Page 1

E721

E721

/ SAFE

/ SAFE

< (1)

BUS

2EASY

< (2)

< OPEN A

< GND

< OPEN B / CLOSE

/ SAFE

<STOP

<FSWOP

< GND

<FSWCL

<+24

(PE-N-L)

< MAIN

TRANS

<PRIM

/ SAFE

F

-

RADIO XF

F

< SEC

TRANS

F

< BATTERY

<M

OR

OT

<L

FCC

AMP

FCA

RADIO1

< LOCK

RADIO2

RELEASE

< LOCK

ERROR

POWER

TTERY

BA

<LOCK

+

SETUP

USB

OUT

-+

Page 2

CONTENTS

1 WARNINGS ..................................................................................................................................................... 2

2 LAYOUT AND COMPONENTS ...........................................................................................................................2

2.1 COMPONENT DESCRI PTION ...................................................................................................................................... 3

2.2 DESCRIPTI ON OF TERMIN AL BLOCK J13 .................................................................................................................... 3

3 TECHNICAL SPECIFICATIONS .......................................................................................................................... 3

4 ELECTRIC CONNECTIONS ............................................................................................................................... 4

4.1 BUS-2EASY PHOTOCELLS ............................................................................................................................................ 5

4.1.1 ADDRESSING BUS-2EASY PHOTOCELLS ..........................................................................................................................5

4.1.2 STORING BUS-2EASY ACCESSORIES .............................................................................................................................5

4.2 TRADITIONAL PHOTOCELLS ....................................................................................................................................... 5

4.3 SAFE IN PUT CONNECTIONS

5 PROGRAMMING ............................................................................................................................................8

5.1 1st LEVEL PROGR AMMI NG ........................................................................................................................................ 8

nd

5.2 2

LEVEL PROGR AMMI NG ...................................................................................................................................... 10

6 STORING RADIO CODE ................................................................................................................................ 12

6.1 STORING DS RADIOCON TROLS ............................................................................................................................... 12

6.2 STORING SLH RADIOCONTROLS ............................................................................................................................. 13

6.3 STORING LC/RC RADIOCONTROLS (ONLY FOR SOME MA RKETS) ............................................................................ 13

6.3.1 STORING LC/RC RADIOCONTROLS REMOTELY ...........................................................................................................13

6.4 RADIOCONTROLS DELETION PROCEDURE .............................................................................................................. 13

7 OPERATIONAL START-UP ............................................................................................................................... 14

7.1

CHECKING THE LEDS ................................................................................................................................................ 14

7.2 BATTERY OPERATION

7.3 POSITION ING LIMIT S WITCHES ....................................................................................................................................

7.4 MASTER / SLAVE CONFIGURATIONS ......................................................................................................................... 16

7.4.1 MASTER / SLAVE WIRING ............................................................................................................................................

7.4.2 MASTER/SLAVE SETUP PROCEDURE .............................................................................................................................

7.5 SETUP ....................................................................................................................................................................... 17

8 TESTING THE AUTOMATED SYSTEM ........................................................................................................... 17

9 ALARM AND ERROR SIGNALS .................................................................................................................. 17

9.1 ALARMS ................................................................................................................................................................... 17

9.2 ERRORS .................................................................................................................................................................. 17

10 FUNCTION LOGICS .................................................................................................................................... 18

.........................................................................................................................7

............................................................................................................................... 14

ENGLISH

16

16

CE DECLARATION OF CONFORMITY

Manufacturer: FAAC S.p.A.

Address: Via Calari, 10 - 40069 Zola Predosa BOLOGNA - ITALY

Declares that: Control board E721

• conforms to the essential safety requirements of the following EEC directives

2006/95/EC Low Voltage Directive

2004/108/EC Electromagnetic Compatibility Directive

Additional note:

This product has undergone testing in a typical

standard configuration (all products built by FAAC S.p.A. )

Bologna, 01-12-2010

The Managing Director

A. Marcellan

WARNINGS

• Attention! To ensure the safety of people, it is important that you read all the following instructions.

• Incorrect installation or incorrect use of the product could cause serious harm to people.

• Carefully read the instructions before beginning to install the product and keep for future reference.

• The symbol highlights notes that are important for personal safety and the protection of the automated

system.

• The symbol

calls your attention to notes on product specifications or operation.

1

Page 3

E721

SAFE

/ SAFE

1 WARNINGS

Before attempting any work on the control board (connections, maintenance), always turn off power.

Install, upstream of the system, a differential thermal breaker with adequate tripping threshold.

Connect the earth lead to the appropriate terminal.

Always separate power cables from control and safety cables

(push-button, receiver, photocells, etc.). To avoid any electric

noise, use separate sheaths or a shielded cable (with earthed

shield).

