Page 1

INDEX

1. DESCRIPTION page.12

2. TECHNICAL SPECIFICATIONS page.12

3. PREPARATIONS page.12

4. BOARD LAY-OUT page.13

5. CONNECTION LAY-OUT page.13

6. DESCRIPTION OF CONNECTIONS page.13

6.1. TERMINAL BOARD CN1 page.13

6.2. TERMINAL BOARD CN2 page.14

6.3 MOTOR CONNECTION page.15

6.4. BATTERY KIT page.15

7. DIP-SWITCH ADJUSTMENT page.15

7.1. OPEN BEAM FUNCTION page.16

8. MEMORY STORING THE RADIO CODE page.16

8.1. Memory storage of DS radio controls page.16

8.2. Memory storage of SLH radio controls page.16

8.3. Memory storage of LC radio controls page.17

8.4. Deletion of radio codes page.17

9. OBSTACLE DETECTION SENSITIVITY page.17

10. PROGRAMMING page.18

11. CONTROL LEDs page.18

12. FUNCTION LOGICS page.19

ENGLISH

CE DECLARATION OF CONFORMITY

Manufacturer: FAAC S.p.A.

Address: Via Benini, 1 - 40069 Zola Predosa BOLOGNA - ITALY

Declares that: Control unit mod. E604 24V

• conforms to the essential safety requirements of the following EEC directives:

73/23/EEC and subsequent amendment 93/68/EEC.

89/336/EEC and subsequent amendment 92/31/EEC and 93/68/EEC

Additional information:

This product underwent a test in a typical uniform configuration (all products manufactured by FAAC S.p.A.).

Bologna, 10-10-2007

Managing Director

A. Bassi

The symbol indicates notes that are important for the safety of persons and for the good condition of the

Read this installation manual to the full before you begin installing the product.

The symbol draws your attention to the notes on the characteristics and operation of the product.

Notes on reading the instruction

automated system.

11

Page 2

CONTROL UNIT E604

1. DESCRIPTION

Thanks to its high powered microprocessor, this 24 Vdc control unit for automatic barriers offers a wide range of

adjustments, including deceleration and motor control.

Thanks to its integrated encoder, the control unit constantly controls rod position and movement, intervening as

soon as a faulty situation is detected.

The FAILSAFE function makes it possible to detect any faults in the operation of the photocells.

The main operating modes and functions are set by a dip-switch, whereas the adjustment of work and pause times

is done by self learning during programming.

2. TECHNICAL SPECIFICATIONS

Power supply voltage 230 (+6% -10%) 50 Hz / 115 Vac 60 Hz

Supply voltage of control unit

Absorbed power 3 W

Motor nominal power 48 W

Accessories max. load 500 mA

ENGLISH

Flashing lamp max. load 15 W

Max. load for beam lights 15 W

Max. load for courtesy light/indicator light 5 W

Operating ambient temperature -20° +55°

Protective fuse F1=8 A F2=500 mA F3=630 mA (resettable)

Function logics Automatic - Condo - Semi-automatic

Opening / closing time Through self-learning during programming

Pause time Through self-learning during programming

Obstacle detection Trimmer-adjustable

Selectable functions

Terminal board inputs

Inputs with connector Battery kit - Radio connector

Terminal board outputs

Board dimensions 79 x 158 mm

Characteristics of optional batteries See kit on price list

a According to mains voltage, there may be different output values on the board power feed terminals.

Before putting into service, always check if the output voltage on the secondary winding of the transformer

is from 20 Vac to 26 Vac. Voltage must always be measured load free.

Type of logic - Operation of open command - No mains

power supplied function - Beam lights flashing - Safety

Power supply - Earth - Close - Open - Open/Close - Stop

Power supply for accessories - On beam lights - Indicator

24 Vac nominal a

devices behaviour

- Safety devices - Failsafe

light - Flashlight

3. PREPARATIONS

To ensure people’s safety, all warnings and instructions in this booklet must be carefully observed. Incorrect

installation or incorrect use of the product could cause serious harm to people.

Make sure that an adequate differential switch is installed upstream of the system as specified by current

•

regulations.

On the main power supply, install a thermal breaker with omnipolar switching.

•

Make sure that an adequate earthing system is available.

•

To lay cables, use adequate rigid and/or flexible tubes.

•

Always separate the connecting cables of low voltage accessories from those supplying 230/115 Vac, using

•

separate sheaths to avoid possible interference.

