Page 1

voor de natuur

100% kringlooppapier

para la naturaleza

100% papel reciclado

740-741 &

740-741 &

740D

740D

ist umweltfreundlich

100% Altpapier

pour la nature

papier recyclé 100%

for nature

recycled paper 100%

per la natura

carta riciclata 100%

Page 2

EC DECLARATION OF CONFORMITY FOR MACHINES

(DIRECTIVE 98/37/EC)

Manufacturer: FAAC S.p.A.

Address: Via Benini, 1 - 40069 Zola Predosa BOLOGNA - ITALY

Declares that: 740 / 741 mod. operator with electronic control unit 740D

• is built to be integrated into a machine or to be assembled with other machinery to create a machine under

the provisions of Directive 98/37/EC;

• conforms to the essential safety requirements of the following EEC directives:

73/23/EEC and subsequent amendment 93/68/EEC.

89/336/EEC and subsequent amendment 92/31/EEC and 93/68/EEC

and also declares that it is prohibited to put into service the machinery until the machine in which it will be

integrated or of which it will become a component has been identified and declared as conforming to the

conditions of Directive 98/37/EC.

Bologna, 01 January 2004

The Managing Director

A. Bassi

WARNINGS FOR THE INSTALLER

GENERAL SAFETY OBLIGATIONS

1) ATTENTION! To ensure the safety of people, it is important that you read

all the following instructions. Incorrect installation or incorrect use of the

product could cause serious harm to people.

2) Carefully read the instructions before beginning to install the product.

3) Do not leave packing materials (plastic, polystyrene, etc.) within reach of

children as such materials are potential sources of danger.

4) Store these instructions for future reference.

5) This product was designed and built strictly for the use indicated in this

documentation. Any other use, not expressly indicated here, could

compromise the good condition/operation of the product and/or be

a source of danger.

6) FAAC declines all liability caused by improper use or use other than that

for which the automated system was intended.

7) Do not install the equipment in an explosive atmosphere: the presence

of inflammable gas or fumes is a serious danger to safety.

8) The mechanical parts must conform to the provisions of Standards EN

12604 and EN 12605.

For non-EU countries, to obtain an adequate level of safety, the

Standards mentioned above must be observed, in addition to national

legal regulations.

9) FAAC is not responsible for failure to observe Good Technique in the

construction of the closing elements to be motorised, or for any

deformation that may occur during use.

10) The installation must conform to Standards EN 12453 and EN 12445.

For non-EU countries, to obtain an adequate level of safety, the

Standards mentioned above must be observed, in addition to national

legal regulations.

11) Before attempting any job on the system, cut out electrical power .

12) The mains power supply of the automated system must be fitted with

an all-pole switch with contact opening distance of 3mm or greater.

Use of a 6A thermal breaker with all-pole circuit break is recommended.

13) Make sure that a differential switch with threshold of 0.03 A is fitted upstream

of the system.

14) Make sure that the earthing system is perfectly constructed, and connect

metal parts of the means of the closure to it.

15) The automated system is supplied with an intrinsic anti-crushing safety

device consisting of a torque control. Nevertheless, its tripping

threshold must be checked as specified in the Standards indicated

at point 10.

16) The safety devices (EN 12978 standard) protect any danger areas

against mechanical movement Risks, such as crushing, dragging,

and shearing.

17) Use of at least one indicator-light (e.g. FAACLIGHT ) is recommended

for every system, as well as a warning sign adequately secured to the

frame structure, in addition to the devices mentioned at point “16”.

18) FAAC declines all liability as concerns safety and efficient operation

of the automated system, if system components not produced by

FAAC are used.

19) For maintenance, strictly use original parts by FAAC.

20) Do not in any way modify the components of the automated system.

21) The installer shall supply all information concerning manual operation

of the system in case of an emergency, and shall hand over to the

user the warnings handbook supplied with the product.

22) Do not allow children or adults to stay near the product while it is

operating.

23) Keep remote controls or other pulse generators away from children,

to prevent the automated system from being activated involuntarily.

24)

Transit is permitted only when the automated system is idle.

25) The user must not attempt any kind of repair or direct action whatever

and contact qualified personnel only.

26) Maintenance: check at least every 6 months the efficiency of the

system, particularly the efficiency of the safety devices (including,

where foreseen, the operator thrust force) and of the release

devices.

27 ) Anything not expressly specified in these instructions is not permitted.

15

Page 3

AUTOMATED SYSTEM 740-741

322

These instructions apply to the following models:

FAAC 740 - 741

The 740-741 gearmotor is an electro-mechanical operator designed

for moving sliding gates.

The non-reversing reduction system ensures the gate is mechanically

locked when the gearmotor is not operating, therefore it is not

necessary to install any electric lock

1. DESCRIPTION AND TECHNICAL SPECIFICATIONS

햲

햻

햳

햺

A convenient manual release with customised key makes it possible

to move the gate in the event of a power failure or malfunction of

the operator.

The 740-741 gearmotor was designed and built for controlling vehicle

access. AVOID ANY OTHER USE WHATEVER.

1. Motor lid

2. Electronic control unit

3. Release device

4. Gearmotor body

5. Foundation plate

6. Pinion

7. Limit switch

8. Motor cover

9. Cable holes

10. Capacitor

11. Protective side panels

햹

햸

햵

햽

햷

햴

햶

LEDOM047147V511047V511147

)%01-%6+(ylppusrewoP zH05~V032zH05~V032zH06~V511zH06~V511

)W(rewopdebrosbA 053005053006

)A(tnerrucdebrosbA 5.12.232.5

)Fµ(roticapaC 015.210305

)Nad(noinipnotsurhT 54565456

)mN(euqroT 81428142

)C°(noitcetorplamrehtgnidniW 041041041041

)gK(thgiewxamfaeL 005009005009

noinipfoepyT 61Z61Z61Z61Z

)nim/m(deepsetaG 21214141

)m(htgnelxametaG 51515151

hctiwstimilfoepyT lacinahceMlacinahceMlacinahceMlacinahceM

hctulC cinortcelEcinortcelEcinortcelEcinortcelE

ycneuqerfesU %03-3S%04-3S%03-3S%04-3S

)C°(erutarepmetgnitarepO 55+02-55+02-55+02-55+02-

)gK(thgiewrotomraeG 01110111

ssalcnoitcetorP 44PI44PI44PI44PI

snoisnemidllarevorotomraeG 20.giFeeS20.giFeeS20.giFeeS20.giFeeS

Fig.01

2. DIMENSIONS

Values are expressed in mm

221

16

5

1

8

0

9

2

Fig.02

Page 4

3. MAXIMUM USE CURVE

d

)

)

)

)

)

The curve makes it possible to

establish maximum work time (T)

according to use frequency (F).

With reference to IEC 34-1 Standard, the 740-741 gearmotor with

an S3 duty, can operate at a use

frequency of 30-40%.

To ensure efficient operation, it is

necessary to operate in the work

range below the curve.

Important: The curve is obtained

at a temperature of 20°C.

Exposure to the direct sun rays

can reduce use frequency

down to 20%.

Percentuale

i lav. %

100

90

80

70

60

50

40

30

20

10

0

Tempo (h

% Fréquence

d'utilisation

Temps (h

% Benutzungsfrequenz

10 11 12

Zeit (Std.

% Duty cycle

12345678910

Time (h

% Frecuencia

de utilización

Tiempo (h

Calculation of use frequency

Use frequency is the percentage of effective work time (opening +

closing) compared to total time of cycle (opening + closing + pause times).

Calculation formula:

Ta + Tc

% F = X 100

Ta + Tc + Tp + Ti

where:

Ta = opening time

Tc = closing time

Tp = pause time

Ti = time of interval between two complete cycles

4. ELECTRICAL SET-UP (standard system)

9a[PP

Warning: The arrow on the foundation plate must always point to

the gate, see Figs. 05-06.

3- After determining the position of the foundation plate, make

a plinth as shown in Fig. 07 and wall the plate, providing several

sheaths for routing the cables. Using a spirit level, check if the

plate is perfectly level. Wait for the cement to set.

4- Lay the electric cables for connection to the accessories and

power supply as shown in diagram of Fig. 03. To facilitate

connections to the control unit, allow the cables to protrude by

at least 50 cm from the hole on the foundation plate.

