Page 1

1 BOX LAYOUT ..................................................................................................................2

2 WARNINGS ....................................................................................................................3

3 LAYOUT AND CONNECTIONS .........................................................................................3

4 TECHNICAL SPECIFICATIONS ........................................................................................4

4.1 DESCRIPTION OF COMPONENTS ...........................................................................................4

4.2 DESCRIPTION OF TERMINAL-BOARDS ....................................................................................4

5 PROGRAMMING THE LOGIC ..........................................................................................4

6 PROGRAMMING THE SPEED ........................................................................................... 4

7. START-UP ........................................................................................................................5

7.1 LEDS CHECK ........................................................................................................................5

DIPS-SWITCH PROGRAMMING

7.2

7.3 PRE-FLASHING ....................................................................................................................5

7.4 TIME LEARNING - SET-UP.......................................................................................................5

7.4.1 AUTOMATIC SET-UP ........................................................................................................................5

7.4.2 MANUAL SET-UP .............................................................................................................................5

8 INSTALLATION OF BUS ACCESSORIES .............................................................................6

8.1 ADDRESSING BUS ENCODER ................................................................................................6

8.2 ADDRESSING THE BUS PHOTOCELLS ....................................................................................6

8.3 MEMORY STORAGE OF BUS ACCESSORIES..........................................................................7

9 MEMORY STORING THE RADIO CODE ............................................................................ 7

9.1 MEMORY STORAGE OF DS RADIO CONTROLS ......................................................................8

9.2 MEMORY STORAGE OF SLH RADIO CONTROLS ....................................................................8

9.3 MEMORY STORAGE OF LC RADIO CONTROLS (for some markets only) .............................8

9.3.1 REMOTE MEMORY STORAGE OF LC RADIO CONTROLS .................................................................9

9.4 RADIO CONTROLS DELETION PROCEDURE ...........................................................................9

10 CONNECTION OF BUFFER BATTERIES (OPTIONAL) ........................................................... 9

10.1 BATTERY KIT .......................................................................................................................... 9

11 AUTOMATED SYSTEM TEST..............................................................................................9

12 LOGIC TABLES ...............................................................................................................10

INDEX

..............................................................................................5

CE DECLARATION OF CONFORMITY

Manufacturer: FAAC S.p.A.

Address: Via Benini, 1 - 40069 Zola Predosa BOLOGNA - ITALY

Declares that: Control board mod. E 700,

• conforms to the essential safety requirements of the following EEC directives:

73/23/EEC and subsequent amendment 93/68/EEC.

89/336/EEC and subsequent amendment 92/31/EEC and 93/68/EEC

Additional information:

This product underwent a test in a typical, uniform configuration

(all products made by FAAC S.p.A)

Bologna, 01 January 2007. The Managing Director

A. Bassi

ENGLISH

• Important! For the safety of people, it is important that all the instructions be carefully observed.

WARNINGS

• Incorrect installation or incorrect use of the product could cause serious harm to people.

• Carefully read the instructions before beginning to install the product and keep them for future

reference.

• The symbol

of the automated system.

• The symbol

product.

indicates notes that are important for the safety of persons and for the good condition

draws your attention to the notes on the characteristics and operation of the

1

Page 2

ELECTRICAL BOX E700

1 BOX LAYOUT

The box contains the E700 electronic unit and the devices

to power it. It must therefore be handled with care during all

installation stages, to avoid damaging its components.

The dimensions of the box are shown in Fig.1:

ENGLISH

306

The lid hinges can be moved upward to allow opening the box

housing (Fig. 3); they can also be removed and re-positioned

in order to enable the lid to open to the right or left.

Fig. 3

When you have secured the box in the selected position, cover

the securing holes (ref. Fig.2) and the screws with the supplied

plugs as shown in Fig.4.

64

130

225

Dimensions in mm

Fig. 1

Fig. 2 shows the four 5 mm diam. holes for securing the

box (ref.) to the wall, the three fittings M16/M20/M25 for

installing the cable grippers (ref.) and the two lid hinges

(ref.).

Fig. 2

Fig. 4

After you have finished the operations to connect the control

board with the various parts of the automated system, close

the box, positioning the lid in its seat with seal.

Connect the supply as shown in Fig. 5.

Fig. 5

Next, tighten the four supplied screws to guarantee the degree

of protection against external agents (Fig.6).

Fig. 6

2

Page 3

2 WARNINGS

Before attempting any work on the control unit (connections, maintenance), always turn off power.

- Install, upstream of the system, a differential thermal breaker with adequate tripping threshold,

- Always separate power cables from control and safety cables (push-button, receiver, photocells, etc.).

- To avoid any electrical disturbance, use separate sheaths or a screened cable (with the screen earthed).

