Page 1

E145

E145

Page 2

CE DECLARATION OF CONFORMITY

The manufacturer

Company name:

Address:

hereby declares that the following product:

Description: control board

Model: E145

conforms to the essential safety requirements of the following ECC directives:

ENGLISH

st

Bologna, January the 1

2016 CEO

FAAC S.p.A. Soc. Unipersonale

Via Calari, 10 - 40069 Zola Predosa BOLOGNA - ITALY

Low Voltage Directive 2014/35/EU

Electromagnetic Compatibility Directive 2014/30/EU

Directive ROHS 2011/65/EU

Furthermore, the following harmonised standards have been applied:

EN 60335-1:2012 + A11:2014 - EN 61000-6-2:2005 - EN 61000-6-3:2007 + A1:2011

Additional note: this product underwent tests in a typical uniform configuration (all products

manufactured by FAAC S.p.A.).

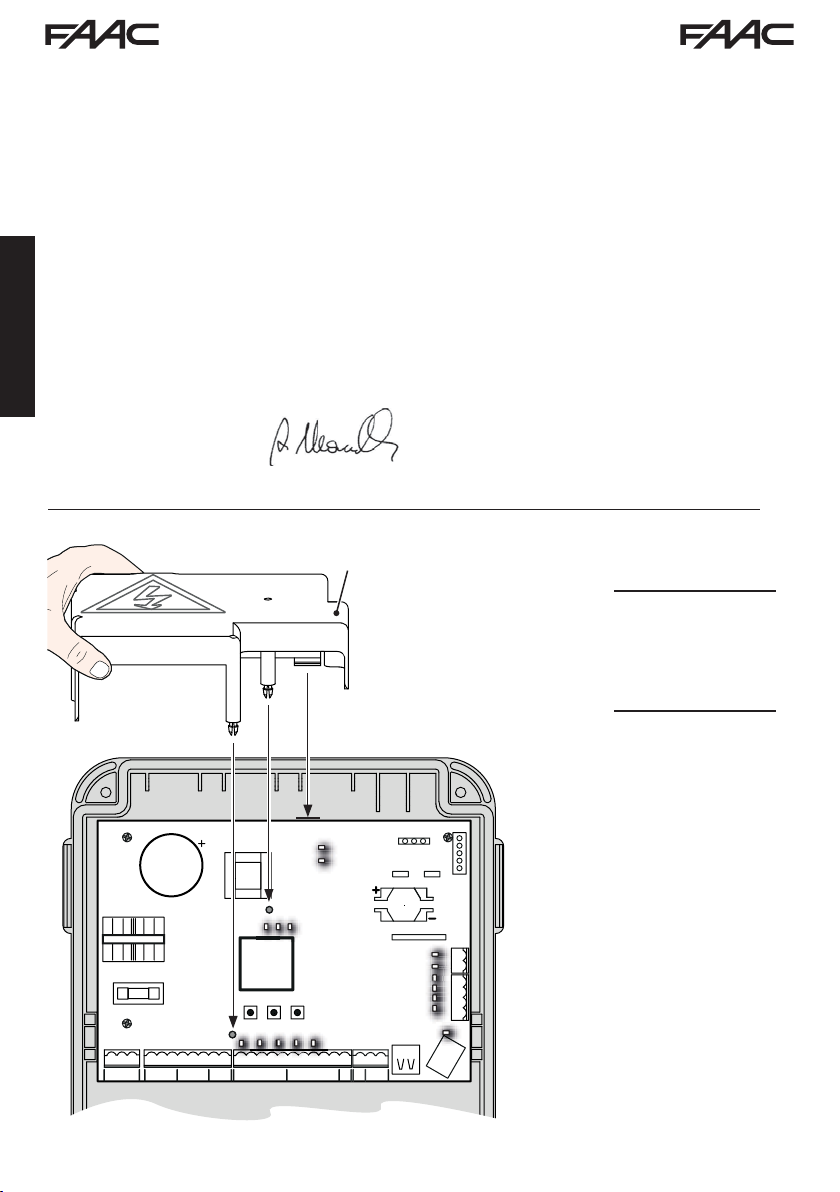

1

A

B

F

· Interrupt the electrical power

sup-ply before working on the

control unit. The protection cover

(1) needs to be installed before

switching on the power supply.

C

TF1

8.8.

E145 2 732784 - Rev. B

Page 3

WARNINGS FOR THE INSTALLER

GENERAL SAFETY OBLIGATIONS

1. ATTENTION! To ensure the safety of people, it

is important that you read all the following

instructions. Incorrect installation or incorrect

use of the product could cause serious harm

to people.

2. Carefully read the instructions before beginning

to install the product.

3. Do not leave packing materials (plastic, polystyrene, etc.) within reach of children as such

materials are potential sources of danger.

4. Store the instructions for future reference.

5. This product was designed and built strictly for

the use indicated in this documentation. Any

other use, not expressly indicated here, could

compromise the good condition/operation of

the product and/or be a source of danger.

6. FAAC S.p.A. declines all liability caused by improper use or use other than that for which the

automated system was intended.

7. Do not install the equipment in an explosive atmosphere: the presence of inflammable gas

or fumes is a serious danger to safety.

8. FAAC S.p.A. is not responsible for failure to

observe Good Technique in the construction

of the closing elements to be motorised, or for

any deformation that may occur during use.

9. The installation must conform to Standards EN 12453 and EN 12445.

For non-EU countries, to obtain an adequate

level of safety, the Standards mentioned above must be observed, in addition to national

legal regulations.

10. Before attempting any job on the system, cut out

electrical power and disconnect the batteries

if present.

11. The mains power supply of the automated system

must be fitted with an all-pole switch with contact opening distance of 3mm or greater. Use

of a 6A thermal breaker with all-pole circuit

break is recommended.

12. Make sure that a differential switch with threshold

of 0.03 A is fitted upstream of the system.

13. Make sure that the earthing system is perfectly

constructed, and connect metal parts of the

means of the closure to it.

14. The automated systems that feature a built-in anticrushing safety device in any case require a

functional check in accordance with the provisions of the Standards indicated at point 9.

15. The safety devices (EN 12978 standard) protect

any danger areas against mechanical movement Risks, such as crushing, dragging,

shearing, lifting.

16. Use of at least one indicator-light (e.g.: flashing

lamp) is recommended for every system, as

well as a warning sign adequately secured.

AAC S.p.A. declines all liability as concerns sa-

17. F

fety and efficient operation of the automated

system, if system components not produced

by FAAC S.p.A. are used.

18. For maintenance, strictly use original parts by

FAAC S.p.A.

19. Do not in any way modify the components of the

automated system.

20. The installer shall provide the User with all information concerning manual operation of the

system in case of an emergency.

21. Do not allow children or adults to stay near the

product while it is operating.

22. Keep radio controls or other pulse generators

away from children, to prevent the automated

system from being activated involuntarily.

23. Transit is allowed only when the automation is

fully open.

24. The User must not attempt any kind of repair or

direct action whatever and contact qualified

personnel only.

25. Anything not expressly specified in these instructions is not permitted.

ENGLISH

MEANING OF THE SYMBOLS USED

Important for the safety of persons and for the

good condition of the automated system.

E145 3 732784 - Rev. B

Notes on the characteristics and operation of

the product.

Page 4

INDEX

CE DECLARATION OF CONFORMITY .....................................................................................2

WARNINGS FOR THE INSTALLER ...........................................................................................3

1. TECHNICAL SPECIFICATIONS ............................................................................................5

2. PREPARING FOR INSTALLATION .......................................................................................6

3. BOARD LAYOUT ...................................................................................................................6

4. ELECTRICAL CONNECTIONS .............................................................................................8

4.1 J1 - Mains primary Power Supply ...................................................................................8

4.2 J2 - Motors and Flashing lamp .......................................................................................8

4.3 J3 - Low-voltage accessories - inputs/outputs .............................................................9

4.4 J12 - programmable outputs - electric locks .................................................................10

ENGLISH

4.5 J12 -J6 - LIMIT SWITCH AND GATECODER ...................................................................10

4.6 J10 - BUS-2EASY ACCESSORIes ..................................................................................1 1

BUS-2EASY photocells ........................................................................................................11

Address assignment of BUS-2EASY photocells ..................................................................12

Connection of BUS-2EASY photocells .................................................................................

BUS-2EASY

Connection - Address assignment of BUS-2EASY

4.7 J5 - XF module RAPID CONNECT

4.8 J14 - Decoder/Minidec/RP RAPID CONNECTOR

4.9 M1A - MODULe RAPID CONNECT

4.10 traditional photocells .....................................................................................................15

5. PROGRAMMING ...................................................................................................................18

5.1 Basic PROGRAMMING functions ...................................................................................19

5.2 Advanced PROGRAMMING functions ............................................................................24

5.6 BUS-2EASY DEVICE INSTALLATION .............................................................................30

5.6.1 BUS-2EASY DEVICE ENTRY .......................................................................................

Checking the securing devices entered on the board ..........................................................

5.4 TIME LEARNING - SETUP ................................................................................................32

5.5 TESTING THE AUTOMATED SYSTEM ............................................................................33

6. MEMORISING THE RADIO CODE ........................................................................................34

6.1 MEMORISING THE SLH/SLH LR RADIO CONTROLS ...................................................34

6.2 MEMORISING LC/RC RADIO CONTROLS (ONLY 433 MHz) .........................................35

6.2.1

6.3 MEMORISING DS RADIO CONTROLS ............................................................................36

6.4 DELETING THE RADIO CONTROLS ...............................................................................

7. START-UP ..............................................................................................................................38

7.1 CHECKING THE LEDs ......................................................................................................38

8. SIGNALLING ERRORS AND ALARMS ................................................................................39

8.1 ERRORS ............................................................................................................................39

8.2 ALARMS ............................................................................................................................40

9. TROUBLESHOOTING ...........................................................................................................41

10. MANAGING THE CONFIGURATION FILE – J8 USB .......................................................42

11. FUNCTION LOGICS ............................................................................................................45

encoder ...........................................................................................................13

Encoder ................................................13

OR .............................................................................14

...........................................................14

OR ............................................................................14

REMOTE MEMORISATION OF LC/RC RADIO CONTROLS ...................................36

12

30

31

37

E145 4 732784 - Rev. B

Page 5

CONTROL BOARD E145

We thank you for having chosen one of our products. FAAC is certain that from it you will obtain

all the performance you require. All our products are the result of years of experience in the field of

automated systems.

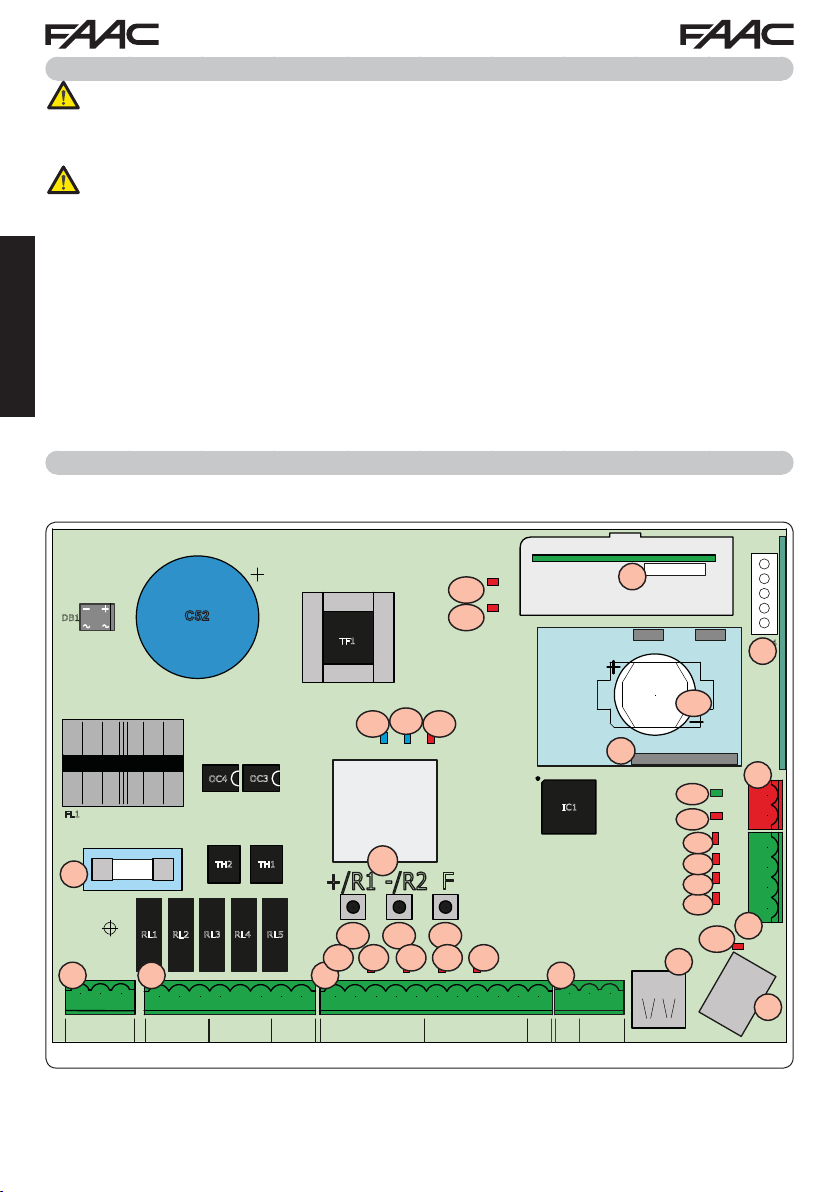

1. TECHNICAL SPECIFICATIONS

PURPOSE: this electronic control board has been

designed and built to control swing-leaf and/or

sliding gates for vehicle and pedestrian access

control.