°

Values are expressed in mm

Values are expressed in mm

Values are expressed in mm

±5

56

±5

56

0÷50

0

2

3

1

8

0

0÷50

0

1

90

Fig.05

°

0

9

Fig.06

8

9

,

5

6

100

2

0

0

5

3

3

Fig.07

1- Operator with unit

2- Photocells

3- Key-operated push button

4- Flashing lamp

5- Radio receiver

Fig.03

5. INSTALLING THE AUTOMATED SYSTEM

5.1. Preliminary checks

To ensure safety and efficiency of the automated system, make sure

the following requirements are observed before installing the system:

• The gate structure must be suitable for automation. The following

are necessary in particular: wheel diameter must be in proportion

to the weight of the gate, an upper track must be provided, plus

mechanical travel stops to prevent the gate derailing.

• The soil must guarantee a perfect stability of the foundation plinth.

• There must be no pipes or electric cables in the plinth excavation

area.

• If the gearmotor is located in the vehicle transit or manoeuvre

area, adequate means of protection should be provided against

accidental impact.

• Check if an efficient earthing is available for connection to the

gearmotor.

5.2. Masonry for

Values are expressed in mm

foundation plate

1- Assemble the foundation

plate as shown in figure 04.

2- In order to ensure that the

pinion and rack engage

correctly, the foundation plate

must be positioned as shown

60-80

5.3. Mechanical installation

1- Remove the cover, Fig. 08 ref. 1.

2- Position the operator on the

foundation plate, using the

supplied washers and nuts as

shown in Fig. 09. During this

operation, route the cables

through the appropriate openings

in the motor body (See Fig.01 ref.9).

If necessary, the two holes can be

joined using a hammer to obtain

a wider space.

3- Adjust the height of the

gearmotor and the distance from

the gate, referring to dimensions in

Fig. 10.

Attention: This operation is

necessary to ensure the rack is

correctly secured and to enable

any new adjustments.

4- Secure the gearmotor to the

plate, tightening the nuts.

5- Prepare the operator for manual

operation as described in

paragraph 8.

1

Fig.08

in Fig. 05 (right closing) or Fig.

06 (left closing).

Fig.04

Fig.09

17

Page 5

Values are expressed in mm

Values are expressed in mm

90 (Z16)

42

56

12,5 ÷ 50

Fig.10

5.4. Assembling the rack

5.4.1. Steel rack to weld (Fig. 11)

1) Fit the three threaded pawls on the rack element, positioning

them at the bottom of the slot. In this way, the slot play will

enable any future adjustments to be made.

2) Manually take the leaf into its closing position.

3) Lay the first section of rack level on

the pinion and weld the threaded

pawl on the gate as shown in Fig.

13.

4) Move the gate manually,

checking if the rack is resting on the

pinion, and weld the second and

third pawl.

5) Position another rack element end

Fig.11

to end with the previous one, using a section of rack (as shown

in Fig. 14) to synchronise the teeth of the two elements.

6) Move the gate manually and weld the three threaded pawls,

thus proceeding until the gate is fully covered.

5.4.2. Steel rack to screw (Fig. 12)

1) Manually take the leaf into its closing position.

2) Lay the first section of rack level on the pinion and place the

spacer between the rack and the

gate, positioning it at the bottom of

the slot.

3) Mark the drilling point on the gate.

Drill a Ø 6,5 mm hole and thread

with an M8 male tap. Screw the bolt.

4) Move the gate manually, checking

if the rack is resting on the pinion,

and repeat the operations at point

Fig.12

3.

5) Position another rack element end to end with the previous

one, using a section of rack (as shown in figure 14) to synchronise

the teeth of the two elements.

6) Move the gate manually and carry out the securing

operations as for the first element, thus proceeding until the

gate is fully covered.

Fig.15

6. START-UP

6.1. Control board connection

Before attempting any work on the board (connections,

programming, maintenance), always turn off power.

Follow points 10, 11, 12, 13 and14 of the GENERAL SAFETY

OBLIGATIONS.

Following the instructions in Fig. 3, route the cables through the

raceways and make the necessary electric connections to the

selected accessories.

Always separate power cables from control and safety cables (pushbutton, receiver, photocells, etc.). To avoid any electric noise

whatever, use separate sheaths.

6.1.1. Earthing

Connect the earth cables as shown in Fig.16 ref.A.

Fig.16

6.1.2. Electronic control unit

In the gearmotors, the electronic control unit is fitted to an

adjustable support (Fig. 16 ref. 1) with transparent lid (Fig. 16 ref.

3).

The board programming push buttons (Fig. 16 ref. 4) have been

located on the lid. This allow the board to be programmed without

removing the lid.

For correct connection of the control unit, follow indications the

specific instructions:

Notes on rack installation

• Make sure that, during the gate travel, all the rack elements

do not exit the pinion.

• Do not, on any account, weld the rack elements either to the

spacers or to each other.

• When the rack has been installed, to ensure it meshes correctly

with the pinion, it is advisable to lower the gearmotor position

by about 1.5 mm (Fig.15).

• Manually check if the gate correctly reaches the mechanical

limit stops maintaining the pinion and rack coupled and make

sure there is no friction during gate travel.

• Do not use grease or other lubricants between rack and pinion.

Fig.13

Fig.14

6.2. Positioning the limit switches

The operator has a mechanical travel stop

with spring-lever, which commands gate

movement to stop when a profiled steel plate,

secured on the top of the rack, activates the

spring until the microswitch is tripped. The plate

support can be fitted to all racks with max.

width of 13 mm.

Procedure for correct positioning of the two

travel stop plates supplied:

1) Fit and secure the 2 profiled steel plates on the 2 U-supports,

using the supplied nuts and washers, as shown in figure 17.

2) Prepare the operator for manual operation as described in

paragraph 8.

3) Power up the system.

4) Securing the opening limit switch: manually take the gate to

opening position, leaving 20 mm from the mechanical travel

stop.

5) Allow the plate to slide over the rack in opening direction

(Fig.18). As soon as the opening limit switch LED on the control

board goes off, take the plate forward by about 20÷30 mm

and secure it provisionally on the rack, using the supplied screws.

6) Repeat the operations at points 4 and 5 for the closing limit

switch, Fig. 19.

18

Fig.17

Page 6

1

2

Fig.18

Important:

a) The plate must activate the limit-switch on the profiled part as

shown in figure 20.

b) If the wheel and the travel stop plate are too close, it may be

necessary to shorten the limit-switch spring by a couple of turns.

Procedure for shortening the spring:

- To remove the spring, turn it clockwise. This operation requires

some force.

- Shorten the spring as shown in Fig. 22: two turns correspond

to about 3 mm.

- Fit the spring turning it clockwise, Fig. 23, until the stop is

reached; see Fig. 24.

- Once the spring is back in place, ensure the wheel is horizontal.

A wrong wheel orientation may jeopardise the operation

of the limit switches.

