Page 1

INSTALLATION

INSTRUCTIONS

AND SAFETY INFORMATION

FOR THE VIKING H-10 GATE OPERATOR

CLASS I, CLASS II, CLASS III,

AND CLASS IV

Residential and Commercial

Vehicular Slide Gate Operator

Page 2

The H-10™ gate operator has the capacity to operate slide gates up

to 2200 lbs. and 75 ft. in length at 100% duty cycle under extreme

conditions. This effi cient operator provides a solution for high traffi c

residential and commercial slide gate applications. The Viking H-10™

gate operator offers effi ciency and technology combined in a single

package.

THE VIKING H-10™ SLIDE GATE OPERATOR

Page 3

H-10 Vehicular Gate Operator • Revision H10NXMN10.D • October 2013

Page 4

VIKING TECHNICAL SUPPORT 1.800.908.0884

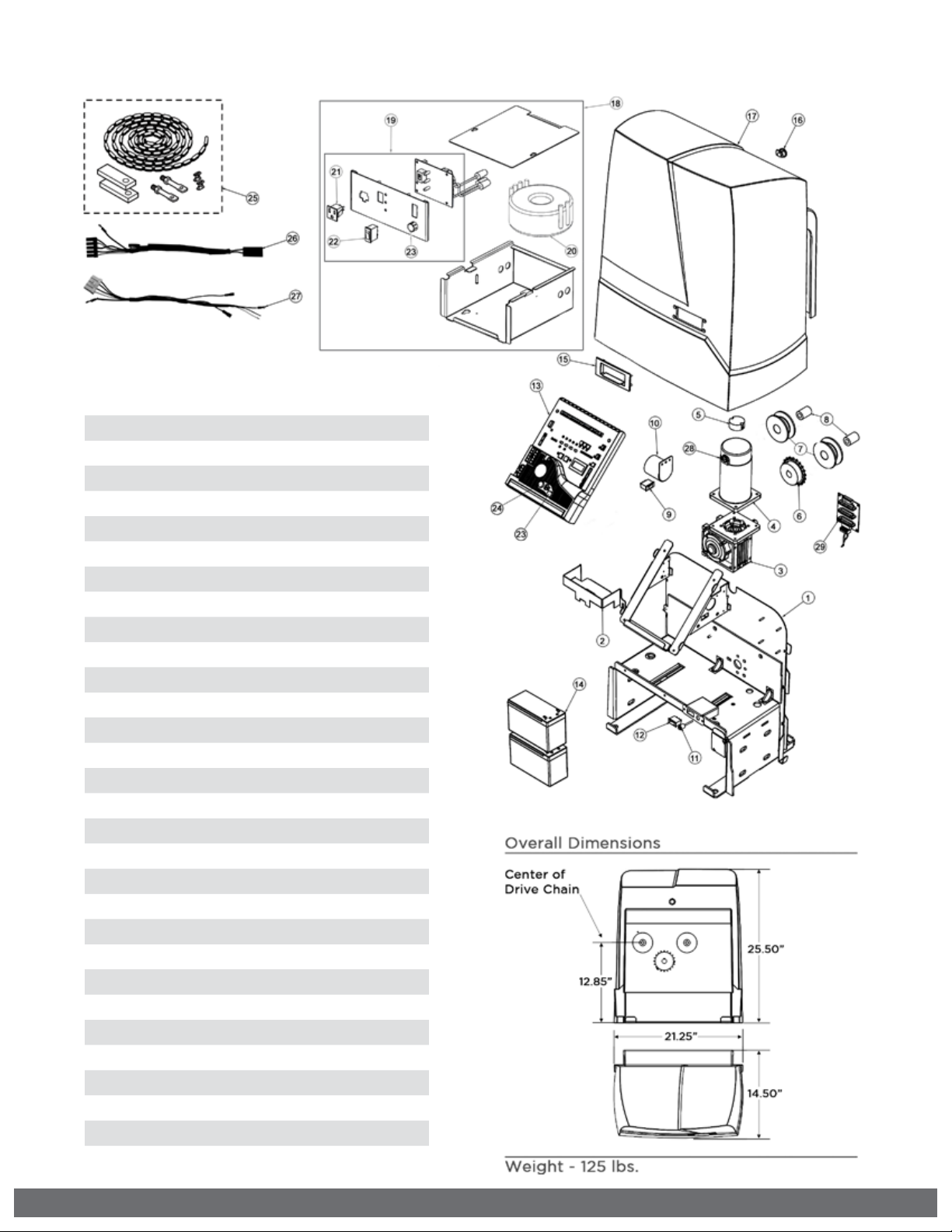

PARTS DIAGRAM:

Item Description Part No.

1 Chassis VNXL3CH

2 Chassis Battery Bracket VNXCHBBRK

3 Gear Box VNXL3GB

4 Motor VNXH10MO

5 Electronic Positioning Sensor 2 (EPS2) VNXSLEPS2

6 40B17 Sprocket VAL3SP17

7 Idler Pulley DSIP10

8 Idler Bushing (w/hardware) DSIB10

9 Battery Switch DUMRS20

10 Alarm DUAL10

11 Alarm Reset Switch VNXDUARS

12 Manual Release Switch DUMRS20

13 Control Board VFLEXPCB

14 Battery DUBA12

15 Access Door VNXAD

16 Key and Lock VNXSLCL

17 Operator Cover VNXCV

18 Modular Power Box Assembly VNXMPB

19 Power Box Panel Assembly VNXUPBPA

20 Toroid Transformer - 15 amp DUTT15

21 120V Receptacle DUOL120

22 120VAC Power Switch DUMRS10

23 Fuse - 4 amp VNXF4A

24 Fuse - 20 amp VNXF20A

25 25’ #40 Chain Kit, Nickle Coated VAL3CKN

26 Motor Harness VNXH10MH

27 Power Harness VNXL3PH

28 Brush Kit VAH10MBK

29 Loop Rack VA-LR

2

Page 5

VIKING TECHNICAL SUPPORT 1.800.908.0884

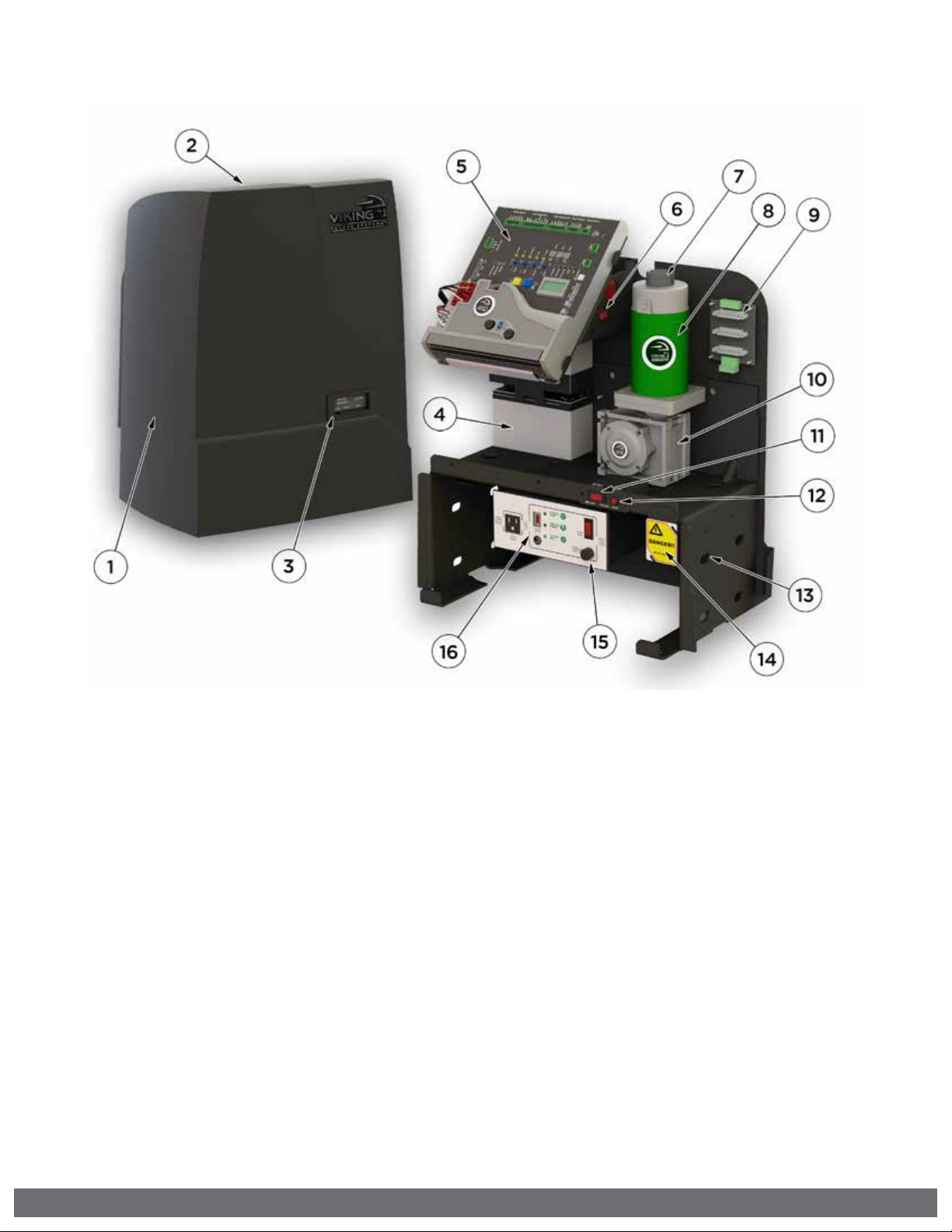

OPERATOR REFERENCES:

1.

OPERATOR COVER

2.

COVER LOCK

3.

ACCESS DOOR

external access to the Manual Release Switch and

Alarm Reset Button

4.

BATTERY BACKUP SYSTEM

5.

VFLEX CONTROL BOARD

6.

BATTERY SWITCH

disconnects batteries from the charging circuit

during troubleshooting

7.

EPS (ELECTRONIC POSITIONING SENSOR)

sensor for the digital limits

8.

MOTOR

9.

LOOP RACK

for convenient loop detector installation

10.

GEARBOX

11.

MANUAL RELEASE/MOTOR SWITCH

discontinues power to the motor and allows for

manual operation of the gate

12.

ALARM RESET BUTTON

resets the operators alarm

13.

POST MOUNTING U-BOLT HOLES

for optional post mount installation

14.

J-BOX

high voltage power supply connection

15.

EMI FUSE

main power supply protection

16.

