Page 1

FTB-5600

Distributed PMD Analyzer for FTB-500

User Guide

Page 2

Copyright © 2009 EXFO Electro-Optical Engineering Inc. All rights reserved.

No part of this publication may be reproduced, stored in a retrieval system

or transmitted in any form, be it electronically, mechanically, or by any

other means such as photocopying, recording or otherwise, without the

prior written permission of EXFO Electro-Optical Engineering Inc. (EXFO).

Information provided by EXFO is believed to be accurate and reliable.

However, no responsibility is assumed by EXFO for its use nor for any

infringements of patents or other rights of third parties that may result from

its use. No license is granted by implication or otherwise under any patent

rights of EXFO.

EXFO’s Commerce And Government Entities (CAGE) code under the North

Atlantic Treaty Organization (NATO) is 0L8C3.

The information contained in this publication is subject to change without

notice.

Trademarks

EXFO’s trademarks have been identified as such. However, the presence

or absence of such identification does not affect the legal status of any

trademark.

Units of Measurement

Units of measurement in this publication conform to SI standards and

practices.

Version number 2.0.0

ii FTB-5600

Page 3

Contents

Contents

Certification Information ........................................................................................................v

1 Introducing the FTB-5600 Distributed PMD Analyzer ................................ 1

Basic Distributed PMD Analyzer Operation .............................................................................2

Frequently Used Terms ............................................................................................................3

Conventions ............................................................................................................................5

2 Safety Information ....................................................................................... 7

3 Getting Started with your FTB-5600 ........................................................... 9

Inserting and Removing Test Modules ....................................................................................9

Starting the Distributed PMD Analyzer Application ..............................................................14

Exiting the Application .........................................................................................................16

4 Setting up and Operating your Distributed PMD Analyzer ..................... 17

Cleaning and Connecting Optical Fibers ...............................................................................18

Installing the EXFO Universal Interface (EUI) .........................................................................20

Setting up General Acquisition Parameters ...........................................................................21

Setting up the Graph Display ................................................................................................23

Setting up Storage Options ..................................................................................................25

Displaying PMD-Related Columns in the Main Window ........................................................29

Setting up Cable Information ...............................................................................................31

Performing an Acquisition ....................................................................................................33

Using the Bidirectional File Creator .......................................................................................47

5 Managing Results ....................................................................................... 55

Opening an Existing File .......................................................................................................57

Saving a File ..........................................................................................................................59

Using Zoom Controls ............................................................................................................62

Section Event Table ...............................................................................................................63

Section Status .......................................................................................................................65

Positioning Markers on the Display .......................................................................................69

Editing Sections ....................................................................................................................70

Using Markers to Measure PMD Differences (Delta PMD Tab) ...............................................81

Estimating Results ................................................................................................................83

Viewing Trace Information ....................................................................................................85

Generating Reports ...............................................................................................................93

Distributed PMD Analyzer iii

Page 4

Contents

6 Maintenance ................................................................................................95

Cleaning EUI Connectors ......................................................................................................96

Recalibrating the Unit ...........................................................................................................98

Recycling and Disposal (Applies to European Union Only) ....................................................99

7 Troubleshooting ........................................................................................101

Obtaining Online Help ........................................................................................................101

Contacting the Technical Support Group ............................................................................102

Transportation ....................................................................................................................103

8 Warranty ....................................................................................................105

General Information ...........................................................................................................105

Liability ...............................................................................................................................106

Exclusions ...........................................................................................................................107

Certification ........................................................................................................................107

Service and Repairs .............................................................................................................108

EXFO Service Centers Worldwide ........................................................................................109

A Technical Specifications ............................................................................111

B Distributed Cumulative PMD Measurement Theory ...............................113

C Acquisition Data .......................................................................................117

D Optimizing Measurements .......................................................................121

Basic Verification Steps .......................................................................................................121

Use a Larger Number of SOPs and Wavelengths .................................................................122

Perform Two-Sided Measurements .....................................................................................123

Perform Multiple Measurements .........................................................................................123

Select an Optimized PMD Scale for the Acquisition ............................................................124

Use an Appropriate Residual PMD for the Acquisition ........................................................125

Use an Optimized Number of Averagings ...........................................................................127

Use an Appropriate OTDR Pulse Length ..............................................................................128

Use an Appropriate Spatial Smoothing Filter Value ............................................................129

Use a Receive Fiber .............................................................................................................134

Index ...............................................................................................................135

iv FTB-5600

Page 5

Certification Information

Certification Information

F.C.C. Information

Electronic test equipment is exempt from Part 15 compliance (FCC) in

the United States. However, compliance verification tests are

systematically performed on most EXFO equipment.

Information

Electronic test equipment is subject to the EMC Directive in the European

Union. The EN61326 standard prescribes both emission and immunity

requirements for laboratory, measurement, and control equipment.

This unit has undergone extensive testing according to the European Union

Directive and Standards.

Distributed PMD Analyzer v

Page 6

Certification Information

Application of Council Directive(s): 2006/95/EC - The Low Voltage Directive

2004/108/EC - The EMC Directive

And their amendments

Manufacturer’s Name: EXFO Electro-Optical Engineering Inc.

Manufacturer’s Address: 400 Godin Avenue

Quebec, Quebec

Canada, G1M 2K2

(418) 683-0211

Equipment Type/Environment: Test & Measurement / Industrial

Trade Name/Model No.: FTB-5600

Distributed PMD Analyzer

Standard(s) to which Conformity is Declared:

EN 61010-1:2001 Safety Requirements for Electrical Equipment for Measurement,

Control, and Laboratory Use, Part 1: General Requirements.

EN 61326-1:2006 Electrical Equipment for Measurement, Control and Laboratory

Use - EMC Requirements – Part 1: General requirements

EN 60825-1:1994 +A2:2001

+A1:2002

Safety of laser products – Part 1: Equipment classification,

requirements, and user’s guide

EN 55022: 1998 +A2: 2003 Information technology equipment - Radio disturbance

characteristics - Limits and methods of measurement

I, the undersigned, hereby declare that the equipment specified above conforms to the above Directive and Standards.

Manufacturer

Signature:

Full Name: Stephen Bull, E. Eng

Position: Vice-President Research and

Development

Address: 400 Godin Avenue, Quebec (Quebec),

Canada, G1M 2K2

Date: January 09, 2009

DECLARATION OF CONFORMITY

vi FTB-5600

Page 7

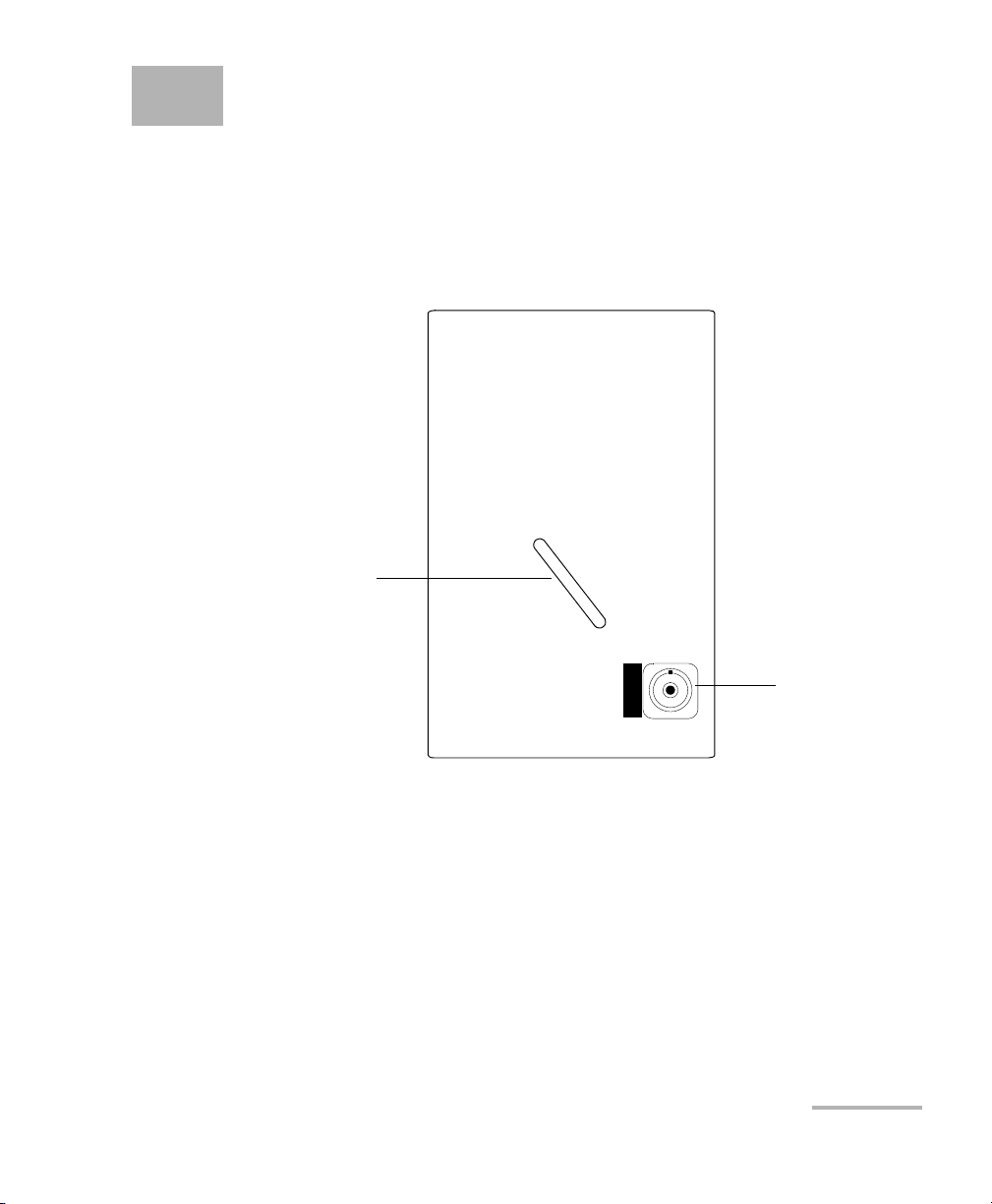

1 Introducing the FTB-5600

FTB-5600

DISTRIBUTED PMD ANALYZER

Handle

Detector port

Distributed PMD Analyzer

The FTB-5600 is composed of an OTDR, a tunable laser source and a

polarization scrambler. It characterizes PMD along a link. Its key feature is

to identify fiber sections with a strong PMD value, then enabling the

correction of the link by replacing faulty sections.

The results include:

³ A cumulative PMD curve and an OTDR trace

³ A PMD section table that provides the PMD for each section identified

by the instrument.

³ An estimation table that can be used to analyze the effect of removing

strong PMD sections of the link.

The result of the acquisition will be displayed as a graph, as well as several

Distributed PMD Analyzer 1

result tables to help you analyze the data better.

Page 8

Introducing the FTB-5600 Distributed PMD Analyzer

Basic Distributed PMD Analyzer Operation

Basic Distributed PMD Analyzer Operation

IMPORTANT

In order to use the FTB-5600 to its most optimised level, you must

have a solid knowledge on how OTDRs function.

You can make acquisitions according to three different modes:

³ Quick Check

³ Standard

³ Advanced

Each mode is explained in Setting up General Acquisition Parameters on

page 21.

The FTB-5600 does a series of actions in taking a measurement.

³ The instrument takes an OTDR trace and displays it. This step only

takes a few seconds. At this point, you should inspect the trace to see if

there are any problems.

³ Then, the instrument measures the SOPs. This will take more or less

time depending on the accuracy and sensitivity requested. The

remaining time and SOPs to measure are indicated in the status bar of

the application. After measuring about 10 SOPs, you will see a

temporary cumulative PMD curve.

³ Once all of the SOPs are acquired, the instrument computes the actual

PMD curve.

2 FTB-5600

Page 9

Introducing the FTB-5600 Distributed PMD Analyzer

Frequently Used Terms

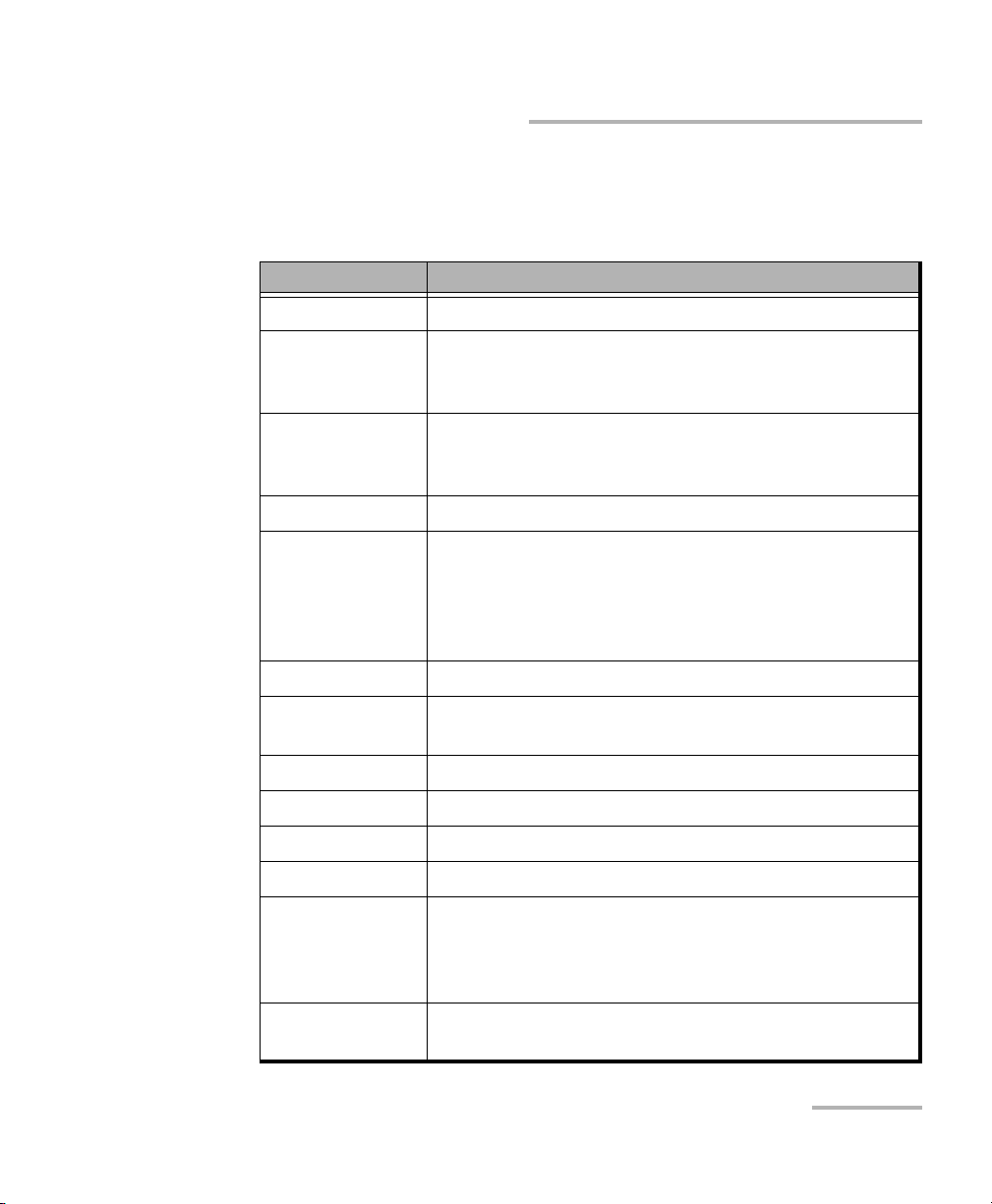

Frequently Used Terms

Some specific terms are used frequently in this user guide.

Term Definition

APD Avalanche photo diode.

Beating length Length required in the fiber for the Fast Polarization to

be ahead by one complete period over the Slow

Polar iza tio n.

Bidirectional A combination of two traces taken from opposite

directions of a same fiber. The trace can overlap fully,

partly, or not at all.

Cumulative PMD The PMD value up to a distance in a fiber.

Depolarization Light that is not polarized. In the case of the FTB-5600,

we use this term to define zone on the fiber where the

instrument cannot perform a measurement since light

is entirely depolarised. For more information, see page

67.

DGD Differential group delay.

Estimation table Table used to estimate the PMD value of a link by

changing values of target strong PMD sections.

FUT Fiber under test

OTDR Optical time domain reflectometer.

PBS Polarization beam splitter

PMD Polarisation mode dispersion.

PMD coefficient Represents the PMD characteristics of one particular

length of the fiber. Since PMD adds to the square, its

unit is typically calculated in picoseconds per square

root of kilometer.

PMD resolution Sets the minimum PMD value to be measured on the

link.

Distributed PMD Analyzer 3

Page 10

Introducing the FTB-5600 Distributed PMD Analyzer

Frequently Used Terms

Term Definition

PMD scale Sets the best scale to measure a PMD of this value.

PMD section The PMD value of a fiber section

Pulse width Width of the OTDR pulse, in nanoseconds, used to

measure the link. A longer pulse allows you to probe

further along the fiber, but results in a lower resolution.

A shorter pulse width provides higher resolution , but a

smaller distance range.

RS-POTDR Random-scrambling tuneable polarization-sensitive

OTDR

Sensitivity Sets the electronic sensitivity.

SOP State of polarisation. Here, SOP has a broader sense: it

means a group of OTDR traces taken at different

frequencies, but with the same SOP. The SOP is the unit

that is used to compute the distributed PMD curve.

SOA Semiconductor optical amplifier

4 FTB-5600

Page 11

Introducing the FTB-5600 Distributed PMD Analyzer

Conventions

Conventions

Before using the product described in this manual, you should understand

the following conventions:

WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in component damage. Do not proceed unless you

understand and meet the required conditions.

IMPORTANT

Refers to information about this product you should not overlook.

Distributed PMD Analyzer 5

Page 12

Page 13

2 Safety Information

CLASS 1

LASER PRODUCT

WARNING

Do not install or terminate fibers while a light source is active.

Never look directly into a live fiber and ensure that your eyes are

protected at all times.

WARNING

Use of controls, adjustments and procedures for operation and

maintenance other than those specified herein may result in

hazardous radiation exposure or impair the protection provided by

this unit.

Your instrument is a Class 1 laser product in compliance with standards

IEC60825-1: 2001, 2007 and 21CFR1040.10. Laser radiation may be

encountered at the output port.

The following label indicates that a product contains a Class 1 source:

Note: Label shown for information purposes only. It is not affixed to your product.

Distributed PMD Analyzer 7

Page 14

Page 15

3 Getting Started with your

FTB-5600

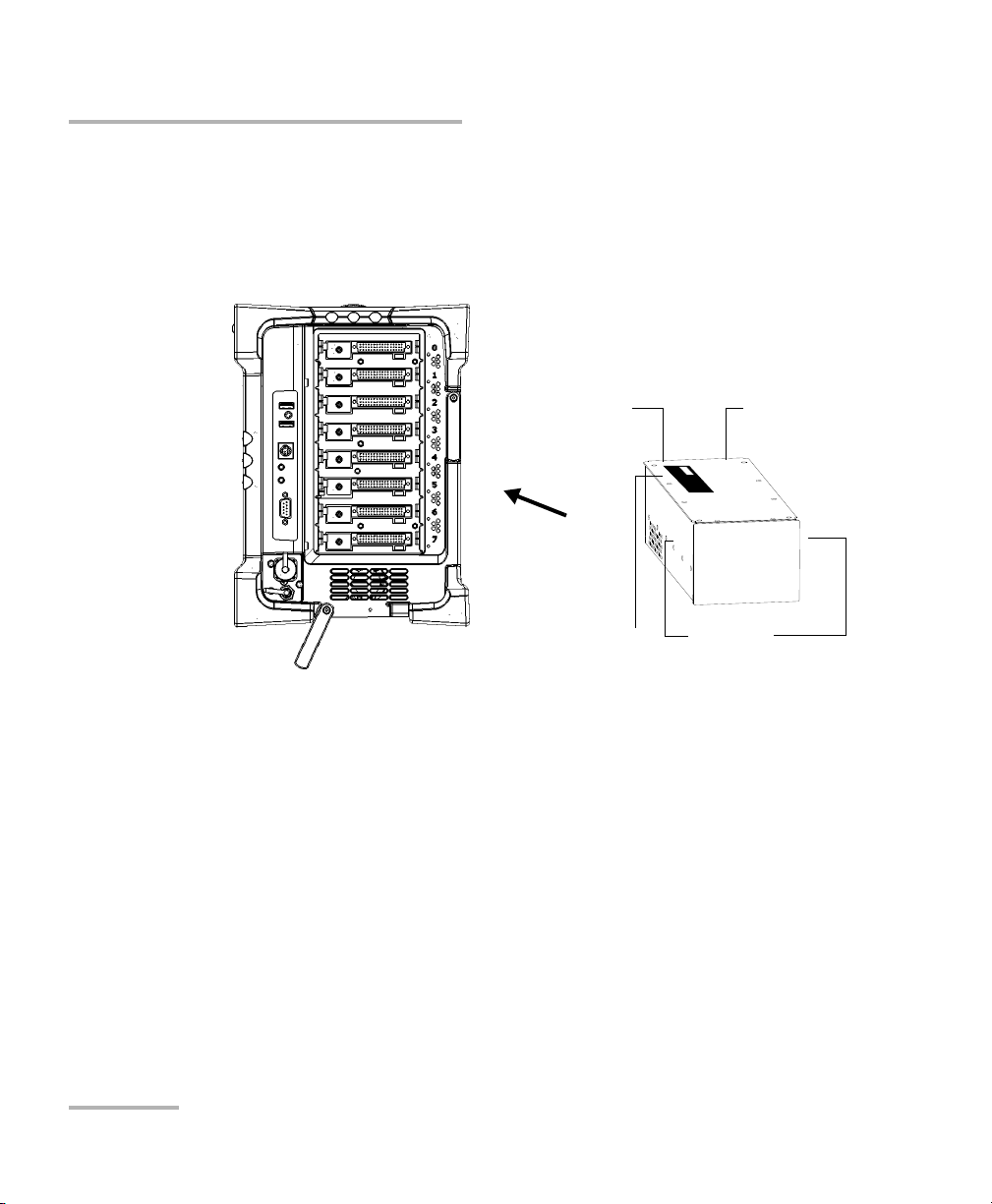

Inserting and Removing Test Modules

CAUTION

Never insert or remove a module while the FTB-500 is turned on.

