Page 1

FTB-610

Advanced WB Copper Test Module

User Guide

Page 2

Copyright Information

Copyright Information

Copyright © 2012–2014 EXFO Inc. All rights reserved. No part of this

publication may be reproduced, stored in a retrieval system or transmitted

in any form, be it electronically, mechanically, or by any other means such

as photocopying, recording or otherwise, without the prior written

permission of EXFO Inc. (EXFO).

Information provided by EXFO is believed to be accurate and reliable.

However, no responsibility is assumed by EXFO for its use nor for any

infringements of patents or other rights of third parties that may result from

its use. No license is granted by implication or otherwise under any patent

rights of EXFO.

EXFO’s Commerce And Government Entities (CAGE) code under the North

Atlantic Treaty Organization (NATO) is 0L8C3.

The information contained in this publication is subject to change without

notice.

Trademarks

EXFO’s trademarks have been identified as such. However, the presence

or absence of such identification does not affect the legal status of any

trademark.

Units of Measurement

Units of measurement in this publication conform to SI standards and

practices.

September 12, 2014

Version number: 6.0.0

ii FTB-610

Page 3

Contents

Copyright Information ............................................................................................................ii

Certification Information ......................................................................................................vii

1 Introducing the FTB-610 Advanced WB Copper Test Module .................... 1

Key Features and Benefits .......................................................................................................1

Typical Applications ................................................................................................................2

Software Options ....................................................................................................................3

Conventions ............................................................................................................................4

2 Safety Information ....................................................................................... 5

Electrical Safety Information ...................................................................................................6

Equipment Ratings .................................................................................................................7

3 Getting Started ............................................................................................ 9

Starting Module Application ...................................................................................................9

Cable Connections ................................................................................................................10

Inserting and Removing Test Modules ................................................................................12

Performing FTB-1 Software Updates .....................................................................................17

Usual Tab Elements ...............................................................................................................18

4 Advanced WB Copper Application ............................................................ 21

Using the Graphical User Interface .......................................................................................21

Main Window .......................................................................................................................21

Status Bar .............................................................................................................................22

Title Bar ................................................................................................................................23

Test Information and Control ................................................................................................23

Main Menu ...........................................................................................................................23

Application buttons ..............................................................................................................24

5 Copper Tests: Using the Main Menu ......................................................... 27

Start/Stop Button ..................................................................................................................27

Cable Book ...........................................................................................................................28

Phone Book ..........................................................................................................................36

Dialer ....................................................................................................................................46

Config/Profile ........................................................................................................................50

Application Settings .............................................................................................................66

Factory Default .....................................................................................................................73

Save Test ...............................................................................................................................74

Copper Test iii

Page 4

6 Reading and Exporting Saved Results .......................................................79

Result File .............................................................................................................................79

Reading the Result File ..........................................................................................................80

Export Results .......................................................................................................................87

7 Pair Detective Test ......................................................................................89

Pair Detective ........................................................................................................................89

Multimeter ............................................................................................................................96

TDR .......................................................................................................................................97

Summary ..............................................................................................................................98

8 Auto Test ......................................................................................................99

POTS Auto Test .....................................................................................................................99

Summary ............................................................................................................................104

User Auto Test .....................................................................................................................105

Summary ............................................................................................................................113

9 FaultMapper Test ......................................................................................115

FaultMapper .......................................................................................................................115

TDR .....................................................................................................................................120

Summary ............................................................................................................................121

10 Multimeter Tests .......................................................................................123

Multimeter Main Page ........................................................................................................124

Voltage Test ........................................................................................................................125

Current Test ........................................................................................................................134

Resistance Test ....................................................................................................................143

Capacitance/Opens Test ......................................................................................................150

Resistive Balance Test ..........................................................................................................157

Balance Test ........................................................................................................................161

11 Multimeter 2 Tests ....................................................................................169

Multimeter 2 Main Page .....................................................................................................169

Isolation Test .......................................................................................................................170

Locator Tone Test ................................................................................................................176

Load Coils Test ....................................................................................................................179

Station Ground ...................................................................................................................182

12 TDR Test .....................................................................................................187

Auto TDR ............................................................................................................................188

Manual TDR ........................................................................................................................191

Xtalk TDR ............................................................................................................................199

Summary ............................................................................................................................202

iv FTB-610

Page 5

13 RFL Test ..................................................................................................... 203

RFL-2-Wire ...........................................................................................................................203

RFL-4-Wire ...........................................................................................................................206

RFL-K-Test ............................................................................................................................209

Setting Cable Parameters ....................................................................................................212

Summary ............................................................................................................................214

14 Signal Test ................................................................................................. 215

Signal Main Page ................................................................................................................215

WB Balance Test ..................................................................................................................216

WB Attenuation Test ...........................................................................................................222

TX/RX Tone Test ...................................................................................................................228

15 Noise Tests ................................................................................................ 235

Noise Main Page .................................................................................................................235

VF Noise Test .......................................................................................................................236

Power Influence Test ...........................................................................................................241

WB PSD Noise Test ..............................................................................................................246

NEXT ...................................................................................................................................254

16 Impulse Tests ............................................................................................ 263

Impulse Main Page .............................................................................................................263

VF Impulse Noise Test .........................................................................................................265

WB Impulse Noise Test ........................................................................................................269

Impulse Scope Test ..............................................................................................................275

Impulse Duration ................................................................................................................282

17 Test Lead Compensation .......................................................................... 289

Summary ............................................................................................................................290

18 Copper Tests: Result Summary ................................................................ 291

Summary ............................................................................................................................291

19 Maintenance ............................................................................................. 293

Recalibrating the Unit .........................................................................................................294

Recycling and Disposal (Applies to European Union Only) ..................................................295

20 Troubleshooting ....................................................................................... 297

Solving Common Problems .................................................................................................297

Contacting the Technical Support Group ............................................................................299

Transportation ....................................................................................................................300

Copper Test v

Page 6

21 Warranty ....................................................................................................301

General Information ...........................................................................................................301

Liability ...............................................................................................................................302

Exclusions ...........................................................................................................................303

Certification ........................................................................................................................303

Service and Repairs .............................................................................................................304

EXFO Service Centers Worldwide ........................................................................................305

A Technical Specifications ............................................................................307

Index ...............................................................................................................313

vi FTB-610

Page 7

Certification Information

Certification Information

North America Regulatory Statement

This unit was certified by an agency approved in both Canada and the

United States of America. It has been evaluated according to applicable

North American approved standards for product safety for use in Canada

and the United States.

Electronic test and measurement equipment is exempt from FCC part 15,

subpart B compliance in the United States of America and from ICES-003

compliance in Canada. However, EXFO Inc. makes reasonable efforts to

ensure compliance to the applicable standards.

The limits set by these standards are designed to provide reasonable

protection against harmful interference when the equipment is operated in

a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance

with the user guide, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely

to cause harmful interference in which case the user will be required to

correct the interference at his own expense.

Modifications not expressly approved by the manufacturer could void the

user's authority to operate the equipment.

Copper Test vii

Page 8

Certification Information

European Community Declaration of Conformity

An electronic version of the declaration of conformity for your product is

available on our website at www.exfo.com. Refer to the product’s page on

the Web site for details.

viii FTB-610

Page 9

1 Introducing the FTB-610

Advanced WB Copper Test

Module

The FTB-610 Advanced WB Copper Test Module is designed to qualify and

troubleshoot the copper-loop plant by using pass/fail-driven automated

functionality. The module provides a comprehensive offering of test

features such as Pair Detective, Auto Test, FaultMapper, Multimeter, TDR,

RFL, Signal, and Noise.

