Page 1

FTB-5700

Single-Ended Dispersion Analyzer

for FTB-500

User Guide

Page 2

Copyright © 2007–2009 EXFO Electro-Optical Engineering Inc. All rights

reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted in any form, be it electronically,

mechanically, or by any other means such as photocopying, recording or

otherwise, without the prior written permission of EXFO Electro-Optical

Engineering Inc. (EXFO).

Information provided by EXFO is believed to be accurate and reliable.

However, no responsibility is assumed by EXFO for its use nor for any

infringements of patents or other rights of third parties that may result from

its use. No license is granted by implication or otherwise under any patent

rights of EXFO.

EXFO’s Commerce And Government Entities (CAGE) code under the North

Atlantic Treaty Organization (NATO) is 0L8C3.

The information contained in this publication is subject to change without

notice.

Trademarks

EXFO’s trademarks have been identified as such. However, the presence

or absence of such identification does not affect the legal status of any

trademark.

Units of Measurement

Units of measurement in this publication conform to SI standards and

practices.

EXFO’s Universal Interface is protected by US patent 6,612,750.

Protected by international PCT patent application (published under

WO2007/036051) and several other pending applications.

Version number: 3.0.1

ii FTB-5700

Page 3

Contents

Contents

Certification Information ........................................................................................................v

1 Introducing the FTB-5700 Single-Ended Dispersion Analyzer ................... 1

Typical Applications ................................................................................................................1

Basic FTB-5700 Single-Ended Dispersion Analyzer Operation ..................................................2

Conventions ............................................................................................................................4

2 Safety Information ....................................................................................... 5

3 Getting Started with the Single-Ended Dispersion Analyzer .................... 7

Inserting and Removing Test Modules ....................................................................................7

Starting the Single-Ended Dispersion Analyzer Application ..................................................12

Exiting the Application .........................................................................................................14

4 Setting Up the Single-Ended Dispersion Analyzer ................................... 15

Setting up Application Details ..............................................................................................15

Customizing Thresholds ........................................................................................................20

Setting the Wavelength Range .............................................................................................22

Setting PMD and CD Acquisition Parameters ........................................................................24

Defining the Automatic Fiber Name Format .........................................................................28

Managing Test Configurations ..............................................................................................29

Setting Test Preferences ........................................................................................................35

5 Operating the Single-Ended Dispersion Analyzer .................................... 37

Cleaning and Connecting Optical Fibers ...............................................................................37

Installing the EXFO Universal Interface (EUI) .........................................................................39

Performing a Test ..................................................................................................................40

6 Managing Results ....................................................................................... 43

Modifying Analysis Parameters and Related Information ......................................................46

Opening Existing Files ...........................................................................................................54

Removing Unwanted Results ................................................................................................55

Closing Result Files ...............................................................................................................56

Generating a Report .............................................................................................................57

7 Maintenance ............................................................................................... 59

Cleaning EUI Connectors ......................................................................................................60

Recalibrating the Unit ...........................................................................................................62

Recycling and Disposal (Applies to European Union Only) ....................................................63

Single-Ended Dispersion Analyzer iii

Page 4

Contents

8 Troubleshooting ..........................................................................................65

Solving Common Problems ...................................................................................................65

Obtaining Online Help ..........................................................................................................72

Contacting the Technical Support Group ..............................................................................73

Transportation ......................................................................................................................74

9 Warranty ......................................................................................................75

General Information .............................................................................................................75

Liability .................................................................................................................................76

Exclusions .............................................................................................................................77

Certification ..........................................................................................................................77

Service and Repairs ...............................................................................................................78

EXFO Service Centers Worldwide ..........................................................................................79

A Technical Specifications ..............................................................................81

Index .................................................................................................................83

iv FTB-5700

Page 5

Certification Information

Certification Information

F.C.C. Information

Electronic test equipment is exempt from Part 15 compliance (FCC) in

the United States. However, compliance verification tests are

systematically performed on most EXFO equipment.

Information

Electronic test equipment is subject to the EMC Directive in the European

Union. The EN61326 standard prescribes both emission and immunity

requirements for laboratory, measurement, and control equipment.

This unit has undergone extensive testing according to the European Union

Directive and Standards.

Single-Ended Dispersion Analyzer v

Page 6

Certification Information

DECLARATION OF CONFORMITY

Application of Council Directive(s): 2006/95/EC - The Low Voltage Directive

Manufacturer’s Name: EXFO Electro-Optical Engineering Inc.

Manufacturer’s Address: 400 Godin Avenue

Quebec, Quebec

(418) 683-0211

Equipment Type/Environment: Test & Measurement / Industrial

Trade Name/Model No.: FTB-5700

Standard(s) to which Conformity is Declared:

EN 61010-1:2001 Safety Requirements for Electrical Equipment for Measurement,

EN 61326-1:2006 Electrical Equipment for Measurement, Control and Laboratory

EN 60825-1:1994 +A2:2001

+A1:2002

EN 55022: 1998 +A2: 2003 Information technology equipment - Radio disturbance

I, the undersigned, hereby declare that the equipment specified above conforms to the above Directive and Standards.

Manufacturer

Signature:

Control, and Laboratory Use, Part 1: General Requirements.

Use - EMC Requirements – Part 1: General requirements

Safety of laser products – Part 1: Equipment classification,

requirements, and user’s guide

characteristics - Limits and methods of measurement

2004/108/EC - The EMC Directive

And their amendments

Canada, G1M 2K2

Single-Ended Dispersion Analyzer

Full Name: Stephen Bull, E. Eng

Position: Vice-President Research and

Address: 400 Godin Avenue, Quebec (Quebec),

Date: January 09, 2009

Development

Canada, G1M 2K2

vi FTB-5700

Page 7

1 Introducing the FTB-5700

Single-Ended Dispersion

Analyzer

The FTB-5700 Single-Ended Dispersion Analyzer is the world’s first

combined CD and PMD analyzer doing both measurements from a single

end of the fiber. It features a single connector port and software for both

type of measurements; CD and PMD are characterized by pressing a single

button. This is done without the need for a remote unit or light source.

As long as the remote end of the fiber is unterminated and with a UPC

connector, a single technician can perform advanced testing, that is, CD

and PMD measurements. The results are also compiled into a single test

file and a single report for both tests.

Typical Applications

With its dynamic range, level of accuracy and feature set, the FTB-5700

Single-Ended Dispersion Analyzer is a perfect tool for any network

manager or technician to perform advance testing of 10 Gbit/s networks or

faster, on any fiber length up to 120 km. The FTB-5700 Single-Ended

Dispersion Analyzer helps validating fiber quality for the given speed or

providing information enabling compensation.

Single-Ended Dispersion Analyzer 1

Page 8

Introducing the FTB-5700 Single-Ended Dispersion Analyzer

Basic FTB-5700 Single-Ended Dispersion Analyzer Operation

Basic FTB-5700 Single-Ended Dispersion

Analyzer Operation

The purpose of the FTB-5700 Single-Ended Dispersion Analyzer unit is to be

simple of use, with minimal parameter setting requirements. The

parameter most likely to be changed by a user is the fiber type.

In order to achieve optimal measurements, you must however remember

a few concepts:

³ The measurement technique for the unit requires only a strong

reflective event at the end of the link to perform CD and PMD

measurements. The measurement is taken at the location of this

reflective event at a wavelength of 1550 nm.

Note: Reflective events are caused by an abrupt discontinuity in the index of

refraction. They cause a significant portion of the energy initially launched

into the fiber to be reflected back toward the source.

³ You must have a UPC connector at the end of the fiber to measure the

overall link. If the appropriate termination is not found, the unit returns

an error message (see Troubleshooting on page 65 for details).

Note: Other reflective terminations include mirror connectors, fiber pigtailed

mirrors, cleaved fibers. However, do not use fiber loop mirrors or

Faraday-type mirrors.

2 FTB-5700

Page 9

Introducing the FTB-5700 Single-Ended Dispersion Analyzer

Basic FTB-5700 Single-Ended Dispersion Analyzer Operation

Once the fiber end event position is found, the unit checks the dynamics

and evaluates the wavelength range over which to perform the

measurement. It then selects the acquisition conditions and sequence of

the measurement before starting the acquisition itself.

You must also remember that the fiber under test (FUT) must meet the

following requirements for optimal testing conditions:

³ The FUT length must be terminated by a UPC connector.

³ The FUT length must be less than 120 km.

³ The FUT must not have a filter at 1550 nm.

Note: Since the instrument is single ended, it cannot measure through

components that allow light to travel only in one direction, such as

amplifiers and circulators.

Single-Ended Dispersion Analyzer 3

Page 10

Introducing the FTB-5700 Single-Ended Dispersion Analyzer

Conventions

Conventions

Before using the product described in this manual, you should understand

the following conventions:

WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in component damage. Do not proceed unless you

understand and meet the required conditions.

IMPORTANT

Refers to information about this product you should not overlook.

4 FTB-5700

Page 11

2 Safety Information

WARNING

Do not install or terminate fibers while a light source is active.

Never look directly into a live fiber and ensure that your eyes are

protected at all times.

WARNING

Use of controls, adjustments and procedures for operation and

maintenance other than those specified herein may result in

hazardous radiation exposure or impair the protection provided by

this unit.

Your instrument is a Class 1 laser product in compliance with standards

IEC 60825-1 Amendment 2: 2001 and 21 CFR 1040.10. Laser radiation may

be encountered at the output port.

The following label indicates that a product contains a Class 1 source:

CLASS 1

LASER PRODUCT

Note: Label shown for information purposes only. It is not affixed to your product.

Single-Ended Dispersion Analyzer 5

Page 12

Page 13

3 Getting Started with the

Single-Ended Dispersion

Analyzer

Inserting and Removing Test Modules

CAUTION

Never insert or remove a module while the FTB-500 is turned on.

This will result in immediate and irreparable damage to both the

module and unit.

WARNING

When the laser safety LED ( ) is flashing on the FTB-500, at least

one of your modules is emitting an optical signal. Please check all

modules, as it might not be the one you are currently using.

To insert a module into the FTB-500:

1. Exit ToolBox and turn off your unit.

2. Position the FTB-500 so that its right panel is facing you.

Single-Ended Dispersion Analyzer 7

Page 14

Getting Started with the Single-Ended Dispersion Analyzer

Inserting and Removing Test Modules

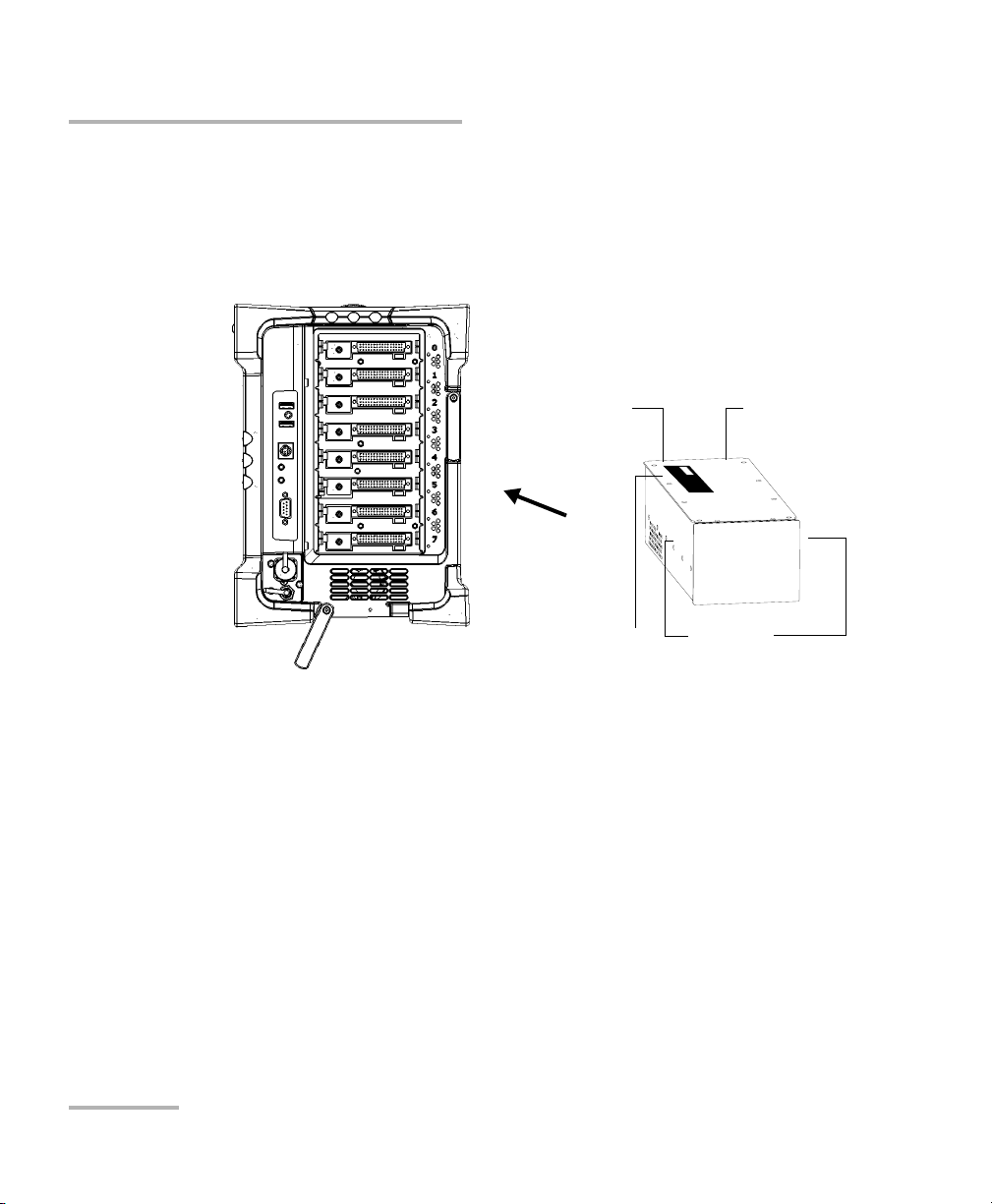

3. Take the module and place it so that the connector pins are at the

back, as explained and shown below.

Identification sticker must be facing up and connector pins at the right

of the retaining screw hole.

FTB-500 right panel

4. Insert the protruding edges of the module into the grooves of the

5. Push the module all the way to the back of the slot, until the retaining

6. Place the FTB-500 so that its left panel is facing you.

Retaining screw

hole at the

back

Identification sticker

facing up

receptacle’s module slot.

screw makes contact with the receptacle casing.