Thanks to the innovative power supply switching

system, the board is able to automatically adapt

to different input voltages (from 90V~ to 260V~),

maintaining constant the output value of accessories, without being affected by variations.

Tab. Technical specifications

During programming you can choose between

different function logics.

2 programming levels are available from the board (BASIC and ADVANCED), using buttons and

LCD display.

This board also allows you the programming using

PC or MAC, connected via USB-B.

ENGLISH

Mains primary power supply

Power absorbed from mains

MAX load for motors

Accessories power supply

MAX. accessories current

Operating ambient temperature

Power supply safety fuses

W

ork time

Pause time

Motor power

Connector inputs

T

erminal board inputs

erminal board outputs

T

E145 5 732784 - Rev. B

With power supply switching from 90 V~ to 260 V~; 50/60Hz

*

stand By = 4W sleep < 2 W

*

FUNCTION THAT CAN BE ENABLED FROM A PC/MAC

800 W

"

24 V

+24V MAX 500 mA BUS 2easy MAX 500 mA

LOCK (FAAC) 12 V~ / 24 V"LOCK (not FAAC) 24 V

500mA (3A peak)

from -20°C to +55°C

F1 = F10AH250V

Self-learned through SETUP - (Max 4 min and 10 sec)

Programmable (from 0 to 9 min and 50 sec)

Programmable on 50 levels

Decoder/Minidec/RP, XF433/868 Module, USB-A, USB-B

Mains power supply from 90 to 260V ~, Inputs from IN1 to

IN5, Limit switch, BUS 2easy

Flashing lamp, Motors, Electric lock (LOCK1 and LOCK2),

OUT1 and OUT2 (programmable),

Accessories power supply

MAX ~ 800 W

"

Page 6

2. PREPARING FOR INSTALLATION

For safety reasons, it is important for people to carefully follow all the warnings and

instructions contained in this manual. Incorrect installation or incorrect use of the

product can cause serious harm to people. Before proceeding with product installation,

carefully read the entire manual. Keep these instructions for further reference.

Always cut off the electrical power before carrying out any work on the control unit

(connections, maintenance).

Always separate the power cables from the control and safety cables (button, receiver,

BUS 2easy encoder, photocells, etc.). Avoid any electrical disturbance using separate

sheathing or a shielded cable (with shield connected to the earth).

• Ensure that upstream of the system there is a suitable magnetothermic differential switch with

omnipolar cut-off, as provided for in current safety regulations.

Check for the presence of an adequate earthing system.

•

ENGLISH

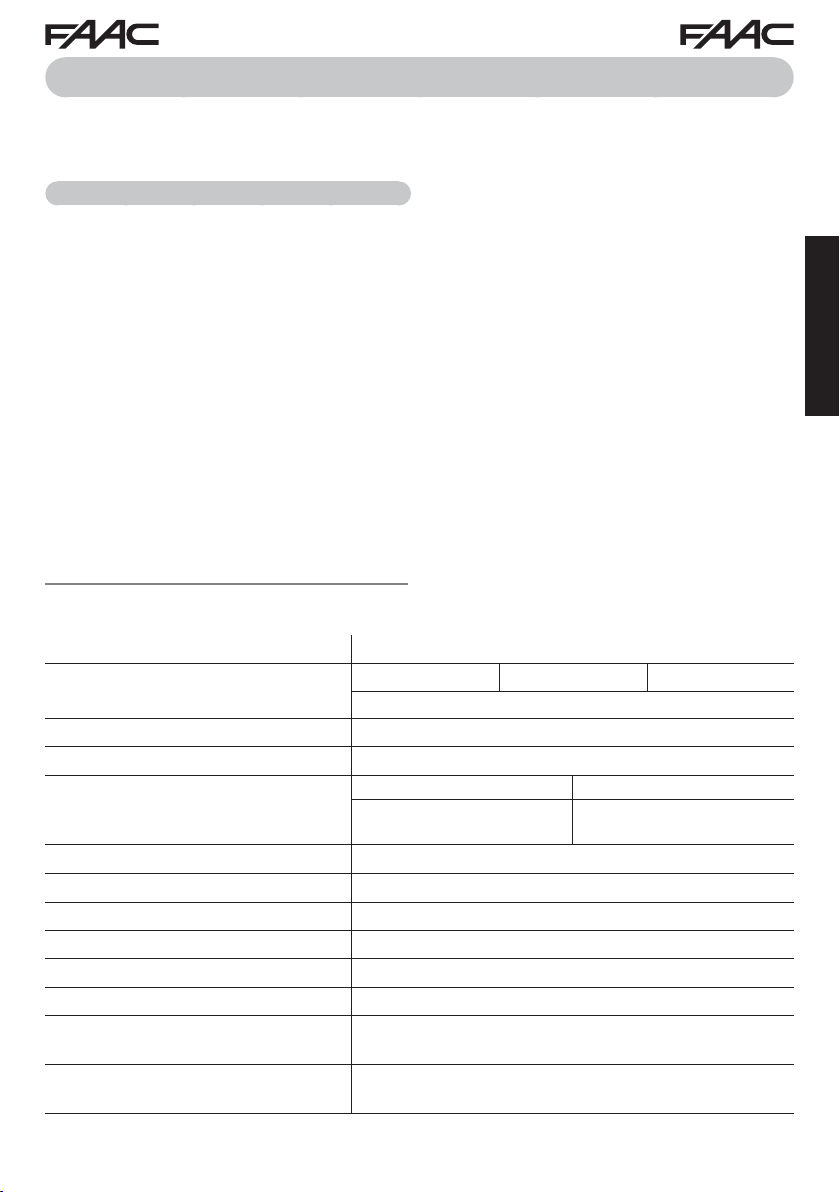

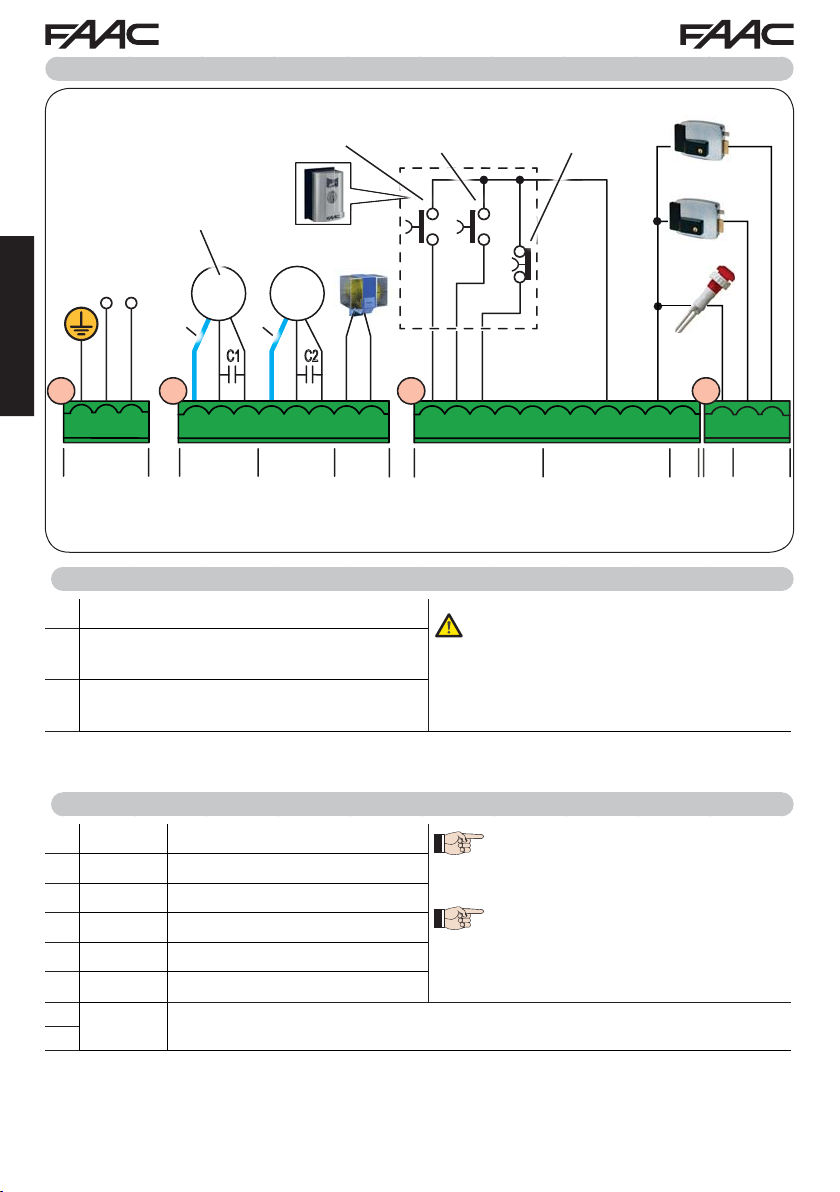

3. BOARD LAYOUT

DB1

FL1

F1

F1

J1

J1 J2 J3

PE N L

PENL

AC MAIN

C52

OC3

OC4

TH2 TH1

RL3 RL4RL1

RL2

J2

RL5

1 2 3 4 5 6 7 8

12 45678

3

M1

COM

OP

M2

COM

CL

LAMP

CL

OP

RADIO 1

TF1

DL16

DL16

5V

DL17

DL17

24V

DL13

DL13

ERROR

DL11

DL11

DL12

DL12

RADIO 2

RADIO XF 433-868

CONNECTIVITY

IC1

8.8.

LCD1

LCD

+/R1

SW1 SW2

SW1 SW2 SW3

DL8

DL9

DL8DL9

IN1

J3

9 10 11 12 13 14 15 16 17 18 19

91011 12 13 14 15 16 17 18 19

IN1

IN3

IN2

OP-A

STOPCLOP

OP-B

F

-/R2

SW3

DL7

DL6

DL7 DL6 DL5

IN2

IN3

IN4

IN5

IN4

---

FSW

DL5

IN5

J12

J12

20 21 22

20

OUT1

+

OUT2

+

24V

21

LOCK1LOCK

J5

M1A

22

2

J5

BAT1

CR2032

BAT1

DL14

DL15

J8

J8

DL14

DL15

DL4

DL4

DL3

DL3

DL2

DL2

DL1

DL1

BUS MON

BUS

DL10

DL10

FCC1 FCA1

FCC2 FCA2

RP/DEC

J4

J4

J10

J10

.

23

24

25

26

26 25 24 23

J6

J6

USB

J9

J9

USB-BUSB-A

E145 6 732784 - Rev. B

Page 7

LCD Signalling/Programming display

SW1 “+/R1” Programming button

SW2 “-/R2” Programming button

SW3 “F” Programming button

DL1 “FCC2” Input status control LED

DL2 “FCA2” Input status control LED

DL3 “FCC1” Input status control LED

DL4 “FCA1” Input status control LED

“IN5” Input status control LED (default

DL5

FSW OP

“IN4” Input status control LED (default FSW

DL6

CL)

“IN3” Input status control LED (default

DL7

STOP)

“IN2” Input status control LED (default

DL8

OPEN-B

“IN1” Input status control LED (default

DL9

OPEN-A

DL10 “

DL11 “

DL12 “

DL13 “

“BUS MON” BUS 2easy

DL14

LED

DL15 Device signalling LED to

)

)

)

USB

” Signalling LED

RADIO1-

XF” Signalling LED

RADIO2-

XF” Signalling LED

ERROR

” Error/alarm signalling LED

(OMNIDEC)

(OMNIDEC)

diagnostic signalling

BUS 2easy ACTIVE

DL16 Microprocessor power presence LED

"

Accessories power supply presence

+24V

DL17

LED

J1 90V~ a 260V~ Power supply connector

Motors and flashing lamp power supply

J2

connector

J3 Input/Output connector

Decoder/Minidec/RP Receiver connector:

Channel 1 (Decoder/Minidec/RP) - OPEN A

J4

(Total Opening)

Channel 2 (RP2) -

XF433/XF868 (OMNIDEC) receiver module

connector

J5

Channel 1

Channel 2

J6 Limit switch input connector

HOST USB-A

J8

DEVICE USB-B

J9

connector

BUS 2easy

J10

J12 OUT2 and LOCK 1-2 output connector

G-COM, WI-COM,

M1A

nector

BAT1 CR2032 buffer battery for board date/time

F1 Motor and power supply safety fuse

OPEN B (Partial Opening)

-

OPEN A

(Total Opening)

-

OPEN B

(Partial Opening)

for Mass Memories connector

for connection to

device connector

Net-COM module con-

PC/MAC

ENGLISH

E145 7 732784 - Rev. B

Page 8

4. ELECTRICAL CONNECTIONS

OPEN A

Total gate opening

(contact N.O.)

Motor for SINGLE-LEAF or

FIRST LEAF when opening

(closes for the second)

MIN

90V~

MAX

260V~

50/60 Hz

Mot1 Mot2

230V~

MAX 60W

* *

ENGLISH

J1 J2 J3

J1

C1 C2

OPEN B

Partial gate opening (contact N.O.)

STOP

Gate stop

(contact

N.C.)

24V

3W

J12

J12J3J2

12V ~

24V

12V ~

24V

PE N L

PE N L

AC MAIN

*

Blue or grey

1 2 3 4 5 6 7 8

123

M1

COM OP CL

456

COM OP CL

78

LAMP

M2

Photocells and safety de-

vices: for connections, see

the related paragraph.

