Page 1

The Chamberlain Group, Inc.

845 Larch Avenue

Elmhurst, Illinois 60126-1196

www.liftmaster.com

MODEL HCT 5011O3

COMMERCIAL HIGH-TRAFFIC OVERHEAD GATE OPERATOR

OWNER'S MANUAL

Page 2

Page 3

TABLE OF CONTENTS

2

3

3

4

5

5

6

7

8

9

10

11

12

12

13

14

15

15

16

17

18

19

20

21

22-23

24

24

25

26

27

28

29

30

30

31

32

For Toll Free Technical Support: 1-800-528-2806

www.liftmaster.com

Features and Specifications

Role of Specifiers and Designers

Role of Dealers, Installers and Trained System Technicians

UL Gate Classifications

Role of End Users

Overhead Gate Systems

Safety Installation Instructions

Steps 1-2 Installation of Operator

Steps 3-5 Mounting the Operator

Step 6 How to Connect Power (120 Vac) Earth Ground Rod

Step 7 Mounting and Wiring of the Reset Switch

Step 8 Adjusting the Traveling Distance (Limit Switches)

Step 9 Two Way Adjustable Reversing Sensor

Step 10 Adjustable Timer

Step 11 Terminal Input Connections

Steps 12-13 IMPORTANT INFORMATION

Operating Instructions for Optional Systems

Three Push Button System

House Alarm / Proximity Switch Connections

Optional Relay Adapter Connection

Secondary Entrapment Protection (Contact Sensor)

Secondary Entrapment Protection (Non-Contact Sensor)

Optional Plug-In Loop Detectors

Wiring External Loop Detectors

Programming the Radio Receiver

Replacing the Control Board

Audio Alarm

Important Safety Instructions

MANUAL RELEASE

Troubleshooting Table

Troubleshooting / LED Information

Parts Illustrations

Parts List

Maintenance

Accessories

Operator Notes

Important:

DO NOT attempt repair or

service of your commercial gate operator

unless you are an Authorized Service

Technician.

MAINTENANCE

& OPERATION

INSTALLATION

1

Page 4

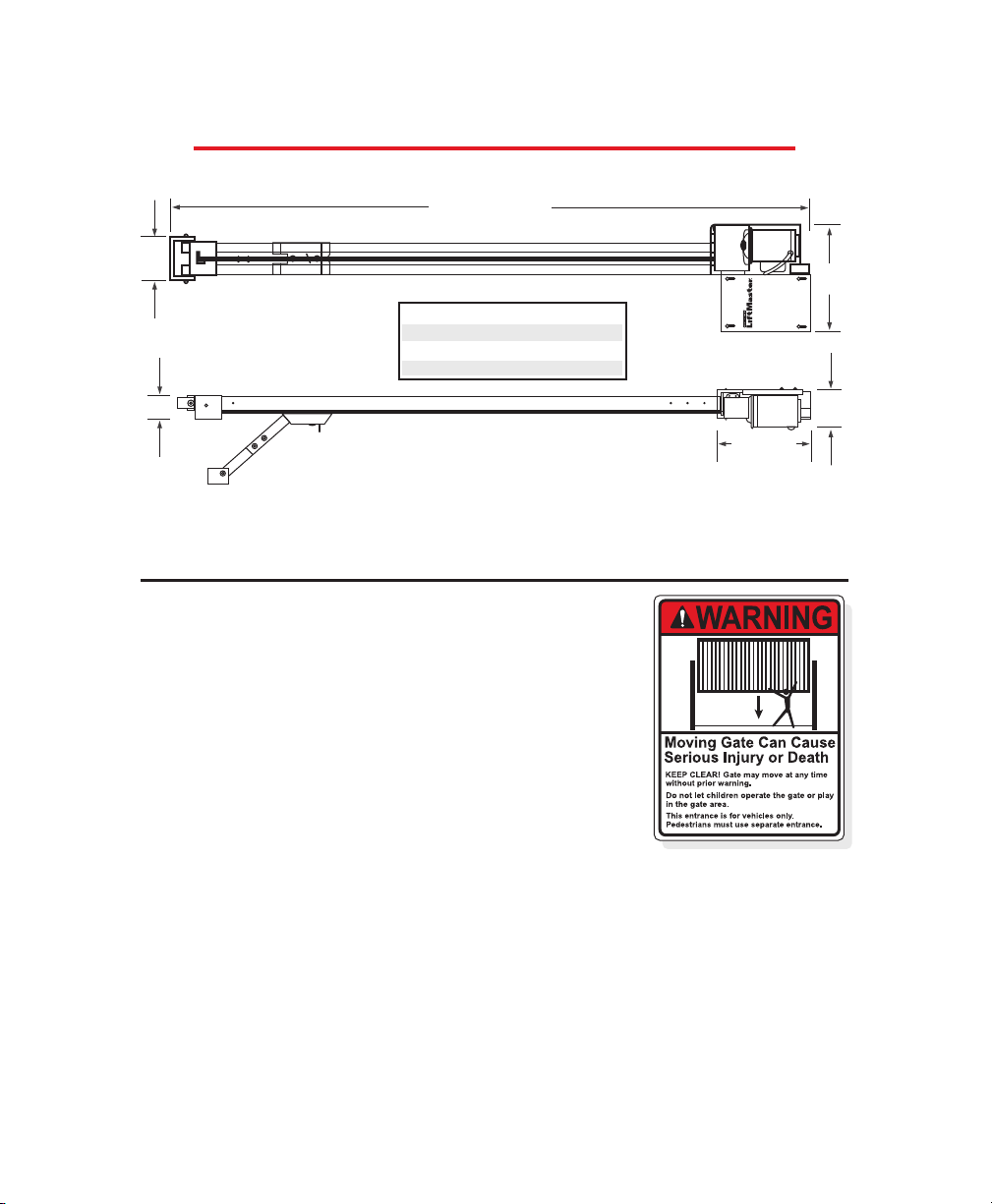

8.25"

FEATURES AND SPECIFICATIONS

141"

VARIABLE OPERATING LENGTHS

Gate Height Operator Length

8 ft. Gate 141 in.

10 ft. Gate 165 in.

12 ft. Gate 189 in.

22.01"

4"

8.36"

18.875"

CONTINUOUS CYCLE 1/2 HP – 120 Vac

240 LBS. MAX. PULL 1PH – 60HZ – 4.8 AMPS

COMMERCIAL GATE OPERATOR, CLASS II, III, IV WEIGHT 123 LBS

MOTOR - 120 Vac 4.8 Amp 1/2 HP instant reversing parking gate

Leeson Motor

GEAR BOX - 40 to 1 ratio, lubrication by oil bath gives smooth,

quiet operation and features positive gate locking.

NOISE ISOLATOR - Heavy duty rubber attachments isolate

vibration, absorb shock and eliminate noise.

TWO WAY REVERSING SENSOR - Can be set for close/open

cycles. While closing, if the gate hits an object it reverses; while

opening, if it hits an object it stops.

ENTRAPMENT ALARM SYSTEM - Alarm activates anytime the

Use warning sign on front of gate

to prevent injury to children.

moving gate is physically stopped by an unwanted object.

MODULAR ELECTRONIC CONTROL BOARD - All electronic parts are on a single board.

BALL BEARING SUPPORTS - All wear points run on full ball bearing supports for a long, quiet life.

TROLLEY ASSEMBLY - Chain drive trolley assembly operates on 6 UHMW wheels to eliminate

noise, shock and vibration.

FINISHING - Metal parts are gold-zinc plated and/or powder coated for rust-proof purposes.

MANUAL RELEASE - In case of power failure, it can be easily disconnected by a security key.

2

Page 5

ROLE OF SPECIFIERS AND DESIGNERS

ROLE OF DEALERS, INSTALLERS

AND TRAINED SYSTEM TECHNICIANS

Specifiers and designers should design an automatic vehicular gate system to:

Installers, during the course of the installation steps for each job, should:

Read and fully understand the manual.

Confirm that the operator being installed is appropriate for the application.

Confirm that the gate is designed and built according to current published industry standards.

Confirm that all appropriate features and accessory devices are being incorporated, including both

primary and secondary entrapment protection devices.

Make sure that the gate works freely before installing the operator.

Repair or service worn or damaged hardware before installing the operator.

Adjust the operator clutch or load-sensing device to the minimum force setting that allows reliable

operation.

