to secure it firmly up to about 10cm from the floor surface. After

having secured the pit, finish the street surface using the same type of material.

Dimensions in mm

STREET SURFACE

1000

CONCRETE

800

350300

1000

800

ENGLISH

300

GRAVEL

Lay the pipelines that are necessary for the connection between the control unit and any additional device

(i.e. traffic lights – inductive loops – card reader – etc.) and every other bollards, if any. Prepare the electrical

connection and the earthing.

To connect the bollard to the control

board, use a cable, type FG7OR-0,6/1kV16G1,5, having a max. length of 50 m.

N.B.: every pipe must be laid in compliance

with the current rules.

At the end, remove the protective film

from the upper plates.

300

Fig. 7

7

Page 9

5 ELECTRIC WIRING

For the connection of the bollard to the control unit, use a multi-pole cable, type FG7OR-0,6/ kV- 6G 1,5 ( 16 cables of 1,5mm2)

with max. length of 50 m. This cable must be laid inside a sheath ø 40mm.

Perform the electric wiring in the junction box on the bollard side, as shown in the figure below. For easier wiring, the junction box

can be removed.

Any additional accessory (i.e. photocells, opening/closing push-buttons, etc.), that have to be connected to

the control unit, must compulsorily have double insulation.

ENGLISH

Earth

Motor phase

Motor neutral wire

Motor phase

+24V

Lights

Limit switch UP N.C.

Limit switch DOWN N.C.

{

{

Fig. 8

8

Page 10

6 MANUAL OPERATION

To lower the bollard by hand, you need to act on the release device.

1. Loosen the closing screw located on the bollard head (fig.

9 ref.

).

2. Introduce the supplied key into the relevant hole.

3. Turn counter-clockwise to lower the bollard (fig. 9 ref.

).

Fig. 9

8 STANDARD PROCEDURE FOR A 6-MONTHLY VERIFY

Ordinary maintenance standard procedure:

1. Clean the pit and remove any settled material by suction

2. Clean the water drainage systems on the pit bottom

3. Check (and repair, if necessary) any oil leakages from the

driving piston

4. Check the correct tightening of the bollard screws

5. Clean the driven cylinder and touch up paint, if necessary

6. Check the hydraulic unit and top up oil, if necessary. Check

the setting of the operating pressure

7. Check and set, if installed, the functions of the safety pressure

switch (40 Kg.)

7 AUTOMATIC OPERATION

To restore the automatic operation:

1. Introduce the supplied key into the relevant hole.

).

Fig. 10

2. Turn clockwise till end of stroke (fig. 10 ref.

3. Tighten again the closing screw on the bollard head (fig. 10

).

ref.

We advise to perform the abovwe mentioned operation at least

every six months.

ENGLISH

9

Page 11

JE275 CONTROL UNIT

The JE275 control unit is supplied with the control board 624 BLD and the housing, model E.

Always cut the power supply before performing any intervention on the control unit (connections, maintenance).

- Install a differential thermal-magnetic switch with suitable threshold (0.03A) upstream of the system.

- Connect the earth cable to the relevant terminal on the connector J9 of the unit (see figure below).

- Check if the power disconnecting switch is provided with locking key exept if it’s installed under operator/

maintenance man control.

- The control unit installation must be done between 0,4 m and 2,0 m height

9 ELECTRICAL CONNECTIONS

BOLLARD SIDE624BLD BOARD SIDE

ENGLISH

Motor

{

Motor

Lights

+24V

230Vac ~

{

+24V

+24V

Lights

Limit switch

UP

Limit switch

DOWN

Limit switch DOWN

10

Limit switch UP

Fig. 11

Page 12

10 PRE-SETTING SELECTION

After having connected the board and after having supplied it with power according to the previous paragraph, you must select the

work pre-setting for the bollard J200HA following the operations below:

1. Enter the 1

on the display.

2. Release key F and select 07 with the key +

3. Simultaneously press keys F and - to exit programming and save the changes performed.

For any further information on the unit programming, please refer to the relevant

instructions.

st

level programming, holding down key F on the board. The initials dF will appear

11 POSITIONING THE LOOPS

Below you will find some examples for the realization of magnetic loops with one or more bollards:

1. Installation of a single bollard and two magnetic loops to detect vehicle transit.

2. Installation of a single bollard and of a magnetic loop to protect the perimeter.

3. Installation of four bollards (on a single 624BLD) and four loops to protect large passages

4. Installation of eight bollards (4 on 624BLD MASTER board + 4 on 624BLD SLAVE board, see par. 12.2) and eight loops to

protect large passages

The loops must be realized according to the instructions provided for the magnetic detector (control unit); they must be connected

each other in series or you can use more magnetic detectors and connect the relevant relay contacts in series.

