Page 1

GSLG-A

Slide Gate Operator

Installation Guide

Operator models contained in this manual

conform to UL325 standard for use in

Class I, II, III, and IV applications

USA & Canada (800) 421-1587 & (800) 392-0123

(760) 438-7000 - Toll Free FAX (800) 468-1340

www.linearcorp.com

Page 2

Table of Contents

Pre-installation Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Before You Begin... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Always Check the Gate’s Action . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Gate Operator Classifi cations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Approved Obstruction Detection Devices . . . . . . . . . . . . . . . . . . . . . 1

Safety Information and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Regulatory Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Wiring Specifi cations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

AC Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

DC Control and Accessory Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Mounting Pad Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Gate Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Mounting Specifi cations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Gate Bracket and Chain Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Operator Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Vent Plug Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Operator Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Controller Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Manual Disconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

AC Power Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Earth Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Open and Close Limit Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Limit Nuts Rough Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Limit Nuts Fine Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Torque Limiter Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Controller Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Indicator Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Terminal Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Operator Accessory Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Basic Controller Programming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Programming Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Entering Programming Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Exiting Programming Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Programming Keystrokes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Left or Right Hand Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Dual Gate Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Auto Close Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Run Alarm and Pre-start Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Maximum Open Direction Current Setting . . . . . . . . . . . . . . . . . . . . 12

Maximum Close Direction Current Setting . . . . . . . . . . . . . . . . . . .12

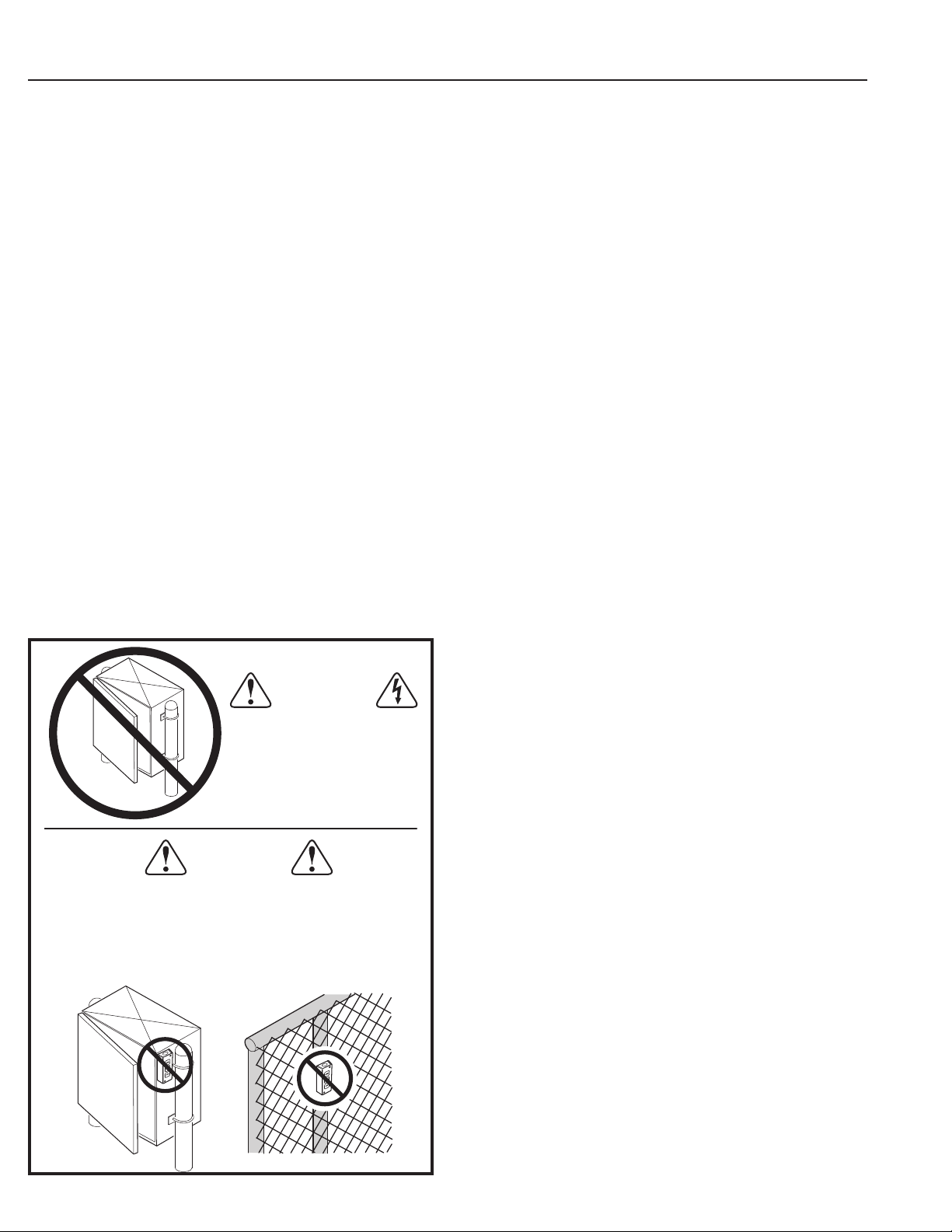

WARNING

ONLY QUALIFIED TECHNICIANS

SHOULD WORK ON

LINEAR SLIDE GATE

OPERATORS

WARNING

CONTROLS INTENDED FOR USER ACTIVATION MUST BE

LOCATED AT LEAST SIX FEET (6') AWAY FROM ANY MOVING

PART OF THE GATE AND WHERE THE USER IS PREVENTED

FROM REACHING OVER, UNDER, AROUND OR THROUGH THE

GATE TO OPERATE THE CONTROLS. OUTDOOR OR EASILY

ACCESSIBLE CONTROLS SHALL HAVE A SECURITY FEATURE

TO PREVENT UNAUTHORIZED USE.

Advanced Controller Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Entering Advanced Programming Mode . . . . . . . . . . . . . . . . . . . . .13

Maximum Run Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Single Button Input Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Stagger Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Stagger Delay Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Auxiliary Relay Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Reverse Delay Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Brake Delay Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Constant Pressure Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Shadow Loop Open Prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Reset Cycle Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Maintenance Alert Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Mid-travel Stop Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Anti-tailgate Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Radio Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Antenna Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Radio Transmitter Learn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Radio Transmitter Delete . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

MGT Obstacle Transmitter Learn . . . . . . . . . . . . . . . . . . . . . . . . . .16

MGT Obstacle Transmitter Delete . . . . . . . . . . . . . . . . . . . . . . . . . .16

Motor Type Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Loop Layout Illustration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Safety Edge Layout Illustration #1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Safety Edge Layout Illustration #2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Photoeye Installation Illustration . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Picket Gate Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Track Gate Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Dual Gate Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Optional In-Cabinet Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Gate Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Open Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Close Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Stop Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Single Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Fire Department Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Open Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Open Obstruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Close Obstruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Reverse Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Open Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Reverse Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Shadow/reset Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Operation Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Power-up Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Idle Condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Last Gate Position/Condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Pre-start Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Reverse Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Run Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Error Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Entrapment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

COMM LINK Connection Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

MGT Obstacle Transmitter Trouble . . . . . . . . . . . . . . . . . . . . . . . . .25

Maximum Run Time Exceeded . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

How to Order Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . .26

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Contacting Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Operator fails to start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Motor operates, but gate does not move . . . . . . . . . . . . . . . . . . . . .26

Motor sounds like it is working harder than normal . . . . . . . . . . . . .26

Limit switch getting out of time . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Gate stopping part way open or closed

(but no visible obstruction) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Gate staying open with automatic system . . . . . . . . . . . . . . . . . . . . 26

Preventative Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6-Month Preventative Maintenance . . . . . . . . . . . . . . . . . . . . . . . . .27

FCC Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Model GSLG-A Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Single Phase Controller Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Three Phase Controller Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Gate Operator Installation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . .32

GSLG-A Slide Gate Operator Installation Guide - ii - P1222 Revision X5 6-22-2011

Page 3

Pre-installation Information

Before You Begin...

Before unpacking, inspect the carton for exterior damage. If

you fi nd damage, advise the delivery carrier of a potential

claim. Inspect your package carefully. You can check your

accessory box parts with the enclosed packing slip for your

convenience. Claims for shortages will be honored for only

30 days from the date of shipment.

Before installing the operator, read this manual completely to

ensure all requirements for proper installation are present. Verify

that the voltage to be used matches the voltage of the operator.

If you have any questions about the requirements for proper

installation of this gate operator contact technical support at

800-421-1587

Always Check the Gate’s Action

It’s very important before installing the gate operator to

make sure the gate’s slides free and level throughout

the entire opening distance. If the gate does not seem to

operate properly, it may affect the operator performance

or greatly shorten the life of the unit. The gate should

also be designed so that airfl ow is ample to prevent

wind resistance and drag.

Gate Operator Classifi cations

All gate operators can be divided into one of four different

classifi cations, depending on their design and usage. Install

this gate operator only when the operator is appropriate for

the construction and usage class as defi ned below:

• Class I Residential Vehicular Gate Operator

A vehicular gate operator intended for use in a home or for one to

four single family dwellings with a common garage or parking area

associated with these dwellings.

• Class II Commercial / General Access Vehicular Gate Operator

A vehicular gate operator intended for use in a commercial location or

building such as a multi-family housing unit of fi ve or more single family

units, hotel, retail store or other building servicing the general public.

• Class III Industrial / Limited Access Vehicular Gate Operator

A vehicular gate operator intended for use in an industrial location or

building such as a factory or loading dock area or other location not

intended to service the general public.

• Class IV Restricted Access Vehicular Gate Operator

A vehicular gate operator intended for use in a guarded industrial

location or building such as an airport security area or other restricted

access locations not servicing the general public, in which unauthorized

access is prevented via supervision by security personnel.

Approved Obstruction Detection Devices

The following contact or non-contact obstruction detection

devices have been approved for use with this slide gate

operator as part of a UL325 compliant installation:

• Contact Edges

Miller Edge Models MGO20, MGR20, MGS20, ME120

• Photoeyes

MMTC Model IR-55 (165’ range - P/N 2520-441)

MMTC Model E3K (28’ range - P/N 2520-031)

Safety Information and Warnings

THE FOLLOWING FORMATS ARE USED FOR SAFETY NOTES

IN THESE INSTRUCTIONS.

CAUTION

This type of warning note is used to

indicate the possibility of damage to the

gate or gate operator.

WARNING

This type of warning note is used to

indicate possible mechanical hazards that

may cause serious injuries or death.

WARNING

This type of warning note is used to indicate

possible electrical shock hazards that may

cause serious injuries or death.

Regulatory Warnings

Read the following before beginning to install this slide gate

operator:

IMPORTANT INSTALLATION SAFETY INSTRUCTIONS

WARNING

TO REDUCE THE RISK OF SEVERE INJURY OR DEATH

TO PERSONS, REVIEW THESE INSTALLATION SAFETY

STEPS BEFORE PROCEEDING

1. READ AND FOLLOW ALL INSTALLATION INSTRUCTIONS.

2. Read the yellow “Safety Instructions” brochure enclosed with the

packet of information. If any pages are missing or are unreadable,

or you do not have the safety instructions, please call Linear at

1-800-333-1717 to request additional copies.

3. ALL ELECTRICAL CONNECTIONS TO THE POWER SUPPLY MUST

BE MADE BY A LICENSED ELECTRICIAN AND MUST OBSERVE ALL

NATIONAL AND LOCAL ELECTRICAL CODES.

4. A separate power-disconnect switch should be located near the

operator so that primary power can be turned off when necessary.

5. Install the enclosed warning signs on both sides of the gate. A

minimum of two (2) WARNING SIGNS shall be installed, one on each

side of the gate where easily visible.

6. Never reach between, through or around the fence to operate the

gate.

7. Never connect a button station within reach of the gate or on the

side of the gate operator.

8. Do not adjust the operator controller’s current sensing feature too

high. It should be adjusted high enough to keep the gate from falsely

triggering the sensing, but no higher than necessary for the gate to

operate. DO NOT DEFEAT THE PURPOSE OF THIS FUNCTION!

9. You must install all required safety equipment.

10. UL325 Compliance requires the use of contact edges or photoelectric

controls on all automatic or remotely-controlled gate operators.

11. The operator is intended for installation only on gates used for

vehicles. Pedestrians must be supplied with a separate access

opening. The pedestrian access opening shall be designed to

promote pedestrian usage. Locate the gate such that persons will

not come into contact with the vehicular gate during the entire path

of travel of the vehicular gate.

GSLG-A Slide Gate Operator Installation Guide - 1 - P1222 Revision X5 6-22-2011

Page 4

Wiring Specifi cations

Refer to the following steps for details on power and

accessory wiring for the operator.

WARNING

ALL AC ELECTRICAL CONNECTIONS TO THE POWER SOURCE AND

THE OPERATOR MUST BE MADE BY A LICENSED ELECTRICIAN

AND MUST OBSERVE ALL NATIONAL AND LOCAL ELECTRICAL

CODES.

USE COPPER WIRE ONLY!

AC Power Wiring

1. Find the listing on this page corresponding to the model, voltage and

horsepower rating of your operator.