MODULAR POWER BOX

removable; provides a convenient solution for

optional low voltage installations

3

Page 6

VIKING TECHNICAL SUPPORT 1.800.908.0884

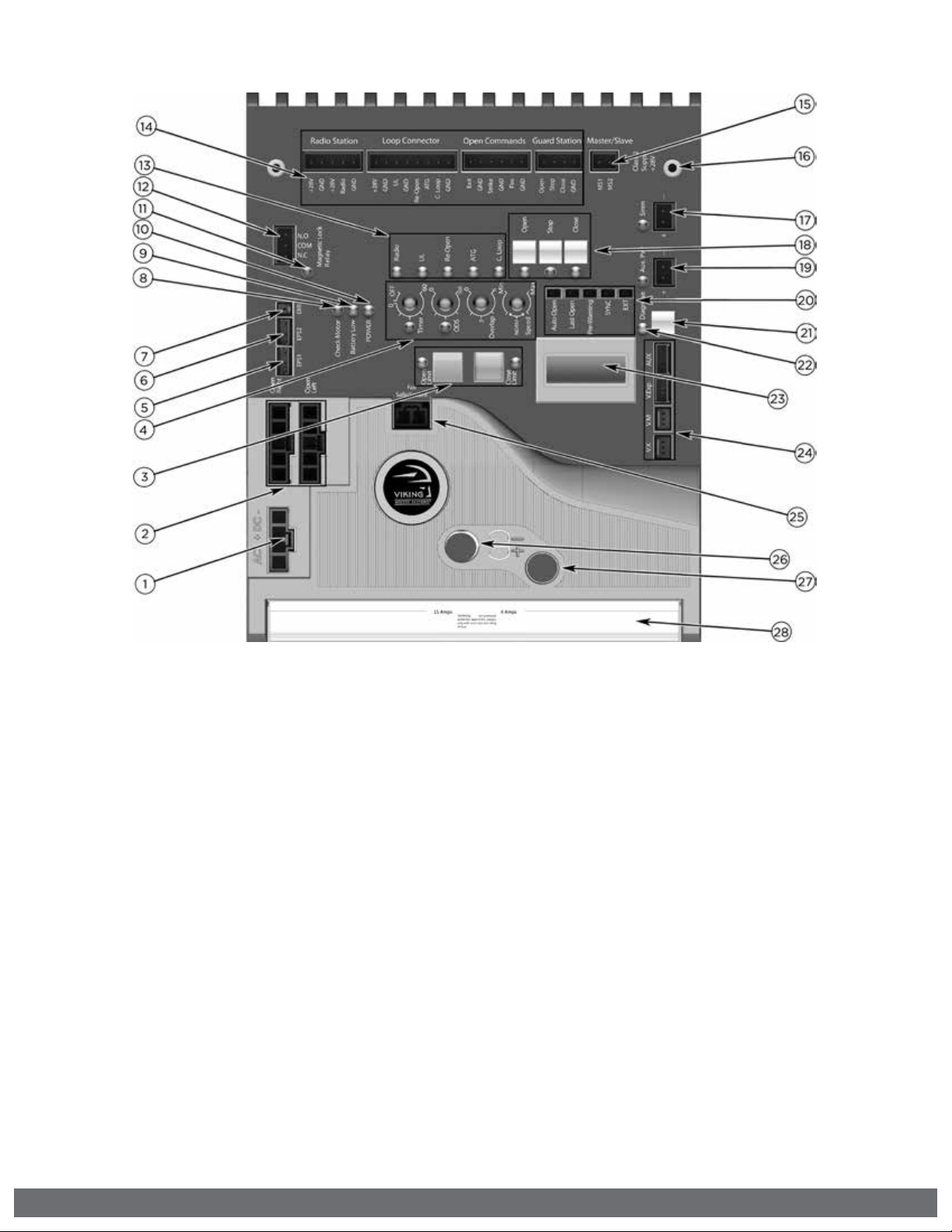

CONTROL BOARD REFERENCES:

1.

POWER HARNESS CONNECTOR

provides power to the control board.

pg 18-19

2.

“OPEN LEFT” & “OPEN RIGHT”

provides power to the motor. pg 20

3.

LIMIT SETUP BUTTONS

sets limit positions. pg 20-21

4.

FEATURE ACTIVATION TRIM POTS

activate and set features. pg 24

5.

“EPS1” CONNECTOR

available for future developments

6.

“EPS2” CONNECTOR

monitors the limit positions.

7.

EMI BOARD CONNECTOR

monitors the high voltage power

supply.

8.

“CHECK MOTOR” Status LED

indicates motor power status. pg 36

9.

“LOW BATTERY” Status LED

indicates battery power status. pg 36

10.

“POWER” Status LED

control board power status. pg 18,36

11.

“MAGNETIC LOCK” Status LED

status of this on-board relay. pg 34, 36

12.

“MAGNETIC LOCK” Terminal Block

connect electric locks here. pg 34, 36

13.

INPUT STATUS LEDS

indicates input status. pg 36-37

14.

ACCESS CONTROL TERMINAL BLOCKS

accessory connections. pg 29-32, 42-44

15.

“Master/Slave” Terminal Block

wired master/slave connection. pg 22

16.

CONTROL BOARD MOUNTING HOLES

secures and grounds the control board.

17.

“Siren” Terminal Block

Vikings UL Siren is connected here.

18.

ON-BOARD 3 BUTTON STATION

controls the gate during set up.

19.

“BRAKE” Terminal Block

used for solar applications & in-motion

warning devices. pg 19, 25

20.

FEATURE ACTIVATION PIN HEADERS

active features by placing a jumper

onto the pin headers. pg 25

21.

“DIAGNOSE” Button

allows you to navigate through the

Diagnostics LCD Display. pg 38-40

22.

“DIAGNOSE” LED

informs that errors have been detected

and available on LCD Display. pg 38-40

23.

LCD DIAGNOSTICS DISPLAY

provides error messages, diagnostics

and operator status information.

pg 38-40

24.

EXPANSION PRODUCT CONNECTIONS

connections for additional products

from Viking Access Systems. pg 46

25.

“FAIL SAFE/SECURE” Jumper

power failure option. pg 25

26.

MOTOR FUSE

27.

CHARGER FUSE

28.

HEAT SINK

secures the control board and

dissipates heat.

4

Page 7

TABLE OF CONTENTS:

22-23

46

42-45

PARTS DIAGRAM/PARTS LIST 2

OPERATOR REFERENCES 3

CONTROL BOARD REFERENCES 4

IMPORTANT SAFETY INFORMATION 6-12

Important Safety Instructions 6

Important Installation Instructions 7

Maintenance 8

General Safety Precautions 8-9

Operator Classification 9

Photo Beam (non-contact sensor) Installation 10

Edge Sensor (contact sensor) Installation 11

Manual Release 11

Audible Alarm Reset Installation 12

Warning Placard Installation 12

IMPORTANT INSTALLATION INFORMATION 13

Specifications 13

GATE OPERATOR INSTALLATION 14-17

Concrete Pad Option 14

Post Mounting Option 15

Operator Positioning 16-17

ELECTRICAL INSTALLATION 18-19

High Voltage Supply Option 18

Low Voltage Supply Option 19

Solar Supply Option 19

LIMITS SETUP 20-21

MASTER/SLAVE SET UP 22-23

Two Wire Communication 22

Wireless Communication Options 23

CONTROL BOARD SETUP 24-27

Initial Settings 24-25

Obstruction Detection Sensor (Primary Entrapment Protection) 26

Heater, Lock Mode................................................................................................................. 27

ACCESSORY CONNECTIONS 29-35

Re-Open Photo Beam (Vehicular Safety) 29

Radio Receiver (Typical) 30

Anti-Tail Gate, Open Commands, Guard Station 31

Viking Loop Rack 32

Guidelines for Loop Installations 33

Magnetic Lock, Lock Solenoid 34

Barrier Arm (B-12) Synchronization Option 35

TROUBLESHOOTING 36-41

LED References 36-37

LCD Display References 38-40

Solutions 41

APPENDIX A, B & C 42-45

VIKING EXPANSION PRODUCTS 46

VIKING TECHNICAL SUPPORT 1.800.908.0884

5

Page 8

VIKING TECHNICAL SUPPORT 1.800.908.0884

IMPORTANT SAFETY INFORMATION

! WARNING! Not Following these instructions may cause severe injury or death.

IMPORTANT SAFETY INSTRUCTIONS

! WARNING! To reduce the risk of severe injury or death.

1.

READ AND FOLLOW ALL INSTRUCTIONS.

2.

Never let children operate or play with gate controls. Keep the remote away

from children.

3.

Always keep people and objects away from the gate. NO ONE SHOULD

CROSS THE PATH OF THE MOVING GATE.

4.

Test the gate operator monthly. The gate MUST reverse on contact with

a rigid object or when an object activates the non-contact sensors. After

adjusting the force or the limit travel, retest the gate operator. Failure to

adjust and retest the gate operator properly can increase the risk of injury or

death.

5.

Use the manual release only when the gate is not moving.

6.

KEEP GATES PROPERLY MAINTAINED. Read the owners manual. Have a

qualified service person make repairs to gate hardware.

7.

The entrance is for vehicles only. Pedestrians must use a separate entrance.

8.

Every gate operator installation MUST have secondary protection devices

against entrapment, such as edge sensors and photo beams more in

particularly in places where the risk of entrapment is more likely to occur.

9.

SAVE THESE INSTRUCTIONS.

IMPORTANT INSTALLATION INSTRUCTIONS

1.

Install the gate operator only when:

a.

The operator is appropriate for the construction of the gate and usage

Class of the gate (refer to page 5),

b.

All openings of a horizontal slide gate are guarded or screened from the

bottom of the gate to a minimum of 4 feet (1.22 m) above the ground to

prevent a 2-1/4 inch (57.2 mm) diameter sphere from passing through the

openings anywhere in the gate, and in that portion of the adjacent fence

that the gate covers in the open position,

c.

ALL EXPOSED PINCH POINTS ARE ELIMINATED OR GUARDED, AND

d.

GUARDING IS SUPPLIED FOR EXPOSED ROLLERS.

2.

The Operator is intended for installation only on gates used for vehicles.

Pedestrians must be supplied with a separate access opening. The pedestrian

access opening shall be designed to promote pedestrian usage. Locate the

gate such that persons will not come into contact with the vehicular gate

during the entire path of travel of the vehicular gate.

3.

The gate must be installed in a location so that enough clearance is supplied

between the gate and adjacent structures when opening and closing to

reduce the risk of entrapment. Swinging gates shall not open in to the public

access areas.

4.

The gate must be properly installed and work freely in both directions prior to

the installation of the gate operator. Do not over-tighten the operator clutch

or pressure relief valve to compensate for a damaged gate.

5.

The gate operator controls must be placed so that the user has full view of

the gate area when the gate is moving AND AWAY FROM THE GATE PATH

PERIMETER.

6

Page 9

VIKING TECHNICAL SUPPORT 1.800.908.0884

IMPORTANT SAFETY INFORMATION

! WARNING! Not Following these instructions may cause severe injury or death.