Install operator inside fence line. (DO NOT install operator on public side of fence line.)

Install a proper electrical ground to the operator.

Install keypad controls where users cannot touch, or reach through gate while operating controls.

Install controls where user has full view of operation.

Install all warning signs (in accordance with UL325) on both sides of the gate to warn persons in

the area of potential hazards associated with automatic vehicular gate operation.

Test all features for proper functions before placing the automatic vehicular system into service.

Demonstrate the basic functions and safety features of the system to owners/end users/general

contractors, including how to turn off power and how to operate the manual disconnect feature.

Leave safety instructions, product literature, installation manual and maintenance manual with end

user.

Explain to the owners the importance of a service/maintenance contract that includes a routine

re-testing of the entire system including the entrapment protection devices, and explain the need

for the owners to insure that this testing is performed routinely.

Offer the owner/end user a maintenance contract, or contact them regularly to offer maintenance.

Incorporate UL325 compliant equipment.

Utilize an operator suited for system type, size, frequency of use, location and user population.

(For gates refer to UL325 for usage class definitions.)

Separate pedestrian access from vehicle access.

Reduce or eliminate pinch points.

Reduce risk of entrapment injuries by minimizing all gaps in the gate and enclosing the area of the

travel of the gate.

Secure controls from unauthorized use.

Locate all controls out of reach from the gate.

Allow the user full view of the gate when operating.

Consider special populations, such as children or the elderly.

Prominently display all warnings and instructions.

Be consistent with DASMA’s Automatic Gate Opener System Safety Guide.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

3

Page 6

UL GATE CLASSIFICATIONS

Class II –

Commercial/General access vehicular gate operator

A vehicular gate operator (or system) intended for use in a commercial

location or building such as a multi-family housing unit (five or more

single family units) hotel, garages, retail store or other building

servicing the general public.

Class III –

Industrial/Limited access vehicular gate operator

A vehicular gate operator (or system) intended for use in a industrial

location or building such as a factory or loading dock area or other

locations not intended to service the general public.

Class IV –

Restricted access vehicular gate operator

A vehicular gate operator (or system) intended for use in a guarded

industrial location or building such as an airport security area or other

restricted access locations not servicing the general public, in which

unauthorized access is prevented via supervision by security

personnel.

4

Page 7

ROLE OF END USERS

OVERHEAD GATE SYSTEMS

Read and fully understand the manual.

Contact a trained system technician to maintain and repair the system. (End users should never

attempt to repair the system.)

Retain and utilize the installation/maintenance manual and safety instructions.

Routinely check of all operator functions and gate movement.

Discontinue use if safety systems operate improperly, the gate is damaged, or the gate is difficult

to move.

Prominently display and maintain warning signs on both sides of the gate.

Keep all obstructions clear of the vicinity of the path of the system.

Actively discourage pedestrian use of the vehicular operating system.

Prevent anyone from playing near any part of the system.

Never allow anyone to climb under, over or through a gate or the adjacent fence area.

Never allow children to operate system.

Keep portable controls out of reach of children.

Never allow anyone to install an operating control within reach of the gate.

Always be certain that the area is clear of pedestrians before operating the system.

End users should be made aware that they must:

READ AND FOLLOW ALL INSTRUCTIONS.

Gate - A moving barrier such as a swinging, sliding, raising lowering, rolling, or like, barrier, that is

a stand-alone passage barrier or is that portion of a wall or fence system that controls entrance

and/or egress by persons or vehicles and completes the perimeter of a defined area.

Vehicular Vertical Pivot-Gate Operator (or System) - A vehicular gate operator (or system) that

controls a gate that moves in an arc in a vertical plane that is intended for use for vehicular

entrances or exits to a drive, parking lot, or the like.

Entrapment Zone Hazard - Body parts may become entrapped between a gate and a stationary

object when the gate begins to move, which can result in serious injury or death. Pedestrians must

stay clear of the gate path, and any area where gate motion is close to stationary objects.

Pinch Points Hazard - The opening mechanism may have arms that can overlap with a scissoring

effect, which can result in serious injury. Pedestrians must stay clear of the opening mechanism at

all times, particularly when gate is opening.

Be sure that warning signs are prominently displayed on both sides of the gate and any other place

where danger exists.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

WARNING: To reduce the risk of SERIOUS INJURY or DEATH:

•

5

Page 8

SAFETY INSTALLATION INSTRUCTIONS

2)

3)

4)

5)

6)

1)

Vehicular gate systems provide convenience and security. Gate systems are comprised of many component parts. The

gate operator is only one component. Each gate system is specifically designed for an individual application.

Gate operating system designers, installers and users must take into account the possible hazards associated with each

individual application. Improperly designed , installed or maintained systems can create risks for the users as well as

bystanders. Gate systems design and installation must reduce public exposure to potential hazards.

A gate operator can create high levels of force in its function as a component part of a gate system. Therefore, safety

features must be incorporated into every design. Specific safety features include:

• Gate edges • Guards for Exposed Rollers • Photoelectric Sensors

• Screen Mesh • Vertical Posts • Instructional and Precautionary Signage

Install the gate operator only when:

A) The operator is appropriate for the construction and the usage class of the gate.

B) All openings of a horizontal slide gate are guarded or screened from the bottom of the gate to a minimum of 4' (1.2 m) above the

ground to prevent a 2 1/4" (6 cm) diameter sphere from passing through the openings anywhere in the gate, and in that portion of

the adjacent fence that the gate covers in the open position.

C) All exposed pinch points are eliminated or guarded, and guarding is supplied for exposed rollers.

The operator is intended for installation only on gates used for vehicles. Pedestrians must be supplied with a separate

access opening. The pedestrian access opening shall be designed to promote pedestrian usage. Locate the gate such that

persons will not come in contact with the vehicular gate during the entire path of travel of the vehicular gate.

The gate must be installed in a location so that enough clearance is supplied between the gate and adjacent structures

when opening and closing to reduce the risk of entrapment. Swinging gates shall not open into public access areas.

The gate must be properly installed and work freely in both directions prior to the installation of the gate operator.

Controls intended for user activation must be located at least 6' (1.8 m) away from any moving part of the gate and where

the user is prevented from reaching over, under, around or through the gate to operate the controls. Outdoor or easily

accessible controls shall have a security feature to prevent unauthorized use.

The Reset Button must be located in the line-of-sight of the gate. Activation of the reset control shall not cause the

operator to start.

A minimum of two (2) WARNING SIGNS shall be installed, one on each side of the gate where easily visible.

For a gate operator utilizing a non-contact sensor:

A) Reference owner’s manual regarding placement of non-contact sensor for each type of application.

B) Care shall be exercised to reduce the risk of nuisance tripping, such as when a vehicle trips the sensor while the gate is still

moving.

C) One or more non-contact sensors shall be located where the risk of entrapment or obstruction exists, such as the perimeter

reachable by a moving gate or barrier.

For a gate operator utilizing a contact sensor such as an edge sensor:

A) Reference owner’s manual regarding placement of non-contact sensor for each type of application.

B) One or more contact sensors shall be located where the risk of entrapment or obstruction exists, such as at the leading edge,

trailing edge and post mounted both inside and outside of a vehicular horizontal slide gate.

C) One or more contact sensors shall be located at the bottom edge of a vehicular vertical lift gate.

D) A hard wired contact sensor shall be located and its wiring arranged so the communication between the sensor and the gate

operator is not subject to mechanical damage.

E) A wireless contact sensor such as the one that transmits radio frequency (RF) signals to the gate operator for entrapment

protection functions shall be located where the transmission of the signals are not obstructed or impeded by building structures,

natural landscaping or similar obstruction. A wireless contact sensor shall function under the intended end-use conditions.

F) One or more contact sensors shall be located on the inside and outside leading edge of a swing gate. Additionally, if the bottom

edge of a swing gate is greater than 6" (152 mm) above the ground at any point in its arc of travel, one or more contact sensors

shall be located on the bottom edge.

G) One of more contact sensors shall be located at the bottom edge of a vertical barrier (arm).