Fig.19

Fig.20

2

3

3

Fig.25

Fig.26

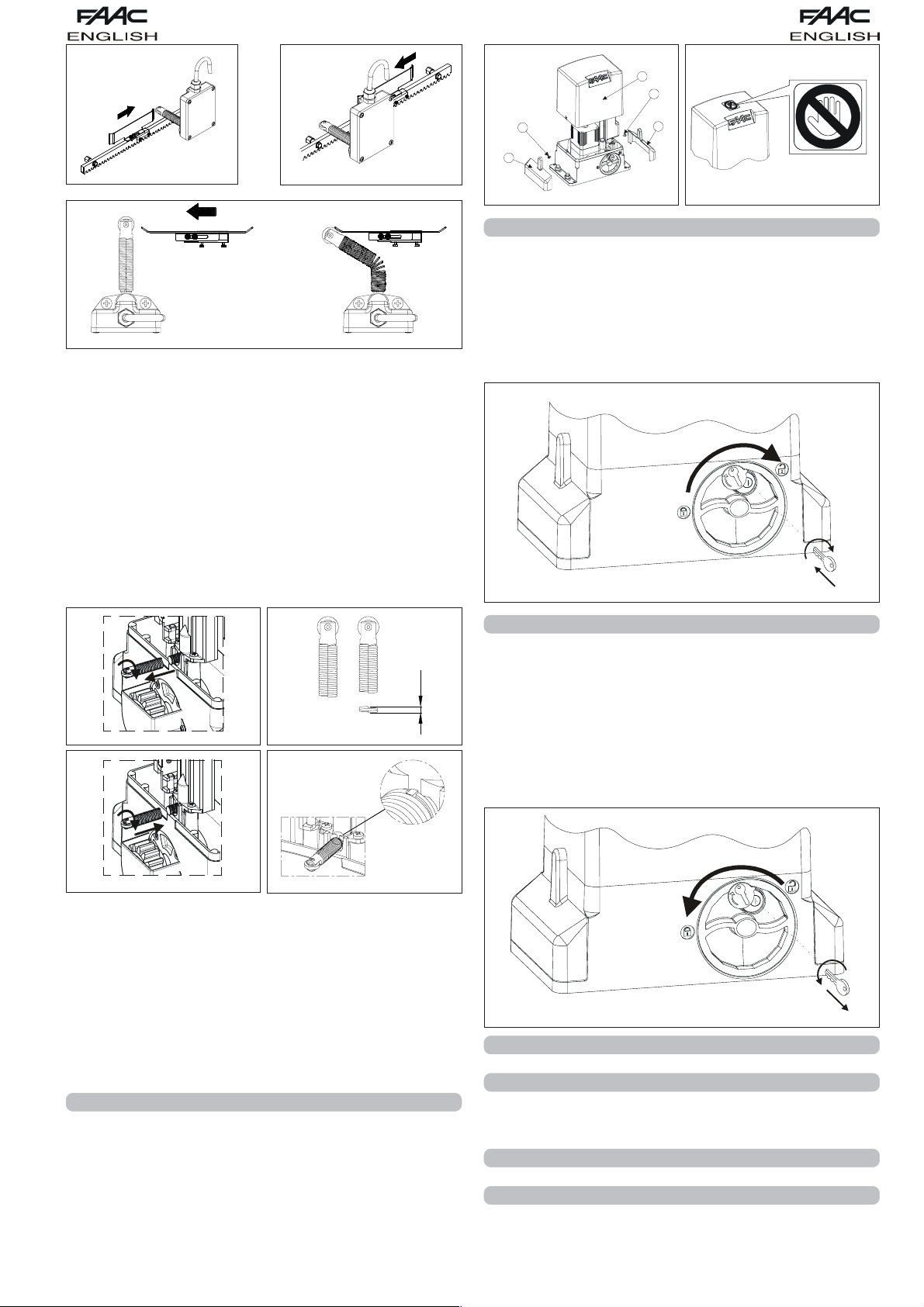

8. MANUAL OPERATION

Warning: Cut power to the system to prevent an involuntary

pulse from activating the gate during the release manoeuvre.

To release the operator proceed as follows:

1) Insert the key provided and turn it clockwise as shown in Fig. 27

ref. 1 and 2.

2) Turn the release system clockwise, until the mechanical stop

is reached, Fig. 27 ref. 3.

3) Open and close the gate manually.

3

2

1

Fig.27

Fig.21

Fig.23

8) Re-lock the system (see paragraph 9).

Important: Before sending a pulse, make sure that the gate

cannot be moved manually.

9) Command a complete gate cycle to check if the limit switch is

tripped correctly.

Warning: To avoid damaging the operator and/or interrupting

operation of the automated system, allow a space of about

20 mm from the mechanical travel stops.

10) Appropriately adjust the position of the travel stop plates and

definitively secure them on the rack.

7. TESTING THE AUTOMATED SYSTEM

After installing the operator, carefully check operating efficiency of

all accessories and safety devices connected to it.

Return the board support to its original position. Fit the cover (Fig. 25

ref. 1), tighten the two side screws provided (Fig. 25 ref 2) and snap-fit

the side panels (Fig. 25 ref.3).

Apply the danger sticker on the top of the cover (Fig. 26).

Hand the “User’s Guide” to the Customer and explain correct

operation and use of the gearmotor, indicating the potentially

dangerous areas of the automated system.

Values are expressed in mm

Fig.22

Fig.24

9. RESTORING NORMAL OPERATION

Warning: Cut power to the system to prevent an involuntary pulse

from activating the gate during the manoeuvre for restoring

normal operation.

To restore normal operation proceed as follows:

1) Turn the release system anti-clockwise, until its stop is reached,

Fig. 28 ref. 1.

2) Turn the key anti-clockwise and remove it from the lock, Fig. 28

ref. 2 and 3.

3) Move the gate until the release system meshes (corresponds

to gate locking)

4) Power up the system.

1

2

3

Fig.28

10. SPECIAL APPLICATIONS

There are no special applications.

11. MAINTENANCE

Check the operational efficiency of the system at least once every

6 months, especially as regards the efficiency of the safety and

release devices (including operator thrust force).

12. REPAIRS

For any repairs, contact the authorised Repair Centres.

13. AVAILABLE ACCESSORIES

Refer to the catalogue for available accessories.

19

Page 7

CONTROL BOARD 740D

1. WARNINGS

3. LAYOUT AND COMPONENTS

Important: Before attempting any work on the control board

(connections, maintenance), always turn off power.

- Install, upstream of the system, a differential thermal breaker

with adequate tripping threshold.

- Connect the earth cable to the appropriate terminal on the

J7 connector of the equipment (see fig. 30).

- Always separate power cables from control and safety

cables (push-button, receiver, photocells, etc.). To avoid

any electric noise, use separate sheaths or a shielded cable

(with earthed shield).

2. TECHNICAL SPECIFICATIONS

Model 740D-115V 740D-230V

Power supply V~

( +6% -10%) 50 Hz

115 230

Absorbed power (W) 10 10

Motor max. load (W) 1200 1000

Accessories max. load (A) 0.5 0,5

Operating ambient temperature -20 °C +55 °C

Protection fuses 2 (see fig. 29)

Function logics: Automatic / “Stepped” automatic / Semi-automatic / Safety

devices / Semi-automatic B / Dead-man C / “Stepped” semi-automatic /

Mixed B/C logic

Work time Programmable (from 0 to 4 min.)

Pause time Programmable (from 0 to 4 min.)

Thrust force Adjustable over 50 levels

Terminal board inputs Open / Pàartial opening / Safety devices at opng. /

Safety devices at clsng. / Stop / Edge / Power supply + Earth

On-connector inputs Opening and closing limit-switches / Encoder

Terminal board outputs Flashing lamp - Motor - 24 Vdc accessories power

supply - 24 Vdc indicator-light / Timed output. - Fail safe

Rapid connector 5-pin card connection for Minidec, Decoder or RP receivers

Programming 3 keys (+, -, F) and display, "basic" or "advanced" mode

Basic mode programmable functions Function logic - Pause time - Thrust Force

- Gate direction

Advanced mode programmable functions: Torque at initial thrust - Braking - Fail safePre-flashing - Indicator-light/Timed output/Electric lock or 'traffic lights' command Opening and closing safety devices logic - Encoder/ Anti-crushing sensitivity Decelerations - Partial opening time - Work time - Assistance request - Cycle counter

RADIO

J2

ENCODER

J5

J5

LIMITS ENCODER

DL SIGNALLING AND PROGRAMMING DISPLAY

Led INPUTS STATUS CONTROL LED

J1 LOW VOLTAGE TERMINAL BOARD

J2 CONNECTOR FOR DECODER/MINIDEC/RP RECEIVER

J3 ENCODER CONNECTOR

J5 LIMIT -SWITCH CONNECTOR

J6 MOTORS AND FLASHING LAMP CONNECTION TERMINAL BOARD

J7

F1

F2 LOW VOLTAGE AND ACCESSORIES FUSE (T 800mA)

F "F" PROGRAMMING PUSH-BUTTON

– "–" PROGRAMMING PUSH-BUTTON

4. ELECTRIC CONNECTIONS

+ "+" PROGRAMMING PUSH-BUTTON

DL

F

-

+

F

–+

J2

FCA

OPEN

FSW

STOP

OP

B

F2

F2

F1

Led

FCC

J3

J3

POWER SUPPLY TERMINAL BOARD 115Vac(740D-115V)-230Vac(740D-230V

FSW

OPEN

A

A

OPEN

1 2 3 4 5 6 7 8 9 10 11 12

EDGE

CL

SAFE

STOP

EDGE

ACCESSORIES

24V

--

+

+

TX-FSW

OP

CL

B

OPEN

FSW

FSW

J1

W.L.

