Page 1

ENGLISH ENGLISH

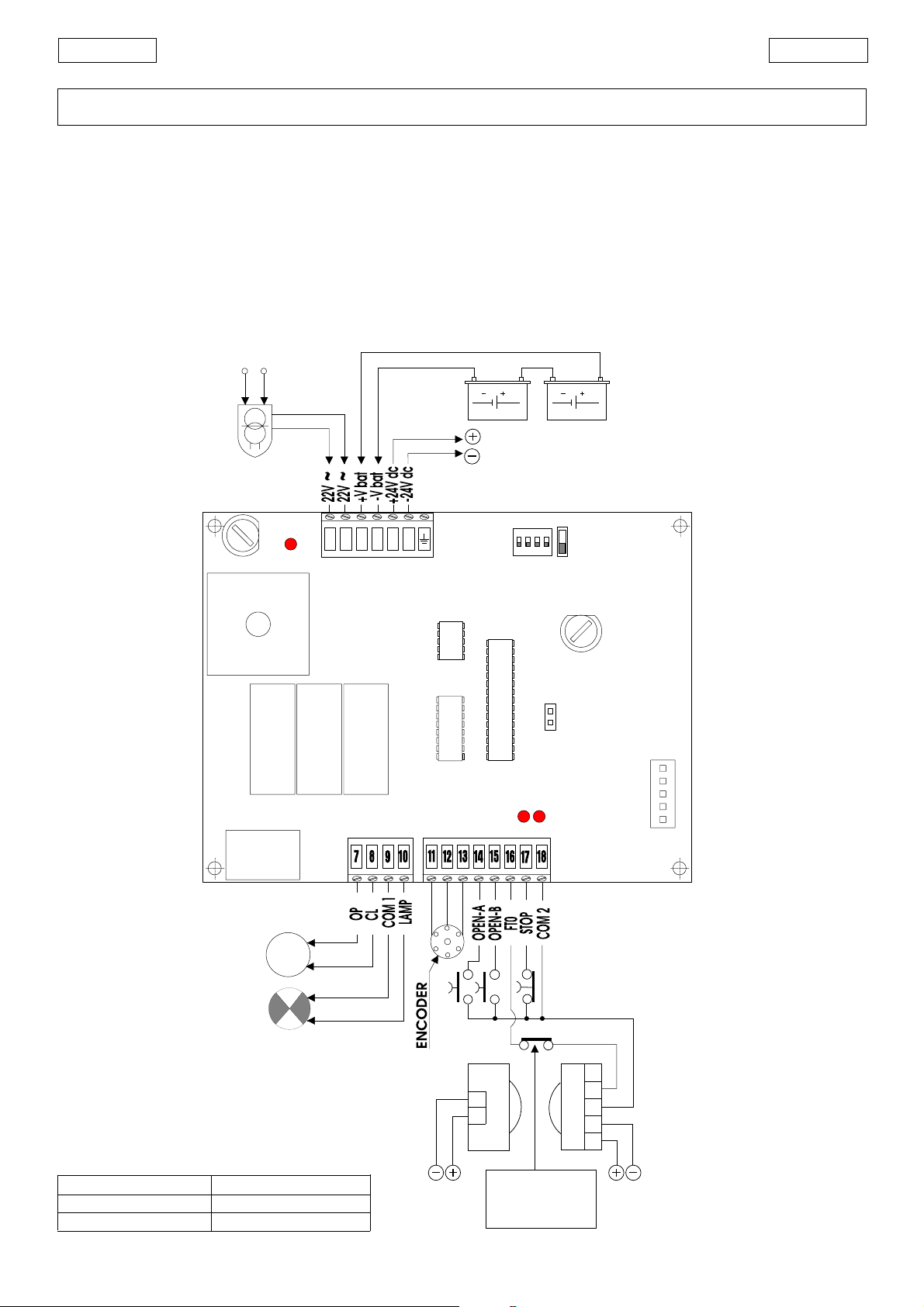

724MPS - MICROPROCESSOR CONTROL UNIT FOR 24 Vdc SLIDING GATES WITH ENCODER

4. GENERAL CHARACTERISTICS

Thank to its high powered microprocessor, this control unit for 24 Vdc sliding gates offers a wide range of functions and adjustments, including

deceleration and motor control.