Key Features and Benefits

SmartR™ Automatic results analysis

High-voltage isolation testing

Wideband impulse noise scope/analysis

Ideal for FTTh repairs with platform built-in optical power meter

Copper Test 1

Page 10

Introducing the FTB-610 Advanced WB Copper Test Module

Typi c a l A pp licat i o ns

Typical Applications

Perfect for troubleshooting fiber-to-the-cab service

Complete suite of manual and automated advanced metallic tests

30 MHz wideband spectrum analysis

High-power isolation for finding resistive faults and insulation failures

Leverages FTB-1 platform connectivity to capture and upload results

Wideband impulse noise analysis

2 FTB-610

Page 11

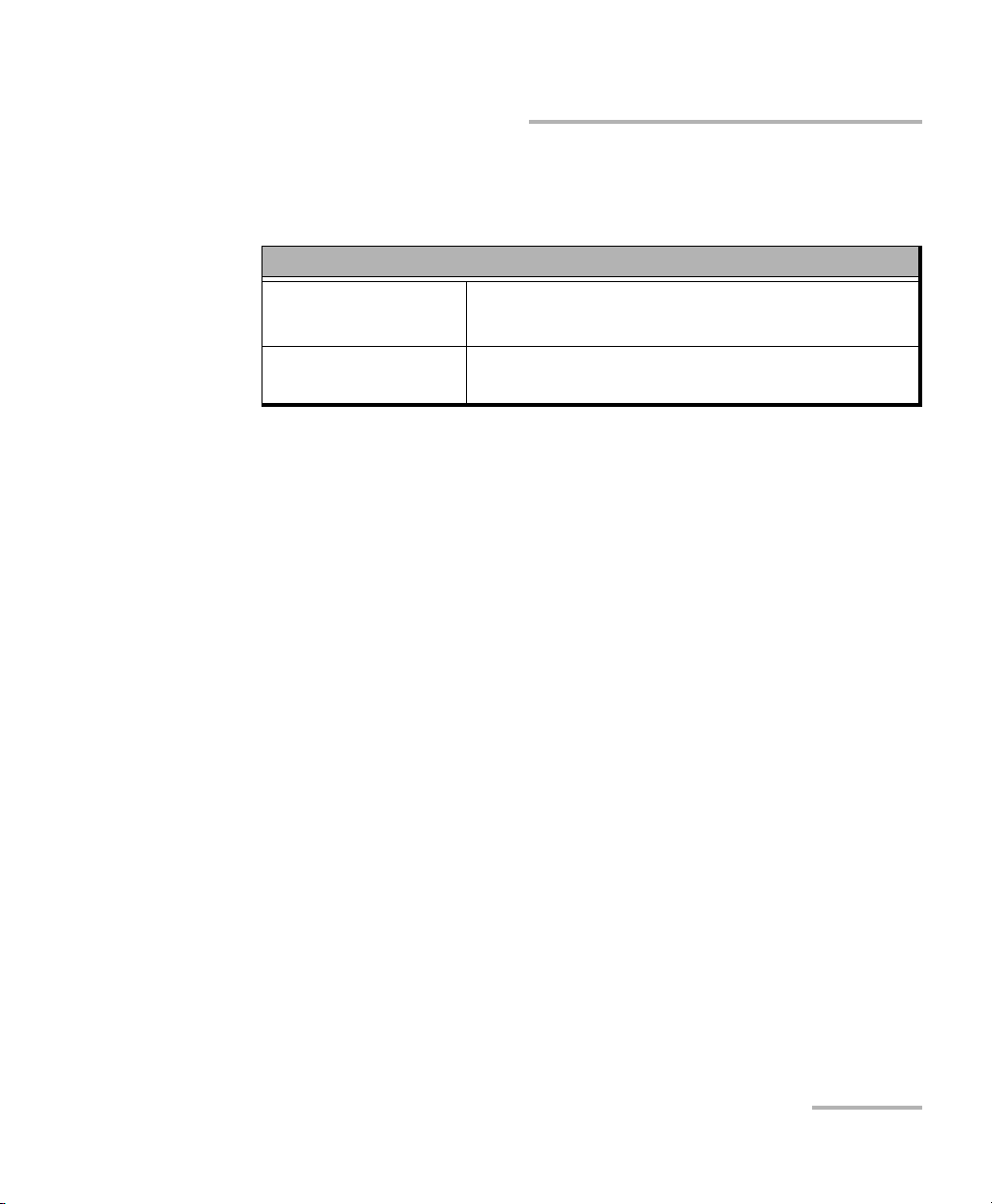

Introducing the FTB-610 Advanced WB Copper Test Module

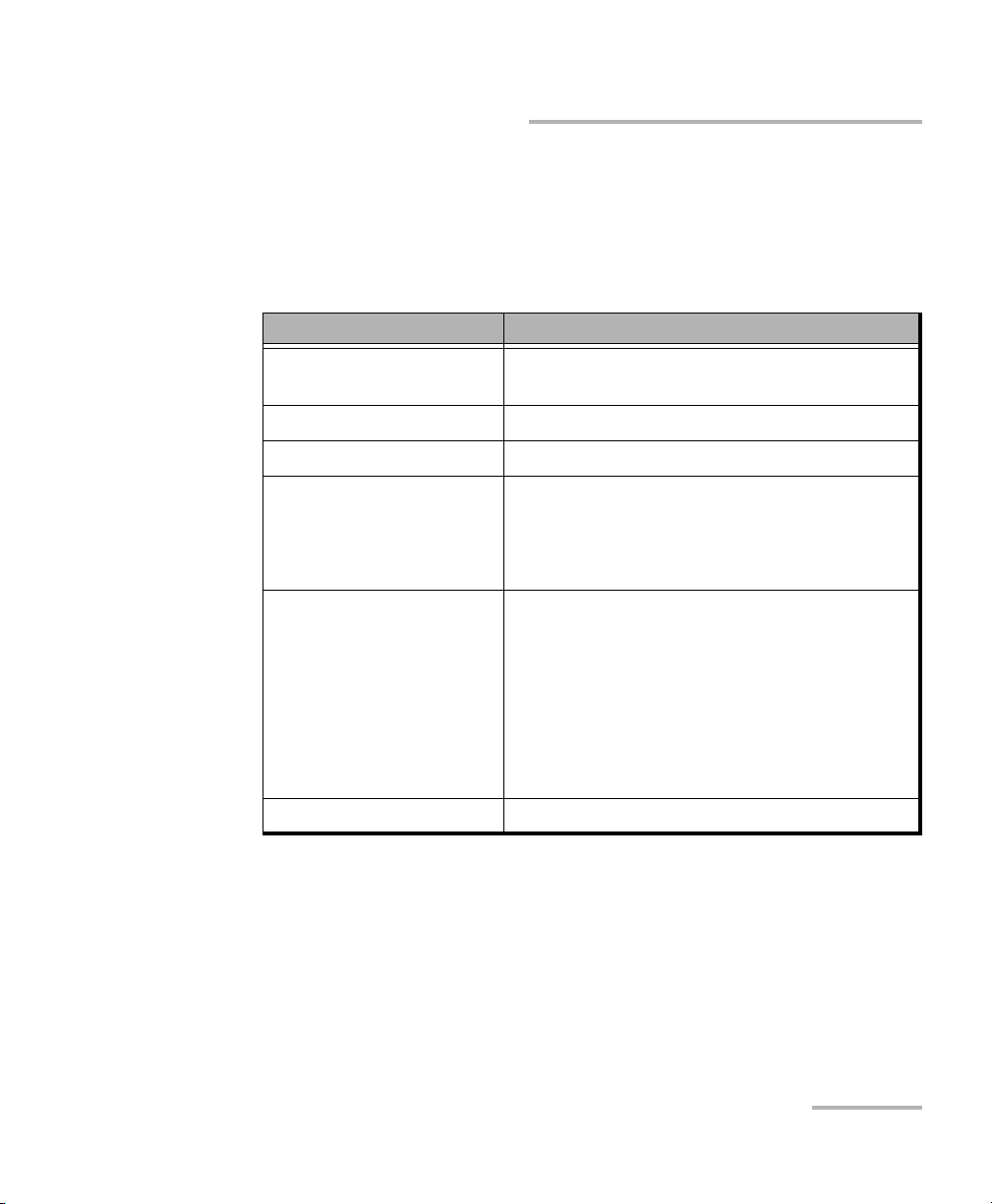

Software Options

Software Options

Software keys are available to enable additional services. For information

on how to install and activate software options, refer to the FTB-1 User

Guide.

Options Description

SmartR Enables Pair Detective and FaultMapper tests;

both include TDR.

RFL Enables support for RFL test.

TDR Enables support for TDR test.

WBAND

Enables support for WB Balance and WB

Attenuation from Signal test.

Enables support for WB PSD Noise and

WB Impulse Noise from Noise Test.

HIVOLT If this software option is activated, the

following options is added for Soak Voltage

parameter under Isolation test.

250 V

300 V

400 V

500 V

NEXT Enables Near End Crosstalk.

Note: These options are also available as EXFO Connect floating options.

Copper Test 3

Page 12

Introducing the FTB-610 Advanced WB Copper Test Module

Conventions

Conventions

Before using the product described in this guide, you should understand

the following conventions:

WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in component damage. Do not proceed unless you

understand and meet the required conditions.

IMPORTANT

Refers to information about this product you should not overlook.

4 FTB-610

Page 13

2 Safety Information

WARNING

The use of controls, adjustments and procedures other than those

specified herein may result in exposure to hazardous situations or

impair the protection provided by this unit.

IMPORTANT

When you see the following symbol on your unit , make sure

that you refer to the instructions provided in your user

documentation. Ensure that you understand and meet the required

conditions before using your product.

IMPORTANT

Other safety instructions relevant for your product are located

throughout this documentation, depending on the action to

perform. Make sure to read them carefully when they apply to your

situation.

WARNING

Use only accessories that meet EXFO specifications.

Copper Test 5

Page 14

Safety Information

Electrical Safety Information

Electrical Safety Information

If you need to ensure that the unit is completely turned off, disconnect the

power cable and remove the batteries.

Use the external power supply indoors only.

Position the unit so that the air can circulate freely around it.

Operation of any electrical instrument around flammable gases

or fumes constitutes a major safety hazard.

To avoid electrical shock, do not operate the unit if any part of

the outer surface (covers, panels, etc.) is damaged.

Only authorized personnel should carry out adjustments,

maintenance or repair of opened units under voltage. A person

qualified in first aid must also be present. Do not replace any

components while power cable and battery are connected.

WARNING

Capacitors inside the unit may be charged even if the unit has

been disconnected from its electrical supply.

Use only the AC adapter/charger provided by EXFO with your

unit.

6 FTB-610

Page 15

Equipment Ratings

Equipment Ratings

Tem pe rat ur e

Operation 0 °C to 40 °C (32 °F to 104 °F)

Safety Information

Equipment Ratings

Maximum operation

3000 m (9842 ft)

altitude

For more information on product safety and equipment ratings, refer to the

user documentation of your platform.

Copper Test 7

Page 16

Page 17

3 Getting Started

The Copper Test application is pre-installed on the FTB-1. If the module is

not already installed, refer to the FTB-1 User Guide for more information on

how to install the application.

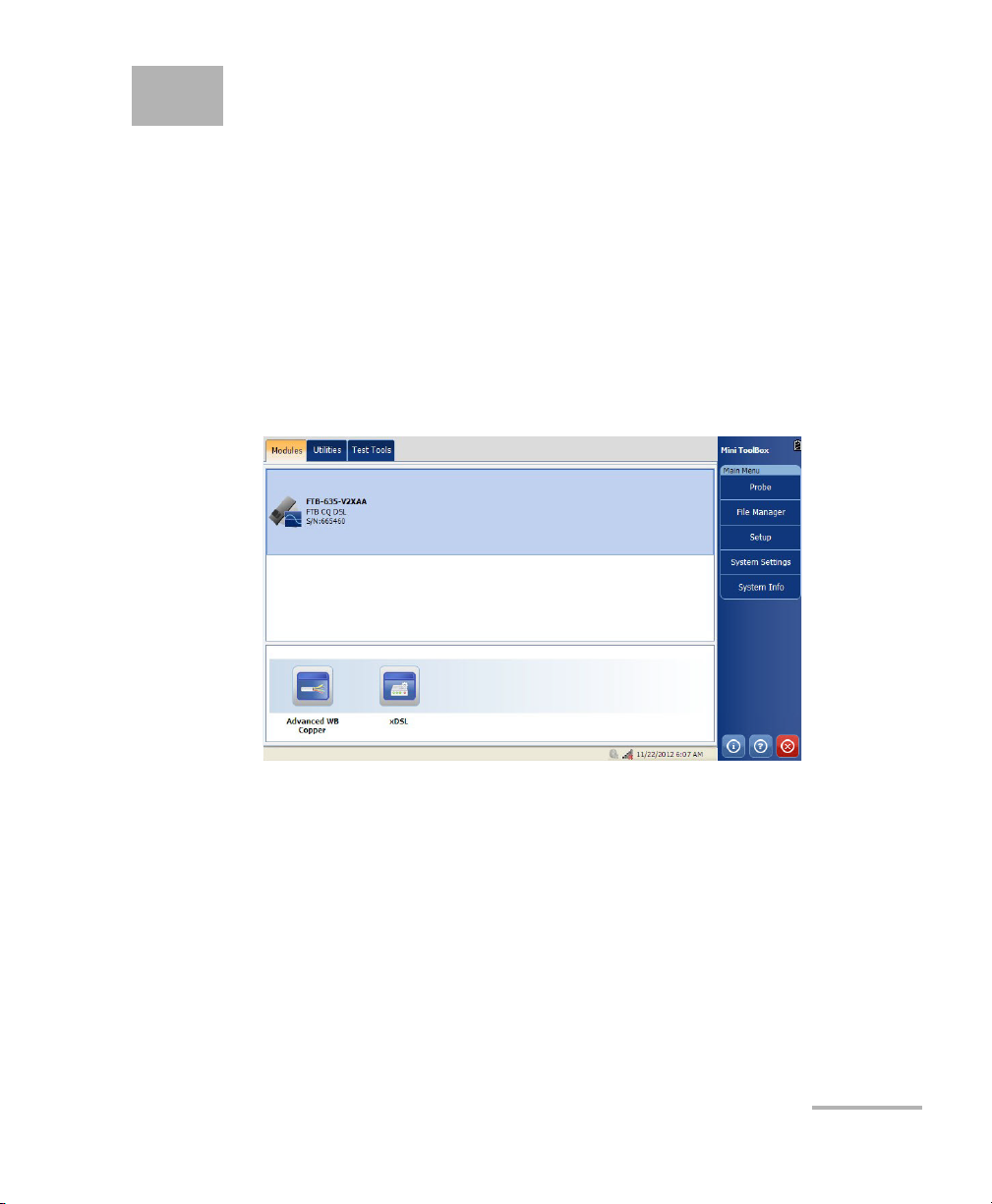

Starting Module Application

The module can be configured and controlled by starting the Wideband

Copper application.