200 cm

100 cm

ENGLISH

200 cm

60 cm

60 cm

100 cm

100 cm

100 cm

100 cm

100 cm

624BLD MASTER 624BLD SLAVE

11

Fig. 12

Page 13

12 CONNECTING MORE BOLLARDS

12.1 CONNECTION OF UP TO 4 BOLLARDS ON A SINGLE BOARD

Up to 4 bollards can be connected to the same unit and operate simultaneously.

Follow the instructions below for a correct wiring and operation (par. 12.3).

ENGLISH

Fig. 13

12.2 CONNECTION OF UP TO 8 BOLLARDS ON TWO 624BLD MASTER – SLAVE CONNECTION

You can connect 2 624BLD units in a MASTER-SLAVE configuration for the simultaneous control of 8 bollards. Follow the instructions

below for a correct wiring and operation (par.12.4).

Fig. 14

12

Page 14

12.3 WIRING OF UP TO 4 BOLLARDS ON A SINGLE BOARD

Connection of 4 motors Connection of lights / buzzer

BOARD SIDE

BOLLARD SIDE

Fig. 15

BOLLARD SIDE

Lights 1

Buzzer 1

Lights 2

Buzzer 2

Lights 3

Buzzer 3

Lights 4

Buzzer 4

BOARD SIDE

ENGLISH

Fig. 16

Connection of 4 limit switches DOWN in parallel.

The bollards stop when all 4 limit switches

are engaged

BOLLARD SIDE BOARD SIDE BOLLARD SIDE BOARD SIDE

Limit switch

DOWN 1

Limit switch

DOWN 2

Limit switch

DOWN 3

Limit switch

DOWN 4

Fig. 17

Connection of 4 limit switches UP in parallel.

The bollards stop when all 4 limit switches

are engaged

Limit switch

UP 1

Limit switch

UP 2

Limit switch

UP 3

Limit switch

UP 4

Connection of 4 pressure switches in series.

The fi rst operation of a pressure switch causes the

reversal of all bollards

BOLLARD SIDE BOARD SIDE

Pressure switch

1

Fig. 18

Pressure switch

2

Pressure switch

3

Pressure switch

4

Fig. 19

13

Page 15

12.4 WIRING OF UP TO 8 BOLLARDS ON TWO 624BLD IN MASTER – SLAVE CONNECTION

ENGLISH

DOWN 5

Limit switch

DOWN 6

Limit switch

UP 5

UP 6

Limit switch

DOWN 7

DOWN 8

Limit switch

UP 7

UP 8

Buzzer 1

Buzzer 2

Light 5

Light 6

Buzzer 3

Buzzer 4

Light 7

Light 8

Buzzer 5

Buzzer 6

Buzzer 7

Buzzer 8

Limit switch

Limit switch

Limit switch

DOWN 1

Limit switch

DOWN 2

Limit switch

Limit switch

Limit switch

DOWN 3

DOWN 3

Limit switch

Light 1

Light 2

Light 3

Light 4

UP 1

UP 2

Limit switch

Limit switch

Limit switch

UP 3

UP 4

Limit switch

14

1

2

3

Pressure switch

Pressure switch

Pressure switch

4

5

6

Pressure switch

Pressure switch

Pressure switch

7

8

Pressure switch

Pressure switch

Fig. 20

Page 16

13 TROUBLESHOOTING

The indications below will help you locate and solve particular conditions.

CONDITION ADVICE

1 The bollard rises for a few centime-

tres and then lowers immediately

2 As soon as the bollard reaches the

position, it reverses immediately

3 The bollard does not rise, it remains

down.

4 The bollard remains up in closed

position.

5 The buzzer and the LED fl ashing

lamp do not operate

• Make sure you have selected the default no. 7 on the 624BLD board

• Check if the safety pressure switch wiring was performed correctly, (optional,

see the related instructions)

• Make sure that the LED DL3 (FSW) on the 624BLD board remains ON for the

whole movement

• Adjust the pressure switch (if installed)

• Replace the pressure switch

• Check if the wiring of the limit stops was performed correctly, see fi g. 11 or fi g.