9)

8)

7)

10)

11)

12)

6

Page 9

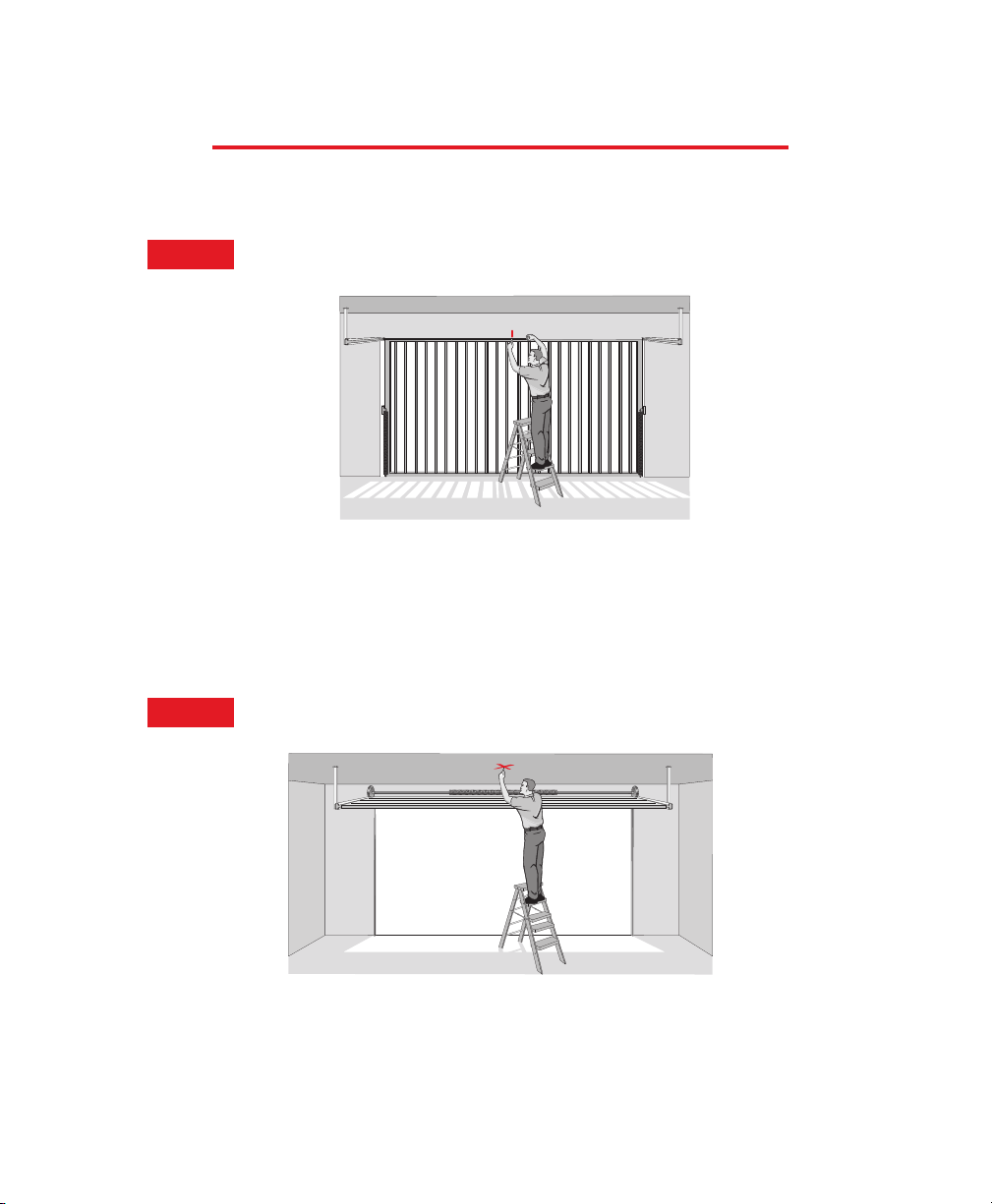

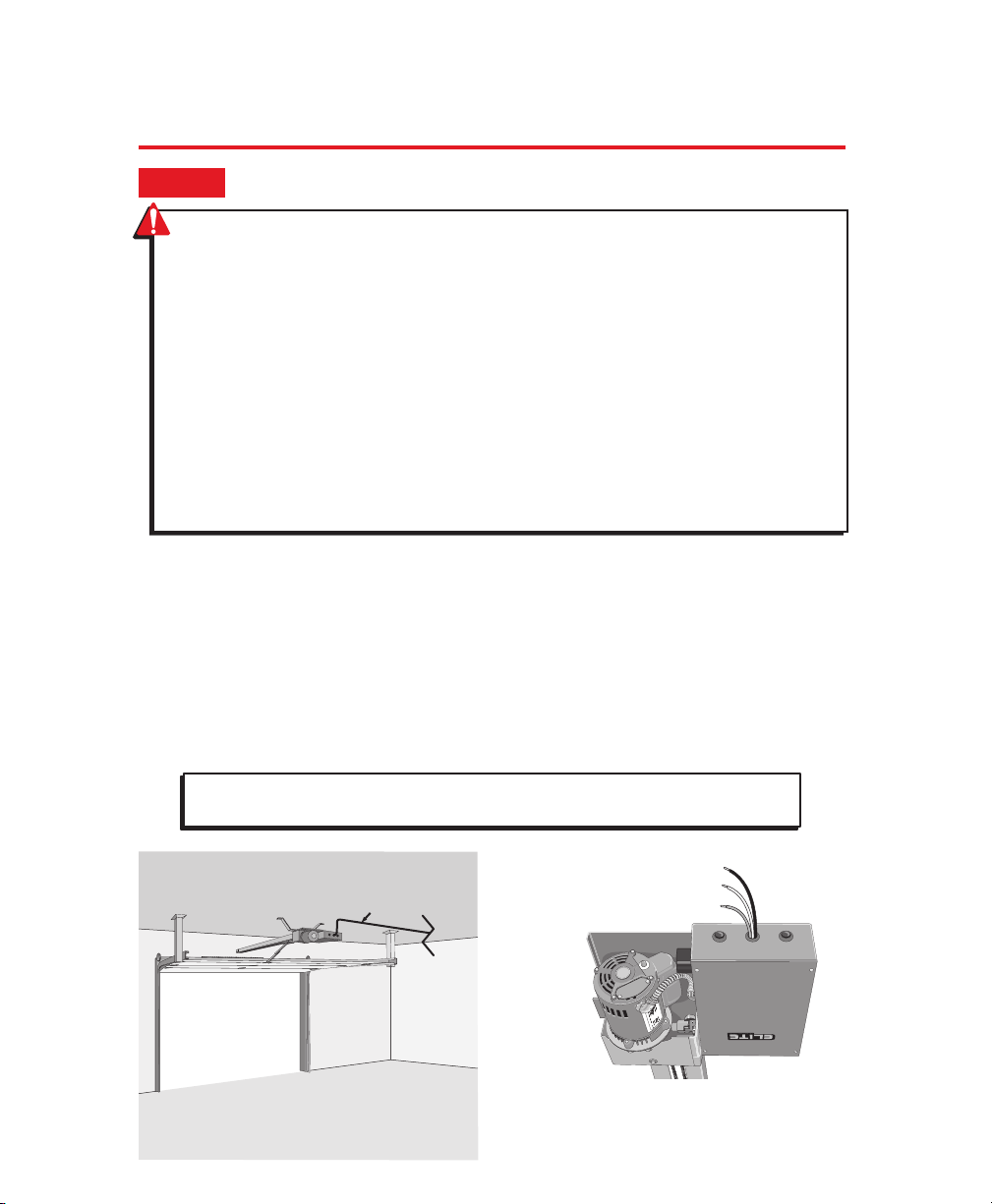

INSTALLATION OF OPERATOR

STEP 1

STEP 2

Make sure the gate opens and closes smoothly.

Gate should stay in the open position when springs are properly balanced.

With the gate closed, mark the center of the gate.

Open the gate and mark the center point of the gate on the ceiling.

C

L

Gate

7

Page 10

Gate Arm

C

L

C

L

C

L

Header Bracket

MOUNTING THE OPERATOR

Lift the operator and align with center mark on ceiling. Have someone hold the

operator in place or use something as a support post, and bolt to ceiling. (A support

post is not part of the operator. Use only for installation.)

Bolt or weld arm to gate.

STEP 3

STEP 4

STEP 5

Concrete

Anchor

1/2" x 3 1/2"

Support

Post

Make sure the header bracket is in the center of the opening. Bolt or weld the end of the

track (header bracket) to wall.