2. The distance shown in the table is measured in feet from the

operator to the power source. DO NOT EXCEED THE MAXIMUM

DISTANCE. These calculations have been based on standard 115 V

and 230 V supplies with a 10% drop allowable. If your supply is under

the standard rating, the runs listed may be longer than what your

application will handle, and you should not run wire too near the

maximum distance for the gauge of wire you are using.

3. When large-gauge wire is used, a separate junction box (not

supplied) may be needed for the operator power connection.

4. Wire length calculations are based on the National Electrical Code,

Article 430 and have been carefully determined based on motor

inrush, brake solenoids, and operator requirements.

5. Connect power in accordance with local codes. The green ground

wire must be properly connected.

6. Wire insulation must be suitable to the application.

7. Electrical outlets are supplied in all 115 VAC models for convenience

with occasional use or low power consumption devices only. If

you choose to run dedicated equipment from these devices, it will

decrease the distance for maximum length and the charts will no

longer be accurate.

DC Control and Accessory Wiring

1. All control devices are now 24 VDC, which can be run up to 2000

feet with 14 AWG wire.

2. Control wiring must be run in a separate conduit from power wiring.

Running them together may cause interference and faulty signals in

some accessories.

3. A three-wire shielded conductor cable is required to connect two

operators together for dual operation. You must use Belden 8760

Twisted Pair Shielded Cable (or equivalent) only – P/N 2500-1982,

per foot). See Page 25 for details of this connection. Note: The shield

wire should be connected in both the operators.

MODEL GSLG-A SINGLE PHASE POWER WIRING

VOLTS & HP

115 VOLTS

1/2-HP

115 VOLTS

3/4-HP

115 VOLTS

1-HP

208 VOLTS

1/2-HP

208 VOLTS

3/4-HP

208 VOLTS

1-HP

230 VOLTS

1/2-HP

230 VOLTS

3/4-HP

230 VOLTS

1-HP

MODEL GSLG-A THREE PHASE POWER WIRING

VOLTS & HP

208 VOLTS

1/2-HP

208 VOLTS

3/4-HP

208 VOLTS

1-HP

230 VOLTS

1/2-HP

230 VOLTS

3/4-HP

230 VOLTS

1-HP

460 VOLTS

1/2-HP

460 VOLTS

3/4-HP

460 VOLTS

1-HP

MAXIMUM DISTANCE (FEET)

SINGLE DUAL

222 111 12

354 177 10

566 283 8

900 450 6

1430 715 4

178 89 12

282 141 10

450 255 8

716 358 6

1140 570 4

160 80 12

254 127 10

406 203 8

646 323 6

1026 513 4

760 380 12

1200 600 10

1924 962 8

3060 1830 6

4864 2432 4

604 302 12

958 478 10

1526 763 8

2424 1212 6

3856 1928 4

544 272 12

864 432 10

1374 686 8

2184 1092 6

3476 1738 4

894 447 12

1422 711 10

2264 1132 8

3600 1800 6

5724 2862 4

710 355 12

1128 564 10

1796 898 8

2852 1426 6

4538 2269 4

640 320 12

1016 508 10

1616 808 8

2570 1285 6

4090 2045 4

MAXIMUM DISTANCE (FEET)

SINGLE DUAL

1142 571 12

1816 908 10

2890 1445 8

920 460 12

1464 732 10

2330 1165 8

714 357 12

1136 568 10

1804 902 8

1344 672 12

2137 1069 10

3400 1700 8

1084 542 12

1723 862 10

2741 1371 8

840 420 12

1336 668 10

2124 1062 8

3841 1921 12

6106 3053 10

9712 4856 8

3279 1640 12

5212 2606 10

8291 4146 8

2689 1345 12

4274 2437 10

6798 3399 8

WIRE GAUGE

WIRE GAUGE

GSLG-A Slide Gate Operator Installation Guide - 2 - P1222 Revision X5 6-22-2011

Page 5

Mounting Pad Installation

The gate operator mounts bolted to posts secured in

concrete footings. The posts support the operator and

prevent it from moving during operation. For optional pad

mounting instructions, see Linear drawing #2700-360.

Gate Preparation

Before installing, make sure the gate rolls or slides freely,

and that all exposed rollers are properly covered. The gate

must be covered with fabric with openings no larger than

2-1/4” in size, to a minimum height of 72” above ground

level. On picket-style gates, if pickets are spaced less than

2-1/4” apart, mesh is optional.

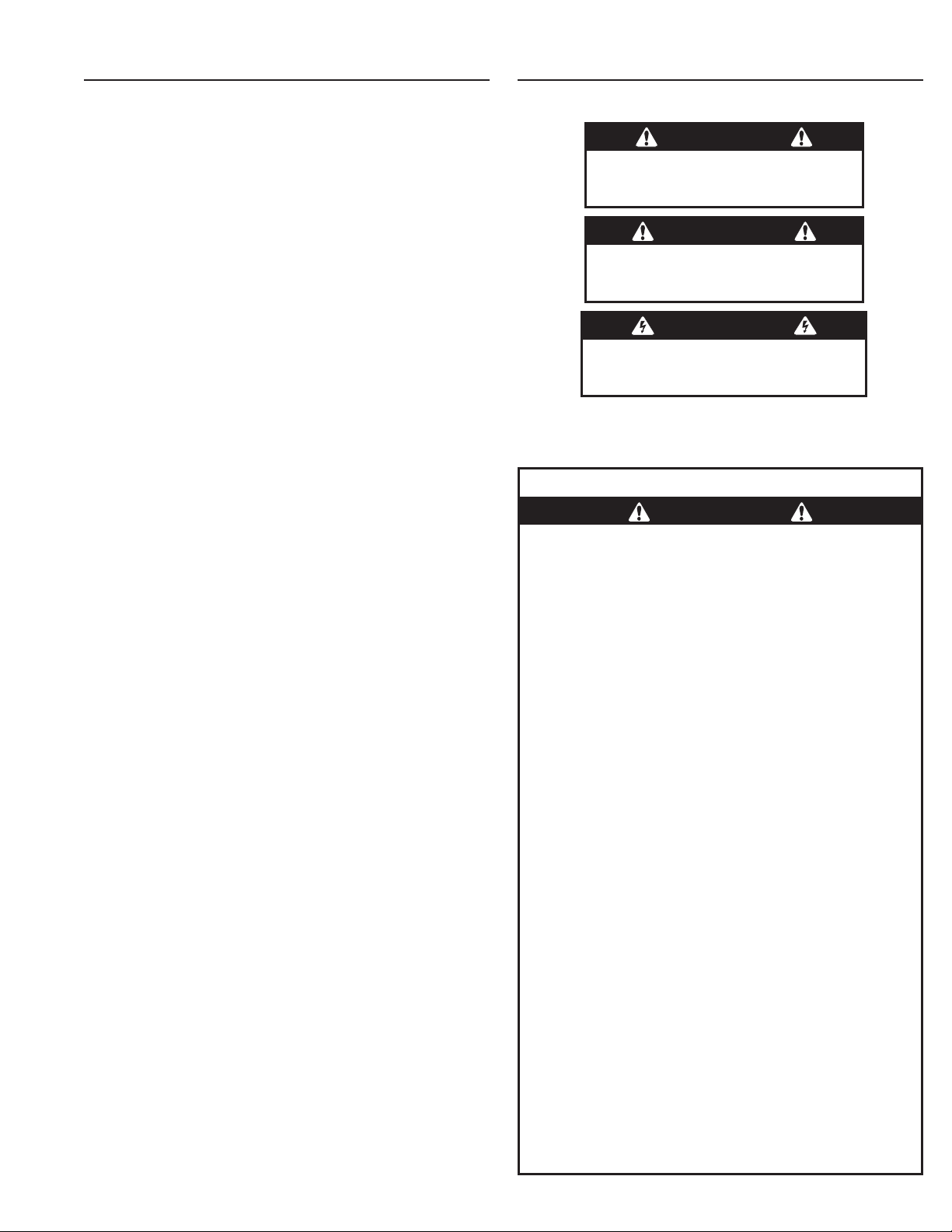

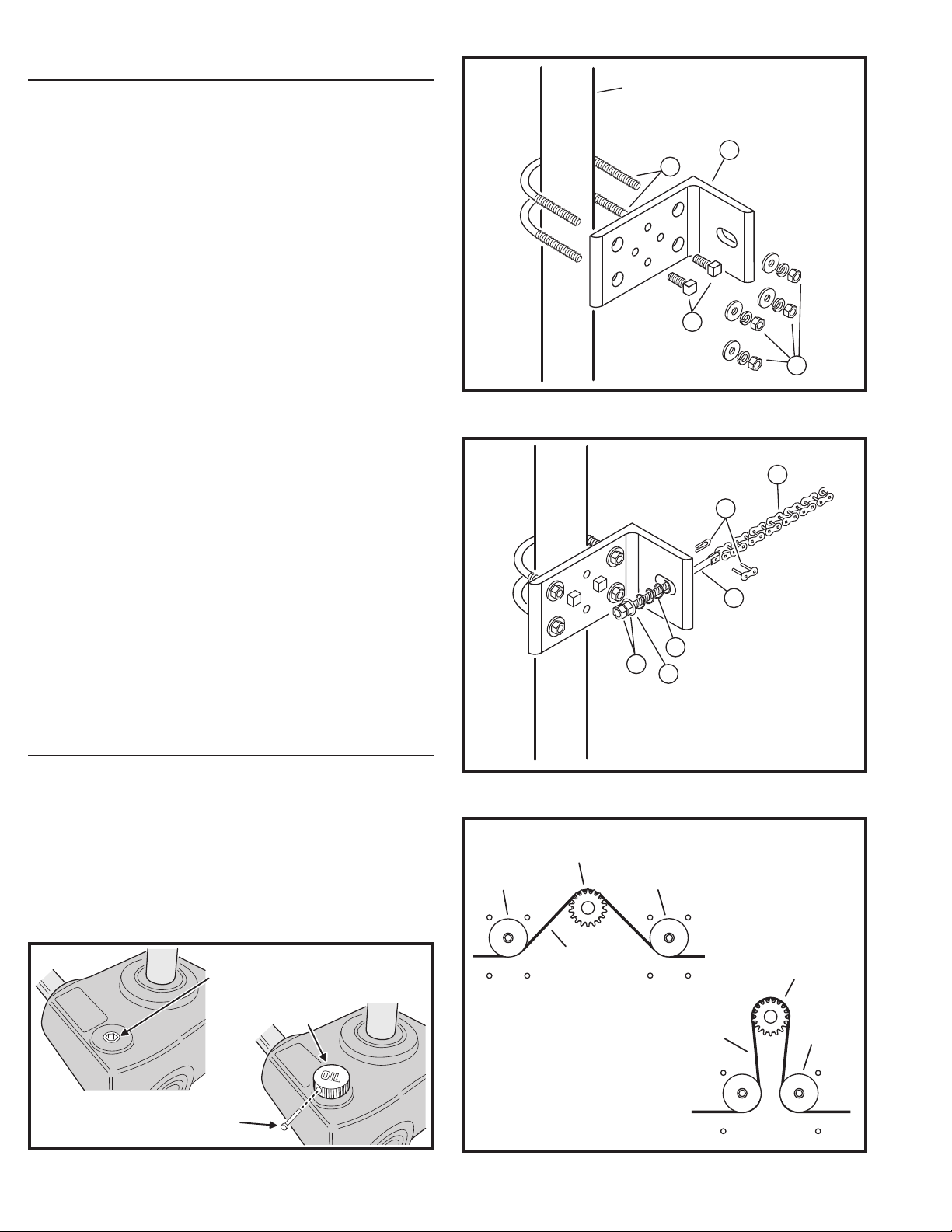

Mounting Specifi cations

Use two 3 - 3-1/2” OD galvanized posts and secure with

concrete footings as shown, length to be determined by

local codes, frost line depth and soil conditions.

Attach the operator with the U-bolts, side plates and

hardware provided. Four 3/16” side plates go on the outside

top and bottom, two 1/2” side plates go on the inside top,

and two 3/16” side plates go on the inside bottom (see the

illustration at right).

To assemble the drive chain and gate brackets, refer to

Page 4. Make sure that the chain sag does not exceed

recommended sizes and that the chain does not come into

contact with the moving parts of the gate or ground.

WARNING

The operator is intended for installation only on gates used for

vehicles. Pedestrians must be supplied with a separate access

opening. The pedestrian access opening shall be designed to

promote pedestrian usage. Locate the gate such that persons

will not come into contact with the vehicular gate during the

entire path of travel of the vehicular gate.

WARNING

The gate must be installed in a location so that enough

clearance is supplied between the gate and adjacent

structures when opening and closing to reduce the risk of

entrapment.

Figure 1. Side

Plate Installation

72”

Figure 2. Post Mounting Specifi cations

GSLG-A Slide Gate Operator Installation Guide - 3 - P1222 Revision X5 6-22-2011

Page 6

Gate Bracket and Chain Assembly

✓ NOTE: The item numbers shown in these illustrations

are for reference only. For the actual part numbers, refer

to the parts lists in the rear of this manual.

Assemble a gate bracket (1) to the front edge of the gate,

using two U-bolts (2), and mounting hardware (3). Before

tightening down completely, be sure the bracket is parallel

to the gate. Tighten the U-bolt hardware the rest of the way,

then screw the square head bolts (4) into the threaded

holes in the gate plate until they bottom out against the gate.

