Page 1

FTB-7000 Series

OTDR for FTB-200 v2

User Guide

Page 2

Copyright © 2006–2011 EXFO Inc. All rights reserved. No part of this

publication may be reproduced, stored in a retrieval system or transmitted

in any form, be it electronically, mechanically, or by any other means such

as photocopying, recording or otherwise, without the prior written

permission of EXFO Inc. (EXFO).

Information provided by EXFO is believed to be accurate and reliable.

However, no responsibility is assumed by EXFO for its use nor for any

infringements of patents or other rights of third parties that may result from

its use. No license is granted by implication or otherwise under any patent

rights of EXFO.

EXFO’s Commerce And Government Entities (CAGE) code under the North

Atlantic Treaty Organization (NATO) is 0L8C3.

The information contained in this publication is subject to change without

notice.

Trademarks

EXFO’s trademarks have been identified as such. However, the presence

or absence of such identification does not affect the legal status of any

trademark.

Units of Measurement

Units of measurement in this publication conform to SI standards and

practices.

Patents

EXFO’s Universal Interface is protected by US patent 6,612,750.

Version number: 17.0.6

ii FTB-7000 Series

Page 3

Contents

Contents

Certification Information ..................................................................................................... viii

1 Introducing the Optical Time Domain Reflectometer ................................ 1

Main Features .........................................................................................................................3

Trace Acquisition Modes .........................................................................................................4

Optional Software Packages ...................................................................................................4

Data Post-Processing ..............................................................................................................4

Bidirectional Analysis Application ...........................................................................................5

Available OTDR Models ...........................................................................................................5

OTDR Basic Principles ..............................................................................................................8

Conventions ..........................................................................................................................10

2 Safety Information ..................................................................................... 11

Laser Safety Information (Models without VFL) ....................................................................11

Laser Safety Information (Models with VFL) ..........................................................................12

3 Getting Started with Your OTDR ............................................................... 13

Inserting and Removing Test Modules ..................................................................................13

Starting Module Applications ...............................................................................................19

Timer ....................................................................................................................................20

4 Preparing Your OTDR for a Test ................................................................. 21

Installing the EXFO Universal Interface (EUI) .........................................................................21

Cleaning and Connecting Optical Fibers ...............................................................................22

Naming Trace Files Automatically .........................................................................................24

Enabling or Disabling the First Connector Check ..................................................................28

Setting Macrobend Parameters .............................................................................................29

Launch Conditions for Multimode Measurements ................................................................31

5 Testing Fibers in Auto Mode ...................................................................... 33

6 Testing Fibers in Advanced Mode ............................................................. 37

Setting the Autorange Acquisition Time ...............................................................................42

Setting the IOR, RBS Coefficient, and Helix Factor ................................................................43

Setting Distance Range, Pulse Width, and Acquisition Time .................................................45

Enabling the High-Resolution Feature ...................................................................................49

Enabling or Disabling Analysis After Acquisition ...................................................................51

Setting Pass/Fail Thresholds ..................................................................................................53

Setting a Default Span Start and Span End ...........................................................................58

OTDR iii

Page 4

Contents

7 Testing Fibers in Template Mode ...............................................................61

Template Principle .................................................................................................................61

Restrictions of Template Mode ..............................................................................................62

Acquiring the Reference Trace ..............................................................................................64

Acquiring Traces in Template Mode ......................................................................................66

Selecting a Reference Trace ...................................................................................................74

8 Testing Fibers in Fault Finder Mode ...........................................................75

Acquiring Traces in Fault Finder Mode ..................................................................................75

Naming Fault Finder Files Automatically ...............................................................................78

Selecting the Default File Format for the Fault Finder Traces .................................................80

Enabling or Disabling the Confirmation of Fault Finder File Name ........................................82

Enabling or Disabling the Storage Feature ............................................................................84

Enabling or Disabling the First Connector Check for Fault Finder .........................................85

Enabling or Disabling the Touchscreen Keyboard ..................................................................87

Setting Trace Display Parameters ..........................................................................................88

Selecting the Distance Units .................................................................................................90

9 Customizing Your OTDR ..............................................................................93

Selecting the Default File Format ..........................................................................................93

Enabling or Disabling File Name Confirmation .....................................................................94

Selecting the Distance Units .................................................................................................96

Customizing the Acquisition Distance Range Values .............................................................98

Customizing the Acquisition Time Values ...........................................................................100

Enabling or Disabling the Touchscreen Keyboard ................................................................102

Displaying or Hiding the Optional Features ........................................................................103

iv FTB-7000 Series

Page 5

Contents

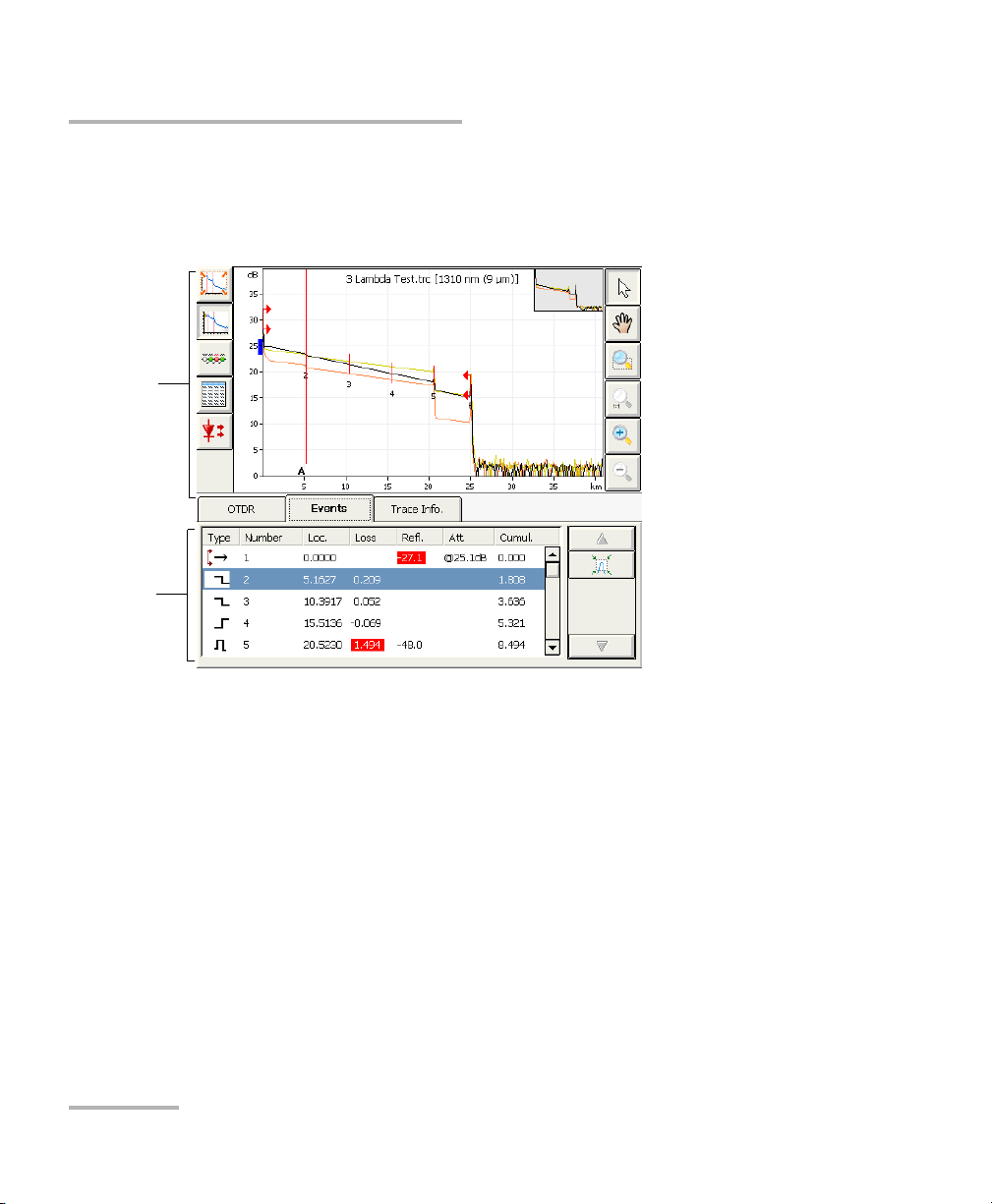

10 Analyzing Traces and Events ................................................................... 105

Graph View .........................................................................................................................106

Linear View .........................................................................................................................108

Summary Table ...................................................................................................................110

Events Tab ...........................................................................................................................112

Measure Tab .......................................................................................................................116

Trace Info. Tab ....................................................................................................................116

Displaying the Graph in Full Screen ....................................................................................117

Selecting the Default View ..................................................................................................119

Automatically Displaying the Event Table after Acquisitions ...............................................121

Automatically Zooming in on the Fiber Span ......................................................................122

Using Zoom Controls ..........................................................................................................123

Setting Trace Display Parameters ........................................................................................126

Customizing the Event Table ...............................................................................................128

Displaying or Hiding a Trace ...............................................................................................130

Clearing Traces from the Display .........................................................................................132

Viewing and Modifying Current Trace Settings ...................................................................133

Modifying Events ................................................................................................................138

Inserting Events ..................................................................................................................142

Deleting Events ...................................................................................................................144

Changing the Attenuation of Fiber Sections .......................................................................146

Setting the Analysis Detection Thresholds ..........................................................................148

Analyzing or Reanalyzing a Trace ........................................................................................151

Analyzing the Fiber on a Specific Fiber Span .......................................................................153

Enabling or Disabling the Detection of Reflective Ends of Fiber ..........................................154

Swapping Traces .................................................................................................................158

Opening Trace Files .............................................................................................................159

11 Analyzing the Results Manually .............................................................. 163

Selecting the Attenuation and Loss Values that Will Be Displayed ......................................163

Using Markers .....................................................................................................................165

Getting Event Distances and Relative Powers ......................................................................166

Getting Event Loss (Four-Point and Least-Square Approximation) ......................................167

Getting Attenuation (Two-Point and Least-Square Approximation) ....................................172

Getting Reflectance ............................................................................................................174

Getting Optical Return Loss (ORL) .......................................................................................175

12 Managing Trace Files from the OTDR Test Application .......................... 177

Saving a Trace in a Different Format ...................................................................................177

OTDR Trace File Compatibility .............................................................................................178

Copying, Moving, Renaming, or Deleting Trace Files ..........................................................180

OTDR v

Page 6

Contents

13 Creating Reports .......................................................................................181

Adding Information to the Test Results ...............................................................................181

Generating a Report ...........................................................................................................183

14 Using the OTDR as a Light Source or VFL ................................................189

15 Analyzing Traces with the Bidirectional Analysis Application ...............193

Starting and Exiting the Bidirectional Analysis Application .................................................195