IMPORTANT INSTALLATION INSTRUCTIONS (Continued)

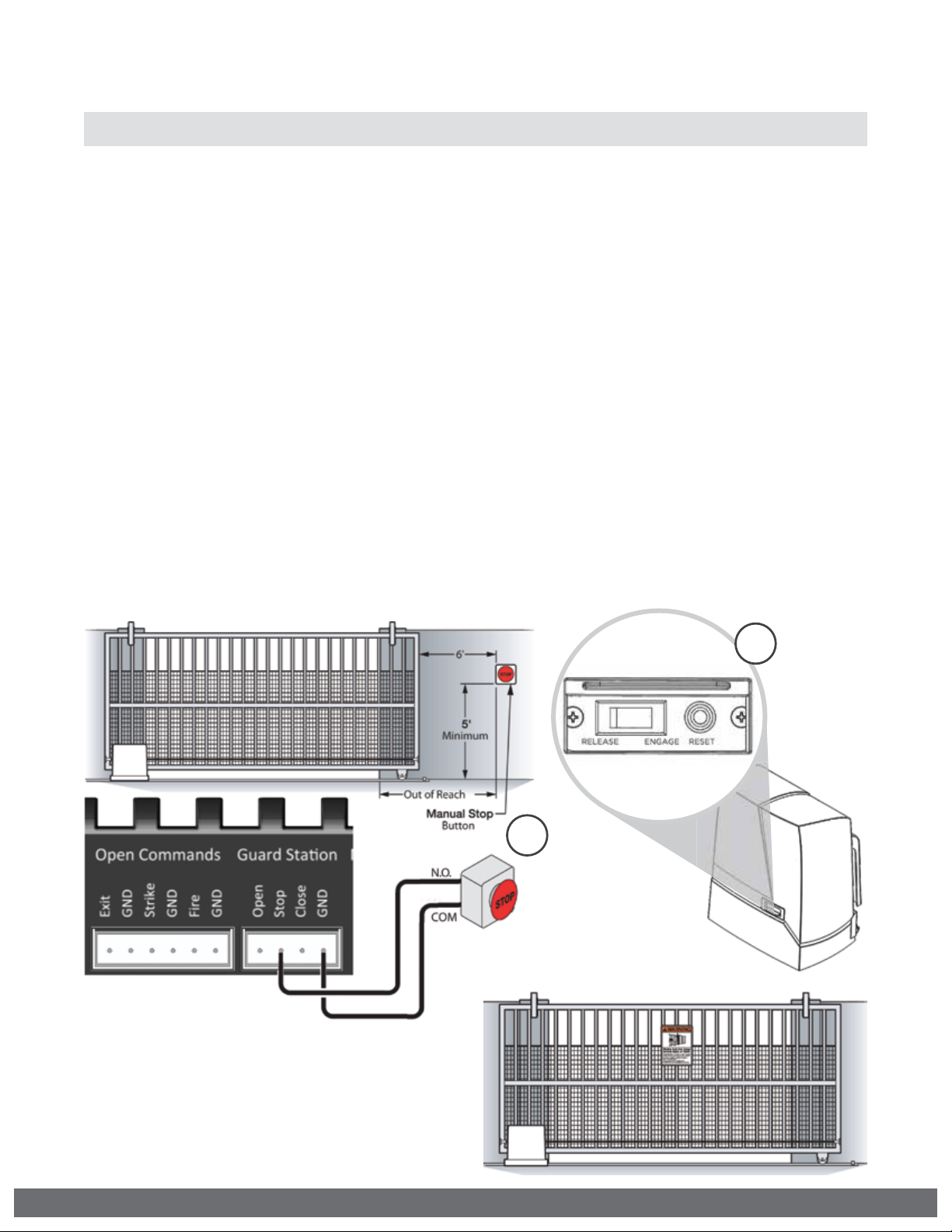

6.

Controls intended for user activation must be located at least six feet (6’)

away from any moving part of the gate and where the user is prevented from

reaching over, under, around or through the gate to operate the controls.

Outdoor or easily accessible controls shall have a security feature to prevent

unauthorized use.

7.

The Stop and/or Reset button must be located in the line-of-sight of the gate.

Activation of the reset control shall not cause the operator to start.

8.

All warning signs and placards must be installed where visible in the area of the

gate. A minimum of two placards shall be installed. A placard is to be installed

in the area of each side of the gate and the gate be visible to persons located

on the side of the gate on which the placard is installed.

9.

For gate operators using non-contact sensors (Photo Beams or like) in

accordance with section 31.1.1 of the UL standard:

a.

The operator is appropriate for the construction of the gate and usage

Class of the gate (refer to page 5),

b.

Care shall be exercised to reduce the risk of nuisance tripping, such as

when a vehicle, trips the sensor while the gate is still moving, and

c.

One or more non-contact sensors shall be located where the risk of

entrapment or obstruction exists, such as the perimeter reachable by a

moving gate or barrier (refer to page 6).

d.

Use only Omron E3K-R10K4 photoelectric eye to comply with UL 325

10.

For a gate operator utilizing a contact sensor (Edge sensor or like) in

accordance with section 31.1.1 of the UL 325 standard:

a.

One or more contact sensors shall be located where the risk of entrapment

or obstruction exists, such as a the leading edge, trailing edge, and post

mounted both inside and outside os a vehicular horizontal slide gate (refer

to page 7).

b.

One or more contact sensors shall be located at the bottom of a vehicular

vertical lift gate.

c.

One or more contact sensors shall be located at the pinch point of a

vehicular vertical pivot gate.

d.

A hardwired contact sensor shall be located and its wiring arranged so

that the communication between the sensor and the gate operator is not

subject to mechanical damage.

e.

A wireless contact sensor such as one that transmits radio frequency

(RF) signals to the gate operator for entrapment protection functions

shall be located where the transmission of the signals are not obstructed

or impeded by building structures, natural landscaping or similar

obstructions. A wireless contact sensor shall function under the intended

end-use conditions.

f.

One or more contact sensors shall be located on the inside and outside

leading edge of a swing gate. Additionally, if the bottom edge of a swing

gate is grater than 6 inches (152 mm) above the ground at any point in its

arc of travel, one or more contact sensors shall be located at the bottom

edge (refer to page 7).

g.

One or more contact sensors shall be located at the bottom edge of a

vertical barrier (arm).

h.

Only Use Miller Edge Model MGR20 or MGS20 edge sensor to comply with

UL325

7

Page 10

VIKING TECHNICAL SUPPORT 1.800.908.0884

IMPORTANT SAFETY INFORMATION

! WARNING! Not Following these instructions may cause severe injury or death.

MAINTENANCE

Remove the Power Harness from the Control Board (refer to page 18)

•Cleanandlubricatetheturningpinsandgatehingesusingtherecommended

lubricant.

•Checkthatallmountinghardwareofthegateoperatorisproperlytighten.

•Ensurethatthegatemovesfreely.

•Checkforcorrodedpartsandreplaceifnecessary.

•Checkthebatteryforthefollowing:

- Battery connections must be free of corrosion.

- Battery voltage must be 26v DC (fully charged battery).

Reconnect the Power Harness for the Control Board (refer to page 18)

•Checkandconfirmtheproperoperationofallsafetydevices(photoelectric

eye, edge sensors or like).

•Checkandconfirmtheoperationofallinstalledaccessories.

•CheckandconfirmtheoperationofallspecialfeaturessuchastheIntelligent

Obstruction Sensor, Hold Open Timer (refer to page 24 and 26)

•Checkandconfirmtheoperationofthemanualrelease(refertopage7)

•Verifybatterybackupfunctionallybyturningoffthepowersource(120vAC

and 220v AC). DO NOT FORGET TO TURN ON THE POWER SOURCE AFTER

VERIFICATION.

GENERAL SAFETY PRECAUTIONS

The following precautions are an integral and essential part of the product and must be

supplied to the user. Read them carefully as they contain important indications for the

safe installation, use and maintenance.

•Theseinstructionmustbekeptandforwardedtoallpossiblefutureusersofthe

system.

•Thisproductmustbeusedonlyforthatwhichithasbeenexpresslydesigned.

•Anyotheruseistobeconsideredimproperandthereforedangerous.

•Themanufacturercannotbeheldresponsibleforpossibledamagecausedby

improper, erroneous or unreasonable use.

•Avoidoperatingintheproximityofthehingesormovingmechanicalparts.

•Donotenterthepathofthemovinggatewhileinmotion.

•Donotobstructthemotionofthegateasthismaycauseasituationofdanger.

•Donotallowchildrentoplayorstaywithinthethepathofthemovinggate.

•Keepremotecontroloranyothercontroldevicesoutofthereachofchildren,in

order to avoid possible involuntary activation of the gate operator.

•Incaseofbreakdownormalfunctioningoftheproduct,disconnectfromthemain

power source. Do not attempt to repair or intervene directly, contact only qualified

personnel for repair.

•Failuretocomplywiththeabovemaycreateasituationofdanger.

•Allcleaning,maintenanceorrepairworkmustbecarriedoutbyqualifiedpersonnel.

•Inordertoguaranteethatthesystemworksefficientlyandcorrectlyitisimportant

to have the manufacturer’s instructions on maintenance of the gate and operator

carried out by qualified personnel.

•Inparticular,regularchecksarerecommendedinordertoverifythatthesafety

devices are operating correctly.

All installation, maintenance and repair work must be documented and made

available to the user.

8

Page 11

VIKING TECHNICAL SUPPORT 1.800.908.0884

IMPORTANT SAFETY INFORMATION

! CAUTION: To Reduce the Risk of Fire or Injury to Persons:

a.

Use only the following type and size battery(ies): Yuasa NP7-12

b.

Donotdisposeofthebattery(ies)inre.Thecellsmayexplode.Checkwithlocal

codes for possible disposal instructions.

c.

Do not open or mutalate the battery(ies). Released electrolyte is corrosive and may

cause damage to the eyes or skin. It may be toxic if swallowed.

d.

Exercise care in handling batteries in order not to short the battery with

conductying materials such as rings, bracelets and keys.

e.

Changethebattery(ies)providedwithoridentiedforusewiththisproductonlyin

accordancewiththeinstructionsandlimitationsspeciedinthismanual.

f.

Observe proper polarity orientation between the battery(ies) and charging circuit.

g.

Do not mix batteries of differ ant sizes or from different manufactures in this

product (applies to products employing more than one user replaceable secondary

battery).

h.

A battery-operated product employing a secondary battery supply intended to be

chargedwithintheproductshallcontainspecicinstructionsconcerningtheproper

method of charging.

UL325 Gate Operator Classification

GLOSSARY

RESIDENTIAL VEHICULAR GATE OPERATOR

CLASS I -

for use in a home of one-to four single family dwelling,

or a garage or parking area associated therewith.

COMMERCIAL/GENERAL ACCESS VEHICULAR GATE OPERATOR

CLASS II –

intended for use in a commercial location or building

such as a multi-family housing unit (five or more single

family units), hotel, garages, retail store, or other

building servicing the general public.

INDUSTRIAL/LIMITED ACCESS VEHICULAR GATE OPERATOR

CLASS III –

intended for use in an industrial location or building

such as a factory or loading dock area or other

locations not intended to service the general public.

RESTRICTED ACCESS VEHICULAR GATE OPERATOR

CLASS IV –

intended for use in a guarded industrial location or

building such as an airport security area or other

restricted access locations not servicing the general

public, in which unauthorized access is prevented via

supervision by security personnel.

A vehicular gate operator (or system) intended

A vehicular gate operator (or system)

A vehicular gate operator (or system)

A vehicular gate operator (or system)

Install the gate operator only when:

The operator is appropriate for the construction of the gate and the Usage Class of

the gate.

9

Page 12

VIKING TECHNICAL SUPPORT 1.800.908.0884

IMPORTANT SAFETY INFORMATION

! WARNING! Not Following these instructions may cause severe injury or death.