These will help keep the bracket from twisting on the pipe.

Slide a threaded chain pin (5) through the bracket as shown,

with spring (6), fl at washer (10), and two hex nuts (7). Attach

one end of the drive chain (8) to the chain pin using master

link (9) and begin unrolling the chain toward the operator.

Remove the rain cover from the back of the slide gate

operator. Carefully thread the drive chain under the fi rst

idler, over the drive sprocket, and then under the last idler.

Make sure you feed most of the chain through the idlers and

sprocket before attaching the chain to the back end of the

gate.

Assemble the other gate bracket on the rear edge of the

gate, using the same process as the front gate bracket.

Once this is done, take the other chain pin, spring and jam

nuts and assemble with the end of drive chain and the other

master link.

At this point you should be able to adjust the chain tension

by tightening the jam nuts on each end. Approximately

1/4” to 3/8” of slack per foot of drive chain is acceptable.

Make sure the chain does not drag on the ground, across

the gate rollers or the idler frame of the operator.

Additional mounting holes have been provided in the gate

bracket for installer convenience.

END OF GATE PIPE SHOWN

REFERENCE ONLY

1

2

4

Figure 2. Mounting Gate Bracket to Gate

8

9

5

6

7

10

3

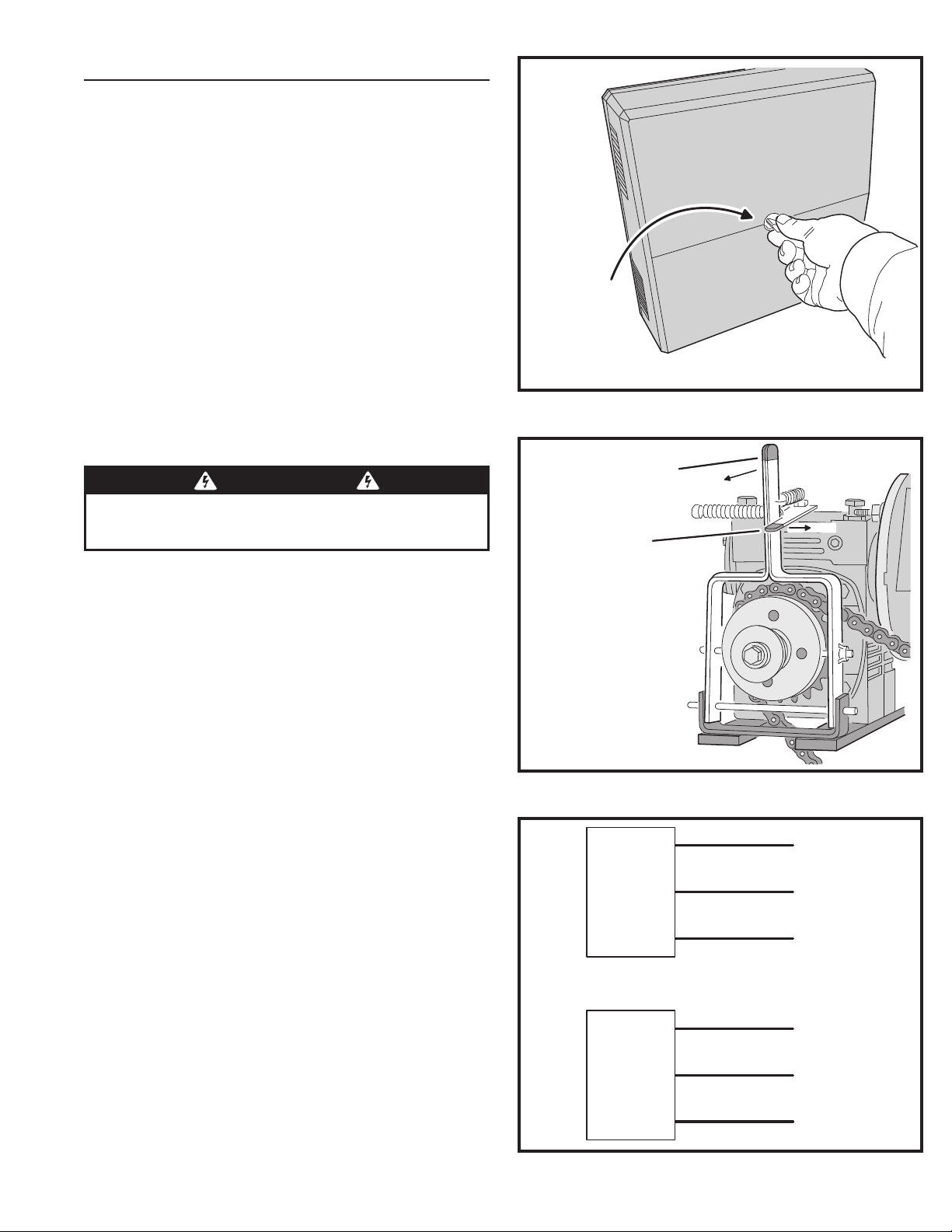

Operator Preparation

Vent Plug Installation

In order to keep gear oil from spilling out during shipping,

gear reducers used in this gate operator has either a solid

plug, or a sealed vent plug, installed at the factory.

For operators with a solid plug, replace the solid plug with

the vent plug provided (see Figure 5).

With the vent plug installed, remove the vent plug’s breather

pin to allow the gear box to vent (see Figure 5).

GEAR

REDUCER

INSTALL THE VENT PLUG

(IF NOT ALREADY INSTALLED)

GSLG-A Slide Gate Operator Installation Guide - 4 - P1222 Revision X5 6-22-2011

REMOVE THE

SOLID PLUG

WITH AN ALLEN

WRENCH

REMOVE THE

BREATHER PIN

INSTALL THE

VENT PLUG

(IF NOT ALREADY

INSTALLED)

IDLER WHEEL

NOTE: IDLER CONFIGURATION

MAY APPEAR DIFFERENT DEPENDING

ON THE SLIDE OPERATOR MODEL

Figure 3. Chain Pin and Chain Assembly

DRIVE SPROCKET

IDLER WHEEL

CHAIN

PATH

CHAIN

PATH

DRIVE

SPROCKET

Figure 4. Chain PathFigure 5. Vent Plug Installation

IDLER

WHEEL

Page 7

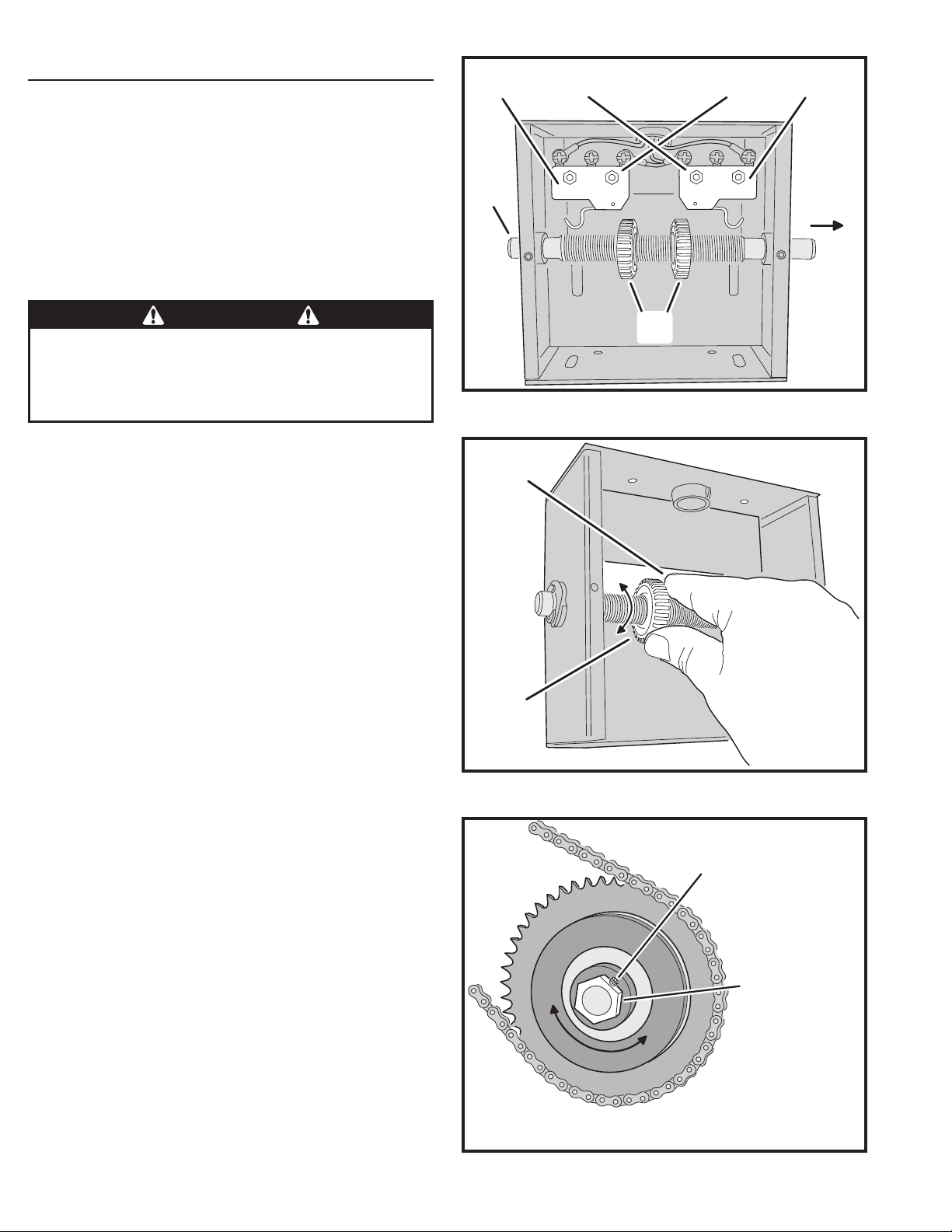

Operator Setup

Controller Access

The Controller is protected by a plastic dust cover (single

phase models only). To remove the dust cover, loosen the

cover’s wing-screw and lift the cover off (see Figure 5).

Manual Disconnect

The manual disconnect shifter lever and the locking lever is

illustrated in Figure 8. They can be found at the center and

to the left inside the operator cabinet. (The handle of each

has been fi nished in easy to spot red fi rm-grip coating.)

To disconnect the unit for manual operation, grasp the

handle of the spring-loaded shifter lever and pull it directly

toward you until the spring-loaded locking lever snaps into

place behind it. This action disengages the pinned shifter

block from the drive mechanism and holds the block in the

disengaged position.

To re-engage the operator, move the locking lever to the

right, releasing the spring-loaded shifter lever to snap back

into the engaged position.

WARNING

ALL AC ELECTRICAL CONNECTIONS TO THE POWER SOURCE AND

THE OPERATOR MUST BE MADE BY A LICENSED ELECTRICIAN AND

MUST OBSERVE ALL NATIONAL AND LOCAL ELECTRICAL CODES

AC Power Connection

All Linear gate operators are supplied with a power

disconnect switch to turn on and off the power available to

the operator (see Figure 6). Following wiring specifi cations

on Page 2, incoming power should be brought into the

operator and connected to the labeled pigtails from the

disconnect box. A wiring connections print can also be

found on the label inside the cover of the operator.

Proper thermal protection is supplied with the operator. The

motor contains a thermal overload protector to guard from

overheating the motor due to overload or high-frequency

operation. This overload protector will reset automatically

after the motor cools down.

LOOSEN KNOB

TO REMOVE

CONTROLLER

COVER

Figure 5. Controller Access

MANUAL DISCONNECT

SHIFTER LEVER

PULL TO DISENGAGE

LOCKING LEVER

PUSH TO RIGHT TO

RE-ENGAGE OPERATOR

TO MANUALLY MOVE THE GATE,

PULL SHIFTER LEVER TO

DISENGAGE THE DRIVE TRAIN

GATE LIMIT SETTINGS WILL

NOT BE AFFECTED WHEN

GATE IS MANUALLY MOVED

Figure 6. Manual Disconnect Lever

PULL

PUSH

Earth Ground

Install a ground rod and connect it to the operator’s frame

in every gate operator installation. A good earth ground

is necessary to allow the Controller’s built-in surge and

lightning protection circuitry to work effectively. The physical

bolting of the operator to the mounting pad is not suffi cient

110 VOLT

OPERATOR

POWER

DISCONNECT

BOX

BLACK

WHITE

GREEN

HOT

NEUTRAL

GROUND

for a good earth ground.

✓ NOTE: Do not splice the ground wire. Use a single piece of solid

copper 12 AWG wire between the ground rod and the operator.

1. Install an 8-foot long copper ground rod next to the operator mounting

pad within three feet of the operator.

2. Use a clamp to connect a solid copper 12 AWG ground wire to the

ground rod.

3. Route the ground wire to the operator.

4. Connect the ground wire to the operator’s frame.

220 VOLT

OPERATOR

POWER

DISCONNECT

BOX

BLACK

WHITE

GREEN

HOT

HOT

GROUND

Figure 7. Power Disconnect Box Wiring

GSLG-A Slide Gate Operator Installation Guide - 5 - P1222 Revision X5 6-22-2011

Page 8

Operator Setup (Cont.)