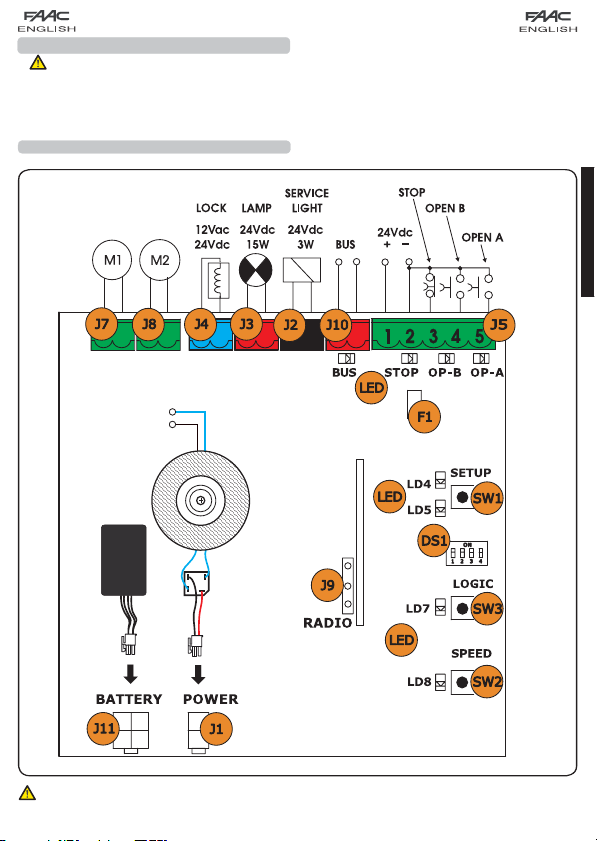

3 LAYOUT AND CONNECTIONS

(PARTIAL OPENING)

(TOTAL OPENING)

230 Vac 50Hz

or

115 Vac 60Hz *

1

ENGLISH

1

*

The power supply is related to the E700 purchased version.

Fig. 7

3

Page 4

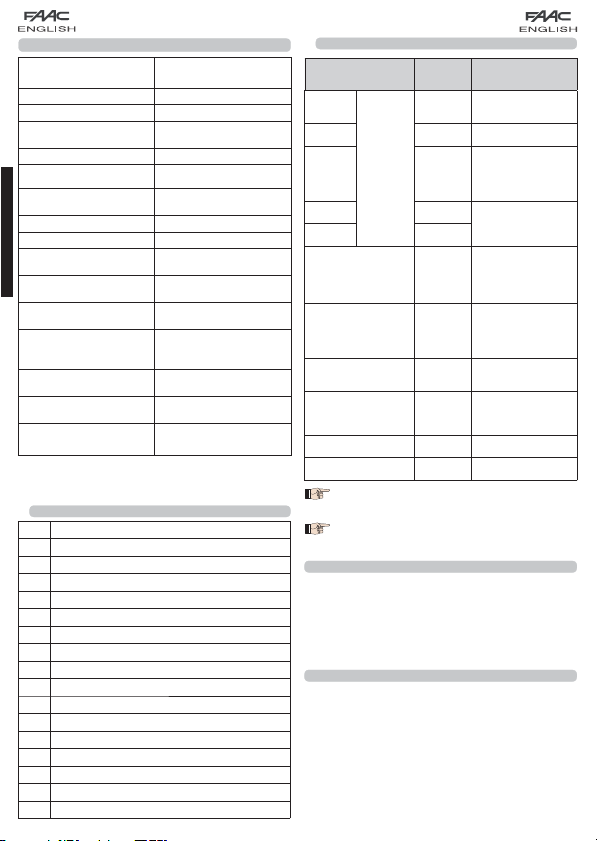

4 TECHNICAL SPECIFICATIONS

3

STOP

Device with NC

contact which causes

the automated

system to shut down

230Vac (+6% -10%) - 50Hz

Power supply voltage

Absorbed power

Motor max. load

Accessories max. current

(+24V)

BUS Accessories max.current

Operating ambient

temperature

2

Fuses

*

Function logics

Work time (time-out)

ENGLISH

Pause time

Terminal board inputs

Connector inputs

Terminal board outputs

Programmable functions

Learning functions

Integrated radio channels

type

2

*

The power supply and the fuse are related to the purchased

version.

2

*

or

115Vac (+6% -10%) - 60Hz

20W

150W x 2

100 mA

400 mA

-20°C - +55°C

F1 = self-resetting;

F2 = T2A-250V or T4A-120V

EP, A

3 minute (fixed)

Varies according to learning

(max. 10 min.)