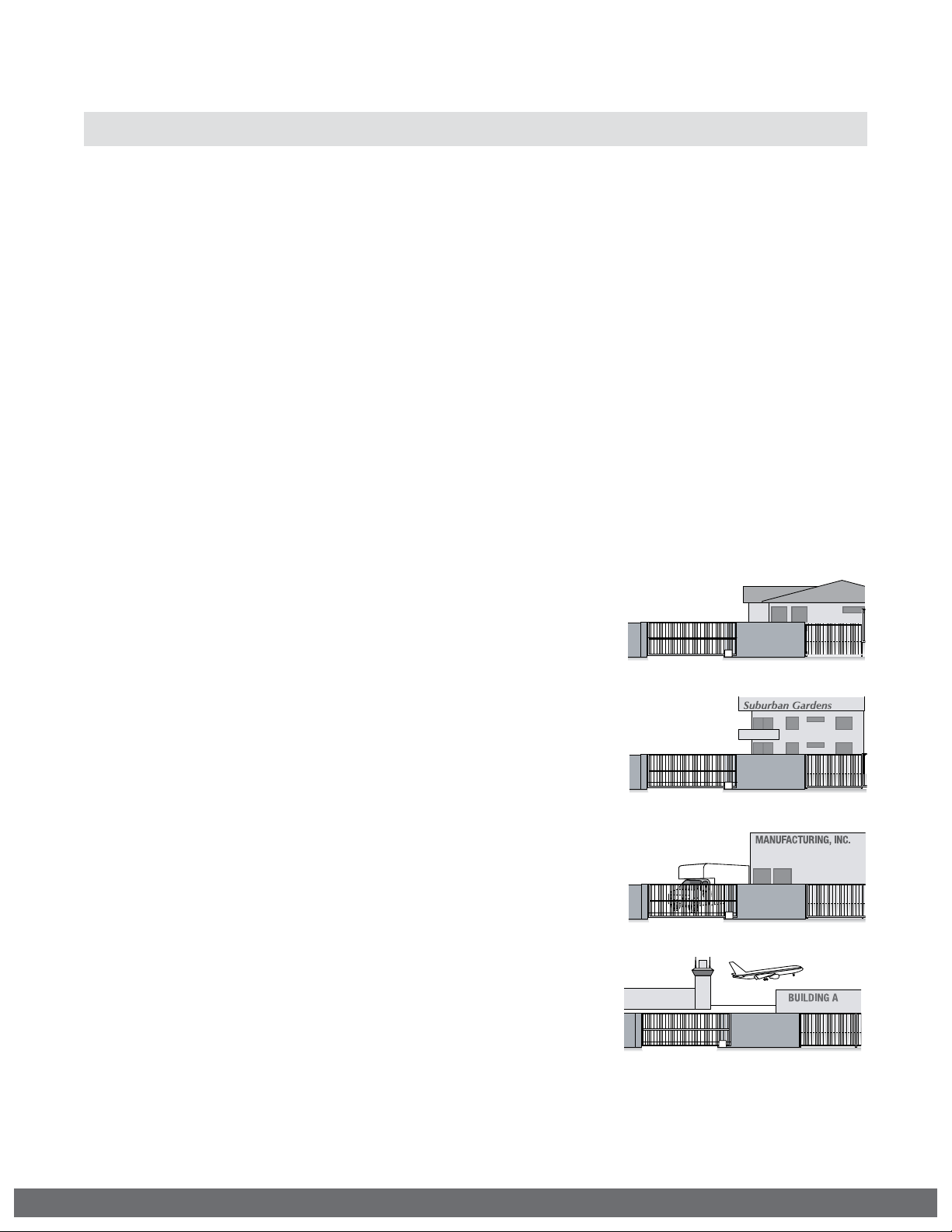

NOTE: This type on installation DOES NOT reverse the gate all the way back to

its limits when the photo beam is obstructed. This installation is only to protect

against entrapment and to comply with UL325.

Secondary Entrapment Protection

Photo Beam (non-contact sensor) Installation

•

Photo beams or like must be installed to reduce the risk of entrapment.

•

Use only Omron E3K-R10K4 photoelectric eye to comply with UL325

•

Make the electrical connections of the photoelectric sensor as described here in

this page.

•

Care shall be exercised to reduce the risk of nuisance tripping, such as when a vehicle, trips the sensor while the gate is still moving, and;

•

One or more non-contact sensors shall be located where the risk of entrapment or

obstruction exists, such as the perimeter reachable by a moving gate or barrier.

Consult the installation manual for the UL325 device (photo beam or like) for detail

information about the usage, installation and maintenance.

10

Page 13

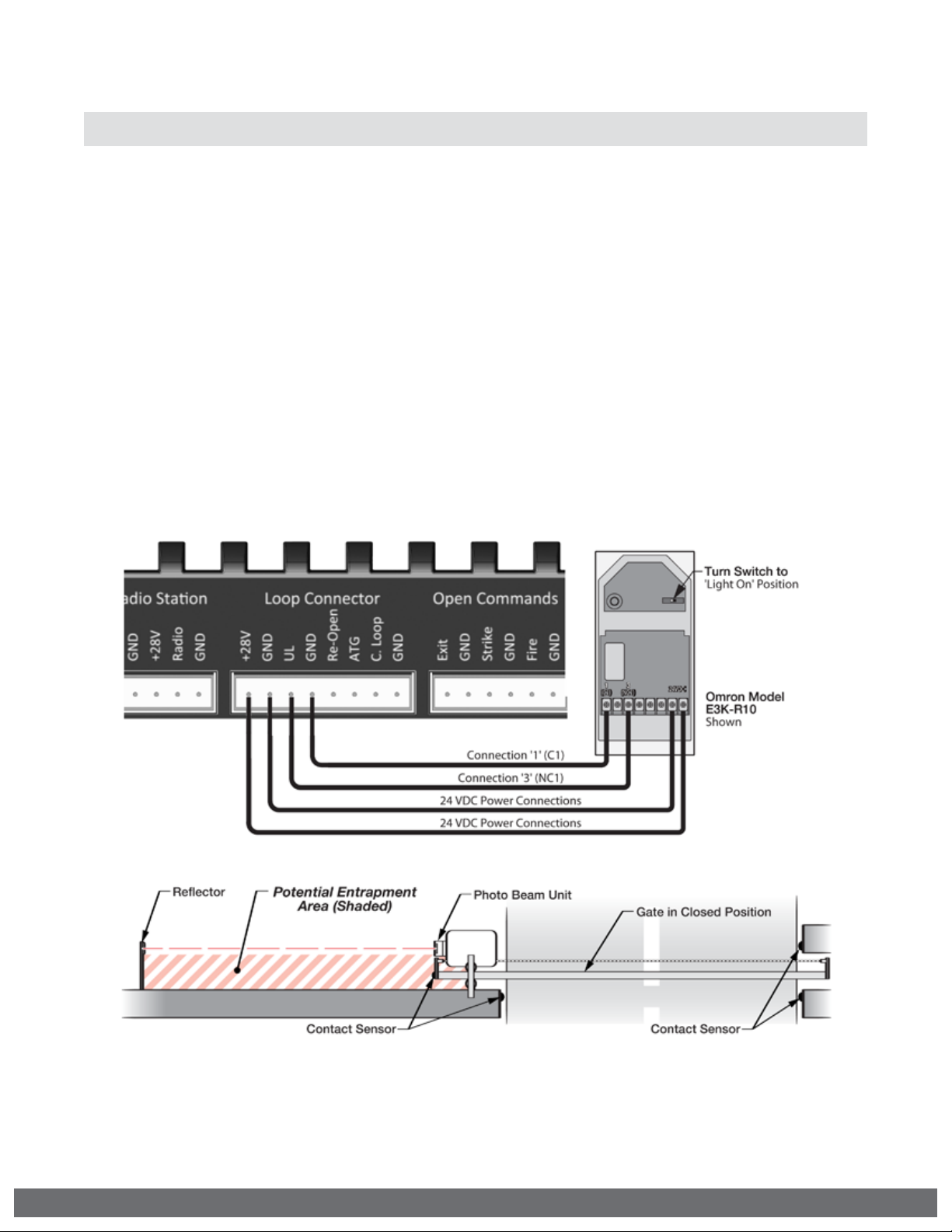

IMPORTANT SAFETY INFORMATION

! WARNING! Not Following these instructions may cause severe injury or death.

NOTE: This type on installation DOES NOT reverse the gate all the way back to

its limits when the edge sensor is obstructed. This installation is only to protect

against entrapment and to comply with UL325.

Secondary Entrapment Protection

Edge Sensor (non-contact sensor) Installation

•

Edge Sensors or like must be installed to reduce the risk of entrapment.

•

Use only Miller Edge 3-sided activation type MGR20 or MGS20 to comply with

UL325

•

One or more contact sensors shall be located on the inside and outside leading

edge of a swing gate. Additionally, if the bottom edge of a swing gate is greater

than 6 inches (152 mm) above the ground at any point in its arc of travel, one or

more contact sensors shall be located on the bottom edge.

1.

A hardwired contact sensor shall be located and its wiring arranged so that the

communication between the sensor and the gate operator is not subjected to

mechanical damage.

2.

A wireless contact sensor such as one that transmits radio frequency (RF) signals to the gate operator for entrapment protection functions shall be located

where the transmission of the signals are not obstructed or impeded by building

structures, natural landscaping or similar obstruction. A wireless contact sensor

shall function under the intended end-use conditions.

Manual Release

When manual operation is required:

1.

Lift the Access Door, located on the

front of the cover.

2.

Press the Manual Release Switch to

the “RELEASE” Position.

The gate can now be moved manually.

To resume normal operation, press

the switch to the “ENGAGE” position.

VIKING TECHNICAL SUPPORT 1.800.908.0884

11

Page 14

IMPORTANT SAFETY INFORMATION

! WARNING! Not Following these instructions may cause severe injury or death.

Audible Alarm Reset Switch Installation

Manual Reset for the Audible Alarm

•

UL325 standard requires an audible alarm to go off after two consecutive events

detected by the primary entrapment protection of the gate operator (obstruction

sensor).

•

The audible alarm will continue to sound for 5 minutes or until a stop command

gets actuated.

•

The Stop command can be actuated in three different forms:

1.

Using the Built in Stop switch on the Control Box or;

2.

Using an External Stop button within the sight of the gate, away from moving

parts of the gate and out of reach of children.

a.

Controls intended for user activation must be located at least six feet (6’)

away from any moving part of the gate and where the user is prevented from

reaching over, under, around or through the gate to operate the controls.

Outdoor or easily accessible controls shall have a security feature to prevent

unauthorized use.

b.

The Stop and/or Reset button must be located in the line-of-sight of the gate.

Activation of the reset control shall not cause the operator to start.

3.

Using the Reset Button on the operator that is externally accessible from the

covers Access Door.

Warning Placard Installation

•

All Warning Placards must be installed

where visible in the area of the gate.

•

A minimum of two placards shall be installed.

•

A placard is to be installed in the area of

each side of the gate and be visible.

3

2

12

VIKING TECHNICAL SUPPORT 1.800.908.0884

Page 15

VIKING TECHNICAL SUPPORT 1.800.908.0884

IMPORTANT INSTALLATION INFORMATION

! CAUTION: To Reduce the Risk of Fire or Injury to Persons:

! WARNING: For use with gates at a maximum 2200 lbs. in weight or 75 ft. in length.