A sophisticated electronic control monitors the power circuit at all times and disables the control unit in the event of malfunctions that could

impair efficiency of the electronic clutch.

Main settings and function modes are executed by dip switches, whereas timing, and also power of motor are adjusted through self-learning

at installation.

3 built-in LEDs constantly indicate status of both control unit and gearmotor.

The control unit is designed for installation in a container on the gearmotor itself or in the watertight container for outdoor use, which is also

designed to house 2 optional batteries and a torodial transformer, with the characteristics in the table below.

230Vac 50Hz

batteries

toroidal

transformer

power supplies to

external accessories

F2

T 10A - 250V

gearmotor

POWER

M1

123

M1

45

M2

1234

6

ON

OFF

S1 S2

F 3.15A - 250V

RESET

STOPFTO

M3

PROG

OFF

F1

M5

flashlight

FUSE PROTECTING

F1 = F 3.15A 250V 5x20 Logic / Accessories output

F2 = T 10A 250V 5x20 Motor

TX RX

1

2

Altre sicurezze

Other safeties

Autres sécurités

Andere Sicherheiten

Otros disp. seg.

10

1

2

3

4

5

Fig. 12

Page 2

ENGLISHENGLISH

5. TECHNICAL SPECIFICATIONS

Supply voltage of transformer 230V~ (+ 6 % - 10 %) 50Hz

Supply voltage of control unit 22V~ (+ 6 % - 10 %) 50Hz

Power consumption 3 W

Motor max. load 70 W

Accessories max. load 24Vdc 500mA

Flashlight max. load 24Vdc 15W max

Ambient temperature -20 ÷ +55 °C

Fuse 2

Function logics Automatic / Stepped

Opening / closing time Through self-learning at installation

Pause time Through self-learning at installation

Thrust force Two levels selected by Dip-switch

Deceleration At opening and closing through self-learning

Terminal board inputs Encoder / 22V~ Power supply / Battery power supply

Total opening / Opening for pedestrians / Stop / Photocells

Quick connector For decoding - RP receivers card

Terminal board outputs 24 Vdc accessories power supply / 24Vdc Motor

24 Vdc Flashlight

Card dimensions 150 x 130 mm

Characteristics of toroidal transformer

prim. 230V~ sec. 22V~ / 150VA / dimens. Ø 105 x 40 mm

Characteristics of optional batteries

12V 4.5Ah / dimensioni 90 x 70 x 108 mm

Characteristics of outdoor container

305 x 225 x 125 mm - IP55

6. INSTRUCTIONS

WARNING: To ensure people's safety, all warnings and instructions in

this booklet must be carefully observed. Incorrect installation or use

of the product could cause serious harm to people.

Make sure there is an adequate differential switch upstream of the

system as specified by current laws, and install a thermal breaker with

all-pole switch on the electrical mains.

To lay electrical cables, use adequate rigid and/or flexible tubes.

Always separate connection cables of low voltage accessories from

those operating at 230 V~.

To prevent any interference whatever, use separate sheaths.

In the version with control unit installed on the gearmotor, some

connections and units described in these instructions (motor,

transformer, encoder, etc) are factory prewired.

In the version with control unit housed in the watertight outdoor use

container, maximum length of connection cables between control unit

and motor/encoder must not exceed 3 m., using 2x2.5mm² cables for

the motor and 3x0.5mm² cables for the encoder.