12

Page 3

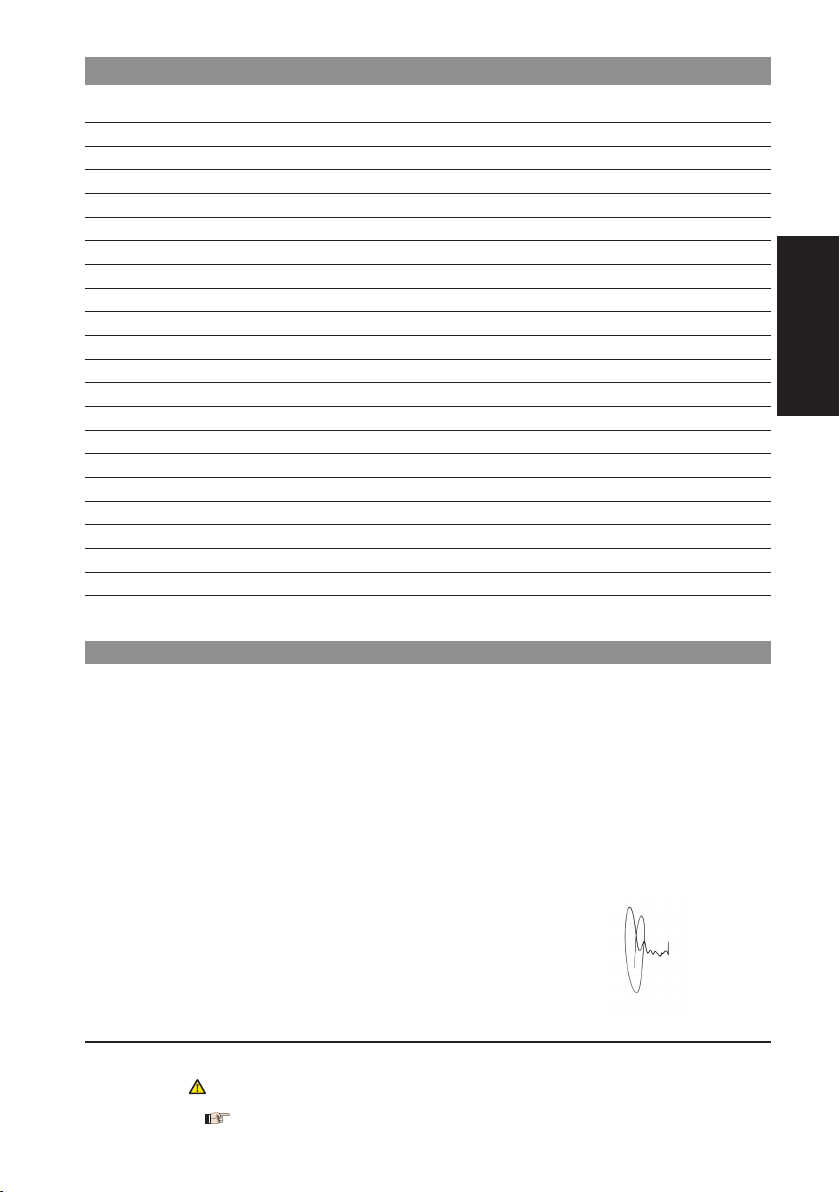

4. BOARD LAY-OUT

CN1 Power supply terminal-board

CN1 Power supply terminal-board

CN2 Commands terminal-board

CN2 Commands terminal-board

JP2 Battery kit connector

JP2 Battery kit connector

JP3 Connector for receiver module

JP3 Connector for receiver module

JP4 Power supply to RH closing motor

JP4 Power supply to RH closing motor

JP5 Power supply to LH closing motor

JP5 Power supply to LH closing motor

Trimmer for adjusting obstacle detection

Trimmer for adjusting obstacle detection

TR1

TR1

sensitivity

sensitivity

P1 Programming push-button

P1 Programming push-button

P2 OPEN channel memory storage push-button

P2 OPEN channel memory storage push-button

P3

OPEN/CLOSE channel memory storage push-button

P3

OPEN/CLOSE channel memory storage push-button

F1 Board protection fuse

F1 Board protection fuse

DL1 CLOSE contact LED

DL1 CLOSE contact LED

DL2 OPEN contact LED

DL2 OPEN contact LED

DL3 OPEN/CLOSE contact LED

DL3 OPEN/CLOSE contact LED

DL4 STOP contact LED

DL4 STOP contact LED

DL5 Photocells status LED

DL5 Photocells status LED

DL6 OPEN contact signalling LED

DL6 OPEN contact signalling LED

DL7 OPEN/CLOSE contact signalling LED

DL7 OPEN/CLOSE contact signalling LED

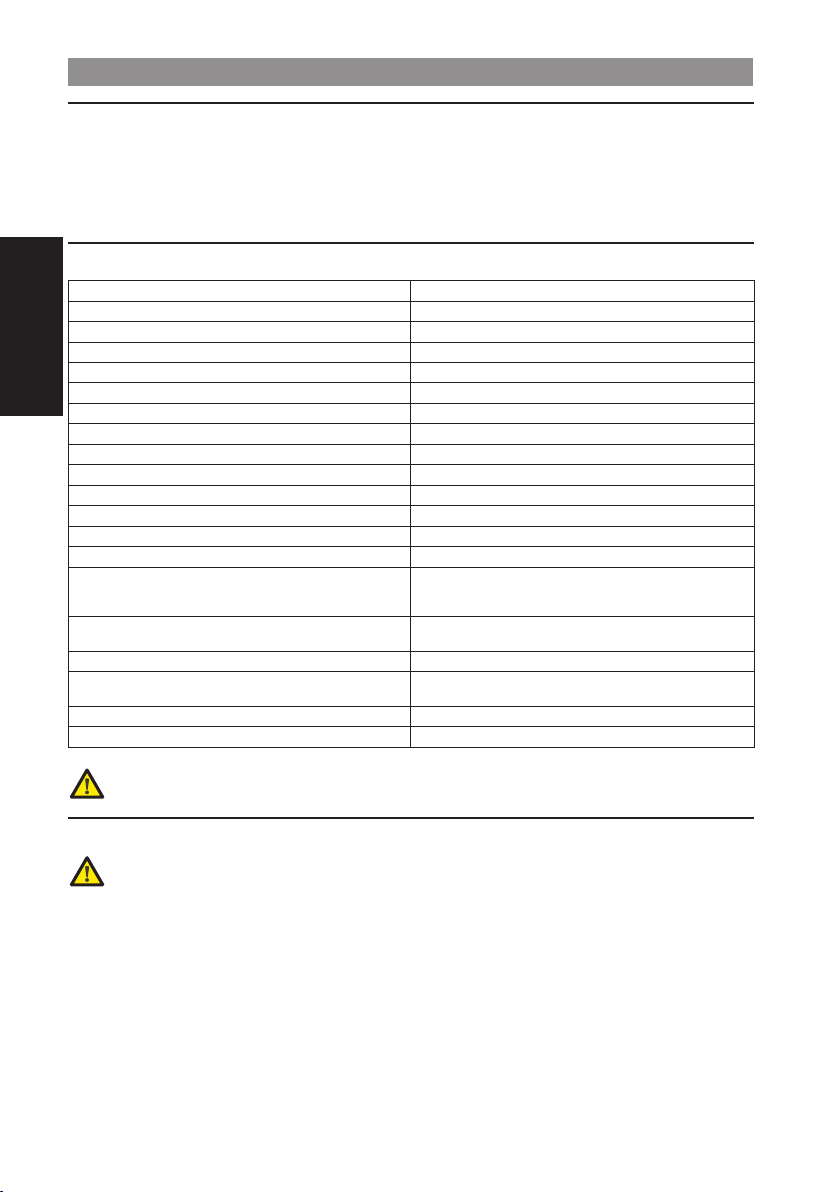

5. CONNECTION LAY-OUT

COMPONENTS

COMPONENTS

Fig. 1Fig. 1

ENGLISH