To start the copper test application:

From the Mini Toolbox, tap the Advanced WB Copper icon.

Copper Test 9

Page 18

Getting Started

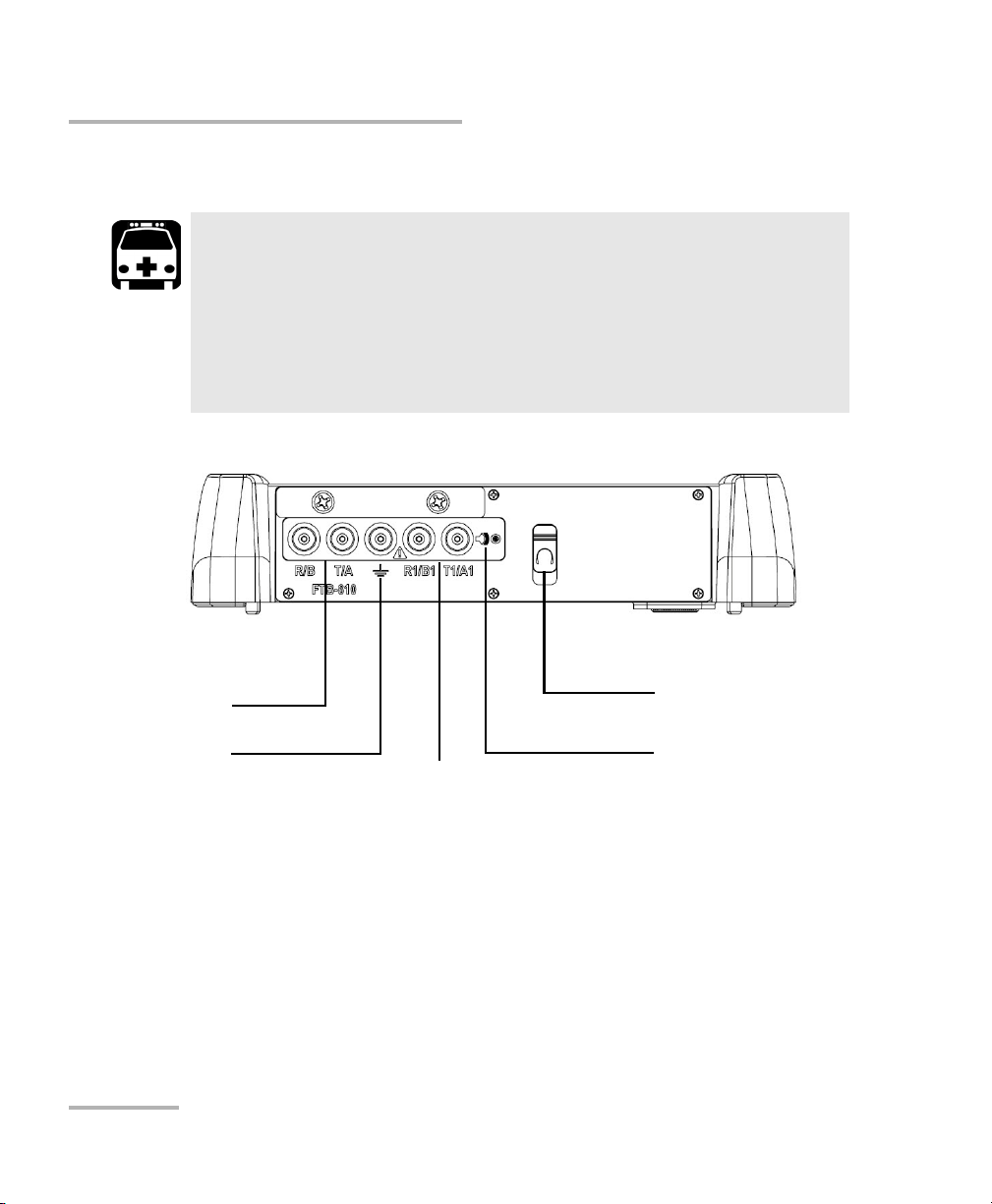

Primary tip/ring (A/B)

connectors

Ground (Earth)

terminal

Secondary tip/ring (A/B)

connectors

Headset

POTS Speaker

Cable Connections

Cable Connections

These connections are intended for the express purpose of electrical

testing of common telephone line conductors, within the ranges

specified in the Technical Specifications on page 307. The device is

not intended to be used on telephone lines having voltages greater

than 280 VAC or 400 VDC, and it is also not intended to be used on

power distribution circuits.

WARNING

10 FTB-610

Page 19

Getting Started

Shield of phone

line

Secondary Ring/B

wire of phone

line

Secondary Tip/A

wire of phone

line

Primary Ring/B wire of phone line

Primary Tip/A wire of phone line

Cable Connections

WARNING

A 50/100/125/500 Vcc limited power source may be present on connector R/T/R1/T1 when the unit is testing isolation resistance. Use

with caution.

The unit is protected against damage caused by fault voltages that

may be present on lines under test. Do not connect the unit if the

maximum expected fault voltage is greater than 500 volts.

Copper Test 11

CAUTION

Page 20

Getting Started

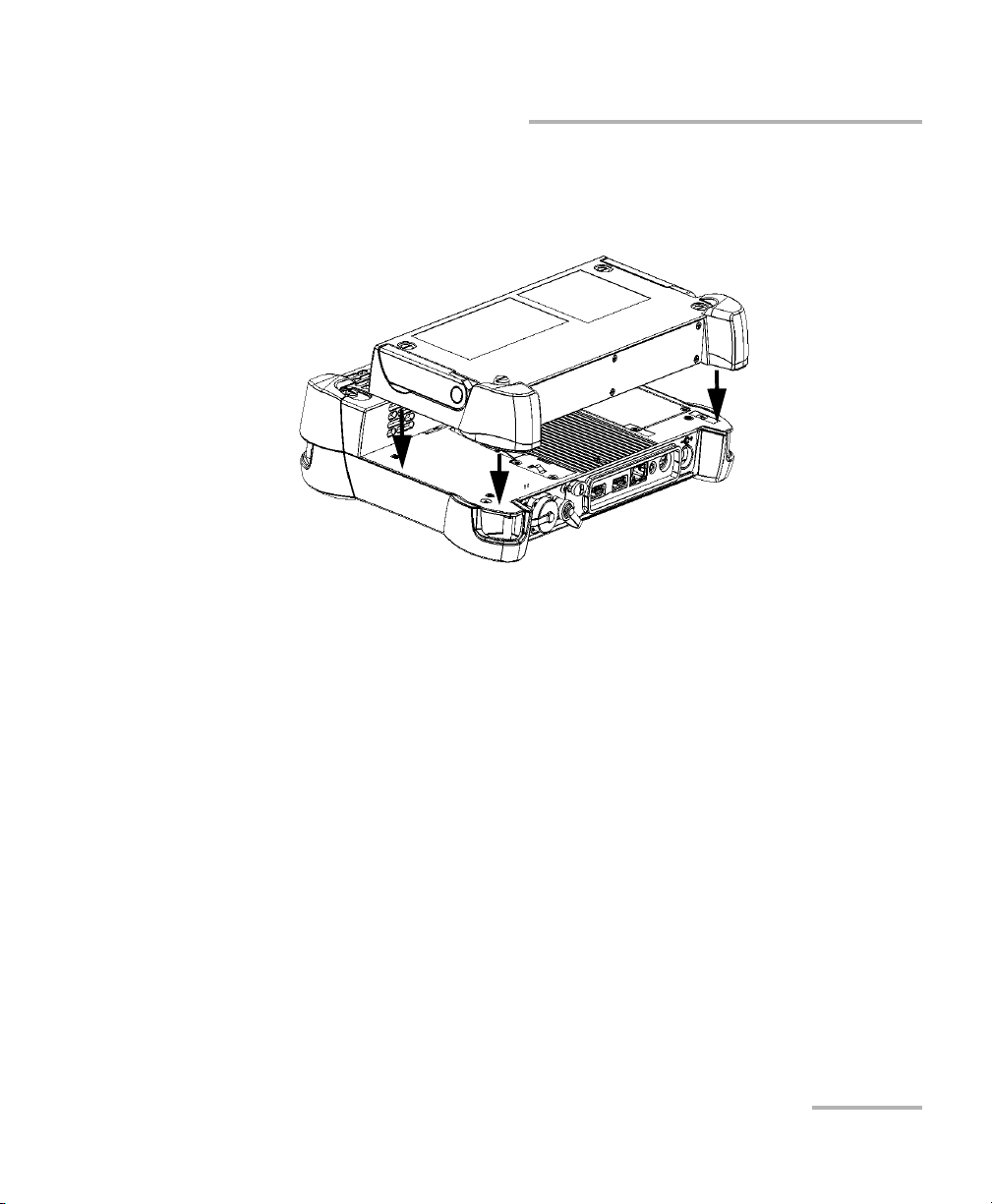

Inserting and Removing Test Modules

Inserting and Removing Test Modules

Never insert or remove a module while the FTB-1 is turned on. This

will result in immediate and irreparable damage to both the

module and unit.

To avoid damaging your unit, use it only with modules approved by

EXFO.

To insert a module into the FTB-1:

1. Turn off your unit (shutdown, not hibernate or standby).

2. Position the unit so that its front panel rests on a flat surface such as a

table.