ENGLISH

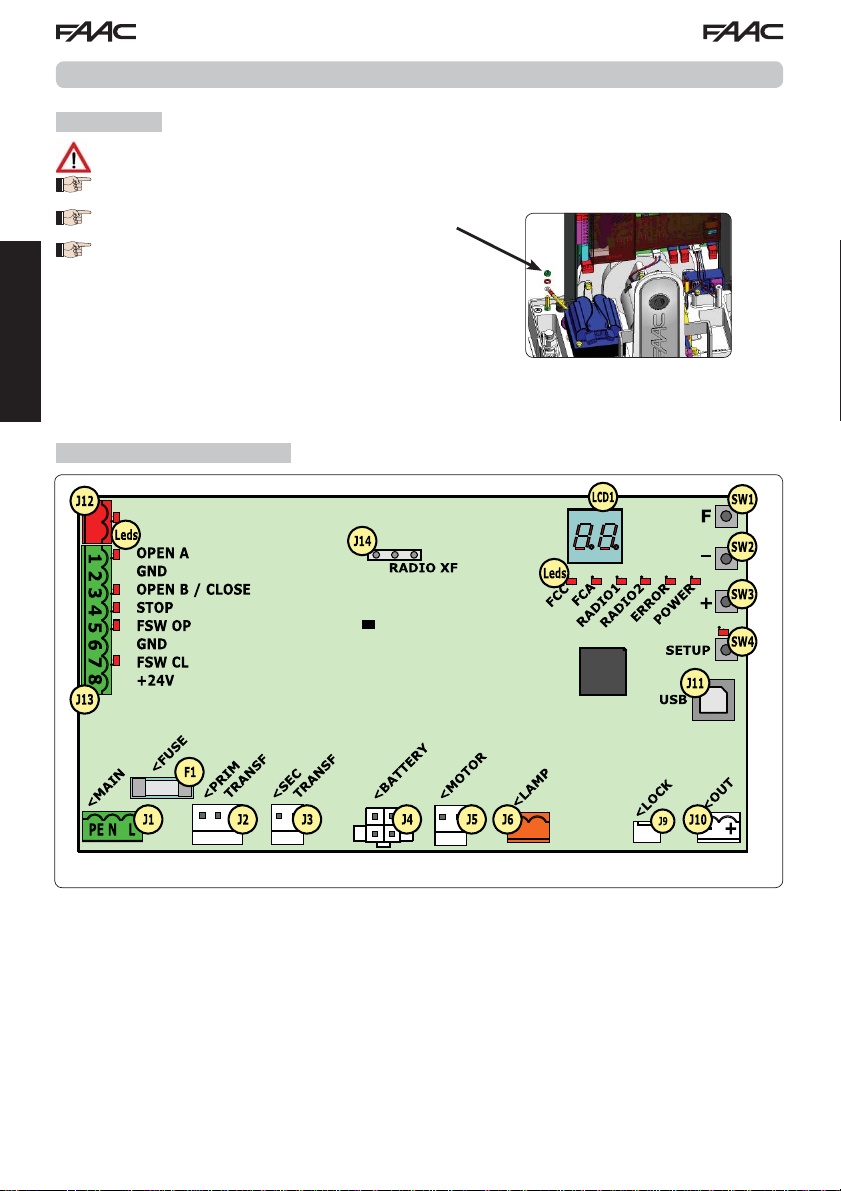

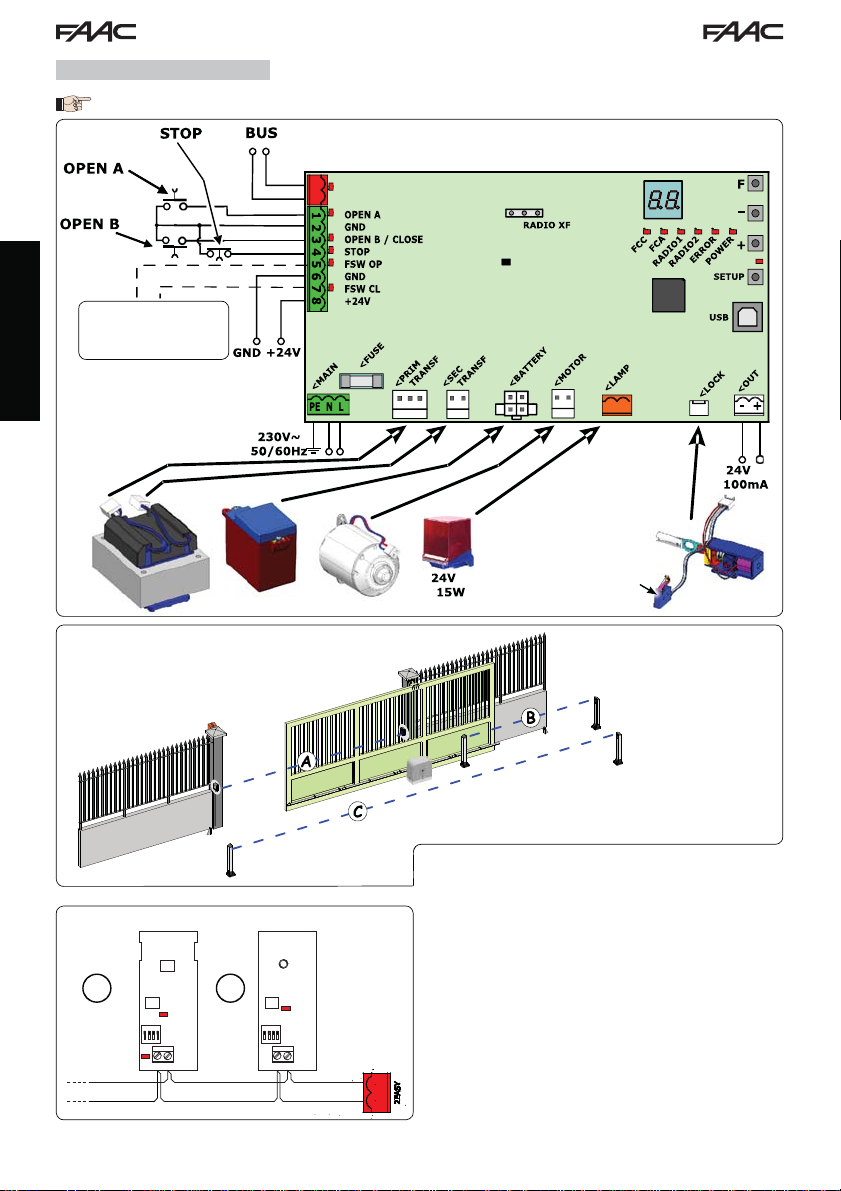

2 LAYOUT AND COMPONENTS

/

SAFE

/ SAFE

SENSOR

LIMIT SWITCH

Fig. 1

2

Page 4

2.1 COMPONENT DESCRIPTION

LCD SIGNALLING AND PROGRAMMING DISPLAY

SW1 PROGRAMMING PUSH-BUTTON "F".

SW2 PROGRAMMING PUSH-BUTTON "-".

SW3 PROGRAMMING PUSH-BUTTON "+".

SW4 “SETUP” PUSH-BUTTON

LEDs INPUTS STATUS CONTROL LED

J1 MAIN POWER SUPPLY CONNECTOR

J2 TRANSFORMER PRIMARY WINDING CONNECTOR

J3 TRANSFORMER SECONDARY WINDING CONNECTOR

J4 EMERGENCY BATTERY CONNECTOR (ACCESSORY)

J5 MOTOR CONNECTOR

J6 FLASHING LAMP CONNECTOR (24 V= - 15W)

MOTOR LOCK AND

J9

CONTACT

MOTOR RELEASE

CONNECTOR

J10 OUT OUTPUT CONNECTOR

J11 USB CONNECTOR FOR PC CONNECTION

J12 BUS-2EASY DEVICE CONNECTION CONNECTOR

J13 INPUT CONNECTOR IN CONNECTOR BLOCK

J14 RADIO RECEIVER MODULE CONNECTOR FOR OMNIDEC

LCD1 SIGNALLING AND PROGRAMMING DISPLAY

F1 PROTECTION FUSE

2.2 DESCRIPTION OF TERMINAL BLOCK J13

INPUT No DESCRIPTION

1 OPEN A Device with N.O. contact

2-6 GND Accessory power

3

(1)

4

(1)

OPEN B

(DEFAULT)

CLOSE

SAFE Device with N.C. contact

STOP

(DEFAULT)

SAFE Device with N.C. contact

5 FSW OP Device with N.C contact

7 FSW CL Device with N.C contact

8 +24 V= Accessory power supply

that causes total opening

of the gate

supply negative

Device with N.O. contact

that causes partial opening

of the gate

Device with

that causes the immediate

and complete reversal of

N.O.

that closes the gate

contact

the gate

Device with N.C. contact

that halts the gate

that causes the immediate

and complete reversal of

the gate

that reverses the motion

during gate opening

that reverses the motion

during gate closing

positive

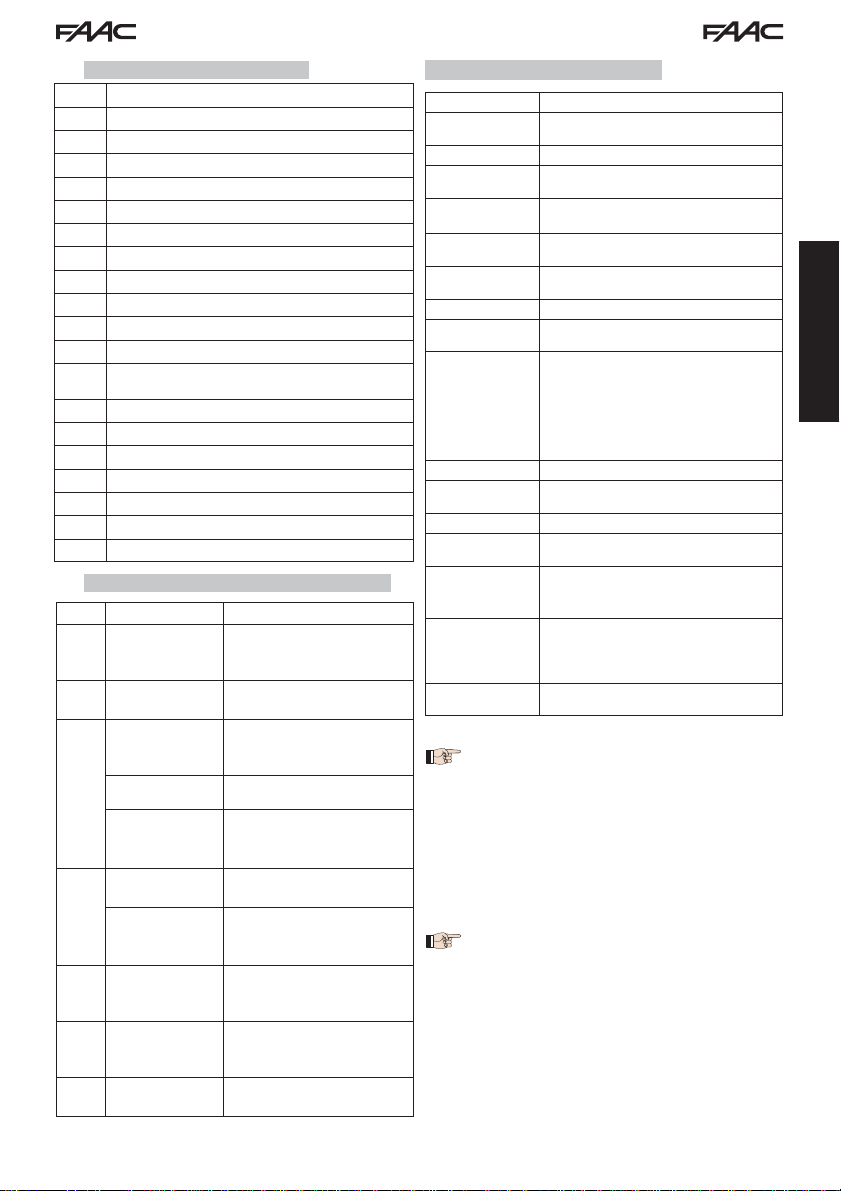

3 TECHNICAL SPECIFICATIONS

Power supply 230 V~ 50 Hz

Power consumption

from mains stand-by

Motor max. load 10A

Accessory

power supply

Accessory

max. current

Environmental

temperature

Flashing lamp

load

Output load 24 V= - 100 mA (2)

Protection

fuses

Function

logics

Work time Programmable (from 0 to 10 min.)

Pause time

OPEN A / OPEN B

Motor power Adjustable over 50 levels

Opening-closing

motor speed

Connector Inputs/

Outputs

Inputs/Outputs in

terminal block

Programming

(1) The uses of inputs 3 and 4 can be set by

configuring the corresponding parameters

at programming level 2 (parameters Ob

and

to operate the automated system with the

chosen logics, please refer to the tables

featured at the end of this manual (Par.

10 - OPERATION LOGICS. As for the wiring

required using these SAFE configured

inputs, please refer to the diagrams shown

in Fig.12 and Fig. 13

(2) The output load must be considered

as already included in the max. current

available for the accessories

Semiautomatic, Semiautomatic “step“,

Automatic, Automatic “step”, Auto-

matic with timer function, Automatic

Safety devices, Automatic Safety devices

“step“, Automatic with reverse on pause,

Semiautomatic “b”, Mixed logic “bC ”,

Programmable (from 0 to 10 min.)

Power supply, Battery, Motor, Module

XF433/868,

BUS-2EASY, OPEN A, OPEN B/CLOSE/SAFE,

STOP/SAFE, GND, Opening and closing

photocells, +24 V=, Mains power supply,

Flasher, Electric release

1st and 2nd level with 3 keys (+, -, F) and

SP

). For the exact description on how

10 W

24 V=

24 V= max. 500 mA

BUS-2EASY max. 500 mA

(-20 - +55) °C

24 V= - 15 W

F1 = T1A - 250V~

Dead-man.

Adjustable over 10 levels

Motor lock electric release bat-

teries, Motor Lock,

USB

motor lock, OUT

display.

ENGLISH

3

Page 5

ON

1 2 3 4

BUSBUS

DL2

DL1

DS1

ON

1 2 3 4

BUSBUS

DL2

DS1

RX - TX

4 ELECTRIC CONNECTIONS

The wiring shown in Fig. 2 refers to the inputs of the board with DEFAULT configuration.

/ SAFE

/ SAFE

To connect the photocells

and safety devices, con-

sult paragraph 4.2

ENGLISH

(Locks the motor when

the motor release han-

=

A: Photocells that operate during CLOSING

B: Photocells that operate during OPENING

C: Photocells that operate during OPENING and CLOSING

MOTOR RELEASE

CONTACT

dle is operated)

=

Fig. 2

Fig. 4

RX TX

Fig. 3

Before connecting the photocells, it is advisable to select

the type of operation on the basis of the area of movement

that they need to protect:

Safety devices during closing: operate only during the

DL1 = Align-

ment

DL2 = BUS2EASY/Power

supply status

DS1 = Dipswitches for

programming

automated system closing movement and are therefore

suitable for protecting the closing area from the risk of

impact.