6. DESCRIPTION OF CONNECTIONS

6.1. TERMINAL BOARD CN1

6.1.1. power supply

Terminals “1 & 2”. The secondary winding wires of the toroidal transformer must be connected to these terminals.

Before making this connection, check if the voltage at the transformer output is in the range from 20 Vac to 26 Vac

6.1.2. eArthing

Terminal “3”. To this terminal, connect the earthing wire coming from the terminal inside the motor body.

The connection is absolutely necessary for correct operation of the control unit.

13

Fig. 2Fig. 2

Page 4

6.1.3. FAlsAFe

Terminal “4 ”. Connect to this terminal, the negative terminal of the photocell transmitters. By making this

connection, the control unit, before every manoeuvre, runs a test on the photocells, controlling correct operation. If

you use photocells, this terminal must be connected to ensure the control unit operates correctly.

6.1.4. power supply For Accessories

Terminals “5 & 6”. 24 Vdc output max. 500 mA for feeding the external accessories.

• Maximum load of this output is 500 mA.

• Observe the power supply polarity.

6.2. TERMINAL BOARD CN2

6.2.1. beAm lights

Terminals “7 & 10”. Output 24 Vdc max.15 W. The wires feeding the luminous strip should be connected to these

terminals. The operation of the luminous strip is defined by using dip-switch 5 - see paragraph 7.

Terminal “10” is the negative polarity output.