Connector

pins at the

back

Protruding

edges on top

8 FTB-5700

Page 15

Getting Started with the Single-Ended Dispersion Analyzer

Inserting and Removing Test Modules

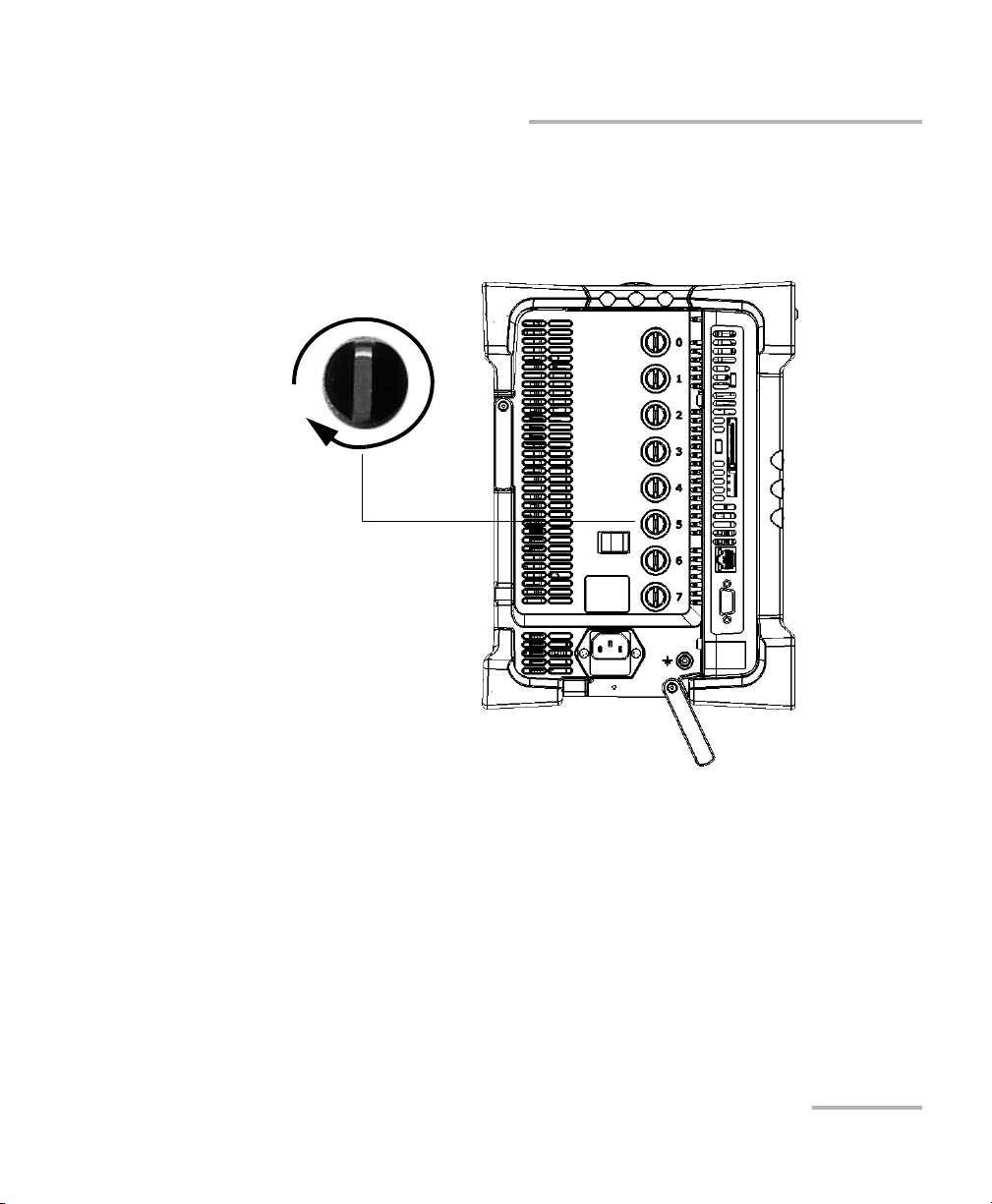

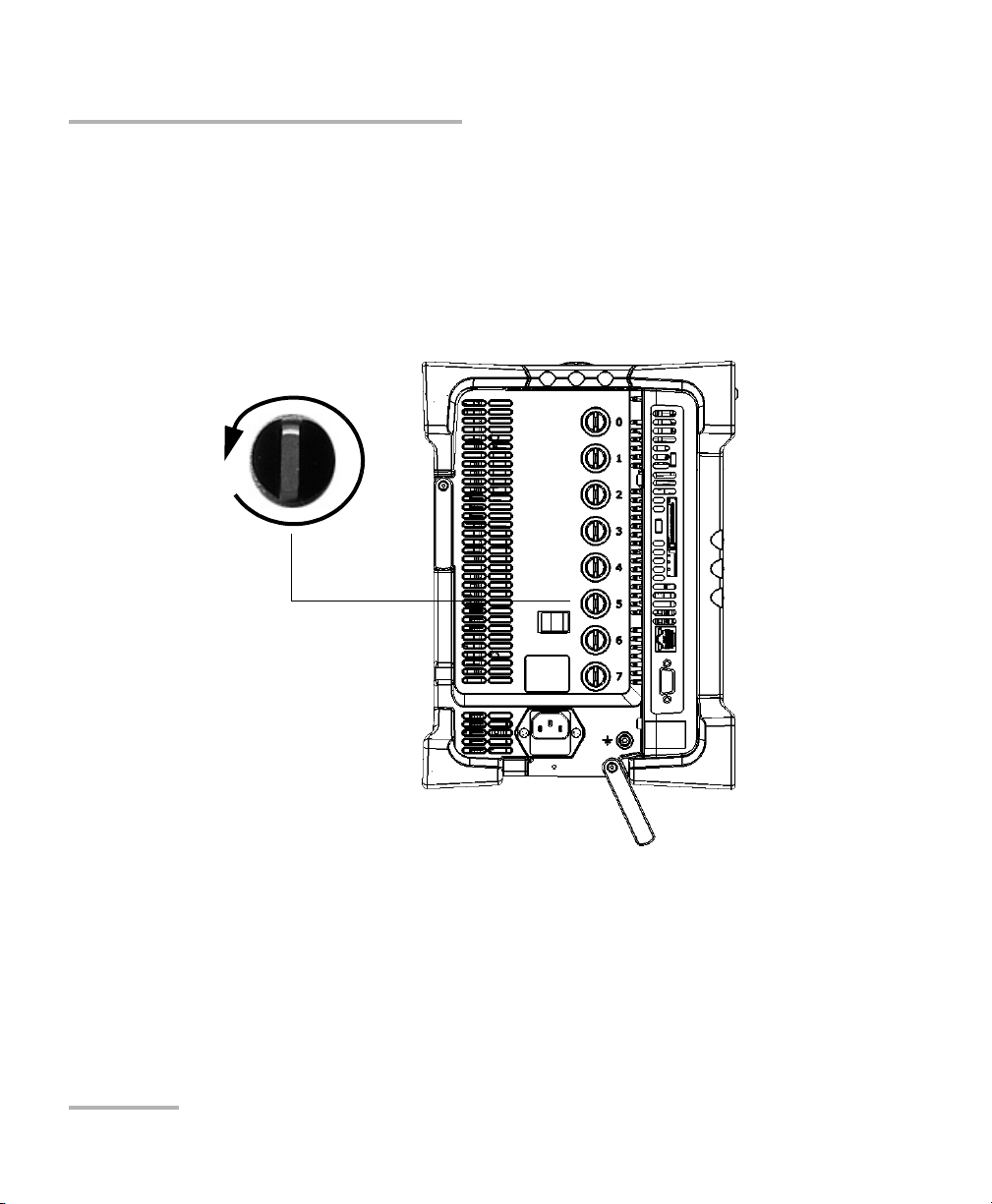

7. While applying slight pressure to the module, turn the retaining screw

clockwise until it is tightened.

This will secure the module into its “seated” position.

Turn retaining screw knob

clockwise

FTB-500 left panel

When you turn on the unit, the startup sequence will automatically detect

the module.

Single-Ended Dispersion Analyzer 9

Page 16

Getting Started with the Single-Ended Dispersion Analyzer

Inserting and Removing Test Modules

To remove a module from the FTB-500:

1. Exit ToolBox and turn off your unit.

2. Position the FTB-500 so that the left panel is facing you.

3. Turn the retaining screw counterclockwise until it stops.

The module will be slowly released from the slot.

Turn retaining screw knob(s)

counterclockwise

FTB-500 left panel

4. Place the FTB-500 so that the right panel is facing you.

10 FTB-5700

Page 17

Getting Started with the Single-Ended Dispersion Analyzer

Inserting and Removing Test Modules

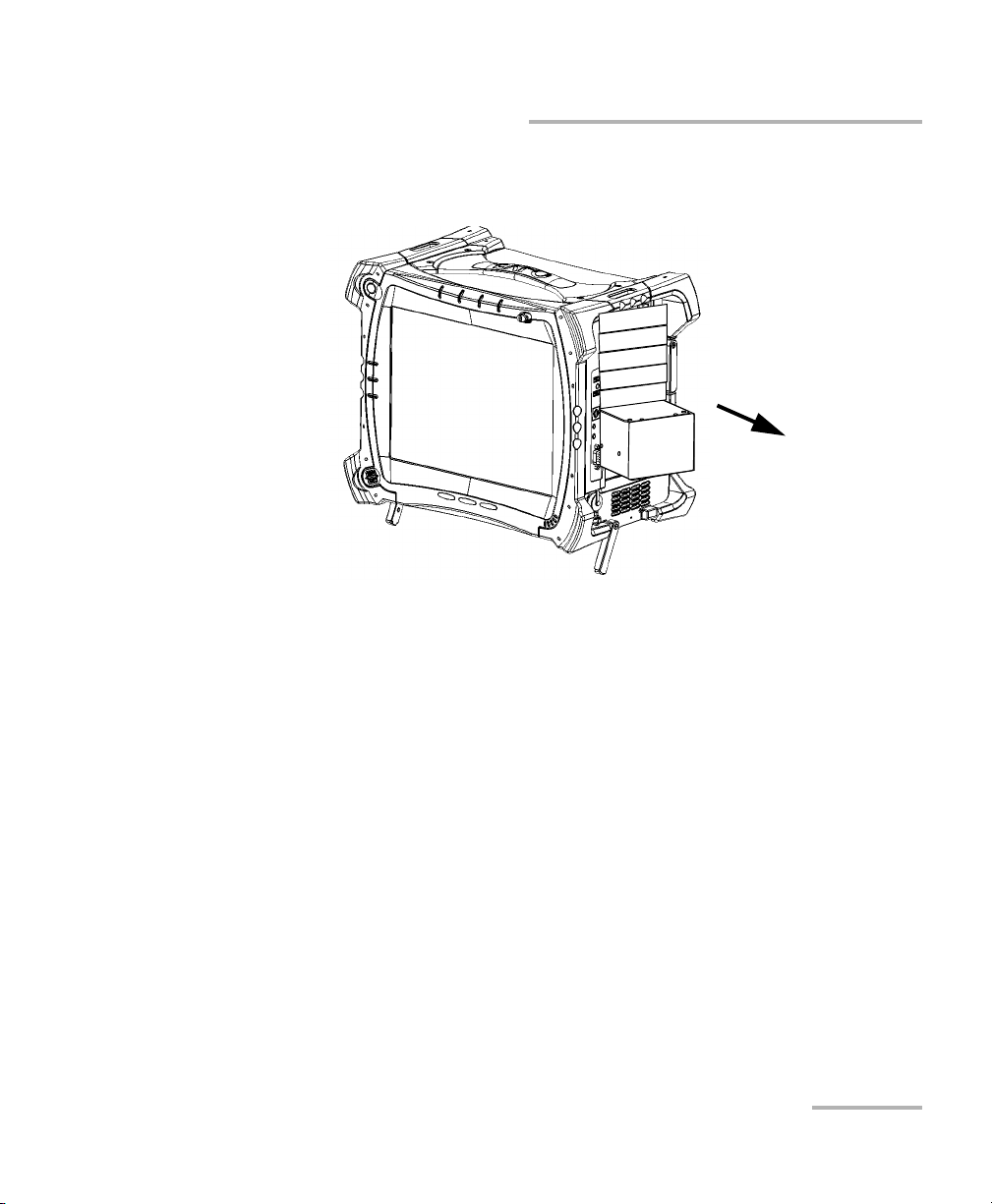

5. Hold the module by its sides or by the handle (NOT by the connector)

and pull it out.

Single-Ended Dispersion Analyzer 11

Page 18

Getting Started with the Single-Ended Dispersion Analyzer

Starting the Single-Ended Dispersion Analyzer Application

Starting the Single-Ended Dispersion Analyzer

Application

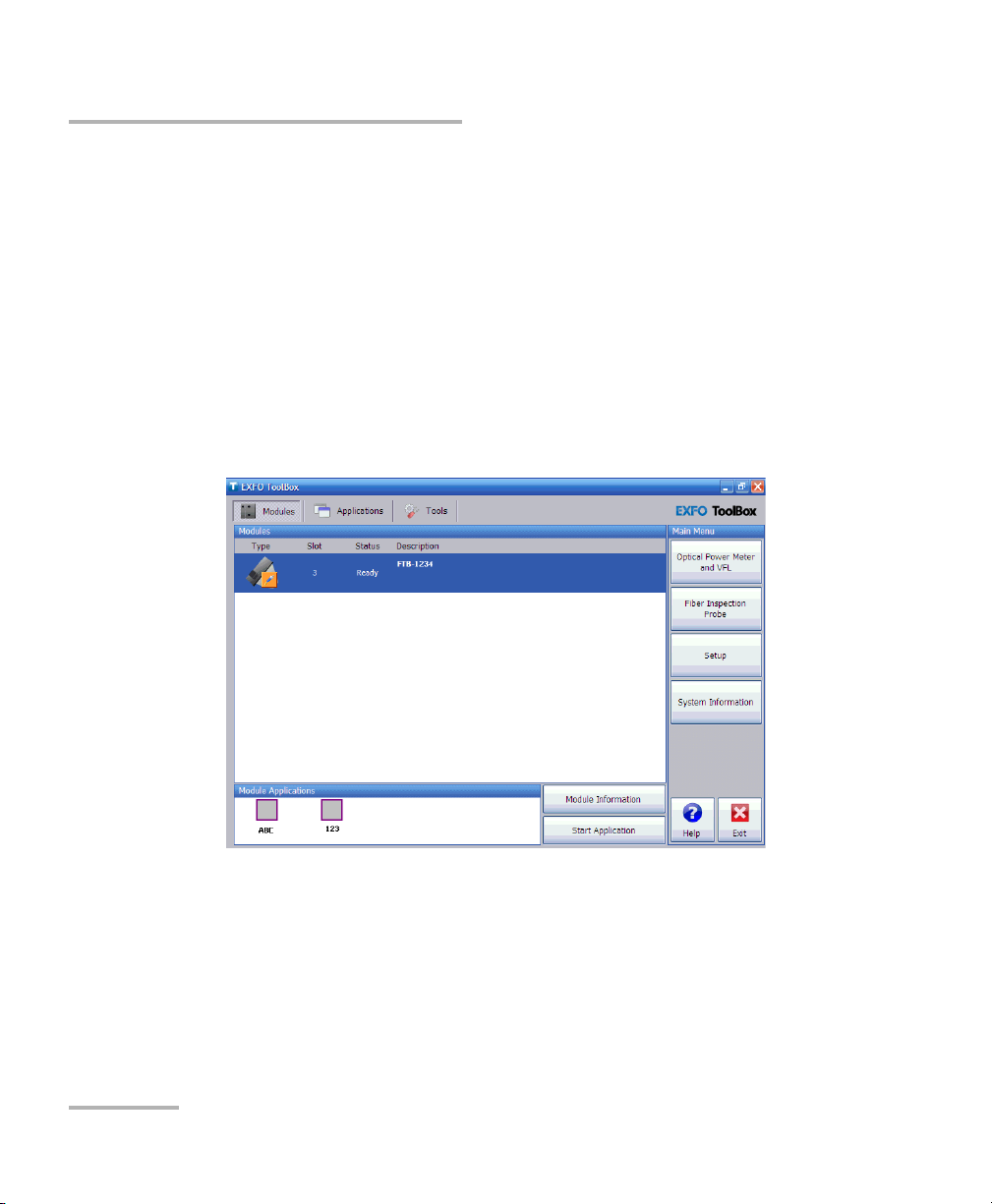

Your FTB-5700 Single-Ended Dispersion Analyzer module can be

configured and controlled from its dedicated ToolBox application.

Note: For details about ToolBox, refer to the FTB-500 user guide.