Safety devices during opening: operate only during

the automated system opening movement and are

therefore suitable for protecting the opening area from

the risk of impact.

Safety devices during opening/closing: operate during

both the automated system opening and closing

movements and are therefore suitable for protecting

the entire movement area from the risk of impact.

4

Page 6

OUT

OUT

OUT

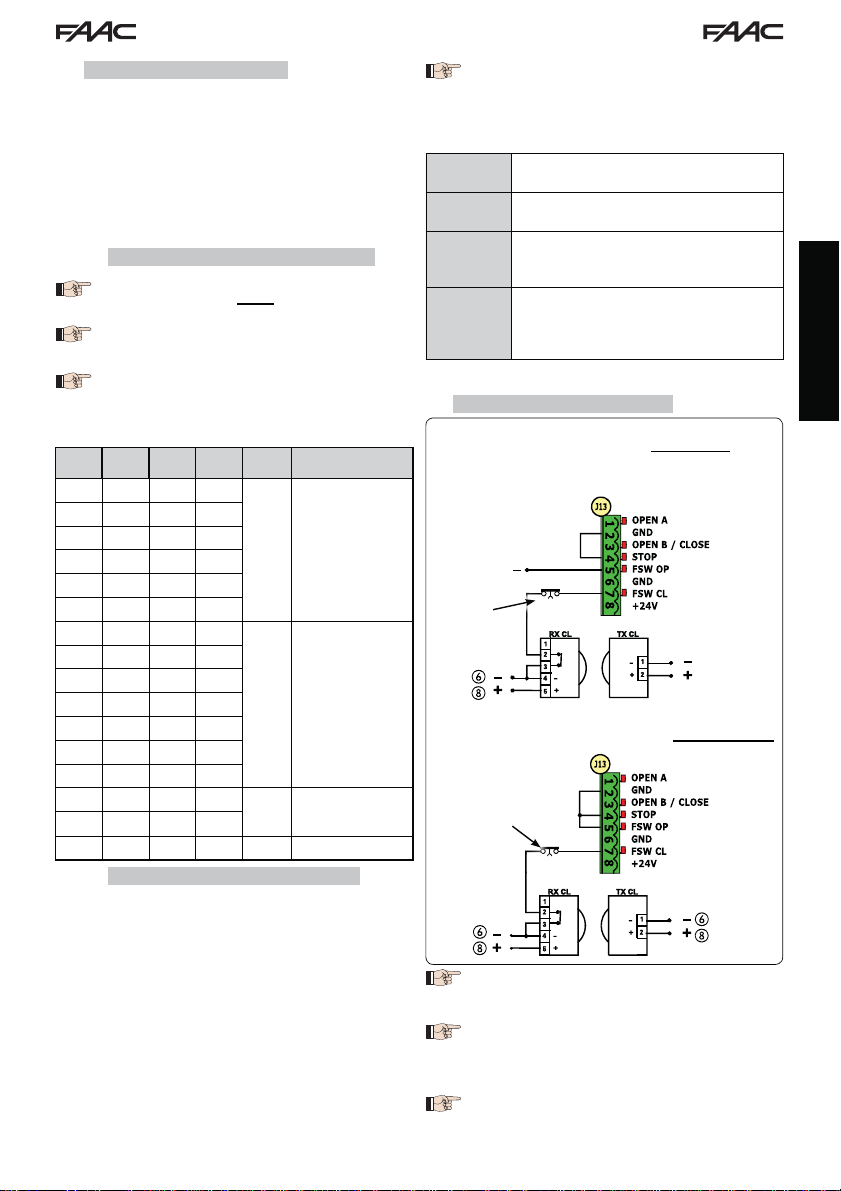

4.1 BUS-2EASY PHOTOCELLS

This board is equipped with a BUS-2EASY circuit that can

be used to easily connect a high number of auxiliary BUS2EASY devices to the safety device (e.g. up to 16 pairs of

photocells), appropriately programmed, using only two

cables without polarity.

Before connecting the photocells, it is advisable to select

the type of operation (Fig. 3) on the basis of the area of

movement the cells must protect and to position the dip

switches on both the transmitter and receiver (see Fig. 4)

as in Tab. 1.

4.1.1 ADDRESSING BUS-2EASY PHOTOCELLS

It is important to give both the transmitter

and the receiver the same address.

Ensure that there are not two or more pho-

tocell pairs with the same address.

If no BUS-2EASY accessory is used, leave the

BUS-2EASY connector (J12 - fig. 1) free.

Tab. 1 - Addressing BUS-2EASY photocells

Dip1 Dip2 Dip3 Dip4 Re. Type

OFF OFF OFF OFF

OFF OFF OFF ON

OFF OFF ON OFF

OFF OFF ON ON

OFF ON ON OFF

OFF ON ON ON

ON OFF OFF OFF

ON OFF OFF ON

ON OFF ON OFF

ON OFF ON ON

ON ON OFF OFF

ON ON OFF ON

ON ON ON OFF

OFF ON OFF OFF

OFF ON OFF ON

ON ON ON ON / OPEN PULSE

C

4.1.2 STORING BUS-2EASY ACCESSORIES

At any time it is possible to add BUS-2EASY photocells

and accessories to the system, simply by following the

procedure below:

1. Install and programme the accessories with the

required address (see par. 4.1.1).

2. Cut off power to the board.

3. Connect both cables of the BUS-2EASY accessories to

the red terminal block J12 (polarity irrelevant).

4. Power the board.

5. Quickly press the SETUP push-button (SW4) once to

register the accessories. Check the operation of the

installed BUS-2EASY devices.

6. The board has stored the BUS-2EA SY accessories.

Follow the instructions in the following table to check that

the BUS-2EASY connection status is efficient.

B

A

OPENING

Max. 6 pairs

CLOSING

Max. 7 pairs

OPENING and

CLOSING

Max. 2 pairs

The same procedure must be performed on a

MASTER unit also when acquiring a SLAVE unit

connected to the BUS- 2EASY with POLARISED

connection

Tab. 2 - Description of BUS-2EASY LED

Fixed ON

Slow

flasher

Normal activity (LED on even without photocells). No registered photocell engaged.

At least one registered photocell engaged

or not aligned.

Off (flash

every

BUS-2EASY line short-circuited.

2.5 secs)

- BUS-2EASY line disabled (does not supply

Off

power)

- Battery operation

- Unit programmed as a SLAVE

4.2 TRADITIONAL PHOTOCELLS

Connection of 1 pair of closing photocells

with FAIL-SAFE safety device

activated

Set in second level of programming

o1 = 01

OUT

Other safety

devices

Connection of 1 pair of closing photocells

with FAIL-SAFE and STOP safety device

Other safety

devices

If the FAIL-SAFE safety device is

used, connect the power supply of the

transmitters to terminals 6 and 8 of J13.

If the FAIL-SAFE safety device is used, connect

the power supply of the transmitters to OUT

after setting it as appropriate (see 2nd

level programming and Fig. 5).

If the FAIL-SAFE safety device is used, even the

unused safety inputs must be connected via a

shunt lead to the negative of OUT (see Fig. 5).

5

deactivated

OUT

OUT

not

ENGLISH

Fig. 5

Page 7

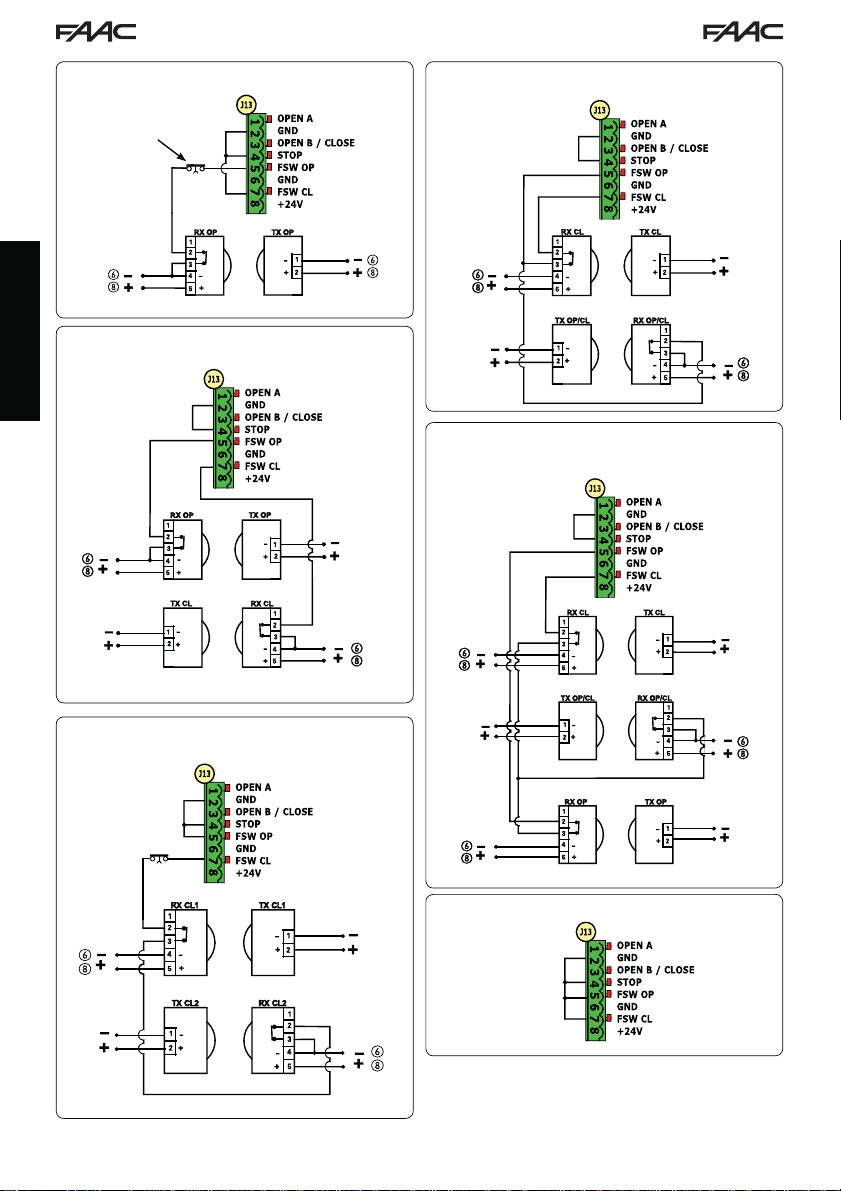

Connection of a pair of opening photocells

Other safety

devices

Connection of a pair of closing photocells and a pair of

opening/closing photocells

Fig. 6

Connection of a pair of closing photocells and a pair of

opening photocells

ENGLISH

Connection of two pairs of closing photocells

Fig. 9

Connection of a pair of closing photocells, a pair of open-

ing photocells and a pair of opening/closing photocells

Fig. 7

Fig. 10

Connection of no safety and stop device

Fig. 8

Fig. 11

6

Page 8

4.3 SAFE INPUT CONNECTIONS

If the Fail Safe safety device is enabled (parameter that can be set in programming level 2), the negative

used for managing the SAFE input is - OUT (see Fig. 12).