This will result in immediate and irreparable damage to both the

module and unit.

WARNING

When the laser safety LED ( ) is flashing on the FTB-500, at least

one of your modules is emitting an optical signal. Please check all

modules, as it might not be the one you are currently using.

To insert a module into the FTB-500:

1. Exit ToolBox and turn off your unit.

2. Position the FTB-500 so that its right panel is facing you.

Distributed PMD Analyzer 9

Page 16

Getting Started with your FTB-5600

Protruding

edges on top

Identification sticker

facing up

Connector

pins at the

back

Retaining screw

hole at the

back

FTB-500 right panel

Inserting and Removing Test Modules

3. Take the module and place it so that the connector pins are at the

back, as explained and shown below.

Identification sticker must be facing up and connector pins at the right

of the retaining screw hole.

4. Insert the protruding edges of the module into the grooves of the

receptacle’s module slot.

5. Push the module all the way to the back of the slot, until the retaining

screw makes contact with the receptacle casing.

6. Place the FTB-500 so that its left panel is facing you.

10 FTB-5600

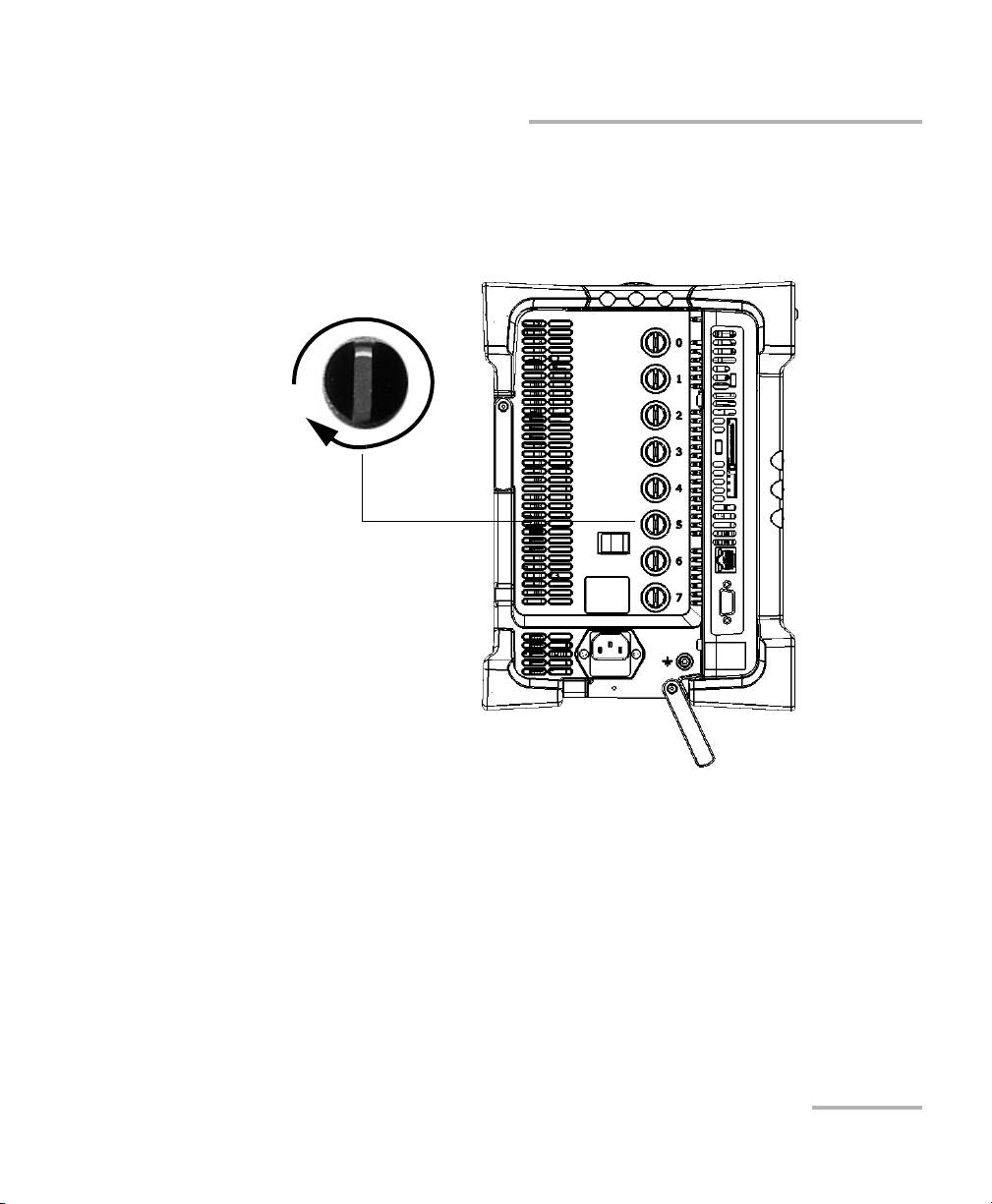

Page 17

Getting Started with your FTB-5600

Turn retaining screw knob

clockwise

FTB-500 left panel

Inserting and Removing Test Modules

7. While applying slight pressure to the module, turn the retaining screw

clockwise until it is tightened.

This will secure the module into its “seated” position.

When you turn on the unit, the startup sequence will automatically detect

the module.

Distributed PMD Analyzer 11

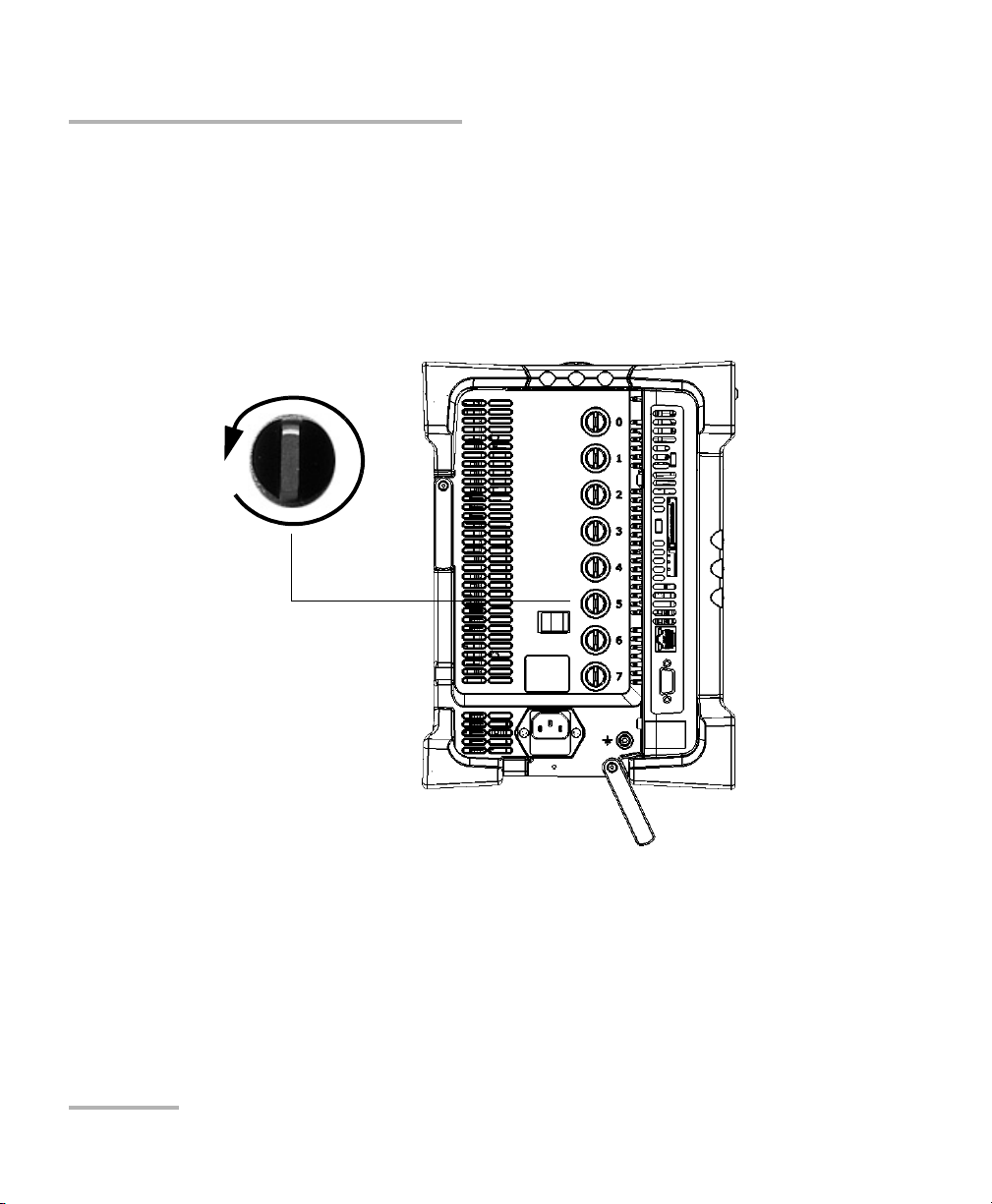

Page 18

Getting Started with your FTB-5600

Turn retaining screw knob(s)

counterclockwise

FTB-500 left panel

Inserting and Removing Test Modules

To remove a module from the FTB-500:

1. Exit ToolBox and turn off your unit.

2. Position the FTB-500 so that the left panel is facing you.

3. Turn the retaining screw counterclockwise until it stops.

The module will be slowly released from the slot.

4. Place the FTB-500 so that the right panel is facing you.

12 FTB-5600

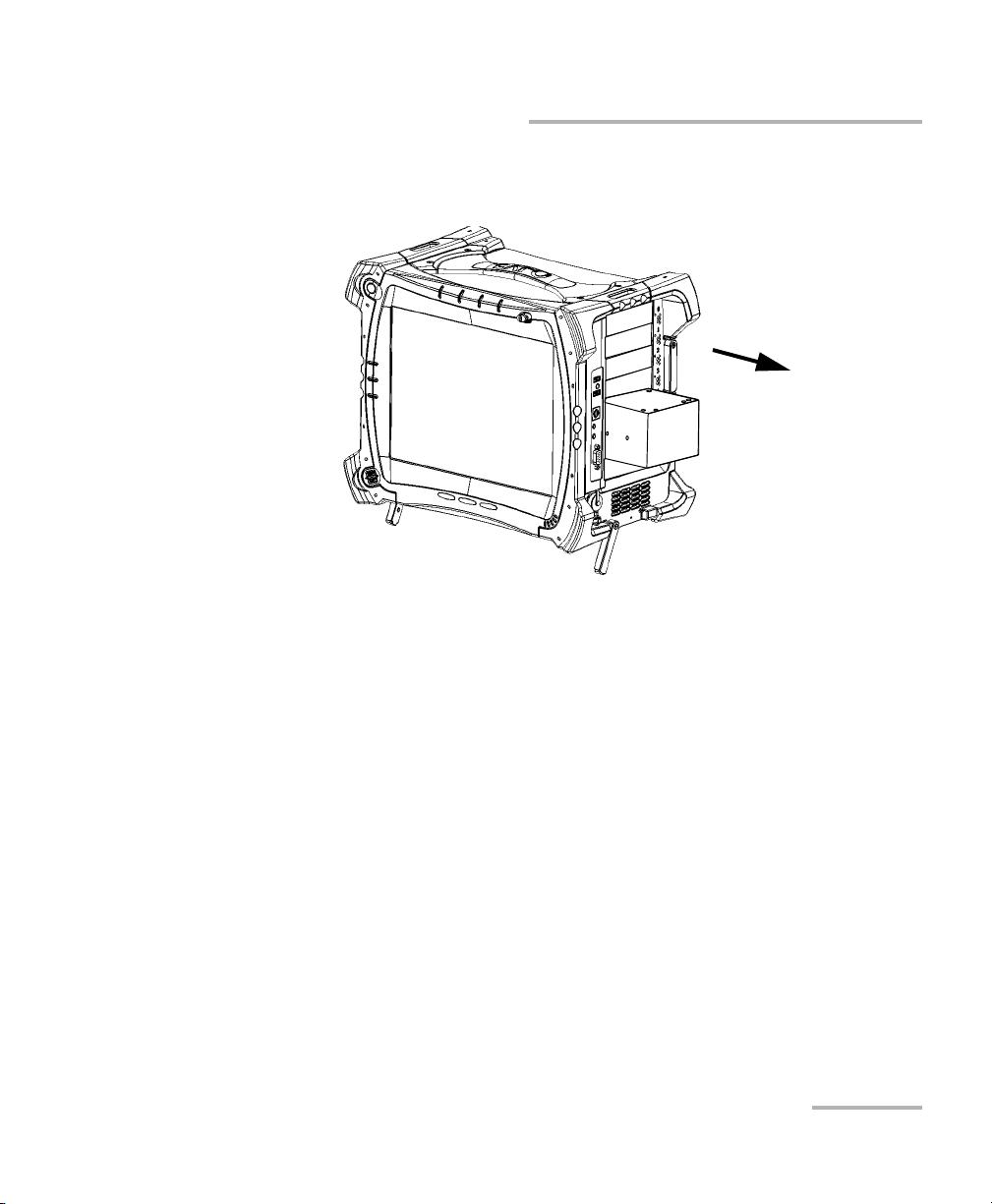

Page 19

Getting Started with your FTB-5600

Inserting and Removing Test Modules

5. Hold the module by its sides or by the handle (NOT by the connector)

and pull it out.

Distributed PMD Analyzer 13

Page 20

Getting Started with your FTB-5600

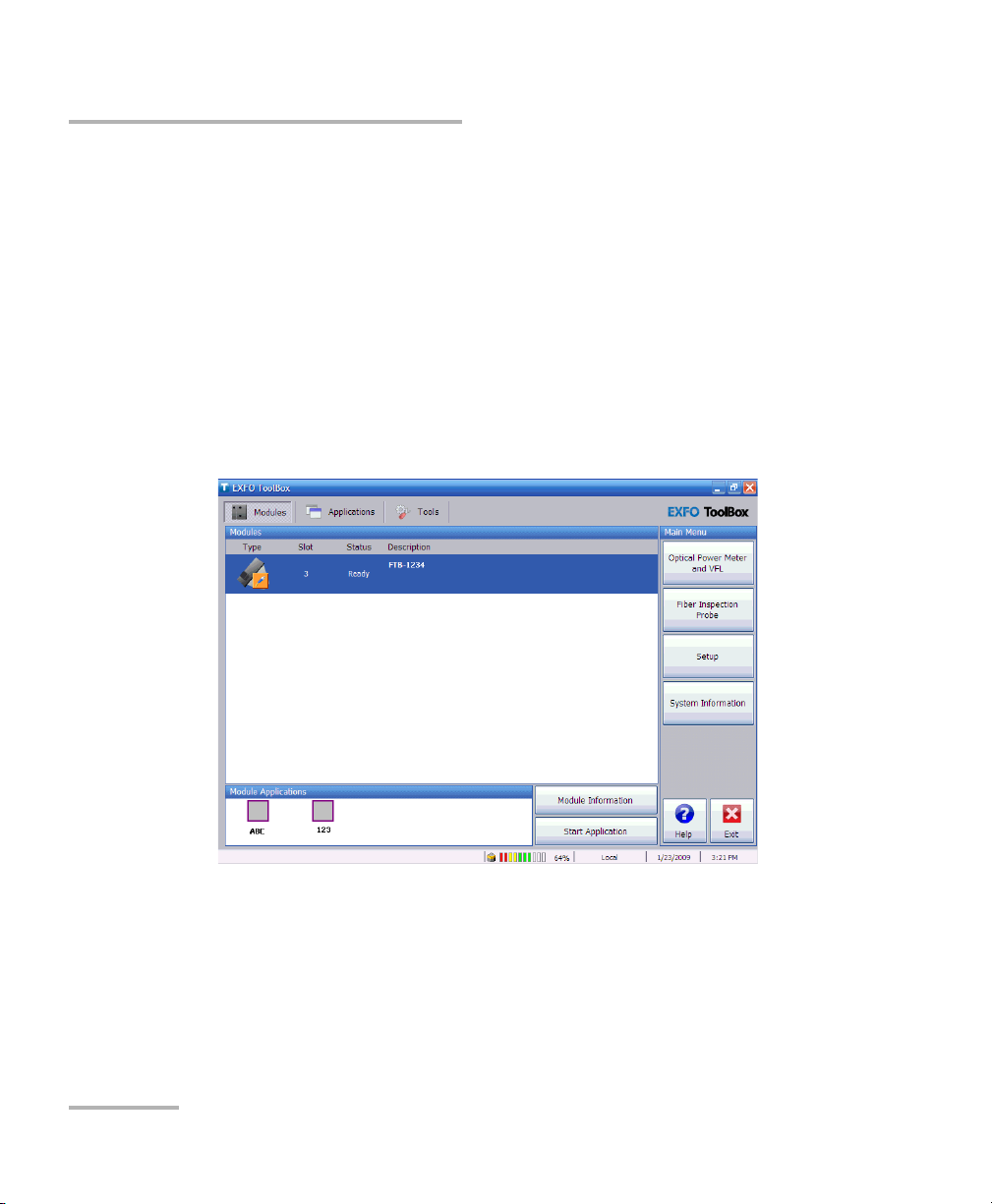

Starting the Distributed PMD Analyzer Application

Starting the Distributed PMD Analyzer

Application

Your FTB-5600 Distributed PMD Analyzer module can be configured and

controlled from its dedicated ToolBox application.

Note: For details about ToolBox, refer to the FTB-500 user guide.

To start the application:

1. From the main window, select the module to use.

It will turn blue to indicate that it is highlighted.