Open A, Open B, Stop, BUS

(I/O)

Power supply, battery

module XF 433 or XF 868

Motors, flashing lamp, power

supply to accessories,

electric lock, service light

contact (90 sec fixed)

Logic (A, EP), Speed (high

4.8°/sec and low 3.7°/sec)

Pause time, leaf 2 delay at

closing

DS, SLH (max 250 channels)

LC (max 250 channels - FOR

SOME MARKETS ONLY)

4.1 DESCRIPTION OF COMPONENTS

J1 POWER SUPPLY connector

J2

SERVICE LIGHT command terminal-board

J3 FLASHING LAMP terminal-board

J4 ELECTRIC LOCK terminal-board

J5 COMMANDS terminal-board

J7 MOTOR 1 terminal-board

J8 MOTOR 2 terminal-board

J9 Rapid connection for XF MODULE

J10 BUS terminal-board

J11 BATTERY connector

SW1 SET-UP push-button

SW2 SPEED push-button

SW3 LOGIC push-button

DS1 Programming Dip-switch

F1 Accessories protective fuse

F2 Fuses protecting transformers and motors

LED Signalling LEDs

4.2 DESCRIPTION OF TERMINAL-BOARDS

Terminal and/or

terminal-board

1

Description Device connected

Power supply for

+24V

accessories

2 GND Negative

Device with NC

STOP

BUS

SERVICE

LIGHT

LAMP

LOCK

contact which causes

the automated

system to shut down

Device with N.O

contact (see chap.

FUNCTION LOGICS)

Safety and control

devices with BUS

technology

Service Light control

output (connect a

relay coil at 24Vdc100mA max)

Flashing lamp 24Vdc

- 15W

Electric lock 12Vac or

24 Vdc (to be installed

on leaf 1)

J5

3

4 OPEN B

5 OPEN A

J10

RED terminal

J2

GREY terminal

J3

ORANGE terminal

J4

BLUE terminal

J7 MOT1 Motor 1 (leaf 1)

J8 MOT2 Motor 2 (leaf 2)

Leaf 1 means the leaf which opens first during

the opening operation.

The service light control is active during the

entire gate opening or closing movement and

for the successive 90 seconds.

5 PROGRAMMING THE LOGIC

The function logic can be selected at any time by pressing

push-button SW3.

The selected logic is then displayed on LED LD7:

LED on = AUTOMATIC logic (A)

LED off = SEMIAUTOMATIC STEPPED logic (EP)

6 PROGRAMMING THE SPEED

The operating speed can be adjusted at any time by pressing

push-button SW2.

The selected logic is then displayed on LED LD8:

LED on = HIGH speed (4.8 °/sec)

LED off = LOW speed (3.7 °/sec)

4

Page 5

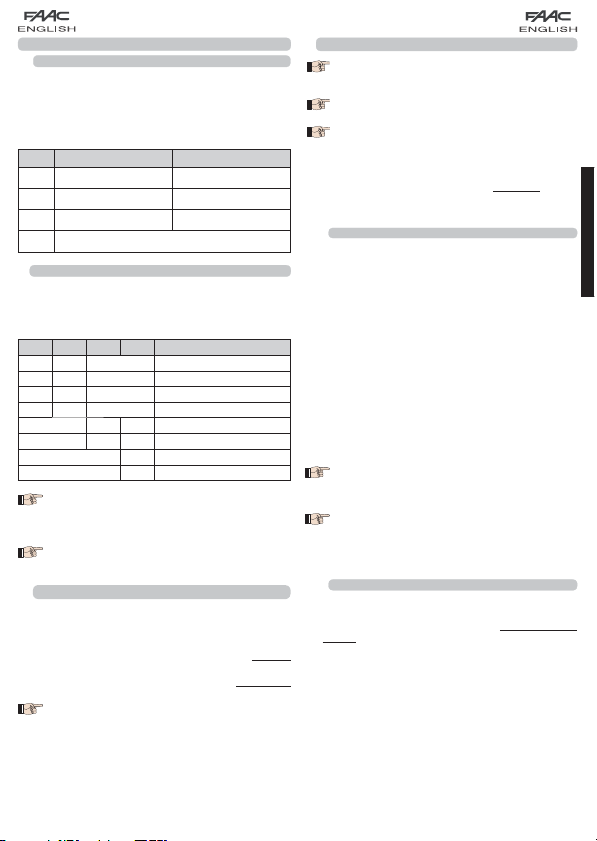

7. START-UP

7.1 LEDS CHECK

The following table shows the status of the LEDs in relation to

the status of the inputs (the closed at rest automated system

condition is shown in bold).

Check the status of the signalling LEDs as per table below:

Before any moviment is executed, the Encoders

Tab.1 – Operation of inputs status LEDs

LED ON (closed contact) OFF (open contact)

STOP Command disabled Command enabled

OPEN A Command enabled Command disabled

OPEN B Command enabled Command disabled

BUS

7.2 DIPS-SWITCH PROGRAMMING

The following tables show the settings of the DS1 dip-switches

for programming encoder sensitivity, reverse thrust, and operator force.