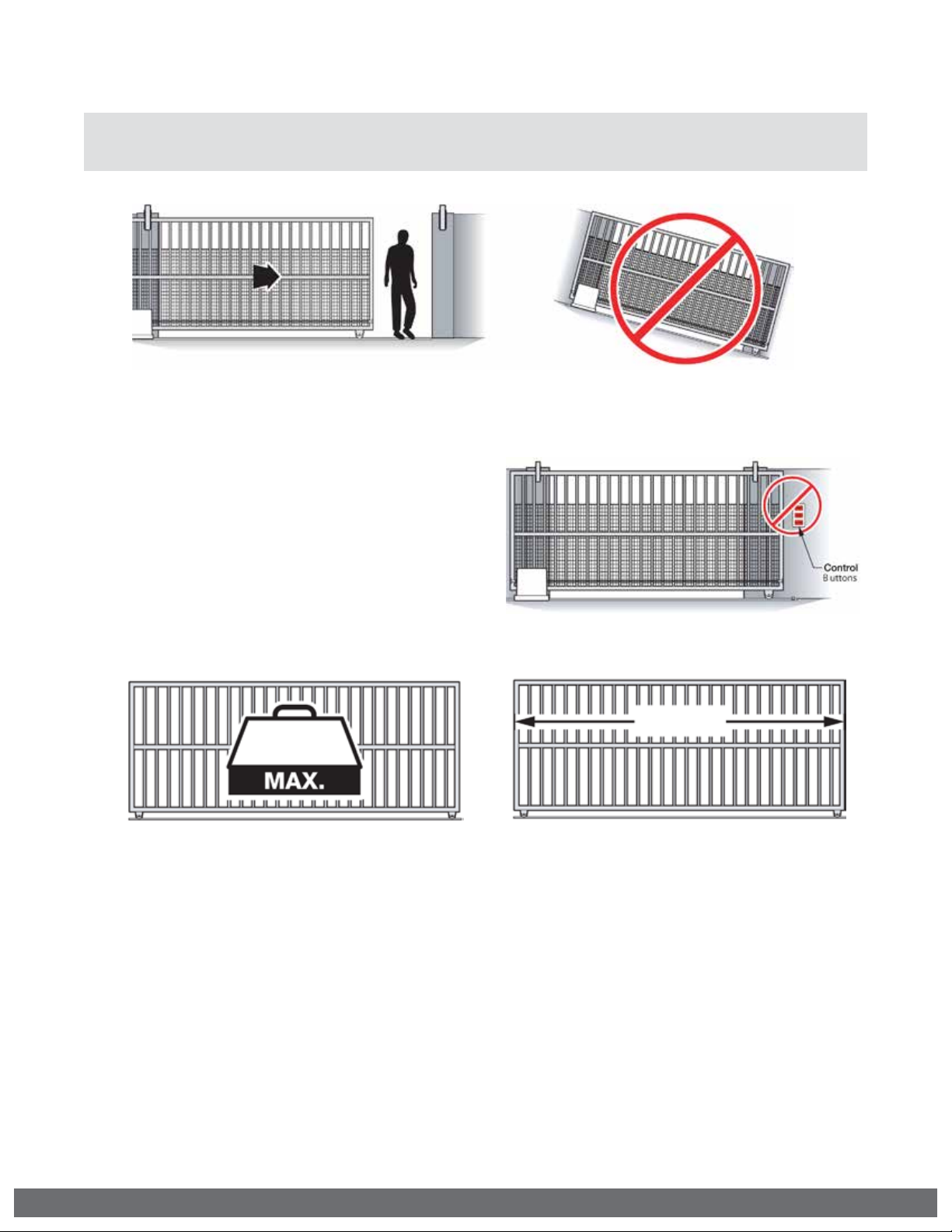

DO NOT allow pedestrian use of this gate DO NOT install the gate operator to lift gates

Locate Control Buttons:

1.

Within sight of the gate,

2.

At a minimum height of 5 feet

so small children are not able to

reach it; and

3.

At least 6 feet away from all

moving parts of the gate.

75 ft

2200 lb.

Specications

Maximum Gate Length: 75 ft.

Maximum Gate Weight: 2200 lb.

Operating Temperature: -20ºF (-28ºC) to 158ºF (70ºC)

Power Requirements: 115v / 230v AC (4 amp / 2 amp)

Single Phase (50 Hz / 60 Hz)

13

Page 16

VIKING TECHNICAL SUPPORT 1.800.908.0884

GATE OPERATOR INSTALLATION

Concrete Pad Option

1.

Follow the local building code to determine the required depth of the concrete pad.

2.

Pad measurements recommended by Viking Access Systems are at lease

24” long, 18” wide and 24” deep to ensure the stable operation of the operator, and a minimum of 4” above level grade to avoid any flooding of the

machinery.

3.

Provide a sufficient number of conduit pathways for all low power accessories such as loop detector leads, maglock, non-contact sensors, contact

sensors, safety and other commands. Also provide conduit for the power

supply to the operator.

! DO NOT run low voltage and high voltage wiring in the same conduit.

! Provide at least 12” separation between low and high voltage conduits.

14

Page 17

VIKING TECHNICAL SUPPORT 1.800.908.0884

GATE OPERATOR INSTALLATION

Post Mounting Option

TIP:

The operator is equipped for post mount applications and is ready for installation.

You will only need to supply the posts and u-bolts.

1.

Consult the local building codes for the depth and concrete requirements.

2.

Maximum 3.00” OD pipe.

3.

Provide a sufficient number of conduit pathways for all low power accessories such as loop detector leads, maglock, non-contact sensors, contact

sensors, safety and other commands. Also provide conduit for the power

supply to the operator.

! DO NOT run low voltage and high voltage wiring in the same conduit.

! Provide at least 12” separation between low and high voltage conduits.

15

Page 18

VIKING TECHNICAL SUPPORT 1.800.908.0884

GATE OPERATOR INSTALLATION

Operator Positioning

! IMPO R TA NT: All openings of a horizontal slide gate are guarded or screened from the bot-

tom of the gate to a minimum of 4 feet (1.22 m) above the ground to prevent a 2-1/2 inch

(57.2 mm) diameter sphere from passing through the openings anywhere in the gate, and

in that portion of the adjacent fence that the gate covers in the open position.

16

Page 19

VIKING TECHNICAL SUPPORT 1.800.908.0884

GATE OPERATOR INSTALLATION

! TECHNICAL TIP: Before starting the installation procedure;

•

Openandclosethegatemanually,makingsurethereissufcientspacebetweenthegate

and adjacent walls.

•

Check that the wheels are turning freely on the track and there are no restrictions while

pushing the gate to the open and closed positions.

•

Conrmthatthereisadequatespacingfortheguiderollersandthatthereareno

restrictions throughout the travel of the gate.

STEP 1

Before securing the chassis to the

concrete pad or posts, make sure

the gate and operator is LEVEL and

PARALLEL. Minimum distance between

the operator and gate is 3”.

STEP 2

Chain Installation: Before welding the

provided chain brackets, make sure the

chain will be in a straight line with, and at

the same height as, the chain leaving the

gate operator rollers.

14.375"

17

Page 20

VIKING TECHNICAL SUPPORT 1.800.908.0884

ELECTRICAL INSTALLATION

1a

1b

3a

3b

3c

High Voltage Supply Option

!

Caution: Always turn off power breakers when working with high voltage. DO NOT

connect the “Power Harness” to the Control Board until the electrical installation is

complete and ready for verification.

STEP 1

!

WARNING: If 230VAC is supplied,

disconnect the “120V Receptacle” from

the EMI Board.

At the “Power Box”:

a.

Set the “Voltage Selector” according

to the voltage supply.

b.

Turn the “120VAC Power” switch ON

STEP 2

!

WARNING: SINGLE PHASE AC ONLY

At the “J-Box”:

a.

Connect the incoming power wires

with the wire nuts provided; matching

the color code.

b.

Turn ON the main facility breaker.

2a

STEP 3

a.

Verify that all three (3) Status LEDs

are illuminated at the front panel of

the Power Box.

b.

Turn the “Battery Switch” ON.

At the Control Board:

c.

Connect the Power Harness and verify

the “POWER” LED is illuminated solid.

! TECHNICAL TIP: If the “Power” LED is

flashing or any of the 3 LEDs on the

“Power Box” are not illuminated, refer

to the Troubleshooting pages.

Tips for proper ground installation:

To minimize the effects caused by lightning, follow

these guidelines.

•

Use a ground rod to provide a ground reference.

•

Consult your city code and be aware of under-ground

services in the site of the gate operator to prevent

inconveniences.

•

Always use a single bonding point for grounding.

•

All ground wires must be as short and as thick as

possible.

•

Prevent unnecessary turns or loops in all ground

wires.

18

Page 21

VIKING TECHNICAL SUPPORT 1.800.908.0884

A

ELECTRICAL INSTALLATION

B

Low Voltage Supply Option

TIP:

The operator is equipped with a Modular Power Box that can be relocated to

provide power for low voltage installations. Supplies 24v AC to the operator.

! Caution: Always turn off power breakers when working with high voltage. DO NOT

connect the “Power Harness” to the Control Board until the electrical installation is

complete and ready for verification.

Remove the “Power Box” from the operators chassis and relocate to the nearest high

voltage source (115v or 230v single phase AC). Follow local codes or guidelines.

MAXIMUM DISTANCE:

400 ft. with 10 AWG wire

Solar Supply Option

Vikings Solar Package (part # VA-SOCHP) is an efficient and effective solution to

powering the operator with solar energy. (See page 46 for package details)

! Tip: For increased solar efficiency:

By activating the “Pre-Warning”

feature , the “Brake” terminals

will provide power to all non-essential

controls beginning 3 seconds prior to

gate movement and while the gate is

moving. (page 25)

Connect the batteries

in series.

A

Connect the two

panels in series.

B

Disconnect the operators

power harness and use the

Solar Harness.

! IMPORTANT: The number of cycles achieved daily is dependent on the average solar

radiation of the geographic location and the power consumption of all accessories

being used. Increased panel and battery capacities may be required. See Appendix C

on page 45 for more important information regarding solar applications.

19

Page 22

LIMITS SETUP

! IMPORTANT: In the event of a complete power failure, including battery backup, the

limits positions may have been cleared and will need to be reset by following the

steps below..

STEP 1

Connect the “Motor Harness” to the

Control Board.

a.

“OPEN RIGHT” Connector if the gate

opens to the Right, when viewed from

inside.

b.

“OPEN LEFT” Connector if the gate

opens to the Leftt, when viewed from

inside.

1a

1b

STEP 2

Move the gate at the desired open

position then press and hold the “Open

Limit” button until the LED stops flashing

and illuminates solid.

“Open Limit” LED

flashes if the open

limit is not set.

STEP 3

Move the gate at the desired close

position then press and hold the “Close

Limit” button until the LED stops flashing

and illuminates solid.

“Close Limit” LED

flashes if the close

limit is not set

Tip: The gate can be moved electronically with the “Open”, “Stop” and “Close” buttons

on the Control Board or manually by following the instructions on page 11.

20

VIKING TECHNICAL SUPPORT 1.800.908.0884

Page 23

LIMITS SETUP

! NOTE:

1.

The 1st cycle after the limit setup is the “Learn Cycle”. Allow a complete cycle to

confirm your settings.

2.

During the initial limit setup, the operator will run at half speed.

Open

Limit

To Readjust the Open Limit:

1.

Clear the current limit setting by

holding down the “Open Limit” button

until the LED is flashing.

2.

Repeat STEP 2 on page 20 to set the

limit.

VIKING TECHNICAL SUPPORT 1.800.908.0884

Close

Limit

To Readjust the Close Limit:

1.

Clear the current limit setting by

holding down the “Close Limit” button

until the LED is flashing.

2.

Repeat STEP 3 on page 20 to set the

limit.

21

Page 24

VIKING TECHNICAL SUPPORT 1.800.908.0884

MASTER/SLAVE SETUP

Two Wire Communication

!

IMPORTANT: DO NOT run the Master/Slave communication cable in the same conduit

or within 12” of 115 - 230v power supply cables.

! Technical Tip: DO NOT set the “Timer” and/or “Overlap” features on both operators

Control Boards. Only turn these features on at the Master Control Board.

CABLE REQUIREMENTS:

•

2 Conductor (wire)

•

18 AWG or better

•

Shielded (overall foil)

•

Drain Wire (non-insulated or bare wire)

Shielded Cable

Master Board

“MS1”

“MS2”

Conduit

Drain Wire

Slave Board

“MS1”

“MS2”

22

Conduit between

Master and Slave

Page 25

VIKING TECHNICAL SUPPORT 1.800.908.0884

MASTER/SLAVE SETUP

Wireless Communication Options

!

Technical Tip: DO NOT set the “Timer” and/or “Overlap” features on both operators

Control Boards. Only turn these features on at the Master Control Board.

REQUIRED ADD-ON: Choose option A or B

A.

Viking Konnect - Wireless Master/Slave Kit

PART# VA-KONNECT-MS

B.

Viking Blue - Wireless Master/Slave Kit

PART# VA-BLUE-MSKT

Connect one Bluetooth Module, provided with VA-BLUE-MSKT, to the “V-Blue” plug &

play connection of each operators Control Board.

Green LEDs will be illuminated

solid when communication is ON.

23

Page 26

CONTROL BOARD SETUP

Initial Settings

“Timer”

Hold Open Timer

Automatically closes the gate after

the selected amount of time from 1-60

seconds.