CAUTION

CAUTION

12 FTB-610

Page 21

Getting Started

Inserting and Removing Test Modules

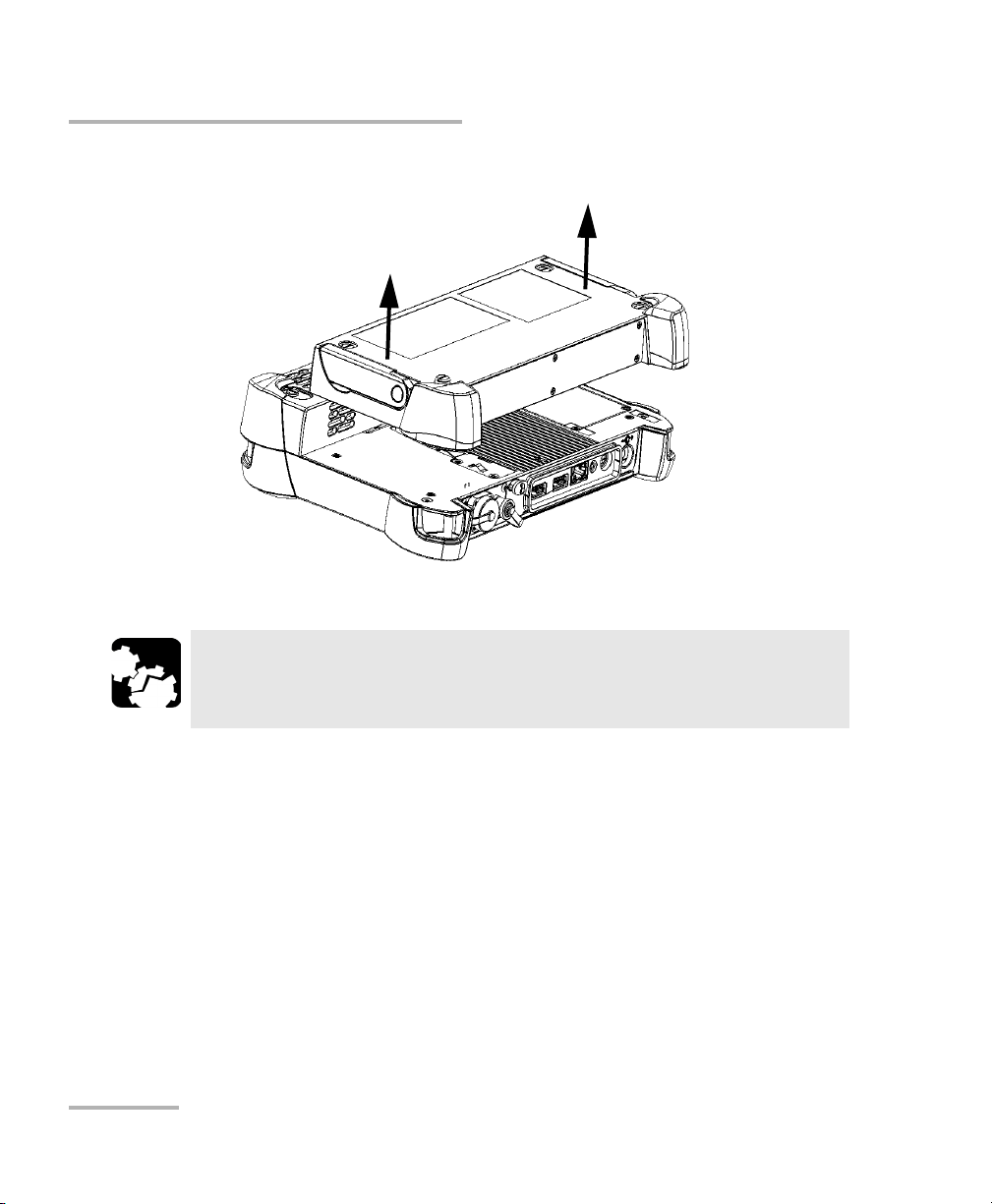

Place the module on the platform making sure that the bumpers and the

shorter sides of the module are flush with those of the platform. If

necessary, slightly move the module until alignment is correct.

Copper Test 13

Page 22

Getting Started

Turn screws

clockwise

Back panel

Inserting and Removing Test Modules

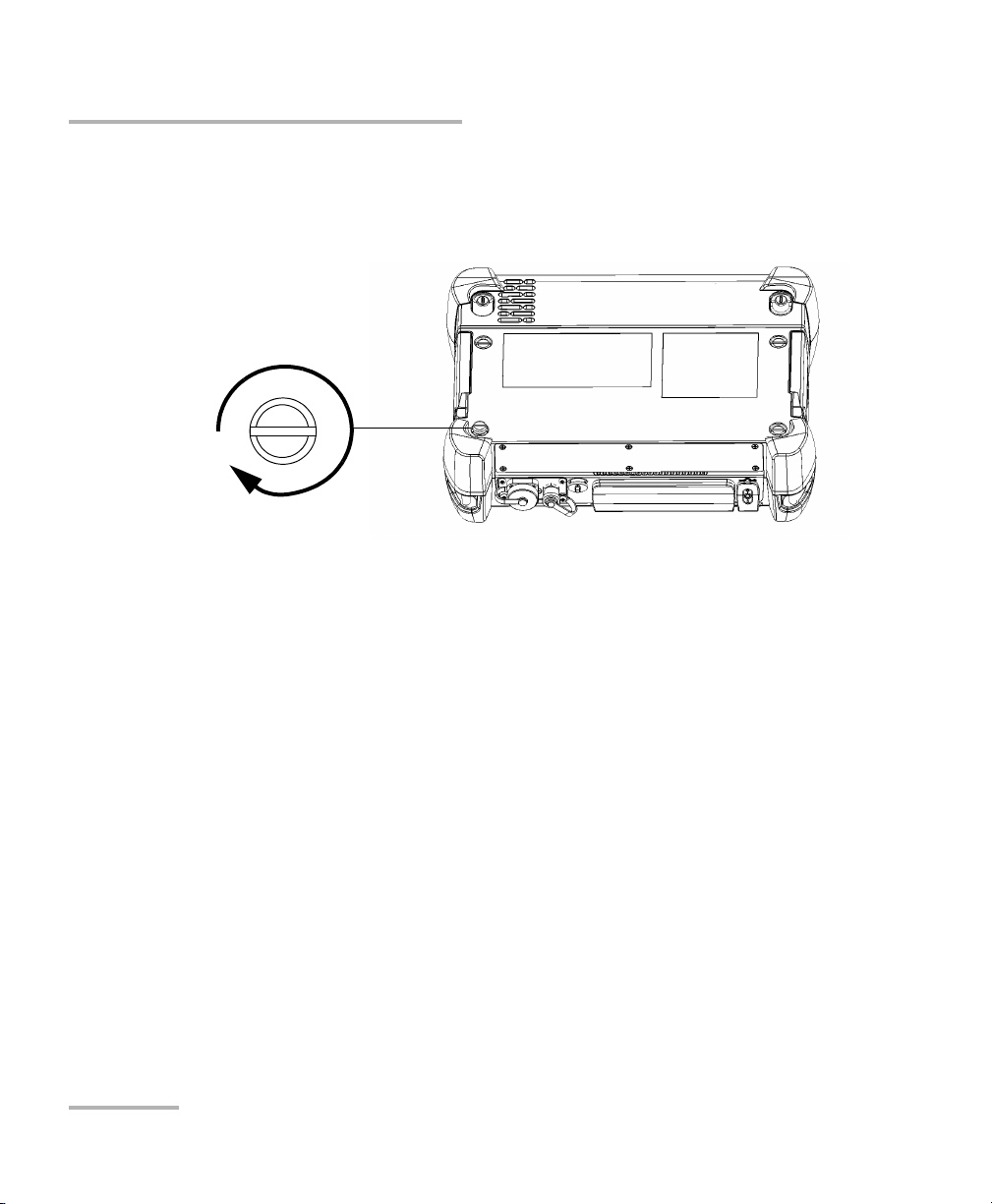

3. Using a flat screwdriver, turn the screws (4) clockwise until they are

tightened.

This will secure the module into its “seated” position.

When you turn on the unit, the startup sequence will automatically detect

the module.

14 FTB-610

Page 23

Getting Started

Turn screws

counterclockwise

Back panel

Inserting and Removing Test Modules

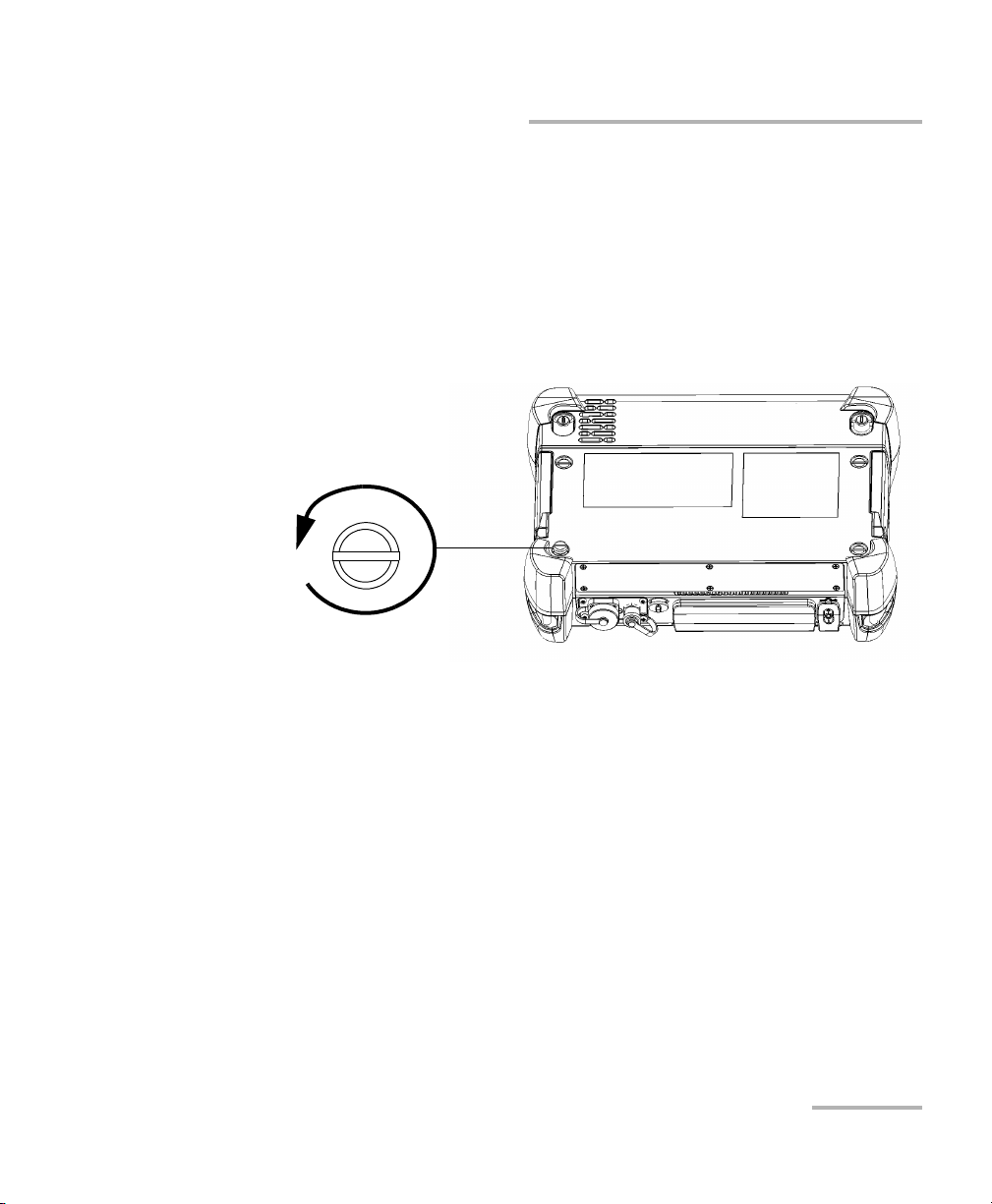

To remove a module from the FTB-1:

1. Turn off your unit (Shutdown).

2. Position the unit so that its front panel rests on a flat surface such as a

table.