6.2.2. indicAtor light

Terminals “8 & 10”. Output 24 Vdc max. 5 W. An indicator light, if any, should be connected to these terminals. The

ENGLISH

indicator light makes it possible to see the beam status from a remote position, e.g. a porter’s lodge - details:

Beam opening is identified by fast flashing.

•

When the beam is open, the indicator light stays lighted on a steady light-beam.

•

Beam closing is identified by slow flashing.

•

When the beam is closed, the indicator light stays OFF.

•

• 24 Vdc max. 5 W lamps can be connected to this output.

• Terminal “10” is the negative polarity output.

6.2.3. FlAshing light

Terminals “9 & 10”. Output 24 Vdc max.15 W. A steady beam flashing light is connected to these terminals - flashing

is controlled by the control unit. The flashing light is active while the beam is moving, whereas when the beam is idle,

whether open or closed, it stays OFF. Pre-flashing of 0.5 sec was inserted before the beam opening manoeuvre, to

signal that the beam is about to move. In addition to signalling beam movement, the flashing light signals - by a

series of flashes - that the beam is being powered by the buffer battery (optional).

Terminal “10” is the negative polarity output.

6.2.4. close

Terminals “10 & 11”. Normally open contact. Connect, between these 2 terminals, any pulse generator (e.g.

push-button, key selector, etc..) which, by closing the contact, commands beam closure only. The status of this

input is signalled by LED “DL1”.

• The CLOSE command is not active during programming.

• If there are several pulse generators, they must be connected in parallel.

6.2.5. open

Terminals “10 & 12”. Normally open contact. Connect, between these 2 terminals, any pulse generator (e.g.

push-button, key selector, etc..) which, by closing the contact, commands beam opening only. The status of this

input is signalled by LED “DL2”.

• The OPEN command is not active during programming.

• If there are several pulse generators, they must be connected in parallel.

6.2.6. open / close

Terminals “10 & 13”. Normally open contact. Connect, between these 2 terminals, any pulse generator (e.g.

push-button, key selector, etc..) which, by closing the contact, commands beam opening and/or closing. The

behaviour of this input is defined by dip-switch 2, see paragraph 7. The status of this input is signalled by LED “DL3”.

• If there are several pulse generators, they must be connected in parallel.

6.2.7. stop

Terminals “10 & 14”. Normally closed contact. Connect, between these 2 terminals, any pulse generator (e.g.

push-button, key selector, etc..) which, by opening the contact, must command immediate stop of the beam and

the de-activation of any automatic re-closure. To resume the normal programmed cycle after this contact has been

activated, use any pulse generator which commands the opening and/or closing of the beam. The status of this

input is signalled by LED “DL4”.

• If there are several pulse generators, they must be connected in series.

14

Page 5

6.2.8. sAFety devices

Terminals “10 & 15”. Normally closed contact. Connect, to these terminals, any safety device (e.g. photocells)

which, by opening the contact, acts on beam motion. They can be active only during closure, or active in both

closing and opening, according to the position of dip-switch 6, see paragraph 7.

Safety devices active at closure

If the safety devices are activated during closure, the control unit immediately reverses beam movement until

opening is complete without disabling - if selected - automatic re-closing of the beam.

Safety devices active at closure and opening:

In this case the safety devices are active on both beam movements. If the safety devices are activated during

closure, the control unit immediately reverses beam movement until opening is complete without disabling - if

selected - automatic re-closing of the beam. If the safety devices are activated during opening, the control unit

immediately stops beam movement and keeps it stopped until the safety device is reset (obstacle removed), and

only then will the opening manoeuvre which had been started be resumed.

The status of this input is signalled by the LED located under the contact.

•If the safety devices are not used, a connection must be made between terminal 4 and terminal 15.

• If there are several safety devices, they must be connected in series.

6.3 MOTOR CONNECTION

The automated system is supplied designed for right hand closure, with the motor connected to connector JP4. For

left hand closure, the motor must be connected to connector JP5.

To identify beam closing direction, look at the automated system from the side of the release device. If the beam

has to descend on the left of the automated system in order to close, left hand closure is involved, vice-versa, if the

beam has to descend on the right of the automated system in order to close, right hand closure is involved.

Two motors cannot be connected to the same control unit.

6.4. BATTERY KIT

A battery kit can be connected to the board - see price list - to make up for a possible power cut.

For correct positioning of the battery kit inside the motor body, refer to the instruction for the mechanical part.

The battery kit must be connected to connector JP2.