Connection of a safety device (other safety devices) to the SAFE input with the FAIL SAFE function enabled

By setting: 2nd level

2nd level

Other safety

If the Fail Safe safety device is disabled (parameter that can be set in programming level 2), the negative

used for managing the SAFE input is - (see Fig. 13).

Connection of a safety device (other safety devices) to the SAFE input with the FAIL SAFE function disabled

By setting: 2nd level

2nd level

SP=01

devices

- OUT

SP=01

Other safety

devices

-

o1=01

(FAIL SAFE ENABLED)

(INPUT 4 = SAFETY EDGE SAFETY)

OPEN A

GND

OPEN B / CLOSE

SAFE

FSW OP

GND

FSW CL

+24V

o1=00

(FAIL SAFE DISABLED)

(INPUT 4 = SAFETY EDGE SAFETY)

OPEN A

GND

OPEN B / CLOSE

SAFE

FSW OP

GND

FSW CL

+24V

/ STOP

/ STOP

By setting: 2nd level

2nd level

Other safety

devices

- OUT

By setting: 2nd level

2nd level

Ob=02

Other safety

devices

-

o1=01

(FAIL SAFE ENABLED)

Ob=02

(INPUT 3 = SAFETY EDGE SAFETY)

OPEN A

GND

SAFE

STOP

FSW OP

GND

FSW CL

+24V

o1=00

(FAIL SAFE DISABLED)

(INPUT 3 = SAFETY EDGE SAFETY)

OPEN A

GND

SAFE

STOP

FSW OP

GND

FSW CL

+24V

/ OPEN B / CLOSE

/ OPEN B / CLOSE

ENGLISH

Fig. 12

Fig. 13

In case N.C. contact devices are not used (other safety devices) the SAFE input must be jumpered to -OUT

with FAIL SAFE enabled or to GND with FAIL SAFE disabled.

7

Page 9

5 PROGRAMMING

It is necessary to access PROGRAMMING mode in order

to program automated system operation.

Programming is divided in two parts: 1st LEVEL and 2nd

LEVEL.

The status of the automated system is

normally shown on the display. When

push-button F is pressed or when F and

+ are pressed simultaneously, this gives

access to 1st or 2nd level programming.

During battery operation the display is off.

Briefly press “+” to view the state of the

automated system.

To restore the default settings, simply reload

the desired default in the first passage of

the 1st level programming.

5.1 1st LEVEL PROGRAMMING

ENGLISH

To access 1st level programming, press push-button F.

• Press F (and hold down) to display the function name.

• If you release the key, the display shows the value of the function that can be modified with keys + and -.

• If you press F again (and hold it down), the display shows the name of the next function, etc.

• When you reach the last function, press push-button F to exit the program and store the parameters. The display

shows again the status of the automated system.

Changes to the programming parameters

become effective as soon as they are

carried out, while final memorisation

occurs only upon exiting programming and

returning to the input state display. If the

unit is powered down before returning to

the input state display, all changes made

will be lost.

It is possible to return to the input status

display and store all the parameters

modified to that moment from any point

st

of the 1

pressing keys F and - simultaneously.

When the board is turned on, the software

version of the board with two figures

separated by a decimal point appears on

the LCD1 display.

and 2nd level programming by

1st LEVEL PROGRAMMING

Display Function

DEFAULT:

dF

1 Configures the parameters with DEFAULT values.

CU If push-button F is released, the value CU appears, this means that the standard

MASTER/SLAVE CONFIGURATION:

Ct

MA Configures the board in MASTER mode

SL Configures the board in SLAVE mode

Configuring the board in SLAVE mode you will not be able to view the parameters

FUNCTION LOGICS:

LO

E Semiautomatic.

EP Semiautomatic “Step”.

A Automatic.

A1 Automatic1.

AP Automatic “Step”.

At Automatic with timer function.

S Automatic “Safety devices”.

SP Automatic Safety Devices "Step”.

SA Automatic with reverse during pause.

b Semiautomatic “b”.

bC Mixed (AP pulse/ CH dead-man).

C Dead-man.

Parameter not displayed in SLAVE mode

PAUSE TIME A:

PA

Pause time with a TOTAL opening command. This has effect only if the automatic logic was

selected. Adjustable from 0 to 59 secs. in one-second steps.

Subsequently, display changes to minutes and tens of seconds (separated by a point) and

time is adjusted in 10-second steps, up to the maximum value of

E.g. if the display shows

Parameter not displayed in SLAVE mode

modified configuration has been selected by means of push-buttons and display

you wish to maintain this programming, press push-button F again, otherwise press +

and select default 1.

LO-PA-Pb-Ph-Op

(for Master/Slave operation see Par. 7.4)

. If

9.5 minutes.

2.5, pause time is 2 min. and 50 secs.

8

Default

1

MA

E

20

1

Page 10

Display Function

PAUSE TIME B:

Pb

Pause time with a PARTIAL opening command. This has effect only if the automatic logic was

selected. Adjustable from 0 to 59 secs. in one-second steps.

Subsequently, display changes to minutes and tens of seconds (separated by a point) and

time is adjusted in 10-second steps, up to the maximum value of

E.g. if the display shows

Parameter not displayed in SLAVE mode

MOTOR POWER:

FO

Adjusts the motor power level

01 = minimum power

50 = maximum power

OPENING SPEED:

So

Adjusts the motor opening speed to 10 levels

01 = minimum speed

CLOSING SPEED:

Sc

Adjusts the motor closing speed to 10 levels.

01 = minimum speed

10 = maximum speed

SLOWING DURING OPENING

ro

Adjusts the slowing space as a percentage of the total gate travel. Adjustable from 5 (with

speed <5), 10 (with speed between 5 and 8), 15 (with speed >8) to 99 % in 1% steps.

5-10-15= minimum slowing

99 = maximum slowing

SLOWING DURING CLOSING:

rc

Adjusts the slowing space as a percentage of the total gate travel. Adjustable from 5 (with

speed <5), 10 (with speed between 5 and 8), 15 (with speed >8) to 99 % in 1% steps.

SPEED DURING SLOWING:

Sr

Adjusts gate speed during slowing.

0 = LOW speed

1 = HIGH speed

STATUS OF AUTOMATED SYSTEM:

St

Exit from programming, data storage, and return to gate status display.

9.5 minutes.

2.5, pause time is 2 min. and 50 secs..

When the power value has been changed, it is advisable to perform a new

SETUP (see par. 7.3)

10 = maximum speed

When the speed value has been changed, it is advisable to perform a new

SETUP (see par. 7.3)

When the speed value has been changed, it is advisable to perform a new

SETUP (see par. 7.3)

5-10-15= minimum slowing

99 = maximum slowing

Default

20

50

08

08

20

20

0

1

ENGLISH

00 = CLOSED

01 = OPEN

02 = Stop then “OPEN”

03 = Stop then “CLOSE”

04 = In “PAUSE”

05 = During opening stage

06 = During closing stage

07 = FAIL SAFE in progress

08 = BUS-2EASY device check in progress

09 = Preflashing then “OPEN”

10 = Preflashing then “CLOSE”

11 = OPEN in Partial Opening

12 = in PAUSE Partial Opening

9

Page 11

5.2 2nd LEVEL PROGRAMMING

To access 2ND LEVEL PROGRAMMING, press push-button F and hold down while pressing push-button +:

• if you also release push-button F, the display shows the value of the function that can be modified with keys + and -.

• if you press key F (and hold down), the display shows the name of the next function. If you release it, the value

that can be modified with keys + and - is displayed.

• when you reach the last function, press F to exit programming, and the display resumes showing the automated

system status.

2nd LEVEL PROGRAMMING

Display Function

bo

ENGLISH

PF

tP

Ph

oP

Ad

EC

MAXIMUM TAKE-OFF POWER:

The motor works at maximum power (ignoring the selected power level) during the movement

take-off.

Y = active

no = excluded

PREFLASHING:

Allows 5 types of preflashing to be selected, with a duration equal to 3 secs.

no = no preflashing.

OC =preflashing before each movement.

CL = preflashing before a closing movement.

OP = preflashing before an opening movement.

PA = preflashing only at end of pause.

PREFLASHING TIME (visible only if preflashing is selected in the previous menu):

Adjusts preflashing time from 1 to 10 sec. in 1 second steps.

01 = minimum preflashing

10 = maximum preflashing

CLOSING PHOTOCELLS:

Activate the function if you want the closing photocells to lock movement and reverse it on

disengagement. Normally, operation of the closing photocells immediately puts the gate

into reverse when this function is off.

Y = reversal on disengagement

no = immediate reversal to opening.