J6

J1

N

COM

OPEN

CLOSE

13 14 15 16 17

J6

MOTOR

LAMP

LAMP

F1

PE

PE N L

MAIN

Fig. 29

L

N

J7

J7

)

MOTORS AND TRANSF. PRIMARY FUSE (740D 115V=F10A - 740D 230V=F 5A)

J5

LIMITS ENCODER

LIMIT-SWITCH

J3

ENCODER

(optional)

24V

--

+

+

TX-FSW

A

OPEN

B

OPEN

OP

FSW

CL

FSW

STOP

EDGE

1 2 3 4 5 6 7 8 9 10 11 12

ACCESSORIES

For connection of the

photocells and safety

devices, see paragraph

4.1.

PARTIALLY OPEN

NB.: The capacitor is supplied with the operator.TOTALLY OPEN

20

W.L.

24 Vdc

3 W

L

OPEN

CLOSE

N

LAMP

COM

J6

J1

13 14 15 16 17

MOTOR

BLUE

M

LAMP

C

115Vac

N

PE

PE N L

MAIN

J7

(740D 115V)

max. 60W

-

230 Vac

(740D 230V)

max. 60W

115Vac 50-60Hz

(740D 115V)

-

230Vac 50-60Hz

(740D 230V)

STOP

Fig. 30

Page 8

V

4.1.

Connection of photocells and safety devices

Before connecting the photocells (or other devices) we advise

you to select the type of operation according to the movement

area they have to protect (see fig. 31):

Opening/closing

safety devices

Opening safety

devices

"Edge" safety devices

Closing safety device

Opening safety devices:

they are tripped when an obstacle is

Fig. 31

detected only during gate opening movement. They

cause immediate closure and resumption of opening

motion on release (see programming in par.5.2).

Closing safety devices:

they are tripped when an obstacle is

detected only during gate closing movement. They cause re-opening, either immediate or on release (see

programming in par.5.2).

Opening/closing safety devices:

they are tripped during the

gate opening and closing movements. They cause

stopping and restart motion on release.

"Edge" safety devices:

they are tripped during the gate opening

and closing movements. They cause immediate reversal

of motion and stopping after two seconds.

Encoder:

it is tripped if there is an obstacle during gate opening

and closing movements. It causes immediate reversal of

motion and stopping after two seconds.

Connection of an "edge" safety device

24V

--

+

+

TX-FSW

W.L.

OPEN

OP

CL

B

A

OPEN

FSW

FSW

STOP

EDGE

1 2 3 4 5 6 7 8 9 10 11 12

Connection of a pair of photocells for opening

24V

--

+

+

TX-FSW

W.L.

A

OPEN

B

OPEN

OP

FSW

CL

FSW

STOP

EDGE

1 2 3 4 5 6 7 8 9 10 11 12

RX

1

2

3

4

-

+

5

TX

1

-

+

2

Connection of a pair of closing photocells

24V

--

+

+

TX-FSW

W.L.

A

OPEN

B

OPEN

OP

FSW

CL

FSW

STOP

EDGE

1 2 3 4 5 6 7 8 9 10 11 12

Fig. 35

Fig. 36

N.B. If two or more safety devices have the same function

(opening, closing, opening and closing, edge), the contacts

must be connected to each other in series (fig. 32).

N.C. contacts must be used.

Connection of two N.C. contacts in series

(e.g. Photocells, Stop, Edge, etc.)

Fig. 32

N.B: If safety devices are not used, jumper connect the terminals

as shown in fig. 33.

Connection of no safety device

24V

--

+

+

TX-FSW

W.L.

A

OPEN

B

OPEN

OP

FSW

CL

FSW

STOP

EDGE

1 2 3 4 5 6 7 8 9 10 11 12

Fig. 33

The most common photocell and safety device lay-outs are

shown below (from fig. 34 to fig. 41).

Connection of a closing safety device and an opening

safety device

24V

--

+

+

TX-FSW

W.L.

A

OPEN

B

OPEN

OP

FSW

CL

FSW

STOP

EDGE

1 2 3 4 5 6 7 8 9 10 11 12

Fig. 34

RX

1

2

3

4

-

+

5

TX

1

-

+

2

Fig. 37

Connection of a pair of opening photocells, a pair of closing

photocell and an edge safety device

24

--

+

+

TX-FSW

W.L.

A

OPEN

B

OPEN

OP

FSW

CL

FSW

STOP

EDGE

1 2 3 4 5 6 7 8 9 10 11 12

RX CL

1

2

3

4

5

TX OP

1

-

+

2

-

+

TX CL

RX OP

1

-

+

2

1

2

3

4

-

+

5

Fig. 38

21

Page 9

V

Connection of two pairs of closing photocells and two

edge safety devices

Connection of a pair of closing photocells and a pair of

opening/closing photocells

24

--

+

+

TX-FSW

A

OPEN

B

OPEN

OP

FSW

CL

FSW

STOP

EDGE

1 2 3 4 5 6 7 8 9 10 11 12

RX CL1

1

2

3

4

5

TX CL2

1

2

-

+

TX CL1

-

+

RX CL2

1

2

1

2

3

4

5

W.L.

Fig. 39

A

OPEN

B

OPEN

OP

FSW

CL

FSW

STOP

EDGE

24V

--

+

+

1 2 3 4 5 6 7 8 9 10 11 12

RX CL TX CL

1

2

3

4

-

+

5

1

2

TX OP/CL

-

+

RX OP/CL

1

2

1

2

3

4

5

Connection of two N.O. contacts in parallel

(e.g. Open A, Open B)

TX-FSW

W.L.

Fig. 41

Connection of a pair of closing photocells, a pair of opening

photocells and a pair of opening/closing photocells

24V

--

+

+

TX-FSW

W.L.

A

OPEN

B

OPEN

OP

FSW

CL

FSW

STOP

EDGE

1 2 3 4 5 6 7 8 9 10 11 12

RX CL TX CL

1

2

3

4

-

+

5

1

2

TX OP/CL

RX OP TX OP

1

2

3

4

-

+

5

-

+

RX OP/CL

-

+

1

2

1

2

3

4

5

1

2

Fig. 40

Fig. 42

4.2. J7 Terminal board - Power supply (fig. 30)

POWER SUPPLY (terminals PE-N-L):

PE: Earth connection

N:Power supply ( Neutral )

L:Power supply ( Line )

NB.: For correct operation, the board must be connected to the

earth conductor in the system. Install an adequate differential

thermal breaker upstream of the system.

4.3. J6 Terminal board - Motors and flashing lamp (fig. 30)

MOTOR - (terminals 13-14-15): Motor connection.

In gearmotors with a built-in control unit, this connection is prewired standard. For leaf opening direction, see basic

programming in par. 5.1.

LAMP - (terminals 16 -17): Flashing lamp output.

4.4. J1 Terminal board - Accessories (fig. 30)

OPEN A - "Total Opening" command (terminal 1): any pulse

generator (push-button, detector, etc.) which, by closing a

contact, commands total opening and/or closing of the

gate leaf.

To install several total opening pulse generators, connect

the N.O. contacts in parallel (see fig. 42).

OPEN B - "Partial opening " or "Closing" command (terminal 2):

any pulse generator (push-button, detector, etc.) which,

by closing a contact, commands partial opening and/or

closing of the gate leaf. In the B, C and B/C logics, it always

commands gate closure.

To install several partial opening pulse generators, connect

the N.O. contacts in parallel (see fig. 42).

22

Page 10

MINIDEC

PLUS

RP

FSW OP - Opening safety devices contact (terminal 3): The

purpose of the opening safety devices is to protect the leaf

movement area during opening. During opening, in the A-

AP-S-E-EP logics the safety devices reverse the movement

of the gate leaves, or stop and restart the movement when

they are released (see advanced programming in Par 5.2).

During the opening cycle in logics B, C and B/C, they

interrupt movement. They never operate during the closing

cycle.

If the Opening safety devices are engaged when the gate

is closed, they prevent the leaf opening movement.

To install several safety devices, connect the N.C. contacts

in series (fig. 32).

NB.: If no opening safety devices are connected, jumper

connect inputs OP and -TX FSW (fig. 33).

FSW CL - Closing safety devices contact (

purpose of the closing safety devices is to protect the leaf

movement area during closing. During closing, in the A-

AP-S-E-EP logics, the safety devices reverse the movement

of the gate leaves, or stop and reverse the movement

when they

Par 5.2

interrupt movement. They never operate during the

opening cycle. If the Closing safety devices are engaged

when the gate is open, they prevent the leaf closing

movement.