C

L

Header Bracket

C

L

8

Page 11

HOW TO CONNECT POWER (120VAC)

Proper grounding gives an electrical charge, such as from an electrical static discharge or a near lightning strike, a

path from which to dissipate its energy safely into the earth.

Without this path, the intense energy generated by lightning could be directed towards the operator. Although

nothing can absorb the tremendous power of a direct lightning strike, proper grounding can protect the operator

in most cases.

The ground wire must be a single, whole piece of wire. Never splice two wires for the ground wire. If you should

cut the ground wire too short, break it, or destroy its integrity, replace it with a single wire length.

Use the proper type earth ground rod for your local area. In certain circumstances, metal water pipes may be

allowed for grounding the operator. Check and follow all local codes for proper grounding procedures.

Black = 120 Vac Wire

White = Neutral Wire

Green = Earth Ground Wire

Use UL Listed

conduit to

enclose

power wires

Chamberlain Professional Products is not

responsible for improper installation or

failure to comply with all necessary local

building codes.

CAUTION:

To avoid damaging gas, power, or other underground utility lines, contact

local underground utility locating companies before digging.

STEP 6

Minimum 12 Gauge Ground

Wire connected to

HCT Earth Ground Wire

• Disconnect power at the fuse box BEFORE

proceeding. Operator MUST be properly

grounded and connected in accordance with

local electrical codes. NOTE: The operator

should be on a separate fused line of

adequate capacity.

• ALL electrical connections MUST be made by

a qualified individual.

• Do not install any wiring or attempt to run

the operator without consulting the wiring

diagram. We recommend that you install an

optional reversing edge BEFORE proceeding

with the control station installation.

• ALL power wiring should be on a dedicated

circuit and well protected. The location of the

power disconnect should be visible and

clearly labeled.

• ALL power and control wiring must be run in

separate conduit.

• BEFORE installing power wiring or control

stations, be sure to follow ALL specifications

and warnings described below. Failure to do

so may result in SEVERE INJURY to persons

and/or damage to operator.

• Entrapment protection devices MUST be

installed to protect anyone who may come

near a moving gate.

WARNING:

To reduce the risk of SERIOUS INJURY or DEATH:

9

Page 12

MOUNTING AND WIRING OF RESET SWITCH

DC-BACKUP

WARNING

STEP 7

WARNING

The reset switch allows the operator to

be reset upon the event of a double

entrapment alarm. When such an event

occurs the alarm will continuously

sound and the operator will not have

any functionality until the board is reset.

To prevent possible SERIOUS INJURY or

DEATH from electrocution, disconnect

electric power to operator BEFORE

installing.

ALL electrical connections MUST be

made by a qualified individual.

1. Disconnect power to the operator.

2. Mount reset switch at a minimum of 6' away from the gate jambs (Figure 1).

3. Plug the interface cable (Figure 2) into the J5 receptacle on the Omni control

board (Figure 3).

4. Connect like wires from the reset switch to the interface cable. Twist together with wire

nuts. NOTE: The wire connecting the interface cable to the reset switch is not provided.

Figure 1

6' min.

R

E

S

E

T

RESET

Figure 3

Figure 2

SYSTEM ON

SENSORS

13

ALARM

SENSOR

COMMAND

PROCESSED

FIRE

DEPT.

EXIT

LOOP

13

Plug Reset

Switch Connector

ALARMSENSOR

DC-BACKUP

TIMER

60

3

13

ON

OFF

SENSOR

REVERSE

OPEN LEFT

OPEN RIGHT

GATE

STRIKE

RADIO

LOCKED

OPEN

RECEIVER

RESET

SAFETY

CENTER

MOTOR

LOOP

LOOP

POWER

OVERLOAD

OPEN

STOPCLOSE

MADE IN USA

to J5 Connector

J5

10

Page 13

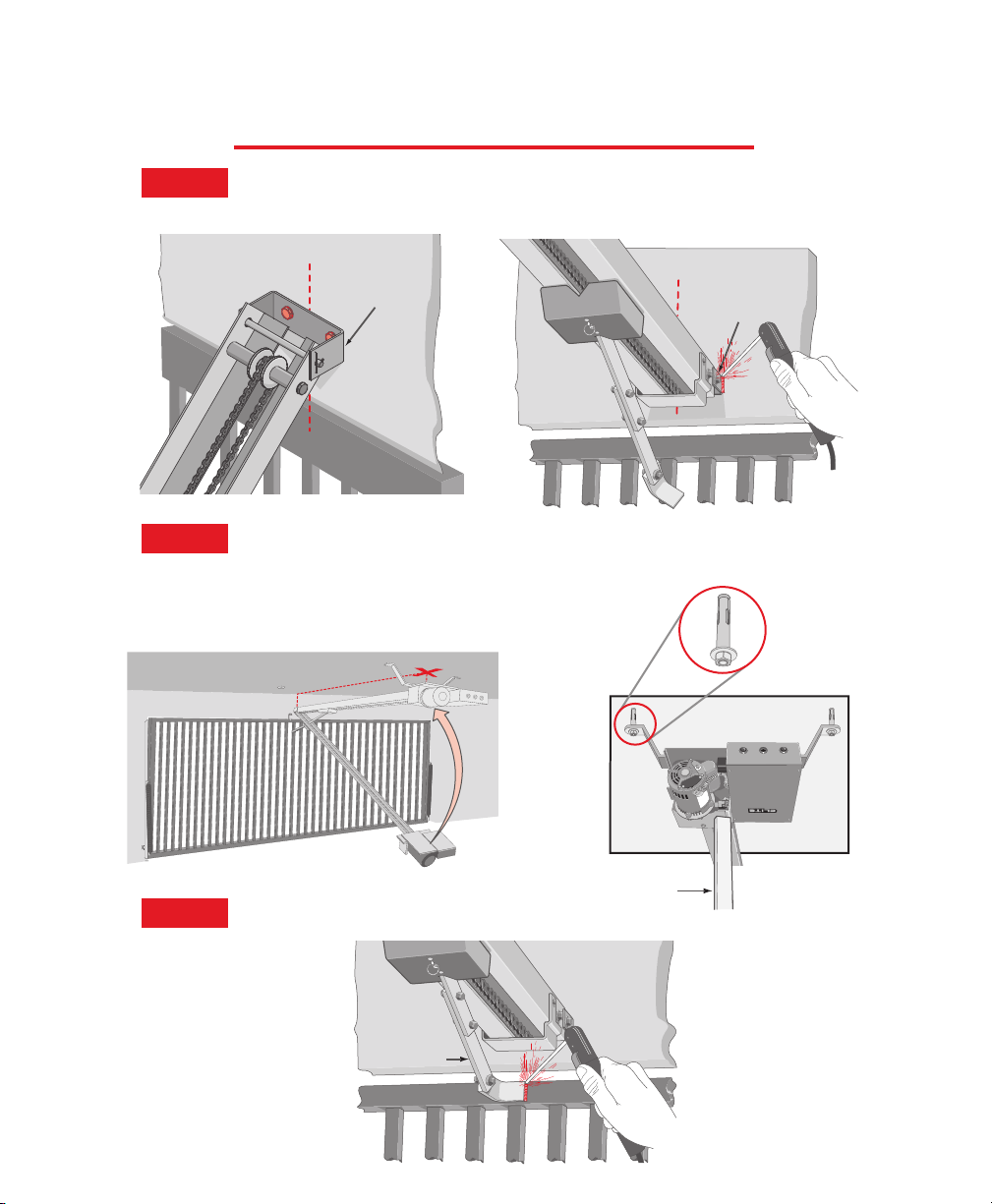

ADJUSTING TRAVELING DISTANCE

Before

Adjusting, Do the Following:

1. Disconnect power to the operator.

2. Push the limit nut lock plate inward. Roll the nut to the direction desired.

3. Place the plate back in the notch.

4. Reapply power to operator.

5. If further adjustment is needed, repeat the process.

Push Plate

STEP 8

11

Page 14

2-WAY ADJUSTABLE REVERSING SENSOR

ADJUSTABLE TIMER

CENTER SAFETY EXIT

CENTER SAFETY EXIT

FIRE

DEPT.