To start the application:

1. From the main window, select the module to use.

It will turn blue to indicate that it is highlighted.

2. Click the corresponding button in the Module Applications box.

12 FTB-5700

Page 19

Getting Started with the Single-Ended Dispersion Analyzer

Starting the Single-Ended Dispersion Analyzer Application

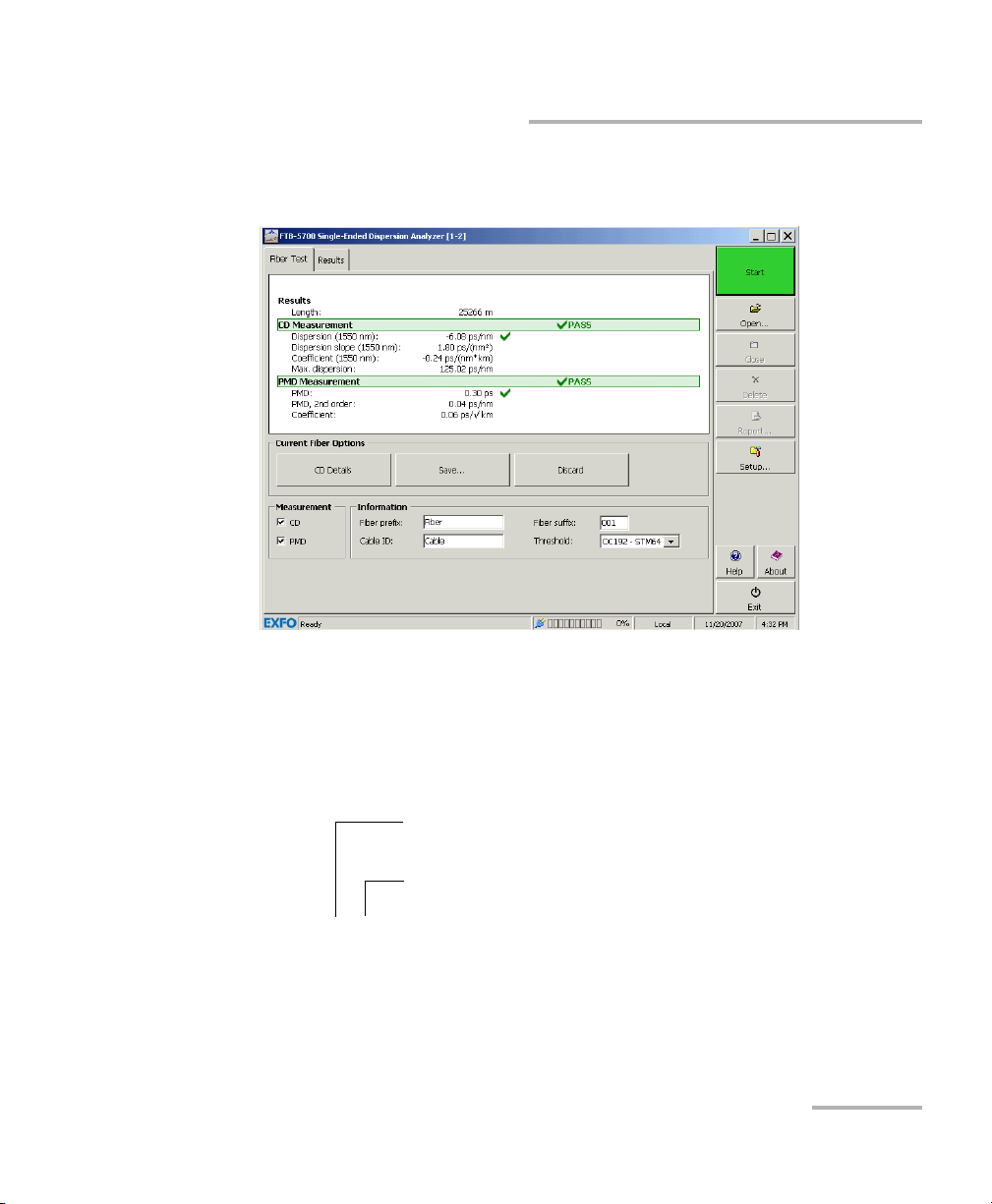

The main window (shown below) contains all the commands required to

control the Single-Ended Dispersion Analyzer:

Title Bar

The title bar is located at the top of the main window. It displays the

module name and its position in the FTB-500. The module position is

identified as follows:

Unit housing the module

(1 identifies FTB-500)

Slot number in which module is inserted

(0 identifies first slot)

[1–1]

Single-Ended Dispersion Analyzer 13

Page 20

Getting Started with the Single-Ended Dispersion Analyzer

Exiting the Application

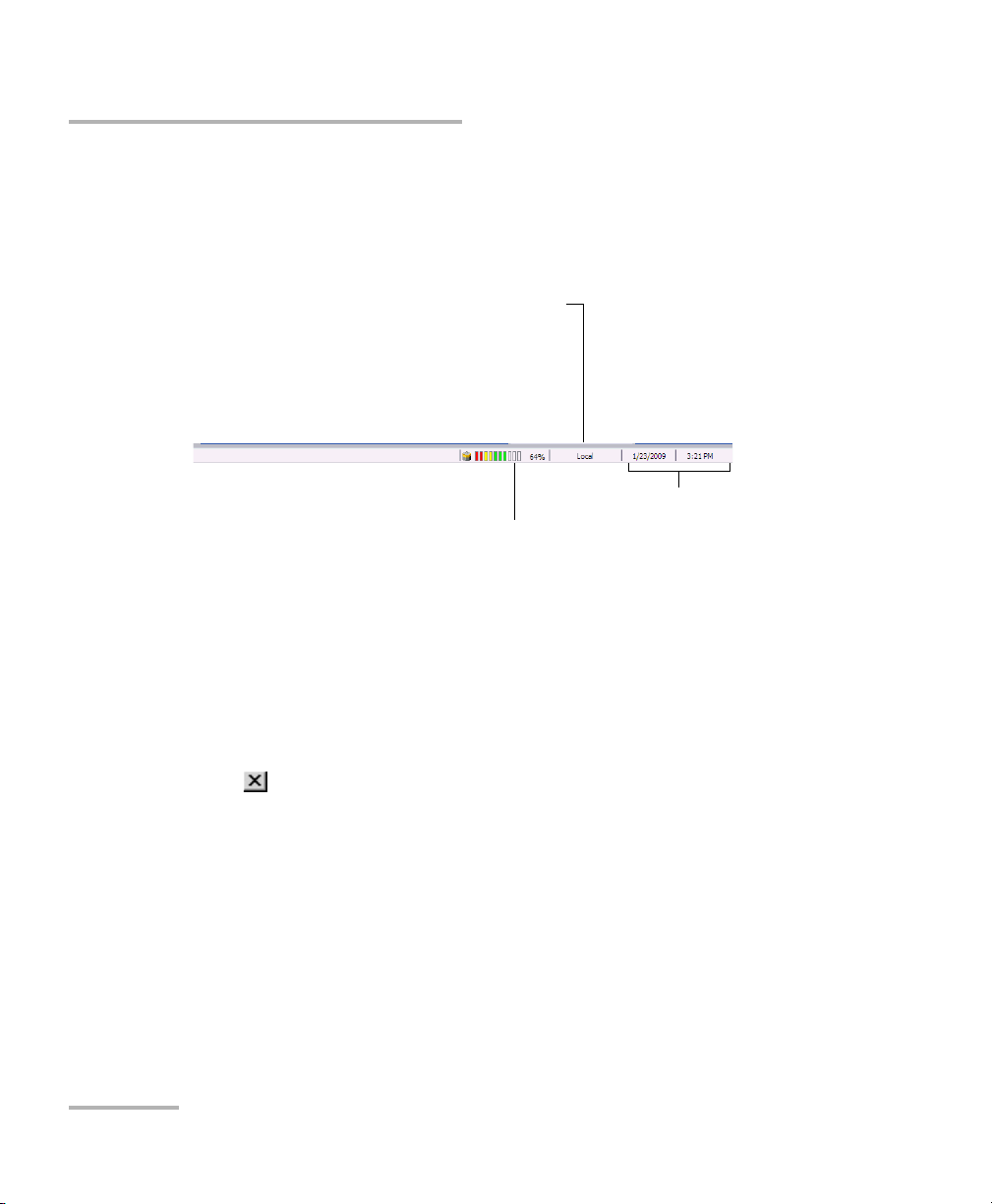

Status Bar

The status bar, located at the bottom of the main window, identifies the

current operational status of the FTB-5700 Single-Ended Dispersion

Analyzer.

Control mode

Local: Module controlled locally only.

Remote: Module controlled remotely, but local

commands can also be used (some products only).

Lockout: Module controlled remotely only.

Current date and time

Battery indicator

Exiting the Application

Closing any application that is not currently being used helps freeing

system memory.

To close the application from the main window:

Click in the top right corner of the main window.

OR

Click the Exit button located at the bottom of the function bar.

14 FTB-5700

Page 21

4 Setting Up the Single-Ended

Dispersion Analyzer

The many features of the Single-Ended Dispersion Analyzer are controlled

by the Windows-compatible ToolBox software. Please refer to the FTB-500

user guide for more information.

The parameters you set will be kept in memory after turning off the

FTB-500.

Setting up Application Details

You can customize the distance units, the CD display values and whether

or not you are warned each time a scan is complete.

You can also keep the intermediate data when performing tests. This

option should be used when there is a problem with the Single-Ended

Dispersion Analyzer or a measurement. Once you have acquired this

intermediate data, which represents all of the actions done by the unit

when performing the test, you can take this file and send it to EXFO for

troubleshooting purposes.

IMPORTANT

Selecting the Keep intermediate data option will increase the size of

your result file in a significant manner.

Single-Ended Dispersion Analyzer 15

Page 22

Setting Up the Single-Ended Dispersion Analyzer

Setting up Application Details

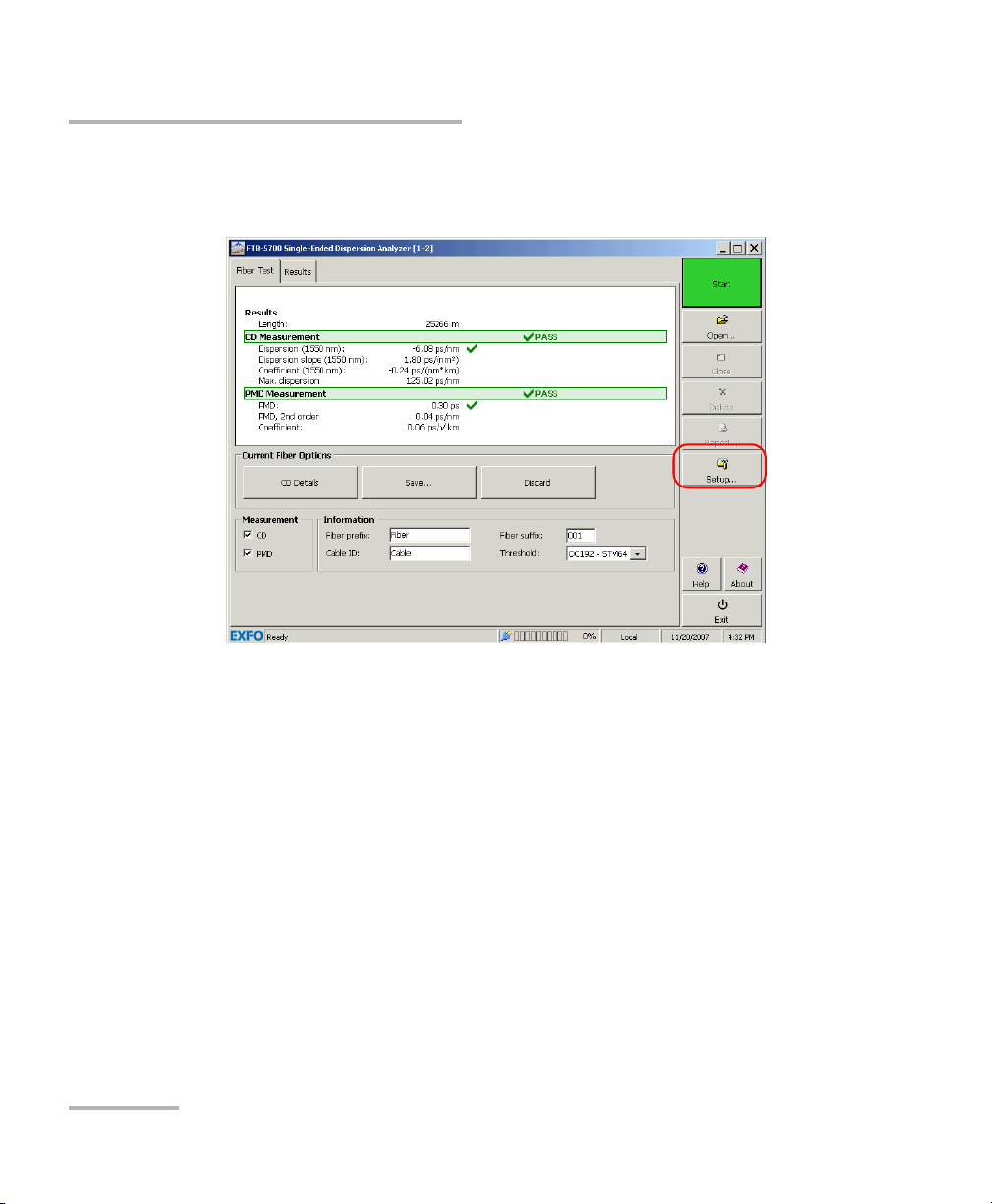

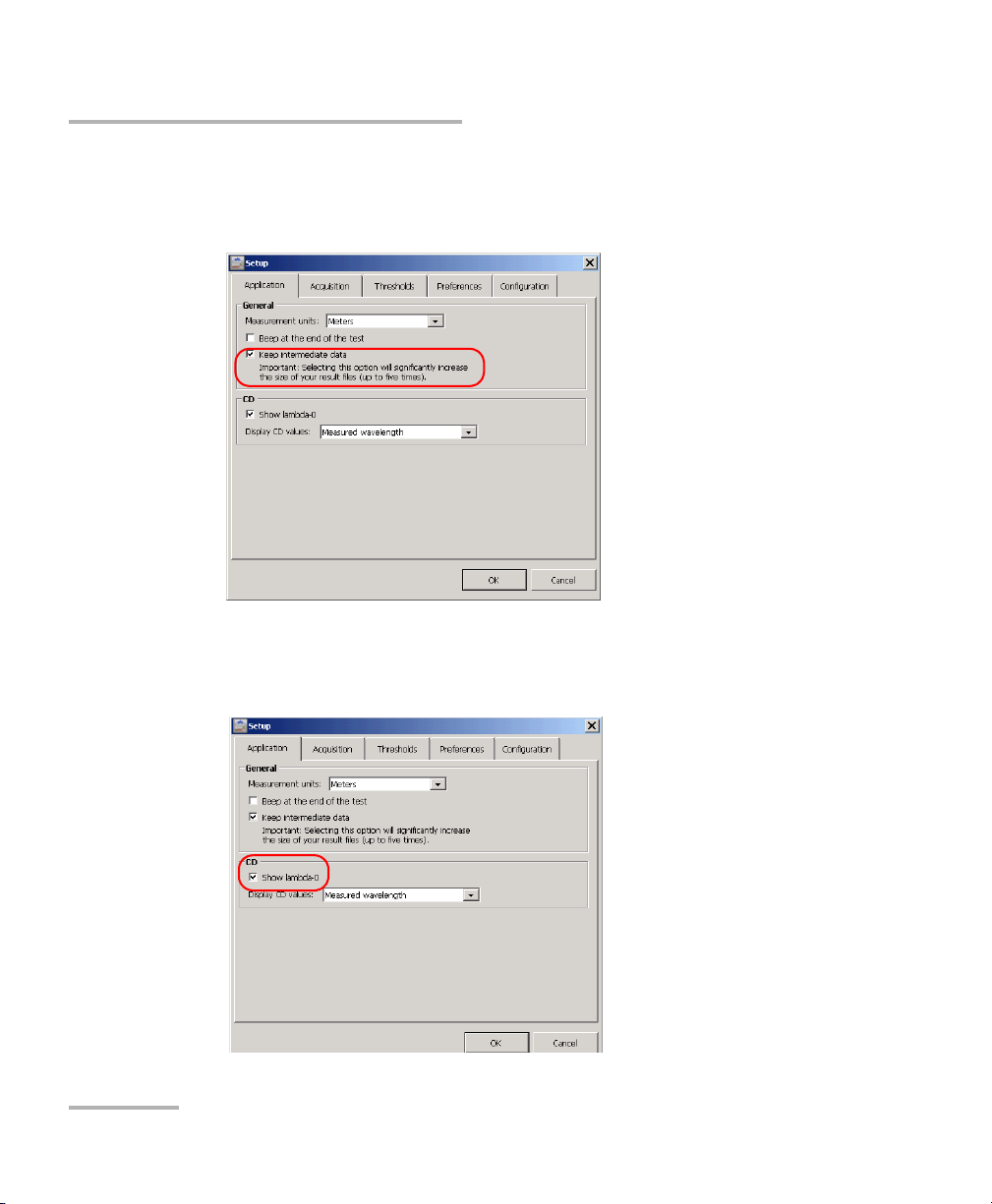

To set up the application details:

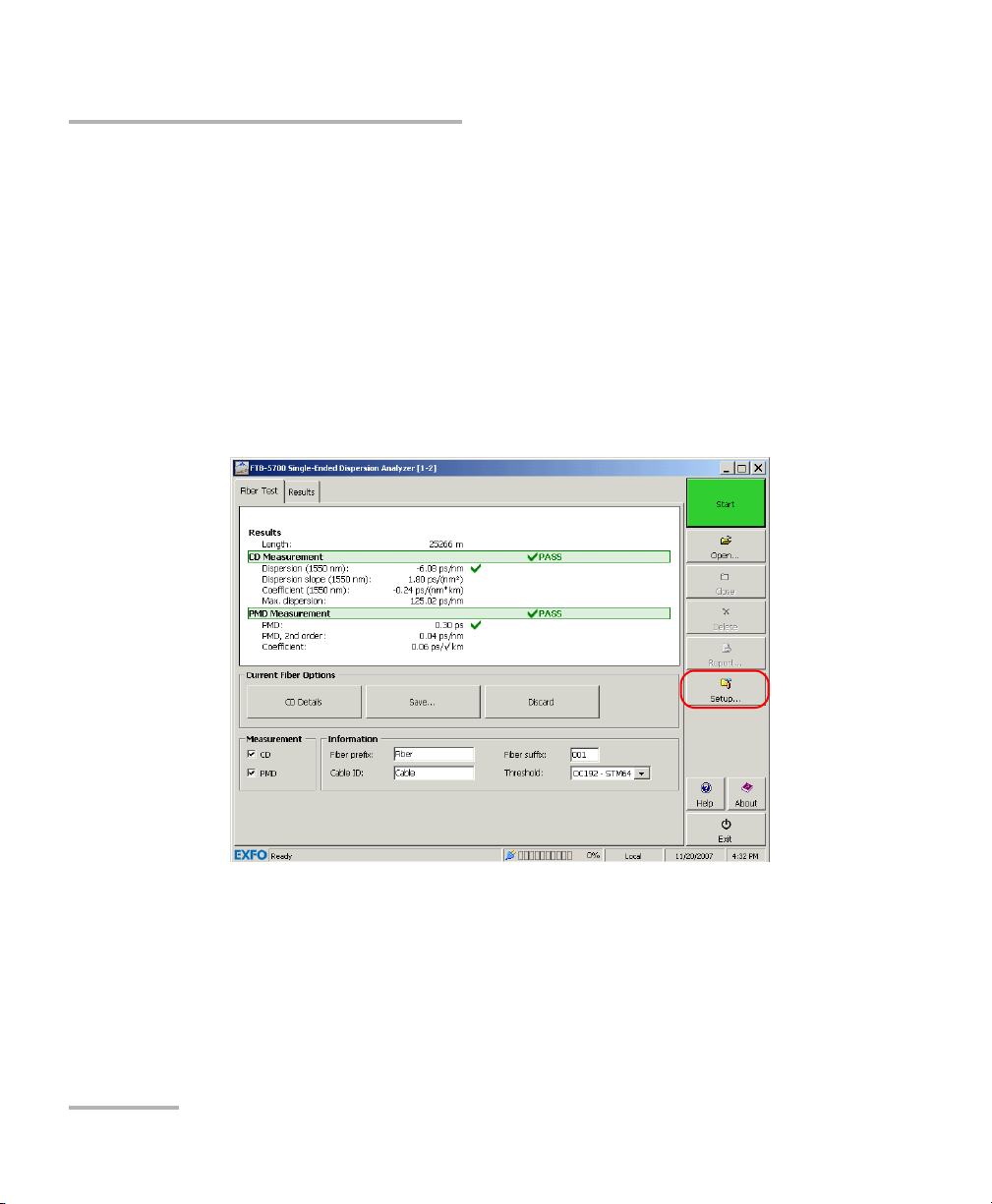

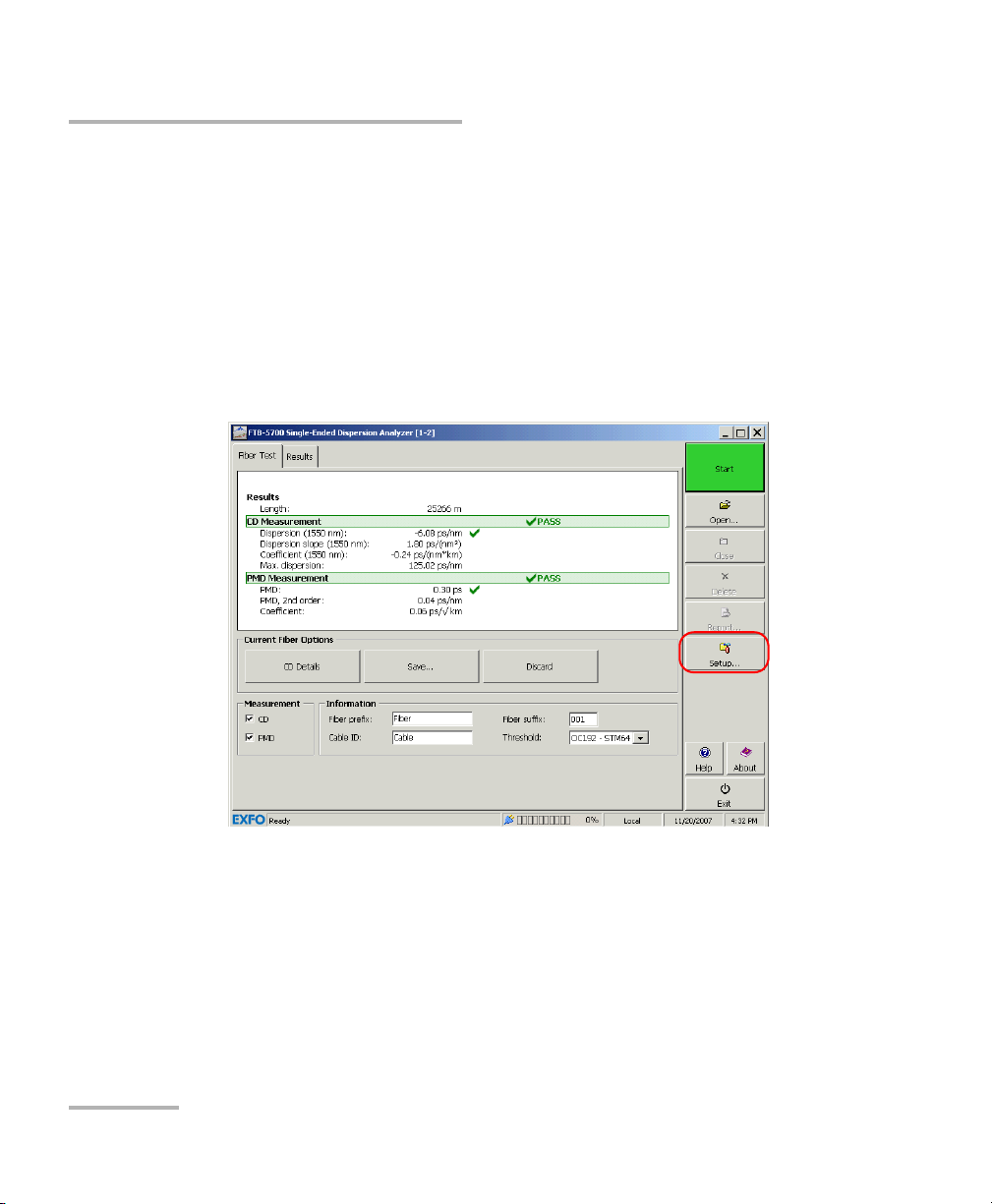

1. From the button bar, click Setup.

2. Select the Application tab.

16 FTB-5700

Page 23

Setting Up the Single-Ended Dispersion Analyzer

Setting up Application Details

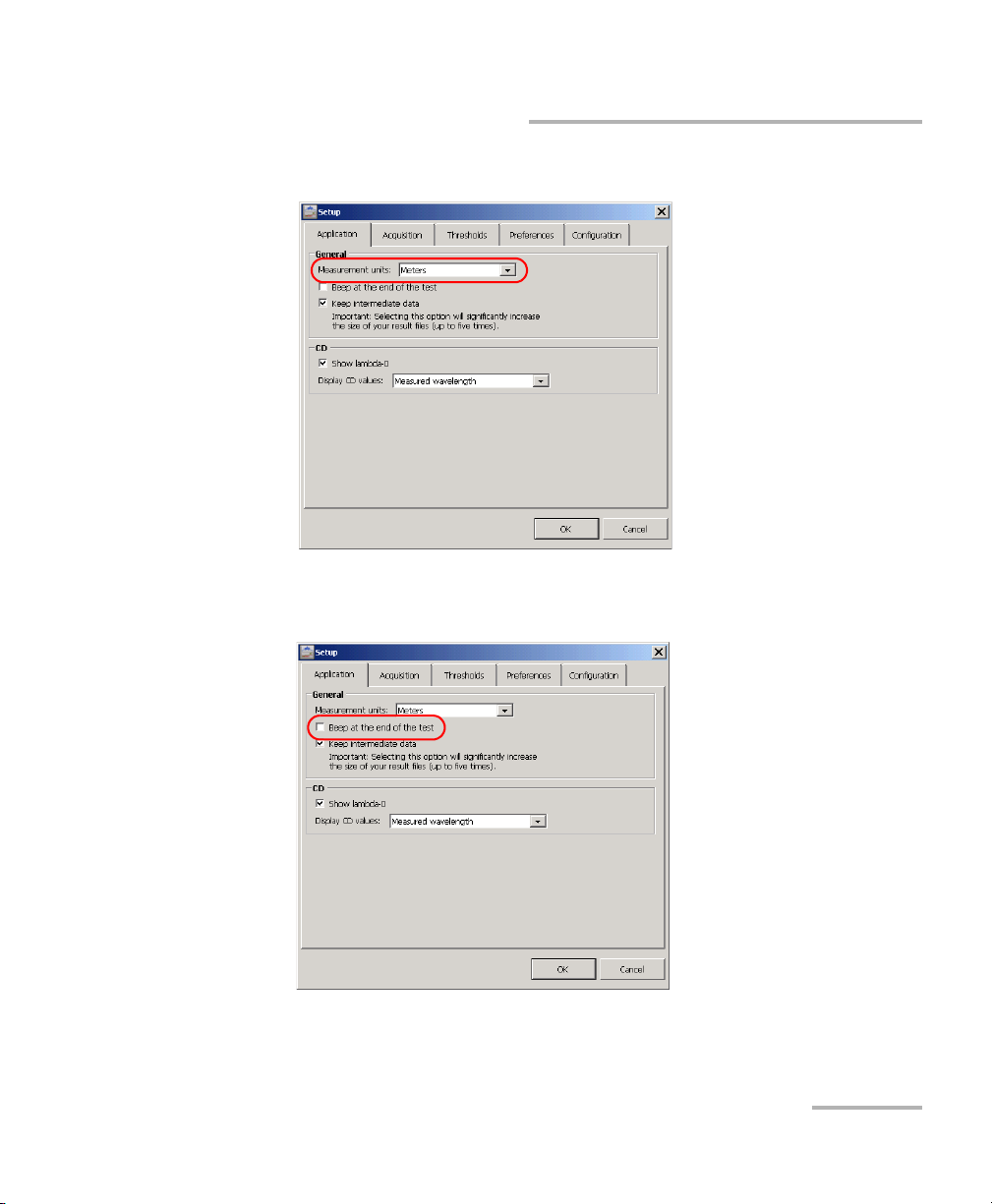

3. Select the units to use for your measurements.

4. If you would like the unit to warn you when a test is complete, select

the corresponding option.

Single-Ended Dispersion Analyzer 17

Page 24

Setting Up the Single-Ended Dispersion Analyzer

Setting up Application Details

5. If you want your Single-Ended Dispersion Analyzer to keep the

intermediate data when performing the analysis, select the

corresponding option.