Creating Bidirectional Measurement Files ...........................................................................197

Opening Existing Bidirectional Measurement Files ..............................................................201

Displaying Traces and Bidirectional Measurement ..............................................................202

Viewing Results ..................................................................................................................204

Reanalyzing Traces and Regenerating the Bidirectional Measurement ................................215

Modifying the Alignment of Unidirectional Traces ..............................................................217

Using Zoom Controls ..........................................................................................................221

Using Markers to Edit Events ..............................................................................................225

Inserting Events ..................................................................................................................227

Modifying Events ................................................................................................................231

Deleting Events ...................................................................................................................235

Changing the Attenuation of Fiber Sections .......................................................................237

Setting General Parameters ................................................................................................240

Customizing the Events Table .............................................................................................243

Saving the Span-Start and Span-End Information ...............................................................246

Setting Pass/Fail Thresholds ................................................................................................247

Modifying Trace Analysis Settings .......................................................................................252

Saving Traces ......................................................................................................................257

Exporting Unidirectional Traces from Bidirectional Files ......................................................259

Adding Information to the Test Results ...............................................................................261

Creating Reports .................................................................................................................263

16 Maintenance ..............................................................................................267

Cleaning EUI Connectors ....................................................................................................268

Verifying Your OTDR ...........................................................................................................270

Recalibrating the Unit .........................................................................................................278

Recycling and Disposal (Applies to European Union Only) ..................................................279

17 Troubleshooting ........................................................................................281

Contacting the Technical Support Group ............................................................................284

Transportation ....................................................................................................................285

vi FTB-7000 Series

Page 7

Contents

18 Warranty ................................................................................................... 287

General Information ...........................................................................................................287

Liability ...............................................................................................................................288

Exclusions ...........................................................................................................................288

Certification ........................................................................................................................288

Service and Repairs .............................................................................................................289

EXFO Service Centers Worldwide ........................................................................................290

A Technical Specifications ........................................................................... 291

B Description of Event Types ...................................................................... 297

Span Start ..........................................................................................................................298

Span End ...........................................................................................................................298

Short Fibers .......................................................................................................................298

Continuous Fiber ...............................................................................................................299

End of Analysis ..................................................................................................................300

Non-Reflective Event ..........................................................................................................301

Reflective Event .................................................................................................................302

Positive Event .....................................................................................................................303

Launch Level ......................................................................................................................304

Fiber Section ......................................................................................................................305

Merged Event ....................................................................................................................306

Echo ..................................................................................................................................312

Reflective Event (Possible Echo) .........................................................................................313

Index .............................................................................................................. 315

OTDR vii

Page 8

Certification Information

Certification Information

FCC Information

Electronic test equipment is exempt from Part 15 compliance (FCC) in

the United States. However, compliance verification tests are

systematically performed on most EXFO equipment.

Information

Electronic test equipment is subject to the EMC Directive in the European

Union. The EN61326 standard prescribes both emission and immunity

requirements for laboratory, measurement, and control equipment.

This unit has undergone extensive testing according to the European Union

Directive and Standards.

Use of shielded remote I/O cables, with properly grounded shields

and metal connectors, is recommended in order to reduce radio

frequency interference that may emanate from these cables.

IMPORTANT

viii FTB-7000 Series

Page 9

Certification Information

Application of Council Directive(s): 2006/95/EC - The Low Voltage Directive

2004/108/EC - The EMC Directive

2006/66/EC - The Battery Directive

93/68/EEC - CE Marking

And their amendments

Manufacturer’s Name: EXFO Inc.

Manufacturer’s Address: 400 Godin Avenue

Quebec, Quebec

Canada, G1M 2K2

(418) 683-0211

Equipment Type/Environment: Test & Measurement / Industrial

Trade Name/Model No.: LAN / WAN ACCESS OTDR / FTB-7200D

Standard(s) to which Conformity is Declared:

EN 61010-1:2001 Edition 2.0 Safety Requirements for Electrical Equipment for Measurement,

Control, and Laboratory Use, Part 1: General Requirements.

EN 61326-1:2006 Electrical Equipment for Measurement, Control and Laboratory

Use - EMC Requirements – Part 1: General requirements

EN 60825-1:2007 Edition 2.0 Safety of laser products – Part 1: Equipment classification,

requirements, and user’s guide

EN 55022: 2006 + A1: 2007 Information technology equipment - Radio disturbance

characteristics - Limits and methods of measurement

I, the undersigned, hereby declare that the equipment specified above conforms to the above Directive and Standards.

Manufacturer

Signature:

Full Name: Stephen Bull, E. Eng

Position: Vice-President Research and

Development

Address: 400 Godin Avenue, Quebec (Quebec),

Canada, G1M 2K2

Date: January 09, 2009

DECLARATION OF CONFORMITY

OTDR ix

Page 10

Certification Information

Application of Council Directive(s): 2006/95/EC - The Low Voltage Directive

2004/108/EC - The EMC Directive

2006/66/EC - The Battery Directive

93/68/EEC - CE Marking

And their amendments

Manufacturer’s Name: EXFO Inc.

Manufacturer’s Address: 400 Godin Avenue

Quebec, Quebec

Canada, G1M 2K2

(418) 683-0211

Equipment Type/Environment: Test & Measurement / Industrial

Trade Name/Model No.: FTTx-PON / MDU OTDR / FTB-7300E

Standard(s) to which Conformity is Declared:

EN 61010-1:2001 Edition 2.0 Safety Requirements for Electrical Equipment for Measurement,

Control, and Laboratory Use, Part 1: General Requirements.

EN 61326-1:2006 Electrical Equipment for Measurement, Control and Laboratory

Use - EMC Requirements – Part 1: General requirements

EN 60825-1:2007 Edition 2.0 Safety of laser products – Part 1: Equipment classification,

requirements, and user’s guide

EN 55022: 2006 + A1: 2007 Information technology equipment - Radio disturbance

characteristics - Limits and methods of measurement

I, the undersigned, hereby declare that the equipment specified above conforms to the above Directive and Standards.

Manufacturer

Signature:

Full Name: Stephen Bull, E. Eng

Position: Vice-President Research and

Development

Address: 400 Godin Avenue, Quebec (Quebec),

Canada, G1M 2K2

Date: January 09, 2009

DECLARATION OF CONFORMITY

x FTB-7000 Series

Page 11

Certification Information

Application of Council Directive(s): 2006/95/EC - The Low Voltage Directive

2004/108/EC - The EMC Directive

2006/66/EC - The Battery Directive

93/68/EEC - CE Marking

And their amendments

Manufacturer’s Name: EXFO Inc.

Manufacturer’s Address: 400 Godin Avenue

Quebec, Quebec

Canada, G1M 2K2

(418) 683-0211

Equipment Type/Environment: Test & Measurement / Industrial

Trade Name/Model No.: METRO / CWDM OTDR / FTB-7400E

Standard(s) to which Conformity is Declared:

EN 61010-1:2001 Edition 2.0 Safety Requirements for Electrical Equipment for Measurement,

Control, and Laboratory Use, Part 1: General Requirements.

EN 61326-1:2006 Electrical Equipment for Measurement, Control and Laboratory

Use - EMC Requirements – Part 1: General requirements

EN 60825-1:2007 Edition 2.0 Safety of laser products – Part 1: Equipment classification,

requirements, and user’s guide

EN 55022: 2006 + A1: 2007 Information technology equipment - Radio disturbance

characteristics - Limits and methods of measurement

I, the undersigned, hereby declare that the equipment specified above conforms to the above Directive and Standards.

Manufacturer

Signature:

Full Name: Stephen Bull, E. Eng

Position: Vice-President Research and

Development

Address: 400 Godin Avenue, Quebec (Quebec),

Canada, G1M 2K2

Date: January 09, 2009

DECLARATION OF CONFORMITY

OTDR xi

Page 12

Certification Information

Application of Council Directive(s): 2006/95/EC - The Low Voltage Directive

2004/108/EC - The EMC Directive

2006/66/EC - The Battery Directive

93/68/EEC - CE Marking

And their amendments

Manufacturer’s Name: EXFO Inc.

Manufacturer’s Address: 400 Godin Avenue

Quebec, Quebec

Canada, G1M 2K2

(418) 683-0211

Equipment Type/Environment: Test & Measurement / Industrial

Trade Name/Model No.: METRO / LONG-HAUL OTDR / FTB-7500E

Standard(s) to which Conformity is Declared:

EN 61010-1:2001 Edition 2.0 Safety Requirements for Electrical Equipment for Measurement,

Control, and Laboratory Use, Part 1: General Requirements.

EN 61326-1:2006 Electrical Equipment for Measurement, Control and Laboratory

Use - EMC Requirements – Part 1: General requirements

EN 60825-1:2007 Edition 2.0 Safety of laser products – Part 1: Equipment classification,

requirements, and user’s guide

EN 55022: 2006 + A1: 2007 Information technology equipment - Radio disturbance

characteristics - Limits and methods of measurement

I, the undersigned, hereby declare that the equipment specified above conforms to the above Directive and Standards.

Manufacturer

Signature:

Full Name: Stephen Bull, E. Eng

Position: Vice-President Research and

Development

Address: 400 Godin Avenue, Quebec (Quebec),

Canada, G1M 2K2

Date: January 09, 2009

DECLARATION OF CONFORMITY

xii FTB-7000 Series

Page 13

Certification Information

Application of Council Directive(s): 2006/95/EC - The Low Voltage Directive

2004/108/EC - The EMC Directive

2006/66/EC - The Battery Directive

93/68/EEC - CE Marking

And their amendments

Manufacturer’s Name: EXFO Inc.

Manufacturer’s Address: 400 Godin Avenue

Quebec, Quebec

Canada, G1M 2K2

(418) 683-0211

Equipment Type/Environment: Test & Measurement / Industrial

Trade Name/Model No.: ULTRA-LONG-HAUL OTDR / FTB-7600E

Standard(s) to which Conformity is Declared:

EN 61010-1:2001 Edition 2.0 Safety Requirements for Electrical Equipment for Measurement,

Control, and Laboratory Use, Part 1: General Requirements.

EN 61326-1:2006 Electrical Equipment for Measurement, Control and Laboratory

Use - EMC Requirements – Part 1: General requirements

EN 60825-1:2007 Edition 2.0 Safety of laser products – Part 1: Equipment classification,

requirements, and user’s guide

EN 55022: 2006 + A1: 2007 Information technology equipment - Radio disturbance

characteristics - Limits and methods of measurement

I, the undersigned, hereby declare that the equipment specified above conforms to the above Directive and Standards.