Parameter not displayed in SLAVE mode

OPENING PHOTOCELLS:

Activate the function if you want the opening photocells to lock movement and reverse it

during closing. Normally, with this function off, operation of the opening photocells determines

the resumption of movement on their disengagement.

no = immediate reversal to closing

no = resumption of motion on disengagement

Parameter not displayed in SLAVE mode

ADMAP FUNCTION

Permits activation of operation in accordance with French standard NFP 25/362.

Y = active

no = excluded

ENCODER:

The "virtual" encoder on the board operates as an anti-crushing device and manages the

slowing and partial opening start points.

If the gate strikes an obstacle during the opening or closing stage, the "virtual" encoder causes

reversal of the motion. The second obstacle detected in the same direction causes the motor

to stop. An alarm is signalled in both cases (see section on alarms).

It is necessary to adjust the sensitivity of the "virtual" encoder by varying the time that the

board waits for before controlling reversal of motion from a minimum of 0 sec to a maximum

10 sec in one-second steps.

of

00 = maximum sensitivity

10 = minimum sensitivity

10

Default

no

no

03

no

no

no

02

1

Page 12

Display Function

PO

t

o1

PARTIAL OPENING:

It is possible to adjust the width of the partial leaf opening as a percentage of the total gate

travel.

Adjustable from 0 to 99% in 1% steps.

00 = no partial opening

01 = minimum partial opening

99 = maximum partial opening

TIME-OUT

It is advisable to set a value higher than the time taken by the gate to open or close fully.

Adjustable from 0 to 59 sec. in 1 second steps. Subsequently, display changes to minutes

and tens of seconds (separated by a point) and time is adjusted in 10-second steps, up to

the maximum value of 9.5 minutes.

E.g.: if the display shows

When using a system with MASTER/SLAVE configuration you must set a WORK TIME

on the MASTER unit that takes into account the movement time of both leaves.

OUT 1:

Allows output OUT (open collector N.O.) to be activated in one of the following functions:

00 = Always enabled (supplies 24V voltage= with a max absorption of 100 mA)

01 = FAIL-SAFE (monitors the correct operation of the connected traditional photocells)

02

= WARNING LIGHT (off when closed, on during opening and open/pause, flashing during closing)

03

= COURTESY LIGHT

04 = ALARM, BATTERY operation

05 = gate OPEN or PAUSED

06 = gate CLOSED

07 = gate in MOTION

08 = gate OPENING

09 = gate CLOSING

10 = ACTIVE safety

11 = timed output that can be activated by second

12 = output that can be activated by second

t1

Ob

SP

IP

Lc

TIMING OF OUT 1 (only if option 03 or 11 is selected at the previous step):

Can be used to adjust timing of output OUT if a timed function was selected

(e.g.

OPEN B / CLOSE / EDGE SAFETY DEVICE:

It is possible to select the use of OPEN B input as partial opening, CLOSE command or EDGE

SAFETY DEVICE.

00 = OPEN B

01 = CLOSE

02 = SAFETY EDGE SAFETY (N.C. contact)

STOP / EDGE SAFETY DEVICE

It is possible to select the use of STOP input as STOP or EDGE SAFETY DEVICE.

00 = STOP

01 = SAFETY EDGE SAFETY (N.C. contact)

PARTIAL REVERSE:

It is possible to set the reverse type (complete or partial) when an obstacle is encountered

or when a safety edge is triggered.

Y

no

MOTOR LOCK:

It is possible to select the use of the motor lock during battery operation:

Y =

no = when the system switches to battery operation, the motor lock remains open.

2.5, pause time is 2 min. and 50 secs.

(see next function)

radio channel

radio channel (step function)

(see next function)

03 or 11) from 1 to 99 minutes in 1 minute steps.

If you select a function logic that involves the use of the CLOSE command (logic b,

bC

, C) this function will be preset to 01 and it will not be possible to change it.

=

Partial reverse activation. When an obstacle is encountered or when a safety edge

is triggered the leaf reverses movement for approximately 2” and will then stop

= Partial reverse deactivation. When an obstacle is encountered or when a leaf safety

edge is triggered it completely reverses movement and will place itself in open or

closed position

the motor lock continues to operate regularly even during battery operation

1

Default

50

2.0

00

ENGLISH

02

00

00

no

Y

11

Page 13

Display Function

AS

nc

ENGLISH

nd

St

SERVICE REQUEST - CYCLE COUNTER (combined with the two successive functions):

Y = when the set number of cycles is reached with successive functions nc and nd, the

system carries out an 8 sec. preflashing sequence (in addition to the sequence already

set using the PF function) before each movement.

no = successive functions nc and nd indicate how many cycles the system has per formed

99.990

up to the maximum possible display of

If the number of cycles is higher than 99.990, the two successive functions

nc and nd will show 99 and 99 respectively.

This function may be useful for setting programmed maintenance operations or for checking

work cycles performed.

CYCLE PROGRAMMING (THOUSANDS):

If AS = Y the display indicates the number of thousands of cycles after which service is

required (may be set from 0 to 99).

If

AS = no the display indicates the number of thousands of cycles performed. The value

displayed is updated with the sequence of cycles, interacting with the value of nd.

If AS = no press keys + and - for 5 sec. to zero the cycle counter.

CYCLE PROGRAMMING (TENS):

If AS = Y the display indicates the number of tens of cycles after which service is required

(may be set from 0 to 99).

If

AS = no the display indicates the number of tens of cycles performed. The value displayed

is updated with the sequence of cycles, interacting with the value of nc.

Example: if the system has performed 11.218, it will display nc = 11 and

nd = 21

STATUS OF AUTOMATED SYSTEM:

Exit from programming, data storage, and return to gate status display.

00 = CLOSED

01 = OPEN

02 = Stop then “OPEN”

03 = Stop then “CLOSE”

04 = In “PAUSE”

05 = During opening stage

.

07 = FAIL SAFE in progress

08 = BUS-2EASY device check in progress

09 = Preflashing then “OPEN”

10 = Preflashing then “CLOSE”

11 = OPEN in Partial Opening

12 = in PAUSE Partial Opening

06 = During closing stage

Default

no

00

00

1

6 STORING RADIO CODE

The control board is

equipped with an integrated dual channel

decoding system (DS,

SLH, LC/RC) known as

OMNIDEC. This system

can use an additional

receiving module (Fig. 5

ref. ) and radiocontrols of the same frequency to store

both total opening (OPEN A) and partial opening (OPEN B)

of the automated system.

The 3 types of radio coding (DS, SLH, LC/

RC) can co-exist at the same time on the

two channels. It is possible to enter up to

256 radio codes subdivided between OPEN

A and OPEN B.

To use the different coding systems on the

same channel, finish the learning process

for each system and then repeat the procedure for another..

Do not connect any radio devices on

SLAVE-configured equipment

Fig. 14

6.1 STORING DS RADIOCONTROLS

It is possible to store a maximum of 256

codes divided between OPEN A and OPEN

B/CLOSE.

1. On the DS radiocontrol, select the required ON - OFF

combination of the 12 dip-switches.

2. Press and hold down push-button

and then press the SETUP push-button (SW4), to store

total opening (OPEN A) or partial opening (OPEN B/

CLOSE) respectively. The corresponding LED will begin

to flash slowly for 5 secs.

3. Release both push-buttons.

4. Within this 5 second period, press the required pushbutton on the radiocontrol.

5. The corresponding LED will come on with a fixed light

for 1 second and then go off to indicate the setting

has been stored.

6. To add other codes other than the one you have recently stored, repeat the procedure from point 1.

12

+

(SW3) or - (SW2)

Page 14

7. To use radiocontrols with the same code, copy the

ON - OFF combination to the other radiocontrols

without the need to change anything on the control

board.

6.2 STORING SLH RADIOCONTROLS

It is possible to store a maximum of

256 codes divided between OPEN A and

OPEN B/CLOSE.

1. On the SLH radiocontrol, press and hold down P1 and

P2 simultaneously.

2. The radiocontrol LED will begin to flash.

3. Release both push-buttons.

4. Press and hold down push-button

and then press the SETUP push-button (SW4), to store

total opening (OPEN A) or partial opening (OPEN B/

CLOSE) respectively. The corresponding LED will begin

to flash slowly for 5 secs.

5. Release both push-buttons.

6. Within this 5 sec. period while the radiocontrol LED is still

flashing, press and hold down the required push-button

on the radiocontrol (the radiocontrol LED will come on

with a fixed light).

7. The corresponding LED will come on with a fixed light

for 2 seconds and then go off to indicate the setting

has been stored.

8. Release the radiocontrol push-button.

9. Press the stored radiocontrol push-button twice in quick

succession.

The automated system will carry out an

opening control. Ensure the automated

device is free of any obstacle by people

or things.

To enable other radiocontrols with the same system code,

transfer the system code of the stored radiocontrol pushbutton to the corresponding push-button of the radiocontrols to be added, following the procedure below:

a. On the stored radiocontrol, press and hold down

P1 and P2 simultaneously.

b. The radiocontrol LED will begin to flash.

c. Release both push-buttons.

d. Press the stored push-button and hold down (the

radiocontrol LED will come on with a fixed light).

e. Bring the radiocontrols closer to one another, press

and hold down the corresponding push-button of

the radiocontrol to be added, releasing only once

the LED on the radiocontrol has issued a double

flash to indicate that it has been stored.

f. Press the stored radiocontrol push-button twice in

quick succession.

The automated system will carry out an

opening control. Ensure the automated

device is free of any obstacle by people

or things.

+

(SW3) or - (SW2)

6.3 STORING LC/RC RADIOCONTROLS

It is possible to store a maximum of

256 codes divided between OPEN A and

OPEN B/CLOSE.

Use the LC/RC remote controls only with a

433 MHz receiving module.

1. Press and hold down push-button

and then press the SETUP push-button (SW4), to store

total opening (OPEN A) or partial opening (OPEN B/

CLOSE) respectively. The corresponding LED will begin

to flash slowly for 5 secs.