3. Using a flat screwdriver, turn the screws (4) counterclockwise until

they are loose. Since they are captive screws, you cannot remove them

completely.

Copper Test 15

Page 24

Getting Started

Inserting and Removing Test Modules

4. Hold the module by its sides (NOT by the connectors) and pull it up.

CAUTION

Pulling a module by its connectors could seriously damage both the

module and connector. Always pull a module by its casing.

16 FTB-610

Page 25

Getting Started

Performing FTB-1 Software Updates

Performing FTB-1 Software Updates

The FTB-1 software updates can only be performed by a Supervisor, since

only Supervisors are given administrative rights (upon FTB-1 login). Since

administrative rights are required in order to use Update Manager, persons

logging in as an Operator will not have access to Update Manager.

After completing the FTB-1 software update using Update Manager, the

Supervisor should always run the newly installed application. The reason

for this is that some updates may require a module firmware update, and

only a Supervisor has the administrative rights to allow this update to

proceed. If a module firmware update is required, but is not performed by

the Supervisor (that is, by running the application), then when an Operator

attempts to start the application the following message is displayed:

Module firmware update required. Please login as Administrator.

The above message may also be displayed if an Operator replaces the

FTB-1 module with a module from another FTB-1 that does not have the

required module firmware. For both cases the Operator will only have

access to the application if a Supervisor logs into the FTB-1 and completes

the installation of the module firmware.

Copper Test 17

Page 26

Getting Started

Usual Tab Elements

Usual Tab Elements

While configuring tests or consulting results, different tabs and buttons

allow you to navigate within the application.

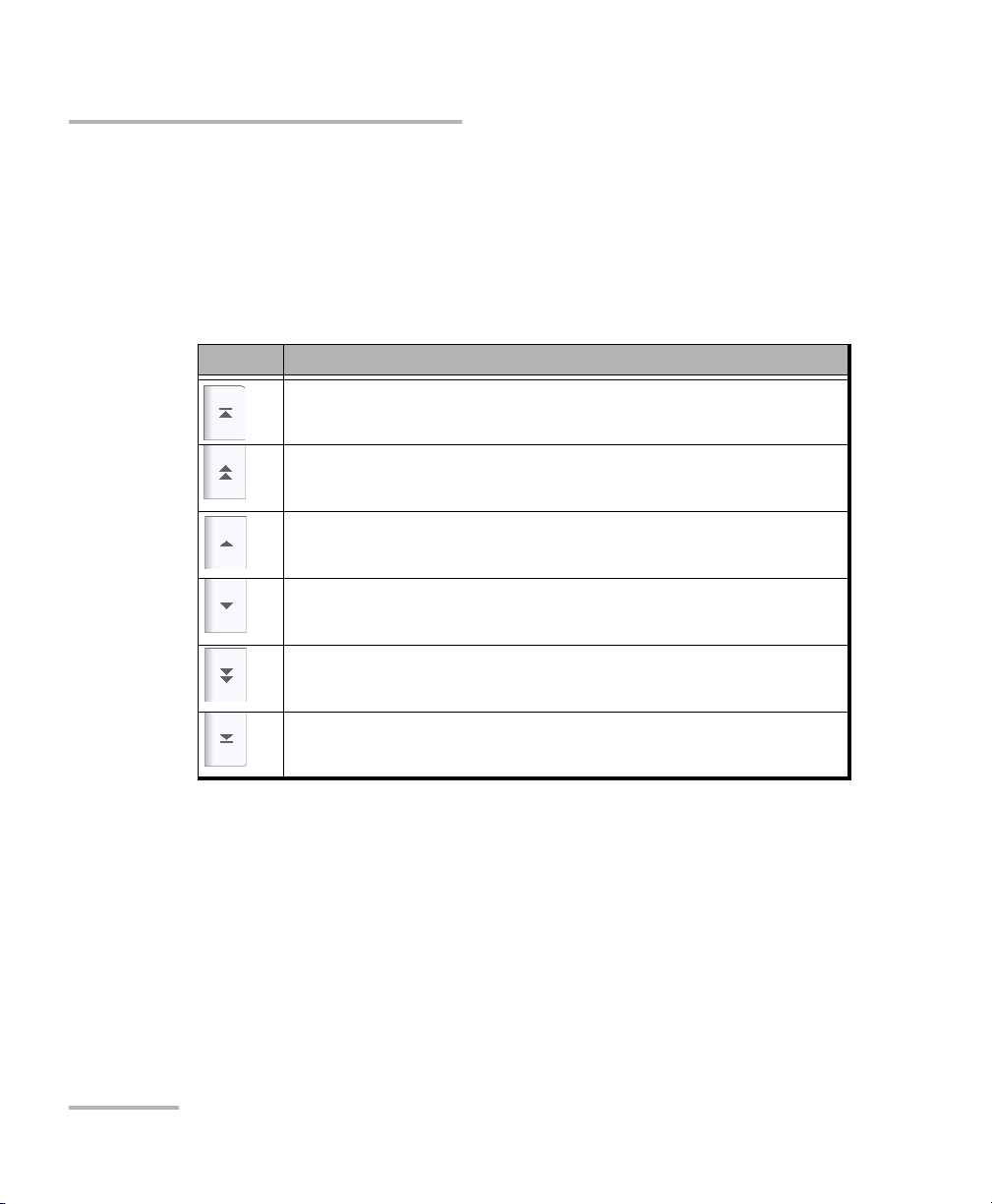

Arrow Buttons

Button Description

Moves to the top of the list.

Moves one page up.

Moves one line up.

Moves one line down.

Moves one page down.

Moves to the end of the list.

18 FTB-610

Page 27

Graph Controls

Button Description

Arrow enables cursor mode (move a vertical cursor to get

precise information about the plot along the x-axis).

Hand is used to pan around the graph.

Used to draw a zoom box to select an area on the graph.

Resets the graph to original size (full view).

Zoom in.

Zoom out.

Getting Started

Usual Tab Elements

Pause is used in the TDR test to hold the current TDR on screen

for comparison to a new live trace.

Mask is used in the WB PSD test to cycle through the selection

of available masks; a long press reverses direction of cycle.

Toggle is used in the Impulse Scope test to switch between the

main and insert graphs on the page.

Copper Test 19

Page 28

Page 29

4 Advanced WB Copper

Title Bar

Main Menu

Main

Window

Status Bar

Application

Button

Te st

Information

and Control

Application

Using the Graphical User Interface

This chapter describes the graphical user interface of the Copper tests

application.

The graphical user interface allows you to configure and start the Copper

tests, view results and statistics, and other information related to the

FTB-610. The application user interface contains:

Main Window

Status Bar

Title Bar

Test M e nu

Application Buttons

Main Window

The main window allows you to view the first and second level tabs for test

groups, the tests within groups, and results as applicable.

Copper Test 21

Page 30

Advanced WB Copper Application

Navigation Path

Test Status

Date and Time

Status Bar

Test Grou ps

The Copper application provides you the following Te st Gr o ups:

Pair Detective

Auto Test

FaultMapper

Multimeter

Multimeter 2

TDR

RFL

Signal

Noise

Impulse

Test Lead Compensation

Tests

The Test s section of the main window displays the selected test or its

sub-tests.

Status Bar

The Status Bar displays the navigation path of the test, date, and time.

22 FTB-610

Page 31

Advanced WB Copper Application

Title Bar

The Title Bar displays the software application name and the battery level

indicator.

Test Information and Control

Yo ur Copper application allows you to view the global indicator, Start/Stop

any test or tool, use control buttons, and use the main menu to setup

tests/tools and view test results.

Start/Stop button: for more details, see Start/Stop Button on page 27.

Application Settings: for more details, see Application Settings on

page 66.

The Buzzer icon is a shortcut for Buzzer tab under Application

settings. For more details, see Buzzer on page 72.

The TDR icon is a shortcut for the TDR test which is activated for

Load Coils, Pair Detective and FaultMapper tests. For more details, see

TDR Test on page 187.

Title Bar

Main Menu

The Main Menu displays the Setup and Result button. Setup allows you to

configure a test or tool, and the Result button allows you to view respective

test results.

Copper Test 23

Page 32

Advanced WB Copper Application

Application buttons

Application buttons

Help Button

The help button displays the help information related to the tab. It is

also possible to navigate through the remainder of the help information.

About Button

You can view the product version details and technical support information

in this window.

To view the information about the product:

1. From the main window, tap .

24 FTB-610

Page 33

Advanced WB Copper Application

Application buttons

2. Ta p Information to view further details about the product, software,

and memory installed on the device.

2a. You can view the complete versioning information by

double-tapping on the Version value.

2b. Double-tap the Version value again to return to the original value.

Copper Test 25

Page 34

Advanced WB Copper Application

Application buttons

3. Ta p View License Agreement to view further details about using the

product and software.

Exit Button

The Exit button closes the application.

26 FTB-610

Page 35

5 Copper Tests: Using the Main

Menu

The FTB-610 is designed to test twisted pair quality, identify and locate

faults, and troubleshoot noise and signal issues. These measurements offer

a quick and thorough method to determine if the cable is capable of

supporting xDSL technology.

Start/Stop Button

The Start/Stop button allows you to start and stop a test. The button text

changes depending on the action performed (toggle button).

Start: when the test is not running.

Stop: when the test is running.

Copper Test 27

Page 36

Copper Tests: Using the Main Menu

Cable Book

Cable Book

The Cable Book menu presents a selection of functions which allow you to

manage the groups of cables relevant to performing the copper tests. The

Cable Book menu allows you to load, add, clone, and delete a cable, as

well as modify its details.

To access Cable Book:

From the Copper Main Menu, select Cable Book

.

28 FTB-610

Page 37

Copper Tests: Using the Main Menu

Cable Book

Load Cable

The page lists entries by Cable ID and Cable Name. There is 1 group of 10

factory default entries which cannot be edited or deleted. The Cable Book

can include a maximum of 50 groups.

To load a cable:

1. From the Main Menu, tap Cable Book.

2. From the Cable Management tab, select the cable that you want to

load.

3. Ta p Load Cable button to load the group/entry.

Copper Test 29

Page 38

Copper Tests: Using the Main Menu

Cable Book

Cable Details

The Cable Details page allows you to view the cable parameter details of

the currently highlighted cable entry.

To view/modify cable details:

1. From the Main Menu, tap Cable Book.

2. From the Cable Management tab, select the cable for which you want

to view details.

3. Select the Cable Details tab to view the details.

4. Ta p Close to exit from the page.

The page displays the following parameters:

Cable ID displays the cable ID number.

Cable Name is the name of the cable in the Cable Book.

Cable Gauge is the gauge system for measuring wire sizes in AWG

(American Wire Gauge) units or mm (metric wire size).