See par. 8.3

Tab. 2 - DS1 programming (the default settings are shown in bold)

DS1 DS2 DS3 DS4 Description

ON ON HIGH FORCE

ON OFF MEDIUM - HIGH FORCE

OFF ON MEDIUM - LOW FORCE

OFF OFF LOW FORCE

7.3 PRE-FLASHING

The pre-flashing function can be activated and disabled

(following an OPEN command, the unit activates the flashing

lamp for 3 seconds before it starts the movement). Procedure:

1.

2.

ON HIGH ENCODER SENSITIVITY

OFF LOW ENCODER SENSITIVITY

ON REVERSE THRUST ON

OFF REVERSE THRUST OFF

If you connect an electric lock to terminal J4,

position DS4 to ON to enable the reversing stroke

(before opening, the motors thrust to close, thus

facilitating the electric lock to uncouple).

If you set dip-switch DS3 to OFF, a special function

is enabled, allowing the gate to operate also

in the event of wind gusts.

Press LOGIC key (SW3) for at least 5 secs. to ACTIVATE

pre-flashing.

Press SPEED key (SW2) for at least 5 secs. to DESACTIVATE

pre-flashing.

In both cases check if the LED of the pressed key

changes its status: in such cases it means that

the function of the key and not the pre-flashing

was changed.

When the board is powered up and a SET-UP cycle has never

been executed, LEDs LD4 and LD5 begin to flash slowly to signal

that a SET-UP cycle must be executed.

There are two possible types of SETUP: AUTOMATIC and

MANUAL

To execute an AUTOMATIC SET-UP, follow the procedure below:

1.

2.

3.

4.

5.

6.

7.

8.

9.

To execute a MANUAL SET-UP, follow the procedure below:

1.

2.

3.

4.

5.

6.

7.

8.

9.

5

7.4 TIME LEARNING - SET-UP

must be wired as explained on chapter 8.1

page 6.

Before any manoeuvre is executed, a SETUP

cycle must first be run.

During SETUP do not interrupt the photocells

because their interruption causes the immediate

stop of the leaves. To end the procedure,

repeat SETUP from the beginning.

7.4.1 AUTOMATIC SET-UP

Take the leaves to mid-opening (very important).

Hold down the SET-UP (SW1) push-button until the 2 adjacent

LEDs (LD4 and LD5) light up on steady beam.

Release the SETUP push-button, LEDs LD4 and LD5 begin

to flash rapidly.

Leaf 2 (if present) starts the closing movement, stopping

when it reaches the closing mechanical stop.

Leaf 1 starts the closing movement, stopping when it

reaches the closing mechanical stop.

Leaf 2 (if present) starts the opening movement after the

Leaf 1 stops opening.

Leaf 2 (if present) stops when it reaches the opening

mechanical stop.

Wait for LEDs LD4 and LD5 to go OFF, which means that the

SETUP procedure has finished.

Give an OPEN pulse to close the gate.

When the SET-UP procedure has been started,

if the leaves at point 4 and 5 open instead of

closing, the motor power supply cables must

be changed over.

When using the AUTOMATIC SET-UP, the slow

down spaces, the leaf opening and closing

delays, and the pause time (30 sec., with A

logic), are all preset by the board and cannot

be modified.

7.4.2 MANUAL SET-UP

Take the leaves to mid-opening (very important).

Hold down the SET-UP (SW1) push-button until the leaf starts

moving.

Release the SET-UP push-button, LEDs LD4 and LD5 begin

to flash rapidly

Leaf 2 (if present) starts the closing movement, stopping

when it reaches the closing mechanical stop

Leaf 1 starts the closing movement, stopping when it

reaches the closing mechanical stop

Leaf 1 starts the closing movement, stopping when it

reaches the closing mechanical stop.

Leaf 2 (if present) starts the opening movement the after

Leaf 1 stops opening.

Leaf 2 (if present) stops when it reaches the opening

mechanical stop.

If LOW force was set, wait for about 5 sec checking if the

flashing lamp goes OFF.

ENGLISH

Page 6

10.

If the A Logic was selected, the board begins to count

the pause time (max 10 min) and, after the required time

has elapsed, give an OPENING pulse to continue the

procedure. Otherwise, if you have selected the EP logic,

give an OPEN pulse to continue the procedure.

11.

Leaf 2 (if present) starts the closing movement an the board

begins to count the delay of the leaf 1 at closing.

12.

After the required time has elapsed, give an OPEN pulse

to make leaf 1 start the closing movement. If leaf 2 is not

present, the pulse given in point 9 directly makes leaf 1

close.

13.

Leaves 1 and 2 (if present) stop when they reach the closing

mechanical stop.

14.

Wait for LEDs LD4 and LD5 to go OFF, which means that the

SETUP procedure has finished.

When the SET-UP procedure has been started,

if the leaves at point 4 and 5 open instead of

closing, the motor power supply cables must

ENGLISH

be changed over.

When using the MANUAL SET-UP, the slow-down

spaces, and leaf delays at opening are preset

by the board and cannot be modified. However,

delay at leaf closing and pause time can be

programmed during learning.