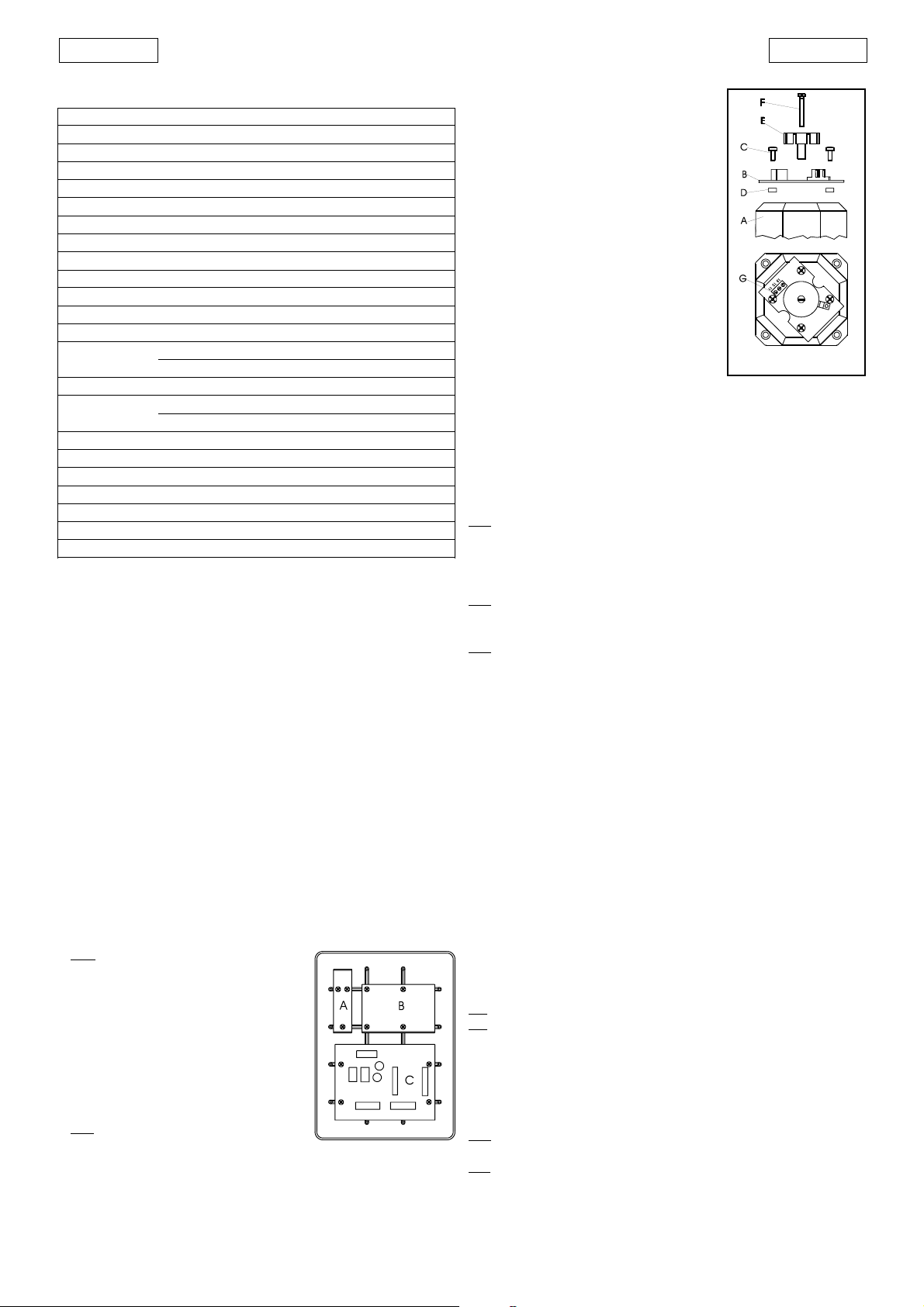

Procedure (referring to fig. 13) for securing components in the watertight

container:

1) Secure the support of the toroidal transformer in position A by fitting

three Ø3.9x6.5 self-tapping screws (supplied) in the guides of the

watertight container.

N.B.

: the support is sized to house a

transformer with characteristics and

dimensions specified in the table in

paragraph 5.

2) Secure the transformer on the support with

2 clamps (supplied).

3)If using floating batteries, secure the

relevant support in position B by fitting four

Ø3.9x6.5 self-tapping screws (supplied) in

the crossover holes of the guides of the

watertight container.