Cable Fill Material is the type of material the cable is filled with:

Aircore, Jelly, Pulp, 5 PR, or 2 PR. The selection influences the cable

capacitance per length, automatically updating the Cap. T/R to GND

field.

30 FTB-610

Page 39

Copper Tests: Using the Main Menu

Cable Book

Capacitance T-R specifies a value for the capacitance per length

constant.

Capacitance T/R to GND specifies a value for the capacitance per

length to ground constant.

Resistance specifies a value for the resistance constant of the cable.

Attenuation @ 300 kHz specifies a value for the reduction in signal

strength or insertion loss of the cable.

Velocity of propagation for the cable as a ratio of the speed of light.

Tem pe ra tu re specifies the temperature of reference at which all cable

parameters have been measured, in either F (Fahrenheit) or C

(Celsius) units. The measurement units are updated based on the

Tem pe ra tu re settings in the Application Settings, General on page 66.

Copper Test 31

Page 40

Copper Tests: Using the Main Menu

Cable Book

Add Cable

The Add Cable page allows you to add a new cable entry into the Cable

Book using the following parameters for the currently highlighted Cable

ID.

To add a Cable:

1. From the Main Menu, tap Cable Book.

2. Select the Cable Management tab and tap Add Cable.

The Add Cable dialog opens.

The page allows you to set the following parameters:

Cable ID displays the cable ID number. This parameter cannot be

modified.

Cable Name is displayed in the Cable Book.

Cable Gauge allows you to enter the Cable Gauge. This is the gauge

system for measuring wire sizes in AWG (American Wire Gauge) units

or mm (metric wire size).

32 FTB-610

Page 41

Copper Tests: Using the Main Menu

Cable Book

Cable Fill Material allows you to select the type of material the cable

can be filled with. Changing the selection to Aircore, Jelly, Pulp 5 PR,

or 2 PR influences the cable capacitance per length, automatically

updates the Capacitance T/R to GND field.

Capacitance T-R allows you to specify a value for the capacitance per

length constant.

Capacitance T/R to GND allows you to specify a value for the

capacitance per length to ground constant.

Resistance allows you specify a value for the resistance constant of the

cable.

Attenuation @ 300 kHz allows you to specify a value for the reduction

in signal strength or insertion loss of the cable.

Velocity of propagation allows you to set the velocity of propagation

for the cable as a ratio of the speed of light.

Temperature allows you to specify the temperature of reference at

which all cable parameters have been measured.

Add button, tap the Add button to append the new cable entry to the

end of the Cable Book. If the maximum number of Cable Book entries

has been reached, delete an entry before adding a new one.

Copper Test 33

Page 42

Copper Tests: Using the Main Menu

Cable Book

Clone Cable

The Clone Cable option allows you to copy the cable details of an existing

entry to a new cable entry in the Cable Book.

To clone a cable entry:

1. From the Main Menu, tap Cable Book.

2. From the Cable Management tab, select the cable ID that you want to

clone.

3. Ta p the Clone Cable button to copy the details of the highlighted entry

and append a new Cable ID to the list.

34 FTB-610

Page 43

Copper Tests: Using the Main Menu

Delete Cable

The Delete Cable page allows you to delete a cable entry from the Cable

Book. The page lists all entries, excluding the 10 factory default cable

entries, by Cable ID and Cable Name.

To delete a cable entry:

1. From the Main Menu, tap Cable Book.

2. Select the Cable Management tab and tap Delete Cable.

The Delete Cable dialog opens.

3. Select the cable ID that you want to delete.

Note: Check the Select All Cables to specify all cable IDs.

4. Ta p the Delete Cable button to remove the entry from the Cable Book.

If you try to delete a cable in use, a warning message pops-up.

Cable Book

Copper Test 35

Page 44

Copper Tests: Using the Main Menu

Phone Book

Phone Book

The Phone Book menu presents a selection of functions which allow you

to manage the groups of phone numbers relevant to performing the copper

tests. It can include a maximum of 50 groups of up to 3 individual entries

each.

To access Phone Book:

From the Copper Main Menu, select Phone Book

.

36 FTB-610

Page 45

Copper Tests: Using the Main Menu

Phone Book

Load Group/Entry

The page lists entries by Group ID and Entry Name/Type. There is 1 group

of 3 factory default entries which cannot be edited or deleted. The Phone

Book can include a maximum of 50 groups.

To load Group/Entry:

1. From the Main Menu, tap Phone Book.

2. From the Phone Book Management tab, select the group which you

want to load.

3. Ta p the Load Group/Entry button to load the group/entry.

Copper Test 37

Page 46

Copper Tests: Using the Main Menu

Phone Book

Phone Book Details

The Phone Book Details page allows you to view and modify the Phone

Book parameters of the currently highlighted phone entry. As well, you can

enable/disable entries 2 and 3 in each phone group. When creating a new

phone group, only entry 1 is enabled. Entries 2 and 3 remain disabled until

entry 1 is filled in.

To view/modify Phone Book details:

1. From the Main Menu, tap Phone Book.

2. From the Phone Book Management tab, select the group which you

want to load.

3. Select the Phone Book Details tab to view the details.

4. Ta p Close to exit from the page.

38 FTB-610

Page 47

Copper Tests: Using the Main Menu

Phone Book

The page displays the following parameters:

Group ID displays the group ID number. This is the only parameter that

cannot be modified however you can navigate between the available

phone groups.

Entry Name is the name of the entry in the Phone Book.

Phone Number is the 10-digit numeric phone number of the entry.

Typ e displays the following list of values:

Milliwatt tone

Drop battery

Quiet line

- (for additional line types)

Accept button validates and updates all the parameters of the Phone

Book.

Copper Test 39

Page 48

Copper Tests: Using the Main Menu

Phone Book

Add Group

The Add Group page allows you to add a new group entry into the Phone

Book using the following parameters for the currently highlighted Group

ID.

To Add Group:

1. From the Main Menu, tap Phone Book.

2. From the Phone Book Management tab, tap Add Group.

The page displays the following parameters:

Group ID displays the group ID number. This parameter that cannot be

modified.

Entry Name is the name of the entry in the Phone Book.

Phone Number is the 10-digit numeric phone number of the entry.

40 FTB-610

Page 49

Copper Tests: Using the Main Menu

Phone Book

Typ e displays the following list of values:

Milliwatt tone

Drop battery

Quiet line

- (for additional line types)

Add function key adds the new group entry to the Phone Book.

Clone Group

The Clone Group page allows you to copy the details of an existing entry to

a new group entry in the Phone Book. The page lists all entries by Group

ID.

The list can display a maximum of 50 entries.

To Clone Group:

1. From the Main Menu, tap Phone Book.

2. From the Phone Book Management tab, select the group you want to

clone.

3. Ta p Clone Group.

Copper Test 41

Page 50

Copper Tests: Using the Main Menu

Phone Book

Delete Group

The Delete Group page allows you to delete a group entry from the Phone

Book. The page lists all entries by Group ID.

To delete a group entry:

1. From the Main Menu, tap Phone Book.

2. From the Phone Book Management tab, select the group you want to

delete.

Note: Select the Select All Groups option to select all group IDs.

3. Ta p the Delete Group button to remove the entry from the Cable

Book. If you try to delete a group in use, a warning message pops-up.

42 FTB-610

Page 51

Copper Tests: Using the Main Menu

Phone Book

Load Phone Book

The Load Phone Book page allows you to import a phone book. The page

displays the file name and date of the last phone book loaded. Only .csv

files are supported.

To load Phone Book:

1. From the Main Menu, tap Phone Book.

2. Ta p the Load Phone Book button.

The Load Phone Book dialog opens.

3. Select the file name to load.

4. Ta p Load and confirm. The unit will remove the existing phone book

and replace it by the loaded one.

OR

5. Ta p Cancel to remove the message.

Copper Test 43

Page 52

Copper Tests: Using the Main Menu

Phone Book

The page displays the following parameters:

The File Storage Location lists the load destinations:

FTB-1 internal memory

Name of the USB Device (if attached)

File Name lists the phone book file name(s) to load.

Load button imports the selected phone book. You will be prompted

for confirmation since this action will overwrite the current phone

book.

Cancel button removes the confirmation/warning message without

impacting the phone book.

Save Phone Book

The Save Phone Book page allows you to save or export a phone book.

To Save Phone Book:

1. From the Main Menu, tap Phone Book.

2. From the Phone Book Management tab, tap the Save Phone Book

button.

The Save Phone Book dialog opens.

44 FTB-610

Page 53

Copper Tests: Using the Main Menu

Phone Book

The page displays the following parameters:

Enter File Name allows you to enter a file name of the current phone

book to save. By default, the name is phone_book.

Select File Storage Location lists the save destinations:

FTB-1 internal memory

Name of the USB Device (if attached)

Save button saves the selected file. Only .csv files are supported.

Note: The platform will overwrite any document with the same file name found

on the disk, without warning.

Copper Test 45

Page 54

Copper Tests: Using the Main Menu

Dialer

Dialer

The Dialer function provides a dial-up path from the module to another

tester (or quiet termination or silent switchman) through a switched circuit

network. DTMF transmission is enabled via the phone keypad allowing you

to place POTS calls. The dialer can be accessed from the Copper Main

Menu and is also integrated into individual test screens to give you quick

access to the manual dialer function, speed dial and last dialed lists,

without exiting the current test application.

The Dialer function allows you to use the unit as a telephone (with a

headset) and the on-screen phone keypad as a dialer when Enter Number

is invoked, whether in the test results screens or through the separate

dedicated Dialer application. An external speaker on top of the module

provides DTMF audio, while a headset jack also lets you connect a headset

and microphone.

To access the Dialer function:

From the Main Menu select Dialer.

46 FTB-610

Page 55

Copper Tests: Using the Main Menu

Dialer

The following functions can be accessed from this page:

Dialing Status shows the current status of the dialed number.

Enter Number displays the telephone number entered or selected

from the Recent Dialed Numbers list or Phone Book.

Recent button opens a list of recently dialed numbers for selection.

Select button allows you to select a number from the Phone Book.

Function Keys

Dial/Hang Up allows you to dial the selected or entered number,

or hang up the dialer.

Add saves the entered number to the Phone Book.

Mute Speaker changes the speaker status.

Volu me adjusts the volume level.

To dial a number:

1. Enter a new phone number using the on-screen or hard keypad, or

select an existing one from the phone book or recent dialed list.

2. Ta p the Dial button to start the call.

Enter Number

The Enter Number box is where you enter the phone number you wish to

dial.

To enter a phone number:

1. Enter the phone number.

2. Delete a character by moving the cursor to the left of the character and

tapping the Del button.

3. Ta p Dial button when you have completed entering a phone number.

Note: Alphabets on the key pad are for reference only. Tapping any of the buttons

will not show the alpha-character in the text box.

Copper Test 47

Page 56

Copper Tests: Using the Main Menu

Dialer

Recent Dialed Numbers

The Recent Dialed Numbers page lists a maximum of 25 recently dialed

telephone numbers which you can select to make your call.