4.1 J1 - MAINS PRIMARY POWER SUPPLY

PE Earthing Connection

Power Supply Connection from 90 V~ to 260

N

V~ Neutral

Power Supply Connection from 90 V~ to 260

L

V~ Line

4.2 J2 - MOTORS AND FLASHING LAMP

1 M1 - COM Common contact motor 1

2 M1 - OP Opening phase motor 1

3 M1 - CL Closing phase motor 1

4 M2 - COM

5 M2 - OP Opening phase motor 2

6 M2 - CL Closing phase motor 2

7

LAMP Flashing lamp connection (MAX 60 W)

8

Common contact motor 2

19

OUT

OUT

1

MAX

100 mA

20 21 22

20

21

LOCK

2

{

9 10 11 12 13 14 15 16 17 18 19

IN2IN1IN3IN4IN

OP-A 1

5

-14-15-16+17+

FSW

OP

{

500 mA

For correct operation, you must con-

nect the switching power supply to the

system’s earthing conductor. Ensure

that upstream a suitable differential

magnetothermic switch has been installed.

M1 = first leaf when opening or single leaf

M2 = second leaf when opening - CAN-

NOT be used for single leaf

To verify correct wiring and direction

of motor rotation, (see 5.4 TIME LEAR-

NING - SETUP)

18910111213

24V

{

MAX

22

LOCK

2OP-B STOP CL

E145 8 732784 - Rev. B

Page 9

4.3 J3 - LOW-VOLTAGE ACCESSORIES - INPUTS/OUTPUTS

9 IN1

10 IN2

To install more than one OPEN A or OPEN B pulse generator, connect the N.O. contacts in

parallel (see related Fig.)

11 IN3

To install more than one STOP device, connect the N.C. contacts in series (see related Fig.).

If stop devices are NOT connected, jumper the terminals STOP and GND.

12 IN4

13 IN5

To install more than one safety device, connect the N.C. contacts in series (see related Fig.).

If safety devices are NOT connected, jumper terminals IN4 and IN5 and GND if the FAIL-SAFE

safety is not active; otherwise jumper IN4 and IN5 and OUT1 (FAIL-SAFE).

14

16

17

18

OPEN A contact - N.O.

TOT AL opening

OPEN B contact - N.O.

PARTIAL opening

STOP contact - N.C.

FSW CL contact - N.C.

closing safety

FSW OP contact - N.C.

opening safety

- GND Accessories power supply negative15

+ +24 Accessories power supply positive (MAX. load = 500mA)

Connect a button or other pulse generator which, by closing

a contact, commands TOTAL opening of both leaves.

Connect a button or other pulse generator which, by closing

a contact, commands the PARTIAL opening.

on 2-motor systems = 100% of leaf 1 opening;

on 1-motor systems = 50% of leaf 1 opening.

When a logic requiring a CLOSE (

the, OPEN B input automatically becomes CLOSE - N.O. (leaves closing command).

Connect a button or other pulse generator which, by opening

a contact, stops movement of the automated system.

Connect a photocell or other device which, by opening a contact, reverses the movement of the automated system during

opening (FSW OP) or during closing (FSW CL).

b, bC, C

) input is selected,

ENGLISH

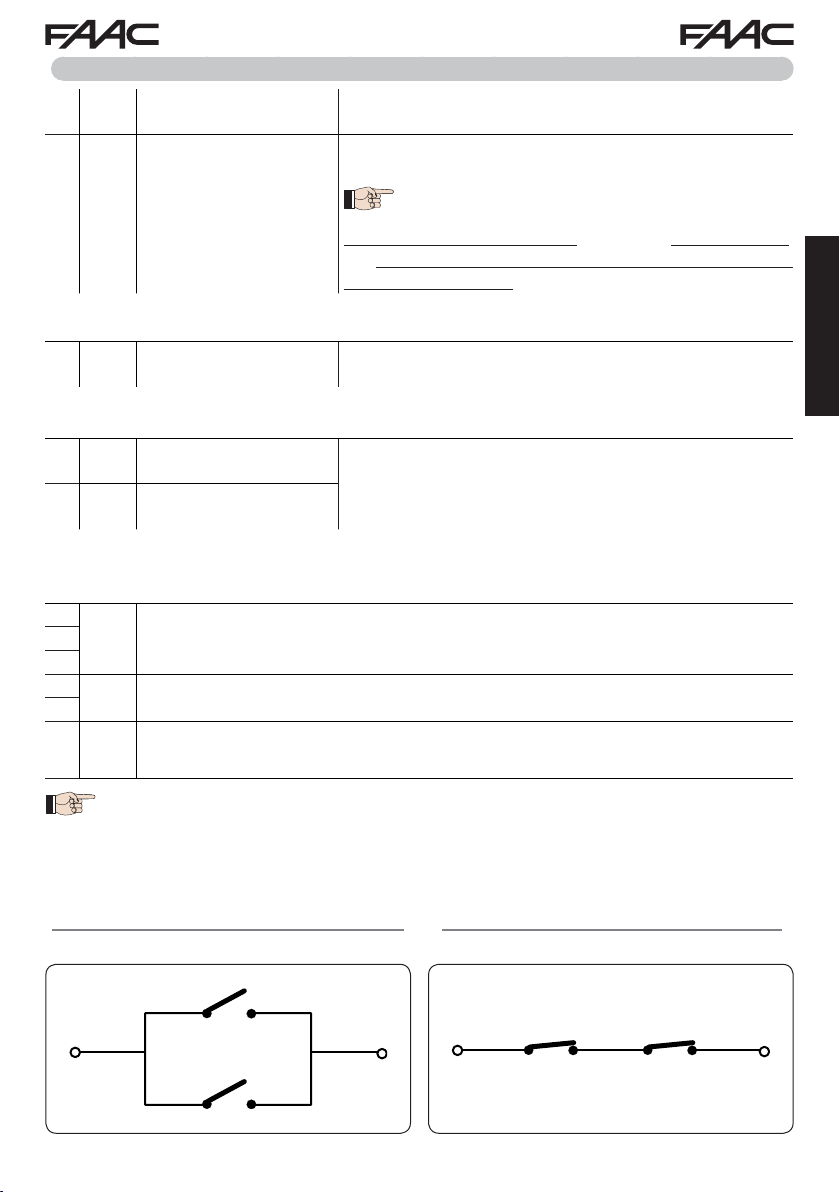

19 OUT1

Fig. e.g.: Connecting 2 N.O. contacts in parallel. Fig. e.g.: Connecting 2 N.C. contacts in series.

E145 9 732784 - Rev. B

24 V" (Open Collector) programmable using function

default: always active.

Other programming options are available by programming via a PC/MAC (see dedicated

instructions).

o1

(advanced programming);

Page 10

4.4 J12 - PROGRAMMABLE OUTPUTS - ELECTRIC LOCKS

20 OUT2

21 LOCK 1

22 LOCK 2

ENGLISH

24 V" (Open Collector) programmable using the function

default: indicator light

Electric lock (12 V~ or 24 V")

operated 2 sec before opening

of leaf 1

Electric lock (12 V~ or 24 V") operated 2 sec before opening

of leaf 2

Other programming options are available by programming via a PC/MAC (see dedicated

instructions).

When BUS 2easy encoder is disabled, the electric

lock is operated before each opening (in whatever

position the stopped leaf is in).

When BUS 2easy encoder is enabled, the electric

lock is operated only before opening the closed leaf.

4.5 J12 -J6 - LIMIT SWITCH AND GATECODER

The limit switch contacts FCC1, FCA1, FCC2, FCA2 are all NC contacts.

They are programmable using the functions

If no limit switches are used, you DO NOT need to jumper the limit switch contacts

FCC1, FCA1, FCC2, FCA2.

You can however use a single GATECODER (only for single leaf); in this case, you do

not need to jumper the unused inputs to the earth.

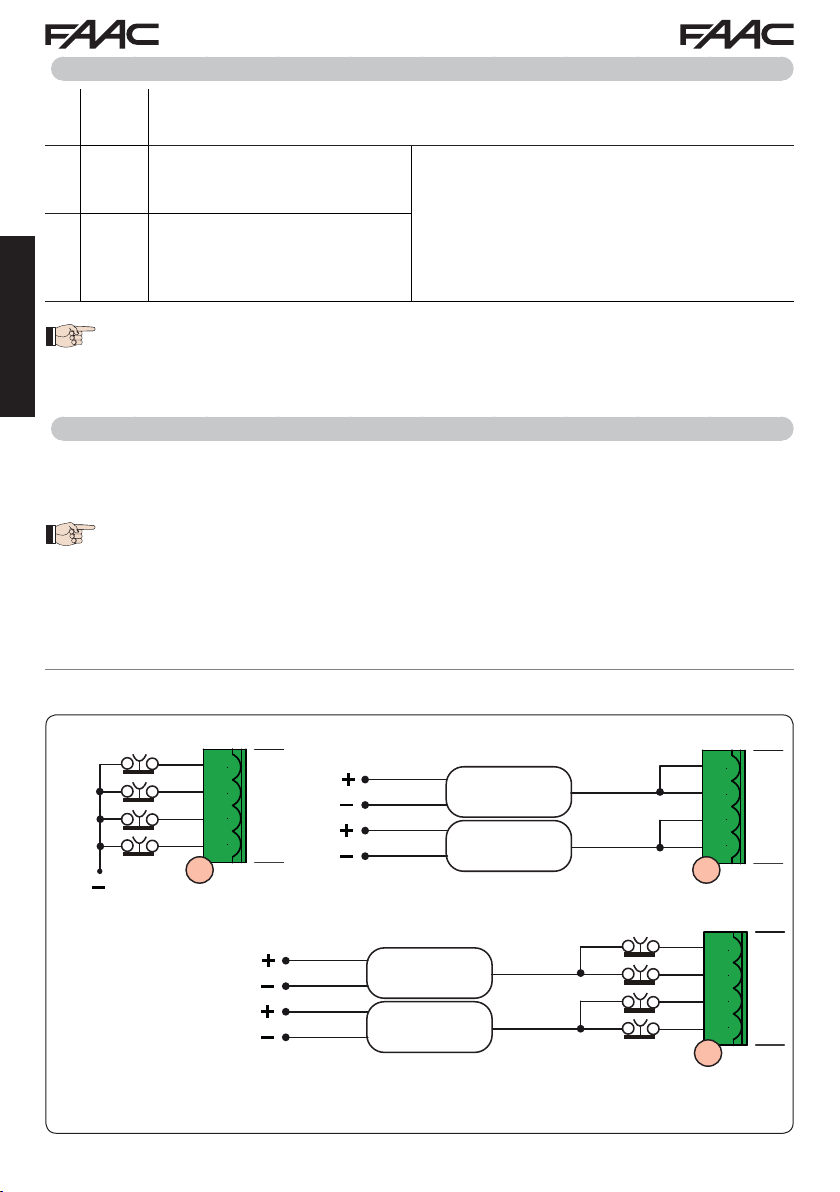

Fig. Limit switch and GATECODER connections (maximum configuration:

FA

and

(basic programming) ; default: disabled.

FC

o2

(advanced programming);

).

햴

햲햳

헁

FCA1

헄

FCC1

헁

FCA2

헄

FCC2

26 25 24 23

J6

J6 J6

헁

GATECODER 1

GATECODER 2

FCA1

FCC1

FCA2

FCC2

26 25 24 23

J6

햴

헄

헁

헄

헁

FCA1, FCC1 and GATECODER1 correspond to LEAF 1;

FCA2, FCC2 and GATECODER2 correspond to LEAF 2.

E145 10 732784 - Rev. B

GATECODER 1

GATECODER 2

FCA1

FCC1

FCA2

FCC2

26 25 24 23

J6

J6

Page 11

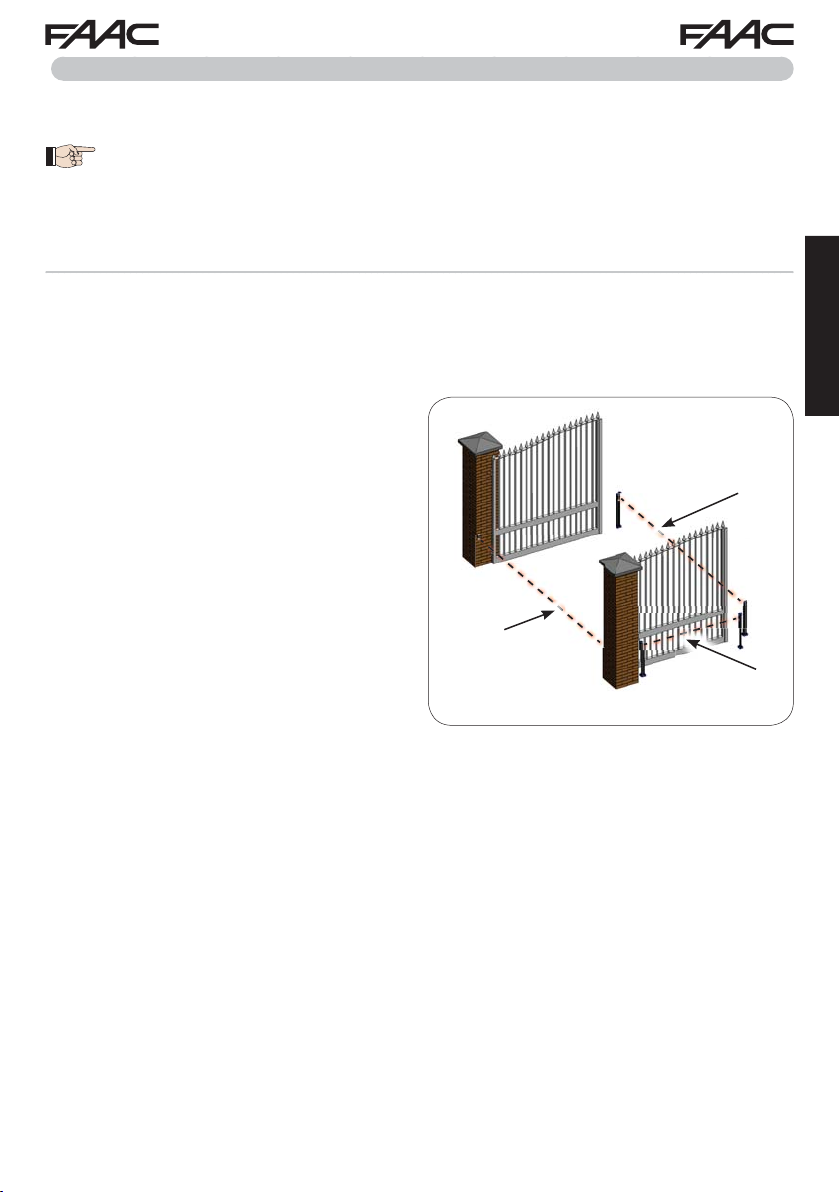

4.6 J10 - BUS 2EASY ACCESSORIES

This board features a

of auxiliary BUS 2easy (MAX 16 pairs of photocells), encoder and control devices.