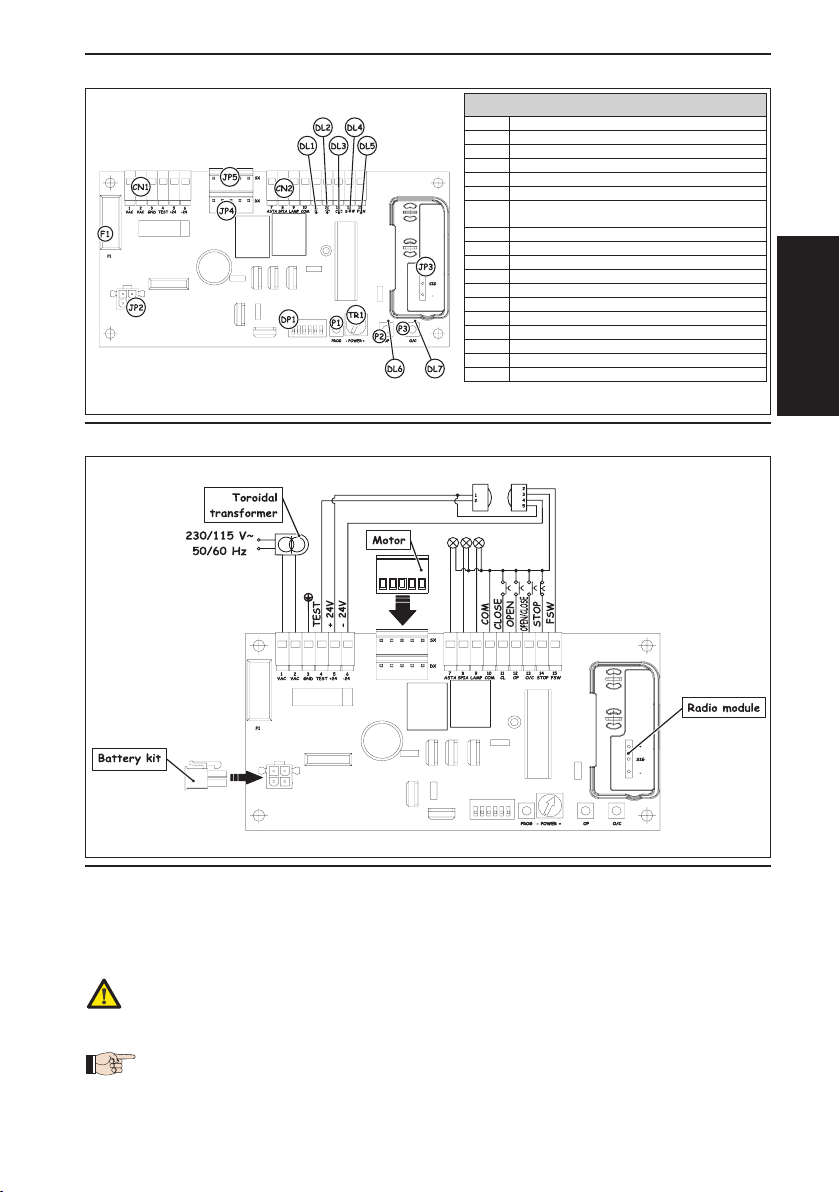

7. DIP-SWITCH ADJUSTMENT

6 dip-switches are located on the control unit. They command the behaviour of the automated system and of the

safety devices connected to it. The behaviour of every dip-switch is summarised on the following table:

CONDO LOGIC

ON Condo logic activated

ON Condo logic activated

OFF Condo logic disabled

OFF Condo logic disabled

ON Open / Stop / Close / Stop ...

ON Open / Stop / Close / Stop ...

OFF Open / Close / Open .....

OFF Open / Close / Open .....

ON Automatic closing activated

ON Automatic closing activated

OFF Automatic closing disabled

OFF Automatic closing disabled

CONDO LOGIC

OPEN/CLOSE INPUT BEHAVIOUR

OPEN/CLOSE INPUT BEHAVIOUR

AUTOMATIC CLOSING

AUTOMATIC CLOSING

ENGLISH

OPEN BEAM (see paragraph 7.1)

ON Open beam function activated

ON Open beam function activated

OFF Open beam function disabled

OFF Open beam function disabled

ON

ON

OFF

OFF

ON Photocells ON both during closing and opening

ON Photocells ON both during closing and opening

OFF Photocells ON during closing only

OFF Photocells ON during closing only

OPEN BEAM (see paragraph 7.1)

BEAM LIGHT

Beam light ON when beam open and closed, flashing

Beam light ON when beam open and closed, flashing

while beam is moving.

while beam is moving.

Beam light OFF when beam open and closed, flashing

Beam light OFF when beam open and closed, flashing

while beam is moving.

while beam is moving.