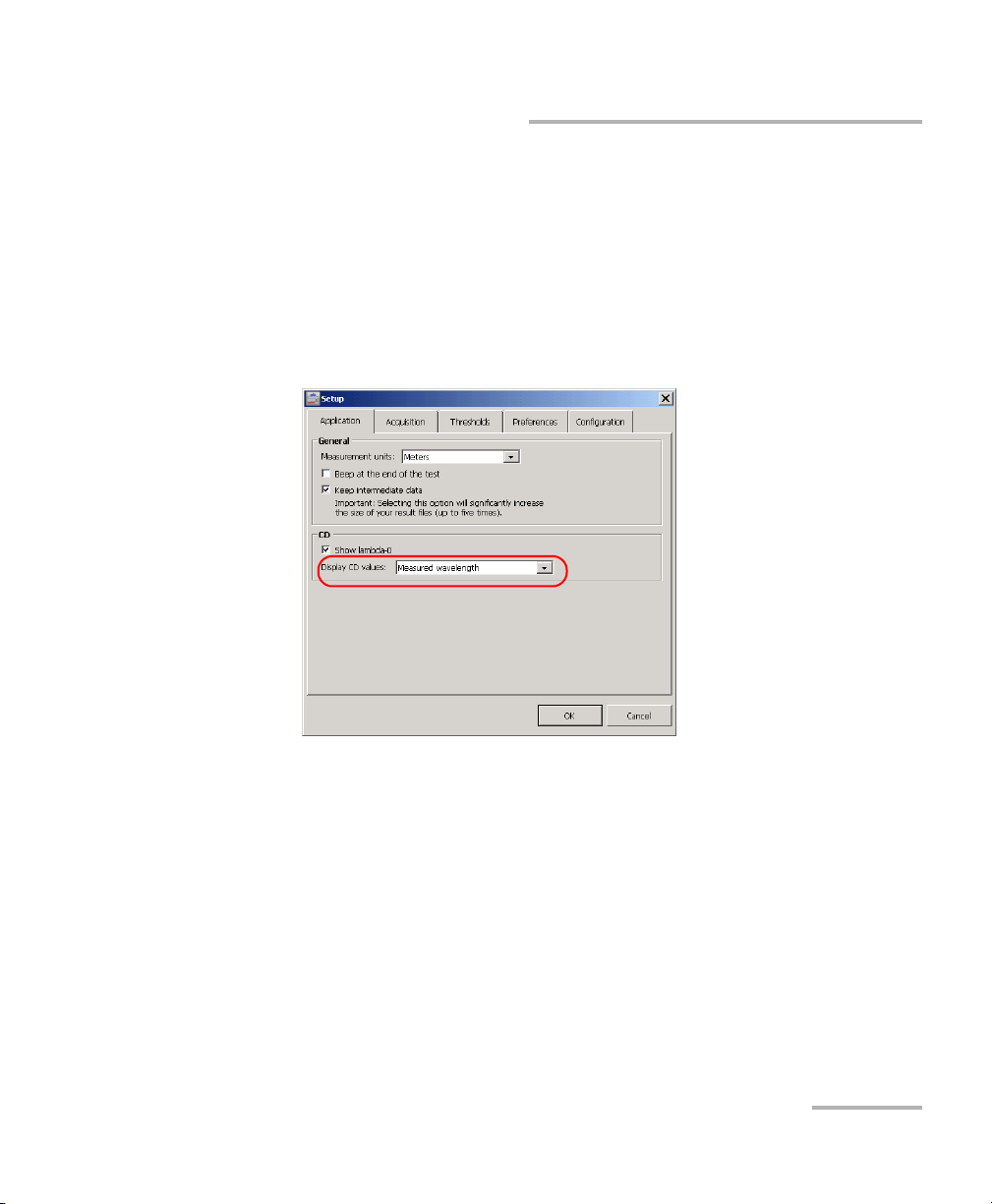

6. Under CD, select the Show lambda-0 check box to show the value if

desired (the lambda-0 value is the extrapolated wavelength at which

the dispersion equals 0).

18 FTB-5700

Page 25

Setting Up the Single-Ended Dispersion Analyzer

Setting up Application Details

7. Select the display type for the CD values amongst the available choices:

³ Measured wavelength (default value)

³ Step by 1 nm

³ ITU-50

³ ITU-100

³ ITU-200

8. To confirm and save the changes, click OK.

Single-Ended Dispersion Analyzer 19

Page 26

Setting Up the Single-Ended Dispersion Analyzer

Customizing Thresholds

Customizing Thresholds

The Single-Ended Dispersion Analyzer allows you to specify thresholds

both for the CD and PMD aspects of your tests to determine if the results

are as expected or if they exceed the specified limits.

Note: You cannot modify or delete the predefined thresholds provided with your

Single-Ended Dispersion Analyzer.

To set the thresholds:

1. From the button bar, click Setup.

20 FTB-5700

Page 27

Setting Up the Single-Ended Dispersion Analyzer

Customizing Thresholds

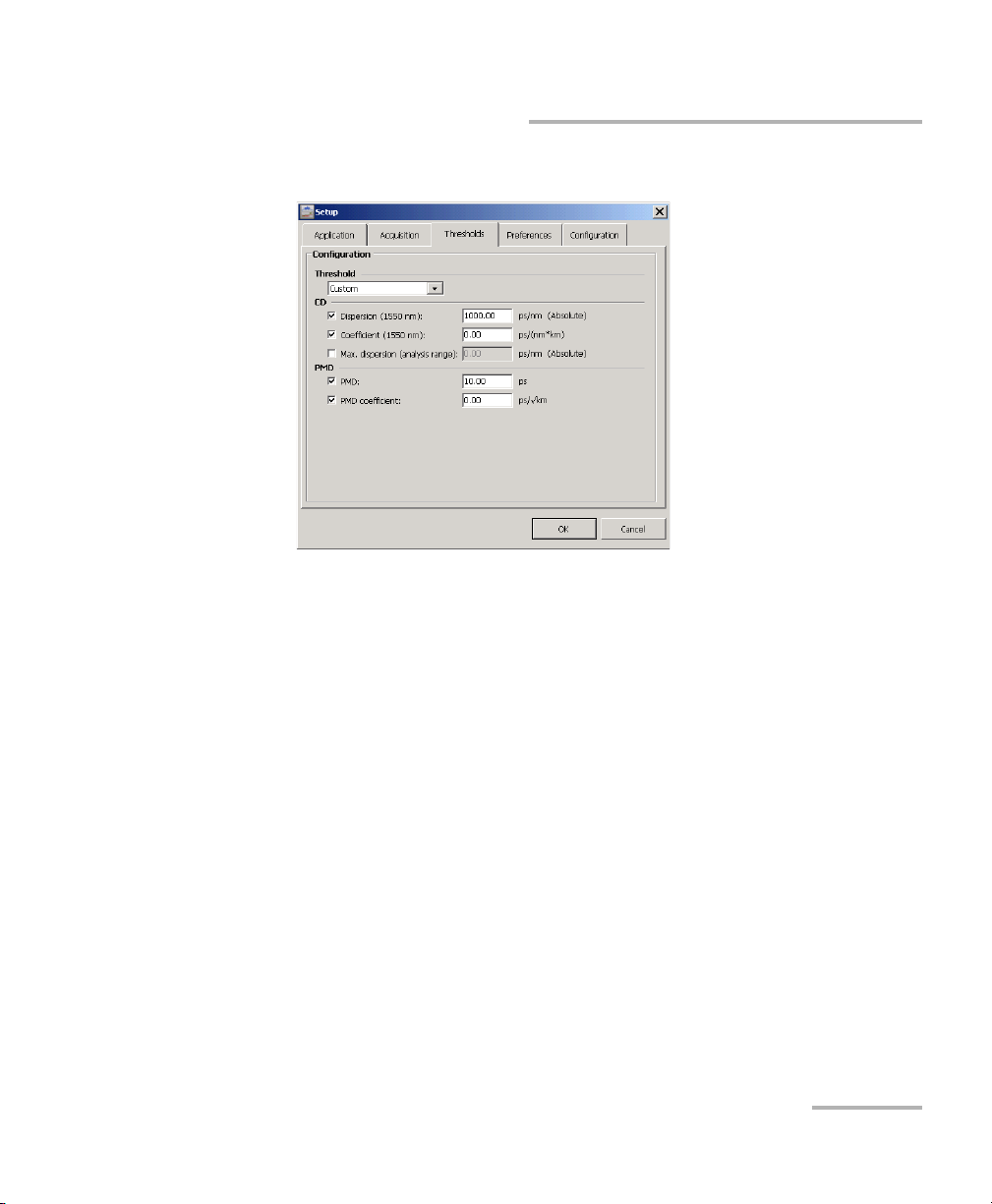

2. Select the Thresholds tab.

3. Select a predefined threshold in the Thresholds list. If you select

Custom, the chromatic dispersion and PMD sections become editable

and you can specify which values to use for the items below.

³ Dispersion (at 1550 nm)

³ Coefficient (at 1550 nm)

³ Max. dispersion (analysis range)

³ PMD

³ PMD coefficient

4. To confirm and save the changes, click OK.

Single-Ended Dispersion Analyzer 21

Page 28

Setting Up the Single-Ended Dispersion Analyzer

Setting the Wavelength Range

Setting the Wavelength Range

You can set the wavelength range within which you want to perform your

acquisitions. You can work with predefined range of the tunable source or

set the wavelength range by using the custom option. This option could be

useful to perform acquisitions in a specific area of a band or between two

bands.

To set the wavelength range:

1. From the button bar, click Setup.

22 FTB-5700

Page 29

Setting Up the Single-Ended Dispersion Analyzer

Setting the Wavelength Range

2. Select the Acquisition tab.

3. Select the range.

³ To use the default range, select the corresponding option. The

default range is directly linked to the type of fiber in use.

³ To use a customized range, disable the Default range option to

activate the minimum and maximum value boxes and enter the

desired values.

4. Click OK to confirm and save your changes.

Single-Ended Dispersion Analyzer 23

Page 30

Setting Up the Single-Ended Dispersion Analyzer

Setting PMD and CD Acquisition Parameters

Setting PMD and CD Acquisition Parameters

Parameters are kept in memory even after turning off the FTB-500.

These parameters include the following:

Parameter Details

CD Fiber Type There are several types of CD fibers. They have a

wavelength range of 1475 nm to 1626 nm, but different

fits.

³ G.652 NDSF (3-term Sellmeier fit)

³ G.653 DSF (quadratic fit)

³ G.655 NZDSF (quadratic fit)

³ G.656 Wideband NZDSF (quadratic fit)

³ Custom (default cubic fit)

Note: The only fiber type with an editable fit is

Custom.

Note: The CD and PMD fiber types are linked,

therefore if you select a fiber type, the

choices available in the other file type list

will change accordingly.

Fit The type of equation applied to measure CD (for

example, quadratic or 3-Term Sellmeier).

Number of

scans

The number of times the module will take measurements

for measuring PMD. A higher scan count will result in

more accurate data, but will take longer to perform.

24 FTB-5700

Page 31

Setting Up the Single-Ended Dispersion Analyzer

Setting PMD and CD Acquisition Parameters

Parameter Details

PMD Fiber type Must be set to one of the following types:

³ Telecommunication: also known as strong coupling.

If you are working directly in the field, you will always

use this fiber type.

³ Polarization-Maintaining (PM): also known as weak

coupling. This type is rarely used and is required for

specific types of tests only.

Note: Traces taken with a particular fiber type

cannot be reanalyzed with a different fiber

type afterwards.

Analysis Range The analysis range is the value used to calculate the ITU

grid and the maximum value for the acquisition. The

analysis range can be different from the wavelength

measurement range.

Fiber with

aerial sections

If the fiber installations are, for example, between

buildings, or suspended to reach the intended location,

the movement created by wind or other outside elements

can affect the PMD measurement. Select this option to

compensate for such possible movements.

Single-Ended Dispersion Analyzer 25

Page 32

Setting Up the Single-Ended Dispersion Analyzer

Setting PMD and CD Acquisition Parameters

To set the acquisition parameters:

1. From the button bar, click Setup.

26 FTB-5700

Page 33

Setting Up the Single-Ended Dispersion Analyzer

Setting PMD and CD Acquisition Parameters

2. Select the Acquisition tab.

3. Change the settings as needed according to the table above.

4. Click OK to confirm and save your changes.

Single-Ended Dispersion Analyzer 27

Page 34

Setting Up the Single-Ended Dispersion Analyzer

Defining the Automatic Fiber Name Format

Defining the Automatic Fiber Name Format

Each time you make a new acquisition, the fiber name changes

automatically according to a pattern you will have previously defined. This

name corresponds to the concatenation of a static part (prefix) and a

variable part that will be incremented.

To define the fiber name format:

1. From the main window, select the Fiber Test tab.

2. Under Information, set the various parameters according to your

needs.

Name for the fiber

Incremental suffix for the fiber (reverts

to 001 once it reaches 999)

Name of the cable containing the fiber

Threshold for your fibers

Note: The fiber name, cable ID and automated additions to the file name such as

the date can be set in the Preferences tab of the Setup window. See Setting

Test Preferences on page 35 for details.

28 FTB-5700

Page 35

Setting Up the Single-Ended Dispersion Analyzer

Managing Test Configurations

Managing Test Configurations

If you often perform the same test types with preset threshold values, you

can speed up your tests by saving configurations.

Note: The configuration files are independent of the unit on which they were

saved. This means that if you transfer or copy the configuration file to

another test unit, you can use it as if it had been saved on this new unit.

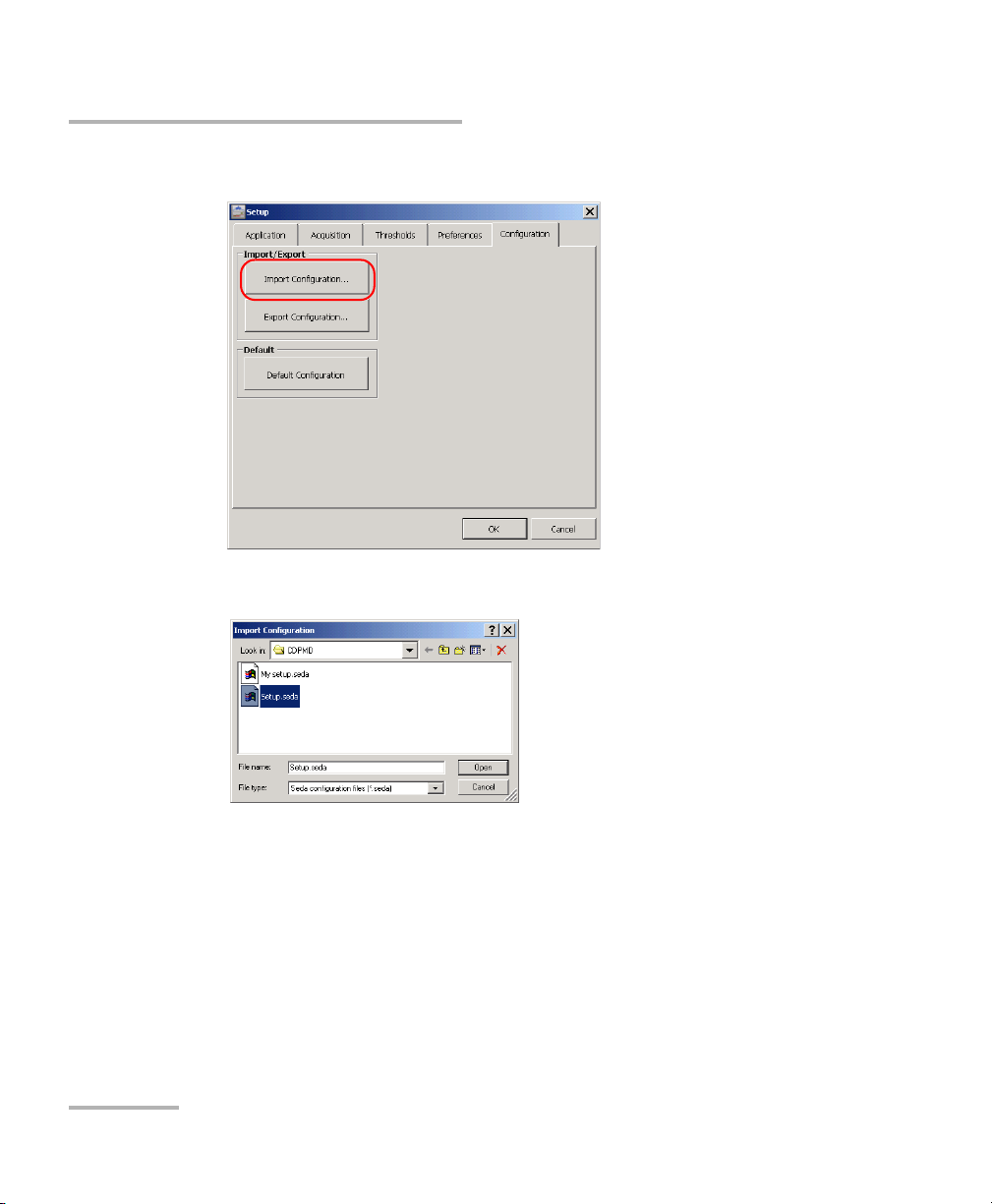

To save a configuration:

1. Set the parameters on your unit as desired.

2. From the main window, click Setup.

3. Select the Configuration tab.

Single-Ended Dispersion Analyzer 29

Page 36

Setting Up the Single-Ended Dispersion Analyzer

Managing Test Configurations

4. Click Export Configuration.

5. Select the location and name for your file, then click Save.

30 FTB-5700

Page 37

Setting Up the Single-Ended Dispersion Analyzer

To retrieve an existing configuration file:

1. From the main window, click Setup.

Managing Test Configurations

2. Select the Configuration tab.

Single-Ended Dispersion Analyzer 31

Page 38

Setting Up the Single-Ended Dispersion Analyzer

Managing Test Configurations

3. Click Import Configuration.

4. Locate the file corresponding to your configuration, then click Open.

32 FTB-5700

Page 39

Setting Up the Single-Ended Dispersion Analyzer

To revert to the default configuration:

1. From the main window, click Setup.

Managing Test Configurations

2. Select the Configuration tab.

Single-Ended Dispersion Analyzer 33

Page 40

Setting Up the Single-Ended Dispersion Analyzer

Managing Test Configurations

3. Click Default Configuration.

34 FTB-5700

Page 41

Setting Up the Single-Ended Dispersion Analyzer

Setting Test Preferences

Setting Test Preferences

You can set the autonaming and information preferences for your tests.