Turning the dial to between “0” and

“OFF” will disable this feature, requiring

a close command to close the gate.

“Overlap”

Overlap Delay

Delays the gate from opening for the

selected amount of time from 1-6

seconds.

! Typically not used on slide gates. For

Master/Slave application, the control

board that has this feature turned on

is the master and will close first.

“ODS”

Obstruction Detection Sensor

Sets the amount of force required to trip

the inherent obstruction sensor.

See page 26 for more details about this

feature.

24

“Speed”

Motor Speed

Increases or decreases the speed of gate

travel.

VIKING TECHNICAL SUPPORT 1.800.908.0884

Page 27

Initial Settings

CONTROL BOARD SETUP

NOTE:

Installing a shunt or jumper on the pins will activate the feature.

“Auto Open” - Power Failure Option

Opens the gate automatically during

power failure. Resumes normal operation

when power is restored.

“Last Open” - Power Failure Option

Will open the gate automatically when

batteries critically low.

“Fail Safe/Secure”

During complete power

failure, including battery

power; determines the force

required to manually move

the gate.

•

Fail Safe Mode:

By removing the wirejumper plug from the “Fail

Safe/Secure” connector:

The gate can move

manually with a relatively

low amount of force.

•

Fail Secure Mode:

By inserting the wirejumper plug into the “Fail

Safe/Secure” connector:

The gate will not move

manually.

“Pre-Warning” Initiates two options for

an audio or visual warning 3 seconds

prior to gate motion and will continue:

1.

Until gate reaches closed limit:

“Magnetic Lock” terminals provide a

contact between “COM” and “N.O”.

2.

While gate is moving:

“Brake” terminals provide a 24v DC.

“Sync” Used only in conjunction with

the Viking Barrier gate operator model

B-12. Activating this feature allows for

synchronized operation with the B-12

operator. See page 33.

“EXT” Available for future developments.

! IMPORTANT: Regardless of the power failure options chosen, the gate can be moved

manually with a relatively low amount of force by following the steps for “Manual

Release” as outlined at on page 11.

VIKING TECHNICAL SUPPORT 1.800.908.0884

25

Page 28

CONTROL BOARD SETUP

Obstruction Sensor (Primary Entrapment Protection)

!

IMPORTANT: The appropriate “ODS” setting is dependant upon the gate installation

and construction. Set this feature accordingly. Additional Safety equipment should

be used to reduce possible risk of injury or vehicle damage.

“ODS” Obstruction Detection Sensor

The Obstruction Sensor detects

obstructions in the path of the traveling

gate. The dial sets the amount of force

required to activate the operators inherent

obstruction detection.

Setting the dial to “0” will require the least

amount of force to activate;

Setting the dial to “100” will require the

maximum amount of force to activate.

UL325 standard requires an audio

alarm to go off after two consecutive

entrapment events sensed by the

Inherent Entrapment Protection of the

Gate Operator.

The audio alarm will sound for a period

of 5 minutes or until the “Stop” Button

or “Alarm Reset” Button is pressed. See

page 12 for more information.

When the Obstruction Sensor detects

an obstruction it will:

1.

Stop the gate’s movement and reverse

it momentarily.

2.

Bring the gate to a resting position.

3.

Disable the Hold Open Timer feature

until the Gate Operator receives a new

command.

If second obstruction is detected before

the gate reaches either limit it will:

1.

Stop the gate’s movement.

2.

Disable the Gate Operator.

3.

Sound the UL Alarm

4.

A STOP command must be provided

to disable the alarm and continue

operation.

! TECHNICAL TIP: The Status LED for the

“ODS” will indicate the following

when it has been triggered.

A.

Solid: Obstruction.

Detected a sudden or abrupt increase

in gate resistance.

B.

Flashing: Overload.

Detected a more subtle, but sustained

increase in gate resistance.

26

VIKING TECHNICAL SUPPORT 1.800.908.0884

Page 29

CONTROL BOARD SETUP

Viking Heater

The operator has an integrated heater that is thermostatically controlled. Activate this

feature when the operator is used in application temperatures down to -20°F (-29°C).

To set the heater to turn on at the Close Limit:

1.

Use the “Diagnose” button to scroll through the LCD

menu to “HEATER CLS”

2.

Press and hold the “Stop” button on the control board.

3.

Press and release the “Diagnose” button to turn this

feature ON and OFF.

To set the heater to turn on at the Open Limit:

1.

Use the “Diagnose” button to scroll through the LCD

menu to “HEATER OPN”

2.

Perform steps 2-3 as described above.

NOTE: If the application requires the gate to be held open for any reason, set the HEATER

ON for both limit positions.

HEATER

CLS ON

HEATER

OPN ON

! IMPORTANT: A POSITIVE STOP must be used on the gate at the limit position(s) the

HEATER has been set for.

Viking Lock Mode

Turning this feature ON will secure the gate at the closed position, preventing

unauthorized manual entry.

Use the LCD Display to activate this feature.

1.

Use the “Diagnose” button to scroll throught the LCD

menu to “LOCK MOD”

2.

Press and hold the “Stop” button on the control board.

3.

Press and release the “Diagnose” button to turn this

feature ON and OFF.

VIKING TECHNICAL SUPPORT 1.800.908.0884

LOCK MOD

ON

27

Page 30

VIKING TECHNICAL SUPPORT 1.800.908.0884

(THIS PAGE LEFT BLANK INTENTIONALLY)

28

Page 31

VIKING TECHNICAL SUPPORT 1.800.908.0884

ACCESSORY CONNECTIONS

Re-Open Photo Beam (vehicular Safety)

NOTE:

to the open limit when the an beam is obstructed. Intended for vehicular safety ONLY.

For the purpose of pedestrian entrapment, see pages 10-11.

This type of photo-beam installation will stop then RE-OPENS the gate all the way

N.O.

Note regarding Photo Beam types:

Fail-Safe type - connect the “N.C.”

terminal of the photo beam to the

“Re-Open” terminal on the control board.

Typically, these are the reflective type

photo beams.

Fail -Secure type - connect the “N.O.”

terminal of the photo beam to the

“Re-Open” terminal on the control board.

Typically, these are the transmitter/

receiver type photo beams.

COM

( - ) ( + )

Check for proper operation:

The “Re-Open” LED will illuminate

solid while the beam is obstructed

and remain off when the beam is

unobstructed.

! TECHNICAL TIP: For more information

regarding accessory connections

to the control board and individual

input terminal functions, refer to

“Appendix (A)”, pages 42-43.

29

Page 32

ACCESSORY CONNECTIONS

COM

N.O.

(-)

(+)

Radio Receiver (Typical)

!

IMPORTANT: The Hold Open “Timer” setting (page 24) effects how the gate will

respond to the radio receiver command.

The control board provides two modes

of operation that a radio receiver can

control the gate:

Open-Stop-Close

1.

By having the radio receiver connected

as illustrated and with the Hold Open

Timer OFF (see page 24):

Every command of the radio transmitter

will control the gate as follow:

a.

First command opens the gate,

b.

Second command stops the gate and

c.

Third command closes the gate

d.

Any subsequent commands will

continue in the same order to control

the gate.

This type of configuration is not

recommended for a commercial

installations.

! TECHNICAL TIP: For more information

regarding accessory connections

and terminal functions, refer to

“Appendix (A)” on pages 42-43.

See “Appendix (B)” on page 44 for

connecting common radio receiver

models.

30

Open Only

2.

By having the radio receiver connected

as illustrated and with the Hold Open

Timer ON (see page 24):

Each command of the radio transmitter is

ALWAYS AN OPEN COMMAND to the gate.

For maximum reception range:

Locate the radio antenna to

the top of the gate column.

VIKING TECHNICAL SUPPORT 1.800.908.0884

Page 33

ACCESSORY CONNECTIONS

Anti-Tail Gate, Open Commands & Guard Station

!

TECHNICAL TIP: For more information regarding accessory connections and terminal

functions, refer to “Appendix (A)” on pages 42-43.

Open Commands

“Exit”, “Fire” and “Strike” input terminals

all provide an open command to the

control board. Any device connected as

shown will open the gate.

-

+ +

N.O.

-

COM

N.O.

COM

-

+

“ATG” Anti-Tailgate

This input will stop the

gate when the vehicle

triggers the sensor, then

closes the gate when the

vehicle leaves the sensor,

preventing unauthorized

vehicles from entry.

N.O.

COM

Guard Station

All three buttons must be a

!

Normally Open “N.O.” type of

switch, and can share the same

common “C” connection to “GND”.

-

+

VIKING TECHNICAL SUPPORT 1.800.908.0884

COM

N.O.

31

Page 34

VIKING TECHNICAL SUPPORT 1.800.908.0884

ACCESSORY CONNECTIONS

Viking Loop Rack

TIP:

This operator may be equipped with a pre-wired Loop Rack that plug-in type loop

detectors can be connected to. This provides a convenient alternative to the box

type loop detectors that would need to be wired to the control board. Viking does

not provide either type of loop detectors.

Loop Rack: Part # VA-LR

Loop Rack Wiring Harness: Part # VA-LRH

32

Page 35

VIKING TECHNICAL SUPPORT 1.800.908.0884

ACCESSORY CONNECTIONS

Guidelines for Loop Installation

1.

Prevent sharp corners in the geometry of the loop sensor.

2.

Install the appropriate number of turns for your loop geometry based on the loop

perimeter. Use Table C (below) as a guide.

3.

Use XLP (cross-linked-polyethylene) type of wire. This wire reduces the effects

of moisture and other environmental events in altering the functionality of the

vehicular loop detector.

4.

Twist the lead wire at least 6 turns per foot.

5.

Use BACKER-ROD to minimize damage to the loop detector wire prior to using the

sealant.

6.

Place the loop detector wire and adjust the sensitivity of the vehicular loop

detector unit in a way to minimize the effects of the gate over the loop detector

wire.

! IMPORTANT! Some of the following parameters may affect the proper

functionality of the vehicular loop detector.

Consult the manufacturer of the vehicular loop detector and/or loop wire.

•Gatesize

•Numberofturnsintheloopsensorwire

•Distanceoftheloopsensorwiretothegateateitherattheopenorcloseposition

Table C - Recommended Number of Turns

Perimeter (ft.) Number of Turns

10 5

20 4

30-40 3

50-100 2

Dimension “A” - 5’ for Single Gate

6’ for Dual Gate

33

Page 36

ACCESSORY CONNECTIONS

Magnetic Lock, Lock Solenoid

NOTE:

can be purchases from your dealer or distributor.

Viking Access Systems does not provide external gate lock devices. These items

Power

Do not use the 24v DC power supplied

by the control board. An external power

Magnetic Lock

( + )

supply, or plug-in transformer, must

be used for the magnetic lock or lock

solenoid. Plug the transformer into the

“120VAC” receptacle provided at the

operators Power Box. This will prevent

rapid drainage of the battery in the event

of power failure.

The control boards “Magnetic Lock” relay

is rated for 10A-250v AC.

( + )

Lock Solenoid

34

( + )

( + )

VIKING TECHNICAL SUPPORT 1.800.908.0884

Page 37

VIKING TECHNICAL SUPPORT 1.800.908.0884

SYNCHRONIZATION WITH B-12

Barrier Arm (B-12) Synchronization Option

NOTE:

synchronized operation with the Viking Barrier Arm Operator model B-12.

This type of application opens and closes in the follow pattern:

1.

2.

3.

STEP 1 (Figure A & B)

Connect the Gate Operator to the Viking

B-12 Barrier Arm Operator as illustrated.

STEP 3 (Figure B)

On the Gate Operator Control Board,

activate Sync Mode by placing a jumper

on to the pin headers labeled “SYNC”.