2. Click the corresponding button in the Module Applications box.

14 FTB-5600

Page 21

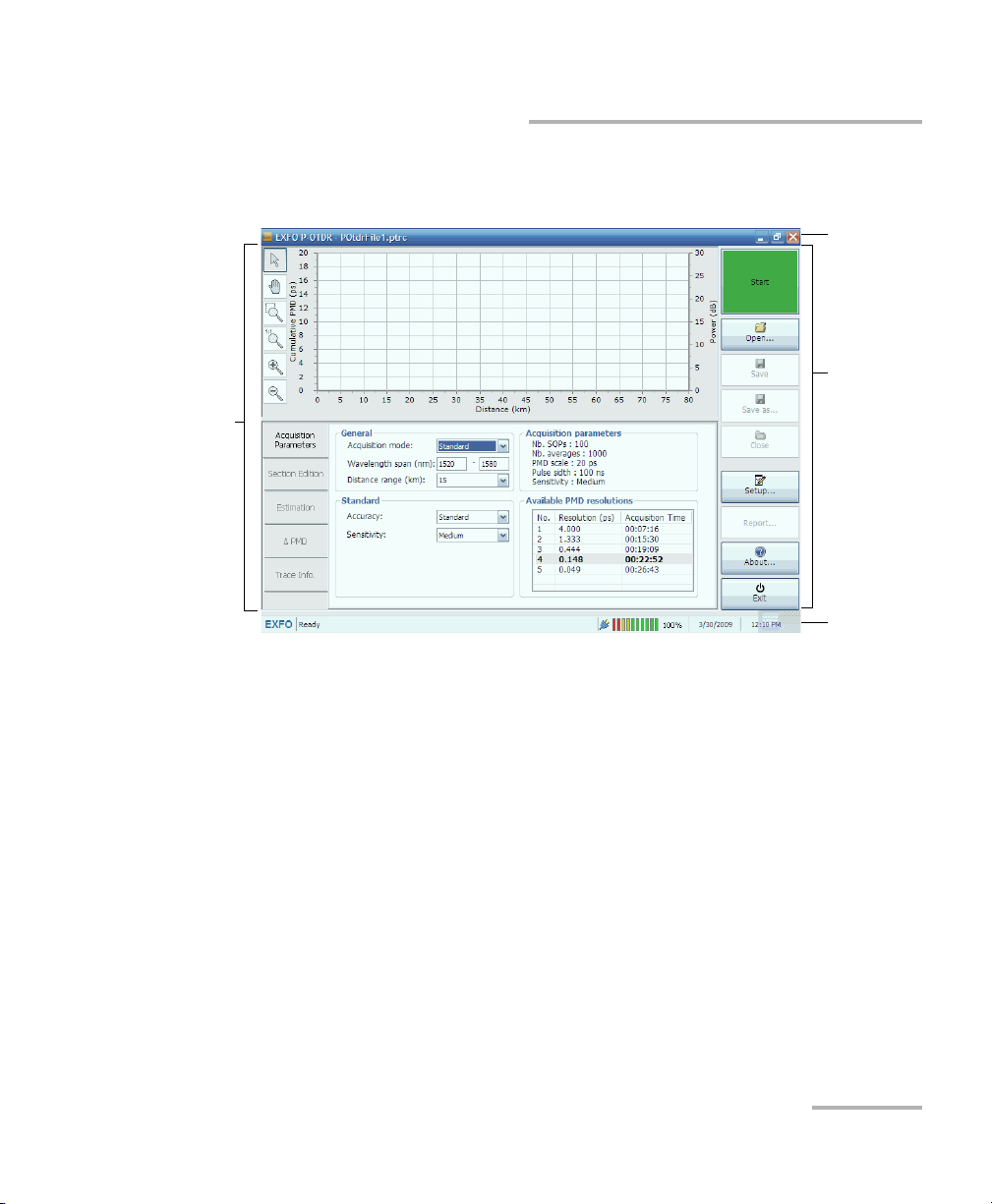

Getting Started with your FTB-5600

Data

display and

control

center

Title bar

Function

buttons

Status bar

Starting the Distributed PMD Analyzer Application

The main window (shown below) contains all the commands required to

control the Distributed PMD Analyzer:

Distributed PMD Analyzer 15

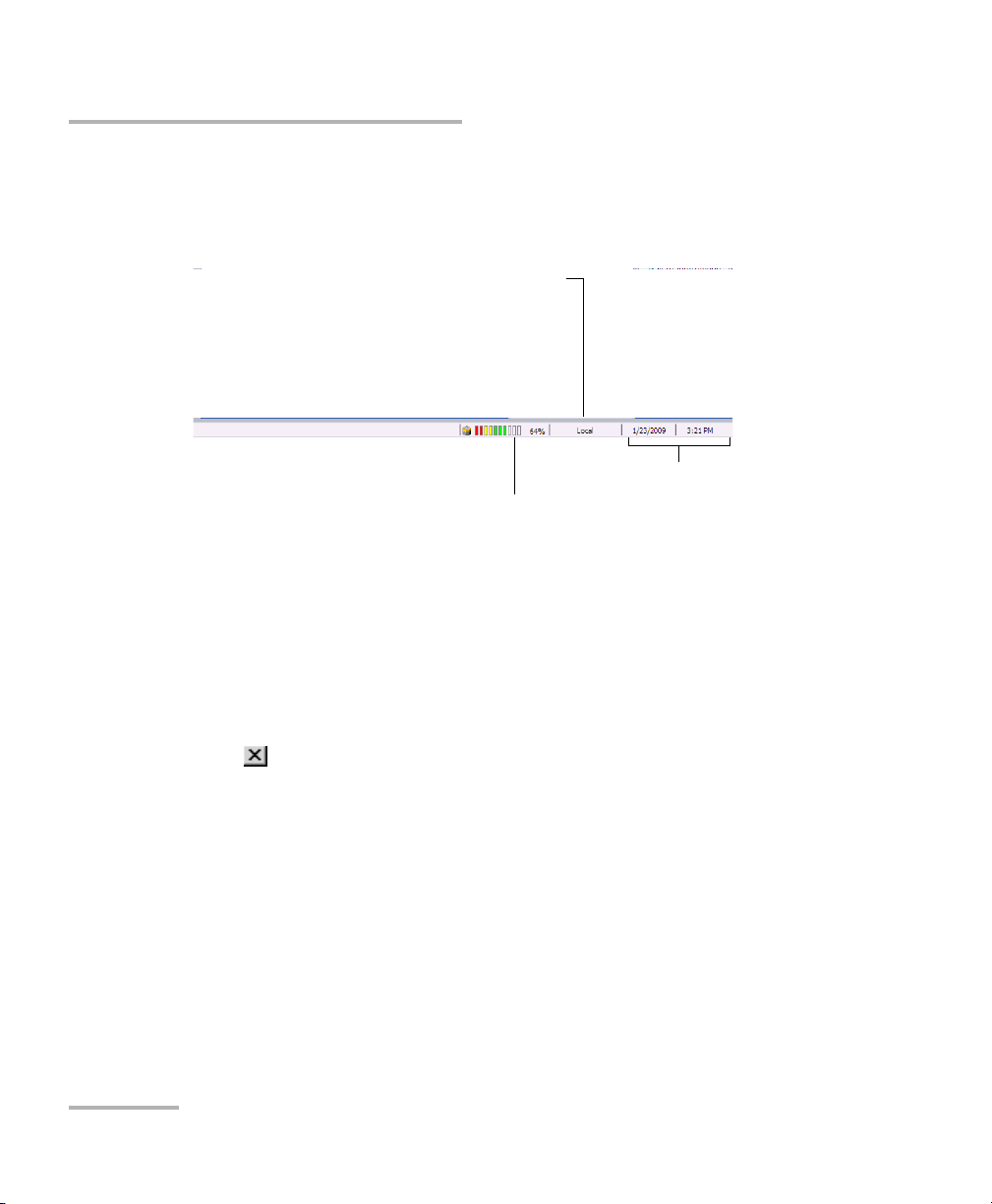

Page 22

Getting Started with your FTB-5600

Current date and time

Local: Module controlled locally only.

Remote: Module controlled remotely, but local

commands can also be used (some products only).

Lockout: Module controlled remotely only.

Battery indicator

Control mode

Exiting the Application

Status Bar

The status bar, located at the bottom of the main window, identifies the

current operational status of the FTB-5600 Distributed PMD Analyzer.

Exiting the Application

Closing any application that is not currently being used helps freeing

system memory.

To close the application from the main window:

Click in the top right corner of the main window.

OR

Click the Exit button located at the bottom of the function bar.

16 FTB-5600

Page 23

4 Setting up and Operating your

Distributed PMD Analyzer

IMPORTANT

In order to use the FTB-5600 to its most optimised level, you must

have a solid knowledge on how OTDRs function. This includes:

³ Interpreting OTDR traces

³ Understanding the effect of the pulse on a trace

³ Understanding the contents of an event trace

³ Manipulating events on a trace

The instructions and theory in this user documentation take into

account that such notions are already known by you.

Distributed PMD Analyzer 17

Page 24

Setting up and Operating your Distributed PMD Analyzer

Cleaning and Connecting Optical Fibers

Cleaning and Connecting Optical Fibers

IMPORTANT

To ensure maximum power and to avoid erroneous readings:

³ Always inspect fiber ends and make sure that they are clean as

explained below before inserting them into the port. EXFO is

not responsible for damage or errors caused by bad fiber

cleaning or handling.

³ Ensure that your patchcord has appropriate connectors. Joining

mismatched connectors will damage the ferrules.

To connect the fiber-optic cable to the port:

1. Inspect the fiber using a fiber inspection microscope. If the fiber is

clean, proceed to connecting it to the port. If the fiber is dirty, clean it as

explained below.

2. Clean the fiber ends as follows:

2a. Gently wipe the fiber end with a lint-free swab dipped in isopropyl

alcohol.

2b. Use compressed air to dry completely.

2c. Visually inspect the fiber end to ensure its cleanliness.

18 FTB-5600

Page 25

Setting up and Operating your Distributed PMD Analyzer

Cleaning and Connecting Optical Fibers

3. Carefully align the connector and port to prevent the fiber end from

touching the outside of the port or rubbing against other surfaces.

If your connector features a key, ensure that it is fully fitted into the

port’s corresponding notch.

4. Push the connector in so that the fiber-optic cable is firmly in place,

thus ensuring adequate contact.

If your connector features a screwsleeve, tighten the connector

enough to firmly maintain the fiber in place. Do not overtighten, as this

will damage the fiber and the port.

Note: If your fiber-optic cable is not properly aligned and/or connected, you will

notice heavy loss and reflection.

Distributed PMD Analyzer 19

Page 26

Setting up and Operating your Distributed PMD Analyzer

Bare metal

(or blue border)

indicates UPC

option

Green border

indicates APC

option

2 3 4

Installing the EXFO Universal Interface (EUI)

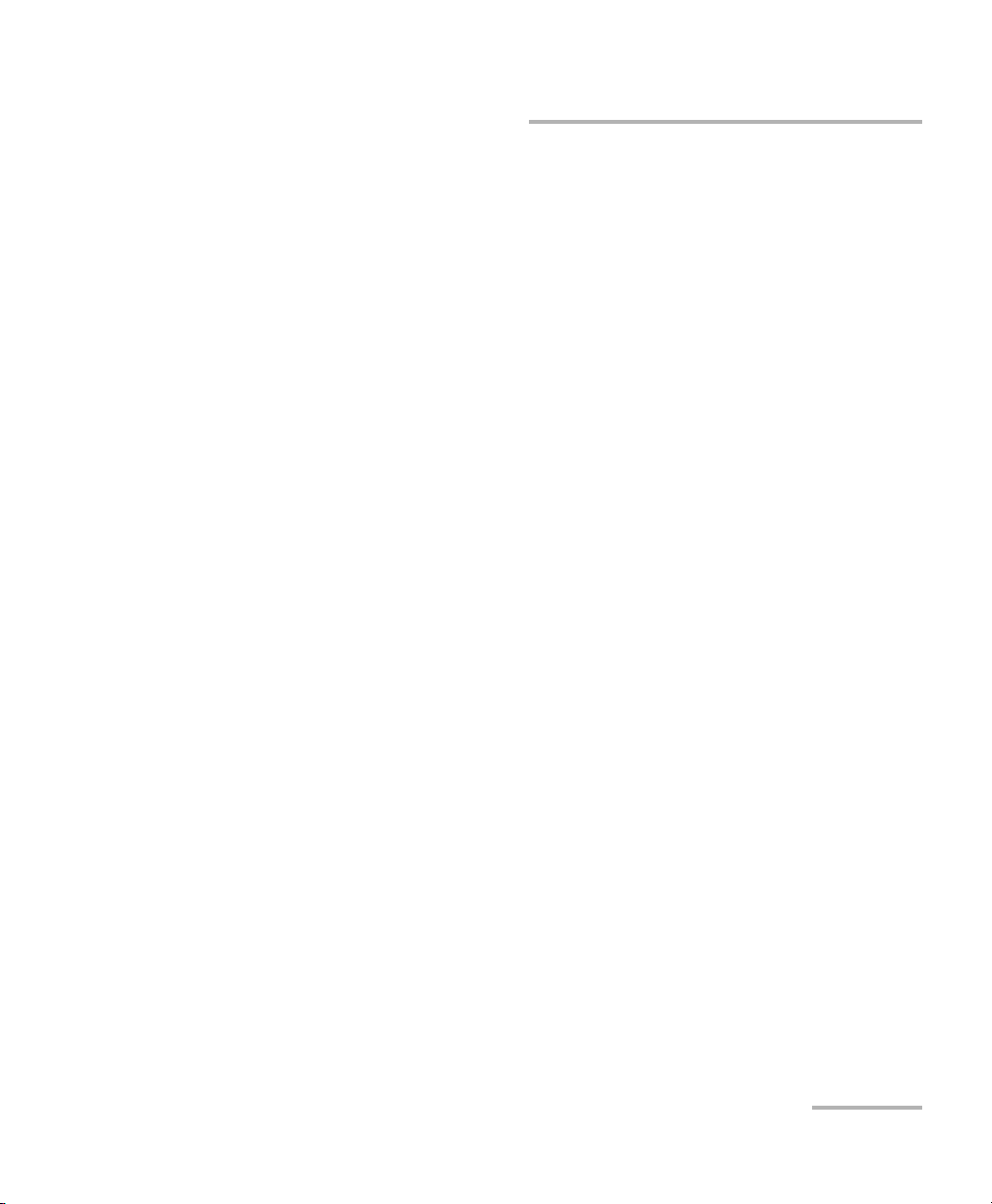

Installing the EXFO Universal Interface (EUI)

The EUI fixed baseplate is available for connectors with angled (APC) or

non-angled (UPC) polishing. A green border around the baseplate

indicates that it is for APC-type connectors.

To install an EUI connector adapter onto the EUI baseplate:

1. Hold the EUI connector adapter so the dust cap opens downwards.

2. Close the dust cap in order to hold the connector adapter more firmly.

3. Insert the connector adapter into the baseplate.

4. While pushing firmly, turn the connector adapter clockwise on the

baseplate to lock it in place.

20 FTB-5600

Page 27

Setting up and Operating your Distributed PMD Analyzer

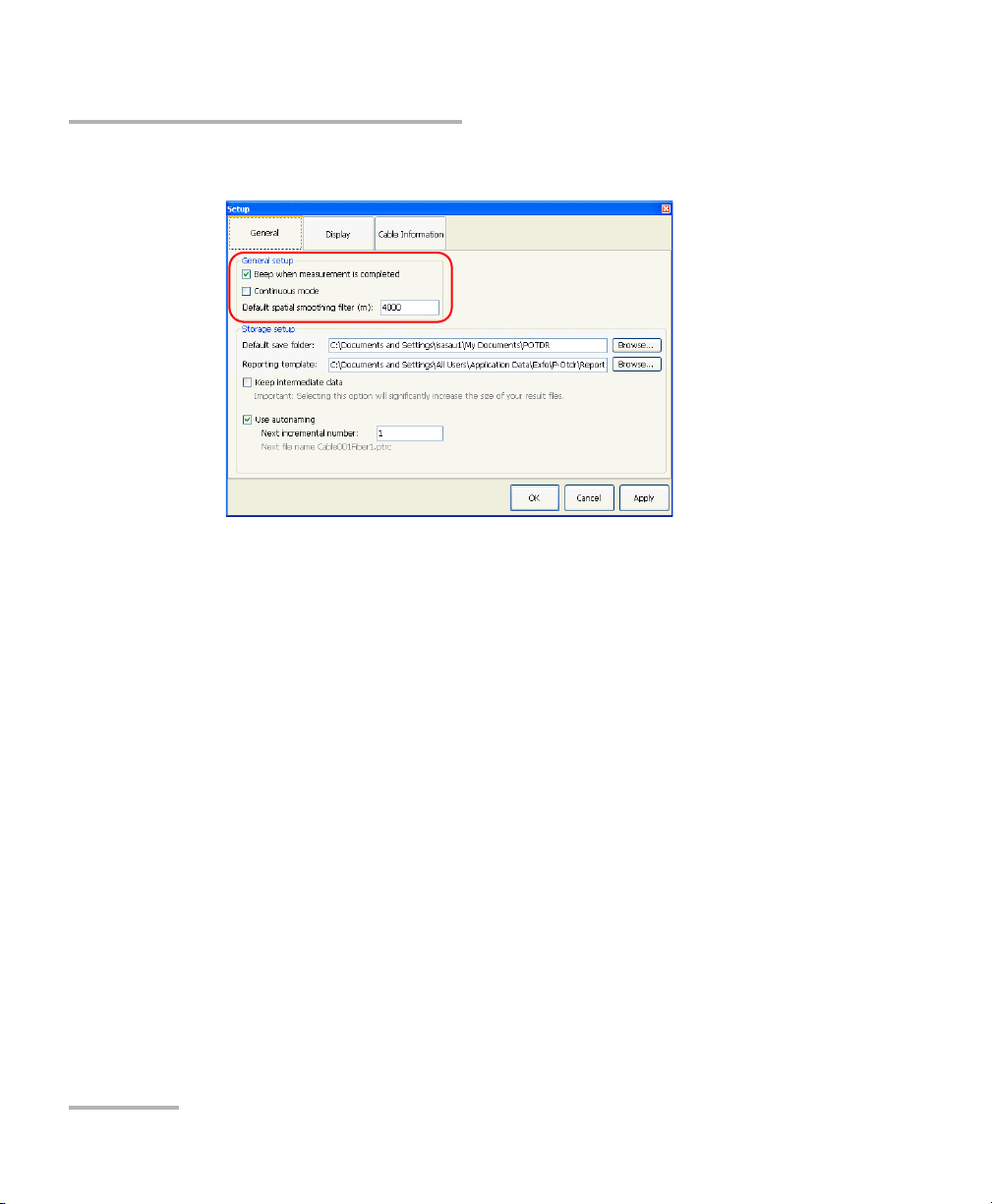

Setting up General Acquisition Parameters

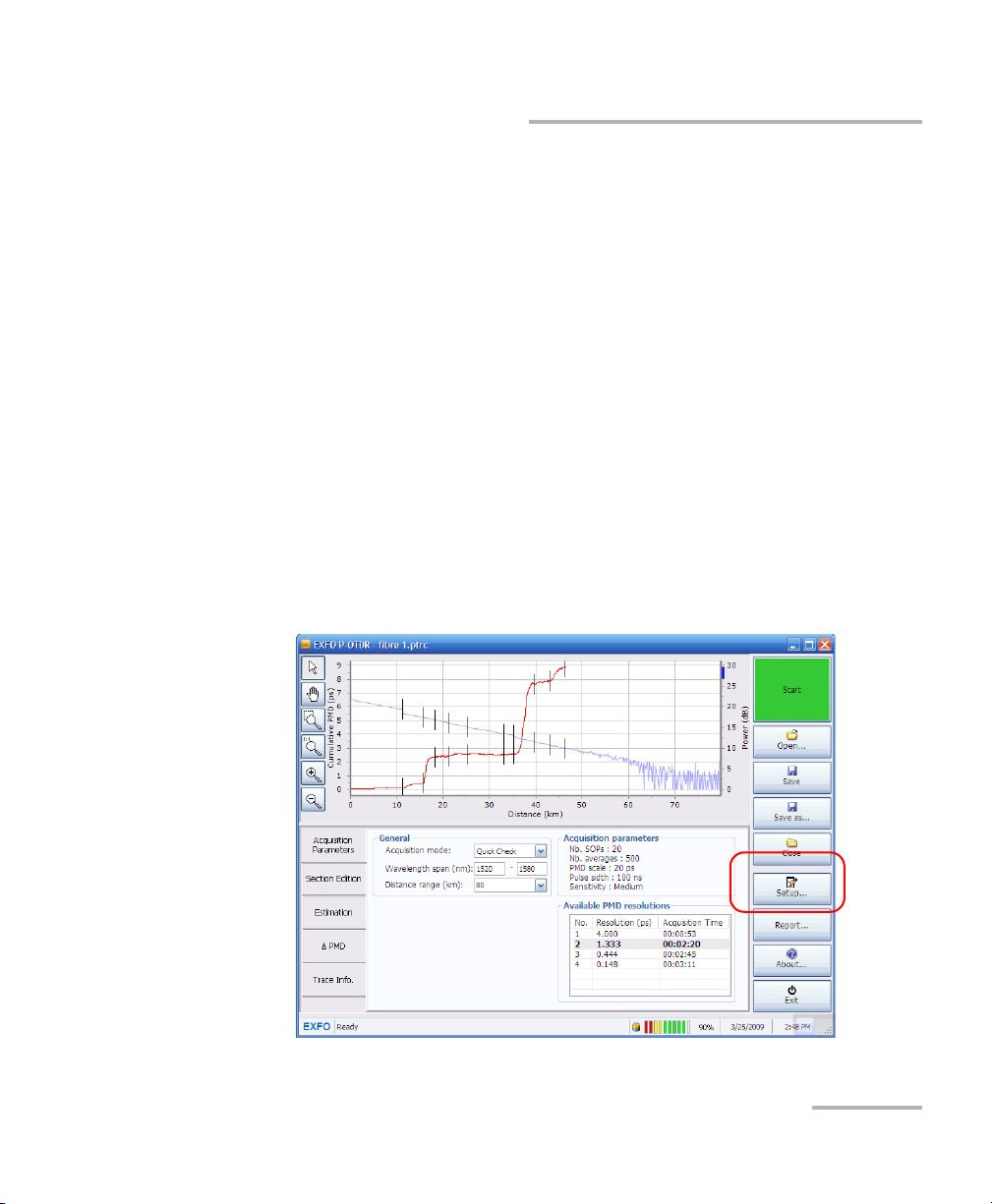

Setting up General Acquisition Parameters

The general acquisition parameters influence how the acquisition occurs.