This will help you better identify the different tests you perform with your

module.

To set the test preferences:

1. From the main window, click Setup.

2. Select the Preferences tab.

Single-Ended Dispersion Analyzer 35

Page 42

Setting Up the Single-Ended Dispersion Analyzer

Setting Test Preferences

3. Enter the information pertaining to your test. This information will be

attached to the acquisitions you perform afterwards.

4. If you want the application to automatically include the fiber prefix,

cable name, A and B location or date in the file name scheme, select

the corresponding option.

5. Click OK to confirm your choice.

36 FTB-5700

Page 43

5 Operating the Single-Ended

Dispersion Analyzer

Cleaning and Connecting Optical Fibers

IMPORTANT

To ensure maximum power and to avoid erroneous readings:

³ Always inspect fiber ends and make sure that they are clean as

explained below before inserting them into the port. EXFO is

not responsible for damage or errors caused by bad fiber

cleaning or handling.

³ Ensure that your patchcord has appropriate connectors. Joining

mismatched connectors will damage the ferrules.

To connect the fiber-optic cable to the port:

1. Inspect the fiber using a fiber inspection microscope. If the fiber is

clean, proceed to connecting it to the port. If the fiber is dirty, clean it as

explained below.

2. Clean the fiber ends as follows:

2a. Gently wipe the fiber end with a lint-free swab dipped in isopropyl

alcohol.

2b. Use compressed air to dry completely.

2c. Visually inspect the fiber end to ensure its cleanliness.

Single-Ended Dispersion Analyzer 37

Page 44

Operating the Single-Ended Dispersion Analyzer

Cleaning and Connecting Optical Fibers

3. Carefully align the connector and port to prevent the fiber end from

touching the outside of the port or rubbing against other surfaces.

If your connector features a key, ensure that it is fully fitted into the

port’s corresponding notch.

4. Push the connector in so that the fiber-optic cable is firmly in place,

thus ensuring adequate contact.

If your connector features a screwsleeve, tighten the connector

enough to firmly maintain the fiber in place. Do not overtighten, as this

will damage the fiber and the port.

Note: If your fiber-optic cable is not properly aligned and/or connected, you will

notice heavy loss and reflection.

38 FTB-5700

Page 45

Operating the Single-Ended Dispersion Analyzer

Installing the EXFO Universal Interface (EUI)

Installing the EXFO Universal Interface (EUI)

The EUI fixed baseplate is available for connectors with angled (APC) or

non-angled (UPC) polishing. A green border around the baseplate

indicates that it is for APC-type connectors.

Green border

indicates APC

option

Bare metal

(or blue border)

indicates UPC

option

To install an EUI connector adapter onto the EUI baseplate:

1. Hold the EUI connector adapter so the dust cap opens downwards.

2 3 4

2. Close the dust cap in order to hold the connector adapter more firmly.

3. Insert the connector adapter into the baseplate.

4. While pushing firmly, turn the connector adapter clockwise on the

baseplate to lock it in place.

Single-Ended Dispersion Analyzer 39

Page 46

Operating the Single-Ended Dispersion Analyzer

Per for ming a Test

Performing a Test

The Single-Ended Dispersion Analyzer allows you to acquire single traces

on a specific fiber. You can test the PMD, the CD, or both at the same time.

IMPORTANT

Your FTB-5700 Single-Ended Dispersion Analyzer was designed to

automatically determine the length of your fiber and test

accordingly. If the test is still performed and the length indicated is

not appropriate, this mean that a strong reflective event is present

on the fiber before the non-reflective termination.

If such a situation occurs, clean the fiber end or add a reflector at

the end of the fiber to improve your results.

40 FTB-5700

Page 47

Operating the Single-Ended Dispersion Analyzer

Performing a Test

To start an acquisition:

1. Set the acquisition parameters as needed. See the corresponding user

guide sections for more details.

2. Select whether the acquisition will include PMD, CD, or both.

3. Verify that the fiber (FUT) is properly connected and that the setup is

appropriate.

IMPORTANT

The FUT must be terminated by a UPC connector.

Single-Ended Dispersion Analyzer 41

Page 48

Operating the Single-Ended Dispersion Analyzer

Per for ming a Test

4. From the button bar, click Start to start a measurement sequence.

When the measurement is complete, the results are displayed in the

grid.

5. If you are satisfied with the results, click Save. The entry will be sent to

the Results tab.

If you are not satisfied with the results, click Discard to clear the test

window and perform a new test.

To stop the acquisition before it is complete:

Click the Stop button. The button changes back to a green Start button.

42 FTB-5700

Page 49

6 Managing Results

Your FTB-5700 Single-Ended Dispersion Analyzer allows you to work with

two types of results:

³ Newly acquired results

³ Results loaded from existing files

To view and analyze your results, the application provides:

³ A graph and a table presenting details for a specific acquisition in the

case of chromatic dispersion

³ A window giving you an overview of all the available acquisitions, plus

the related details

It also offers customizing, saving, export and printing features based on

these results.

IMPORTANT

Your FTB-5700 Single-Ended Dispersion Analyzer was designed to

automatically determine the length of your fiber and test

accordingly. If the test is still performed and the length indicated is

not appropriate, this mean that a strong reflective event is present

on the fiber before the non-reflective termination.

If such a situation occurs, clean the fiber end or add a reflector at

the end of the fiber to improve your results.

Single-Ended Dispersion Analyzer 43

Page 50

Managing Results

To view a specific result and the related information:

From the main window Results tab, once you have taken a measurement

and saved it, or opened measurement files, you can select the fiber for

which you want to view the results.

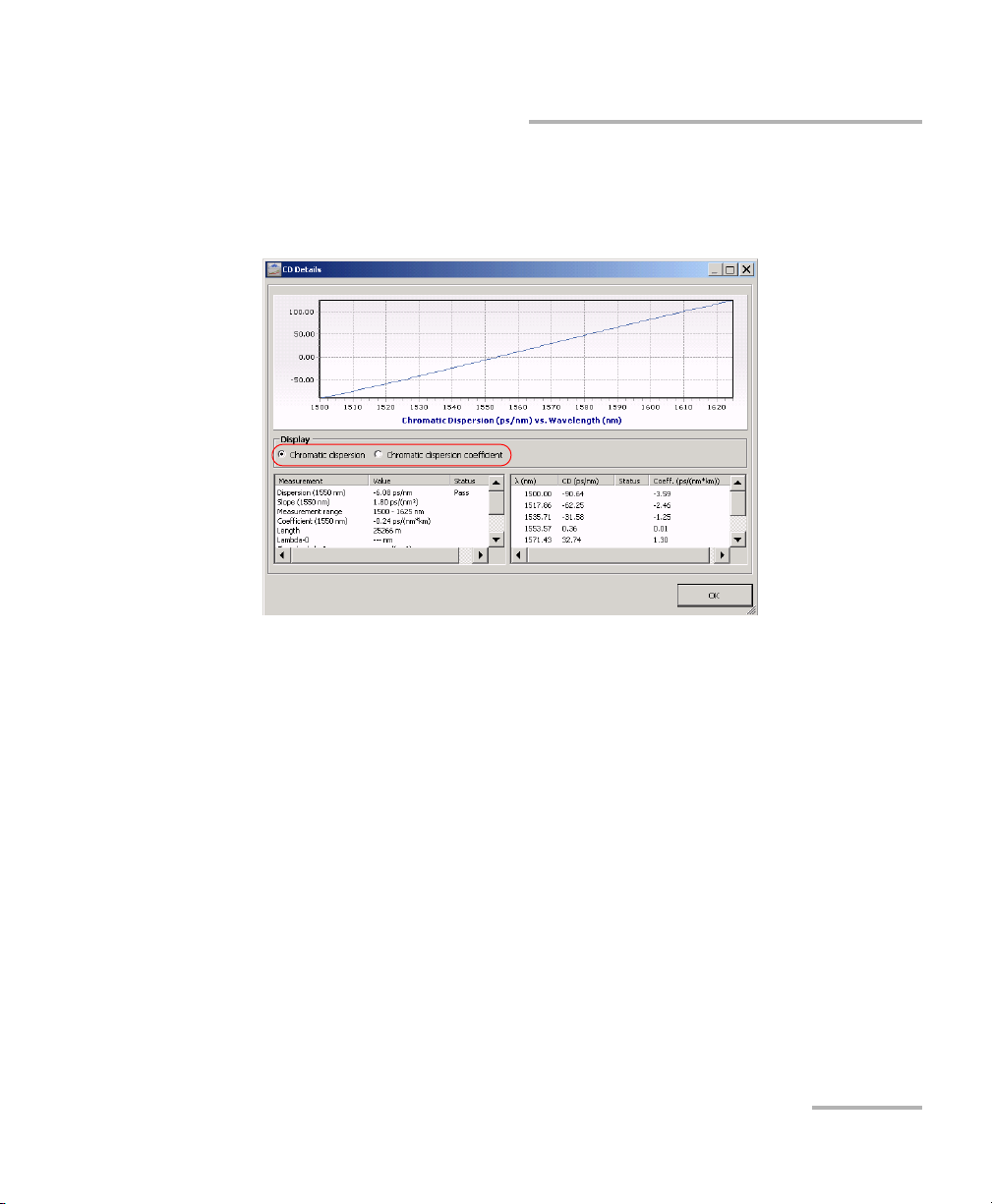

To view CD Details:

In the Fiber Test tab, click Details.

OR

In the Results tab, click CD Details.

44 FTB-5700

Page 51

Managing Results

To specify the type of display to show on the graph:

In the CD Display window, under the graph, select either Chromatic

dispersion or Chromatic dispersion coefficient.

The graph and the results in the Display table will change accordingly.

Single-Ended Dispersion Analyzer 45

Page 52

Managing Results

Modifying Analysis Parameters and Related Information

Modifying Analysis Parameters and Related

Information

Once you have acquired test results, you can modify the parameters and

perform the analysis again with the new settings. You can also add or

modify information about the job and cable at this point.

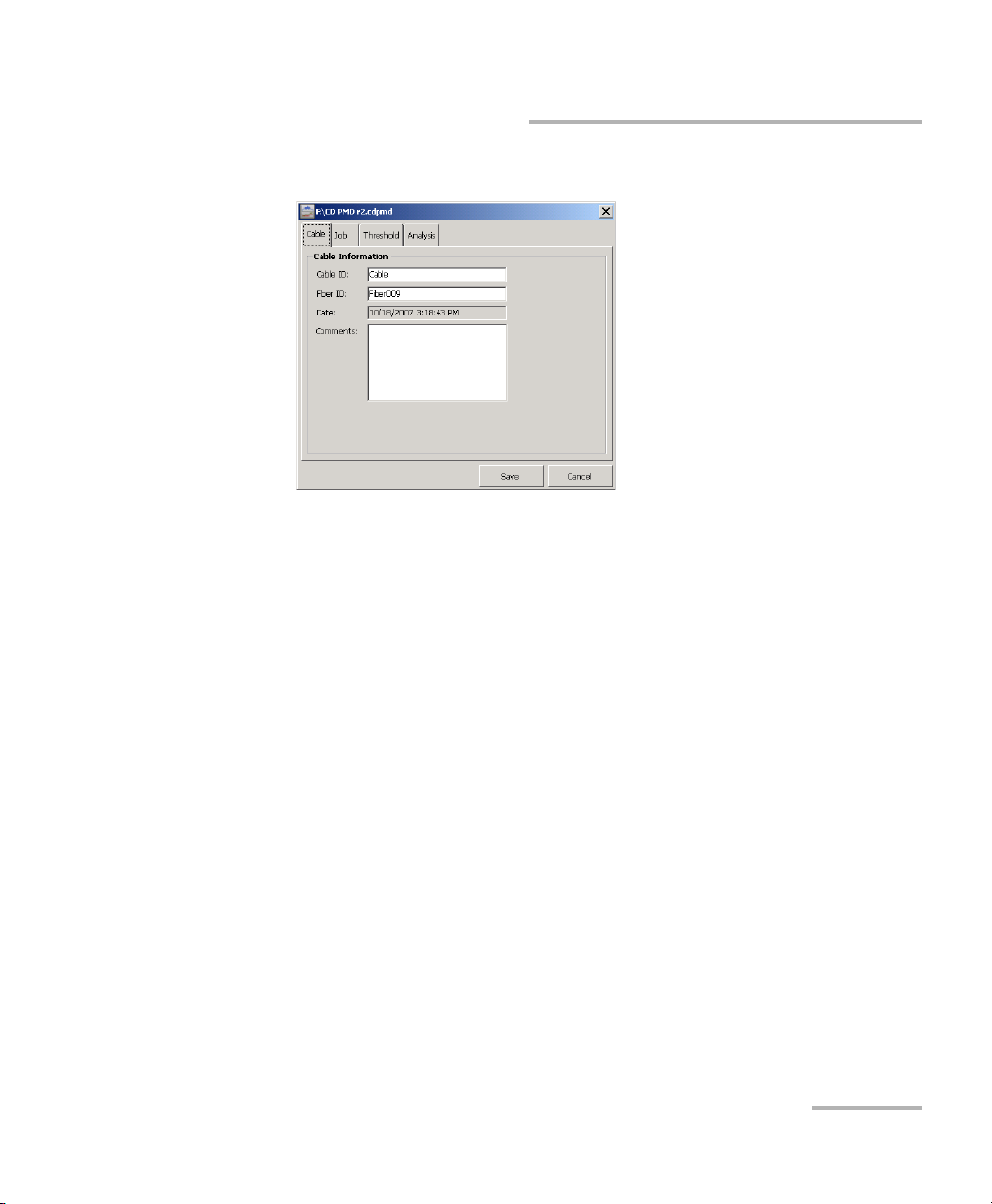

Modifying Cable Information

Since the test was already performed, you can add specific comments on

the cable at this point, or rename it in a easy to recognize manner.

To modify cable information for your test:

1. Acquire test results by performing a scan, or retrieve a file or files from

the Open button.

2. In the Results tab, press Edit.

46 FTB-5700

Page 53

Modifying Analysis Parameters and Related Information

3. Select the Cable tab.

4. Fill the boxes according to your needs.

5. When you are done, click Save.

Managing Results

Single-Ended Dispersion Analyzer 47

Page 54

Managing Results

Modifying Analysis Parameters and Related Information

Modifying Job Information

If the job was performed by a different person than the original settings

indicated, or that the location changed, you may adjust the information

here.

To modify job information for your test:

1. Acquire test results by performing a scan, or retrieve a file or files from

the Open button.