13

STRIKE

OPEN

RADIO

RECEIVER

TIMER

SYSTEM ON

EXIT

LOOP

ALARM

SENSOR

REVERSE

SENSOR

OPEN

STOPCLOSE

SAFETY

LOOP

CENTER

LOOP

GATE

LOCKED

60

POWER

OVERLOAD

OFF

W4

OPEN LEFT

DC-BACKUP

ALARMSENSOR

OPEN RIGHT

3

SENSORS

RESET

MOTOR

13

13

COMMAND

PROCESSED

ON

GB

MS LINK

A

MADE IN USA

CENTER SAFETY EXIT

CENTER SAFETY EXIT

FIRE

DEPT.

13

STRIKE

OPEN

RADIO

RECEIVER

TIMER

SYSTEM ON

EXIT

LOOP

ALARM

SENSOR

REVERSE

SENSOR

OPEN

STOPCLOSE

SAFETY

LOOP

CENTER

LOOP

GATE

LOCKED

60

POWER

OVERLOAD

OFF

W4

OPEN LEFT

DC-BACKUP

ALARMSENSOR

OPEN RIGHT

3

SENSORS

RESET

MOTOR

13

13

COMMAND

PROCESSED

ON

GB

MS LINK

A

MADE IN USA

TIMERTIMER

NSOR

60

OFF

OPEN LEFT OPEN RIGHT

3

13

ONON

Timer ON

TIMERTIMER

NSOR

60

OFFOFF

OPEN LEFT OPEN RIGHT

3

13

ON

Timer OFF

Set Timer

Timer can be set from 1 to 60 seconds (Timer ON),

For push open/push close type operation (Timer OFF).

DO NOT TOUCH ALARM SENSOR

The level of reverse sensitivity has to do with the weight of the gate and the condition of installation.

Too sensitive = If the gate stops or reverses by itself.

Not sensitive enough = If the gate hits an obstruction or vehicle and does not stop or reverse.

Adjusted by Qualified Service Personnel

3

REVERSEREVERSE

SENSORSENSOR

13

Maximum

Sensitivity

Minimum

Sensitivity

Decrease Time

Increase Time

STEP 9

STEP 10

12

Page 15

TERMINAL INPUT CONNECTIONS

Important: Terminals 11 and 12 are the only terminals that will both Open and/or Close with

a single push of a button. All other terminals will only open with a single push of a button.

STEP 11

CENTER SAFETY EXIT

Removable

Terminal

Connectors

Wire

WARNING: To ENSURE proper operation

of safety devices:

• ENSURE bare wire makes good contact

inside removable terminal connectors.

• DO NOT let wire insulation interfere with

connection.

®

OmniControl Surge Suppressor

Center

BBAA

Center

GG

M/S LinkM/S Link

Master/Second Link:

Not used in normal

installation

1 6 5

2

Loop

Loop

Safety

Safety

Loop

Loop

MADE IN USA

STOP

Output Power

CLOSE

Ground (-)

COMMAND

PROCESSED

DEPT.

LOOP

OPEN LEFT

OPEN RIGHT

FIRE

STRIKE

RADIO

RECEIVER

CENTER

LOOP

GATE

LOCKED

RESET

MOTOR

OPEN

EXIT

SAFETY

LOOP

24 Vdc (+)

P/N Q410

P/N Q410

Patent Pending

Patent Pending

Loop

Loop

7 13 12 11 10 9 8

++

––

Class 2

Class 2

Supply

Exit

Exit

Fire Dept.

Fire Dept.

Strike Open

Strike Open

Key Switch

Key Switch

Push Button

Push Button

Radio

Radio

Receiver

Receiver

Supply

24 Volts DC24 Volts DC

13

12

11

++

13

12

11

––

11

––

++

Radio Power

Relay

24 Volt

––

Red 24 Volt

Grey

Black

Grey

3 Wire 24 Vdc

Radio Receiver

4 Wire 24 Vdc

Radio Receiver

4 3

3

4

External ÒSafetyÓ Loop Detector

5

6

External ÒExitÓ Loop Detector

13

Card

10

Reader

9

Push

10

Button

9

Phone

10

9

8

Entry

Fire or

Any Key

Switch

1

2

3

4

5

6

7

8

9

H

E

LP

0

7

Page 16

IMPORTANT INFORMATION

CENTER SAFETY EXIT

CENTER SAFETY EXIT

FIRE

DEPT.

13

STRIKE

OPEN

RADIO

RECEIVER

TIMER

SYSTEM ON

EXIT

LOOP

ALARM

SENSOR

REVERSE

SENSOR

OPEN

STOPCLOSE

SAFETY

LOOP

CENTER

LOOP

GATE

LOCKED

60

POWER

OVERLOAD

OFF

W4

OPEN LEFT

DC-BACKUP

ALARMSENSOR

OPEN RIGHT

3

SENSORS

RESET

MOTOR

13

13

COMMAND

PROCESSED

ON

GB

MS LINK

A

MADE IN USA

Make sure the system is “OPEN TO LEFT”

RADIO

MER

60

OFF

13

ON

OPEN LEFT

OPEN RIGHT

Installers are required to adhere to this procedure: The UL required Warning Signs must be installed

in plain view and on both sides of each commercial gate installed. Each sign is made with fastening

holes in each corner and should be permanently secured in a suitable manner.

STEP 12

STEP 13

14

Page 17

CENTER SAFETY EXIT

CENTER SAFETY EXIT

FIRE

DEPT.

13

STRIKE

OPEN

RADIO

RECEIVER

TIMER

SYSTEM ON

EXIT

LOOP

ALARM

SENSOR

REVERSE

SENSOR

OPEN

STOPCLOSE

SAFETY

LOOP

CENTER

LOOP

GATE

LOCKED

60

POWER

OVERLOAD

OFF

W4

OPEN LEFT

DC-BACKUP

ALARMSENSOR

OPEN RIGHT

3

SENSORS

RESET

MOTOR

13

13

COMMAND

PROCESSED

ON

GB

MS LINK

A

MADE IN USA

QCC

AB

OPEN STOP CLOSE MAGLOCK ALARM

ARMED

M/S LINK

QCC

AB

OPEN STOP CLOSE MAGLOCK ALARM

ARMED

M/S LINK

2 3 4 5 6 7 8 9 10 11 12 13 14 15 1

3 5 1

16

Omni Option Board

see Accessories page

– Open Command

– Stop Command

– Close Command

– Common

– Normally Closed

– Normally Open

Master/Second

RS485

– Burglar Alarm Output

– Burglar Alarm Input

– Ground

– B

– A

10

& 11

12

& 13

14

15

16

Gnd

Gnd

Gnd

Gnd

Gnd

B

A

N.O.

N.O.

N.O.

N.O.

N.C.

N.C.

N.C.

Com

Com

QCC is designed for slide gate operators only!

3-BUTTON STATION

INSTRUCTIONS FOR OPTIONAL SYSTEMS

CENTER SAFETY EXIT

CENTER SAFETY EXIT

FIRE

DEPT.

13

STRIKE

OPEN

RADIO

RECEIVER

TIMER

SYSTEM ON

EXIT

LOOP

ALARM

SENSOR

REVERSE

SENSOR

OPEN

STOPCLOSE

SAFETY

LOOP

CENTER

LOOP

GATE

LOCKED

60

POWER

OVERLOAD

OFF

W4

OPEN LEFT

DC-BACKUP

ALARMSENSOR

OPEN RIGHT

3

SENSORS

RESET

MOTOR

13

13

COMMAND

PROCESSED

ON

GB

MS LINK

A

MADE IN USA

QCC

AB

OPEN STOP CLOSE MAGLOCK ALARM

ARMED

M/S LINK

OPENOPEN STOPSTOP CLOSECLOSE

W4

Omni “Option Board” Needed to Perform This Function

Note: If using the Master/Second board

configuration, unplug the Master/Second

link plug on main board and connect it into

the Omni option board M/S link socket.

Make sure each push button is dry contact

and there are no jumper wires between

them.

N.O.

N.O.

Com

N.C.

1 & 2

3

& 4

5

& 6

7

8

9

6 4 2

Relay Contact Rating

0.5 Amp - 125 Vac

1 Amp - 24 Vdc

WARNING: For proper operation, cut

W4 BEFORE installing option board.

3-Button Station (OPEN-STOP-CLOSE)

Step 1 - Disconnect power.

Step 2 - Cut jumper wire #W4.

Note: If this jumper is not cut,

the stop button will not function.

Step 3 - Install Omni option board.

Step 4 - Connect OPEN push button to # 1 .

Step 5 - Connect STOP push button to # 3 .

Step 6 - Connect CLOSE push button to # 5 .