Open and Close Limit Adjustment

The limit nuts are not preset at the factory and must be adjusted

for the gate in each installation. The limit switches are activated

by two threaded nylon rotary limit nuts which are attached to

a threaded limit shaft driven by a chain and sprockets from

the main drive shaft. REMOVE THE CARDBOARD FILLER

BEFORE ADJUSTING THE LIMIT NUTS.

The Controller is factory setup for right hand installations.

The OPEN limit switch is the one closer to the front of the

operator. In left hand installations, the CLOSE limit switch is

the one closer to the front of the operator (see Figure 8).

RIGHT-HAND INSTALLATION

OPEN LIMITCLOSE LIMIT

LIMIT

SHAFT

LIMIT

SWITCHES

LEFT-HAND INSTALLATION

OPEN LIMIT CLOSE LIMIT

FRONT OF

OPERATOR

CAUTION

If the operator is installed in a left-hand installation. Set the

Controller to left-hand operation BEFORE running the operator

for the fi ne setting of the limit nuts. Failure to do so will result

in over-shooting the limit switches, and can cause damage to

the operator and/or gate. Refer to programming on Page 11.

Limit Nuts Rough Adjustment

Before running the operator, set the limit nuts as follows:

1. With the gate connected to the gate operator in a mid-travel position,

the power disconnect switch turned OFF, disconnect the operator

by using the manual disconnect lever, once the operator has been

disconnected, manually move the gate by hand to within a foot of

its fully open position (the foot of distance is necessary to allow for

coasting of the operator after the limit switch is tripped).

2. Once the gate is in this position, adjust the OPEN limit nut until it

activates the limit switch for open. Press down the detent plate and

rotate the nut along the threaded shaft (see Figure 9).

3. After setting the open limit, move the gate to one foot from fully

closed and repeat the process for the CLOSE limit nut.

Limit Nuts Fine Adjustment

After fi nishing the rough limit nut adjustments, reposition the

gate to approximately the center of travel.

1. Re-engage the operator using the disconnect handle.

2. Turn the power disconnect switch ON.

3. Stand clear of any moving parts and press the OPEN button.

4. After the gate opens, press the CLOSE button.

5. Observe the gate in both directions as it runs through each complete

cycle. Adjust the open or close limit nuts again if necessary. Fine levels

of adjustment can be made by adjusting a few teeth on the nut at a

time. If the gate stops during travel, you may need to adjust the Open or

Close Current Setting or the Maximum Run Timer (see Pages 12-13).

Torque Limiter Adjustments

Before adjusting the torque limiter, make sure the gate is in

good working condition. One person should be able to move

the gate by hand. Be certain the gate moves freely and

without binding throughout its travel. Torque limiters are set

light at the factory and must be adjusted during installation.

Adjust the torque limiter tight enough to keep it from slipping

during normal operation. See Figure 10.

To adjust the torque limiter in model GSLG-A:

1. Loosen the setscrew in the adjustment nut.

2. To increase the output, turn the adjustment nut clockwise

one fl at, or 1/6 turn, at a time until desired output is obtained.

To reduce the output, turn the adjustment nut counterclockwise one

fl at, or 1/6 turn, at a time until desired output is obtained.

3. Retighten the setscrew in the adjustment nut when fi nished.

Figure 8. Limit Box Assembly

PRESS DETENT

PLATE DOWN

ROTATE

LIMIT NUT

Figure 9. Setting the Limits

MORE

TIGHTEN SET SCREW

DURING TESTING

AND WHEN FINISHED !!!

Figure 10. Torque Limiter Adjustment

LIMIT

NUTS

LESS

LOOSEN SET SCREW ON

THE ADJUSTMENT NUT

ADJUSTMENT NUT

TO INCREASE TORQUE

TURN ADJUSTMENT NUT

CLOCKWISE ONE FLAT

THEN RE-TEST

TO DECREASE TORQUE

TURN ADJUSTMENT NUT

COUNTERCLOCKWISE

ONE FLAT THEN RE-TEST

GSLG-A Slide Gate Operator Installation Guide - 6 - P1222 Revision X5 6-22-2011

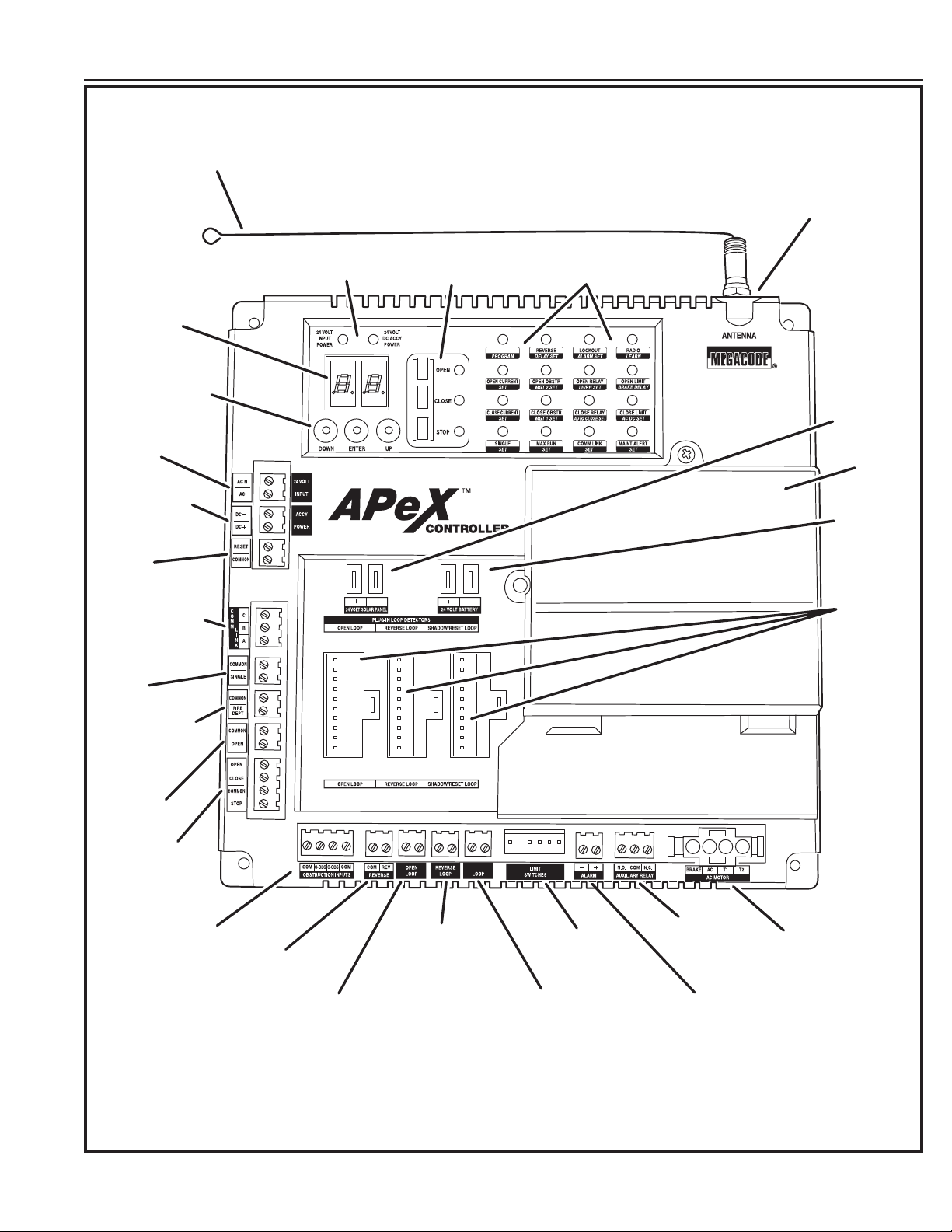

Page 9

Controller Features

WHIP

ANTENNA

ANTENNA

CONNECTOR

DISPLAY

PROGRAMMING

INPUT

POWER

TERMINALS

ACCESSORY

TERMINALS

RESET

BUTTON

TERMINALS

PRIMARY/

SECONDARY

COMM LINK

TERMINALS

SINGLE

INPUT

TERMINALS

BUTTONS

POWER

POWER

INDICATORS

OPERATION

BUTTONS

OPERATION AND

PROGRAMMING

INDICATORS

SOLAR

PANEL

TERMINALS

MOTOR

BOARD

COVER

BATTERY

TERMINALS

PLUG-IN

LOOP

DETECTOR

CONNECTORS

FIRE DEPT

INPUT

TERMINALS

OPEN INPUT

TERMINALS

3-BUTTON

STATION

TERMINALS

OPEN AND CLOSE

OBSTRUCTION

INPUT TERMINALS

REVERSE

INPUT

TERMINALS

OPEN LOOP

INPUT TERMINALS

SHADOW/RESET

REVERSE LOOP

INPUT TERMINALS

SHADOW/RESET LOOP

INPUT TERMINALS

LIMIT SWITCH

INPUT TERMINALS

Figure 11. Controller Features

AUXILIARY

RELAY

TERMINALS

ALARM

OUTPUT

TERMINALS

AC MOTOR

OUTPUT

TERMINALS

GSLG-A Slide Gate Operator Installation Guide - 7 - P1222 Revision X5 6-22-2011

Page 10

Indicator Descriptions

INDICATOR DEFINITION

OPERATION PROGRAMMING

24 VOLT INPUT

POWER

24 VOLT DC

ACCY POWER

LOW VOLTAGE AC POWER IS PRESENT

LOW VOLTAGE DC POWER IS PRESENT

INDICATION WHEN LIT

DURING NORMAL OPERATION

INDICATION WHEN LIT

DURING PROGRAMMING

OPEN SIGNAL PRESENT FROM THE INTERNAL

OPEN

RECEIVER OR AN EXTERNAL DEVICE

CONNECTED TO THE OPEN INPUT TERMINAL

CLOSE

STOP

CLOSE SIGNAL IS PRESENT FROM A DEVICE

CONNECTED TO THE CLOSE INPUT TERMINAL

STOP INPUT TERMINAL IS OPEN AND

NOT CONNECTED TO COMMON

PROGRAM CONTROLLER IS IN PROGRAMMING MODE

REVERSE DELAY SET SIGNAL FROM REVERSING DEVICE IS PRESENT SET REVERSE DELAY TIME

LOCKOUT ALARM SET

RADIO LEARN

OPEN CURRENT SET

CONTROLS AND OPERATOR ARE LOCKED OUT

BECAUSE OF EXISTING TROUBLE CONDITION

BUILT-IN RECEIVER IS DETECTING A RADIO

SIGNAL FROM A REMOTE CONTROL

MOTOR CURRENT HAS EXCEEDED THE

OPEN CURRENT SETTING WHILE OPENING

SET RUN ALARM AND PRE-START ALARM

TRANSMITTERS CAN BE ENTERED INTO

MEMORY (UP TO 40 TRANSMITTERS)