BEAM LIGHT

PHOTOCELLS

PHOTOCELLS

15

Page 6

7.1. OPEN BEAM FUNCTION

With this function, combined or not with the battery kit, the following beam behaviour patterns are possible:

without bAttery kit

Dip-switch 4=OFF: If there is a mains power cut, the beam stays stopped in the position it is in. When mains power

returns, after 2 seconds the control unit automatically commands the beam to close, preparing itself for normal

operation.

Dip-switch 4=ON: If there is a mains power cut, the beam stays stopped in the position it is in. When mains power

returns, a pulse must be sent to ensure that the control unit resumes normal operation.

with bAttery kit

Dip-switch 4=OFF: If there is a mains power cut, the beam continues operating normally. At every opening, the

flashing light flashes twice consecutively, at intervals of 3 seconds between the flashes, for a maximum time of

30 seconds, signalling that the beam is battery powered. When mains power is resumed, the automated system

resumes normal operation.

The number of cycles possible with the automated system battery powered, depends on the battery

charge level, on the time elapsing since mains power was stopped, and on the conditions of the

automated system, external temperature etc...

Dip-switch 4=ON: In the event of a mains power cut, the automated system automatically opens the beam,

stopping it in vertical position and disabling all the commands. When mains power returns, if automatic logic

was selected, the automated system automatically performs a closing movement preparing itself for normal

ENGLISH

operation. Vice-versa, if manual logic was selected, the automated system waits for a pulse to resume normal

operation.

8. MEMORY STORING THE RADIO CODE

The control board has an integrated 2-channel decoding system (DS, SLH, LC) named OMNIDEC. This system makes

it possible to memory-store both OPEN command and the OPEN/CLOSE command of the automated system - this is

made possible by an additional receiver module and radio controls on the same frequency.

• The 3 types of radio codes (DS, LSH, LC) cannot coexist. Only one radio code can be used at a time. To

change over from one code to another, you must delete the existing one (see paragraph 8.3), and repeat

the memory-storage procedure.

• Fitting and, if necessary, removing the receiver module must be done only after cutting power to the board.

• The receiver module can only be inserted in one position. Orient the module correctly without forcing.

8.1. Memory storage of DS radio controls

A maximum of two codes can be stored. One on the OPEN channel and one on the OPEN/CLOSE channel.

On the DS radio control, select the required ON-OFF combination for the 12 dip-switches.

1.

On the control unit, press the push-button of the channel you wish to memory store, P2 for the OPEN channel or

2.

P3 for the OPEN/CLOSE channel.

The relevant LED on the control unit begins to flash - release the push-button.

3.

On the radio control, press the push-button with which you wish to associate the selected channel.

4.

The LED on the control unit lights up on steady beam for about one second, signalling that the radio control was

5.

stored in the memory, then it resumes flashing.

To add other radio controls or memory store the second channel, repeat the operations from point 1

6.

8.2. Memory storage of SLH radio controls

You can memory store up to a maximum of 250 codes, subdivided between the two channels, OPEN and

OPEN/CLOSE.

On the radio control, simultaneously press and hold down push-buttons P1 and P2 (see radio control instructions).

1.

After about one second, the LED of the radio control begins to flash.

2.

Release both push-buttons.

3.

Press and hold down push-button P2 or P3 on the board to respectfully memory store the OPEN or OPEN/CLOSE

4.

channel. The relevant LED begins to flash.

Simultaneously press the push-button of the radio control with which you wish to associate the selected

5.

command.

Check if the LED relating to the command being memory stored (DL6 for the OPEN channel or DL7 for the OPEN/

6.

CLOSE channel) lights up on steady beam for about two seconds to confirm correct memory storage.

To finish programming, press twice in close succession, the push-button of the memory stored radio control.

7.

The automated system will perform an opening manoeuvre - make sure that there are no obstacles inside the

operating range.

To memory store the other channel, repeat all the procedure from point 1.

8.

To add other radio controls, transfer the code of the memory-stored push-button of the radio control to the relevant

push-button of the radio controls to be added, repeating the memory storage procedure or observing the following

procedure:

On the memory stored radio control, simultaneously press and hold down push-buttons P1 and P2 (see radio

•

control instructions).

The radio control LED begins to flash.

•

Release both push-buttons.

•

16

Page 7

Put the two radio controls frontally into contact.

•

On the memory stored radio control, press and hold down the push-button relating to the channel you wish to

•

transfer - the radio control LED lights up on steady beam.

On the radio control to be memory stored, press the required push-button and release it after the radio control has

•

flashed twice.

To finish programming, press twice in close succession, the push-button of the memory stored radio control.

•

The automated system will perform an opening manoeuvre - make sure that there are no obstacles inside the

operating range.