18

• Make sure that the up position limit stops are correctly positioned, see ref. 11

fi g.1

• Make sure you have selected the default no. 7 on the 624BLD board

• Check if the wiring of the solenoid valve was performed correctly, (optional, see

the related instructions)

• Check if the solenoid valve was adjusted correctly

• Replace the solenoid valve

• Make sure the bollard is hydraulically locked, see par. 7

• Make sure nothing between the cylinder and the sliding bush prevents the

bollard movement; try and shake the cylinder to facilitate its downstroke

• Make sure you have selected the default no. 7 on the 624BLD board

• Check if the power connector under the head was fi tted correctly

ENGLISH

14 CLEANING / UNMOUNTING PROCEDURE

In case you need to unmount / clean the bollard, proceed as follows. Each step (to be followed in sequence) allows for the access

to a different part of the bollard:

1) Top limit switch replacement

2) Headlight replacement

3) Cylinder removal for internal cleaning.

4) Piston removal and access to lower limit switch

a

b

15

Page 17

a

ENGLISH

b

16

Page 18

ENGLISH

N.B. Remove the oil pipe clamp before extracting thepiston

17

N.B. Remove the two chain fixing screws before extracting

the cylinder

Page 19

SEDE - HEADQUARTERS

FAAC S.p.A.

Via Calari, 10

40069 Zola Predosa (BO) - ITALY

Tel. +39 051 61724 - Fax +39 051 758518

www.faac.it - www.faacgroup.com

ASSISTENZA IN ITALIA

SEDE

tel. +39 051 6172501

www.faac.it/ita/assistenza

ROMA

tel +39 06 41206137

filiale.roma@faacgroup.com

SUBSIDIARIES

AUSTRIA

FAAC GMBH

Salzburg, Austria

tel. +43 662 8533950

www.faac.at

FAAC TUBULAR MOTORS

tel. +49 30 56796645

faactm.info@faacgroup.com

www.faac.at

AUSTRALIA

FAAC AUSTRALIA PTY LTD

Homebush – Sydney, Australia

tel. +61 2 87565644

www.faac.com.au

MILANO

tel +39 02 66011163

filiale.milano@faacgroup.com

TORINO

tel +39 011 6813997

filiale.torino@faacgroup.com

GERMANY

FAAC GMBH

Freilassing, Germany

tel. +49 8654 49810

www.faac.de

FAAC TUBULAR MOTORS

tel. +49 30 5679 6645

faactm.info@faacgroup.com

www.faac.de

INDIA

FAAC INDIA PVT. LTD

Noida – Delhi, India

tel. +91 120 3934100/4199

www.faacindia.com

PADOVA

tel +39 049 8700541

filiale.padova@faacgroup.com

FIRENZE

tel. +39 055 301194

filiale.firenze@faacgroup.com

BENELUX

FAAC BENELUX NV/SA

Brugge, Belgium

tel. +32 50 320202

www.faacbenelux.com

FAAC TUBULAR MOTORS

Schaapweg 30

NL-6063 BA Vlodrop, Netherlands

tel. +31 475 406014

faactm.info@faacgroup.com

www.faacbenelux.com

SWITZERLAND

FAAC AG

Altdorf, Switzerland

tel. +41 41 8713440

www.faac.ch

CHINA

FAAC SHANGHAI

Shanghai, China

tel. +86 21 68182970

www.faacgroup.cn

UNITED KINGDOM

FAAC UK LTD.

Basingstoke - Hampshire, UK

tel. +44 1256 318100

www.faac.co.uk

FRANCE

FAAC FRANCE

Saint Priest - Lyon, France

tel. +33 4 72218700

www.faac.fr

FAAC FRANCE - AGENCE PARIS

Massy - Paris, France

tel. +33 1 69191620

www.faac.fr

FAAC FRANCE - DEPARTEMENT VOLETS

Saint Denis de Pile - Bordeaux, France

tel. +33 5 57551890

fax +33 5 57742970

www.faac.fr

NORDIC REGIONS

FAAC NORDIC AB

Perstorp, Sweden

tel. +46 435 779500

www.faac.se

SPAIN

F.A.A.C. SA

San Sebastián de los Reyes.

Madrid, Spain

tel. +34 91 6613112

www.faac.es

U.S.A.

FAAC INTERNATIONAL INC

Jacksonville, FL - U.S.A.

tel. +1 904 4488952

www.faacusa.com

FAAC INTERNATIONAL INC

Fullerton, California - U.S.A.

tel. +1 714 446 9800

www.faacusa.com

POLAND

FAAC POLSKA SP.ZO.O

Warszawa, Poland

tel. +48 22 8141422

www.faac.pl

RUSSIA

FAAC RUSSIA LLC

Moscow, Russia

tel. +7 495 6462429

www.faac.ru

MIDDLE EAST

FAAC MIDDLE EAST BRANCH

Dubai Airport Free Zone - Dubai, UAE

tel. +971 42146733

www.faac.ae

732804 - Rev.A

Loading...

Loading...