N.B.

: the support is sized to house two

batteries (not supplied) with characteristics

and dimensions specified in the table in paragraph 5.

4) Position the batteries on the support.

5) Secure the control unit in position C by fitting four Ø3.9x6.5 self-

tapping screws (supplied) in the guides of the watertight container.

Fig. 13

Procedure for securing the encoder on the

gearmotor (fig. 14) :

1) Using the four M4x10 screws C (supplied),

secure card B on cover A, locating the

spacers D between cover and card.

2) Using the M4x30 screw F (supplied), secure

encoder E directly on the thread on the

rotor of the gearmotor.

3) Wire up terminal board G as described

below.

7. CONNECTIONS

7.1 TERMINAL BOARD M1

22V~ Power supply

Terminals “1-2”. This is the input to which the

secondary winding of the transformer,

powered at 22 V~ 50Hz, should be

connected. When power is supplied by the

transformer, this is signalled by the POWER LED lighting up.

Batteries

Terminals “3-4”. The control unit is designed to operate with two floating

batteries (optional item) with minimum characteristics as indicated

on the table in paragraph 5.

When powered, the control unit keeps the batteries charged. The

batteries begin to operate when the transformer no longer supplies

power.

N.B.

: power supplied by batteries should be considered an emergency

situation – the minimum number of gate operations is about 10/15.

In any event, the number of possible operations depends on the quality

of the batteries, structure of gate, and time elapsing since mains power

failed, etc, etc..

N.B.

: observe the power polarity of the batteries

Accessories

Terminals “5-6”. Output for powering external accessories (24 Vdc).

N.B.

: maximum load of accessories is 500 mA.

7.2 TERMINAL BOARD M2

Gearmotor

Terminals “7-8”. Connect the motor to the power supply of 24Vdc 70W

max.

Flashlight

Terminals “9-10”. Use a flashlight with fixed light operating voltage of

24Vdc 15W max. We advise you to connect it before programming,

as it indicates programming stages.

On opening, it pre-flashes steadily for 0.5 seconds, and for 1.5 seconds

at closing.

If the automatic logic is on, when the gate reaches the opening gate

stop, the flashlight stays on for 5 sec to inform the user it will re-close

automatically.

When the gate is open, the flashlight is off, and only flashes when the

safety devices are in use.

If the devices are in use for a long time, flashing only lasts 10 sec.

7.3 TERMINAL BOARD M3

Encoder

Terminals “11-12-13”. Use the encoder supplied with the control unit.

Connect the return signal from encoder terminal “11” to terminal “11”,

connect encoder terminals “12-13” to terminals “12-13”.

NB.

: the control unit will not operate without an encoder.

NB.

: observe the encoder's cable terminals.

Open-A

Terminals “14-18”. Any device (e.g. push-button, remote control, etc.)

can be connected to this circuit.

By closing a contact, the circuit generates a pulse for total opening

and/or closing of the gate. Its operating mode is set by dip-switch 3 –

see paragraph 9.

N.B.

: a OPEN-A pulse during the pedestrian stage always has priority

over that stage

N.B.

: to install several pulse generators, connect the contacts in parallel.

Open-B (For pedestrian use)

Terminals “15-18”. Any device (e.g. push-button, remote control, etc.)

can be connected to this circuit.

Fig. 14

11

Page 3

ENGLISH ENGLISH

By closing a contact, the circuit generates a pulse for partial opening

(30% of total opening ) of the gate.

N.B.

: an OPEN-A pulse during the pedestrian stage always has priority

over that stage.

N.B.

: to install several pulse generators, connect the contacts in parallel.

Photocells

Terminals “16-18”. Any safety device (e.g. photocell, sensitive strip, etc.)

can be connected to this circuit.

By opening a contact, the circuit protects closing motion.

The status of this input is signalled by the FTO LED.

It also has an effect on opening motion, depending on how dip-switch

4 was set – see paragraph 9.

N.B.

: if safety devices are not connected, fit a jumper at input. To install

several safety devices, connect the NC contacts in series.