Figure A

The Control Board provides a convenient solution for applications that require

Open Command is provided only to the Viking B-12 Barrier Arm Operator.

The Barrier Arm will delay to open until this Gate Operator reaches its Open Limit.

The Gate Operator will delay to close until the Barrier Arm reaches its Close Limit.

STEP 2 (Figure A)

At the B-12 Barrier Arm Operator,

connect the primary device that will be

used as the OPEN input.

Figure B

1

2

STEP 4 (Figure C & D)

Connect Viking B-12 Barrier Arm

Operator to the Gate Operator as

illustrated.

Figure C

3

Figure D

4

35

Page 38

VIKING TECHNICAL SUPPORT 1.800.908.0884

TROUBLESHOOTING

LED References

In addition to the LCD Display, the control board LEDs monitor the various circuits of the

control board. Use the table below to identify the corresponding “TS Ref#” and refer to

page 38-41 for further troubleshooting.

# LED Status Meaning

1 “Magnetic

Lock”

2 “Check Motor” OFF Normal Condition.

3 “Battery Low” OFF Normal Condition.

4 “POWER” SOLID Normal Condition.

5 “Radio” OFF Normal Condition.

6 “UL” OFF Normal Condition.

7 “Re-Open” OFF Normal Condition.

8 “ATG” OFF Normal Condition.

OFF At Closed Limit and Magnetic Lock Relay state is closed across “COM” &

“N.C”. (page 34). Gate should be at the Close Limit.

SOLID Not at Closed Limit and Magnetic Lock Relay state is closed across “COM” &

“N.O”. (page 34). Gate should not be at the Close Limit

SOLID The control board is sending power to the motor but the circuit is open.

SOLID Batteries are low. Check power supply to the operator. (pages 18-19).

FLASHING Batteries critically low. Check power supply to the operator. (pages 18-19).

FLASHING Operator is running on batteries only (pages 18-19).

OFF No power to control board.

SOLID Control Board is receiving an input from a device connected to the

Radio terminal (pages 30, 42).

SOLID Control Board is receiving an input from a device connected to the UL

terminal (pages 12-13, 42).

SOLID Control Board is receiving an input from a device connected to the Re-

Open terminal (pages 29, 32, 42).

SOLID Control Board is receiving an input from a device connected to the ATG

terminal (pages 31, 42).

Page 41

TS Ref#(s)

7, 8

1, 2

1, 2

1, 2

1, 2, 4, 5

9, 10

9, 10

9, 10

9, 10

36

Page 39

VIKING TECHNICAL SUPPORT 1.800.908.0884

TROUBLESHOOTING

LED References

Use the table below to identify the corresponding “TS Ref#” and refer to page 38-41 for

further troubleshooting.

Page 41

# LED Status Meaning

9 “C Loop” OFF Normal Condition.

SOLID Control Board is receiving an input from a device connected to the

10 “Open” OFF Normal Condition.

SOLID Control board is receiving an input for a device connected to any of

11 “STOP” OFF Normal Condition.

SOLID Control Board is receiving an input from a device connected to the

12 “Close” OFF Normal Condition.

SOLID Control Board is receiving an input from a device connected to the

13 “Siren”

14 “Brake”

15 “Diagnose” OFF Normal Condition

“Close Limit”

16

17

“Open Limit”

18 “ODS” OFF Normal Condition.

19 “Timer” OFF The close timer is turned OFF or gate is not at the open limit if the timer is

“AC VOLTAGE OUTPUT”

20

“PROTECTION WORKING”

21

“AC VOLTAGE INPUT”

22

23 “120VAC POWER” SOLID Normal Condition for High Voltage installations.

OFF Normal Condition.

SOLID Second consecutive obstruction has been detected. (page 26).

FLASHING Batteries are critically low.

OFF No voltage output on these terminals at the moment.

SOLID There is 24v DC output on these terminals at the moment.

FLASHING Errors have been detected; Check LCD Display for messages (page 38-40).

OFF Gate is not at the close limit position.

SOLID Gate is at the close limit position.

FLASHING Close limit position has been erased or not set (page 20-21).

OFF Gate is not at the open limit position.

SOLID Gate is at the open limit position.

FLASHING Open limit position has been erased or not set (page 20-21).

SOLID Obstruction has been detected. (page 26).

FLASHING Overload has been detected. (page 26).

SOLID Gate is at Open Limit, Timer is turned ON and counting down to close.

FLASHING Gate is at Open Limit, Timer is turned ON but is not timing out due to a

SOLID Normal Condition.

OFF There is no output voltage from the Modular Power Box.

SOLID Normal Condition.

OFF EMI Board is damaged and circuit is not protected . Replace EMI Board.

SOLID Normal Condition.

OFF IncomingpowertoModularPowerBoxisnotsufcient.(page18).

OFF High Voltage is not supplied to the Modular Power Box (page 18).

C Loop terminal (pages 32, 42).

the following input terminals: Exit, Fire, Strike or Open (pages 31, 42).

Stop terminal (pages 31, 42).

Close terminal (pages 31, 42).

turned ON. (page 24).

(page 24).

conictingcommand.(page24).

TS Ref#(s)

9, 10

9, 10

9, 10

9, 10

11, 13, 1, 2

1, 2

6

6

11, 13, 1, 2

11, 13, 1, 2

9, 10

2

1

1

37

Page 40

VIKING TECHNICAL SUPPORT 1.800.908.0884

TROUBLESHOOTING

LCD Display References

The control board is equipped with a LCD Display that provides operator information,

current conditions, settings, diagnostics and error messages. Use the table below to

identify the corresponding “TS Ref#” and refer to page 41 for further troubleshooting.

1.

ErrorMessageswillbedisplayedrst.

2.

The”Diagnose”LEDwillashconsecutively

indicating how many Error Messages are

Call out LCD Display, Diag-

nose Button and Diag-

nose LED

LCD MSG Meaning

available.

3.

Press the Diagnose button to manually

scroll through all of the Messages.

Page 41

TS Ref #s

VIKING

ACCESS

MODEL

H10

GATE IS

IDLE

GATE IS

OPENING

GATE IS

CLOSING

GATE IS

OPENED

GATE IS

CLOSED

STOP BY

OBSTRUCT

Welcome Message

Indicates the Model of the unit

System Status Messages

Gate is stopped between limits

Gate is opening

Gate is closing

Gate is at the limit open position

Gate is at the limit close position

Gate stopped due to an obstruction sensor event

11, 12,

13

STOP BY

OVERLOAD

OVERLAP

TIMING

HOLDING

__ SEC

EPS2

OK

38

Gate stopped due to an overload of the gate system

11, 12

Gate is waiting for the overlap time

Gate is at the limit open position and timing to close - The display shows

the actual time left - prior to time-out

Electronic Positioning Sensor is functioning properly. Will also provide an

error percentage while the motor is running

Page 41

VIKING TECHNICAL SUPPORT 1.800.908.0884

LCD Display References

LCD MSG Meaning

Multi Meter Displays

TROUBLESHOOTING

Page 41

TS Ref #s

MOT AMP

__._ A

MOT VOLT

__._ VDC

AC VOLT

__._ VAC

CHARGE

__._ VDC

BAT VOLT

__._ VDC

EPS2

___% ERR

Speed

xx%

OVERLAP

_._ SEC

This is the motor current amperage during operation

This is the actual motor voltage during operation

This is the actual low voltage AC to the Control Board from the transformer

This is the charging voltage to the batteries

This is the charging voltage when Battery Switch is OFF or the battery

voltage when the low voltage AC is discontinued to the Control Board

Board Settings Messages

Indicates that the Electronic Positioning Sensor (EPS) needs to be tuned.

Error rate is displayed as a percentage

Shows the percentage of speed set by the Speed adjustment on the control

board. (pg. 24)

Shows the number of seconds set by the Overlap Adjustment on the control board. This feature is not available on slide gate operator models

ODS SENS

Shows the amount of force required to trip the obstruction sensor. (pg. 26)

___%

TIMER

__ SEC

HEATER

__ OFF

HEATER

__ ON

LOCK MOD

Shows the time delay to hold the gate open at the limit open position,

before starts closing the gate. (pg. 24)

The Integrated Heater is disabled for the open “OPN” and/or close “CLS”

limits (pg. 27)

The Integrated Heater has been enabled to turn on at the open “OPN” and/

or close “CLS” limits (pg. 27) “*” will be displayed while it is heating

The Lock Mode feature is turned OFF (pg. 27)

OFF

LOCK MOD

The Lock Mode feature is turned ON (pg. 27)

ON

39

Page 42

VIKING TECHNICAL SUPPORT 1.800.908.0884

TROUBLESHOOTING

LCD Display References

LCD MSG Meaning

Error Messages

Page 41

TS Ref #s

ERR AC

LOW

ERR AC

HIGH

ERR AC

NO AC

ERR CHRG

HIGH

ERR CHRG

CHECK 4A

ERR BAT

LOW

ERR EPS2

WRONG

ERR EPS2

MISSING

Indicates that the is 24 VAC supply to the VFlex Board is too low from the

115/230 power supply.

Indicates that the is 24 VAC supply to the VFlex Board is too high from the

115/230 power supply.

Indicates that there is no 24 VAC supply detected to the VFlex Board from

the 115/230 power supply.

Potential problem with the charging voltage from the control board.

a) 4 Amp Fuse is blown

b) There is a problem with the batteries or the control board.

The battery is low

The EPS (Electronic Position Sensor) has one of the following conditions:

a) The EPS is not properly adjusted b) The EPS has a potential connection

problem c) The EPS has the wrong cable harness

Missing or damaged EPS2 cable harness.

1, 3, 20

1, 3, 20

1, 2, 4,

20

1, ?

18, ?

1, 2, 3,

4

?

14, 17

ERR ___

LIMIT

ERR FUSE

20 AMP

ERR EMI

NO EMI

ERR EMI

NO FUSE

ERR EMI

NO AC

ERR EMI

Unknown

ERR EMI

PROTECT

Indicates that the open “OPN”, close “CLS“ or both “NO“ limits are cleared

and need to be set.

20 Amp motor fuse is blown

No EMI board detected

4 Amp main fuse is blown on Power Supply Panel Assembly

There is no AC voltage detected from the EMI Board

There is a problem with the communication between the EMI Board and the

VFlex Board.

Lightning strike protection for the EMI Board, behind the Power Supply

Panel Assembly, needs to be replaced

6

7, 11, 12

15

2

20

21

?

40

Page 43

VIKING TECHNICAL SUPPORT 1.800.908.0884

TROUBLESHOOTING

Solutions

Begin the troubleshooting process by referring to the error messages on the LCD

Display and/or the Status LEDs on the control board. Use pages 36-40 to identify

the Troubleshooting Reference # (TS Ref#) then reference the table below.

TS Ref# CHECK Page Ref#

1

Check that the high voltage power supplied to “J-Box” is within range.

100v-120v or 200v-240v

Remove and check EMI Fuse for continuity.

2

Check that the “Voltage Selector”, on the Modular Power Box, is set according

3

to the high voltage power supply. 115v AC or 230v AC

Check that the “120VAC” switch is turned ON

4

5 Check that the Power Harness is connected to the control board.

Set the limit position.

6

7 Check Motor Fuse on the control board. pg. 4

8 Check that the “Manual Release” switch is turned to the “Engage” position. pg. 3, 11

9

Check the Status LEDs to determine if the control board is receiving an input

from any external devises or if the “ODS” has been triggered.

Remove the external devices from the control board to determine if the control

10

board is responding to an input or problem with the external device or wiring.

11

Check the gate, track and chain for any debris or cause for or resistance. Check

the “ODS” setting on the control board.