Manufacturer

Signature:

Full Name: Stephen Bull, E. Eng

Position: Vice-President Research and

Development

Address: 400 Godin Avenue, Quebec (Quebec),

Canada, G1M 2K2

Date: January 09, 2009

DECLARATION OF CONFORMITY

OTDR xiii

Page 14

Page 15

1 Introducing the Optical Time

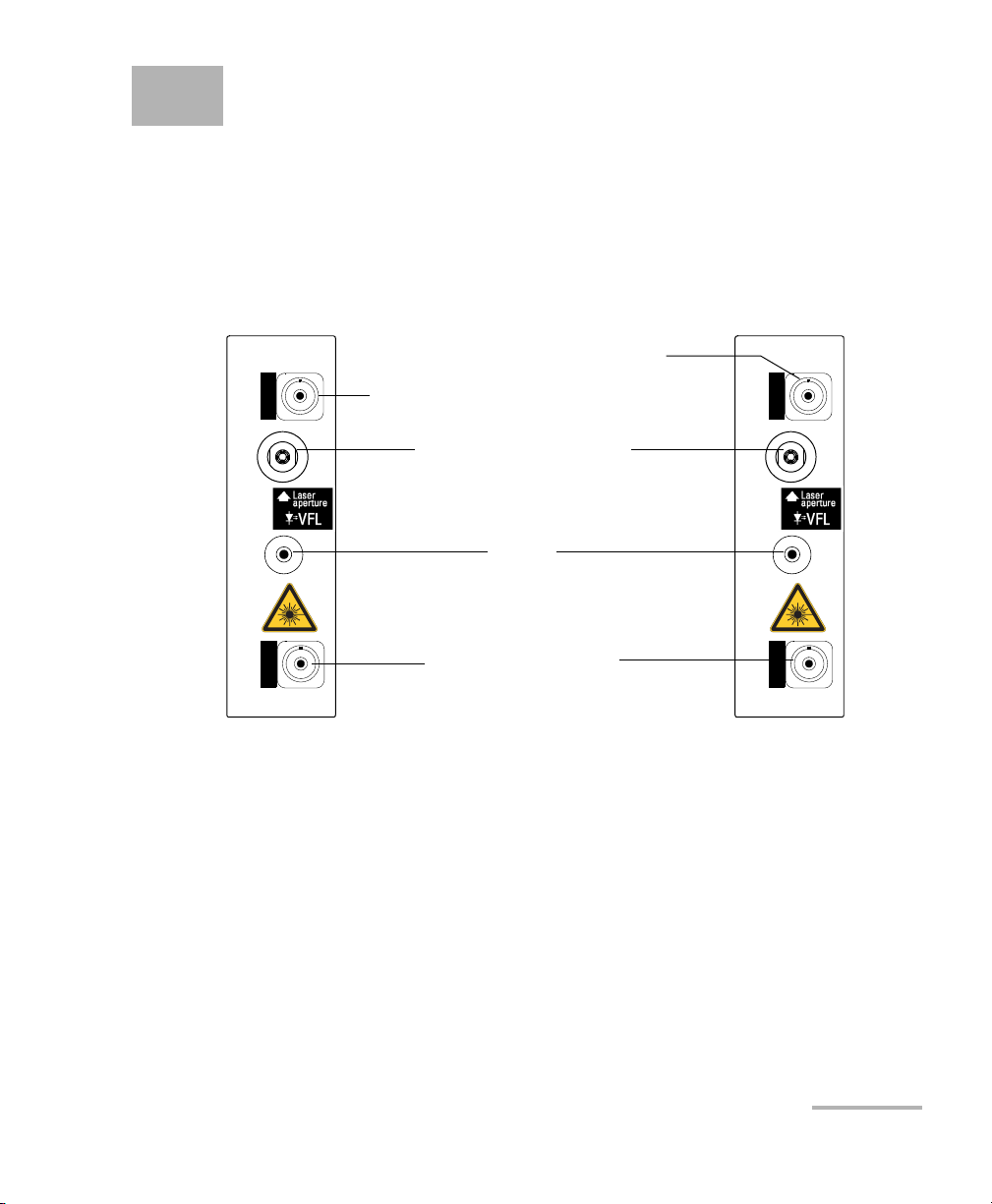

SM / MM OTDR

FTB-7200D

SM

MM

LIVE

Handle

Visual fault locator (VFL) port

(optional)

OTDR port (singlemode)

OTDR port (multimode)

Singlemode and

multimode models

Singlemode and

singlemode live

models

SM OTDR

FTB-7300E

SM

SM

OTDR port (for live-fiber testing)

Domain Reflectometer

The Optical Time Domain Reflectometer allows you to characterize a

fiber-optic span, usually optical fiber sections joined by splices and

connectors. The optical time domain reflectometer (OTDR) provides an

inside view of the fiber, and can calculate fiber length, attenuation, breaks,

total return loss, and splice, connector and total losses.

OTDR 1

Page 16

Introducing the Optical Time Domain Reflectometer

OTDR

OTDR port

(singlemode or multimode)

Other models

Handle

Visual fault locator

(VFL) port (optional)

2 FTB-7000 Series

Page 17

Introducing the Optical Time Domain Reflectometer

Main Features

Main Features

The OTDR:

³ Offers impressive dynamic range with short dead zones.

³ Performs quick acquisitions with low noise levels to enable accurate

low-loss splice location.

³ Acquires OTDR traces made of up to 256 000 points that provide a

sampling resolution as fine as 4 cm.

³ Includes a light source and can include an optional visual fault locator.

OTDR 3

Page 18

Introducing the Optical Time Domain Reflectometer

Trace Acquisition Modes

Trace Acquisition Modes

The OTDR application provides the following trace acquisition modes:

³ Auto: Automatically calculates fiber length, sets acquisition

parameters, acquires traces, and displays event tables and acquired

traces.

³ Advanced: Offers all the tools needed to perform integral OTDR tests

and measurements and gives you control over all test parameters.

³ Temp l at e (op t ional ): Tests fibers and compares the results to a

reference trace that was previously acquired and analyzed. This allows

you to save time when testing a large number of fibers. Reference trace

documentation is also automatically copied to new acquisitions.

³ Fault Finder: Rapidly locates fiber ends and displays the length of the

fiber under test. This allows you to perform quick tests without having

to set all the acquisition parameters.

Optional Software Packages

An optional software package is offered with the application. With this

package, you can find macrobends, view the related information. The

software package also give you access to the “linear view”, which displays

the events sequentially, from left to right.

Note: Optional Software Packages were meant to function on FTB-200 v2 units

and not on FTB-200 units.

Data Post-Processing

You can install the OTDR Viewer (available on the CD that came with your

product) on a computer to view and analyze traces without having to use

an FTB-200 v2 Compact Modular Platform and an OTDR. You can also

access more features such as:

³ customized printout

4 FTB-7000 Series

Page 19

Introducing the Optical Time Domain Reflectometer

Bidirectional Analysis Application

³ batch printing

³ conversion of traces to many formats such as Telcordia or ASCII

Bidirectional Analysis Application

You can improve the accuracy of your loss measurements with the

bidirectional analysis application. This utility uses OTDR acquisitions from

both ends of a fiber span (singlemode traces only) to average loss results

for each event.

Available OTDR Models

A wide variety of multimode and singlemode OTDR models is offered at

several wavelengths to cover all fiber applications from long-haul or WDM

networks to metropolitan networks.

OTDR Models Description

Singlemode

FTB-7200D-B

OTDR 5

³ 1310 nm and 1550 nm.

³ 35 dB dynamic range and 1 m event dead zone, useful

to locate closely spaced events.

³ High-resolution feature to obtain more data points per

acquisition. Data points will be closer to each other,

resulting in a greater distance resolution for the trace.

Page 20

Introducing the Optical Time Domain Reflectometer

Available OTDR Models

OTDR Models Description

Singlemode and

multimode

FTB-7200D-12CD-23B

Singlemode and

singlemode live (SM Live)

FTB-7300E-XXXB

Singlemode

FTB-7400E-XXXXB

³ Four wavelengths: two multimode (850 nm and

1300 nm) and two singlemode (1310 nm and 1550 nm)

in a single module.

³ 26 dB (850 nm)/25 dB (1300 nm)/35 dB

(1310 nm)/34 dB (1550 nm) dynamic range and 1 m

event dead zone, particularly useful to locate closely

spaced events.

³ 4.5 m of attenuation dead zone for both singlemode

and multimode.

³ Allows tests on both 50 μm (C type) and 62.5 μm

(D type) multimode fibers.

³ Optimized for metro network installation and

troubleshooting, access and FTTx test applications

(end-to-end links), and inside plant testing.

³ Test through splitter for FTTH PON characterization.

³ Live fiber out-of-band testing with filtered SM Live port

at 1625 nm or 1650 nm.

³ Attenuation and event dead zone of, respectively, 4 m

and 0.8 m.

³ 38 dB dynamic range.

³ Attenuation dead zone of 4 m for pinpoint event

location

³ Up to 40 dB dynamic range with 0.8 m event dead

zone.

³ Acquires up to 256 000 data points while sampling a

single trace.

³ Up to four test wavelengths (1310 nm, 1383 nm,

1550 nm,1625 nm) for CWDM and DWDM link

characterization

6 FTB-7000 Series

Page 21

Introducing the Optical Time Domain Reflectometer

OTDR Models Description

Available OTDR Models

Singlemode

FTB-7500E-XXXXB

Singlemode

FTB-7600E-XXXXB

³ Event dead zone of 0.8 m and attenuation dead zone of

4 m for pinpoint event location

³ Up to 45 dB dynamic range (on NZDSF with a 20 μs

pulse)

³ High-launch power level minimizes noise effects on

signal.

³ Acquires up to 256 000 data points while sampling a

single trace.

³ Suitable for long-range applications and recommended

when measuring time is a key factor.

³ Up to 50 dB dynamic range (on NZDSF with a 20 μs

pulse)

³ Event dead zone of 1.5 m and attenuation dead zone of

5 m with a 5 ns pulse for high resolution

³ Acquires up to 256 000 data points while sampling a

single trace

³ Suitable for characterization of ultra long cables

³ Best in class analysis for accurate measurement of

loss, reflectance and attenuation.