8 INSTALLATION OF BUS ACCESSORIES

This board is supplied with a BUS circuit enabling easy

connection of a high number of BUS accessories (e.g. up to

16 photocells pairs), using only two cables.

Below we describe the addressing and memory storage of the

encoders and BUS photocells.

For other future accessories, refer to the specific instructions.

8.1 ADDRESSING BUS ENCODER

Connection of the BUS input to the control board is via the

bipolar cables which come out of the encoders.

Unlike the case of the photocell devices, the polarity of the BUS

line connection determines whether the encoder belongs to

one leaf rather then the other.

This is why you must pay great attention to the indications of

the status LEDs on the body of each encoder (Fig.8).

Below we list the functions of LEDs LD1, DL2, and DL3, and their

statuses:

DL1

Tab. 3 - Encoder connection and LED status

LED LIGHTED FLASHING OFF

Power ON

and BUS

DL 1

communicating

with board

DL 2 Leaf 1 encoder / Leaf 2 encoder

Leaf

DL 3

not moving

DL 1 must always be lighted to guarantee correct connection

•

between encoder and board.

DL 2 determines the leaf on which the encoder is installed.

•

Providing the configuration is correct, the automated system

will show: an encoder with DL 2 lighted in the leaf 1, and an

encoder with DL 2 OFF in the leaf 2. If there is an incorrect

connection, i.e. indicating two encoders with the same

status of the DL 2 LEDs, during the learning procedure of the

BUS accessories, the DL 1 LEDs of both encoders show the

FLASHING status. In this situation, refer to the configuration

in TAB.3 to define which encoder connection to rotate.

DL 3 indicates, on a steady flashing beam, the reading

•

of the pulses while the leaf is moving. When the leaf is

motionless, DL 3 can be either lighted or OFF.

N.B. in particular motionless leaf positions, DL3 may flutter

considerably. This signal must not be considered a fault.

Power ON

but BUS not

communicating

Pulses read

while leaf

moving

8.2 ADDRESSING THE BUS PHOTOCELLS

Important: the same address must be given to

both transmitter and receiver.

Make sure that there are no two or more

photocells pairs with the same address.

If no BUS accessory is used, leave the BUS

connector free (J10 - Fig. 7).

Fig. 8

OFF

DL2

DL3

No Power or BUS

communication

Leaf not moving

DL3

DL3

DL1

DL2

DL2

LEAF 1 LEAF 2

ON

LEAF 2 LEAF 1

OFF

6

DL1

DL3

DL2

ON

DL1

Page 7

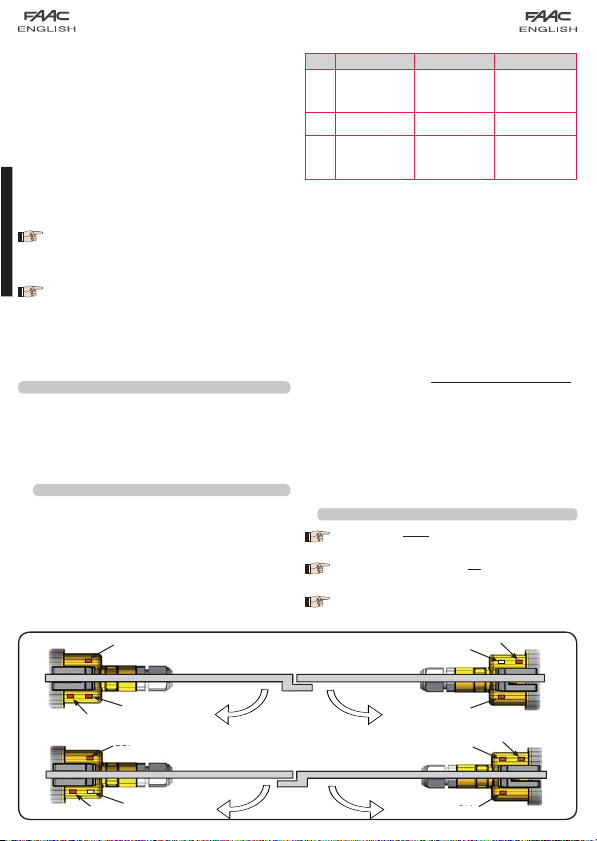

Fig. 9

A maximum of 16 BUS photocell pairs can be connected to

the board.

The photocells are split into groups:

Opening photocells: max 6

Closing photocells: max 7

Opening /Closing photocells: max 2

Photocell used as an OPEN pulse: max 1

Fig. 9 shows a 2-swing leaf automated system indicating the

coverage beams of the photocells:

A: Photocells with OPENING and CLOSING action

B: Photocells with OPENING action

C: Photocells with OPENING action

D: Photocells with CLOSING action

Table 4 shows the programming operations of the dip-switch

inside the transmitter and of the BUS Photocells receiver.