SET MAXIMUM OPEN CURRENT

OPEN OBSTRUCTION TERMINAL CONNECTED

OPEN OBSTR MGT 2 SET

TO COMMON BY BEAM OR SAFETY EDGE, OR

SET MGT #2 FUNCTION

SIGNAL FROM MGT OBSTACLE TRANSMITTER

OPEN RELAY LH/RH SET OPEN RELAY IS ACTIVATED SET LEFT-HAND RIGHT-HAND OPERATION

OPEN LIMIT BRAKE DELAY OPEN LIMIT SWITCH IS ACTIVATED

CLOSE CURRENT SET

MOTOR CURRENT HAS EXCEEDED THE

CLOSE CURRENT SETTING WHILE CLOSING

SET MAXIMUM CLOSE CURRENT

CLOSE OBSTRUCTION TERMINAL CONNECTED

CLOSE OBSTR MGT 1 SET

TO COMMON BY BEAM OR SAFETY EDGE, OR

SET MGT #1 FUNCTION

SIGNAL FROM MGT OBSTACLE TRANSMITTER

CLOSE RELAY AUTO CLOSE SET CLOSE RELAY IS ACTIVATED SET AUTO-CLOSE TIME

CLOSE LIMIT AC DC SET CLOSE LIMIT SWITCH IS ACTIVATED SET MOTOR TYPE

SINGLE SET

SINGLE TERMINAL CONNECTED TO COMMON

BY AN EXTERNAL PUSHBUTTON OR RADIO

SET SINGLE BUTTON INPUT FUNCTION

MAX RUN SET MAXIMUM RUN TIMER HAS BEEN EXCEEDED SET MAXIMUM RUN TIME

COMM LINK SET

DUAL OPERATOR CONNECTION DETECTED,

BLINKS IF CONNECTION HAS FAILED

MAINT ALERT SET MAINTENANCE IS REQUIRED ON OPERATOR SET MAINTENANCE ALERT CYCLE COUNT

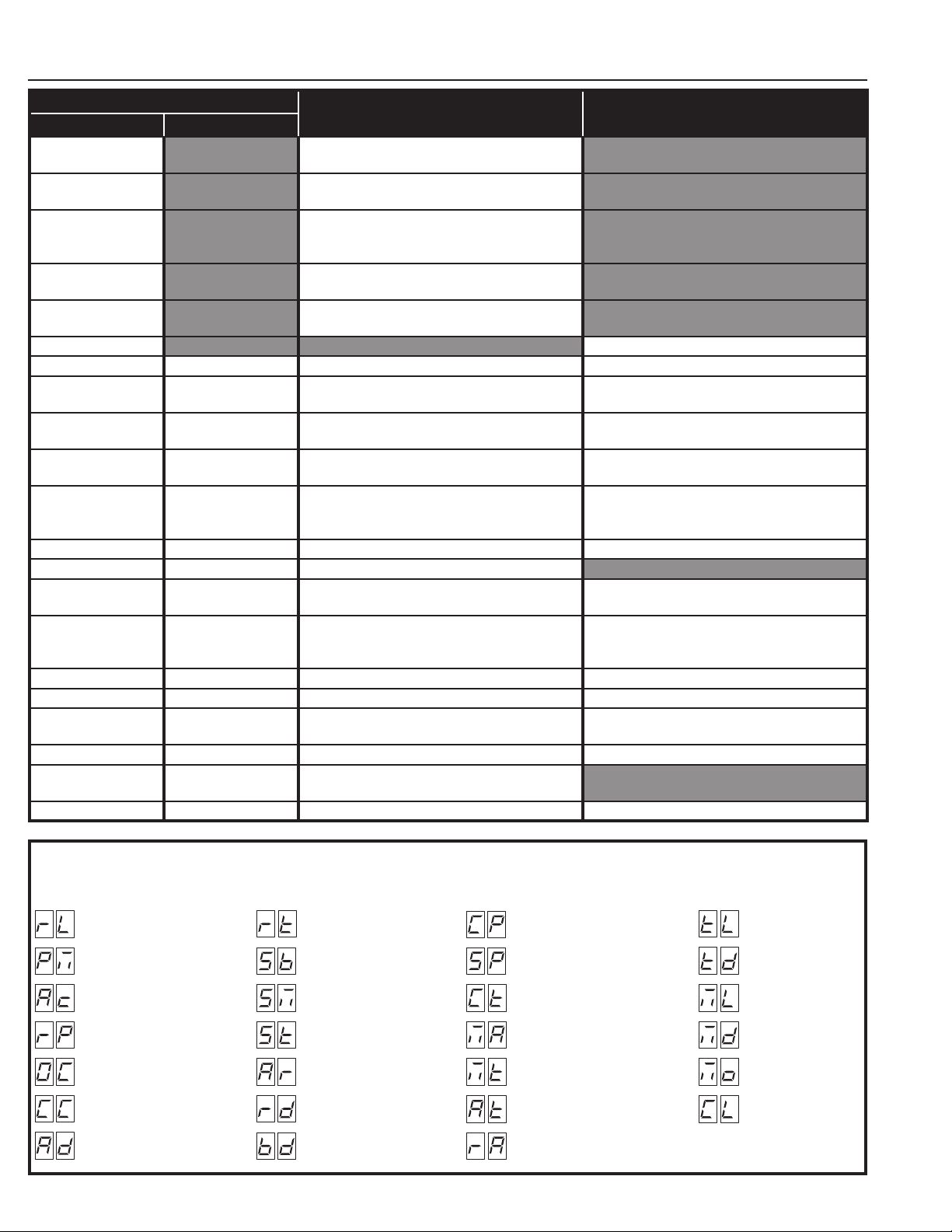

APEX FUNCTION DISPLAY INDICATIONS

"RL"

"PM"

"AC"

"RP"

"OC"

"CC"

"AD"

LEFT OR RIGHT

HAND OPERATION

SINGLE OR

DUAL GATE

AUTO CLOSE

TIMER

RUN ALARM

PRE-START ALARM

MAXIMUM OPEN

CURRENT

MAXIMUM CLOSE

CURRENT

ADVANCED

PROGRAMMING

"RT"

"SB"

"SM"

"ST"

"AR"

"RD"

"BD"

MAXIMUM

RUN TIMER

SINGLE BUTTON

INPUT SETUP

STAGGER

MODE

STAGGER

TIME

AUXILIARY

RELAY MODE

REVERSE

DELAY TIME

BRAKE

DELAY TIME

CONSTANT

"CP"

PRESSURE MODE

SHADOW LOOP

"SP"

OPEN INHIBIT

RESET CYCLE

"CT"

COUNT

MAINTENANCE ALERT

"MA"

TRIGGER

MID-TRAVEL

"MT"

STOP POSITION

ANTI-TAILGATE

"AT"

ENABLE

RADIO

"RA"

ENABLE

GSLG-A Slide Gate Operator Installation Guide - 8 - P1222 Revision X5 6-22-2011

"TL"

"TD"

"ML"

"MD"

"MO"

"CL"

LEARN

TRANSMITTERS

DELETE

TRANSMITTERS

LEARN MGT

TRANSMITTERS

ERASE MGT

TRANSMITTERS

MOTOR TYPE

SELECTION

RESET TO

FACTORY DEFAULTS

Page 11

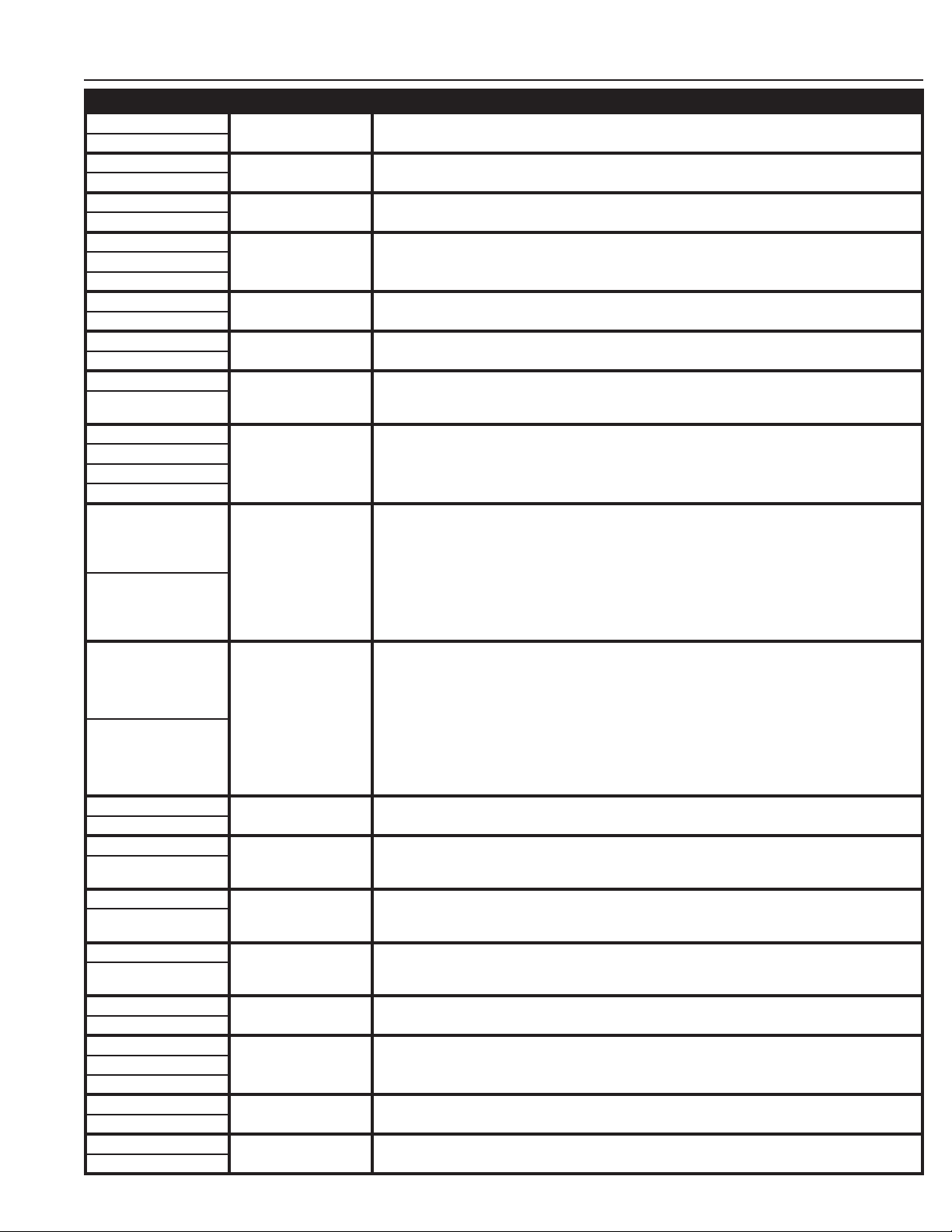

Terminal Descriptions

TERMINAL GROUP FUNCTION

AC N

AC

DC DC +

RESET

COMMON

C

A

COMMON

SINGLE

COMMON

FIRE DEPT

COMMON

OPEN

OPEN

CLOSE

COMMON

STOP

24 VOLT INPUT

ACCESSORY POWER PROVIDES 24 VOLT DC POWER FOR ACCESSORIES. (.5A MAX)

RESET BUTTON FACTORY CONNECTED TO THE CONTROLLER’S RESET BUTTON.

COMM LINK FOR 3-WIRE NETWORK CONNECTION TO SECOND OPERATOR IN DUAL GATE INSTALLATIONS.B

SINGLE BUTTON INPUT

FIRE BOX INPUT CONNECT TO NORMALLY OPEN SWITCH IN FIRE BOX FOR FIRE DEPARTMENT ACCESS.

OPEN INPUT

3-BUTTON

STATION INPUT

FACTORY CONNECTED TO 24 VAC FROM TRANSFORMER OR

24 VDC FROM CONTINUOUS DUTY DC SUPPLY.

CONNECT TO NORMALLY OPEN SWITCH FOR SINGLE BUTTON OPERATION. ALTERNATES

BETWEEN OPEN-CLOSE OR OPEN-STOP-CLOSE DEPENDING ON PROGRAMMING.

CONNECT TO NORMALLY OPEN DEVICES (KEYPAD, CARD READER, KEYSWITCH,

TELEPHONE ENTRY SYSTEM) TO OPEN THE GATE. A CONSTANT OPEN INPUT WILL

OVERRIDE THE MID-TRAVEL STOP AND HALT THE AUTO CLOSE TIMER UNTIL RELEASED.

CONNECT TO 3-BUTTON STATION FOR OPEN-CLOSE-STOP CONTROL. A CONSTANT OPEN INPUT

WILL OVERRIDE THE MID-TRAVEL STOP AND HALT THE AUTO CLOSE TIMER UNTIL RELEASED.

COM

O-OBS

C-OBS

COM

COM

REV

OPEN LOOP

OPEN LOOP

REVERSE LOOP

REVERSE LOOP

SHADOW/RESET LOOP

SHADOW/RESET LOOP

+

N.O.

COM

N.C.

+

+

-

CONNECT TO NORMALLY OPEN DEVICES (GATE EDGE, PHOTO BEAM) TO DETECT AN

OBSTRUCTION DURING OPENING. WHILE GATE IS MOVING, ANY OPEN OBSTRUCTION

OPEN

OBSTRUCTION

INPUT

CLOSE

OBSTRUCTION

INPUT

REVERSE

OPEN LOOP

REVERSE LOOP

SHADOW/RESET LOOP

ALARM FACTORY CONNECTED TO THE ALARM BEEPER.

AUX RELAY

24 VOLT SOLAR PANEL NOT USED WITH THIS MODEL OPERATOR

24 VOLT BATTERY NOT USED WITH THIS MODEL OPERATOR

SIGNAL WILL CAUSE THE GATE TO STOP, REVERSE A SHORT DISTANCE, AND THEN STOP

AGAIN. AT THIS TIME THE AUTO CLOSE TIMER IS DISABLED, AND A RENEWED INPUT

WILL BE REQUIRED TO START THE GATE AGAIN. SHOULD THE GATE BE RESTARTED

AND THE OBSTACLE SIGNAL OCCUR AGAIN PRIOR TO REACHING A LIMIT, THE GATE

WILL STOP AGAIN, LOCKOUT, AND SOUND THE CONTINUOUS TONE ALARM.

CONNECT TO NORMALLY OPEN DEVICES (GATE EDGE, PHOTO BEAM) TO DETECT AN

OBSTRUCTION DURING CLOSING. WHILE GATE IS MOVING, ANY CLOSE OBSTRUCTION

SIGNAL WILL CAUSE THE GATE TO STOP, THEN REVERSE AND TRAVEL TO THE FULL

OPEN POSITION. SHOULD A OPEN OBSTRUCTION INPUT OR AN OPEN DIRECTION

INHERENT ENTRAPMENT CONDITION OCCUR PRIOR TO THE GATE REACHING THE

OPEN LIMIT, THE OPERATOR WILL LOCKOUT AND SOUND THE CONTINUOUS TONE

ALARM. IF THE AUTO CLOSE TIMER IS SET, WHEN THE CLOSE OBSTRUCTION INPUT

IS CLEARED, THE GATE WILL CLOSE WHEN THE AUTO CLOSE TIMER EXPIRES.