8.3. Memory storage of LC radio controls

You can memory store up to a maximum of 250 codes, subdivided between the two channels, OPEN and

OPEN/CLOSE.

Use LC remote controls only with receiver module at 433 MHz.

1.

On the control unit, press the push-button of the channel you wish to memory store, P2 for the OPEN channel or

2.

P3 for the OPEN/CLOSE channel.

The relevant LED on the control unit begins to flash - release the push-button.

3.

On the radio control, press the push-button with which you wish to associate the selected channel.

4.

The LED on the control unit lights up on steady beam for about one second, signalling that the radio control was

5.

stored in the memory, then it resumes flashing.

During this stage further radio controls can be stored in the memory.

6.

After about 10 seconds, the control unit automatically exits the learning stage.

7.

To add other radio controls or memory store the second channel, repeat the operations from point 1

8.

8.3.1. remote memory storAge oF lc rAdio controls

Other radio controls can be remotely stored only with the LC radio controls, i.e. without using the push-buttons of the

control unit,, but using a previously stored radio control.

Get a radio control already memory stored on one of the 2 channels.

1.

Step near to the automated system.

2.

Press and hold down push-buttons P1 and P2 (see radio control instructions) simultaneously for about 5 seconds.

3.

Within 5 seconds, press, on the memory stored radio control , the push-button you wish to transfer to the new

4.

radio control. In this way the learning stage on the selected channel is activated on the control unit.

Within 5 seconds, press, on the new radio control, the push-button you wish to associate with the selected

5.

channel.

After the new radio control has been stored in the memory, the control unit keeps the learning mode active on

6.

the selected channel for about 5 seconds.

During these 5 seconds, other radio controls can be memory stored on the control unit, as ever associated with

7.

the activated channel.

When 5 seconds have elapsed from memory-storage of the last radio control, the control unit automatically

8.

exits the learning stage.

To check if the radio control was correctly memory stored, wait for 5 seconds after sending the code.

9.

8.4. Deletion of radio codes

To delete all the radio controls stored in the memory, go through the following procedure:

Press and hold down one of the two push-buttons P2 or P3.

1.

The relevant LED begins to flash.

2.

After five seconds, the LED starts to flash at high speed.

3.

After another five seconds both LEDS, DL6 and DL7 light up on steady beam.

4.

Release the push-button.

5.

This operation is irreversible, and all radio controls associated with both the OPEN and the OPEN/CLOSE

command will be deleted.

ENGLISH

9. OBSTACLE DETECTION SENSITIVITY

The obstacle detection device enables the control unit to detect any obstacles while the beam is moving. As this is

an electronic device, it stays constant through time and is not subject to variations - this guarantees an automated

system with a constant safety level.

By using the TR1 trimmer, you can increase or reduce the obstacle detection sensitivity. Turn the trimmer clockwise to

increase detection sensitivity, vice-versa turn it anti-clockwise to reduce obstacle detection sensitivity.

This device is active both during the beam closing stage and during the beam opening stage.

If it operates during the opening stage, it stops the operation of the automated system and reverses motion for 1

second. At this point, a pulse must be sent to the control unit, to resume normal programmed operation.

If it operates during the closing stage, it reverses operation until the automated system is completely open without

disabling any automatic closing.

If it operates three times in succession, it blocks the operation of the automated system and locates itself in stop

position, disabling automatic closing, if it was activated. To restore normal operation, you must command the beam

to open or close. Behaviour patterns will differ, according to the command sent:

OPEN or OPEN/CLOSE pulse: In this case, the beam starts an opening manoeuvre at slower speed until the beam is

completely open. When complete opening has been reached, the beam resumes its normal operating cycle,

re-activating automatic re-closing, if it had been enabled.

CLOSE pulse: In this case, the beam starts a closing manoeuvre at slower speed until the beam is completely closed.

When closed, the beam resumes its normal operating cycle, re-activating automatic re-closing, if it had been

enabled.

17

Page 8

10. PROGRAMMING

When the control unit is first powered up, a programming cycle must be performed. The board keeps all

commands disabled, with the exception of programming push-button P1, and of the pulse generators

connected to the OPEN/CLOSE input

When you have made the connections of all the accessories and generators, program the operating cycle.

To program the control unit, follow the instructions below:

Turn the differential switch of the control unit, to make sure that the automated system is not powered.

1.

Release the automated system, using the release device - see instructions for the mechanical part - and position

2.

the beam at about half of its opening angle (45°).

Re-lock the beam and make sure that it cannot be moved manually.

3.

Power up the system.

4.

Press P1 for about 1 second, the flashing lamp goes on at steady beam.

5.

Supply an OPEN/CLOSE command by means of any device connected to this input: the beam starts moving.