If no BUS 2easy accessories are used, leave the BUS 2easy connector free.

BUS 2easy photocells

Before connecting the photocells, arrange them for the duly address assignment, depending on their

position and operation mode:

Photocells during closing:

closing of the automated system - suitable for

protecting the closing area from risk of impact.

Photocells during opening:

opening of the automated system - suitable for

protecting the opening area from risk of impact.

Photocells during opening/closing:

both the opening and closing - suitable for protec-

ting the entire movement area from risk of impact.

Pulse generators: used as pulse generators for

opening the automated system

BUS 2easy

circuit for facilitating connection to the safety devices of a high number

trip only during the

Opening/clo-

trip only during the

trip during

.

Closing

safety devices

sing safety

devices

Opening

safety devices

ENGLISH

E145 11 732784 - Rev. B

Page 12

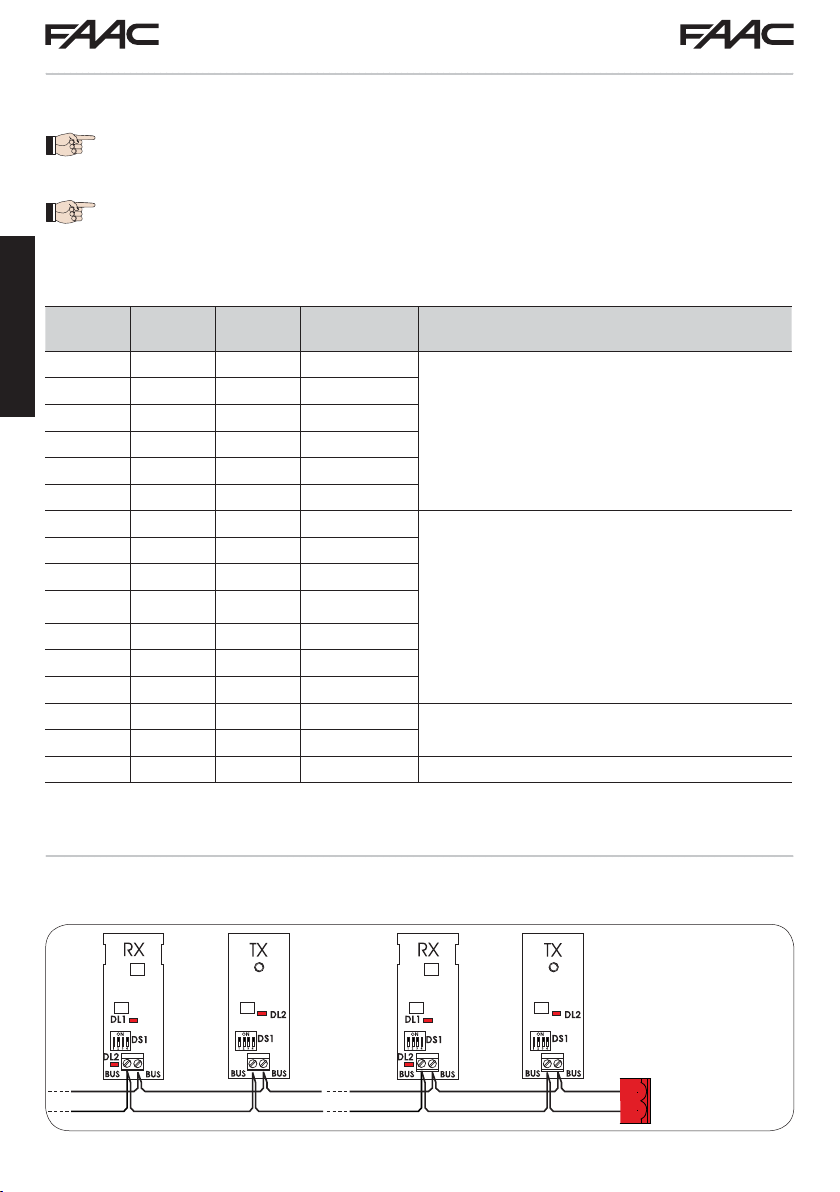

Address assignment of BUS 2easy photocells

To assign the address to each pair of photocells, you must set the Dip-Switches (DS1) located on the

transmitter and corresponding receiver.

The transmitter and receiver of a pair of photocells must have the same

DIP-SWITCH setting.

Two or more pairs of photocells must not have the same DIP-SWITCH setting.

Other programming options are available by programming via a PC/MAC (see dedicated

instructions).

Dip1 Dip2 Dip3 Dip4 TYPE OF PHOTOCELLS

OFF OFF OFF OFF

ENGLISH

OFF OFF OFF ON

OFF OFF ON OFF

OFF OFF ON ON

OPENING (max 6 pairs)

OFF ON ON OFF

OFF ON ON ON

ON OFF OFF OFF

ON OFF OFF ON

ON OFF ON OFF

ON OFF ON ON

CLOSING (max 7 pairs)

ON ON OFF OFF

ON ON OFF ON

ON ON ON OFF

OFF ON OFF OFF

OFF ON OFF ON

ON ON ON ON

OPENING and CLOSING (max 2 pairs)

OPEN PULSE (1 pair)

Connection of BUS 2easy photocells

For connecting you have to use two cables without polarity (see the specific device instructions).

DL1

= Alignment

DL2

= BUS 2easy status/

Power supply

DS1

= Programming

Dip-switches

BUS 2easy

J10

E145 12 732784 - Rev. B

Page 13

BUS 2easy encoder

BUS 2easy encoder connection is done using the bi-polar cables supplied with.

Connection - Address assignment of BUS 2easy Encoder

The polarity of the BUS 2easy line connection determines the correspondence of the

encoder to one leaf or the other.

pay careful attention to the indications of the status LEDs located on the body of each

encoder.

LEAF 1 opens first and closes last.

A

SAFEcoder S800 ENC

J10

BUS-2easy

DL

DL2

DL

3

1

DL1

DL2

DL3

DL1

DL2

DL3

DL

DL2

DL

3

1

ENGLISH

J10

BUS-2easy

: 2 LED on

M1

B

M2

: 1 LED on

DL1

DL2

DL3

DL1

DL2

DL3

· Note: to correct the coupling of the encoder with motor

M1 or M2, swap both wires on the terminals.

E145 13 732784 - Rev. B

M2

M1

M1

M2

DL1

DL2

DL3

DL1

DL2

DL3

Page 14

RADIO XF 433-868

RADIO 1

DL12

DL11

RADIO 2

J5

J4

RP/DEC

CONNECTIVITY

Tab. BUS 2easy Encoder LEDs Status

LED ON FLASHING OFF

Power present

Communication present

DL1

Power present

Communication absent

DL1 must always be on to confirm correct encoder/board connection.

Leaf 1 / Leaf 2

DL2

DL2 indicates the leaf on which the encoder is installed; it must be on for leaf 1 and off for

leaf 2.

Stationary leaf Leaf in motion Stationary leaf

DL3

DL3

indicates pulse reading during leaf movement using steady flashing. In stationary status

of the leaf, the DL3 can be either on or off.

In case of incorrect connection (DL2 on or off for both of the encoders), during the

ENGLISH

BUS 2easy accessories learning procedure, the DL1 leds of both encoders are

FLASHING.

4.7 J5 - XF MODULE RAPID CONNECT OR

Plug-in rapid connector dedicated to OMNIDEC

2-channel decoding module.

ALW A YS cut off power to the board BEFORE inserting/removing the module.

Power absent

Communication absent

4.8 J14 - DECODER/MINIDEC/RP RAPID CONNECTOR

Rapid connector dedicated to Decoder/Minidec/RP/RP2.

Connect the accessory with the components facing inside the board.

ALWAYS cut off power to the board BEFORE inserting/removing plug-in boards.

The RP2 2-channel receiver lets you control two different radio channels of the automated system

(OPEN A and OPEN B/CLOSE) using a 2-channel radio control.

The 1-channel receiver (Decoder/Minidec/RP) lets you control only one radio channel: OPEN

Other programming options are available by programming via a PC/MAC (see dedicated

instructions).

4.9 M1A - MODULE RAPID CONNECTOR

Plug-in connector dedicated to G-COM, WI-COM, Net-COM modules.

ALWAYS cut off power to the board BEFORE inserting/removing the module.

Other programming options are available by programming via a PC/MAC (see dedicated

instructions).

E145 14 732784 - Rev. B

A.