³ You can select whether the unit beeps after each measurement or not.

³ You can set the acquisition to be continuous, or requiring that you start

each measurement manually.

³ You can set the default spatial smoothing filter, in meters. The spatial

smoothing filter helps improving the measurement results in filtering

the cumulative PMD curve. The default value is 4000 m. Increase this

value if the PMD cumulative curve is appropriate, but wavy, for

example. Decrease this value if you are interested in seeing where the

PMD begins to increase. You can find more information on the spatial

smoothing filter in Use an Appropriate Spatial Smoothing Filter Value

on page 129.

To change the general acquisition parameters:

1. From the main window, press Setup.

Distributed PMD Analyzer 21

Page 28

Setting up and Operating your Distributed PMD Analyzer

Setting up General Acquisition Parameters

2. Select the General tab.

3. Modify the parameters as desired under General setup.

4. Press Apply to use the new settings, or OK to use the new settings and

close the window.

22 FTB-5600

Page 29

Setting up and Operating your Distributed PMD Analyzer

Setting up the Graph Display

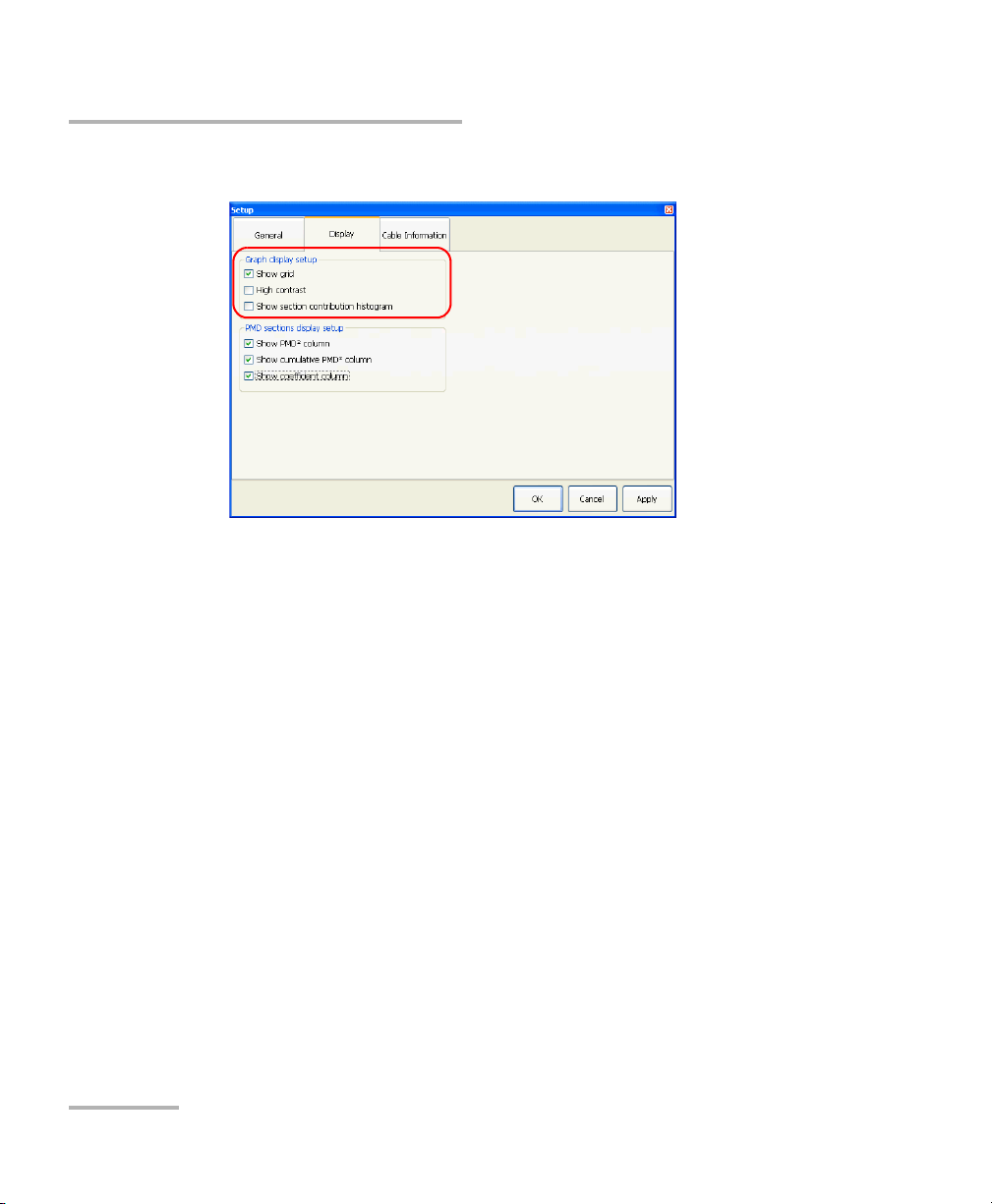

Setting up the Graph Display

The graph display parameters will help you improve how result graphs are

displayed.

³ You can display or hide the grid.

³ You can use the high contrast view if the lighting quality prevents you

from seeing the graph properly (glare from the sun, darkness).

³ You can show or hide the section contribution histogram. This

histogram is a graphic representation of the contents of the Contr.%

column in the section table.

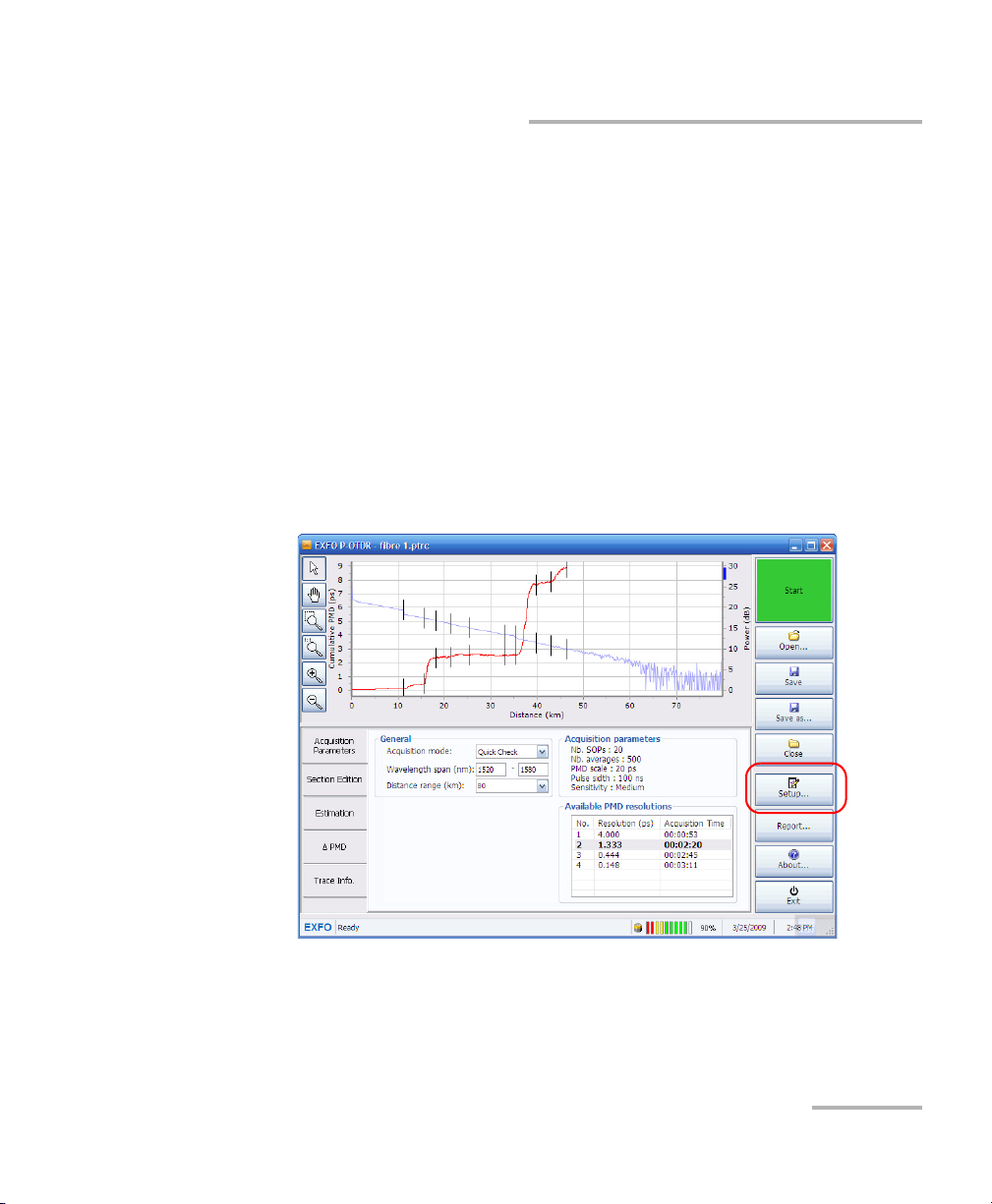

To change the graph display parameters:

1. From the main window, press Setup.

Distributed PMD Analyzer 23

Page 30

Setting up and Operating your Distributed PMD Analyzer

Setting up the Graph Display

2. Select the Display tab.

3. Modify the parameters as desired under Graph display setup.

4. Press Apply to use the new settings, or OK to use the new settings and

close the window.

24 FTB-5600

Page 31

Setting up and Operating your Distributed PMD Analyzer

Setting up Storage Options

Setting up Storage Options

The FTB-5600 will automatically save the acquisition files during the test.

You can set where the unit saves the data, select which template is used

for creating reports, and you can use an autonaming scheme to facilitate

and speed up your work.

You can also decide to keep the intermediate data while performing

acquisitions. This option should be used when there is a problem with your

unit or a measurement. Once you have acquired this data, which

represents all of the actions done by the unit when performing the test, you

can take the resulting file and send it to EXFO for troubleshooting

purposes.

IMPORTANT

Keeping the intermediate data will increase the size of the result file

in a significant manner.

Distributed PMD Analyzer 25

Page 32

Setting up and Operating your Distributed PMD Analyzer

Setting up Storage Options

To set up the storage options:

1. From the main window, select Setup.

2. Select the General tab.

26 FTB-5600

Page 33

Setting up and Operating your Distributed PMD Analyzer

Setting up Storage Options

3. Under Storage setup, enter the paths for the default save folder and

the reporting template. You can also use the Browse button to open a

standard navigation window.

4. If desired, select the Keep intermediate data option.

Distributed PMD Analyzer 27

Page 34

Setting up and Operating your Distributed PMD Analyzer

Setting up Storage Options

5. If desired, activate the autonaming feature. If you want the

incrementation to start on a specific number, enter it in the Next

incremental number box. You will see a preview of the next file name

at the bottom of the window.

Note: If your acquisition is set to continuous, the autonaming feature is

automatically selected and you cannot change this setting.

IMPORTANT

If you had previously saved files that have the same name as those

created by the autonaming feature, they will be replaced without

any notification.

6. Press Apply to use the new settings, or OK to use the new settings and

close the window.

28 FTB-5600

Page 35

Setting up and Operating your Distributed PMD Analyzer

Displaying PMD-Related Columns in the Main Window

Displaying PMD-Related Columns in the Main

Window

You can decide to hide or display the following columns in the main

window:

³ PMD

³ Cumulative PMD

³ PMD coefficient

Note: If you decide to hide or display those columns, the change will take effect

immediately in the result tabs

To display PMD-related columns in the main window:

1. From the main window, press Setup.

2

2

Distributed PMD Analyzer 29

Page 36

Setting up and Operating your Distributed PMD Analyzer

Displaying PMD-Related Columns in the Main Window

2. Select the Display tab.

3. Under PMD sections display setup, select which column or columns

you want to display.

4. Press Apply to use the new settings, or OK to use the new settings and

close the window.

30 FTB-5600

Page 37

Setting up and Operating your Distributed PMD Analyzer

Setting up Cable Information

Setting up Cable Information

The cable information is useful to help you differentiate your various

acquisitions. It will also appear in reports you generate for your

acquisitions.

To set the cable information:

1. From the main window, select Setup.

Distributed PMD Analyzer 31

Page 38

Setting up and Operating your Distributed PMD Analyzer

Setting up Cable Information

2. Select the Cable Information tab.

3. Enter the information as needed.

4. Press Apply to confirm the information, or OK to confirm the

information and close the window.

32 FTB-5600

Page 39

Setting up and Operating your Distributed PMD Analyzer

Performing an Acquisition

Performing an Acquisition

IMPORTANT

When measuring PMD, it is very important that the launch fiber is

not moved.

You can perform the test according to three acquisition modes:

³ Quick Check: This mode is used to obtain a fast overview of a link. All

you have to do is set the distance range for the link. To perform a Quick

Check, see Performing a Quick Check Acquisition on page 35.

³ Standard: This mode is the general test mode. All you have to set is the

accuracy and sensitivity levels. This mode is selected by default when

you open the application. To perform a standard acquisition, see

Performing a Standard Acquisition on page 37.

³ Advanced: This mode is used to perform an optimized acquisition. You

will have to set all of the parameters individually. This acquisition will

take more time to per form, but will return more details and can be fully

optimized. To perform an advanced acquisition, see Pe r for m i n g an

Advanced Acquisition on page 41.

Distributed PMD Analyzer 33

Page 40

Setting up and Operating your Distributed PMD Analyzer

Performing an Acquisition

The FTB-5600 does a series of actions in taking a measurement.

³ The instrument takes an OTDR trace and displays it. This step only

takes a few seconds. At this point, you should inspect the trace to see if

there are any problems.

³ Then, the instrument measures the SOPs. This will take more or less

time depending on the accuracy and sensitivity requested. The

remaining time and SOPs to measure are indicated in the status bar of

the application. After measuring about 10 SOPs, you will see a

temporary cumulative PMD curve.

³ At this point, considering that the overall measurement process is quite

long, EXFO strongly recommends that you make a general inspection

of the OTDR trace to verify that the instrument is properly connected

and that the FUT is OK.

³ Once all of the SOPs are acquired, the instrument computes the actual

PMD curve.

34 FTB-5600

Page 41

Setting up and Operating your Distributed PMD Analyzer

Performing an Acquisition

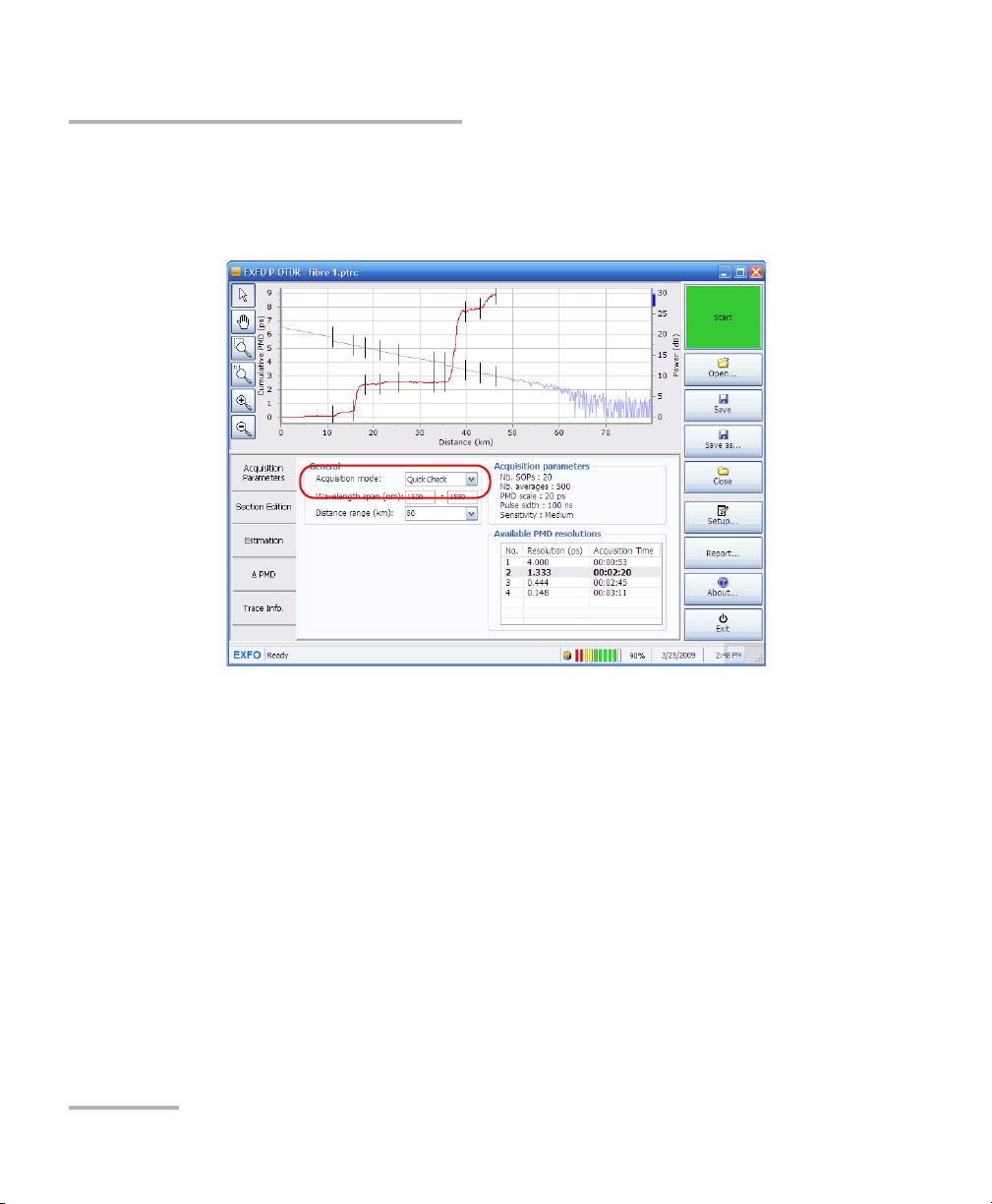

Performing a Quick Check Acquisition

The main purpose of the quick check is to have an estimate of the

cumulative PMD of the link to select the appropriate PMD scale.

Using the Quick Check OTDR trace and cumulative PMD curve, you can

verify the following:

³ The injection level: it should be within the injection level accepted

range, as it is the case with an OTDR. If it is not, correct the connection

at the instrument. This will improve the dynamic range.

³ The link length: the range value may be updated with the link length

seen on the trace. This reduces the size of the file and accelerates both

processing and acquisition times.

³ The link PMD maximum value could be used to set the PMD scale of

the advanced settings. This may have a major impact on the

acquisition time.

³ Where the PMD trace ends. If it ends very far from the end of the link,

then the number of averages could be increased to improve the

dynamic range.

This mode uses a low number of SOPs, therefore the measurement will not

be accurate. You should not use this acquisition mode to characterize

entire links. The default PMD scale for this mode is 20 ps.

Distributed PMD Analyzer 35

Page 42

Setting up and Operating your Distributed PMD Analyzer

Performing an Acquisition

To perform a Quick Check acquisition:

1. From the main window, under General, select the Quick Check

acquisition mode.

36 FTB-5600

Page 43

Setting up and Operating your Distributed PMD Analyzer

Performing an Acquisition

2. Set the distance range, in kilometers, from the list of available values.

You can also type in the value directly. Reducing the range to the part of

the link that you want to measure will increase measurement speed

and decrease the resulting file size. If you do not know the length of the

link, you can rely on the OTDR trace to estimate it.

3. Press Start.

The acquisition starts. You can see the remaining time in the status bar.