2. In the Results tab, press Edit.

48 FTB-5700

Page 55

Modifying Analysis Parameters and Related Information

3. Select the Job tab.

4. Fill the boxes according to your needs.

5. When you are done, click Save.

Managing Results

Single-Ended Dispersion Analyzer 49

Page 56

Managing Results

Modifying Analysis Parameters and Related Information

Modifying Threshold Parameters

Any change in the threshold parameters will take effect when you

reanalyze the trace file.

To modify threshold parameters for your test:

1. Acquire test results by performing a scan, or retrieve a file or files from

the Open button.

2. In the Results tab, press Edit.

3. Select the Threshold tab.

50 FTB-5700

Page 57

Managing Results

Modifying Analysis Parameters and Related Information

4. Change the desired threshold settings (for details on the settings, see

Customizing Thresholds on page 20).

5. Save your analysis parameters; the results are changed accordingly by

your unit.

Single-Ended Dispersion Analyzer 51

Page 58

Managing Results

Modifying Analysis Parameters and Related Information

Modifying Analysis Parameters

The analysis parameters include the analysis range and the fiber type.

To modify analysis parameters for your test:

1. Acquire test results by performing a scan, or retrieve a file or files from

the Open button.

2. In the Results tab, press Edit.

3. Select the Analysis tab.

52 FTB-5700

Page 59

Managing Results

Modifying Analysis Parameters and Related Information

4. Change the desired analysis settings (for details on the settings, see

Setting PMD and CD Acquisition Parameters on page 24).

5. Save your analysis parameters; the results are changed accordingly by

your unit.

Single-Ended Dispersion Analyzer 53

Page 60

Managing Results

Opening Existing Files

Opening Existing Files

You can open existing files without losing the current results and

information.

If a file is already selected in the list, the opened file will replace the

selected file. If no file was selected, the new file will be added at

the bottom of the list.

To open an existing file:

1. From the button bar, click Open.

IMPORTANT

A standard Open dialog box is displayed, allowing you to select the

desired file.

2. When you are done, from the displayed dialog box, click Open to load

the files.

54 FTB-5700

Page 61

Managing Results

Removing Unwanted Results

Removing Unwanted Results

When a problem occurs, such as a fiber break, you may want to remove

the corresponding erroneous measurement. This could be useful to avoid

distorting results and statistics.

IMPORTANT

Removing a saved file using the Delete button will remove the file

from the drive.

To remove unwanted results from the disk:

1. From the main window Results tab, once you have taken a and saved

a measurement or opened measurement files, you can select the fiber

to remove.

2. Select the desired fiber by clicking on it once, then click Delete.

3. A confirmation message will be displayed. Click Yes to confirm.

Single-Ended Dispersion Analyzer 55

Page 62

Managing Results

Closing Result Files

Closing Result Files

For easier result management, you may want to close the result files

manually.

Note: You do not need to close files manually before exiting the Single-Ended

Dispersion Analyzer application. You will be prompted if some result files

have not been saved.

To c l os e f i le s :

1. In the Results tab, select the file to close.

2. Click Close.

56 FTB-5700

Page 63

Managing Results

Generating a Report

You can generate an html report for the currently selected file.

To generate a report:

1. From either the Fiber Test or Results window, click Report.

2. Select a name and location for your report.

Generating a Report

3. Click Save to create the report.

Single-Ended Dispersion Analyzer 57

Page 64

Page 65

7 Maintenance

To help ensure long, trouble-free operation:

³ Always inspect fiber-optic connectors before using them and clean

them if necessary.

³ Keep the unit free of dust.

³ Clean the unit casing and front panel with a cloth slightly dampened

with water.

³ Store unit at room temperature in a clean and dry area. Keep the unit

out of direct sunlight.

³ Avoid high humidity or significant temperature fluctuations.

³ Avoid unnecessary shocks and vibrations.

³ If any liquids are spilled on or into the unit, turn off the power

immediately and let the unit dry completely.

Use of controls, adjustments, and procedures for operation and

maintenance other than those specified herein may result in

hazardous radiation exposure.

WARNING

Single-Ended Dispersion Analyzer 59

Page 66

Maintenance

Cleaning EUI Connectors

Cleaning EUI Connectors

Regular cleaning of EUI connectors will help maintain optimum

performance. There is no need to disassemble the unit.

If any damage occurs to internal connectors, the module casing will

have to be opened and a new calibration will be required.

To clean EUI connectors:

1. Remove the EUI from the instrument to expose the connector

baseplate and ferrule.

IMPORTANT

Turn

Push

2. Moisten a 2.5 mm cleaning tip with one drop of isopropyl alcohol

(alcohol may leave traces if used abundantly).

3. Slowly insert the cleaning tip into the EUI adapter until it comes out on

the other side (a slow clockwise rotating movement may help).

Pull

3

4

5

4. Gently turn the cleaning tip one full turn, then continue to turn as you

withdraw it.

60 FTB-5700

Page 67

Cleaning EUI Connectors

5. Repeat steps 3 to 4 with a dry cleaning tip.

Note: Make sure you don’t touch the soft end of the cleaning tip.

6. Clean the ferrule in the connector port as follows:

6a. Deposit one drop of isopropyl alcohol on a lint-free wiping cloth.

IMPORTANT

Isopropyl alcohol may leave residues if used abundantly or left to

evaporate (about 10 seconds).

Avoid contact between the tip of the bottle and the wiping cloth,

and dry the surface quickly.

6b. Gently wipe the connector and ferrule.

6c. With a dry lint-free wiping cloth, gently wipe the same surfaces to

ensure that the connector and ferrule are perfectly dry.

6d. Verify connector surface with a portable fiber-optic

microscope(for example, EXFO’s FOMS) or fiber inspection

probe(for example, EXFO’s FIP).

Maintenance

WARNING

Verifying the surface of the connector WHILE THE UNIT IS ACTIVE

WILL result in permanent eye damage.

7. Put the EUI back onto the instrument (push and turn clockwise).

8. Throw out cleaning tips and wiping cloths after one use.

Single-Ended Dispersion Analyzer 61

Page 68

Maintenance

Recalibrating the Unit

Recalibrating the Unit

Manufacturing and service center calibrations are based on the

ISO/IEC 17025 Standard, which states that calibration documents must not

contain a recommended calibration interval, unless this has been

previously agreed upon with the customer.

Validity of specifications depends on operating conditions. For example,

the calibration validity period can be longer or shorter depending on the

intensity of use, environmental conditions and unit maintenance. You

should determine the adequate calibration interval for your unit according

to your accuracy requirements.

Under normal use, EXFO recommends calibrating your unit every year.

62 FTB-5700

Page 69

Maintenance

Recycling and Disposal (Applies to European Union Only)

Recycling and Disposal

(Applies to European Union Only)

Recycle or dispose of your product (including electric and

electronic accessories) properly, in accordance with local

regulations. Do not dispose of it in ordinary garbage receptacles.

This equipment was sold after August 13, 2005 (as identified by

the black rectangle).

³ Unless otherwise noted in a separate agreement between EXFO and a

customer, distributor, or commercial partner, EXFO will cover costs

related to the collection, treatment, recovery, and disposal of

end-of-lifecycle waste generated by electronic equipment introduced

after August 13, 2005 to an European Union member state with

legislation regarding Directive 2002/96/EC.

³ Except for reasons of safety or environmental benefit, equipment

manufactured by EXFO, under its brand name, is generally designed to

facilitate dismantling and reclamation.

For complete recycling/disposal procedures and contact information, visit

the EXFO Web site at www.exfo.com/recycle.

Single-Ended Dispersion Analyzer 63

Page 70

Page 71

8 Troubleshooting

Solving Common Problems

Before calling EXFO’s technical support, you may want to consider the

following solutions to problems that could occur.

Note: Should you have problems, you can activate the Keep intermediate data

option in the Acquisition tab of the Setup window and send the resulting

file to EXFO. This will allow us to help troubleshooting the problem.

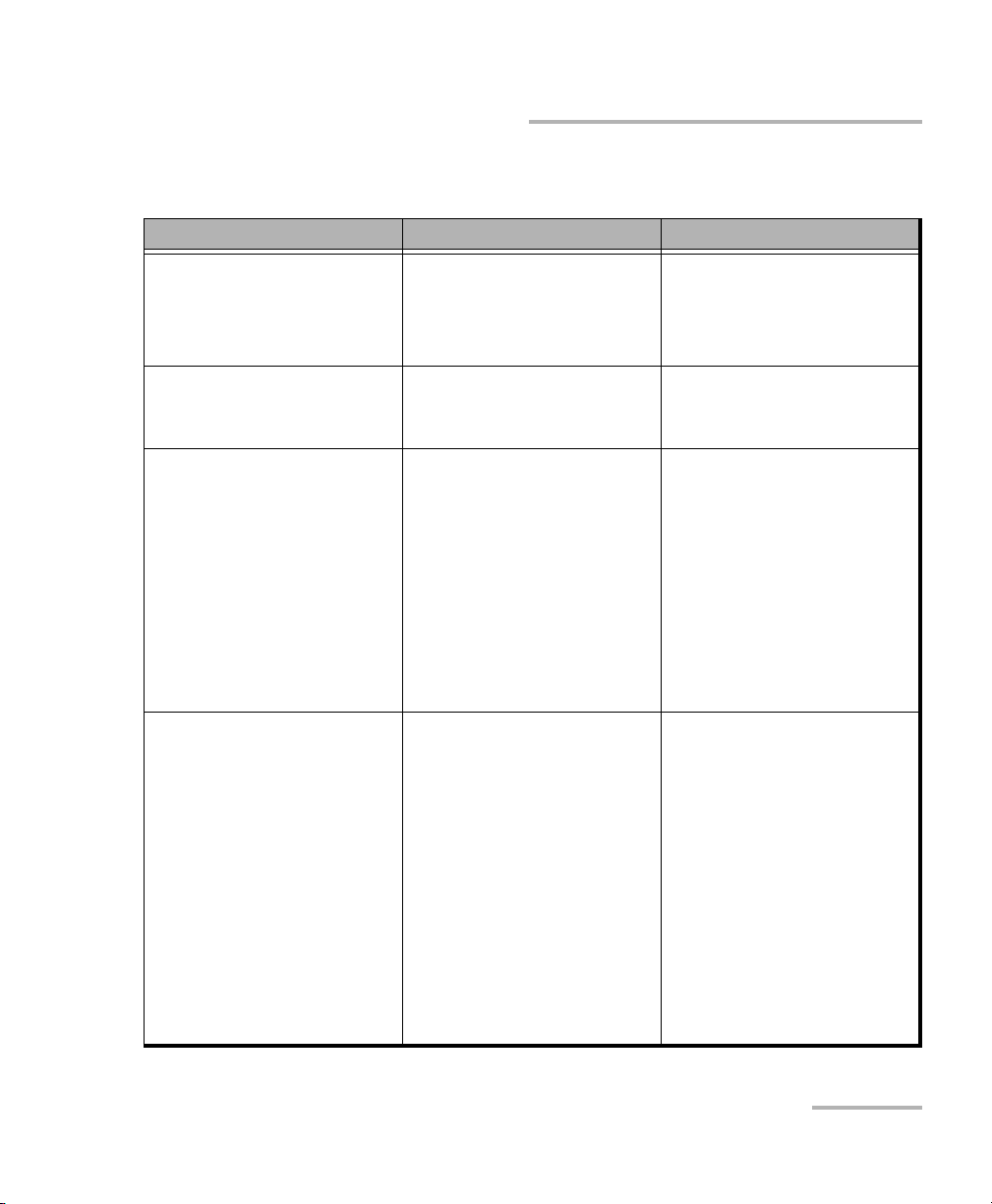

General Problems

Message Possible cause Solution

No fiber is connected or

there is a bad connection.

A non-reflective fiber end

was found at [distance].

The signal fall-in noise is at

[distance].

³ The fiber is not properly

connected.

³ The connector is

broken.

³ There is a strong loss at

the very beginning of

the link.

The fiber under test is not

terminated by a UPC

connector.

³ The fiber under test is

not terminated by a UPC

connector.

³ The distance is above

the dynamic range.

³ Verify that the fiber is

properly connected.

³ Verify that the connector

is not broken.

³ Verify that the beginning

of the fiber under test

does not show strong

losses.

³ Clean the connector.

Verify that the fiber under

test is terminated by a UPC

connector.

³ Verify that the fiber

under test is terminated

by a UPC connector.

³ Make sure that the

distance is within the

dynamic range.

Single-Ended Dispersion Analyzer 65

Page 72

Troubleshooting

Solving Common Problems

Message Possible cause Solution

Unable to find a reflective

fiber end. Please verify that

Too much loss in the fiber

under test

the fiber under test is

properly connected and

terminated by a UPC

connector.

Optical power is too low. Too much loss in the fiber

under test.

Unable to find a valid

wavelength range.

³ Too much loss in the

fiber under test.

³ The wavelength range is

too large.

³ Clean the fiber end.

³ Add a reflective

termination at the end

of the fiber.

³ Clean the fiber end.

³ Add a reflective

termination at the end

of the fiber.

³ Clean the fiber end.

³ Add a reflective

termination at the end

of the fiber.

³ Reduce the wavelength

range in the Acquisition

tab of the Setup

window, or select

Default as the

wavelength range value.

66 FTB-5700

Page 73

Troubleshooting

Solving Common Problems

PMD-Related Problems

Message Possible cause Solution

Conditions are not optimal

for measuring polarization

mode dispersion. Cannot

perform measurement.

Unable to ensure a correct

PMD measurement over the

selected wavelength range.

Optical power is not strong

enough to ensure a correct

PMD measurement over the

selected wavelength range.

Unable to ensure a correct

PMD measurement over the

selected wavelength range

because the detector is

saturated.

Too much loss in the fiber

under test.

Measurement wavelength

range is to wide.

Too much loss in the fiber

under test.

³ Fiber end is too

reflective.

³ Unsuitable selected

wavelength range for

the measured FUT (out

of the FUT bandwidth).

³ Unsuitable FUT. The

FUT must not cut the

1550 nm wavelength.

³ Clean the fiber end.

³ Add a reflective

termination at the end

of the fiber.

Try to narrow down the

measurement wavelength

range.

³ Clean the fiber end.

³ Add a reflective

termination at the end

of the fiber.

³ Reduce the wavelength

range in the Acquisition

tab of the Setup

window, or select

Default as the

wavelength range value.

³ If you have put a

reflective termination at

the end of the fiber,

remove it.

³ Select a wavelength

range that suits the FUT

and the instrument

range. You can set the

wavelength range in the

Acquisition tab of the

Setup window.

Single-Ended Dispersion Analyzer 67

Page 74

Troubleshooting

Solving Common Problems

Message Possible cause Solution

Unable to ensure a correct

PMD measurement over the

selected wavelength range

because of a combination of

saturated detector and low

optical power.

The measurement range is

too short for a PMD

measurement

Impossible to find a valid

measurement range.

³ Fiber end is too

reflective.

³ Unsuitable selected

wavelength range for

the measured FUT (out

of the FUT bandwidth).

³ Unsuitable FUT. The

FUT must not cut the

1550 nm wavelength.

Measurement range is too

short.

³ Too much loss in the

fiber under test.

³ Unsuitable FUT. The

FUT must not cut the

1550 nm wavelength.

³ If you have put a

reflective termination at

the end of the fiber,

remove it.

³ Select a wavelength

range that suits the FUT

and the instrument

range. You can set the

wavelength range in the

Acquisition tab of the

Setup window.

Try to use a larger

measurement range.

³ Clean the fiber end.

³ Add a reflective

termination at the end

of the fiber.