To install several safety devices, connect the N.C. contacts

in series (fig. 32).

are released (see advanced programming in

). During the closing cycle in logics B, C and B/C, they

terminal

4): The

NB.: If no closing safety devices are connected, jumper

connect terminals CL and -TX FSW (fig. 33).

STOP - STOP contact (

button) which, by opening a contact, is able to stop gate

movement.

To install several STOP devices, connect the N.C. contacts

in series.

terminal

5): any device (e.g. a push-

NB.: If STOP devices are not connected, jumper connect

the STOP and - terminals.

EDGE - EDGE safety device contact (terminal 6): The purpose of

the "edge" safety device is to protect the leaf movement

area during opening/closing against fixed obstacles (pillars,

walls, etc.). In all logics, during opening and closing, the

safety devices reverse gate leaf movement for 2 seconds. If

the safety devices operate again during the 2-seconds

reversing time, they STOP movement without any reversing.

If the Edge safety devices are engaged while the gate is

closed or open, they prevent the leaves movement.

To install several safety devices, connect the N.C. contacts

in series (fig. 32).

NB.: If edge safety devices are not connected, jumper

connect the EDGE and - inputs. (fig. 33).

– Negative for power supply to accessories (terminals 7 and

8)

+ 24 Vdc - Positive for power supply to accessories (terminals

9 and 10)

Important: Accessories max. load is 500 mA. To calculate

absorption values, refer to the instructions for individual

accessories.

TX -FSW - Negative for power supply to photocell transmitters

(terminal 11)

If you use this terminal for connecting the negative for

supplying power to the photocell transmitters, you may, if

necessary, also use the FAIL SAFE function (see advanced

programming in par. 5.2).

If this function is enabled, the equipment checks operation

of the photocells before every opening or closing cycle.

W.L. - Power supply to indicator light / timed exit / electric lock/

'traffic lights' (terminal 12)

Connect any 24 Vdc - 3 W max indicator light, timed exit,

command device for electric lock or 'traffic lights' between

this terminal and the +24V (see advanced programming

in par. 5.2). To avoid geopardising correct operation of

the system, do not exceed the indicated power.

4.5.

Connector J2 - Rapid connection to Minidec,

Decoder and RP

This is used for rapid connection of Minidec, Decoder and RP

receivers (see fig.

43, 44, 45). Connect the accessory, with the

components side facing the inside of the board. Insert and

remove after cutting power.

PLUS

740D 740D

DECODER

Fig. 43

Fig. 44

740D

Fig. 45

4.6. Connector J6 - Limit-switches rapid connection (fig. 30)

This input is intended for rapid connection of the opening and

closing limit-switches designed to stop the leaf, or for start of

decelerations or for braking (see advanced programming in

Par. 5.2.). In gearmotors with a built-in control unit, this connection

is pre-wired as standard (fig. 30). For leaf opening direction, see

advanced programming in Par 5.2.

4.7. Connector J3 - Encoder rapid connection (fig. 30)

This input is designed for rapid connection of the Encoder

(optional). To fit the encoder on the motor, refer to the

relevant instructions.

The presence of the encoder is signalled - when the gearmotor

is running - by the flashing of the "Encoder" LED on the board.

When the encoder is used, the control unit knows the exact

position of the gate while it is moving.

The encoder controls the adjustments of some of the control

unit's functions in a different way (partial opening or

deceleration - see advanced programming in Par 5.2) and as

an anti-crushing device.

If the gate strikes an obstacle during opening or closing, the

encoder immediately reverses the gate leaf for 2 seconds. If

the encoder operates again during the 2 seconds reversing

time, it STOPS movement without commanding any reversing.

23

Page 11

5. PROGRAMMING

To program operation of the automated system, you have to

access the "

Programming is split into two parts:

5.1. BASIC PROGRAMMING

To access BASIC PROGRAMMING, press key F:

•if you press it (and hold it down), the display shows the name

of the first function.

•if you release the key, the display shows the value of the

function that can be modified with keys + and -.

•if you press F again (and hold it down), the display shows the

name of the next function, etc.

•when you reach the last function, press F to exit the program,

and the display resumes showing the gate status.

The following table shows the sequence of functions accessible

in BASIC PROGRAMMING:

PROGRAMMING

" mode.

BASIC

and

ADVANCED

.

5.2. ADVANCED PROGRAMMING

To access ADVANCED PROGRAMMING, press key F and, as you

hold it down, press key

•if you release key + , the display indicates the name of the first

function.

•if you release key F too, the display shows the value of the

function that can be modified with keys + and -.

•if you press key F (and hold it down), the display shows the

name of the next function, and if you release it, the value that

can be modified with keys + and - is shown.

•when you reach the last function, press F to exit the program,

and the display resumes showing the gate status.

The following table shows the sequence of functions accessible

in ADVANCED PROGRAMMING:

+:

BASIC PROGRAMMING

Display Function Default

FUNCTION LOGICS (see table of logics):

= Automatic

= "Stepped" automatic

= "Safety" Automatic

= Semi-automatic

= "Stepped" Semi-automatic

= Dead-man

= "B" Semi-automatic

= Mixed Log. (B opening / C closing)

PAUSE TIME:

This has effect only if the automatic logic

was selected. Adjustable from

sec. in one-second steps.

Subsequently, display changes to minutes

and tens of seconds (separated by a

point) and time is adjusted in 10-second

steps, up to the maximum value of

minutes.

E.g. if the display shows , pause time

is 2 min. and 50 sec.

FORCE:

Adjusts Motor thrust.

= minimum force

= maximum force

OPENING DIRECTION:

Indicates the gate opening movement and makes

it possible not to change the motor and limitswitches connections on the terminal board.

= Right-hand opening movement

= Left-hand opening movement

STATUS OF AUTOMATED SYSTEM:

Exit from programming, save data, and

return to gate status viewing.

= Closed

= Now opening

= At "STOP"

= Open

= Pause

= "FAIL SAFE" tripped

= Now closing

= Now reversing

= Photocells tripped

F

to

ADVANCED PROGRAMMING

Display Function Default

MAXIMUM TORQUE AT INITIAL THRUST:

The motor operate at maximum torque

(ignoring the torque setting) at start of

movement. Useful for heavy leaves.

= Active

= Disabled

FINAL BRAKING:

When the gate engages the opening or

closing limit-switch, a braking stroke can be

selected to ensure the leaf is stopped

immediately. If decelerations are selected,

braking starts when they finish.

At value, braking is disabled.

Time can be adjusted from to in

0.01-second steps.

= Braking disabled

from

FAIL SAFE:

If this function is activated, it enables a

function test of the photocells before any

gate movement. If the test fails (photocells

not serviceable signalled by value on

the display), the gate does not start moving.

= Active

PRE-FLASHING (5 s):

Activates the flashing lamp for 5 seconds

before start of movement.

to = Timed braking

= Disabled

= Disabled

= Only before opening

= Only before closing

= Before every movement

F

+

+

24

Page 12

Display Function Default Display Function Default

INDICATOR-LIGHT:

If is selected, the output functions as a

standard indicator-light (lighted at opening

and pause, flashing at closing, and off when

gate closed).

Courtesy light: Different figures correspond

to timed activation of the output, which can

be used (by a relay) to power a courtesy

lamp. Time can be adjusted from

sec. in 1-second steps, and from to

min. in 10-second steps.

Electric lock command and 'traffic lights'

functions:

If you press key - from the setting, the

command for the closing electric lock is

activated;

If you press - again, the command for the

closing and opening electric lock is set;

if you press the - key again, you can set the

'traffic lights' functions and .

= Standard indicator-light

from to = Timed output.

= electric lock command before

opening movement

= electric lock command before

opening and closing movements

= 'traffic lights' function: the output is

active in "open" and "open on pause" status

and is disabled 3 seconds before the closing

manoeuvre starts.

Note: there is 3 seconds of pre-flashing before

the closing manoeuvre.

= 'traffic lights' function: the output is

active only in "closed" status.

Attention: do not exceed the output's maximum

load (24Vdc-3W). If necessary, use a relay and

a power supply source outside the equipment.

to

ENCODER:

If the encoder is used, you may select its

presence.

If the encoder is present and enabled,

"decelerations" and "partial opening" are

controlled by the encoder (see relevant

paragraphs).