Step 7 - Connect COMMON to # 6 .

15

Page 18

ALARM/PROXIMITY SWITCH CONNECTIONS

CENTER SAFETY EXIT

CENTER SAFETY EXIT

FIRE

DEPT.

13

STRIKE

OPEN

RADIO

RECEIVER

TIMER

SYSTEM ON

EXIT

LOOP

ALARM

SENSOR

REVERSE

SENSOR

OPEN

STOPCLOSE

SAFETY

LOOP

CENTER

LOOP

GATE

LOCKED

60

POWER

OVERLOAD

OFF

W4

OPEN LEFT

DC-BACKUP

ALARMSENSOR

OPEN RIGHT

3

SENSORS

RESET

MOTOR

13

13

COMMAND

PROCESSED

ON

GB

MS LINK

A

MADE IN USA

Omni Option Board

Proximity Switch

see Accessories page

12Vdc

Alarm System

Dry Contact

Use Low Voltage

Wire 20 AWG

QCC

A B

OPEN STOP CLOSE MAGLOCK ALARM

ARMED

M/S LINK

10 11 12 13

QCC

A B

OPEN STOP CLOSE MAGLOCK ALARM

ARMED

M/S LINK

Omni “Option Board” needed to perform this function. See Accessories page.

Alarm

10 – Common

11 – Normally Open

Armed

12 – Normally Closed

13 – Ground

2"

Max.

16

Page 19

OPTIONAL RELAY ADAPTER CONNECTION

CENTER SAFETY EXIT

CENTER SAFETY EXIT

FIRE

DEPT.

13

STRIKE

OPEN

RADIO

RECEIVER

TIMER

SYSTEM ON

EXIT

LOOP

ALARM

SENSOR

REVERSE

SENSOR

OPEN

STOPCLOSE

SAFETY

LOOP

CENTER

LOOP

GATE

LOCKED

60

POWER

OVERLOAD

OFF

W4

OPEN LEFT

DC-BACKUP

ALARMSENSOR

OPEN RIGHT

3

SENSORS

RESET

MOTOR

13

13

COMMAND

PROCESSED

ON

GB

MS LINK

A

MADE IN USA

Connection of a Solenoid or Magnetic Lock can be made

using the “Optional” Relay Adapter Module.

Relay Contact Rating

2 Amp - 125 AC/DC

2 Amp switching load capability

Normally Closed

Normally Open

Optional Relay Adapter Module

Optional Relay Adapter Module

Common

Common

Plug-In

Transformer

Solenoid Lock

Solenoid Lock

Ground

To OmniControl Board

To OmniControl Board

Ground

Power

Magnetic Lock

Plug-In

Transformer

Magnetic

Lock

Ground

Ground

Power

Relay Light On: Indicates

actuation of OmniControl board

Relay Module LEDs

Power Light On: Indicates

power is being received

See Accessories page for Relay Adapter Module

17

Page 20

Edge Sensor Wiring

If you are going to use a contact sensor as a secondary entrapment protection, you should use a

recognized component to comply with the revised UL325 intended to be used in class I or class II

gate operator.

Note:

If multiple sensors are being used, all of

the edge sensors are to be connected in parallel at

the sensor input on the OmniControl board.

SECONDARY ENTRAPMENT PROTECTION

Secondary Entrapment Protection (Contact Sensor)

When touched, the electrically activated edge sensors

immediately signal the gate operator to stop and reverse.

Property owners are obligated to test edges regularly.

UL Listed Edge Sensor

(3-Sided Activation)

Strike Open

Push Button

Strike Open

Push Button

24 Volts DC24 Vo lts DC

Fire Dept

Key Switch

Fire Dept

Key Switch

M/S LinkM/S Link

Class 2

Supply

Class 2

Supply

Center

Loop

Center

Loop

Safety

Loop

Safety

Loop

Radio

Receiver

Radio

Receiver

Exit

Loop

Exit

Loop

GG

BBAA

––

++

OmniControl Surge Suppressor

P/N Q410

Patent Pending

P/N Q410

Patent Pending

®

7 1312111098

1 654 3 2

18

Page 21

Mount Photo Beam Sensor at Recommended Height and Align Properly

SECONDARY ENTRAPMENT PROTECTION

Secondary Entrapment Protection (Non-Contact Sensor)

If you are going to use a non-contact sensor as a secondary entrapment protection, you should use a

recognized component to comply with the revised UL325 intended to be used in class I or class II

gate operator.

Strike Open

Push Button

Strike Open

Push Button

24 Volts DC24 Volts DC

Fire Dept

Key Switch

Fire Dept

Key Switch

M/S LinkM/S Link

Class 2

Supply

Class 2

Supply

Center

Loop

Center

Loop

Safety

Loop

Safety

Loop

Radio

Receiver

Radio

Receiver

Exit

Loop

Exit

Loop

GG BB AA

––

++

OmniControl Surge Suppressor

P/N Q410

Patent Pending

P/N Q410

Patent Pending

®

4

3

If an obstruction breaks the light beam while the gate is

closing, the gate will stop and reverse to full open position.

CenterCenter

Safety

Loop

Safety

Loop

Exit

Loop

Exit

Loop

OmniControl Surge S

19

Page 22

Off Off

Off Off

On On

On On

On On

Off Off

Off Off

Off Off

On On

Off Off

Off

Gate

Operator

Main

Room

Eug. Rm

Oper. Rm

Eug. Dept.

Manu. 1 Rm

Main Dept.

Manu. 2 Rm

Air (1)

Conditioner

Air (2)

Conditioner

Conference

Room 1

Conference

Rm 2, 3

Refer.

Bus 1, 2, 3

Conference

Room 2

Comp.

Serve 2

Comp.

Serve 1

CENTER SAFETY EXIT

CENTER SAFETY EXIT

FIRE

DEPT.

13

STRIKE

OPEN

RADIO

RECEIVER

TIMER

SYSTEM ON

EXIT

LOOP

ALARM

SENSOR

REVERSE

SENSOR

OPEN

STOPCLOSE

SAFETY

LOOP

CENTER

LOOP

GATE

LOCKED

60

POWER

OVERLOAD

OFF

W4

OPEN LEFT

DC-BACKUP

ALARMSENSOR

OPEN RIGHT

3

SENSORS

RESET

MOTOR

13

13

COMMAND

PROCESSED

ON

GB

MS LINK

A

MADE IN USA

Wire-Loop “Exit Loop”

Wire-Loop “Safety Loop”

CAUTION: Use different frequencies for

every single loop detector. Turn off

operator power (breaker switch from

main power source) before installation.

Twisted wires must be 6 turns per foot “Minimum”

Plug-In Loop detectors needed to perform

this function. See Accessories page.

OPTIONAL PLUG-IN LOOP DETECTORS

20

Page 23

Strike Open

Push Button

Strike Open

Push Button

24 Volts DC24 Volts DC

Fire Dept

Key Switch

Fire Dept

Key Switch

M/S LinkM/S Link

Class 2

Supply

Class 2

Supply

Center

Loop

Center

Loop

Safety

Loop

Safety

Loop

Radio

Receiver

Radio

Receiver

Exit

Loop

Exit

Loop

GG

BB AA

––

++

OmniControl Surge Suppressor

P/N Q410

Patent Pending

P/N Q410

Patent Pending

®

7 13 12 11 10 9 8

1 6 5 4 3 2

WIRING EXTERNAL LOOP DETECTORS

External 115 Vac “Exit” Loop Detector -

Allows operator to automatically open for

exiting vehicles.

6

5

3

4

External 115 Vac “Safety” Loop Detector -

Allows system to stay open when vehicles are

obstructing path.

Caution: To PREVENT damage to vehicles

shorter than 14 feet, a center loop system should

be installed.

Note:

External 115 Vac Loop Detectors

OUT

Safety

Loop

Exit

Loop

IN

Safety

Loop

Normally Open

Common

Normally Open

Common

If the “Inside” and “Outside” safety loops are connected

to the same loop detector:

• They should be series connected to the detector

• Have the same dimensions.

• Have the same number of wire turns.

21

Page 24

SET SECURITY MODE

The Universal Receiver can be used with up to

15 rolling code remotes or passwords in HIGH

security mode. Alternately, it can be used with

up to 31 of any type remote in NORMAL

security mode, including any combination of

rolling code, billion code, or dip switch remotes.