Tab. 4 - Addressing of BUS Photocells

Dip1 Dip2 Dip3 Dip4 Ref. Type

OFF OFF OFF OFF

OFF OFF OFF ON

OFF OFF ON OFF

OFF OFF ON ON

OFF ON ON OFF

OFF ON ON ON

ON OFF OFF OFF

ON OFF OFF ON

ON OFF ON OFF

ON OFF ON ON

ON ON OFF OFF

ON ON OFF ON

ON ON ON OFF

OFF ON OFF OFF

OFF ON OFF ON

ON ON ON ON / OPEN PULSE

B -C OPENING

D CLOSING

OPENING and

A

CLOSING

8.3 MEMORY STORAGE OF BUS ACCESSORIES

You can add the BUS photocells to the system at any time,

simply by memory-storing them on the board, observing the

following procedure:

1.

Install and program the accessories using the required

address (see paragraph

2.

Cut power to the board.

3.

Connect the two accessories cables to the red

terminal-board J10 (any polarity will do).

4.

Power up the board, taking care to first connect the

main power supply (transformer output) and then any

batteries.

5.

Quickly press once only the SW1 (SET-UP) push-button, to

execute learning. The BUS LED flashes.

6.

Give an OPEN impulse, leaves will move and the BUS

learning procedure is over.

The board has memory stored the BUS accessories. Follow the

instructions in the table below to check if the BUS connection

is correct.

8.2)

Tab. 5 - Description of BUS LED

Steady light

Slow flashing

lamp

every 0.5 sec)

Light OFF

(flash every 2.5

sec)

Fast flashing

lamp

every 0.2 sec)

Normal operation (LED ON even in the

absence of photocells)

At least one input engaged: photocell

engaged or not aligned, Open A or Open

(flash

B or Stop input engaged

BUS line short circuited

If you have detected a BUS connection

error, repeat the acquisition procedure. If

the error is repeated, make sure that there

(flash

is not more than one accessory with the

same address in the system (also see the

accessories instructions)

9 MEMORY STORING THE RADIO CODE

The control board has an integrated 2-channel decoding

system (DS, SLH, LC) named OMNIDEC. This system makes it

possible to memory-store both total opening (OPEN A) and

partial opening (OPEN B) of the automated system - this is

made possible by an additional receiver module (Fig.10 ref.

) and radio controls on the same frequency.

The 3 types of radio codes (DS, LSH, LC) cannot

coexist.

Only one radio code can be used at a time.

To change over from one code to another, you

must delete the existing one (see paragraph

on deletion), and repeat the memory-storage

procedure.

7

ENGLISH

Page 8

ENGLISH

9.1 MEMORY STORAGE OF DS RADIO CONTROLS

A maximum of two codes can be stored. One

on the OPEN A channel and one on the OPEN B

channel

1.

On the DS radio control, select the required ON-OFF

combination for the 12 dip-switches.

2.

Press the LOGIC (SW3) or SPEED (SW2) push-button, to

memory store respectively total opening (OPEN A) or partial

opening (OPEN B), and as you hold it down, also press the

SETUP (SW1) push-button. The relevant LED starts to flash

slowly for 5 sec.

3.

Release both push-buttons.

4.

Within these 5 sec., press the appropriate push-button on

the radio control.

5.

The relevant LED lights up on steady beam for 1 second and

then goes OFF, indicating that storage was executed.

6.

To add other radio controls, set the same ON - OFF

combination used in point 1.

9.2 MEMORY STORAGE OF SLH RADIO CONTROLS

A maximum of 250 codes can be memory

stored, split between OPEN A and OPEN B.

1.

On the SLH radio control, simultaneously press and hold

down push-buttons P1 and P2.

2.

The radio control LED begins to flash.

3.

Release both push-buttons.

4.

Press the LOGIC (SW3) or SPEED (SW2) push-button, to

memory store respectively total opening (OPEN A) or partial

opening (OPEN B), and as you hold it down, also press the

SET-UP (SW1) push-button. The relevant LED starts to flash

slowly for 5 sec.

5.

Release both push-buttons.

6.

Within these 5 sec., while the radio control LED is still flashing,

press and hold down the required push-button on the radio

control (the radio control LED lights up on steady beam).

7.

The LED on the board lights up on steady beam for 1

second and then goes OFF, indicating that storage was

executed.

8.

Release the radio control push-button.

9.

Quickly press twice the memory stored radio control

push-button.

Fig. 10

The automated system performs one opening

operation. Make sure that the automated

system is free of any obstacle created by

persons or things.

To add other radio controls, transfer the code of the

memory-stored push-button of the radio control to the relevant

push-button of the radio controls to be added, observing the

following procedure.

•

On the memory stored radio control, simultaneously press

and hold down push-buttons P1 and P2.

•

The radio control LED begins to flash.

•

Release both push-buttons.

•

Press the memory stored push-button and hold it down

(the radio control LED lights up on steady beam).