CONNECT TO NORMALLY OPEN DEVICES TO CAUSE A REVERSAL WHEN THE GATE IS

TRAVELING CLOSED. THE GATE WILL REVERSE TO THE FULL OPEN POSITION.

CONNECT TO OPEN LOOP/FREE EXIT LOOP. THE GATE WILL OPEN

WHEN THE LOOP IS TRIGGERED, AND REMAIN OPEN AS LONG AS

THE LOOP IS TRIGGERED. REQUIRES LOOP DETECTOR.

CONNECT TO REVERSE LOOP. TRIGGERING THE LOOP WILL CAUSE A

REVERSAL WHEN THE GATE IS TRAVELING CLOSED. THE GATE WILL REVERSE

TO THE FULL OPEN POSITION. REQUIRES LOOP DETECTOR.

CONNECT TO SHADOW/RESET LOOP TO KEEP THE GATE IN ITS FULLY OPEN

POSITION AS LONG AS THE SIGNAL IS PRESENT. USED TO KEEP GATE OPEN

WHILE VEHICLE IS PASSING THROUGH. REQUIRES LOOP DETECTOR.

FOR CONNECTION TO AUXILIARY DEVICES (MAGNETIC LOCK, SOLENOID LOCK,

STROBE LIGHT) FOR ACTIVATION (OR DEACTIVATION) DURING GATE OPERATION.

GSLG-A Slide Gate Operator Installation Guide - 9 - P1222 Revision X5 6-22-2011

Page 12

Operator Accessory Connections

3-BUTTON STATION

KEYSWITCH

FIRE ACCESS SWITCH

TELEPHONE ENTRY

KEYPAD

SOLENOID LOCK

EXTERNAL POWER

PHOTOEYE FOR REVERSE

PHOTOEYE FOR CLOSE OBSTRUCTION

PHOTOEYE FOR OPEN OBSTRUCTION

SINGLE-CHANNEL RADIO RECEIVER

TWO-CHANNEL RADIO RECEIVER

CHANNEL #1

OPEN/CLOSE

MAGLOCK

GATE EDGE SENSOR FOR REVERSE

WARNING STROBE OR AUDIBLE SOUNDER

WIRELESS GATE EDGE SENSOR

MGT

TRANSMITTER

Figure 12. Operator Accessory Connections

GSLG-A Slide Gate Operator Installation Guide - 10 - P1222 Revision X5 6-22-2011

Page 13

Basic Controller Programming

Programming Overview

The Controller can be programmed with various options for the operator.

The programming fi elds are defi ned as “functions” that have “options”.

To make setup easier for the installer, the Controller’s programming is

divided into two groups: basic and advanced. The basic programming

group contains the functions commonly used in most slide gate

installations. The advanced programming group contains functions less

commonly used (i.e. dual gate stagger delay, maximum run timer, etc.).

Entering Programming Mode

Enter programming mode by pressing the UP and DOWN buttons

together for one second. While in programming mode the PROGRAM

indicator will light.

Exiting Programming Mode

Exit programming mode at any time by pressing the UP and DOWN

buttons together. The Controller will automatically exit programming

mode after three minutes of inactivity.

Programming Keystrokes

(Typical Programming Method)

While in programming mode, press the UP or DOWN buttons to scroll

through the programming functions. When the desired function is

displayed press the ENTER button to display the currently set option for

the function. When an option is displayed, the decimal points are lit.

To change the option, press and hold the ENTER button for 1 second. To

indicate that an option is ready to be changed, the display will fl ash. While

the display is fl ashing, press the UP or DOWN button to display the other

options available for that function.

When the desired option is displayed, press the ENTER button to store

it into memory. To select another function, press ENTER, UP, or DOWN.

Left or Right Hand Operation

The factory default is for right hand operation (operator on right side of

the driveway when viewed from the inside of the gate). For left hand

installations, program the Controller for left hand operation.

Dual Gate Enable

The factory default is for single gate operation. For dual gate operation,

wire the two gate controllers together through the COMM LINK terminals

(see Page 25) and enable dual gate operation with this programming

step.

✓ NOTE: The Mid-travel Stop feature is disabled when dual gate

operation is enabled for paired units.

Auto Close Timer

The factory default turns off the Auto Close Timer. The timer can be set

from 1 to 59 seconds and from 1 to 9 minutes. When the Auto Close

Timer is set, after opening, the gate will wait for the length of the Auto

Close Timer then close automatically.

DOWN UP

PRESS DOWN AND UP

BUTTONS TOGETHER

FOR ONE SECOND

ENTERING

PROGRAMMING

SELECT

FUNCTION

UP

OR

DOWN

PRESS UP OR DOWN

TO SCROLL DISPLAY

THROUGH FUNCTIONS

ENTER

PROGRAMMING

KEYSTROKES

FUNCTION

"RL"

LEFT HAND

RIGHT HAND

FUNCTION

"PM"

SINGLE GATE

DUAL GATE

FUNCTION

"AC"

PRESS UP OR

DOWN TO CYCLE

THROUGH OPTIONS

PRESS ENTER TO

SELECT AN OPTION

PROGRAM

INDICATOR

AND

PROGRAM INDICATOR

WILL LIGHT WHEN SYSTEM

IS IN PROGRAM MODE

CURRENTLY

SET OPTION

PRESS ENTER TO

DISPLAY CURRENTLY

OPTION READY

TO CHANGE

ENTER ENTER ENTER

PRESS ENTER FOR

ONE SECOND TO

SELECT OPTION

(THE DISPLAY

WILL FLASH)

SET OPTION

DOWN TO CYCLE

THROUGH OPTIONS

PRESS ENTER TO

SELECT AN OPTION

DOWN TO CYCLE

THROUGH OPTIONS

PRESS ENTER TO

SELECT AN OPTION

TO CHANGE

OPTIONS

PRESS UP OR

OPTIONS

PRESS UP OR

OPTIONS

CHOOSE

OPTION

UP

OR

DOWN

PRESS ENTER

PRESS UP

OR DOWN

OPTION

RIGHT HAND INSTALLATION

(OPERATOR ON RIGHT OF GATE

WHEN VIEWED FROM INSIDE)

LEFT HAND INSTALLATION

(OPERATOR ON LEFT OF GATE

WHEN VIEWED FROM INSIDE)

SINGLE GATE INSTALLATION

DUAL GATE INSTALLATION

AUTO CLOSE TIMER DISABLED

SET TIMER VALUE

1 TO 59 SECONDS

SET TIMER VALUE

1 TO 9 MINUTES

TO STORE

OPTION

PRESS UP, DOWN

OR ENTER SELECT

NEXT FUNCTION

OPTION

STORED

OR

UP

OR

DOWN

SELECT

FUNCTION

AUTO CLOSE

TIMER

GSLG-A Slide Gate Operator Installation Guide - 11 - P1222 Revision X5 6-22-2011

Page 14

Basic Controller Programming (Cont.)

Run Alarm and Pre-start Alarm

The factory default is Run Alarm on and a 3-second Pre-start Alarm. The

operator’s beeper will sound 3 seconds before the operator starts. The

options are:

• Run Alarm Off and Pre-start Alarm Off

• Run Alarm On and Pre-start Alarm Off

• Run Alarm On and Pre-start Alarm On for 1-9 Seconds

Maximum Open Direction Current Setting

To detect obstacles or mechanical problems with the gate, the operator

monitors its motor current. If the open current load exceeds the

programmed maximum load range number, the operator will stop, reverse

a short distance, then stop again. The Auto Close Timer will be disabled,

and another open request will be required to start the operator again. If

after restart, the overload or an open obstacle happens again before the

open limit is reached, the operator will lockout and sound the alarm.

To measure the motor load used during opening, while this function is

being displayed, push and hold the OPEN button to fully open the gate.

During movement, the motor current will be displayed as a load number

from 0 to 99. This number is useful for troubleshooting but not for setting

the motor current. At the end of travel, a different number will fl ash. This

number indicates the range above and below the average motor current

during the run. Using the + and - buttons, set the programmed range

number so that a minimal force (50-75 lbs.) will activate a reversal should

an obstruction occur, but high enough to keep the gate moving under

normal conditions without interruption.

FUNCTION

"RP"

PRESS UP OR

DOWN TO CYCLE

THROUGH OPTIONS

PRESS ENTER TO

SELECT AN OPTION

RUN ALARM

PRE-START ALARM

FUNCTION

"OC"

MAX OPEN

CURRENT

FUNCTION

"CC"

OPTIONS

RUN ALARM OFF

PRE-START ALARM OFF

RUN ALARM ON

PRE-START ALARM OFF

RUN ALARM ON

PRE-START ALARM ON FOR 1 - 9 SECONDS

OPTIONS

PRESS AND HOLD THE OPEN BUTTON

UNTIL THE OPERATOR RUNS FULLY OPEN

SUGGESTED MINIMUM NUMBER WILL

FLASH, ADJUST TO THE PROPER FORCE

PRESS ENTER TO STORE THE FORCE

ENTER

OPTIONS

PRESS AND HOLD THE CLOSE BUTTON

UNTIL THE OPERATOR RUNS FULLY CLOSED

Maximum Close Direction Current Setting

To detect obstacles or mechanical problems with the gate, the

operator monitors its motor current. If the close current load exceeds

the programmed maximum load range number, the operator will stop,

reverse, and travel to the full open position. Should a open obstruction

input or an open direction inherent entrapment condition occur prior to

the gate reaching the open limit, the operator will lockout and sound the

continuous tone alarm. Another close request will be required to start the

operator again. If after restart, the overload or a close obstacle happens

again before the close limit is reached, the operator will lockout and

sound the alarm. If the auto close timer is set, when the close obstruction

input is cleared, the gate will close when the auto close timer expires.

To measure the motor load used during closing, while this function is

being displayed, push and hold the CLOSE button to close the gate.

During movement, the motor current will be displayed as a load number

from 0 to 99. This number is useful for troubleshooting but not used for

setting the motor current. At the end of travel, a different number will fl ash.

This number indicates the range above and below the average motor

current during the run. Using the + and - buttons, set the programmed

range number so that a minimal force (50-75 lbs.) will activate a reversal

should an obstruction occur, but high enough to keep the gate moving

under normal conditions without interruption.

MAX CLOSE

CURRENT

SUGGESTED MINIMUM NUMBER WILL

FLASH, ADJUST TO THE PROPER FORCE

PRESS ENTER TO STORE THE FORCE

ENTER

GSLG-A Slide Gate Operator Installation Guide - 12 - P1222 Revision X5 6-22-2011

Page 15

Advanced Controller Programming

Entering Advanced Programming Mode

To access and program the Advanced Programming functions, for each

programming session, Advanced Programming must be enabled.

After exiting programming, the Advanced Programming functions

will be available on the programming display during the next

programming session unless the operator has run 50 or more

cycles. After that, Advanced Programming must be enabled again.

Maximum Run Time

The factory default for the Maximum Run Time (MRT) is 99 seconds.

When the operator starts, a timer will begin counting. If a open or close

limit is not reached or an obstacle or reversing input is not received

before the timer expires, the operator will stop, the unit locks out and the

alarm sounds. The timer can be set for 10 to 99 seconds, but should be

left at 99 in most applications. Setting it too close to the actual run time

may cause the time to expire with changing ambient temperature, gate

conditions, etc…

If AC is present and an open or close limit is not reached or an obstacle

or reversing input is not received before this timer exceeds MRT, the

operator will stop, the unit locks out and the alarm sounds.

Single Button Input Setup

This function is used for selecting the operation for single button controls

and radio receivers.

The factory default sets the SINGLE input terminal so successive inputs

will cycle the operator in OPEN-STOP-CLOSE-STOP order.

Alternately, the SINGLE input can be set to cause the gate to OPEN

unless the gate is fully open. If the gate is fully open, the input will cause

the gate to CLOSE.

Stagger Mode

(Rarely used in slide gate installations)

This function is used in dual gate installations only. The factory

default sets the Stagger Mode to OFF. In dual gate installations the two

operators communicate through the 3-wire COMM LINK interface. When

using the Stagger Mode, set one operator for delayed opening and the

other operator for delayed closing. The Stagger Delay Time programming

function (see below) sets the length of the delay.

✓ NOTE: This function will only be displayed if dual gate operation is

selected.

Stagger Delay Time

(Rarely used in slide gate installations)

This function is used in dual gate installations only. The factory

default sets the Stagger Time to 0 seconds (OFF). The Stagger Time

sets the delay for the Stagger Mode. The Stagger Time can be set from

1-99 seconds.

✓ NOTE: This function will only be displayed if dual gate operation is

selected.