To select a recently dialed number:

1. Ta p Recent button to open the Recent Dialed Numbers page.

2. Select the number.

3. Tap the OK button. The number is automatically entered in the Enter

Number field of the Dialer page.

Select from Phone Book

The Select Phone Book Entry page lists entries by Group ID and Entry

Name/Type. There is 1 group of 3 factory default entries which cannot be

edited or deleted. The Phone Book can include a maximum of 50 groups.

Group # in Use displays the group number in use.

To select a group and entry:

1. Ta p Select button to open the Select Phone Book Entry page.

2. Select the desired entry and tap OK. The Group # in Use is updated

with the current selection and automatically entered in the Enter

Number field of the Dialer page.

48 FTB-610

Page 57

Copper Tests: Using the Main Menu

Dialer

Add to Phone Book

The Add Phone Group page allows you to add a new group entry into the

Phone Book using the following parameters for the currently highlighted

Group ID.

Group ID displays the group ID number. This parameter that cannot be

modified.

Entry Name is the name of the entry in the Phone Book.

Phone Number is the 10-digit numeric phone number of the entry.

Typ e displays the following list of values:

Milliwatt tone

Drop battery

Quiet line

- (for additional line types)

Add button adds the new group entry to the Phone Book.

To add a number to the phone book:

1. Tap Add on the Dialer page.

2. Enter the required details.

3. Ta p the Add button to append the new group entry to the end of the

Phone Book. If the maximum number of Phone Book entries has

been reached, delete an entry before adding a new one.

Copper Test 49

Page 58

Copper Tests: Using the Main Menu

Config/Profile

Config/Profile

The Config/Profile menu presents a selection of functions, which allows

you to manage the profiles and view the profile details. The FTB-610

Advanced WB Copper Test Module supports several types of copper test

applications. Configuration parameters are saved into a test configuration

profile. A Profile Default is provided with a predefined set of parameters

for all test applications.

To access Config/Profile:

From the Copper Main Menu, select Config/Profile

.

50 FTB-610

Page 59

Copper Tests: Using the Main Menu

Config/Profile

Load

The Profile Management page lists the available profiles in the internal

memory, by Profile Name and Modification Date.

To load Profile:

1. From the Main Menu, tap Config/Profile.

2. From the Profile Management tab, select the profile which you want

to load.

3. Ta p the Load button to load the Profile.

Copper Test 51

Page 60

Copper Tests: Using the Main Menu

Config/Profile

Profile Details

You can view any of your saved profiles on the FTB-610 Advanced WB

Copper Test Module from the Profile Details menu by selecting the

desired test icon. An asterisk “*” on the currently Selected Profile name

indicates that modifications have been made to this profile in the threshold

settings or parameters of a particular test.

Each test displays a sub-menu of test icons to select and setup.

To view Profile details:

1. From the Main Menu, tap Config/Profile.

2. From the Profile Details tab, select the test for which you want to view

the details.

52 FTB-610

Page 61

Copper Tests: Using the Main Menu

The page displays the following tests:

Pair Detective

Auto Test

FaultMapper

Multimeter

Multimeter 2

TDR

Signal

Noise

Impulse

Config/Profile

Copper Test 53

Page 62

Copper Tests: Using the Main Menu

Config/Profile

Pair Detective Profile Details

The profile details Pair Detective main menu allows you to view the test

threshold and parameters.

To view the Pair Detective Profile details:

1. From the Main Menu, tap Config/Profile.

2. Ta p the Profile Details tab.

3. From the Te s t G roup s , select the Pair Detective test.

4. From the Te sts menu, select the test for which you want to view the

details.

54 FTB-610

Page 63

Copper Tests: Using the Main Menu

Config/Profile

Auto Test Profile Details

The profile details Auto Test main menu allows you to view the test

threshold and parameters of the following tests:

Pots Auto Test

User Auto Test

To view the Auto Test Profile details:

1. From the Main Menu, tap Config/Profile.

2. Ta p the Profile Details tab.

3. From the Te s t G roup s , select the Auto test.

4. From the Te sts menu, select the test for which you want to view the

details.

Copper Test 55

Page 64

Copper Tests: Using the Main Menu

Config/Profile

FaultMapper Test Profile Details

The profile details FaultMapper Test main menu allows you to view the

test threshold and parameters.

To view the FaultMapper Test Profile details:

1. From the Main Menu, tap Config/Profile.

2. Ta p the Profile Details tab.

3. From the Te s t G roup s , select the FaultMapper test.

4. From the Te sts menu, select the test for which you want to view the

details.

56 FTB-610

Page 65

Copper Tests: Using the Main Menu

Config/Profile

Multimeter Test Profile Details

The profile details Multimeter main menu allows you to view the test

threshold and parameters of the following tests:

Voltage

Current

Resistance

Capacitance/Opens

Resistive Balance

Balance

To view the Multimeter Test Profile details:

1. From the Main Menu, tap Config/Profile.

2. Ta p the Profile Details tab.

3. From the Te s t G roup s , select the Multimeter test.

4. From the Te sts menu, select the test for which you want to view the

details.

Copper Test 57

Page 66

Copper Tests: Using the Main Menu

Config/Profile

Multimeter 2 Test Profile Details

The profile details Multimeter 2 main menu allows you to view the test

threshold and parameters of the following tests:

Isolation

Station Ground

To view the Multimeter 2 Test Profile details:

1. From the Main Menu, tap Config/Profile.

2. Ta p the Profile Details tab.

3. From the Te s t G roup s , select the Multimeter 2 test.

4. From the Te sts menu, select the test for which you want to view the

details.

58 FTB-610

Page 67

Copper Tests: Using the Main Menu

Config/Profile

TDR Test Profile Details

The profile details TDR main menu allows you to view the test threshold

and parameters of the following tests:

Auto TDR

Manual TDR

Xtalk TDR

To view the TDR Test Profile details:

1. From the Main Menu, tap Config/Profile.

2. Ta p the Profile Details tab.

3. From the Te s t G roup s , select the TDR test.

4. From the Te sts menu, select the test for which you want to view the

details.

Copper Test 59

Page 68

Copper Tests: Using the Main Menu

Config/Profile

Signal Test Profile Details

The profile details Signal main menu allows you to view the test threshold

and parameters of the following tests:

WB Balance

WB Attenuation

TX/RX Tone

To view the Signal Test Profile details:

1. From the Main Menu, tap Config/Profile.

2. Ta p the Profile Details tab.

3. From the Te s t G roup s , select the Signal test.

4. From the Te sts menu, select the test for which you want to view the

details.

60 FTB-610

Page 69

Copper Tests: Using the Main Menu

Config/Profile

Noise Test Profile Details

The profile details Noise main menu allows you to view the test threshold

and parameters of the following tests:

VF Noise

Power Influence

WB PSD Noise

NEXT

To view the Noise Test Profile details:

1. From the Main Menu, tap Config/Profile.

2. Ta p the Profile Details tab.

3. From the Te s t G roup s , select the Noise test.

4. From the Te sts menu, select the test for which you want to view the

details.

Copper Test 61

Page 70

Copper Tests: Using the Main Menu

Config/Profile

Impulse Test Profile Details

The profile details Impulse main menu allows you to view the test

threshold and parameters of the following tests:

VF Impulse Noise

WB Impulse Noise

Impulse Scope

Impulse Duration

To view the Impulse Test Profile details:

1. From the Main Menu, tap Config/Profile.

2. Ta p the Profile Details tab.

3. From the Te s t G roup s , select the Impulse test.

4. From the Te sts menu, select the test for which you want to view the

details.

62 FTB-610

Page 71

Copper Tests: Using the Main Menu

Copy from USB

Copy from USB allows you to copy all profiles found on an external USB

device to the unit.

To copy the profile details:

1. From the Main Menu, tap Config/Profile.

2. From the Profile Management tab, tap the Copy from USB button. The

Copy From USB page opens.

3. Select the USB drive from the USB Drives list.

4. Select the profile to copy.

Note: Check Select All Profiles to select all profile names.

5. Ta p the Copy button to start the copying process.

Copy to USB

Copy to USB allows you to copy all profiles found in the internal memory

to an external USB device. If the profile name already exists in the

destination folder, Copy (x) will be appended to the profile name, where x

corresponds to the number of copies starting from 1.

Config/Profile

To copy the profile details:

1. From the Main Menu, tap Config/Profile.

2. From the Profile Management tab, tap the Copy to USB button.

The Copy From USB page opens.

3. Select the profile to copy.

Note: Check Select All Profiles to select all profile names.

4. Select the USB drive from the USB Drives list.

5. Ta p the Copy button to start the copying process.

Copper Test 63

Page 72

Copper Tests: Using the Main Menu

Config/Profile

Delete Profile

Delete allows you to delete a profile (except the default profile) on the unit.

To delete a profile:

1. From the Main Menu, tap Config/Profile.

2. From the Profile Management tab, select the profiles to delete.

3. Ta p the Delete button. The selected profiles are deleted.

Save

Save allows you to save changes made to selected profile. An asterisk “*”

on the Selected Profile name indicates that modifications have been

made in the threshold settings or parameters of a particular test.

To s av e a p r o fi le :

1. From the Main Menu, tap Config/Profile.

2. From the Profile Management tab, select the profiles and tap Save.

Save allows you to save to the currently selected profile name.

Save As opens the alphanumeric editor screen allowing you to

enter a new name for the profile selected.

64 FTB-610

Page 73

Copper Tests: Using the Main Menu

Config/Profile

Default

Default resets the current test setup to the factory default profile. If

selected, a dialogue box pops up to confirm that all single and auto test

settings will revert to factory test settings.

To reset the setup:

1. From the Main Menu, tap Config/Profile.

2. From the Profile Management tab, tap the Default button. A warning

is displayed to confirm that settings will be reset to factory defaults.

3. Ta p OK to continue or Cancel to abort.

Copper Test 65

Page 74

Copper Tests: Using the Main Menu

Application Settings

Application Settings

Before executing the copper tests, set up the software settings and values

for the cables. The module allows you to save standard parameter settings

to different profiles and reuse them as needed.

To access Application Settings:

1. From the Main Menu, select Setup.

2. Ta p App. Setting.

The page displays the following tabs:

General

The General tab allows you to configure the cable temperature, test

startup mode, report format, etc. for the application.

The page allows you to set the following parameters:

Cable Temperature specifies the temperature of the cable under test

in either F (Fahrenheit) or C (Celsius) units.

66 FTB-610

Page 75

Copper Tests: Using the Main Menu

Application Settings

Capacitance Measurement is either 3 Terminal or 2 Terminal. The

latter method measures the capacitance across the 2 terminals

specified (either T-R, T-G, R-G or A-B, A-E, B-E), whereas the 3 Terminal

method measures the capacitance across the 2 terminals specified,

and shorts the remaining (or unspecified) terminal to G/E.

Note: In order to correctly determine cable length by using the capacitance

measurement, the Cable Book must contain both 3/2 Terminal values.