Page 15

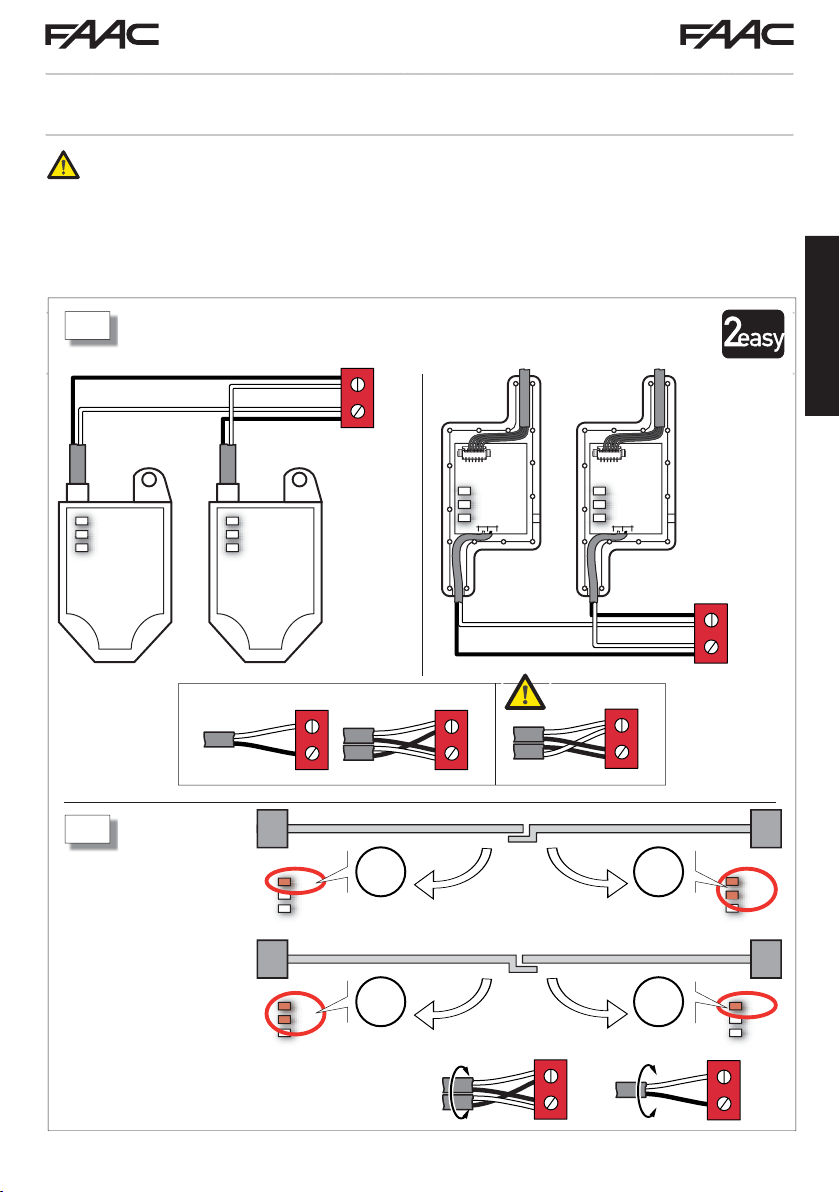

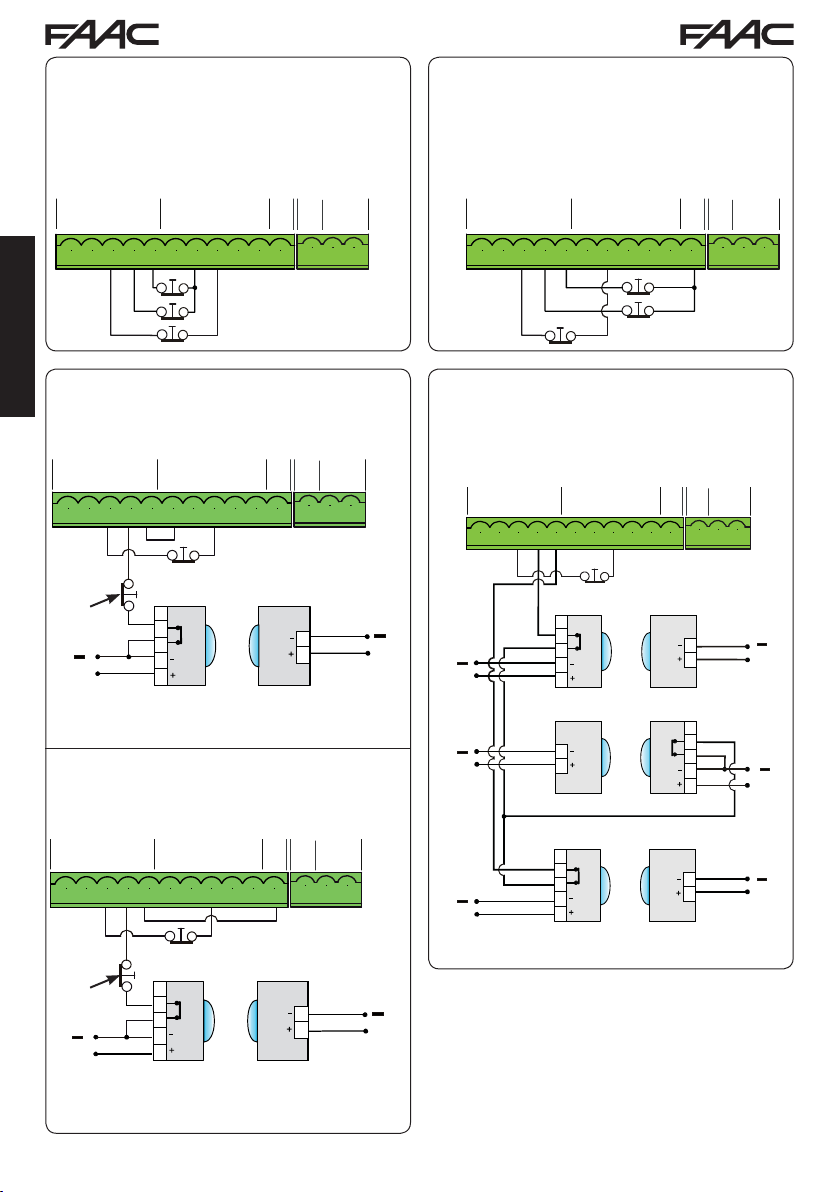

4.10 TRADITIONAL PHOTOCELLS

o1

01

This board lets you use traditional photocells (contact N.C. with relay).

Before connecting the photocells, it is best to identify the operating type, which depends on the movement area they have to protect:

Closing photocells:

trip only during the automated system closing - suitable for protecting the

closing area from risk of impact.

Opening photocells:

trip only during the auto-

Safety devices for

opening/closing

mated system opening - suitable for protecting the

opening area from risk of impact.

Photocells for opening/closing:

trip during both

the opening and closing - suitable for protecting the

entire movement area from risk of impact.

Pulse generators: used as pulse generators for

opening the automated system

.

Closing

safety devices

Opening

safety devices

Fail Safe function

This function lets you monitor the correct alignment and operation of the photocells before each move-

=

ment. To enable the Fail Safe function, enter the ADVANCED Programming and set the

With Fail Safe disabled: connect the transmitter (TX) power supply to terminals 15 and

o1

function.

01

18 of J3.

With Fail Safe enabled:

Then jumper the unused safety inputs with OUT1.

OUT1.

connect the power supply negative of the transmitters (TX) to

Hereafter are provided the drawings for some connection examples.

ENGLISH

No safety device and no stop device

FAIL SAFE disabled

9 10 11 12 13 14 15 16 17 18 19

IN1 IN2 IN3 IN4 IN5

OP-A OP-B STOP CL FSW OP

---

+

20 21 22

OUT1 OUT2 LK1 LK2

+

24V

9 10 11 12 13 14 15 16 17 18 19 20 21 22

No safety device and no stop device

FAIL SAFE enabled

9 10 11 12 13 14 15 16 17 18 19

IN1 IN2 IN3 IN4 IN5

OP-A OP-B STOP CL FSW OP

---

+

20 21 22

OUT1 OUT2 LK1 LK2

+

24V

9 10 11 12 13 14 15 16 17 18 19 20 21 22

E145 15 732784 - Rev. B

Page 16

One closing safety device, one opening safety device, one STOP device.

FAIL SAFE disabled

One closing safety device, one opening safety device, one STOP device.

FAIL SAFE enabled

9 10 11 12 13 14 15 16 17 18 19

IN1 IN2 IN3 IN4 IN5

OP-A OP-B STOP CL FSW OP

---

+

20 21 22

OUT1 OUT2 LK1 LK2

+

24V

ENGLISH

One pair of closing photocells.

FAIL SAFE disabled

9 10 11 12 13 14 15 16 17 18 19

IN1 IN2 IN3 IN4 IN5

OP-A OP-B STOP CL FSW OP

---

+

20 21 22

+

OUT1 OUT2 LK1 LK2

24V

9 10 11 12 13 14 15 16 17 18 19 20 21 22

Other

safety

devices

헁

+

헄

One pair of closing photocells.

FAIL SAFE enabled

RX CL

1

2

3

4

5

TX CL

1

2

9 10 11 12 13 14 15 16 17 18 19

IN1 IN2 IN3 IN4 IN5

OP-A OP-B STOP CL FSW OP

---

+

20 21 22

OUT1 OUT2 LK1 LK2

+

24V

9 10 11 12 13 14 15 16 17 18 19 20 21 22 9 10 11 12 13 14 15 16 17 18 19 20 21 22

One pair of closing photocells, one pair of

opening photocells and one pair for opening/

closing.

FAIL SAFE disabled

9 10 11 12 13 14 15 16 17 18 19

IN1 IN2 IN3 IN4 IN5

OP-A OP-B STOP CL FSW OP

---

+

9 10 11 12 13 14 15 16 17 18 19 20 21 22

RX CL

1

헁

헄

+

헁

+

헄

헁

헄

+

2

3

4

5

TX OP/CL RX OP/CL

1

2

20 21 22

OUT1 OUT2 LK1 LK2

+

24V

TX CL

1

2

1

2

3

4

5

헁

+

헄

헁

헄

+

9 10 11 12 13 14 15 16 17 18 19

IN1 IN2 IN3 IN4 IN5

OP-A OP-B STOP CL FSW OP

---

+

9 10 11 12 13 14 15 16 17 18 19 20 21 22

Other

safety

devices

헁

헄

+

RX CL

1

2

3

4

5

20 21 22

OUT1 OUT2 LK1 LK2

+

24V

TX CL

RX OP

1

2

3

헁

헄

+

1

2

헅

헄

+

4

5

TX OP

1

2

E145 16 732784 - Rev. B

헁

+

헄

Page 17

헁

헄

헁

헄

Two pairs of closing photocells.

FAIL SAFE disabled

One pair of opening photocells and one for

closing.

FAIL SAFE disabled

9 10 11 12 13 14 15 16 17 18 19

IN1 IN2 IN3 IN4 IN5

OP-A OP-B STOP CL FSW OP

---

+

20 21 22

+

OUT1 OUT2 LK1 LK2

24V

9 10 11 12 13 14 15 16 17 18 19 20 21 22

Other

safety

devices

헁

+

헄

헁

헄

+

RX CL1

1

2

3

4

5

TX CL2 RX CL2

1

2

One pair of opening photocells.

FAIL SAFE disabled

9 10 11 12 13 14 15 16 17 18 19

IN1 IN2 IN3 IN4 IN5

OP-A OP-B STOP CL FSW OP

---

TX CL1

OUT1 OUT2 LK1 LK2

+

+

24V

20 21 22

1

2

1

2

3

4

5

9 10 11 12 13 14 15 16 17 18 19 20 21 22

9 10 11 12 13 14 15 16 17 18 19

IN1 IN2 IN3 IN4 IN5

OP-A OP-B STOP CL FSW OP

---

+

20 21 22

+

OUT1 OUT2 LK1 LK2

24V

9 10 11 12 13 14 15 16 17 18 19 20 21 22

RX CL

헁

헄

+

+

헁

헄

+

+

1

2

3

4

5

TX OP RX OP

1

2

One pair of closing photocells

and one for opening/closing.

FAIL SAFE disabled

9 10 11 12 13 14 15 16 17 18 19

IN1 IN2 IN3 IN4 IN5

OP-A OP-B STOP CL FSW OP

---

TX CL

1

2

1

2

3

4

5

+

24V

+

+

20 21 22

OUT1 OUT2 LK1 LK2

+

헁

헄

ENGLISH

헁

헄

9 10 11 12 13 14 15 16 17 18 19 20 21 22

Other

safety

devices

헁

+

헄

RX OP

1

2

3

4

5

TX OP

1

2

헁

헄

헁

+

헄

+

헁

헄

+

RX CL

1

2

3

4

5

TX OP/CL RX OP/CL

1

2

E145 17 732784 - Rev. B

TX CL

1

2

1

2

3

4

5

헁

헄

+

헁

헄

+

Page 18

5. PROGRAMMING

-

www.faacgroup.c om

-

+

-

1

Programming is divided in two levels:

• BASIC programming

• ADVANCED programming

The programming phases are (see Tab.):

1. to access PROGRAMMING (1A or 1B);

2. to show the set values and modify them, if

you want. Changing the values is effective

immediately, while the final memorisation must

be carried out upon exiting programming (

3. exit the programming by using

Y to SAVE the configuration you just

Select

performed, otherwise select

THOUT SAVING any changes.

ENGLISH

You can EXIT programming at anytime:

• press and hold F and then also

directly to

St.

+

F

-/R2

Tab. BASIC programming phases.

PRESS AND HOLD

F:

THE FIRST

FUNCTION

APPEARS

F

1

RELEASE F:

THE FUNCTION

IS

VALUE

DISPLAYED

F

St function.

no to EXIT WI-

to switch

USING+OR

SCROLL THE

VALUES

AVAILABLE

THE DESIRED

UNTIL

ONE

-/

+/

R1

St).

R2

This board also allows programming using a PC

or MAC.

This programming requires connection to PC/MAC

via USB cable and USB-B relevant port.

The programming SOFTWARE with relevant instructions, must be downloaded from the website:

www.faacgroup.com

The programming using a PC/MAC, with the de-

fault PASSWORD does not inhibit the programming by board.

The writing

PC will be displayed in

correspondence with the modified values. Notes:

when you modify the values by board the previous

PC/MAC programming will be overwrote.

The default password is 0000.

The programming using a PC/MAC, with a modified PASSWORD (different from the default one),

will inhibit the programming by board. If one of the

buttons is pressed, the display will show

gramming for 5 sec and changes will be allowed

only by PC /MAC.

,

PRESS F:

TO MOVE TO

NEXT

THE

FUNCTION

F

1

FUNCTION St

(LAST FUNCTION)

SELECT Y TO SAVE

PROGRAMMING

THE

OTHERWISE

no TO EXIT

SELECT

PROGRAMMING

THE

SAVING

WITHOUT

PRESS

TO CONFIRM;

F

AT THE END THE

DISPLAY

VISUALIZE THE

TO

AUTOMATED

F

PC pro-

THE BUTTON

RETURNS

SYSTEM

STA TUS

Tab. ADVANCED programming phases

PRESS AND HOLD

AND THEN ALSO

F

:

THE FIRST

FUNCTION

APPEARS

+

F

+/

R1

1

RELEASE THE

THE FUNCTION

BUTTONS

IS

VALUE

DISPLAYED

+/

R1

:

F

+

USING+OR

SCROLL THE

VALUES

AVAILABLE

THE THE

UNTIL

ONE

DESIRED

+/

R1

-/

R2

,

PRESS F:

TO MOVE TO

NEXT

THE

FUNCTION

F

FUNCTION St

(LAST FUNCTION)

1

SELECT Y TO SAVE

PROGRAMMING

THE

OTHERWISE

no TO EXIT

SELECT

PROGRAMMING

THE

SAVING

WITHOUT

1

THE FUNCTION IS DISPLAYED UNTIL YOU HOLD

PRESS

THE BUTTON

TO CONFIRM;

F

AT THE END THE

RETURNS

DISPLAY

VISUALIZE THE

TO

AUTOMATED

STA TUS

F

SYSTEM

E145 18 732784 - Rev. B

Page 19

5.1 BASIC PROGRAMMING FUNCTIONS

Display Basic Function

CF

MOTOR TYPE:

Displays and allows you to change the motor type set on the board:

1 Motors for swing-leaf gates

2 Motors for sliding gates

PC Mixed configuration from a PC/MAC (e.g.: a swing and a slide)

At the time of changing the set motor type on the board, the

relevant defaults are uploaded.

dF

DEFAULT:

Y indicates that all the set values correspond to the default values.

no indicates that one or more set values are different from the default.

Y if you want to restore the default settings.