•

Bring the radio controls near, press and hold down the

push-button of the radio control to be added, releasing

it only after the double flash of the radio control LED,

which indicates memory storage executed.

•

Quickly press twice the push-button of the memory stored

radio control.

The automated system performs one opening

operation. Make sure that the automated

system is free of any obstacle created by

persons or things.

9.3 MEMORY STORAGE OF LC RADIO CONTROLS

(for some markets only)

A maximum of 250 codes can be memory

stored, split between OPEN A and OPEN B.

Use LC remote controls only with receiver module at 433

1.

MHz.

Press the LOGIC (SW3) or SPEED (SW2) push-button, to

2.

memory store respectively total opening (OPEN A) or partial

opening (OPEN B), and as you hold it down, also press the

SETUP (SW1) push-button. The relevant LED starts to flash

slowly for 5 sec.

Release both push-buttons. Within these 5 sec., press the

3.

appropriate push-button on the LC remote control.

The LED lights up on steady beam for 1 second, indicating

4.

memory storage executed, and then resumes flashing for

another 5 sec., during which another radio control (point

4) can be memory stored.

When the 5 sec. have elapsed, the LED goes OFF indicating

5.

the end of the procedure.

To add other radio controls, repeat the operation at point 1.

6.

8

Page 9

+

9.3.1 REMOTE MEMORY STORAGE OF LC RADIO

CONTROLS

Other radio controls can be remotely stored only with the

LC radio controls, i.e. without using the LOGIC-SPEED-SETUP

push-buttons, but using a previously stored radio control.

1.

Get a radio control already stored on one of the 2 channels

(OPEN A or OPEN B ).

2.

Press and hold down push-buttons P1 and P2 simultaneously

until both the LEDs flash slowly for 5 sec.

3.

Within 5 sec. press the push-button of the radio control

that had been memory stored to enable learning on the

selected channel.

4.

The LED on the board relating to the channel being learned

flashes for 5 sec., within which time the code of another

radio control must be transmitted.

5.

The LED lights up on steady beam for 2 seconds, indicating

memory storage executed, and then resumes flashing for

5 sec., during which other radio controls can be memory

stored, and then goes OFF.

9.4 RADIO CONTROLS DELETION PROCEDURE

To delete ALL the input radio control codes, press

push-button LOGIC (SW3) or SPEED (SW2) and, while holding it

down, also press push-button SETUP (SW1) for 10 sec.

The LED relating to the pressed push-button flashes for

1.

the first 5 sec, and then flashes more quickly for the next

5 sec.

Both LEDs light up on steady beam for 2 sec and then go

2.

OFF (deletion completed).

Release both push-buttons.

3.

This operation is NOT reversible. All codes of

radio controls stored as OPEN A and OPEN B will

be deleted.

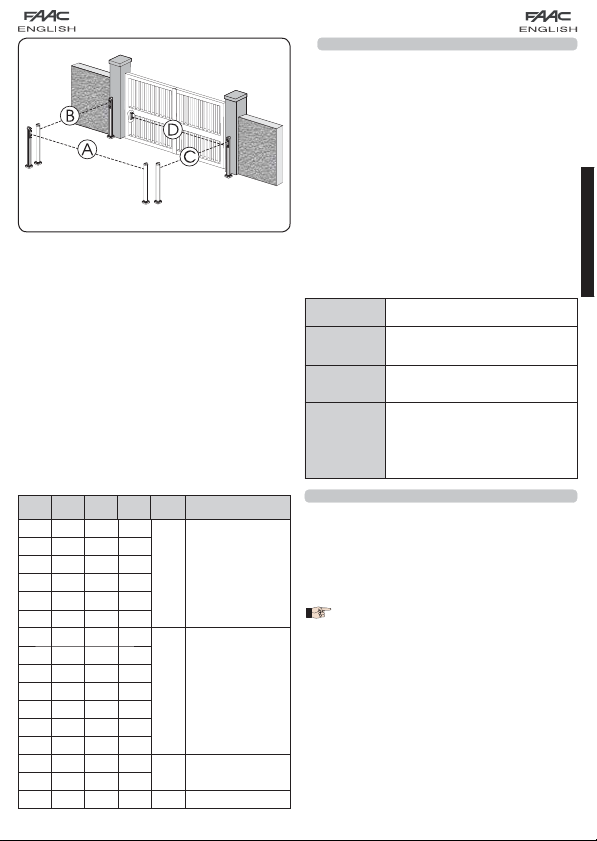

10.1 BATTERY KIT

The buffer battery kit was built for insertion inside the control

board support.

This support (Fig.11 ref.) was pre-moulded to permit the

battery housing to be opened.

Remove the board support material covering the

1.

battery housing, cutting the material connections along

the perimeter.

Fig. 11

Insert the battery in the housing you have just created, and

2.

secure it on the anchoring supports (Fig.12).