2. Release the push-button.

3. Within this 5 second period, press the required pushbutton on the LC/RC remote control.

4. The LED will come on with a fixed light for 1 second,

indicating that the unit has been stored, and then

resume flashing for an additional 5 seconds during

which time another radiocontrol may be stored.

5. Once the 5 seconds are up, the LED will go off to

indicate that the procedure is complete.

6.3.1 STORING LC/RC RADIOCONTROLS REMOTELY

With LC/RC radiocontrols, other radiocontrols may be

stored in remote mode, i.e. without operating directly on

the board, using a previously stored radiocontrol.

1. Obtain a radiocontrol already stored on one of its

2 channels (OPEN A or OPEN B/CLOSE).

2. Press and hold down push-buttons P1 and P2 simultaneously until both LEDs flash slowly for 5 secs.

3. Within 5 seconds, push the previously stored radiocontrol push-button to activate the learning stage on the

selected channel.

4. The LED on the board corresponding to the channel

being stored flashes for 5 seconds, within which time

the code of another radiocontrol must be sent.

5. The LED will come on with a fixed light for 1 second,

indicating that the unit has been stored, and then

resume flashing for an additional 5 seconds during

which time other radiocontrols may be stored and

then it will go off.

+

(SW3) or - (SW2)

6.4 RADIOCONTROLS DELETION PROCEDURE

To delete ALL the codes of the radiocontrols entered,

simply press down together the two push-buttons

and

-

(SW2), then press the SETUP push-button (SW4) for

1 second, and hold the first two push-buttons pressed for

10 secs.

• The 2 LEDs RADIO1 and RADIO2 will flash quickly for

10 secs.

• The 2 LEDs will come on with a fixed light for 2 seconds

and then go off (deletion carried out).

• Release both push-buttons.

This operation is NOT reversible. All the codes

of the radiocontrols stored as OPEN A and

as OPEN B/CLOSE will be deleted.

+

(SW3)

ENGLISH

13

Page 15

BUS

2EASY

< OPEN A

RADIO XF

SETUP

OUT

-+

F

+

-

USB

< GND

< OPEN B / CLOSE

<STOP

<FSWOP

< GND

<FSWCL

<+24

<

MAIN

(PE-N-L)

< BATTERY

<M

OT

OR

<L

AMP

< LOCK

< LOCK

< LOCK

<PRIM

TRANS

F

<

SEC

TRANS

F

RADIO1

RADIO2

ERROR

POWER

RELEASE

BATTERY

FCA

FC

C

< (1)

< (2)

< SAFE

/ SAFE

7 OPERATIONAL START-UP

7.1

CHECKING THE LEDS

After making all the connections and powering the board, check the status of the LEDs against the status of the inputs

in the following table (in Fig. 15, the condition where the automated system is closed in stand-by).

These LEDs indicate the status of the board inputs and are of considerable importance to automated system movement:

Note that:

LED ON = contact closed

< SAFE

/ SAFE

LED OFF = contact open

ENGLISH

Fig. 15

Leds FCA and FCC represent the N.C. contacts of the limit

switch built into the board that open when engaged and

turn off the associated LED:

Automated system

CLOSED

Automated system

OPEN

FCA

FCC FCC engaged

FCA engaged

FCA

FCC

Tab. 3 - Description of POWER LED

Fixed ON Mains-powered

Flashing Battery-powered

Off Board off

7.2

BATTERY OPERATION

ATTENTION

To optimise energy consumption and protect the charge, during battery operation, when the automated system is

stopped and the system is on stand-by, the LCD1 display, the BUS 2easy LED and the FCC and FCA LED will be off

while the POWER LED flashes.

In this phase it is in any case possible to view the state of the automated system. To do this it is sufficient to briefly press

“+” on the board. Following brief pressure, the LCD1 display shows the state of the automated system for approximately

2 seconds to then go off again. Instead, during normal operation all the diagnostic LEDs and the display state signals

become consistent with the state of the automated system (see Fig. 15).

The STOP (SAFE), FSW CL, FSW OP, OPEN B inputs

configured as SAFE are safety inputs with N.C.

(Normally Closed) contact and therefore the

corresponding LEDs must be ON when the

automated system is at rest, and off when

the connected device is used.

The OPEN A, OPEN B/CLOSE inputs are inputs

with N.O. (Normally Open) contact and

therefore the corresponding LEDs must be

OFF when the automated system is at rest,

and on when the connected device is used.

When using equipment programmed as

SLAVE the LEDs corresponding to terminal

board J13 must be off.

ERROR LED flashing indicates alarm in

progress (situation does not impair gate

operation)

ERROR LED on with a fixed light indicates

an error in progress (situation that locks

operation until the cause of the error has

been removed)

14

Page 16

RADIO1

RADIO2

ER

FCA

FCC

RADIO1

RADIO2

ER

FCAFCA

FCC

7.3 POSITIONING LIMIT SWITCHES

To ensure correct positioning of the limit switch magnets, the control unit must be installed and

correctly connected with all control and safety accessories.

The operator is equipped with a magnetic limit switch sensor built directly into the electronic control board.

The gate is stopped, during opening or closing, when the polarised magnet secured to the upper part of the rack

activates the sensor.

1. Check that the operator is set for manual operating mode as described in the instructions

for the operator.

2. Move the gate to opening position manually, leaving 40 mm from the limit switch mechanical stop (see Fig. 16).

3. Slide the magnet with the CIRCLE on the rack in the direction of the motor. As soon as

the LED for the FCA limit switch on the board goes off, secure with the appropriate screws.

4. Move the gate to closing position manually, leaving 40 mm from the limit switch mechanical stop.

5. Slide the magnet with the SQUARE on the rack in the direction of the motor. As soon as

the LED for the FCC limit switch on the board goes off, secure with the appropriate screws.

6. Check that the relevant limit switch LED goes off correctly at the end of the opening and

closing movement and make the necessary changes to the position of the limit switch

magnet position if necessary.

To avoid damage to the operator and/or interruptions in the operation of the

automated system, approximately 40 mm must be left from the mechanical

limit switch stops.

For correct operation of the operator, the magnet with

the CIRCLE must be

used as an OPENING limit switch and

the magnet with the

SQUARE must be used

as a CLOSING limit

switch.

(SEE FIG. 16)

When using a system

with MASTER/SLAVE

configuration, the

limit switch magnets

must be installed as

shown in Fig. 17.

ENGLISH

Fig. 16

MASTER/SLAVE

Fig. 17

15

Page 17

7.4 MASTER / SLAVE CONFIGURATIONS

(1)

(2)

BUS

2 EASY

(1)

(2)

BUS

2 EASY

Should you need to build a system with opposing leaves that must be activated simultaneously

for opening and closing the gate, you must connect and configure two E721 devices in Master/Slave mode.

The MASTER equipment (parameter Ct of the first programming level configured as MA ) must have all the necessary

connections for correct operation of the system (photocells, safety switches, radio, opening pulses, flashing light)

while the SLAVE equipment (parameter

terminal board J13, as all the inputs present are completely ignored. The two devices will communicate with each

other through BUS-2EASY using two-pole POLARISED wiring on the J12 terminal board.

The MASTER device will completely control the SLAVE device through BUS-2EASY and will manage all the movements

and time of both leaves.

Avoid any type of connection and wiring to terminal board J13 of the SLAVE unit.

The BUS connection between the two boards must be POLARISED following the sequence of the

poles of the J12 terminal board (POLE (1) - POLE (2)) - (see Fig. 18).

When a unit is configured as a SLAVE, this will force the values of some programming parameters

ENGLISH

no longer displayed in the menu (

again, the previously forced values are stored in the program.

7.4.1 MASTER / SLAVE WIRING

Ct of the first programming level configured as SL), must not be wired with

LO-PA-Pb-Ph-Op

). By placing the board in MASTER mode

Do not connect

anything to this

terminal board

E721 MASTER E721 SLAVE

Fig. 18

7.4.2 MASTER/SLAVE SETUP PROCEDURE

The SETUP request signalled by the flashing S0 on the display can occur both on the MASTER unit

and on the SLAVE unit. In the latter case, the MASTER unit will display an error

SETUP procedure can only be started from the MASTER unit.

To SETUP a MASTER/SLAVE system, follow the steps below:

1. Release both leaves, place them in the middle of travel and lock again (see procedure no.1 Par. 7.5 SETUP)

2. Keep pressed the SETUP button on the MASTER board until the MASTER gate begins to move.

3. At this point the MASTER gate will perform a complete SETUP procedure (see Par. 7.5 SETUP)

4. Once you have correctly completed the SETUP of the MASTER board, the complete SETUP procedure of the SLAVE

board begins (see Par. 7.5 SETUP).

5. Once this procedure has also been completed the MASTER checks the position of the SLAVE leaf and places it in

the same position (open or closed) as the MASTER leaf.

6. Procedure completed.

In case of error or non-completion of the above-mentioned SETUP procedure, you must repeat it

completely starting from point no.1.

16

91. In any case, the

Page 18

7.4 SETUP

When the board is powered when no SETUP

has ever been carried out, or if the board

requires it, the code S0 will flash on the

display together with the SETUP LED to indicate that SETUP must be carried out.

To ensure the effective outcome of the

SETUP procedure, carefully check the correct polarity of the magnetic limit switches

as described in the previous paragraph.

Proceed as follows to carry out the SETUP:

1. Place the gate at half its travel (very important for a

successful SETUP) and check that both the FCA and

FCC LEDs are on. Otherwise, the board will signal

error 12 (see tab. 5)

2. Press and hold the SETUP (SW4) push-button until the

gate begins to move slowly and stops when it reaches

the limit switch. If the limit switch reached is the closing

switch (with the SQUARE) the device stores that point

as the closing stop, conversely if the limit switch is the

opening switch (with the CIRCLE) the device stores

that point as the opening stop. During that stage,

flashes on the display

3. The gate automatically begins to move slowly in the

opposite direction and then stops when it reaches the

limit switch. If the limit switch reached is the opening

switch (with the SQUARE) the device stores that point

as the opening stop, conversely if the limit switch is

the closing switch (with the SQUARE) the device stores

that point as the closing stop. During that stage,

S1

S3 flashes on the display

4. According to the final limit switch reached, the device takes up a status of closed (

In the second case, issue an OPEN pulse to close the

gate.