Set

LO

FUNCTION LOGICS:

E Semi-automatic

EP Semi-automatic Step-by-Step

S Automatic Safety Devices

SA Automatic with reversal during pause

SP Automatic Step-by-Step Safety Devices

A1 Automatic 1

A Automatic

AP Automatic Step-by-Step

At Automatic timer

b Semi-automatic “b”

bC Mixed (Pulses for opening / Dead-man commands for closing)

C Dead-man

CU Logic modified from a PC/MAC

Default

ENGLISH

Y

E

When a logic requiring a CLOSE (b, bC, C ), input is selected,

the OPEN B inputs will automatically be changed to CLOSE. , if

you choose a logic that does not require the use of CLOSE inputs,

these inputs will change to OPEN B. The simultaneous presence

of CLOSE and OPEN B is possible only using the PC/MAC software.

For a description of how the logics operate, see the related paragraph.

E145 19 732784 - Rev. B

Page 20

Display Basic Function

PA

ENGLISH

PAUSE A TIME (visualised only with Automatic logics)

Is the pause time in a TOTAL opening (it is enabled only if a logic with pause

time has been selected).

Adjustable from

Next the value 59, the viewing changes to minutes and tenths of a second

(separated by a decimal point) and time is adjusted in 10-second steps up to

the maximum value of

e.g.: if the display shows

00 to 59 sec, in 1-second steps.

9.5

minutes.

2.5, the time is 2 min and 50 sec.

Default

30

Pb

Mn

PAUSE TIME B (visualised only with Automatic logics):

Is the pause time in a PARTIAL opening (it is effective only if a logic with pause

time has been selected).

Adjustable from

Next the value 59, the viewing changes to minutes and tenths of a second

(separated by a decimal point) and time is adjusted in 10-second steps up to

the maximum value of

Es: if the display shows

NR. OF MOTORS:

You can select the number of motors present in the system:

00 to 59 sec, in 1-second steps.

9.5

minutes.

2.5, the time is 2 min and 50 sec.

1 = 1 motor

2 = 2 motors

If the SETUP is performed with only one motor, and later two mo-

tors are used, the board will signal error

which can be deleted by repeating the SETUP with two motors or

by returning to one motor.

If a SETUP is performed with two motors and later only one is used,

the board will not signal an error. Only the motor connected to input

M1 will move.

When programming from a PC/MAC, you can select different partial

openings.

14 - configuration error,

30

2

(swing-

leaf)

1

(sliding)

E145 20 732784 - Rev. B

Page 21

Display Basic Function

F1

MOTOR 1 POWER:

You can adjust the maximum power of motor 1, which is the same during

both opening and closing.

01 = minimum power

50 = maximum power

If the power is modified, we recommend performing a new SETUP

- see the related paragraph.

If hydraulic motors are used, power must be programmed to maximum

50).

level (

Default

25

F2

En

FA

MOTOR 2 POWER (visualised only with the function Mn = 2):

You can adjust the maximum power of motor 2, which is the same during

both opening and closing.

01 = minimum power

50 = maximum power

If the power is modified, we recommend performing a new SETUP

- see the related paragraph.

If hydraulic motors are used, power must be programmed to maximum

50).

level (

ENCODER USE:

You can enable/disable the use of encoders (both BUS and GATECODER

encoders):

Y = encoders on both motors

no = encoders disabled

LIMIT SWITCH WHEN OPENING (displayed only if function CF = 1 or

CF = PC):

Lets you set or disable use of the opening limit switch on swing-leaves .

In case of mixed configuration (CF = PC) this function works only

on the swing-leaves. The limit switch on the SLIDING leaf is required

and determines when the leaf stops.

no = opening limit switches disabled

01 = the limit switch determines the stopping of motion

02 = the limit switch determines the start of deceleration

25

no

no

ENGLISH

After having changed the value of this function, SETUP is required:

the card will signal error

performed again or until the previous value is restored

E145 21 732784 - Rev. B

14 (configuration error) until the SETUP is

Page 22

Display Basic Function

Default

FC

ENGLISH

Br

LIMIT SWITCH WHEN CLOSING (displayed only if function CF = 1 or

CF = PC):

Lets you set or disable use of the closing limit switch on swing-leaves.

In case of mixed configuration (CF = PC) this function works only

on the swing-leaf. The limit switch on the SLIDING leaf is required

and determines when the leaf stops.

no = closing limit switches disabled

01 = the limit switch determines the stopping of motion

02 = the limit switch determines the start of deceleration

After having changed the value of this function, SETUP is required:

the card will signal error

performed again or until the previous value is restored.

SLIDING LEAF BRAKING (displayed only if function CF = 2 or CF

=

PC):

Lets you set the braking time of sliding leaves.

14 (configuration error) until the SETUP is

00 = braking disabled

10 = maximum braking time

no

05

Cd

bu

E145 22 732784 - Rev. B

DELA Y FOR CLOSING LEAF (visualised only with the function Mn = 2):

Is the delay time for starting leaf 1 closing with respect to leaf 2. Makes it

possible to avoid overlapping of the two leaves.

Adjustable from

Next the value 59, the viewing changes to minutes and tenths of a second

(separated by a decimal point) and time is adjusted in 10-second steps up to

the maximum value of

e.g.: if the display shows

BUS 2easy DEVICES ENTRY:

See the related paragraph.

00 to 59 sec, in 1- second steps.

3

minutes.

1.2, the time is 1 min and 20 sec

05

no

Page 23

Display Basic Function

-

M2

MOTOR 2 dead-man DRIVE mode (visualised only with the function

Mn = 2)

+/

R1

OPENS (visualising

-/

R2

CLOSES (visualising

Default

--

oP) until the button is held down

cL) until the button is held down

M1

tL

St

MOTOR 1 dead-man DRIVE mode

+/

R1

OPENS (visualising

-/

R2

CLOSES (visualising

WORK TIME LEARNING (SETUP):

See the related paragraph.

AUTOMATED SYSTEM STATUS:

You can exit programming, choosing whether or not to save the configuration

you just performed.

1. set the choice:

oP) until the button is held down

cL) until the button is held down

Y to SAVE and EXIT the programming

no to EXIT the programming WITHOUT SAVING

2. press the button F to confirm; at the end the display returns to visualize

the automated system status:

00 = CLOSED

01 = OPEN

02 = Stationary then “OPENS”

03 = Stationary then “CLOSES”

04 = In “PAUSE”

05 = during Opening

06 = during Closing

07 = FAIL SAFE in progress

08 = checking BUS 2easy devices in progress

09 = Pre-flash then “OPENS”

10 = Pre-flash then “CLOSES”

11 = Emergency open

12 = Emergency close

HP = Hold position

--

ENGLISH

--

Y

WARNING If power is lost to the board prior to confirmation (step

2.), all changes made will be lost.

You can EXIT programming at any time: press and hold F and

then also

+

F

-/R2

E145 23 732784 - Rev. B

to switch directly to St.

Page 24

5.2 ADVANCED PROGRAMMING FUNCTIONS

Display Advanced Function

bo

ENGLISH

cS

TIME OF MAXIMUM POWER AT STARTING:

You can set the starting time. During start the motors work at maximum power

for starting the movement.

Adjustable from

selected with

FINAL STROKE WHEN CLOSING (RAM STROKE) (NOT displayed if

function

Lets you enable/disable the ram stroke on swing-leaves.

The ram stroke facilitates latching of the electric lock by activating the motors

at maximum power during final closing.

FC = 1):

Y = enabled (for 2 sec)

no = disabled

In case of systems with an absolute encoder, to enable this function

a setup must be performed using the automatic leaf stop on the

mechanical contact point.

Default

01

00 to 10 sec, in 1-second steps (ignoring the power level

F1 and F2).

no

rS

REVERSE STROKE WHEN OPENING displayed if function FC = 1):

Lets you enable/disable the reverse stroke on leaf doors.

The reverse stroke facilitates unlatching of the electric lock. When the automatic system is closed, before starting to open, the motors give a brief push

to close.

Y = enabled (for 2 sec)

no = disabled

In case of systems with an absolute encoder, to enable this function

a setup must be performed using the automatic leaf stop on the

mechanical contact point.

E145 24 732784 - Rev. B

no

Page 25

Display Advanced Function

Default

Od

r1

r2

DELA Y FOR OPENING LEAF (visualised only with the function Mn = 2):

You can set the delay time for starting leaf 2 opening with respect to leaf 1, in

order to avoid overlapping of the two leaves.

Adjustable from

Next the value 59, the viewing changes to minutes and tenths of a second

(separated by a decimal point) and time is adjusted in 10-second steps up to

the maximum value of

e.g.: if the display shows

LEAF 1 DECELERATION:

You can adjust the deceleration space as a percentage of the total travel of

leaf 1.

Adjustable from

00 to 59 sec, in 1- second steps.

1.3

minutes.

1.2, the time is 1 min and 20 sec.

00

to 99

%, in 1% steps.

00 = no deceleration

01 = minimum deceleration space

99 = maximum deceleration space

LEAF 2 DECELERATION (visualised only with the function Mn = 2):

You can adjust the deceleration space as a percentage of the total travel of

leaf 2.

Adjustable from

00

to 99

%, in 1% steps.

00 = no deceleration

01 = minimum deceleration space

99 = maximum deceleration space

02

ENGLISH

20

20

PF

PRE-FLASHING:

You can enable/disable the pre-flashing. Pre-flashing duration = 3 sec.

You can choose:

no = disabled

OC = pre-flashing before each movement

CL = pre-flashing before a closing movement

OP = pre-flashing before an opening movement

PA = pre-flashing only at the end of the pause time

E145 25 732784 - Rev. B

no

Page 26

Display Advanced Function

Ph

CLOSING PHOTOCELLS:

The intervention of closing photocells causes the reversing of automated

system (opening).

You can choose:

Y = operate the reversal only after the photocells are released

no = operate the reversal immediately

Default

no

Ad

ENGLISH

EC

r8

ADMAP FUNCTION:

Allows operation in compliance with French regulation NFP 25/362.

Y = enabled

no = disabled

ANTI-CRUSHING SENSITIVITY (visualised only with the function En

=

Y):

Varying this function varies the amount of time after which, in case of obstacle, the board commands reversal of the leaves, or it will command a stop

if the leaves are in the contact point search space (see the parameter

The fourth consecutive obstacle detected in the same direction and position

will be defined as a contact point and the leaf will stop in that position.

rB).

00 = minimum sensitivity (maximum time before reversal)

10 = maximum sensitivity (minimum time before reversal)

MECHANICAL STOP SEARCH ANGLE (displayed only if function En =

Y and functions Fc and FA = no or = 02):

You can adjust the contact point search angle within which the board will stop

movement without reversing, if it encounters an obstacle or the contact point.

0.3

Adjustable from

From

0.3 to 9.9 degrees, adjustments are made in 0.1 degree steps.

From

10 to 20 degrees, adjustments are made in 1 degree steps.

to 20 degrees.

no

05

4.0

tA

E145 26 732784 - Rev. B

ADDITIONAL OPERA TING TIME (displayed only if function En = no and

functions

You can add a work time at the end of movement.

Adjustable from

Fc and FA = no or = 02):

0 to 30 sec in 1 sec steps.

This time is not considered when calculating the deceleration per-

centage.

03

Page 27

Display Advanced Function

o1

OUT 1:

You can set the output OUT1 (open collector N.O.) in one of the following

functions:

00 = always active

0 1 = FAIL-SAFE

02 = INDICATOR LIGHT (off = closed; on = during opening and open/

in pause; flashing = during closing)

03 = COURTESY LIGHT (stays on for the duration of the movement

(even in SETUP) in addition to the set time of function

= ACTIVE ERROR

04

05 = automated system OPEN or in PAUSE

06 = automated system CLOSED

07 = automated system MOVING

08 = automated system in EMERGENCY

09 = automated system in OPENING

10 = automated system in CLOSING

11 = DISABLED

12 = safety device ACTIVE

13 =

TRAFFIC LIGHT function (active when OPENING and with automated

system OPEN)

14 = timed output which can be activated from the second radio channel

OMNIDEC

15 = output which can be activated from the second radio channel

OMNIDEC (step-by-step function)

16 = active during movement of leaf 1

17 = active during movement of leaf 2

18 = active during breach alarm

If tr is displayed, it indicates that the output is used as a TIMER

set from the PC/MAC software.

Default

00

t1

ENGLISH

(see function t1)

t1

o2

t2

E145 27 732784 - Rev. B

OUT 1 TIMING (visualised only with the function o1 = 03 or o1 = 14):

You can adjust the timing of OUT 1 output if a timed function has been selected

with a time from

from

1 to 59 sec in 1-second steps for function 11

OUT 2:

You can set the output OUT2 (open collector N.O.).

See the options as

OUT 2 TIMING (visualised only with the function o2 = 03 or o2 = 14):

Adjustable as for

1 to 59 minutes in 1-minute steps for functions 03-14 and

o1.

t1.

02

02

02

Page 28

Display Advanced Function

+

AS

MAINTENANCE REQUEST - CYCLE COUNTER (linked to the subsequent

two functions):

You can enable the signaling of maintenance request, or the cycle counter.

Y = enable the SIGNALING when the programmed number of cycles has

been reached (as defined in subsequent two functions

Signaling consists of a pre-flashing of 8 sec (in addition to the time

may already be set with the function

If using a PC/MAC a maintenance request is set with a number of

cycles greater than 99,990, the subsequent two functions

nd will display 99 and 99, respectively.

no = enable the CYCLE COUNTER, that will be displayed in the subse-

ENGLISH

quent two functions

If the number of cycles performed is greater than 99,990 the subse-

quent two functions

Default

no

nc and nd).