The encoder operates as an anti-crushing

device: If the gate strikes an obstacle during

opening or closing, the encoder

immediately reverses gate leaf movement

for 2 seconds. If the encoder operates

again during the 2-seconds reversing time,

it stops movement (STOP) without

commanding any reversing. If no sensor is

supplied, the parameter must be set on

. If there is the encoder, adjust the

sensitivity of the anti-crushing system, by

varying the parameter between

(maximum sensitivity) and (minimum

sensitivity).

from to = Encoder active and

sensitivity adjustment

= Encoder disabled

Pre-limit switch DECELERATION:

You can select gate deceleration before

the opening and closing limit-switches have

been tripped.

Time can be adjusted from to in

0.04-second steps.

If an encoder is used, the adjustment is not

determined by time but by motor revs, thus

obtaining greater deceleration precision.

= Deceleration disabled

from to = Deceleration enabled

CLOSING PHOTOCELLS LOGIC:

Select the tripping mode of the closing

photocells.

They operate for the closing movement only:

they stop movement and reverse it when

they are released, or they reverse it

immediately.

= Reverse on release

= Reverse immediately to opening

OPENING PHOTOCELLS LOGIC:

Select the tripping mode of the opening

photocells.

They operate for the opening movement

only: they stop the movement and restart it

when they are released, or they reverse it

immediately.

= Reverse immediately to closing

= Restart movement on release

Post-limit switch DECELERATION:

You can select gate deceleration after the

opening and closing limit-switches have

been tripped.

Time can be adjusted from to in

0.02-second steps.

If an encoder is used, the adjustment is not

determined by time but by motor revs, thus

obtaining greater deceleration precision.

= Deceleration disabled

from to = Deceleration enabled

PARTIAL OPENING:

You can adjust the width of partial leaf

opening.

Time can be adjusted from to in

1-second steps.

If an encoder is used, the adjustment is not

determined by time but by motor revs, thus

obtaining greater partial-opening precision.

For example, with pinion Z20, partial opening

can vary from about 60 cm to 4 m.

25

Page 13

Display Function Default

WORK TIME (time-out):

We advise you to set a value of 5 to 10

seconds over the time taken by the gate to

travel from the closing limit-switch to the

opening limit-switch and vice versa.

Adjustable from to sec. in onesecond steps.

Subsequently, display changes to minutes

and tens of seconds (separated by a point)

and time is adjusted in 10 second steps, up

to a maximum value of minutes.

Attention: the set value does not exactly

matchthe motor's maximum operating time,

because the latter is modified according to

the performed deceleration spaces.

ASSISTANCE REQUEST (combined with next

function):

If activated, at the end of countdown

(settable with the next function i.e. "Cycle

programming") it effects 2 sec. (in addition

to the value already set with the PF function)

of pre-flashing at every Open pulse (job

request). Can be useful for setting scheduled

maintenance jobs.

= Active

= Disabled

CYCLE PROGRAMMING:

For setting countdown of system operation

cycles. Settable (in thousands) from to

thousand cycles.

The displayed value is updated as cycles

proceed.

This function can be used to check use of the

board or to exploit the "Assistance request".

6. START-UP

6.1. INPUTS CHECK

The table below shows the status of the LEDs in relation to to the

status of the inputs.

Note the following:

Check the status of the LEDs as per Table.

Operation of the signalling status LEDs

LEDS LIGHTED OFF

FCA Limit-switch free Limit-switch engaged

FCC Limit-switch free Limit-switch engaged

OPEN B Command activated Command inactive

OPEN A Command activated Command inactive

FSW OP Safety devices disengaged Safety devices engaged

FSW CL Safety devices disengaged Safety devices engaged

STOP Command inactive Command activated

EDGE Safety devices disengaged Safety devices engaged

LED

LIGHTED

LED

= closed contact

OFF

= open contact

NB.:

• The status of the LEDs while the gate is closed at rest are shown in

bold.

7. FINAL OPERATIONS

At end of programming, run a few complete cycles to check if the

automated system and the accessories connected to it are

operating correctly, giving special attention to safety devices,

operator thrust force adjustment, and to the anti-crushing device

(Encoder sensor, optional). Hand over the "User's guide" page (in

the operator instructions) to the customer, and describe how the

system works, as well as the operator release and locking operations

indicated in the said guide.

GATE STATUS:

Exit from programming, data saving, and return

to viewing gate status (see par. 5.1.).

NB.: modification of programming parameters comes into effect

immediately, whereas definitive memory storage occurs only when

you exit programming and return to gate status viewing. If the

equipment is powered down before return to status viewing, all

modifications will be lost.

To restore the default settings of the programming disconnect

terminal strip J1, press the three buttons +, -, F simultaneously and

keep them pressed for 5 seconds.