FUNCTION

"AD"

ADVANCED

PROGRAMMING

FUNCTION

"RT"

MAXIMUM RUN

TIMER

FUNCTION

"SB"

SINGLE BUTTON

INPUT SETUP

FUNCTION

"SM"

PRESS UP OR

DOWN TO CYCLE

THROUGH OPTIONS

PRESS ENTER TO

SELECT AN OPTION

STAGGER

MODE

FUNCTION

"ST"

OPTIONS

ADVANCED PROGRAMMING FUNCTIONS

WILL NOT BE DISPLAYED

ADVANCED PROGRAMMING OPTIONS

WILL BE DISPLAYED

PRESS UP OR

DOWN TO CYCLE

THROUGH OPTIONS

PRESS ENTER TO

SELECT AN OPTION

OPTIONS

ENTER

ENTER

OPTIONS

SINGLE INPUT WILL CYCLE OPERATOR

IN ORDER OF OPEN-STOP-CLOSE-STOP

SINGLE INPUT WILL OPEN OPERATOR,

IF OPERATOR IS ALREADY OPEN, SINGLE

INPUT WILL CLOSE OPERATOR

PRESS UP OR

DOWN TO CYCLE

THROUGH OPTIONS

PRESS ENTER TO

SELECT AN OPTION

OPTIONS

DISABLES STAGGER FUNCTION

SETS THIS OPERATOR FOR

DELAYED OPEN

SETS THIS OPERATOR FOR

DELAYED CLOSE

OPTIONS

STAGGER TIMER DISABLED

SET STAGGER DELAY VALUE

1 TO 99 SECONDS

NOTE: ADVANCED PROGRAMMING

WILL STAY ENABLED AFTER

EXITING PROGRAMMING UNTIL

THE GATE CYCLES 50 TIMES

DISPLAY SHOWS CURRENT

MAXIMUM RUN TIME SETTING

PRESS ENTER FOR 1 SECOND

WHILE DISPLAY IS FLASHING, PRESS

UP OR DOWN TO CHANGE THE

MAXIMUM RUN TIME (10-99 SECONDS)

PRESS ENTER TO STORE THE VALUE

DUAL GATES

ONLY

PRESS UP OR

DOWN TO CYCLE

THROUGH OPTIONS

STAGGER

DELAY TIME

GSLG-A Slide Gate Operator Installation Guide - 13 - P1222 Revision X5 6-22-2011

PRESS ENTER TO

SELECT AN OPTION

DUAL GATES

ONLY

Page 16

Advanced Controller Programming (Cont.)

Auxiliary Relay Mode

The Auxiliary Relay has normally open and normally closed contacts.

The factory setting disables the Auxiliary Relay. The relay can be set for:

• Maglock: To deactivate a magnetic or solenoid gate lock, the relay

will energize during any pending or actual gate motion (open only).

• M4: To deactivate a magnetic or solenoid gate lock, the relay will

energize during any pending or actual gate motion (open only).

3 seconds after the gate starts to move, the relay will de-energize.

This option is used for higher current solenoid locks.

• Ticket Dispenser: The relay will energize while the gate is moving

in the open direction and at the full open limit, or in an entrapment

condition.

• Strobe: To activate a warning strobe light, the relay will energize

during any pending or actual gate motion (either open or close).

• Alarm: The relay will energize if the gate is manually forced open

from the full closed position.

Reverse Delay Time

The factory default sets the Reverse Delay to 1 second. The operator

will wait the length of the delay before reversing direction. This feature

will not change the reversal time when the operator is responding to an

entrapment condition from an obstruction input or inherent entrapment

protection sensor. The Reverse Delay can be set from 1 to 9 seconds.

Heaver gates require a longer delay to allow time for the gate to stop.

Brake Delay Time

The factory default sets the Brake Delay to no delay (0 seconds). Heavy

gates may require delayed braking to allow the gate to slow down before

stopping it. The operator can be set to wait the length of the delay after

running before applying the brake. The Brake Delay can be set from

0 to 3 seconds.

Constant Pressure Mode

The factory default allows momentary pressure on a control station’s

OPEN or CLOSE button to cycle the operator. The controller can be set

to require constant pressure on the OPEN, CLOSE, or both buttons to

run the operator.

✓ NOTE: If a button is set for constant pressure, and it is released

before the operator reaches the open or close limit, the operator will

stop the gate at its current position.

Shadow Loop Open Prevention

If the shadow loop is triggered, it always prevents the gate from closing if

the Auto Close Timer activates or a CLOSE command is given while the

gate is at the full open position.

The controller can also be set to prevent the gate from opening if the

shadow loop is triggered while the gate is at the close limit position. This

prevents a swing gate from opening into a vehicle if it’s parked near the

gate on the inside.

FUNCTION

"AR"

PRESS UP OR

DOWN TO CYCLE

THROUGH OPTIONS

PRESS ENTER TO

SELECT AN OPTION

AUXILIARY

RELAY MODE

FUNCTION

"RD"

REVERSE

DELAY TIME

FUNCTION

"BD"

BRAKE

DELAY TIME

FUNCTION

"CP"

PRESS UP OR

DOWN TO CYCLE

THROUGH OPTIONS

PRESS ENTER TO

SELECT AN OPTION

CONSTANT

PRESSURE MODE

FUNCTION

"SP"

OPTIONS

OPTIONS

PRESS UP OR

DOWN TO CYCLE

THROUGH OPTIONS

PRESS ENTER TO

SELECT AN OPTION

OPTIONS

PRESS UP OR

DOWN TO CYCLE

THROUGH OPTIONS

PRESS ENTER TO

SELECT AN OPTION

OPTIONS

OPTIONS

AUXILIARY RELAY DISABLED

AUXILIARY RELAY USED FOR

MAGLOCK CONTROL

AUXILIARY RELAY USED FOR

MAGLOCK OR SOLENOID CONTROL

3 SECOND DELAY TO RE-ENERGIZE

AUXILIARY RELAY USED FOR

TICKET DISPENSER CONTROL

AUXILIARY RELAY USED FOR

WARNING STROBE LIGHT

AUXILIARY RELAY USED FOR

CONNECTION TO ALARM DEVICE

SET TIMER VALUE

1 TO 9 SECONDS

SET TIMER VALUE

0 TO 3 SECONDS

CONSTANT PRESSURE SET TO OFF

(MOMENTARY PRESSURE ON)

OPEN BUTTON SET FOR

CONSTANT PRESSURE

CLOSE BUTTON SET FOR

CONSTANT PRESSURE

OPEN AND CLOSE BUTTONS BOTH SET

FOR CONSTANT PRESSURE

STANDARD OPERATION

SHADOW LOOP INHIBITS CLOSING ONLY

OPEN INHIBIT ON, SHADOW LOOP INHIBITS

OPENING AND CLOSING

PRESS UP OR

DOWN TO CYCLE

THROUGH OPTIONS

SHADOW LOOP

OPEN PREVENTION

GSLG-A Slide Gate Operator Installation Guide - 14 - P1222 Revision X5 6-22-2011

PRESS ENTER TO

SELECT AN OPTION

Page 17

Advanced Controller Programming (Cont.)

Reset Cycle Count

The Controller counts of the number of times the operator has been

cycled full open and close. The cycle count can be displayed. The display

will scroll the cycle count number, fl ashing two digits at a time from left

to right.

To reset the Cycle Count, press and hold the ENTER button for 2 seconds

while the Cycle Count is displayed.

If the Maintenance Alert has been triggered, resetting the Cycle Count

will also reset the Maintenance Alert indicator.

Maintenance Alert Trigger

The Controller has a MAINT ALERT indicator that can be programmed

to light when the number of activations exceeds a set number of cycles.

The factory default sets the Maintenance Alert Trigger to 10,000 cycles.

The Maintenance Alert Trigger can be programmed for 5, 10, 15, or 25

thousand cycles.

The Maintenance Cycle Count can be reset independently from the

operator’s absolute Cycle Count.

Mid-travel Stop Position

The Controller can be programmed so the gate will stop at a mid-travel

point instead of fully opening. This can be useful in installations where a

large gate, that takes a long time to open and close fully, only needs to

be opened partway to allow traffi c to pass.

The factory default sets the Controller for full open operation. Alternately,

the Controller can be programmed to open for 1 to 99 seconds then stop,

before reaching the open limit.

When a Mid-travel Stop Position time has been programmed, the gate

will still fully open if the Fire Department input is triggered, if the OPEN

button is held down beyond the Mid-travel Stop Position, or a close

obstruction or reverse loop input is triggered.

✓ NOTE: The Mid-travel Stop feature is disabled when dual gate

operation is enabled for paired units.

Anti-tailgate Enable

The factory default sets the Anti-tailgate Enable to OFF. With this setting,

during a gate cycle, after the shadow loop has been triggered by the

vehicle and then has cleared after the vehicle passes, the Auto Close

Timer or a CLOSE command is required to begin closing the gate.

If the Anti-tailgate Enable is set to ON, the gate will close immediately

as soon as the shadow loop has cleared. Any subsequent shadow loop

triggers while the gate is closing will stop the gate. When the shadow loop

clears, the gate will continue closing.

Radio Enable

The Controller contains a built-in MegaCode® radio receiver to allow

activation from up to 40 access control transmitters and two Model MGT

(gate edge) transmitters. The factory default enables the internal radio

receiver. Alternately, the internal receiver can be disabled.

Antenna Installation

A local whip antenna is included for use with the operator as a remote

antenna. If using a remote antenna, connect coax cable from the antenna

to the ANTENNA connector.

FUNCTION

"CT"

RESET CYCLE

COUNT

FUNCTION

"MA"

PRESS UP OR

DOWN TO CYCLE

THROUGH OPTIONS

PRESS ENTER TO

SELECT AN OPTION

MAINTENANCE

ALERT TRIGGER

FUNCTION

"MT"

MID-TRAVEL

STOP POSITION

FUNCTION

"AT"

ANTI-TAILGATE

ENABLE

FUNCTION

"RA"

RADIO

ENABLE

PRESS ENTER TO START THE CYCLE COUNT DISPLAY

1ST DISPLAY

NOTE: PRESS ENTER FOR 2 SECONDS

WHILE THE "CT" FUNCTION IS DISPLAYED

TO RESET THE CYCLE COUNT TO ZERO

2ND DISPLAY 3RD DISPLAY 4TH DISPLAY

EXAMPLE ABOVE SHOWS 10,420 CYCLES

OPTIONS

DISABLES THE MAINTENANCE ALERT

FUNCTION

SETS THIS MAINTENANCE ALERT TRIGGER

FOR 5, 10, 15, OR 25 THOUSAND CYCLES

RESETS THE MAINTENANCE ALERT

INDICATOR AND SETS THE MAINTENANCE

ALERT COUNT TO ZERO

OPTIONS

MID-TRAVEL STOP DISABLED

(GATE RUNS FULL TRAVEL)

SET LENGTH OF OPENING TIME

FROM 1 TO 99 SECONDS

PRESS UP OR

DOWN TO CYCLE

THROUGH OPTIONS

PRESS ENTER TO

SELECT AN OPTION

OPTIONS

ANTI-TAILGATE ENABLE OFF

GATE REQUIRES AUTO OR MANUAL CLOSE

ANTI-TAILGATE ENABLE ON

GATE CLOSES WHEN SHADOW LOOP CLEARS

PRESS UP OR

DOWN TO CYCLE

THROUGH OPTIONS

PRESS ENTER TO

SELECT AN OPTION

OPTIONS

INTERNAL RADIO RECEIVER DISABLED

INTERNAL RADIO RECEIVER ENABLED

PRESS UP OR

DOWN TO CYCLE

THROUGH OPTIONS

PRESS ENTER TO

SELECT AN OPTION

DECIMAL POINT LIT

ON 4TH DISPLAY

GSLG-A Slide Gate Operator Installation Guide - 15 - P1222 Revision X5 6-22-2011

Page 18

Advanced Controller Programming (Cont.)

Radio Transmitter Learn

The Controller’s built-in MegaCode® radio receiver can store the IDs of up to

40 transmitters. Refer to the fi gure for the steps required to learn transmitters.

✓ NOTE: This function will NOT be displayed if the transmitter memory

is full, or if the radio receiver is disabled.

Radio Transmitter Delete

Transmitters can be deleted from the Controller’s memory either

individually, or all at the same time. Refer to the fi gure for the steps

required to delete transmitters.

✓ NOTE: This function will NOT be displayed if no transmitters are

stored in memory, or if the radio receiver is disabled.

MGT Obstacle Transmitter Learn

The Controller supports one or two Model MGT Obstacle Transmitters.

The transmitters can be programmed to function as Open Obstruction,

Close Obstruction, Reverse, or Stop. Refer to the fi gure for the steps

required to learn MGT transmitters.

✓ NOTE: This function will NOT be displayed if two MGT transmitters

are already stored in memory, or if the radio receiver is disabled.

MGT Obstacle Transmitter Delete

MGT transmitters can be deleted from the Controller’s memory either

individually, or all at the same time. Refer to the fi gure for the steps

required to delete MGT transmitters.

✓ NOTE: This function will NOT be displayed if no MGT transmitters are

stored in memory, or if the radio receiver is disabled.

Motor Type Selection

The factory sets the default for the Controller to match the type of motor in

the operator. If required, change the motor selection option to a different

type of motor used in the operator. The only two options used with this

model operator are:

• AC Motor Only

• 3 Phase AC Motor

Reset Controller to Factory Defaults

The Controller can be reset with this function. ALL PROGRAMMED

DATA WILL BE LOST, and the factory defaults will be loaded. This

function will not erase radio transmitters, current sense values, or motor

type. Transmitters must be deleted with the two functions above.