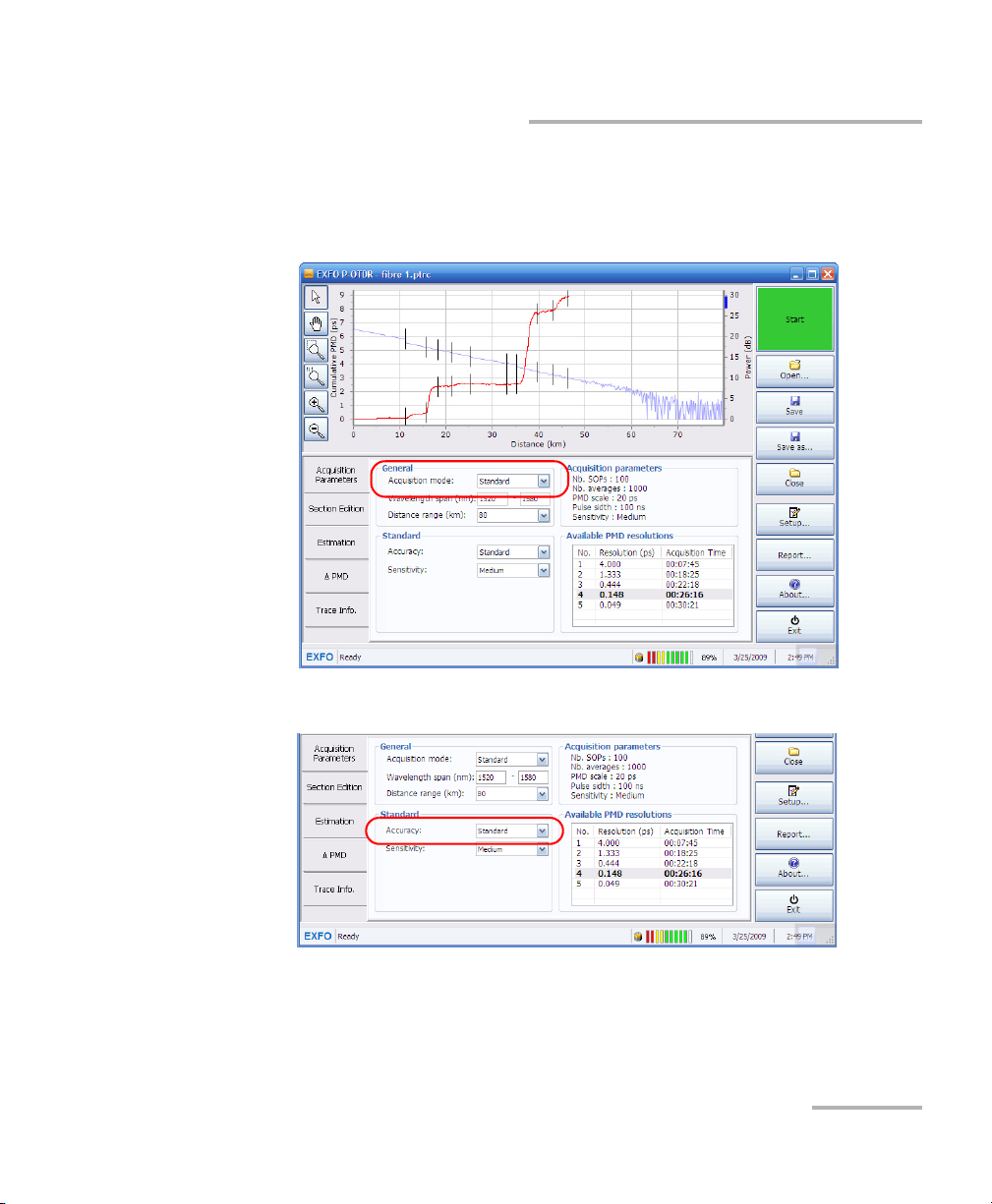

Performing a Standard Acquisition

The acquisitions are more optimized for characterizing the link correctly

rather than for the acquisition time. The default PMD scale for this mode is

20 ps. EXFO recommends setting the accuracy to the standard level and

the sensitivity to the medium level for an acquisition of about 30 minutes.

The accuracy of the measurement changes the number of SOPs and

residual PMD. A higher level of SOPs will yield a more accurate result, but

longer acquisition time.

Accuracy Number of SOPs PMD Resolution (fs)

Low 50 1333

Medium 100 148

High 200 50

Distributed PMD Analyzer 37

Page 44

Setting up and Operating your Distributed PMD Analyzer

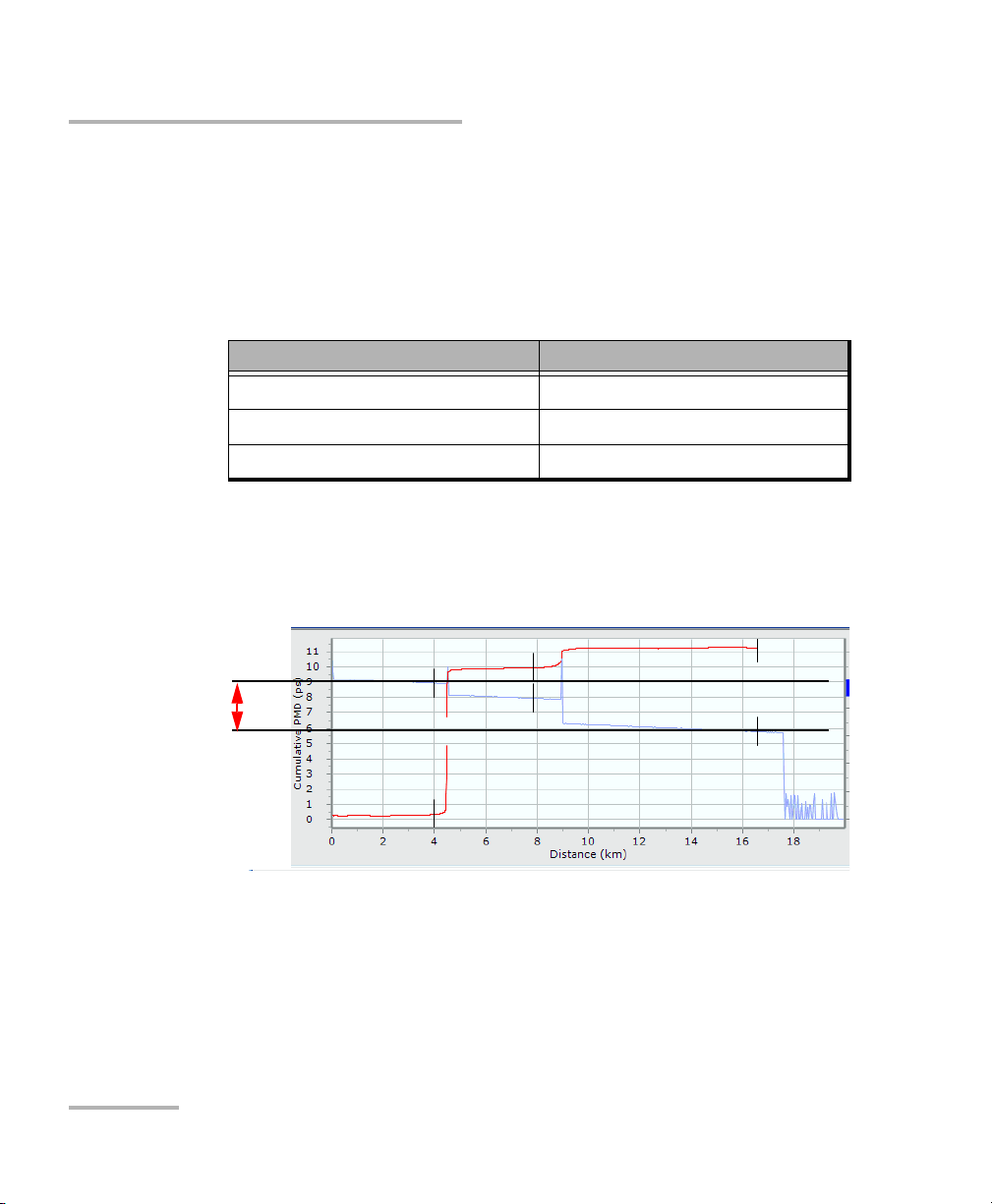

Difference between

injection and OTDR

trace level where

the PMD curve ends

Performing an Acquisition

The sensitivity of the measurement allows you to increase the PMD

measurement range. A greater sensitivity increases the number of averages

and will take longer to be achieved.

Sensitivity

Number of

Averages

Electronic

Sensitivity

Low 500 Low APD gain

Medium 1000 High APD gain

High 2000 High APD gain

To improve the dynamic range for your acquisition, consider the following:

³ For less than 13 dB, put the sensitivity to low. This means an acquisition

of about 15 minutes with three resolutions.

³ Setting the sensitivity to medium will improve the dynamic range and

means an acquisition of about 30 minutes with three resolutions.

³ Setting the sensitivity to high will give you the optimal dynamic range

and means an acquisition of about 1 hour with three resolutions.

Note: You can obtain the dynamic range of the trace by subtracting the

backscatter level at the fiber end from the injection level accepted range

value.

38 FTB-5600

Page 45

Setting up and Operating your Distributed PMD Analyzer

Performing an Acquisition

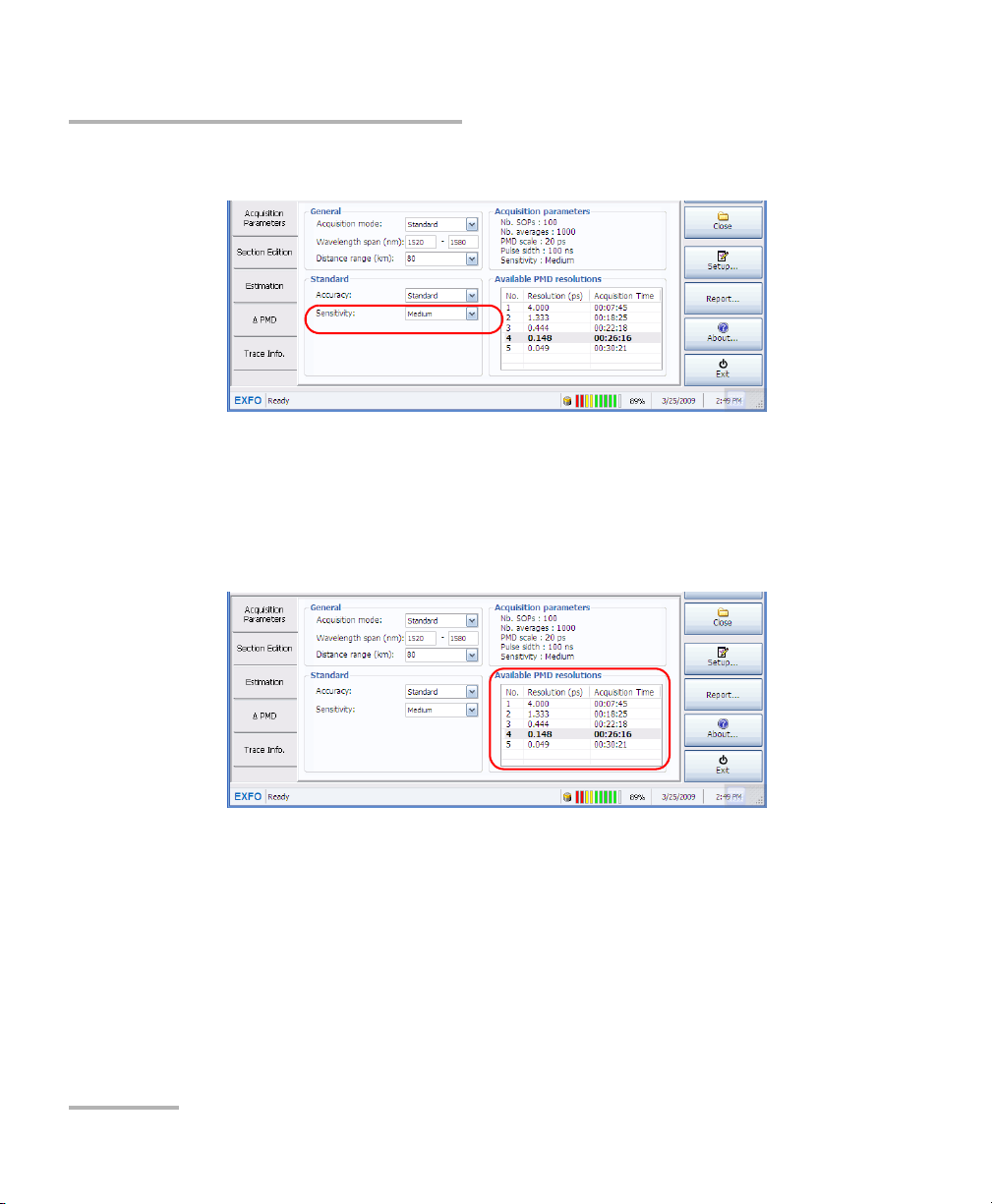

To perform a standard acquisition:

1. From the main window, under General, select the Standard

acquisition mode.

2. Set the accuracy of the measurement by selecting a value in the list.

Distributed PMD Analyzer 39

Page 46

Setting up and Operating your Distributed PMD Analyzer

Performing an Acquisition

3. Set the sensitivity of the measurement by selecting a value in the list.

4. Select the PMD resolution that can best fit the minimum measurable

value for your PMD scale.

Note: The PMD resolution will influence the acquisition time; the estimated value

is next to each scale.

5. Press Start.

The acquisition starts. You can see the remaining time in the status bar.

40 FTB-5600

Page 47

Setting up and Operating your Distributed PMD Analyzer

Performing an Acquisition

Performing an Advanced Acquisition

The advanced acquisition parameters will help you perform a more

accurate test. For more information on setting the parameters to optimize

your acquisition, see Optimizing Measurements on page 121.

³ The number of polarization states (SOP) used will change the accuracy

for your acquisition as it increases. However, it will also increase the

acquisition time accordingly.

EXFO recommends a measurement of at least 100 SOPs in order to

have a significant cumulative PMD curve. A value of 50 SOPs will return

a crude measurement. The most accurate measurements will be done

with a number of SOPs ranging from 400 to 1000.

³ The number of averages sets each individual OTDR trace number of

averages. These OTDR traces are used to build the cumulative PMD

curve. A higher number of averages decreases the noise and increases

the acquisition time.

EXFO recommends a value of 500 averages; use more if the

measurement range is too small. A value below 500 may affect the

precision of the acquisition estimated time.

³ The PMD scale sets the target value of the cumulative PMD of the FUT

to be measured. If you already know the PMD value of the FUT, select

the closest value in the list. You can also crudely evaluate this value by

performing a Quick Check (see Performing a Quick Check Acquisition

on page 35 for details). If you see that the PMD curve is very wavy and

is at the same level as the PMD resolution, the PMD scale value is too

high.

³ The pulse width sets the length of the OTDR pulse used to characterize

the PMD cumulative curve. Increasing the value also increase

acquisition time. EXFO recommends using a pulse width of 100 ns. If

more dynamic range is required and that there are no depolarized

sections, you can use a pulse width of up to 275 ns. If there are

depolarized sections, using a lower value such as 50 ns may help.

Distributed PMD Analyzer 41

Page 48

Setting up and Operating your Distributed PMD Analyzer

Difference between

injection and OTDR

trace level where

the PMD curve ends

Performing an Acquisition

³ The sensitivity parameter sets the electronic APD gain. You should use

the high setting unless you are interested only in the very beginning of

the link. The sensitivity of the measurement is dependant on the PMD

range. A greater sensitivity increases the number of averages and will

take longer to be achieved. Consider the following to improve your

dynamic range.

Sensitivity Number of Averages to Select

Low 500

Medium 1000

High 2000

Note: You can obtain the dynamic range of the trace by subtracting the

backscatter level at the fiber end from the injection level accepted range

value.

42 FTB-5600

³ The PMD resolution is the minimum value to be measured. EXFO

recommends setting this value to the lowest value of interest for your

testing purposes. A smaller PMD resolution signifies a larger number of

PMD steps and increases acquisition time.

Page 49

Setting up and Operating your Distributed PMD Analyzer

Performing an Acquisition

For rough measurements in links with high PMD, you should use a

value between 0.4 and 1 ps. For low PMD measurements, use a value

around 50 ps and at least 100 SOPs. For faster measurements of small

PMD values, use a lower setting, such as 2 ps.

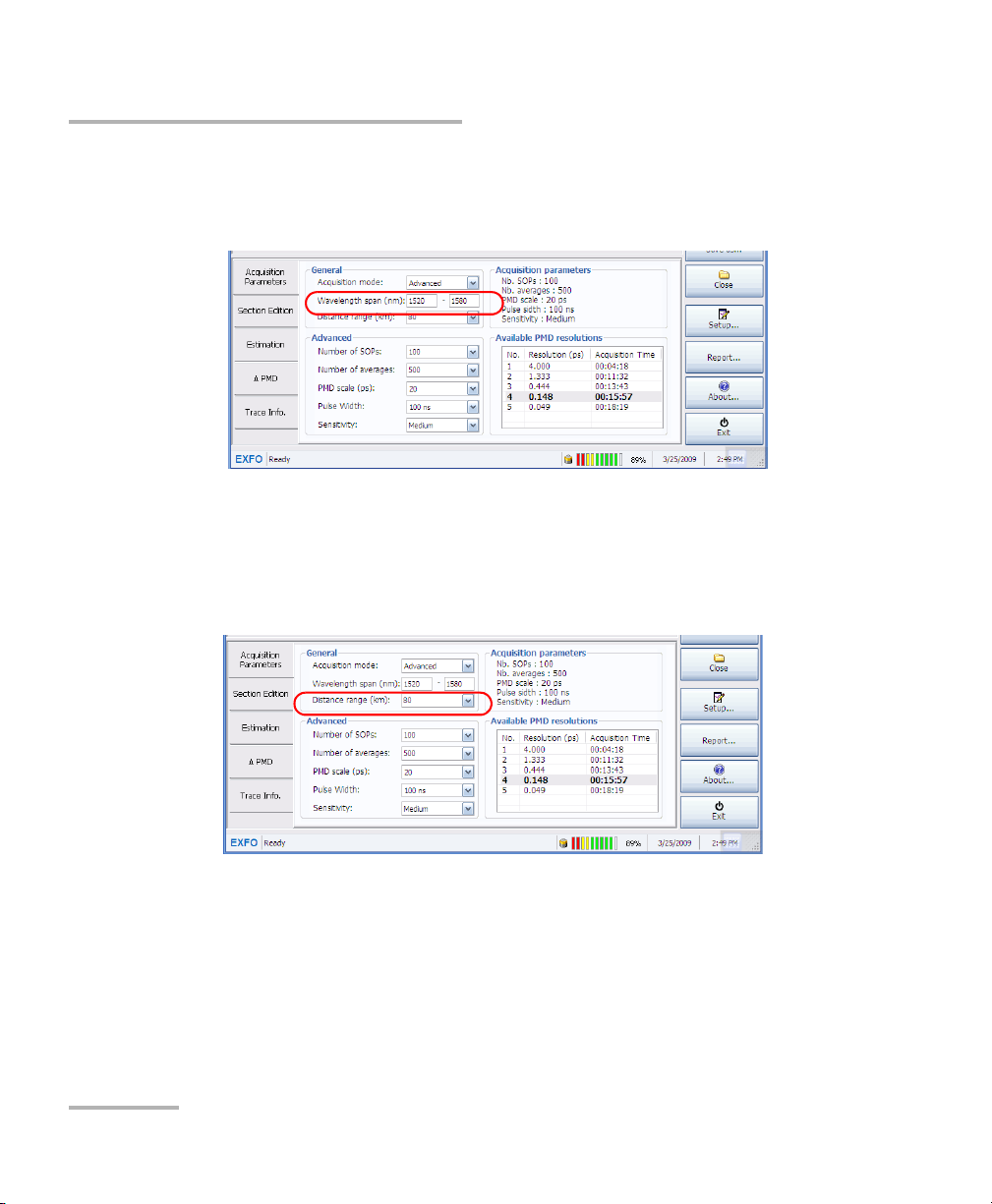

To perform an advanced acquisition:

1. From the main window, under General, select the Advanced

acquisition mode.

Distributed PMD Analyzer 43

Page 50

Setting up and Operating your Distributed PMD Analyzer

Performing an Acquisition

2. Set the wavelength span for your test. The default range is 1520 nm to

1580 nm. EXFO does not recommend changing this range unless you

want to perform a very specific test.

3. Set the distance range, in kilometers, from the list of available values,

or you can enter your own manually. Reducing the range to the part of

the link that you want to measure will increase measurement speed

and decrease the resulting file size. If you do not know the length of the

link, you can rely on the OTDR trace to estimate it.