Stop

Terminals “17-18”. Any device (e.g. push-button, remote control, etc.)

can be connected to this circuit.

By opening a contact, the circuit stops gate movement.

The status of this input is signalled by the STOP LED.

The set cycle will restart only if a successive opening or closing pulse is

received.

N.B.

: if STOP devices are not connected, fit a jumper at input. To install

several STOP devices, connect the NC contacts in series.

8. FITTING DECODING/RP RECEIVER CARDS

Installation procedure: turn off power and fit the module in container

M5 inside the control unit. Then observe the radio-receiver instructions

to store data on the remote-control. After the necessary data has been

stored, the remote-control activates OPEN-A like any other command

device.

5) If the gate moves to open, touch the two RESET pins with a screwdriver

– the control unit will immediately stop the movement generated

by the automation.

6) Cut power to the control unit, reverse polarity of the two cables

powering the motor,and repeat the operation at point 1.

7) After the OPEN-A command is given, the gate moves to close, until

it reaches the closing gate stop.

8) After about two seconds, the gate restarts opening automatically

until it reaches the opening gate stops.

9) The control unit begins counting pause time. After the required time

has elapsed, press the OPEN-A command again, and the gate will

close completely.

10) Programming is now finished. Turn switch S2 back to OFF – the

flashlight goes off.

11) Fit the cover on the operator by means of the screws provided, as

shown in figure 15.

12. OPERATION OF ELECTRONIC CLUTCH

This is a very important device for safety. Its setting does not alter through

time, as the device is not subject to wear or setting changes.

It is active both at closing and opening. When it operates it reverses

motion direction without inhibiting automatic closing if enabled.

If it operates twice in succession, it moves to STOP position, disabling

any automatic command.

This is why: if the clutch operates twice, this means the obstacle is still

present and any further manoeuvres could be dangerous, thus obliging

the user to give an opening or closing command.

In that case the control unit executes an EMERGENCY procedure as

follows: full opening at slow speed up to the opening gate stop, followed

by automatic closing to enable the gate stops to re-synchronise

independently.

9. SETTINGS WITH DIP-SWITCH S1

SW1 ELECTRONIC CLUTCH

ON Maximum force, minimum sensitivity

OFF Minimum force, maximum sensitivity

SW2 FUNCTION LOGIC

ON Automatic

OFF Stepped

SW3 OPERATION OF OPENING COMMAND

ON One state only at each pulse; open, stop, close, stop, open etc.

OFF One movement only at each pulse: open, close, open, close, etc.

SW4 OPERATION OF PHOTOCELLS

ON Stops at opening, restarts on release, stops at closing and reverses

OFF Stops and reverses at closing only

13. MANUAL OPERATION

Should the need arise to operate the gate manually because of a

power failure or malfunction, release it by means of the releasing device

(fig. 1 - ref. 6).

Proceed as follows:

• open the lid of the lock and insert the relative key in the lock (fig. 16);

• turn the key clockwise and open the cover of the releasing device

as shown in figure 16.

To re-lock the system, return the cover of the releasing device to its

initial position.

Important

moved manually.

N.B.:

: before giving a signal, ensure that the gate cannot be

re-lock always the operator with gate in closed position.

10. CONTROL LEDS

LED LIGHTED OFF

POWER - power with transformer on battery (if used)

FTO - photocells photocells not covered photocells covered

STOP - stop command inactive command active

N.B.

: LED status shown in bold with gate closed and control unit

powered.

11. PROGRAMMING

Programming of work times, deceleration and electronic clutch is

executed during self-learning. At this stage, leaf movement is at slow

speed.

Procedure:

1) Release the leaf, take it to about midway through opening travel,

and then lock it.

2) Power up the control unit (power ON is signalled by the POWER LED).

3) Turn switch S2 to PROG: the flashlight goes on at steady light to signal

programming.

4) Press the push-button connected to the OPEN-A terminals or the

remote-control, if already programmed. The first operation the

automation performs must be CLOSING.

12

Fig. 15

Fig. 16

Loading...

Loading...