Test Startup Mode lists the test startup type:

Auto (default) automatically starts a test when you select the

respective icon from the test sub-menu.

Manual requires that you tap the Start button on the Main Menu to

start a test.

Result File Storage Location allows you to select where to save your

results: to a USB or the internal memory.

Report Format is HTML, MHTML, XML, or PDF as the generated report

format.

Prompt To Save Results allows you to enable popup confirmation

messages before leaving a test and not saving results, by checking the

box.

Show Connection Diagram On Test Startup allows you to enable the

hookup diagram upon startup by checking the boxes of the following

tests:

Xtalk

Station Ground

NEXT

Copper Test 67

Page 76

Copper Tests: Using the Main Menu

Application Settings

Standard

The Standard tab allows you to set Measurement unit and Test Parameter

Preset values.

The page allows you to set the following parameters:

Standard Selection

Standard allows you to specify if the copper tests should conform to

the ITU (International Telecommunications) or ANSI (American

National Standards Institute) standard.

Note: Selecting the Standard resets the default Measurement Units, Label

Customization, and Test Parameters Preset for the page.

Measurement Units

Distance lists the measurement units for distance in feet or meters.

Tem pe ra tu re lists the measurement units for temperature in

F (Fahrenheit) or C (Celsius).

Level lists the units of power level in dBm or dBRN.

Capacitance lists the units of capacitance for Tip and Ring in

(nF/km or nF/mi).

68 FTB-610

Page 77

Copper Tests: Using the Main Menu

Application Settings

Resistance lists the units for resistance in (Ω/km or Ω/mi).

Attenuation lists the units for the reduction in signal strength or

insertion loss of the cable, in (dB/km or dB/mi).

Power Spectral Density (PSD) lists the units to measure the noise

energy at a point in a noise spectrum. Units are dependent on the

previously selected Level.

Label Customization

Connection lists the type of cable connection: T-R-G or A-B-E.

Test Parameters Preset

Power Line Frequency lists the frequency value of the power line.

Termination Impedance lists the values for the impedance of the

dummy load connected to the line.

Noise Filter lists the type of noise filters to use.

Copper Test 69

Page 78

Copper Tests: Using the Main Menu

Application Settings

Identification

The Identification tab allows you to preset values to identify each single

and auto test result file when saving them.

The page allows you to set the following parameters:

User Name/User ID allow you to enter up to 25 alphanumeric

characters, in each field.

Test Fr o m/To list the following values: DSLAM, NID, CPE, CROSSBOX,

FRAME - up to 20 entries each, including user defined values.

Test Fr o m/To List Setup buttons open separate list management

pages.

A maximum of 20 different entries can be added.

To manage the list:

1. Select the entries.

2. Ta p Add button to add an entry just below the selected entry in the list.

3. To edit an entry, select the entry and tap Modify button.

4. Ta p Delete button to delete any entry you have added.

70 FTB-610

Page 79

Copper Tests: Using the Main Menu

Application Settings

File Name

The File Name tab sets up the standard configuration for automatically

naming a result file. You can only select/deselect the entries. All enabled

entries are considered for file name generation.

The page allows you to set the following parameters:

File Name Preview displays a preview of the file name. The actual

values of the selected entries are not shown.

Date and Time value format depends on the format selected in

System Settings. This entry cannot be deselected.

Separator allows you to choose a value to separate the enabled

entries in the file name, e.g.: Space ( ), Dash (-), Underscore (_).

Up and down arrows allow you to change the order of the

identification field.

Copper Test 71

Page 80

Copper Tests: Using the Main Menu

Application Settings

Buzzer

The buzzer is always on when the module is powered, to provide audible

and visual warnings of hazardous voltages on the line under test.

The Buzzer tab allows you to configure values for the buzzer settings.

The page allows you to set the following parameters:

Buzzer Threshold Voltage allows you to configure the hazardous

voltage level from 70 to 150 volts. Default is 80 volts.

Hush Time allows you to configure the hush timeout from

1to15minutes. Default is 3minutes.

Hush Buzzer button mutes the sounding buzzer.

72 FTB-610

Page 81

Copper Tests: Using the Main Menu

Factory Default

Factory Default

The Factory Default allows you to restore the Application Settings, Phone

Book settings or both of them to factory default settings.

To access Factory Default Settings:

1. From the Main Menu, select Setup.

2. Ta p Fact or y D efault.

3. Select the option to reset to factory default.

4. Ta p Confirm Factory Default button to confirm selection.

5. Ta p Close to exit from the page.

The page displays the following parameters:

Application Settings allows you to reset all the application settings to

factory default values.

Phone Book allows you to reset the phone book to the factory default

values.

All these options allows you to reset Application Settings and Phone

Book to the factory default values.

Copper Test 73

Page 82

Copper Tests: Using the Main Menu

Save Test

Save Test

You can save a snapshot of test results into a result/report file during or

after a test performed with the FTB-610. Each copper test includes a Save

Tes t button which opens a page where results can be saved to an internal

memory or external USB drive. Reports can be created in the following

formats: HTML, MHTML, XML, or PDF.

Alternately, when a test is completed or stopped and you select another

test to start, Save dialogue box pops up. Selecting Save displays the Save

Tes t screen.

74 FTB-610

Page 83

Copper Tests: Using the Main Menu

The page allows you to set the following parameters:

Identification Fields

User Name/User ID display the values set up in the Application

Settings/Identification tab. You can edit this field using the editor

screen.

Test Fr o m/To display the values set up in the Application

Settings/Identification tab. You can edit this field using the

choices from the list box.

Job ID allows you to create/edit a unique identifier for the task.

Customer Name is the name of the customer for which the test

was run.

Circuit ID allows you to create/edit a unique identifier for the

circuit under test.

Comments allows you to add any relevant information.

Results

Save Test

Select Result File button displays a list of existing file names

where you can save your results.

If the result file already exists, a warning message is displayed to

overwrite the existing file.

Tap OK to overwrite the existing file or Cancel to abort.

Copper Test 75

Page 84

Copper Tests: Using the Main Menu

Save Test

Result File Storage Location gives you the option of storing results

either in the FTB-1 internal memory or a USB device. The default

selection comes from Application Settings/General tab.

Result File Name allows you to preview and edit the result file

name. The proposed file name is based on current auto-naming

parameters configured in Setup/Application Settings/File Name.

Save Results button confirms if the Result File Name is saved

successfully.

Report

Select Report button displays a list of existing report file names

where you can save your results.

Report File Storage gives you the option of storing your report

either in the FTB-1 internal memory or a USB device.

Report File Name allows you to preview and edit the report file

name. The proposed file name is based on current auto-naming

parameters configured in Setup/Application Settings/File Name.

Report Format is HTML, MHTML, XML, or PDF.

You can generate reports from any saved test result. Reports

include:

General Information including Pass/Fail status.

Identification

Profile/Result Summary

Blank entries for your Signature and the Date.

Save Report button confirms if the Report File Name is saved

successfully. If a USB device is not inserted, the following warning

dialogue box appears: USB device not present.

76 FTB-610

Page 85

Copper Tests: Using the Main Menu

Save Test

Select Result File

Select Result File page displays a list of existing file names where you can

save your results.

To save your results to an existing File Name:

1. Select the desired File Name.

2. Ta p OK to confirm your selection.

Note: The selected result file is overwritten with the new results.

Copper Test 77

Page 86

Copper Tests: Using the Main Menu

Save Test

Select Report File

Select Report page displays a list of existing file names where you can

save your reports.

To save your reports to an existing File Name:

1. Select the desired Report File Name.

2. Ta p OK to confirm your selection.

Note: The selected report file is overwritten with the new report.

78 FTB-610

Page 87

6 Reading and Exporting Saved

Results

You can view and or export any of your saved results by selecting the

Read/Export Results from the Main Menu.

Result File

The Result File page allows you to select a Result File Name and view the

results of files previously saved. The page lists all saved result files by test

date and time. The format of Modification Date is per the selection in

System Settings. Result files can be loaded from either the FTB-1 internal

memory or a USB.

To open previously saved test results:

1. Tap to select the file to open.

2. Ta p Select to open the result file or Cancel to exit the page.

Copper Test 79

Page 88

Reading and Exporting Saved Results

Reading the Result File

Reading the Result File

Once you open a saved result file, you are presented with the saved

measured result details and cable parameters of the selected test. The

following tabs and buttons are displayed dependent on the test saved:

Summary tab displays a list of the names of the executed tests, the

date and time each test was run, and pass/fail status of the test. Refer

to Summary on page 319.

Profile Details displays the thresholds and setup parameters of the

test.

Result Summary displays general information and parameters of the

test under the following tabs:

Save Test displays pass/fail status, general and identification

information, along with comments.

Phone Book displays the phone entries dialed during the test.

Supplemental displays the status, date and time of the last Test

Lead Compensation performed.

80 FTB-610

Page 89

Reading and Exporting Saved Results

Reading the Result File

Profile Details

The Profile Details page displays read-only Test Thresholds and Tes t

Parameters information about the setup of the selected test.

The page displays the following parameters:

Test Grou p is the overall test group of the selected saved results file,

for example Multimeter.

Test Identification is the test type of the group, for example Voltage.

Profile Name is the file name of the selected saved results.

Copper Test 81

Page 90

Reading and Exporting Saved Results

Reading the Result File

Result Summary

The Save Test tab displays pass/fail status, general and identification

information, along with comments, for the test.

General Information displays read-only information pertaining to the

test result.

Result File Name

Test Da te an d Time

Test Gr oup

Test Identification

Test Mo des

Editable Identification Fields display values from the loaded file. You

can edit all fields using the editor screen or by selecting an entry from

the list box.

User Name/ID

Test Fro m /To

Job ID

82 FTB-610

Page 91

Reading and Exporting Saved Results

Reading the Result File

Customer Name

Circuit ID

Comments

Save button keeps any current changes with the current file name.

Save As button saves the current changes under a different file name

that you can configure in the editor screen.

The Save As dialog opens.

The page displays the following parameters:

Result File Storage Location gives you the option of storing results

either in the FTB-1 internal memory or USB device. The default

selection comes from Application Settings/General tab.

Result File Name allows you to preview and edit the result file

name. The proposed file name is based on current auto-naming

parameters configured in Setup/Application Settings/File Name.

Save button confirms your selections.

Cancel button exits the dialog box.

Copper Test 83

Page 92

Reading and Exporting Saved Results

Reading the Result File

Save Report allows you to load a result file, update the ID fields, and

generate a report.

The Save Report dialog opens.

The page displays the following parameters:

Report File Storage Location gives you the option of storing the

report either in the FTB-1 internal memory or USB device. The

default selection comes from Application Settings/General tab.

Report File Name allows you to preview and edit the result file

name. The proposed file name is based on current auto-naming

parameters configured in Setup/Application Settings/File Name.

Report Format allows you to select HTML, MHTML, XML, or PDF

for the generated report.

Save button confirms your selections.

Cancel button exits the dialog box.