44 FTB-5600

Page 51

Setting up and Operating your Distributed PMD Analyzer

Performing an Acquisition

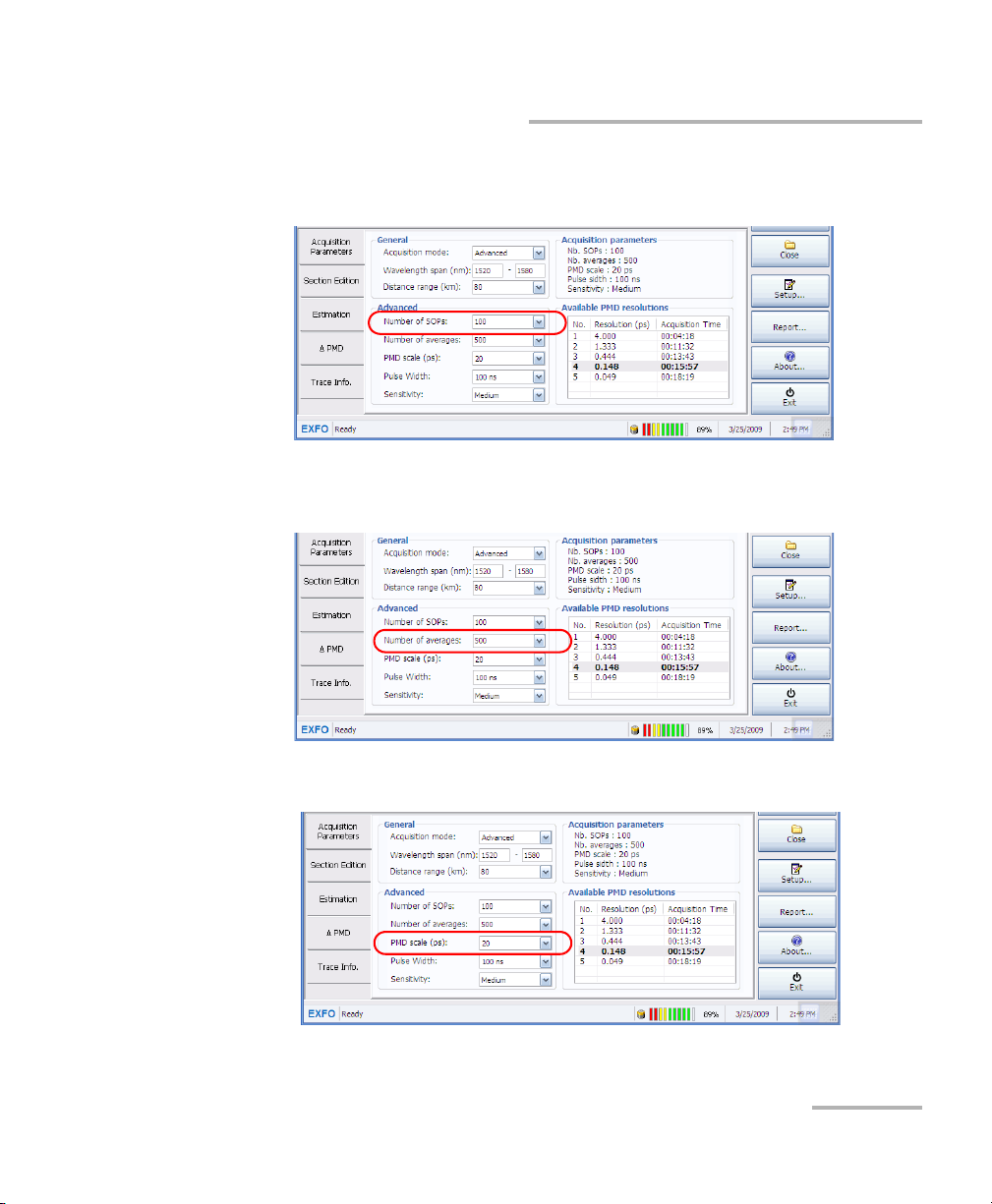

4. Under Advanced, select the number of SOPS from the list of available

values. You can also type in a value directly.

5. Select the number of averages for the measurement. You can also type

in a value directly.

6. Select the PMD scale, in ps.

Distributed PMD Analyzer 45

Page 52

Setting up and Operating your Distributed PMD Analyzer

Performing an Acquisition

7. Select the pulse width, in ns

8. Select the sensitivity level.

46 FTB-5600

Page 53

Setting up and Operating your Distributed PMD Analyzer

Using the Bidirectional File Creator

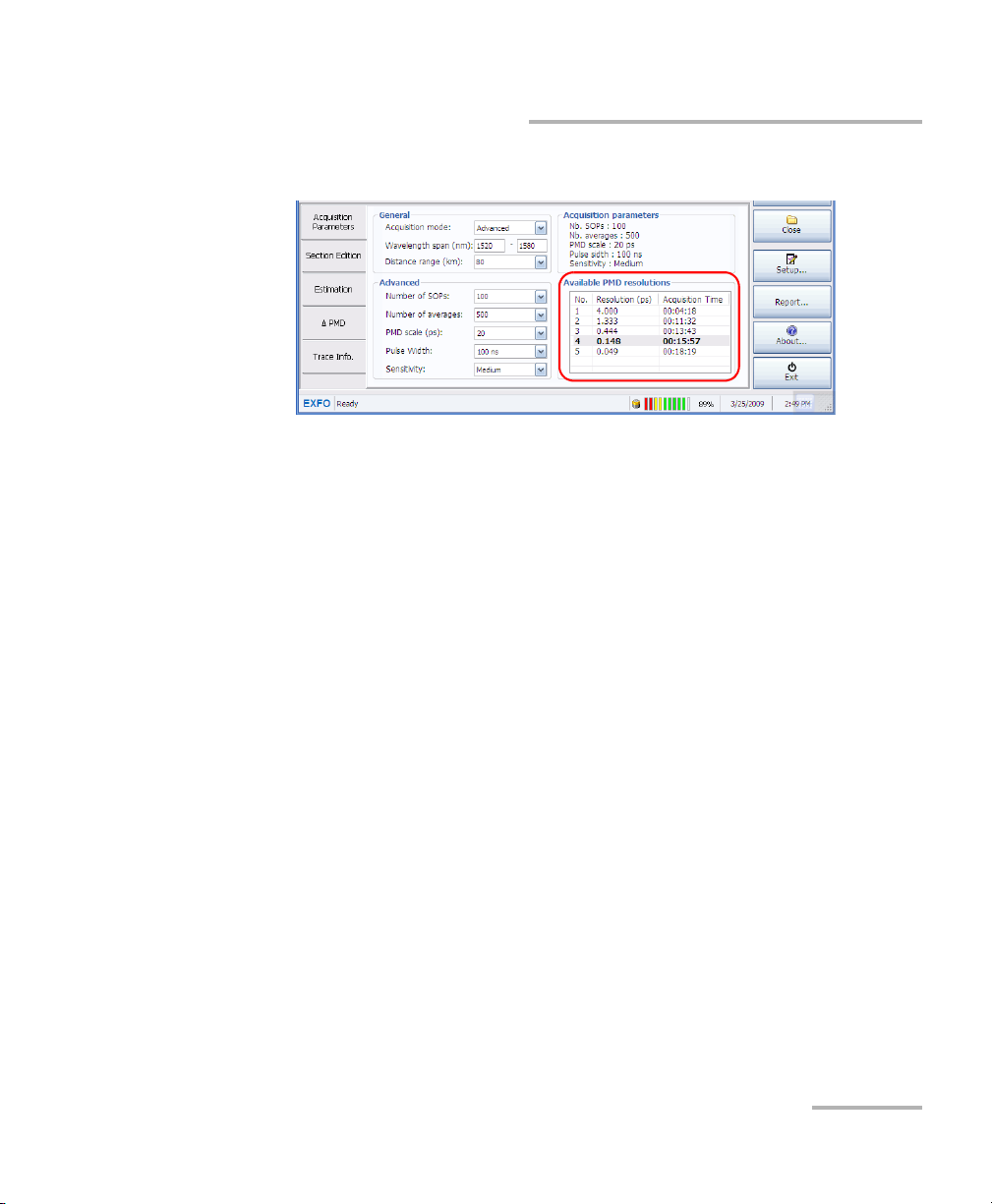

9. Select the appropriate PMD resolution from the list.

A summary of the parameters is displayed on-screen.

10. Press Start.

The acquisition starts. You can see the remaining time and number of

SOPs in the status bar.

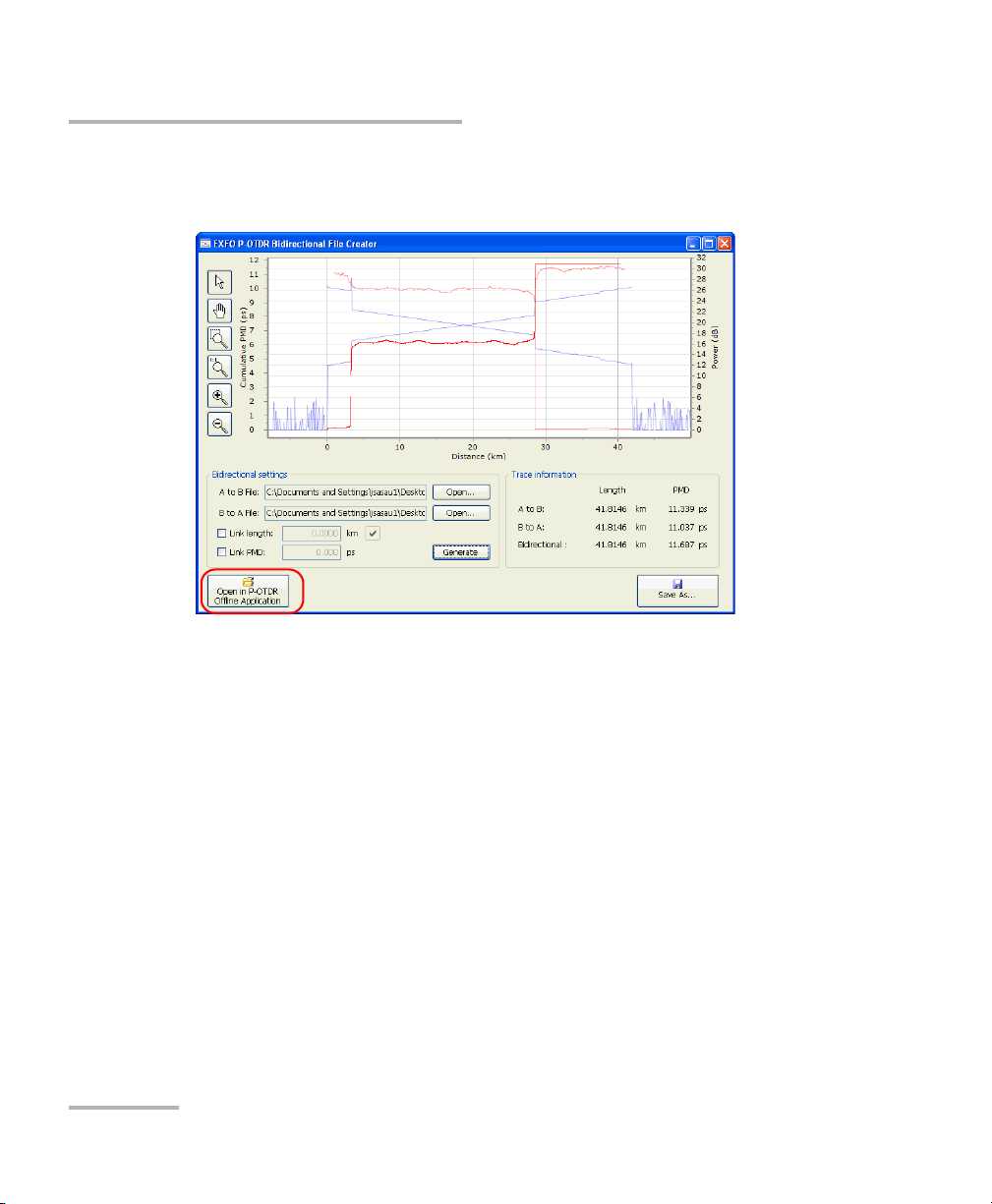

Using the Bidirectional File Creator

Since PMD accumulates in quadratic manner, the higher the PMD, the

more difficult it is to measure weak PMD variations. Using a measurement

coming from each end of the link you want to characterize and combining

the two measurements into one bidirectional trace file can help you

improve the precision of the measurement all over the link.

When measuring links that are too long for the dynamic range of the unit,

creating a bidirectional trace by combining the traces coming from each

end doubles the effective measurement range.

The files can therefore overlap fully, partly, or not overlap at all.

Note: You cannot use a bidirectional file you have already created to create a

new bidirectional file.

Distributed PMD Analyzer 47

Page 54

Setting up and Operating your Distributed PMD Analyzer

Using the Bidirectional File Creator

To create a bidirectional file:

1. From Windows, select start, then All Programs > EXFO > Programs.

OR

From ToolBox, select the Applications tab, then P-OTDR Bidirectional

File Creator.

2. Select the trace file you want to use for the A -> B side by using the

corresponding Open button.

48 FTB-5600

Page 55

Setting up and Operating your Distributed PMD Analyzer

Using the Bidirectional File Creator

3. Select the trace file you want to use for the B -> A side by using the

corresponding Open button.

Distributed PMD Analyzer 49

Page 56

Setting up and Operating your Distributed PMD Analyzer

Using the Bidirectional File Creator

4. If the two traces do not allow the automatic calculation of the length of

the link (for example, they do not cover the same distance), or if you

want to specify a length yourself, select the corresponding option, then

enter the value you want.

50 FTB-5600

Page 57

Setting up and Operating your Distributed PMD Analyzer

Using the Bidirectional File Creator

5. If you want to specify an estimation of the PMD on the link, select the

corresponding option.

6. Click Generate to start the bidirectional file creation.

Distributed PMD Analyzer 51

Page 58

Setting up and Operating your Distributed PMD Analyzer

Using the Bidirectional File Creator

The resulting traces appear on-screen once the application is done

creating the file.

52 FTB-5600

Page 59

Setting up and Operating your Distributed PMD Analyzer

Using the Bidirectional File Creator

To save the created bidirectional trace:

1. Select Save as, then select a name and location for your file.

2. Select Save.

Note: For information on using the zooming tools, see Using Zoom Controls on

page 62.

Distributed PMD Analyzer 53

Page 60

Setting up and Operating your Distributed PMD Analyzer

Using the Bidirectional File Creator

To open the created trace in the P-OTDR application to analyze it:

Once the trace was created and saved, select Open in P-OTDR.

Note: A bidirectional file is always identified as such in the title bar of the P-OTDR

application window.