The jumper must be set at the HIGH position for

the receiver to operate in HIGH security mode.

It must be set at NORMAL position to operate at

the NORMAL mode.

When changing from NORMAL to HIGH security

mode, any previous remote codes must be

erased. Repeat Steps 2 and 3 in the

Programming Section on the next page to

reprogram the receiver for each remote control in

use.

The receiver is factory set at HIGH. To verify

frequency, please refer to the label on the unit.

PROGRAMMING THE RADIO RECEIVER

WARNING:

To reduce the risk of

SERIOUS INJURY or DEATH from

electrocution:

• Be sure power is not connected BEFORE

installing the receiver.

To reduce the risk of SERIOUS INJURY or

DEATH from a moving gate:

• ALWAYS keep remote controls out of

reach of children. NEVER permit children

to operate, or play with remote control.

• Activate gate ONLY when it can be seen

clearly, is properly adjusted, and there

are no obstructions to gate travel.

• ALWAYS keep gate in sight until

completely closed. NEVER permit anyone

to cross path of moving gate.

NOTICE: To comply with FCC and or Industry Canada (IC) rules, adjustment or modifications of this

receiver and/or transmitter are prohibited, except for changing the code setting or replacing the

battery. THERE ARE NO OTHER USER SERVICEABLE PARTS.

Tested to Comply with FCC Standards for home or office use. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

HIGH SECURITY MODE NORMAL SECURITY MODE

Security Mode

Terminals

Jumper

Security Mode

Terminals

Jumper

22

Page 25

SET OUTPUT DURATION

For commercial applications, the receiver can be set for either constant or momentary closure on the

output contacts. Use of constant closure is prohibited on residential garage door openers because it

overrides the safety reversal devices.

With the jumper in the “M” (Momentary) position, the contacts will close for 1/4 second regardless of

the length of radio transmission. With the jumper in “C” (Constant) position, the contacts will stay

closed as long as the radio continues transmitting.

The receiver is factory set at M.

Pry open the front panel of

receiver case with a coin or

a screwdriver. Re-connect

power to opener.

Press and release the

“learn” button on the

receiver. The learn

indicator light will glow

steadily for 30 seconds.

Within 30 seconds, press and hold the button

on the hand-held remote that you wish to

operate your operator.

The opener will now operate when the push

button on either the receiver or the remote

control is pressed.

Repeat Steps 2 and 3 for each remote control

that will be used to operate the opener.

WARNING:

To reduce the risk of SERIOUS INJURY or DEATH, the

use of CONSTANT OPERATION on residential openers is PROHIBITED.

OPENING RECEIVER

Connect

Antenna

Output

Duration

Terminals

Jumper

M

CONSTANT

OPERATION

Output

Duration

Terminals

Jumper

M

MOMENTARY

OPERATION

TO ERASE ALL REMOTE CONTROL CODES

Press and hold the “learn” button on the

receiver panel until the indicator light turns off

(about 6 seconds). All remote codes are now

erased. Then follow the programming steps to

reprogram each remote control.

Learn Button

Indicator Light

Output

Duration

Terminals

Security

Mode

Powe r

Supply

Jumper

OPEN RECEIVER

24V 12V

HIGH

NORM

C

P2

M

PROGRAMMING THE RADIO RECEIVER

1.

2.

3.

PROGRAMMING THE REMOTE TO THE RECEIVER

23

Page 26

Gate hits obstruction.

HOW TO REPLACE THE CONTROL BOARD

AUDIO ALARM

When one of the following events happens Twice Consecutively, an Alarm will Sound!

Check for one or more of the following:

Check for broken

spring or hardware.

Ensure trolley is not

hitting the chassis

or an unwanted

object.

Strike Open

P

ush B

utton

Strike Open

P

ush B

utton

2

4 V

o

l

ts

DC2

4 V

o

l

ts

DC

F

i

re Dept.

Key Swi

tch

F

i

re Dept.

Key Swi

tch

M/S

LinkM/S Link

Class 2

Supply

Class 2

Supply

Center

L

oop

Center

L

oop

Safety

Loop

Safety

Loop

Radio

Receiver

Radio

Receiver

E

xit

Lo

op

E

xit

Lo

op

GG

BB

AA

––

++

OmniControl

Surge Suppressor

P/N Q4

1

0

Pat

en

t

Pen

d

in

g

P/N Q4

1

0

Pat

en

t

Pen

d

in

g

®

1. Disconnect power.

2. Disconnect wire harnesses from OmniControl

board. Unscrew 3 nuts and remove board.

Strike Ope

n

P

ush Bu

t

ton

Strike Ope

n

P

ush Bu

t

ton

24

Vo

l

ts

DC24

Vo

l

ts

DC

F

i

re Dept.

Key Swi

tch

F

i

re Dept.

Key Swi

tch

M/S

LinkM/S

Link

Class 2

Supply

Class 2

Supply

Center

L

oop

Center

L

oop

Safety

Loo

p

Safety

Loo

p

Radio

Receiver

Radio

Receiver

E

xit

Lo

op

E

xit

Lo

op

GG BB AA

––

++

OmniControl Surge Su

ppressor

P/

N

Q4

10

P

a

ten

t Pen

d

ing

P/

N

Q4

10

P

a

ten

t Pen

d

ing

®

Check for broken wheel or

damaged track.

WARNING: To reduce the risk of SERIOUS INJURY or DEATH,

the alarm MUST NOT be disabled.

WARNINGWARNING

To prevent possible SERIOUS

INJURY or DEATH from electrocution,

disconnect electric power to operator

BEFORE installing.

ALL electrical connections MUST be

made by a qualified individual.

24

Page 27

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS.

NEVER let children operate or play with gate controls. Keep the

remote control away from children.

Personnel should keep away from a gate in motion and keep the

moving gate in sight until it is completely closed or opened.

NO

ONE SHOULD CROSS THE PATH OF A MOVING GATE.

Test the safety features monthly. The gate MUST reverse on

contact with a rigid object or stop when an object activates the

non-contact sensors. After adjusting the force or the limit of travel,

retest the operator. Failure to adjust and retest the operator

properly may cause SERIOUS INJURY or DEATH.

Use the emergency release ONLY when the gate is not moving.

Weak or broken springs may cause the gate to fall rapidly causing

SERIOUS INJURY or DEATH.

Keep gates properly maintained. Read the manual. An improperly

operating or balance gate could cause SERIOUS INJURY or DEATH.

Have a qualified service technician make repairs to the gate or gate

hardware.

The entrance is for vehicles ONLY. Pedestrians MUST use separate

entrance.

1)

2)

3)

4)

5)

6)

8)

7)

WARNING:

To reduce the risk of SERIOUS INJURY or DEATH:

SAVE THESE INSTRUCTIONS.

25

Page 28

Trolley will automatically re-engage when power is restored and run command is

given. When the cylinder lock is in the locked position, the release ring will not

disengage. If the cylinder lock is in the unlocked position, the release ring will always

be accessible to disengage.

MANUAL RELEASE

STEP 1

Insert key and turn to unlock position.

STEP 2

Pull down the release ring.

Lift the gate up.

STEP 3

Lift the gate up until fully open.

STEP 4

WARNING: To reduce the risk of SERIOUS INJURY or DEATH from a

falling gate:

• If possible, use manual release to disengage trolley ONLY when gate

is CLOSED. Weak or broken springs or unbalanced gate could result

in an open gate falling rapidly and/or unexpectedly.

• NEVER use emergency release unless gateway is clear of persons

and obstructions.

26

Page 29

TROUBLESHOOTING TABLE

Condition Possible Causes Solution

Overload LED On

and

Power LED On

System On LED

Flashing

Reverse Sensor LED On

Alarm Sensor LED On

Audio Alarm On

Command Processed

LED On

Continuously

Timer LED Blinking and

Command Processed

LED Blinking

Timer LED Blinking,

Command Processed LED

Blinking and Reverse

Sensor LED On

Any “Loop LED” On and

No Vehicle on the

Sensing Area

1. Short circuit at terminals 11 and 13.

2. Short circuit at any of the loop detector

in the board.

3. Short circuit in the control board.

4. Voltage is over 138 Vac.

1. Remove the short circuit condition at the

terminals.

2. Remove the defective loop detector.

3. Reduce the accessories load from surge

suppressor terminal 13.

4. Verify your electrical power.

1. Remove the short circuit condition at the

terminals.

