Page 1

Руководство пользователя

EPM-50/ELS-50

Power Meter/Light Source

User Guide

Guide d’utilisation

用户指南

Guía del usuario

Guia do utilizador

Page 2

Copyright © 2010 EXFO Electro-Optical Engineering Inc. All rights reserved. No part

of this publication may be reproduced, stored in a retrieval system or transmitted in

any form, be it electronically, mechanically, or by any other means such as

photocopying, recording or otherwise, without the prior written permission of EXFO

Electro-Optical Engineering Inc. (EXFO).

Information provided by EXFO is believed to be accurate and reliable. However, no

responsibility is assumed by EXFO for its use nor for any infringements of patents or

other rights of third parties that may result from its use. No license is granted by

implication or otherwise under any patent rights of EXFO.

EXFO’s Commerce And Government Entities (CAGE) code under the North Atlantic

Treaty Organization (NATO) is 0L8C3.

The information contained in this publication is subject to change without notice.

Trademarks

EXFO’s trademarks have been identified as such. However, the presence or

absence of such identification does not affect the legal status of any trademark.

Units of Measurement

Units of measurement in this publication conform to SI standards and practices.

Version number: 2.0.0

ii

Page 3

Contents

Certification Information ................................................................................. iv

1 Introducing the EPM-50/ELS-50 ................................................ 1

Main Features ................................................................................................... 1

Power Sources .................................................................................................. 3

Typical Applications .......................................................................................... 3

Conventions ......................................................................................................3

2 Safety Information ................................................................... 4

3 Getting Started ......................................................................... 5

Turning the Unit On and Off ............................................................................. 5

Activating Automatic Shutdown (Auto-Off) ...................................................... 6

Interchanging connector adaptaters .................................................................6

Cleaning and Connecting Optical Fibers ........................................................... 7

4 Measuring Power or Loss (EPM-50) .......................................... 8

Nulling Electrical Offsets ................................................................................... 8

Referencing Your Power Meter to a Source ....................................................... 9

Measuring Power or Loss ................................................................................ 10

5 Using a Light Source (ELS-50) ................................................. 12

Activating/Deactivating a Light Source ........................................................... 12

Modulating the Source Signal ........................................................................ 12

6 Maintenance ............................................................................ 13

Cleaning EUI Connectors ................................................................................ 14

Cleaning Fixed Connectors .............................................................................. 16

Cleaning Detector Ports .................................................................................. 17

Replacing Batteries ......................................................................................... 18

Recalibrating the Unit .....................................................................................18

Recycling and Disposal (Applies to European Union Only) .............................. 19

7 Troubleshooting ...................................................................... 20

Solving Common Problems ............................................................................. 20

Error Codes and Descriptions .......................................................................... 20

Contacting the Technical Support Group ........................................................ 21

Transportation ................................................................................................ 22

8 Warranty .................................................................................. 23

General Information ....................................................................................... 23

Liability ........................................................................................................... 23

Exclusions .......................................................................................................24

Certification .................................................................................................... 24

Service and Repairs ......................................................................................... 25

EXFO Service Centers Worldwide .................................................................... 26

A Technical Specifications .......................................................... 27

EPM-50/ELS-50 iii

Page 4

Certification Information iv

Certification Information

F.C.C. Information

Electronic test equipment is exempt from Part 15 compliance (FCC) in the United

States. However, compliance verification tests are systematically performed on

most EXFO equipment.

Information

Electronic test equipment is subject to the EMC Directive in the European Union.

The EN61326 standard prescribes both emission and immunity requirements for

laboratory, measurement, and control equipment. This unit has undergone

extensive testing according to the European Union Directive and Standards.

DECLARATION OF CONFORMITY

Application of Council Directive(s): 2004/108/EC - The EMC Directive

Manufacturer’s Name: EXFO Electro-Optical Engineering Inc.

Manufacturer’s Address: 400 Godin Avenue

Quebec, Quebec

(418) 683-0211

Equipment Type/Environment: Test & Measurement / Industrial

Trade Name/Model No.: EPM-50 / Power Meter

Standard(s) to which Conformity is Declared:

EN 61326-1:2006 Electrical Equipment for Measurement, Control and Laboratory

EN 60825-1:2007 Edition 2.0 Safety of laser products – Part 1: Equipment classification and

EN 55022: 2006 + A1: 2007 Information technology equipment — Radio disturbance

I, the undersigned, hereby declare that the equipment specified above conforms to the above Directive and Standards.

Manufacturer

Signature:

Full Name: Stephen Bull, E. Eng

Position: Vice-President Research and

Address: 400 Godin Avenue, Quebec (Quebec),

Date: December 03, 2009

Development

Canada, G1M 2K2

Use - EMC Requirements

requirements

characteristics — Limits and methods of measurement

2006/66/EC - The Battery Directive

93/68/EEC - CE Marking

And their amendments

Canada, G1M 2K2

ELS-50 / Light Source

Page 5

1 Introducing the

EPM-50/ELS-50

This user guide covers the following products (unless otherwise specified,

descriptions apply to all):

³ EPM-50 Power Meter

³ ELS-50 Light Source

Main Features

The EPM-50 Power Meter offers:

³ a rugged design

³ Interchangeable connector adapters

³ 300 hours of battery life

³ tone recognition for fiber identification

³ a universal push-pull interface

³ reference function for direct loss measurements

The ELS-50 Light Source offers:

³ a rugged design

³ excellent power stability for reliable loss measurements

³ interchangeable connectors interface

³ up to 60 hours of battery life

³ interchangeable connector adapters

³ tone generation for fiber identification

EPM-50/ELS-50 1

Page 6

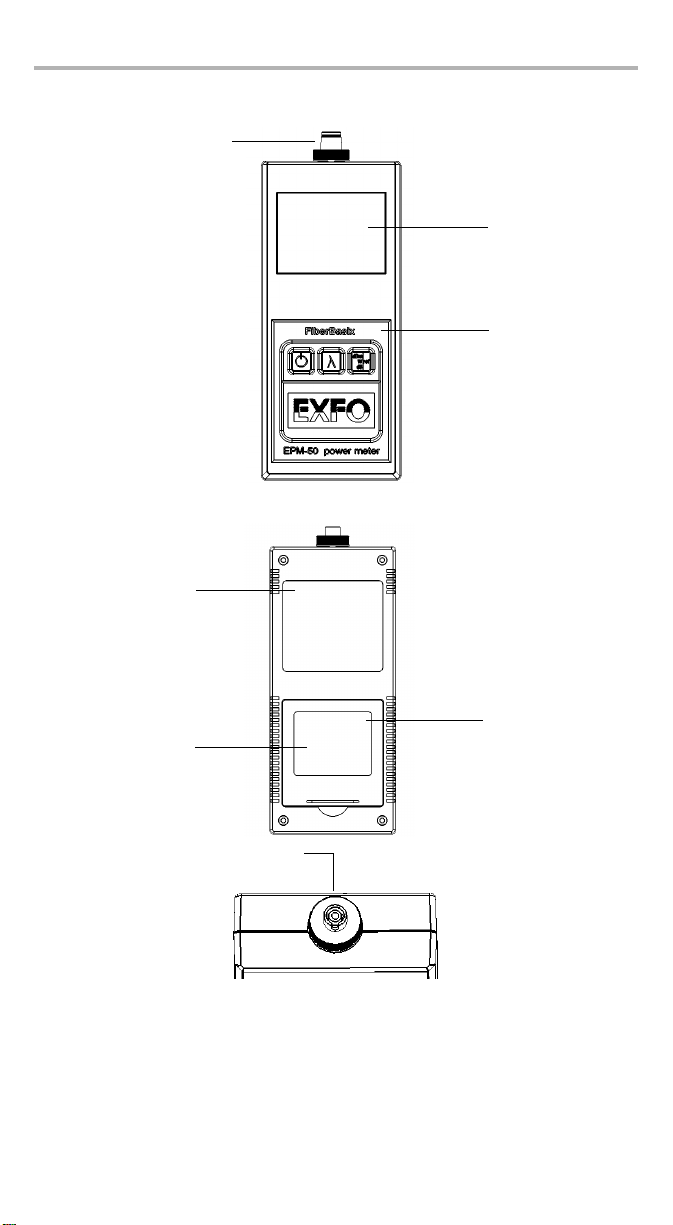

Introducing the EPM-50/ELS-50 2

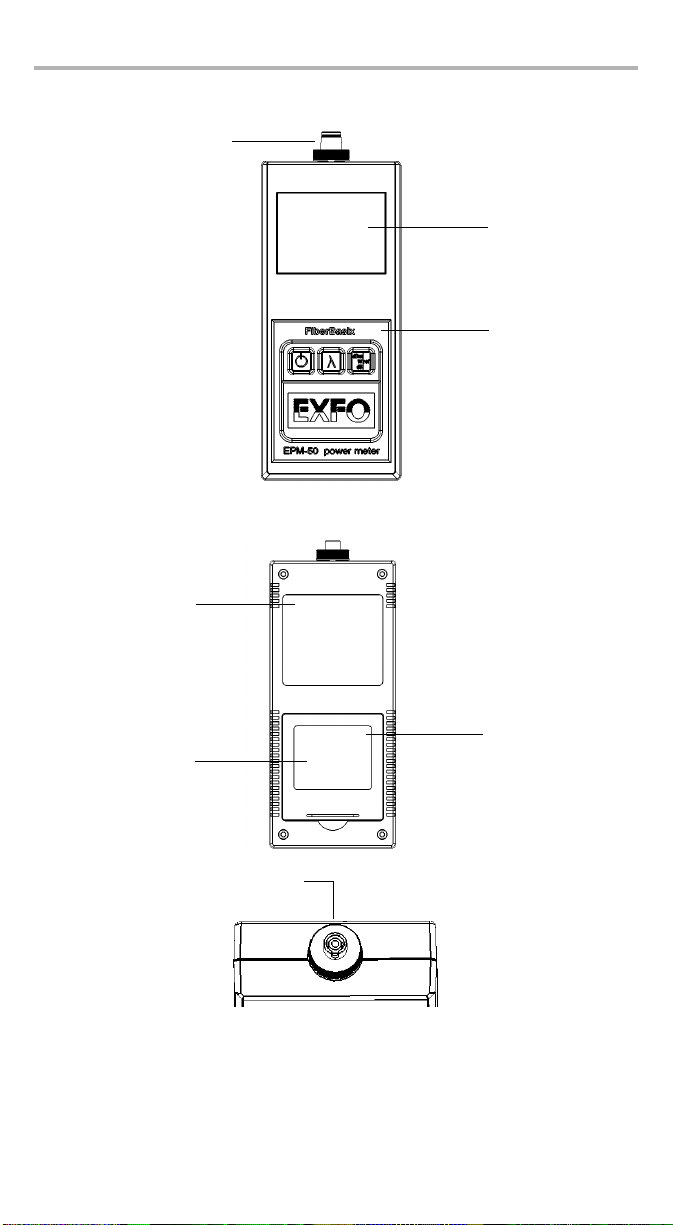

Front View

Protector Cap

LCD display

Keypad

(EPM-50 shown)

Back View

Safety label and

serial number

Battery compartment

(3 alkaline or

rechargeable

batteries)

Connector port

Quick reference

label

Page 7

Power Sources

The units operate with 3 AA alkaline or rechargeable batteries.

IMPORTANT

If the battery level becomes too low, the unit turns itself off.

Typical Applications

The units offer specific typical applications.

EPM-50 Power Meter:

³ High power model for CATV and Telco applications

³ Enterprise/LAN for singlemode and multimode measurements

ELS-50 Light Source:

³ Telco/CATV and FTTH models; dual and triple wavelenghts

³ Enterprise/LAN models; singlemode and multimode

Conventions

Before using the product described in this manual, you should understand the

following conventions:

WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in component damage. Do not proceed unless you

understand and meet the required conditions.

IMPORTANT

Refers to information about this product you should not overlook.

EPM-50/ELS-50 3

Page 8

Safety Information 4

2 Safety Information

WARNING

Do not install or terminate fibers while a laser source is active. Never

look directly into a live fiber and ensure that your eyes are protected

at all times.

WARNING

Use of controls, adjustments and procedures for operation and

maintenance other than those specified herein may result in

hazardous radiation exposure.

Your instrument is a Class 1 laser product in compliance with standards IEC 60825-1

and 21 CFR 1040.10. Laser radiation may be encountered at the output port.

The following label indicates that a product contains a Class 1 source:

CLASS 1

LASER PRODUCT

Note: The label is affixed to your product.

Page 9

3 Getting Started

Turning the Unit On and Off

When you turn off the EPM-50, it saves the current wavelength, unit and reference

power.

IMPORTANT

If you remove the batteries, the unit will turn off without saving the

above values.

If batteries are low, the unit will save the above values and turn off.

Note: Offset nulling values are always returned to factory settings.

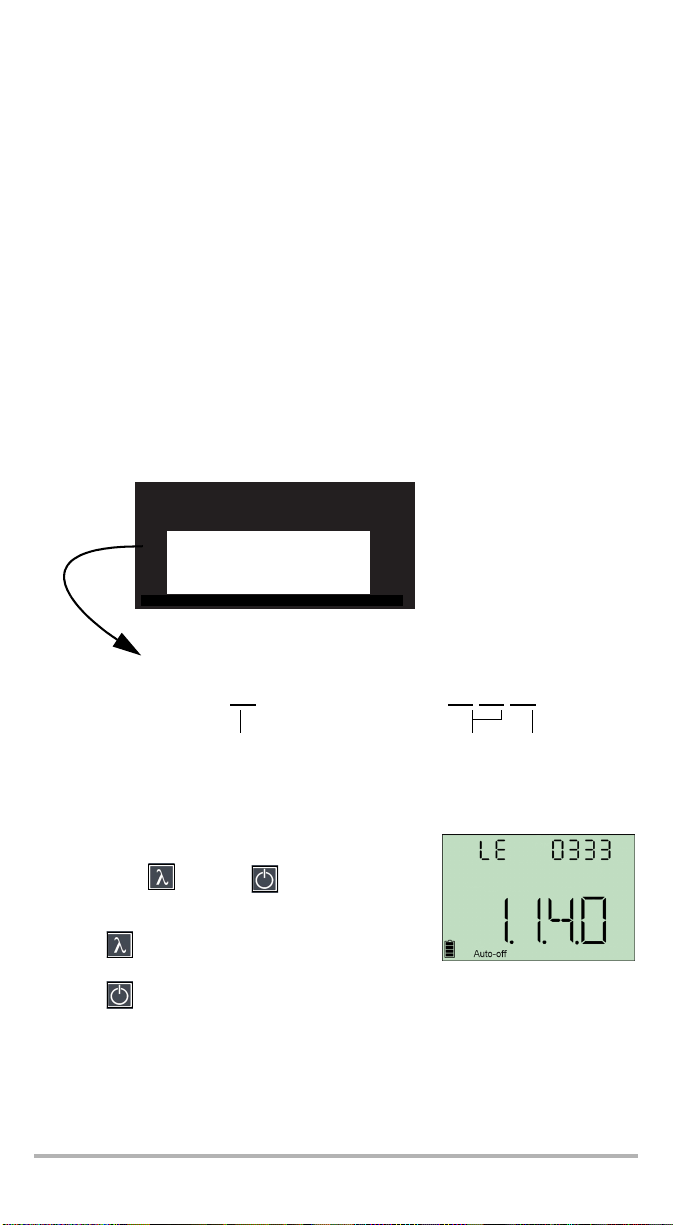

To turn on the unit:

Press . You may use the unit immediately under normal conditions.

To turn off the unit:

From normal operating mode, hold down a few seconds.

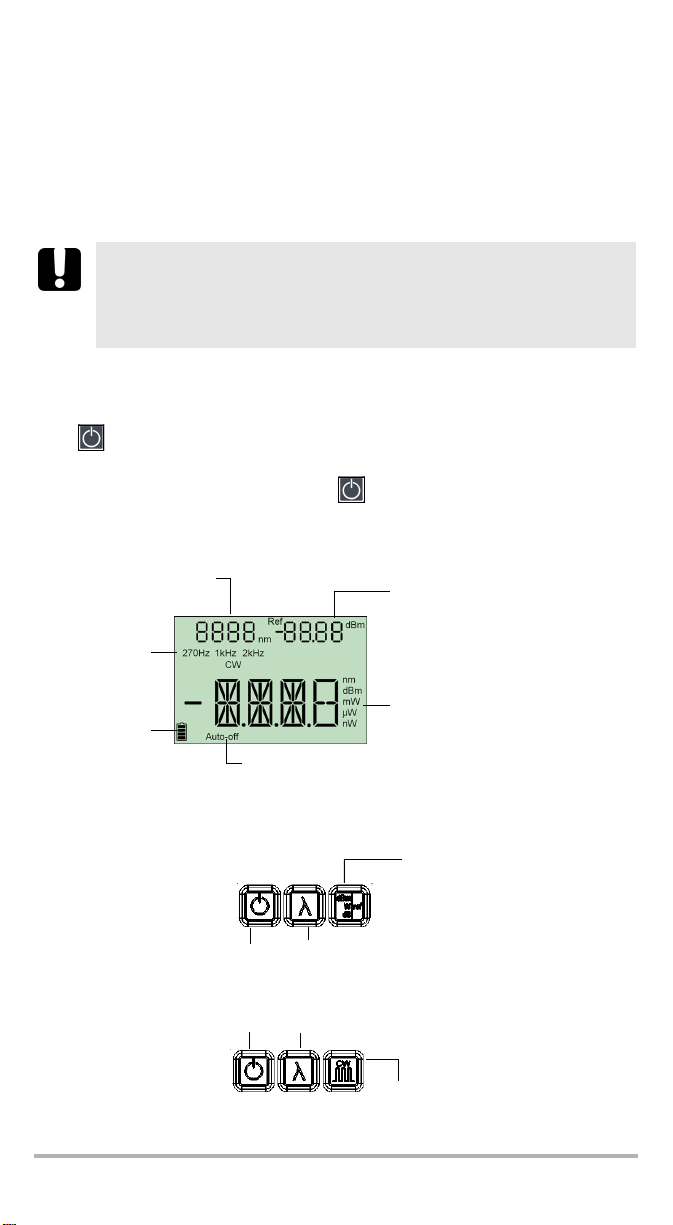

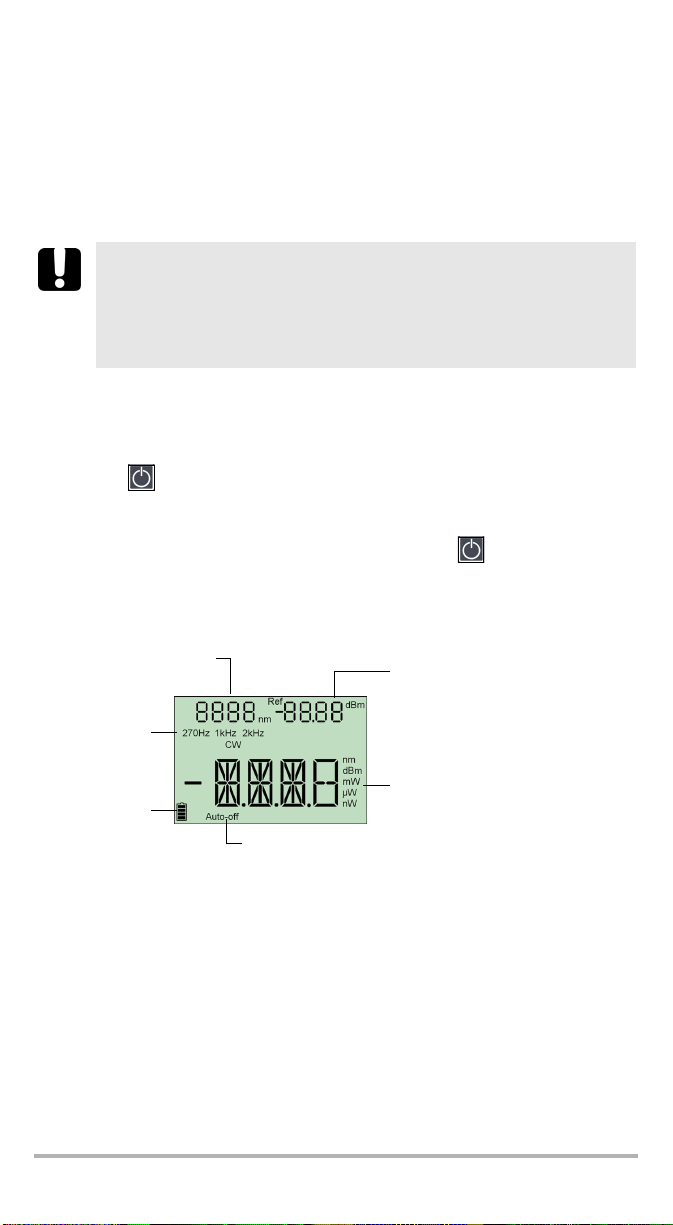

Display

Power meter wavelength

modulation

Detected

modulation

(EPM-50)

Batteries level

(EPM-50)

Source

(ELS-50)

Auto-off activated

Reference power (EPM-50)

Measured power/loss (EPM-50)

Active source wavelength (ELS-50)

Keypad

PRESS: Switches between

units

EPM-50

HOLD: Turns unit on/off

PRESS: Controls

auto-off

PRESS: Exits special

modes

PRESS: Changes

wavelengths

PRESS: Activates next source

HOLD: Deactivates current source

HOLD: Sets input power as

reference power

ELS-50

PRESS: Switches between

modulation values

EPM-50/ELS-50 5

Page 10

Getting Started 6

Activating Automatic Shutdown (Auto-Off)

When auto-off is activated, the unit will turn off after

10 minutes of idle time.

Auto-off is activated by default when you turn on the

unit.

To deactivate/reactivate auto-off:

When unit is on, press .

Note: Auto-off is automatically disabled when you perform an offset nulling.

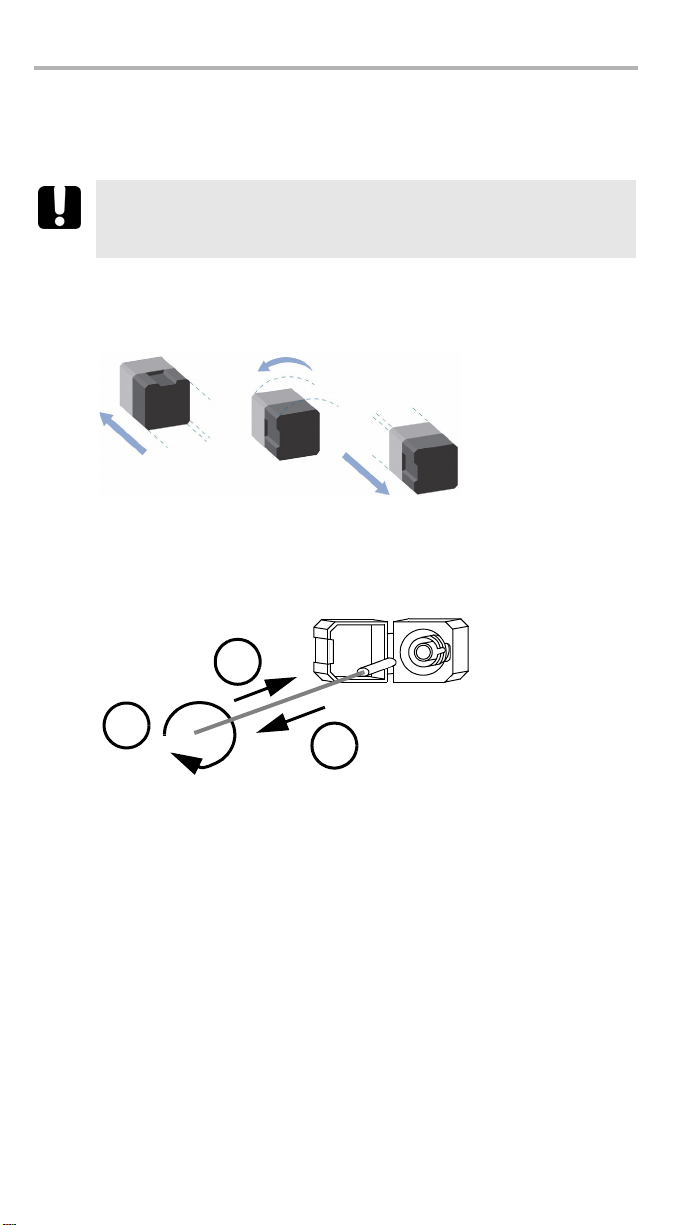

Changing Connector Adapters

The connector adapters are optional accessories available on the EPM-50 Power

Meter and ELS-50 Light Source. Depending on the type of connector on the fiber you

need to test, you might have to change them.

To change connector adapters:

1. Hold the unit so the connector port is facing you.

2. Turn the connector adapter counterclockwise to unscrew it.

3. Screw in the adapter you want to use.

Page 11

Cleaning and Connecting Optical Fibers

IMPORTANT

To ensure maximum power and to avoid erroneous readings:

³ Always clean fiber ends as explained below before inserting

them into the port. EXFO is not responsible for damage or errors

caused by bad fiber cleaning or handling.

³ Ensure that your patchcord has appropriate connectors. Joining

mismatched connectors will damage the ferrules.

To connect the fiber-optic cable to the port:

1. Inspect the fiber using a fiber inspection microscope. If the fiber is clean,

proceed to connecting it to the port. If the fiber is dirty, clean it as explained

below.

2. Clean the fiber ends as follows:

2a. Gently wipe the fiber end with a lint-free swab dipped in isopropyl alcohol.

2b. Use compressed air to dry completely.

2c. Visually inspect the fiber end to ensure its cleanliness.

3. Carefully align the connector and port to prevent the fiber end from touching the

outside of the port or rubbing against other surfaces.

If your connector features a key, ensure that it is fully fitted into the port’s

corresponding notch.

4. Push the connector in so that the fiber-optic cable is firmly in place, thus

ensuring adequate contact.

If your connector features a screwsleeve, tighten the connector enough to firmly

maintain the fiber in place. Do not overtighten, as this will damage the fiber and

the port.

Note: If your fiber-optic cable is not properly aligned and/or connected, you

will notice heavy loss and reflection.

EPM-50/ELS-50 7

Page 12

Measuring Power or Loss (EPM-50) 8

4 Measuring Power or Loss

(EPM-50)

Nulling Electrical Offsets

Temperature and humidity variations affect the performance of electronic circuits

and optical detectors. Nulling the electrical offsets eliminates these effects. Your un i t

has been designed not to require offset nulling under normal operation, but you

should perform it whenever environmental conditions change significantly or when

measuring very low power values.

IMPORTANT

If light reaches the detector when nulling offsets, LIGH appears on

the display and the nulling is not performed. You will need to press a

key to return to the previous display.

Note: Factory-defined values will be reinstated when you turn off the unit.

To perform an offset nulling:

Hold down and a few seconds. The unit

displays NULL while nulling the offsets, then returns to

normal mode.

Note: Keypad is disabled during the operation.

Page 13

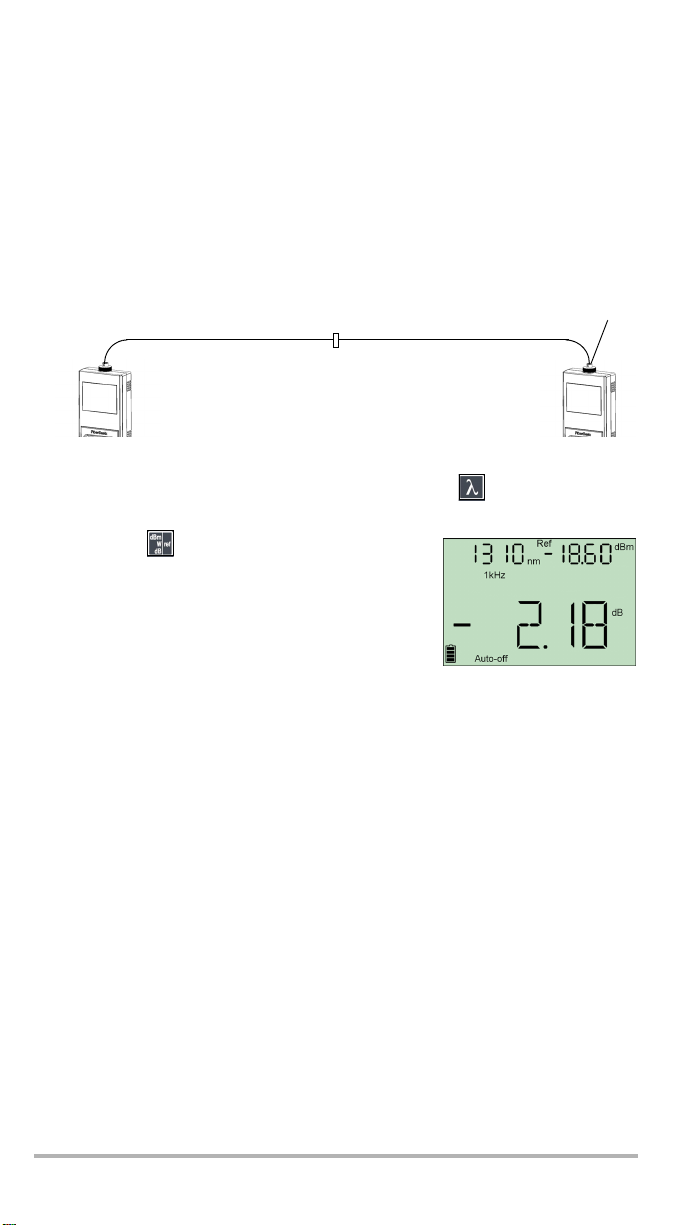

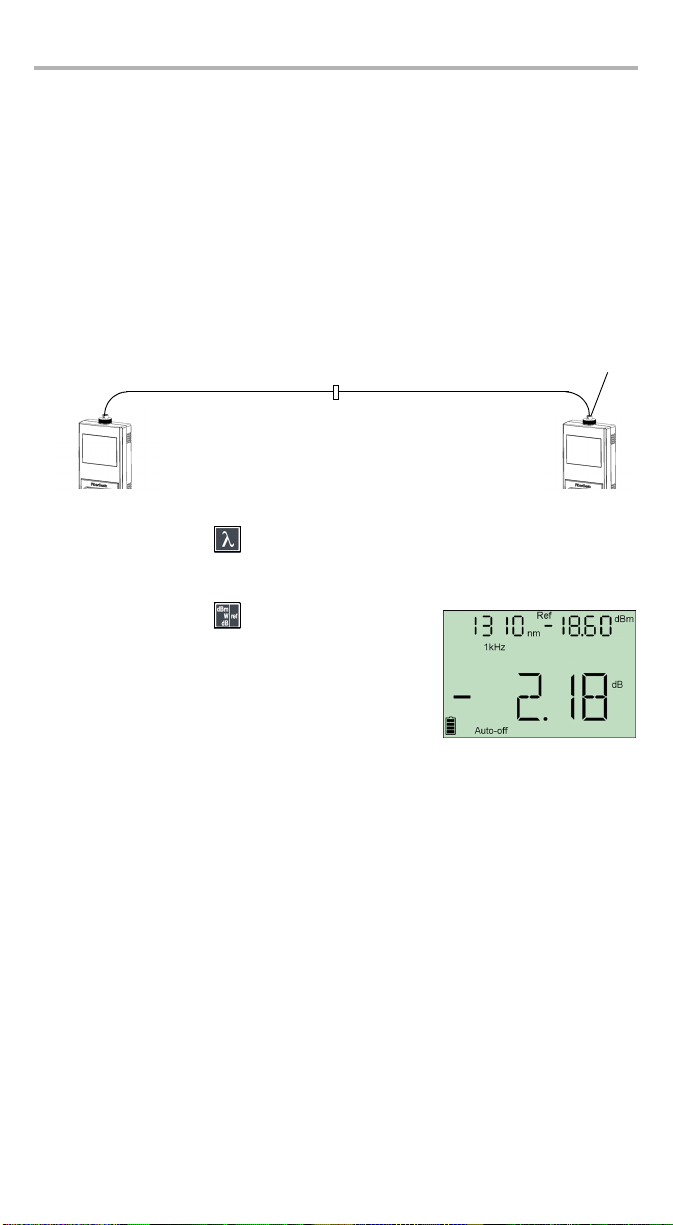

Referencing Your Power Meter to a Source

In reference mode, your unit displays the loss created by the fiber under test only,

since a reference value is subtracted from the measured power.

Note: You must set a reference value separately for each wavelength.

To reference the power meter to a source manually:

1. Using the proper adapter, connect a light source (such as ELS-50) to the

detector port of your power meter.

Reference

test jumper

Power

meter

Light

source

test jumper

Bulkhead

connector

2. Activate the source at the desired wavelength.

3. Match the source and power meter wavelenghts using .

Wavelength is displayed in the top left corner.

4. Hold down for a few seconds. The power meter

stores the currently detected power as the new

reference power.

Reference power is displayed in the top right corner

(in dBm) and current loss reading is automatically

switched to dB.

5. Repeat the procedure for each wavelength you want to reference.

AdapterReference

Note: Once all desired wavelengths have been referenced, do not disconnect

the Reference Test Jumper from the source port until all measurements

have been done.

EPM-50/ELS-50 9

Page 14

Measuring Power or Loss (EPM-50) 10

Measuring Power or Loss

Measuring absolute power is done the same way as referencing the power meter to

a source, except for the referencing step.

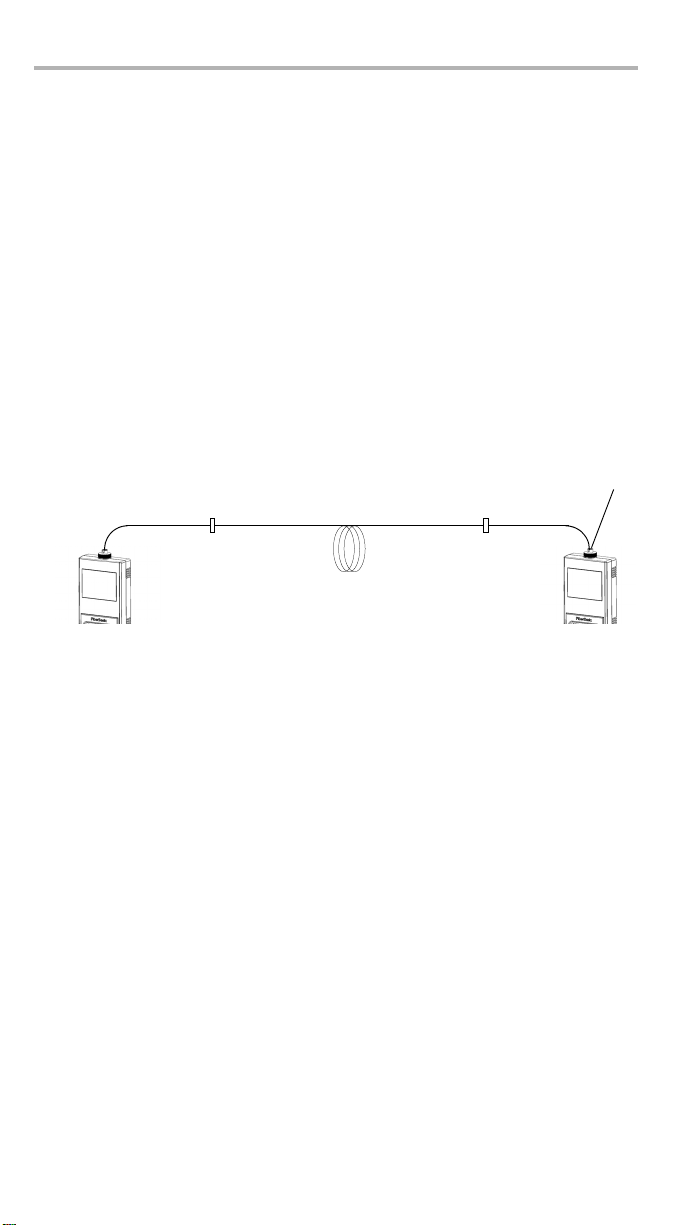

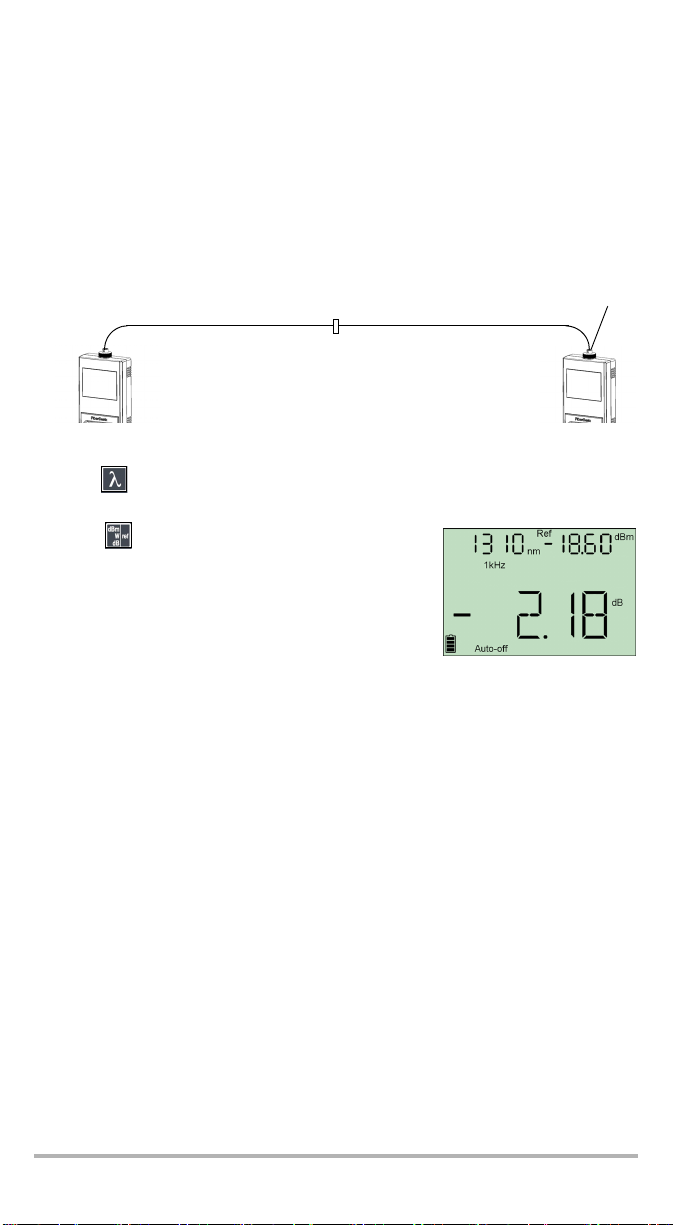

To perform power or loss measurements:

1. If necessary, perform an offset nulling (see Nulling Electrical Offsets on page 8).

2. Check and clean your fibers appropriately for optimum performance

(see Cleaning and Connecting Optical Fibers on page 7).

3. For loss measurements, reference your power meter to a light source

(see Referencing Your Power Meter to a Source on page 9), then deactivate the

light source.

4. Using the proper adapter and test jumpers, connect a fiber under test to a light

source (such as ELS-50) and to the detector port of your unit.

Note: If you have referenced your power meter to a source, simply connect a

fiber under test to the test jumpers used for referencing.

Te st

jumper

Light

source

Bulkhead

connector

Fiber under test

jumper

Bulkhead

connector

Power

meter

Te st

Adapter

Page 15

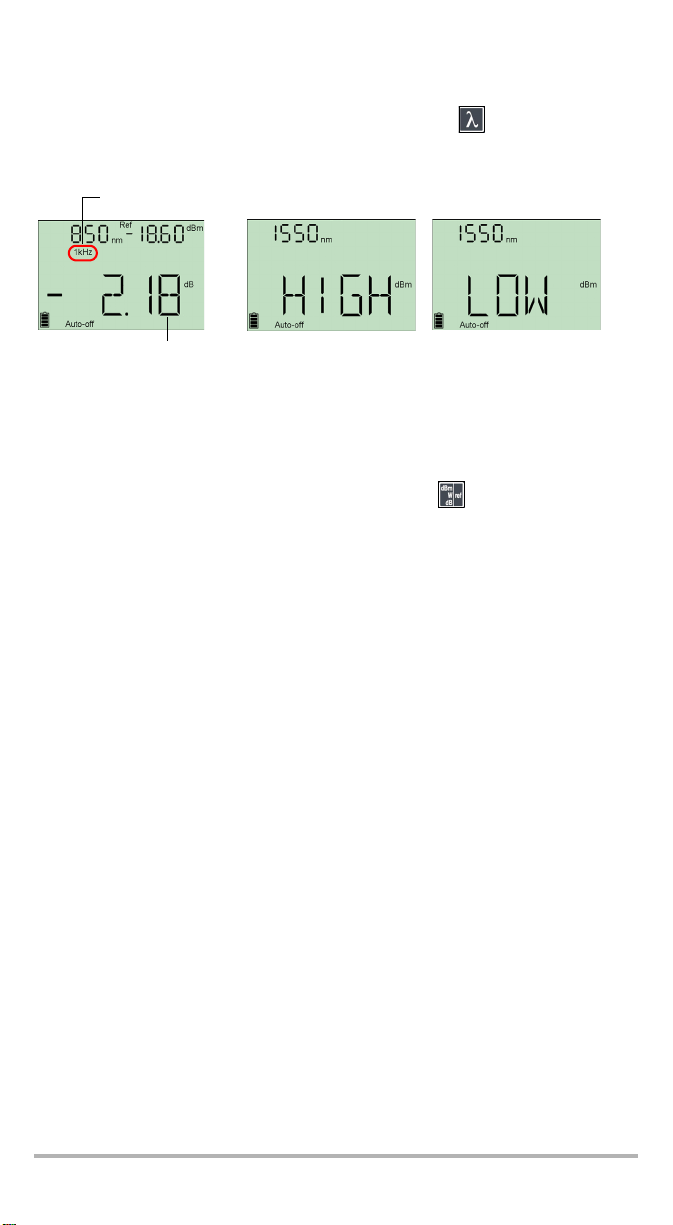

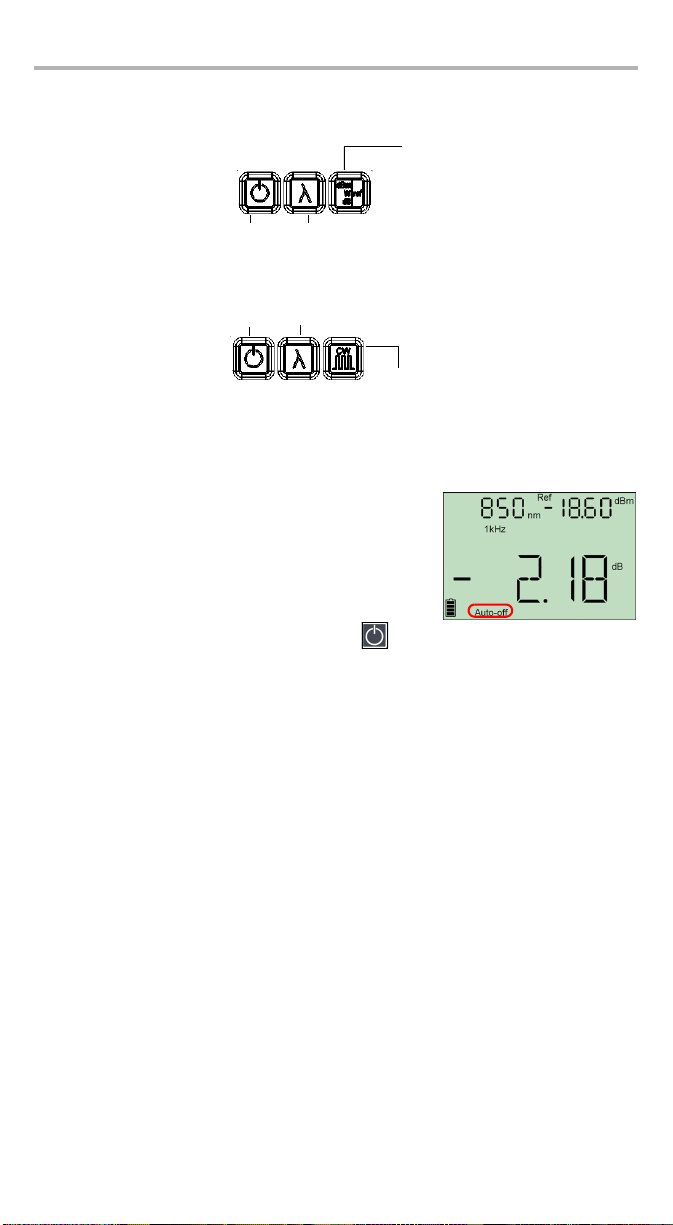

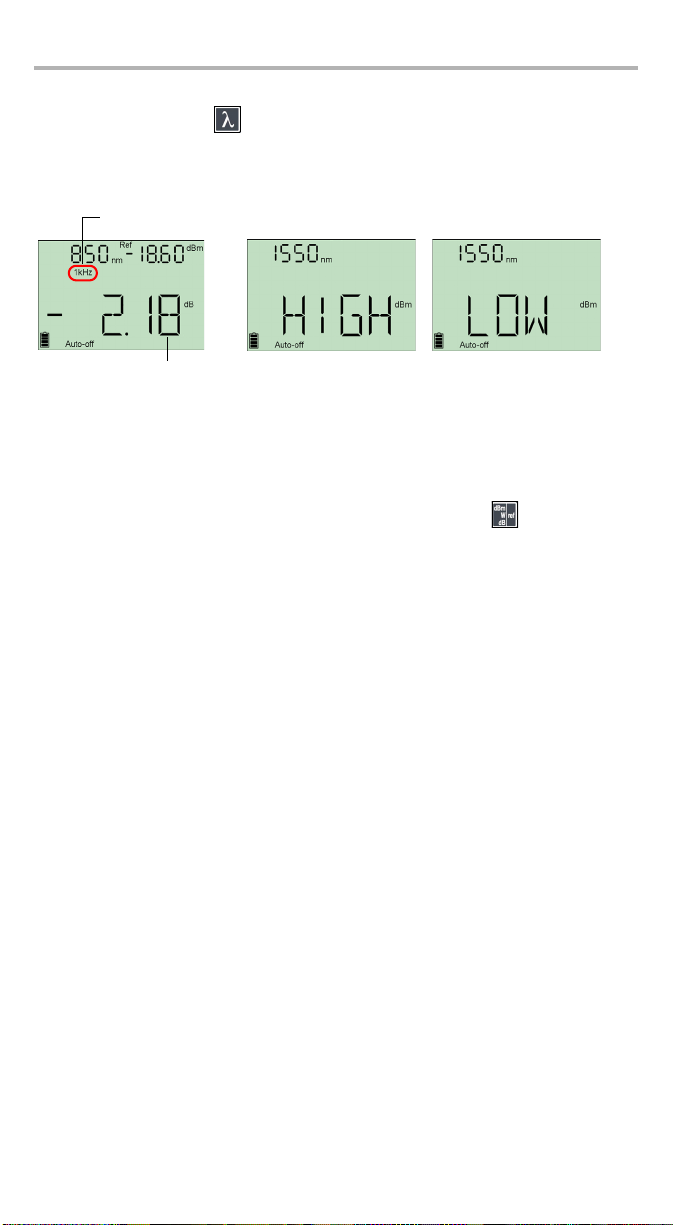

5. Activate the source at the desired wavelength.

6. Match the source and power meter wavelengths using .

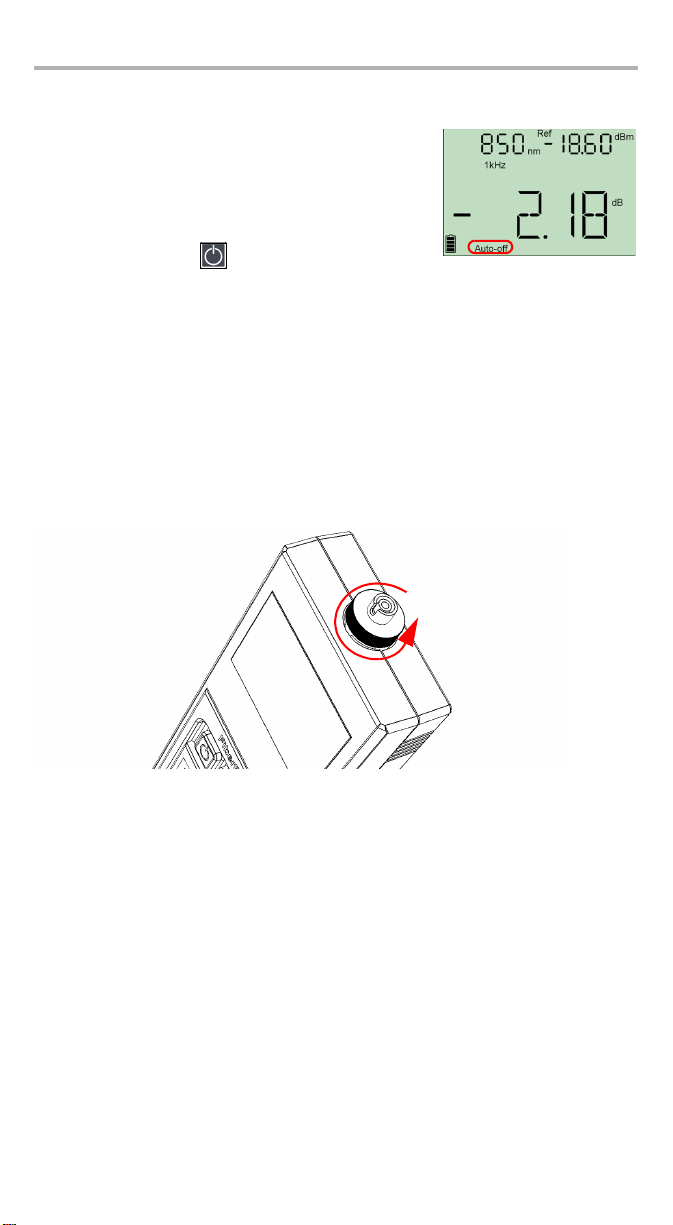

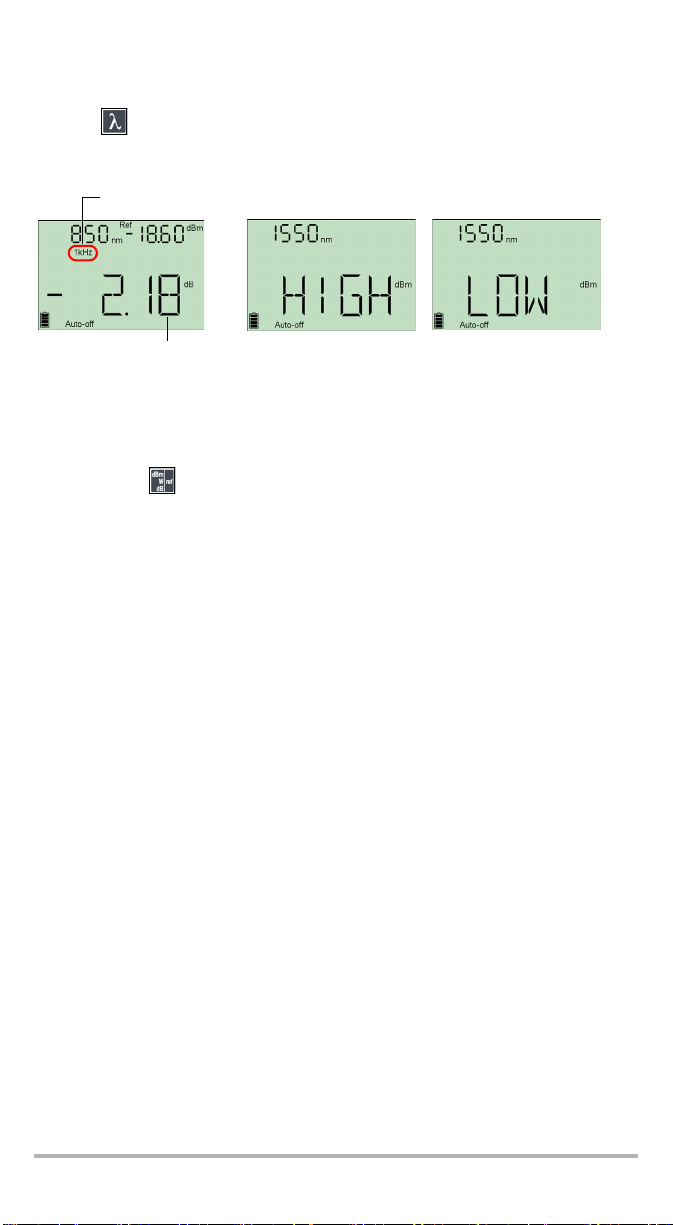

Modulation detected

Actual power

or loss

of fiber under test

When power or loss is outside power limits

(see Technical Specifications on page 27)

When the unit detects a modulated signal, it displays the modulation value and

average measured power or loss (see left illustration above). You may notice a

slightly unstable last digit.

7. If necessary, change the displayed units by pressing .

8. Repeat the procedure for other wavelengths.

EPM-50/ELS-50 11

Page 16

Using a Light Source (ELS-50) 12

5 Using a Light Source

(ELS-50)

The ELS-50 may contain up to three sources.

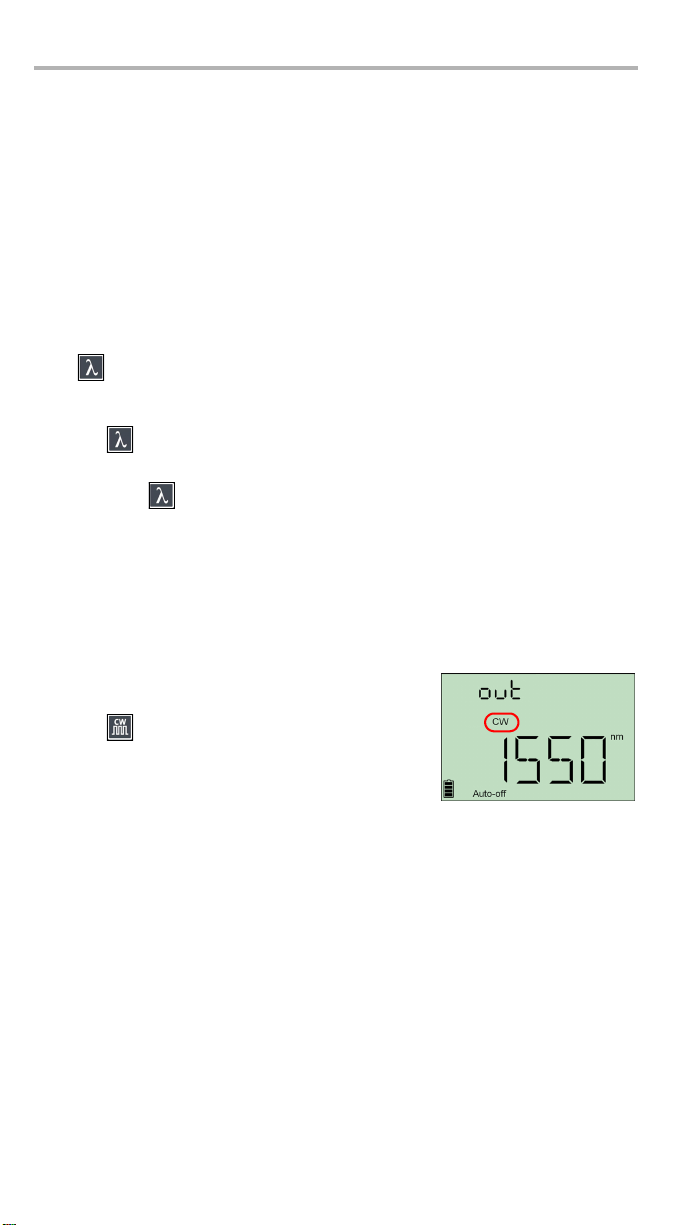

Activating/Deactivating a Light Source

Only one source may be active at a time. When no source is active, the unit displays

OFF and leaves the top left corner empty.

To activate a light source and change the wavelength:

Press

and modulation.

To deactivate the light source:

³ Press

³ Hold down

Modulating the Source Signal

When you activate the first source, the signal is always CW (unmodulated). When

you switch sources, the modulation remains the same. Modulation is indicated in

the top left corner.

Available modulation values are: CW, 270 Hz, 1 kHz and 2 kHz.

To change the signal modulation:

1. Activate the source.

2. Press to switch between available modulations.

to activate each available source in turn. The unit displays the wavelength

until you get past the last source.

OR

a few seconds.

Note: When the output signal is modulated

(270Hz, 1kHz, 2kHz), you will notice the

mention out blinking in the top left corner of the display.

Page 17

6 Maintenance

This product contains no user-serviceable parts. However, it contains sensitive

electronic and optical components, and should be handled carefully and stored in

its carrying case when not in use.

To help ensure long, trouble-free operation:

³ Always inspect fiber-optic connectors before using them and clean them if

necessary.

³ Keep the unit free of dust.

³ Clean the unit casing and front panel with a cloth slightly dampened with water.

³ Store unit at room temperature in a clean and dry area. Keep the unit out of

direct sunlight.

³ Avoid high humidity or significant temperature fluctuations.

³ Avoid unnecessary shocks and vibrations.

³ If any liquids are spilled on or into the unit, turn off the power immediately,

disconnect from any external power source, remove the batteries and let the

unit dry completely.

WARNING

Use of controls, adjustments, and procedures for operation and

maintenance other than those specified herein may result in

hazardous radiation exposure.

EPM-50/ELS-50 13

Page 18

Maintenance 14

Cleaning EUI Connectors

Regular cleaning of EUI connectors will help maintain optimum performance. There

is no need to disassemble the unit.

IMPORTANT

If any damage occurs to internal connectors, the module casing will

have to be opened and a new calibration will be required.

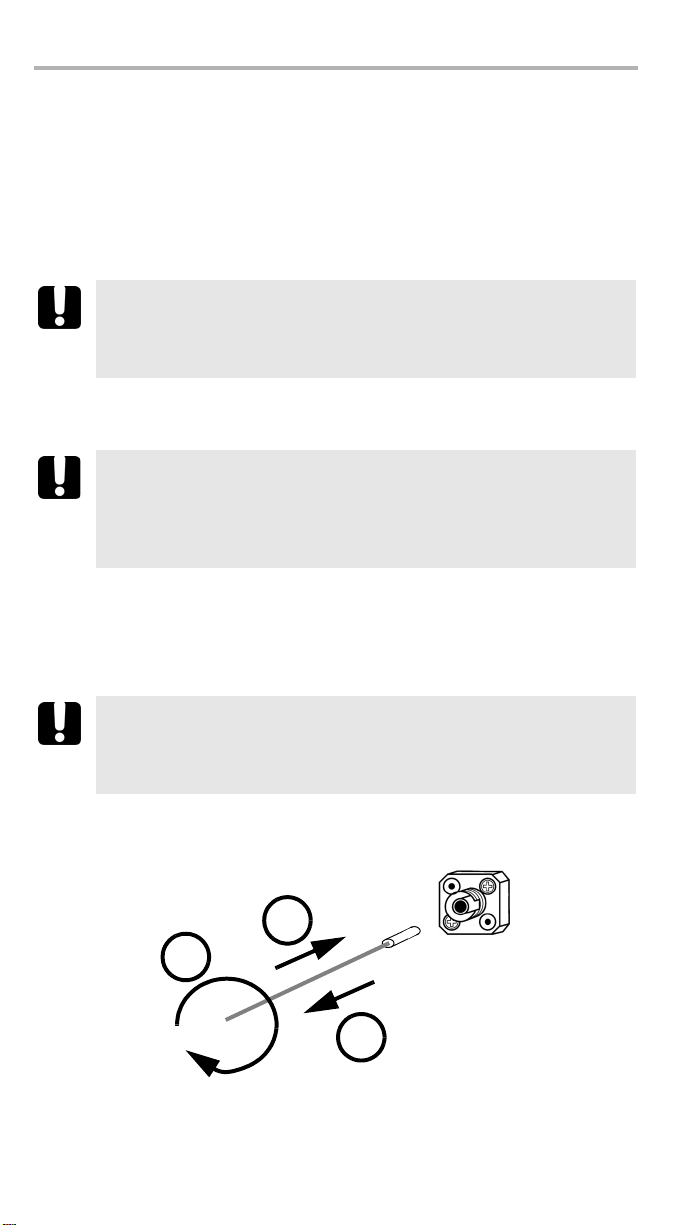

To clean EUI connectors:

1. Remove the EUI from the instrument to expose the connector baseplate and

ferrule.

Tur n

Push

2. Moisten a 2.5 mm cleaning tip with one drop of isopropyl alcohol (alcohol may

leave traces if used abundantly).

3. Slowly insert the cleaning tip into the EUI adapter until it comes out on the other

side (a slow clockwise rotating movement may help).

Pull

3

4

5

4. Gently turn the cleaning tip one full turn, then continue to turn as you withdraw

it.

Page 19

5. Repeat steps 3 to 4 with a dry cleaning tip.

Note: Make sure you don’t touch the soft end of the cleaning tip.

6. Clean the ferrule in the connector port as follows:

6a. Deposit one drop of isopropyl alcohol on a lint-free wiping cloth.

IMPORTANT

Since isopropyl alcohol is not absolutely pure, it may leave residues

if used abundantly or left to evaporate (about 10 seconds).

Avoid contact between the tip of the bottle and the wiping cloth,

dry the surface quickly, and use a bottle that distributes only a drop

of alcohol at a time.

6b. Gently wipe the connector and ferrule.

6c. With a dry lint-free wiping cloth, gently wipe the same surfaces to ensure

that the connector and ferrule are perfectly dry.

6d. Verify connector surface with a portable fiber-optic microscope (for

example, EXFO’s FOMS) or fiber inspection probe (for example, EXFO’s

FIP).

WARNING

Verifying the surface of the connector WHILE THE UNIT IS ACTIVE

WILL result in permanent eye damage.

7. Put the EUI back onto the instrument (push and turn clockwise).

8. Throw out cleaning tips and wiping cloths after one use.

EPM-50/ELS-50 15

Page 20

Maintenance 16

Cleaning Fixed Connectors

Regular cleaning of connectors will help maintain optimum performance. Do not try

to disassemble the unit. Doing so would break the connector.

To clean fixed connectors:

1. Fold a lint-free wiping cloth in four to form a square.

2. Moisten the center of the lint-free wiping cloth with only one drop of isopropyl

alcohol.

IMPORTANT

Alcohol may leave traces if used abundantly. Avoid contact between

the tip of the bottle and the wiping cloth, and do not use bottles

that distribute too much alcohol at a time.

3. Gently wipe the connector threads three times with the folded and moistened

section of the wiping cloth.

IMPORTANT

Isopropyl alcohol takes approximately ten seconds to evaporate.

Since isopropyl alcohol is not absolutely pure, evaporation will leave

microscopic residue. Make sure you dry the surfaces before

evaporation occurs.

4. With a dry lint-free wiping cloth, gently wipe the same surfaces three times with

a rotating movement.

5. Throw out the wiping cloths after one use.

6. Moisten a cleaning tip (2.5 mm tip) with only one drop of isopropyl alcohol.

IMPORTANT

Alcohol may leave traces if used abundantly. Avoid contact between

the tip of the bottle and the cleaning tip, and do not use bottles that

distribute too much alcohol at a time.

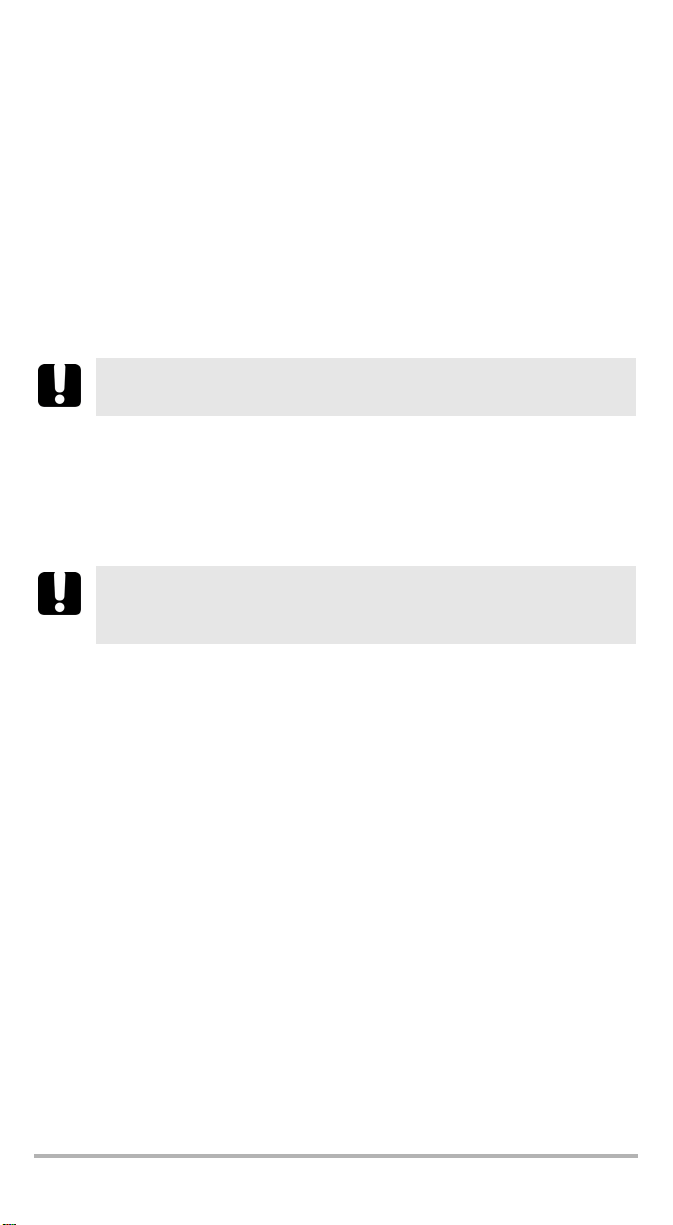

7. Slowly insert the cleaning tip into the connector until it reaches the ferrule

inside (a slow clockwise rotating movement may help).

7

8

9

8. Gently turn the cleaning tip one full turn.

Page 21

9. Continue to turn as you withdraw the cleaning tip.

10. Repeat steps 7 to 9, but this time with a dry cleaning tip (2.5 mm tip provided by

EXFO).

Note: Make sure you don’t touch the soft end of the cleaning tip and verify the

cleanliness of the cotton tip.

11. Throw out the cleaning tips after one use.

Cleaning Detector Ports

Regular cleaning of detectors will help maintain measurement accuracy.

IMPORTANT

Always cover detectors with protective caps when unit is not in use.

To clean detector ports:

1. Remove the protective cap and adapter (FOA) from the detector.

2. If the detector is dusty, blow dry with compressed air.

3. Being careful not to touch the soft end of the swab, moisten a cleaning tip with

only one drop of isopropyl alcohol.

IMPORTANT

Alcohol may leave traces if used abundantly. Do not use bottles that

distribute too much alcohol at a time.

4. While applying light pressure (to avoid breaking the detector window), gently

rotate the cleaning tip on the detector window.

5. Repeat step 4 with a dry cleaning tip or blow dry with compressed air.

6. Discard the cleaning tips after one use.

EPM-50/ELS-50 17

Page 22

Maintenance 18

Replacing Batteries

Your unit requires three AA alkaline or rechargeable

batteries.

To replace batteries:

1. Turn off the unit.

2. Open the battery compartment door located at the

back of the unit.

3. Replace batteries, respecting the polarity as shown.

4. Close the battery compartment door.

WARNING

Do not throw batteries into fire or water and do not short-circuit

the batteries’ electrical contacts. Do not disassemble.

Recalibrating the Unit

Manufacturing and service center calibrations are based on the ISO/IEC 17025

Standard, which states that calibration documents must not contain a

recommended calibration interval, unless this has been previously agreed upon

with the customer.

Validity of specifications depends on operating conditions. For example, the

calibration validity period can be longer or shorter depending on the intensity of use,

environmental conditions and unit maintenance. You should determine the

adequate calibration interval for your unit according to your accuracy requirements.

Under normal use, EXFO recommends calibrating your unit every year.

Note: The FlexCare warranty program includes Calibration/Verification

Note: Recalibration only applies to the EPM-50 Power Meter.

packages (see Service and Repairs on page 25).

Page 23

Recycling and Disposal (Applies to European

Union Only)

Recycle or dispose of your product (including electric and electronic

accessories) properly, in accordance with local regulations. Do not

dispose of it in ordinary garbage receptacles.

This equipment was sold after August 13, 2005 (as identified by the

black rectangle).

³ Unless otherwise noted in a separate agreement between EXFO and a

customer, distributor or commercial partner, EXFO will cover costs related to

the collection, treatment, recovery and disposal of end-of-lifecycle waste

generated by electronic equipment introduced after August 13, 2005 to an

European Union member state with legislation regarding Directive 2002/96/EC.

³ Except for reasons of safety or environmental benefit, equipment manufactured

by EXFO, under its brand name, is generally designed to facilitate dismantling

and reclamation.

For complete recycling/disposal procedures and contact information, visit the EXFO

Web site at www.exfo.com/recycle.

EPM-50/ELS-50 19

Page 24

Troubleshooting 20

7 Troubleshooting

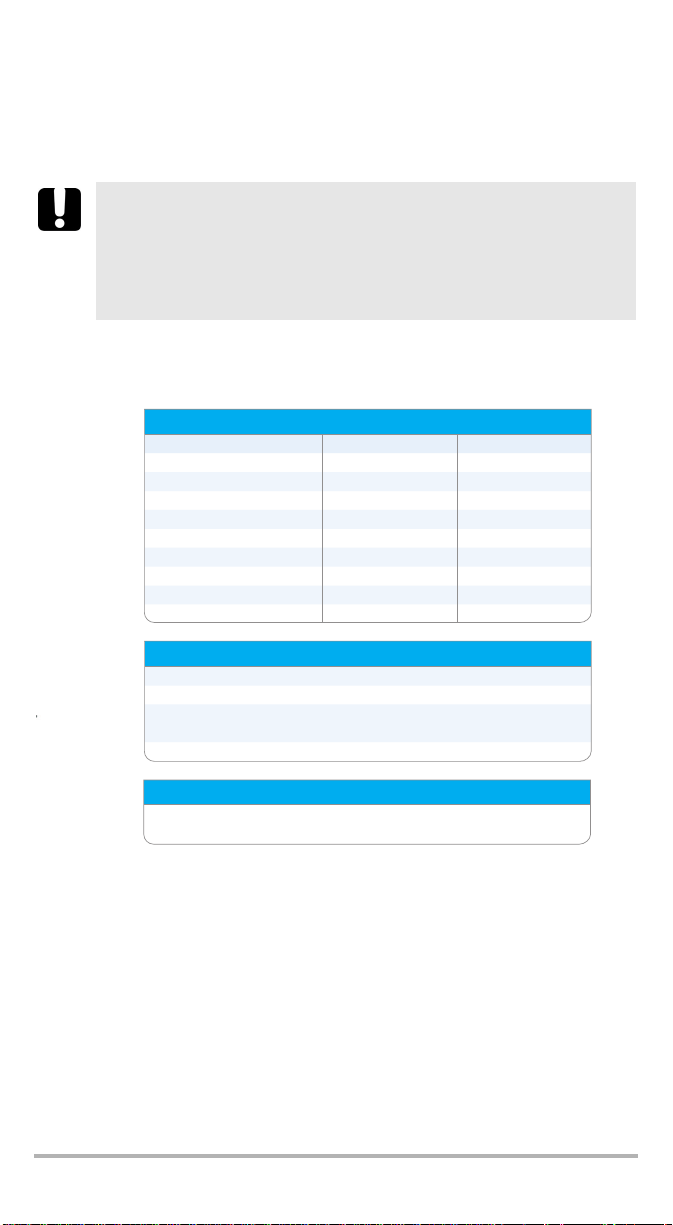

Solving Common Problems

Problem Possible Cause Solution

The unit does not turn on. Batteries are discharged. Replace batteries.

Reference power different than

source output power.

Error Codes and Descriptions

ER: error code displayed until you press a key.

Received power outside

detector’s range.

Change source output

power.

Error

Code

LIGH

Light detected while nulling offsets.

(EPM-50

Nulling is not performed.

only)

3/11 Embedded software problem. Contact EXFO.

7 Hardware problem. Replace unit.

13 Non-volatile memory corrupted

(would occur during unit

initialization).

Description Solution

Correctly place protective cap on

detector port, then retry.

³ Hold down all 3 buttons during

initialization to reset unit.

³ Unit must be recalibrated.

Contact EXFO.

Page 25

Contacting the Technical Support Group

To obtain after-sales service or technical support for this product, contact EXFO at

one of the following numbers. The Technical Support Group is available to take your

calls from Monday to Friday, 8:00 a.m. to 7:00 p.m. (Eastern Time in North America).

For detailed information about technical support, visit the EXFO Web site at

www.exfo.com.

Technical Support Group

400 Godin Avenue

Quebec (Quebec) G1M 2K2

CANADA

To accelerate the process, please have information such as the name and the serial

number (see the product identification label—an example is shown below), as well

as a description of your problem, close at hand.

1 866 683-0155 (USA and Canada)

Tel.: 1 418 683-5498

Fax: 1 418 683-9224

support@exfo.com

P/N

**************** A

542392-3D

S/N

Made in Canada QST442B

January 2020

EPM-50XX

Detector

type

Ver.

Mfg.

date

465 Godin Avenue

Vanier (Quebec) G1M 3G7 CANADA

ELS-50-XX-XX-XX

Source

ports

Source

connector

You may also be requested to provide the embedded software version numbers.

To display the embedded software version, the

manufacturing date, and the serial number:

1. Hold down

The unit displays the main embedded software

and press at the same time.

version.

2. Press again to view the serial number and

manufacturing date.

3. Press to return to normal mode.

EPM-50/ELS-50 21

Page 26

Troubleshooting 22

Transportation

Maintain a temperature range within specifications when transporting the unit.

Transportation damage can occur from improper handling. The following steps are

recommended to minimize the possibility of damage:

³ Pack the unit in its original packing material when shipping.

³ Avoid high humidity or large temperature fluctuations.

³ Keep the unit out of direct sunlight.

³ Avoid unnecessary shocks and vibrations.

Page 27

8 Warranty

General Information

EXFO Electro-Optical Engineering Inc. (EXFO) warrants this equipment against

defects in material and workmanship for a period of one year from t

shipment. EXFO also warrants that this equipment will meet applicable

original

specifications under normal use.

During the warranty period, EXFO will, at its discretion, repair, replace, or issue

credit for any defective product, as well as verify and adjust the product free of

charge should the equipment need to be repaired or if the original calibration is

erroneous. If the equipment is sent back for verification of calibration during the

warranty period and found to meet all published specifications, EXFO will charge

standard calibration fees.

IMPORTANT

The warranty can become null and void if:

³ unit has been tampered with, repaired, or worked upon by

unauthorized individuals or non-EXFO personnel.

³ warranty sticker has been removed.

³ case screws, other than those specified in this guide, have been

removed.

³ case has been opened, other than as explained in this guide.

³ unit serial number has been altered, erased, or removed.

³ unit has been misused, neglected, or damaged by accident.

he date of

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES EXPRESSED, IMPLIED,

OR STATUTORY, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. IN NO EVENT

SHALL EXFO BE LIABLE FOR SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES.

Liability

EXFO shall not be liable for damages resulting from the use of the product, nor shall

be responsible for any failure in the performance of other items to which the

product is connected or the operation of any system of which the product may be a

part.

EXFO shall not be liable for damages resulting from improper usage or unauthorized

modification of the product, its accompanying accessories and software.

EPM-50/ELS-50 23

Page 28

Warranty 24

Exclusions

EXFO reserves the right to make changes in the design or construction of any of its

products at any time without incurring obligation to make any changes whatsoever

on units purchased. Accessories, including but not limited to fuses, pilot lamps,

batteries and universal interfaces (EUI) used with EXFO products are not covered by

this warranty.

This warranty excludes failure resulting from: improper use or installation, normal

wear and tear, accident, abuse, neglect, fire, water, lightning or other acts of nature,

causes external to the product or other factors beyond EXFO’s control.

IMPORTANT

EXFO will charge a fee for replacing optical connectors that were

damaged due to misuse or bad cleaning.

Certification

EXFO certifies that this equipment met its published specifications at the time of

shipment from the factory.

Page 29

Service and Repairs

EXFO commits to providing product service and repair for five years following the

date of purchase.

To send any equipment for service or repair:

1. Call one of EXFO’s authorized service centers (see EXFO Service Centers

Worl dw id e on page 26). Support personnel will determine if the equipment

requires service, repair, or calibration.

2. If equipment must be returned to EXFO or an authorized service center, support

personnel will issue a Return Merchandise Authorization (RMA) number and

provide an address for return.

3. If possible, back up your data before sending the unit for repair.

4. Pack the equipment in its original shipping material. Be sure to include a

statement or report fully detailing the defect and the conditions under which it

was observed.

5. Return the equipment, prepaid, to the address given to you by support

personnel. Be sure to write the RMA number on the shipping slip. EXFO will

refuse and return any package that does not bear an RMA number.

Note: A test setup fee will apply to any returned unit that, after test, is found to

meet the applicable specifications.

After repair, the equipment will be returned with a repair report. If the equipment is

not under warranty, you will be invoiced for the cost appearing on this report. EXFO

will pay return-to-customer shipping costs for equipment under warranty. Shipping

insurance is at your expense.

Routine recalibration is not included in any of the warranty plans. Since

calibrations/verifications are not covered by the basic or extended warranties, you

may elect to purchase FlexCare Calibration/Verification Packages for a definite

period of time. Contact an authorized service center (see EXFO Service Centers

Worl dw id e on page 26).

EPM-50/ELS-50 25

Page 30

Warranty 26

EXFO Service Centers Worldwide

If your product requires servicing, contact your nearest authorized service center.

EXFO Headquarters Service Center

400 Godin Avenue

Vanier (Quebec) G1M 2K2

CANADA

EXFO Europe Service Center

Le Dynasteur

10/12, rue Andras Beck

92366 Meudon la Forêt Cedex

FRANCE

EXFO China Service Center/

Beijing OSIC

Beijing New Century Hotel

Office Tower, Room 1754-1755

No. 6 Southern Capital Gym Road

Beijing 100044

P. R . C H I N A

1 866 683-0155 (USA and Canada)

Tel.: 1 418 683-5498

Fax: 1 418 683-9224

quebec.service@exfo.com

Tel.: +33.1.40.83.85.85

Fax: +33.1.40.83.04.42

europe.service@exfo.com

Tel.: +86 (10) 6849 2738

Fax: +86 (10) 6849 2662

beijing.service@exfo.com

Page 31

A Technical Specifications

OPTIONAL ACCESSORIES

PMA-22 (FC connector adapter for EPM-50 power meter)

PMA-32 (ST connector adapter for EPM-50 power meter)

PMA-54 (SC connector adapter for EPM-50 power meter)

STANDARD ACCESSORIES

Soft pouch, PMA-22 FC connector adapter, quick reference sticker in five languages,

Certificate of Calibration, Certificate of Compliance, three AA batteries

GENERAL SPECIFICATIONS

Size (H x W x D)

189 mm x 78 mm x 37 mm (7 7/16 in x 3 1/16 in x 1 7/16 in)

Weight

0.4 kg (0.9 lb)

Temperature operating

—10 °C to 50 °C (14 °F to 122 °F)

storage

—40 °C to 70 °C (–40 °F to 158 °F)

Relative humidity

0 % to 95 % non-condensing

SPECIFICATIONS

a

MODEL EPM-53 EPM-53X

Power meter port

InGaAs InGaAsX

Power range b (dBm)

10 to –60 26 to –50

Number of calibrated wavelengths

c

55

Power uncertainty

d

±5 % ±5 %

Resolution (dB)

0.01 0.01

Display units

dB/dBm/W dB/dBm/W

Tone detection (Hz)

270, 1 k, 2 k 270, 1 k, 2 k

Battery life (hours)

d

>300 >300

Warranty (year)

11

IMPORTANT

The following technical specifications can change without notice.

The information presented in this section is provided as a reference

only. To obtain this product’s most recent technical specifications,

visit the EXFO Web site at www.exfo.com.

EPM-50 Specifications

Notes

a. All specifications valid at 23 °C ± 3 °C, with an FC/UPC connector

b. In CW mode

c. Wavelengths: 850 nm, 1300 nm, 1310 nm, 1490 nm, 1550 nm

d. Typical

EPM-50/ELS-50 27

Page 32

Technical Specifications 28

SPECIFICATIONS

MODEL

23BL

235BL

12C

Central wavelength (nm)

b

b, c

b, d

b

Tone generation (Hz)

Warranty (year)

STANDARD ACCESSORIES

Soft pouch, LSA-89 FC connector adapter, quick reference sticker in five languages,

Certificate of Compliance, three AA batteries

GENERAL SPECIFICATIONS

Size (H x W x D)

189 mm x 78 mm x 37 mm (7 7/16 in x 3 1/16 in x 1 7/16 in)

Weight

0.4 kg (0.9 lb)

Temperature operating

storage

—10 °C to 50 °C (14 °F to 122 °F)

—40 °C to 70 °C (–40 °F to 158 °F)

Relative humidity

0 % to 95 % non-condensing

OPTIONAL ACCESSORIES

LSA-89 (FC connector adapter for ELS-50 Light Source)

LSA-90 (ST connector adapter for ELS-50 Light Source)

LSA-91 (SC connector adapter for ELS-50 Light Source)

ELS-50 Specifications

Notes

a. All specifications valid at 23 °C ± 3 °C, with an FC/UPC connector

b. Typical

c. rms for lasers and —3 dB width for LEDs

d. After 15 minutes warmup; expressed as ± half the difference between the maximum and minimum values measured

over 8 hours

Page 33

NOTICE

抩⛙

CHINESE REGULATION ON RESTRICTION OF HAZARDOUS SUBSTANCES

NAMES AND CONTENTS OF THE TOXIC OR HAZARDOUS SUBSTANCES OR ELEMENTS

▔⚺⦷㦻 EXFO ℶ❐₼䤓㦘㹡㦘⹂䓸德㒥⏒侯䤓⚜䱿✛⚺摞

Indicates that this toxic or hazardous substance contained in all of the homogeneous

materials for this part is below the limit requirement in SJ/T11363-2006

O

嫷䯉年㦘㹡㦘⹂䓸德⦷年捷ↅ㓏㦘⧖德㧟㠨₼䤓⚺摞⧖⦷ SJ/T11363-2006 㪖屓⸩䤓棟摞尐

㻑ⅴₚᇭ

Indicates that this toxic or hazardous substance contained in at least one of the

homogeneous materials used for this part is above the limit requirement in SJ/T11363-2006

X

嫷䯉年㦘㹡㦘⹂䓸德咂⺠⦷年捷ↅ䤓㩟⧖德㧟㠨₼䤓⚺摞怔⒉ SJ/T11363-2006 㪖屓⸩䤓

棟摞尐㻑ᇭ

Par t Na me

捷ↅ⚜䱿

Enclosure

⮥⮂

Electronic and

electrical

sub-assembly

䟄✛䟄兓ↅ

Optical

sub-assembly

⏘ⷵ兓ↅ

Mechanical

sub-assembly

㧉㬿兓ↅ

a. If applicable.

Ⱁ㨫抑䞷ᇭ

a

a

a

a

₼⦌␂ℝ☀⹂䓸德棟Ⓟ䤓屓⸩

CONTAINED IN THIS EXFO PRODUCT

Toxic or hazardous Substances and Elements

Cadmium

Mercury

Lead

㻭

杔

(Hg)

(Pb)

OO O O O O

XO X O X X

XO O O O O

OO O O O O

MARKING REQUIREMENTS

㦘㹡㦘⹂䓸德✛⏒侯

Hexavalent

Chromium

椣

(Cd)

㪖㽷尐㻑

⏼ↆ杻

(Cr VI)

Pol yb ro mi na te d

biphenyls

⮩䅃勣啾

(PBB)

Pol yb r om in at ed

diphenyl ethers

⮩䅃ℛ啾搩

(PBDE)

Pro duct

ℶ❐

This Exfo product

㦻 EXFO ℶ❐

Battery

䟄㻯

a. If applicable.

Ⱁ㨫抑䞷ᇭ

a

a

Environmental protection use period (years)

䘾⬒≬㔳∎䞷㦮棟 ( )

10

5

Logo

㪖㉦

EPM-50/ELS-50 29

Page 34

Page 35

EPM-50/ELS-50

Wattmètre/Source lumineuse

Guide d’utilisation

Page 36

Copyright © 2010 EXFO Electro-Optical Engineering Inc. Tous droits réservés.

La reproduction, le stockage dans un système d’extraction ou la transmission de

tout ou partie de la présente publication, que ce soit par voie électronique,

mécanique ou tout autre moyen, notamment par photocopie, enregistrement ou

autre, sans l’autorisation écrite préalable de EXFO Electro-Optical Engineering Inc.

(EXFO) sont formellement interdits.

Les informations fournies par EXFO sont considérées comme exactes et fiables.

Cependant, EXFO ne saurait être tenu pour responsable de l’utilisation de ces

informations ou de la violation de brevets ou de tout autre droit de tiers pouvant en

découler. Aucune licence, implicite ou autre, n’est concédée selon les termes du

brevet d’EXFO.

Le code CAGE (code d’identification pour les entreprises et organismes

gouvernementaux américains) d’EXFO, en vertu de l’Organisation du Traité de

l’Atlantique Nord (OTAN), est le 0L8C3.

Les informations contenues dans la présente publication sont sujettes à

modification sans avis préalable.

Marques commerciales

Les marques commerciales d’EXFO sont identifiées comme telles. Cependant, la

présence ou l’absence d’une telle identification n’affecte aucunement le statut légal

des marques commerciales.

Unités de mesure

Les unités de mesure mentionnées dans la présente publication sont conformes

aux normes et aux pratiques SI.

Version : 2.0.0

ii

Page 37

Table des matières

Informations relatives à la certification ............................................................ iv

1 Présentation du EPM-50/ELS-50 ................................................ 1

Caractéristiques principales .............................................................................. 1

Sources d’alimentation ..................................................................................... 3

Applications courantes ..................................................................................... 3

Conventions ......................................................................................................3

2 Informations relatives à la sécurité ......................................... 4

3 Initiation .................................................................................... 5

Mise sous et hors tension de l’unité ................................................................. 5

Activation de l’arrêt automatique ..................................................................... 6

Changement des adaptateurs de connecteur ................................................... 6

Nettoyage et connexion des fibres optiques ..................................................... 8

4 Mesure de la puissance ou de la perte (EPM-50) .................... 9

Annulation des déviations électriques .............................................................. 9

Référencement de votre wattmètre à une source ...........................................10

Mesure de la puissance ou de la perte ............................................................ 11

5 Utilisation d’une Source lumineuse (ELS-50) ......................... 13

Activation/désactivation d’une source lumineuse ........................................... 13

Modulation du signal source ..........................................................................13

6 Entretien .................................................................................. 14

Nettoyage des connecteurs de l’interface universelle EXFO (EUI) .................... 15

Nettoyage des connecteurs fixes ..................................................................... 17

Nettoyage des ports du détecteur .................................................................. 19

Remplacement des piles ................................................................................. 20

Réétalonnage de l’unité .................................................................................. 20

Recyclage et mise au rebut (Union européenne uniquement) ......................... 21

7 Dépannage .............................................................................. 22

Résolution de problèmes courants .................................................................. 22

Codes d’erreur et descriptions ........................................................................ 22

Contacter l’équipe d’assistance technique ...................................................... 23

Transport ........................................................................................................ 24

8 Garantie ................................................................................... 25

Informations générales ................................................................................... 25

Responsabilité .................................................................................................26

Exclusions .......................................................................................................26

Certification .................................................................................................... 26

Entretien et réparation ................................................................................... 27

EXFO Centres de service dans le monde .......................................................... 28

A Caractéristiques techniques ................................................... 29

EPM-50 ........................................................................................................... 29

ELS-50 ............................................................................................................. 30

EPM-50/ELS-50 iii

Page 38

Informations relatives à la certification iv

Informations relatives à la certification

Informations FCC

L’équipement de test électronique est exempté d’obligation de conformité à la

partie 15 (FCC) aux États-Unis. Cependant, la plupart des équipements EXFO sont

soumis à des tests de vérification de conformité périodiques.

Informations

L’équipement de test électronique est soumis à la norme EMC dans l’Union

européenne. La norme EN61326 prévoit des exigences en matière d’émission et

d’immunité applicables au matériel de laboratoire ainsi qu’aux équipements de

mesure et de commande. Cet appareil a été soumis à des tests poussés,

conformément aux normes et exigences de l’Union européenne.

DECLARATION OF CONFORMITY

Application of Council Directive(s): 2004/108/EC - The EMC Directive

Manufacturer’s Name: EXFO Electro-Optical Engineering Inc.

Manufacturer’s Address: 400 Godin Avenue

Quebec, Quebec

(418) 683-0211

Equipment Type/Environment: Test & Measurement / Industrial

Trade Name/Model No.: EPM-50 / Power Meter

Standard(s) to which Conformity is Declared:

EN 61326-1:2006 Electrical Equipment for Measurement, Control and Laboratory

EN 60825-1:2007 Edition 2.0 Safety of laser products – Part 1: Equipment classification and

EN 55022: 2006 + A1: 2007 Information technology equipment — Radio disturbance

I, the undersigned, hereby declare that the equipment specified above conforms to the above Directive and Standards.

Manufacturer

Signature:

Full Name: Stephen Bull, E. Eng

Position: Vice-President Research and

Address: 400 Godin Avenue, Quebec (Quebec),

Date: December 03, 2009

Development

Canada, G1M 2K2

Use - EMC Requirements

requirements

characteristics — Limits and methods of measurement

2006/66/EC - The Battery Directive

93/68/EEC - CE Marking

And their amendments

Canada, G1M 2K2

ELS-50 / Light Source

Page 39

1 Présentation du

EPM-50/ELS-50

Ce guide d’utilisation s’applique aux produits suivants (sauf mention contraire,

les descriptions s’appliquent à tous les produits) :

³ Wat t mè t re E P M- 5 0

³ Source lumineuse ELS-50

Caractéristiques principales

Le Wattmètre EPM-50 offre :

³ une conception robuste

³ des adapteurs de connecteur interchangeables

³ une durée de vie des piles de 300 heures

³ une reconnaissance de tonalité pour l’identification des fibres

³ une interface PP universelle

³ une fonction de référence pour les mesures de perte directes

Le Source lumineuse ELS-50 offre :

³ une conception robuste

³ une excellente stabilité électrique pour des mesures de perte fiables

³ une interface à connecteurs interchangeables

³ une durée de vie des piles allant jusqu’à 60 heures

³ des adapteurs de connecteur interchangeables

³ une composition de tonalités pour l’identification des fibres

EPM-50/ELS-50 1

Page 40

Présentation du EPM-50/ELS-50 2

Vue de face

Capuchon

de protection

Affichage LCD

Clavier

(EPM-50 illustré)

Vue de dos

Étiquette de

sécurité et

numéro de série

Compartiment à piles

(3 piles alcalines ou

rechargeables)

Port de connecteur

Étiquette de

référence rapide

Page 41

Sources d’alimentation

L’unité fonctionne avec 3 piles AA alcalines ou rechargeables.

IMPORTANT

Si le niveau des piles est trop faible, l’unité se met elle-même hors

tension.

Applications courantes

Les unités offrent des applications courantes spécifiques :

Wattmètre EPM-50 :

³ Modèle grande puissance pour les applications CATV et Telco

³ Entreprise/LAN pour les mesures en monomode et multimode

Source lumineuse ELS-50 :

³ Modèles Telco/CATV et FTTH ; deux et trois longueurs d’onde

³ Modèles Entreprise/LAN ; monomode et multimode

Conventions

Avant d’utiliser le produit décrit dans le présent manuel, vous devez maîtriser les

conventions suivantes :

AVERTISSEMENT

Indique un danger potentiel susceptible d’entraîner la mort ou des

blessures graves. Ne poursuivez pas l’opération à moins d’avoir

compris les conditions requises et de les respecter.

MISE EN GARDE

Indique un danger potentiel susceptible d’entraîner des blessures

légères ou moyennement graves. Ne poursuivez pas l’opération à

moins d’avoir compris les conditions requises et de les respecter.

MISE EN GARDE

Indique un danger potentiel susceptible d’entraîner des dommages

matériels. Ne poursuivez pas l’opération à moins d’avoir compris les

conditions requises et de les respecter.

IMPORTANT

Fait référence aux informations relatives au produit, à prendre en

compte impérativement.

EPM-50/ELS-50 3

Page 42

Informations relatives à la sécurité 4

2 Informations relatives à

la sécurité

AVERTISSEMENT

N’installez pas et ne retirez pas de fibre si une source laser est active.

Ne regardez jamais directement dans une fibre active et veillez à

toujours protéger vos yeux.

AVERTISSEMENT

L’utilisation de commandes, réglages et procédures à des fins

d’exploitation et d’entretien autres que celles indiquées dans le

présent document peut entraîner une exposition à des radiations

dangereuses.

Vous êtes en possession d’un produit laser Classe 1 conforme aux normes

CEI 60825-1 et 21 CFR 1040.10. Des radiations laser peuvent être émises au niveau

du port de sortie.

L’étiquette suivante indique que le produit contient une source Classe 1 :

CLASS 1

LASER PRODUCT

Note : Cette étiquette est apposée sur votre produit.

Page 43

3 Initiation

Mise sous et hors tension de l’unité

Lorsque vous mettez le EPM-50 hors tension, la longueur d’onde, l’unité et la

puissance de référence sont enregistrées.

IMPORTANT

Si vous retirez les piles, l’unité se met hors tension sans enregistrer

les valeurs indiquées ci-dessus.

Si le niveau des piles est faible, l’unité enregistre les valeurs

indiquées ci-dessus et se met hors tension.

Note : Les valeurs d’annulation de déviation sont toujours redéfinies sur les

paramètres usine.

Pour mettre l’unité sous tension :

Appuyez sur . Vous pouvez immédiatement utiliser l’appareil dans des

conditions normales.

Pour mettre l’unité hors tension :

En mode de fonctionnement normal, maintenez la touche enfoncée pendant

quelques secondes.

Écran

Longueur d’onde du

wattmètre (EPM-50)

Modulation de la

source (ELS-50)

Modulation

détectée

(EPM-50)

Niveau des piles

Arrêt automatique activé

Puissance de

référence(EPM-50)

Puissance/perte mesurée (EPM-50)

Longueur d’onde source active

(ELS-50)

EPM-50/ELS-50 5

Page 44

Initiation 6

Clavier

PRESSION COURTE : passe d’une

unité à l’autre.

EPM-50

PRESSION LONGUE : Allume ou

PRESSION COURTE : Contrôle

PRESSION COURTE : Quitte les

éteint l’appareil.

l’arrêt automatique.

modes spéciaux.

PRESSION COURTE : change de longueur d’onde.

PRESSION COURTE : active la source suivante.

PRESSION LONGUE : désactive la source actuelle.

PRESSION LONGUE : définit la

puissance d’entrée comme

puissance de référence.

ELS-50

PRESSION COURTE : passe d’une

valeur de modulation à une autre.

Activation de l’arrêt automatique

Lorsque l’arrêt automatique est activé, l’unité se met

hors tension après 10 minutes d’inactivité.

L’arrêt automatique est activé par défaut lorsque vous

mettez l’unité sous tension.

Pour désactiver/réactiver la fonction d’arrêt

automatique :

Lorsque l’unité est sous tension, appuyez sur .

Note : L’arrêt automatique sera automatiquement désactivé si vous procédez

à une annulation de déviation.

Page 45

Changement des adaptateurs de connecteur

Les adaptateurs de connecteur sont des accessoires en option sur les modèles

Wattmètre EPM-50 et Source lumineuse ELS-50. Selon le type de connecteur utilisé

sur la fibre à tester, il se peut que vous deviez changer les adaptateurs.

Pour changer les adaptateurs de connecteur :

1. Tenez l’unité avec le port du connecteur vous faisant face.

2. Dévissez l’adaptateur du connecteur dans le sens contraire des aiguilles d’une

montre et enlevez-le.

3. Placez l’adaptateur dont vous avez besoin et vissez-le.

EPM-50/ELS-50 7

Page 46

Initiation 8

Nettoyage et connexion des fibres optiques

IMPORTANT

Pour garantir une puissance maximale et éviter toute lecture

erronée :

³ Nettoyez toujours les extrémités de la fibre comme expliqué

ci-après avant de les insérer dans le port. EXFO ne peut être tenu

responsable des dommages ou erreurs provoqué(e)s par une

manipulation ou un nettoyage inapproprié(e) des fibres.

³ Vérifiez que votre câble de raccordement dispose des

connecteurs adéquats. Le raccordement de connecteurs

inadaptés peut endommager les férules.

Pour connecter le câble à fibres optiques au port :

1. Inspectez la fibre à l’aide du microscope d’inspection de fibre optique. Si la fibre

est propre, connectez-la au port. Si la fibre est sale, nettoyez-la en suivant la

procédure ci-après.

2. Nettoyez les extrémités de la fibre comme suit :

2a. Nettoyez doucement l’extrémité de la fibre à l’aide d’un chiffon non

pelucheux trempé dans de l’alcool isopropylique.

2b. Séchez complètement la fibre avec de l’air comprimé.

2c. Effectuez une inspection visuelle de l’extrémité de la fibre afin de vous

assurer de sa propreté.

3. Alignez avec précaution le connecteur et le port afin d’éviter que l’extrémité de

la fibre n’entre en contact avec la partie externe du port ou toute autre surface.

Si votre connecteur est équipé d’un ergot, assurez-vous de bien le positionner

dans l’encoche correspondante du port.

4. Enfoncez le connecteur dans le port de sorte que le câble à fibres optiques soit

correctement positionné, garantissant ainsi un bon contact.

Si le connecteur est équipé d’une bague filetée, serrez le connecteur de sorte à

maintenir fermement la fibre en place. Un serrage excessif peut endommager

la fibre et le port.

Note : Si votre câble à fibres optiques n’est pas correctement aligné et/ou

branché, vous remarquerez une réflexion et une perte très importantes.

Page 47

4 Mesure de la puissance ou

de la perte (EPM-50)

Annulation des déviations électriques

Les variations de température et d’humidité affectent les performances des circuits

électroniques et des détecteurs optiques. L’annulation des déviations électriques

élimine ces effets. Votre appareil a été conçu pour que, dans des conditions de

fonctionnement normales, il ne soit pas nécessaire de procéder à l’annulation des

déviations. Toutefois, celle-ci s’avèrera nécessaire à chaque évolution significative

des conditions environnementales ou en cas de valeurs très faibles.

IMPORTANT

Si le détecteur est exposé à de la lumière lors de l’annulation des

déviations, le code LIGH s’affiche à l’écran et l’annulation n’est pas

effectuée. Vous devez appuyer sur une touche pour revenir à l’écran

précédent.

Note : Les valeurs usine sont restaurées lorsque vous mettez l’unité hors

tension.

Pour procéder à l’annulation des déviations :

Maintenez les touches et enfoncées quelques

secondes. L’unité affiche NULL pendant l’annulation

des déviations, puis retourne en mode normal.

Note : Pendant cette opération, le clavier est

désactivé.

EPM-50/ELS-50 9

Page 48

Mesure de la puissance ou de la perte (EPM-50) 10

Référencement de votre wattmètre à une

source

En mode référence, votre unité affiche uniquement la perte générée par la fibre

testée, car elle soustrait une valeur de référence de la puissance mesurée.

Note : Vous devez définir une valeur de référence distincte pour chaque

longueur d’onde.

Pour référencer manuellement le wattmètre à une source :

1. À l’aide de l’adaptateur approprié, connectez une source lumineuse (telle que

ELS-50) au port du détecteur du wattmètre.

de référence

Connecteur de

l’adaptateur

Source

lumineuse

2. Activez la source à la longueur d’onde souhaitée.

3. À l’aide de la touche , faites correspondre les longueurs d’onde de la source

et du wattmètre.

La longueur d’onde est affichée dans le coin supérieur gauche.

4. Maintenez la touche enfoncée pendant

quelques secondes. Le wattmètre enregistre la

puissance détectée comme la nouvelle puissance

de référence.

La puissance de référence s’affiche dans le coin

supérieur droit (en dBm) et la lecture de perte

passe automatiquement à dB.

5. Répétez cette procédure pour chaque longueur d’onde à référencer.

traversant

Cavalier de test

de référence

Wattmètre

AdaptateurCavalier de test

Note : Une fois toutes les longueurs d’onde requises référencées, ne

déconnectez pas le cavalier de test de référence du port source tant que

toutes les mesures n’ont pas été effectuées.

Page 49

Mesure de la puissance ou de la perte

La mesure de la puissance absolue s’effectue selon la même procédure que le

référencement du wattmètre à une source, à l’exception de l’étape de

référencement.

Pour mesurer la puissance ou la perte :

1. Si nécessaire, procédez à une annulation des écarts (voir Annulation des

déviations électriques à la page 9).