54 FTB-5600

Page 61

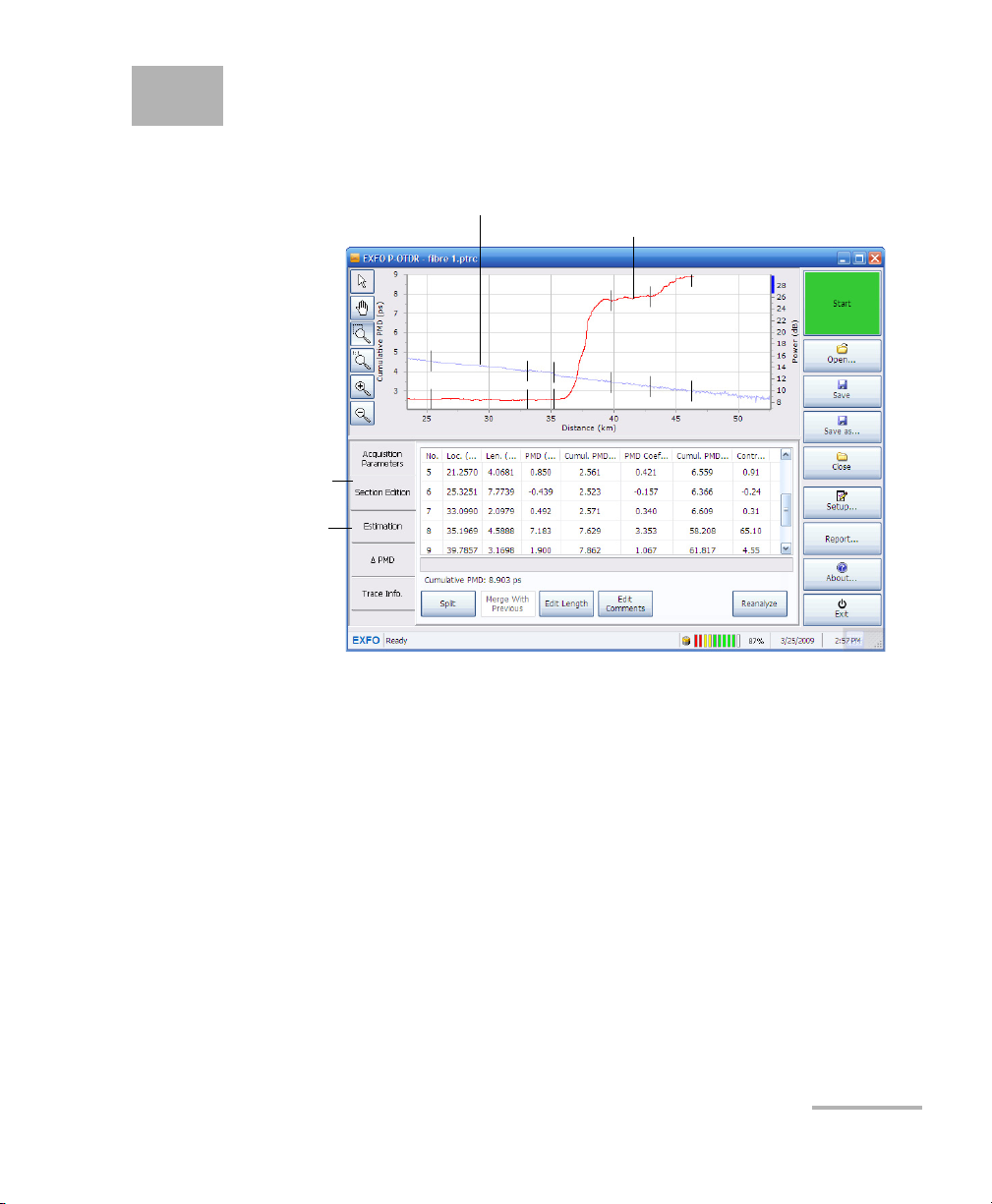

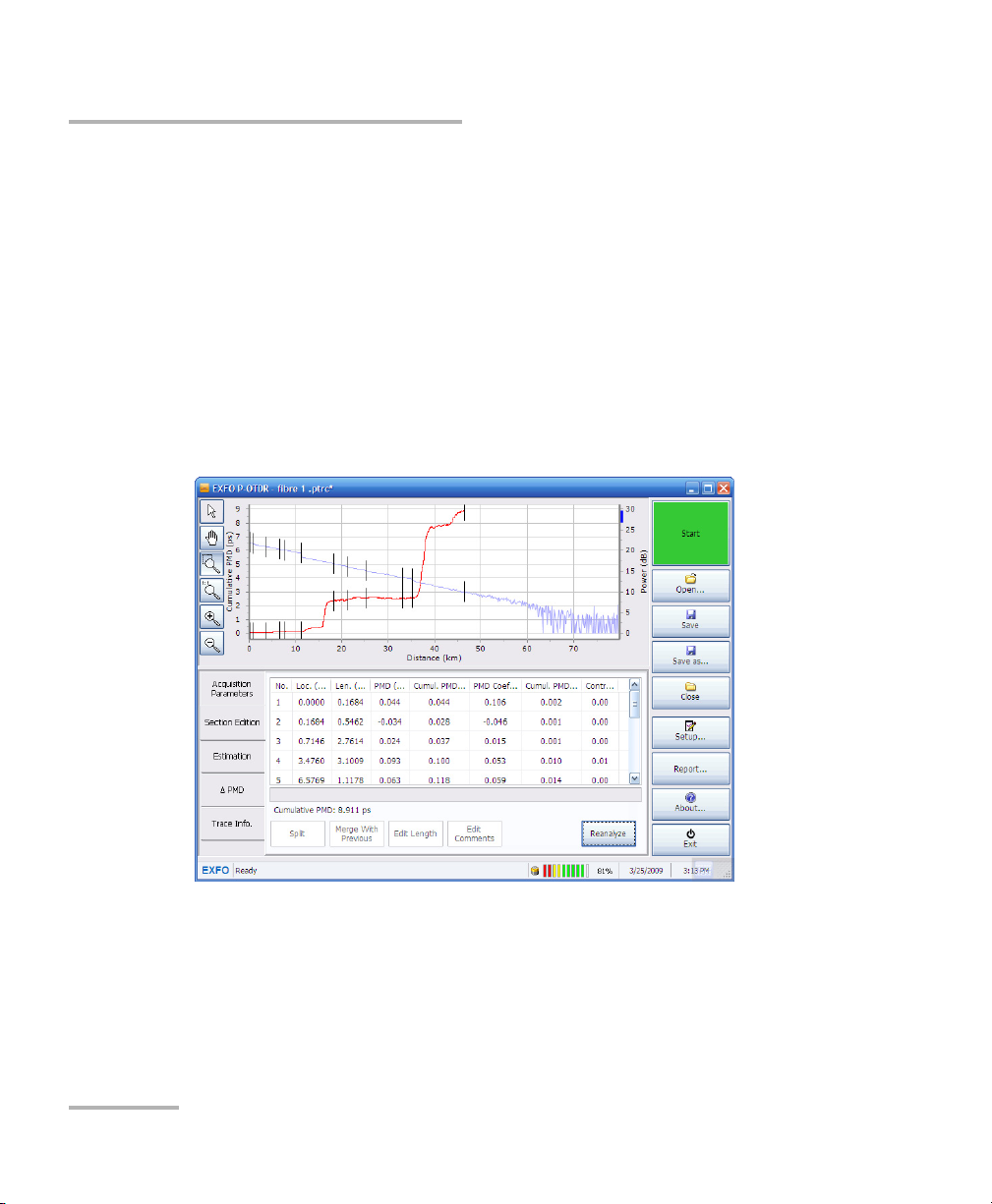

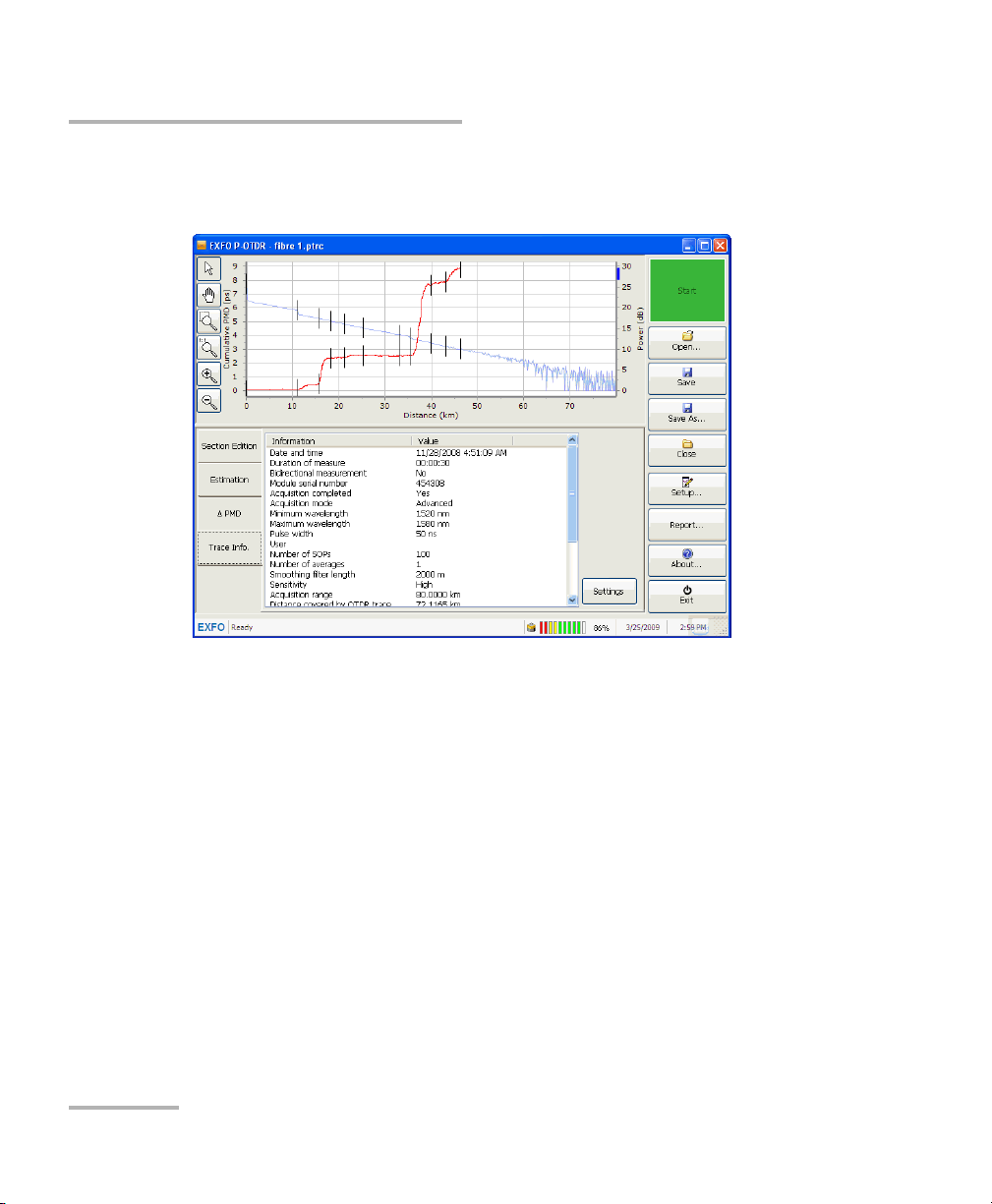

5 Managing Results

OTDR Trace

Cumulative PMD curve as

function of the distance

PMD section table to

view and edit current

sections

PMD estimation table to

analyze the effect of

modifying sections

Once the acquisition is complete, you can see data appear on-screen.

Distributed PMD Analyzer 55

You can perform result analyses directly in the FTB-5600, but you can also

use the offline application that you can access through ToolBox. The offline

application is identical to the online application, except that you cannot

make acquisitions with it; therefore, you will see that the Start button, as

well as the Acquisition Parameters are disabled.

Page 62

Managing Results

To access the offline application:

1. From ToolBox, select the Applications tab.

Note: Depending on which applications are installed on your platform, the

Applications tab may look different.

2. Select P-OTDR.

3. Press Start Application.

56 FTB-5600

Page 63

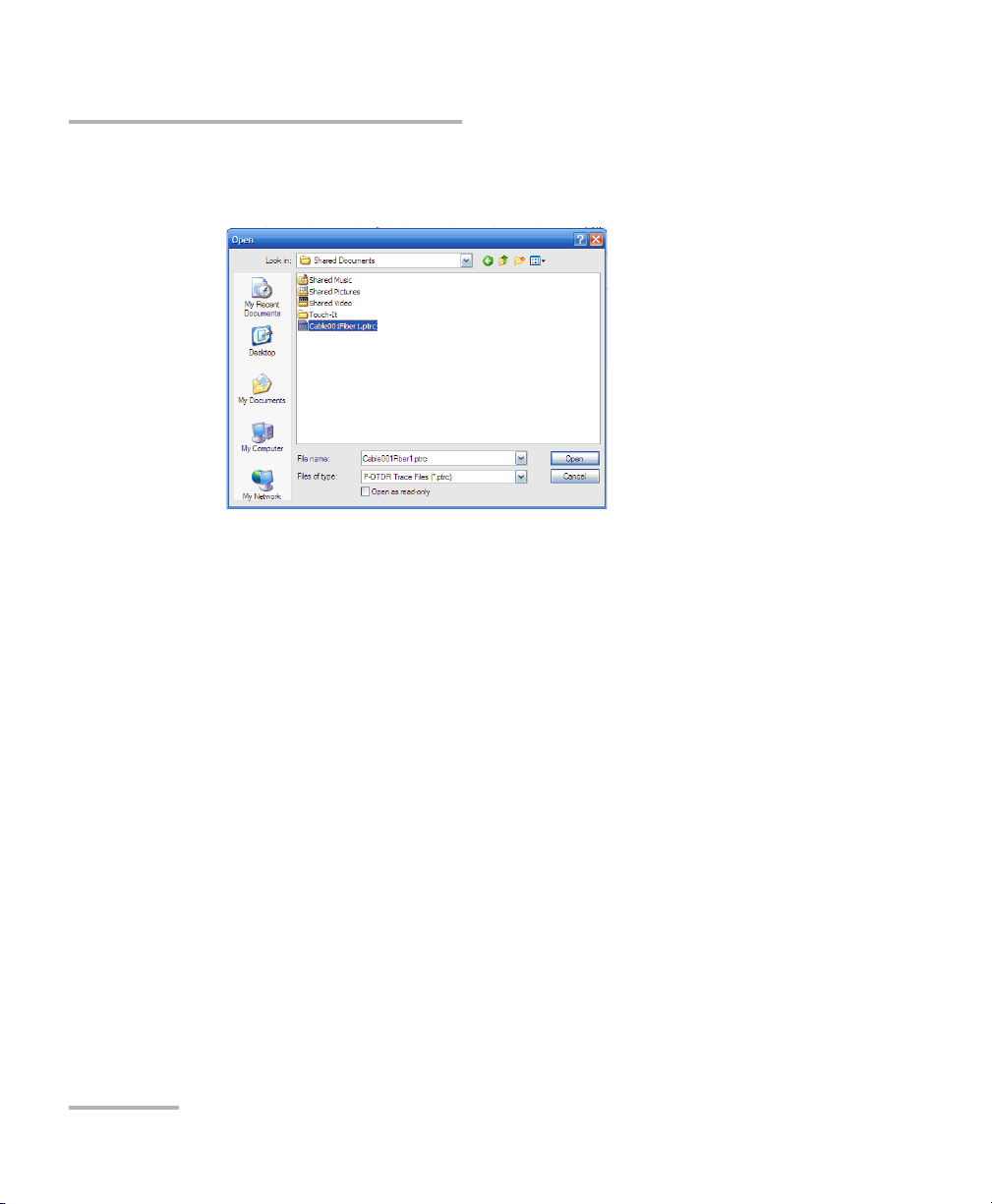

Managing Results

Opening an Existing File

Opening an Existing File

If you are working with the offline mode of the application, or want to open

a file you have previously acquired, you can either open it and modify it as

needed, or open it as a read-only file, to avoid any accidental modification.

To open an existing file:

1. From the main window, press Open.

Distributed PMD Analyzer 57

Page 64

Managing Results

Opening an Existing File

2. Select the file you want to open. If you want the file to open in

read-only mode, select the corresponding option.

3. Press Open.

58 FTB-5600

Page 65

Managing Results

Saving a File

Saving a File

Files can be saved either using the autonaming scheme or using a

personalized name.

The autonaming scheme is only available if you have selected the option as

explained in Setting up Storage Options on page 25 and if the file you are

saving is a new acquisition (as opposed to an already existing file that you

have opened).

IMPORTANT

Since acquisition files can be extremely large, they are directly sent

to the storage location and are not kept in memory to optimize the

operation speed of the unit.

If the location you have selected for saving files is external to the

unit (for example, a USB key or a drive linked through a network),

you must leave the external storage device or link in place while you

are working on your files. Otherwise, the unit cannot save the data

and you will lose any change made since the time you removed the

storage device or connection.

Distributed PMD Analyzer 59

Page 66

Managing Results

Saving a File

To save a file using the autonaming scheme:

From the main window, press Save.

60 FTB-5600

Page 67

To save a file using a personalized name:

1. From the main window, press Save As.

Managing Results

Saving a File

2. Enter a name for the file, then press Save.

Distributed PMD Analyzer 61

Page 68

Managing Results

Selection mode

Move view area

Zoom in on the defined area

Automatic zoom in

Full view

Automatic zoom out

Using Zoom Controls

Using Zoom Controls

Use the zoom controls to change the scale of the trace display.

Note: You cannot move the markers with the button.

To view specific portions of the graph:

³ You can define which portion of the graph will be visible by selecting

the button and dragging the graph with the stylus or your finger.

³ You can also zoom in on a specific area by selecting the button

and defining the zoom area with the stylus or your finger (a rectangle

with dotted lines will appear to help you define the area). Once you

release the stylus, the application automatically zooms in on the graph.

³ You can zoom in or out on the center of the portion of the graph that is

displayed by using, respectively, the or the button. The

application automatically adjusts the zoom.

To revert to the complete graph view:

Press the button.

62 FTB-5600

Page 69

Managing Results

PMD characteristics of of one

particular length of fiber

Squared PMD contribution to the

total cumulative PMD value of the

section to the link

Squared cumulative PMD value

Value of the cumulative PMD

curve at the end of the section

Computed PMD value of the section

Distance between the beginning and

end of the section

Beginning of the section

Section Event Table

Section Event Table

After the acquisition is complete, you can see that a trace and a curve

appeared on-screen. They are the OTDR trace, and the cumulative PMD

curve. The latter is computed from a set of data that is called an SOP (state

of polarization). Several SOPs make one final cumulative PMD curve.

In order to interpret the measurements in the section table corresponding

to the PMD curve and working with them, you must take into account that

the PMD curve is square rooted. This means that the PMD value for each

section is the square root difference of the PMD cumulative curve section’s

last value and the PMD cumulative curve section’s first value.

Several indicators in the cumulative PMD table will help you with your

measurements :

You will also notice the cumulative PMD value at the bottom of the table.

This is particularly useful when you have many sections in your FUT and do

not want to go up and down the table constantly between operations to

see the cumulative value.

Distributed PMD Analyzer 63

Page 70

Managing Results

PM DSe ction CumulPMDSectionLastValue2CumulPMDSectionFirstValue

2

–=

Section Event Table

The PMD section value provides the PMD of a particular section over the

link. The section's PMD value is the square root difference of the PMD

cumulative curve section's last value and the PMD cumulative curve

section's first value. The formula is:

The contribution value provides a way to evaluate the contribution of a

specific section of the cumulative PMD of a link. Since PMD adds up to the

square, the contribution is computed in squares. The percentage of

contribution values are provided in square since it is mathematically not

possible to provide a square rooted percentage. Values would simply not

add up to 100 % and be harder to interpret.

Below, you can see an example of a fiber with two sections. The first

section has a value of 5 ps and the second section, of 10 ps. This will result

in a 11.2 ps of total cumulative PMD.

64 FTB-5600

Page 71

The percentage value of the first section is :

Contribution

52100%⋅

10

252

+

------------------------20%==

Contribution

102100%⋅

10

252

+

--------------------------- 80%==

The percentage value of the second section is :

Managing Results

Section Status

In this example, removing the 10-ps section will make the cumulative PMD

square of the link fall from 125 ps

2

to 25 ps2. In a linear scale, it would fall

from 11.18 ps to 5 ps. You must therefore always remember that the

contribution is computed as square values.

Section Status

You can view the status of the section at all times in the table. If there is a

problem with the PMD of a section, you can see a status in the table that

will help you identify the quality of the measurement.

The statuses are explained in the table below:

Distributed PMD Analyzer 65

Page 72

Managing Results

Section Status

Status In PMD column In Status column Suggestion

Valid The PMD value is

shown

Under Range

(UnRg)

The first or last point in

the section has a PMD

value that is too weak

according to the

residual PMD of the

measurement.

Over Range

(OvRg)

The first or last point in

the section has a PMD

value that is too high

according to the

selected PMD range.

Low SNR

(LoSNR)

The dynamics of the

first or last point in the

section are not

sufficient to measure

PMD correctly for the

section.

The section is valid

A significant portion of

the cumulated PMD

curve for the section is

to weak according to

the measurement

resolution.

A significant portion of

the cumulated PMD

curve for the section is

too high according to

the selected PMD

scale.

The dynamics on the

section is not sufficient

to measure the

cumulated PMD curve

correctly.

Select a lower scale or

a smaller PMD range in

the acquisition

parameters

Select a higher scale or

broader PMD range in

the acquisition

parameters.

Lessen the losses

through the

connectors, increase

the number of

averagings or increase

the pulse size.

For more information,

see Use an Optimized

Number of Averagings

on page 127 and Use

an Appropriate OTDR

Pulse Length on

page 128.

66 FTB-5600

Page 73

Managing Results

Section Status

Status In PMD column In Status column Suggestion

High

Depolarization

(HiDep)

The first or last point in

the section shows a

high intrinsic

polarization level that

causes the

measurement to be

imprecise.

The concerned section

shows a strong level of

intrinsic that causes

the measurement to

be imprecise.

The beating length, the

local variations that

have to be measured,

is a lot shorter than the

size of the pulse.

Therefore the

polarization fluctuation

measured by the unit

vanished through the

pulses spatial

averaging and is not

picked up.

To improve the

situation, you can try

to move the section

cursors outside the

region where the

results are invalid,

increase the spatial

smoothing filter value

or taking a

measurement with a

shorter pulse.

Distributed PMD Analyzer 67

Page 74

Managing Results

Section Status

Status In PMD column In Status column Suggestion

Unstable Link

(Unst)

The first or last point in

the section shows

strong polarization

unstability.

The section shows

strong polarization

unstability.

Unstable sections

occur when on the

link, the polarization

moves at a speed

faster than the

acquisition time of a

wavelength’s step.

This phenomenon can

occur mainly when

measuring aerial links

when there are strong

winds.

Any section after an

unstable section is

unstable as well. To

improve the situation,

you can decrease

significantly the

number of averages.

68 FTB-5600

Page 75

Managing Results

Marker A

Marker B

Positioning Markers on the Display

Positioning Markers on the Display

Correctly positioning the cursors is a key element in having the appropriate

results. The fundamental element is to set the first maker just before the

beginning of the transition and the last marker just after the end of the

transition.

Note: When you position the markers for the PMD, you will see that they might

not fit exactly with the automatically detected OTDR events on the trace.

Working with the exact location of the OTDR event markers will take the

network constraint into account, but adjusting the markers manually will

provide you with optimized measurements for your link.

If you use the spatial smoothing filter, you may have to adjust the markers,

as the curve may change.

Distributed PMD Analyzer 69

Page 76

Managing Results

Trace before treatment

Editing Sections

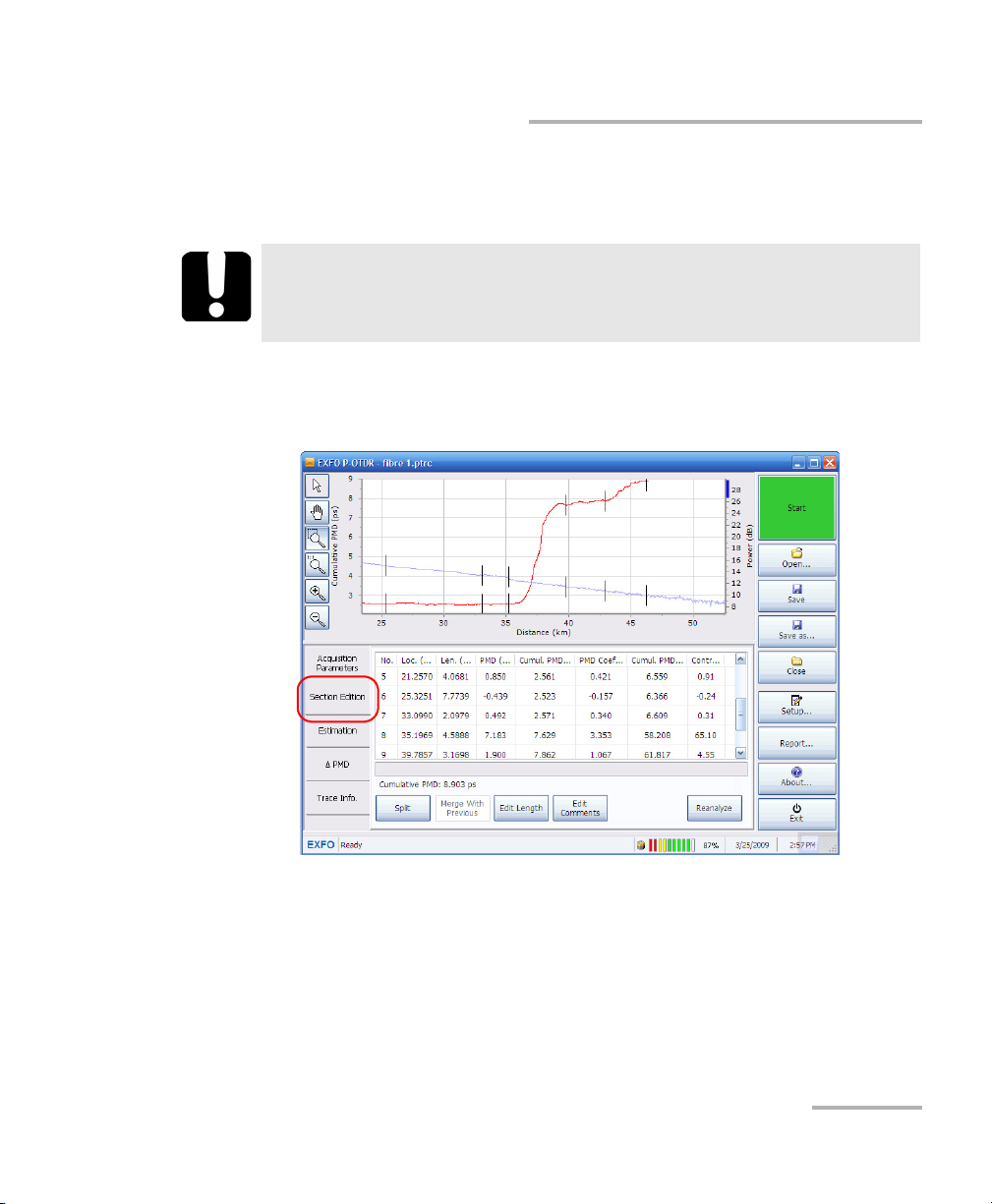

Editing Sections

Once your acquisition is complete the FTB-5600 built its own PMD section

table based on the OTDR automatic detection event algorithm. Since most

OTDR events do not coincide with PMD events, you may find that the table

contains events that are irrelevant to your test. You may want to edit some

sections of the link to improve your results.