FUNCTION

"TL"

LEARN

TRANSMITTERS

FUNCTION

"TD"

DELETE

TRANSMITTERS

FUNCTION

"ML"

LEARN MGT

TRANSMITTERS

FUNCTION

"MD"

ENTER

ENTER

ENTER

UP DOWN

OR

ENTER

ENTER

OR

UP DOWN

ENTER

ENTER

ENTER

PRESS ENTER (ONCE FOR EACH TRANSMITTER,

UP TO 40 TRANSMITTERS TOTAL)

"TL" WILL BLINK FOR 30 SECONDS WHILE

THE CONTROLLER IS READY TO

LEARN A TRANSMITTER

ACTIVATE THE TRANSMITTER

DISPLAY WILL SHOW "- -" THEN THE

TRANSMITTER ID NUMBER - IF TRANSMITTER

IS ALREADY ENTERED, "dU" WILL BE DISPLAYED,

IF DECODE IS BAD "ERROR" WILL BE DISPLAYED

PRESS ENTER

"TD" WILL BLINK FOR 30 SECONDS WHILE THE CONTROLLER

IS READY TO DELETE ONE OR MORE TRANSMITTERS,

(TO EXIT WITHOUT DELETING ANY, PRESS ENTER)

TO DELETE ALL TRANSMITTERS, PRESS ENTER FOR

2 SECONDS, OR TO PICK TRANSMITTERS GO TO NEXT STEP

PRESS UP OR DOWN TO SCROLL THROUGH THE LIST

OF TRANSMITTER ID NUMBERS

THE TRANSMITTER ID NUMBER IS DISPLAYED

(TO EXIT WITHOUT DELETING, PRESS ENTER)

(TO PICK A DIFFERENT TRANSMITTER ID, PRESS UP OR DOWN)

PRESS ENTER FOR 2 SECONDS TO DELETE THE

TRANSMITTER DISPLAYED

PRESS ENTER, "ML" WILL BLINK FOR 30 SECONDS WHILE

THE CONTROLLER IS READY TO LEARN AN MGT

TRANSMITTER

ACTIVATE THE MGT TRANSMITTER, THE DISPLAY WILL

FLASH "rE" - IF THE TRANSMITTER IS ALREADY ENTERED,

"DU" WILL BE DISPLAYED, IF DECODE IS BAD "ERROR" WILL

BE DISPLAYED

PRESS UP OR DOWN TO SELECT THE MGT FUNCTION:

"rE" = REVERSE "St" = STOP

"OP" = OPEN OBSTRUCTION "CL" = CLOSE OBSTRUCTION

PRESS ENTER TO ACCEPT THE SELECTION

DISPLAY WILL SHOW "--" FOR 5 SECONDS, THEN SHOW THE

TRANSMITTER'S ID NUMBER - REPEAT STEPS FOR

SECOND MGT TRANSMITTER IF USED

PRESS ENTER

"MD" WILL BLINK FOR 30 SECONDS WHILE THE CONTROLLER

IS READY TO DELETE ALL MGT TRANSMITTERS

TO DELETE ALL MGT TRANSMITTERS, PRESS ENTER FOR

2 SECONDS, (TO EXIT WITHOUT DELETING ANY, QUICKLY

PRESS ENTER)

THE DISPLAY WILL SHOW "DELETE ALL" AND THE

CONTROLLER RETURNS TO PROGRAMMING MODE

AC MOTOR ONLY

DO NOT SELECT

NOT USED IN THIS MODEL

DO NOT SELECT

NOT USED IN THIS MODEL

3 PHASE AC MOTOR

DO NOT SELECT

NOT USED IN THIS MODEL

DO NOT SELECT

NOT USED IN THIS MODEL

NOTE: SELECTION

MUST MATCH

MOTOR BOARD!

FUNCTION

"CL"

RESET TO

FACTORY DEFAULTS

WHILE "CL" IS DISPLAYED, PRESS ENTER

ENTER

ALL PROGRAMMED DATA WILL BE CLEARED

AND THE FACTORY DEFAULTS WILL BE

STORED IN MEMORY.

NOTE: THIS FUNCTION WILL NOT ERASE

TRANSMITTERS, CURRENT SENSE VALUES,

OR MOTOR TYPE.

ERASE MGT

TRANSMITTERS

FUNCTION

"MO"

PRESS UP OR

DOWN TO CYCLE

THROUGH OPTIONS

PRESS ENTER TO

SELECT AN OPTION

MOTOR TYPE

SELECTION

OPTIONS

GSLG-A Slide Gate Operator Installation Guide - 16 - P1222 Revision X5 6-22-2011

Page 19

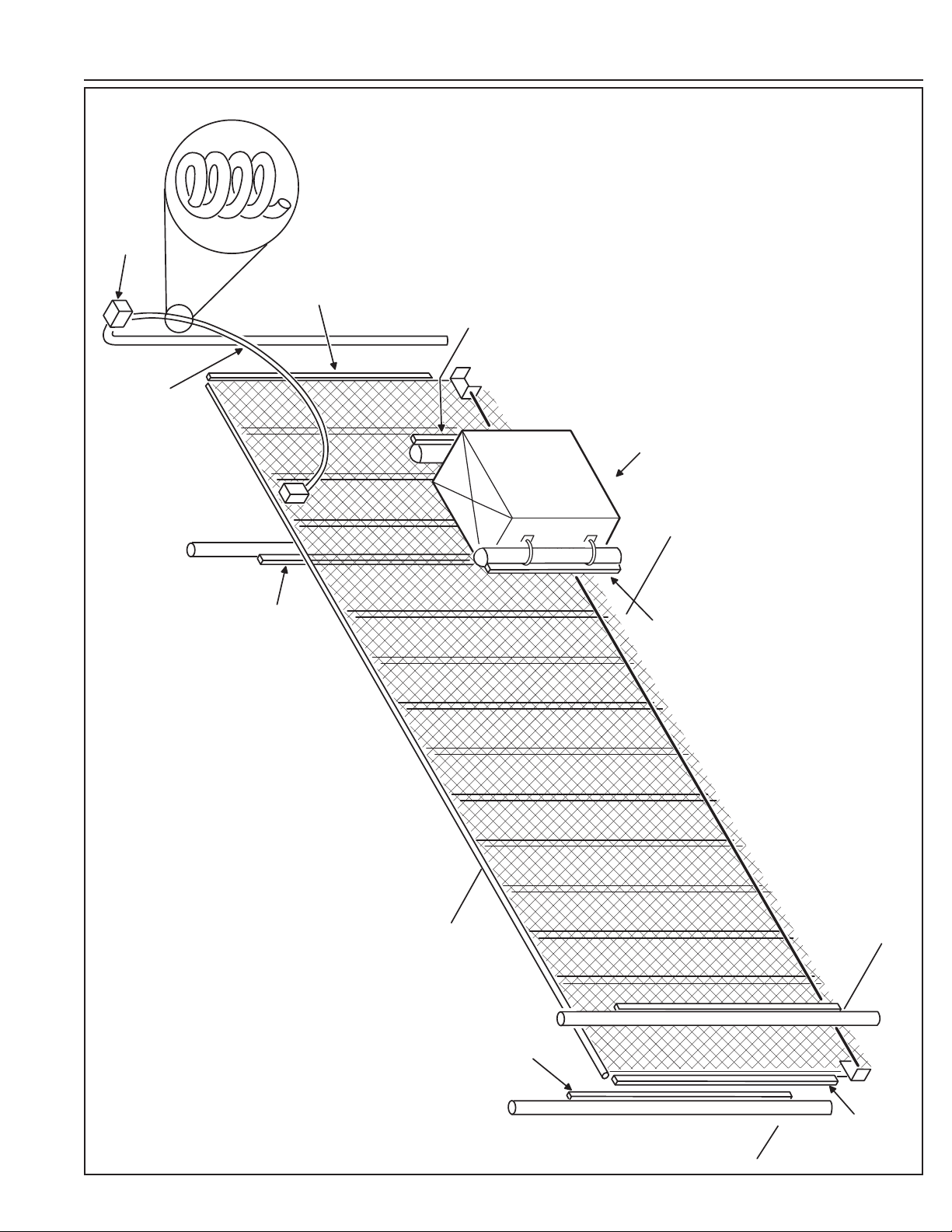

Loop Layout Illustration

LOOP

3/8"

SEALANT

MULTIPLE TURNS

FOR DETAILS

REFER TO LOOP

INSTALLATION NOTES

2"

2" MAX.

FOOT

AT LEAST SIX TIMES PER

TWIST WIRE FROM END OF

LOOPS BACK TO OPERATOR

AT CORNERS

USE RELIEF CUTS

SEPARATE PEDESTRIAN

MINIMUM DISTANCE

FROM GATE

GATE REQUIRED 7 FEET

GSLG-A Slide Gate Operator Installation Guide - 17 - P1222 Revision X5 6-22-2011

Page 20

Safety Edge Layout Illustration #1

1

REVERSING EDGE

ASSY CLOSEUP

SEE NOTE

4

ITEM #4

3

6

5

2

5 8-32 X 1" SCREWS (3)

4 SPACERS (3)

6 RETAINING BRACKET

3 EDGE EXTRUSION

1 GATE (REFERENCE ONLY)

2 EDGE

ITEM DESCRIPTION

SEE NOTE

ITEM #1

SLIDE GATE OPERATOR WITH

RADIO RECEIVER MOUNTED INSIDE

SEE NOTE

ITEM #2

SEE NOTE

SEE NOTE

ITEM #1

FOR CLARITY, FENCE AND

MAY EXIST DEPENDING ON EACH SPECIFIC INSTALLATION.

OBSTRUCTION SENSING DEVICES. OTHER AREAS OF ENTRAPMENT

LOCATIONS FOR THE INSTALLATION OF CONTACT OR NON-CONTACT

THIS DRAWING IS INTENDED TO DRAW ATTENTION TO POSSIBLE

GSLG-A Slide Gate Operator Installation Guide - 18 - P1222 Revision X5 6-22-2011

PEDESTRIAN GATE NOT SHOWN

ITEM #2

NOTES:

1. WIRE THESE EDGES FOR CLOSE OBSTRUCTION

2. WIRE THESE EDGES FOR OPEN OBSTRUCTION

3. ON LEADING EDGE, WIRE FOR CLOSING OBSTRUCTION

OR REVERSING IF DESIRED

SOR EDGES ARE HARD WIRED TO THE OPERATOR, CARE

MUST BE TAKEN IN ROUTING THE WIRES SUCH THAT THEY DO

4. ON TRAILING EDGE, WIRE FOR OPEN OBSTRUCTION

REFER TO ACCESSORY CONNECTIONS PAGES FOR DETAILS

5. IF SEN

SEE NOTE

ITEM #1

NOT BECOME DAMAGED DURING NORMAL OPERATION

(AVOID PINCHING AND ABRASION)

SEE NOTE

ITEM #3

Page 21

Safety Edge Layout Illustration #2

JUNCTION BOX MOUNTED

TO FENCE POST

SEE NOTE

ITEM #4

SEE NOTE

ITEM #1

SLIDE GATE OPERATOR WIRED DIRECT TO EDGE

USING JUNCTION BOX AND COIL CORD

SOR EDGES ARE HARD WIRED TO THE OPERATOR, CARE

COILED CORD SHOULD EXTEND

EQUALLY DURING OPEN AND CLOSE

ITEM #2

SEE NOTE

NOTES:

SEE NOTE

ITEM #2

2. WIRE THESE EDGES FOR OPEN OBSTRUCTION

1. WIRE THESE EDGES FOR CLOSE OBSTRUCTION

3. ON LEADING EDGE, WIRE FOR CLOSING OBSTRUCTION

OR REVERSING IF DESIRED

4. ON TRAILING EDGE, WIRE FOR OPEN OBSTRUCTION

REFER TO ACCESSORY CONNECTIONS PAGES FOR DETAILS

NOT BECOME DAMAGED DURING NORMAL OPERATION

(AVOID PINCHING AND ABRASION)

MUST BE TAKEN IN ROUTING THE WIRES SUCH THAT THEY DO

5. IF SEN

SEE NOTE

ITEM #1

SEE NOTE

ITEM #1

SEE NOTE

MAY EXIST DEPENDING ON EACH SPECIFIC INSTALLATION.

OBSTRUCTION SENSING DEVICES. OTHER AREAS OF ENTRAPMENT

LOCATIONS FOR THE INSTALLATION OF CONTACT OR NON-CONTACT

THIS DRAWING IS INTENDED TO DRAW ATTENTION TO POSSIBLE

GSLG-A Slide Gate Operator Installation Guide - 19 - P1222 Revision X5 6-22-2011

ITEM #3

Page 22

Photoeye Installation Illustration

PHOTOEYE TO GUARD

POCKET AREA. WIRED

FOR OPEN OBSTRUCTION

PHOTOEYE CAN BE MOUNTED ACROSS DRIVE WIRED

FOR REVERSE ONLY, ON EITHER SIDE OF THE GATE

OUTSIDE OF PROTECTED AREA

WIRED FOR OPEN OBSTRUCTION

PHOTOEYE TO PROTECT FENCE LINE

MAY EXIST DEPENDING ON EACH SPECIFIC INSTALLATION.

OBSTRUCTION SENSING DEVICES. OTHER AREAS OF ENTRAPMENT

LOCATIONS FOR THE INSTALLATION OF CONTACT OR NON-CONTACT