OTDR 7

Page 22

Introducing the Optical Time Domain Reflectometer

Distance

c

n

---

t

2

---

×=

OTDR Basic Principles

OTDR Basic Principles

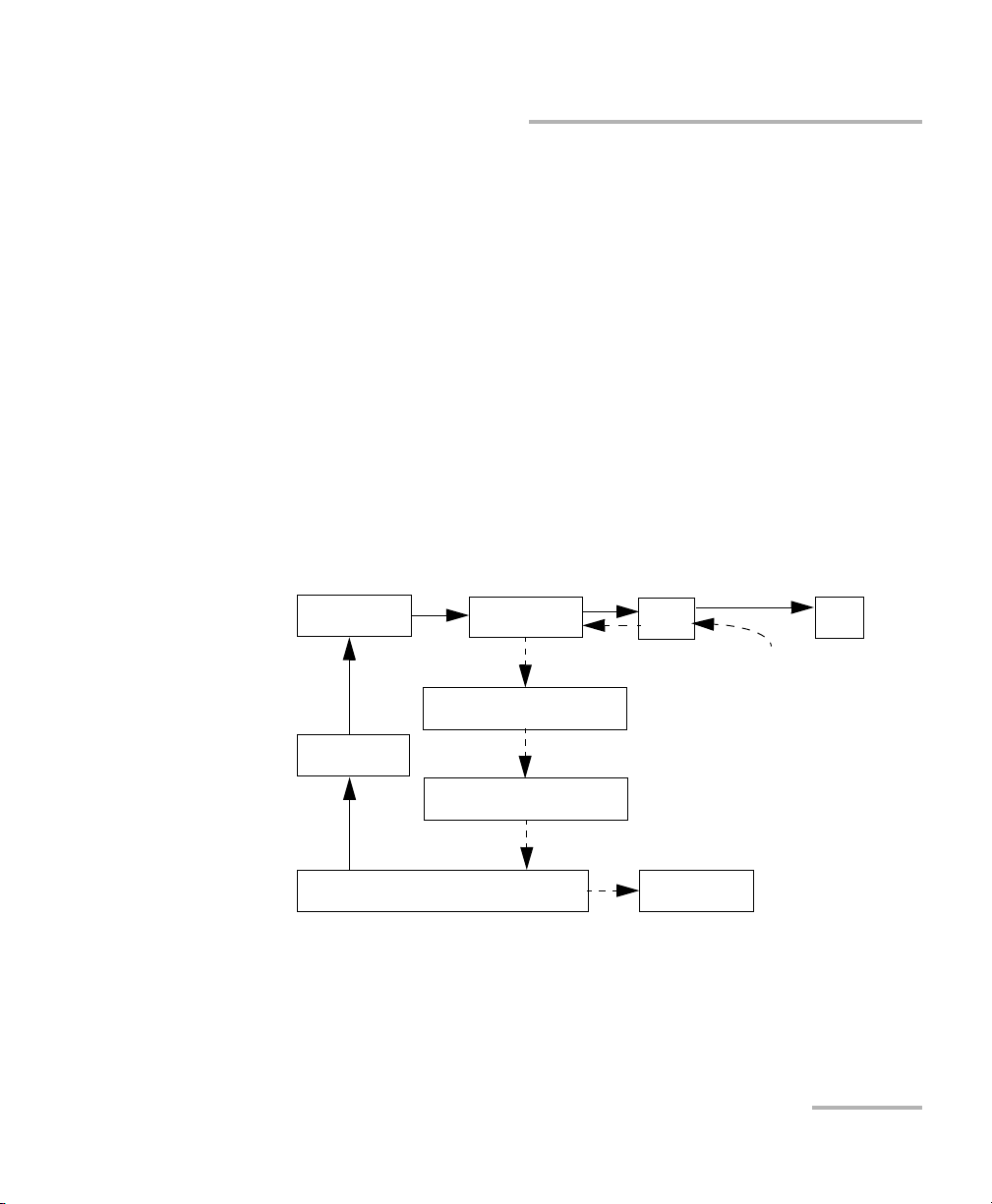

An OTDR sends short pulses of light into a fiber. Light scattering occurs in

the fiber due to discontinuities such as connectors, splices, bends, and

faults. An OTDR then detects and analyzes the backscattered signals. The

signal strength is measured for specific intervals of time and is used to

characterize events.

The OTDR calculates distances as follows:

where

c = speed of light in a vacuum (2.998 x 10

t = time delay from the launch of the pulse to the reception of the

pulse

n = index of refraction of the fiber under test (as specified by the

manufacturer)

8

m/s)

8 FTB-7000 Series

Page 23

Introducing the Optical Time Domain Reflectometer

Microprocessor

Pulse

generator

Avalanche

photodetector (APD)

Display

Reflections come back

to the OTDR

Set of

instructions

Light pulses

Light pulses

Analog-to-digital

converter (A/D)

Returned signal

Analyzed signal

Laser

diode

Optical

coupler

OTDR

port

Fiber

OTDR Basic Principles

An OTDR uses the effects of Rayleigh scattering and Fresnel reflection to

measure the fiber’s condition, but the Fresnel reflection is tens of

thousands of times greater in power level than the backscatter.

³ Rayleigh scattering occurs when a pulse travels down the fiber and

small variations in the material, such as variations and discontinuities

in the index of refraction, cause light to be scattered in all directions.

However, the phenomenon of small amounts of light being reflected

directly back toward the transmitter is called backscattering.

³ Fresnel reflections occur when the light traveling down the fiber

encounters abrupt changes in material density that may occur at

connections or breaks where an air gap exists. A very large quantity of

light is reflected, as compared with the Rayleigh scattering. The

strength of the reflection depends on the degree of change in the index

of refraction.

When the full trace is displayed, each point represents an average of many

sampling points. You will have to zoom to see each point.

OTDR 9

Page 24

Introducing the Optical Time Domain Reflectometer

Conventions

Conventions

Before using the product described in this manual, you should understand

the following conventions:

WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in component damage. Do not proceed unless you

understand and meet the required conditions.

IMPORTANT

Refers to information about this product you should not overlook.

10 FTB-7000 Series

Page 25

2 Safety Information

Affixed to module’s

side panel

WARNING

Do not install or terminate fibers while a light source is active.

Never look directly into a live fiber and ensure that your eyes are

protected at all times.

WARNING

Use of controls, adjustments and procedures for operation and

maintenance other than those specified herein may result in

hazardous radiation exposure or impair the protection provided by

this unit.

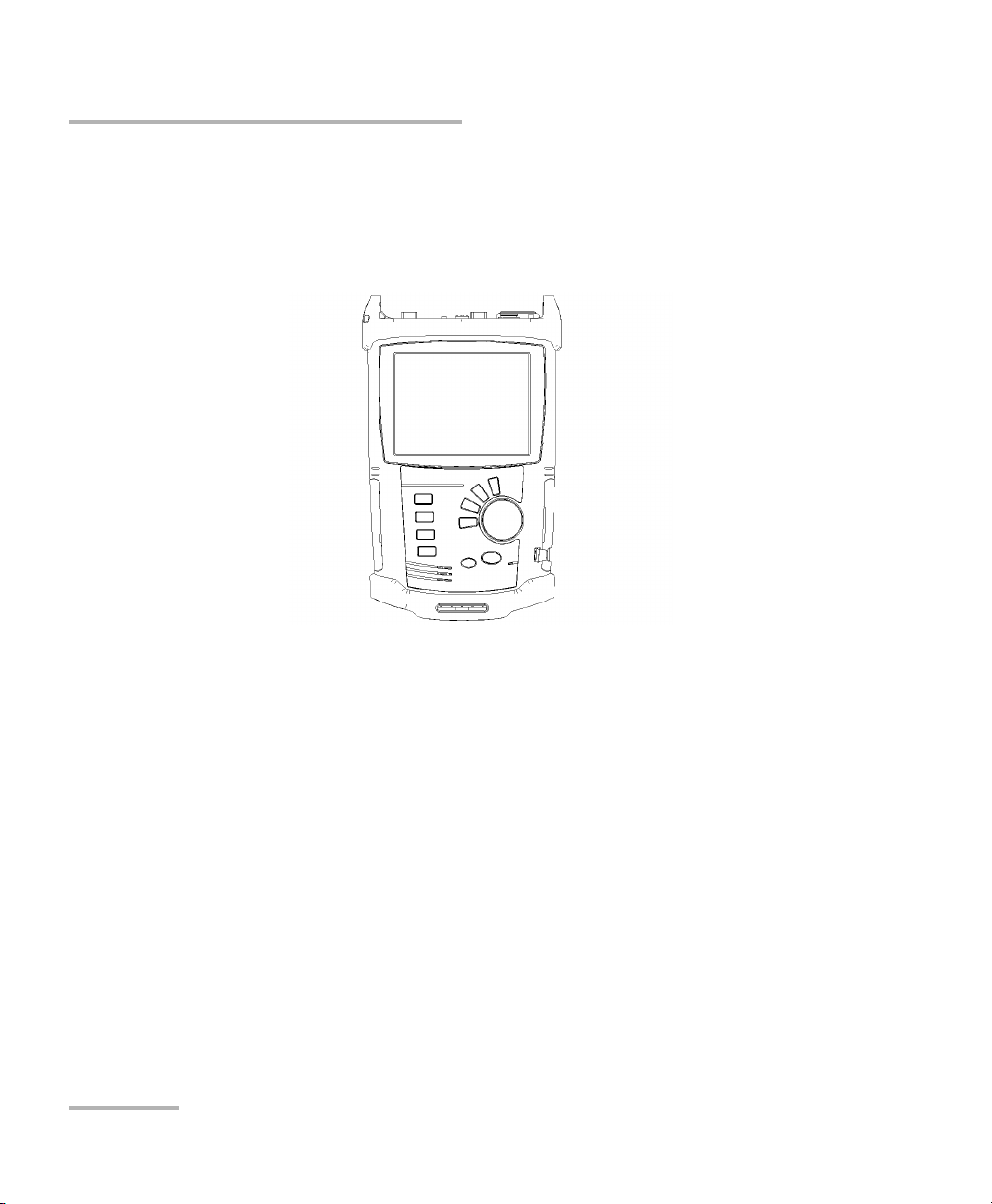

Laser Safety Information (Models without VFL)

Your instrument is a Class 1M laser product in compliance with standards

IEC 60825-1 and 21 CFR 1040.10. Invisible laser radiation may be

encountered at the output port.

The product is safe under reasonably foreseeable conditions of operation

but it may be hazardous if you use optics within a diverging or collimated

beam. Do not view directly with optical instruments.

OTDR 11

Page 26

Safety Information

Affixed to module’s

side panel

Laser Safety Information (Models with VFL)

Laser Safety Information (Models with VFL)

Your instrument is a Class 3R laser product in compliance with standards

IEC 60825-1 and 21 CFR 1040.10. It is potentially harmful in direct

intrabeam viewing.

The following label(s) indicate that the product contains a Class 3R source:

12 FTB-7000 Series

Page 27

3 Getting Started with Your

OTDR

Inserting and Removing Test Modules

CAUTION

Never insert or remove a module while the FTB-200 v2 Compact

Modular Platform is turned on. This will result in immediate and

irreparable damage to both the module and unit.

WARNING

When the laser safety LED is flashing, at least one of your modules

is emitting an optical signal. Please check all modules, as it might

not be the one you are currently using.