68 FTB-5700

Page 75

Troubleshooting

Solving Common Problems

Message Possible cause Solution

The unit has detected too

important polarization

fluctuations on the fiber. No

PMD measurement was

performed.

³ The unit was moved

during the

measurement

³ The fiber moved during

the measurement

³ Make sure not to move

the unit.

³ Make sure that the fiber

does not move during

the measurement.

³ If some movement is

inevitable (fiber is

outside with aerial

sections), make sure

that the Fiber with

aerial sections option is

selected in the Setup

tab of the Acquisition

window.

³ Contact EXFO if the

problem is still not

solved.

Single-Ended Dispersion Analyzer 69

Page 76

Troubleshooting

Solving Common Problems

CD-Related Problems

Message Possible cause Solution

Conditions are not

optimal for measuring

chromatic dispersion.

Cannot achieve good

measurement quality.

There are not enough

points to compute the

model fit. Use a lower

order fiber model.

There are not enough

valid points to compute

the model fit due to low

power conditions in the

selected range.

³ Too much l o ss in

the fiber under test.

³ Multiple strong

reflections close to

each other at the

end of fiber.

The wavelength range

is too big.

³ Too much l o ss in

the fiber under test.

³ The wavelength

range is unsuitable

for this FUT.

³ Clean the fiber end.

³ Add a reflective termination at

the end of the fiber.

³ In this case, add a receive fiber

of at least 200 m. This will

remove that condition.

Reduce the wavelength range in the

Acquisition tab of the Setup

window, or select Default as the

wavelength range value.

To reduce the constraints on the fit,

it may be possible, if applicable, to

lower the fit model order (for

example, select a 3-term Sellmeier

instead of a 5-term Sellmeier

model).

³ Clean the fiber end.

³ Add a reflective termination at

the end of the fiber.

³ Select a wavelength range that

suits the FUT and the instrument

range. You can set the

wavelength range in the

Acquisition tab of the Setup

window.

70 FTB-5700

Page 77

Troubleshooting

Solving Common Problems

Message Possible cause Solution

There are not enough

valid points to compute

the model fit due to

detector saturation

conditions in the

selected range.

There are not enough

valid points to compute

the model fit due to a

combination of detector

saturation and low

power conditions in the

selected range.

³ Fiber end is too

reflective.

³ Unsuitable FUT.

The FUT must not

cut the 1550 nm

wavelength.

³ Fiber end is too

reflective.

³ Unsuitable selected

wavelength range

for the measured

FUT (out of the FUT

bandwidth).

³ Unsuitable FUT.

The FUT must not

cut the 1550 nm

wavelength.

³ If you have put a reflective

termination at the end of the

fiber, remove it.

³ If you have put a reflective

termination at the end of the

fiber, remove it.

³ Select a wavelength range that

suits the FUT and the instrument

range. You can set the

wavelength range in the

Acquisition tab of the Setup

window.

Single-Ended Dispersion Analyzer 71

Page 78

Troubleshooting

Obtaining Online Help

Obtaining Online Help

An online version of the FTB-5700 Single-Ended Dispersion Analyzer user

guide is conveniently available at all times from the application.

Note: You will also find a printable PDF version on your installation CD.

To access online help:

Click the Help button on the function bar.

72 FTB-5700

Page 79

Troubleshooting

Contacting the Technical Support Group

Contacting the Technical Support Group

To obtain after-sales service or technical support for this product, contact

EXFO at one of the following numbers. The Technical Support Group is

available to take your calls from Monday to Friday, 8:00 a.m. to 7:00 p.m.

(Eastern Time in North America).

For detailed information about technical support, visit the EXFO Web site at

www.exfo.com.

To accelerate the process, please have information such as the name and

the serial number (see the product identification label—an example is

shown below), as well as a description of your problem, close at hand.

P/N

**************** A

542392-3D

S/N

Made in Canada QST442B

January 2020

Ver.

Mfg.

date

465 Godin Avenue

Vanier (Quebec) G1M 3G7 CANADA

FTB-5700-XX-XX

Model

Connector

You may also be requested to provide software and module version

numbers.This information, as well as technical support contact

information, can be found by clicking About in the function bar

Single-Ended Dispersion Analyzer 73

Page 80

Troubleshooting

Transportation

Transportation

Maintain a temperature range within specifications when transporting the

unit. Transportation damage can occur from improper handling. The

following steps are recommended to minimize the possibility of damage:

³ Pack the unit in its original packing material when shipping.

³ Avoid high humidity or large temperature fluctuations.

³ Keep the unit out of direct sunlight.

³ Avoid unnecessary shocks and vibrations.

74 FTB-5700

Page 81

9 Warranty

General Information

EXFO Electro-Optical Engineering Inc. (EXFO) warrants this equipment

against defects in material and workmanship for a period of one year from

the date of original shipment. EXFO also warrants that this equipment will

meet applicable specifications under normal use.

During the warranty period, EXFO will, at its discretion, repair, replace,

or issue credit for any defective product, as well as verify and adjust the

product free of charge should the equipment need to be repaired or if the

original calibration is erroneous. If the equipment is sent back for

verification of calibration during the warranty period and found to meet all

published specifications, EXFO will charge standard calibration fees.

The warranty can become null and void if:

³ unit has been tampered with, repaired, or worked upon by

unauthorized individuals or non-EXFO personnel.

³ warranty sticker has been removed.

IMPORTANT

³ case screws, other than those specified in this guide, have been

removed.

³ case has been opened, other than as explained in this guide.

³ unit serial number has been altered, erased, or removed.

³ unit has been misused, neglected, or damaged by accident.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES EXPRESSED,

IMPLIED, OR STATUTORY, INCLUDING, BUT NOT LIMITED TO, THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. IN NO EVENT SHALL EXFO BE LIABLE FOR

SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

Single-Ended Dispersion Analyzer 75

Page 82

Warranty

Liability

Liability

EXFO shall not be liable for damages resulting from the use of the product,

nor shall be responsible for any failure in the performance of other items to

which the product is connected or the operation of any system of which

the product may be a part.

EXFO shall not be liable for damages resulting from improper usage or

unauthorized modification of the product, its accompanying accessories

and software.

76 FTB-5700

Page 83

Warranty

Exclusions

EXFO reserves the right to make changes in the design or construction of

any of its products at any time without incurring obligation to make any

changes whatsoever on units purchased. Accessories, including but not

limited to fuses, pilot lamps, batteries and universal interfaces (EUI) used

with EXFO products are not covered by this warranty.

This warranty excludes failure resulting from: improper use or installation,

normal wear and tear, accident, abuse, neglect, fire, water, lightning or

other acts of nature, causes external to the product or other factors beyond

the control of EXFO.

IMPORTANT

EXFO will charge a fee for replacing optical connectors that were

damaged due to misuse or bad cleaning.

Certification

Exclusions

EXFO certifies that this equipment met its published specifications at the

time of shipment from the factory.

Single-Ended Dispersion Analyzer 77

Page 84

Warranty

Service and Repairs

Service and Repairs

EXFO commits to providing product service and repair for five years

following the date of purchase.

To send any equipment for service or repair:

1. Call one of EXFO’s authorized service centers (see EXFO Service

2. If equipment must be returned to EXFO or an authorized service

3. If possible, back up your data before sending the unit for repair.

4. Pack the equipment in its original shipping material. Be sure to include

5. Return the equipment, prepaid, to the address given to you by support

Centers Worldwide on page 79). Support personnel will determine if

the equipment requires service, repair, or calibration.

center, support personnel will issue a Return Merchandise

Authorization (RMA) number and provide an address for return.

a statement or report fully detailing the defect and the conditions under

which it was observed.

personnel. Be sure to write the RMA number on the shipping slip. EXFO

will refuse and return any package that does not bear number.

Note: A test setup fee will apply to any returned unit that, after test, is found to

meet the applicable specifications.

After repair, the equipment will be returned with a repair report. If the

equipment is not under warranty, you will be invoiced for the cost

appearing on this report. EXFO will pay return-to-customer shipping costs

for equipment under warranty. Shipping insurance is at your expense.

Routine recalibration is not included in any of the warranty plans. Since

calibrations/verifications are not covered by the basic or extended

warranties, you may elect to purchase FlexCare Calibration/Verification

Packages for a definite period of time. Contact an authorized service center

(see EXFO Service Centers Worldwide on page 79).

78 FTB-5700

Page 85

Warranty

EXFO Service Centers Worldwide

EXFO Service Centers Worldwide

If your product requires servicing, contact your nearest authorized service

center.

EXFO Headquarters Service Center

400 Godin Avenue

Quebec (Quebec) G1M 2K2

CANADA

EXFO Europe Service Center

Omega Enterprise Park, Electron Way

Chandlers Ford, Hampshire S053 4SE

ENGLAND

EXFO China Service Center/

Beijing OSIC

Beijing New Century Hotel

Office Tower, Room 1754-1755

No. 6 Southern Capital Gym Road

Beijing 100044

P. R . C H I N A

1 866 683-0155 (USA and Canada)

Tel.: 1 418 683-5498

Fax: 1 418 683-9224

quebec.service@exfo.com

Tel.: +44 2380 246810

Fax: +44 2380 246801

europe.service@exfo.com

Tel.: +86 (10) 6849 2738

Fax: +86 (10) 6849 2662

beijing.service@exfo.com

Single-Ended Dispersion Analyzer 79

Page 86

Page 87

A Technical Specifications

IMPORTANT

The following technical specifications can change without notice.

The information presented in this section is provided as a reference

only. To obtain this product’s most recent technical specifications,

visit the EXFO Web site at www.exfo.com.

SPECIFICATIONS

Measured wavelength range (nm) 1475 to 1626

Maximum measurement distance (km) ≥120 (140 with reflector)

Distance uncertainty (km) ± (0.01 +1%xdistance)

Chromatic dispersion

Number of test points 8

CD uncertainty (ps/nm) ±10

Test time (s) 40

c

PMD

PMD range (strong mode coupling) (ps) 0.1 to 20

PMD uncertainty (strong mode coupling) (ps)

Test time (s) < 180

a

b

d

± (0.2 +5%xPMD)

GENERAL SPECIFICATIONS

Temperature

Operating 0 °C to 50 °C (32 °F to 122 °F)

Storage —40 °C to 70 °C (—40 °F to 158 °F)

Relative humidity 0 % to 93 % non-condensing

Size (HxWxD) 96mmx50mmx281mm (33/4 inx2inx11in)

Weight 1.3 kg (2.8 lb)

SAFETY

21 CFR 1040.10 and IEC:A2:2001:

CLASS 1 LASER PRODUCT

Notes

a. Typical.

b. At 1550 nm, on 100 km of G.652 singlemode fiber.

c. For a fiber length ≥ 100 m.

d. For strong mode coupling PMD (telecom fiber) up to 15 ps, with averaging.

Single-Ended Dispersion Analyzer 81

Page 88

Page 89

Index

Index

A

About button .............................................. 73

acquisition

parameter setup .................................... 24

stopping ................................................ 42

after-sales service ........................................ 73

analysis parameters..................................... 52

application

exiting ................................................... 14

starting, single-module.......................... 12

application details ....................................... 16

automatic names for fibers ......................... 28

B

bad results, removing.................................. 55

Busy, module status .................................... 14

C

cable information........................................ 46

calibration

certificate............................................... 62

interval .................................................. 62

caution

of personal hazard................................... 4

of product hazard.................................... 4

CD

graph..................................................... 45

parameters ............................................ 24

results.................................................... 40

thresholds.............................................. 20

viewing details....................................... 44

certification information ................................v

chromatic dispersion, measuring................. 42

cleaning

EUI connectors....................................... 60

fiber ends .............................................. 37

front panel............................................. 59

closing files.................................................. 56

coefficient

chromatic dispersion.............................. 45

threshold ............................................... 20

configurations ............................................. 29

connectors, cleaning.................................... 60

conventions, safety........................................ 4

coupling

strong .................................................... 25

weak ...................................................... 25

customer service.......................................... 78

D

defining

acquisition parameters........................... 24

fiber name .............................................28

thresholds .............................................. 20

details, application ...................................... 16

detecting module .......................................... 9

display, CD graph ........................................ 45

E

equipment returns....................................... 78

EUI

connector adapter ................................. 39

dust cap................................................. 39

EUI connectors, cleaning .............................60

exiting application....................................... 14

F

fiber

defining name format............................ 28

type ....................................................... 25

fiber ends, cleaning ..................................... 37

files

closing ...................................................56

opening .................................................54

Single-Ended Dispersion Analyzer 83

Page 90

Index

front panel, cleaning................................... 59

FUT, naming................................................ 28

G

generating report........................................ 57

H

help. see online user guide

I

identification label ...................................... 73

identification, slot ....................................... 13

information

cable...................................................... 46

job ......................................................... 48

inserting a module ........................................ 7

J

job information ........................................... 48

L

label, identification ..................................... 73

M

maintenance

EUI connectors....................................... 60

front panel ............................................ 59

general information............................... 59

module

detection ................................................. 9

insertion .................................................. 7

removal ................................................... 7

status..................................................... 14

module position.......................................... 13

mounting EUI connector adapter ................ 39

N

naming fibers.............................................. 28

negligible coupling fiber.............................. 25

O

online user guide......................................... 72

opening file ................................................. 54

P

parameters, analysis .................................... 52

parameters, defining ................................... 24

parameters, threshold .................................50

PDF. see online user guide

performing a test ........................................ 40

PMD

parameters............................................. 24

results .................................................... 40

thresholds.............................................. 20

polarization maintaining fiber ..................... 25

position, module ......................................... 13

preferences, test.......................................... 35

product

identification label ................................. 73

specifications ......................................... 81

R

random coupling fiber................................. 25

range, wavelength....................................... 22

Ready, module status .................................. 14

recalibration ................................................ 62

removing a module ....................................... 7

removing bad results................................... 55

reports, generating...................................... 57

results, viewing............................................ 44

return merchandise authorization (RMA) .... 78

S

safety

caution .................................................... 4

conventions .............................................4

warning ...................................................4

service and repairs....................................... 78

84 FTB-5700

Page 91

Index

service centers............................................. 79

setting wavelength range............................ 22

shipping to EXFO ........................................ 78

slot number................................................. 13

software. see application

specifications, product ................................ 81

starting acquisition ..................................... 40

status bar .................................................... 14

stopping an acquisition............................... 42

storage requirements .................................. 59

strong coupling fiber................................... 25

symbols, safety.............................................. 4

T

technical specifications................................ 81

technical support ........................................ 73

telecom fiber............................................... 25

temperature for storage.............................. 59

test

performing ............................................ 40

viewing results....................................... 44

test configurations ...................................... 29

test preferences........................................... 35

threshold parameters .................................. 50

title bar ....................................................... 13

transportation requirements ................. 59, 74

type of fiber ................................................ 25

exclusions .............................................. 77

general................................................... 75

liability ................................................... 76

null and void.......................................... 75

wavelength range........................................ 22

weak coupling fiber..................................... 25

U

unit recalibration......................................... 62

user guide. see online user guide

V

viewing

CD details .............................................. 44

results.................................................... 44

W

warranty

certification ........................................... 77

Single-Ended Dispersion Analyzer 85

Page 92

NOTICE

通告

CHINESE REGULATION ON RESTRICTION OF HAZARDOUS SUBSTANCES

中国关于危害物质限制的规定

NAMES AND CONTENTS OF THE TOXIC OR HAZARDOUS SUBSTANCES OR ELEMENTS

CONTAINED IN THIS EXFO PRODUCT

包含在本 EXFO 产品中的有毒有害物质或元素的名称和含量

Indicates that this toxic or hazardous substance contained in all of the homogeneous