12

Check that the gate can be move manually with low resistance throughout its

full length of travel.

Check the limit position.

13

14

Check the cable for the Electronic Positioning Sensor for damage. Clean the

connection pins.

15 Check the EMI cable is properly connected to the “EMI” Connector on the

control board.

16

Check the LCD Display for Error Messages

17

Check that the cable from the Electronic Positioning Sensor is connected to the

“EPS2” port on the Control Board.

Check 4 Amp fuse on the control board

18

19

Manually adjust any setting on the Control Board to clear all wireless override

settings

20

Check for 24VAC out from the Toroidal Transformer and Power Harness

21

Check the EMI Cable and contacts betwen the EMI Board and the VFlex Board

The Control Board or EMI board may be damaged. Call Viking Techical Support

?

for further assistance

pg. 18

pg. 3, 18

pg. 3, 18

pg. 3, 18

pg. 4, 18

pg. 20-21

pg. 26,

29-32,

36,37

pg. 29-32,

36

pg. 8, 12,

26

pg. 8, 17

pg. 20-21

pg. 4

pg. 4

pg. 40

pg. 3-4

pg. 4

pg. 3, 18

pg. 2, 4

41

Page 44

Appendix (A)

“N.O.”

Anti -Tailgat e

“N.O.”

Access Control Connections

Power Connections

The control board provides a 24v DC output to power external devices and controls.

Alternatively, for devices that require a power supply other than 24v DC, the

operators Power Box contains a convenient 120v AC receptacle to connect a plug-in

transformer.

“C” = Common

Terminals Connections and Input Functions:

“N.O.” = Normally Open

Viking Terminal Function Device Terminal

“+28v” --------------------- DC Positive --------------- “+”

“GND” --------------------- DC Negative --------------- “ –”

“GND” --------------------- Relay Common --------------- “C”

“Radio” ------------------------------------------------------------- “N.O.”

If “Timer” OFF: Open - Stop - Close

If “Timer” ON: Open / Stop while closing

“U L” (see pages 10 & 11) “N.O.”

If Input is brief: Stops gate then Reverses 12 inches

If input is longer: Stops gate, does not reverse

“Re-Open” “N.O.”

If stopped: No function

If closing: Stops then Opens gate

“ATG ” A n ti-Tailgate “N.O.”

Input is received: Stops gate if closing

Input is released: Closes gate to prevent tailgating

“C. Loop” “N.O.”

If not at open limit: No function

If at open limit: Prevents gate from Closing

“Open”, “Exit”, “Fire” & “Strike” “N.O.”

If stopped: Opens gate

If closing: Stops then Opens gate

“Stop” “N.O.”

If traveling: Stops gate

“Close” “N.O.”

If stopped: Closes gate

If traveling: No function

! TECHNICAL TIP: Each input Terminal (i.e. Radio, Exit, Re-Open, UL) has a corresponding

Status LED that when illuminated indicates an input is currently being provided to the

terminal and the gate is responding accordingly. (See pages 36-37 LED References)

42

VIKING TECHNICAL SUPPORT 1.800.908.0884

Page 45

VIKING TECHNICAL SUPPORT 1.800.908.0884

Relays In General

EXIT

+28V

GND

GND

APPENDIX (A)

NOTE:

controls. These items can be purchases from your dealer or distributor.

In General

In regards to the Viking control board,

all external safety devices and access

controls contain, and are, simple relays

that provide an input to the Viking

control board when the device is

activated.

When these devices are activated,

their internal relays create a contact,

or short, between the “C” and “N.O.”

terminals This contact is what provides

the command to the Viking control

board.

! TECHNICAL TIP: Viking uses the

Normally Open “N.O.” contact from the

device, excluding “fail-safe” type photo

beams. In such instances, the Normally

Closed “N.C.” will be used instead.

Viking Access Systems does not provided the external safety devices and access

Glossary of Terms

1.

Terminal: Wire Connections.

2.

Input Terminal: On the Viking

control board, the terminal which is

labeled for a specific command (ReOpen, Exit, Radio, etc.). The N.O.

contact from the access control

device is to be connected to the Input

Terminal.

3.

Terminal Block: On the Viking

control board, a removable block

containing multiple terminals.

4.

Relay: The component of an access

control or safety device that provides

an input or command to the Viking

control board.

5.

“C” Relay Common Terminal: This is

the relay terminal that makes contact

(a short) to the N.O. terminal when the

device is activated. Always wire this

relay terminal to any “GND” terminal at

the control board.

6.

“N.O.” Relay Normally Open

Terminal: The relay terminal that has

an open contact to “C” while the relay

is not activated, and a closed contact

+

—

COM N.O.

N.C.

Not

Used

when the relay is activated. Almost

always wire this relay terminal to an

“Input Terminal” at the control board,

7.

“N.C.” Relay Normally Closed

Terminal: The relay terminal that has

a closed contact to “C” while the relay

is not activated, and an open contact

when the relay is activated. This

terminal is rarely used.

8.

Relay Coil: Contains the terminals

that provide power at the relay.

9.

“+” Relay Positive Terminal: The

positive power pole for the relay coil.

Always wire this relay terminal to any

“+28v” terminal at the control board.

10.

“–” Relay Negative Terminal: The

negative power pole for the relay coil.

Always wire this relay terminal to any

“GND” terminal at the control board.

43

Page 46

VIKING TECHNICAL SUPPORT 1.800.908.0884

Appendix (B)

Common Radio Receivers - Connections

44

Page 47

VIKING TECHNICAL SUPPORT 1.800.908.0884

Solar Applications

APPENDIX (C)

NOTE:

applications. Alternatively, individual and third party solar components can be used.

The following are minimum system requirements and installation information.

Viking recommends Solar Package (part # VA-SOCHP) for most general solar

Panels

•

Voltage 24V

•

Wattage 80W (minimum)

Cut the wires coming from the toroidal

transformer.

Connect the solar panel cables to the

power harness as shown.

Batteries & Fuse

Voltage 24V

Amp Hour 35Ah (minimum)

Fuse 10A (minimum)

Replace the operators batteries with

35Ah or greater.

! IMPORTANT: The chart provided can be used as a guide to an idea of the number of

cycles the gate will operate per day. The chart is for a single gate operator with just:

a.

One Radio Receiver

b.

One low voltage, low current loop detector

c.

One low voltage, low current photo beam

If more specific information is needed please consult with Viking Access Systems.

For more information regarding solar energy refer to www.nrel.gov/solar

45

Page 48

VIKING TECHNICAL SUPPORT 1.800.908.0884

VIKING EXPANSION PRODUCTS

VIKING KONNECT Master/Slave Kit Secure and reliable

Master/Slave communication using Vikings Konnect technology. Paired

with the Viking App, each module also doubles as a diagnostic tool.

Part# VA-KONNECT-MS

***Q-7, B-12 & ECU Operators require (2) Antenna Extension Cables (part# VA-RPSMA)***

VIKING KONNECT Diagnostic Tool On-site remote

access to the operator from the convenience of a compatible hand held

device. With the Viking App, this tool becomes and wireless extension

of the control board allowing you to view and change settings, review

diagnostic information, operate the gate for testing and update the

control boards firmware. Part# VA-KONNECT-D

***Q-7, B-12 & ECU Operators require (1) Antenna Extension Cable (part# VA- RPSMA)***

VIKING MONITOR Off-site access to operator diagnostics

and perform firmware updates from just about anywhere with cellular

service. With the Viking App, this tool allows you to monitor and label

multiple operators by site and location for quick reference. Provides error

notifications, operator status, settings and diagnostic information.

Part# VA-MONITOR

***Q-7, B-12 & ECU Operators require (1) Antenna Extension Cable (part# VA- RPSMA)***

VIKING APP Mobile device user interface application for Viking

Konnect and Viking Monitor. Available for iOS, Android and Windows

8 operating systems. Free for download from your mobile device

application store or www.vikingaccess.com

VIKING AC SURGE PRO Adds another layer of protection to

the high voltage power supply of your gate operator. Connecting the AC

Surge Pro in parallel to the incoming power wires provides protection

from surges up to 20,000 Volts / 10,000 Amps. Part# VA-SURGEPROAC

VIKING SOLAR KIT The components included in this package

are intended to provide sufficient power for general applications.

Part# VA-SOCHP

This Kit includes the following components:

(2) 12V 40W Solar Panels Part# VA-SO40W (wired in series = 24V 80W)

(2) 12V 35Ah batteries Part# DUBA35 (wired in series = 24V 35Ah)

(1) Solar Charger Part# SOCHR10

(1) Solar Power Harness Part# SOHAR

46

! NOTE: The number of cycles achieved from this kit are dependent upon

the following and may require increased panel and battery capacities:

•

Power consumption of all accessories being used

•

Average solar radiation of geographic location

Page 49

OUR CONTINUOUS COMMITMENT TO EXCELLENCE

Viking Access Systems is continuously working hard to identify and

design products that will appeal to the industry and it’s needs. As

technology continues to advance, we have developed a completely

effi cient and intelligent line of gate operators to meet the changing

demands. These machines offer; full UL325 and UL991 compliance,

soft-start and soft-stop, intelligent obstruction sensors, continuous

operation (100% duty cycle) and extreme power effi ciency. Innovative

features include; adaptive and self-learning algorithms, redundancy

design in both hardware and software to ensure operation and

functionality, protection from lightning, short circuit and power surges,

and our exclusive helical gearing offering the highest effi ciency rating

in the industry. Our entire product line is continually modifi ed and

improved based on the latest technology and our customer’s valuable

feedback. The results are products that offer accuracy, effi ciency,

reliability and performance, all in sleek, high-tech designs.

We pledge to continue establishing ourself as the leader in high quality,

innovative gate operators by developing “Next Level” technology. We

are committed to providing safety and convenience with innovative

solutions for every security gate need.

Page 50

STANDARD FEATURES

AND OPERATOR SPECIFICATIONS

• UL325 and UL991 Compliant by Underwriter

Laboratories (UL) standards.

• Externally accessible Manual Release Switch

• Fail-Safe option sets the gate to

automatically transfer to a fail-safe mode

in the event of a power failure, allowing the

gate to be pushed open without the use of

special knowledge of the equipment

• Fail- Secure option sets the gate to

electronically lock in the event of a power

failure, allowing no manual movement

without the use of the manual release

• Elegant design, appealing to any

architectural project

• Plated and powder coated steel chassis

• Adjustable travel speed

• Up to 60’ maximum gate opening

• 100% duty cycle

• Modular Power Supply Box for convenient

low voltage installations

• 100 cycles of operation on backup battery

(1000 lb. gate and 20’ length)

• Intelligent speed control with smooth start

and stop, self-adjust system

• Anti-Tailgating and Operation Pre-Warming

features

• On-Board LCD Display provides diagnostics,

operator status, settings and real-time volt

and amp readings

• Intelligent obstruction detection with

adjustable sensitivity

• Built-in climate control for cold weather

applications

• Built-in protection against lightning strikes

or similar electrical surges

• Inherent overload protection in the regulated

power supply for external accessories with

multiple devices of protection

• Modular connectors for easy access control

installation

• Solar panel and low voltage wiring

compatibility

• LED indicators display gate and operator

status for easy troubleshooting

INSTALLATION DATE: __________________________________

COMPANY / INSTALLER: ________________________________

CO N TACT: __________________________________________

SERIAL NUMBER(S): ____________________________________

ALL INSTALLATION, MAINTENANCE AND REPAIR WORK MUST BE

DOCUMENTED AND MADE AVAILABLE TO THE USER.

VIKING ACCESS SYSTEMS

631 Wald Irvine, CA 92618

Phone 800.908.0884

Fax 949.753.1640

www.vikingaccess.com

Loading...

Loading...