OTDR 13

Page 28

Getting Started with Your OTDR

Inserting and Removing Test Modules

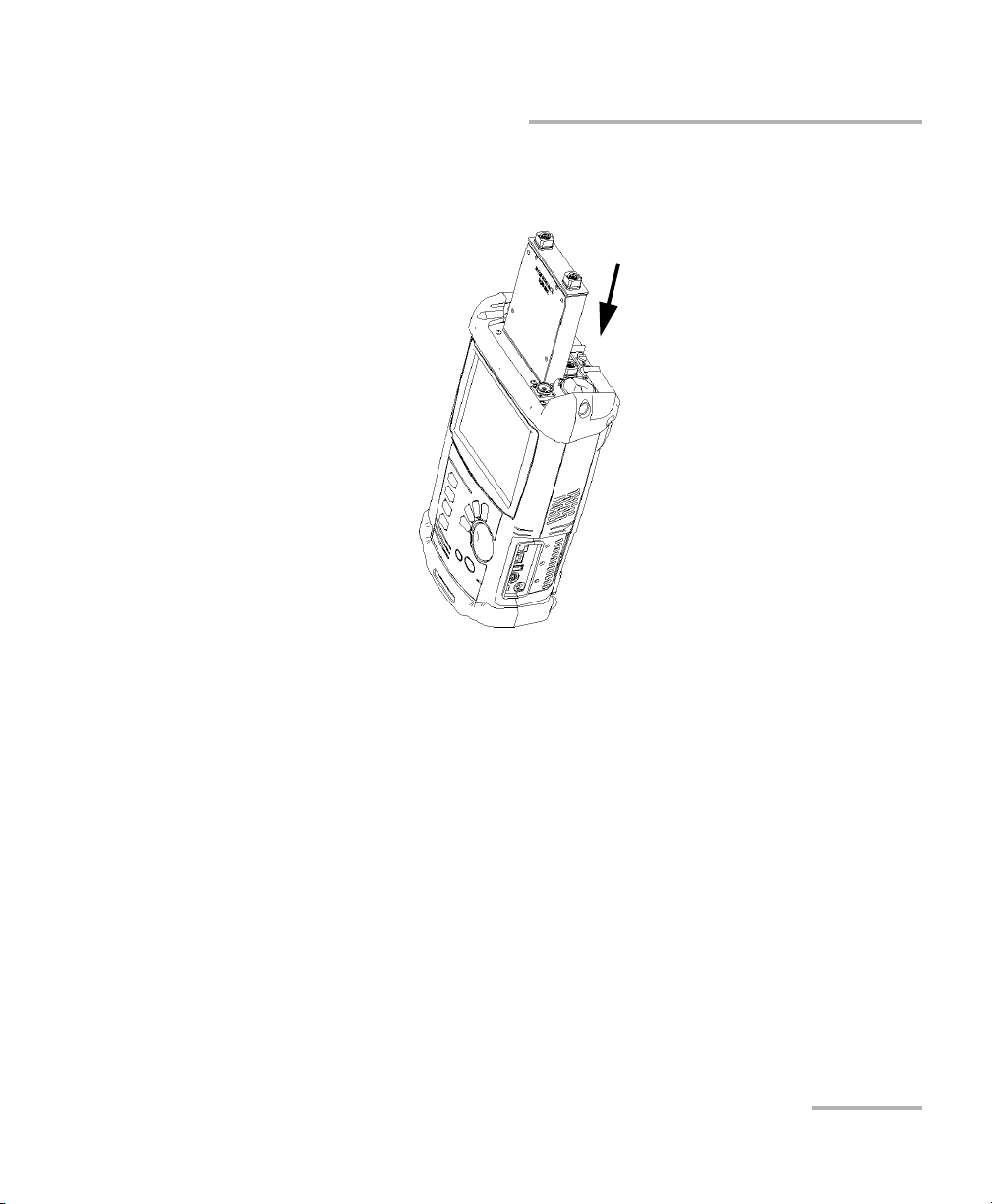

To insert a module into the FTB-200 v2 Compact Modular

Platform:

1. Turn off your unit.

2. Position the unit so that its front panel is facing you.

14 FTB-7000 Series

Page 29

Getting Started with Your OTDR

Inserting and Removing Test Modules

3. Take the module and place it vertically so that the retaining screw hole

is at the left of the connector pins.

4. Insert the protruding edges of the module into the grooves of the unit’s

module slot.

5. Push the module all the way to the bottom of the slot, until the

retaining screw makes contact with the unit casing.

6. Place the unit so that its bottom panel is facing you.

OTDR 15

Page 30

Getting Started with Your OTDR

Turn retaining screws

clockwise

Bottom panel

Inserting and Removing Test Modules

7. While applying slight pressure to the module, lift the mobile part of the

retaining screw and use it to turn the retaining screw clockwise until it

is tightened.

This will secure the module into its “seated” position.

When you turn on the unit, the startup sequence will automatically detect

the module.

16 FTB-7000 Series

Page 31

Getting Started with Your OTDR

Turn retaining screws

counterclockwise

Bottom panel

Inserting and Removing Test Modules

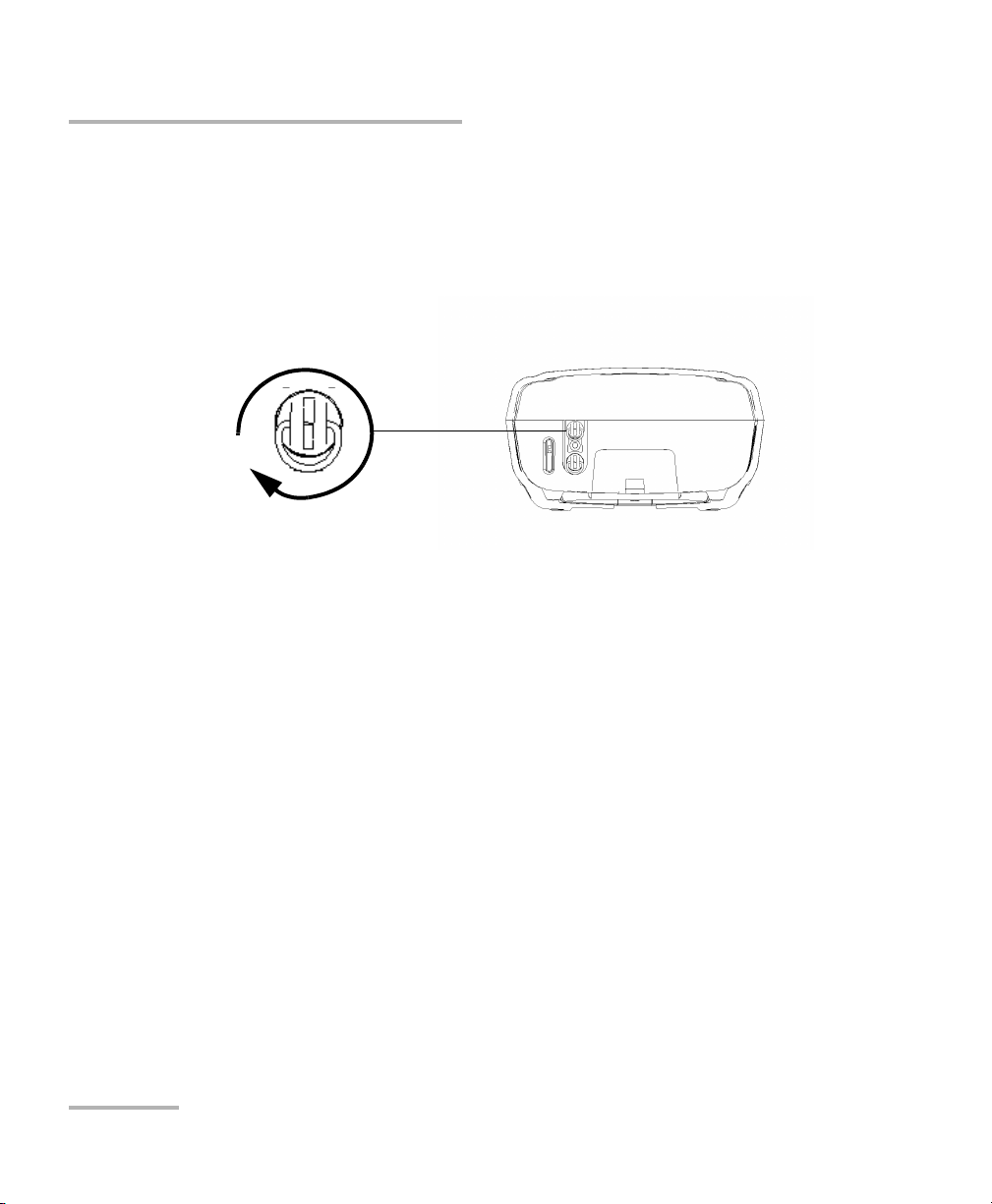

To remove a module from the FTB-200 v2 Compact Modular

Platform:

1. Turn off your unit.

2. Position the unit so that the bottom panel is facing you.

3. Lift the mobile part of the retaining screw and use it to turn the

retaining screw counterclockwise until it stops.

The module will be slowly released from the slot.

4. Place the FTB-200 v2 Compact Modular Platform so that the top panel

is facing you.

OTDR 17

Page 32

Getting Started with Your OTDR

Inserting and Removing Test Modules

5. Hold the module by its sides or by the handle (NOT by the connector)

and pull it out.

CAUTION

Pulling out a module by a connector could seriously damage both

the module and connector. Always pull out a module by its casing.

6. Cover empty slots with the supplied protective covers.

18 FTB-7000 Series

Page 33

Starting Module Applications

Starting Module Applications

Your modules can be configured and controlled from their dedicated

applications in Compact ToolBox.

To start a module application:

1. From Compact ToolBox, select the module to use.

It will turn blue to indicate that it is highlighted.

2. Under Applications, select an application, then press Start.

To start the Power Meter or Probe application:

From Main Menu, press Power Meter or Probe.

OTDR 19

Page 34

Timer

Data

display

Function

tabs

Button bar

The main window (shown below) contains all the commands required to

control the OTDR:

Timer

Once the acquisition has begun, a timer is displayed on the right-hand side

of the screen, indicating the remaining time until the next acquisition.

20 FTB-7000 Series

Page 35

4 Preparing Your OTDR for a Test

Bare metal

(or blue border)

indicates UPC

option

Green border

indicates APC

option

2 3 4

Installing the EXFO Universal Interface (EUI)

The EUI fixed baseplate is available for connectors with angled (APC) or

non-angled (UPC) polishing. A green border around the baseplate

indicates that it is for APC-type connectors.

To install an EUI connector adapter onto the EUI baseplate:

1. Hold the EUI connector adapter so the dust cap opens downwards.

2. Close the dust cap in order to hold the connector adapter more firmly.

3. Insert the connector adapter into the baseplate.

4. While pushing firmly, turn the connector adapter clockwise on the

baseplate to lock it in place.