26

Page 14

)2("2rofnepootsesreveR

)1(emitesuapsdaoleR

)2("2rofesolcotsesreveR

)delbasidNEPO(

)2("2rofnepootsesreveR

)2("2rofesolcotsesreveR

emitesuapsdaoleR

)delbasidNEPO(

)2("2rofnepootsesreveR

)1(emitesuapsdaoleR

)2("2rofesolcotsesreveR

)delbasidNEPO(

)2("2rofnepootsesreveR

)2("2rofesolcotsesreveR

)delbasidNEPO(

tceffeoN

otsesrever,esaelerno,dnaskcoL

)1(emitesuapsdaoleR

)delbasidNEPO(

nepo

)3()1(emitesuapsdaoleR

.2.5hpargarapees

tceffeoN

)delbasidANEPO.gnpo.trapnofi(

)NEPOsevas(

tceffeoN

tceffeoN

)delbasidNEPO(

tceffeoN

seunitnoc,esaelerno,dnaskcoL

gninepo

tceffeoN

)delbasidNEPO(

tceffeoN

otsesrever,esaelerno,dnaskcoL

emitesuapsdaoleR

)delbasidNEPO(

nepo

)3(emitesuapsdaoleR

.2.5hpargarapees

)delbasidNEPO(

tceffeoN

)delbasidANEPO.gnpo.trapnofi(

)NEPOsevas(

tceffeoN

tceffeoN

)delbasidNEPO(

tceffeoN

seunitnoc,esaelerno,dnaskcoL

gninepo

tceffeoN

)delbasidNEPO(

tceffeoN

otsesrever,esaelerno,dnaskcoL

"5retfasesolc,esaelernO

)delbasidNEPO(

nepo

NEPO("5retfasesolc,esaelernO

.2.5hpargarapees

)3()delbasid

tceffeoN

)delbasidANEPO.gnpo.trapnofi(

)NEPOsevas(

tceffeoN

tceffeoN

)delbasidNEPO

tceffeoN

seunitnoc,esaelerno,dnaskcoL

gninepo

)NEPOsevas(

tceffeoN

tceffeoN

)delbasidNEPO(

)delbasidNEPO(

tceffeoN

tceffeoN

otsesrever,esaelerno,dnaskcoL

nepo

.2.5hpargarapees

)delbasidNEPO(

)3(tceffeoN

tceffeoN

)delbasidANEPO.gnpo.trapnofi(

)NEPOsevas(

tceffeoN

tceffeoN

)delbasidNEPO(

tceffeoN

seunitnoc,esaelerno,dnaskcoL

gninepo

tceffeoN

)delbasidNEPO(

tceffeoN

)delbasidNEPO(

tceffeoN

noitarepo

spotS

retfasesolcdnaemitgninepo

laitrapehtroffaelsnepO

)1(emitesuap

)1(yletaidemmifaelehtsnepo-eR

)3()1(emitesuapsdaoleR

)3(faelehtsesolC

)3()1(tceffeoN .2.5hpargarapeestceffeoN

sesolcdnafaelehtsnepO

)1(emitesuapretfati

)delbasidNEPO(

tceffeoN

)delbasidNEPO(

tceffeoN

noitarepo

spotS

retfasesolcdnaemitgninepo

laitrapehtroffaelsnepO

emitesuap

)3(noitarepospotS

sesolcdnafaelehtsnepO

emitesuapretfati

,degagnesecivedytefaSgnisolChtiw(faelehtsesolC

yletaidemmifaelehtsnepo-eR

)3()eslupdn2ehttasnepo

)3(noitarepospotS .2.5hpargarapeestceffeoN

)delbasidNEPO(

tceffeoN

)delbasidNEPO(

tceffeoN

noitarepo

spotS

retfasesolcdnaemitgninepo

laitrapehtroffaelsnepO

emitesuap

)3(yletaidemmifaelehtsesolc-eR

sesolcdnafaelehtsnepO

emitesuapretfati

)3(yletaidemmifaelehtsesolc-eR .2.5hpargarapees

yletaidemmifaelehtsnepo-eR

)3(faelehtsesolC

)delbasidNEPO(

tceffeoN

)delbasidNEPO(

tceffeoN

noitarepo

spotS

laitrapehtroffaelsnepO

emitgninepo

)3(yletaidemmifaelehtsesolc-eR

faelehtsnepO

,degagnesecivedytefaSgnisolChtiw(faelehtsesolC

yletaidemmifaelehtsnepo-eR

)3()eslupdn2ehttasnepo

)3(noitarepospotS .2.5hpargarapeestceffeoN

SUTATSETAGA-NEPOB-NEPOPOTSSECIVEDYTEFASGNINEPOSECIVEDYTEFASGNISOLCECIVEDYTEFASLC/POECIVEDYTEFASEGDE

"A"cigoL SESLUP

Tab. 3/a

ESUAPnoNEPO

GNINEPO

DESOLC

GNISOLC

DEKCOL

SUTATSETAGA-NEPOB-NEPOPOTSSECIVEDYTEFASGNINEPOSECIVEDYTEFASGNISOLCECIVEDYTEFASLC/POECIVEDYTEFASEGDE

"PA"cigoL SESLUP

Tab. 3/b

ESUAPnoNEPO

GNINEPO

DESOLC

GNISOLC

DEKCOL

SUTATSETAGA-NEPOB-NEPOPOTSSECIVEDYTEFASGNINEPOSECIVEDYTEFASGNISOLCECIVEDYTEFASLC/POECIVEDYTEFASEGDE

"S"cigoL SESLUP

Tab. 3/c

ESUAPnoNEPO

GNINEPO

DESOLC

GNISOLC

DEKCOL

SUTATSETAGA-NEPOB-NEPOPOTSSECIVEDYTEFASGNINEPOSECIVEDYTEFASGNISOLCECIVEDYTEFASLC/POECIVEDYTEFASEGDE

"E"cigoL SESLUP

DESOLC

NEPO

GNINEPO

GNISOLC

DEKCOL

Tab. 3/d

27

Page 15

)2("2rofnepootsesreveR

)2("2rofesolcotsesreveR

)2("2rofnepootsesreveR

)delbasidB/A-NEPO(

)2("2rofnepootsesreveR

)delbasidB/A-NEPO(

)2("2rofnepootsesreveR

)delbasidB/A-NEPO(

tceffeoN

)delbasidNEPO(tceffeoN

)delbasidANEPO(

tceffeoN

seunitnoc,esaelerno,dnaskcoL

otsesrever,esaelerno,dnaskcoL

)delbasidB/A-NEPO(

)delbasidBNEPO(

noitarepospotS

gninepo

nepo

)3()delbasidNEPO(tceffeoN )delbasidNEPO(tceffeoN

tceffeoN )delbasidNEPO(tceffeoN

)NEPOselbasidti,esolctsumtifi(

tceffeoN

tceffeoN

)delbasidBNEPO(

)delbasidB-NEPO(

noitarepospotS

tceffeoN

tceffeoN

tceffeoN )2("2rofesolcotsesreveR

tceffeoN

)delbasidANEPO(

tceffeoN

)delbasidBNEPO(

tceffeoN

)delbasidB-NEPO(

)delbasidBNEPO(

noitarepospotS

tceffeoN

tceffeoN

)delbasidB/ANEPO(

tceffeoN

)delbasidB/A-NEPO(

noitarepospotS

)delbasidBNEPO(

tceffeoN

tceffeoN )2("2rofesolcotsesreveR

tceffeoN

)delbasidANEPO(

tceffeoN

)delbasidBNEPO(

noitarepospotS

tceffeoN

)delbasidB-NEPO(

)delbasidBNEPO(

noitarepospotS

tceffeoN

tceffeoN

)delbasidB/ANEPO(

tceffeoN

)delbasidB/A-NEPO(

)delbasidBNEPO(

tceffeoN

tceffeoN )2("2rofesolcotsesreveR

ANEPO.gnpo.trapnofi(tceffeoN

)delbasid

)delbasidNEPO(

tceffeoN

noitarepo

spotS

laitrapehtroffaelsnepO

emitgninepo

)3(yletaidemmifaelehtsesolc-eR

noitarepospotS )NEPOsevas(tceffeoN.2.5hpargarapees

)NEPOselbasidti,nepotsumtifi(

)delbasidA-NEPO(

)delbasidANEPO(

tceffeoN

)delbasidNEPO(

tceffeoN

)3(noitceridesrevernitnemevomstratseR

)potSaretfasesolcsyawla(

)3(noitarepospotS .2.5hpargarapeestceffeoN

tceffeoN

)delbasidANEPO(

tceffeoN

)delbasidB/A-NEPO(

tceffeoN

)delbasidA-NEPO(

faelehtsesolC

tceffeoN

)delbasidA-NEPO(

noitarepospotS

tceffeoN

noitarepospotS

tceffeoN

)delbasidANEPO(

tceffeoN

NEPO(tceffeoN

)delbasidB

)delbasidA-NEPO(

)ANEPOsevas(

noitarepospotS

tceffeoN

tceffeoN

)delbasidANEPO(

tceffeoN

)delbasidB/ANEPO(

tceffeoN

noitarepo

spotS

)ANEPOsevas(

tceffeoN

tceffeoN

)delbasidBNEPO(

tceffeoN

spotS

)delbasidA-NEPO(

)delbasidA-NEPO(

noitarepospotS

tceffeoN

NEPO(tceffeoN

)delbasidB/A

noitarepo

SUTATSETAGA-NEPOB-NEPOPOTSSECIVEDYTEFASGNINEPOSECIVEDYTEFASGNISOLCECIVEDYTEFASLC/POECIVEDYTEFASEGDE

"PE"cigoL SESLUP

Tab. 3/e

)delbasidB-NEPO(

faelehtsnepO

GNINEPO

DESOLC

GNISOLC

NEPO

DEKCOL

Tab. 3/f

faelehtsnepO

SUTATSETAG)gninepo(A-NEPO)gnisolc(B-NEPOPOTSSECIVEDYTEFASGNINEPOSECIVEDYTEFASGNISOLCECIVEDYTEFASLC/POECIVEDYTEFASEGDE

"C"cigoLNWODDLEHSYAWLASLORTNOC SESLUP

DESOLC

noitarepospotS/

tceffeoN

/noitarepospotS

GNINEPO

GNISOLC

NEPO

Tab. 3/g

faelehtsnepOtceffeoN

SUTATSETAG)gninepo(A-NEPO)gnisolc(B-NEPOPOTSSECIVEDYTEFASGNINEPOSECIVEDYTEFASGNISOLCECIVEDYTEFASLC/POECIVEDYTEFASEGDE

"B"cigoL SESLUP

DESOLC

nepootsesreveRtceffeoN

tceffeoNfaelehtsesolC

GNISOLC

NEPO

faelehtsnepOfaelehtsesolC

tceffeoNtceffeoN

GNINEPO

DEKCOL

faelehtsnepOtceffeoN

"C/B"cigoLSLORTNOCNUROTDLOHGNISOLC/ESLUPGNINEPO SESLUP

SUTATSETAG)gninepo(A-NEPO)gnisolc(B-NEPOPOTSSECIVEDYTEFASGNINEPOSECIVEDYTEFASGNISOLCECIVEDYTEFASLC/POECIVEDYTEFASEGDE

DESOLC

Tab. 3/h

nepootsesreveRtceffeoN

tceffeoNfaelehtsesolC

GNISOLC

NEPO

faelehtsnepOfaelehtsesolC

tceffeoNtceffeoN

GNINEPO

DEKCOL

(1) If maintained, it prolongs the pause until disabled by the command (timer function) (3) During the partial opening cycle, an OPEN A pulse causes total opening.

(2) If a new pulse occurs within 2 seconds after reversing, it immediately stops operation. NB.: Effects on other active pulse inputs in brackets.

28

Page 16

Users guide

3

2

1

Fig.01 Fig.02

AUTOMATED SYSTEM 740-741

Read the instructions carefully before using the product and

keep them for future consultation.