8 TESTING THE AUTOMATED SYSTEM

After installation and programming, check the system is

operating correctly. Above all, check that the safety devices operate correctly and ensure that the current safety

regulations are met.

Remember that the second programming

level features the encoder configuration

parameter (parameter

encoder located on the board acts as

an anti-crushing device. During the open/

closing phase, should the gate collide

with an obstacle, the “virtual” encoder

will cause the motion to reverse. At the

next motion in the same direction, an

obstacle in the same position will cause

the motor to stop. It is essential to correctly

configure this parameter to adjust the

correct sensitivity of the “virtual” encoder

with respect to obstacles during motion.

00) or open (01).

EC

). This “virtual”

9 ALARM AND ERROR SIGNALS

If alarms occur (conditions that do not impair the operation of the gate) or errors (conditions that lock the gate

operation) the display shows a number relating to the

current condition.

The ALARM or ERROR signals disappear at

the next cycle only if the triggering cause

is removed.

9.1 ALARMS

When an ALARM occurs, the ERROR LED

begins to flash and a number relating to

the current fault appears on the display

when the + and - keys are pressed.

Tab. 4 indicates all the alarms that may be shown on the

display.

Tab. 4 - Alarms

Limited MOTOR current

22

LAMP output short-circuited

24

Obstacle detection (visible for 10 secs)

27

XF radio code memory-module full (visible

30

for 10 secs)

Service request

40

Forced default programming reset

46

9.2 ERRORS

When an ERROR occurs, LED DL20 comes

on with a fixed light and a number relating

to the current fault appears on the display

when the + and - keys are pressed.

Tab. 5 indicates all the errors that may be shown on the

display.

Tab. 5 - Errors

Board faulty

01

Motor faulty

03

Motor lock locked closed (check the motor

06

lock and replace if necessary)

Gate too heavy or too much friction (try to

07

increase motor power)

BUS-2EASY device error (e.g. same address

08

on two photocell pairs; check address)

Both limit switches with the same polarity

10

Limit switch engaged at the beginning of

12

SETUP

Time-out finished

15

No communication with the SLAVE unit -

90

SLAVE unit missing

Error on the SLAVE unit

91

Error on the SLAVE unit

92

Errors 90 91 and 92 are displayed

only on E721 configured as MASTER and

in particular 91and 92 indicate errors

present on the SLAVE unit. Should such

errors be displayed, we recommend you

check on the SLAVE unit the type of error

shown on the display to solve it and restore

correct operation of the system.

ENGLISH

17

Page 19

10 FUNCTION LOGICS

In brackets, the effects on the other inputs when

the pulse is active.

The CLOSE command can be enabled on the OPEN

B input from programming level 2.

LOGIC "E" PULSES

STATUS OF AUTOMATED SYSTEM

CLOSED opens the gate opens the gate partially no effect

DURING OPENING locks operation (1) locks operation recloses the gate locks operation see 2nd level prog. no effect

OPEN recloses the gate (1) recloses the gate recloses the gate

DURING CLOSING reopens the gate reopens the gate no effect locks operation no effect

ENGLISH

LOCKED closes the gate closes the gate closes the gate

LOGIC "EP" PULSES

STATUS OF AUTOMATED SYSTEM

CLOSED opens the gate opens the gate partially n o effect

DURING OPENING locks operation (1) locks operation recloses the gate locks operation see 2nd level prog. no effect

OPEN recloses the gate (1) recloses the gate recloses the gate

DURING CLOSING locks operation locks operation no effect locks operation no effect

LOCKED

LOGIC "A" PULSES

STATUS OF AUTOMATED SYSTEM

CLOSED

DURING OPENING no effect (1) no effect recloses the gate locks operation see 2nd level prog. no effect

OPEN IN PAUSE reloads pause time (1) reloads pause time B recloses the gate locks operation no effect

DURING CLOSING reopens the gate reopens the gate no effect locks operation no effect

LOCKED closes the gate closes the gate closes the gate

LOGIC "A1" PULSES

STATUS OF AUTOMATED SYSTEM

CLOSED

DURING OPENING no effect (1) no effect recloses the gate locks operation see 2nd level prog.

OPEN IN PAUSE reloads pause time (1) reloads pause time B recloses the gate locks operation no effect

DURING CLOSING reopens the gate reopens the gate no effect locks operation no effect

LOCKED closes the gate closes the gate closes the gate

OPEN A OPEN B CLOSE STOP FSW OP FSW CL FSW CL/OP

OPEN A OPEN B CLO SE STOP FSW OP FSW CL FSW CL/OP

resumes motion in reverse

direction. After STOP, always

OPEN A OPEN B CL O SE STOP FSW OP FSW CL FSW CL/OP

opens and recloses after

the pause time

OPEN A OPEN B CLO SE STOP FSW OP FSW CL FSW CL/OP

opens and recloses after

the pause time

closes

resumes motion in reverse

direction. After STOP, always

closes

opens the gate partially

and closes it after pause

time B

opens the gate partially

and closes it after pause

time B

closes the gate

no effect

no effect

If enabled during leaf motion, the SAFE command

will immediately and completely reverse it; when

the automated system is stopped, if kept enabled

it will prevent its movement.

no effect

(OPEN inhibited)

no effect

(OPEN/CLOSE inhibited)

no effect

(OPEN/CLOSE inhibited)

no effect

(OPEN inhibited)

no effect

(OPEN/CLOSE inhibited)

no effect

(OPEN/CLOSE inhibited)

no effect

(OPEN inhibited)

no effect

(OPEN/CLOSE inhibited)

no effect

(OPEN inhibited)

no effect

(OPEN/CLOSE inhibited)

(1) During the partial opening cycle, an OPEN A pulse causes total opening

no effect

(OPEN inhibited)

no effect

no effect

(OPEN inhibited)

no effect

(OPEN inhibited)

no effect

no effect

(OPEN inhibited)

no effect

(OPEN inhibited)

no effect

(OPEN inhibited)

no effect

(OPEN inhibited)

no effect

(OPEN inhibited)

18

no effect

no effect

(CLOSE inhibited)

reverses to opening (see

2nd level prog.)

no effect

(CLOSE inhibited)

no effect

no effect

(CLOSE inhibited)

reverses to opening (see

2nd level prog.)

no effect

(CLOSE inhibited)

no effect

reloads pause time

(CLOSE inhibited)

reverses to opening (see

2nd level prog.)

no effect

(CLOSE inhibited)

no effect

continues to open and

recloses immediately

locks and immediately

closes on disengagement

reverses to opening (see

2nd level prog.)

no effect

(CLOSE inhibited)

no effect

(OPEN inhibited)

locks and opens on

disengagement (OPEN

locks - stores CLOSE)

no effect

(OPEN/CLOSE inhibited)

locks and opens on

disengagement (OPEN

locks - stores CLOSE)

no effect (OPEN locks

- stores CLOSE)

no effect

(OPEN inhibited)

locks and opens on

disengagement (OPEN

locks - stores CLOSE)

no effect

(OPEN/CLOSE inhibited)

locks and opens on

disengagement (OPEN

locks - stores CLOSE)

no effect (OPEN locks

- stores CLOSE)

no effect

(OPEN inhibited)

locks and opens on

disengagement

(stores CLOSE)

reloads pause time

(CLOSE inhibited)

locks and opens on

disengagement

(stores CLOSE)

no effect

(OPEN/CLOSE inhibited)

no effect

(OPEN inhibited)

locks and opens on

disengagement

(stores CLOSE)

reloads pause time

(CLOSE inhibited)

locks and opens on

disengagement

(stores CLOSE)

no effect

(OPEN/CLOSE inhibited)

Page 20

LOGIC "AP" PULSES

STATUS OF AUTOMATED SYSTEM

CLOSED

OPEN A OPEN B CLO SE STOP FSW OP FSW CL FSW CL/OP

opens and recloses after

the pause time

opens the gate partially

and closes it after pause

time B

no effect

no effect

(OPEN inhibited)

no effect

(OPEN inhibited)

no effect

DURING OPENING locks operation (1) locks operation recloses the gate locks operation see 2nd level prog. no effect

OPEN IN PAUSE locks operation (1) locks operation recloses the gate locks operation no effect

DURING CLOSING reopens the gate reopens the gate no effect locks operation no effect

LOCKED closes the gate closes the gate closes the gate

no effect

(OPEN/CLOSE inhibited)

no effect

(OPEN inhibited)

reloads pause time

(CLOSE inhibited)

reverses to opening (see

2nd level prog.)

no effect

(CLOSE inhibited)

LOGIC "At" (2) PULSES

STATUS OF AUTOMATED SYSTEM

CLOSED

OPEN A OPEN B CLO SE STOP FSW OP FSW CL FSW CL/OP

opens and recloses after

the pause time

opens the gate partially

and closes it after pause

time B

no effect

no effect

(OPEN inhibited)

no effect

(OPEN inhibited)

no effect

DURING OPENING no effect (1) no effect recloses the gate locks operation reverses to closing (1) no effect

OPEN IN PAUSE reloads pause time (1) reloads pause time recloses the gate locks operation no effect

DURING CLOSING reopens the gate reopens the gate no effect locks operation no effect

LOCKED closes the gate closes the gate closes the gate

no effect

(OPEN/CLOSE inhibited)

no effect

(OPEN inhibited)

reloads pause time

(CLOSE inhibited)

reverses to opening (see

2nd level prog.)

no effect

(CLOSE inhibited)

LOGIC "S" PULSES

STATUS OF AUTOMATED SYSTEM

CLOSED

DURING OPENING reverses to closing (1) reverses to closing (1) recloses the gate locks operation see 2nd level prog.