PF) before each movement.

nc and

nc and nd up to a displayed maximum of 99,990.

nc and nd will display 99 and 99, respectively.

nc

CYCLE PROGRAMMING (THOUSANDS):

AS = Y the display will show the number of thousands of cycles after which

If

the signaling of maintenance request begins (can be set from

If

AS = no the display will show the number of thousands of work cycles

performed. The value displayed is updated with the succession of the cycles,

interacting with the value in

When AS = no you can reset the cycle counter: press simultaneously

and - for 5 sec.

nd.

0 to 99).

00

E145 28 732784 - Rev. B

Page 29

Display Advanced Function

-

nd

CYCLE PROGRAMMING (TENS):

AS = Y the display will show the number of tens of cycles after which the

If

signaling of maintenace request begins (can be set from

AS = no the display will show the number of tens of work cycles performed.

If

The value displayed is updated with the succession of the cycles,

interacting with the value in

e.g.: if the system has performed 11,218 cycles, nc = 1 1 and nd = 21

will be displayed

Default

00

0 to 99).

nc.

St

AUTOMATED SYSTEM STATUS:

You can exit programming, choosing whether or not to save the configuration

you just performed.

1. set the choice:

Y to SAVE and EXIT the programming

no to EXIT the programming WITHOUT SAVING

2. press the button F to confirm; at the end the display returns to visualize

the automated system status:

00 = CLOSED

01 = OPEN

02 = Stationary then “OPENS”

03 = Stationary then “CLOSES”

04 = In “PAUSE”

05 = Opening

06 = Closing

WARNING If power is lost to the board prior to confirmation (step

2.), all changes made will be lost.

-/R2

You can EXIT programming at any time: press and hold F and

then also

+

F

to switch directly to St.

07 = FAIL SAFE in progress

08 = checking BUS 2easy devices in progress

09 = Pre-flash then “OPENS”

10 = Pre-flash then “CLOSES”

11 = Emergency open

12 = Emergency close

HP = Hold position

Y

ENGLISH

E145 29 732784 - Rev. B

Page 30

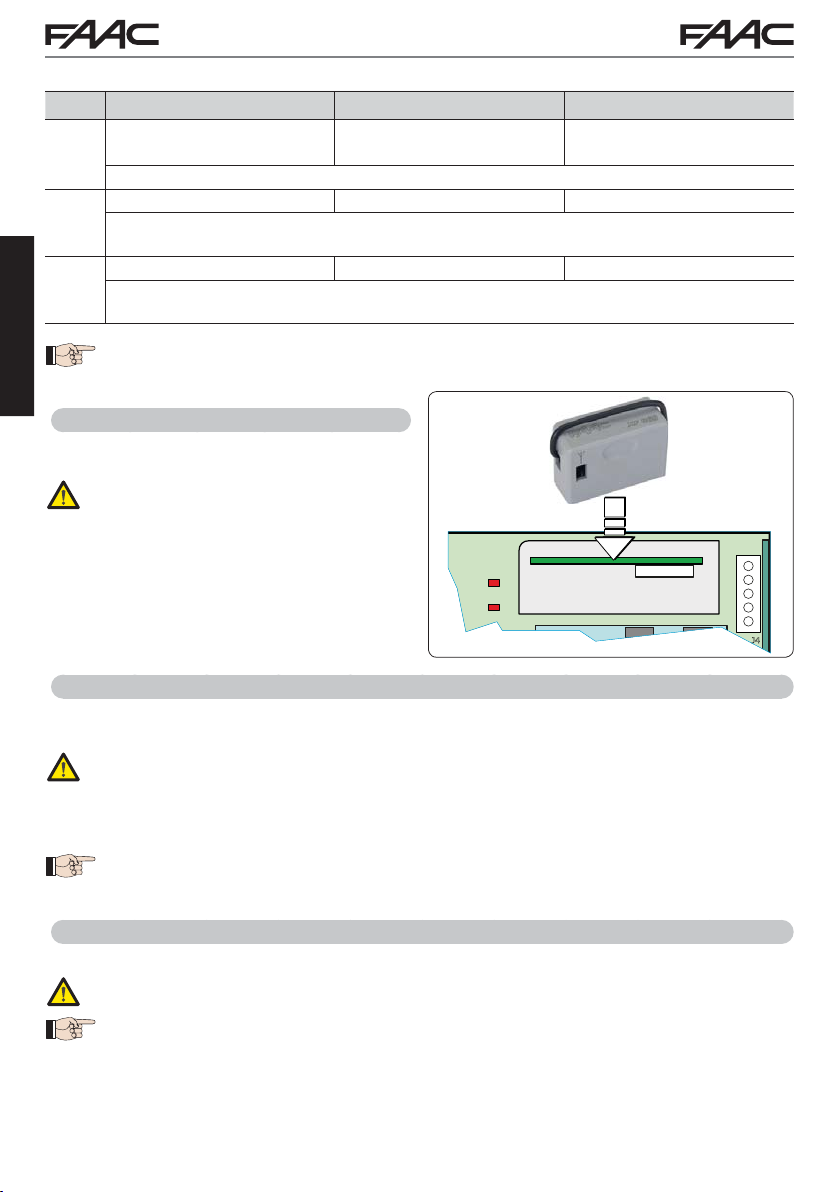

5.6 BUS 2EASY DEVICE INSTALLATION

+

+

You can add BUS 2easy devices to the system at any time, proceeding as follows:

1. Cut off the electrical power to the board.

2. Install and set the BUS 2easy accessories according to the instructions of the devices.

3. Connect the BUS 2easy

4. Power up the board.

5. Complete the procedure for BUS 2easy

5.6.1 BUS 2easy DEVICE ENTRY

Access BASIC programming and scroll through the functions up until

1.

display will show the BUS 2easy devices status (see the figure).

2. Perform the entry: simultaneously press and hold

display will blink).

ENGLISH

will appear as a confirmation of entry completion.

3.

Y

4. Release the

devices according to the instructions of Chapter ELECTRICAL CONNECTIONS.

device entry.

. When F is released, the

bu

and - for at least 5 sec (during this time, the

and - buttons. The status of the BUS 2easy devices will be displayed.

If no BUS device has ever been entered in the board, the display will read

Opening photocells:

ON = entered and engaged

Encoder 1: ON = correctly connected

Opening photocells

and Closing photocells:

ON = entered and engaged

OPEN photocell:

ON = entered and engaged

Closing photocells:

ON = entered and engaged

Fig. Visualising the BUS 2easy status in the function

of device.

E145 30 732784 - Rev. B

bu

and entered

BUS Status: always ON

Encoder 2:

ON = correctly connected and

entered

: each segment of the display shows one type

no

.

Page 31

Fig. examples of BUS 2easy status visualization on display.

+

In STAND BY (gate closed and in stand-by) with

BUS 2easy Encoder on leaf 1 and leaf 2 and

BUS 2easy Photocells

entered.

In case of BUS 2easy Encoder on leaf1 and leaf 2

and BUS 2easy Photocells correctly connected and

entered and with closing photocells engaged:

correctly connected and

Checking the securing devices entered on the board

To verify the types of BUS device recognised through the entry:

1. Press and hold the

one entered device will go ON. E.g.:

To check the condition of the BUS 2easy connection, verify the LED on the board:

LED DL15 (Red)

ON Safety device engaged or pulse generator active

OFF NO safety device engaged neither pulse generator active

LED DL14 (Green)

ON steady Normal activity (led ON even if there are no devices).

Slow blinking (blink

every 2,5 sec)

Rapid blinking (blink

every 0.5 sec)

OFF Board in Sleep mode (if used).

button during stand-by visualisation; the segments corresponding to at least

at least one pair of opening

photocells correctly entered

Encoder on leaf 1 correctly

entered

+/

R1

Encoder on leaf 2 correctly

entered

at least one pair of closing

photocells correctly entered

BUS 2easy line short-circuit.

Error in the BUS 2easy connection.

Repeat the device entry

- That there are no more than one device in the system with the same

address.

- Calling error (number > or < the connected BUS devices).

SAFE error on the BUS device.

- FAIL

. If the error occurs again, check:

ENGLISH

E145 31 732784 - Rev. B

Page 32

5.4 TIME LEARNING - SETUP

+

-

+

FA

FA

01

FA

02

When the board is powered, if a SETUP has never been performed, or if the board requests it, on the

display

S0 indicates that a SETUP must be performed.

During SETUP, the connected BUS 2easy accessories are always entered.

The BUS 2easy encoders are to be enabled before SETUP: set the parameter En = Y (see

BASIC Programming)

For SETUP, proceed as follows:

During SETUP all safety devices are disabled! Therefore, carry out the operation avoiding

any transit in the leaf movement area.

ENGLISH

If a system without an encoder is installed, mechanical stops will be required for the leaves.

1. Enter BASIC programming and go to the parameter

2. Ensure that the gate leaves are closed. Otherwise, proceed as follows:

- Press and hold -/R2 to close leaf 2

- Press and hold +/R1 to close leaf 1

Should pressing +/R1 and/or -/R2 command opening of the corresponding leaf, cut off power

and, on terminal board J2, invert the phase cables of the corresponding motor (terminals 2-3

for leaf 1 motor and terminals 5-6 for leaf 2 motor).

3. With the gate leaves closed, launch SETUP by pressing and holding

on the display (about 3 sec).

4. Release

Stop movement by sending an OPEN A

pulse as soon as leaf 1 reaches the contact

point.

5. On the display

Stop movement by sending an OPEN A

pulse as soon as leaf 2 reaches the contact

point.

e -. Leaf 1 begins its opening movement.

Operation WITHOUT Encoder

will flash (only if 2 motors have been selected): leaf 2 begins opening.

S2

Operation WITHOUT Encoder

Steps 4 and 5 with function

=

FA

motion is ignored.

FA

after involving the opening limit switch.

(the limit switch determines the stopping of motion) the OPEN A pulse for stopping

01

=

(the limit switch determines the start of deceleration) send an OPEN A pulse only

02

FA

:

tL, when F is released ---- will appear.

and

Operation WITH Encoder

Leaf 1 will stop as soon as it reaches the

contact point. If there is no mechanical

stop, stop the leaf movement at the desired

point by sending an OPEN A pulse.

Operation WITH Encoder

Leaf 2 will stop as soon as it reaches the

contact point. If there is no mechanical

stop, stop the leaf movement at the desired

point by sending an OPEN A pulse.

until S1 begins to flash

E145 32 732784 - Rev. B

Page 33

6. On the display S3 will flash (only if 2 motors have been selected): leaf 2 begins closing.

FC

FC

01

FC

02

CF

Operation WITHOUT Encoder

Stop movement by sending an OPEN A

pulse as soon as leaf 2 reaches the contact

point.

7. On the display

Operation WITHOUT Encoder

Stop movement by sending an OPEN

A pulse as soon as leaf 1 reaches the

contact point.

Steps 6 and 7 with function

=

FC

01

motion is ignored.

=

FC

02

after involving the closing limit switch.

SET-UP for SLIDING LEAFS (

Steps 4, 5, 6 and 7 :

the leaf stop is determined by the limit switch. Any OPEN A impulses are ignored.

8. The board will automatically exit the programming menu and will display the automated system status

00) to confirm that the SETUP procedure has been completed correctly. If the procedure is not

(

completed correctly, on the display S0 will start flashing, indicating that a new SETUP procedure

must be performed.

The deceleration spaces can be configured and modified from the display using the parameters

flashes: leaf 1 begins closing.

S4

:

FC

(the limit switch determines the stopping of motion) the OPEN A pulse for stopping

(the limit switch determines the start of deceleration) send an OPEN A pulse only

02

)

CF= 02

Operation WITH Encoder

Leaf 2 will stop as soon as it reaches the

contact point. If there is no mechanical

stop, stop the leaf movement at the desired point by sending an OPEN A pulse.

Operation WITH Encoder

Leaf 1 will stop as soon as it reaches the

contact point. If there is no mechanical

stop, stop the leaf movement at the desired

point by sending an OPEN A pulse.

r1 and r2 (see Advanced Programming) without repeating the SETUP.