Here is an example of a trace before and after irrelevant sections are

cleaned out:

70 FTB-5600

Page 77

Managing Results

Trace after treatment

Editing Sections

Distributed PMD Analyzer 71

Page 78

Managing Results

Editing Sections

Splitting Fiber Sections

Splitting sections can allow you to define a new segment by separating an

existing segment in two. This could help you pinpoint events that are more

relevant to your analysis than those automatically detected.

Splitting a fiber section cannot be undone, unless you reanalyze the

trace, as explained in Viewing Trace Information on page 85.

To split a fiber section:

1. From the main window, select the Section Edition tab.

IMPORTANT

72 FTB-5600

Page 79

Managing Results

2. Select the section you want to edit by pressing on it once.

3. Press Split.

Editing Sections

Distributed PMD Analyzer 73

Page 80

Managing Results

Editing Sections

4. Move the cursor using the arrow buttons to the desired location where

you want to split the segment. You can also click-drag the cursor to the

desired location.

The new segment you are creating is indicated in red in the table. You

will also see the two segments in gray on the graph.

Note: If you had comments in the segment you are splitting, they will remain with

the left-hand segment.

5. Press on Apply to split the segment, or on Cancel to return to the

Section Edition tab.

74 FTB-5600

Page 81

Managing Results

Editing Sections

Merging Fiber Sections

Merging fiber sections can be useful for removing irrelevant events.

IMPORTANT

Merging fiber sections cannot be undone, unless you reanalyze the

trace, as explained in Viewing Trace Information on page 85.

To merge a fiber section to another:

1. From the main window, select the Section Edition tab.

2. Select the section you want to merge by pressing on it once. The

section is always merged with the one above it.

Distributed PMD Analyzer 75

Page 82

Managing Results

Editing Sections

3. Press Merge with Previous.

The selected section is merged with the one above it, and you can see

the results on-screen.

Note: If there were comments in either section, they will be merged as well.

4. Press Apply to accept the merge, or Cancel to return to the Section

Edition tab.

76 FTB-5600

Page 83

Managing Results

Editing Sections

Editing Section Length

Editing the section length can allow you to include part of another section

to improve the section table measurements.

IMPORTANT

Editing a fiber section length cannot be undone, unless you

reanalyze the trace, as explained in Viewing Trace Information on

page 85.

To edit a fiber section length:

1. From the main window, select the Section Edition tab.

2. Select the section you want to edit by pressing on it once.

Distributed PMD Analyzer 77

Page 84

Managing Results

Editing Sections

3. Press Edit Length.

4. Use the arrow buttons to move the right end of the segment to its new

location. You can also click-drag the cursor to the desired position.

The other surrounding segments are updated accordingly.

5. Press Apply to accept the new segment length, or Cancel to return to

the Section Edition tab.

78 FTB-5600

Page 85

Managing Results

Editing Sections

Adding Comments to Segments

You can add comments to each fiber section to include important

information, or details on the events that could be helpful in later analyses.

To add comments to a segment:

1. From the main window, select the Section Edition tab.

2. Select the segment for which you want to add a comment by pressing

on it once.

Distributed PMD Analyzer 79

Page 86

Managing Results

Editing Sections

3. Press Edit Comments.

4. Type in the comment you want to add, then press Apply to keep the

comment, or Cancel to leave without adding a comment.

80 FTB-5600

Page 87

Managing Results

ΔPMD

CumulPMDCursorB2CumulPMDCursorA

2

–

CumulPMDCursorB

2

CumulPMDCursorA

2

–

----------------------------------------------------------------------------------------------------------------------=

Using Markers to Measure PMD Differences (Delta PMD Tab)

Using Markers to Measure PMD Differences

(Delta PMD Tab)

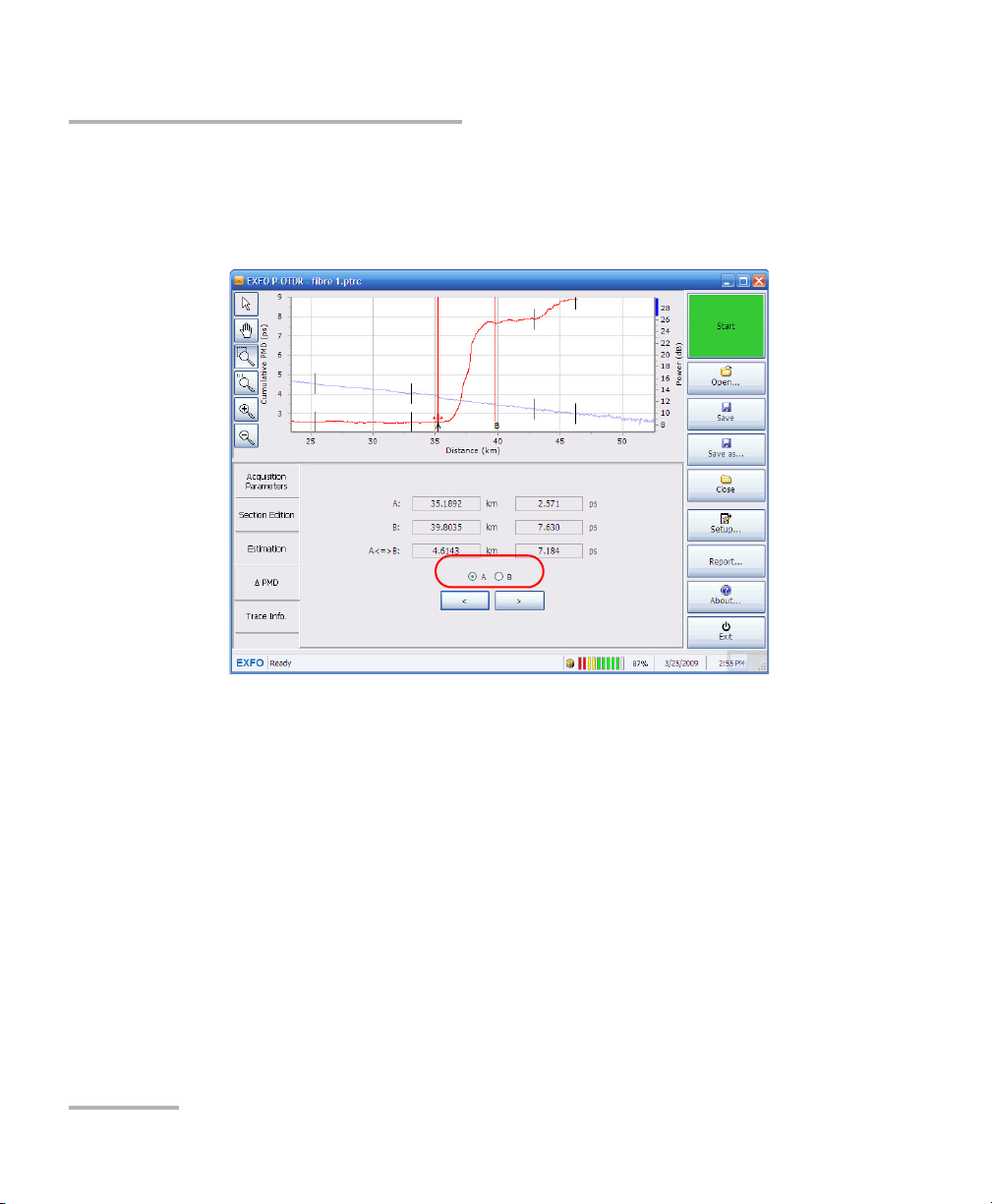

The Delta PMD tab is used to measure sections along the cumulative PMD

curve. The measurement is performed with two cursors; cursor A indicates

the beginning of the measurement and cursor B indicates the end. On

screen, you will see the positions of the markers, as well as the PMD

cumulative values. The application then computes and displays the square

rooted difference between cumulative PMD at the position of the two

markers.

The equation below illustrates how the difference is calculated.

Distributed PMD Analyzer 81

Page 88

Managing Results

Using Markers to Measure PMD Differences (Delta PMD Tab)

To move the markers:

1. Select the Δ PMD tab.

2. Select which cursor to move.

3. Use the arrow buttons to move the cursor. You can also click-drag the

cursor to the desired position.

82 FTB-5600

Page 89

Managing Results

Estimating Results

Estimating Results

You can manage the fiber sections as desired to obtain a better

characterization. The FTB-5600 allows you to evaluate fiber section

replacement scenarios in the link without actually replacing the section

itself.

This is done by modifying one or some strong PMD sections of the link to

analyze. By modifying the PMD value or the coefficient of the section in

those links, you can see the simulated cumulative PMD value that will

result from those changes.

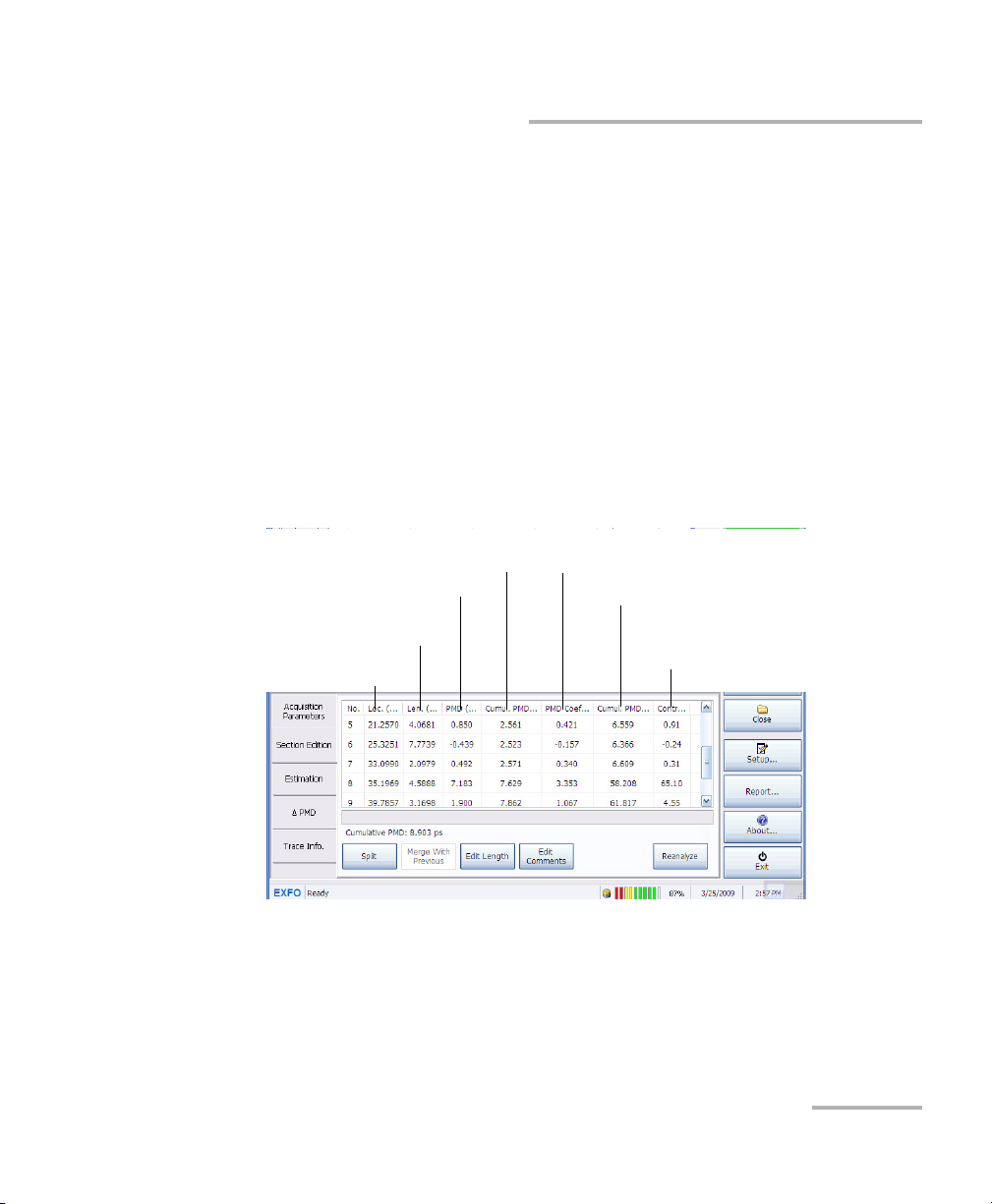

For example, you have made an acquisition with several sections. Let us

verify what happens to the cumulative PMD of the link if we set PMD value

of the eighth section to zero. The link cumulative PMD goes from 8.903 ps

to 5.273 ps.

Distributed PMD Analyzer 83

Page 90

Managing Results

Estimating Results

To work with the PMD estimation table:

1. From the main window, select the Estimation tab.

2. Select the row for which you want to change a value by pressing on it

once.

3. Modify the PMD or PMD coefficient values, as desired.

4. Press Apply to se the changes to the link.

To revert to the original values for the selected row, press Restore.

84 FTB-5600

Page 91

Managing Results

Viewing Trace Information

Viewing Trace Information

Once your acquisition is complete, you can view the details about it in the

Trace Info. tab. This information can be useful for future reference, or to

perform other tests. For example, if you have performed a quick check on

a link, you can now use the distance value calculated by the OTDR to put in

a standard or advanced acquisition for the distance range value.

From the Trace Inf o. tab, you can also change the cable and job

information, reanalyze a trace and change the spatial smoothing filter.

Note: You can find more information about the spatial smoothing filter in Setting

up General Acquisition Parameters on page 21 and Use an Appropriate

Spatial Smoothing Filter Value on page 129.

IMPORTANT

Reanalyzing a trace or changing the spatial smoothing filter will

delete the current estimation table, all of the comments you may

have added, as well as the modifications and estimations you have

performed in the section table. If you want to retain this

information for further use, you must save it before reanalyzing the

trace.

Distributed PMD Analyzer 85

Page 92

Managing Results

Viewing Trace Information

To view the trace information:

From the main window, select the Trace Inf o. tab.

86 FTB-5600

Page 93

Managing Results

Viewing Trace Information

If you are viewing the trace information for a bidirectional trace file you

have created with the Bidirectional File Creator utility, the information you

see is that of the A -> B trace. However, some of the information is

displayed differently :

³ The minimum wavelength is that of both measurements.

³ The maximum wavelength is that of both measurements.

³ The maximum number of SOPs is that of both measurements.

³ The number of averagings is the maximum value of both

measurements.

³ The acquisition range is the maximum value of both measurements.

³ The PMD scale is the maximum value of both measurements.

³ The PMD resolution is the minimum value of both measurements.

³ The distance covered by the OTDR trace is the length of the link.

³ The distance covered by the PMD trace is the length analyzed in

bidirectional mode.

Distributed PMD Analyzer 87

Page 94

Managing Results

Viewing Trace Information

To change the cable and job information:

1. From the main window, select the Trace I nfo. tab.

2. Press Settings.

3. Select the Information tab.

88 FTB-5600

Page 95

Managing Results

Viewing Trace Information

4. Enter information as desired. If you have already entered some

information in the Cable Information window as explained in Setting

up Cable Information on page 31, it will already be in the

corresponding boxes.

5. Press Apply to use the new information, then Close to exit the window.

To perform a new analysis on a trace:

1. From the main window, select the Trace I nfo. tab.

2. Press Settings.

Distributed PMD Analyzer 89

Page 96

Managing Results

Viewing Trace Information

3. Select the Analysis tab.

4. Press Reanalyze.

5. Press Close to return to the application.

90 FTB-5600

Page 97

Viewing Trace Information

To change the spatial smoothing filter:

1. From the main window, select the Trace I nfo. tab.

2. Press Settings.

Managing Results

3. Select the Analysis tab.

Distributed PMD Analyzer 91

Page 98

Managing Results

Viewing Trace Information

4. Change the filter value to the desired value in the list.

5. Press Apply to use this new value, then Close to exit the window.

92 FTB-5600

Page 99

Managing Results

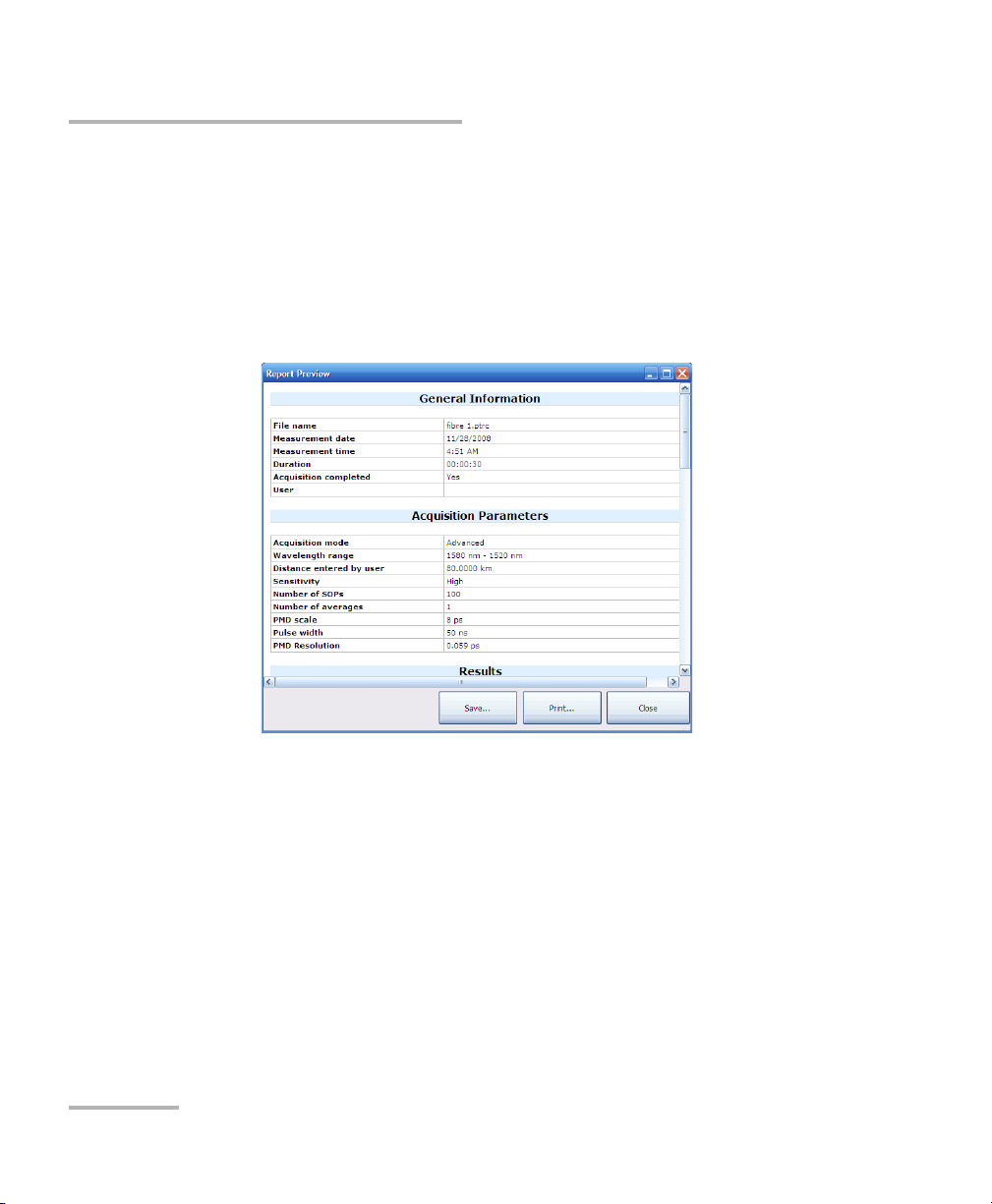

Generating Reports

Generating Reports

Once your trace is cleaned up and that your measurements are optimized,

you can generate a report. This report can then be printed, or saved for

future consultation.

To generate a report:

1. From the main window, press Report.

Distributed PMD Analyzer 93

Page 100

Managing Results

Generating Reports

2. In the Report Preview window, select what you want to do:

³ Press Save to store the file. A standard Save As window opens to

³ Press Print to send the document to your printer. A standard Print

³ Press Close to return to the main window.

let you select a name and location.

window opens to let you select the printing options.

94 FTB-5600

Loading...

Loading...