2. Remove the defective loop detector.

3. Reduce the accessories load from surge

suppressor terminal 13.

4. Verify your electrical power.

1. Excessive current draw at terminal 13.

2. Over-voltage at the 120 Vac line input.

1. Motor thermal fuse has popped-out

(Rapid Flashing).

OR

2. One limit switch is faulty (Rapid Flashing).

1. Reset the motor.

OR

2. Test the limit switches and wire connections,

fix the fault.

1. The loop detector needs to be reset.

2. The wire loop has been disrupted.

3. The loop detector needs to work in a

different frequency.

4. The loop detector is too sensitive.

1. Reset the loop detector (If you use Plug-in

Loop detectors, change the setting for

sensitivity and come back to your original

setting).

2. Verify and correct connections.

3. Set a different working frequency.

4. Decrease the sensitivity of the loop detector.

1. Gate has encountered an obstruction

during traveling.

2. Reverse sensor is extra sensitive.

1. Remove the obstruction.

2. Turn the reverse sensor switch counter

clockwise a little more and try again.

1. Gate encountered an obstruction

during traveling.

2. Alarm sensor is extra sensitive.

1. Remove the obstruction.

2. Turn the alarm sensor switch counter

clockwise a little more and try again.

1. There is a continuous command present.

1. This is a normal response of the gate

operator. It does not represent necessarily

that there is a problem.

1. There is a command holding the

gate open.

1. This is a normal response of the gate

operator. It does not represent necessarily

that there is a problem. Check inputs for

command.

1. Gate has reopened because it

encountered an obstruction while closing.

1. Any re-new command will resume normal

operation. Check for obstructions.

1. Gate has encountered two

consecutive obstructions while trying

to close or open.

1. Any re-new command will resume normal

operation but not a radio command. Check

for obstructions.

2.

You can stop the alarm by using the stop

button.

For Toll Free Technical Support: 1-800-528-2806

Overload LED ON

and

Power LED ON

27

Page 30

CENTER SAFETY EXIT

CENTER SAFETY EXIT

FIRE

DEPT.

13

STRIKE

OPEN

TIMER

SYSTEM ON

EXIT

LOOP

ALARM

SENSOR

REVERSE

SENSOR

OPEN

STOPCLOSE

SAFETY

LOOP

CENTER

LOOP

GATE

LOCKED

60

POWER

OVERLOAD

OFF

W4

OPEN LEFT

DC-BACKUP

ALARMSENSOR

OPEN RIGHT

3

SENSORS

13

13

COMMAND

PROCESSED

ON

GB

MS LINK

A

MADE IN USA

RESET

MOTOR

RADIO

RECEIVER

FIRE

DEPT.

13

STRIKE

OPEN

TIMER

SYSTEM ON

EXIT

LOOP

ALARM

SENSOR

REVERSE

SENSOR

OPEN

STOPCLOSE

SAFETY

LOOP

CENTER

LOOP

GATE

LOCKED

60

POWER

OVERLOAD

OFF

OPEN LEFT

DC-BACKUP

ALARMSENSOR

OPEN RIGHT

3

SENSORS

13

13

COMMAND

PROCESSED

ON

MADE IN USA

RESET

MOTOR

RADIO

RECEIVER

TROUBLESHOOTING LED INFORMATION

CENTER SAFETY EXIT

CENTER SAFETY EXIT

FIRE

DEPT.

13

STRIKE

OPEN

RADIO

RECEIVER

TIMER

SYSTEM ON

EXIT

LOOP

ALARM

SENSOR

REVERSE

SENSOR

OPEN

STOPCLOSE

SAFETY

LOOP

CENTER

LOOP

GATE

LOCKED

60

POWER

OVERLOAD

OFF

W4

OPEN LEFT

DC-BACKUP

ALARMSENSOR

OPEN RIGHT

3

SENSORS

13

13

COMMAND

PROCESSED

ON

GB

MS LINK

A

MADE IN USA

RESET

MOTOR

Resetting Motor

“Reset Motor” LED Light flashes once

then

“System On” LED flashes rapidly

Gate Will Not Close!

Gate Will Not Open!

Symptom:

The radio receiver LED on the control

board remains “ON” when using the remote

control.

Possible Solutions:

Stuck remote control button.

The radio receiver has malfunctioned in the “ON”

position.

Symptom:

The radio receiver LED on the control

board remains “OFF” when using the remote

control.

Possible Solutions:

Dead battery in the remote

control. Remote control code switches are different

from radio receiver code switches. The radio

receiver has malfunctioned in the “OFF” position.

Press firmly to reset thermal

breaker on the motor.

28

Page 31

PARTS ILLUSTRATIONS

Q027

1941240D

Q097

Q092

Q029

Q006

Q400DHCT

Q170

Q070

Q074

Q075

Q082

Q081

Q076

Q079

Q080

Q07710

Q07712

Q07714

178B34

Q078

Q089

Q086

Q200

Q088

Q083

Q094

Q095

Q091

Q092

Q096

Q093

Q090

Q085

Q087

Q084

Q118

Q250

Q018

Q067

Q404

Q410

Q620

Q068

Q073

Q072

Q248

Q071

312HM

APBS1

10-10203

10-10204

RESET

29

Page 32

PARTS LIST

312HM - Single Channel Radio Receiver

1941240D - Chain #41 (per 10' box)

Q006 - PC Board Nuts (Set)

Q027 - Motor Capacitor

Q029 - Limit Switch (Sold Individually)

Q067 - Chassis

Q068 - Electronic Box

Q070 - Drive Sprocket

Q073 - Gear Box Cover Post 1/99

Q074 - Coupling (3/4 x 5/8) 3 pcs

Q075 - Limit Switch Ball Bearing

Q076 - Turn Buckle

Q07710 - 10' Track, One Pair

Q07712 - 12' Track, One Pair

Q07714 - 14' Track, One Pair

Q078 - Trolley Wheel Shaft

Q079 - Trolley Body

Q080 - Trolley Latch

Q081 - Limit Switch Bolt

Q082 - Limit Switch Nuts

Q083 - Trolley Wheels

Q084 - Emergency Key Release

Q085 - Trolley Cover

Q086 - Retaining Spring Clip

Q087 - Emergency Pulling Ring

Q088 - Gate Arm

Q089 - Trolley Body Assembly

Q090 - Plastic Plug

Q091 - Idler Sprocket

Q092 - Rubber Isolator

Q093 - Idler Sprocket Cover

Q094 - Arm Bracket

Q095 - Arm Bushing

Q096 - Header Bracket

10-10203 - Curved Arm Assembly

10-10204 - Alternate Mounting Bracket

178B34 - Straight Arm Assembly

Q097 - Mounting Plate

Q118 - Manual Release Key

Q170 - Electronic Box Cover (Black)

Q200 - Chain Coupling/Release

Q248 - Gear Reducer (40:1) Post 2/99

Q250 - 1/2 HP Electric Motor Post 2/99

Q400E-1 - OmniControl Board

Q404 - Omni Alarm

Q410 - Surge Suppressor Terminal Block

Q620 - Motor Harness Omni

APBS1 - Reset Button

40-3505 - U.L. Warning Sign (not shown)

MAINTENANCE

1. Make sure the gate operates smoothly without the operator.

2. Make sure the gate track runs smoothly.

3. For chain maintenance, you can adjust the turn buckle.

4. Check external entrapment protection systems monthly for proper operation.

30

Page 33

ACCESSORIES

OMNIEXB

Omni Option Board

AELD

Plug-In Loop Detector

Q400MAU

Omni Relay Adapter Module

377LM

Wireless Keyless Entry

371LM

1-Button Remote

372LM

2-Button Remote

373LM

3-Button Remote

374LM

4-Button Remote

370LM

3-Button Mini Remote

APRS

Proximity Switch

EL 25

Access Control System

Single/Multi-Tenant

EL 2000

Access Control System

Commercial Applications and Gated Communities

02-103

3-Button Station

Indoor Surface Mount

CPTK33PH

Passport 3-Button Remote

with HID Proximity

MG1300

Magnetic Lock

AEXITP

Stop Button

AUG 10, 2007

WELCOME

STAR 450

Access Control Receiver

31

Page 34

OPERATOR NOTES

32

Page 35

Page 36

© 2011, The Chamberlain Group, Inc.

01-34678F All Rights Reserved

Loading...

Loading...