OTDR 21

Page 36

Preparing Your OTDR for a Test

Cleaning and Connecting Optical Fibers

Cleaning and Connecting Optical Fibers

To ensure maximum power and to avoid erroneous readings:

³ Always inspect fiber ends and make sure that they are clean as

explained below before inserting them into the port. EXFO is

not responsible for damage or errors caused by bad fiber

cleaning or handling.

³ Ensure that your patchcord has appropriate connectors. Joining

mismatched connectors will damage the ferrules.

To connect the fiber-optic cable to the port:

1. Inspect the fiber using a fiber inspection microscope. If the fiber is

clean, proceed to connecting it to the port. If the fiber is dirty, clean it as

explained below.

2. Clean the fiber ends as follows:

IMPORTANT

2a. Gently wipe the fiber end with a lint-free swab dipped in isopropyl

alcohol.

2b. Use compressed air to dry completely.

2c. Visually inspect the fiber end to ensure its cleanliness.

22 FTB-7000 Series

Page 37

Preparing Your OTDR for a Test

Cleaning and Connecting Optical Fibers

3. Carefully align the connector and port to prevent the fiber end from

touching the outside of the port or rubbing against other surfaces.

If your connector features a key, ensure that it is fully fitted into the

port’s corresponding notch.

4. Push the connector in so that the fiber-optic cable is firmly in place,

thus ensuring adequate contact.

If your connector features a screwsleeve, tighten the connector

enough to firmly maintain the fiber in place. Do not overtighten, as this

will damage the fiber and the port.

Note: If your fiber-optic cable is not properly aligned and/or connected, you will

notice heavy loss and reflection.

OTDR 23

Page 38

Preparing Your OTDR for a Test

Naming Trace Files Automatically

Naming Trace Files Automatically

Each time you start an acquisition, the application suggests a file name

based on autonaming settings. This file name appears on the upper part of

the graph and the linear view.

The file name is made of a static part (alphanumeric) and a variable part

(numeric) that will be incremented or decremented, according to your

selection, as follows:

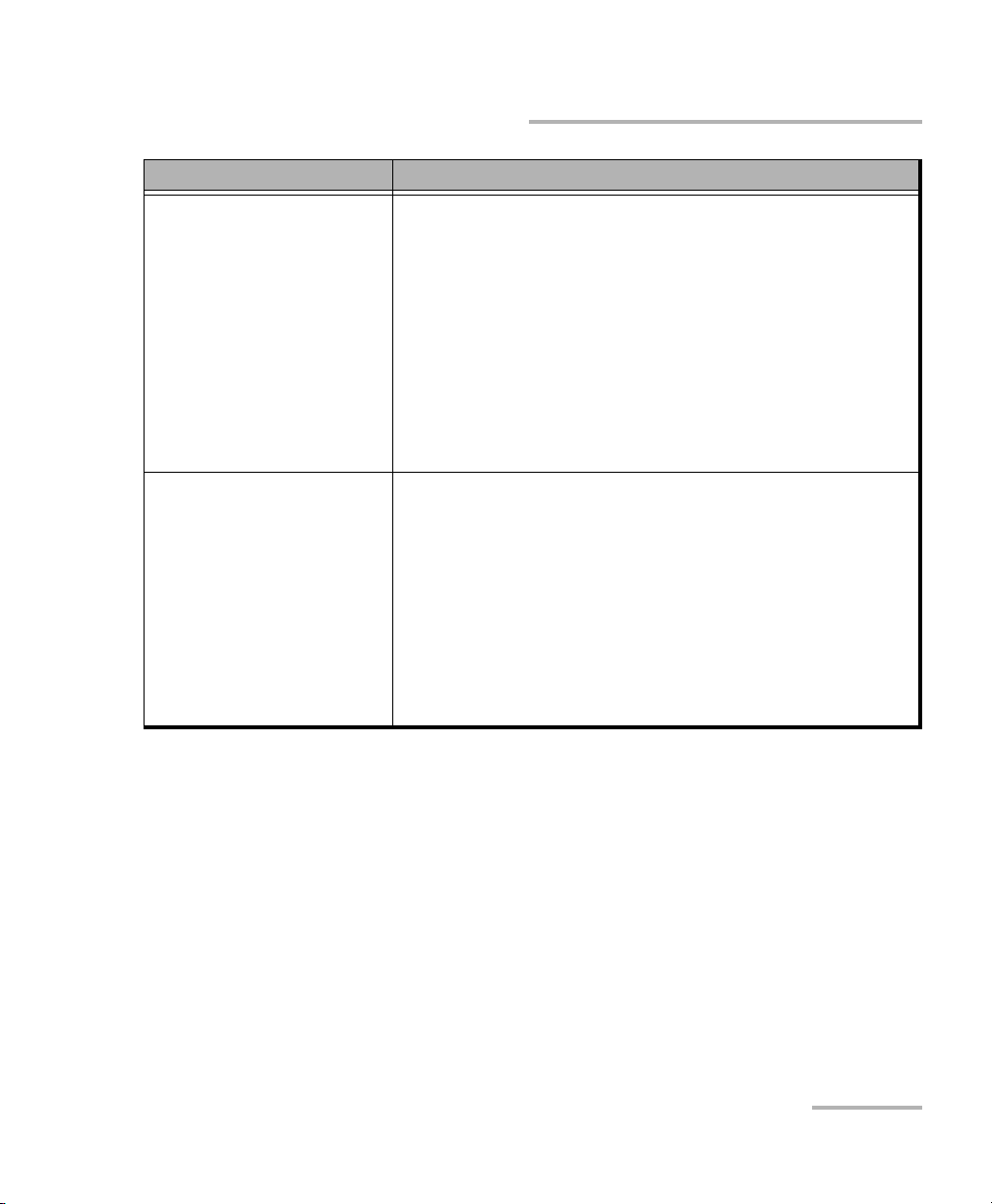

If you choose incrementation... If you choose decrementation...

Variable part increases until it

reaches the highest possible value

with the selected number of digits

(for example, 99 for 2 digits), then

restarts at 0.

After saving a result, the unit prepares the next file name by incrementing

(or decrementing) the suffix.

Note: If you choose not to save a particular trace file, the suggested file name will

remain available for the next trace you acquire.

This function is particularly useful when working in Template mode or

when testing multiple-fiber cables.

If you deactivate the automatic file naming function, the application will

prompt you to specify a file name. The default file name is Unnamed.trc.

By default, traces are saved in native (.trc) format, but you can configure

your unit to save them in Bellcore (.sor) format (see Selecting the Default

File Format on page 93).

Variable part decreases until it

reaches 0, then restarts at the highest

possible value with the selected

number of digits (for example, 99 for

2 digits).

24 FTB-7000 Series

Page 39

Preparing Your OTDR for a Test

Naming Trace Files Automatically

Note: If you select the Bellcore (.sor) format, the unit will create one file per

wavelength (for example, TRACE001_1310.sor and TRACE001_1550.sor, if

you included both 1310 nm and 1550 nm in your test). The native format

contains all wavelengths in a single file.

To configure the automatic file naming:

1. From the button bar, press OTDR Setup.

2. Select the Acquisition tab.

3. Press Default Trace Information.

OTDR 25

Page 40

Preparing Your OTDR for a Test

Number of digits

composing the

variable part

Value at which the

autonumbering

sequence starts

The variable part will

increase or decrease

depending on your

choice

Naming Trace Files Automatically

4. Fill out the required information in the corresponding boxes and select

the direction for your trace files.

5. Press the button appearing next to the Fiber ID box to change the

contents of the fiber identification.

6. Change the criteria as needed, then press OK to confirm your new

settings and return to the Default Trace Information window.

26 FTB-7000 Series

Page 41

Preparing Your OTDR for a Test

This preview is

updated

automatically as you

make your selections

Items that can be

included in the file

name

To select the separator in

the automatic

numbering section

To add personalized

information not included

in the filename criteria

To modify the order of appearance of the

selected components in the file name

Naming Trace Files Automatically

7. Press File Autonaming to set up the trace file name options.

8. In the File Name window, select the desired components to include in

the file name. You can change the order of apparition with the up and

down arrow buttons.

OTDR 27

9. Press OK to confirm your new settings.

Page 42

Preparing Your OTDR for a Test

Enabling or Disabling the First Connector Check

Enabling or Disabling the First Connector

Check

Note: This function is available in all OTDR modes. However, the first connector

check parameter used in Fault Finder mode is independent from the one

used in the other OTDR modes (Auto, Advanced and Template).

The first connector check feature is used to verify that the fibers are

properly connected to the OTDR. It verifies the injection level and displays

a message when an unusually high loss occurs at the first connection,

which could indicate that no fiber is connected to the OTDR port. By

default, this feature is not enabled.

Note: The first connector check is only performed when you test at singlemode

wavelengths.

To enable or disable the first connector check:

1. From the Main Menu, press OTDR Setup then press the General tab.

2. To enable the first connector check, select the First connector check

box.

OR

To disable it, clear the box.

28 FTB-7000 Series

Page 43

Preparing Your OTDR for a Test

Setting Macrobend Parameters

Setting Macrobend Parameters

Note: This function is available both in Advanced and Auto modes.

Your unit can locate macrobends by comparing the loss values measured

at a certain location, for a certain wavelength (for example, 1310 nm) with

the loss values measured at the corresponding location, but for a greater

wavelength (for example, 1550 nm).

The unit will identify a macrobend when comparing two loss values if:

³ Of the two loss values, the greater loss occurred at the greater

wavelength.

AND

³ The difference between the two loss values exceeds the defined delta

loss value. The default delta loss value is 0.5 dB (which is suitable for

most fibers), but you can modify it.

You can also disable macrobend detection.

Note: Macrobend detection is only possible with singlemode wavelengths.

Filtered wavelengths or wavelengths of dedicated OTDR ports are not

available for macrobend detection.

For information on how the information about macrobends is available

after an acquisition, see Linear View on page 108 and Summary Table on

page 110.

OTDR 29

Page 44

Preparing Your OTDR for a Test

Setting Macrobend Parameters

To set macrobend parameters:

1. From the Main Menu, press OTDR Setup then select the General tab.

2. To enable the macrobend detection, select the Show macrobend

check box.

OR

To disable it, clear the check box.

3. If necessary, set the delta value as follows:

3a. From the Wavelengths list, select the pair of wavelengths for

which you want to define the delta value.

Only the combinations of wavelengths your module can support

will be available.

For more significant results, EXFO recommends to always select

the combination of wavelengths including the smallest possible

wavelength and the greatest wavelength (for example, if your

module supports 1310 nm, 1550 nm, and 1625 nm, you would

select the 1310 nm/1625 nm combination).

3b. In the Delta (loss) box, enter the desired value.

3c. Repeat steps 3a and 3b for all combinations of wavelengths.

To revert to default settings:

1. Press Default.

2. When the application prompts you, answer Yes if you want to apply the

settings to all combinations of wavelengths.