6.

The first manoeuvre the beam carries out is in closing. If the automated system starts an opening manoeuvre,

check if the motor connector is correctly connected, as described in paragraph 6.3.

Restore power and repeat the procedure from point 5.

7.

When the closing mechanical stop is reached, the beam begins the opening manoeuvre.

8.

When maximum opening is achieved, the pause time count for automatic re-closure begins.

9.

When the required time has elapsed, supply another OPEN/CLOSE pulse, and the automated system will begin

10.

the closing stage.

ENGLISH

When the closing position is reached, the flashing lamp goes off and programming has finished.

11.

During the programming procedure, the beam moves more slowly and the safety devices are disabled.

11. CONTROL LEDs

There are 7 control LEDs on the control unit. The meanings of the LEDs are shown on the table below:

INPUT LEDS

LED ON OFF

DL1 - CLOSE Input Active command Inactive command

DL2 - OPEN input Active command Inactive command

DL3 - OPEN/CLOSE input Active command Inactive command

DL4 - STOP input Inactive command Active command

DL5 - FSW input Safety devices free Safety devices engaged

PROGRAMMING LEDS

LED ON OFF

DL6 - OPEN channel Active input Inactive input

DL7 - OPEN/CLOSE channel Active input Inactive input

The bold print indicates the condition of the LEDs with the control unit powered up and the beam closed in

rest position.

18

Page 9

commands

Disables OPEN

at release resets

Disables commands

pause time

opens at release

restarts after release

Stops movement and

Stops movement and

commands

Disables OPEN

Disables commands

opens at release

restarts after release

Stops movement and

Stops movement and

PHOTOCELLS

STOP

INPUTS

OPEN / CLOSE

No effect

it disables all

No effect (if active,

Opens and re-closes

pause time

at release resets

Disables commands

commands)

Stops operation

after pause time

Reverses motion on

Re-closes immediately

opening

Reverses motion on

Stops operation No effect

Stops operation

closing

opening

Reverses motion on

PHOTOCELLS

STOP

INPUTS

OPEN / CLOSE

No effect

Disables all

commands

commands)

it disables all

No effect (if active,

Stops operation No effect

closing

Reverses motion on

opening

Reverses motion on

ENGLISH

Stops operation

opening

Reverses motion on

12. FUNCTION LOGICS

LOGIC A (Automatic) DIP-SWITCH 1=ON / DIP-SWITCH 3=OFF

DIP-SWITCH 2=ON DIP-SWITCH 2=OFF DIP-SWITCH 6=OFF DIP-SWITCH 6=ON

Opens and re-closes

after pause time

Stops operation and,

at next pulse, closes

at next pulse, opens

Stops operation and,

LOGIC E (Semi-automatic) DIP-SWITCH 1=OFF / DIP-SWITCH 3=OFF

DIP-SWITCH 2=ON DIP-SWITCH 2=OFF DIP-SWITCH 6=OFF DIP-SWITCH 6=ON

BARRIER STATUS

OPEN CLOSE

No effect

after pause time

Opens and re-closes

CLOSED

OPEN IN PAUSE Reloads pause time Closes immediately Stops operation

AT OPENING No effect Closes

AT CLOSING Reverses on opening No effect

19

BARRIER STATUS

OPEN CLOSE

CLOSED Opens No effect Opens Opens

OPEN No effect Closes immediately Re-closes immediately Re-closes immediately Stops operation

AT CLOSING Reverses on opening No effect Stops operation

AT OPENING No effect Closes Stops operation

Page 10

Disables OPEN

PHOTOCELLS

pause time

commands

Disables commands

and at release resets

Stops movement and

opens at release

restarts after release

Stops movement and

ENGLISH

INPUTS

LOGIC CN (Condo) DIP-SWITCH 1=ON / DIP-SWITCH 3=ON

No effect

STOP

it disables all

No effect (if active,

Opens and re-closes

OPEN / CLOSE

DIP-SWITCH 2=ON DIP-SWITCH 2=OFF DIP-SWITCH 6=OFF DIP-SWITCH 6=ON

Opens and re-closes

No effect

pause time

Disables commands

and at release resets

commands)

after pause time

after pause time

Reverses motion on

opening

Reverses motion on

Stops operation

opening

Reverses motion on

opening

No effect No effect Stops operation No effect

Reverses motion on

closing

BARRIER STATUS

OPEN CLOSE

after pause time

Opens and re-closes

CLOSED

OPEN IN PAUSE Reloads pause time Closes immediately Reloads pause time Re-closes immediately Stops operation

20

AT CLOSING Reverses on opening No effect

AT OPENING No effect

Loading...

Loading...