10 mm

ENGLISH

10 CONNECTION OF BUFFER BATTERIES (OPTIONAL)

The buffer battery kits will activate the automated system also

in the event of a power cut. The housing of the batteries is

specified in different configurations according to the type of

batteries used.

For correct positioning, observe the following instructions,

referring to your type of battery.

The batteries come into operation when a mains

power cut occurs.

16 mm

+

Fig. 12

To correctly fasten and connect the kit to the control

3.

unit, consult the instructions enclosed with the

battery kit.

11 AUTOMATED SYSTEM TEST

When you have finished programming, check if the system is

operating correctly. In particular, check if the safety devices

are operating correctly.

9

Page 10

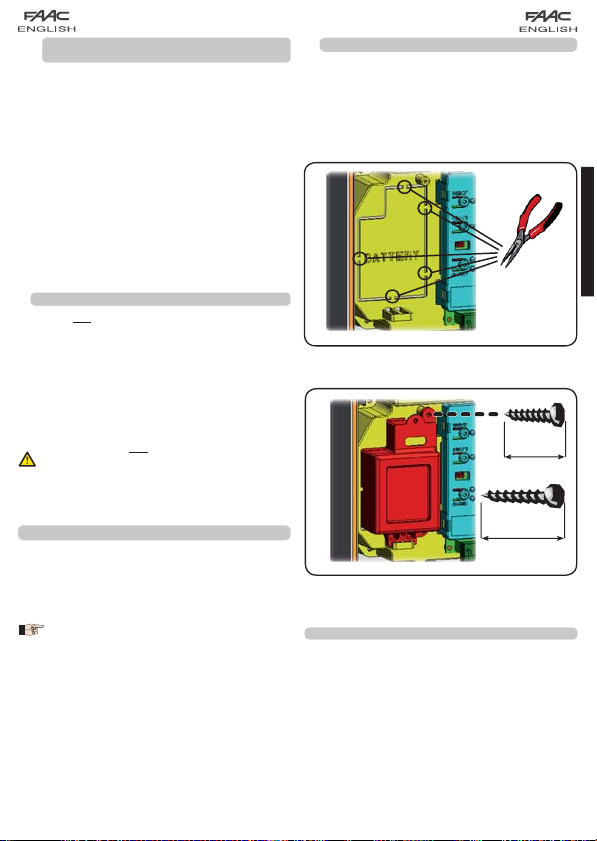

12 LOGIC TABLES

ENGLISH

FSW-OPEN

opens leaves and

closes after pause

no effect (opening

no effect

no effect (opening

no effect (opening

opens leaf 1 and

closes after pause

OPEN A OPEN B STOP FSW-OP FSW-CL FSW-OP/CL

opens leaves and

closes after pause

time

no effect (1)

inhibited)

to open at

stops and continues

no effect

inhibited)

at closing

reverses immediately

inhibited)

time

time

time

recharges pause

(closing inhibited) (1)

time

disengagement

recharges pause

(closing inhibited)

time

recharges pause

(closing inhibited)

at opening

opens leaves

reverses immediately

stops and, at

disengagement,

no effect (opening

reverses at opening

and closing inhibited)

inhibited)

at opening

no effect (closing

reverses immediately

inhibited)

no effect (opening

stops operation no effect

no effect (opening

and closing inhibited)

at opening

reverses immediately

at opening

reverses immediately

opens leaves

inhibited)

no effect (opening

no effect

inhibited)

no effect (opening

inhibited)

no effect (opening

OPEN A OPEN B STOP FSW-OP FSW-CL FSW-OP/CL FSW-OPEN

opens leaves opens leaf 1

no effect (1)

no effect (1)

inhibited)

to open at

disengagement

no effect (closing

stops and continues

inhibited)

no effect

no effect (closing

no effect

at closing

reverses immediately

inhibited)

no effect (closing

at opening

opens leaves

reverses immediately

stops and, at

disengagement,

no effect (opening

reverses at opening

and closing inhibited)

inhibited)

at opening

no effect (closing

reverses immediately

inhibited)

no effect (opening

no effect (opening

and closing inhibited)

direction

After STOP: Re-closes the leaf/ves

After OPEN: Restarts moving in reverse

(1)

immediately

Tab. 5

LOGIC “A” PULSES

STATUS OF AUTOMATED

SYSTEM

CLOSED

OPENING no effect stops operation

OPEN IN PAUSE recharge the pause time stops operation no effect

CLOSING

STOPPED closes closes

SYSTEM

CLOSED

LOGIC “EP” PULSES

STATUS OF AUTOMATED

Tab. 6

10

OPEN closes closes

OPENING stops operation (1) stops operation stops operation

CLOSING stops operation stops operation stops operation no effect

STOPPED

(1) If the cycle began with OPEN-B (partial opening), an OPEN-A pulse will activate both leaves to open.

Loading...

Loading...