30 FTB-7000 Series

Page 45

Preparing Your OTDR for a Test

Launch Conditions for Multimode Measurements

Launch Conditions for Multimode

Measurements

In a multimode fiber network, the attenuation of a signal is highly

dependent on the mode distribution (or launch condition) of the source

that emits this signal.

In the same way, the attenuation reading performed by any test instrument

will also depend on the mode distribution of its light source.

A single light source cannot be conditioned for both 50 μm (50 MMF) and

62.5 μm (62.5 MMF) fibers at the same time:

³ A source conditioned for 50 MMF testing will be under-filled for

62.5 MMF testing.

³ A source conditioned for 62.5 MMF will be overfilled for 50 MMF testing.

TIA/EIA-455-34A (FOTP34, Method A2) is providing a target launch

condition that is obtained when using an overfilled source followed by

mandrel-wrap mode filter (five close-wound turns around a mandrel tool

of a given diameter).

Your product has been conditioned for 62.5 MMF testing. However, you can

also test with 50 MMF fibers.

OTDR 31

Page 46

Preparing Your OTDR for a Test

Launch Conditions for Multimode Measurements

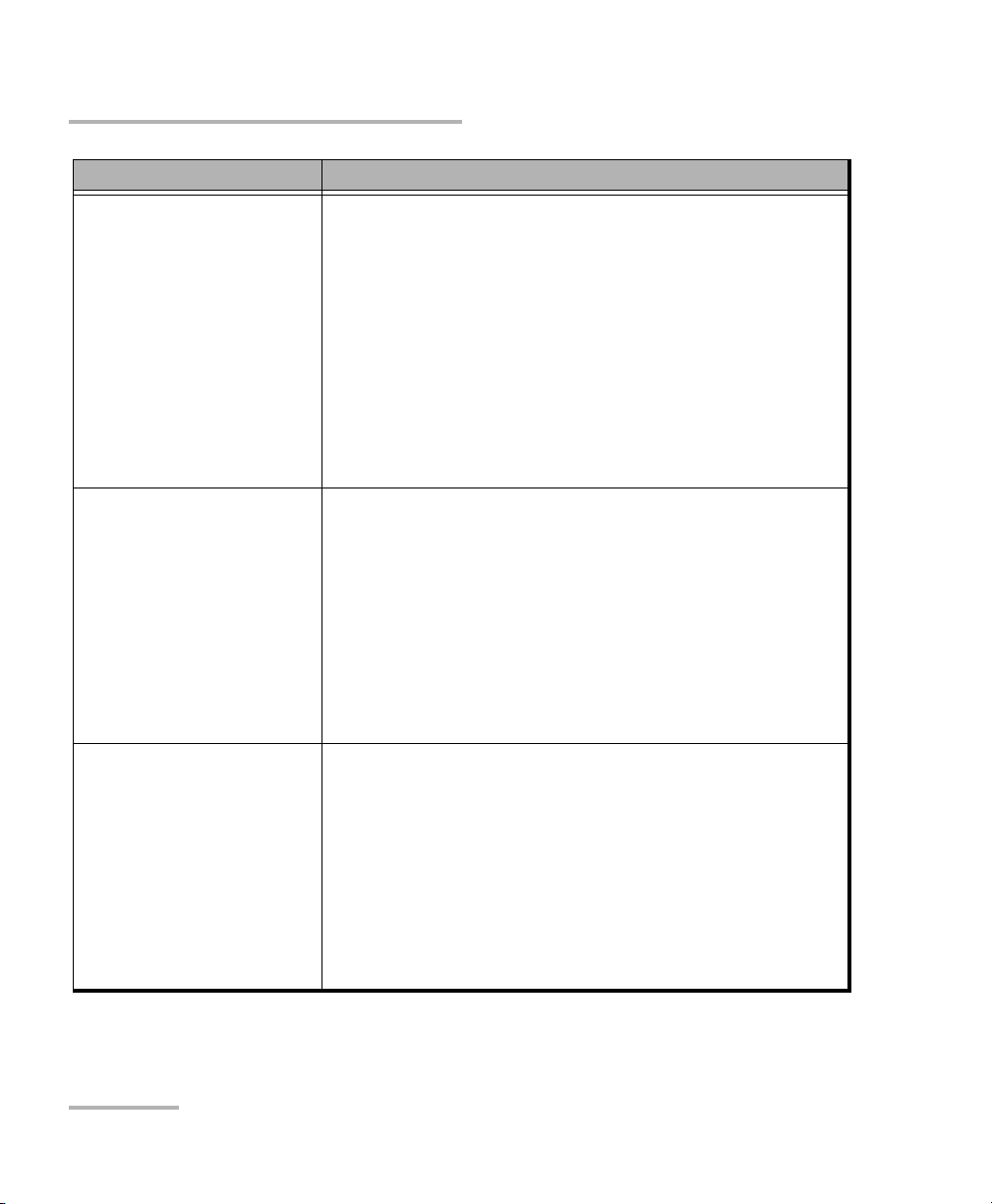

The table below gives information about tests with the 50 μm and 62.5 μm

fibers.

Fiber type Recommended mode filter Remarks

50 μm Perform a five-turn

mandrel-wrap (wrapping the

patchcord a minimum of five

turns around the mandrel tool)

on the patchcord connecting

the OTDR to the fiber under

test.

As per FOTP-34:

³ For fibers with 3 mm

jacket: use a mandrel tool

with a diameter of 25 mm.

³ For fibers without jacket:

use a mandrel tool with a

diameter of 22 mm.

62.5 μm No mode filter required. Loss measurements similar to

Nominal launch conditions are

overfilled.

Loss measurements can be

slightly pessimistic (higher loss)

when compared to loss

measurements done with a

50 MMF source compliant to

FOTP34, Method A2.

those obtained with a power

meter and a source that is

conditioned according to

FOTP34, Method A2.

IMPORTANT

If you test with 50 μm fibers, EXFO recommends that you use a

mode filter (mandrel-wrap). Otherwise, you may obtain results with

a 0.1 to 0.3 dB excess loss.

32 FTB-7000 Series

Page 47

5 Testing Fibers in Auto Mode

Auto mode automatically evaluates fiber length, sets acquisition

parameters, acquires traces, and displays event tables and acquired traces.

In Auto mode, you can set the following parameters directly:

³ Test w a ve lengt h s ( all selected by default)

³ Fiber type (singlemode, singlemode live, or multimode) for models

supporting these fiber types

³ Autorange acquisition time

³ IOR (group index), RBS coefficient and helix factor

For all other parameters, the application uses those defined in Advanced

mode, except that analysis is always performed after acquisitions.

If you ever need to modify other parameters, go to Advanced mode (see

Testing Fibers in Advanced Mode on page 37 and Preparing Your OTDR for

a Test on page 21).

In Auto mode, the application will automatically evaluate the best settings

according to the fiber link currently connected to the unit (in less than

5 seconds). If you interrupt it, no data will be displayed.

Fiber characteristics are evaluated only once per session. Other fibers you

connect to, within the same cable, will be tested with the same settings.

When you start testing another link, you can reset these parameters.

Once this evaluation is complete, the application starts acquiring the trace.

The trace display is continually updated.

Note: You can interrupt the acquisition at any time. The application will display

the information acquired to that point.

OTDR 33

Page 48

Testing Fibers in Auto Mode

Event

pane

Tra ce

display

Once the acquisition is complete or interrupted, the analysis starts for

acquisitions of 5 seconds or more.

After analysis, the trace is displayed and events appear in the events table.

The application will also display status messages if you have selected to

display pass/fail messages (see Setting Pass/Fail Thresholds on page 53).

You can save the trace after analysis. If former results have not been saved

yet, the application prompts you to save them before starting a new

acquisition.

34 FTB-7000 Series

Page 49

Testing Fibers in Auto Mode

To acquire traces in Auto mode:

1. Clean the connectors properly.

2. Connect a fiber to the OTDR port.

If your unit is equipped with two OTDR ports, ensure that you connect

the fiber to the appropriate port (singlemode, singlemode live, or

multimode), depending on the wavelength you intend to use.

CAUTION

Never connect a live fiber to the OTDR port without a proper setup.

Any incoming optical power ranging from –65 dBm to –40 dBm will

affect the OTDR acquisition. The way the acquisition will be

affected depends on the selected pulse width.

Any incoming signal greater than –20 dBm could damage your

OTDR permanently. For live-fiber testing, refer to the SM Live port

specifications for the characteristics of the built-in filter.

3. Set the autorange acquisition time (see Setting the Autorange

Acquisition Time on page 42).

4. Go to the OTDR tab.

5. If your OTDR supports singlemode, singlemode live, or multimode

wavelengths, under Wavelengths, from the list, select the desired fiber

type (for live-fiber testing, select SM Live; for C fiber, select 50 μm and

for D fiber, select 62.5 μm).

OTDR 35

Page 50

Testing Fibers in Auto Mode

6. Select the boxes corresponding to the desired test wavelengths. You

must select at least one wavelength.

7. If you want to clear the settings the OTDR has determined to start with

a new set of OTDR settings, press Reset.

8. Press Start or from the keypad.

If the first connector check feature is enabled, a message will appear if

there is a problem with the injection level (see Enabling or Disabling

the First Connector Check on page 28).

9. Once the analysis is complete, save the trace by pressing Quick Save

in the button bar or from the keypad.

The application will use a file name based on the autonaming

parameters you defined (see Naming Trace Files Automatically on

page 24). This file name appears at the top of the graph and at the top

of the linear view table.

Note: The application will only display the Save File dialog box if you have

activated the feature to always be prompted when you save a file. From

this dialog box, you can change the location, the file name and the file

format.

9a. If necessary, change the folder to which the file will be saved by

pressing the Location button.

9b. If necessary, specify a file name.

IMPORTANT

If you specify the name of an existing trace, the original file will be

overwritten and only the new file will be available.

10. Press OK to confirm.

36 FTB-7000 Series

Page 51

6 Testing Fibers in Advanced

Mode

Advanced mode offers all the tools you need to perform complete OTDR

tests and measurements manually and gives you control over all test

parameters.

Note: Most parameters can only be set if you select Advanced mode first. Once

you have finished selecting your settings, you can simply return to the test

mode you prefer.

By default, in Advanced mode, all available test wavelengths are selected.

In this mode, you can either set the acquisition parameters yourself or let

the application determine the most appropriate values.

In the latter case, the application will automatically evaluate the best

settings according to the fiber link currently connected to the unit:

³ The pulse width will be determined using a factory-defined

signal-to-noise ratio (SNR) requirement specified where the

End-of-Fiber (EoF) event has been detected.

The EoF event detection algorithm uses the end-of-fiber threshold

defined in the tab of the application setup. If you are not sure about

which value to choose, revert to the factory default value for this

parameter.

³ The range will then be set automatically. This optimum value may

differ from the values currently associated with the Distance dial of the

main window. In this case, the application will “add” the required

value and mark it with a * symbol.