OPEN IN PAUSE recloses the gate (1) recloses the gate recloses the gate locks operation no effect

DURING CLOSING reopens the gate reopens the gate no effect locks operation no effect

LOCKED closes the gate closes the gate closes the gate

OPEN A OPEN B CLO SE STOP FSW OP FSW CL FSW CL/OP

opens and recloses after

the pause time

opens the gate partially

and closes it after pause

time B

no effect

no effect

(OPEN inhibited)

no effect

(OPEN/CLOSE inhibited)

no effect

(OPEN inhibited)

no effect

(OPEN inhibited)

no effect

continues to open and

recloses immediately

locks and immediately

closes on disengagement

reverses to opening (see

2nd level programming)

and closes immediately at

no effect

(CLOSE inhibited)

the end

no effect

(OPEN inhibited)

locks and opens on

disengagement (OPEN

locks - stores CLOSE)

reloads pause time

(CLOSE inhibited)

locks and opens on

disengagement (OPEN

locks - stores CLOSE)

no effect

(OPEN/CLOSE inhibited)

no effect

(OPEN inhibited)

locks and opens on

disengagement

(stores CLOSE)

reloads pause time

(CLOSE inhibited)

locks and opens on

disengagement

(stores CLOSE)

no effect

(OPEN/CLOSE inhibited)

no effect

(OPEN inhibited)

locks and opens

on disengagement (stores

CLOSE)

locks and closes on

disengagement

locks and on disengage-

ment opens and at the

end immediately closes

no effect

(OPEN/CLOSE inhibited)

ENGLISH

LOGIC "SP" PULSES

STATUS OF AUTOMATED SYSTEM

CLOSED

OPEN A OPEN B CLO SE STOP FSW OP FSW CL FSW CL/OP

opens and recloses after

the pause time

opens the gate partially

and closes it after pause

time B

no effect

no effect

(OPEN inhibited)

no effect

(OPEN inhibited)

DURING OPENING locks operation (1) locks operation recloses the gate locks operation see 2nd level prog.

OPEN IN PAUSE recloses the gate (1) recloses the gate recloses the gate locks operation no effect

DURING CLOSING locks operation locks operation n o effect locks operation no effect

LOCKED

resumes motion in reverse

direction. After STOP, always

closes

resumes motion in reverse

direction. After STOP, always

closes

recloses the gate

no effect

(OPEN/CLOSE inhibited)

(1) During the partial opening cycle, an OPEN A pulse causes total opening

no effect

(OPEN inhibited)

19

no effect

continues to open and

recloses immediately

locks and immediately

closes on disengagement

reverses to opening (see

2nd level prog.)

no effect

(CLOSE inhibited)

no effect

(OPEN inhibited)

locks and on disengagement

opens and at the end immediately

closes (OPEN locks - stores CLOSE)

locks and immediately

closes on disengagement

locks and opens on

disengagement

(stores CLOSE)

no effect

(OPEN/CLOSE inhibited)

Page 21

LOGIC "SA" PULSES

STATUS OF AUTOMATED SYSTEM

CLOSED

OPEN A OPEN B CLO SE STOP FSW OP FSW CL FSW CL/OP

opens and recloses after

the pause time

Opens the gate partially

and closes it after pause

time B

no effect

no effect

(OPEN inhibited)

no effect

(OPEN inhibited)

DURING OPENING no effect (1) no effect recloses the gate locks operation see 2nd level prog. no effect

OPEN IN PAUSE recloses the gate (1) recloses the gate recloses the gate locks operation no effect

DURING CLOSING reopens the gate reopens the gate no effect locks operation no effect

LOCKED closes the gate closes the gate closes the gate

no effect

(OPEN/CLOSE inhibited)

no effect

(OPEN inhibited)

LOGIC "B" PULSES

STATUS OF AUTOMATED SYSTEM

ENGLISH

CLOSED opens the gate / no effect

OPEN A / C LO S E STOP FSW OP FSW CL FSW CL/OP

no effect

(OPEN inhibited)

no effect

(OPEN inhibited)

DURING OPENING no effect / closes the gate locks operation see 2nd level prog. no effect

OPEN no effect / closes the gate

no effect

(OPEN/CLOSE inhibited)

no effect

DURING CLOSING opens the gate / no effect locks operation no effect

LOCKED opens the gate / closes the gate

LOGIC bC

STATUS OF AUTOMATED SYSTEM

PULSES DURING OPENING/COMMANDS MAINTAINED

DURING CLOSING

OPEN A / C LO S E STOP FSW OP FSW CL FSW CL/OP

CLOSED opens the gate / no effect

no effect

(OPEN/CLOSE inhibited)

no effect

(OPEN inhibited)

no effect

(OPEN inhibited)

PULSES

no effect

(OPEN inhibited)

DURING OPENING no effect / closes the gate locks operation see 2nd level prog. no effect

OPEN no effect / closes the gate

no effect

(OPEN/CLOSE inhibited)

no effect

DURING CLOSING opens the gate / no effect locks operation no effect

LOCKED opens the gate / closes the gate

no effect

(OPEN/CLOSE inhibited)

no effect

(OPEN inhibited)

LOGIC "C" COMMANDS MAINTAINED PULSES

STATUS OF AUTOMATED SYSTEM

CLOSED opens the gate / no effect

OPEN A / C LO S E STOP FSW OP FSW CL FSW CL/OP

no effect

(OPEN inhibited)

no effect

(OPEN inhibited)

DURING OPENING no effect / closes the gate locks operation see 2nd level prog. no effect

OPEN no effect / closes the gate

no effect

(OPEN/CLOSE inhibited)

no effect

no effect

reloads pause time

(CLOSE inhibited)

reverses to opening (see

2nd level prog.)

no effect

(CLOSE inhibited)

no effect

no effect

(CLOSE inhibited)

reverses to opening (see

2nd level prog.)

no effect

(CLOSE inhibited)

no effect

no effect

(CLOSE inhibited)

reverses to opening (see

2nd level prog.)

no effect

(CLOSE inhibited)

no effect

no effect

(CLOSE inhibited)

no effect

(OPEN inhibited)

locks and opens on

disengagement

(stores CLOSE)

reloads pause time

(CLOSE inhibited)

locks and opens on

disengagement

(stores CLOSE)

no effect

(OPEN/CLOSE inhibited)

no effect

(OPEN inhibited)

locks and opens on

disengagement (stores

OPEN/CLOSE)

no effect

(OPEN/CLOSE inhibited)

locks and opens on

disengagement (stores

OPEN/CLOSE)

no effect

(OPEN/CLOSE inhibited)

no effect

(OPEN inhibited)

locks and opens on

disengagement (stores

OPEN/CLOSE)

no effect

(OPEN/CLOSE inhibited)

locks and opens on

disengagement (stores

OPEN/CLOSE)

no effect

(OPEN/CLOSE inhibited)

no effect

(OPEN inhibited)

locks and on disengage-

ment 2nd level prog.

no effect

(OPEN/CLOSE inhibited)

DURING CLOSING opens the gate / no effect locks operation no effect locks operation locks operation

LOCKED opens the gate / closes the gate

(2) When turned on, the board checks the inputs and if an OPEN A or B command is active, it opens the leaf or gate. Otherwise it closes it.

no effect

(OPEN/CLOSE inhibited)

(1) During the partial opening cycle, an OPEN A pulse causes total opening

no effect

(OPEN inhibited)

no effect

(CLOSE inhibited)

no effect

(OPEN/CLOSE inhibited)

20

Page 22

Le descrizioni e le illustrazioni del presente manuale non sono impegnative. La FAAC si riserva il diritto, lasciando inalterate le caratteristiche essenziali dell’apparecchiatura, di apportare in qualunque momento e senza impegnarsi

ad aggiornare la presente pubblicazione, le modifiche che essa ritiene convenienti per miglioramenti tecnici o per

qualsiasi altra esigenza di carattere costruttivo o commerciale.

The descriptions and illustrations contained in the present manual are not binding. FAAC reserves the right, whilst

leaving the main features of the equipments unaltered, to undertake any modifications it holds necessary for either

technical or commercial reasons, at any time and without revising the present publication.

Les descriptions et les illustrations du présent manuel sont fournies à titre indicatif. FAAC se réserve le droit d’apporter à

tout moment les modifications qu’elle jugera utiles sur ce produit tout en conservant les caractéristiques essentielles,

sans devoir pour autant mettre à jour cette publication.

Die Beschreibungen und Abbildungen in vorliegendem Handbuch sind unverbindlich. FAAC behält sich das Recht

vor, ohne die wesentlichen Eigenschaften dieses Gerätes zu verändern und ohne Verbindlichkeiten in Bezug auf die

Neufassung der vorliegenden Anleitungen, technisch bzw. konstruktiv/kommerziell bedingte Verbesserungen vorzunehmen.

Las descripciones y las ilustraciones de este manual no comportan compromiso alguno. FAAC se reserva el derecho,

dejando inmutadas las características esenciales de los aparatos, de aportar, en cualquier momento y sin comprometerse a poner al día la presente publicación, todas las modificaciones que considere oportunas para el perfeccionamiento técnico o para cualquier otro tipo de exigencia de carácter constructivo o comercial.

De beschrijvingen in deze handleiding zijn niet bindend. FAAC behoudt zich het recht voor op elk willekeurig moment de

veranderingen aan te brengen die het bedrijf nuttig acht met het oog op technische verbeteringen of alle mogelijke

andere productie- of commerciële eisen, waarbij de fundamentele eigenschappen van de apparaat gehandhaafd

blijven, zonder zich daardoor te verplichten deze publicatie bij te werken.

FAAC S.p.A.

Via Calari, 10

40069 Zola Predosa (BO) - ITALIA

Tel. 0039.051.61724 - Fax. 0039.051.758518

www.faacgroup.com

532014 - Rev. B

Loading...

Loading...