ENGLISH

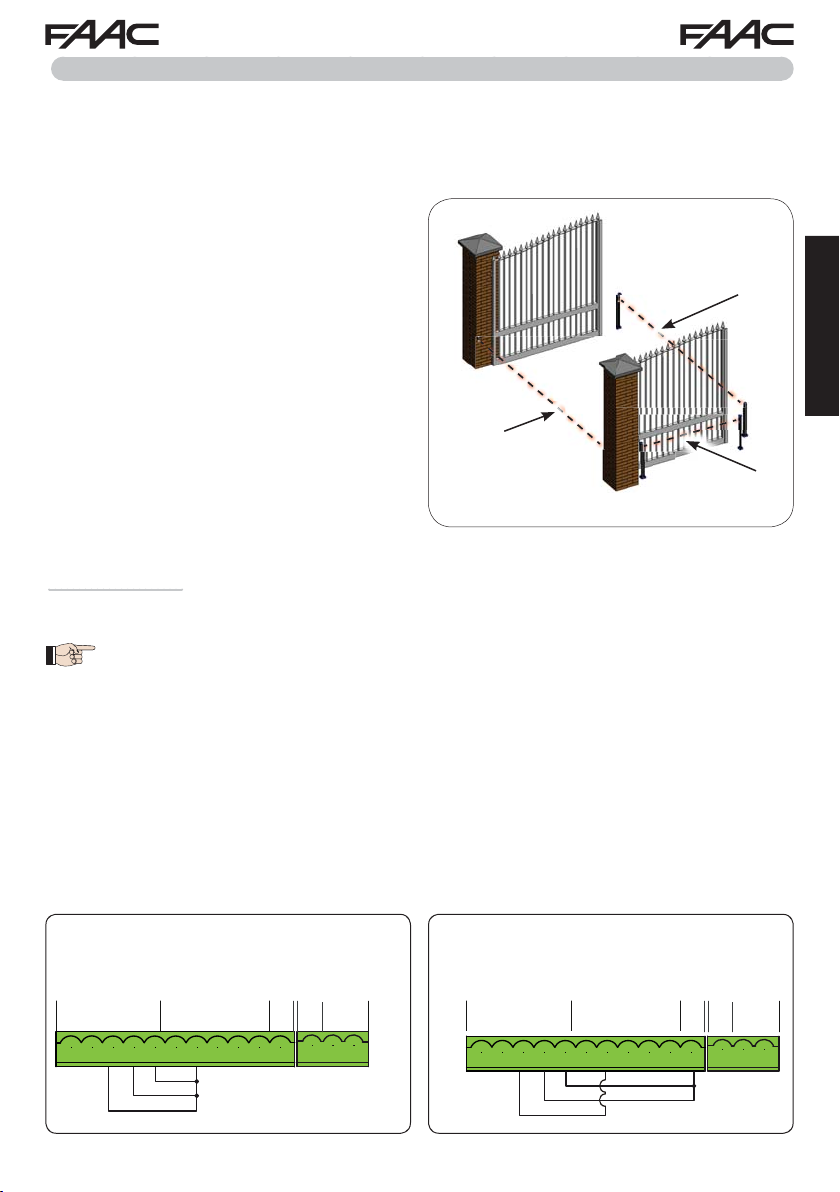

5.5 TESTING THE AUTOMATED SYSTEM

Once installation and programming is completed, ensure that the system is operating correctly.

Be especially careful that the safety devices operate correctly and ensure that the system complies

with all current safety regulations. Close the cover in the provided seat with gasket.

E145 33 732784 - Rev. B

Page 34

OK

OK

MAX

5”

MAX

20 ”

6. MEMORISING THE RADIO CODE

The control board features an integrated 2-channel decoding system (DS, SLH/SLH LR, RC) called

OMNIDEC. This system lets you memorise, using an additional receiver module (on J5 connector)

and more radio controls having different technology but the same frequency.

both total opening (OPEN A) and partial opening (OPEN B).

The different types of radio code (DS, SLH/SLH LR, LC/RC) can coexist simultaneously

on the two channels. You can enter up to 1600 radio codes divided between OPEN A

and OPEN B/CLOSE.

T o use different encoding systems on the same channel, you must complete the learning of

each encoding system and then repeat the procedure for the other one.

, more detailed, programming options are available using a PC/MAC (see dedicated

Other

PC/MAC instructions). For example, you can set an automatic OPEN command on the radio

channel to command an automatic cycle (open-pause-close) regardless of the selected logic.

Keep the remote control at least 30 cm from the receiver.

ENGLISH

6.1 MEMORISING THE SLH/SLH LR RADIO CONTROLS

1. Press and hold +/R1 - SW1 (OPEN

• After keeping the button pressed for about 5 sec, the corresponding radio LED (DL11 or DL12)

will begin to flash slowly for about 20 sec.

2. Release the button.

3. Simultaneously press and hold P1 and P2 on the SLH/SLH LR radio control (only MASTER radio

control).

• The radio control LED will begin to flash.

4. Release both buttons.

Ensure that LED DL11 or DL12 on the board is still flashing (see point 2) and, while the radio con-

•

trol LED is still flashing, press and hold the desired button on the radio control (the radio control

LED will go on steady).

• The corresponding LED on the board (DL11 or DL12) will go on steady for 1 sec and then go off,

indicating that memorisation has been completed.

5. Release the radio control button.

6. To complete memorisation, press the button of the memorised radio control twice in succession.

• The automated system will perform an opening cycle.

Ensure that there are no obstacles (by people or things) during the automated system

movement.

A programming) or -/R2 - SW2 (OPEN B/CLOSE programming).

You can thus control

MAX

RX

> 30 cm

> 5”

+/

R1

DL11

RADIO 1

E145 34 732784 - Rev. B

TX

2”

P1 + P2

+/

R1

MAX

20”

5”

1”

OK

1”

OK

2 x 2”

Page 35

MAX

5”

OK

OK

OK

MAX

20 ”

MAX

20 ”

To enable other radio controls with the same system code, you must transfer the system code of

the memorised radio control button to the button corresponding to the radio control you wish to add:

1. Simultaneously press and hold P1 and P2 on the memorised radio control.

• The radio control LED will begin to flash.

2. Release both buttons.

3. Press and hold, while the radio control LED is still flashing, the memorised button (the radio control

LED will go on steady).

4. Bring the radio controls close together, press and hold the corresponding button of the radio control

you wish to add, and release only after the radio control LED flashes twice, indicating that memorisation has been completed.

5. Press the button of the memorised radio control twice in succession.

• The automated system will perform an opening cycle.

Ensure that there are no obstacles (by people or things) during the automated system

movement.

> 30 cm

TX

TX

MAX

5”

OK

+

x

2

2”

1”

DL11

RADIO 1

f, indicating that the procedure has been

OK

RX

> 30 cm

2”

P1 + P2

6.2 MEMORISING LC/RC RADIO CONTROLS (ONLY 433 MHZ)

1. Press and hold +/R1 - SW1 (OPEN A programming) or -/R2 - SW2 (OPEN B/CLOSE programming).

• After keeping the button pressed for about 5 sec, the corresponding radio LED (DL11 or DL12)

will begin to flash slowly for about 20 sec.

2. Release the button.

3. During radio LED flashing, press the desired button of the LC/RC radio control.

The corresponding LED on the board (DL11 or DL12) will go on steady for 1 second, indicating

•

that memorisation has been completed, and will begin flashing again for another 20 sec during

which you can memorise another radio control.

• When the 20 sec have elapsed, the LED will turn of

completed.

4. To add other radio controls, repeat the procedure from point 1.

RX

ENGLISH

> 5”

+/

R1

DL11

RADIO 1

E145 35 732784 - Rev. B

+/

R1

MAX

20”

1”

OK

MAX

20”

Page 36

OK

MAX

20 ”

6.2.1 REMOTE MEMORISATION OF LC/RC RADIO CONTROLS

With LC/RC radio controls you can remotely memorise other radio controls, i.e. without working directly

on the board, using a previously memorised radio control.

Take a radio control that has already been memorised on one of the 2 channels (OPEN

1.

B/CLOSE) and move to the vicinity of the board.

2. Simultaneously press and hold P1 and P2 until both LEDs flash slowly for 5 sec.

3. Within 5 seconds, press the previously memorised radio control button to activate the learning phase

for the selected channel.

4. The LED on the board corresponding to the channel in learning mode will flash for 20 sec within which

another radio control code is transmitted by pressing the button.

• The corresponding LED on the board will go on steady for 2 sec (indicating that memorisation has

been completed) and will begin flashing again for another 20 sec, during which you can memorise

other radio controls, and will finally go off.

6.3 MEMORISING DS RADIO CONTROLS

ENGLISH

the DS radio control, choose the desired ON - OFF combination of the 12 dip-switches.

1. On

2. Press and hold +/R1 - SW1 (OPEN

• After keeping the button pressed for about 5 sec, the corresponding radio LED (DL11 or DL12)

will begin to flash slowly for about 20 sec.

3. Release the button.

4. During radio LED flashing, press the button of the radio control you wish to program.

• The corresponding LED on the board (DL11 or DL12) will go on steady for 1 second and then go

off, indicating that memorisation has been completed.

5. To add other different codes, repeat the procedure starting from point 1.

6. To add other radio controls with the same code, set the 12 dip-switches according to the same combination as the already memorised radio control.

A programming) or -/R2 - SW2 (OPEN B/CLOSE programming).

A or OPEN

RX

> 30 cm

> 5”

+/

R1

DL11

RADIO 1

E145 36 732784 - Rev. B

TX

+/

R1

MAX

20”

1”

OK

Page 37

6.4 DELETING THE RADIO CONTROLS

This operation CANNOT be reversed. This will delete ALL the radio control codes memorised as both OPEN A and OPEN B/CLOSE. The cancellation procedure is active only

in gate status visualisation mode.

-/

R2

1. Press and hold -/R2

.

• After pressing for about 5 sec, the DL12 LED begins to flash slowly; after another 5 sec of slow

flashing and holding, the LEDs DL11 and DL12 begin flashing more rapidly (cancellation has started).

• Once rapid flashing has stopped, LEDs DL11 and DL12 will go on steady, confirming the cancellation

of all the radio codes (OPEN A and OPEN B/CLOSE) from the board memory.

2. Release -/R2

. The LEDs will go off, indicating correct cancellation.

-/R2

ENGLISH

E145 37 732784 - Rev. B

Page 38

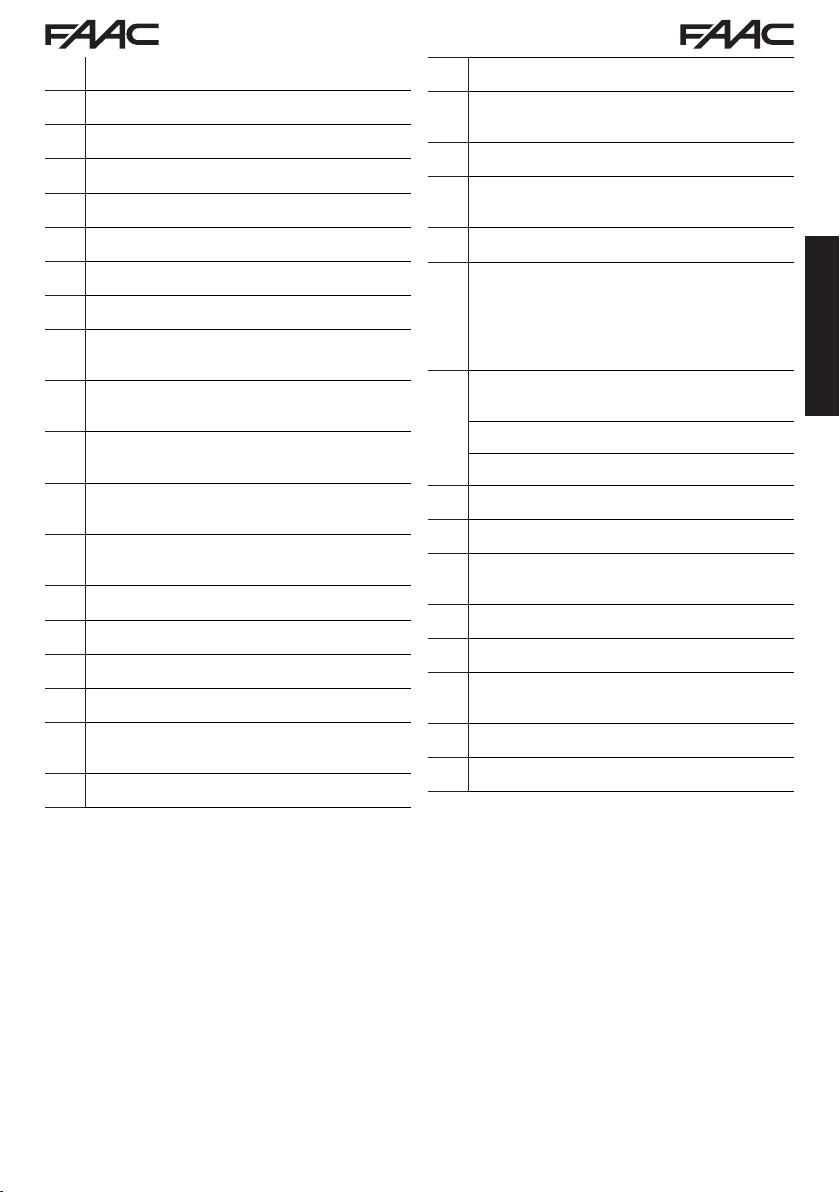

RADIO XF 433-868

RADIO 1

DL12

DL11

RADIO 2

DL1

DL2

DL3

DL4

IC1

24V

DL14

DL6

DL5

DL10

TF1

J6

J10

FCC2 FCA2

FCC1 FCA1

J8

J5

BUS MON

.

+/R1

ERROR

SW3

SW1 SW2

IN5

DL13

DL17

DL16

USB

IN4

DL7

DL8

DL9

OC4

J9

BUS

F

5V

IN3

IN2

IN1

C52

F1

DB1

J2

FL1

J1

B

J4

9 10 11 12 13 14 15 16 17 18 19

20 21 22

26 25 24 23

PE N L

112131415161718

TOPCLOP

FSW

---

24V

+

+

LOCK

2

2

12 4567

COM

OP

COM

CL

LA

3

CL

1 2 3 4 5 6 7 8

PENL

TH2 TH1

RP/DEC

DL15

BAT1

CR2032

USB-BUSB-A

AC MAIN

M1

OP

M2

N3

IN4

IN5

8.8.

23

24

25

26

CONNECTIVITY

TF1

9 10 11 12 13 14 15 16 17 18 19

V

A

TH2

TH1

A

A

2

2

2

111

A1

A

3

23

A2

A2

5

4

4

868

1

2L11

2

5

1

NNE

NNENENENENENEEEENCTIVITYYYY

Y

1

0

7. START-UP

7.1 CHECKING THE LEDs

After having made all the connections and powered the board, check the status of the LEDs in relation

to the status of the inputs (the Figure shows the condition of closed automated system).

LED ON = contact closed LED OFF = contact open

ADIO