³ The application uses the acquisition time defined in the Acquisition

tab of the OTDR setup (for more information, see Setting the Autorange

Acquisition Time on page 42). The default value is 15 seconds. Longer

acquisitions give better OTDR results.

OTDR 37

Page 52

Testing Fibers in Advanced Mode

Event

pane

Tra ce

display

Although the application sets the acquisition parameters, you can modify

these values as needed, even while the acquisition is in progress. The

OTDR simply restarts the averaging each time a modification is made.

Note: You can interrupt the acquisition at any time. The application will display

the information acquired to that point.

Once the acquisition is complete or interrupted, the analysis starts for

acquisitions of 5 seconds or more.

After analysis, the trace is displayed. Events appear both in the events table

and in the linear view (if you purchased the optional software package).

The application will also display pass/fail messages if you have selected

this feature. For more information, see Setting Pass/Fail Thresholds on

page 53.

You can save the trace after analysis. If former results have not been saved

yet, the application prompts you to save them before starting a new

acquisition.

38 FTB-7000 Series

Page 53

Testing Fibers in Advanced Mode

To acquire traces:

1. Clean the connectors properly (see Cleaning and Connecting Optical

Fibers on page 22).

2. Connect a fiber to the OTDR port.

If your unit is equipped with two OTDR ports, ensure that you connect

the fiber to the appropriate port (singlemode, singlemode live, or

multimode), depending on the wavelength you intend to use.

CAUTION

Never connect a live fiber to the OTDR port without a proper setup.

Any incoming optical power ranging from –65 dBm to –40 dBm will

affect the OTDR acquisition. The way the acquisition will be

affected depends on the selected pulse width.

Any incoming signal greater than –20 dBm could damage your

OTDR permanently. For live-fiber testing, refer to the SM Live port

specifications for the characteristics of the built-in filter.

3. If you want the application to provide automatic acquisition values, set

the autorange acquisition time (see Setting the Autorange Acquisition

Time on page 42).

4. If you want to set your own IOR (group index), RBS coefficient or helix

factor, see Setting the IOR, RBS Coefficient, and Helix Factor on

page 43.

5. Go to the OTDR tab.

6. If you want to test in high resolution, simply select the feature (see

Enabling the High-Resolution Feature on page 49).

OTDR 39

Page 54

Testing Fibers in Advanced Mode

7. If your OTDR supports singlemode, singlemode live, or multimode

wavelengths, under Wavelengths, from the list, select the desired fiber

type (for live-fiber testing, select SM Live; for C fiber, select 50 μm and

for D fiber, select 62.5 μm).

8. Select the boxes corresponding to the desired test wavelengths. You

must select at least one wavelength.

9. Select the desired distance, pulse, and time values. For more

information, see Setting Distance Range, Pulse Width, and Acquisition

Time on page 45.

10. Press Start or from the keypad. If the first connector check

feature is enabled, a message will appear if there is a problem with the

injection level (see Enabling or Disabling the First Connector Check on

page 28).

You can modify the acquisition parameters as needed, while the

acquisition is in progress. The OTDR simply restarts the averaging each

time a modification is made.

11. Once the analysis is complete, save the trace by pressing Quick Save

in the button bar or from the keypad.

The application will use a file name based on the autonaming

parameters you defined (see Naming Trace Files Automatically on

page 24). This file name appears at the top of the graph and at the top

of the linear view table.

40 FTB-7000 Series

Page 55

Testing Fibers in Advanced Mode

Note: The application will only display the Save File dialog box if you have

activated the feature to always be prompted when you save a file. From

this dialog box, you can change the location, the file name and the file

format.

11a.If necessary, change the folder to which the file will be saved by

pressing the Location button.

11b.If necessary, specify a file name.

IMPORTANT

If you enter the name of an existing trace, the original file will be

replaced with the new file.

12. Press OK to confirm.

OTDR 41

Page 56

Testing Fibers in Advanced Mode

Setting the Autorange Acquisition Time

Setting the Autorange Acquisition Time

Note: This function is available both in Advanced and Auto modes.

When performing automatic acquisitions in Advanced mode (see Te st in g

Fibers in Advanced Mode on page 37) or before activating Auto mode (see

Testing Fibers in Auto Mode on page 33), you can set an autorange

acquisition time for the OTDR to average acquisitions over a set time

period.

The application uses this value to determine the best settings for the test.

Note: In Template mode, the acquisition time of the reference trace is used for all

trace acquisitions, not the autorange acquisition time.

To set the autorange acquisition time:

1. From the button bar, press OTDR Setup then go to the Acquisition tab.

2. Go to the Autorange acquisition time box and press the up or down

arrow to select your preference. The default value is 30 seconds.

3. Press Exit OTDR Setup to return to the OTDR application.

42 FTB-7000 Series

Page 57

Testing Fibers in Advanced Mode

Setting the IOR, RBS Coefficient, and Helix Factor

Setting the IOR, RBS Coefficient, and Helix

Factor

Note: This function is available both in Advanced and Auto modes.

You s ho u ld s et t he I O R ( g rou p in dex ) , RBS coefficient and helix factor

before performing tests in order to apply them to all newly acquired traces.

However, if you are in Advanced mode, you can also set them at a later

time in the Trace Info. tab to reanalyze a specific trace.

³ The index of refraction (IOR) value (also known as group index) is

used to convert time-of-flight to distance. Having the proper IOR is

crucial for all OTDR measurements associated with distance (event

position, attenuation, section length, total length, etc.). IOR is provided

by the cable or fiber manufacturer.

The test application determines a default value for each wavelength.

You can set the IOR value for each available wavelength. You should

verify this information before each test.

³ The Rayleigh backscatter (RBS) coefficient represents the amount of

backscatter in a particular fiber. The RBS coefficient is used in the

calculation of event loss and reflectance, and it can usually be

obtained from the cable manufacturer.

The test application determines a default value for each wavelength.

You can set the RBS coefficient for each available wavelength.

³ The helix factor takes into consideration the difference between the

length of the cable and the length of the fiber inside the cable. Fibers

within a cable are spiraling around the cable core. The helix factor

describes the pitch of that spiral.

By setting the helix factor, the length of the OTDR distance axis is

always equivalent to the physical length of the cable (not the fiber).

To set the IOR, RBS, and helix factor parameters:

1. From the button bar, press OTDR Setup.

OTDR 43

Page 58

Testing Fibers in Advanced Mode

Wavelength for which

RBS and IOR will be

defined

Index of refraction

Rayleigh backscatter

coefficient

Setting the IOR, RBS Coefficient, and Helix Factor

2. From the OTDR Setup window, go to the Acquisition tab.

3. Use the up or down arrow located on the side of the wavelength box to

select the desired wavelength.

IMPORTANT

Change the default RBS coefficient only if you have values provided

by the fiber manufacturer. If you set this parameter incorrectly, your

reflectance measurements will be inaccurate.

4. Select the default settings by pressing Default. When the application

prompts you, answer Yes only if you want to apply the new settings to

all wavelengths.

OR

Enter your own values in the boxes, for each available wavelength.

Note: You cannot define a different helix factor for each wavelength. This value

takes into account the difference between the length of the cable and the

length of the fiber inside the cable; it does not vary with wavelengths.

5. Press Exit OTDR Setup.

44 FTB-7000 Series

Page 59

Testing Fibers in Advanced Mode

Setting Distance Range, Pulse Width, and Acquisition Time

Setting Distance Range, Pulse Width, and

Acquisition Time

The distance range, pulse width and acquisition time are set with the

controls in the Advanced main window.

³ Distance: corresponds to the distance range of the fiber span to be

tested according to the selected measurement units (see Selecting the

Distance Units on page 96).

Changing the distance range alters the available settings of the pulse

width and leaves only the settings available for the specified range. You

can select either Auto or one of the predefined values.

If your OTDR model is FTB-7000D or later, youYou can customize the

available distance range values (see Customizing the Acquisition

Distance Range Values on page 98). If you select Auto, the application

will evaluate the fiber length and set the acquisition parameters

accordingly.

³ Pulse: corresponds to the pulse width for the test. A longer pulse

allows you to probe further along the fiber, but results in less

resolution. A shorter pulse width provides higher resolution, but less

distance range. The available distance ranges and pulse widths

depend on your OTDR model.

Note: Not all pulse widths are compatible with all distance ranges.

You can select either Auto or one of the predefined values.

If you select Auto, the application will evaluate the fiber type and length

and set the acquisition parameters accordingly.

OTDR 45

Page 60

Testing Fibers in Advanced Mode

Setting Distance Range, Pulse Width, and Acquisition Time

³ Time: corresponds to the acquisition duration (period during which

results will be averaged). Generally, longer acquisition times generate

cleaner traces (this is especially true with long-distance traces)

because as the acquisition time increases, more of the noise is

averaged out. This averaging increases the signal-to-noise ratio (SNR)

and the OTDR’s ability to detect small events.

The time settings will also determine how the timer (displayed in the

toolbar) counts time during testing (see Timer on page 20).

If the predefined values do not suit your needs, you can customize one

or all of them. For more information, see Customizing the Acquisition

Time Values on page 100.

In addition to the displayed values, the following time modes are

available:

³ Real: used to immediately view changes in the fiber under test. In

this mode, the SNR of the trace is lower and the trace is refreshed

instead of averaged until you press Stop.

You can alternate between real mode and averaging time interval

mode while an acquisition is in progress.

Note: The Real item will be available if only one wavelength is selected.

³ Auto: the application will use the autorange acquisition time that

you have previously defined (see Setting the Autorange Acquisition

Time on page 42). It will also evaluate the fiber type and length and

set the acquisition parameters accordingly.

You can use the same distance range, pulse width and acquisition time

parameters for testing at all wavelengths on a multiwavelength OTDR.

IMPORTANT

To test using the high-resolution feature, the acquisition time must

be of at least 15 seconds.

46 FTB-7000 Series

Page 61

Testing Fibers in Advanced Mode

Parameters setting dials

Selection

marker

Setting Distance Range, Pulse Width, and Acquisition Time

To set the parameters:

From the OTDR tab:

³ Press the dial corresponding to the parameter you wish to set (the

selection marker will move clockwise) or use the selection dial located

on the front of the unit.

OR

³ Press directly the value to select it. The selection marker will go to that

value immediately.

If you want the application to provide automatic acquisition values, move

at least one dial to the Auto position. The other dials are automatically set

accordingly.

Note: If your OTDR supports singlemode, singlemode live, or multimode

wavelengths, settings would be applied to either singlemode, singlemode

live, or multimode wavelengths, depending on the selected fiber type

(same settings for 50 μm and 62.5 μm).

OTDR 47

Page 62

Testing Fibers in Advanced Mode

Setting Distance Range, Pulse Width, and Acquisition Time

To use the same pulse and acquisition time for all wavelengths: