Page 1

POWER METER/LIGHT SOURCE/

NETWORK TESTING

OPTICAL LOSS TEST SET

EPM-500/ELS-500/EOT-500

USER GUIDE

Page 2

Copyright © 2006 EXFO Electro-Optical Engineering Inc. All rights reserved. No part

of this publication may be reproduced, stored in a retrieval system or transmitted in

any form, be it electronically, mechanically, or by any other means such as

photocopying, recording or otherwise, without the prior written permission of EXFO

Electro-Optical Engineering Inc. (EXFO).

Information provided by EXFO is believed to be accurate and reliable. However, no

responsibility is assumed by EXFO for its use nor for any infringements of patents or

other rights of third parties that may result from its use. No license is granted by

implication or otherwise under any patent rights of EXFO.

EXFO’s Commerce And Government Entities (CAGE) code under the North Atlantic

Treaty Organization (NATO) is 0L8C3.

The information contained in this publication is subject to change without notice.

Trademarks

EXFO’s trademarks have been identified as such. However, the presence or

absence of such identification does not affect the legal status of any trademark.

Units of Measurement

Units of measurement in this publication conform to SI standards and practices.

Patents

EXFO’s Universal Interface is protected by US patent 6,612,750.

ii

Page 3

Contents

Certification Information .................................................................................. v

1 Introducing the EPM-500/ELS-500/EOT-500 .............................. 1

Main Features ................................................................................................... 1

Power Sources .................................................................................................. 3

Typical Applications .......................................................................................... 3

Conventions ...................................................................................................... 3

2 Safety Information ................................................................... 4

Electrical Safety Information ............................................................................. 4

Laser Safety Information (ELS-500 and EOT-500 without VFL) .......................... 4

Laser Safety Information (Units with VFL) ......................................................... 5

3 Getting Started ......................................................................... 6

Turning the Unit On and Off ............................................................................. 6

Activating Automatic Shutdown (Auto-Off) ...................................................... 6

Activating the Backlight .................................................................................... 7

Accessing and Navigating Setup Menus ........................................................... 7

Installing the EXFO Universal Interface (EUI) ..................................................... 8

Cleaning and Connecting Optical Fibers ........................................................... 9

4 Measuring Power or Loss (EPM-500 and EOT-500) ................ 10

Nulling Electrical Offsets ................................................................................. 10

Referencing Your Power Meter to a Source ..................................................... 11

Measuring Power or Loss ................................................................................ 12

Automatically Detecting Wavelength .............................................................. 14

Setting Pass/Fail Thresholds ............................................................................ 15

5 Using a Light Source (ELS-500 and EOT-500) or VFL .............. 16

Activating/Deactivating a Light Source or VFL ................................................. 16

Modulating the Source Signal ........................................................................ 17

Using Auto-Switching Mode ........................................................................... 17

Sending Source Power Value with Signal ........................................................ 18

6 Saving and Recalling Power/Loss Values ............................... 20

Setting Autonaming Scheme .......................................................................... 20

Saving, Recalling and Deleting Data ............................................................... 21

Transferring Data to a Computer .................................................................... 23

7 Maintenance ............................................................................ 24

Cleaning EUI Connectors ................................................................................ 25

Cleaning Detector Ports .................................................................................. 27

Recharging the Battery ................................................................................... 27

Replacing Battery ............................................................................................ 28

Recalibrating the Unit ..................................................................................... 28

Recycling and Disposal (Applies to European Union Only) .............................. 29

EPM-500/ELS-500/EOT-500 iii

Page 4

Contents iv

8 Troubleshooting ...................................................................... 30

Solving Common Problems ............................................................................. 30

Reverting Unit to Factory Settings .................................................................. 31

Error Codes and Descriptions .......................................................................... 31

Contacting the Technical Support Group ........................................................ 32

Finding Information on the EXFO Web Site .................................................... 33

Transportation ................................................................................................ 33

9 Warranty .................................................................................. 34

General Information ....................................................................................... 34

Liability ........................................................................................................... 34

Exclusions ....................................................................................................... 35

Certification .................................................................................................... 35

Service and Repairs ......................................................................................... 36

EXFO Service Centers Worldwide .................................................................... 37

A Technical Specifications .......................................................... 38

Page 5

Certification Information

F.C.C. Information

Electronic test equipment is exempt from Part 15 compliance (FCC) in the United

States. However, compliance verification tests are systematically performed on

most EXFO equipment.

Information

Electronic test equipment is subject to the EMC Directive in the European Union.

The EN61326 standard prescribes both emission and immunity requirements for

laboratory, measurement, and control equipment. This unit has undergone

extensive testing according to the European Union Directive and Standards.

DECLARATION OF CONFORMITY

Application of Council Directive(s): 73/23/EEC - The Low Voltage Directive

Manufacturer’s Name: EXFO ELECTRO-OPTICAL ENG.

Manufacturer’s Address: 400 Godin Avenue

Equipment Type/Environment: Industrial Scientific Equipment

Trade Name/Model No.: EPM-500 Power Meter, ELS-500 Light Source,

Standard(s) to which Conformity is Declared:

EN 60825-1: 1994/

A2: 2001

EN 61326: 1997/ A2:

2001

EN 55022: 1998/ A1:

2000

I, the undersigned, hereby declare that the equipment specified above conforms to the above Directive and Standards.

Manufacturer

Signature:

Full Name: Stephen Bull, E. Eng

Position: Vice-President Research and

Address: 400 Godin Avenue Vanier, Quebec,

Date: December 22, 2004

Safety of Laser Products-Part 1: Equipment Classification, Requirement, and

User’s guide

Electrical Equipment for Measurement, Control and Laboratory

Use - EMC Requirements

Limits and methods of measurement of radio disturbance characteristics of

information technology equipment

Development

Canada

89/336/EEC - The EMC Directive

Vanier, Québec

Canada G1M 2K2

(418) 683-0211

EOT-500 OLTS

EPM-500/ELS-500/EOT-500 v

Page 6

Introducing the EPM-500/ELS-500/EOT-500 1

1 Introducing the

EPM-500/ELS-500/EOT-500

This user guide covers the following products (unless otherwise specified,

descriptions apply to all):

³ EPM-500 Power Meter

³ ELS-500 Light Source

³ EOT-500 Optical Loss Test Set: combines both a power meter and a light source

Main Features

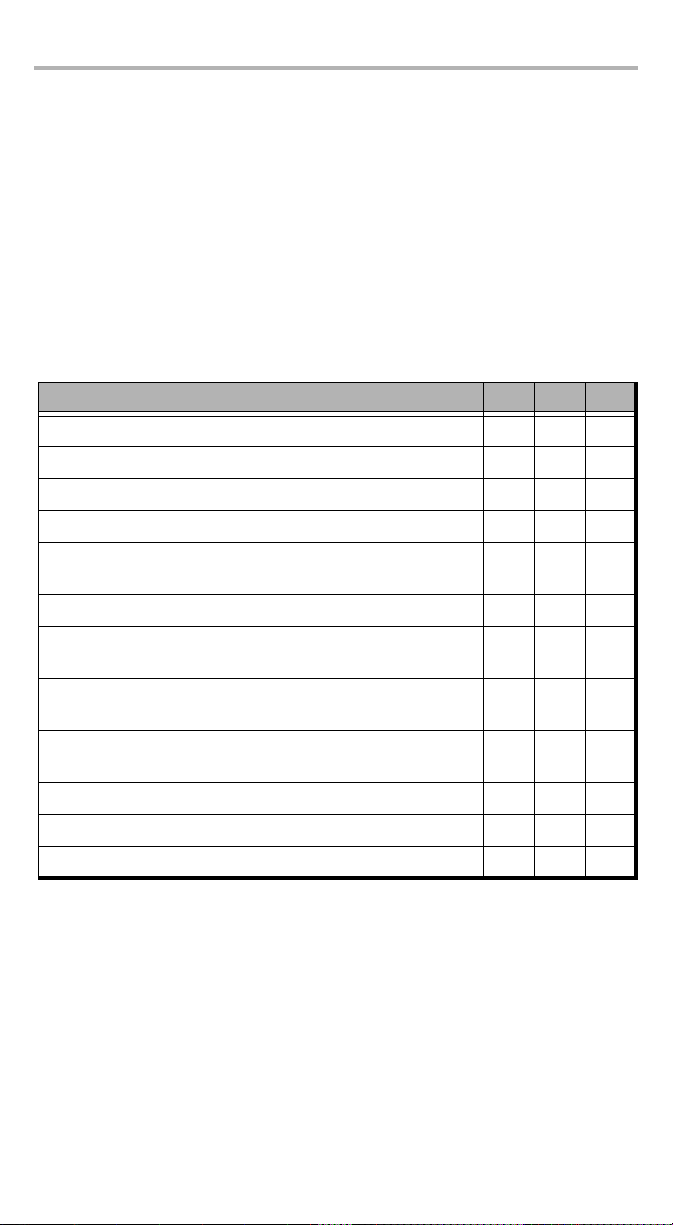

EPM ELS EOT

Ge or GeX detector with 6 calibrated wavelengths X X

Absolute power and link loss measurements X X

Automatic wavelength detection X X

No offset nulling of detectors required in normal operation X X

Multiple source configurations on a single port [EOT-500] or

on one or two ports [ELS-500]

Optional visual fault locator X X X

Transmission of editable power value with source’s signal for

automatic reference with compatible power meter

Transmission of wavelength to compatible power meter in

automatic wavelength or auto-switching mode

Modulated signal emission or detection (270 Hz, 1 kHz and

2 kHz) compatible with other EXFO units

Data storage on unit and USB transfer to a computer X X

User-configurable pass/fail thresholds with LED indicator X X

Automatic shutdown after 10 minutes of idle time (auto-off) X X X

XX

XX

XX

XXX

Page 7

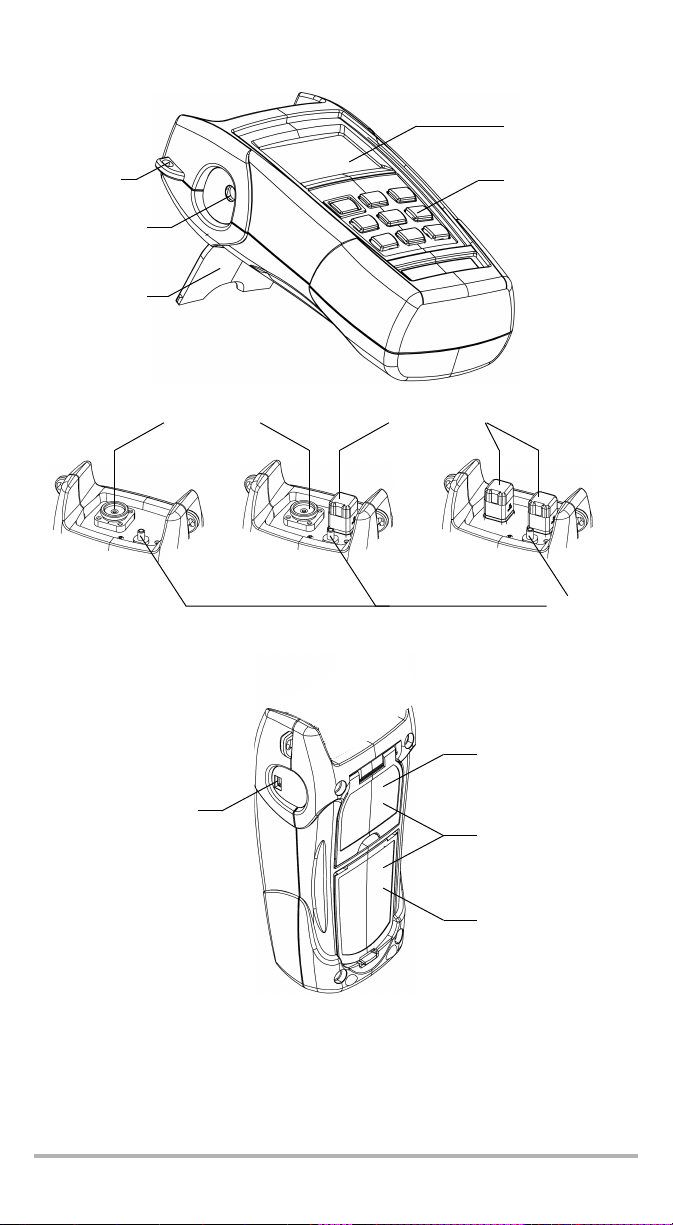

LCD display

Shoulder

strap eyelet

DC connector

Stand

Power meter

detector port

USB connector

Keypad

(EOT-500 shown)

Light source

ports

EOT-500 ELS-500EPM-500

Visual fault

locator port

Safety label

and serial number

(under the stand)

Quick reference labels

Battery compartment

EPM-500/ELS-500/EOT-500 2

Page 8

Introducing the EPM-500/ELS-500/EOT-500 3

Power Sources

The units operate with the following power sources:

³ AC adapter (connected to standard power outlet—indoor use only)

Compatible car outlet adapter available upon request.

³ Li-Ion rechargeable battery (automatically takes over if you unplug the

AC adapter)

IMPORTANT

If the battery level becomes too low, the unit turns itself off.

Typical Applications

³ Transmitter power measurements (dBm and W)

³ Fiber-link loss testing (dB)

³ Component insertion-loss testing (dB)

³ Fiber identification with 270-Hz, 1-kHz and 2-kHz signals

³ Fiber installation and maintenance applications

³ FTTx: testing of passive optical networks (PONs)

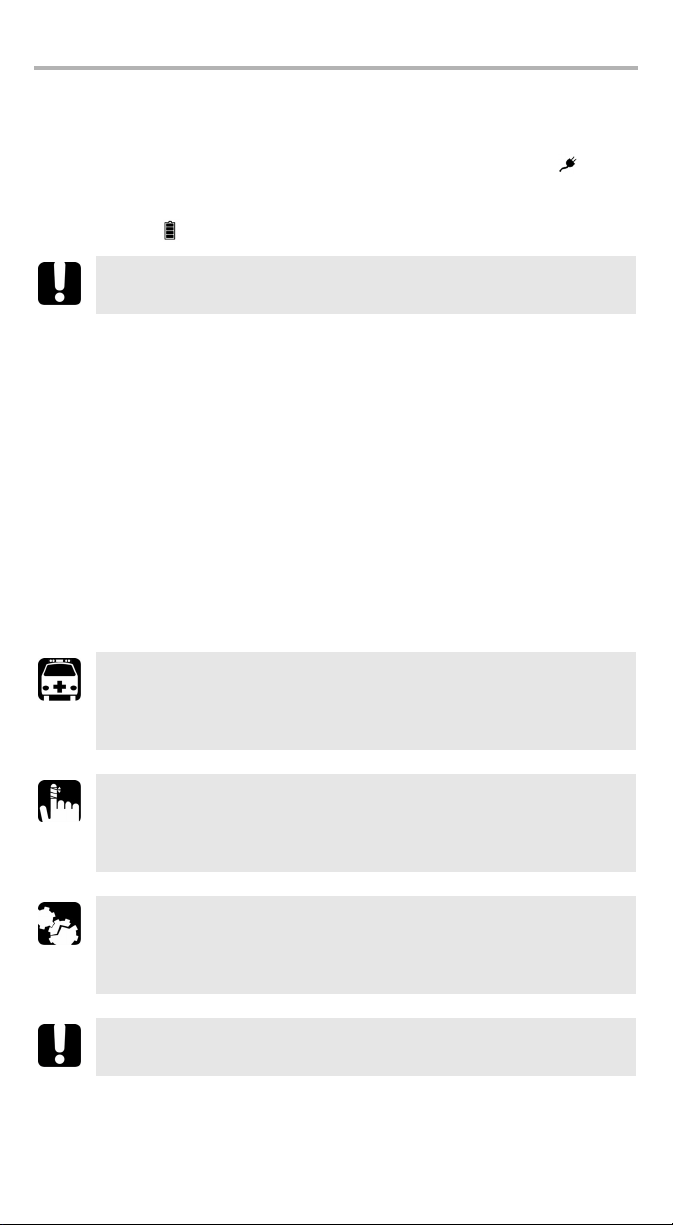

Conventions

Before using the product described in this manual, you should understand the

following conventions:

WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in component damage. Do not proceed unless you

understand and meet the required conditions.

IMPORTANT

Refers to information about this product you should not overlook.

Page 9

2 Safety Information

Electrical Safety Information

WARNING

Use the AC adapter provided with this product

indoors only.

Laser Safety Information (ELS-500 and EOT-500 without VFL)

WARNING

Do not install or terminate fibers while a laser source is active. Never

look directly into a live fiber and ensure that your eyes are protected

at all times.

WARNING

Use of controls, adjustments and procedures for operation and

maintenance other than those specified herein may result in

hazardous radiation exposure.

Your instrument is a Class 1M laser product in compliance with standards

IEC 60825-1 Amendment 2: 2001 and 21 CFR 1040.10. Invisible laser radiation may

be encountered at the output port.

The product is safe under reasonably foreseeable conditions of operation but it may

be hazardous if you use optics within a diverging or collimated beam. Do not view

directly with optical instruments.

Note: Label shown for information purposes only. It is not affixed to your

product.

Note: Units without VCSEL sources are Class 1 products.

EPM-500/ELS-500/EOT-500 4

Page 10

Safety Information 5

Laser Safety Information (Units with VFL)

Your instrument is a Class 3R laser product in compliance with standards

IEC 60825-1 Amendment 2: 2001 and 21 CFR 1040.10. It is potentially harmful in

direct intrabeam viewing.

The following label(s) indicate that the product contains a Class 3R source:

If VFL option is available

IEC 60825-1:1993+A2:2001

21 CFR 1040.10

LASER RADIATION

AVOID DIRECT EYE EXPOSURE

CLASS 3R LASER PRODUCT

λ: 650 ±10 nm

P

maximum < 5mW (into free space)

out

VFL LASER APERTURE

Affixed to back

(under the stand)

Indicated on

connector panel

Page 11

3 Getting Started

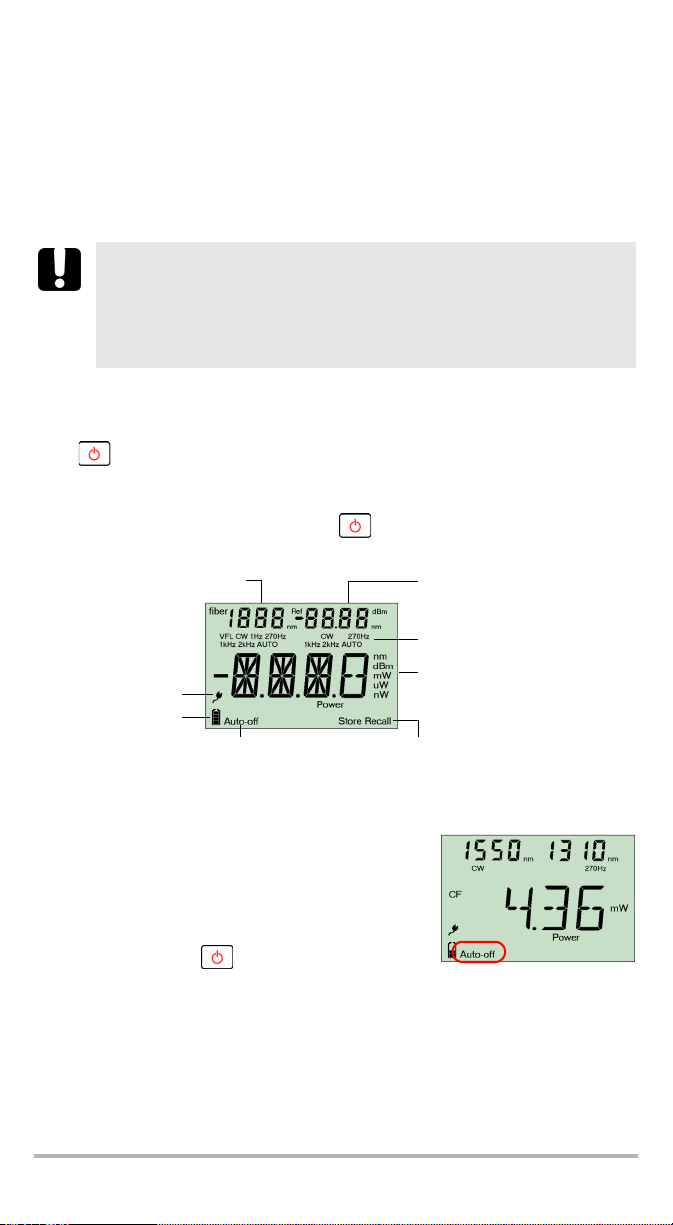

Turning the Unit On and Off

When you turn off the EPM-500 or the EOT-500, it saves the current wavelength, unit

and reference power.

IMPORTANT

If you remove batteries (and the AC adapter is unplugged), the unit

will turn off without saving the above values.

If batteries are low (and the AC adapter is unplugged), the unit will

save the above values and turn off.

Note: Offset nulling values are always returned to factory settings.

To turn on the unit:

Press . The unit displays EXFO for a few seconds. You may use it immediately

under normal conditions.

To turn off the unit:

From normal operating mode, hold down a few seconds.

Source wavelength (EOT)

Batteries in use

Fiber number

AC adapter

plugged in

(with level)

Auto-off activated

Display

Data storage or recall modes

Power meter wavelength or

reference power (EPM/EOT)

Modulation values

Measured power/loss (EPM/EOT)

Active source wavelength (ELS)

Activating Automatic Shutdown (Auto-Off)

When auto-off is activated, the unit will turn off after

10 minutes of idle time.

Auto-off is activated by default when you turn on the

unit.

To deactivate/reactivate auto-off:

When unit is on, press .

EPM-500/ELS-500/EOT-500 6

Page 12

Getting Started 7

Activating the Backlight

When operating the unit in the dark, use the backlight to make data on the display

more visible. The keypad buttons will also lighten for about 10 seconds.

Note: When backlight is activated, you must always press a button once to

lighten the keypad, then press the actual button you want.

To activate/deactivate the backlight:

From normal operating mode, press .

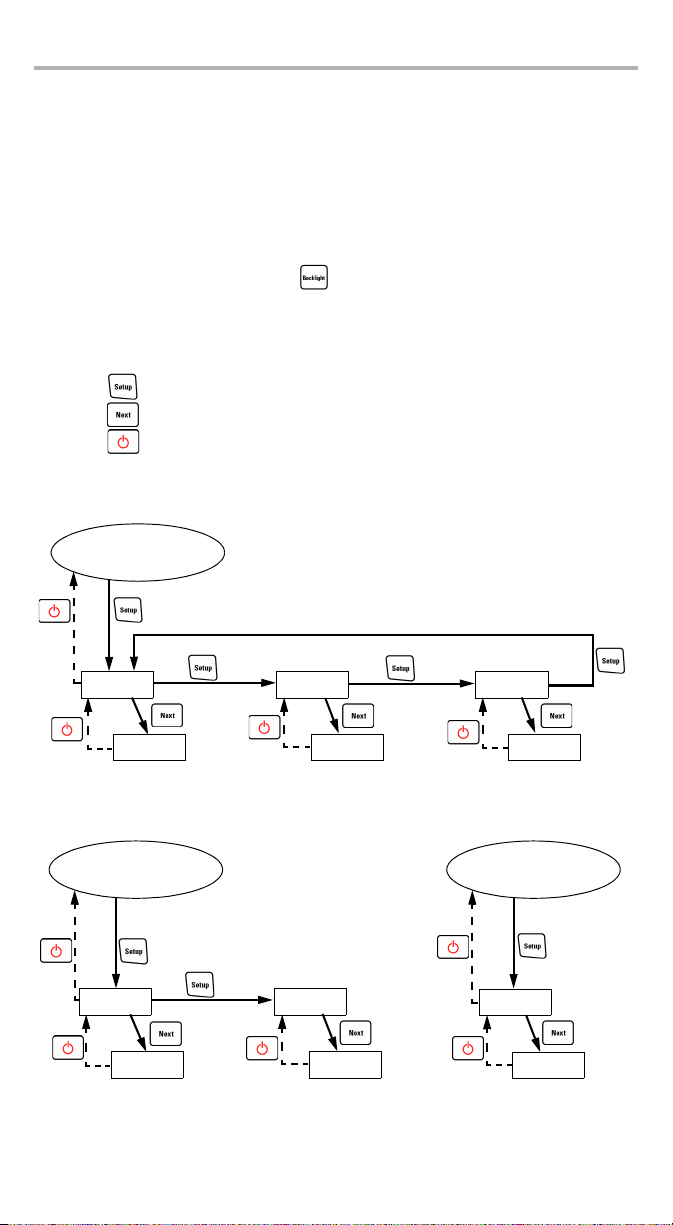

Accessing and Navigating Setup Menus

Setup menus differ in each model. You may access and navigate menus as follows:

³ Press repeatedly to switch between options in a menu level.

³ Press once to access a submenu from the main level.

³ Press to exit menus (one level at a time).

Note: Details about each menu option are given in this user guide.

EOT-500

Normal Mode

PM DATA SRC

P/F CAB 1

*

PREF

*: Default cable name

EPM-500 ELS-500

Normal Mode

PM DATA

P/F CAB 1

*: Default cable name

Normal Mode

SRC

*

PREF

Page 13

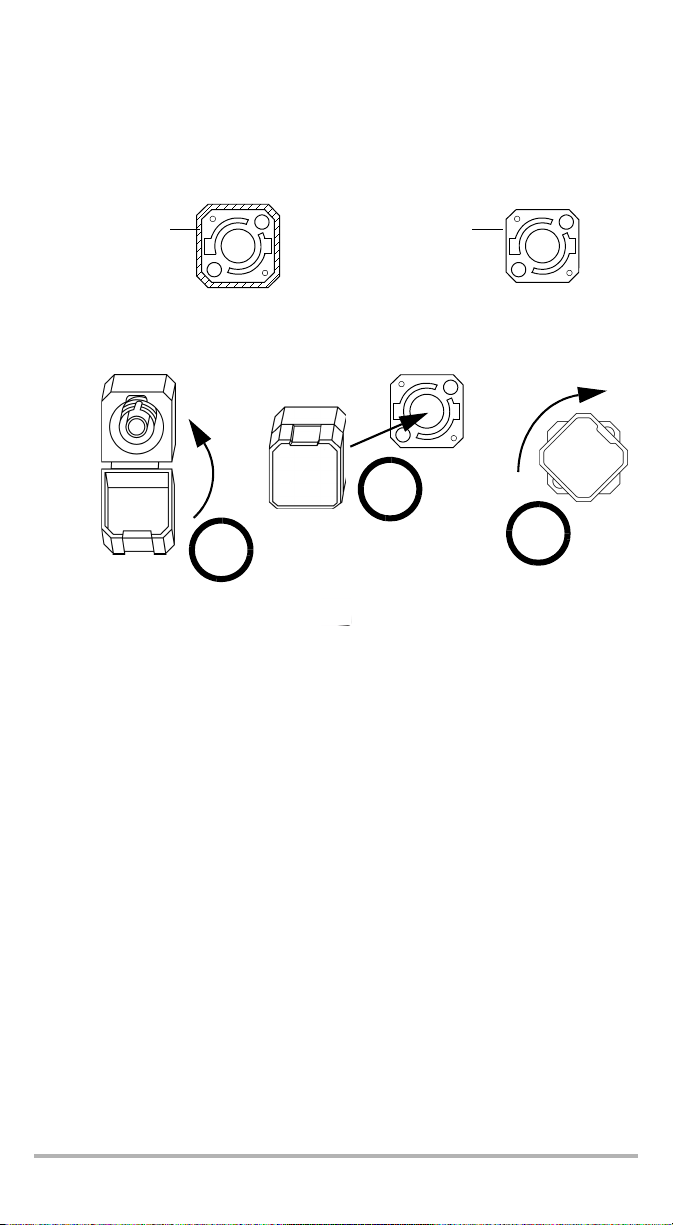

Installing the EXFO Universal Interface (EUI)

The EUI fixed baseplate is available for connectors with angled (APC) or non-angled

(UPC) polishing. A green border around the baseplate indicates that it is for

APC-type connectors, as shown below:

Green border

indicates APC

option

To install an EUI connector adapter onto the EUI baseplate:

1. Hold the EUI connector adapter so the dust cap opens downwards.

indicates UPC option

Bare metal

(or blue border)

3

4

2

2. Close the dust cap in order to hold the connector adapter more firmly.

3. Insert the connector adapter into the baseplate.

4. While pushing firmly, turn the connector adapter clockwise on the baseplate to

lock it in place.

EPM-500/ELS-500/EOT-500 8

Page 14

Getting Started 9

Cleaning and Connecting Optical Fibers

IMPORTANT

To ensure maximum power and to avoid erroneous readings:

³ Always clean fiber ends as explained below before inserting

them into the port. EXFO is not responsible for damage or errors

caused by bad fiber cleaning or handling.

³ Ensure that your patchcord has appropriate connectors. Joining

mismatched connectors will damage the ferrules.

To connect the fiber-optic cable to the port:

1. Clean the fiber ends as follows:

1a. Gently wipe the fiber end with a lint-free swab dipped in isopropyl alcohol.

1b. Use compressed air to dry completely.

1c. Visually inspect the fiber end to ensure its cleanliness.

2. Carefully align the connector and port to prevent the fiber end from touching the

outside of the port or rubbing against other surfaces. If your connector features

a key, ensure that it is fully fitted into the port’s corresponding notch.

3. Push the connector in so that the fiber-optic cable is firmly in place, thus

ensuring adequate contact.

If your connector features a screwsleeve, tighten the connector enough to firmly

maintain the fiber in place. Do not overtighten, as this will damage the fiber and

the port.

Note: If your fiber-optic cable is not properly aligned and/or connected, you

will notice heavy loss and reflection.

Page 15

4 Measuring Power or Loss

(EPM-500 and EOT-500)

Nulling Electrical Offsets

Temperature and humidity variations affect the performance of electronic circuits

and optical detectors. Nulling the electrical offsets eliminates these effects. Your unit

has been designed not to require offset nulling under normal operation, but you

should perform it whenever environmental conditions change significantly or when

measuring very low power values.

IMPORTANT

If light reaches the detector when nulling offsets, LIGH appears on

the display and the nulling is not performed. You will need to press a

key to return to the previous display.

Note: Factory-defined values will be reinstated when you turn off the unit.

To perform an offset nulling:

Hold down a few seconds. The unit displays NULL

while nulling the offsets, then returns to normal mode.

Note: Keypad is disabled during the operation.

EPM-500/ELS-500/EOT-500 10

Page 16

Measuring Power or Loss (EPM-500 and EOT-500) 11

Referencing Your Power Meter to a Source

In reference mode, your unit displays the loss created by the fiber under test only,

since a reference value is subtracted from the measured power.

Note: You must set a reference value separately for each wavelength.

Compatible sources (such as EOT-500 and ELS-500) can transmit a power value to

your power meter, avoiding the need for manual referencing.

IMPORTANT

The value sent is not the source’s actual power. It is a user-defined

value that may not take the optical link’s loss into account.

To receive the reference power value from a compatible source:

1. Connect a compatible source to your power meter

(as shown below, with or without a fiber under

test).

2. Use the source to emit the signal that contains its

power value (see Sending Source Power Value

with Signal on page 18).

³ If reference value or units change, the power

meter beeps.

³ The new reference power is displayed in the top right corner (in dBm) and

current loss reading is automatically switched to dB.

Note: When using this feature, you cannot change the power meter’s

wavelength manually. The power meter behavior is totally determined

by the source.

To reference the power meter to a source manually:

1. Using the proper adapter, connect a light source (such as ELS-500 or EOT-500)

to the detector port of your power meter.

test jumper

Bulkhead

connector

Light

source

2. Activate the source at the desired wavelength.

Reference

test jumper

Power

meter

AdapterReference

Page 17

3. Match the source and power meter wavelengths:

³ If the source emits an auto-wavelength signal

or is in auto-switching mode (see

Automatically Detecting Wavelength on

page 14 and Using Auto-Switching Mode on

page 17), the power meter automatically

matches the source wavelength.

³ Press to switch between calibrated wavelengths.

4. Hold down a few seconds. The power meter

stores the currently detected power as the new

reference power.

Reference power is displayed in the top right

corner (in dBm) and current loss reading is

automatically switched to dB.

5. Repeat the procedure for each wavelength you

want to reference (if you use auto-switching mode, the power meter

automatically references wavelengths one at a time).

Note: When using dB units, press to display the current wavelength for a

few seconds. To change this wavelength, press again while it is

displayed.

Measuring Power or Loss

Measuring absolute power or link loss is done the same way, except for the

referencing step.

To perform power or loss measurements:

1. If necessary, perform an offset nulling (see Nulling Electrical Offsets on page 10).

2. Check and clean your fibers appropriately for optimum performance

(see Cleaning and Connecting Optical Fibers on page 9).

3. For loss measurements, reference your power meter to a light source

(see Referencing Your Power Meter to a Source on page 11), then deactivate the

light source.

EPM-500/ELS-500/EOT-500 12

Page 18

Measuring Power or Loss (EPM-500 and EOT-500) 13

4. Using the proper adapter and test jumpers, connect a fiber under test to a light

source (such as ELS-500 or EOT-500) and to the detector port of your unit.

Note: If you have referenced your power meter to a source, simply connect a

fiber under test to the test jumpers used for referencing.

Te st

jumper

Light

source

Bulkhead

connector

jumper

Bulkhead

connector

Fiber under test

Power

meter

Adapter

Te st

5. Activate the source at the desired wavelength.

6. Match the source and power meter wavelengths:

³ If the source emits an auto-wavelength signal

or is in auto-switching mode (see

Automatically Detecting Wavelength on

page 14 and see Using Auto-Switching Mode

on page 17), the power meter automatically

matches the source wavelength.

OR

³ Press to switch between calibrated wavelengths.

Modulation detected

Actual power or loss

of fiber under test

When power or loss is outside power limits

(see Technical Specifications on page 38)

When the unit detects a modulated signal, it beeps and displays the modulation

value and average measured power or loss (see left illustration above). You may

notice a slightly unstable last digit.

7. If necessary, change the displayed units by pressing .

8. Repeat the procedure for other wavelengths.

Page 19

Automatically Detecting Wavelength

Compatible sources (such as EOT-500 and ELS-500) can transmit their wavelength

value through the fiber, avoiding the need to manually match the source and power

meter wavelengths.

Note: When you receive an auto-wavelength signal or when the source is in

auto-switching mode, you cannot manually change the power meter

wavelength. The power meter behavior is totally determined by the

source.

To receive the auto-wavelength signal or detect the source's

auto-switching mode:

1. Connect a compatible source to your power meter.

2. Activate the source in Auto mode (EOT-500 and

ELS-500: see Modulating the Source Signal on

page 17) or in auto-switching mode (see Using

Auto-Switching Mode on page 17).

Your power meter automatically matches the

source wavelength. If the wavelengths differ, it also

beeps and returns you to normal operating mode.

EPM-500/ELS-500/EOT-500 14

Page 20

Measuring Power or Loss (EPM-500 and EOT-500) 15

Setting Pass/Fail Thresholds

You can define thresholds to specify acceptable power (dBm) or loss (dB) values for

each wavelength. Thresholds are often supplied by system manufacturers and

depend on the system deployed.

When a threshold is activated, the PASS/FAIL LED

is turned on. If it is green, the threshold

succeeded, if the PASS/FAIL LED is red, the

threshold failed.

To set pass/fail thresholds:

1. From normal operating mode, press

repeatedly until you reach PM.

2. Press to access the first submenu, then press

3. Press to switch between power (dBm) and

4. Press to switch between available wavelengths. An asterisk (*) appears

5. Press to activate/deactivate the displayed threshold. The PASS/FAIL LED

6. Edit the pass/fail threshold as follows:

7. Press twice to exit setup menus.

repeatedly until you reach the P/F menu.

loss (dB) values.

beside activated thresholds. If no threshold is set for a wavelength, the unit

indicates “----”.

will lighten (green or red) when you return to normal mode.

6a. Hold down a few seconds. The first digit of the threshold blinks.

6b. Clear all digits by holding down a few seconds.

AND/OR

Select a digit to change by holding until it blinks, then increase its

value by pressing (it returns to 0 after 9). After the last digit, all digits

blink: you may add/remove the “–” sign by pressing .

6c. While a digit blinks, hold down a few seconds to save the modified

value (it remains in memory even when you turn off the unit) or press

to return to the previous value without saving.

Page 21

5 Using a Light Source

(ELS-500 and EOT-500) or

VFL

The ELS-500 may contain up to three sources (one-port models) or up to four

sources (two-port models). The EOT-500 may contain up to three sources.

Note: The VFL option may also be present on the EPM-500.

Activating/Deactivating a Light Source or VFL

Only one source may be active at a time. When no source is active, the unit displays

OFF.

Source wavelength (and VFL indicator)

and modulation (when active)

EOT-500 ELS-500

To activate a light source (or VFL) and change the wavelength:

Press to activate each available source in turn, including the VFL. The unit

displays the wavelength and modulation.

To deactivate the light source:

Press until you get past the last source.

Active source

port

EPM-500/ELS-500/EOT-500 16

Page 22

Using a Light Source (ELS-500 and EOT-500) or VFL 17

Modulating the Source Signal

When you activate the first source (after turning on the unit), the signal is always

CW (unmodulated). When you switch sources, the modulation remains the same

(VFL remembers its own modulation). Modulation is indicated in the top left

(port #1) or top right (port #2) corner.

Available modulation values are: CW, Auto, auto-switching mode, 270 Hz, 1 kHz and

2kHz (VFL: CW and 1Hz only).

Note: Auto is a modulated signal detected by compatible units (see

Automatically Detecting Wavelength on page 14). It provides greater

autonomy than CW, but covers a reduced power range.

Note: Auto-switching mode is a special signal detected by compatible units

To change the signal modulation:

1. Activate the source.

2. Press to switch between available

(see Using Auto-Switching Mode on page 17).

modulations.

Using Auto-Switching Mode

In auto-switching mode, your source automatically

switches from one wavelength to another. The power

meter connected to this source displays the power

value for each wavelength one at a time. The

wavelength value appearing on the display changes

every two seconds.

To activate auto-switching mode:

1. Press to activate the source.

2. Press to switch between available modulations until the Auto indicator

blinks on your display.

Page 23

Sending Source Power Value with Signal

Your source can transmit a user-defined power value to compatible power meters

(such as EOT-500 and EPM-500) through the fiber. If the reference source is far from

the power meter, you can connect your source to the power meter to send the

reference value. With this feature you can also correct for power variations.

Note: If you connect a fiber between EOT-500’s source and detector ports, the

unit can use the actual source output power as reference power.

Note: For details about how compatible power meters receive this power

value, see Referencing Your Power Meter to a Source on page 11.

IMPORTANT

The value sent is not (and will not affect) the source’s actual power.

It is a user-defined value that may not take the optical link’s loss into

account.

To define the source power value to use as reference:

1. From normal operating mode, press repeatedly until you reach SRC.

2. Press to access the first submenu, then press repeatedly until you

reach the PREF menu.

3. Press to switch between available source wavelengths and select one. The

unit displays the currently defined power value for this wavelength.

4. Edit the power value as follows:

4a. Hold down a few seconds. The first digit of the power value blinks.

4b. Revert all digits to 0 by holding down a few seconds.

AND/OR

Select a digit to change by pressing until it blinks, then increase its

value by pressing (it returns to 0 after 9). After the last digit, all digits

blink: you may add/remove the “–” sign by pressing .

4c. While a digit blinks, hold down a few seconds to save the modified

value (it remains in memory even when you turn off the unit) or press

to return to the previous value without saving.

5. Press twice to exit setup menus.

EPM-500/ELS-500/EOT-500 18

Page 24

Using a Light Source (ELS-500 and EOT-500) or VFL 19

To use the actual source output power as reference (EOT-500 only):

1. Connect a fiber between the source and power meter of same unit.

2. Activate the source at the desired wavelength.

3. Match the source and power meter wavelengths:

³ If the source emits an auto-wavelength signal

or is in auto-switching mode (see

Automatically Detecting Wavelength on

page 14 and Using Auto-Switching Mode on

page 17), the power meter automatically

matches the source wavelength.

OR

³ Press to switch between calibrated wavelengths.

4. From normal operating mode, hold down and . The unit displays PREF

for a few seconds while saving the value, then returns to normal mode.

To send the source power value:

1. Activate the source.

2. Change the modulation signal to AUTO or auto-switching.

If you use auto-switching mode, the power value of each wavelength will

automatically be sent.

3. Hold down and to send the power value with an auto-wavelength

signal. The unit displays Send for a few seconds, then returns to normal mode.

Page 25

6 Saving and Recalling

Power/Loss Values

You can save 1000 power/loss values in your unit, along with references. You will

save and recall this data according to cable names and fiber numbers. To free up

memory, you can transfer saved data to a computer or simply delete all.

Setting Autonaming Scheme

When saving data, the unit suggests fiber IDs based on autonaming settings. After

saving a value, the unit prepares the next fiber ID according to the selected

increment (0, 1 or 2).

To define the cable name and the starting fiber ID and increment value:

1. From normal operating mode, press

repeatedly until you reach DATA.

2. Press to access CAB1 or the last cable name

edited.

3. Hold down until the first character of the cable

name blinks.

4. Select a character to change by pressing until it blinks, then increase its

value by pressing (it returns to 0 after Z).

5. While a digit blinks, hold down a few seconds to save the modified value

(it remains in memory even when you turn off the unit) or press to return

to the previous value without saving.

6. Press twice to exit setup menus.

EPM-500/ELS-500/EOT-500 20

Page 26

Saving and Recalling Power/Loss Values 21

Saving, Recalling and Deleting Data

IMPORTANT

³ You cannot recover deleted data. Ensure that you transfer your

data to a computer if you intend to use it later.

³ Deleting a single value does not free memory. To free memory,

you must delete all data at once.

To save a power/loss value:

1. If you want to view or change the fiber ID before

saving:

1a. From normal operating mode, press or

to view the fiber ID that will be used next.

1b. Change the fiber ID by using and to

move forward or backward in the list.

2. Hold down a few seconds to save the

measured value under the selected fiber ID.

To recall saved data:

1. From normal operating mode, hold down a

few seconds. The Recall indicator is displayed

with the cable name, then the last saved value and

its fiber ID.

2. When fiber ID is displayed, hold down a few

seconds to return to the cable name list. Select the

cable in which you want to recall saved data by

using and to move forward or backward. The last saved value in the

selected cable and its fiber ID will be displayed after 3 seconds.

3. View values you want by using and to move forward or backward in

saved data. You can also change the units by pressing .

4. Press to return to normal mode.

To delete a single saved value from the unit:

1. From normal operating mode, hold down a

few seconds. The Recall indicator is displayed

with the cable name, then the last saved value and

its fiber ID.

2. When fiber ID is displayed, hold down a few

seconds to return to the cable name list. Select the

cable in which you want to recall saved data by

using and to move forward or backward. The last saved value in the

selected cable and its fiber ID will be displayed after 3 seconds.

3. Select the value to delete by using and to move forward or backward

in saved data.

4. Hold down a few seconds. The unit displays “dEL”, then displays another

saved data.

5. Press to return to normal mode.

Page 27

To delete a cable name:

1. From normal operating mode, hold down a

few seconds. The Recall indicator is displayed

with the last cable name, then the last saved value

and its fiber ID.

2. When fiber ID is displayed, hold down a few

seconds to return to the cable name list, then,

select the cable you want to delete by using

and to move forward or backward.

3. Hold down a few seconds. The unit displays “dEL”, then displays another

cable name.

4. Press to return to normal mode.

To delete all saved data from the unit:

1. From normal operating mode, hold down a

few seconds.The Recall indicator is displayed with

the last cable name, then the last saved value and

its fiber ID.

2. When fiber ID is displayed, hold down both

and a few seconds. The unit displays “dEL”

and “ALL”, then automatically returns to normal

mode.

EPM-500/ELS-500/EOT-500 22

Page 28

Saving and Recalling Power/Loss Values 23

Transferring Data to a Computer

Using an appropriate USB cable and the Handheld Data Transfer software, you can

transfer saved data from your handheld unit to a computer. This way, you can

increase storage capacity, perform better analyses on your data and create reports.

IMPORTANT

Transferred data is not automatically deleted from your unit.

To transfer data to a computer:

1. Using a USB cable, connect your unit to an available USB port of the computer.

USB connector

USB port

2. Turn on both the computer and your handheld unit. Connect your unit to a

power outlet to ensure that your unit will remain on during the transfer.

3. On the computer, launch the Handheld Data Transfer application and start the

operation.

The unit displays “REM” and temporarily deactivates the keyboard and auto-off.

Note: For details about setting up the software and transferring data, refer to

the Handheld Data Transfer online help.

Page 29

7 Maintenance

This product contains no user-serviceable parts. However, it contains sensitive

electronic and optical components, and should be handled carefully and stored in

its carrying case when not in use.

To help ensure long, trouble-free operation:

³ Always clean fiber-optic connectors before using them.

³ Keep the unit free of dust.

³ Clean the unit casing and front panel with a cloth slightly dampened with water.

³ Store unit at room temperature in a clean and dry area. Keep the unit out of

direct sunlight.

³ Avoid high humidity or significant temperature fluctuations.

³ Avoid unnecessary shocks and vibrations.

³ If any liquids are spilled on or into the unit, turn off the power immediately and

let the unit dry completely.

WARNING

Use of controls, adjustments and procedures for operation and

maintenance other than those specified herein may result in

hazardous radiation exposure.

EPM-500/ELS-500/EOT-500 24

Page 30

Maintenance 25

Cleaning EUI Connectors

Regular cleaning of EUI connectors will help maintain optimum performance. There

is no need to disassemble the unit.

IMPORTANT

If any damage occurs to internal connectors, the module casing will

have to be opened and a new calibration will be required.

To clean EUI connectors:

1. Remove the EUI from the instrument to expose the connector baseplate and

ferrule.

Tu rn

Push

2. Moisten a 2.5 mm cleaning tip provided by EXFO with one drop of isopropyl

alcohol (alcohol may leave traces if used abundantly).

3. Slowly insert the cleaning tip into the EUI adapter until it comes out on the other

side (a slow clockwise rotating movement may help).

Pull

3

4

5

4. Gently turn the cleaning tip one full turn, then continue to turn as you withdraw

it.

5. Repeat steps 3 to 4 with a dry cleaning tip.

Note: Make sure you don’t touch the soft end of the cleaning tip.

6. Clean the ferrule in the connector port as follows:

6a. Deposit one drop of isopropyl alcohol on a lint-free wiping cloth.

Page 31

IMPORTANT

Since isopropyl alcohol is not absolutely pure, it may leave residues

if used abundantly or left to evaporate (about 10 seconds).

Avoid contact between the tip of the bottle and the wiping cloth,

dry the surface quickly, and use a bottle that distributes only a drop

of alcohol at a time.

6b. Gently wipe the connector and ferrule.

6c. With a dry lint-free wiping cloth, gently wipe the same surfaces to ensure

that the connector and ferrule are perfectly dry.

6d. Verify connector surface with a portable fiber-optic microscope

(e.g., EXFO’s FOMS) or fiber inspection probe (e.g., EXFO’s FIP).

WARNING

Verifying the surface of the connector WHILE THE UNIT IS ACTIVE

WILL result in permanent eye damage.

7. Put the EUI back onto the instrument (push and turn clockwise).

8. Throw out cleaning tips and wiping cloths after one use.

EPM-500/ELS-500/EOT-500 26

Page 32

Maintenance 27

Cleaning Detector Ports

Regular cleaning of detectors will help maintain measurement accuracy.

IMPORTANT

Always cover detectors with protective caps when unit is not in use.

To clean detector ports:

1. Remove the protective cap and adapter (FOA) from the detector.

2. If the detector is dusty, blow dry with compressed air.

3. Being careful not to touch the soft end of the swab, moisten a supplied cleaning

tip with only one drop of isopropyl alcohol.

IMPORTANT

Alcohol may leave traces if used abundantly. Do not use bottles that

distribute too much alcohol at a time.

4. While applying light pressure (to avoid breaking the detector window), gently

rotate the cleaning tip on the detector window.

5. Repeat step 4 with a dr y cleaning tip or blow dry with compressed air.

6. Discard the cleaning tips after one use.

Recharging the Battery

The Li-Ion battery will last about 70 hours (power meter) or 50 hours (source in Auto

mode) in normal operation. The charge status is shown on the unit display (lower

left corner).

IMPORTANT

³ The battery is not charged at the factory. Fully charge it (about 4

hours) before using it for the first time.

³ The battery functions and charges properly between 0

o

45

C (32oF and 113oF). It will not charge if the temperature is

below -10

³ Never store battery at temperatures above 60

³ Charge only with specified charger.

To recharge the Li-Ion battery:

Connect the unit to a power outlet (or car outlet) using the AC adapter/charger. The

charge cycle will start and end automatically.

Note: While charging, the battery indicator animates continuously. It does not

reflect the actual charge status until charging is complete.

o

C (14oF) or above 45oC (113oF).

o

o

C (140oF).

C and

Page 33

Replacing Battery

Your unit requires one Li-Ion battery.

To replace the battery:

1. Turn off the unit (if the AC adapter is plugged in, you may replace the battery

while unit is on).

2. Open the battery compartment door located at the back of the unit.

3. Replace the battery, respecting the polarity.

4. Close the battery compartment door.

WARNING

Do not throw batteries into fire or water and do not short-circuit

the batteries’ electrical contacts. Do not disassemble.

Recalibrating the Unit

Manufacturing and service center calibrations are based on the ISO/IEC 17025

Standard, which states that calibration documents must not contain a

recommended calibration interval, unless this has been previously agreed upon

with the customer.

Validity of specifications depends on operating conditions. For example, the

calibration validity period can be longer or shorter depending on the intensity of use,

environmental conditions and unit maintenance. You should determine the

adequate calibration interval for your unit according to your accuracy requirements.

Under normal use, EXFO recommends calibrating your unit every year.

Note: The FlexCare warranty program includes Calibration/Verification

packages (see Service and Repairs on page 38).

To view the last calibration date (EOT-500 and EPM-500 only):

1. From normal operating mode, hold down and

2. Press until you reach the calibration date (and

3. Press to return to normal mode.

EPM-500/ELS-500/EOT-500 28

for a few seconds. The unit displays the first

embedded software version.

version) of the power meter.

Page 34

Maintenance 29

Recycling and Disposal (Applies to European Union Only)

Recycle or dispose of your product (including electric and electronic

accessories) properly, in accordance with local regulations. Do not

dispose of it in ordinary garbage receptacles.

This equipment was sold after August 13, 2005 (as identified by the

black rectangle).

³ Unless otherwise noted in a separate agreement between EXFO and a

customer, distributor or commercial partner, EXFO will cover costs related to

the collection, treatment, recovery and disposal of end-of-lifecycle waste

generated by electronic equipment introduced after August 13, 2005 to an

European Union member state with legislation regarding Directive 2002/96/EC.

³ Except for reasons of safety or environmental benefit, equipment manufactured

by EXFO, under its brand name, is generally designed to facilitate dismantling

and reclamation.

For complete recycling/disposal procedures and contact information, visit the EXFO

Web s ite a t www.exfo.com/recycle.

Page 35

8 Troubleshooting

Solving Common Problems

Problem Possible Cause Solution

The unit does not turn on.

The unit takes very long to turn

on.

Battery does not charge as

expected.

Unable to change power meter

wavelength.

³ You did not press

long enough.

³ AC adapter/charger

not connected.

³ Main battery

discharged.

³ Weather too cold.

Too many values saved in

memory.

³ Temperature too

high.

³ Battery incorrectly

connected.

³ Incorrect charger

used.

³ Unit receiving Auto

(or REF) signal from

source.

Press for 2

seconds.

Connect AC

adapter/charger and

charge battery.

Delete all data from the

unit.

Ensure temperature is

within specifications.

Ensure battery is

connected properly.

Use the required

charger.

Change source mode

(see Modulating the

Source Signal on

page 17), then retry.

³ Only one wavelength

in list.

Unable to change power meter

dB unit or reference power.

OR

Changed unit or reference

value are replaced by other

values after a while.

Many beeps, unstable optical

power and blinking Auto (or

modulation) indicator.

EPM-500/ELS-500/EOT-500 30

Unit receiving REF signal

from source. See Sending

Source Power Value with

Signal on page 18.

Power too low to

recognize Auto mode

(or modulation).

Add wavelengths.

Wait a few seconds

until power value is

received, then retry.

Increase source power

or switch source to

CW.

Page 36

Troubleshooting 31

Problem Possible Cause Solution

Reference power different than

source output power.

Unit displays FULL even after

you deleted a few values.

Going from the first value to the

last value in recalled data is

very slow.

Received power outside

detector’s range.

You must d e l e t e all

values from the unit to

free memory.

Too many values saved in

memory.

Change source output

power.

Delete all values as

explained in Saving,

Recalling and Deleting

Data on page 21.

Delete all data from the

unit.

Reverting Unit to Factory Settings

You can revert most parameters on your unit to their factory state. When you

perform this operation, you will lose all customized parameters.

To revert unit to factory settings:

1. Turn off your unit.

2. While holding down , press . When your unit beeps, release .

Error Codes and Descriptions

³ ER: error code displayed until you press a key.

³ WR: warning code displayed for 3 seconds, then unit returns to normal.

Error

Code

LIGH Light detected while nulling offsets.

Nulling is not performed.

FULL Storage memory full. Delete data.

EMPt Storage memory empty:

³ You p r e s s e d Recall but no data

³ Last saved data deleted.

³ All data deleted.

Calibration errors. Contact EXFO.

29/30/

34/36/

56/57

18/52 Incompatible wavelengths or

power too low in PREF on EOT-500.

Description Solution

Correctly place protective cap on

detector port, then retry.

Add data.

was saved.

Match source and power meter

wavelengths or increase source

power.

Page 37

Contacting the Technical Support Group

To obtain after-sales service or technical support for this product, contact EXFO at

one of the following numbers. The Technical Support Group is available to take your

calls from Monday to Friday, 7:30 a.m. to 8:00 p.m. (Eastern Time in North America).

Technical Support Group

400 Godin Avenue

Vanier (Quebec) G1M 2K2

CANADA

To accelerate the process, please have information such as the name and the serial

number (see the product identification label—an example is shown below), as well

as a description of your problem, close at hand.

1 866 683-0155 (USA and Canada)

Tel.: 1 418 683-5498

Fax: 1 418 683-9224

support@exfo.com

P/N

**************** A

542392-3D

S/N

Made in Canada QST442B

January 2003

EPM-50XX-XX

Detector

type

Ver.

Mfg.

date

465 Godin Avenue

Vanier (Quebec) G1M 3G7 CANADA

VFL option

ELS-500-XX-XX-XX-XX

Source

ports

Source

connector

EOT-50XX-XX-XX-XX

You may also be requested to provide the embedded software’s version numbers.

To display the embedded software version:

1. From normal operating mode, hold down and

for a few seconds. The unit displays the first

software version.

2. Press to switch between the software and

hardware versions.

3. Press to return to normal mode.

EPM-500/ELS-500/EOT-500 32

Page 38

Troubleshooting 33

Finding Information on the EXFO Web Site

The EXFO Web site provides answers to frequently asked questions (FAQs)

regarding the use of your Power Meter/Light Source/Optical Loss Test Set.

To access FAQs:

1. Ty pe http://www.exfo.com in your Internet browser.

2. Click on the Support tab.

3. Click on FAQs and follow the on-screen instructions. You will be given a list of

questions pertaining to your subject.

The EXFO Web site also provides the product’s most recent technical specifications.

Transportation

Maintain a temperature range within specifications when transporting the unit.

Transportation damage can occur from improper handling. The following steps are

recommended to minimize the possibility of damage:

³ Pack the unit in its original packing material when shipping.

³ Avoid high humidity or large temperature fluctuations.

³ Keep the unit out of direct sunlight.

³ Avoid unnecessary shock and vibration.

Page 39

9 Warranty

General Information

EXFO Electro-Optical Engineering Inc. (EXFO) warrants this equipment against

defects in material and workmanship for a period of one year from the date of

original shipment. EXFO also warrants that this equipment will meet applicable

specifications under normal use.

During the warranty period, EXFO will, at its discretion, repair, replace, or issue

credit for any defective product, as well as verify and adjust the product free of

charge should the equipment need to be repaired or if the original calibration is

erroneous. If the equipment is sent back for verification of calibration during the

warranty period and found to meet all published specifications, EXFO will charge

standard calibration fees.

IMPORTANT

The warranty can become null and void if:

³ unit has been tampered with, repaired, or worked upon by

unauthorized individuals or non-EXFO personnel.

³ warranty sticker has been removed.

³ case screws, other than those specified in this guide, have been

removed.

³ case has been opened, other than as explained in this guide.

³ unit serial number has been altered, erased, or removed.

³ unit has been misused, neglected, or damaged by accident.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES EXPRESSED, IMPLIED,

OR STATUTORY, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. IN NO EVENT

SHALL EXFO BE LIABLE FOR SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES.

Liability

EXFO shall not be liable for damages resulting from the use of the product, nor shall

be responsible for any failure in the performance of other items to which the

product is connected or the operation of any system of which the product may be a

part.

EXFO shall not be liable for damages resulting from improper usage or unauthorized

modification of the product, its accompanying accessories and software.

EPM-500/ELS-500/EOT-500 34

Page 40

Warranty 35

Exclusions

EXFO reserves the right to make changes in the design or construction of any of its

products at any time without incurring obligation to make any changes whatsoever

on units purchased. Accessories, including but not limited to fuses, pilot lamps,

batteries and universal interfaces (EUI) used with EXFO products are not covered by

this warranty.

This warranty excludes failure resulting from: improper use or installation, normal

wear and tear, accident, abuse, neglect, fire, water, lightning or other acts of nature,

causes external to the product or other factors beyond EXFO’s control.

IMPORTANT

EXFO will charge a fee for replacing optical connectors that were

damaged due to misuse or bad cleaning.

Certification

EXFO certifies that this equipment met its published specifications at the time of

shipment from the factory.

Page 41

Service and Repairs

EXFO commits to providing product service and repair for five years following the

date of purchase.

To send any equipment for service or repair:

1. Call one of EXFO’s authorized service centers (see EXFO Service Centers

Worl dw id e on page 37). Support personnel will determine if the equipment

requires service, repair, or calibration.

2. If equipment must be returned to EXFO or an authorized service center, support

personnel will issue a Return Merchandise Authorization (RMA) number and

provide an address for return.

3. If possible, back up your data before sending the unit for repair.

4. Pack the equipment in its original shipping material. Be sure to include a

statement or report fully detailing the defect and the conditions under which it

was observed.

5. Return the equipment, prepaid, to the address given to you by support

personnel. Be sure to write the RMA number on the shipping slip. EXFO will

refuse and return any package that does not bear an RMA number.

Note: A test setup fee will apply to any returned unit that, after test, is found to

meet the applicable specifications.

After repair, the equipment will be returned with a repair report. If the equipment is

not under warranty, you will be invoiced for the cost appearing on this report. EXFO

will pay return-to-customer shipping costs for equipment under warranty. Shipping

insurance is at your expense.

Routine recalibration is not included in any of the warranty plans. Since

calibrations/verifications are not covered by the basic or extended warranties, you

may elect to purchase FlexCare Calibration/Verification Packages for a definite

period of time. Contact an authorized service center (see EXFO Service Centers

Worl dw id e on page 37).

EPM-500/ELS-500/EOT-500 36

Page 42

Warranty 37

EXFO Service Centers Worldwide

If your product requires servicing, contact your nearest authorized service center.

EXFO Headquarters Service Center

400 Godin Avenue

Vanier (Quebec) G1M 2K2

CANADA

1 866 683-0155 (USA and Canada)

Tel.: 1 418 683-5498

Fax: 1 418 683-9224

quebec.service@exfo.com

EXFO Europe Service Center

Le Dynasteur

10/12, rue Andras Beck

92366 Meudon la Forêt Cedex

FRANCE

EXFO China Service Center/

Beijing OSIC

Beijing New Century Hotel

Office Tower, Room 1754-1755

No. 6 Southern Capital Gym Road

Beijing 100044

P. R . C H I N A

Tel.: +33.1.40.83.85.85

Fax: +33.1.40.83.04.42

europe.service@exfo.com

Tel.: +86 (10) 6849 2738

Fax: +86 (10) 6849 2662

beijing.service@exfo.com

Page 43

A Technical Specifications

Model EPM-502 EPM-502X

Detector

4

Ge GeX

Power range5(dBm) 10 to −70 26 to −55

Wavelength range (nm) 800 to 1650 800 to 1650

Number of calibrated wavelengths 6 6

Power uncertainty

6

± 5 % ± 0.1 nW ± 5 % ± 3 nW

Automatic offset nulling7Yes Ye s

Display units dB, dBm, W dB, dBm, W

Tone detection 270 Hz, 1 kHz and 2 kHz 270 Hz, 1 kHz and 2 kHz

Automatic wavelength recognition8Yes Ye s

Warm-up period9(min) 0 0

Data storage (items) up to 1000 up to 1000

Battery life (hours) (typical) 70 70

Warranty and recommended

recalibration interval (years) 1 1

VFL Option Specifications

10

Emitter type Laser

Wavelength (nm) 650

Output power (dBm) 3

Notes

1. Guaranteed unless otherwise specified.

2. All specifications valid at 23 °C ± 1 °C, with an FC connector.

3. rms for FP lasers and VCSEL; −3 dB width for LEDs (typical values for LEDs and VCS EL).

4. All specifications valid at 1550 nm and 23 °C ± 1 °C, with an FC connector.

5. In CW mode; sensitivity defined as 6 x rms noise level.

6. For calibration wavelengths. Valid up to 20 dBm for EOT/EPM-5 02X.

7. For power > −40 dBm for EOT/EPM-502, and > −25 dBm for EOT/EPM-502X.

8. At 850 nm, 1300 nm, 1310 nm, 1490 nm, 1550 nm and 1625 nm; for power > −50 dBm

for EOT-502/EPM-502, and > −40 dBm (typical) for EOT/EPM-502X.

9. For a variation of ≤ 0.06 dB at power levels ≥−40 dBm for EOT/EP M-502 and ≥−25 dBm

for EOT/EPM-502X.

10. Typical values for 62.5/125 μm fiber.

Model

2

12D 23BL 235BL 01-VCL

Central wavelength (nm) 850 ± 25 1310 ± 20 1310 ± 20 850 ± 20

1300 +50/−10 1550 ± 20 1490 ± 10

1550 ± 20

Spectral width3(nm) 50/135 ≤ 5 ≤ 5 ≤ 1

Output power (dBm) ≥−18/≥−18 (62.5/125 μm) ≥ 1/≥ 1 ≥ 1/≥−4.5/≥−3 ≥−3 (50/125 μm)

Automatic wavelength recognition Yes Yes Yes Yes

Tone generation 270 Hz, 1 kHz, 2 kHz 270 Hz, 1 kHz, 2 kHz 270 Hz, 1 kHz, 2 kHz 270 Hz, 1 kHz, 2 kHz

Battery life (hours) (typical in Auto mode) 50 50 50 60

Warranty and recommended calibration interval (year) 1 1 1 1

IMPORTANT

The following technical specifications can change without notice.

The information presented in this section is provided as a reference

only. To obtain this product’s most recent technical specifications,

visit the EXFO Web site at www.exfo.com.

EPM-500 Specifications

ELS-500 Specifications

EPM-500/ELS-500/EOT-500 38

Page 44

Technical Specifications 39

Model EOT-502 EOT-502X

Detector

4

Ge GeX

Power range5(dBm) 10 to −70 26 to −55

Wavelength range (nm) 800 to 165 0 800 to 1650

Number of calibrated wavelengths 6 6

Power uncertainty

6

± 5 % ± 0.1 nW ± 5 % ± 3 nW

Automatic offset nulling

7

Yes Ye s

Display units dB, dBm, W dB, dBm, W

Tone detection 270 Hz, 1 kHz and 2 kHz 270 Hz, 1 kHz and 2 kHz

Automatic wavelength recognition8Yes Ye s

Warm-up period9(min) 0 0

Data storage (items) more than 1000 more than 1000

Battery life (hours) (typical) 70 70

Warranty and recommended calibration period (year) 1 1

Model

2

12D 23BL 235BL 01-VCL

Central wavelength (nm) 850 ± 25 1310 ± 20 1310 ± 20 850 ± 20

1300 +50/−10 1550 ± 20 1490 ± 10

1550 ± 20

Spectral width3(nm) 50/135 ≤ 5 ≤ 5 ≤ 1

Output power (dBm) ≥−18 (62.5/125 μm) ≥ 1 ≥ 1 ≥−3 (50/125 μm)

≥−18 (62.5/125 μm) ≥−4.5

≥−3

Tone generation 270 Hz, 1 kHz, 2 kHz 270 Hz, 1 kHz, 2 kHz 270 Hz, 1 kHz, 2 kHz 270 Hz, 1 kHz, 2 kHz

Automatic wavelength recognition Yes Yes Yes Yes

Battery life (hours) (typical in Auto mode) 50 50 50 60

Warranty and recommended calibration period (years) 1 1 1 1

GENE RAL SPECIFICATIONS

Size (H x W x D) 19.0 cm x 10.0 cm x 6.2 cm (7 1/2in x 4 in x 2 1/2in)

Weight 0.48 kg (1.1 lb)

Temperature operating −10 °C to 50 °C (14 °F to 122 °F)

storage −40 °C to 70 °C (−40 °F to 158 °F)

Relative humidity 0 % to 95 % non-condensing

STANDARD ACCESSORIE S

User guide, Certificate of Calibration, instrument stickers in six languages, AC

adapter/charger, lithium ion battery, shoulder strap, alcohol cleaning pads, soft

carrying case.

EOT-500 Specifications

Page 45

P/N:1043429

www.exfo.com · info@exfo.com

CORPORATE

HEADQUARTERS

EXFO AMERICA 4275 Kellway Circle, Suite 122 Addison TX, 75001 USA

EXFO EUROPE Le Dynasteur

EXFO ASIAPACIFIC

TOLL-FREE (USA and Canada) 1 800 663-3936

© 2006 EXFO Electro-Optical Engineering Inc. All rights reserved.

Printed in Canada (2006-01)

400 Godin Avenue Vanier (Quebec) G1M 2K2 CANADA

10/12, rue Andras Beck

151 Chin Swee Road

#03-29, Manhattan House

Tel.: 1 418 683-0211 · Fax: 1 418 683-2170

Tel.: 1 972 836-0100 · Fax: 1 972 836-0164

92366 Meudon la Forêt Cedex FRANCE

Tel.: +33.1.40.83.85.85 · Fax: +33.1.40.83.04.42

SINGAPORE 169876

Tel.: +6563338241 · Fax: +6563338242

Loading...

Loading...