GENERAL SAFETY RULES

If installed and used correctly, the 740-741 automated system will

ensure a high degree of safety.

Some simple rules regarding behaviour will avoid any accidental

trouble:

• Do not stand near the automated system and do not allow

children and other people or things to stand there, especially

while it is operating.

• Keep radiocontrols or any other pulse generator well away from

children to prevent the automated system from being activated

involuntarily.

• Do not allow children to play with the automated system.

• Do not willingly obstruct gate movement.

• Prevent any branches or shrubs from interfering with gate

movement.

• Keep light signalling systems efficient and clearly visible.

• Do not attempt to activate the gate by hand unless you have

released it.

• In the event of malfunctions, release the gate to allow access

and wait for qualified technical personnel to do the necessary

work.

• After enabling manual operation, switch off the power supply to

the system before restoring normal operation.

• Do not make any alterations to the components of the automated

system.

• Do not attempt any kind of repair of direct action whatsoever

and contact qualified personnel only.

• Call in qualified personnel at least every 6 months to check the

efficiency of the automated system, safety devices and earth

connection.

DESCRIPTION

The 740-741 automated system is ideal for controlling vehicle access

areas of medium transit frequency.

The 740-741 automated system for sliding gates is an electromechanical operator transmitting motion to the sliding gate via a

rack pinion or chain appropriately coupled to the gate.

Operation of the sliding gate is controlled by an electronic control

unit housed inside the operator or in a hermetically sealed outdoor

enclosure.

When, with the gate closed, the unit receives an opening command

by radiocontrol or from another suitable device, it activates the

motor until the opening position is reached.

If automatic operation was set, the gate re-closes automatically

after the selected pause time has elapsed.

If the semi-automatic operation was set, a second pulse must be

sent to close the gate again.

An opening pulse during re-closing, always causes movement to

be reversed.

A stop pulse (if provided) always stops movement.

The light signalling indicates that the gate is currently moving.

For details on sliding gate behaviour in different function logics,

consult the installation technician.

The automated systems include obstacle-detection and/or safety

devices (photocells, edges) that prevent the gate from closing when

1

2

3

there is an obstacle in the area they protect.

The system ensures mechanical locking when the motor is not

operating and, therefore, it is not necessary to install any lock.

Manual opening is, therefore, only possible by using the release system.

The gearmotor does not have a mechanical clutch and, therefore, it

is coupled to a unit with an electronic clutch offering the necessary

anti-crushing safety if the system is completed with the necessary safety

devices.

A convenient manual release with customised key makes it possible

to move the gate in the event of a power failure or malfunction.

MANUAL OPERATION

Warning: Cut power to the system to prevent an involuntary pulse

from activating the gate during the release manoeuvre

To release the operator proceed as follows:

1) Insert the key provided and turn it clockwise as shown in Fig. 01

ref. 1 and 2.

2) Turn the release system clockwise, until the mechanical stop is

reached, Fig. 01 ref. 3.

3) Open and close the gate manually.

RESTORING NORMAL OPERATION

Warning: Cut power to the system to prevent an involuntary pulse

from activating the gate during the manoeuvre for restoring

normal operation.

To restore normal operation proceed as follows:

1) Turn the release system anti-clockwise, until its stop is reached, Fig.

02 ref. 1.

2) Turn the key anti-clockwise and remove it from the lock, Fig. 02 ref.

2 and 3.

3) Move the gate until the release system meshes (corresponds to

gate locking).

4) Power up the system.

MAINTENANCE

To ensure trouble-free operation and a constant safety level, an overall

check of the system should be carried out every 6 months. A form for

recording routine maintenance operations is enclosed.

REPAIRS

For any repairs, contact the authorised Repair Centres.

AVAILABLE ACCESSORIES

Refer to catalogue for available accessories.

Page 17

Page 18

Le descrizioni e le illustrazioni del presente manuale non sono impegnative. La FAAC si riserva il diritto, lasciando

inalterate le caratteristiche essenziali dell’apparecchiatura, di apportare in qualunque momento e senza

impegnarsi ad aggiornare la presente pubblicazione, le modifiche che essa ritiene convenienti per miglioramenti

tecnici o per qualsiasi altra esigenza di carattere costruttivo o commerciale.

The descriptions and illustrations contained in the present manual are not binding. FAAC reserves the right, whilst

leaving the main features of the equipments unaltered, to undertake any modifications it holds necessary for either

technical or commercial reasons, at any time and without revising the present publication.

Les descriptions et les illustrations du présent manuel sont fournies à titre indicatif. FAAC se réserve le droit

d’apporter à tout moment les modifications qu’elle jugera utiles sur ce produit tout en conservant les caractéristiques

essentielles, sans devoir pour autant mettre à jour cette publication.

Die Beschreibungen und Abbildungen in vorliegendem Handbuch sind unverbindlich. FAAC behält sich das Recht

vor, ohne die wesentlichen Eigenschaften dieses Gerätes zu verändern und ohne Verbindlichkeiten in Bezug auf

die Neufassung der vorliegenden Anleitungen, technisch bzw. konstruktiv/kommerziell bedingte Verbesserungen

vorzunehmen.

voor de natuur

100% kringlooppapier

Las descripciones y las ilustraciones de este manual no comportan compromiso alguno. FAAC se reserva el

derecho, dejando inmutadas las características esenciales de los aparatos, de aportar, en cualquier momento

y sin comprometerse a poner al día la presente publicación, todas las modificaciones que considere oportunas

para el perfeccionamiento técnico o para cualquier otro tipo de exigencia de carácter constructivo o comercial.

De beschrijvingen in deze handleiding zijn niet bindend. FAAC behoudt zich het recht voor op elk willekeurig

moment de veranderingen aan te brengen die het bedrijf nuttig acht met het oog op technische verbeteringen

of alle mogelijke andere productie- of commerciële eisen, waarbij de fundamentele eigenschappen van de

apparaat gehandhaafd blijven, zonder zich daardoor te verplichten deze publicatie bij te werken.

FAAC per la natura

• La presente istruzione è realizzata al 100% in carta riciclata.

• Non disperdete nell'ambiente gli imballaggi dei componenti dell'automazione bensì selezionate

i vari materiali (es. cartone, polistirolo) secondo prescrizioni locali per lo smaltimento rifiuti e le

norme vigenti.

FAAC for the environment

• The present manual is produced in 100% recycled paper

• Respect the environment. Dispose of each type of product packaging material (card, polystyrene)

in accordance with the provisions for waste disposal as specified in the country of installation.

FAAC écologique

• La présente notice a été réalisée 100% avec du papier recyclé.

• Ne pas jeter dans la nature les emballages des composants de l’automatisme, mais sélectionner

les différents matériaux (ex.: carton, polystyrène) selon la législation locale pour l’élimination des

déchets et les normes en vigueur.

FAAC der Umwelt zuliebe

• Vorliegende Anleitungen sind auf 100% Altpapier gedruckt.

• Verpackungsstoffe der Antriebskomponenten (z.B. Pappe, Styropor) nach den einschlägigen

Normen der Abfallwirtschaft sortenrein sammeln.

FAAC por la naturaleza.

• El presente manual de instrucciones se ha realizado, al 100%, en papel reciclado.

• Los materiales utilizados para el embalaje de las distintas partes del sistema automático (cartón,

poliestireno) no deben tirarse al medio ambiente, sino seleccionarse conforme a las prescripciones

locales y las normas vigentes para el desecho de residuos sólidos.

FAAC voor de natuur

• Deze gebruiksaanwijzing is gedrukt op 100% kringlooppapier.

• Laat de verpakkingen van de componenten van het automatische systeem niet in het milieu

achter, maar scheidt de verschillende materialen (b.v. karton, polystyreen) volgens de plaatselijke

voorschriften op de afvalverwerkingen en de geldende normen.

para la naturaleza

100% papel reciclado

ist umweltfreundlich

100% Altpapier

pour la nature

papier recyclé 100%

FAAC S.p.A.

Via Benini, 1

40069 Zola Predosa (BO) - ITALIA

Tel.: 051/61724 - Fax: 051/758518

www.faacgroup.com

Timbro del Rivenditore:/Distributor’s Stamp:/Timbre de l’Agent:/ Fachhändlerstempel:/Sello del Revendedor:/Stempel van de dealer:

for nature

recycled paper 100%

per la natura

carta riciclata 100%

732484 - Rev. B -

Loading...

Loading...