2. Vérifiez vos fibres et nettoyez-les correctement pour des performances

optimales (voir Nettoyage et connexion des fibres optiques à la page 8).

3. Pour les mesures de perte, référencez votre wattmètre à une source lumineuse

(voir Référencement de votre wattmètre à une source à la page 10), puis

désactivez la source lumineuse.

4. À l’aide de l’adaptateur et des cavaliers de test appropriés, connectez une fibre

à tester à une source lumineuse (telle que ELS-50) et au port du détecteur de

votre unité.

Note : Si vous avez référencé votre wattmètre à une source, connectez la fibre

testée aux cavaliers de test de référence utilisés pour le référencement.

Cavalier

de test

Source

lumineuse

Connecteur de

l’adaptateur

traversant

Fibre testée

Cavalier

de test

Connecteur de

l’adaptateur

traversant

Wattmètre

Adaptateur

EPM-50/ELS-50 11

Page 50

Mesure de la puissance ou de la perte (EPM-50) 12

5. Activez la source à la longueur d’onde souhaitée.

6. À l’aide de la touche , faites correspondre les longueurs d’onde de la source

et du wattmètre.

Modulation détectée

Puissance ou perte

de la fibre testée

réelle

Lorsque la puissance ou la perte est

en-dehors des limites de puissance

(voir Caractéristiques techniques à la page 29)

Lorsque l’unité détecte un signal modulé, elle affiche la valeur de modulation et

la puissance ou perte moyenne mesurée (voir l’illustration ci-dessus à gauche).

Le dernier chiffre peut être légèrement instable.

7. Si nécessaire, changez les unités affichées en appuyant sur .

8. Répétez cette procédure pour les autres longueurs d’onde.

Page 51

5 Utilisation d’une Source

lumineuse (ELS-50)

L’unité ELS-50 peut contenir jusqu’à trois sources.

Activation/désactivation d’une source

lumineuse

Une seule source à la fois peut être active. Lorsqu’aucune source n’est active,

l’unité affiche OFF et rien n’apparaît dans le coin supérieur gauche.

Pour activer une source lumineuse et modifier la longueur d’onde :

Appuyez sur

la longueur d’onde et la modulation.

Pour désactiver la source lumineuse :

³ Appuyez sur

OU

³ Maintenez la touche

Modulation du signal source

Lors de l’activation de la première source, le signal est toujours Stable

(non modulé). Lorsque vous commutez les sources, la modulation reste identique.

La modulation est indiquée dans le coin supérieur gauche.

Les valeurs de modulation disponibles sont les suivantes : Stable, 270 Hz, 1 kHz et

2kHz.

Pour changer la modulation du signal :

1. Activez la source.

2. Appuyez sur pour passer d’une modulation

disponible à une autre.

pour activer chaque source disponible une à une. L’appareil affiche

jusqu’à ce que vous dépassiez la dernière source.

enfoncée quelques secondes.

Note : Si le signal de sortie est modulé

(270 Hz, 1 kHz, 2 kHz), vous verrez

la mention « out » clignoter dans le coin supérieur gauche de l’affichage.

EPM-50/ELS-50 13

Page 52

Entretien 14

6 Entretien

Ce produit ne contient aucune pièce remplaçable par l’utilisateur. Il comprend

toutefois des composants électroniques et optiques sensibles et doit être manipulé

avec soin et stocké dans son boîtier portatif lorsqu’il n’est pas utilisé.

Pour assurer un fonctionnement sans problème et durable de votre appareil :

³ Inspectez toujours les connecteurs à fibres optiques avant de les utiliser et

nettoyez-les si nécessaire.

³ Conservez l’appareil à l’abri de la poussière.

³ Nettoyez le boîtier et le panneau avant de l’appareil à l’aide d’un chiffon

légèrement imbibé d’eau.

³ Entreposez l’appareil dans un endroit propre, sec et à température ambiante.

Évitez toute exposition directe aux rayons du soleil.

³ Évitez d’exposer l’appareil à un taux d’humidité élevé ou à des variations

importantes de température.

³ Dans la mesure du possible, évitez les chocs et les vibrations.

³ Si des liquides sont renversés sur l’appareil ou à l’intérieur de celui-ci, mettez-le

immédiatement hors tension, déconnectez-le de toute source d’alimentation

externe, retirez la batterie et les piles et laissez-le sécher complètement.

AVERTISSEMENT

L’utilisation de contrôles, réglages et procédures à des fins

d’exploitation et d’entretien autres que celles indiquées dans le

présent document peut entraîner une exposition à des radiations

dangereuses.

Page 53

Nettoyage des connecteurs de l’interface

universelle EXFO (EUI)

Un nettoyage régulier des connecteurs de l’ interface universelle EXFO (EUI)

permet de garantir des performances optimales. Il n’est pas nécessaire de

démonter l’appareil.

IMPORTANT

Si les connecteurs internes sont endommagés, vous devez ouvrir le

boîtier du module et procéder à un nouvel étalonnage.

Pour nettoyer les connecteurs de l’interface universelle EXFO (EUI) :

1. Retirez l’interface universelle EXFO (EUI) de l’appareil afin de pouvoir accéder à

la plaque de connecteurs et à la férule.

To ur n ez

Poussez

2. Humectez un embout de nettoyage de 2,5 mm à l’aide d’une goutte d’alcool

isopropylique (l’alcool peut laisser des traces s’il est utilisé en trop grande

quantité).

3. Insérez lentement l’embout dans l’adaptateur de l’interface universelle EUI

jusqu’à ce qu’il ressorte de l’autre côté (une rotation lente dans le sens des

aiguilles d’une montre peut s’avérer utile).

Tirez

3

4

5

4. Tournez doucement l’embout de nettoyage en lui faisant faire un tour complet,

puis continuez à tourner lorsque vous le retirez.

5. Répétez les étapes 3 à 4 avec un embout de nettoyage sec.

Note : Prenez soin de ne pas toucher son extrémité.

EPM-50/ELS-50 15

Page 54

Entretien 16

6. Nettoyez la férule du port de connecteur en procédant comme suit :

6a. Déposez une goutte d’alcool isopropylique sur un chiffon non pelucheux.

IMPORTANT

L’alcool isopropylique peut laisser des résidus si vous l’utilisez en

trop grande quantité ou si vous le laissez s’évaporer (au bout de

10 secondes environ).

Évitez tout contact entre l’embout de la bouteille et le chiffon,

essuyez la surface rapidement et utilisez une bouteille de type

compte-gouttes pour l’alcool.

6b. Essuyez doucement le connecteur et la férule.

6c. Réessuyez-les doucement à l’aide d’un chiffon sec non pelucheux afin de

vous assurer qu’ils sont parfaitement secs.

6d. Vérifiez la surface des connecteurs à l’aide d’un microscope à fibres

optiques portatif (FOMS d’EXFO par exemple) ou d’une sonde d’inspection

fibre (FIP d’EXFO par exemple).

AVERTISSEMENT

Vous risquez des dommages oculaires irréversibles si vous vérifiez la

surface du connecteur LORSQUE L’APPAREIL EST ACTIF.

7. Replacez l’interface universelle EXFO (EUI) sur l’appareil en la poussant et en

effectuant une rotation dans le sens des aiguilles d’une montre.

8. Ne réutilisez ni les embouts de nettoyage ni les chiffons.

Page 55

Nettoyage des connecteurs fixes

Un nettoyage régulier des connecteurs permet de garantir des performances

optimales. Ne tentez pas de démonter l’appareil sous peine d’endommager les

connecteurs.

Pour nettoyer les connecteurs fixes :

1. Pliez un chiffon non pelucheux en quatre afin de former un carré.

2. Humectez le centre de ce carré à l’aide d’une seule goutte d’alcool

isopropylique.

IMPORTANT

L’alcool peut laisser des traces s’il est utilisé en trop grande quantité.

Évitez tout contact entre l’embout de la bouteille et le chiffon et

n’utilisez pas de bouteille à débit important.

3. Avec la partie pliée et humectée du chiffon, essuyez doucement à trois reprises

le filetage des connecteurs.

IMPORTANT

L’alcool isopropylique s’évapore en dix secondes environ. N’étant

pas tout à fait pur, son évaporation laisse des résidus

microscopiques. Assurez-vous de sécher les surfaces avant que

l’évaporation n’ait lieu.

4. Avec un mouvement de rotation, réessuyez-les doucement à trois reprises à

l’aide d’un chiffon sec non pelucheux.

5. Ne réutilisez pas les chiffons.

6. Humectez un embout de nettoyage (2,5 mm) à l’aide d’une seule goutted’alcool

isopropylique.

IMPORTANT

L’alcool peut laisser des traces s’il est utilisé en trop grande quantité.

Évitez tout contact entre l’embout de la bouteille et l’embout de

nettoyage et n’utilisez pas de bouteille à débit important.

EPM-50/ELS-50 17

Page 56

Entretien 18

7. Insérez lentement l’embout dans le connecteur jusqu’à ce qu’il y atteigne la

férule (une rotation lente dans le sens des aiguilles d’une montre peut s’avérer

utile).

7

8

9

8. Tournez doucement l’embout de nettoyage en lui faisant faire un tour complet.

9. Continuez à tourner lorsque vous le retirez.

10. Répétez les étapes 7 à 9, cette fois avec un embout de nettoyage sec (embout

de 2,5 mm fourni par EXFO).

Note : Prenez soin de ne pas toucher son extrémité et vérifiez que le coton-tige

est bien propre.

11. Ne réutilisez pas les embouts de nettoyage.

Page 57

Nettoyage des ports du détecteur

Le nettoyage régulier des détecteurs permet de garantir la précision des mesures.

IMPORTANT

Couvrez systématiquement les détecteurs à l’aide de capuchons de

protection lorsque vous n’utilisez pas l’unité.

Pour nettoyer les ports du détecteur :

1. Retirez le capuchon de protection et l’adaptateur (FOA) du détecteur.

2. Si le détecteur est poussiéreux, nettoyez-le à l’air comprimé.

3. Prenez soin de ne pas toucher l’extrémité du coton-tige et humectez un embout

de nettoyage à l’aide d’une seule goutte d’alcool isopropylique.

IMPORTANT

L’alcool peut laisser des traces s’il est utilisé en trop grande quantité.

N’utilisez pas de bouteille à débit important.

4. Tout en appliquant une légère pression (afin d’éviter le bris de la fenêtre du

détecteur), passez doucement l’embout de nettoyage sur la fenêtre du

détecteur.

5. Répétez l’étape 4 à l’aide d’un embout de nettoyage sec ou séchez la surface à

l’air comprimé.

6. Ne réutilisez pas les embouts de nettoyage.

EPM-50/ELS-50 19

Page 58

Entretien 20

Remplacement des piles

Votre appareil fonctionne avec trois piles AA alcalines

ou rechargeables.

Pour remplacer les piles :

1. Mettez l’appareil hors tension.

2. Ouvrez le capot du compartiment à piles situé à

l’arrière de l’appareil.

3. Remplacez les piles en respectant la polarité

comme indiqué.

4. Fermez le capot du compartiment à piles.

AVERTISSEMENT

Veillez à ne pas jeter les piles au feu ou dans l’eau et à ne pas

court-circuiter leurs contacts électriques. Ne tentez pas de

démonter l’appareil.

Réétalonnage de l’unité

Les étalonnages des centres de fabrication et de service sont basés sur la

norme ISO/IEC 17025, qui stipule que les documents d’étalonnage ne doivent pas

indiquer d’intervalle d’étalonnage recommandé, sauf accord préalable avec le

client.

La validité des caractéristiques dépend des conditions de fonctionnement.

Par exemple, la période de validité de l’étalonnage peut être plus ou moins longue

selon la fréquence d’utilisation, les conditions environnementales et l’entretien de

l’appareil. Déterminez l’intervalle d’étalonnage de votre appareil en fonction de vos

exigences de précision.

Dans des conditions d’utilisation normales, EXFO recommande de procéder à un

étalonnage annuel de l’appareil.

Note : Le programme de garantie FlexCare inclut des ensembles d’étalonnage

et de vérification (consultez la section Entretien et réparation à la

page 27).

Note : Le réétalonnage ne s’applique qu’au Wattmètre EPM-50.

Page 59

Recyclage et mise au rebut

(Union européenne uniquement)

Recyclez et mettez votre produit au rebut (accessoires électriques et

électroniques inclus) conformément aux réglementations en vigueur.

Ne le jetez pas dans les bacs à ordures ordinaires.

La date de vente de l’appareil est postérieure au 13 août 2005 (comme

l’indique le rectangle noir).

³ Sauf indication contraire stipulée dans un contrat annexe entre EXFO et le

client, le distributeur ou le partenaire commercial, EXFO prendra en charge les

coûts de collecte, de traitement, de récupération et de mise au rebut des

équipements électroniques en fin de vie introduits après le 13 août 2005 dans

un état membre de l’Union européenne, conformément à la

directive 2002/96/EC.

³ Excepté pour des raisons de sécurité ou d’intérêt écologique, les appareils

fabriqués par EXFO et portant la marque de la société sont généralement

conçus pour un démontage et un recyclage faciles.

Pour connaître les procédures complètes de recyclage/mise au rebut et obtenir des

coordonnées, visitez le site Web d’EXFO sur www.exfo.com/recycle.

EPM-50/ELS-50 21

Page 60

Dépannage 22

7 Dépannage

Résolution de problèmes courants

Problème Cause possible Solution

L’unité ne se met pas sous

tension.

Puissance de référence

différente de la puissance

de sortie source.

Codes d’erreur et descriptions

ER : code d’erreur affiché jusqu’à ce que vous appuyiez sur une touche.

Les piles sont

déchargées.

La puissance reçue n’est

pas comprise dans la

plage du détecteur.

Remplacez les piles.

Modifiez la puissance

de sortie source.

Code

d’erreur

LIGH

(EPM-50

uniquement)

3/11 Problème lié au logiciel intégré. Contactez EXFO.

13 Mémoire non volatile

De la lumière a été détectée

pendant l’annulation des

déviations. L’annulation n’est

pas effectuée.

7 Problème matériel. Remplacez l’appareil.

corrompue (se produit pendant

l’initialisation de l’appareil).

Description Solution

Placez le capuchon de protection

correctement sur le port du

détecteur, puis réessayez.

³ Maintenez les trois boutons

enfoncés pendant

l’initialisation afin de

réinitialiser l’appareil.

³ L’appareil doit être réétalonné.

Contactez EXFO.

Page 61

Contacter l’équipe d’assistance technique

Pour obtenir un service après-vente ou une assistance technique sur ce produit,

contactez EXFO à l’un des numéros suivants. L’équipe d’assistance technique est à

votre service du lundi au vendredi, de 8 h 30 à 19 h (heure de l’Est en Amérique du